Page 1

Bulletin 75.2

D103095X012

March 2021

Type Dosaodor-D

Type Dosaodor-D Odorant Injection System

Figure 1. Type ROC809 Remote Telemetry Unit

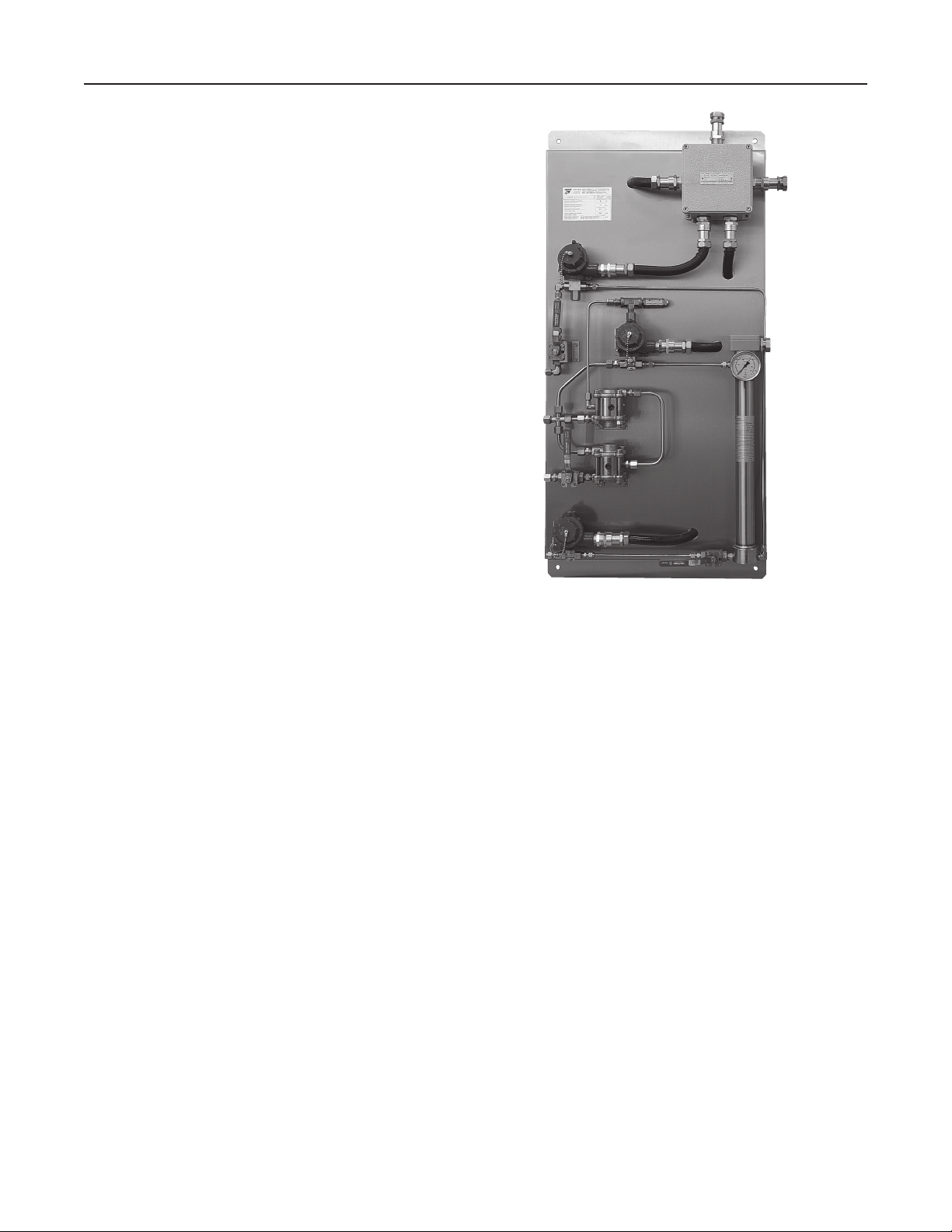

Figure 2. Standard Wick Insert Figure 3. Type Dosaodor-D Pneumatic Panel

Introduction

Type Dosaodor-D is a computerized odorant injection

system for natural gas using patented solenoid

injector technology that eliminates the need for

plunger pumps.

