Page 1

A-Frame Operator’s Manual

A-Frame Fault Locator

Model FT-103 Transmitter and

Model FR-30 Receiver

• Français – 15

• Castellano – pág. 33

Page 2

-Frame Fault Locator

A

Table of Contents

Recording Form for Machine Serial Number .....................................................................1

Safety Symbols.....................................................................................................................2

General Safety Rules

Work Area Safety...............................................................................................................2

Electrical Safety.................................................................................................................2

Personal Safety .................................................................................................................2

Equipment Use and Care ..................................................................................................2

Service ..............................................................................................................................3

Specific Safety Information

A-Frame Fault Locator Safety............................................................................................3

RIDGID Contact Information................................................................................................4

Description............................................................................................................................4

Transmitter.........................................................................................................................4

Receiver ............................................................................................................................5

Specifications.......................................................................................................................5

Standard Equipment..........................................................................................................6

Changing/Installing Batteries..............................................................................................6

Transmitter.........................................................................................................................7

Receiver (A-Frame) ...........................................................................................................7

Pre-Operation Inspection ....................................................................................................7

Set-Up And Operation Instructions ....................................................................................7

Fault Locating

Connecting Transmitter......................................................................................................8

Locating.............................................................................................................................9

Locating Below Paved Surfaces ......................................................................................10

Multiple Faults..................................................................................................................11

Path Locating

Direct Connect Path Locating Method .............................................................................11

Inductive Clamp Path Locating........................................................................................12

Broadcast Inductive Path Locating ..................................................................................12

Storage ................................................................................................................................13

Maintenance

Cleaning ..........................................................................................................................13

Calibration .......................................................................................................................13

Service And Repair..........................................................................................................13

Optional Equipment ...........................................................................................................14

Disposal ..............................................................................................................................14

Battery Disposal ..............................................................................................................14

EC Declaration of Conformity............................................................................................14

FCC Statement....................................................................................................................14

Electromagnetic Compatibility (EMC) ..............................................................................14

Lifetime Warranty.................................................................................................Back Cover

*Original Instructions - English

ii

999-995-095.10_REV. A

Page 3

A-Frame Fault Locator

A-Frame Fault Locator

Model FT-103 Transmitter and

Model FR-30 Receiver

WARNING!

Read this Operator’s Man ual

carefully before using this

tool. Failure to understand

and follow the contents of this

manual may result in electrical shock, fire and/or serious

person al injury.

A-Frame Fault Locator

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Page 4

-Frame Fault Locator

A

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to

communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

his is the safety alert symbol. It is used to alert you to potential personal injury hazards.

T

bey all safety messages that follow this symbol to avoid possible injury or death.

O

DANGER

W

CAUTION

OTICE

N

ARNING

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling

or using this equipment to reduce the risk of eye injury.

This symbol indicates the risk of electrical shock.

General Safety Rules

WARNING

Read all safety warnings and instructions. Failure to follow the warnings and

instructions may result in electric shock,

fire and/or serious injury.

SAVE ALL WARNINGS

AND INSTRUCTIONS FOR

FUTURE REFERENCE!

Work Area Safety

• Keep your work area clean and well lit.

Cluttered or dark areas invite accidents.

• Do not operate equipment in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. E quip -

ment can create sparks which may ignite

the dust or fumes.

• Keep children and by-standers a way

while operating equipment. Distrac tions

can cause you to lose control.

Electrical Safety

• Avoid body contact with earthed or

ground ed surfaces such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if

your body is earthed or grounded.

• Do not expose equipment to rain or wet

conditions. Water en tering equipment will

increase the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing

and use common sense when operating equipment. Do not use equipment

while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating

equipment may result in serious personal

injury.

• Use personal protective equipment. Al -

ways wear eye protection. Protective equipment such as dust mask, non-skid safety

shoes, hard hat or hearing protection used

for appropriate conditions will reduce personal injuries.

• Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected situations.

• Do not let familiarity gained from fre-

quent use of tools allow you to become

complacent and ignore tool safety principles. A careless action can cause severe

injury within a fraction of a second.

Equipment Use and Care

• Do not force equipment. Use the correct

equipment for your application. The cor-

2

999-995-095.10_REV. A

Page 5

ect equipment will do the job better and

r

safer at the rate for which it is designed.

• Do not use equipment if the switch does

not turn it ON and OFF. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

• Remove the battery pack from the equip-

ment before making any adjustments,

changing accessories, or storing. Such

preventive safety measures reduce the risk

of injury.

• Store idle equipment out of the reach of

children and do not allow persons unfamiliar with the equipment or these instructions to operate the equipment.

Equipment can be dangerous in the hands

of untrained users.

• Maintain equipment. Check for missing

parts, breakage of parts and any other

condition that may affect the equipment’s

operation. If damaged, have the equipment repaired before use. Many accidents

are caused by poorly maintained equipment.

• Use the equipment and accessories in

accordance with these instructions,

taking into account the working conditions and the work to be performed.

Use of the equipment for operations different from those intended could result in a

hazardous situation.

• Keep handles and grasping surfaces

dry, clean and free from oil and grease.

Slippery handles and grasping surfaces

do not allow for safe handling and control of

the tool in unexpected situations.

Service

• Have your equipment serviced by a qual i fied repair person using on ly identical

replacement parts. This will ensure that the

safety of the tool is maintained.

Specific Safety

Information

WARNING

This section contains important safety information that is specific to this tool.

Read these precautions carefully before

using the RIDGID®A-Frame Fault Locator

to reduce the risk of electrical shock or

serious personal injury.

A-Frame Fault Locator

SAVE ALL WARNINGS

AND INSTRUCTIONS FOR

FUTURE REFERENCE!

Keep this manual with the tool for use by

the operator.

A-Frame Fault Locator Safety

• Do not expose the equipment to water

or rain. This increases the risk of electrical

shock.

• Do not operate the transmitter if opera-

tor or transmitter is standing in water.

Operating transmitter while in water increases the risk of electrical shock.

• Do not connect to live voltage or ac-

tive utility lines. Disconnect the conductor

to be tested from any other service, components, or anything that might be affected

by high voltage. De-energize any circuits in

or around the work area.

• Always attach transmitter test leads be-

fore turning unit ON and turn unit OFF

before disconnecting leads. This will re-

duce the risk of electrical shock.

• Never turn transmitter ON when anyone

is touching the conductor, ground stake,

or any part of the transmitter. Turn OFF

transmitter before touching test lead or any

un-insulated conductor.

• Do not use where a danger of high volt-

age contact is present. Do not attach

leads to high voltage conductors. The

equipment is not designed to provide high

voltage protection and isolation.

• Locating equipment uses electromag-

netic fields that can be distorted and interfered with. More than one utility may

be present in a given area. Follow local

guidelines and one call/call before you dig

service procedures. Exposing a utility is

the only way to verify its existence, location

and depth.

• Avoid traffic. Pay close attention to mov-

ing vehicles when using on or near

roadways. Wear visible clothing or reflec-

tor vests.

• Before operating the RIDGID A-Frame

Fault Locator, read and understand this

operator’s manual and the instructions

for any other equipment used. Failure to

follow all instructions and warnings may result in property damage and/or serious injury.

999-995-095.10_REV. A

3

Page 6

-Frame Fault Locator

A

Use this manual in conjunction with all

•

company, utility or facility procedures

and policies. Familiarize yourself with all

required procedures and policies, including

safety practices, prior to entering an area

and using the equipment.

