Page 1

ATCA-7150 and RTM-ATCA-7150

Getting Started

Document: 6806800G42B

December 2008

Embedded Computing for

Business-Critical Continuity

TM

Page 2

©

2008 Emerson

All rights reserved.

Trademarks

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service

marks of Emerson Electric Co.

owners.

®

Intel

is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

™

and all other Java-based marks are trademarks or registered trademarks of Sun Microsystems, Inc. in the U.S. and other

Java

countries.

Microsoft

Microsoft Corporation.

PICMG

Industrial Computer Manufacturers Group.

UNIX

®

, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

®

, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

®

is a registered trademark of The Open Group in the United States and other countries.

©

2008 Emerson Electric Co. All other product or service names are the property of their respective

Notice

While reasonable efforts have been made to assure the accuracy of this document, Emerson assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Emerson reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Emerson to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

a Emerson website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Emerson,

It is possible that this publication may contain reference to or information about Emerson products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Emerson intends to announce such Emerson products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Emerson.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Emerson Network Power - Embedded Computing

Lilienthalstr. 15

85579 Neubiberg/Munich

Germany

Page 3

Contents

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.3 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.3.1 Supported Board Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1.3.2 Board Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2 Installation of the RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2 Unpacking and Inspecting RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.3 Environmental and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4 Module Installation and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.1 Ejector Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.4.2 ESD Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.5 Installation Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.5.1 Wearing the ESD-Preventive Wrist Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.5.2 Removing Filler Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.6 Installing and Replacing Daughter Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.6.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.6.2 Preparations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.6.3 GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.6.3.1 Installation Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.6.3.2 Installing the GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.6.3.3 Replacing the GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.6.4 FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.6.4.1 Installation Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

3

Page 4

Contents

Contents

Contents

2.6.4.2 Installing the FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.6.4.3 Replacing the FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.7 Installing and Removing the RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.7.1 Installing RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.7.2 Removing RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.8 Connecting External Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.8.1 Connecting KVM Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

2.8.2 Connecting Network Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.8.3 Connecting Optical Fibers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3 Hardware Installation of ATCA-7150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.2 Unpacking and Inspecting the Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.3 Environmental and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.4 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.4.1 ESD Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.5 Checking the Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.5.1 Wearing the ESD-Preventive Wrist Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.5.2 Removing Blank Filler Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.6 Installing Blade Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.6.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.6.2 Optional Components Supported by the ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.6.3 Preparations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.6.4 DIMM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.6.4.1 Installing the DIMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.6.4.2 Replacing the DIMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.6.5 Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.6.5.1 Installing the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.6.5.2 Replacing the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.7 Installing and Removing the Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.7.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.7.1.1 Installing the ATCA-7150 in a Powered Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.7.1.2 Checking the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 5

Contents

3.7.1.3 Power-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.7.2 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.7.2.1 Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.7.2.2 Removing the ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.8 Ejector Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

A Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

A.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

A.2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

A.3 Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

A.4 Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

A.5 Contacting Emerson Network Power for Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

A.6 LED Display Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

A.6.1 LEDs Are Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

A.6.2 In Service (IS) LED Blinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

A.7 Power-On Startup Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

A.8 Component Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

A.8.1 Component Is Unavailable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

A.8.2 Number of DIMMs Is Inconsistent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

A.9 Power Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

A.9.1 ATCA-7150 Cannot Be Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

A.9.2 ATCA-7150 Automatically Shuts Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

A.10 Peripheral Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

A.10.1 Keyboard Cannot Be Used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

A.10.2 Mouse Cannot Be Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

A.10.3 Monitor Remains Dark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

A.10.4 Monitor Display Is Abnormal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

A.10.5 No Information Is Displayed on the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

A.11 Other Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

A.11.1 USB Interface Cannot Be Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

A.11.2 Network Connection Is Faulty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

A.11.3 A Fault Occurs in Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

A.12 Uncertain Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

A.13 POST Code Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.14 DIM Code Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

5

Page 6

Contents

Contents

Contents

A.15 ACPI Code Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

B Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

B.1 Emerson Network Power - Embedded Computing Documents . . . . . . . . . . . . . . . . . . . . . . . . . . 119

B.2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 7

List of Tables

Table 1-1 Functions of the ATCA-7150 and the RTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 1-2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 1-3 Product Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 1-4 Available Board Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 2-1 Environmental Requirements RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 2-2 Power Requirements RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 3-1 List of Packing Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 3-2 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 3-3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 3-4 Environment for Installing the ATCA-7150 Suite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 3-5 Optional Components Supported by the ATCA-7150 Suite . . . . . . . . . . . . . . . . . . . . . . . 80

Table 3-6 DIMM Configuration on the ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 3-7 Insertion and Removal of the ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 3-8 Power-On and Power-Off of the ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table A-1 POST code checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Table A-2 DIM code checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table A-3 ACPI code checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table B-1 Emerson Network Power - Embedded Computing Publications . . . . . . . . . . . . . . . . . . 119

Table B-2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

7

Page 8

List of Tables

8

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 9

List of Figures

Figure 1-1 Connection Between the ATCA-7150 and the RTM . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2-1 Wearing the ESD-Preventive Wrist Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 2-2 Removing the Filler Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 2-3 Structure of RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 2-4 Installing the GE Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 2-5 Replacing the GE Daughter Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 2-6 Installing the FC Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 2-7 Replacing the FC Daughter Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 2-8 Installing RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 2-9 Removing RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 2-10 Connecting the KVM Cables to RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 2-11 Connecting the Network Cables to RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 2-12 Connecting the Optical Fibers to RTM-ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 3-1 Wearing the ESD-Preventive Wrist Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 3-2 Removing the Blank filler blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 3-3 Positions of the DIMM Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 3-4 Installing the DIMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 3-5 Removing the DIMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 3-6 Installing the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 3-7 Removing the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 3-8 Installing the ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 3-9 Removing the ATCA-7150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

9

Page 10

List of Figures

10

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 11

About this Manual

Overview of Contents

This document describes the ATCA-7150 and RTM-ATCA-7150 server suite (hereinafter

referred to as the ATCA-7150 and RTM-ATCA-7150 suite) in the following aspects:

z Functions, features, and appearance of the ATCA-7150 and RTM-ATCA-7150

z How to install, deploy, and maintain the ATCA-7150 and RTM-ATCA-7150

The user must be a professional engineer in the server device field, who has been trained and is

able to identify danger levels when operating the device.

The body part focuses on the operation process, while the appendix part contains a lot of

supporting information. This helps you to get the required information quickly and accurately.

This manual is divided into the following chapters and appendices.

z Safety Notes on page 17 lists safety notes applicable to the blade.

z Sicherheitshinweise on page 23 is the German translation of the previous English safety

notes (this had to be included for legal reasons).

z Chapter 1, Introduction, on page 29 describes the main features of the ATCA-7150 and

RTM-ATCA-7150.

z Chapter 2, Installation of the RTM-ATCA-7150, on page 35 describes the installation of the

RTM.

z Chapter 3, Hardware Installation of ATCA-7150, on page 69 describes installation

prerequisites including the blade installation itself of the front blade.

z Tro ub le sh oo ti ng on page 99 provides troubleshooting information.

z Related Documentation on page 119 provides links to further ATCA-7150 and RTM-ATCA-