Automatic calibration during operation adjusts for any

changes in mechanical components and also detects

failures for alarming. Report by exception alarming is a

congurable option.

The solenoid injectors provide odorant injection

accuracy to be maintained over the entire ow range

of the system, approaching innite turn down.

The system can also be configured to use

redundant injectors and/or an emergency backup or

bypass absorption system.

Page 2

Type Dosaodor-D

Specications

The Specications section on this page provides the ratings and other specications for Type Dosaodor-D.

Pneumatic Panel:

Material

Stainless steel plate

Installation

Wall mount

Weight

55 to 100 lbs / 25 to 45 kg

(based on configuration)

Overpressure Relief Valve

Stainless Steel with Following Rating Options:

200 psi / 13.8 bar

550 psi / 37.9 bar

870 psi / 60.0 bar

Electrical Protection

Explosion proof

Class I, Division 1 and 2 - Groups B, C, D

Class I, Zone 1 and 2 - Groups IIB+H2, IIA

Mechanical Connections

Odorant Inlet and Discharge

1/4 in. / 6.4 mm OD Tube fitting (double ferrule)

Gas Inlet and Discharge

3/8 in. / 10 mm OD Tube fitting (single ferrule)

Maximum Working Pressure

Supply: 1450 psi / 100 bar

Injection: 870 psi / 60.0 bar

Odorant Flow Rate

0.13 to 3.70 gal/hr / 0.5 to 14.0 l/hr

(0.89 to 24.97 lbs/hr at 6.75 lbs/gal)

Temperature Range

14 to 140°F / -10 to 60°C

Solenoid Valves:

Body Material

304 Stainless steel

Gasket Material

Fluorocarbon (FKM)

Valve Operation

Electromagnetic

Maximum Working Pressure

870 psi / 60.0 bar

Power Requirements

12 Vdc

Electrical Protection

Explosion proof

Class I, Division 1 - Groups A, B, C, D

Stabilizer Filter Type SA/2:

Body Material

Steel

Maximum Working Pressure

1450 psi / 100 bar

Gasket Material

Nitrile (NBR) rubber

Type ROC809 Remote Telemetry Unit:

Refer to Type ROC809 technical specifications.

please go to:

http://www.emersonprocess.com/remote/

Odorant Calibration Cylinder:

Body Material

304 Stainless steel

Maximum Working Pressure

870 psi / 60.0 bar

Maximum Emergency Design Pressure

1450 psi / 100 bar

2

Page 3

Real time and historical data can be read locally or

remotely by a laptop computer using ROCLINK 800

conguration software, or remotely using third party

SCADA products utilizing ROC or modbus protocol.

ROCLINK 800 software is available for complete

conguration and operation of the system including:

• Display of real time and historical data

• Configuration of alarms

• Archival of historical data

Benets

• Uniform distribution of odorant due to frequent

smaller injections and enhanced absorption from

the wick insertion.

• High turndown ratio. For example, one specific

configuration would evenly distribute odorant at

flow rates from 2000 to 1,000,000 SCFH / 53.6 to

26,800 Nm3/h without mechanical adjustment.

• Automatic calibration of injection system during

normal operation ensuring consistent odorization.

• Environmentally friendly with no venting of gas or

odorant while operating.

• Extremely low maintenance cost.

• Variety of redundancy and backup options for

reliable odorization.

• User friendly configuration software.

• Standard and scalable hardware platform that

supports additional station I/O for AGA flow

calculations and PID control algorithms.

Operation

The Type Dosaodor-D odorant injection system operates

on the basic principle of a fixed differential pressure and

orifice used to measure a non-compressible fluid.

