Page 1

ROC800:ROC800L Product Data Sheet

D301678X012 April 2020

Remote Automation Solutions

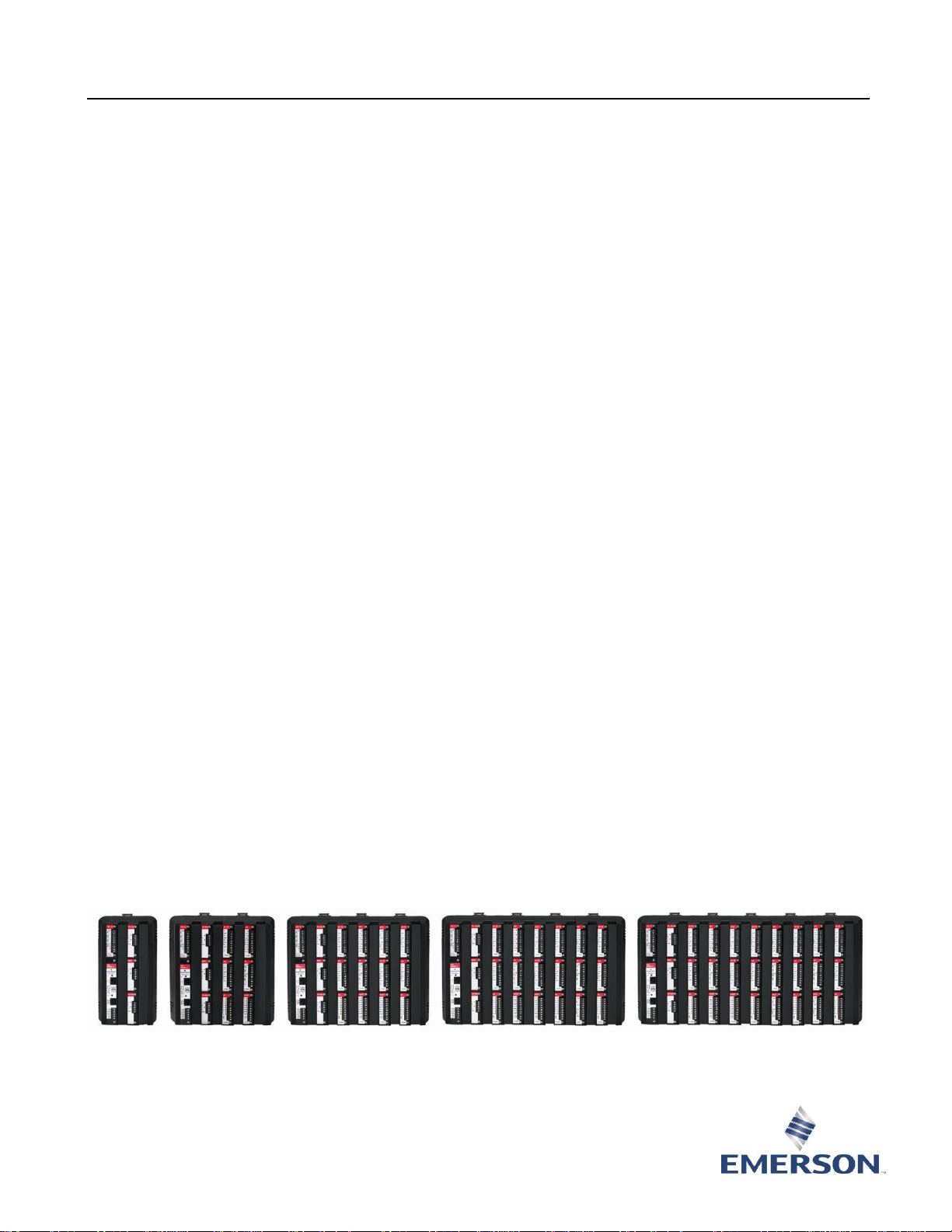

ROC800L Remote Operations Controller

The ROC800L Remote Operations Controller (ROC800L) is a

microprocessor-based controller that provides the functions

required for a variety of field automation applications,

including liquid measurement. The ROC800L monitors,

measures, and controls equipment in a plant or remote

environment. The ROC800L is ideal for any application

requiring flow computation; Proportional, Integral, and

Derivative (PID) control loops; logic sequencing control; and

up to six liquid meter runs. Two versions of the ROC800L are

available: the ROC809L (with nine module slots) and the

ROC827L (which is expandable from three to 27 module

slots).

