Page 1

EA Version

RTM-ATCA-F140

Installation and Use

P/N: 6806800M97A

October 2011

Embedded Computing for

Business-Critical Continuity

TM

Page 2

EA Version

©

2011 Emerson

All rights reserved.

Trademarks

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service

marks of Emerson Electric Co.

owners.

®

is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

Intel

™

and all other Java-based marks are trademarks or registered trademarks of Sun Microsystems, Inc. in the U.S. and other

Java

countries.

®

Microsoft

Microsoft Corporation.

PICMG

Industrial Computer Manufacturers Group.

UNIX

, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

®

, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

®

is a registered trademark of The Open Group in the United States and other countries.

©

2011 Emerson Electric Co. All other product or service names are the property of their respective

Notice

While reasonable efforts have been made to assure the accuracy of this document, Emerson assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Emerson reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Emerson to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

a Emerson website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Emerson,

It is possible that this publication may contain reference to or information about Emerson products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Emerson intends to announce such Emerson products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Emerson.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Emerson Network Power - Embedded Computing

2900 South Diablo Way, Suite 190

Tempe, AZ 85282

USA

Page 3

Contents

EA Version

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.3 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.4 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2 Hardware Preparation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2 Unpacking and Inspecting the RTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.3 Environmental and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.4 RTM Installation and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.4.1 Installing the RTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.4.2 Removing the RTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3 Controls, LEDs, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2 Face Plate Connectors and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2.1 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2 Management Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.1 FRU Serial EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.2 Temperature Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.3 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2.4 I2C Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3 1 Gbps SFP Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3.1 Connectivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3.2 Front-Blade Port Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.3.3 SFP Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

RTM-ATCA-F140 Installation and Use (6806800M97A)

3

Page 4

Contents

Contents

EA Version

Contents

4.3.3.1 I2C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3.3.2 SFP Status Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3.3.3 SFP Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4 10 Gbps SFP+ Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4.1 Connectivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4.2 Front-Blade Port Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4.3 BCM8727 Configuration Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4.4 Transmitter Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4.5 BCM8727 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4.6 SFP+ Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4.6.1 I2C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4.6.2 SFP+ Status Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.4.6.3 SFP Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.4.6.4 PHY Management Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5 10Gbps Fabric Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5.1 Fabric Connectivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.5.2 Fabric Front Blade Port Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.5.3 BCM84754 Configuration Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.5.4 Transmitter Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.5.5 BCM84754 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.6 Fabric SFP+ Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.6.1 SFP+ I2C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.6.2 SFP+ Status Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.6.3 SFP+ Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.7 PHY Management Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.6 40Gbps Fabric Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.6.1 Fabric Connectivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.6.2 Fabric Front Blade Port Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.6.3 BCM84740 Configuration Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.6.4 Transmitter Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.6.5 BCM84740 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.6.6 Fabric QSFP+ Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.6.6.1 QSFP+ I2C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.6.6.2 QSFP+ Status Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.6.6.3 QSFP+ Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.6.7 PHY Management Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 5

Contents

EA Version

4.7 GPS Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.7.1 1PPS Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.7.2 10MHz Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.7.3 Time-Of-Day Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.8 FPGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.8.1 Front-blade Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.8.2 SFP/SFP+/QSFP+ Control and Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.8.3 BCM8727 Control and Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.8.4 BCM84754 Control and Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.8.5 BCM84740 Control and Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.8.6 Reset Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.8.7 Synchronous Ethernet Clock Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.8.8 SPI Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.8.9 FPGA Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.8.10 FPGA Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.9 Reset Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.10 Zone 3 Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.11 Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.11.1 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1 Emerson Network Power - Embedded Computing Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

RTM-ATCA-F140 Installation and Use (6806800M97A)

5

Page 6

Contents

Contents

EA Version

Contents

6

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 7

List of Tables

Table 1-1 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

EA Version

Table 1-2 RTM-ATCA-F140 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 1-3 Blade Variants - Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 2-1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 4-1 Temperature Sensor Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 4-2 PCF 8574 Port Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 4-3 I2C Bus Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 4-4 Front-Blade Port Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 4-5 SFP Connector Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 4-6 SFP+ Connector Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 4-7 BCM8727 PHY Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 4-8 BCM84754 PHY Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 4-9 QSFP+ Connector Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 4-10 BCM84740 PHY Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 4-11 1PPS Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 4-12 10MHz Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 4-13 Time-Of-Day RJ45 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 4-14 FPGA Configuration Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 4-15 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table A-1 Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

RTM-ATCA-F140 Installation and Use (6806800M97A)

7

Page 8

List of Tables

EA Version

8

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 9

List of Figures

Figure 1-1 Declaration of Conformity - TBD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

EA Version

Figure 3-1 Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 4-1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 4-2 1GB Base Channel Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 4-3 Fabric 10 GB Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 4-4 Fabric 10Gb Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 4-5 Fabric 40Gb Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 4-6 Synchronous Ethernet Reference Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

RTM-ATCA-F140 Installation and Use (6806800M97A)

9

Page 10

List of Figures

EA Version

10

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 11

About this Manual

EA Version

Overview of Contents

This manual is divided into the following chapters and appendices.

Introduction describes the main features of the RTM.

Hardware Preparation and Installation installation prerequisites and the installation itself.

Controls, LEDs, and Connectors describes external interfaces such as connectors and LEDs.

Func tional Descr iption contains a block diagram of the RTM and provides some information

on the IPMI functionality of the RTM.

Related Documentation lists further Emerson user manuals that are related to the RTM and

the ATCA-F140.

Safety Notes summarizes the safety instructions in the manual.

Sicherheitshinweise is a German translation of the Safety Notes chapter.

Abbreviations

RTM-ATCA-F140 Installation and Use (6806800M97A)

This document uses the following abbreviations:

