Page 1

Reference Manual

00809-0100-4102, Rev AA

Rosemount 2051 Wireless Series

Pressure, Level, and Flow Solutions with WirelessHART™

Protocol

June 2012

Page 2

Page 3

Reference Manual

00809-0100-4102, Rev AA

Rosemount 2051 Wireless Series Scalable Pressure,

Flow, and Level Solutions

Title Page

June 2012

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

Asia Pacific- 65 777 8211

Europe/ Middle East/ Africa - 49 (8153) 9390

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of these areas, contact your local Rosemount

®

representative.

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

i

Page 4

Title Page

June 2012

Reference Manual

00809-0100-4102, Rev AA

Failure to follow these installation guidelines could result in death or serious injury:

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please review

the approvals section of this manual for any restrictions associated with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, ensure the

instruments are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

Process leaks could result in death or serious injury.

Install and tighten process connectors before applying pressure.

Do not attempt to loosen or remove process connectors while the transmitter is in

service.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

The Rosemount 2051 and all other wireless devices should be installed only after the Smart

Wireless Gateway has been installed and is functioning properly. Wireless devices should

also be powered up in order of proximity from the Smart Wireless Gateway, beginning with

the closest. This will result in a simpler and faster network installation.

Shipping considerations for wireless products (Lithium Batteries: Green Power Module,

model number 701PGNKF):

The unit was shipped to you without the Power Module installed. Please remove the

Power Module from the unit prior to shipping.

Primary lithium batteries are regulated in transportation by the U. S. Department of

Transportation, and are also covered by IATA (International Air Transport Association),

ICAO (International Civil Aviation Organization), and ARD (European Ground

Transportation of Dangerous Goods). It is the responsibility of the shipper to ensure

compliance with these or any other local requirements. Please consult current

regulations and requirements before shipping.

Using the Rosmeount 3051 Wireless Pressure Transmitter in a manner other than what is

specified by the menufacturer may impair the protection provided by the equipment.

ii

Page 5

Reference Manual

00809-0100-4102, Rev AA

Contents

1Section 1: Introduction

2Section 2: Configuration

Table of Contents

June 2012

1.1 Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2.1 Warnings (). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Required Bench Top Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.1 Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 Device Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.4.1 Join Device to Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.2 Configure Update Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.4.3 Remove Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Review Configuration Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.1 Review Pressure Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.2 Review Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.3 Review Sensor Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.4 Review Radio Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.6 Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.7 Check Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.7.1 Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.8 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.8.1 Set Process Variable Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.8.2 Set Transfer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.8.3 Damping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.8.4 Write Protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.9 LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.9.1 LCD Display Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.10Detailed Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.10.1Configure Process Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Tab le of C ontents

2.10.2Sensor Temperature Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.11Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.11.1Master Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

iii

Page 6

Table of Contents

June 2012

3Section 3: Installation

Reference Manual

00809-0100-4102, Rev AA

2.11.2Join Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.11.3Number of Available Neighbors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.12Advanced Functions for HART Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.12.1Saving, Recalling, and Cloning Configuration Data . . . . . . . . . . . . . . . . . . 22

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Warnings () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3 Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.2 Wireless. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.3 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.4 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4 Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4.1 Mount the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4.2 Process Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.3 Consider Housing Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4.5 Power Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4.6 Installing the LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5 Rosemount 304, 305 and 306 Integral Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.5.1 Rosemount 305 Integral Manifold Installation Procedure. . . . . . . . . . . . . 37

3.5.2 Rosemount 306 Integral Manifold Installation Procedure. . . . . . . . . . . . . 37

3.5.3 Rosemount 304 Conventional Manifold Installation Procedure. . . . . . . . 38

3.5.4 Manifold Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4Section 4: Commissioning

4.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.1.1 Warnings () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2 Network Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3 Verify Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5Section 5: Operation and Maintenance

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.1 Sensor Trim overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

iv

Table of Contents

Page 7

Reference Manual

00809-0100-4102, Rev AA

6Section 6: Troubleshooting

Table of Contents

June 2012

5.2.2 Zero Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.2.3 Sensor Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.2.4 Recall Factory Trim—Sensor Trim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

5.2.5 Line Pressure Effect (Range 2 and Range 3) . . . . . . . . . . . . . . . . . . . . . . . . . .50

5.2.6 Compensating for Line Pressure (Range 4 and Range 5) . . . . . . . . . . . . . . .50

5.3 LCD Screen Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

5.3.1 Startup Screen Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

5.3.2 Diagnostic button screen sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

5.3.3 Network diagnostic status screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

5.3.4 Device Diagnostic Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

6.2 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

AAppendix A: Specifications and

Reference Data

6.2.1 Warnings (). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

6.3 Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

6.3.1 Remove from Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

6.3.2 Remove Feature Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

6.4 Reassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

6.4.1 Reassemble the Process Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

A.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

A.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

A.3 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

A.3.1 Range and Sensor Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

A.4 Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

A.5 Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

A.6 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

A.6.1 Options (Include with selected model number) . . . . . . . . . . . . . . . . . . . . . .86

A.6.2 Options (Include with selected model number) . . . . . . . . . . . . . . . . . . . . . .93

A.6.3 Options (Include with selected model number) . . . . . . . . . . . . . . . . . . . . . .98

A.6.4 Options (Include with selected model number) . . . . . . . . . . . . . . . . . . . . 105

Tab le of C ontents

A.6.5 Options (Include with selected model number) . . . . . . . . . . . . . . . . . . . . 110

A.6.6 Options (Include with selected model number) . . . . . . . . . . . . . . . . . . . . 115

BAppendix B: Product Certifications

B.1 Wireless Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

v

Page 8

Table of Contents

June 2012

Reference Manual

00809-0100-4102, Rev AA

B.1.1 Approved manufacturing locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

B.1.2 European directive information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

B.1.3 Telecommunication compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

B.1.4 FCC and IC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

B.1.5 Ordinary location certification for FM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

B.1.6 North American certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

B.1.7 CSA - Canadian Standards Association . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

B.1.8 European certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

B.1.9 Japanese Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.1.10China (NEPSI) Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

vi

Table of Contents

Page 9

Reference Manual

00809-0100-4102, Rev AA

Section 1 Introduction

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

1.1 Using This Manual

Section 1: Introduction

June 2012

The sections in this manual provide information on installing, operating, and maintaining the

Rosemount 2051 Wireless pressure transmitter with WirelessHART

organized as follows:

Section 2: Configuration provides instruction on commissioning and operating 2051

Wireless transmitters. Information on software functions, configuration parameters,

and online variables is also included.

Section 3: Installation contains mechanical and electrical installation instructions.

Section 4: Commissioning contains techniques for properly commissioning the device.

Section 5: Operation and Maintenance contains operation and maintenance

techniques.

Section 6: Troubleshooting provides troubleshooting techniques for the most common

operating problems.

Appendix A: Specifications and Reference Data supplies reference and specification

data, as well as ordering information.

Appendix B: Product Certifications contains approval information.

1.2 Models Covered

The following Rosemount 2051 Pressure Transmitters are covered by this manual:

™

protocol. The sections are

Introduction

Rosemount 2051CD Differential Pressure Transmitter

Measures differential pressure up to 2000 psi (137,9 bar).

Rosemount 2051CG Gage Pressure Transmitter

Measures gage pressure up to 2000 psi (137,9 bar).

1

Page 10

Section 1: Introduction

June 2012

Rosemount 2051CA Absolute Pressure Transmitter

Measures absolute pressure up to 4000 psia (275,8 bar).

Rosemount 2051T Gage and Absolute Pressure Transmitter

Measures gage pressure up to 10000 psi (689,5 bar).

Rosemount 2051L Liquid Level Transmitter

Provides precise level and specific gravity measurements up to 300 psi (20,7 bar) for a wide

variety of tank configurations.