NOTICE

Ridge Tool Company, its affiliates

and suppliers, will not be liable for any injury or

any direct, indirect, incidental or consequential

damages sustained or incurred by reason of

the use of the A-Frame Fault Locator.

RIDGID Contact

Information

If you have any question concerning this

®

RIDGID

product:

– Contact your local RIDGID distributor.

– Visit RIDGID.com to find your local

RIDGID contact point.

– Contact Ridge Tool Technical Service

De partment at rtctechservices@emer son.com, or in the U.S. and Canada call

(800) 519-3456.

Description

The RIDGID®A-Frame Fault Locator is a highly

sensitive transmitter and receiver specifically

designed to detect the location of a path to

ground fault (Direct Fault Finding (DFF)) in

the insulation of a buried conductor (such as a

wire or cable). Damaged insulation, severed

conductor, and other faults with ground leakage are easily and precisely located.

Model FT-103 Transmitter connects to the insulated conductor and establishes a current flow,

the current leaks to ground through the insulation fault and back to the ground stake. Model

FR-30 Receiver detects the current flow to

ground through the insulation fault. The receiver provides audio and visual indications of

both signal strength and direction to assist in

detecting and locating the fault. For the AFrame fault detector to work, the conductor

must be in contact with the earth – it will not

work with conductors in conduit.

Additionally, the transmitter can be used to

apply a signal to the conductor for path locating with other receivers, such as RIDGID

SeekTech

done by direct connect and inductive methods.

Multiple frequencies and power levels are provided.

®

or NaviTrack®Locators. This can be

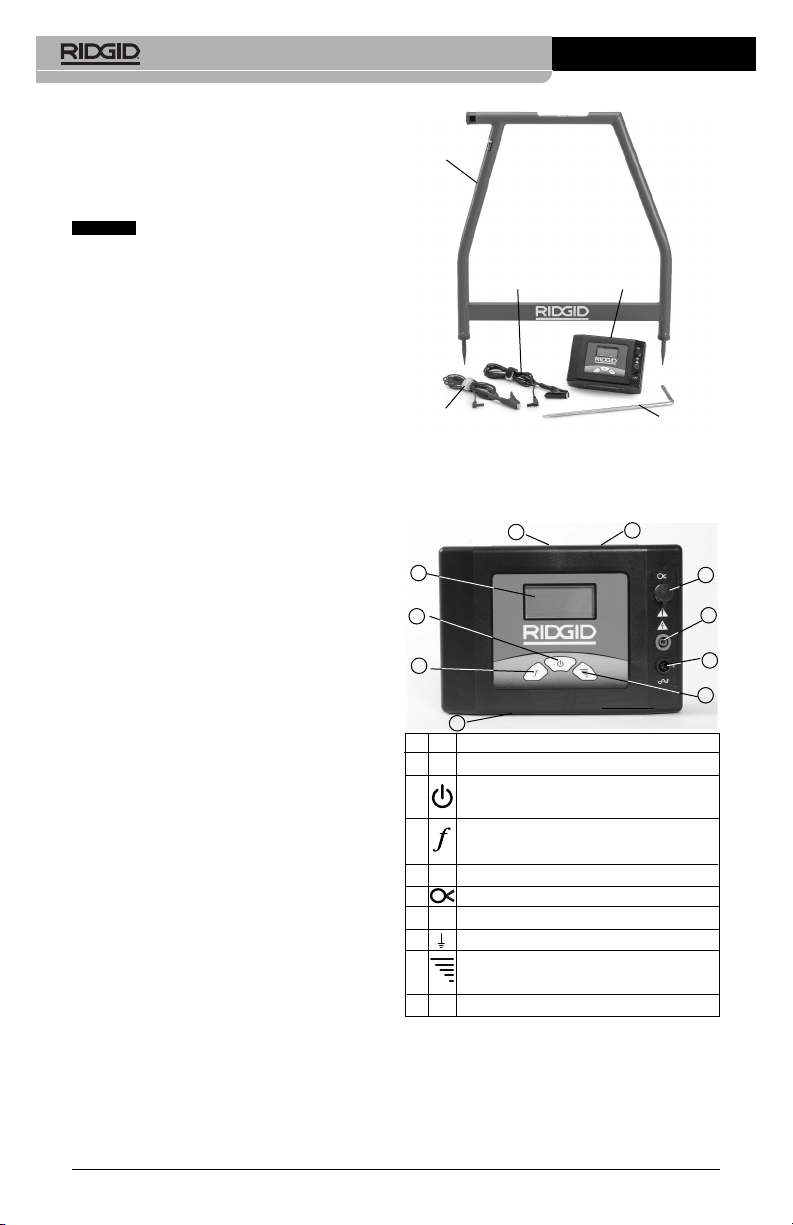

Receiver

Black Test Lead

(To Ground Stake)

Red Test Lead

To Conductor)

(

Figure 1 – A-Frame Fault Locator

ransmitter

T

Ground Stake

Transmitter

Transmitter Controls:

9

1

2

3

9

# Icon Description

1. — LCD Screen

2. ON/OFF and Inductive Mode Switch

Main Power Switch – Short press turns unit ON/OFF

Long press (5 seconds) enables Broadcast Inductive mode.

3. Frequency Selection

Selects the frequency of transmitter from preloaded frequencies. See Specifications for frequencies

4. — Serial and Warning Label (back of unit)

5. Inductive Clamp Jack

6. — Positive Terminal (to Conductor)

7. Negative Terminal (to Ground Stake)

8. Signal Power Setting

Depressing the Signal Power Button cycles the Signal

Power between Low, Medium and High

9. — Broadcast Inductive Decal (top and bottom)

Figure 2 – Transmitter Controls

4

5

6

7

8

4

999-995-095.10_REV. A

Page 7

A-Frame Fault Locator

ransmitter Display:

T

2

3

4

Number Icons Description

1–––kHz Frequency. “dFF” shown for fault finding.

2 Signal Power - # Of Bars On Increases with Increasing Power. Three Levels – Low, Medium

3

4 Voltage Warning – Transmitter connected to energized conductor – risk of electrical shock.

5 Transmitter Set for Fault Finding (dFF displayed in Frequency area (1)).

6 Transmitter Set for Inductive Clamp Use for Path Locating (Insert Inductive clamp into Jack)

7 Transmitter Set for Direct Connect Use for Fault Finding or Path Locating.

8 Transmitter Set for Broadcast Inductive Mode for Path Locating.

9 Transmitter Battery Status.

–––

and High.

Circuit Information, mA, V or Resistance in Ohms. Transmitter cycles through each at 2

second intervals.

Do not touch transmitter, leads or connections. Use high voltage precautions to disconnect.