Abbreviation Definition

AMC Alarm Management Controller

ARP Address Resolution Protocol

ATCA Advanced Telecom Computing Architecture

BIX Base Interface Switch

CP-TA Communications Platforms Trade Association

FIX Fabric Interface Switch

IO Input/Output

PICMG PCI Industrial Computer Manufacturers Group

PCI Peripheral Component Interconnect

RTM Rear Transition Module

SPI Serial Peripheral Interface

11

Page 12

About this Manual

About this Manual

EA Version

Conventions

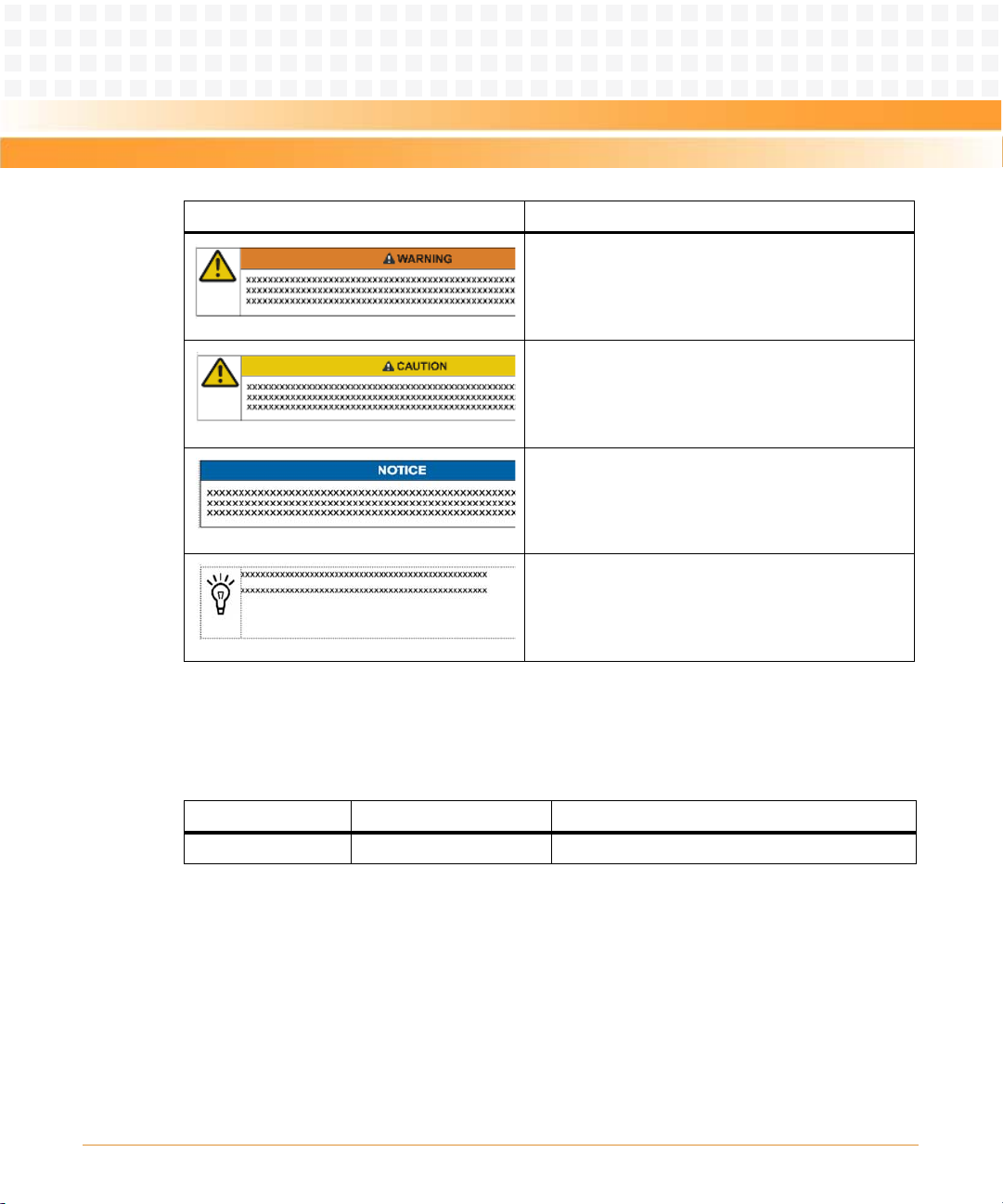

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related elements

Courier + Bold Used to characterize user input and to separate it

Reference Used for references and for table and figure

File > Exit Notation for selecting a submenu

0 through F), for example used for addresses and

offsets

or commands in body text

from system output

descriptions

12

<text> Notation for variables and keys

[text] Notation for software buttons to click on the screen

and parameter description

... Repeated item for example node 1, node 2, ..., node

12

.

.

.

.. Ranges, for example: 0..4 means one of the integers

|Logical OR

Omission of information from example/command

that is not necessary at the time being

0,1,2,3, and 4 (used in registers)

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 13

About this Manual

Notation Description

EA Version

Summary of Changes

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury

Indicates a property damage message

No danger encountered. Pay attention to important

information

RTM-ATCA-F140 Installation and Use (6806800M97A)

This manual has been revised and replaces all prior editions.

Part Number Publication Date Description

6806800M97A August 2011 First edition

13

Page 14

About this Manual

About this Manual

EA Version

14

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 15

Introduction

EA Version

1.1 Features

The RTM-ATCA-F140 provides the I/O connection for the ATCA-F140 switch blade towards the

back of the system. RTM-ATCA-F140 is directly connected to and powered by the front board.

The RTM-ATCA-F140 is a rear transition module (RTM) as defined in PICMG 3.0 Revision 3.0

Advanced TCA Base Specification and PICMG 3.1 Revision 1.0 Specification Ethernet/Fiber

Channel for AdvancedTCA Systems. It provides several Base and Fabric Channel Ethernet

interfaces connected to the front board through the Zone 3 connector.

The main features of the RTM-ATCA-F140 are:

Single slot RTM form factor (70mm x 322mm)

1x 40Gbit Ethernet uplink (FIX) according to IEEE 802.3ba with 1 QSFP+ type connector

4x 10Gbit Ethernet uplinks (FIX) according to IEEE 802.3ap with 4 SFP+ type connectors

Chapter 1

2x 10Gbit Ethernet uplinks (BIX) according to IEEE 802.3ap with 2 SFP+ type connectors

4x 1Gbit Ethernet interfaces (BIX) with 4 SFP type connectors

GPS 1PPS SMA input

GPS 10MHz SMA input

GPS time-of-day and optional 1PPS with RJ45 connector

Hot-plug ability

Serial EEPROM accessible by front-blade IPMC

Four status LEDs and ejector handle switch accessible by front-blade IPMC

RTM-ATCA-F140 Installation and Use (6806800M97A)

15

Page 16

Introduction

1.2 Standard Compliances

EA Version

The product is designed to meet the following standards.

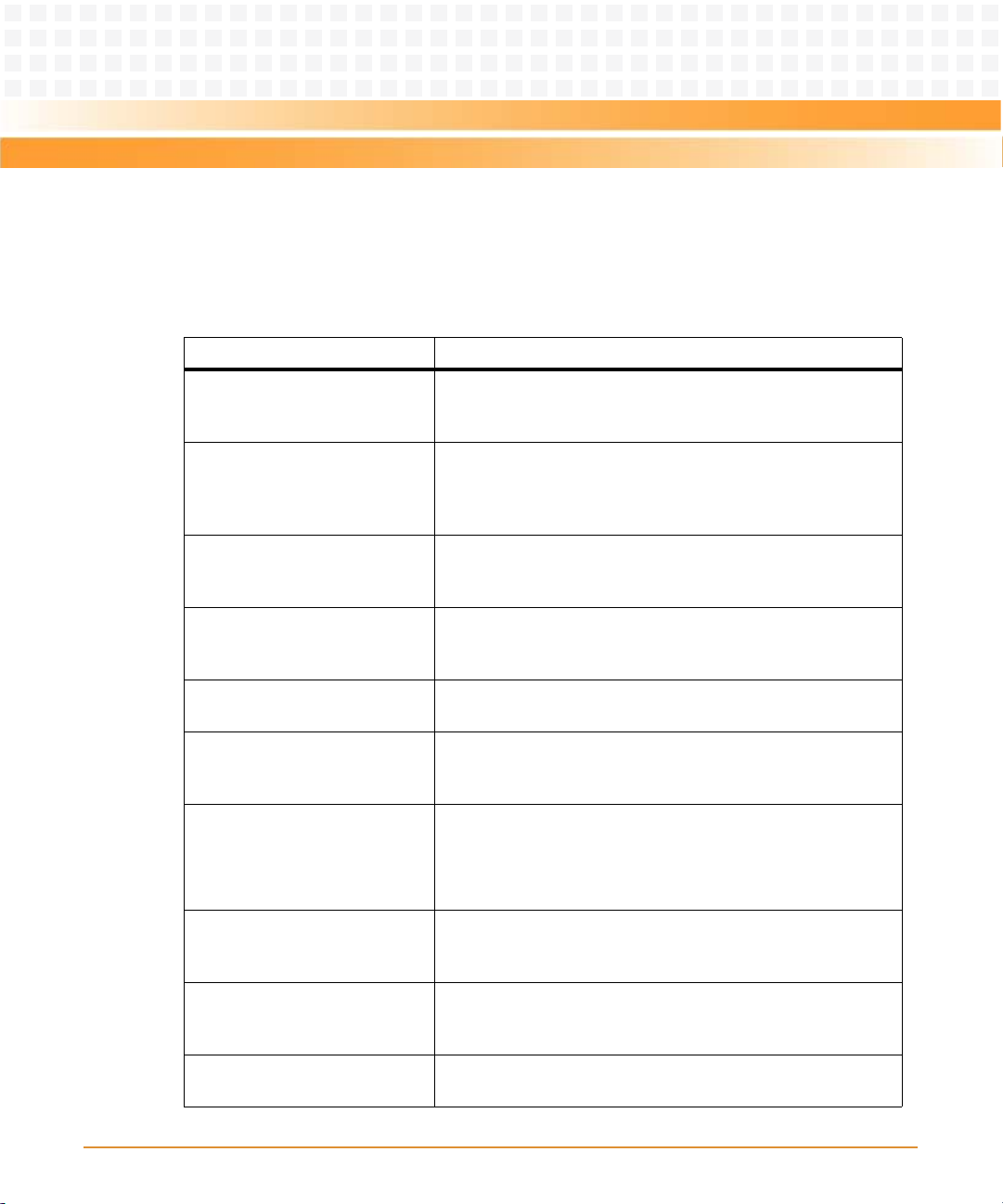

Table 1-1 Standard Compliances

Standard Description

ANSI Fire Spread Criteria The product is designed to pass the ANSI T1.319-2002 fire

spread test method as well as the NEBS GR-63-CORE fire spread

test method.

