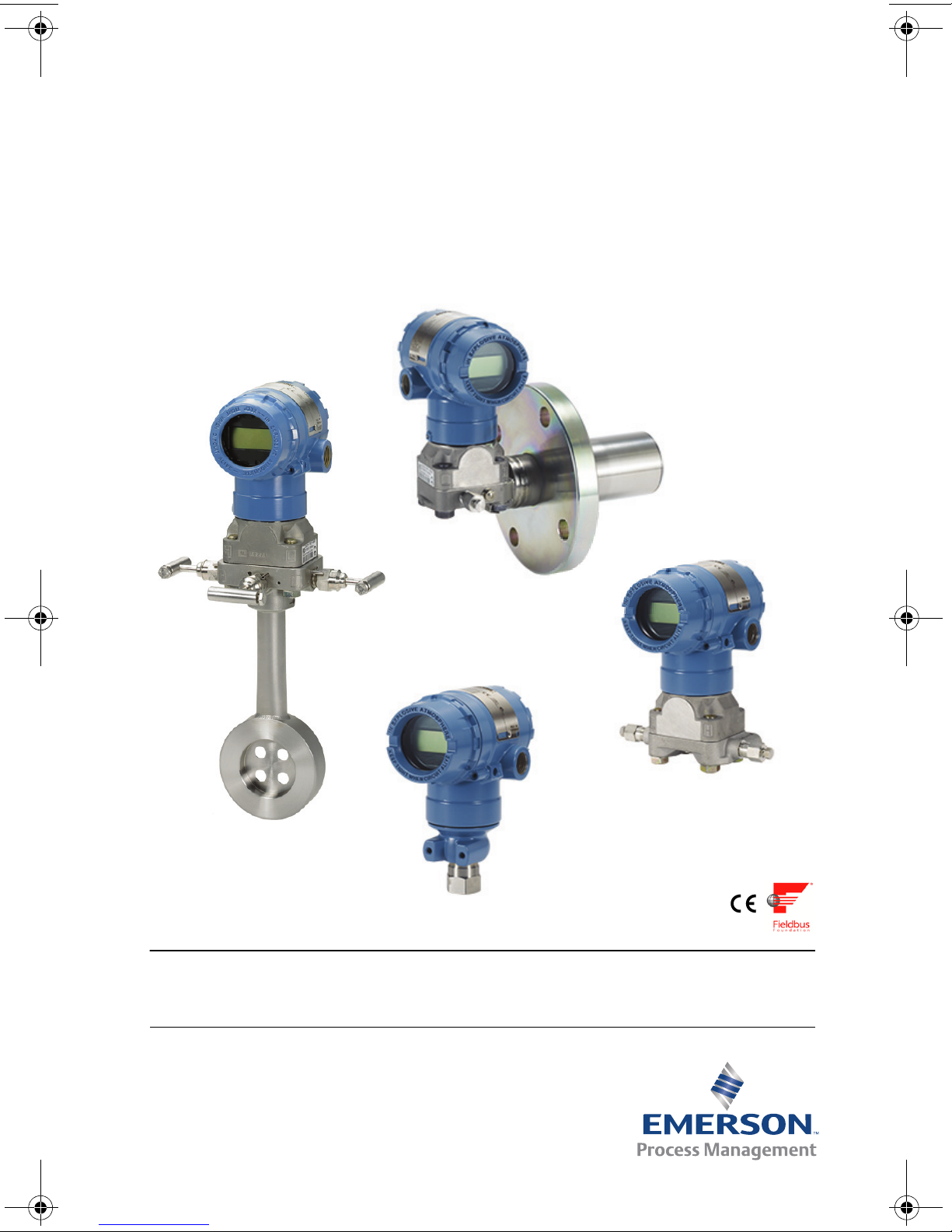

Emerson Rosemount 2051, Rosemount 2051CF series Quick Start Manual

Quick Start Guide

00825-0200-4101, Rev FC

September 2016

Rosemount™ 2051 Pressure Transmitter

Rosemount 2051CF Series Flowmeter

with FOUNDATION™ Fieldbus Protocol

Note

Before installing the transmitter, confirm the correct device driver is loaded on the host systems.

See “System readiness” on page 3.

Quick Start Guide

September 2016

NOTICE

This guide provides basic guidelines for Rosemount 2051 Transmitters. It does not provide instructions for

configuration, diagnostics, maintenance, service, troubleshooting, Explosion-Proof, Flame-Proof, or

intrinsically safe (I.S.) installations. Refer to the Rosemount 2051 Reference Manual

This manual is also available electronically on EmersonProcess.com/Rosemount

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate local,

national, and international standards, codes, and practices. Review the approvals section of the Rosemount

2051 Reference Manual

In an Explosion-proof/Flameproof installation, do not remove the transmitter covers when power is

applied to the unit.

Process leaks may cause harm or result in death.

To avoid process leaks, only use the o-ring designed to seal with the corresponding flange adapter.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and the terminals. High voltage that may be present on leads can cause

electrical shock.

Conduit/cable entries

Unless marked, the conduit/cable entries in the transmitter housing use a

marked “M20” are M20 ⫻ 1.5 thread form. On devices with multiple conduit entries, all entries will have

the same thread form. Only use plugs, adapters, glands, or conduit with a compatible thread form when

closing these entries.

When installing in a hazardous location, use only appropriately listed or Ex certified plugs, adapters, or

glands in cable/conduit entries.

for any restrictions associated with a safe installation.

for more instruction.

.