1

5

6

7

8

9

Figure 3 – Transmitter Display

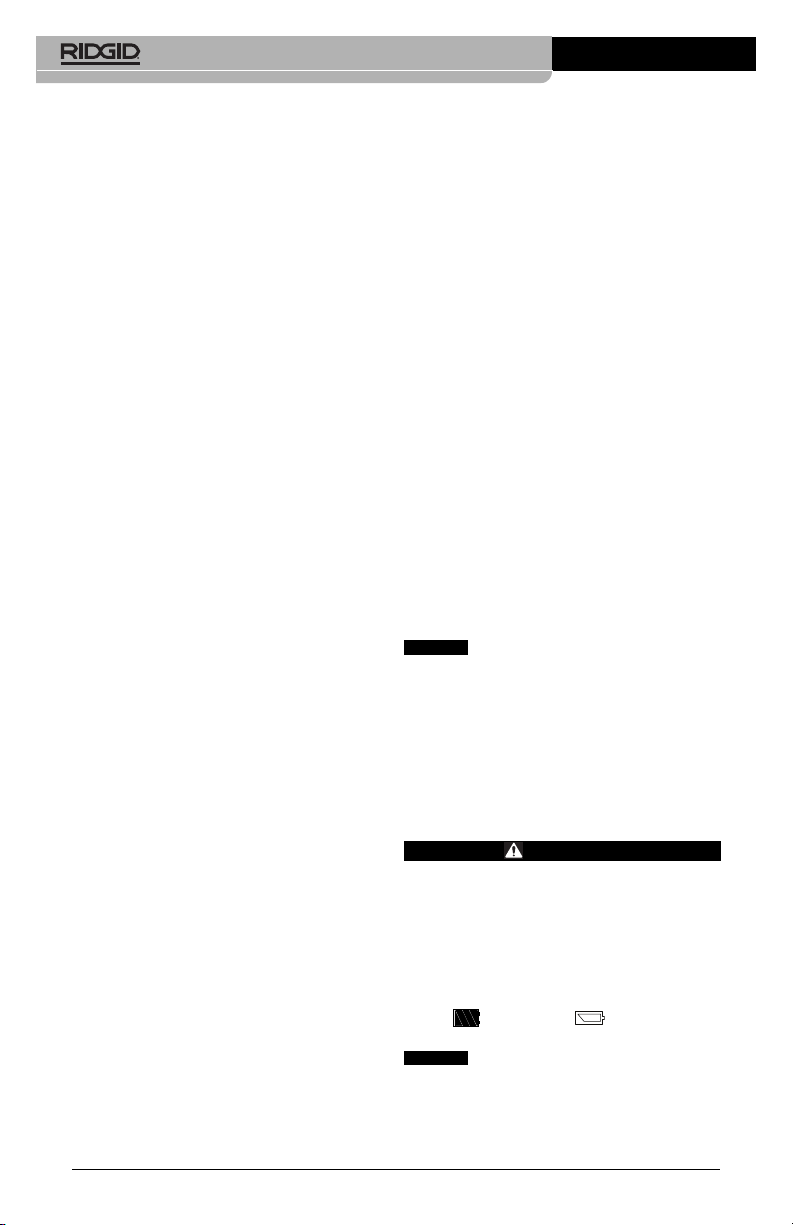

Receiver

Battery

Compartment

Serial Label

Display

Screen and

Controls

Receiver Controls/Display:

1

2

3

4

Warning

Label

Rear

Spike

Figure 4 – A Frame Receiver

999-995-095.10_REV. A

Front

Spike

5

# Icon Description

1 Reference Button

Ref

Stores and displays starting signal strength when pressed.

2 ON/OFF Button

Main Power Switch – Press to turn unit ON/OFF

3 Directional Arrow

Indicates direction of fault

4

Signal Strength

––

Displays absolute signal Strength from 0 to 99.

5 Low Battery Indicator

Figure 5 – Receiver Controls

Specifications

FT-103 Transmitter:

Operating

Frequencies .......Direct Fault Finding:

797 Hz - “dFF” displayed

5

Page 8

-Frame Fault Locator

A

Path locating:

128 Hz, 1 kHz, 8 kHz, 33

Hz, 93 kHz

k

Direct Connect:

128 Hz, 1 kHz, 8 kHz, 33

kHz, 93 kHz

Inductive Clamp:

8 kHz, 33 kHz, 93 kHz

Broadcast Inductive:

33 kHz, 93 kHz

Load Range .......5 Ω to 2M Ω

Output Power.....Up to 3 Watts (Low,

medium and high settings)

Output Voltage ...5 Volts - 600 Volts

Power Supply .....8 × C (R14) Cell

Batteries, 12 Volt

Battery Life.........Continuous: up to 15 hours,

Intermittent: up to 60 hours

(on low at 1000 Ohm load)

Operating

Temperature.......-4°F to 133°F

(-20°C to 55°C)

Storage

Temperature.......-13°F to 140°F

(-25°C to 60°C)

IP Rating ............IP54

Size....................8.5" x 5.8" x 2.5"

(21 cm x 15 cm x 6 cm)

Weight................2.2 lbs. (1 kg)

Test Lead

Jacks..................0.16" (4mm) as per

IEC61010

FR-30 A-Frame Receiver:

Operating

Frequencies .......Fault Finding:

797 Hz - “dFF” displayed

Direct Connect:

ower Supply.....6 × AA (LR6) Batteries,

P

9 Volt

Battery Life..........Continuous: up to 40 hours,

Intermittent: up to 82 hours

Operating

Temperature.......-4°F to 133°F

(-20°C to 55°C)

Storage

Temperature.......-13°F to 140°F

(-25°C to 60°C)

IP Rating ............IP54

Size....................30.3" x 30.4" x 1.5"

(77 cm x 77 cm x 4 cm)

Weight................3 lbs. (1.3 kg)

Standard Equipment

The A-Frame Fault Locator package includes

the following items:

• FR-30 A-Frame Receiver

• FT-103 Transmitter

• Ground Stake

• Red and Black Test Leads (7.5' (2.3 m) long)

• Carry Cases

• Batteries

• Operator’s Manual Pack

NOTICE

This equipment is used for conductor fault and path locating. Incorrect use or

improper application may result in incorrect or

inaccurate locating. Selection of appropriate locating methods for the conditions and proper

operation is the responsibility of the user.

Changing/Installing

Batteries

WARNING

Switch unit OFF and remove any connections from the Transmitter/Receiver

before changing batteries.

Fault Finding

Depth .................Up to 20' (6m) (depend-

ing on conditions)

Fault Finding

Length................Up to 3 miles (4800 m)

(depending on conditions)

Display ...............Black and White LCD

Audio

Indication ...........Piezo Response

6

The A-Frame Fault Locator is supplied without

the batteries installed. Remove the batteries

prior to storage to avoid battery leakage. When

the low battery indicator appears on the transmitter ( ) or receiver ( ) display, the batteries need to be replaced.

NOTICE

Use the batteries that are of same

type. Do not mix battery types. Do not mix

new and used batteries. Mixing batteries can

cause overheating and battery damage.

999-995-095.10_REV. A

Page 9

Transmitter:

1. With device OFF, remove the battery compartment cover. If needed, remove batteries (Figure 6).

Battery Compartment

+

-

+

-

+

-

Batteries

Figure 6 – Changing the Batteries (Transmitter)

+

-

Cover

2. Install eight new C Cell alkaline batteries

(R14), observing correct polarity as indicated in the battery compartment.

3. Securely reinstall the battery compartment cover.

Receiver (A-Frame):

1. With device OFF, unscrew the battery

com partment cover on the top tube (Fi -

gure 7). If needed, remove batteries.

Battery

Compartment Cover

A-Frame Fault Locator

ault Locator and correct any problems

F

to reduce the risk of serious injury from

electric shock and other causes, and

prevent equipment damage.

1. Make sure the transmitter and receiver

units are OFF.

2. Remove the batteries and inspect for

signs of damage. Replace if necessary.

Do not use if the batteries are damaged.

3. Clean the equipment. This aids inspection

and helps prevent the tool from slipping

from your grip.

4. Inspect the locator for the following:

• Proper assembly, maintenance and com -

pleteness.