AS/NZS CISPR 22 Class A

(Australia/New Zealand)

AT&T Document ATT-TP-76200 The product is designed to comply with the latest version of the

EN 55024 (EU) The product complies with EN55024 (EU) Information

EN 60950-1 This product complies with EN 60950-1 Safety of Information

EN55022 Class A (EU) The product complies with EN55022 Class A (EU), Information

ETSI Acoustic Noise ETS 300 753

Class 3.1

ETSI Stationary Use: EN 300 0192-3 Class 3.1

ETSI Storage EN 300 019-2-1

Class 1.2

ETSI Transportation: EN 300 0192-2 Class 2.3

The product complies with AS/NZS CISPR 22 Class A

(Australia/New Zealand), Limits and Methods of Measurement

of Radio Disturbance Characteristics of Information Technology

Equipment.

AT&T Document ATT-TP-76200: Network Equipment Power,

Grounding, Environmental, And Physical Design Requirements.

Technology Equipment - Immunity Characteristics - Limits and

Methods of Measurements.

Technology Equipment.

Technology Equipment - Radio Disturbance Characteristics Limits and Methods of Measurements.

The product will not prevent the system from complying

with the ETSI acoustic noise requirements per Class 3.1 of ETSI

ETS 300 753, Equipment Engineering (EE); Acoustic noise

emitted by

The product is designed to comply with ETSI Stationary Use: EN

300 019-2-3, Class 3.1 equipment (temperature controlled

locations).

The product is designed to comply with ETSI Storage: EN 300

019-2-1, Class 1.2 equipment (not temperature controlled

storage locations).

The product is designed to comply with ETSI Transportation: EN

300 019-2-2, Class 2.3 equipment (public transportation).

telecommunications equipment.

16

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 17

Introduction

Table 1-1 Standard Compliances (continued)

EA Version

Standard Description

FCC 47 CFR Part 15 Subpart B

(US), Class A

GR-1089 - Ports and Intrabuilding Lightning

GR-1089-CORE Products are designed to comply with all applicable

GR63-CORE The product is designed to comply with all applicable

IEC 60950-1 CB Scheme The product complies with IEC 60950-1 CB Scheme including all

NEBS Level 3 Module is designed to pass all testing to Criteria Level 3 per

Safety Mark for U.S. and Canada The product is designed to certify to UL/CSA No. 60950-1 with

UL/CSA No. 60950-1 The product complies with UL/CSA 60950-1Safety of

VCCI Class A (Japan) The product complies with VCCI Class A (Japan), Voluntary

The product complies with FCC 47 CFR Part 15 Subpart B (US),

Class A.

All externally accessible ports shall be designed to comply with

the applicable GR-1089 requirements for Telecommunication

Ports.

requirements for Type 2 Equipment referenced in Telcordia

Document GR-1089-CORE.

requirements of Telcordia GR-63-CORE, NEBS Requirements:

Physical Protection.

National Deviations Safety of Information Technology

Equipment. Testing shall be by an accredited lab.

Telcordia SR-3580.

no devi ation s and s hall bea r the Reco gni tion M ark o f an NRTL for

US and Canada.

Information Technology Equipment.

Control Council for Interference by Information Technology

Equipment.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Verizon CHECKLIST The product is designed to comply with the latest version of the

Verizon Document VZ.NEBS.TE.NPI.2004.015: NEBS Checklist.

17

Page 18

Introduction

Figure 1-1 Declaration of Conformity - TBD

EA Version

18

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 19

Introduction

1.3 Mechanical Data

EA Version

Table 1-2 RTM-ATCA-F140 Mechanical Data

Data Value

Dimensions 8U x 6 HP form factor - 30 mm x 351 mm x 143 mm (including face plate

handles and alignment posts)

Weight 0.725 Kg

1.4 Ordering Information

The following table lists the blade variants that were available as of the time of writing this

manual. Consult your local Emerson sales representative for the availability of further variants.

Table 1-3 Blade Variants - Ordering Information

Part Number Description

RTM-ATCA-F140 RTM for the ATCA-F140 with SFP and SFP+ sockets

RTM-ATCA-F140 Installation and Use (6806800M97A)

19

Page 20

Introduction

EA Version

20

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 21

Hardware Preparation and Installation

EA Version

2.1 Overview

Inspect the shipment and unpack the RTM.

Make sure environmental and power requirements are met.

Install the RTM.

2.2 Unpacking and Inspecting the RTM

Damage of Circuits

Chapter 2

Electrostatic discharge and incorrect installation and removal of the blade can damage

circuits or shorten its life.

Before touching the blade or electronic components, make sure that you are working in

an ESD-safe environment.

The shelf should provide minimum airflow to the RTM slot according to the class B.4

requirements of the CP-TA Inter-operability document AdvancedTCA Book 1.1. This includes

the following:

2.0 cfm at 25 °C ambient temperature

2.8 cfm at 40 °C ambient temperature

4.4 cfm at 55 °C ambient temperature

Shipment Inspection

To inspect the shipment, perform the following steps:

1. Verify that you have received all items of your shipment:

Printed Quick Start Guide and Safety Notes Summary

RTM-ATCA-F140

RTM-ATCA-F140 Installation and Use (6806800M97A)

21

Page 22

Hardware Preparation and Installation

2. Check for damage and report any damage or differences to the customer service.

EA Version

3. Remove the desiccant bag shipped together with the blade and dispose of it according to

your country’s legislation.

The RTM is thoroughly inspected before shipment. If damage has occurred or items

missing during transportation, contact our customer's service immediately.

Remove the desiccant bag shipped together with the blade and dispose of it according to

your country’s legislation.

2.3 Environmental and Power Requirements

In order to meet the environmental requirements, the blade has to be tested in the system in

which it is to be installed.

Before you power up the blade, calculate the power needed according to your combination of

blade upgrades and accessories.

2.3.1 Environmental Requirements

The environmental conditions must be tested and proven in the shelf configuration used. The

conditions refer to the surrounding of the blade within the user environment.

22

The environmental requirements of the blade may be further limited down due to

installed accessories, such as hard disks or PMC modules, with more restrictive

environmental requirements.

Operating temperatures refer to the temperature of the air circulating around the blade

and not to the actual component temperature.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 23

Hardware Preparation and Installation

Blade Damage

EA Version

Blade surface

Do not operate the blade outside the specified environmental limits. Make sure the

blade is completely dry and there is no moisture on any surface before applying power.

Blade Overheating and Blade Damage

Operating the blade without forced air cooling may lead to blade overheating and thus

blade damage.

When operating the blade, make sure that forced air cooling is available in the shelf.