1

/2–14 NPT thread form. Entries

Contents

System readiness . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mount the transmitter . . . . . . . . . . . . . . . . . . . . 4

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Housing rotation . . . . . . . . . . . . . . . . . . . . . . . . . 9

Set the switches . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2

Wire, ground, and power up . . . . . . . . . . . . . . 10

Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Zero trim the transmitter . . . . . . . . . . . . . . . . 19

Product Certifications . . . . . . . . . . . . . . . . . . . 20

September 2016

Quick Start Guide

1.0 System readiness

1.1 Confirm correct device driver

Verify the correct device driver (DD/DTM

ensure proper communications.

Download the correct device driver at your host vendor download site,

EmersonProcess.com or Fieldbus.org.

Rosemount 2051 device revisions and drivers

Table 1 provides the information necessary to ensure you have the correct device

driver and documentation for your device.

Table 1. Rosemount 2051 FOUNDATION Fieldbus Device Revisions and Files

™

) is loaded on your systems to

Device

revision

(1)

2

1

1. FOUNDATION Fieldbus device revision can be read using a FOUNDATION Fieldbus capable configuration tool.

2. Device driver file names use device and DD revision. To access functionality, the correct device driver must be installed on your

control and asset management hosts, and on your configuration tools.

Host Device driver (DD)

All DD4: DD Rev 1 Fieldbus.org

All DD5: DD Rev 1 Fieldbus.org

AMS™ Device Manager

Emerson

Emerson

Emerson 375/475: DD Rev 2 FieldCommunicator.com

All DD4: DD Rev 4 Fieldbus.org

All DD5: NA N/A

Emerson

Emerson 375/475: DD Rev 2 FieldCommunicator.com

V 10.5 or higher:

DD Rev 2

AMS Device Manager

V 8 to 10.5: DD Rev 1

AMS Device Manager

V 8or higher: DD Rev 2

(2)

Obtain at Device driver (DTM)