Factory installed liquid measurement user programs provide

the American Petroleum Institute (API) calculations in

accordance with Manual for Petroleum Measurement

Systems (MPMS). The liquid measurement user programs

perform the following functions:

▪ Liquid Calculations – Accurately measures liquids

flowing through a meter, and performs volume

corrections based on density, temperature, and

pressure measurements.

▪ Batching – Allows you to configure and schedule

multiple batches to record and control the flow of a

liquid. Batch accuracy is improved through the

retroactive calculation and re-calculation using userdefined variables.

▪ Proving – Performs meter proving by operating a 4-way

control valve, calculating a new meter factor, and

storing meter factor information on up to 24 products

for each of up to six meters. Unidirectional,

bidirectional, large volume, small volume, and master

meter proving are supported. A prover densitometer is

also supported for inferred mass proving.

▪ Reporting – Generates printable reports in compliance

with API MPMS Chapter 12.2.2, 12.2.3, and 21.2. Userdesigned reports can be created using ROCLINK™ 800

Configuration Software.

For additional information on each of the included

programs, refer to Product Data Sheet ROC800:SW1.

The ROC800L has the following features:

▪ Rugged, reduced-maintenance hardware.

▪ High isolation, surge and short circuit protection.

▪ Low power consumption.

▪ Wide operation temperature (–40 to 75C).

▪ Up to 27 easily installed modular I/O cards.

▪ Versatile serial and Ethernet communications.

▪ Class I, Div. 2 & Zone 2 hazardous location approval.

▪ Metering station support for up to 6 liquid runs and

ability to support up to 6 gas runs with an optional AGA

license key installed.

▪ Easy-to-use ROCLINK 800 configuration software.

▪ Custom programming with Function Sequence Tables

(FSTs) or DS800 Development Suite, which allows you

to build IEC 61131-3 compliant programs for use with

the ROC800L.

The Base Unit

The Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS)

plastic housing has removable wire channel covers to

protect the wiring terminals. DIN rail mounting allows the

ROC800L to mount on an enclosure backplane. The rugged

housing is suitable for use over the complete extended

temperature range.

The ROC800L controller eliminates the need for fuses on the

I/O and communications modules through the extensive

use of the latest technology in short-circuit protection. This

results in less maintenance.

The ROC800L economizes its power consumption for

normal operation through the use of internal 3.3 volt

electronics.

The ROC800L uses a power input module to convert

external input power to the voltage levels required by the

ROC800L’s electronics. Two power input modules are

available for the ROC800L: one for 12 volt dc input power

and one for 24 volt dc input power.

ROC827L (with 0, 1, 2, 3, and 4 expansion I/O backplanes)

Page 2

April 2020 ROC800:ROC800L

2 www.Emerson.com/RemoteAutomation

ROC809L

The ROC809L houses a backplane that supports a ROC800Series 2 central processing unit (CPU), a power input

module, Input/Output (I/O) modules, and communication

modules. The ROC809L has nine slots for modules: the first

three slots are for either communication or I/O modules, and

the remaining six slots are for I/O modules only.

ROC827L

The ROC827L houses a backplane that supports a ROC800Series 2 central processing unit (CPU), a power input

module, and up to three modules (communications or I/O).

You can expand the ROC827L by adding up to four

expansion I/O backplanes. Each expansion I/O backplane has

six slots to house I/O modules. The three module slots of the

base ROC827L—when combined with a maximum of four

expansion I/O backplanes (which contain six slots each)—

allow expansion of up to 27 slots.

Memory

The ROC800L has four types of memory:

▪ Boot Flash – System initialization and diagnostics.

▪ Flash – Firmware image and report files.

▪ SRAM (Static Random Access Memory) –

Data Logs and configuration.

▪ SDRAM (Synchronous Dynamic Random Access

Memory) – Firmware execution and execution memory.

The 32-bit microprocessor and the Real-Time Operating

System (RTOS) provide both hardware and software

memory protection.

Firmware

The firmware resides in flash memory and contains the

operating system and application software. The CPU module

provides battery-backed SRAM (Static Random Access

Memory) for saving the configuration, events, alarms, and

historical logs.