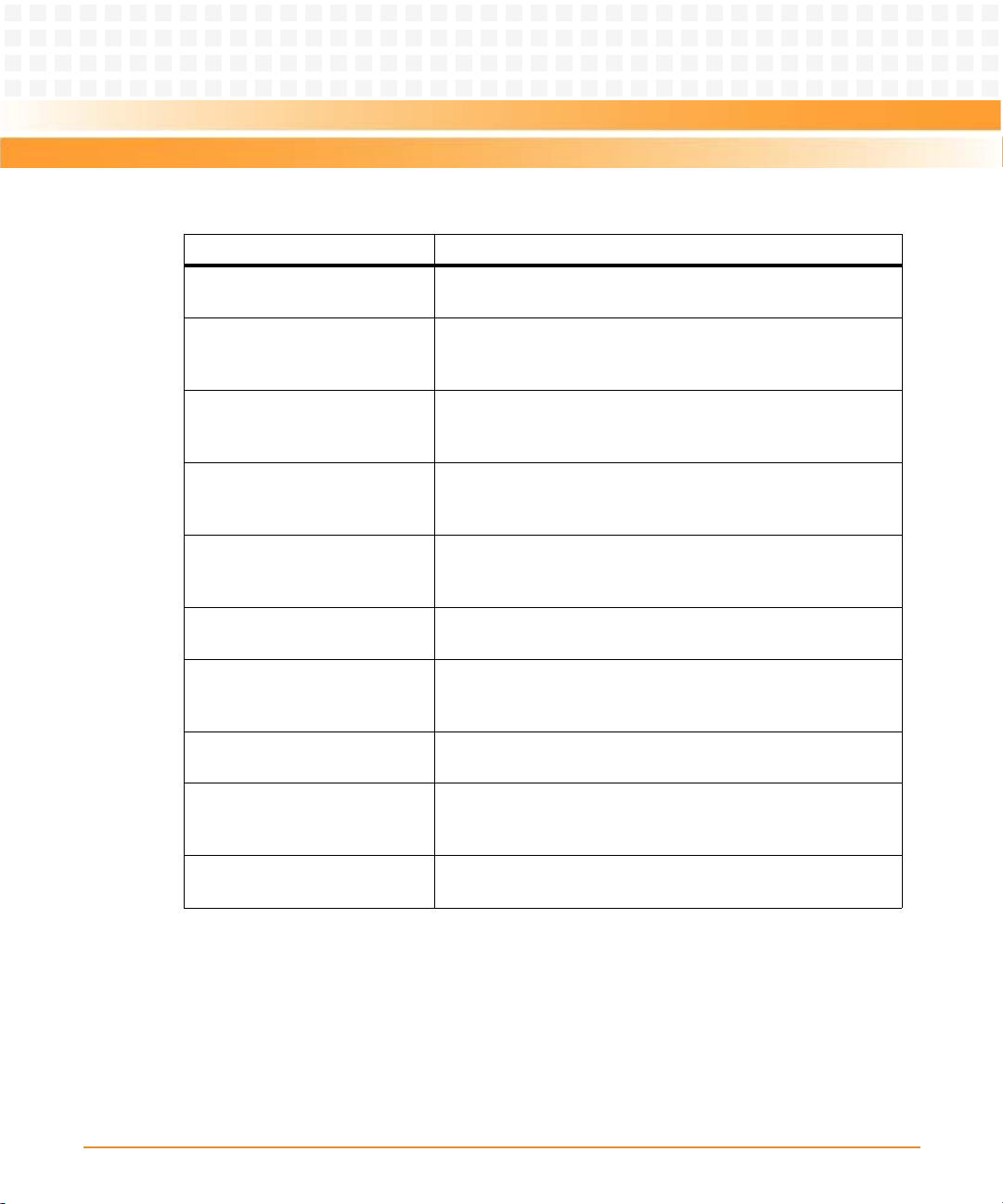

Table 2-1 Environmental Conditions

Requirement Operating Non-Operating

Temperature and airflow per

CP-TA B.4

The RTM shall require no more

than 2.2 CFM at the inlet

ambient of 25°C (77°F).

Under abnormal Short Term

operating conditions such as an

air mover failure, an RTM shall

require no more than 3.0 CFM

at the inlet ambient of 40°C

(104°F).

The RTM shall require no more

than 3.2 CFM at the inlet

ambient of 40°C (104°F) under

normal operating conditions.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Under abnormal Short Term

operating conditions such as an

HVAC failure the RTM shall

require no more than 5.0 CFM

at the inlet ambient of 55°C

(131°F).

23

Page 24

Hardware Preparation and Installation

Table 2-1 Environmental Conditions (continued)

EA Version

Requirement Operating Non-Operating

Airflow Impedance An ATCA RTM shall present less

than 0.1 inches water backpressure at 5 CFM airflow at sea

level.

Temperature 25°C when cooled by an even

airflow of 2.2 CFM

0°C to 40°C when cooled by an

even airflow of 3.0 CFM

-5° C to 55°C w hen coo led by an

even airflow of 5.0 CFM

Temperature change +/- 0.5°C/min +/- 1°C/min

Relative humidity 5% to 95% non-condensing at

40°C

Altitude -300m to 1,800m at 40°C -300m to 13,000m

1,800m to 4,000m at 30°C

Between 106 Kpa and 70 Kpa

air pressure

-40°C to 85°C

5% to 95% non-condensing at

40°C

2.4 RTM Installation and Removal

24

The RTM is fully compatible to the AdvancedTCA standard and is designed to be used in

AdvancedTCA shelves.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 25

Hardware Preparation and Installation

The RT M must onl y be i nsta lled into the s lot as sociated w ith t he proper companion fro nt blade.

EA Version

Damage of Circuits

Electrostatic discharge and incorrect RTM installation and removal can damage circuits

or shorten its life.

Before touching the RTM or electronic components, make sure that you are working in

an ESD-safe environment.

Damage of the RTM

Incorrect installation of the RTM can cause damage of the RTM.

Only use handles when installing or removing the RTM to avoid damage/deformation to

the face plate and/or the PCB.

2.4.1 Installing the RTM

To install the RTM into an AdvancedTCA Shelf, proceed as follows.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Installation Procedure

The following procedure describes the installation of the RTM. It assumes that your system is

powered. If your system is unpowered, you can disregard the blue LED and thus skip the

respective step. In this case it is a purely mechanical installation.

Slow down and give blade insertion your full attention! If there are Rear Transition Modules

(RTMs) to install, install/secure the RTMs first, then install the front blades.

25

Page 26

Hardware Preparation and Installation

1. Visually inspect the RTM and zone 3 connectors on the front blade for damage or bent pins

EA Version

before attempting to insert a board. If any connector damage or pin damage is observed,

stop before inserting the RTM

2. If the corresponding front blade is already installed, perform the following steps.

Otherwise skip to step 3.

On the front blade, verify the face plate screws that secure the blade to the shelf are

tight.

Deactivate the front blade. Unlatch the lower handle by squeezing the lever and the

latch together and turning the handle outward only enough to unlatch the handle from

the face plate. Do not rotate the handle fully outward.

When the blue LED on the front blade is permanently illuminated, proceed to the next

step.

3. Ensure that the top and bottom ejector handles on the RTM are in the outward position by

squeezing the lever and the latch together.

and send the damaged item through proper repair channels.

26

4. Insert the RTM into the shelf by placing the top and bottom edges of the RTM in the card

guides of the shelf. Ensure that the guiding module of the front blade and RTM are aligned

properly.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 27

Hardware Preparation and Installation

5. Apply equal and steady pressure to the RTM to carefully slide the RTM into the shelf until you

EA Version

feel resistance. Continue to gently push the RTM until the connectors engage.

6. Squeeze the lever and the latch together and hook the lower and the upper handle into the

shelf rail recesses

7. Fully insert the blade and lock it to the shelf by squeezing the lever and the latch together

and turning the handles towards the face plate.

RTM-ATCA-F140 Installation and Use (6806800M97A)

8. Tighten the face plate screws which secure the RTM to the shelf.

9. If the front blade has already been installed (as in step 2), activate the front blade by

squeezing its lower lever and latch together and press it back into the face plate.

27

Page 28

Hardware Preparation and Installation

10. If the front blade has not been installed, proceed with the installation instructions in the

EA Version

front blade installation and use manual.

Make sure that the handles of both the RTM and the front blade are closed in order to power

up the blade and RTM payload.

When the RTM's blue LED is switched OFF and the green LED "OK" is switched ON, this

indicates that the RTM’s payload has been powered up and that the RTM is active.

11. Connect cables to the face plate, if applicable.

2.4.2 Removing the RTM

This section describes how to remove the RTM from an AdvancedTCA system.

Removal Procedure

The following procedure describes the removal of the RTM. It assumes that your system is

powered. If your system is unpowered, you can disregard the blue LED and thus skip the

respective step. In this case it is a purely mechanical procedure.

28

1. On the front blade, unlatch the lower handle by squeezing the lever and the latch together

and turning the handle outward only enough to unlatch the handle from the face plate. Do

not rotate the handle fully outward.

The front board blue LED blinks indicating that the blade power-down process is ongoing.

Data Loss

Removing the blade, with the blue LED still blinking, will cause data loss. Wait until the

blue LED is permanently illuminated, before removing the blade.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 29

Hardware Preparation and Installation

2. Wait until the front board blue LED is illuminated permanently.

EA Version

If the LED continues to blink, a possible reason may be that upper layer software rejects the

blade extraction request

3. Remove face plate cables, if applicable.

4. Unfasten the screws of the RTM face plate until the RTM is detached from the shelf.

5. Unlatch the RTM upper and lower handles and rotate fully outward.

6. Remove the blade from the shelf.

RTM-ATCA-F140 Installation and Use (6806800M97A)

29

Page 30

Hardware Preparation and Installation

EA Version

30

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 31

Controls, LEDs, and Connectors

EA Version

3.1 Overview

This chapter describes:

Face plate connectors

Face plate LEDs

Reset key

Rear panel connectors

3.2 Face Plate Connectors and LEDs

The following figure shows the face plate of the RTM.