• Any broken, worn or missing parts.

• Inspect the transmitter test leads for

damaged insulation or exposed wire.

• Presence and readability of the transmit-

ter and receiver warning labels (Figure

2 and 4).

• Any other condition which may prevent

safe and normal operation.

If any problems are found, do not use

the A-Frame Fault Locator until the problems have been repaired.

5. Inspect and maintain any other equipment being used per its instructions to

make sure it is functioning properly.

Figure 7 – Changing the Batteries (Receiver)

Batteries

2. Install six new AA alkaline batteries (LR6),

observing correct polarity as indicated

in the battery compartment.

3. Securely reinstall the battery compartment cover.

Pre-Operation Inspection

WARNING

Daily before use, inspect your A-Frame

999-995-095.10_REV. A

Set-Up And Operation

Instructions

WARNING

Do not connect to live voltage or active

utility lines. Disconnect the conductor

to be tested from any other service, components, or anything that might be affected by high voltage. De-energize any

circuits in or around the work area.

Always attach transmitter test leads before turning unit ON and turn unit OFF before disconnecting leads. This will reduce the risk of electrical shock.

Never turn transmitter ON the unit when

anyone is touching the conductor, ground

stake, or any part of the transmitter. Turn

7

Page 10

-Frame Fault Locator

A

OFF transmitter before touching test lead

or any un-insulated conductor.

o not use where a danger of high volt-

D

ge contact is present. Do not attach

a

leads to high voltage conductors. The

quipment is not designed to provide

e

high voltage protection and isolation.

ocating equipment uses electromag-

L

netic fields that can be distorted and interfered with. More than one utility may

be present in a given area. Follow local

guidelines and one call/call before you dig

service procedures. Exposing a utility is

the only way to verify its existence, location and depth.

Follow set up and operating instructions

to reduce the risk of injury from electrical

shock and other causes and to prevent

tool damage

Model FT-103 Transmitter and Model FR-30

Receiver are used for fault locating of conductors through direct connect method.

The Model FT-103 Transmitter only can be

used for path locating with RIDGID SeekTech

and NaviTrack®Locators. This can be done by

direct connect and inductive methods.

1. Confirm have appropriate work area (See

General Safety Rules). Operate in clear,

level, stable, dry location.Do not use transmitter while standing in water.

2. Determine the correct equipment for the

application, see Description and Specifi -

cations sections.

3. Make sure all equipment has been inspected and set up as directed in their instructions.

Fault Locating

It is good practice to locate the conductor path

before attempting to fault locate. This can be

done using a variety of RIDGID locating equipment. If during the location of the conductor

path an unusual amount of signal loss occurs,

this may give some indication of the conductor

insulation fault location. Additionally, use visual

cues and past history to aid in identifying the

conductor path and potential fault locations.

Once the conductor path is determined, the

RIDGID FT-103 Transmitter and FR-30 A-Frame

Receiver can be used to locate ground faults in

the insulated conductor. The Model FT-103

Transmitter connects to the insulated conductor

and establishes a current flow, the current

leaks to ground through the insulation fault

and back to the ground stake. The Model FR-30

Receiver detects the current flow to ground

hrough the insulation fault. For the A-Frame

t

fault detector to work, the conductor must be in

contact with the earth – it will not work with conductors in conduit. Generally, the A-Frame Fault

Locator works best in earth. Use with gravel,

asphalt, concrete or other ground covers may

not work as well.

The signal strength at the fault depends on

the amount of current leaking there. The greater

the leakage, the greater the signal strength.

Connecting Transmitter

1. Disconnect all loads and grounds from

the conductor to be tested and all neighboring conductors to prevent damage from

high voltage and false reading. Both ends

should be known and disconnected. Dis connecting both ends of the conductor

forces all of the transmitter signal through

the fault, improving the fault locate.

2. Insert supplied ground stake into the earth.

®

Ideally, the ground stake should be in line

with the conductor, 3' to 6' (1m to 2m)

from the end. If conditions require, the

ground stake can be placed to the side of

the conductor. Do not to place the ground

stake over the conductor. It is not recommended to use other existing grounds,

existing grounds may result in signal being

inadvertently applied to non-target cables.

A good ground results in a stronger tracing

signal. To get a good ground, insert the

ground stake as far as possible into the

earth. Moist earth will give a better ground

than dry earth. Wetting the earth around

the ground stake can improve grounding.

This lowers the resistance of the circuit.

While moist earth around the ground stake

improves the circuit, do not use the transmitter in areas that are wet, this can increase the risk of electrical shock.

3. Make sure that the transmitter is OFF.

4. Connect BLACK test lead to the ground

stake. Always connect to the ground stake

first.

5. Connect the BLACK and RED test leads

to the Transmitter.

6. Connect the RED test lead to the conductor to be tested (see Figure 9).

8

999-995-095.10_REV. A

Page 11

Transmitter

A-Frame Fault Locator

Red

Black

Ground Rod

3" – 6"

1 – 2 m)

(

Figure 8 – Transmitter Connections for Fault Locating

Buried Conductor

Locating

1. Make sure that no one is near or touching

the conductor, transmitter, leads or ground

stake. Press the ON/OFF button on the

eceiver

R

eturn Path

R

Through Soil

THE TRANSMITTER, LEADS OR CONNECTIONS. The target conductor is energized and

there is the risk of electrical shock. Use high

voltage precautions to disconnect.

transmitter to turn the transmitter ON.

When the transmitter is turned on, it is set

to the last used frequency. If needed,

press the frequency button on the transmitter until “dFF” is shown on screen

(Figure 9).