The firmware has a database for events, alarms, and history

that stores the last 450 events, the last 450 alarms, and 35

days of hourly records. The weights and measures database

stores up to 1000 weights and measures events. The history

database holds up to 240 points in 13 segments, providing

over 224,000 unique entries. You can configure each

segment to archive at different time intervals and with

different contract hours.

Meter Runs and Stations

The ROC800L supports up to six liquid meter runs and up to

six stations. You can group meter runs and stations in any

combination. Typically, you associate meter runs with a

station if the meter runs have common parameters, such as

fluid type and base temperature.

Grouping similarly configured meter runs with stations

provides significant benefits in batching, configuration, and

reporting. For example, you can configure parameters at the

station level. The system then applies those configuration

parameters to all meters belonging to the station, reducing

configuration time.

You can configure the ROC800L either to provide individual

reports for each meter or to generate station reports that

consolidate multiple meters. Station reports eliminate

redundant meter run data, reduce the need to download

and upload, and result in a more efficient reporting process.

Communications

The ROC800L provides up to six communication ports. Three

communication ports are built-in:

▪ Local Operator Interface – LOI.

▪ Ethernet – Comm1.

▪ EIA-232 (RS-232) – Comm2.

The Local Operator Interface (LOI) port’s EIA-232 (RS-232D)

standard RJ-45 connector provides a direct link between the

ROC800L and a personal computer.

You can install up to three communication modules to

provide additional ports for communicating with a host

computer or other devices. The ROC800L accommodates

three modules in any combination of the following types:

▪ EIA-232 (RS-232) for point-to-point asynchronous serial

communications.

▪ EIA-422/EIA-485 (RS-422/RS-485) for

asynchronous serial communications,

EIA-422 for point-to-point, EIA-485 for

multiple-point, 2- and 4-wire.

▪ Dial-up modem for communications over a telephone

network.

The ROC800L allows the use of a variety of communication

protocols, including ROC Plus or Modbus Slave (ASCII or

RTU) on all ports. In addition to these, the ROC800L allows

the use of Modbus host on all ports except the LOI and

Ethernet ports.

The Ethernet port allows the following communication

protocols:

▪ ROC Plus protocol.

▪ Modbus encapsulated in TCP/IP protocol (slave only).

▪ Modbus TCP/IP protocol (slave only).

▪ DS800 Development Suite 800 software

communications.

Page 3

ROC800:ROC800L April 2020

www.Emerson.com/RemoteAutomation 3

Input/Output Options

The isolated I/O modules can be added to satisfy a wide

variety of field I/O requirements. You can add up to nine I/O

modules to the ROC809L and up to 27 modules to the

ROC827L with the optional expansion I/O backplanes. I/O

modules include:

▪ Analog Inputs (AI)

▪ Analog Outputs (AO)

▪ Alternating Current Inputs/Outputs (AC I/O)

▪ Advanced Pulse Module (APM)

▪ Discrete Inputs (DI)

▪ Discrete Outputs (DO)

▪ Discrete Output Relay (DOR)

▪ HART Inputs/Outputs (HART)

▪ Multi-Variable Sensor I/O (MVS I/O)

▪ Pulse Inputs (PI) – High or Low Speed

▪ RTD Inputs (RTD)

▪ Thermocouple I/O

Module Installation

Installation and replacement of any I/O or communication

module is easily accomplished by removing the two captive

screws accessible from the front of the unit. Some modules

are hot-swappable, meaning you can remove the module

and install another module of the same kind while under

power. The new module acquires the previous module’s

configuration. Some modules are hot-pluggable, meaning

they may be installed directly into unused module slots

under power. To determine if a module is hot-swappable or

hot-pluggable, refer to the specific module’s product data

sheet.

Software

ROCLINK 800 configuration software is an easy-to-use

Windows® based application program used to configure,

calibrate, monitor and retrieve historical data from the

ROC800L. The ROC800L is supported by ROCLINK 800

version 1.88 or later.

The software uses the Windows style navigation tree with

drop-down menus and context-based dialog boxes. It is well

organized and functional for the standard station and meter

run firmware application.