EmersonProcess.com

EmersonProcess.com

EmersonProcess.com

EmersonProcess.com

EmersonProcess.com

Manual document

number

00809-0200-4101,

Rev BA or newer

00809-0200-4101,

Rev AA

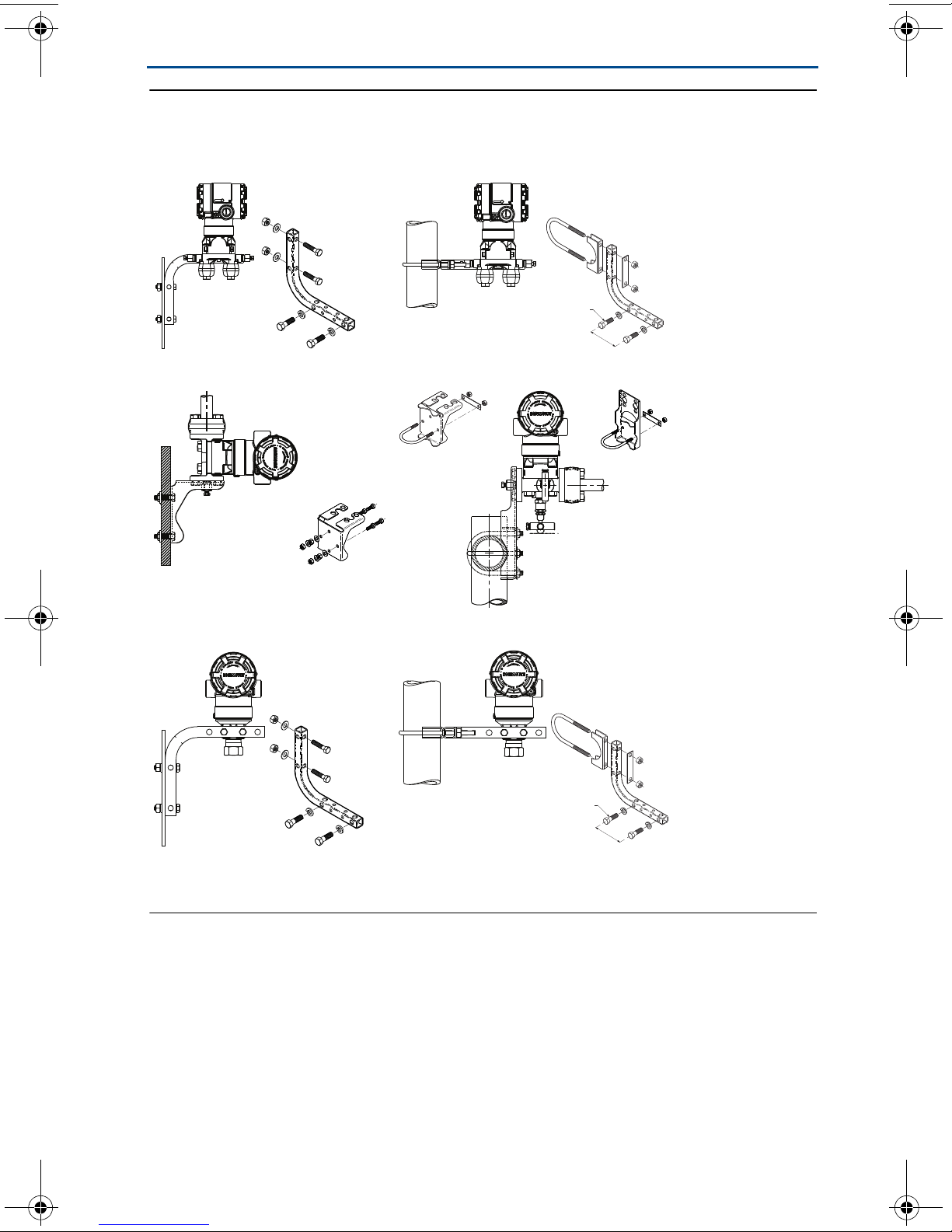

Figure 1. Installation Flowchart

3

Quick Start Guide

2.0 Mount the transmitter

September 2016

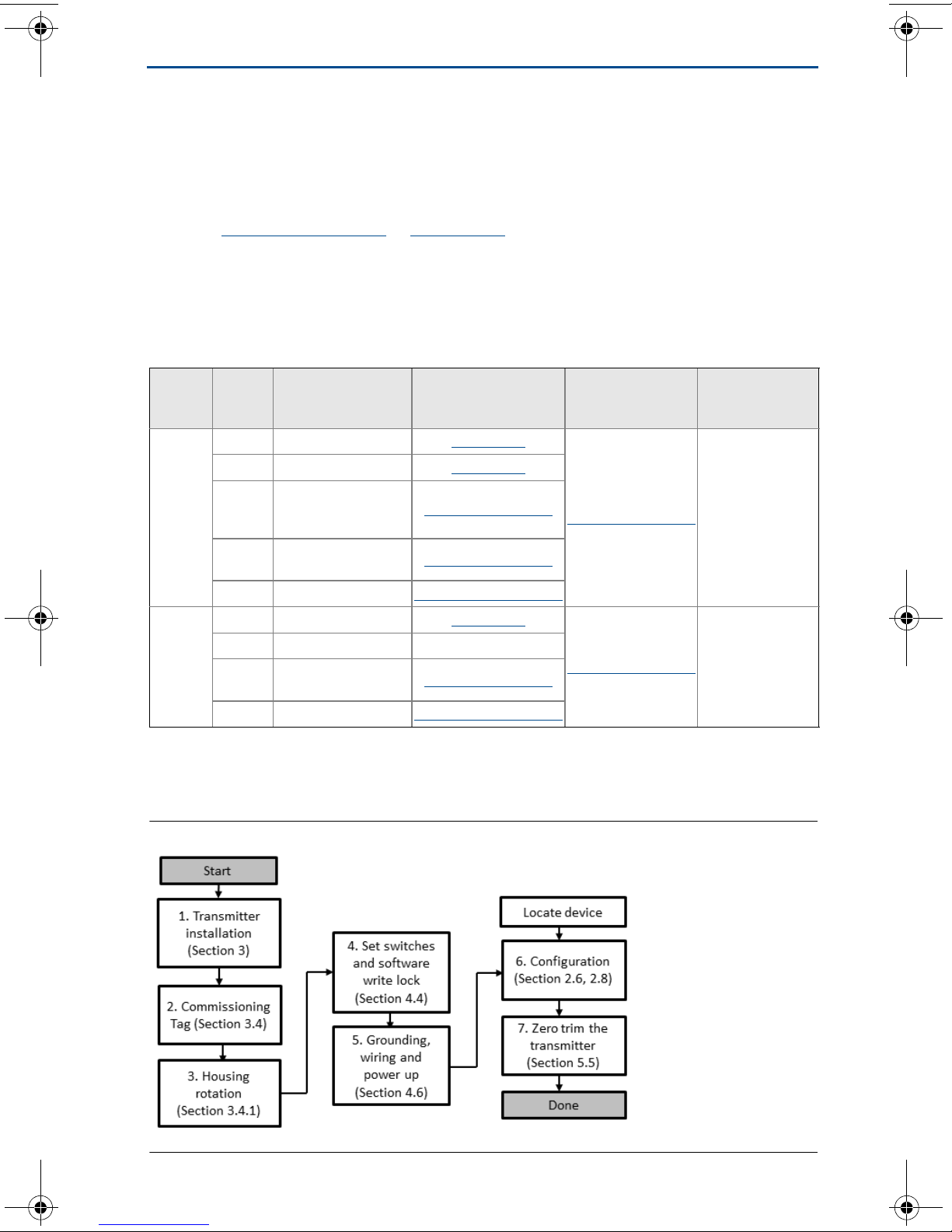

2.1 Liquid applications

1. Place taps to the side of the

line.

2. Mount beside or below the

taps.

3. Mount the transmitter so the

drain/vent valves are oriented

upward.

2.2 Gas applications

1. Place taps in the top or side of

the line.

2. Mount beside or above the

taps.

Coplanar In-line

2.3 Steam applications

1. Place taps to the side of the

line.

2. Mount beside or below the

taps.

3. Fill impulse lines with water.

4

September 2016

Figure 2. Panel and Pipe Mounting

Panel mount

(1)

Coplanar flange

Traditional flange

Quick Start Guide

Pipe mount

Rosemount 2051T

1. 5/16 ⫻ 11/2 panel bolts are customer supplied.