7150-related documentation.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

11

Page 12

About this Manual

About this Manual

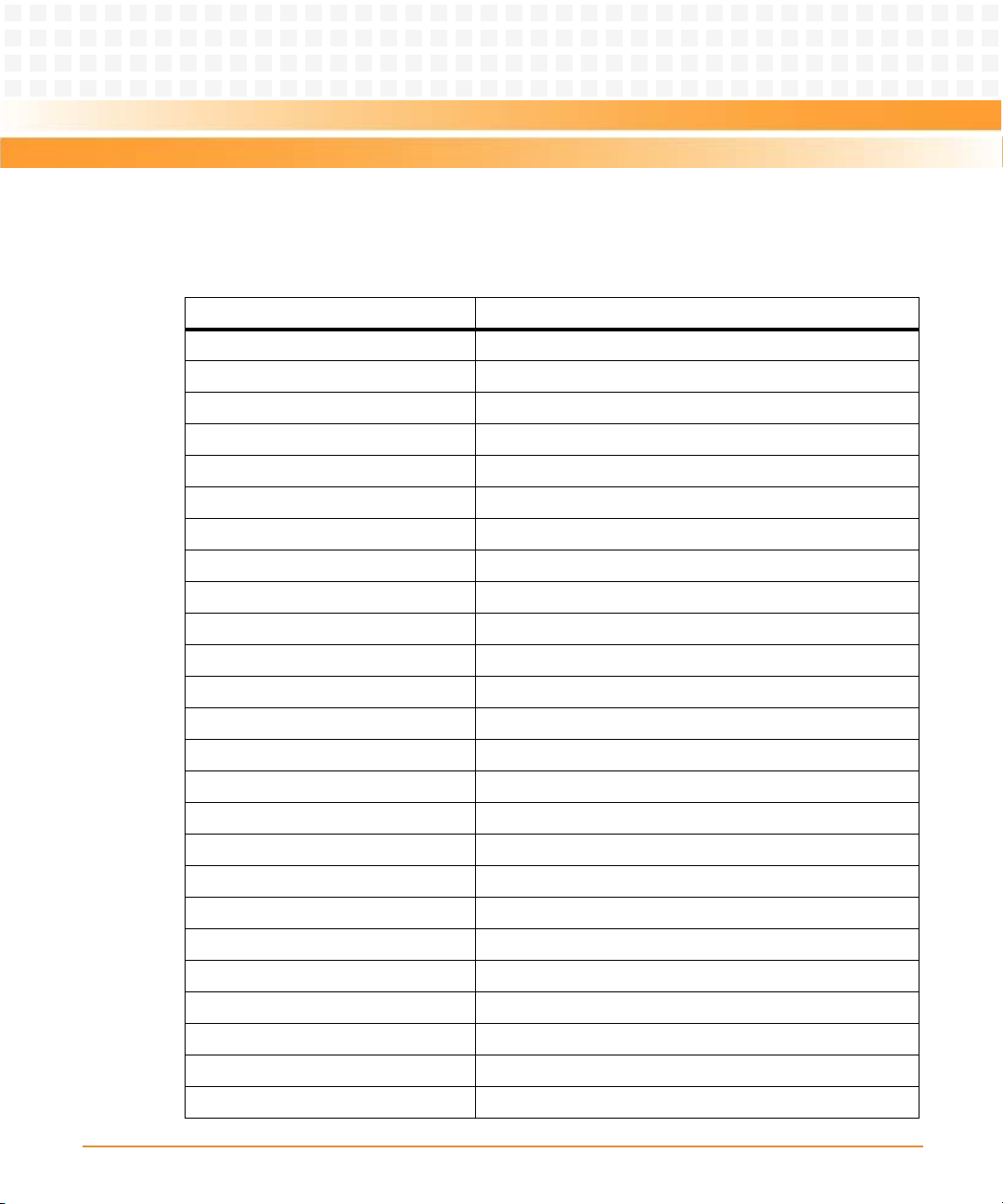

Abbreviations

This document uses the following abbreviations:

Abbreviation Definition

ACA Australian Communications Authority

BIOS Basic Input/Output System

BMC Baseboard Management Controller

CMOS Complementary Metal Oxide Semiconductor

CPU Central Processing Unit

DC Direct Current

DIMM Dual Inline Memory Module

ECC Error Checking and Correcting

EIA Electronics Industries Association

EMC Electromagnetic Compatibility

ESD Electro-Static Discharge

FBD Fully Buffer DIMM

FC Fiber Channel

FCC Federal Communications Commission

FRU Field Replaceable Unit

GE Gigabit Ethernet

IEC International Electrotechnical Commission

IPMB Intelligent Platform Management BUS

IPMI Intelligent Platform Management Interface

KVM Keyboard, Video, and Mouse

OOS Out of Service

PCI Peripheral Component Interconnect

PEM Power Entry Module

POST Power-On Self Test

RAID Redundant Arrays of Independent Disks

12

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 13

About this Manual

Abbreviation Definition

RTM Rear Transition Module

SAS Serial Attached Small Computer System Interface

SCSI Small Computer System Interface

SDR Sensor Data Record

SEL System Event Log

ShMC Shelf Management Controller

SOL Serial Over LAN

UL Underwriters Laboratories Inc

USB Universal Serial Bus

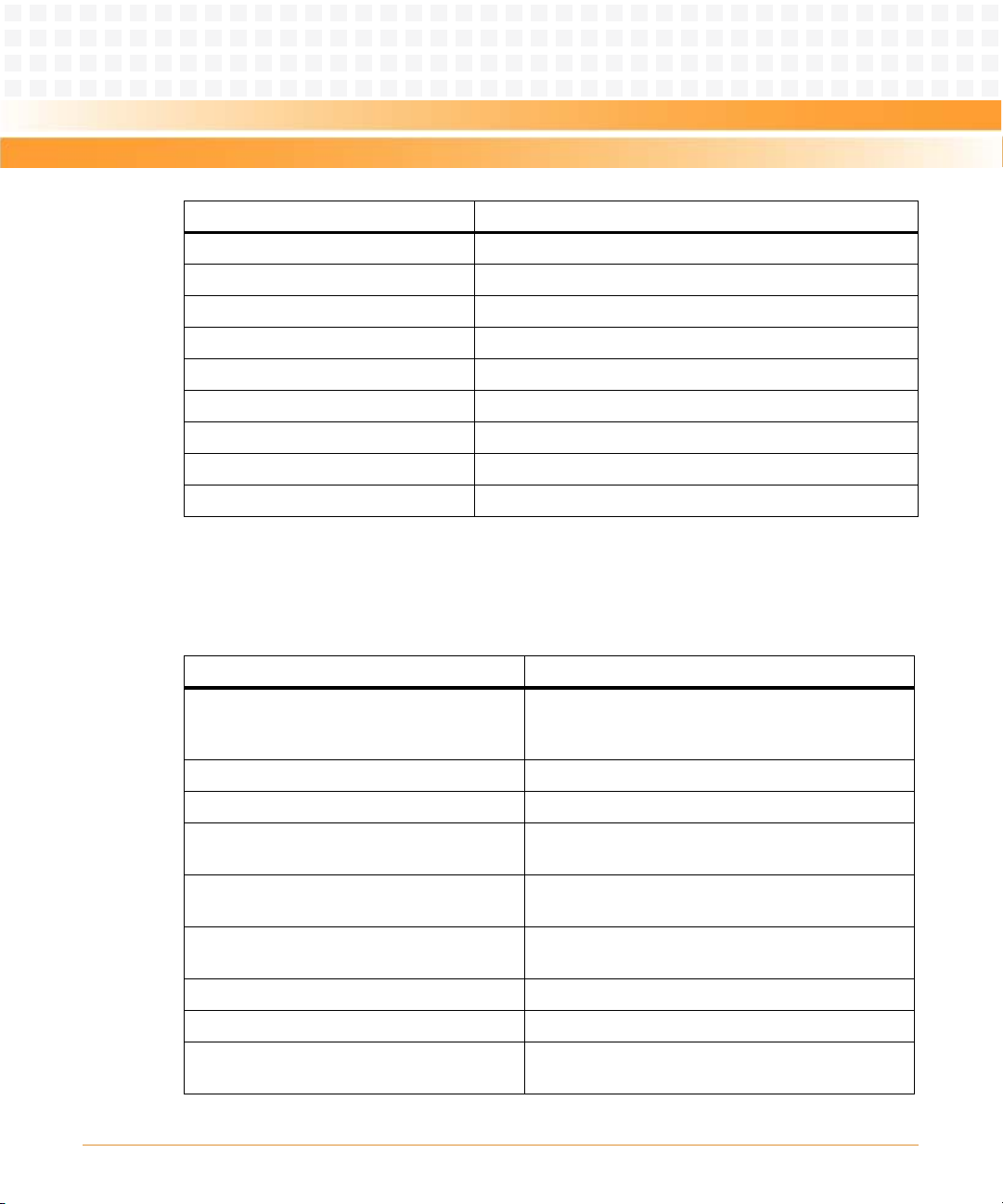

Conventions

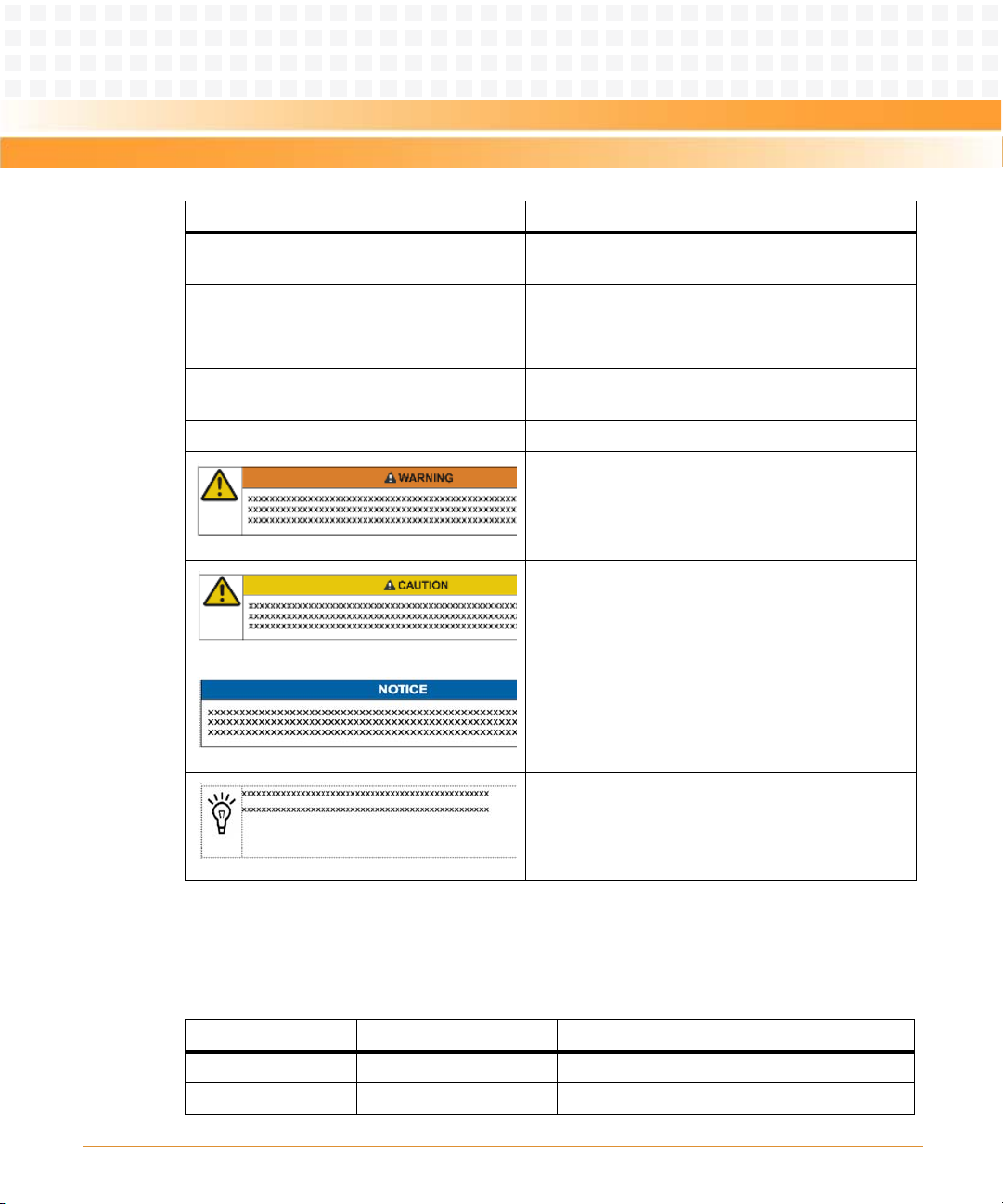

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are

0b0000 Same for binary numbers (digits are 0 and 1)