ROCLINK 800 also provides program customization through

Function Sequence Tables (FSTs). FSTs may be built from a

library of functions and commands to provide special control

capability, mathematical and logical operations, and

database access operations.

The software provides security for controlling access to

functions in ROCLINK 800 software. Passwords restrict logon to both ROCLINK 800 and the ROC800L controller.

Options

▪ I/O and Communications – The ROC800L supports a

wide variety of I/O and communications modules to suit

many applications.

▪ ROC Keypad Display – The ROC Keypad Display allows

local users to view and change parameters in the

ROC800L.

▪ Power Input Modules – The ROC800L unit supports 12

volt dc or 24 volt dc power input modules, which

provide 12 volt dc power to the backplane.

▪ License Keys – Optional license keys are available that

grant access to corresponding applications, such as

DS800 Development Suite Software and gas meter run

calculations.

▪ Orifice and Linear Meter Calculations – Up to six gas

meter runs using American Gas Association (AGA) or

ISO calculations for any combination of orifice, turbine,

ultrasonic, and/or Coriolis meter types are enabled with

an optional license key. This allows the ROC800L to

measure up to six gas meter runs simultaneously with

the liquid meter runs.

▪ Development Suite 800 (IEC 61131-3) – DS800

Development Suite Software is an integrated

development environment allowing you to build IEC

61131-3 compliant programs. The DS800 software can

be used to develop programs independent of ROCLINK

800 Configuration Software and is enabled with an

optional license key. For more information, refer to

Product Data Sheet DS800.

Compatibility

The ROC800L uses a ROC800-Series 2 CPU and Series 2compatible modules. For module compatibility questions,

refer to the individual module’s product data sheet.