5

Quick Start Guide

September 2016

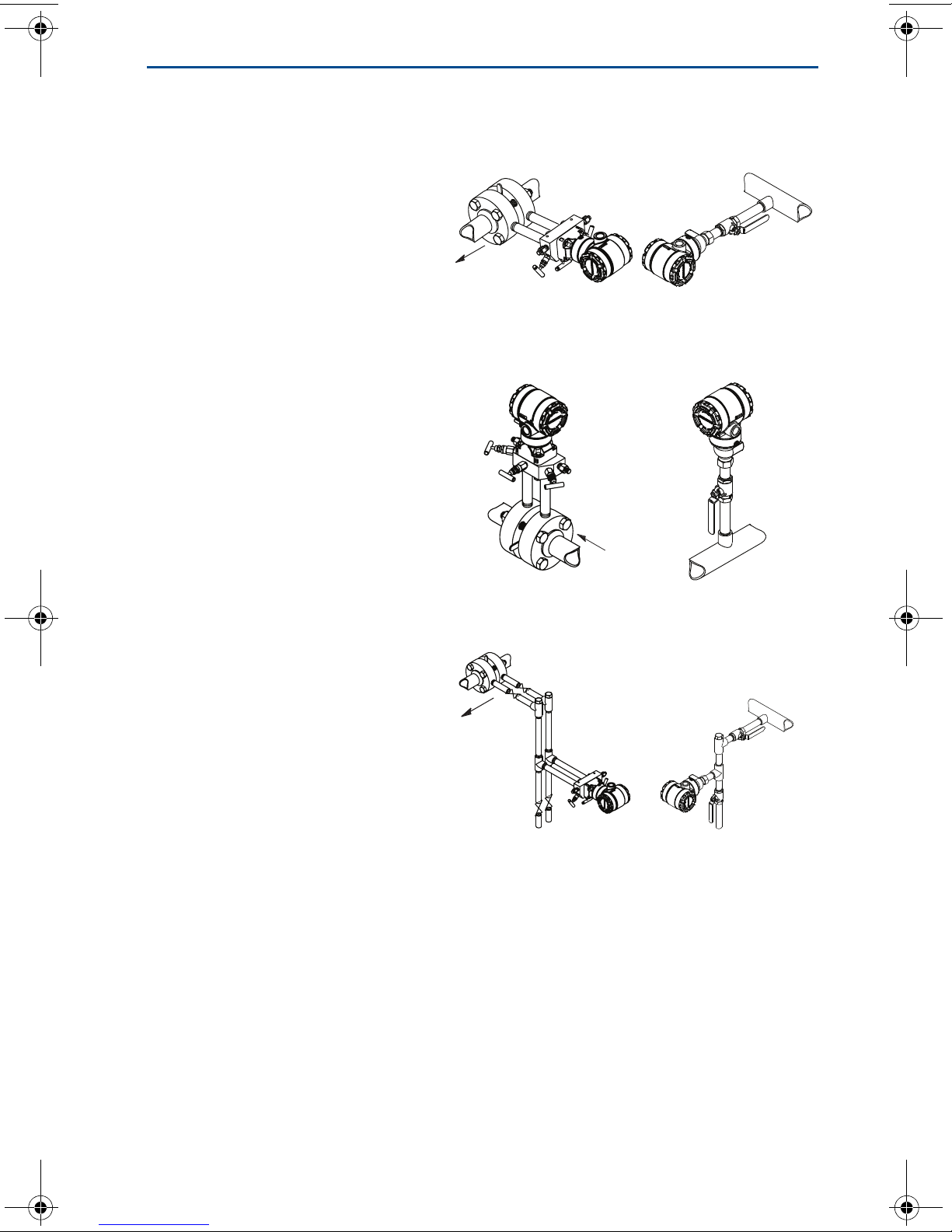

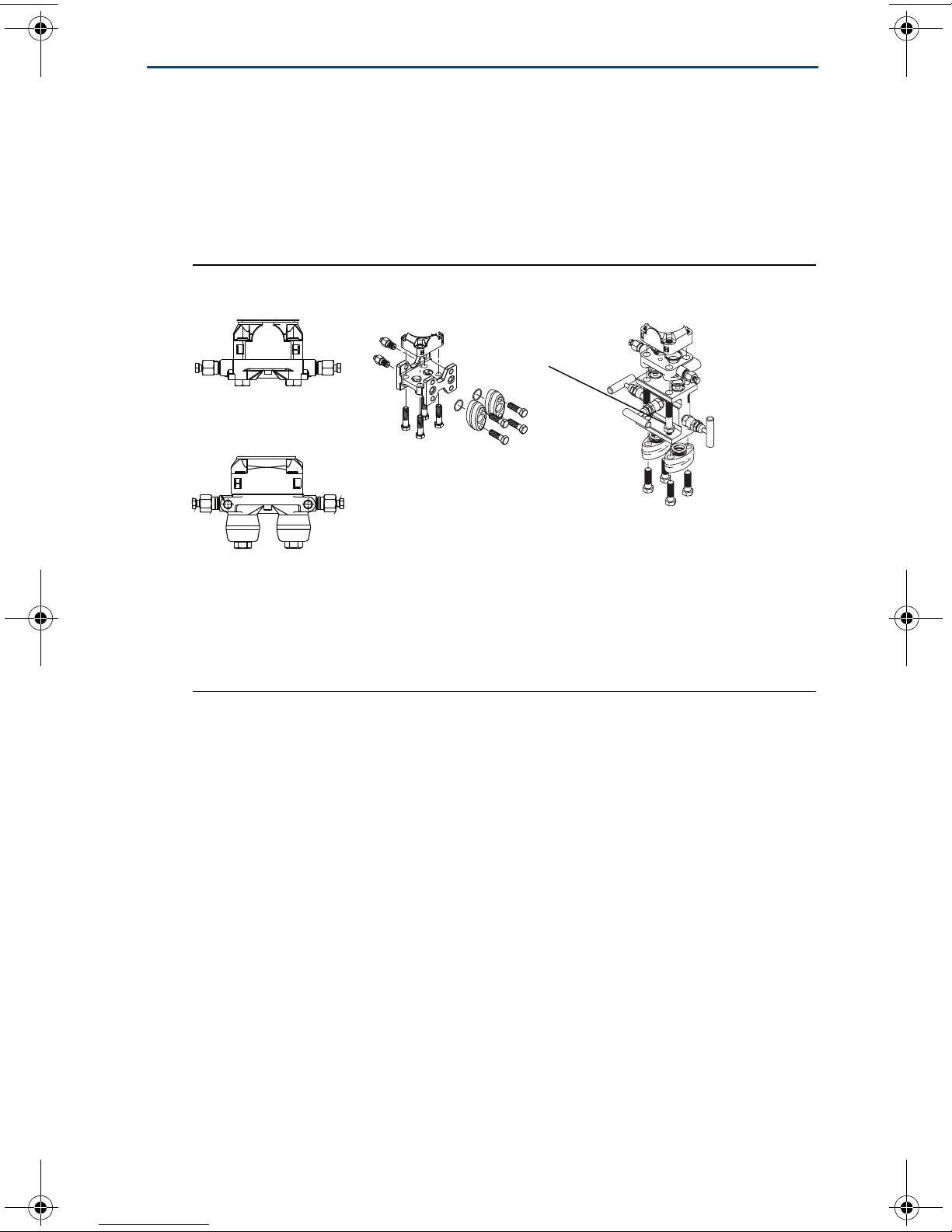

2.4 Bolting considerations

If the transmitter installation requires assembly of the process flanges, manifolds,

or flange adapters, follow the assembly guidelines to ensure a tight seal for

optimal performance characteristics of the transmitters. Use only bolts supplied

™

with the transmitter or sold by Emerson

illustrates common transmitter assemblies with the bolt length required for

proper transmitter assembly.

Figure 3. Common Transmitter Assemblies

A

4 × 1.75-in.

(44 mm)

C

as spare parts. Figure 3 on page 6

D

4 × 2.25-in.

(57 mm)

B

4 × 2.88-in.

(73 mm)

A. Transmitter with coplanar flange

B. Transmitter with coplanar flange and optional flange adapters

C. Transmitter with traditional flange and optional flange adapters

D. Transmitter with coplanar flange and optional manifold and flange adapters

4 × 1.75-in.

(44 mm)

4 × 1.50-in.

(38 mm)

4 × 1.75-in.

(44 mm)

Bolts are typically carbon steel or stainless steel. Confirm the material by viewing

the markings on the head of the bolt and referencing Table 2. If bolt material is

not shown in Table 2, contact a local Emerson Process Management

representative for more information.

Carbon steel bolts do not require lubrication and the stainless steel bolts are

coated with a lubricant to ease installation. However, no additional lubricant

should be applied when installing either type of bolt.

Use the following bolt installation procedure:

1. Finger tighten the bolts.

2. Torque the bolts to the initial torque value using a crossing pattern.

See Ta bl e 2 for initial torque value.

3. Torque the bolts to the final torque value using the same crossing pattern.

See Table 2 for final torque value.

4. Verify the flange bolts are protruding through the sensor module bolt holes

before applying pressure.