1.3 Service Support

To expedite the return process outside of the United States, contact the nearest Emerson

Process Management representative.

Reference Manual

00809-0100-4102, Rev AA

Within the United States, call the Emerson Process Management Instrument and Valves

Response Center using the 1-800-654-RSMT (7768) toll-free number. This center, available 24

hours a day, will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of and understand the hazard. If the product being returned was exposed to a

hazardous substance as defined by OSHA, a copy of the required Material Safety Data Sheet

(MSDS) for each hazardous substance identified must be included with the returned goods.

Shipping considerations for wireless products (Lithium Batteries: Green Power Module,

model number 701PGNKF):

The unit was shipped to you without the Power Module installed. Please remove the Power

Module from the unit prior to shipping.

Primary lithium batteries (charged or discharged) are regulated in transportation by the U.

S. Department of Transportation, and are also covered by IATA (International Air Transport

Association), ICAO (International Civil Aviation Organization), and ARD (European Ground

Transportation of Dangerous Goods). It is the responsibility of the shipper to ensure

compliance with these or any other local requirements. Please consult current regulations

and requirements before shipping.

2

Introduction

Page 11

Reference Manual

00809-0100-4102, Rev AA

The Power Module contains one “D” size primary lithium/thionyl chloride battery (Green Power

Module, model number 701PGNKF). Each Power Module contains approximately 5 grams of

lithium. Under normal conditions, the Power Module materials are self-contained and are not

reactive as long as the batteries and the module integrity are maintained. Care should be taken

to prevent thermal, electrical or mechanical damage. Contacts should be protected to prevent

premature discharge. Power Module hazards remain when cells are discharged.

Power Module should be stored in a clean and dry area. For maximum battery life, storage

temperature should not exceed 30° C.

Emerson Process Management Instrument and Valves Response Center representatives will

explain the additional information and procedures necessary to return goods exposed to

hazardous substances.

1.4 Product Recycling/Disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in

accordance with local and national legislation/regulations.

Section 1: Introduction

June 2012

Introduction

3

Page 12

Section 1: Introduction

June 2012

Reference Manual

00809-0100-4102, Rev AA

4

Introduction

Page 13

Reference Manual

00809-0100-4102, Rev AA

Section 2 Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Required Bench Top Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Device Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Review Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Check Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Detailed Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Advanced Functions for HART Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Section 2: Configuration

June 2012

2.1 Overview

This section contains information on configuration and verification that should be performed

prior to installation.

Field Communicator and AMS instructions are given to perform configuration functions. For

convenience, Field Communicator fast key sequences are labeled “Fast Keys” for each software

function below the appropriate headings.

Example Software Function

Fast Keys

1, 2, 3, etc.

2.2 Safety Messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

5Configuration

Page 14

Section 2: Configuration

June 2012

2.2.1 Warnings ( )

Explosions can result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure the

instruments are installed in accordance with intrinsically safe or nonincendive field

wiring practices.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference this device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20cm

from all persons.

Reference Manual

00809-0100-4102, Rev AA

2.3 Required Bench Top Configuration

Bench top configuration requires a Field Communicator, AMS, or any WirelessHART

Communicator. Connect the Field Communicator leads to the terminals labeled “COMM” on the

terminal block. See Figure 2-1 on page 7.

Bench top configuration consists of testing the transmitter and verifying transmitter

configuration data. 2051 Wireless transmitters must be configured before installation.

Configuring the transmitter on the bench before installation using a Field Communicator, AMS,

or any WirelessHART Communicator ensures that all network settings are working correctly.

When using a Field Communicator, any configuration changes made must be sent to the

transmitter by using the “Send” key (F2). AMS configuration changes are implemented when

the “Apply” button is clicked.

AMS Wireless Configurator

AMS is capable of connecting to devices either directly, using a HART modem, or wirelessly via

the Smart Wireless Gateway. When configuring the device, double click the device icon or right

click and select Configure.

2.3.1 Connection Diagrams

Bench Hook-up

Connect the bench equipment as shown in Figure 2-1, and turn on the Field Communicator by

pressing the ON/OFF key or log into AMS. The Field Communicator or AMS will search for a

HART-compatible device and indicate when the connection is made. If the Field Communicator

or AMS fail to connect, it indicates that no device was found. If this occurs, refer to Section 6:

Tro u bl esh o oti ng .

6

Configuration

Page 15

Reference Manual

00809-0100-4102, Rev AA

Section 2: Configuration

June 2012

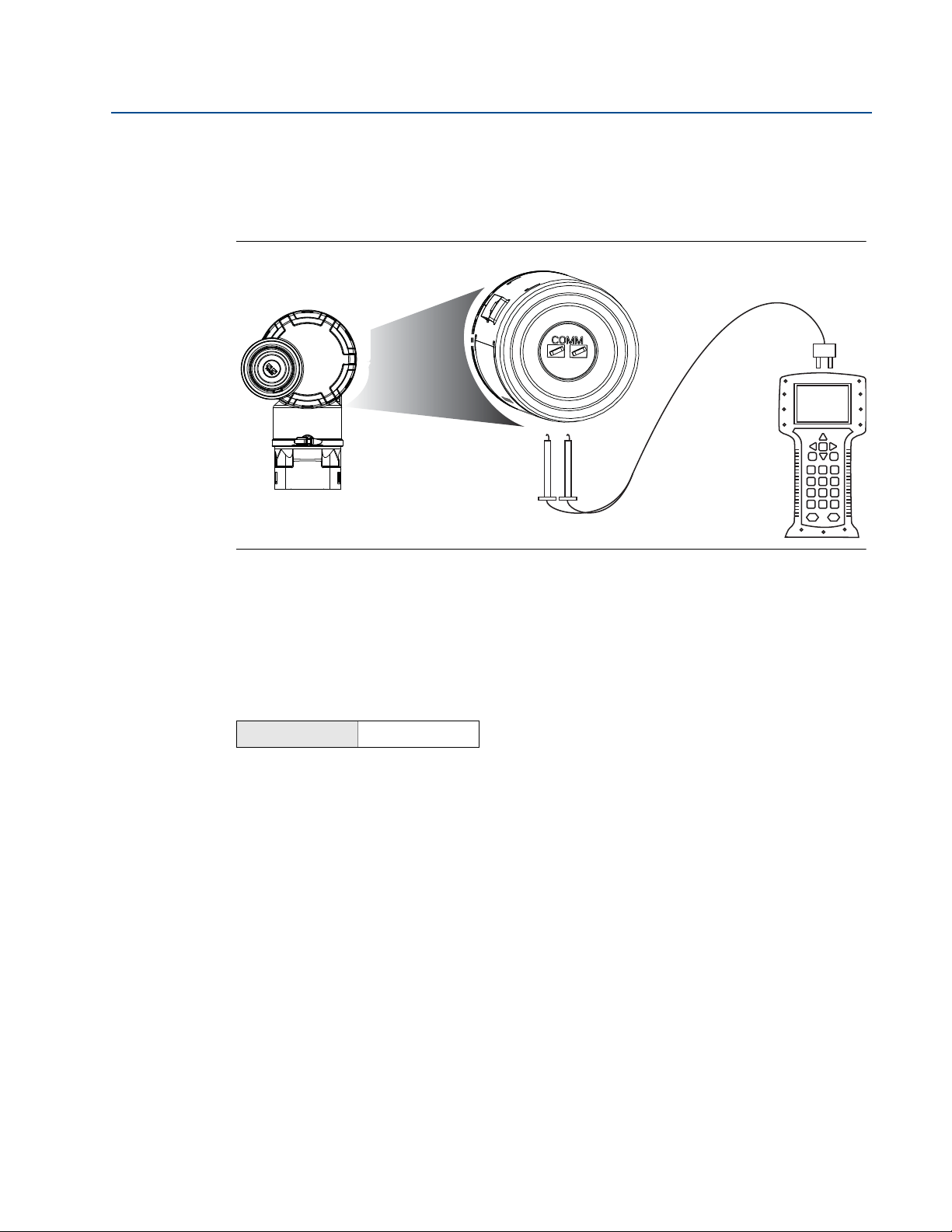

Field Hook-up

Figure 2-1 illustrates the wiring for a field hook-up with a Field Communicator or AMS. The Field

Communicator or AMS may be connected at “COMM” on the transmitter terminal block.