Page 4

April 2020 ROC800:ROC800L

4 www.Emerson.com/RemoteAutomation

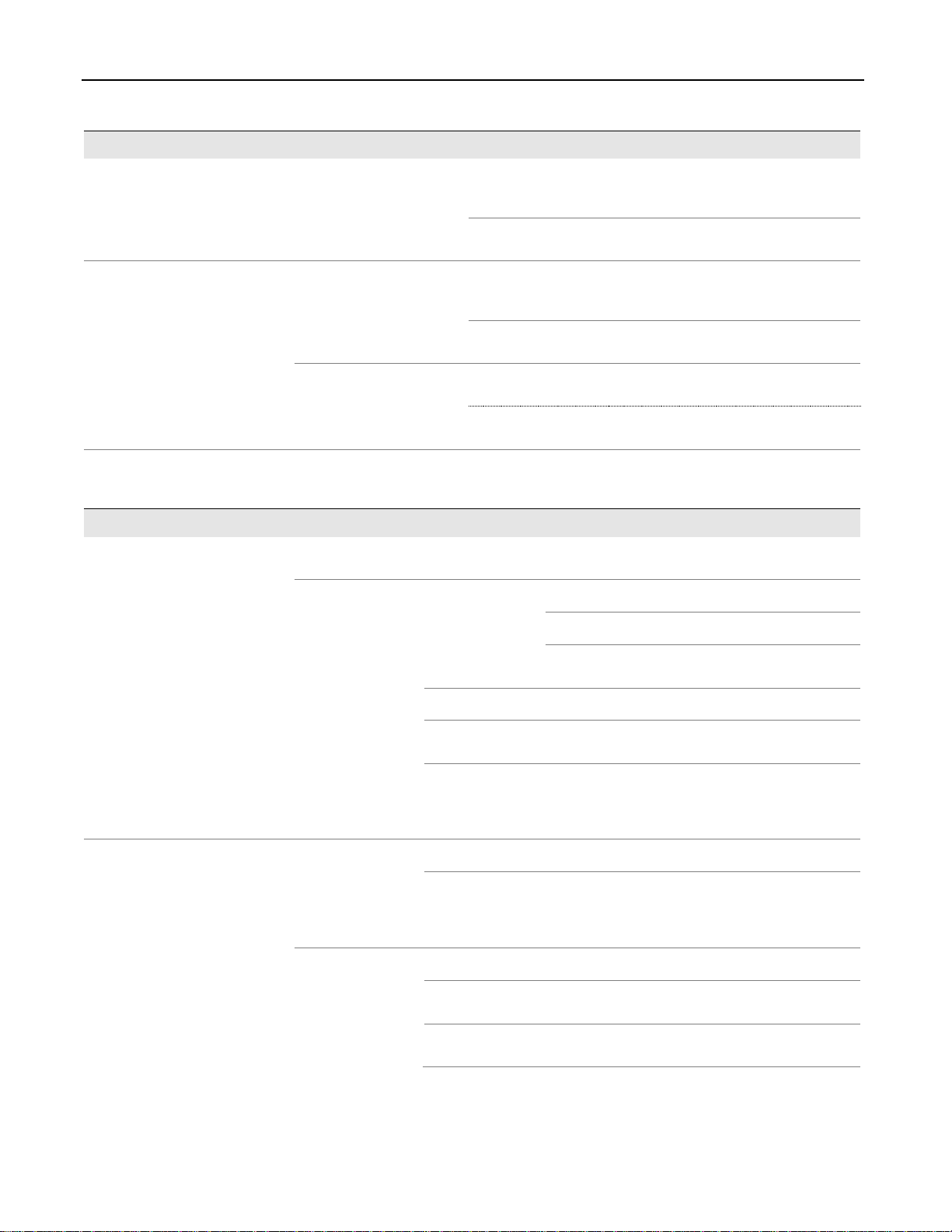

ROC800L Remote Operations Controller

CPU Module

Processor

32-bit microprocessor based on the Motorola MPC862 Quad Integrated Communications

Controller (PowerQUICC™) PowerPC processor running at 65 MHz

Memory

Boot Flash

256 KB for system initialization and diagnostics

Flash

16 MB for firmware image and report files

SRAM

2 MB for historical data logs and configuration

Synchronous

DRAM

32 MB for firmware execution and execution memory

Battery Backup

Type

Sanyo 3 V CR2430 lithium, user-replaceable

Normal use life

10 years while power is applied to unit

Backup life

1 year minimum while maintaining RTC and SRAM data and no power

is applied to unit

Shelf life

10 years

Clock

Type

32 KHz crystal oscillator with regulated supply, battery-backed

Year/Month/Day and Hour/Minute/Second

Clock Accuracy

0.01%

Watchdog Timer

Hardware monitor expires after 3 seconds and resets the processor

Diagnostics

Board

Temperature

Accuracy

1% typical, 2% maximum

Voltage Monitor

Accuracy

0.75% typical, 1% maximum

Light-Emitting Diodes (LEDs)

Status

Indicates normal function, low battery voltage, system AI alarm, and

firmware status.

COL (Ethernet)

Indicates that packet collisions occurred when transmitting or

receiving data through the Ethernet port

ACT (Ethernet)

Indicates that the ROC800L is transmitting or receiving data through

the Ethernet port

DTR (RS-232)

Data Terminal Ready

RTS (RS-232)

Request to Send

Tx (RS-232)

Indicates that the ROC800L is transmitting data through an EIA-232

(RS-232) communication port

Rx (RS-232)

Indicates that the ROC800L is receiving data through an EIA-232 (RS-

232) communication port

Communications

Ports on CPU module

LOI (Local

Operator

Interface)

EIA-232D (RS-232D) Standard. 115.2 Kbps maximum data rate

Page 5

ROC800:ROC800L April 2020

www.Emerson.com/RemoteAutomation 5

Ethernet

10BASE-T twisted pair. IEEE multi-segment 10 MB/second baseband

Ethernet

Maximum

Segment

100 m (330 ft)

EIA-232 (RS-232)

PORT

Single. 115.2 Kbps maximum data rate

Communication Modules

(optional)

EIA-232 (RS232)

Single. 115.2 Kbps maximum data rate. For more information, refer to

Product Data Sheet ROC800:COM.

EIA-422/485

(RS-422/485)

Single. 115.2 Kbps maximum data rate. For more information, refer to

Product Data Sheet ROC800:COM.

Dial-up Modem

Module

Single. 14.4 Kbps maximum data rate. For more information, refer to

Product Data Sheet ROC800:COM.

Network Radio

Module

Provides a wireless solution for importing and/or exporting over-theair messages and information. For more information, refer to Product

Data Sheet ROC800:NRM.