0 through F), for example used for addresses and

offsets

bold Used to emphasize a word

Screen Used for on-screen output and code related elements

or commands in body text

Courier + Bold Used to characterize user input and to separate it

from system output

Reference Used for references and for table and figure

descriptions

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

[text] Notation for software buttons to click on the screen

and parameter description

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

13

Page 14

About this Manual

About this Manual

Notation Description

... Repeated item for example node 1, node 2, ..., node

.

.

.

.. Ranges, for example: 0..4 means one of the integers

|Logical OR

12

Omission of information from example/command

that is not necessary at the time being

0,1,2,3, and 4 (used in registers)

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury

Summary of Changes

This manual has been revised and replaces all prior editions.

Part Number Publication Date Description

6806800G42A June 2008 First edition

6806800G42B December 2008 Updated to Emerson layout, editorial changes

14

Indicates a property damage message

No danger encountered. Pay attention to important

information

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 15

About this Manual

Comments and Suggestions

We welcome and appreciate your comments on our documentation. We want to know what

you think about our manuals and how we can make them better.

Mail comments to us by filling out the following online form:

http://www.emersonnetworkpowerembeddedcomputing.com/ > Contact Us > Online Form

In "Ar ea of I ntere st" selec t "Tec hni cal Doc ument ati on" . Be sur e to inc lud e th e ti tle, p ar t nu mber,

and revision of the manual and tell us how you used it.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

15

Page 16

About this Manual

About this Manual

16

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 17

Safety Notes

This section provides warnings that precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed during all phases of

operation, service, and repair of this equipment. You should also employ all other safety

precautions necessary for the operation of the equipment in your operating environment.

Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

Emerson Network Power intends to provide all necessary information to install and handle the

product in this manual. Because of the complexity of this product and its various uses, we do

not guarantee that the given information is complete. If you need additional information, ask

your Emerson Network Power representative.

The product has been designed to meet the standard industrial safety requirements. It must

not be used except in its specific area of office telecommunication industry and industrial

control.

Only personnel trained by Emerson Network Power or persons qualified in electronics or

electrical engineering are authorized to install, remove or maintain the product.

The information given in this manual is meant to complete the knowledge of a specialist and

must not be used as replacement for qualified personnel.

Keep away from live circuits inside the equipment. Operating personnel must not remove

equipment covers. Only Factory Authorized Service Personnel or other qualified service

personnel may remove equipment covers for internal subassembly or component replacement

or any internal adjustment.

Do not install substitute parts or perform any unauthorized modification of the equipment or

the warranty may be voided. Contact your local Emerson Network Power representative for

service and repair to make sure that all safety features are maintained.

EMC

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

17

Page 18

Safety Notes

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense. Changes or

modifications not expressly approved by Emerson Network Power Embedded Computing

could void the user's authority to operate the equipment. Board products are tested in a

representative system to show compliance with the above mentioned requirements. A proper

installation in a compliant system will maintain the required performance. Use only shielded

cables when connecting peripherals to assure that appropriate radio frequency emissions

compliance is maintained.

Operation

Damage of the Product

Surface of the Product

High humidity and condensation on the product surface causes short circuits.

Do not operate the product outside the specified environmental limits. Make sure the product

is completely dry and there is no moisture on any surface before applying power.

Do not operate the product below -5°C.

Overheating and Damage of the Product

Operating the product without forced air cooling may lead to overheating and thus damage of

the product.

When operating the product, make sure that forced air cooling is available in the shelf.

Configuration Jumpers

Malfunction of the Product

Reserved jumpers might carry production-related functions and can cause the product to

malfunction if their setting is changed.

Therefore, do not change settings of jumpers marked as "Reserved".

18

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 19

Installation

Damage of the Product and Additional Devices and Modules

Incorrect installation or removal of additional devices or modules may damage the product or

the additional devices or modules.

Before installing or removing additional devices or modules, read the respective

documentation.

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product or electronic components, make sure that your are working in an

ESD-safe environment.

Safety Notes

Damage of the Product

Incorrect installation of the product can cause damage of the product.

Only use handles when installing/removing the product to avoid damage/deformation to the

face plate and/or PCB.

Damage to the Product/Backplane or System Components

Bent pins or loose components can cause damage to the product, the backplane, or other

system components.

Therefore, carefully inspect the product and the backplane for both pin and component

integrity before installation.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

19

Page 20

Safety Notes

Emerson Network Power Embedded Computing (ENPEC) and our suppliers take significant

steps to ensure there are no bent pins on the backplane or connector damage to the boards

prior to leaving the factory. Bent pins caused by improper installation or by inserting boards

with damaged connectors could void the ECC warranty for the backplane or boards.

Incorrect installation of the product can cause blade damage.

Only use handles for when installing/removing the product to avoid damage/deformation to

the face plate and/or PCB

Cabling and Connectors

Damage of the Product

The RJ-45 connector(s) on the face plate are either twisted-pair Ethernet (TPE) or E1/T1/J1

interfaces. Connecting an E1/T1/J1 line to an Ethernet connector may damage the product.

z Make sure that TPE connectors near your working area are clearly marked as network

connectors.

z Verify that the length of an electric cable connected to a TPE bushing does not exceed 100

meters.

z Make sure the TPE bushing of the product is connected only to safety extra low voltage

circuits (SELV circuits).

If in doubt, ask your system administrator.

Laser

This product is a Class 1 laser product. The use of controls or adjustments or performance of

procedures other than those specified herein may result in hazardous radiation exposure.

Environment

Always dispose of used blades, system components and RTMs according to your country’s

legislation and manufacturer’s instructions.

20

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 21

Battery

Board/System damage

Incorrect exchange of lithium batteries can result in a hazardous explosion.

When exchanging the on-board lithium battery, make sure that the new and the old battery

are exactly the same battery models.

If the respective battery model is not available, contact your local Emerson Network Power

sales representative for the availablity of alternative officially approved battery models.

Safety Notes

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

21

Page 22

Safety Notes

22

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 23

Sicherheitshinweise

Dieses Kapitel enthält Hinweise, die potentiell gefährlichen Prozeduren innerhalb dieses

Handbuchs vorrangestellt sind. Beachten Sie unbedingt in allen Phasen des Betriebs, der

Wartung und der Reparatur des Systems die Anweisungen, die diesen Hinweisen enthalten

sind. Sie sollten außerdem alle anderen Vorsichtsmaßnahmen treffen, die für den Betrieb des

Produktes innerhalb Ihrer Betriebsumgebung notwendig sind. Wenn Sie diese

Vorsichtsmaßnahmen oder Sicherheitshinweise, die an anderer Stelle diese Handbuchs

enthalten sind, nicht beachten, kann das Verletzungen oder Schäden am Produkt zur Folge

haben.

Emerson ist darauf bedacht, alle notwendigen Informationen zum Einbau und zum Umgang

mit dem Produkt in diesem Handbuch bereit zu stellen. Da es sich jedoch um ein komplexes

Produkt mit vielfältigen Einsatzmöglichkeiten handelt, können wir die Vollständigkeit der im

Handbuch enthaltenen Informationen nicht garantieren. Falls Sie weitere Informationen

benötigen sollten, wenden Sie sich bitte an die für Sie zuständige Geschäftsstelle von Emerson.

Das System erfüllt die für die Industrie geforderten Sicherheitsvorschriften und darf

ausschließlich für Anwendungen in der Telekommunikationsindustrie und im Zusammenhang

mit Industriesteuerungen verwendet werden.

Einbau, Wartung und Betrieb dürfen nur von durch Emerson ausgebildetem oder im Bereich

Elektronik oder Elektrotechnik qualifiziertem Personal durchgeführt werden. Die in diesem

Handbuch enthaltenen Informationen dienen ausschließlich dazu, das Wissen von

Fachpersonal zu ergänzen, können dieses jedoch nicht ersetzen.

Halten Sie sich von stromführenden Leitungen innerhalb des Produktes fern. Entfernen Sie auf

keinen Fall Abdeckungen am Produkt. Nur werksseitig zugelassenes Wartungspersonal oder

anderweitig qualifiziertes Wartungspersonal darf Abdeckungen entfernen, um Komponenten

zu ersetzen oder andere Anpassungen vorzunehmen.