Figure 2-1. Field Communicator Connection

For HART communication, a 2051 WirelessHART DD is required.

2.4 Device Network Configuration

2.4.1 Join Device to Network

Fast Keys

In order to communicate with the Smart Wireless Gateway, and ultimately the Host System, the

transmitter must be configured to communicate over the wireless network. This step is the

wireless equivalent of connecting wires from a transmitter to the host system.

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 1: Join Device to Network.

Using a Field Communicator or AMS, enter the Network ID and Join Key so that they match the

Network ID and Join Key of the Smart Wireless Gateway and other devices in the network. If the

Network ID and Join Key are not identical to those set in the Gateway, the transmitter will not

communicate with the network. The Network ID and Join Key may be obtained from the Smart

Wireless Gateway on the Setup>Network>Settings page on the web server.

2, 1, 1

Configuration

7

Page 16

Section 2: Configuration

June 2012

2.4.2 Configure Update Rate

Reference Manual

00809-0100-4102, Rev AA

Fast Keys

The Update Rate is the frequency at which a new measurement is taken and transmitted over

the wireless network. This by default is 1 minute. This may be changed at commissioning, or at

any time via AMS Wireless Configurator. The Update Rate is user selectable from 8 seconds to 60

minutes.

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 2: Configure Update Rate.

When device configuration is completed, remove the Power Module and replace the housing

cover. Tighten the cover so that metal contacts metal.

2, 1, 2

2.4.3 Remove Power Module

After the sensor and network have been configured, remove the Power Module and replace the

housing cover. The Power Module should be inserted only when the device is ready to be

commissioned.

Use caution when handling the Power Module. The Power Module may be damaged if dropped

from heights in excess of 20 ft.

8

Configuration

Page 17

Reference Manual

00809-0100-4102, Rev AA

2.5 Review Configuration Data

The following is a list of factory default configurations that can be viewed by using the Field

Communicator or AMS. Follow the steps below to review the transmitter configuration

information.

Note

Information and procedures in this section that make use of Field Communicator fast key

sequences and AMS assume that the transmitter and communication equipment are

connected, powered, and operating correctly.

2.5.1 Review Pressure Information

Section 2: Configuration

June 2012

Fast Keys

2, 2, 2

To view pressure information:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Pressure.

4. Select from the corresponding number to view each field:

1 Unit

2 Transfer Function

3 Damping

4 Upper Range Value

5 Lower Range Value

6 Maximum

7 Minimum

8 Minimum Span

2.5.2 Review Device Information

Fast Keys

2, 2, 4, 3

Configuration

To view device information:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 4: Device Information.

4. Select 3: Device.

5. Select from the corresponding number to view each field:

1 Manufacturer

2 Model

9

Page 18

Section 2: Configuration

June 2012

3 Final Assembly Number

4 Universal

5 Field Device

6 Software

7 Hardware

8 Descriptor

9 Message

10 Date

11 Model Number I

12 Model Number II

13 Model Number III

14 SI Unit Restriction

15 Country

16 Device ID

Reference Manual

00809-0100-4102, Rev AA

10

Configuration

Page 19

Reference Manual

00809-0100-4102, Rev AA

2.5.3 Review Sensor Information

Section 2: Configuration

June 2012

Fast Keys

2, 2, 4, 4

To vi ew sensor i nformation:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 4: Device Information.

4. Select 4: Sensor.

5. Select from the corresponding number to view each field:

1 Measurement Type

2 Module Type

3 Module Serial Number

4 Sensor Materials

• Isolator Material

• Fill Fluid

5 Process Connector

• Connector Type

• Connector Material

•O Ring Material

•Drain Vent Material

6 Remote Seal

•Number of Seals

•Seal Type

• Diaphragm Material

• Seal Fill Fluid

2.5.4 Review Radio Information

Fast Keys

To vi ew radio informatio n:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 4: Device Information.