Protocols

LOI Port

ROC Plus, Modbus slave (ASCII or RTU), DS800 Development Suite 800

software communications

EIA-232 and EIA422/485

ROC Plus, Modbus host and slave (ASCII or RTU), DS800 Development

Suite 800 software communications

Ethernet Port

ROC Plus, Modbus host and slave (ASCII or RTU) encapsulated in TCP/IP

or via TCP/IP, DS800 Development Suite 800 software

communications

Dial-up Modem

ROC Plus, Modbus slave (ASCII or RTU)

Inputs/Outputs Modules (optional)

Alternating Current

Input/Output

6 channels: selectable as input or output. For more information, refer to Product Data Sheet

ROC800:ACIO.

Analog Input-12

4 channels; 12 bits of resolution. For more information, refer to Product Data Sheet

ROC800:AI.

Analog Input-16

4 channels; 16 bits of resolution. For more information, refer to Product Data Sheet

ROC800:AI.

Analog Output

4 channels. For more information, refer to Product Data Sheet ROC800:AO.

Advanced Pulse Input

4 channels pulse, 2 prover. For more information, refer to Product Data Sheet ROC800:APM.

Discrete Input

8 channels. For more information, refer to Product Data Sheet ROC800:DI.

Discrete Output

5 channels. For more information, refer to Product Data Sheet ROC800:DO.

Discrete Output Relay

5 channels. For more information, refer to Product Data Sheet ROC800:DOR.

HART Input/Output

4 channels, each capable of communications with up to 5 HART devices (when in input

multi-drop mode. For more information, refer to Product Data Sheet ROC800:HART.

MVS Input/Output

Supports up to 6 sensors. For more information, refer to Product Data Sheet ROC800:MVS.

Pulse Input

2 channels; user-selectable high speed or low speed per channel. For more information,

refer to Product Data Sheet ROC800:PI.

RTD Input

2 channels. For more information, refer to Product Data Sheet ROC800:RTD.

Thermocouple Input/Output

4 channels. For more information, refer to Product Data Sheet ROC800:TC2.

Page 6

April 2020 ROC800:ROC800L

6 www.Emerson.com/RemoteAutomation

Power

ROC809L Input Power

Series 2 Base Unit (power

module, backplane, and

CPU)

12 Vdc Power Input

Module (PM-12)

88 mA. For more information, refer to

Product Data Sheet ROC800:PIM.

24 Vdc Power Input

Module (PM-24)

102 mA. For more information, refer to

Product Data Sheet ROC800:PIM.

ROC827L Input Power

Series 2 Base Unit (power

module, backplane, and

CPU)

12 Vdc Power Input

Module (PM-12)

104 mA. For more information, refer to

Product Data Sheet ROC800:PIM.

24 Vdc Power Input

Module (PM-24)

110 mA. For more information, refer to

Product Data Sheet ROC800:PIM.

ROC827L Input Power

(continued)

Series 2 Expansion I/O

Backplane

12 Vdc Power Input

Module (PM-12)

25 mA

24 Vdc Power Input

Module (PM-24)

12.5 mA

Note: To determine the unit’s final input power requirements, add the input power requirements of the base unit, any

optional expansion I/O backplanes, and all appropriate communication or I/O modules together. Input power

requirements for individual modules are listed on each module’s product data sheet.

Physical

Dimensions

ROC809L

241 mm H by 244 mm W by 174 mm D (9.5 in. H by 9.6 in. W by 6.85

in. D). Allow an addition depth of 19 mm (0.75 in.) for cables.

ROC827L

Width

Each End Cap

27.1 mm (1.07 in.)

Base Unit

93.2 mm (3.67 in.)

Expansion I/O

Backplane

93.2 mm (3.67 in.)

Height

241 mm (9.5 in.)

Depth

174 mm (6.85 in.). Allow an additional 19 mm

(0.75 in.) for cables

Note: To determine the unit’s final width, add the widths of a base

backplane, a left end cap, a right end cap, and the

appropriate number of expansion I/O backplanes (up to

four).

Weight

ROC809L

1.65 kg (3.65 lb) for housing, backplane, and CPU.

Note: To determine the unit’s final weight, add the weight of the

ROC809L, and the appropriate number of I/O and

communications modules. Weights for individual modules

are listed on each module’s product data sheet.