Chapter 3

RTM-ATCA-F140 Installation and Use (6806800M97A)

31

Page 32

Controls, LEDs, and Connectors

Figure 3-1 Face Plate

EA Version

32

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 33

Controls, LEDs, and Connectors

3.2.1 LEDs

EA Version

RTM-ATCA-F140 provides four panel-visible LEDs that provide the standard ATCA management

LED functions:

Red (out of service)

Green (in service)

Blue (hot-swap initializing/ shutting down)

Amber (attention)

RTM-ATCA-F140 Installation and Use (6806800M97A)

33

Page 34

Controls, LEDs, and Connectors

EA Version

34

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 35

Functional Description

EA Version

4.1 Block Diagram

Figure 4-1 Block Diagram

Chapter 4

RTM-ATCA-F140 Installation and Use (6806800M97A)

35

Page 36

Functional Description

4.2 Management Resources

EA Version

The RTM-ATCA-F140 does not include its own management controller (MMC) and cannot

independently support the ATCA hot-swap protocol. However, it does support hot-plugging.

The RTM-ATCA-F140 provides the necessary resources to allow management by the frontblade IPMC. These resources are associated with a dedicated I2C port connected to the frontblade IPMC.

4.2.1 FRU Serial EEPROM

The RTM-ATCA-F140 provides a 128Kb (16K byte) I2C serial EEPROM. This is a 24LC128T-type

device. The EEPROM resides at I2C address 0xA0. It is supplied with +3.3V management power

and thus is available regardless of payload power.

This serial EEPROM is intended to hold FRU data and any additional parameters that are

required.

4.2.2 Temperature Sensors

The RTM-ATCA-F140 has provision for three temperature sensors that are located on the

primary side of the board close to the top, middle and bottom of the RTM. These sensors are

I2C-based LM75-type devices.

36

The over-temperature outputs from the three sensors are connected to the RTM FPGA to allow

an interrupt to the service processor to be generated in the event of an over-temperature

condition.

Table 4-1 Temperature Sensor Thresholds

Sensor Non-Critical Threshold / C Critical Threshold / C Non-recoverable Threshold / C

Upper 58 69 85

Middle 56 65 81

Lower 54 61 72

The I2C addresses for these devices are 0x90 (upper), 0x92 (middle) and 0x94 (lower).

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 37

Functional Description

4.2.3 LEDs

EA Version

The RTM-ATCA-F140 provides four panel-visible LEDs that provide the standard ATCA

management LED functions:

Red - Out of Service

Green - In Service

Blue - Hot swap (initializing / shutting down)

Amber - Attention

The LEDs are controlled by a PCF8574-type I2C parallel I/O expander. The ports of this are

connected as shown below.

Table 4-2 PCF 8574 Port Usage

Port Direction Connection

0 Output H/S LED (Blue)

1 Output OOS LED (Red)

2 Output IS LED (Green)

3 Output ATTN LED (Amber)

4 Output OOS LED (Amber)

5 Output FPGA PROM select

RTM-ATCA-F140 Installation and Use (6806800M97A)

6N/A (not connected)

7 Input FPGA DONE

The I/O expander interrupt line is not connected.

For the red, green and amber LEDs the cathodes are connected directly to the I/O expander

pins and the anodes are connected to the management 3.3V supply through current limiting

resistors selected to limit the LED current to 15mA. Since the I/Os power-up in the high state,

this ensures that the LEDs will remain off until explicitly turned on by the IPMC.

For the blue LED an external FET inverter is used to ensure the LED is on at power-up and a

charge pump is used to provide adequate forward voltage in the case the LED cannot be

operated directly from 3.3V.

37

Page 38

Functional Description

The I/O expander resides at I2C address 0x40.

4x SFP

4x 1GbE to Base Switch (SGMII)

Front Panel

Base Switch (BIX)

Zone 3 Connector

EA Version

4.2.4 I2C Address Map

Table 4-3 summarizes the I2C address assignments.

Table 4-3 I2C Bus Address Map

Address Device

0x40 I/OExpander (LED control)

0x90 Temperature sensor (top)

0x92 Temperature sensor (middle)

0x94 Temperature sensor (bottom)

0xA0 Serial EEPROM

4.3 1 Gbps SFP Ports

The RTM-ATCA-F140 provides four 1 Gbps SFP module sites which are connected to the frontblade base switch.

4.3.1 Connectivity

38

Four 1000Base-BX serdes connections from the front-blade are routed directly from the zone

3 connectors to four SFP sites as shown in Figure 4-2. These are all dedicated ports on the front

blade base switch. The RTM-ATCA-F140 does not include AC-coupling capacitors on the inputs

from the front blade since they are provided by the SFP module.

Figure 4-2 1GB Base Channel Interconnect

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 39

Functional Description

4.3.2 Front-Blade Port Mapping

EA Version

The four SFP sites are connected to the front-blade base switch according to the table below.

Table 4-4 Front-Blade Port Mapping

RTM Port Front Blade Base Switch Port

ETH1 ge20

ETH2 ge21

ETH3 ge22

ETH4 ge23

4.3.3 SFP Connection

The SFP sites allow the fitting of a wide range of third-party SFP modules to support 1000BaseT, long and short range optical connection. Refer to the ATC A-F140 Installation and Use Manual

for a list of SFP devices tested with this product.

The following table shows the SFP connector pin assignments.

Table 4-5 SFP Connector Pin Assignment

RTM-ATCA-F140 Installation and Use (6806800M97A)

Pin Signal Pin Signal

1GND 11GND

2TX_FAULT 12RX-

3TX_DISABLE 13RX+

4 I2C_SDA 14 GND

5 I2C_SCL 15 VCCr (+3.3V)

6 MOD_ABS 16 VCCt (+3.3V)

7RATE_SEL 17GND

8 LOS 18 TX+

9 GND 19 TX-

10 GND 20 GND

39

Page 40

Functional Description

4.3.3.1 I2C Bus

EA Version

The SFP I2C bus signals (I2C_SDA and I2C_SCL) from each SFP site are individually connected

to the RTM FPGA. An I2C controller within the FPGA allows the front-blade service processor to

access these ports to obtain SFP status and diagnostic information. Refer to the Chapter 4,

FPGA, on page 52 for details.

4.3.3.2 SFP Status Signals

The SFP status signals, MOD_ABS, TX_FAULT and LOS, are individually connected to the RTM

FP GA to all ow mon itori ng by the ser vice processor. Refer to the Chapter 4, FPGA, on page 52 for

details.

4.3.3.3 SFP Control Signals

The SFP control signals, TX_DISABLE and RATE_SEL, are individually connected to the RTM

FPGA to allow control by the service processor. Refer to the Chapter 4, FPGA, on page 52 for

details.

4.4 10 Gbps SFP+ Ports

The RTM-ATCA-F140 provides a two 10Gbps SFP+ module sites connected to the base switch

on the front blade.

40

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 41

Functional Description

4.4.1 Connectivity

DUAL PHY

BCM8727

2x SFP+

2x SFI2x 10GbE to Base Switch (XAUI)

Front Panel

Base Switch

Zone 3 Connector

EA Version

The two 10Gbps XAUI ports from the front blade base switch connect to a BCM8727 dual

XAUI-to-SFI PHY which then connect to two individual SFP+ connectors using an SFI interface

as show n in Figure 4-3. The RTM-ATCA-F140 includes 0.1μF AC-coupling capacitors on the XAUI

inputs from the front blade. Similarly, capacitors are expected to be provided on the front

blade for signals from the RTM. The SFP+ specification requires AC-coupling capacitors in the

module so they are not needed on the board SFI interface.

Figure 4-3 Fabric 10 GB Interconnect

4.4.2 Front-Blade Port Mapping

The two base channel ports connect to the front blade ports BIX_XG0 and BIX_XG1. These

ports connect directly to dedicated ports on the ATCA-F140 front blade base switch. BIX_XG0

is connected to BCM8727 channel 2 while BIX_XG1 is connected to BCM8727 channel 1.