Fixed differential pressure is maintained using double

cut regulation by fixed differential pressure regulators

(Type SA/2 regulators) which reference P2 and reduce

the inlet pressure of a regulating station to

P2 + ΔP. ΔP = 8.7 to 21.7 psi / 0.60 to 1.5 bar,

ΔPmax = 21.7 psi / 1.5 bar (an alternate high

pressure source can be used). This pressure loading

of the odorant calibration cylinder filled with odorant

is used to inject liquid odorant into the downstream

pipeline through an on/off valve (the fixed orifice

with a known flow coefficient that is controlled by the

automated system. The objective of the automated

control system is to maintain an injection rate specified

(1)

)

Type Dosaodor-D

Figure 4. Type Dosaodor-D Intrinsically Safe Panel

by the user which is proportional to the gas flow.

Accuracy of injection is accomplished utilizing relatively

small injections which are automatically resized over a

wide range dependent upon variations in the gas flow.

This results in a turn down ratio for the system that can

exceed 500:1 (the addition of a simple by-pass system

utilizing the odorant storage tank can allow the turn down

ratio to approach infinity). An odorant calibration cylinder

with a fixed volume is utilized to recalibrate the injection

valve flow coefficient each time the odorant calibration

cylinder is refilled.

During the refill cycle the pressure used for injection is

relieved into the downstream pipeline which eliminates

venting of gas to atmosphere or an expansion tank.

Liquid odorant refill of the odorant calibration cylinder is

typically accomplished by using all or some part of the

+ ΔP pressure to load the odorant storage tank thus

P

2

pushing the liquid out of the tank and into the odorant

calibration cylinder, ΔP = 8.7 to 21.7 psi / 0.60 to 1.5 bar.

Since the unit uses only pressure for injection there

are few moving parts in the system resulting in very

little maintenance. Relatively low cost options for both

automated and emergency redundancy for odorization

are also available.

1. Although the valve orice is xed for a specic application the valve can be adjusted manually to accommodate ow rates as small as 2 MSCFH to over 33,000 MSCFH with one injector.