4. Select 5: Radio.

5. Select from the corresponding number to view each field:

1 Manufacturer

Configuration

2, 2, 4, 5

11

Page 20

Section 2: Configuration

June 2012

2 Device Type

3 Device Revision

4 Software Revision

5 Hardware Revision

Reference Manual

00809-0100-4102, Rev AA

12

Configuration

Page 21

Reference Manual

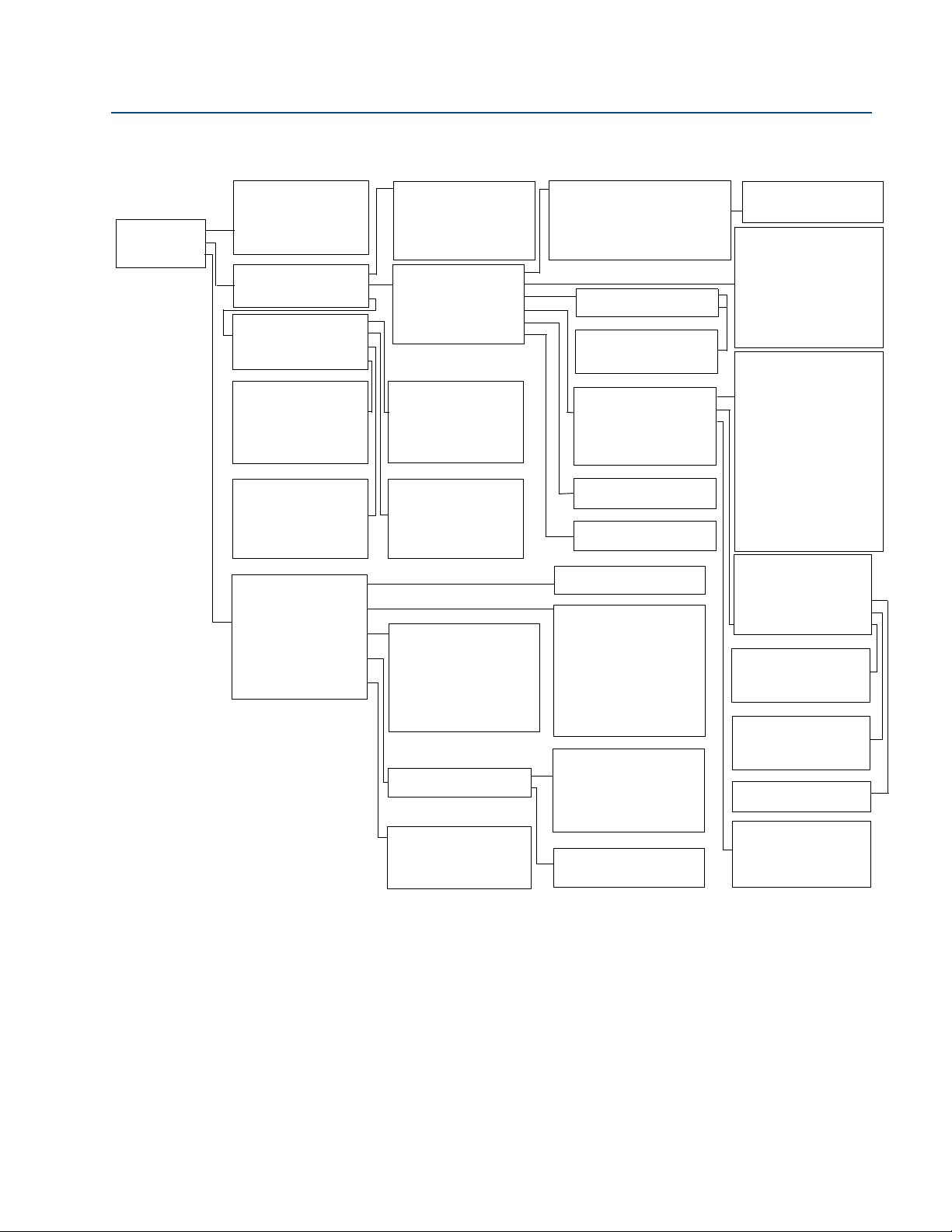

1. Overview

2. Configure

3. Service Tools

1. Active Alerts

2. Communication Status

3. Pressure

4. Pressure Status

5. Last Update Time

1. Join Device to Network

2. Configure Update Rate

3. Zero Trim

4. Configu re Device Display

5. Configure Process Alarms

6. Basic Setup

1. Guided Setup

2. Manual Setup

3. Alert Setup

1. Wireless

2. Pressure

3. Device Temperatures

4. Device Information

5. Device Display

6. Other

1. Network ID

2. Join Device to Network

3. Broadcast Rates

4. Configure Broadcast Power Level

5. Power Mode

6. Power Source

1. Unit

2. Transfer Function

3. Damping

4. Upper Range Value

5. Lower Range Value

6. Maximum

7. Minimum

8. Minimum Span

9. Range Using Applied Value

1. Sensor Temperature

2. Electronics Temperature

1. Unit

2. Maximum

3. Minimum

1. HI-HI Alarm

2. HI Alarm

3. LO Alarm

4. LO-LO Alarm

1. Configure LO-LO Alarm

2. Mode

3. Variable

4. Alarm Direction

5. Alarm Limit

6. Dead Band

1. Configure LO Alarm

2. Mode

3. Variable

4. Alarm Direction

5. Alarm Limit

6. Dead Band

1. Configure HI-HI Alarm

2. Mode

3. Variable

4. Alarm Direction

5. Alarm Limit

6. Dead Band

1. Configure HI Alarm

2. Mode

3. Variable

4. Alarm Direction

5. Alarm Limit

6. Dead Band

1. Mode

2. Display Options

1. Measu rement and

Status Log

1. Alerts

2. Variables

3. Communications

4. Routine Maintenance

5. Simulate

1. Active Alerts

2. History

1. Percent of Range

2. Pressure

3. Pressure Status

4. Sensor Temperature

5. Sensor Temperature Status

6. Electronics Temperature

7. Electronics Temp Status

8. Supply Voltage

9. Supply Voltage Status

10. Last Update Time

1. Join Status

2. Communication Status

3. Join Mode

4. Number of Available

Neighbors

5. Number of Advertisements

Heard

6. Number of Join Attempts

1. Sensor Calibration

2. Other

1. Current Lower Trim

2. Current Upper Trim

3. Zero Sensor Trim

4. Lower Sensor Trim

5. Upper Sensor Trim

6. Recall Factory Trim

1. Master Reset

2. Measurement History

3. Advertise to New Devices

1. Pressure

2. Sensor Temperature

3. Electronics Temperature

4. Supply Voltage

1. Tag

2. Long Tag

3. Device

4. Sensor

5. Radio

6. Write Protect

1. Manufacturer

2. Model

3. Final Assembly Number

4. Universal

5. Field Device

6. Software

7. Hardware

8. Descriptor

9. Message

10. Date

11. Model Number I

12. Model Number II

13. Model Number III

14. SI Unit Restriction

15. Country

16. Device ID

1. Measurement Type

2. Module Type

3. Module Serial Number

4. Sensor Materials

5. Process Connector

6. Remote Seal

1. Isolator Fluid

2. Fill Fluid

1. Number of Seals

2. Seal Type

3. Diaphragm Material

4. Seal Fill Fluid

1. Connector Type

2. Connector Material

3. O Ring Material

4. Drain Vent Material

1. Manufacturer

2. Device Type

3. Device Revision

4. Software Revision

5. Hardware Revision

1. Configure Up date Rate

2. Message 1

3. Message 2

00809-0100-4102, Rev AA

2.6 Field Communicator

Section 2: Configuration

June 2012

Configuration

13

Page 22

Section 2: Configuration

June 2012

2.7 Check Output

Before performing other transmitter operations, ensure that the transmitter is operating

properly by checking the operating parameters.

2.7.1 Operating Parameters

Reference Manual

00809-0100-4102, Rev AA

Fast Keys

3, 2

The pressure output value in both engineering units and percent of range will reflect the applied

pressure even when the applied pressure is outside of the configured range as long as the

applied pressure is between the upper and lower range limit of the transmitter. For example, if a

Range 2 2051T (LRL = 0 psi, URL = 150 psi) is ranged from 0 to 100 psi, an applied pressure of

150 psi will return a % of range output of 150% and an engineering output of 150 psi.

To v iew the Operating Parameters menu:

1. From the Home screen, select 3: Service Tools.

2. Select 2: Variables.

The Operating Parameters menu displays the following information pertaining to the device:

Percent of Range

Pressure

Pressure Status

Sensor Temperature

Sensor Temperature Status

Electronics Temperature

Electronics Temperature Status

Supply Voltage

Supply Voltage Status

Last Update Time

2.8 Basic Setup

2.8.1 Set Process Variable Unit

Fast Keys

The PV Unit command sets the process variable units to allow you to monitor your process using

the appropriate units of measure.

To select a unit of measure for the PV:

14

2, 2, 2, 1

Configuration

Page 23

Reference Manual

00809-0100-4102, Rev AA

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Pressure.

4. Select 1: Unit to select from the following engineering units:

inH

inHg mbar atm

ftH

mmH

mmHg Pa mmH

psi kPa

O bar torr

2

O g/cm

2

O kg/cm

2

2

2

MPa

inH2O at 4 °C

Section 2: Configuration

June 2012

O at 4 °C

2

Configuration

15

Page 24

Section 2: Configuration

Sq. Root

Curve

Transition Point

Linear Section

Slope=1

Slope=42

Trans ition Point

Sq. Root Curve

Full Scale

Flow (%)