6

September 2016

B7M

A

B

Rosemount 3051S/3051/2051

C

D

Table 2. Torque Values for the Flange and Flange Adapter Bolts

Bolt material Head markings Initial torque Final torque

Carbon Steel (CS) 300 in-lb 650 in-lb

Quick Start Guide

316

Stainless Steel (SST) 150 in-lb 300 in-lb

316

R

B8M

STM

316

316

SW

316

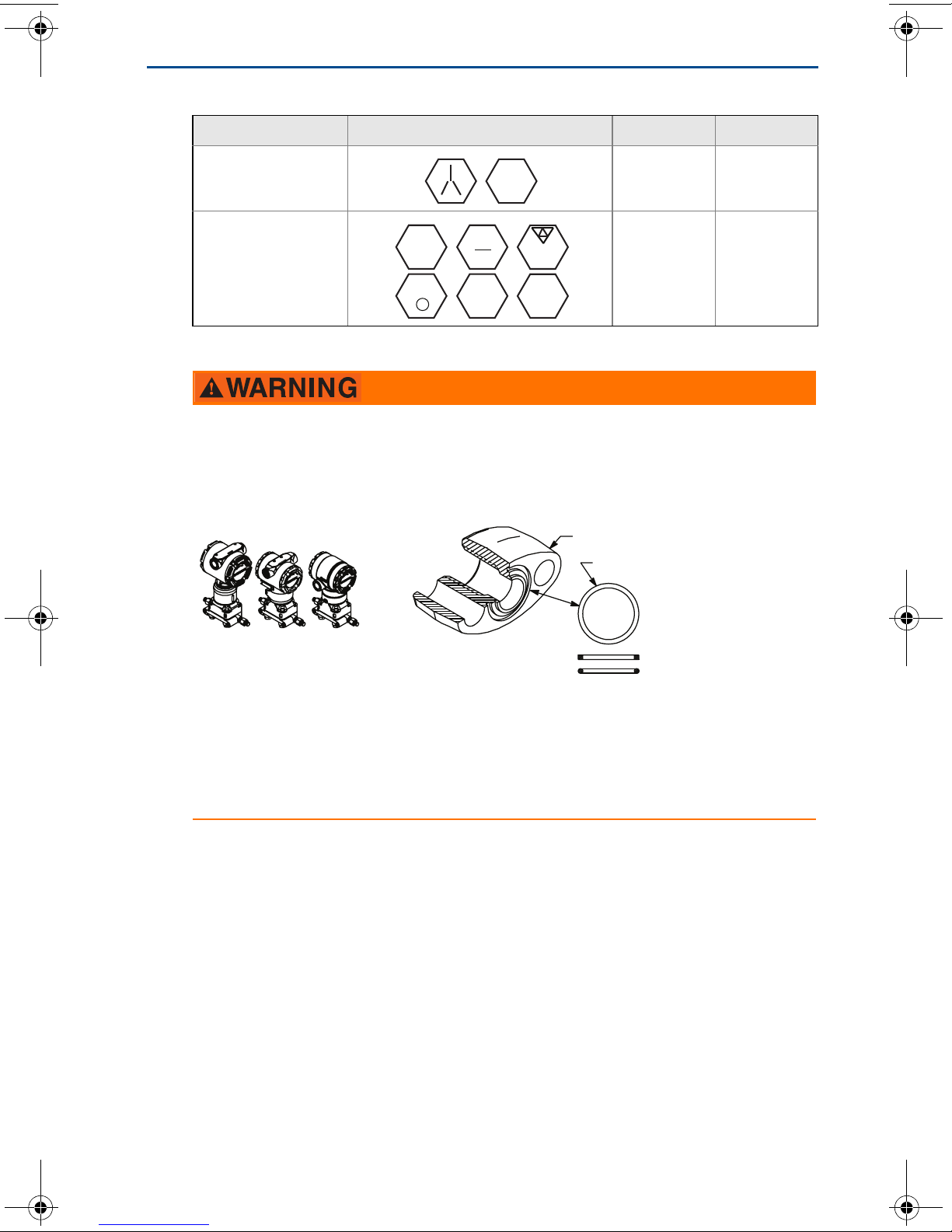

2.5 O-rings with flange adapters

Failure to install proper flange adapter O-rings may cause process leaks, which can result in death or

serious injury. The two flange adapters are distinguished by unique O-ring grooves. Only use the O-ring

that is designed for its specific flange adapter, as shown below:

O-ring location

A. Flange adapter

B. O-ring

C. PTFE based (profile is square)

D. Elastomer (profile is round)

Whenever the flanges or adapters are removed, visually inspect the O-rings. Replace them if there are

any signs of damage, such as nicks or cuts. If you replace the O-rings, re-torque the flange bolts and

alignment screws after installation to compensate for seating of the PTFE O-ring.

2.6 Environmental seal for housing

Thread sealing (PTFE) tape or paste on male threads of conduit is required to

provide a water/dust tight conduit seal and meets requirements of NEMA®

Type 4X, IP66, and IP68. Consult factory if other Ingress Protection ratings are

required.

For M20 threads, install conduit plugs to full thread engagement or until

mechanical resistance is met.