3

Page 4

Type Dosaodor-D

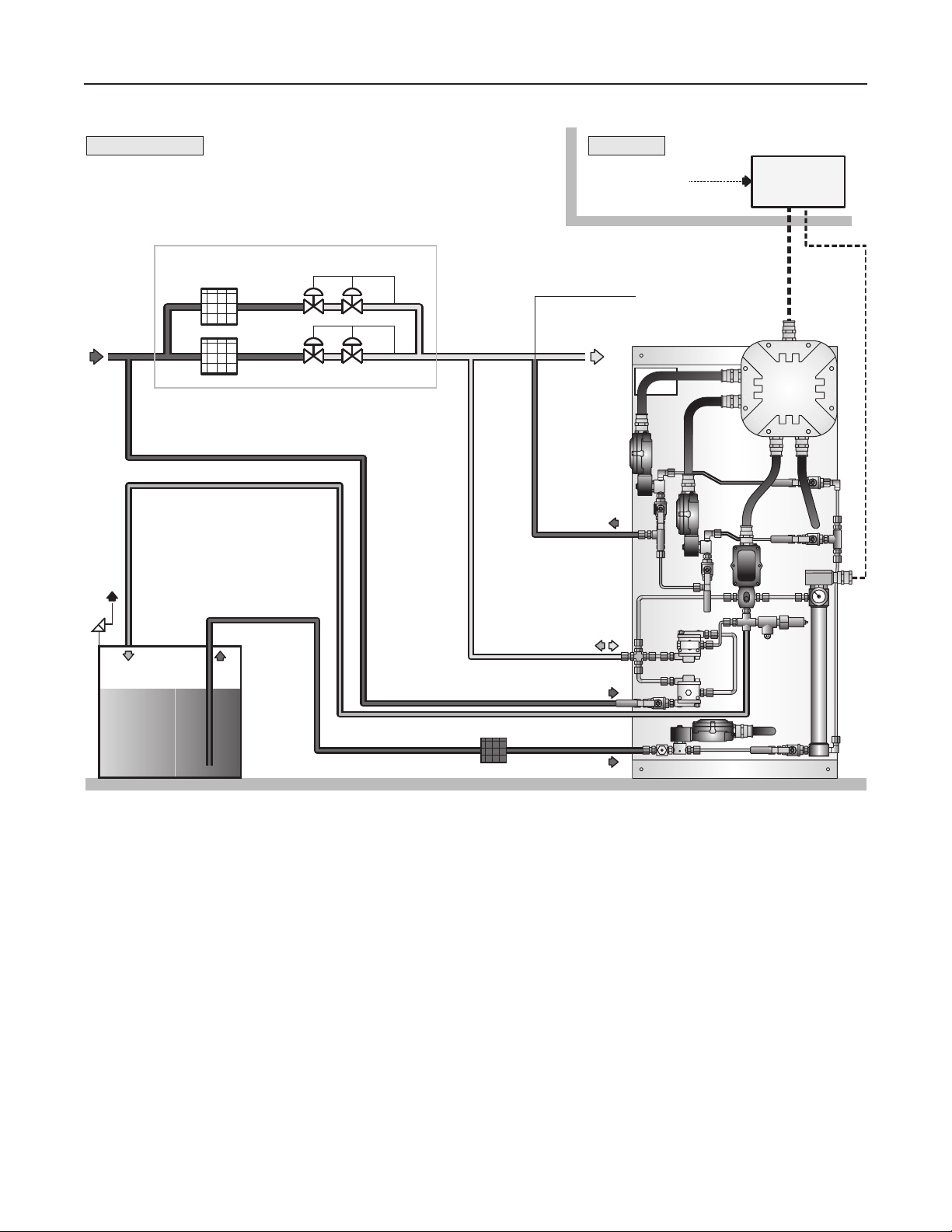

HAZARDOUS AREA

REGULATING STATION

P1 P2

SAFE AREA

SIGNALS FROM

FLOW COMPUTER

LIQUID

INJECTION POINT

TYPE ROC809

PNEUMATIC PANEL

ODORANT

TANK

Figure 5. General Installation Schematic

The gas flow rate is obtained through either a corrected

gas volume pulse input or an instantaneous flow rate

analog input (4 to 20mA) signal. The gas flow rate can

also be configured manually to a fixed value. Odorant

injection rate is then calculated using accumulated flow

in order to reduce variability.

In cases where the station does not have a flow

computer, the Type ROC809 can be connected directly

to a pulse output from the turbine or an analog output

from a differential pressure transmitter (Rosemount

Types 3051, 3095, etc.).

4

Page 5

Type Dosaodor-D

HAZARDOUS AREA SAFE AREA

SIGNALS FROM

FLOW COMPUTER

REGULATING STATION

TYPE ROC809

P1 P2H P2L P2

SOLENOID VALVE SOLENOID VALVE

2

3

1

ODORANT

TANK

SUPPLIED BY SYSTEM INTEGRATOR *ASCO SOLENOID PN #JBEF8320G140V

AUTOMATED PRESSURE BALANCING SYSTEM WITH BYPASS SCHEMATIC

REGULATING STATION INLET PRESSURE

ODORANT CALIBRATION CYLINDER LOADING PRESSURE

REGULATING STATION OUTLET PRESSURE

ODORANT INJECTION PRESSURE

3

ODORANT FILTER

PNEUMATIC PANEL 1

1

2

1

2

3

Figure 6. Type Dosaodor Automated Pressure Balancing System with Bypass Schematic

Variability between the calculated and actual injection

volume is used to automatically adjust injection

parameters for any changes in the system and to

detect alarm conditions or system failure, the odorant

calibration cylinder is used to monitor the actual use

Type Dosaodor-D is designed to purge the odorant

back into the tank in the event that mechanical

maintenance is required. Odorant is pushed back

into the tank and gas is purged through the system to

absorb any remaining liquid.

of odorant. In the event of power failure, configuration

information and archived historical data are maintained.

5

Page 6

Type Dosaodor-D

Modes of Operation

The system is designed to operate in one of six modes which determine the system function and how

outputs will be controlled.