June 2012

2.8.2 Set Transfer Function

Reference Manual

00809-0100-4102, Rev AA

Fast Keys

2, 2, 2, 2

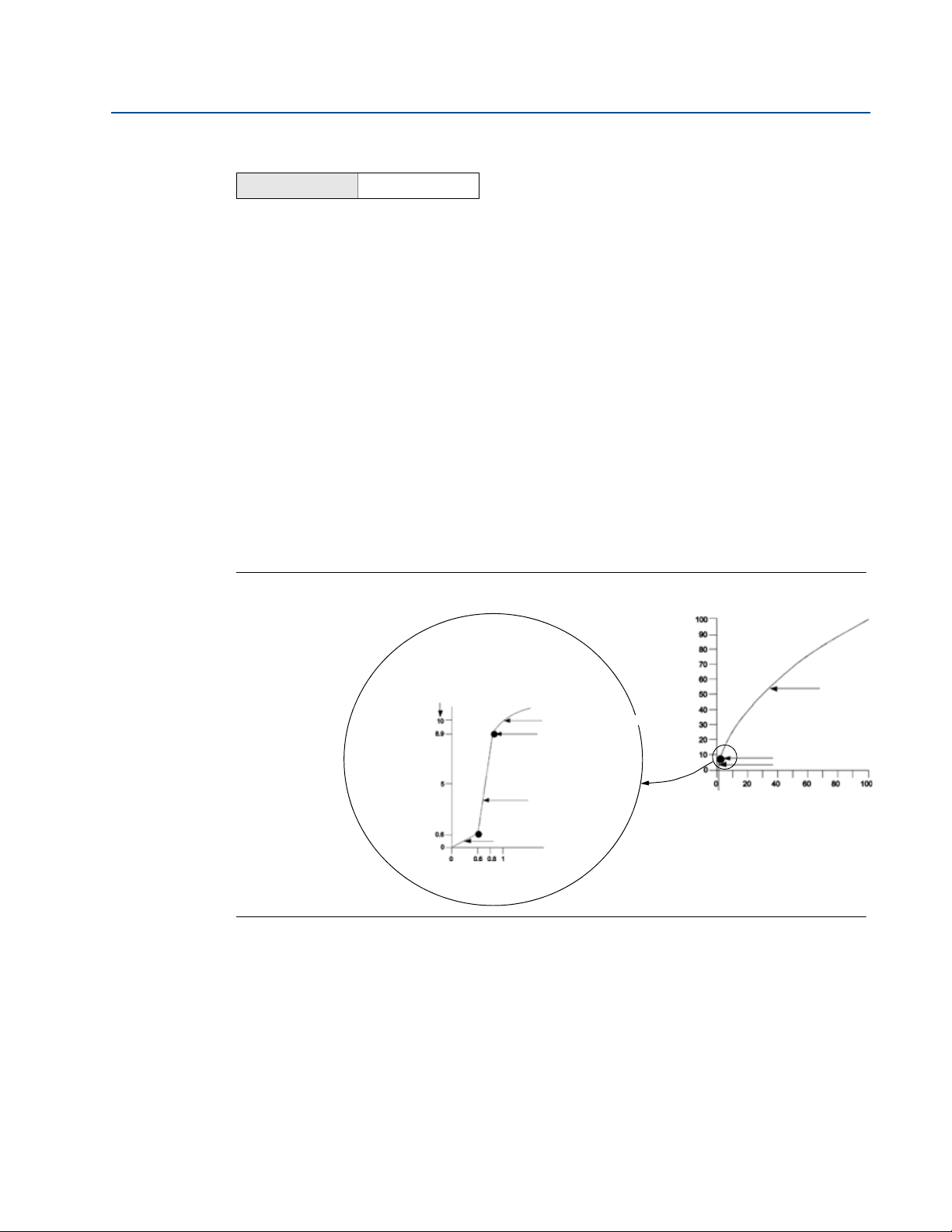

The 2051 Wireless has two output settings: Linear and Square Root. Activate the square root

output option to make output proportional to flow. As input approaches zero, the 2051

Wireless automatically switches to linear output in order to ensure a more smooth, stable

output near zero (see Figure 2-2).

From 0 to 0.6 percent of the ranged pressure input, the slope of the curve is unity (y = x). This

allows accurate calibration near zero. Greater slopes would cause large changes in output (for

small changes at input). From 0.6 percent to 0.8 percent, curve slope equals 42 (y = 42x) to

achieve continuous transition from linear to square root at the transition point.

To select the output transfer function:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Pressure.

4. Select 2: Transfer Function and choose either Linear or Square Root.

Figure 2-2. Square Root Output Transition Point

16

Configuration

Page 25

Reference Manual

00809-0100-4102, Rev AA

2.8.3 Damping

Section 2: Configuration

June 2012

Fast Keys

The Damping command introduces a delay in processing which increases the response time of

the transmitter; smoothing variations in output readings caused by rapid input changes. In the

2051 Wireless pressure transmitter, damping only takes effect when the device is placed in high

power refresh mode and during calibration. In normal power mode, the effective damping is 0.

Note that when the device is in high power refresh mode, battery power will be depleted rapidly.

Determine the appropriate damp setting based on the necessary response time, signal stability,

and other requirements of the loop dynamics of your system. The damping value of your device

is user selectable from 0 to 25.6 seconds.

To determine the current damping value:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Pressure.

4. Select 3: Damping.

2.8.4 Write Protect

Fast Keys

2, 2, 2, 3

2, 2, 4, 6

The 2051 Wireless has a software write protect security feature.

The view write protect security settings:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 4: Device Information.

4. Select 6: Write Protect.

Configuration

17

Page 26

Section 2: Configuration

June 2012

2.9 LCD Display

2.9.1 LCD Display Configuration

Reference Manual

00809-0100-4102, Rev AA

Fast Keys

The LCD display indicates output and abbreviated diagnostic messages.

Note

Use Rosemount Wireless LCD Part Number: 00753-9004-0002.

The LCD display features a four-line display and a bar graph. The first line of five characters

displays the output description, the second line of seven digits displays the actual value, the

third line of six characters displays engineering units and the fourth line displays “Error” when

the transmitter is in alarm. The LCD display can also display diagnostic messages. The bar graph

represents the network connectivity status.

See “LCD Screen Messages” on page 53 for more information on LCD messages.

To configure LCD display options:

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 4: Configure Device Display.

2, 1, 4

18

Configuration

Page 27

Reference Manual

Deadband

Assigned Value

Alert Set Point

Alert “OFF” Alert “ON” Alert “OFF”

Units of Measurement

Time

Deadband

Assigned Value

Alert Set Point

Alert “OFF” Alert “ON” Alert “OFF”

Units of Measurement

Time

00809-0100-4102, Rev AA

2.10 Detailed Setup

2.10.1 Configure Process Alarms

Section 2: Configuration

June 2012

Fast Keys

2, 1, 5

Alerts allow the user to configure the transmitter to output a HART message when the

configured data point is exceeded. A process alert will be transmitted continuously if the set

points are exceeded and the alert mode is ON. An alert will be displayed on a Field

Communicator, AMS status screen or in the error section of the LCD display. The alert will reset

once the value returns within range.

Note

HI alert value must be higher than the LO alert value. Both alert values must be within the

pressure or temperature sensor limits.

Example 1: Rising Alert

Example 2: Falling Alert

To configure the process alerts, perform the following procedure:

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 5: Configure Process Alarms and follow the on-screen instructions to complete

configure of process alarms.

Configuration

19

Page 28

Section 2: Configuration

June 2012

2.10.2 Sensor Temperature Unit

Reference Manual

00809-0100-4102, Rev AA

Fast Keys

The Sensor Temperature Unit command selects between Celsius and Fahrenheit units for the

sensor temperature. The sensor temperature output is accessible via HART only.

To select the sensor temperature unit:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 3: Device Temperatures.

4. Select 1: Sensor Temperature.

5. Select 1: Unit to select from Celsius or Fahrenheit.

2, 2, 3, 1, 1

2.11 Diagnostics and Service

Diagnostics and service functions listed below are primarily for use after field installation. The

Transmitter Test feature is designed to verify that the transmitter is operating properly, and can

be performed either on the bench or in the field.

2.11.1 Master Reset

Fast Keys

The master reset function will reset the device electronics. To perform a master reset:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Routine Maintenance.

3. Select 2: Other.

4. Select 1: Master Reset.

2.11.2 Join Status

Fast Keys

To view the join status of the device, perform the following procedure:

1. From the Home screen, select 3: Service Tools.

2. Select 3: Communications.

3. Select 1: Join Status.

3, 4, 2, 1

3, 3, 1

20

Configuration

Page 29

Reference Manual

00809-0100-4102, Rev AA

Wireless devices join the secure network through a four step process:

Step 1. Network Found

Step 2. Network Security Clearance Granted

Step 3. Network Bandwidth Allocated

Step 4. Network Join Complete

2.11.3 Number of Available Neighbors

Section 2: Configuration

June 2012

Fast Keys

3, 3, 4

In a self-organizing network, the more neighbors a device has, the more robust the network will

be. To view the number of available neighbors for the wireless device, perform the following

procedure:

1. From the Home screen, select 3: Service Tools.

2. Select 3: Routine Maintenance.

3. Select 4: Number of Available Neighbors.

Configuration

21

Page 30

Section 2: Configuration

June 2012

Reference Manual

00809-0100-4102, Rev AA

2.12 Advanced Functions for HART Protocol

2.12.1 Saving, Recalling, and Cloning Configuration Data

Fast Keys

Use the cloning feature of the Field Communicator or the AMS “User Configuration” feature to

configure several 2051 Wireless transmitters similarly. Cloning involves configuring a

transmitter, saving the configuration data, then sending a copy of the data to a separate

transmitter. Several possible procedures exist when saving, recalling, and cloning configuration

data. For complete instructions refer to the Field Communicator manual (publication no.