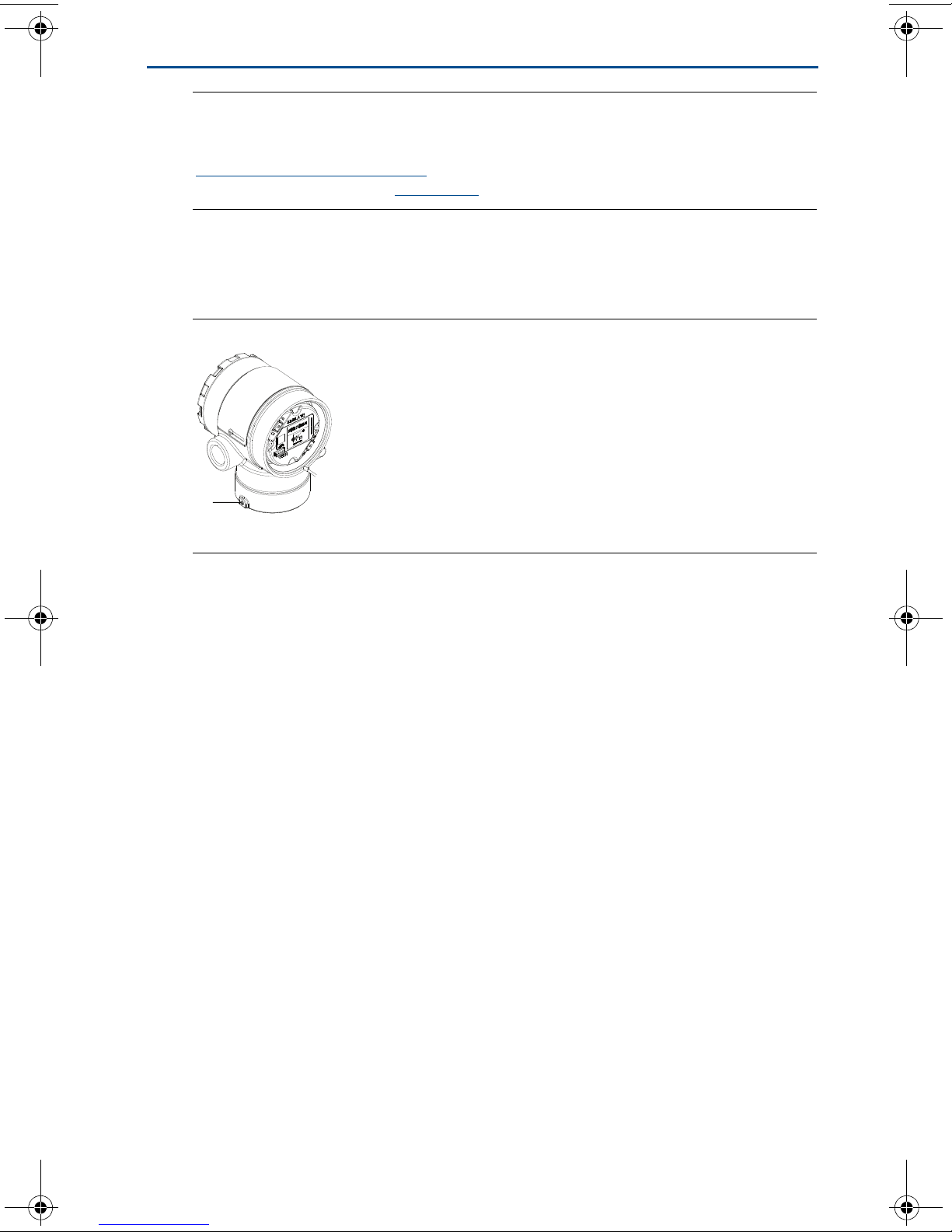

2.7 In-line gage transmitter orientation

The low side pressure port (atmospheric reference) on the in-line gage

transmitter is located in the neck of the transmitter, behind the housing.

The vent path is 360° around the transmitter between the housing and sensor.

(See Figure 4.)

7

Quick Start Guide

September 2016

Keep the vent path free of any obstruction, including but not limited to paint,

dust, and lubrication by mounting the transmitter so fluids can drain away.

Figure 4. In-line Gage Low Side Pressure Port

A

A. Pressure port location

3.0 Tagging

3.1 Commissioning (paper) tag

To identify which device is at a particular location use the removable tag provided

with the transmitter. Ensure the physical device tag (PD tag field) is properly

entered in both places on the removable commissioning tag and tear off the

bottom portion for each transmitter.

Note

The device description loaded in the host system must be at the same revision as this

device, see “System readiness” on page 3.

Figure 5. Commissioning Tag

Commissioning Tag

DEVICE ID:

0011512051010001440-12169809172

DEVICE REVISION: 1.1

PHYSICAL DEVICE TAG

DEVICE ID:

0011512051010001440 -12169809172

Device Barcode

DEVICE REVISION: 1.1

S / N :

PHYSICAL DEVICE TAG

A

Commissioning Tag

DEVICE ID:

001151AC00010001440-12169809172

DEVICE REVISION: 2.1

PHYSICAL DEVICE TAG

DEVICE ID:

001151AC00010001440-12169 809172

Device Barcode

DEVICE REVISION: 2.1

S / N :

PHYSICAL DEVICE TAG

A. Device revision

8

September 2016

A

Note

The device description loaded in the host system must be at the same revision as this

device. The device description can be downloaded from the host system website or

EmersonProcess.com/Rosemount

Quick Links. You can also visit Fieldbus.org and select End User Resources.

by selecting Download Device Drivers under Product

4.0 Housing rotation

To improve field access to wiring or to better view the optional LCD display:

Figure 6. Housing Rotation

Quick Start Guide

A. Housing rotation set screw (5/64-in.)

1. Loosen the housing rotation set screw.

2. First rotate the housing clockwise to the desired location.

3. If the desired location cannot be achieved due to thread limit, rotate the

housing counter clockwise to the desired location (up to 360° from thread

limit).

4. Re-tighten the housing rotation set screw to no more than 7 in-lb when

desired location is reached.