Mode of

Operation

Auto

Set system on-line

Accumulate ow

Proportional Injection

Manual and

Minimum Rate

Set system on-line

Injection proportional

to xed rate ow

Set system on-line

Start odorant calibration

cylinder ll timer

Auto Mode

System is set on-line. Injection rate is calculated

based on current flow rate input (pulse or analog

input) and configured concentration.

Manual Mode

System is set on-line. Injection rate is calculated based

on configured manual gas flow rate and concentration.

Minimum Rate Mode

System is set on-line. Injection rate is calculated based

on configured minimum flow rate and concentration.

Refill Mode

Injector is off-line. Odorant calibration cylinder is refilled

with odorant and calculation is performed to verify

injector volume rate. Once refill is complete, system

returns to prior mode (during normal operation).

Purge/Wash Mode

System is set off-line. Odorant is emptied from

odorant calibration cylinder and back to the supply

tank. During Gas Wash Cycle, solenoids are opened

to allow gas flow through the odorant calibration

cylinder and injectors. Gas Wash Cycle and Injector

Flush Cycle are available.

Rell

Purge/Wash

Set system o-line

Purge panel

of liquids

Disabled

Set system o-line

Emergency bypass

enabled (if installed)

Disabled Mode

Injector and panel functions are off-line. Emergency

bypass system enabled if available.

ROCLINK 800 Configuration Software

ROCLINK 800 Configuration Software, a Windows®

based program, enables complete configuration either

local or remote of the Type Dosaodor-D odorant

system. This allows the viewing of data in real time,

management of the historical data and control of

the alarm conditions. Connection is via serial port,

ethernet port or remote communications.

ROCLINK 800 software has an user friendly Windows

interface. The Configuration Tree navigation interface

makes accessing features quick and easy. Drop-down

menus simplify accessing the software functions.

Dialog boxes and drop-down list boxes help direct

selections and data entry. Actions can be performed

with the keyboard or a mouse.

The main specifications of the ROCLINK 800 software

are as follows:

• MS Windows interface

• Single configuration point for all connectable

odorizing units

• Complete configuration for each parameter of the

odorizer system

• Display of real time data, historical data and alarms

6

Page 7

Type Dosaodor-D

Figure 7. Type Dosaodor-D Configuration Display

Minimum Software and Hardware

Requirements

• Pentium®-class processor (233 MHz or

greater recommended)

• CD-ROM drive

• Windows 98, ME, NT 4.0 (Service Pack 6), 2000

(Service Pack 2) or XP

• 64 MB of RAM (Random Access Memory)

• 15 to 75 MB of available hard disk space,

depending on operating system and revision level

Configuration Selection

The purpose of this section is to facilitate Ordering

Guide selections.

The minimum requirements for product installation are

as follows:

1. There must be a differential pressure of at

least 14.5 psi / 1 bar between upstream and

downstream of the regulation station.

2. The tank containing the odorant fluid must be

pressurized. The odorant storage tank is usually

pressurized by the system up to 8.7 to 21.7 psi /

0.60 to 1.5 bar higher than outlet pressure.

3. Downstream pressure must be maintained as

constant as possible in order to maintain accuracy

of odorant injection.

If these conditions are not fulfilled, please contact your

Emerson representative for alternate configurations.

A) Base Panel

A6 Option

• Construction based on North American standards

with CSA certified components.

7

Page 8

Type Dosaodor-D

• Configuration does not include the Type ROC809

controller necessary for the functioning of the

system. The Type ROC809 is available from the

Remote Automation Solutions.

B) Model (Select One)

B1 Option – Single Injector

• This option provides only one injection solenoid.

B2 Option – Dual Injector

• This option provides two injection solenoids

installed in parallel for redundancy in the event

of an injector failure.

• An alternate use of dual injectors is for increased

turndown. In the event the flow conditions

vary, it is possible to create a low flow injector

and a high flow injector for scenarios such as

seasonal loads.