00809-0100-4276) or AMS Books Online. One common method is as follows:

left arrow, 1, 2

Field Communicator

1. Completely configure the first transmitter.

2. Save the configuration data:

a. Select F2 SAVE from the Field Communicator HOME/ONLINE screen.

b. Ensure that the location to which the data will be saved is set to MODULE. If it is not,

select 1: Location to set the save location to MODULE.

c. Select 2: Name, to name the configuration data. The default is the transmitter tag

number.

d. Ensure that the data type is set to STANDARD. If the data type is NOT

select 3: Data Type to set the data type to STANDARD.

e. Select F2 SAVE.

STANDARD,

3. Connect and power the receiving transmitter and Field Communicator.

4. Select the back arrow from the HOME/ONLINE screen. The Field Communicator menu

appears.

5. Select 1: Offline, 2: Saved Configuration, 1: Module Contents to reach the MODULE

CONTENTS menu.

6. Use the DOWN ARROW to scroll through the list of configurations in the memory

module, and use the RIGHT ARROW to select and retrieve the required configuration.

7. Select 1: Edit.

8. Select 1: Mark All.

9. Select F2 SAVE.

10. Use the DOWN ARROW to scroll through the list of configurations in the memory

module, and use the RIGHT ARROW to select the configuration again.

11. Select 3: Send to download the configuration to the transmitter.

12. Select OK after the control loop is set to manual.

13. After the configuration has been sent, select OK.

22

Configuration

Page 31

Reference Manual

00809-0100-4102, Rev AA

Section 2: Configuration

June 2012

When finished, the Field Communicator informs you of the status. Repeat Steps 3 through 13 to

configure another transmitter.

Note

The transmitter receiving cloned data must have the same software version (or later) as the

original transmitter.

AMS creating a Reusable Copy

To create a reusable copy of a configuration perform the following procedure:

1. Completely configure the first transmitter.

2. Select View then User Configuration View from the menu bar (or click the toolbar

button).

3. In the User Configuration window, right click and select New from the context menu.

4. In the New window, select a device from the list of templates shown, and click OK.

5. The template is copied into the User Configurations window, with the tag name

highlighted; rename it as appropriate and press Enter.

Note

A device icon can also be copied by dragging and dropping a device template or any other

device icon from AMS Explorer or Device Connection View into the User Configurations window.

The “Compare Configurations” window appears, showing the Current values of the copied

device on one side and mostly blank fields on the other (User Configuration) side.

6. Transfer values from the current configuration to the user configuration as appropriate

or enter values by typing them into the available fields.

7. Click Apply to apply the values, or click OK to apply the values and close the window.

AMS Applying a User Configuration

Any amount of user configurations can be created for the application. They can also be saved,

and applied to connected devices or to devices in the Device List or Plant Database.

To apply a user configuration perform the following procedure:

1. Select the desired user configuration in the User Configurations window.

2. Drag the icon onto a like device in AMS Explorer or Device Connection View. The

Compare Configurations window opens, showing the parameters of the target device

on one side and the parameters of the user configuration on the other.

Configuration

3. Transfer parameters from the user configuration to the target device as desired, Click

OK to apply the configuration and close the window.

23

Page 32

Section 2: Configuration

June 2012

Reference Manual

00809-0100-4102, Rev AA

24

Configuration

Page 33

Reference Manual

00809-0100-4102, Rev AA

Section 3 Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Installing the LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

Rosemount 304, 305 and 306 Integral Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

3.1 Overview

The information in this section covers installation considerations. A Quick Installation Guide

(document number 00825-0100-4100) is shipped with every transmitter to describe basic

installation and startup procedures. Dimensional drawings for each Rosemount 2051 Wireless

variation and mounting configuration are included in Appendix A: Specifications and Reference

Data.

Section 3: Installation

June 2012

Field Communicator and AMS instructions are given to perform configuration functions. For

convenience, Field Communicator fast key sequences are labeled “Fast Keys” for each software

function below the appropriate headings.

3.2 Safety Messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operation. Information that raises potential safety issues is

indicated with a warning symbol ( ). Refer to the following safety messages before

performing an operation preceded by this symbol.

Installation

25

Page 34

Section 3: Installation

June 2012

3.2.1 Warnings ( )

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Explosions can result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please review

the approvals section of the 2051 Wireless reference manual for any restrictions associated

with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, make sure the

instruments are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage may be present on leads can

cause electrical shock.

Reference Manual

00809-0100-4102, Rev AA

Process leaks could result in death or serious injury.

Install and tighten process connectors before applying pressure.

Do not attempt to loosen or remove process connectors while the transmitter is

in service.

Replacement equipment or spare parts not approved by Rosemount Inc. for use as spare

parts could reduce the pressure retaining capabilities of the transmitter and may render the

instrument dangerous.

Use only bolts supplied or sold by Rosemount Inc. as spare parts.

Improper assembly of manifolds to traditional flange can damage SuperModule

For safe assembly of manifold to traditional flange, bolts must break back plane of

™

.

flange web (i.e., bolt hold) but must not contact module housing.

The Power Module with the wireless unit contains one “D” size primary lithium/thionyl

chloride battery (Green Power Module, model number 701PGNKF). Each Power Module

contains approximately 5 grams of lithium. Under normal conditions, the Power Module

materials are self-contained and are not reactive as long as the batteries and the pack

integrity are maintained. Care should be taken to prevent thermal, electrical or mechanical

damage. Contacts should be protected to prevent premature discharge.

26

Installation

Page 35

Reference Manual

00809-0100-4102, Rev AA

3.3 Considerations

3.3.1 General

Measurement performance depends upon proper installation of the transmitter and impulse

piping. Mount the transmitter close to the process and use a minimum of piping to achieve best

performance. Also, consider the need for easy access, personnel safety, practical field

calibration, and a suitable transmitter environment. Install the transmitter to minimize

vibration, shock, and temperature fluctuation.

3.3.2 Wireless

Power Up Sequence

The Power Module should not be installed on any wireless device until the Smart Wireless

Gateway is installed and functioning properly. Wireless devices should also be powered up in

order of proximity from the Smart Wireless Gateway beginning with the closest. This will result

in a simpler and faster network installation. Enable High Speed Operation on the Gateway to

ensure that new devices join the network faster. For more information see the Smart Wireless

Gateway Manual (Doc. No. 00809-0200-4420).

Section 3: Installation

June 2012

Field Communicator Connections

In order for the Field Communicator to interface with the 2051, the Power Module must be

connected.

Figure 3-1. Field Communicator Connections

3.3.3 Mechanical

Note

For steam service or for applications with process temperatures greater than the limits of the

transmitter, do not blow down impulse piping through the transmitter. Flush lines with the

blocking valves closed and refill lines with water before resuming measurement.

Installation

Note

When the transmitter is mounted on its side, position the Coplanar flange to ensure proper

venting or draining. Mount the flange as shown in Figure 3.4.2 on page 32, keeping drain/vent

connections on the bottom for gas service and on the top for liquid service.

27

Page 36

Section 3: Installation

START HERE

Bench

Calibration?