Installieren Sie keine Ersatzteile oder führen Sie keine unerlaubten Veränderungen am Produkt

durch, sonst verfällt die Garantie. Wenden Sie sich für Wartung oder Reparatur bitte an die für

Sie zuständige Geschäftsstelle von Emerson. So stellen Sie sicher, dass alle

sicherheitsrelevanten Aspekte beachtet werden.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

23

Page 24

Sicherheitshinweise

EMV

Das Produkt wurde in einem Emerson Network Power Standardsystem getestet. Es erfüllt die

für digitale Geräte der Klasse A gültigen Grenzwerte in einem solchen System gemäß den FCCRichtlinien Abschnitt 15 bzw. EN 55022 Klasse A. Diese Grenzwerte sollen einen

angemessenen Schutz vor Störstrahlung beim Betrieb des Produktes in Gewerbe- sowie

Industriegebieten gewährleisten.

Das Produkt arbeitet im Hochfrequenzbereich und erzeugt Störstrahlung. Bei

unsachgemäßem Einbau und anderem als in diesem Handbuch beschriebenen Betrieb können

Störungen im Hochfrequenzbereich auftreten.

Wird das Produkt in einem Wohngebiet betrieben, so kann dies mit grosser Wahrscheinlichkeit

zu starken Störungen führen, welche dann auf Kosten des Produktanwenders beseitigt werden

müssen. Änderungen oder Modifikationen am Produkt, welche ohne ausdrückliche

Genehmigung von Emerson Network Power EC durchgeführt werden, können dazu führen,

dass der Anwender die Genehmigung zum Betrieb des Produktes verliert. Boardprodukte

werden in einem repräsentativen System getestet, um zu zeigen, dass das Board den oben

aufgeführten EMV-Richtlinien entspricht. Eine ordnungsgemässe Installation in einem System,

welches die EMV-Richtlinien erfüllt, stellt sicher, dass das Produkt gemäss den EMV-Richtlinien

betrieben wird. Verwenden Sie nur abgeschirmte Kabel zum Anschluss von Zusatzmodulen. So

ist sichergestellt, dass sich die Aussendung von Hochfrequenzstrahlung im Rahmen der

erlaubten Grenzwerte bewegt.

Warnung! Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im Wohnbereich

Funkstörungen verursachen. In diesem Fall kann vom Betreiber verlangt werden,

angemessene Maßnahmen durchzuführen.

Betrieb

Beschädigung des Produktes

Hohe Luftfeuchtigkeit und Kondensat auf der Oberfläche des Produktes können zu

Kurzschlüssen führen.

Betreiben Sie das Produkt nur innerhalb der angegebenen Grenzwerte für die relative

Luftfeuchtigkeit und Temperatur. Stellen Sie vor dem Einschalten des Stroms sicher, dass sich

auf dem Produkt kein Kondensat befindet und betreiben Sie das Produkt nicht unter -5°C.

24

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 25

Überhitzung und Beschädigung des Produktes

Betreiben Sie das Produkt ohne Zwangsbelüftung, kann das Produkt überhitzt und schließlich

beschädigt werden.

Bevor Sie das Produkt betreiben, müssen Sie sicher stellen, dass das Shelf über eine

Zwangskühlung verfügt.

Jumper

Fehlfunktion des Produktes

Schalter, die mit 'Reserved' sind, können mit produktionsrelevanten Funktionen belegt sein.

Das Ändern dieser Schalter kann im normalen Betrieb Störungen auslösen.

Installation

Sicherheitshinweise

Beschädigung des Produktes und von Zusatzmodulen

Fehlerhafte Installation von Zusatzmodulen, kann zur Beschädigung des Produktes und der

Zusatzmodule führen.

Lesen Sie daher vor der Installation von Zusatzmodulen die zugehörige Dokumentation.

Beschädigung von Schaltkreisen

Elektrostatische Entladung und unsachgemäßer Ein- und Ausbau des Produktes kann

Schaltkreise beschädigen oder ihre Lebensdauer verkürzen.

Bevor Sie das Produkt oder elektronische Komponenten berühren, vergewissern Sie sich, daß

Sie in einem ESD-geschützten Bereich arbeiten.

Beschädigung des Produktes

Fehlerhafte Installation des Produktes kann zu einer Beschädigung des Produktes führen.

Verwenden Sie die Handles, um das Produkt zu installieren/deinstallieren. Auf diese Weise

vermeiden Sie, dass das Face Plate oder die Platine deformiert oder zerstört wird.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

25

Page 26

Sicherheitshinweise

Beschädigung des Produktes, der Backplane oder von System Komponenten

Verbogene Pins oder lose Komponenten können zu einer Beschädigung des Produktes, der

Backplane oder von Systemkomponenten führen.

Überprüfen Sie daher das Produkt sowie die Backplane vor der Installation sorgältig und stellen

Sie sicher, dass sich beide in einwandfreien Zustand befinden und keine Pins verbogen sind.

Emerson Network Power Embedded Computing (ENPEC) und unsere Zulieferer unternehmen

größte Anstrengungen um sicherzustellen, dass sich Pins und Stecker von Boards vor dem

Verlassung der Produktionsstätte in einwandfreiem Zustand befinden. Verbogene Pins,

verursacht durch fehlerhafte Installation oder durch Installation von Boards mit beschädigten

Steckern kann die durch ECC gewährte Garantie für Boards und Backplanes erlöschen lassen.

Kabel und Stecker

Beschädigung des Produktes

Bei den RJ-45-Steckern, die sich an dem Produkt befinden, handelt es sich entweder um

Twisted-Pair-Ethernet (TPE) oder um E1/T1/J1-Stecker. Beachten Sie, dass ein versehentliches

Anschließen einer E1/T1/J1-Leitung an einen TPE-Stecker das Produkt zerstören kann.

z Kennzeichnen Sie deshalb TPE-Anschlüsse in der Nähe Ihres Arbeitsplatzes deutlich als

Netzwerkanschlüsse.

z Stellen Sie sicher, dass die Länge eines mit Ihrem Produkt verbundenen TPE-Kabels 100 m

nicht überschreitet.

z Das Produkt darf über die TPE-Stecker nur mit einem Sicherheits-Kleinspannungs-

Stromkreis (SELV) verbunden werden.

Bei Fragen wenden Sie sich an Ihren Systemverwalter.

Laser

Einige Varianten des Produktes sind Laserprodukte der Klasse 1. Um nicht schädlicher

Laserstrahlung ausgesetzt zu werden, beachten Sie die folgenden Hinweise: Anpassungen am

Produkt, die Bedienung von Steuerelementen sowie die Durchführung von Prozeduren dür fen

nur gemäß den Anweisungen in diesem Dokument erfolgen.

26

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 27

Umweltschutz

Entsorgen Sie alte Batterien und Blades/RTMs stets gemäß der in Ihrem Land gültigen

Gesetzgebung und den Empfehlungen des Herstellers.

Batterie

Beschädigung des Produktes

Ein unsachgemäßer Einbau der Batterie kann gefährliche Explosionen und Beschädigungen

des Produktes zur Folge haben.

Verwenden Sie deshalb nur den Batterietyp, der auch bereits eingesetzt wurde und befolgen

Sie die Installationsanleitung.

Falls der entsprechende Batterietyp nicht verfügbar ist, kontaktieren Sie Ihren lokalen Emerson

Network Power-Ansprechpartner und erfragen Sie die Verfügbarkeit von alternativen, offiziell

zugelassenen Batteriemodellen.

Sicherheitshinweise

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

27

Page 28

Sicherheitshinweise

28

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 29

Chapter: 1

Introduction

1.1 Features

The ATCA-7150 and RTM-ATCA-7150 server blade suite features the capabilities of high speed

calculation and mass data processing.

The ATCA-7150 and RTM-ATCA-7150 suite consists of:

z ATCA-7150 and RTM-ATCA-7150

z RTM-ATCA-7150

The RTM-ATCA-7150 is the rear transition module (RTM) of the server blade.

A server blade must work with an RTM of the server blade. For example, the ATCA-7150 works

with the RTM-ATCA-7150.

You can install the ATCA-7150 in any node slot of your shelf. The RTM-ATCA-7150 is installed

in the slot that is paired with the ATCA-7150 slot.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

29

Page 30

Introduction

Figure 1-1 shows the connection between the ATCA-7150 and the RTM of the server blade.

RTM of the

server blade

Backplane

ATCA-

7150

Figure 1-1 Connection Between the ATCA-7150 and the RTM

You can choose to use the RTM-ATCA-7150 according to the actual application.

The backplane is one part of the shelf. For details on the backplane and shelf, refer to the

respective system documentation.

30

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 31

Introduction

Table 1-1 lists the functions of the ATCA-7150 and the RTM.

Table 1-1 Functions of the ATCA-7150 and the RTM

Function Description

Processing functions z Supports two dual-core LV Intel Xeon 5138 (2.13 GHz)

processors

z Supports 4 MB L2 cache

z Supports up to four FB-DIMMs

z Supports the DIMM with a capacity of 512 MB, 1 GB, 2 GB, or 4

GB. The maximum capacity is 16 GB

Interface functions z 10/100/1000Base-T

z 1000Base-BX

z 1000Base-BX

z Provides two USB 2.0 interfaces (compatible with USB 1.1)

z Provides one IPMC serial port (also used as the system serial

port, the serial port standards are RS232 and RJ-45)

z Provides serial port to access CPU and IPMC serial console

z Provides two SAS hard disks

z The RTM-ATCA-7150 that works with the ATCA-7150 provides a

monitor interface and a USB 2.0 interface (compatible with

USB1.1). Through optional daughter cards, the RTM-ATCA-7150

can also provide external GE interfaces, and FC interfaces.

Management functions The ATCA-7150 provides the IPMC that is powered independently.

The IPMC is connected to the ShMC through the redundant IPMB.