Notes

The two solenoid valves do not operate

simultaneously. It is therefore not

possible to use the B2 conguration in

order to serve two gas transport lines at

the same time.

The two solenoid valves can work in

exchange mode. When the desired

quantity of odorant (determined by a

parameter accessible by the user) is

injected, the solenoid valve that has just

operated will go into rest mode leaving

the task of injection to the alternate

solenoid valve.

C) Maximum Odorant Injection Rate (Select One)

The injector solenoid is selected based on the

maximum gas ow rate and the desired odorant

concentration. The following information and

calculation will determine this value.

From a theoretical viewpoint, this takes into

account the following:

International Standard Unit

C = concentration of odorant (mg/Sm³)

Qg = maximum gas ow rate (Sm³/h)

ρ = density of liquid odorant (kg/dm³)

Qo = maximum odorant ow rate (l/h)

Qo = C * Qg / (1,000,000 * ρ)

For the purposes of proportioning, we may consider

the odorant density as ρ = 1 kg/dm3.

For example, if the maximum line ow is

90,000 Sm³/h and the odorant used is THT (with

a desired concentration of 40 mg/Sm³) then the

appropriate option from the table below is C4.

By formula:

3

Qo =

40 mg

3

Sm

1 kg

1,000,000 mg

90,000 Sm

h

dm

1 kg

3

1 l

1 dm

Qo = 3.6 l/hr

Using the equation result, the fourth column of Table 1

shows the first value exceeding the calculated value

which will suggest which configuration to choose (in

the specific case of C4).

3

Table 1. Maximum Odorant Injection Rate using International Standard Unit

ORDER FORM CONFIGURATION

C1 12,500 50,000 0.13 / 0.5

C2 25,500 100,000 0.26 / 1.0

C3 50,000 200,000 0.53 / 2.0

C4 100,000 400,000 1.06 / 4.0

C5 150,000 600,000 1.59 / 6.0

C6 200,000 800,000 2.11 / 8.0

C7 250,000 1,000,000 2.64 / 10.0

C8 300,000 1,200,000 3.17 / 12.0

C9 350,000 1,400,000 3.70 / 14.0

8

40 mg/Sm

MAXIMUM GAS VOLUME, Sm

3

(THT) 10 mg/Sm3 (Mercaptan)

3

/h

MAXIMUM INJECTION RATE,

GAL/HR / L/HR

Page 9

Type Dosaodor-D

If different odorant concentrations from those specified

in the table (40 and 10 mg/Sm³) are used, it is

advisable to use the given formula and fourth column

of Table 2 (Maximum Injection Rate) to determine the

correct configuration.

For example, if the maximum line flow is

15,000 Sm³/h and the odorant used is THT (with

a desired concentration of 38 mg/Sm³) then the

appropriate option is C2.

3

Qo =

38 mg

3

Sm

1 kg

1,000,000 mg

15,000 Sm

h

dm

1 kg

3

1 l

1 dm

3

Qo = 0.57 l/hr

North America Standard Unit

C = concentration of odorant (lbs/MMSCF)

ρ = density of liquid odorant (lbs/gal)

Qg = maximum gas flow rate (MMSCF/h)

Qo = maximum odorant flow rate (gal/h)

Qo = C * Qg / ρ

For example, if the maximum line flow is 7 MMSCF/h and

the odorant used is THT (with a desired concentration

of 1.0 lbs/MMSCF) then the appropriate option from

Table 2 is C4.

By formula:

Qo = = 1.04 gal/hr

1 lb

MMSCF

7 MMSCF

h

gal

6.75 lbs

Using the equation result, the fth column of Table 2

shows the rst value exceeding the calculated value

which will suggest which conguration to choose (in

the specic case of C4).

If dierent odorant concentrations from those specied

in the table (1.0 and 0.5 lbs/MMSCF) are used it is

advisable to use the given formula and the table to

determine the correct conguration.

If a dierent density is required, use the fourth column

for selection.

For example, if the maximum line ow is 20 MMSCF/h

and the odorant used is mercaptan (with a desired

concentration of 0.6 lbs/MMSCF) then the appropriate

option from Table 2 is C6.