4.4.3 BCM8727 Configuration Flash

4.4.4 Transmitter Control

RTM-ATCA-F140 Installation and Use (6806800M97A)

The BCM8727 requires an external SPI Flash to store microcode for the internal microcontroller.

A single SPI Flash is connected to the FPGA and the SPI bus from the BCM8727 is similarly

connected to the FPGA. Register settings in the FPGA allow the BCM8727 to connect to the SPI

Flash as well as provide a programming port.

The TXONOFF signals on the BCM8727 are individually connected to the RTM FPGA which

allows them to be driven under software control. This enables software to enable and disable

the SFP+ optical outputs.

41

Page 42

Functional Description

4.4.5 BCM8727 Status

EA Version

The PCMULK, PCDRLK, PLOSB and LASI signals from each BCM8727 port are connected to the

RTM FPGA to allow them to be monitored by software. The PLOSB and LASI signals can also

generate an interrupt to the front-blade. Refer to Chapter 4, FPGA, on page 52 for further

details.

4.4.6 SFP+ Connection

The SFP+ cage accepts industry standard SFP+ optical modules. The SFP+ cage is backwards

compatible with 1 GB optical or copper SFP modules. Refer to the ATCA-F140 Installation and

Use Manual for a list of SFP devices tested with this product. The SFP+ connector assignment

for the 10 Gbps serial interface is described in Tab le 4 -6.

Table 4-6 SFP+ Connector Pin Assignment

Pin Signal Pin Signal

1GND 11GND

2TX_FAULT 12RX-

3TX_DISABLE 13RX+

4 I2C_SDA 14 GND

5 I2C_SCL 15 VCCr (+3.3 V)

6 MOD_ABS 16 VCCt (+3.3 V)

4.4.6.1 I2C Bus

42

7RS0 17GND

8 LOS 18 TX+

9 RS1 19 TX-

10 GND 20 GND

The SFP+ I2C bus signals (I2C_SDA and I2C_SCL) from each SFP+ site are individually

connected to the corresponding BCM8727 which includes a mechanism to allow access to the

port through the phy management channel.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 43

Functional Description

4.4.6.2 SFP+ Status Signals

EA Version

The SFP+ status signals, MOD_ABS, TX_FAULT and LOS, are individually connected to the

corresponding BCM8727 which monitors them. The signals are also connected to the RTM

FPGA to allow fast detection of a loss of signal condition. Refer to Chapter 4, FPGA, on page 52

for further details.

4.4.6.3 SFP Control Signals

The SFP+ TX_DISABLE signals are individually connected to the corresponding BCM8727 which

drives them under software control.

The RS0 and RS1 rate select signals from each SFP+ are individually connected to the RTM FPGA

that allows them to be controlled by software. Refer to Chapter 4, FPGA, on page 52 for further

details.

4.4.6.4 PHY Management Interfaces

The BCM8727 provides a single MDC/MDIO management port to access both channels and

allows bit 0 of the PHY address for each channel to be individually programmed, with bits 1 - 4

being common. Table 4-7 shows the address allocation and management port definition for

each channel.

Table 4-7 BCM8727 PHY Addressing

PHY

Address

High Bits Channel Source

b1011 1 Base b0 22 BIX_XG1 Base SFP+ 2 BIX_XG_MDC/

4.5 10Gbps Fabric Ports

RTM-ATCA-F140 Installation and Use (6806800M97A)

PHY

Address

Low Bits PHY Address Switch Port SFP+ Port

2Baseb123 BIX_XG0Base SFP+ 1

The RTM-ATCA-F140 provides four 10Gbps SFP+ module sites connected to the fabric switch

on the front blade.

Management

Channel

MDIO

43

Page 44

Functional Description

4.5.1 Fabric Connectivity

EA Version

Four 10GbE ports (configured for XFI mode) from the front blade fabric switch connect to a

BCM84754 quad XFI-to-SFI PHY which then connects to four individual SFP+ connectors using

an SFI interface as shown in Figure 4-4. The RTM-ATCA-F140 includes 0.1μF AC-coupling

capacitors on the XFI inputs from the front blade. Similarly, capacitors are expected to be

provided on the front blade for signals from the RTM. The SFP+ specification requires ACcoupling capacitors in the module so they are not needed on the board SFI interface.

Figure 4-4 Fabric 10Gb Interconnect

4.5.2 Fabric Front Blade Port Mapping

Ea ch f abr ic s wit ch p ort o n th e fr ont bla de con sis ts o f fo ur S ERD ES p air s. Th e fo ur fab ric cha nne l

XFI ports connect to front blade port FIX_P15. This is a dedicated port on the ATCA-F140 front

blade fabric switch.

4.5.3 BCM84754 Configuration Flash

4.5.4 Transmitter Control

44

The BCM84754 requires an external SPI Flash to store microcode for the internal

microcontroller. A single SPI Flash is connected to the FPGA and the SPI bus from the

BCM84754 is similarly connected to the FPGA. Register settings in the FPGA allow the

BCM84754 to connect to the SPI Flash as well as provide a programming port.

The TXONOFF signals on the BCM84754 are individually connected to the RTM FPGA which

allows them to be driven under software control. This enables software to enable and disable

the SFP+ optical outputs.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 45

Functional Description

4.5.5 BCM84754 Status

EA Version

The LASI signals from each BCM84754 port are individually connected to the RTM FPGA to

allow them to be monitored by soft ware. The LASI signals can also generate an interrupt to the

front blade. Refer to Chapter 4, GPS Connectors, on page 50 for further details.

4.5.6 Fabric SFP+ Connection

This is the same as the base SFP+ connection. Refer to Chapter 4, SFP+ Connection, on page 42.

4.5.6.1 SFP+ I2C Bus

The SFP+ I2C bus signals (I2C_SDA and I2C_SCL) from e ach SF P+ s ite a re ind iv idu all y co nn ec ted

to the BCM84754 which includes a mechanism to allow access to the port through the PHY

management channel.

4.5.6.2 SFP+ Status Signals

The SFP+ status signals, MOD_ABS, TX_FAULT and LOS, are individually connected to the

BCM84754 which monitors them. The signals are also connected to the RTM FPGA to allow fast

detection of a loss of signal condition. Refer to Chapter 4, GPS Connectors, on page 50 for fur ther

details.

4.5.6.3 SFP+ Control Signals

RTM-ATCA-F140 Installation and Use (6806800M97A)

The SFP+ TX_DISABLE signal is individually connected to the BCM84754 which drives it under

software control.

The RS0 and RS1 rate select signals from each SFP+ that are tied together and connec ted to the

RTM FPGA that allows them to be controlled by software. Refer to Chapter 4, GPS Connectors,

on page 50 for further detail.

45

Page 46

Functional Description

4.5.7 PHY Management Interfaces

EA Version

The BCM84754 provides a single MDC/MDIO management port to access all four channels and

allows bits 0 and 1 of the PHY address for each channel to be individually programmed, with

bits 2 - 4 being common.Table 9 shows the address allocation and management port definition

for each channel.

Table 4-8 BCM84754 PHY Addressing

PHY

Address

High Bits Channel Source

b001 0 Fabric b00 4 FIX_P15

1Fabricb015FIX_P15

2Fabricb106FIX_P15

3Fabricb117FIX_P15

PHY

Address

Low Bits

PHY

Address

Switch

Port

Lane 0

Lane 1

Lane 2

Lane 3

4.6 40Gbps Fabric Ports

The RTM-ATCA-F140 provides a 40Gbps capable QSFP+ module site connected to the fabric

switch on the front blade.

4.6.1 Fabric Connectivity

One 40GbE port fom the front blade fabric switch connects to a BCM84740 quad XLAUI-to-SFI

PHY which then connects to a single QSFP+ connector using an SFI interface as shown in Figure

4-5Fabric 40Gb Interconnect. When the fabric switch is configured for XLAUI mode, the QSFP+

slot supports a single 40GbE logical connection. When the fabric switch is configured for 4x XFI

mode, the QSFP+ slot supports four 10GbE connections. This mode assumes the use of a fiber

breakout cable on the QSFP+ module (MPO to 4x LC cable). The RTM-ATCA-F140 includes

SFP+

Port Management Channel

Fab ric

SFP+ 4

Fab ric

SFP+ 3

Fab ric

SFP+ 2

Fab ric

SFP+ 1

FIX_XG_MDC2/ MDIO2

46

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 47

Functional Description

0.1μF AC-coupling capacitors on the XLAUI inputs from the front blade. Similarly capacitors are

EA Version

expected to be provided on the front blade for signals from the RTM. The QSFP+ specification

requires AC-coupling capacitors in the module so they are not needed on the board SFI

interface.