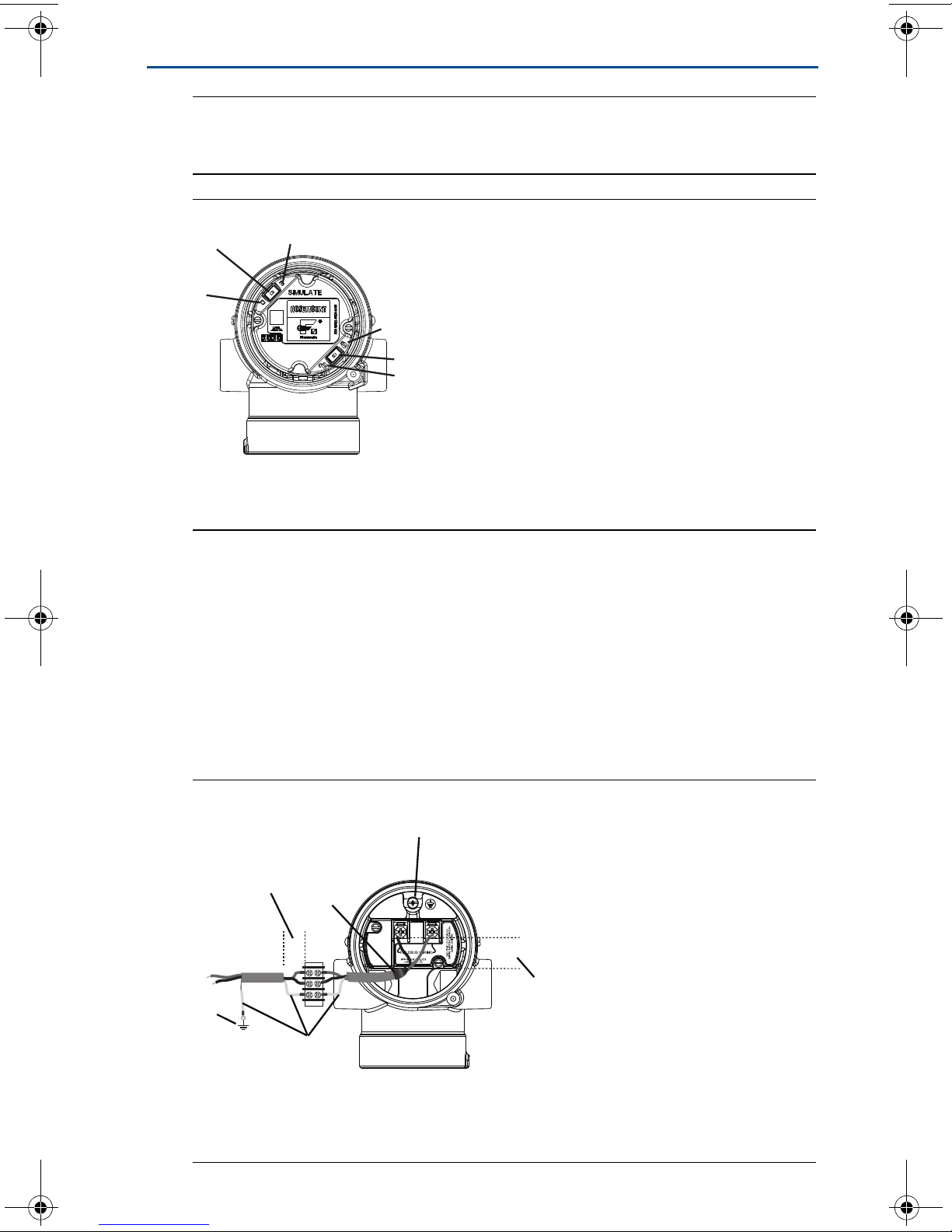

5.0 Set the switches

Set simulate and security switch configuration before installation as shown in

Figure 7.

The simulate switch enables or disables simulated alerts and simulated AI

Block status and values. The default simulate switch position is enabled.

The security switch allows (unlocked symbol) or prevents (locked symbol) any

configuration of the transmitter.

- Default security is off (unlocked symbol).

- The security switch can be enabled or disabled in software.

Use the following procedure to change the switch configuration:

1. If the transmitter is installed, secure the loop, and remove power.

2. Remove the housing cover opposite the field terminal side. Do not remove the

instrument cover in explosive atmospheres when the circuit is live.

3. Slide the security and simulate switches into the preferred position.

4. Replace the housing cover.

9

Quick Start Guide

C

B

A

D

E

F

Note

It is recommended the cover be tightened until there is no gap between the cover and

housing.

Figure 7. Simulate and Security Switches

September 2016

A. Simulate disabled position

B. Simulate switch

C. Simulate enabled position (default)

D. Security locked position

E. Security switch

F. Security unlocked position (default)

6.0 Wire, ground, and power up

Use of copper wire of sufficient size to ensure that the voltage across the

transmitter power terminals does not drop below 9 Vdc. Power supply voltage

can be variable, especially under abnormal conditions such as when operating on

battery backup. A minimum of 12 Vdc under normal operating conditions is

recommended. Shielded twisted pair Type A cable is recommended.

1. To power the transmitter, connect the power leads to the terminals indicated

on the terminal block label.

Figure 8. Wiring Terminals

C

A

B

F

DP

D

A. Minimize distance

B. Trim shield and insulate

C. Protective grounding terminal

(do not ground cable shield at the transmitter)

10

E

D. Insulate shield

E. Minimize distance

F. Connect shield back to the power

supply ground

September 2016

Quick Start Guide

Note

The Rosemount 2051 power terminals are polarity insensitive, which means the electrical

polarity of the power leads does not matter when connecting to the power terminals. If

polarity sensitive devices are connected to the segment, terminal polarity should be

followed. When wiring to the screw terminals, the use of crimped legs is recommended.

2. Ensure full contact with terminal block screw and washer. When using a direct

wiring method, wrap wire clockwise to ensure it is in place when tightening

the terminal block screw. No additional power is needed.

Note

The use of a pin or a ferrule wire terminal is not recommended as the connection may be

more susceptible to loosening over time or under vibration.

6.1 Signal wiring grounding

Do not run signal wiring in conduit or open trays with power wiring, or near heavy

electrical equipment. Grounding terminations are provided on the outside of the

electronics housing and inside the terminal compartment. These grounds are

used when transient protect terminal blocks are installed or to fulfill local

regulations.

1. Remove the field terminals housing cover.

2. Connect the wiring pair and ground as indicated in Figure 8.

a. Trim the cable shield as short as practical and insulate from touching the

transmitter housing.

Note

Do NOT ground the cable shield at the transmitter; if the cable shield touches the

transmitter housing, it can create ground loops and interfere with communications.

b. Continuously connect the cable shields to the power supply ground.

c. Connect the cable shields for the entire segment to a single good earth

ground at the power supply.

Note

Improper grounding is the most frequent cause of poor segment communications.

3. Replace the housing cover. It is recommended that the cover be tightened

until there is no gap between the cover and the housing.

4. Plug and seal unused conduit connections.

6.2 Power supply

The transmitter requires between 9 and 32 Vdc (9 and 30 Vdc for intrinsic safety,

and 9 and 17.5 Vdc for FISCO intrinsic safety) to operate and provide complete

functionality.

11

Loading...

Loading...