The IPMC provides the following functions:

z Environmental sensors temperature, voltage

z System Event Logs

z Watchdog timer

z Power-on, power-off, cold reset

z SOL(Serial Over LAN)

z FRU Hot-swap management

z E-Keying control

Integrity functions z Dual-channel GE controller

z IPMI

z SAS storage controller

z Video controller

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

31

Page 32

Introduction

1.2 Standard Compliances

This product meets the following standards.

Table 1-2 Standard Compliances

Standard Description

UL 60950-1

EN 60950-1

IEC 60950-1

CAN/CSA C22.2 No 60950-1

CISPR 22

CISPR 24

EN 55022

EN 55024

FCC Part 15

Industry Canada ICES-003

VCCI Japan

AS/NZS CISPR 22

EN 300 386

NEBS Standard GR-1089 CORE

Legal safety requirements

EMC re quirements ( legal) on s ystem level ( predefined Emerson

Network Power system)

NEBS Standard GR-63-CORE

ETSI EN 300019 series

PICMG 3.0 Defines mechanics, blade dimensions, power distribution,

Environmental requirements

power and data connectors, and system management

1.3 Ordering Information

When ordering board variants or board accessories, use the order numbers given on the

following pages.

32

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 33

Introduction

1.3.1 Supported Board Models

The following table explains the product nomenclature used for the available board variants.

Table 1-3 Product Nomenclature

Order Number Description

ATCA-7150-0GB ATCA Processor Blade with Dual Core Intel® Xeon® Processor

LV5138.

Can be equipped with up to 16GB DDR2 memory.

1G fabric interface.

ATCA-7X50-MEM-2G 2G Memory Module (min 1, max 4 modules of the same type per

blade)

ATCA-7X50-MEM-4G 4G Memory Module (min 1, max 4 modules of the same type per

blade)

RTM-ATCA-7150-GE Rear Transition Module for ATCA-7150, 2x 1G Ethernet

RTM-ATCA-7150-GE-FC Rear Transition Module for ATCA-7150, 2x 1G Eth, 2x FC

ATCA7X50-HDD1-SAS Enterprise Class HDD, SAS, 72GB

ATCA7X50-HDD2-SAS Enterprise Class HDD, SAS, 146GB

ATCA7X50-HDD3-SATA Automotive HDD, SATA, 80GB

ATCA-7150-8GB-1HDD1 ATCA Processor Blade with Dual Core Intel® Xeon® Processor

LV5138, 8GB (4x 2GB) Memory, 1x Enterprise Class HDD, SAS,

72GB

ATCA7X50-SSD2-SATA Solid State Disk, SATA, 32GB

1.3.2 Board Accessories

As of the printing date of this manual, the following board accessories were available.

Table 1-4 Available Board Accessories

Board Accesories Order Number

Gigabit Ethernet (GE) daughter card MEZC-RTM-7150-GE

Fiber Channel (FC) daughter card MEZC-RTM-7150-FC

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

33

Page 34

Introduction

Table 1-4 Available Board Accessories (continued)

Board Accesories Order Number

ATCA7X50-HDDx-SAS/SATA ATCA7X50-HDD1-SAS

ATCA7X50-HDD2-SAS

ATCA7X50-HDD3-SATA

ATC A7 X5 0

34

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 35

Chapter: 2

Installation of the RTM-ATCA-7150

2.1 Overview

This chapter describes:

z Unpacking and inspecting RTM-ATCA-7150

z Precautions during the operation

z Preparations before installation

z Installation procedure

z Installing and replacing daughter cards

z Connection of external cables

z Removal procedure

2.2 Unpacking and Inspecting RTM-ATCA-7150

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product or electronic components, make sure that your are working in

an ESD-safe environment.

Shipment Inspection

To inspect the shipment, perform the following steps.

1. Verify that you have received all items of your shipment:

Printed "Getting Started" guide

RTM-ATCA-7150

Any optional items ordered

2. Check for damage and report any damage or differences to the customer service.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

35

Page 36

Installation of the RTM-ATCA-7150

3. Remove the desiccant bag shipped together with the blade and dispose of it

according to your country’s legislation.

The product is thoroughly inspected before shipment. If any damage occurred during

transportation or any items are missing, please contact our customer's service immediately.

2.3 Environmental and Power Requirements

The following environmental and power requirements are applicable to the board.

2.3.1 Environmental Requirements

Table 2-1 Environmental Requirements RTM-ATCA-7150

Requirement Operating Non-Operating

Temperature +5ºC (41ºF) to +40ºC (104ºF) (normal operation)

according to NEBS Standard GR-63-CORE

-5ºC to +55ºC (short term operation) according

to NEBS Standard GR-63-CORE

Temp. Change +/- 0.25ºC/min or 15ºC/h (59ºF/h) according to

NEBS Standard GR-63-CORE

Rel. Humidity 5% to 85% non-condensing according to

Emerson Network Power Embedded

Computing-internal environmental

requirements

Altitude <= 4000m

-40ºC (-40ºF) to +70ºC

(158ºF) (may be further

limited by installed

accessories)

+/- 0.25ºC/min or 15ºC/h

(59ºF/h)

5% to 85% non-condensing

according to Emerson

Network Power Embedded

Computing-internal

environmental

requirements

36

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 37

Installation of the RTM-ATCA-7150

Table 2-1 Environmental Requirements RTM-ATCA-7150 (continued)

Requirement Operating Non-Operating

Vibration 1.0g from 5 to 100 Hz and back to 5 Hz at a rate

of 0.1 octave/minute

Shock Half-sine, 11 m/Sec, 30mSec/sec

Free Fall 1,200 mm/all edges and

2.3.2 Power Requirements

Table 2-2 Power Requirements RTM-ATCA-7150

5-20 Hz @ 0.01 g2/Hz

20-200 Hz @ -3.0 dB/octave

Random 5-20 Hz @ 1

2

3

m

/Sec

Random 20-200 Hz @ -3

2

m/Sec

2

Blade level packaging

Half-sine, 6 mSec at 180

2

m/Sec

corners

1.0m (Packaged) per ETSI

300 019-2-2 (Blade level

packaging)

100mm (unpackaged) per

GR-63-CORE

Requirement Operating

Power supply Provided by the server blade

Maximum power consumption 14.2 W

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

37

Page 38

Installation of the RTM-ATCA-7150

2.4 Module Installation and Removal

Personal Damage through Electric Shock

There is current in the power cords and communication cables. Touching the connectors of

the power cords and communication cables may cause electric shock.

Do not touch the connectors of power cords and communication cables

Damage of Circuits

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product or electronic components, make sure that your are working in

an ESD-safe environment.

Module Damage

If the blade is not fully aligned with the interface in the backplane, too much force may twist

the pins on the blade or backplane.

Do not exert too much force when you insert the blade.

Note the following points at the time of installing RTM-ATCA-7150:

z Make sure that you wear an electrostatic discharge (ESD)-preventive wrist strap to prevent

the static electricity from hurting you or damaging the device.

z Keep your personal objects such as your clothes away from RTM-ATCA-7150. To prevent

the static electricity on clothing, you need to put on antistatic clothing.

z RTM-ATCA-7150 is installed in the slot paired with the server blade slot at the back side of

the shelf. You should install RTM-ATCA-7150 before the server blade is installed.

Otherwise, RTM-ATCA-7150 cannot be powered on normally.

38

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 39

Installation of the RTM-ATCA-7150

z Hold the ejector handles and the face plate when you insert or remove RTM-ATCA-7150.

Do not touch the components inside of the blades.

z Keep the blade vertical when you install RTM-ATCA-7150. Align the blade with the slot and

then insert it in the shelf.

2.4.1 Ejector Handles

RTM-ATCA-7150 is powered by the server blade in the slot paired with the RTM-ATCA-7150

slot. RTM-ATCA-7150 does not support hot swap. The face plate of ATCA-7150 and RTM-ATCA7150 provides an upper and a lower ejector handles. The ejector handles help to insert,

remove, fasten, power on, and power off RTM-ATCA-7150.

2.4.2 ESD Prevention

Static electricity may hurt you or damage the device. To minimize the damage, pay attention

to the following points:

z Before you operate the device, wear the ESD-preventive wrist strap. Both terminals of the

ESD-preventive wrist strap must contact well. One terminal touches your bare skin, and

the other is inserted in the jack at the front or back side of the shelf. For details on how to

wear the ESD-preventive wrist strap, refer Wearing the ESD-Preventive Wrist Strap.

z Avoid moving your body as much as possible. Movement gathers static electricity around

you.

z Do not touch the solder point, pin, or bare circuit.

z Do not leave the device in the place where others can operate it.

z Install the device at once after you take it out of the antistatic package. If you need to lay

down the device, place it back in the antistatic package. Do not lay the device on the shelf

or cabinet.

z Monitor the temperature and humidity of the equipment room. Warm air decreases the

humidity and increases the static electricity in the room.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

39

Page 40

Installation of the RTM-ATCA-7150

2.5 Installation Preparations

The installation preparations process includes:

z check the installation environment

z wear the ESD-preventive wrist strap

z remove the blank filler panels

z unpack and check the RTM-ATCA-7150 suite

2.5.1 Wearing the ESD-Preventive Wrist Strap

Module Damage

z Electrostatic discharge can damage circuits or shorten their life.

z The ESD-preventive wrist strap prevents only the static electricity on your body from

da magin g the bla de. To p revent t he s tat ic elec tr ici ty on you r cl oth es, it is r eco mme nde d

to wear the antistatic clothes. Additionally, you have to make sure that the cabinet and

shelf are properly grounded - for details, refer to the corresponding system

documentation.