Figure 4-5 Fabric 40Gb Interconnect

4.6.2 Fabric Front Blade Port Mapping

Each fabric switch port on the front blade consists of four SERDES pairs. The four fabric channel

XLAUI pairs connect to front blade port FIX_P14. This is a dedicated port on the ATCA-F140

front blade fabric switch.

4.6.3 BCM84740 Configuration Flash

4.6.4 Transmitter Control

RTM-ATCA-F140 Installation and Use (6806800M97A)

The BCM84740 requires an external SPI Flash to store microcode for the internal

microcontroller. A single SPI Flash is connected to the FPGA and the SPI bus from the

BCM84740 is similarly connected to the FPGA. Register settings in the FPGA allow the

BCM84740 to connect to the SPI Flash as well as provide a programming port.

QSFP+ does not define a hardware signal for transmitter control. Software controls the

transmitter via byte 86 in the QSFP+ memory map. Refer to the QSFP+ Specification for further

detail.

The TXONOFF signal on the BCM84740 is connected to the RTM FPGA which allows it to be

driven under software control. When asserted, this signal will cause the PHY to drive LPMODE

to the QSFP+ site. This places the PHY and QSFP+ module into low-power mode but may not

actually disable the QSFP+ transmitters, according to the QSFP+ specification. Transmitter

control should be performed through the software method detailed above.

47

Page 48

Functional Description

4.6.5 BCM84740 Status

EA Version

The LASI signal from the BCM84740 is individually connected to the RTM FPGA to allow it to be

monitored by software. The LASI signal can also generate an interrupt to the front blade. Refer

to Chapter 4, GPS Connectors, on page 50 for further details.

4.6.6 Fabric QSFP+ Connection

The QSFP+ cage accepts industry standard QSFP+ optical modules. It also accepts QSFP+

copper and optical direct-attach cables. The site is designed to support power level 2 modules

which are rated up to 2W (Refer to the ATCA-F140 Installation and Use Manual for a list of

QSFP+ devices tested with this product). The QSFP+ connector assignment for the 40Gbps

serial interface is described in Table 4-9"QSFP+ Connector Pin Assignment".

Table 4-9 QSFP+ Connector Pin Assignment

Pin Signal Pin Signal

1GND 38GND

2TX2- 37TX1-

3TX2+ 36TX1+

4GND 35GND

5TX4- 34TX3-

6TX4+ 33TX3+

48

7GND 32GND

8 MODSEL# 31 LPMODE

9 RESET# 30 VCC1 (+3.3V)

10 VCCR (+3.3V) 29 VCCT (+3.3V)

11 I2C_SCL 28 INT#

12 I2C_SDA 27 MODPRS#

13 GND 26 GND

14 RX3+ 25 RX4+

15 RX3- 24 RX4-

16 GND 23 GND

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 49

Functional Description

Table 4-9 QSFP+ Connector Pin Assignment (continued)

EA Version

Pin Signal Pin Signal

17 RX1+ 22 RX2+

18 RX1- 21 RX2-

19 GND 20 GND

4.6.6.1 QSFP+ I2C Bus

The QSFP+ I2C bus signals (I2C_SDA and I2C_SCL) from each SFP+ site are individually

connected to the BCM84740 which includes a mechanism to allow access to the port through

the PHY management channel.

4.6.6.2 QSFP+ Status Signals

The QSFP+ status signals, MODPRS#, and INT#, are individually connected to the BCM84740

which monitors them. The signals are also connected to the RTM FPGA to allow fast detection

of a loss of signal condition. Refer to Chapter 4, GPS Connectors, on page 50 for further details.

4.6.6.3 QSFP+ Control Signals

The QSFP+ LPMODE signal is connected to the BCM84740. This allows software control of the

power mode, or hardware control through deassertion of the TXONOFF signal.

4.6.7 PHY Management Interfaces

RTM-ATCA-F140 Installation and Use (6806800M97A)

The BCM84740 provides a single MDC/MDIO management port to access all four channels and

allows bits 0 and 1 of the PHY address for each channel to be individually programmed, with

bits 2 - 4 being common. Table 4-10"BCM84740 PHY Addressing" shows the address allocation

and management port definition for each channel.

Table 4-10 BCM84740 PHY Addressing

PHY

Address

High Bits Channel Source

b0000Fabricb000FIX_P14

PHY

Address

Low Bits

PHY

Address Switch Port

Lane 0

QSFP+

Port

Fab ric

QSFP+

Management

Channel

FIX_XG_MDC

2/ MDIO2

49

Page 50

Functional Description

Table 4-10 BCM84740 PHY Addressing (continued)

EA Version

PHY

Address

High Bits Channel Source

1Fabricb011FIX_P14

2Fabricb102FIX_P14

3Fabricb113FIX_P14

4.7 GPS Connectors

The RTM-ATCA-F140 design includes three input connectors to allow reception of a 1PPS

signal, 10 MHz clock, and serial time-of-day information from a GPS receiver.

4.7.1 1PPS Input

An SMA connector is provided on the front panel of the RTM-ATCA-F140 for reception of a 1PPS

signal from a GPS receiver. Below are the characteristics of this input:

Table 4-11 1PPS Input Specifications

PHY

Address

Low Bits

PHY

Address Switch Port

Lane 1

Lane 2

Lane 3

QSFP+

Port

Management

Channel

50

1PPS SMA Input

Waveform Positive pulse

Minimum

Pulse Width

Maximum

Pulse Width

Amplitude TTL-compatible

Impedance 50 ohms

100ns

50ms

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 51

Functional Description

4.7.2 10MHz Input

EA Version

An SMA connector is located on the front panel of the RTM-ATCA-F140 to receive a 10MHz

clock signal from a GPS receiver. Characteristics of this input are:

Table 4-12 10MHz Input Specifications

Waveform Sine wave

Minimum

Amplitude

10MHz SMA Input

0.5Vp-p

Maximum

Amplitude

Impedance 50 ohms

Termination 50 ohms

4.7.3 Time-Of-Day Input

An RJ45 connector is provided on the front panel of the RTM-ATCA-F140 for reception of serial

RS-485/RS-422 time-of-day information from a GPS receiver. The serial format is 9600 baud,

8data bits, no parity, and 1 stop bit. There is also a 1PPS input channel on the RJ45 connector

for GPS receivers that transmit 1PPS serially. Below is the pinout of this port:

Table 4-13 Time-Of-Day RJ45 Pinout

Pin Signal

1 1PPS+

2 1PPS-

3No connect

4No connect

5No connect

6GND

5.0Vp-p

RTM-ATCA-F140 Installation and Use (6806800M97A)

7TOD+

8TOD-

51

Page 52

Functional Description

4.8 FPGA

EA Version

The RTM-ATCA-F140 includes a Xilinx XC3S200A-4 FPGA that which performs the following

functions:

Access to control and status signals on SFP, SFP+, and QSFP+

Access to control and status signals on the BCM8727, BCM84754, and BCM84740

Reset handling

Recovery of received clocks from BCM8727 for use as a Synchronous Ethernet reference

clock

Reception of GPS inputs (1PPS, 10MHz, Time-Of-Day)

SPI Flash programmer and multiplexing for BCM8727, BCM84754, and BCM84740

configuration

UART with selectable outputs for the optional GPS receiver (functionality not initially

implemented)

4.8.1 Front-blade Interface

The RTM-ATCA-F140 includes an SPI interface between the front-blade service processor and

the RTM FPGA. There is also an active low interrupt line to the front-blade to request service.

4.8.2 SFP/SFP+/QSFP+ Control and Status

52

The RTM FPGA provides register access to control the following SFP and SFP+ signals:

SFP TX_DISABLE

SFP RATE_SEL

SFP+ RS0/1 (tied together)

The RTM FPGA provides access to the following SFP, SFP+, and QSFP+ signals:

SFP MOD_ABS

SFP TX_FAULT

SFP LOS

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 53

Functional Description

SFP+ MOD_ABS

EA Version

SFP+ TX_FAULT

SFP+ LOS

QSFP+ MODPRS#

QSFP+ INT#

QSFP+ LPMODE

Each signal can be programmed to cause an interrupt when its state changes.