arth

E

Fault

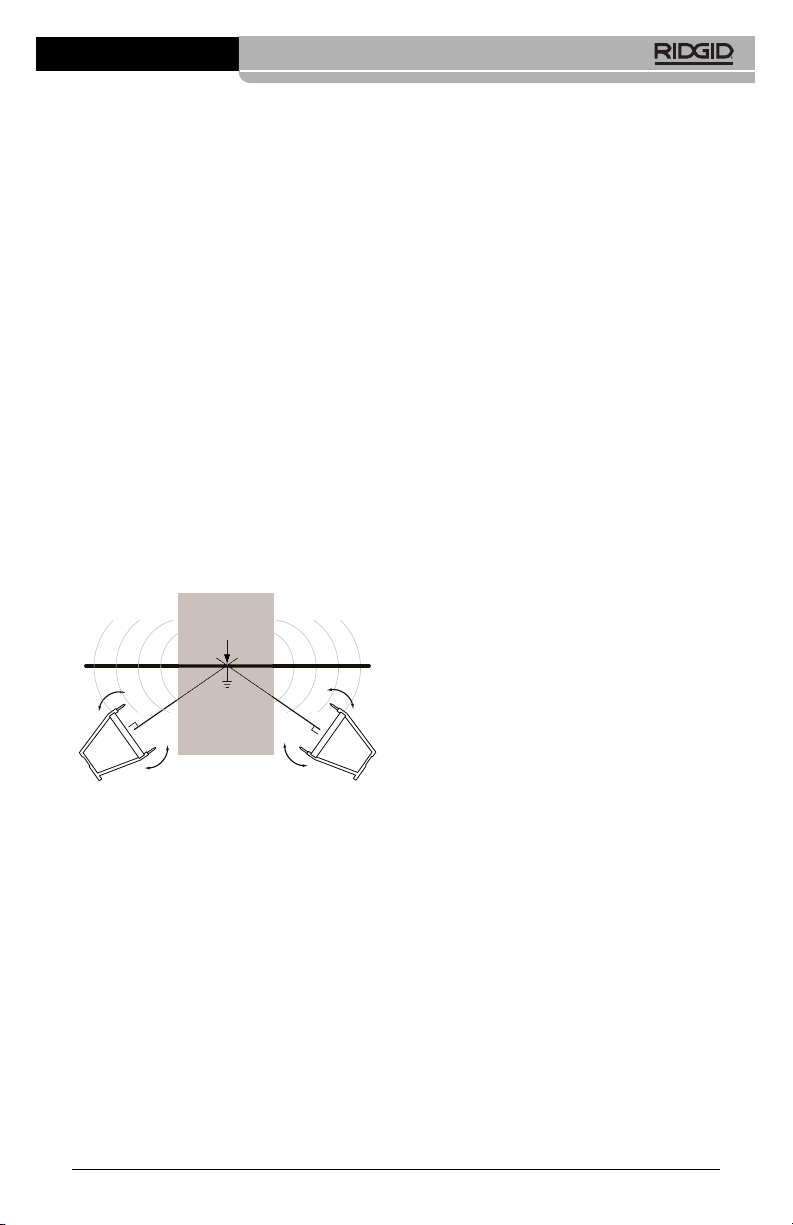

2. When fault locating, generally the receiver

should be used over the conductor, with

the front receiver spike towards the expected fault and the rear receiver spike towards the ground stake. The receiver

spikes should evenly penetrate the earth

to make good electrical contact. The current flowing in and out of the ground

spikes supplies the signal to locate the insulation fault (see Figure 10).

Figure 9 – Transmitter Screen

Adjust the signal power by pressing the signal

power button to cycle through the settings (low,

medium and high). Using high power may result in signal going to ground at non-target

points, low power may mean a circuit is not created. The transmitter will display circuit resistance (OHMS) at the bottom of the LCD. The

lower the resistance the better the locate signal.

To improve the circuit, improve the ground,

check the lead connections or increase the

power.

The transmitter will continuously beep when

there is a circuit. The lower the circuit resistance, the quicker the beep. The transmitter

will beep three times and a pause (repeating) if there is no circuit.

If the transmitter display shows voltage warning (Figure 3), the transmitter is connected to

live voltage. If this happens, DO NOT TOUCH

999-995-095.10_REV. A

Conductor (End View)

Figure 10 – Receiver Positioning

Conductor (Side View)

3. To start the locate, place the A-Frame

receiver between the ground stake and

the transmitter connection to the conductor. Press the A-Frame Receiver ON/OFF

button to turn receiver ON.

The signal strength will appear on the

receiver display. Signal strength will be the

highest near the ground stake and at

faults. Press the “Ref” button to store a reference signal strength near the ground

stake.

The receiver display arrows will indicate

the direction of the fault. Fault direction is

also indicated audibly - a long slow beep

indicates forward direction and a quick

beep indicates backward direction.

9

Page 12

-Frame Fault Locator

A

4. Remove the receiver from the earth and

move several steps as indicated by the

irectional arrow and beeping along the

d

conductor path. Reinsert the receiver

spikes into the earth (Figure 11).

Continue moving away from the ground

stake along the conductor path. Signal

strength should drop (in some cases going

to zero) and then rise as you move towards a fault.

5. Signal strength will peak over the fault. If

you pass the fault, the directional arrow will

change direction and the beep will change

from long slow to quick beep and the signal strength will decrease. Continue to

move the receiver back and forth until

slight movement causes the directional

arrows and beeping to toggle back and

forth. At this point, the fault is centered between the spikes of the receiver.

Compare the signal strength to the reference signal strength taken near the

ground stake. They should be similar. If the

fault signal strength is much lower than the

reference value, you may not have located a fault. For instance, a grounded

splice point would behave as a fault during

the locate, but would give a much lower

signal strength. For a low fault signal

strength, you may want to mark the location and continue down the conductor

ath looking for a fault signal strength

p

closer to the reference signal.

Once a fault is located with a signal similar

to the reference signal, turn the A-Frame

Locator perpendicular to the path of the

conductor. Move the receiver back and

forth until slight movement causes the directional arrows and beeping to toggle

back and forth. At this point, the fault is

centered between the spikes of the receiver. See Figure 12. Mark the location of

the fault.

6. Once the locating is completed, press the

ON/OFF button to turn the transmitter OFF.

Always turn the unit OFF before disconnecting the cable leads to reduce the risk

of electrical shock. Remove the cable lead

from the target conductor first. Always disconnect the cable lead from the target

conductor first before removing the cable

lead from the ground spike to reduce the

risk of electrical shock. Disconnect the

cable lead from the ground spike.

Locating Below Paved

Surfaces

Locating can be difficult if the fault is below a

paved surface, because the receiver spikes

cannot make good electrical contact with

the earth. In this case, there are several

methods that can be used.

Ground Rod

Figure 11 – Signal Strength

Fault

Figure 12 – Final Locate

10

Conductor (End View)

Fault

Conductor (Side View)

Fault

Signal Strength

Signal

Strength

999-995-095.10_REV. A

Page 13

If the paved area is relatively small, the

•

receiver can be used around the periphery

of the area. The receiver can be rotated

side to side, and where the receiver directional arrows and beeping toggle back

and forth, extend a straight line perpendicular to the center of the A-Frame Receiver.

Do this in several locations around the

suspected fault area. The straight lines

should all intersect at the same point. This

is the location of the fault. This method of

locating is less exact than placing the receiver directly over the conductor. See

Figure 13.

• An alternate way to locate below paved

surfaces is to improve the conductivity between the pavement and the receiver with

water. One method is to attach sponges to

the spikes of the receiver. Wet the sponges

with water and keep wet. Conduct the fault

locate normally.

• Another method is to wet the surface of the

pavement with water and conduct the fault

locate normally. Do not do this in the area

of the transmitter – this increases the risk of

electrical shock.

Paved Area

Conductor

Fault

Figure 13 – Locating below paved surfaces

Multiple Faults

If there are multiple faults in the conductor,

the faults will have signals proportional to

the amount of current leaking. The locate is

done the same as for a single fault, but the

signal strength will not be as strong. Typically,

the largest fault (least resistance fault) is

easiest to find. Best practice is to find and repair the first fault and continue the locate

for other faults.

Path Locating

The FT-103 Transmitter can be used with other

commercially available receivers (such as the

RIDGID SeekTech or NaviTrack receivers) to

path locate conductors. The FT-103 transmitter

A-Frame Fault Locator

an be used to apply an active tracing signal to

c

a conductor in three ways:

• Direct Connect – The transmitter’s leads

are connected directly to the target conductor and a suitable ground. This method is

most commonly used when the target utility is accessible. Direct connect should not

be used for energized (live) conductors.

• Inductive Clamp (optional equipment) –

the jaws of the inductive clamp encircle

the target conductor; if the conductor is insulated, there is no metal to metal contact.

This method is commonly used when the

target utility is accessible but direct connect is not possible on an insulated cable.

• Broadcast Inductive Mode – The transmitter generates a field, which in turn induces

a current in the target conductor. There is no

direct connection between the transmitter

and the target conductor. The transmitter is

placed over and inline with the target conductor. The transmitter’s internal antenna induces a signal onto the target conductor.

This method is most commonly used when

the target utility is not accessible.

Disconnect all loads from the conductor to

be tested and all neighboring conductors to

prevent damage from high voltage and false

reading.