40

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 41

Installation of the RTM-ATCA-7150

To wear the ESD-preventive wrist strap, proceed as follows:

1. Wrap the ESD-preventive wrist strap around your wrist, as shown in the figure

below.

2. Fasten the latch. Make sure that the ESD-preventive wrist strap well touches your

bare wrist.

3. Insert the grounding terminal of the ESD-preventive wrist strap in the jack of the

cabinet or shelf.

There is a jack for inserting the ESD-preventive wrist strap respectively in the lower right

corners at both front and back sides of the shelf.

Figure 2-1 Wearing the ESD-Preventive Wrist Strap

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

41

Page 42

Installation of the RTM-ATCA-7150

2.5.2 Removing Filler Blades

After a filler blade is removed, place it in the equipment room or other moisture-proof and

dust-proof places.

You should install a blank filler blade in the slot after removing the blade. Otherwise, it may

effect the ventilation, heat dissipation, electromagnetic shielding and dust prevention of the

shelf.

If this is the first installation for the shelf, the blade is fully configured and the shelf is not

powered on, you can remove all the filler blades. Then, install blades in the slots in order. This

document takes the first installation as an example.

If you want to install multiple blades in the shelf that is powered on shelf, you can remove a

filler blade and then install a blade one by one.

If the slot is occupied with a filler blade you have to remove it first.

42

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 43

Installation of the RTM-ATCA-7150

To remove the filler blade, proceed as follows:

1

1

2

1. As shown in step 1 of the figure below, use a screwdriver to anticlockwise loosen

the two captive screws on a filler blade.

2. As shown in step 2 of the figure below, remove the filler blade.

Figure 2-2 Removing the Filler Blade

2.6 Installing and Replacing Daughter Cards

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

43

Page 44

Installation of the RTM-ATCA-7150

2.6.1 Precautions

Incorrect installation or removal of additional devices or modules may damage the product

or the additional devices or modules.

Before installing or removing additional devices or modules, read the respective

documentation.

Electrostatic discharge and incorrect installation and removal of the product can damage

circuits or shorten their life.

Before touching the product or electronic components, make sure that your are working in

an ESD-safe environment.

Do not exert too much force when you insert the blade.

If the blade is not fully aligned with the interface in the backplane, too much force may twist

the pins on the blade or backplane.

Do not touch the connectors of power cords and communication cables.

There is current in the power cords and communication cables. Touch on the connectors of

the power cords and communication cables may cause electric shock.

Note the following points at the time of installing or replacing components:

z Make sure that you wear an electrostatic discharge (ESD)-preventive wrist strap to prevent

the static electricity from hurting you or damaging the device.

z Keep the area where the components reside clean and keep the components away from

the heat-generating devices, such as radiators.

44

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 45

Installation of the RTM-ATCA-7150

z Ensure that your sleeves are tightened or rolled up above the elbow. For safety purpose, it

is not recommended to wear jewelry, watch, glasses with metal frame, or clothes with

metal buttons.

z Do not exert too much force, or insert or remove the components forcibly. Avoid damage

to the components or plug-ins, for example, the pins are bent or get short circuit.

2.6.2 Preparations

Before you install or replace a component, make the following preparations

z Confirming the feasibility of the operation

— There are available spare parts of the component to be installed or replaced in the

equipment warehouse. When the available spare parts are in short supply, contact

Emerson Network Power Embedded Computing for help in time.

— Make sure that the new component is in good condition, without defects such as

oxidation, chemical corrosion, missing component, or transportation damage.

— By reading this document, you are familiar with how to install and replace the

component and master the skills required by the operation.

z Checking the environment

Make sure that the shelf, power supply, temperature, and humidity meet the operating

requirements of the blades and components. For details, refer to ATCA-7150 Installation

and Use Manual and other related documents.

z Preparing spare parts and tools

— Prepare the component to be installed or replaced.

When you hold or transport the component, use the special antistatic package. In

addition, you need to tidy, record, and repair the component during routine

maintenance.

— Prepare the cross screwdriver, screws, plastic supports, cooling gel, and ESD-

preventive wrist strap.

The supplier provides a list of tools and negotiates with you to decide the tool provider.

z Confirming installation or changing positions

Confirm the positions of the cabinet, the shelf, and the slot where RTM-ATCA-7150 is

installed. Then, stick a label on the face plate of RTM-ATCA-7150 to avoid wrong operation.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

45

Page 46

Installation of the RTM-ATCA-7150

z Others

If a serious problem occurs and cannot be solved when you install or replace the

component, contact Emerson Network Power Embedded Computing for technical

support.

2.6.3 GE Daughter Card

This manual considers the GE daughter card providing two external Ethernet interfaces as an

example, and describes how to install the daughter card on and remove it from RTM-ATCA-

7150.

46

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 47

Installation of the RTM-ATCA-7150

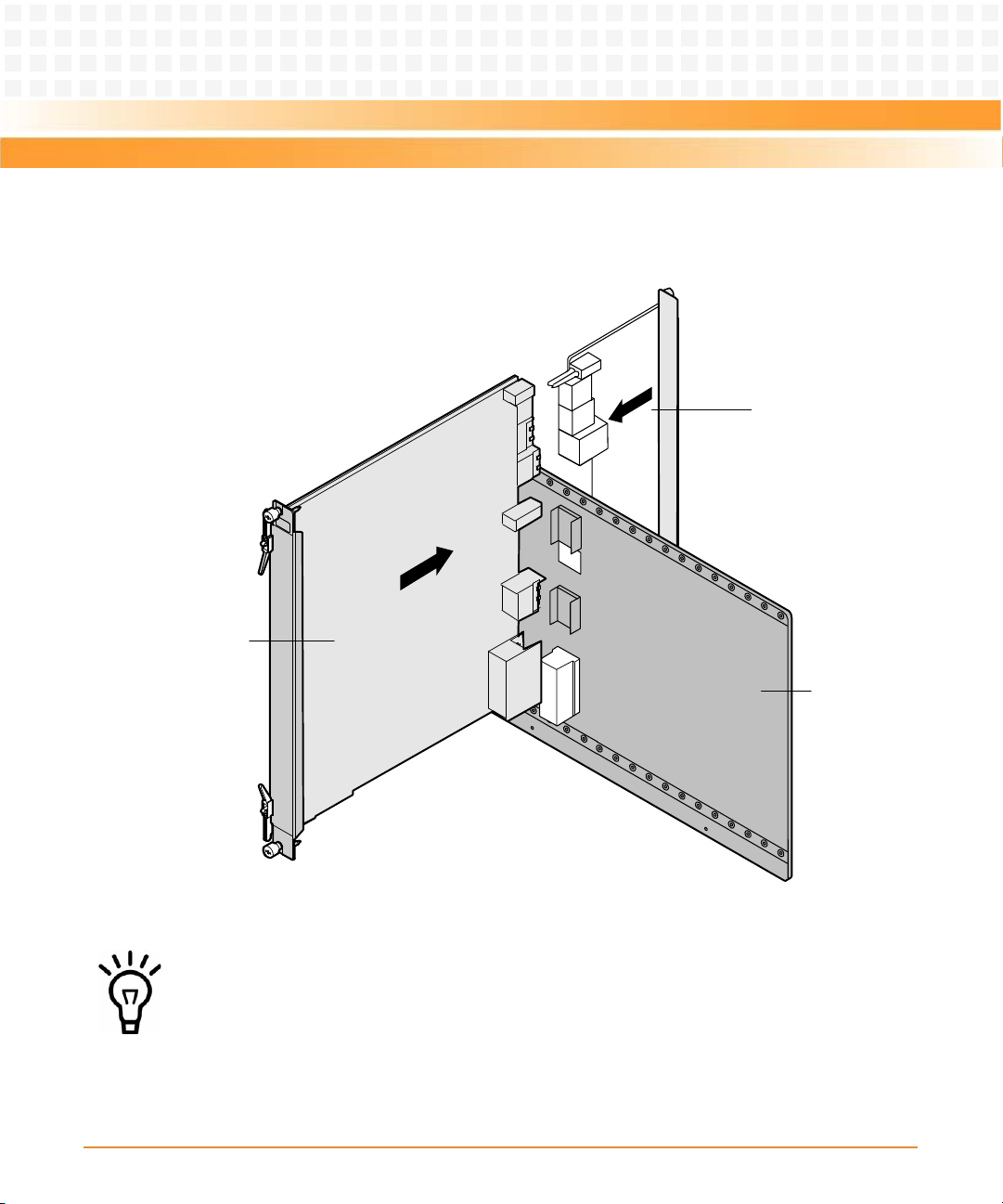

2.6.3.1 Installation Positions

When the GE daughter card is used with the RTM-ATCA-7150 it can be installed on the

daughter card connector J1, J2, J3, J4. The default position as used on the RTM-ATCA-7150-GE

is position J4. The default position as used on the RTM-ATCA-7150-GE-FC is position J1.