Qo = = 1.78 gal/hr

0.6 lb

MMSCF

20 MMSCF

h

gal

6.75 lbs

At 6.75 lbs/gal is equivalent to:

1.78 gal

h

6.75 lbs

gal

= 12 lbs/hr

I) Maximum Working Pressure (Select One)

Select based on maximum working pressure

(downstream pressure, in the injection area). The

density constraint is required to let the "oating

system" present in the odorant calibration cylinder

work properly.

I1 Option

At 6.75 lbs/gal is equivalent to:

1.04 gal

h

Table 2. Maximum Odorant Injection Rate using North American Standard Unit

ORDER FORM

CONFIGURATION

C1 0.89 1.78 0.13 / 0.5 0.89

C2 1.78 3.57 0.26 / 1.0 1.78

C3 3.57 7.13 0.53 / 2.0 3.57

C4 7.13 14.27 1.06 / 4.0 7.13

C5 10.70 21.40 1.58 / 6.0 10.70

C6 14.27 28.53 2.11 / 8.0 14.27

C7 17.83 35.67 2.64 / 10.0 17.83

C8 21.40 42.80 3.17 / 12.0 21.40

C9 24.97 49.93 3.70 / 14.0 24.97

6.75 lbs

gal

MAXIMUM GAS VOLUME, MMSCF/H

1.0 lbs/MMSCF (THT)

= 7 lbs/hr

0.5 lbs/MMSCF

(Mercaptan)

Maximum injection pressure equal to 200 psi /

13.8 bar. A requirement for functioning is that

the density of the liquid odorant is >=5.8 lbs/gal /

0.70 kg/dm

3

.

MAXIMUM

INJECTION RATE,

GAL/HR / L/HR

MAXIMUM

INJECTION RATE, LBS/HR

(AT 6.75 LBS/GAL)

9

Page 10

Type Dosaodor-D

B1 VERSION (SINGLE INJECTOR)

22 / 560

20.1 / 510

44.5 /

1130

46.5 /

1180

B2 VERSION (DUAL INJECTOR)

22 / 560

20.1 / 510

44.5 /

1130

BRACKET

13.8 / 350

OPTIONAL STAINLESS STEEL CABINET

DIMENSIONS IN IN. / mm: 37 x 18.2 x 78.4 / 940 x 460 x 1990

5.9 /

150

7.9 /

200

IN. /

mm

46.5 /

1180

Figure 8. Pneumatic Panel Overall Dimensions

10

Page 11

Type Dosaodor-D

I2 Option

Maximum injection pressure equal to 550 psi /

37.9 bar. A requirement for functioning is that the

density of the liquid odorant is >=

0.55 kg/dm3.

I3 Option

Maximum injection pressure equal to 870 psi /

60.0 bar. A requirement for functioning is that

the density of the liquid odorant is >= 5.8 lbs/gal

0.70 kg/dm3.

M) Installation Options - Wick insert (Select One)

Select based on pipe size.

Option – Standard wick insert (for downstream

size < 10 in. (NPS 10 / DN 250)

Option – Long wick insert (for downstream

size >= 10 in. (NPS 10 / DN 250)

4.6 lbs/gal /

Ordering Guide

O) Installation Options - Fittings (bulk brand

as standard)

If the O item is not selected the standard fittings

will be used (bulk brand).

Option – Swagelok ttings

Stainless steel Swagelok fittings.

Automation software and license key

/

Software for management of the Type Dosaodor-D

system compatible with Type ROC809 platform hardware

and Type Dosaodor-D license key.

The software may be ordered individually or in

combination with the pneumatic panel.

The pneumatic panel must be ordered with the

automation software and license key.

Optional Component - Cabinet for pneumatic panel

A stainless steel cabinet may be selected as an option.

Base Panel

A6 Type Dosaodor-D odorant injection system

completed with:

Pneumatic Panel

• Stainless steel panel

• Installation kit (bracket, pipe connection,

valves, etc.)