Direct Connect Path Locating

Method

1. Insert supplied ground stake into the

earth. Or, if other good grounds are available in the area, they can be used.

A good ground results in a stronger tracing

signal. To get a good ground, insert the

ground stake as far as possible into the

earth. Moist earth will give a better ground

than dry earth. Wetting the earth around

the ground stake can improve grounding.

This lowers the resistance of the circuit.

While moist earth around the ground

stake improves the circuit, do not use the

transmitter in areas that are wet, this can

increase the risk of electrical shock.

The far end of the conductor should be

grounded.

2. Make sure that the transmitter is OFF.

3. Connect BLACK test lead to the ground

stake. Always connect to the ground stake

first.

4. Connect the BLACK and RED test leads

to the Transmitter.

999-995-095.10_REV. A

11

Page 14

-Frame Fault Locator

A

. Connect the RED test lead to the conduc-

5

tor to be tested.

6. Press the ON/OFF button to turn the transmitter ON. When the transmitter is turned

on, it is set to the last used frequency.

Press the frequency selection button to

cycle through frequency settings to the

desired locating frequency.

Adjust the signal power by pressing the

signal power button to cycle through the

settings (low, medium and high). Using

high power can couple into non-target

conductors, low power may mean a circuit

is not created. The transmitter will display

circuit resistance (OHMS) at the bottom of

the LCD. The lower the resistance the better the locate signal. To improve the circuit,

improve the ground, check the lead connections, increase power or change the

frequency.

If the transmitter display shows voltage

warning (Figure 3), the transmitter is con-

nected to live voltage. If this happens,

DO NOT TOUCH THE TRANSMITTER,

LEADS OR CONNECTIONS. The tar-

get conductor is energized and there is

the risk of electrical shock. Use high voltage precautions to disconnect.

7. Check the circuit and adjust signal power,

grounding or connections to ensure locatable field.

8. Turn ON the receiver/locator and follow

the instructions for the receiver. Make sure

the receiver’s frequency is set to match that

on the transmitter. Confirm the receiver is

picking up the transmitted frequency by

holding it near the transmitter and observing the increase in receiver signal.

9. Once the locating is completed, press the

ON/OFF button to turn the transmitter

OFF. Always turn the unit OFF before disconnecting the cable leads to reduce the

risk of electrical shock. Remove the cable

lead from the target conductor first. Always

disconnect the cable lead from the target

conductor first before removing the cable

lead from the ground spike to reduce the

risk of electrical shock. Disconnect the

cable lead from the ground spike.

all instruction for the use of the inductive

clamp.

2. Insert the plug of the inductive clamp

into transmitter (see Figure 2).

3. Clamp the jaws of the inductive clamp

around the target conductor. Make sure

that the jaws of the clamp are fully closed.

(See Figure 14). Both ends of the conductor should be grounded for best results.

Figure 14 – Inductive Clamp Attached to a

Conductor

4. Press the ON/OFF button to turn the trans mitter ON. When the clamp is plugged in

the clamp symbol ( ) shows on the

screen and only clamp frequencies are

available. Press the frequency selection

button to cycle through frequency settings

to the desired locating frequency. Adjust

the signal power by pressing the signal

power button to cycle through the settings

(low, medium and high). The inductive

clamp typically works best with frequencies around 8kHz, 33 kHz, 93kHz.

5. Check the circuit and adjust signal strength

(see Figure 3, Circuit Information).

6. Turn ON the receiver/locator and follow

the instructions for the receiver. Make

sure the receiver’s frequency is set to

match that on the transmitter. Confirm

the receiver is picking up the transmitted

frequency by holding it near the transmitter and observing the increase in receiver signal.

7. Once the locating is completed, press

the ON/OFF button to turn the transmitter

OFF.

Inductive Clamp Path

Locating

1. This method requires an inductive clamp

(Optional equipment). Read and follow

12

Broadcast Inductive Path

Locating

1. Properly place the transmitter relative to

the target conductor (see Figure 15). On

the top of the transmitter is an arrow. Set

999-995-095.10_REV. A

Page 15

ransmitter on ground,

t

align arrow with the

target conductor.

Conductor

2. Press the ON/OFF

button to turn the

trans mitter ON. Press

and hold the power

button for 5 seconds

selection button to

shift transmitter into

broadcast inductive

mode. Broadcast inductive icon ( ) appears on screen and

the transmitter will

start beeping to indicate that it is operating.

Figure 15 –

Orientation to the

Line – Inductive

Mode

Adjust the signal power by pressing the

signal power button to cycle through the

settings (low, medium and high) and

choose high. Press the frequency selection button to cycle through 33khz and

93kHz frequency settings to the desired

locating frequency. When using Broadcast

Inductive Mode, higher frequencies tend

to get a better signal at the receiver.

3. Turn ON the locator and follow its instructions. Make sure to set the receiver to

the same frequency as the transmitter.

A-Frame Fault Locator

uctor. This is called “Air Coup ling”. Operate

d

the receiver at least 30 feet from the transmitter to prevent this. (See Figure 16).

One way to confirm that you are tracing the

target conductor and not the transmitter

field is to look for a strong, stable prox imity

signal and a valid depth measurement on

the receiver. While directly over the energized line you can also raise the receiver a

set distance off of the ground, and verify

that the depth reading on the display e quals the distance that you raised the receiver.

4. Once the locating is completed, press the

Power ON/OFF button for 5 seconds to

exit broadcast inductive mode, then press

the ON/OFF button to turn the transmitter

OFF.

Storage

Remove batteries from tool. Store the A-Frame

Fault Locator in case. Avoid storing in extreme heat or cold.

WARNING

area that is out of reach of children and

people unfamiliar with the RIDGID A-Frame

Fault Locator. The locator is dangerous in

the hands of untrained users.