Figure 2-3 Structure of RTM-ATCA-7150

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

47

Page 48

Installation of the RTM-ATCA-7150

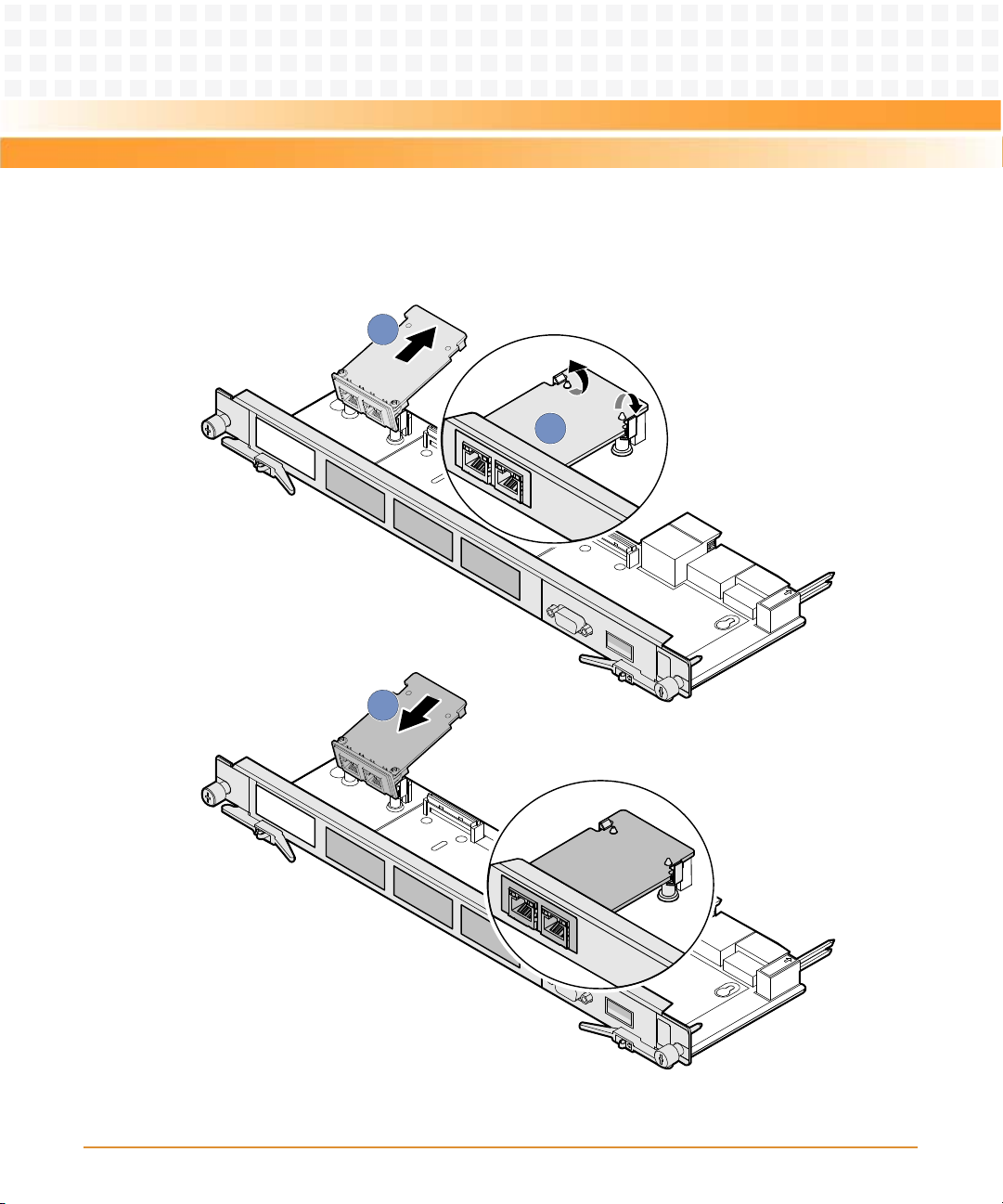

2.6.3.2 Installing the GE Daughter Card

To install the GE daughter card, proceed as follows.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap.

2. Lay RTM-ATCA-7150 where the GE daughter card is to be installed on the antistatic

desktop.

3. As shown in step 1 of the figure below, insert two plastic supports vertically in the

holes used to fasten the GE daughter card.

4. As shown in step 2 of the figure below, at the back side of RTM-ATCA-7150, use a

screwdriver to clockwise fasten the two screws used to fix the plastic supports.

5. Take the GE daughter card out of the antistatic package.

48

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 49

Installation of the RTM-ATCA-7150

6. Insert the GE daughter card in RTM-ATCA-7150 by facing the daughter card at an

angle of 45° to the RTM. Align the daughter card connector with the connector on

RTM-ATCA-7150, and the daughter card positioning holes with the plastic supports

on RTM-ATCA-7150. Exert even power downwards until the daughter card

connector is fully inserted into the connector on RTM-ATCA-7150 and the daughter

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

49

Page 50

Installation of the RTM-ATCA-7150

card is fastened by the plastic latches. See step 3 in the figure below.

1

2

3

Figure 2-4 Installing the GE Daughter Card

50

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 51

Installation of the RTM-ATCA-7150

7. Insert RTM-ATCA-7150 with the GE daughter card installed in the shelf. For more

information refer, Installing RTM-ATCA-7150.

After installation, check if RTM-ATCA-7150 can be powered on and work normally. Use the

network cable to connect RTM-ATCA-7150 to the external network. Check if the network is

connected properly and monitor whether the network port indicator is normal.

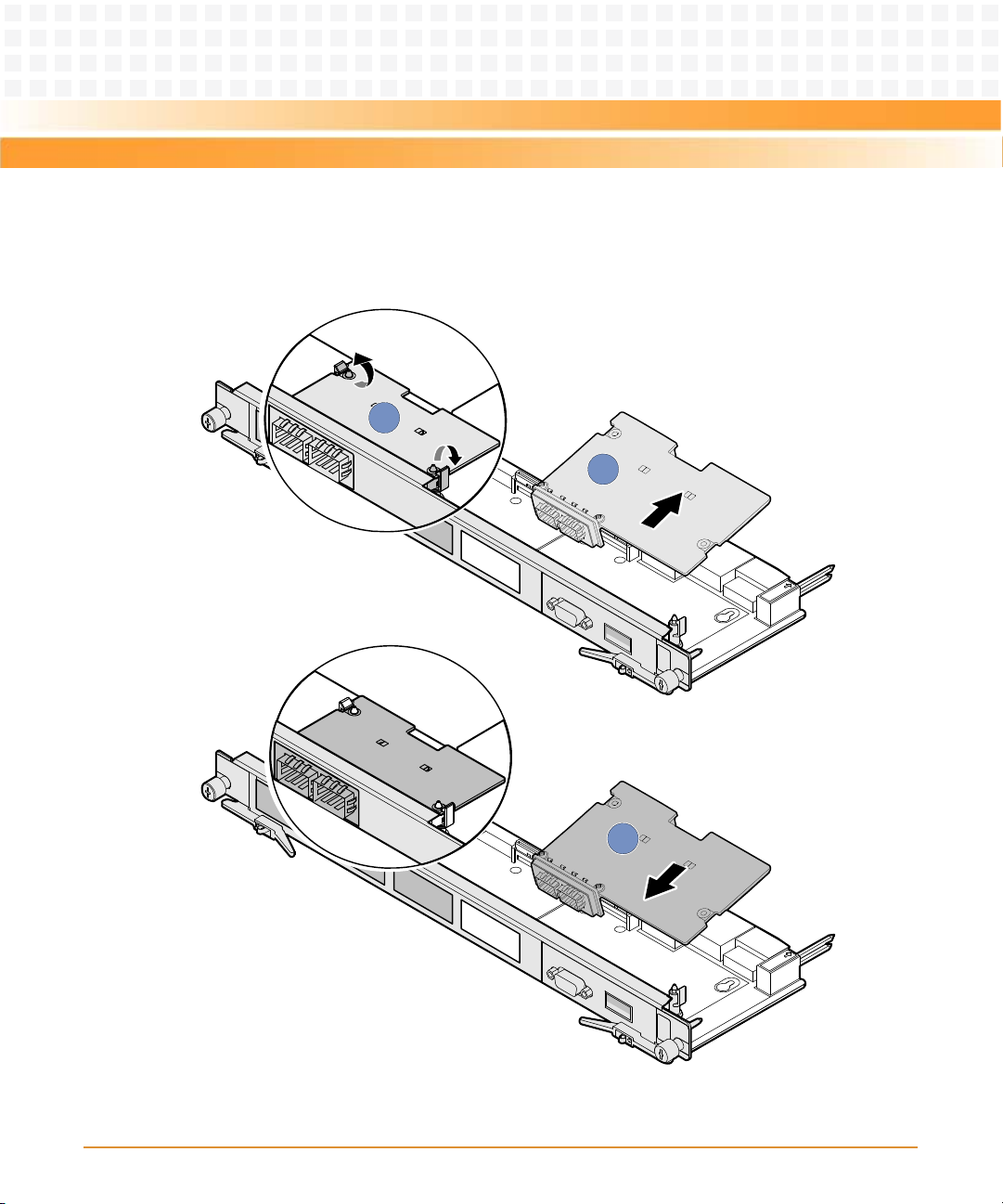

2.6.3.3 Replacing the GE Daughter Card

To replace the GE daughter card, proceed as follows.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap.

2. Remove the RTM-ATCA-7150 whose GE daughter card is to be replaced. For more

information refer, Removing RTM-ATCA-7150.

3. As shown in step 1 of the figure below, open the plastic latches fastening the GE

daughter card.

4. Exert even force upwards until the daughter card connector is removed from the

connector on RTM-ATCA-7150. As shown in step 2 of the figure below, remove the

daughter card by facing the daughter card at an angle of 45° to the RTM.

5. Place the removed GE daughter card in an antistatic package.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

51

Page 52

Installation of the RTM-ATCA-7150

6. Take the new GE daughter card out of the antistatic package.

2

3

1

Figure 2-5 Replacing the GE Daughter Card.