ROC827L

Each End Cap

160 g (5.6 oz)

Base Unit (with

CPU)

770 g (1 lb. 11 oz)

Expansion I/O

Backplane

517 g (1 lb 2 oz)

Page 7

ROC800:ROC800L April 2020

www.Emerson.com/RemoteAutomation 7

Note: To determine the unit’s final weight, add the weight of the

ROC827L base unit, a left end cap, a right end cap, the

appropriate number of expansion I/O backplanes (up to

four), and the appropriate number of I/O and

communications modules. Weights for individual modules

are listed on each module’s product data sheet.

Wiring

Size 12 to 22 American Wire Gauge (AWG) for terminal blocks.

Materials

Housing

Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) Plastic

Wire Channel

Covers

Polypropylene Plastic

Modules

Thermoplastic Polyester, solvent-resistant

Housing

US Government

Patent

6771513

Mounting

DIN Rail

Size 35

Environmental

Operating Temp

–40 to 75 °C (–40 to 167 °F)

Storage Temp

–40 to 85 °C (–40 to 185 °F)

Operating Humidity

IEC68-2-3; 5-95% non-condensing

Radiated Emissions

Meets EN 55011 Class A; ICES-003:1997 Digital Apparatus; and FCC Part 15, Class A

Mechanical Shock

IEC68-2-27; 11 ms, sinusoidal 50 Gs non-operating, 15 Gs operating

Thermal Shock

IEC68-2-14; Air to air from –20 to 85 °C (–4 to 185 °F)

Radiated/Conducted Immunity

Meets requirements of IEC 61326 Electrical Equipment for use in Industrial Locations

Vibration

IEC68-2-6; 0.15 mm or 20m/s2

Approvals

Product Markings for Hazardous

Locations

CSA C/US

Certified as Model W40134

Class I, Division 2, Groups A, B, C, and D, T4

Class I, Zone 2, Group IIC, T4

AEx nA IIC, T4

Approval Standards

CSA/UL Standards

CSA C22.2 No. 142 and No. 213

CAN/CSA E79-0-02 and E79-15-02

UL 1604 – 3rd Edition

UL 508 – 17th Edition

EMC Standards

EN 61326:2003 Immunity and Class A Emissions

EN 61000-4-2 (Electrostatic Discharge)

EN 61000-4-3 (Radiated Immunity)

EN 61000-4-4 (Fast Transients)

EN 61000-4-5 (Surges)

EN 61000-4-6 (Conducted RF)

EN 55011:2002

Page 8

April 2020 ROC800:ROC800L

For customer service and technical support,

visit www.Emerson.com/SupportNet

Global Headquarters,

North America, and Latin America:

Emerson Process Management

Remote Automation Solutions

6005 Rogerdale Road

Houston, TX 77072 U.S.A.

T +1 281 879 2699 | F +1 281 988 4445

www.Emerson.com/RemoteAutomation

© 2010–2020 Remote Automation Solutions, a business unit of Emerson Automation

Solutions. All rights reserved.

This publication is for informational purposes only. While every effort has been made to ensure

accuracy, this publication shall not be read to include any warranty or guarantee, express or

implied, including as regards the products or services described or their use or applicability.

Remote Automation Solutions (RAS) reserves the right to modify or improve the designs or

specifications of its products at any time without notice. All sales are governed by RAS terms

and conditions which are available upon request. RAS accepts no responsibility for proper

selection, use or maintenance of any product, which remains solely with the purchaser and/or

end-user.

Europe:

Emerson Process Management

Remote Automation Solutions

Unit 1, Waterfront Business Park

Dudley Road, Brierley Hill

Dudley DY5 1LX UK

T +44 1384 487200 | F +44 1384 487258

Middle East/Africa:

Emerson Process Management

Remote Automation Solutions

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone – South 2

Dubai U.A.E.

T +971 4 8118100 | F +971 4 8865465

Asia-Pacific:

Emerson Process Management

Remote Automation Solutions

1 Pandan Crescent

Singapore 128461

T +65 6777 8211| F +65 6777 0947

Remote Automation Solutions

Miscellaneous Approvals

RoHS2

RoHS (2) EU Directive 2011/65/EU: This product may be considered

out-of-scope when used for the intended design purpose in a Large

Scale Fixed Installation (LSFI).

Consult https://www.emerson.com/compliance for up-to-date

product information.

RoHS (China)

Loading...

Loading...