Store tool in a dry, secured

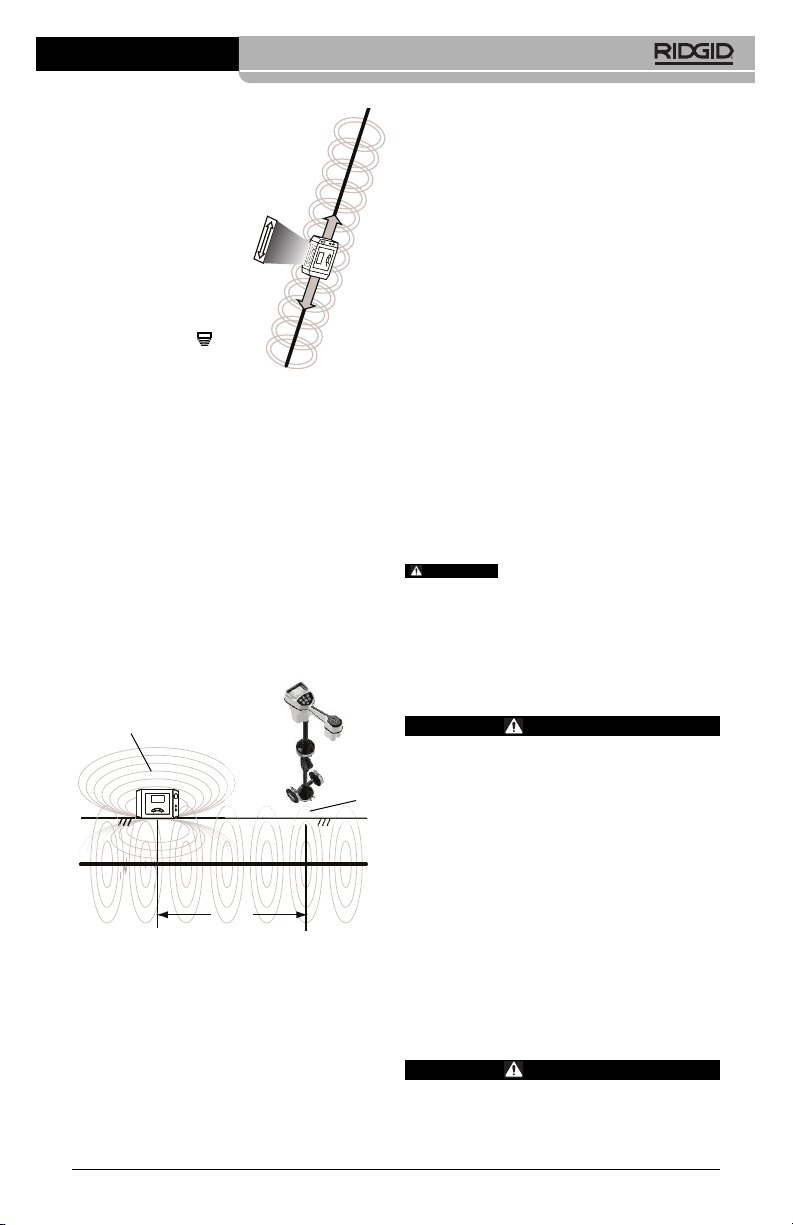

Transmitter Field

Induced

Field on

Target

Conductor

Conductor

30 feet

Minimum

Figure 16 – Orientation to the Line – Inductive

Mode

When the transmitter is in broadcast inductive mode, it generates a field around the

transmitter. This field is in both the ground

(towards the target conductor) and into

the air around the transmitter. When the receiver is within approximately 30 feet (10

meters) of the transmitter, it will measure

the field directly from the transmitter and

not the signal induced on the target con-

999-995-095.10_REV. A

Maintenance

WARNING

Remove batteries from tool before performing maintenance or making any

adjustment.

Cleaning

Do not immerse the A-Frame Fault Locator in

water. Wipe off dirt with a damp soft cloth.

Avoid rubbing too hard. Do not use aggressive

cleaning agents or solutions.

Calibration

The A-Frame Fault Locator is factory calibrated and only requires recalibration if repaired.

Service And Repair

WARNING

Improper ser vice or repair can make

the machine unsafe to operate.

Service and repair on this A-Frame Fault Lo -

13

Page 16

-Frame Fault Locator

A

ator must be performed by a RIDGID Inde -

c

pendent Service Center. Use only RIDGID

service parts.

For information on your nearest RIDGID Inde pen dent Service Center or any service or repair

questions, see Contact Information Section in

this manual.

Optional Equipment

WARNING

To reduce the risk of injury, only use accessories specifically designed and recommended for use with the RIDGID AFrame Fault Locator, such as listed below.

Catalog

No. Description

20973 RIDGID SeekTech 4" (100 mm)

57763 Ground Stake, FT-103

57768 Red and Black Test Leads, FT-103

96967 RIDGID NaviTrack II Locator

19238 RIDGID NaviTrack Scout Locator

22163 RIDGID SeekTech SR-60 Line Locator

21893 RIDGID SeekTech SR-20 Line Locator

44473 RIDGID SR-24 Line Locator with

For a complete listing of RIDGID equipment

avail able for this tool, see the Ridge Tool Cata log online at RIDGID.com or see Contact

Information.

Inductive Signal Clamp

®

Bluetooth

and GPS

Disposal

Parts of this tool contain valuable materials

and can be recycled. There are companies

that specialize in recycling that may be found

locally. Dispose of the components in compliance with all applicable regulations. Contact

your local waste management authority for

more information.

For EC Countries: Do not dispose

of elec trical equipment with household waste!

According to the European Guide line 2012/ 19/EU for Waste Elec trical

imple men tation into national legislation, electrical equipment that is no longer usable must

be collected separately and disposed of in

an environmentally correct manner.

and Electronic Equipment and its

Battery Disposal

For EC countries: Batteries must be recycled

according to the guideline 2006/66/EEC.

EC Declaration of

Conformity

The EC Declaration of Conformity (890-011-

320.10) will accompany this manual as a separate booklet when required.

FCC Statement

This equipment has been found to comply

with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment OFF

and ON, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Consult the dealer or an experienced radio/ TV technician for help.

Electromagnetic

Compatibility (EMC)

The term electromagnetic compatibility is taken

to mean the capability of the product to function

smoothly in an environment where electromagnetic radiation and electrostatic discharges

are present and without causing electromagnet

interference to other equipment.

NOTICE

conform to all applicable EMC standards.

However, the possibility of it causing interference in other devices cannot be precluded. All

EMC related standards that have been tested

are called out in the tool’s technical document.

The RIDGID A-Frame Fault Locator

14

999-995-095.10_REV. A

Page 17

Localisateur de rupture A-Frame

Localisateur de rupture A-Frame

Transmetteur FT-103 et

Récepteur FR-30

AVERTISSEMENT

Familiarisez-vous avec le présent

mode d’emploi avant d’utiliser l’appareil. Tout manque de compréhension ou de respect des consignes ciaprès augmenterait les risques de

choc électrique, d’incendie et/ou d’accident grave.

Localisateur de rupture A-Frame

Pour future référence, notez ci-dessous le numéro de série de l’appareil qui apparait sur sa

plaque signalétique.

No de

série

Page 18

ocalisateur de rupture A-Frame

L

Table des matières

Fiche d’enregistrement du numéro de série de l’appareil..............................................15

Symboles de sécurité.........................................................................................................17

Consignes générales de sécurité

Sécurité des lieux ............................................................................................................17

Sécurité électrique...........................................................................................................17

Sécurité individuelle.........................................................................................................17

Utilisation et entretien du matériel ...................................................................................18

Service après-vente.........................................................................................................18

Consignes de sécurité spécifiques

Sécurité du localisateur de rupture..................................................................................18

Coordonnées RIDGID.........................................................................................................19

Description..........................................................................................................................19

Transmetteur....................................................................................................................20

Récepteur........................................................................................................................21

Caractéristiques techniques .............................................................................................22

Equipements de base......................................................................................................22

Remplacement des piles ...................................................................................................23

Transmetteur....................................................................................................................23

Récepteur A-Frame .........................................................................................................23

Inspection préalable...........................................................................................................23

Préparation et utilisation de l’appareil .............................................................................24

Localisation de rupture

Connexion du transmetteur .............................................................................................25

Localisation .....................................................................................................................25

Localisation sous chaussée ............................................................................................27

Ruptures multiples...........................................................................................................28

Traçage des conducteurs

Traçage par connexion directe.........................................................................................28

Traçage par pince à induction .........................................................................................29

Traçage par transmission inductive .................................................................................30

Stockage .............................................................................................................................30

Entretien

Nettoyage ........................................................................................................................31

Calibrage .........................................................................................................................31

Révisions et réparations..................................................................................................31

Accessoires ........................................................................................................................31

Recyclage............................................................................................................................31

Recyclage des piles.........................................................................................................32

Déclaration de conformité CE ...........................................................................................32

Enoncé FCC........................................................................................................................32

Compatibilité électromagnétique (EMC) ..........................................................................32

Garantie à vie...................................................................................................page de garde

*Traduction de la notice originale

16

999-995-095.10_REV. A

Page 19

Localisateur de rupture A-Frame

Symboles de sécurité

Les symboles et mots clés utilisés à la fois dans ce mode d’emploi et sur l’appareil lui-même

servent à signaler d’importants risques de sécurité. Ce qui suit permettra de mieux comprendre la signification de ces mots clés et symboles..