Field Install

No

Configure

(Section 2)

Set Units

Set Range

Points

Set Network

Parameters

Ver ify

Apply Pressure

Yes

Within

Specifications?

Yes

No

Refer to

Section 4

Operation and

Maintenance

Check Switches

(page 34)

Mount

Tra ns mit te r

(

page 29)

Install Power

Module

(pages 35–34)

Check Process

Connection

(

page 32)

Tri m Transmi tter

for Mounting

Effects

(

page 48)

Done

Review

Tra ns mi tt er

Configuration

(

page 7)

Confirm

Tra ns mit te r

Configuration

(

page 7)

June 2012

3.3.4 Environmental

Access requirements and cover installation on page 29 can help optimize transmitter

performance. Mount the transmitter to minimize ambient temperature changes, vibration,

mechanical shock, and to avoid external contact with corrosive materials. Appendix A:

Specifications and Reference Data lists temperature operating limits.

Figure 3-2. Installation Flowchart

Reference Manual

00809-0100-4102, Rev AA

28

Installation

Page 37

Reference Manual

00809-0100-4102, Rev AA

3.4 Installation Procedures

For dimensional drawing information refer to “Dimensional Drawings” on page 83.

Process Flange Orientation

Mount the process flanges with sufficient clearance for process connections. For safety reasons,

place the drain/vent valves so the process fluid is directed away from possible human contact

when the vents are used. In addition, consider the need for a testing or calibration input.

Housing Rotation

See “Consider Housing Rotation” on page 34.

Power Module Side of Electronics Housing

Mount the transmitter so the Power Module side is accessible. Clearance of 2.75-in. (70 mm) is

required for cover removal.

Section 3: Installation

June 2012

Circuit Side of Electronics Housing

Provide 0.75 in. (19 mm) of clearance for units with out an LCD display. Three inches of

clearance is required for cover removal if a meter is installed.

Cover Installation

Always ensure a proper seal by installing the electronics housing cover(s) so that polymer

contacts polymer. Use Rosemount O-rings.

3.4.1 Mount the Transmitter

Mounting Brackets

Facilitate mounting transmitter to a 2-in. pipe, or to a panel. The B4 Bracket (SST) option is

standard for use with the Coplanar and In-Line flanges. “Coplanar Flange Mounting Configurations” on page 83 shows bracket dimensions and mounting configurations for the B4 option.

Options B1–B3 and B7–B9 are sturdy, epoxy/polyester-painted brackets designed for use with

the traditional flange. The B1–B3 brackets have carbon steel bolts, while the B7–B9 brackets

have stainless steel bolts. The BA and BC brackets and bolts are stainless steel. The B1/B7/BA

and B3/B9/BC style brackets support 2-inch pipe-mount installations, and the B2/B8 style

brackets support panel mounting.

Installation

Note

Most transmitters are calibrated in the horizontal position. Mounting the transmitter in any

other position will shift the zero point to the equivalent amount of liquid head caused by the

varied mounting position. To reset zero point, refer to “Sensor Trim” on page 49.

Position the antenna such that it is vertical, typically straight up (antenna may be pointed down

as well.)

29

Page 38

Section 3: Installation

Carbon Steel (CS) Head Markings

B7M

316

B8M

F593_

Stainless Steel (SST) Head Markings

* The last digit in the F593_ head marking may

be any letter between A and M.

F593_

KM

660

CL A

Alloy K-500 Head Marking

June 2012

Flange Bolts

The 2051 can be shipped with a Coplanar flange or a Traditional flange installed with four

1.75-inch flange bolts. Mounting bolts and bolting configurations for the Coplanar and

Traditional flanges can be found on page 2-6, 7. Stainless steel bolts supplied by Emerson

Process Management are coated with a lubricant to ease installation. Carbon steel bolts do not

require lubrication. No additional lubricant should be applied when installing either type of bolt.

Bolts supplied by Emerson Process Management are identified by their head markings:

Bolt Installation

Reference Manual

00809-0100-4102, Rev AA

Only use bolts supplied with the Rosemount 2051 or sold by Emerson Process Management as

spare parts. When installing the transmitter to one of the optional mounting brackets, torque

the bolts to 125 in-lb. (0,9 N-m). Use the following bolt installation procedure:

1. Finger-tighten the bolts.

2. Torque the bolts to the initial torque value using a crossing pattern.

3. Torque the bolts to the final torque value using the same crossing pattern.

Torque values for the flange and manifold adapter bolts are as follows:

Table 3-1. Bolt Installation

Tor q ue Val ues

Bolt Material Initial Torque Value Final Torque Value

CS-ASTM-A445 Standard 300 in.-lb (34 N-m) 650 in.-lb (73 N-m)

316 SST—Option L4 150 in.-lb (17 N-m) 300 in.-lb (34 N-m)

ASTM-A-193-B7M—Option L5 300 in.-lb (34 N-m) 650 in.-lb (73 N-m)

Alloy K-500—Option L6 300 in.-lb (34 N-m) 650 in.-lb (73 N-m)

ASTM-A-453-660—Option L7 150 in.-lb (17 N-m) 300 in.-lb (34 N-m)

ASTM-A-193-B8M—Option L8 150 in.-lb (17 N-m) 300 in.-lb (34 N-m)

30

Installation

Page 39

Reference Manual

00809-0100-4102, Rev AA

Impulse Piping

The piping between the process and the transmitter must accurately transfer the pressure to

obtain accurate measurements. There are five possible sources of error: leaks, friction loss

(particularly if purging is used), trapped gas in a liquid line, liquid in a gas line, and density

variations between the legs.

The best location for the transmitter in relation to the process pipe depends on the process

itself. Use the following guidelines to determine transmitter location and placement of impulse

piping:

Keep impulse piping as short as possible.

For liquid service, slope the impulse piping at least 1 inch per foot (8 cm per m) upward

For gas service, slope the impulse piping at least 1 inch per foot (8 cm per m) downward

Avoid high points in liquid lines and low points in gas lines.

Make sure both impulse legs are the same temperature.

Use impulse piping large enough to avoid friction effects and blockage.

Section 3: Installation

June 2012

from the transmitter toward the process connection.

from the transmitter toward the process connection.

Vent all gas from liquid piping legs.

When using a sealing fluid, fill both piping legs to the same level.

When purging, make the purge connection close to the process taps and purge

through equal lengths of the same size pipe. Avoid purging through the transmitter.

Keep corrosive or hot (above 250 °F [121 °C]) process material out of direct contact

with the SuperModule and flanges.

Prevent sediment deposits in the impulse piping.

Keep the liquid head balanced on both legs of the impulse piping.

Avoid conditions that might allow process fluid to freeze within the process flange.

Installation

31

Page 40

Section 3: Installation

June 2012

Mounting Requirements

Refer to Figure 3.4.2 for examples of the following mounting configurations:

Liquid Flow Measurement

Place taps to the side of the line to prevent sediment deposits on the process isolators.

Mount the transmitter beside or below the taps so gases vent into the process line.

Mount drain/vent valve upward to allow gases to vent.

Gas Flow Measurement

Place taps in the top or side of the line.

Mount the transmitter beside or above the taps so to drain liquid into the process line.

Steam Flow Measurement

Place taps to the side of the line.

Mount the transmitter below the taps to ensure that impulse piping will remain filled

Fill impulse lines with water to prevent steam from contacting the transmitter directly

Reference Manual

00809-0100-4102, Rev AA

with condensate.

and to ensure accurate measurement start-up.

Note

For steam or other elevated temperature services, it is important that temperatures at the

Coplanar process flanges must not exceed 250 °F (121 °C) for transmitters with silicone fill, or

185 °F (85 °C) for inert fill. For vacuum service, these temperature limits are reduced to 220 °F

(104 °C) for silicone fill and 160 °F (71 °C) for inert fill.