4.8.3 BCM8727 Control and Status

The RTM FPGA provides register access to the BCM8727 TXONOFF signals which allow the SFP+

transmitters to be disabled as well as putting the phys into a low-power mode.

The RTM FGPA provides access to the following BCM8727 status signals:

PCMULK

PCDRLK

PLOSB

LASI

4.8.4 BCM84754 Control and Status

RTM-ATCA-F140 Installation and Use (6806800M97A)

Each signal can be programmed to cause an interrupt when its state changes.

The RTM FPGA provides register access to the BCM84754 TXONOFF signals. This allows the

PHYs to be placed into low-power mode and disables the associated SFP+ transmitters. The

RTM FGPA provides access to the LASI status signals of the BCM84754s. Each signal can be

programmed to cause an interrupt when its state changes.

53

Page 54

Functional Description

4.8.5 BCM84740 Control and Status

EA Version

The RTM FPGA provides register access to the BCM84740 TXONOFF signal. This allows the PHY

to be placed into low-power mode also drives LPMODE to the QSFP+ site. According to the

QSFP+ spec, assertion of LPMODE may or may not cause the transmitter to be disabled. More

detail can be found in section 3.5.6. The RTM FGPA provides access to the LASI status signal of

the BCM84740. This signal can be programmed to cause an interrupt when its state changes.

4.8.6 Reset Handling

The RTM FPGA provides register control of the reset inputs to the BCM8727, BCM84754,

BCM84740, and the QSFP+ port. This allows the front blade control processor to reset the

PHYs and QSFP+. At system reset, as indicated by the zone 3 RTM_RST# signal, the PHYs and

QSFP+ are forced into reset until this is cleared by a register write. This is to ensure that the

PHYs are in reset until the telecom clock subsystem has been programmed if necessary to

provide the PHY reference clocks.

4.8.7 Synchronous Ethernet Clock Recovery

The BCM8727, BCM84754, and BCM84740 PHYs provide clocks recovered from the incoming

data stream of all of their ports. The frequency of these clocks is either 156.25MHz or

161.1328125MHz depending on whether the interface is operating at 1Gbps or 10Gbps

respectively. The RTM FPGA provides two identical blocks that each select between all of these

clock sources (ten total) and convert it to an 8kHz reference that is connected to the front blade

telecom clock subsystem.

54

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 55

Functional Description

The conversion process depends on which input frequency is in use. Figure 4-6Synchronous

Digital

Frequency

Synthesizer

x32

Synchronous

Divider

/25

Synchronous

Divider

/25782,

25781 , 25781 ,

25781

(25781 .25

overall)

161.1328125 MHz

8 kHz

Synchronous

Divider

/19532,

19531 , 19531 ,

19531

(19531 .25

overall)

156.25 MHz

EA Version

Eth ernet Referen ce Recover y shows the process. A register setting for each of the two reference

outputs selects between the two input frequencies.

Figure 4-6 Synchronous Ethernet Reference Recovery

4.8.8 SPI Flash

4.8.9 FPGA Register Map

RTM-ATCA-F140 Installation and Use (6806800M97A)

The SPI ports from the BCM8727, BCM84754, and BCM84740 connect to the FPGA along with

three SPI Flash devices, one for each type. Register settings allow access to be granted to any of

the PHYs and also provide a programming port.

Details of the FPGA register map are included in the RTM FPGA section of the ATCA-F140 FPGA

design guide.

55

Page 56

Functional Description

4.8.10 FPGA Configuration

EA Version

The RTM FPGA configuration is loaded at power-up from one of two SPI Flash devices. One

device is writable/upgradeable and the other is non-writable/golden for recovery purposes.

The selection is which device is used is controlled by switch S1 position 1, according to the

following table.

Table 4-14 FPGA Configuration Controls

Switch Setting FPGA Flash

S1.1 = Off Writable Bank (default)

S1.1 = On Non-writable (golden)

The configuration Flash devices can be field upgraded using a SPI-controlled Flash programmer

in the FPGA.

4.9 Reset Scheme

The front blade provides a single reset signal, RTM_RST#, over the zone 3 connectors. This

signal is asserted when a master reset of the front blade occurs.

4.10 Zone 3 Isolation

56

RTM_RST# directly resets the RTM FPGA. The BCM8727, BCM84754, BCM84740, and QSFP+

slot are reset from a secondary reset generated by the RTM FPGA. This allows software control

of the PHY and QSFP+ resets in addition to hardware control via the RTM_RST# signal. After the

hardware reset, the PHYs and QSFP+ are held in reset until released by software.

Since the front blade does not apply payload power to the RTM until it has identified the RTM,

it is important to ensure the RTM can withstand signal voltages when unpowered and does not

attempt to power itself through input protection diodes.

All the 1Gbps, 10Gbps, and 40Gbps Ethernet ports are AC-coupled at some point in their signal

path and therefore no additional measures are needed.

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 57

Functional Description

The Xilinx Spartan 3A FPGA does not include I/O pad protection diodes unless configured for

EA Version

PCI operation and therefore there is no issue with the signals connected directly to the FPGA

either.

The 156.25MHz Synchronous Ethernet reference clock from the front blade to the RTM is ACcoupled on the front blade using 10nF capacitors prior to being buffered to prevent DC current

flow.

4.11 Power Management

The front-blade provides two separate power supplies using the Zone 3 connectors:

+3.3 V management power — one pin

+12 V payload power — four pins

The maximum current draw, which is limited by the pin’s current handling capability, is 0.8A for

the management power and 3.2A for the payload power.

The management power is used to directly power the devices connected to the front blade I2C

bus, namely for serial EEPROM, temperature sensors and I/O extender device.

+12V payload power is the source for the onboard DC to DC converters needed for the RTM

payload.

4.11.1 Power Requirements

RTM-ATCA-F140 Installation and Use (6806800M97A)

The table below summarizes the power requirements of the RTM-ATCA-F140.

Table 4-15 Power Requirements

Voltage Maximum Current

+3.3V Management 0.2A

+12V Payload 2.1A

57

Page 58

Functional Description

EA Version

58

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 59

ARelated Documentation

EA Version

A.1 Emerson Network Power - Embedded

Computing Documents

The publications listed below are referenced in this manual. You can obtain electronic copies of

Emerson Network Power - Embedded Computing publications by contacting your local

Emerson Sales Office. For released products, you can also visit our Web site for the latest copies

of our product documentation.

1. Go to http://www.emersonnetworkpower.com/EmbeddedComputing.

2. Under Resources, click Technical Documentation.

3. Enter the publication number or the complete name of the product in the search.

Table A-1 Related Documentation

Appendix A

Document Title Publication Number

ATCA-F140 Installation and Use 6806800M67

RTM-ATCA-F140 Installation and Use (6806800M97A)

59

Page 60

Related Documentation

EA Version

60

RTM-ATCA-F140 Installation and Use (6806800M97A)

Page 61

Safety Notes

EA Version

This section provides warnings that precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed during all phases of

operation, service, and repair of this equipment. You should also employ all other safety

precautions necessary for the operation of the equipment in your operating environment.

Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

Emerson intends to provide all necessary information to install and handle the product in this

manual. Because of the complexity of this product and its various uses, we do not guarantee

that the given information is complete. If you need additional information, ask your Emerson

representative.

The product has been designed to meet the standard industrial safety requirements. It must

not be used except in its specific area of office telecommunication industry and industrial

control.

Only personnel trained by Emerson or persons qualified in electronics or electrical engineering

are authorized to install, remove or maintain the product.

RTM-ATCA-F140 Installation and Use (6806800M97A)

The information given in this manual is meant to complete the knowledge of a specialist and

must not be used as replacement for qualified personnel. Keep away from live circuits inside

the equipment. Operating personnel must not remove equipment covers. Only factory

authorized service personnel or other qualified service personnel may remove equipment

covers for internal subassembly or component replacement or any internal adjustment.

Do not install substitute parts or perform any unauthorized modification of the equipment or

the warranty may be voided. Contact your local Emerson representative for service and repair

to make sure that all safety features are maintained.

61

Page 62

Safety Notes

EA Version

Electrical Interference