52

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 53

Installation of the RTM-ATCA-7150

7. Insert the GE daughter card in RTM-ATCA-7150 by facing the daughter card at an

angle of 45° to the RTM. Align the daughter card connector with the connector on

RTM-ATCA-7150, and the daughter card positioning holes with the plastic supports

on RTM-ATCA-7150. Exert even power downwards until the daughter card

connector is fully inserted into the connector on RTM-ATCA-7150 and the daughter

card is fastened by the plastic latches. See step 3 in the figure above.

8. Install RTM-ATCA-7150 whose GE daughter card is replaced. For more information

refer, Installing RTM-ATCA-7150.

After replacement, check if RTM-ATCA-7150 can be powered on and work normally. Use the

network cable to connect RTM-ATCA-7150 to the external network. Check if the network is

connected properly and monitor whether the network port indicator is normal.

2.6.4 FC Daughter Card

This manual considers the FC daughter card providing two external FC interfaces as an

example, and describes how to install the daughter card on and remove it from RTM-ATCA-

7150.

2.6.4.1 Installation Positions

When the FC daughter card is used with the RTM-ATCA-7150 it can be installed on the

daughter card connector J2, J4. The default position as used on the RTM-ATCA-7150-GE-FC is

position J4 and J1.

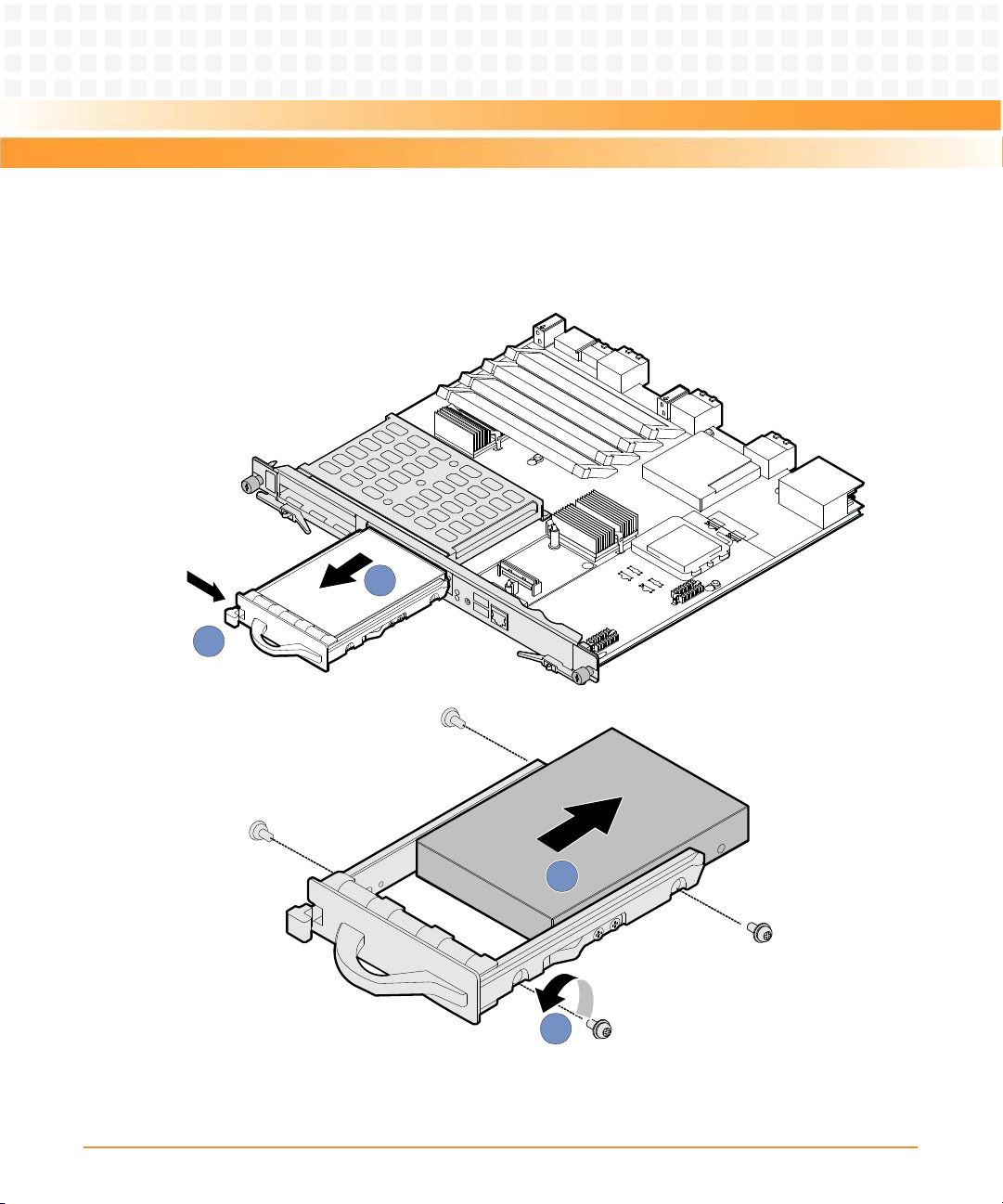

2.6.4.2 Installing the FC Daughter Card

To install the FC daughter card, proceed as follows.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap.

2. Lay RTM-ATCA-7150 where the FC daughter card is to be installed on the antistatic

desktop.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

53

Page 54

Installation of the RTM-ATCA-7150

3. As shown in step 1 of the figure below, insert two plastic supports vertically in the

holes used to fasten the FC daughter card.

4. As shown in step 2 of the figure below, at the back side of RTM-ATCA-7150, use a

screwdriver to clockwise fasten the two screws used to fix the plastic supports.

5. Take the FC daughter card out of the antistatic package.

54

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 55

Installation of the RTM-ATCA-7150

6. Insert the GE daughter card in RTM-ATCA-7150 by facing the daughter card at an

angle of 45° to the RTM. Align the daughter card connector with the connector on

RTM-ATCA-7150, and the daughter card positioning holes with the plastic supports

on RTM-ATCA-7150. Exert even power downwards until the daughter card

connector is fully inserted into the connector on RTM-ATCA-7150 and the daughter

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

55

Page 56

Installation of the RTM-ATCA-7150

card is fastened by the plastic latches. See step 3 in the figure below.

3

2

1

Figure 2-6 Installing the FC Daughter Card

7. Insert RTM-ATCA-7150 with the FC daughter card installed in the shelf. For more

56

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 57

Installation of the RTM-ATCA-7150

information refer, Installing RTM-ATCA-7150.

After installation, check if RTM-ATCA-7150 can be powered on and work normally. Use the

optical fiber to connect RTM-ATCA-7150 to the external storage system. Check if RTM-ATCA7150 can transmit data normally and monitor whether the FC status indicator is normal.

2.6.4.3 Replacing the FC Daughter Card

To replace the FC daughter card, proceed as follows.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap.

2. Remove the RTM-ATCA-7150 whose FC daughter card is to be replaced. For more

information refer, Removing RTM-ATCA-7150.

3. As shown in step 1 of the figure below, open the plastic latches fastening the FC

daughter card.

4. Exert even force upwards until the daughter card connector is removed from the

connector on RTM-ATCA-7150. As shown in step 2 of the figure below, remove the

daughter card by facing the daughter card at an angle of 45° to the RTM.

5. Place the removed FC daughter card in an antistatic package.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

57

Page 58

Installation of the RTM-ATCA-7150

6. Take the new FC daughter card out of the antistatic package.

2

3

1

Figure 2-7 Replacing the FC Daughter Card.

58

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

Page 59

Installation of the RTM-ATCA-7150

7. Insert the FC daughter card in RTM-ATCA-7150 by facing the daughter card at an

angle of 45° to the RTM. Align the daughter card connector with the connector on

RTM-ATCA-7150, and the daughter card positioning holes with the plastic supports

on RTM-ATCA-7150. Exert even power downwards until the daughter card

connector is fully inserted into the connector on RTM-ATCA-7150 and the daughter

card is fastened by the plastic latches. See step 3 in the figure above.

8. Install RTM-ATCA-7150 whose FC daughter card is replaced. For more information

refer, Installing RTM-ATCA-7150.

After replacement, check if RTM-ATCA-7150 can be powered on and work normally. Use the

optical fibre to connect RTM-ATCA-7150 to the external storage system. Check if RTM-ATCA7150 can transmit data normally and monitor whether the FC status indicator is normal.

2.7 Installing and Removing the RTM-ATCA-7150

2.7.1 Installing RTM-ATCA-7150

Product Damage

You can install RTM-ATCA-7150 into a system if the front blade is already installed or if it is

not installed. In case the front blade is already installed, its payload has to be powered down

first.

ATCA-7150 and RTM-ATCA-7150 Getting Started (6806800G42B)

59

Page 60

Installation of the RTM-ATCA-7150

Installation Procedure with Installed Front Blade

The following procedure describes the installation of RTM-ATCA-7150. It assumes that your

system is powered on. If your system is powered off, you can disregard the blue LED and thus

skip the respective step. In this case it is a purely mechanical installation. The same applies to

an installation without an installed front blade. In this case disregard the LEDs and skip the

respective step.

1. Wear the ESD-preventive wrist strap. For more information refer, Wearing the ESD-

Preventive Wrist Strap.

2. Fully open the ejector handles of the front blade.

3. Take RTM-ATCA-7150 out of the antistatic package.

4. Fully open the upper and lower ejector handles of the RTM.

60