3.4.2 Process Connections

2051 Wireless transmitter flange process connection size is 1/4–18 NPT. Flange adapters with

1

/2–14 NPT connections are available as the D2 option. Use your plant-approved lubricant or

sealant when making the process connections. The process connections on the transmitter

flange are on 2

manifold. Rotate one or both of the flange adapters to attain connection centers of 2 inches

(51 mm), 2

Install and tighten all four flange bolts before applying pressure to avoid leakage. When properly

installed, the flange bolts will protrude through the top of the sensor module housing. Do not

attempt to loosen or remove the flange bolts while the transmitter is in service.

To install adapters to a Coplanar flange, perform the following procedure:

1. Remove the flange bolts.

2. Leaving the flange in place, move the adapters into position with the O-ring installed.

1

/8-inch (54 mm) centers to allow direct mounting to a three-valve or five-valve

1

/8 inches (54 mm), or 21/4 inches (57 mm).

32

3. Clamp the adapters and the Coplanar flange to the transmitter module using the longer

of the bolts supplied.

4. Tighten the bolts. Refer to “Flange Bolts” on page 30 for torque specifications.

Installation

Page 41

Reference Manual

Failure to install proper flange adapter o-rings may cause process leaks, which can result in death or

serious injury. The two flange adapters are distinguished by unique o-ring grooves. Only use the

o-ring that is designed for its specific flange adapter, as shown below.

ROSEMOUNT 2051S / 2051 / 2051 / 3001 / 3095 / 2024

ROSEMOUNT 1151

Flange Adapter

O-ring

Flange Adapter

O-ring

PTFE Based

Elastomer

PTFE

Elastomer

00809-0100-4102, Rev AA

Section 3: Installation

June 2012

Note

PTFE O-rings should be replaced if the flange adapter is removed.

Whenever you remove flanges or adapters, visually inspect the Teflon

there are any signs of damage, such as nicks or cuts. If you replace the O-rings, re-torque the

flange bolts after installation to compensate for cold flow. Refer to the process sensor body

reassembly procedure in Section 6: Troubleshooting on page 69.

®

O-rings. Replace them if

Installation

33

Page 42

Section 3: Installation

June 2012

3.4.3 Consider Housing Rotation

The housing can be rotated to improve field access to wiring or to better view the optional LCD

display. Perform the following procedure:

Figure 3-3. Housing rotation

A. Housing rotation screw (5/64-inch hex wrench required)

1. Loosen the housing rotation set screw.

Reference Manual

00809-0100-4102, Rev AA

A

2. Turn the housing up to 180 degrees to the left or right of its original (as shipped)

position.

Note

Do not rotate the housing more than 180 degrees without first performing a disassembly

procedure (see “Remove Feature Assembly” on page 68). Over-rotation may sever the electrical

connection between the sensor module and the feature board.

3. Retighten the housing rotation set screw.

In addition to housing rotation, the optional LCD display can be rotated in 90-degree increments

by squeezing the two tabs, pulling out, rotating and snapping back into place.

Note

If LCD pins are inadvertently removed from the interface board, carefully re-insert the pins

before snapping the LCD display back into place.

3.4.4 Grounding

Transmitter Case

Always ground the transmitter case in accordance with national and local electrical codes. The

most effective transmitter case grounding method is a direct connection to earth ground with

minimal impedance. Methods for grounding the transmitter case include:

34

External Ground Assembly: This assembly is included with the optional transient

protection terminal block (Option Code T1), and it is included with various hazardous

location certifications. The External Ground Assembly can also be ordered with the

transmitter (Option Code V5), or as a spare part.

Installation

Page 43

Reference Manual

00809-0100-4102, Rev AA

3.4.5 Power Module Installation

Figure 3-4. Power Module

A. Housing rotation screw (5/64-inch hex wrench required)

Section 3: Installation

June 2012

A

To make connections, perform the following procedure:

1. Remove the housing cover on the Power Module compartment side. The Power Module

supplies all power to the transmitter.

2. Connect Power Module 701PGNKF.

3. Replace the Power Module cover and tighten to safety specification (metal to metal).

3.4.6 Installing the LCD Display

Transmitters ordered with the LCD display will be shipped with the display installed.

Note

Only use Rosemount Wireless LCD Part Number: 00753-9004-0002

Note

An LCD from a wired device will not function in a wireless device.

In addition to housing rotation, the optional LCD display can be rotated in 90-degree increments

by squeezing the two tabs, pulling out, rotating and snapping back into place.

If LCD pins are inadvertently removed from the interface board, carefully re-insert the pins

before snapping the LCD display back into place.

Installation

Use the following procedure and Figure 3-5 to install the LCD display:

35

Page 44

Section 3: Installation

June 2012

1. Remove the back cover and Power Module.

2. Remove the transmitter cover opposite the field terminal side. Do not remove the

3. Engage the four-pin connector into the LCD display and snap into place.

Note the following LCD temperature limits:

Operating:–40 to 175 °F (–40 to 80 °C)

Storage:–40 to 185 °F (–40 to 85 °C)

Figure 3-5. Optional LCD Display

Reference Manual

00809-0100-4102, Rev AA

instrument covers in explosive environments when the circuit is live.

3.5 Rosemount 304, 305 and 306 Integral Manifolds

The Rosemount 305 is available in two designs: Traditional and Coplanar. The traditional 305

Integral Manifold can be mounted to most primary elements with mounting adapters in the

market today. The Rosemount 306 Integral Manifold is used with In-line transmitters to provide

block-and-bleed valve capabilities of up to 10000 psi (690 bar). The Rosemount 304 comes in

two basic styles: traditional (flange x flange and flange x pipe) and wafer. The 304 traditional

manifold comes in 2, 3, and 5-valve configurations. The 304 wafer manifold comes in 3 and 5

valve configurations.

36

Installation

Page 45

Reference Manual

00809-0100-4102, Rev AA

Figure 3-6. Integral Manifold Designs

Section 3: Installation

June 2012

3.5.1 Rosemount 305 Integral Manifold Installation Procedure

To install a 305 Integral Manifold to a 2051 Wireless transmitter:

1. Inspect the Teflon sensor module O-rings. If the O-rings are undamaged, reusing them

is recommended. If the O-rings are damaged (if they have nicks or cuts, for example),

replace them with new O-rings.

Important

If replacing the O-rings, take care not to scratch or deface the O-ring grooves or the surface of

the isolating diaphragm while you remove the damaged O-rings.

2. Install the Integral Manifold on the sensor module. Use the four 2.25-in. manifold bolts

for alignment. Finger tighten the bolts, then tighten the bolts incrementally in a cross

pattern to final torque value. See “Flange Bolts” on page 30 for complete bolt

installation information and torque values. When fully tightened, the bolts should

extend through the top of the module housing.

3. If the Teflon sensor module O-rings have been replaced, the flange bolts should be

re-tightened after installation to compensate for cold flow of the O-rings.

4. If applicable, install flange adapters on the process end of the manifold using the

1.75-in. flange bolts supplied with the transmitter.

Note

Always perform a zero trim on the transmitter/manifold assembly after installation to eliminate

mounting effects. See Section 5: Operation and Maintenance, “Zero Trim” on page 49.

3.5.2 Rosemount 306 Integral Manifold Installation Procedure

The 306 Manifold is for use only with a 2051T Wireless In-line transmitter.

Assemble the 306 Manifold to the 2051T Wireless In-line transmitter with a thread sealant.

Installation

37

Page 46

Section 3: Installation

June 2012

1. Place transmitter into holding fixture.

2. Apply appropriate thread paste or tape to threaded instrument end of the manifold.

3. Count total threads on the manifold before starting assembly.

4. Start turning the manifold by hand into the process connection on the transmitter.

Note

If using thread tape, be sure the thread tape does no strip when the manifold assembly is

started.