• Explosion proof Class I, Division 1 and

2 - Groups B, C, D - Class I, Zone 1 and 2 Groups IIB+H2, IIA

• Included 1/4 in. fitting connectors for 3/8 and

1/4 in. / 9.5 and 6.4 mm OD tubing

Model (Select One)

B1 Single Injector

B2 Dual Injector

Maximum Odorant Injection Rate (Select One)

C1 0.13 gal/hr / 0.5 l/hr

C2 0.26 gal/hr / 1.0 l/hr

C3 0.53 gal/hr / 2.0 l/hr

C4 1.06 gal/hr / 4.0 l/hr

C5 1.58 gal/hr / 6.0 l/hr

C6 2.11 gal/hr / 8.0 l/hr

C7 2.64 gal/hr / 10.0 l/hr

C8 3.17 gal/hr / 12.0 l/hr

C9 3.70 gal/hr / 14.0 l/hr

Maximum Working Pressure (Select One)

I1 200 psi / 13.6 bar

(odorant ρ >= 5.8 lbs/gal / 0.70 kg/dm

I2 550 psi / 37.9 bar

(odorant ρ >= 4.6 lbs/gal / 0.55 kg/dm3)

I3 870 psi / 60.0 bar

(odorant ρ >=5.8 lbs/gal / 0.70 kg/dm3)

Installation Options - Wick Insert (Select One)

Standard Wick Insert

(for downstream size < 10 in. (NPS 10 / DN 250)

Long Wick Insert

(for downstream size >= 10 in. (NPS 10 / DN 250)

Installation Options - Fittings (Bulk Brand as Standard)

Swagelok Fittings

Automation Software and License Key

Software for pneumatic panel control, available with

Type ROC809 plus Type Dosaodor-D license key

Optional Component

Cabinet for Pneumatic Panel

Stainless steel cabinet for pneumatic panel

- continued -

3

)

11

Page 12

Type Dosaodor-D

Ordering Guide (continued)

Type ROC809 Configurations and Options

Required Components

Quantity Description

1

1

2

1

1

Type ROC809E Controller

Type ROC800 12 Vdc Power Supply

Type ROC800 Discrete Relay Output Card

Type ROC800 Discrete Input Card

Type DS800 Runtime License

Select Input Card Type for Flow Rate Input

(Choose Only One for Configuration)

Quantity Description

1

1

Type ROC800 Analog Input Card

Type ROC800 Pulse Input Card

Optional Equipment

Quantity Description

1

Type ROCLINK800 Software

(at least 1 license required)

1

1

1

1

1

1

1

Type ROC800 LOI Cable

Type ROC800 Ethernet Crossover Cable

Type ROC800 RS232 Comm Module

Type ROC800 RS485 Comm Module

Type ROC800 14.4 Dial-up Modem Comm

Type ROC800 Analog Output Card

Power Supply Charger 12 Vdc

Webadmin.Regulators@emerson.com

Tartarini-NaturalGas.com

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Emerson Process Management s.r.l

Emerson Automation Solutions - Stabilimento di/Site of: Castel Maggiore - Bologna

Sede Legale/Legal Entity: Piazza Meda 5, 20121 Milano, Italy

Sede Amministrativa/Administrative Headquarters: OMT Tartarini, Via Clodoveo Bonazzi 43,

40013 Castel Maggiore (Bologna), Italy

C.F. - P.I. e R.I. di MI 13186130152 - REA di MI/n.1622916

Direz. e Coord. (art. 2497 bis CC): EMERSON ELECTRIC CO. St. Louis (USA) Socio Unico

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D103095X012 © 2007, 2021 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 03/21.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Tartarini™ is a mark owned by one of the companies in the Emerson

Automation Solutions business unit of Emerson Electric Co.

The contents of this publication are presented for informational purposes

only, and while every eort has been made to ensure their accuracy, they

are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which

are available upon request. We reserve the right to modify or improve the

designs or specications of such products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does

not assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

Loading...

Loading...