Ce symbole sert à vous avertir de risques d’accident potentiels. Le respect des consignes qui le

suivent vous permettra d’éviter les risques d’accident grave ou potentiellement mortel.

e terme DANGER signifie une situation dangereuse qui, faute d’être évitée, provo-

DANGER

AVERTISSEMENT

TTENTION

A

VIS IMPORTANT

A

L

querait la mort ou de graves blessures corporelles.

Le terme AVERTISSEMENT signifie une situation dangereuse potentielle qui,

faute d’être évitée, serait susceptible d’entraîner la mort ou de graves blessures

corporelles.

Le terme ATTENTION signifie une situation dangereuse potentielle qui, faute d’être

évitée, serait susceptible d’entraîner des blessures corporelles légères ou modérées.

Le terme AVIS IMPORTANT indique des informations concernant la protection

des biens.

Ce symbole indique la nécessité de bien se familiariser avec la notice d’emploi avant d’utiliser ce

matériel. La notice d’emploi renferme d’importantes consignes de sécurité et d’utilisation du

matériel.

Ce symbole impose le port systématique de lunettes de sécurité à œillères lors de la manipulation ou utilisation de ce matériel afin de limiter les risques de lésion oculaire.

Ce symbole indique un risque de choc électrique.

Consignes générales de

sécurité

AVERTISSEMENT

Familiarisez-vous avec l’ensemble des

consignes de sécurité et d’utilisation. Le

non-respect des consignes ci-après augmenterait les risques de choc électrique,

d’incendie et/ou d’accident grave.

Conservez l’ensemble des consignes

de sécurité et d’utilisation pour

future référence !

Sécurité des lieux

• Assurez-vous de la propreté et du bon

éclairage des lieux. Les chantiers en-

combrés ou mal éclairés sont une invitation

aux accidents.

• N’utilisez pas d’appareils électriques en

présence de substances volatiles telles

que liquides, gaz ou poussières combustibles. Ce type de matériel risque de

produire des étincelles susceptibles d’enflammer les poussières et émanations combustibles.

• Eloignez les enfants et les curieux durant

l’utilisation des appareils électriques.

Les distractions risquent de vous faire perdre le contrôle de l’appareil.

Sécurité électrique

• Evitez tout contact avec des objets reliés

à la terre tels que canalisations, radiateurs, cuisinières et réfrigérateurs. Tout

contact avec la terre augmenterait les

risques de choc électrique.

• N’exposez pas l’appareil à la pluie ou

aux intempéries.Toute pénétration d’eau à

l’intérieur d’un appareil électrique augmenterait les risques de choc électrique.

Sécurité individuelle

• Soyez attentif, restez concentré et faites

preuve de bon sens lors de l’utilisation

de ce type d’appareil. Ne jamais utiliser

ce matériel lorsque vous êtes fatigué ou

sous l’influence de drogues, de l’alcool

ou de médicaments. Lors de l’utilisation

d’un appareil électrique, un instant d’inattention risque d’entraîner de graves lésions corporelles.

• Prévoyez les équipements de protec-

tion individuelle appropriés. Portez systématiquement une protection oculaire.

Selon le cas, le port d’un masque à poussière, de chaussures de sécurité antidérapantes, du casque ou d’une protection auriculaire peut aider à limiter les risques

d’accident grave.

999-995-095.10_REV. A

17

Page 20

ocalisateur de rupture A-Frame

L

• Ne vous mettez pas en porte-à-faux.

aintenez une bonne assiette et un bon

M

équilibre à tout moment. Cela assurera

un meilleur contrôle de l’appareil en cas

d’imprévu.

• Ne laissez pas la familiarité issue d’une

utilisation fréquente des appareils vous

rendre complaisant au point d’ignorer

les principes de sécurité applicables.

Le moindre faux pas peut occasionner de

graves blessures en une fraction de seconde.

Utilisation et entretien de

l’appareil

• Ne forcez pas l’appareil. Prévoyez l’ap-

pareil le mieux adapté aux travaux envisagés. Un appareil adapté produira de

meilleurs résultats et un meilleur niveau

de sécurité lorsqu’il fonctionne au régime

prévu.

• N’utilisez pas d’appareil dont l’interrup-

teur marche/arrêt ne fonctionne pas correctement. Tout appareil qui ne peut pas

être contrôlé par son interrupteur est considéré dangereux et doit être réparé.

• Retirez le bloc-piles de l’appareil avant

tout réglage, remplacement d’outils ou

stockage. De telles mesures préventives

aideront à limiter les risques d’accident.

• Rangez tout appareil non utilisé hors

de la portée des enfants et ne permettez

à aucun individu non familier avec ce

matériel ou les instructions ci-présentes

d’utiliser le matériel. Ce type d’appareil

peut devenir dangereux entre les mains

d’un novice.

• Assurez l’entretien approprié de l’ap-

pareil. Assurez-vous de l’absence d’éléments grippés ou endommagés, voire toute

autre anomalie susceptible de nuire au bon

fonctionnement et à la sécurité de l’appareil. Ne jamais utiliser d’appareil endommage avant sa réparation. De nombreux

accidents sont le résultat d’appareils mal entretenus.

• Utilisez l’appareil et ses accessoires se-

lon les consignes ci-présentes, tout en

tenant compte des conditions d’intervention et du type de travail envisagé.

L’emploi de ce matériel à des fins autres

que celles prévues pourrait entrainer une

situation dangereuse.

Maintenez les poignées et autres sur-

•

faces de prise en main de l’appareil

dans un parfait état de propreté. Cela

assurera une meilleure prise en main du

matériel.

Service après-vente

• Confiez la révision de l’appareil à un réparateur qualifié se servant exclusivement de pièces de rechange identiques

aux pièces d’origine. Cela assurera la

sécurité opérationnelle de l’appareil.

Consignes de sécurité

spécifiques

AVERTISSEMENT

La section suivante contient d’importantes consignes de sécurité visant ce

localisateur en particulier.

Afin de limiter les risques de choc électrique ou autre accident grave, familiarisez-vous avec les consignes suivantes

avant d’utiliser le localisateur de rupture

A-Frame.

Conservez l’ensemble des consignes

de sécurité et d’utilisation pour

future référence !

Gardez ce mode d’emploi avec l’appareil

afin qu’il soit à portée de main de tout utilisateur éventuel.

Sécurité du localisateur de

rupture A-Frame

• N’exposez pas ce matériel à l’eau ou

aux intempéries. Cela augmenterait les

risques de choc électrique.

• N’utilisez pas le transmetteur lorsque

l’opérateur ou le transmetteur a les pieds

dans l’eau. L’utilisation du transmetteur en

présence d’eau augmenterait les risques de

choc électrique.

• Ne connectez pas ce matériel à un objet

sous tension ou à des lignes électriques.

Déconnectez le conducteur à contrôler de

tout service, composant ou autre élément

qui risque d’être sous haute tension. Coupez

le courant à tout circuit électrique sur le

chantier ou dans ses environs.

18

999-995-095.10_REV. A

Page 21

Localisateur de rupture A-Frame

• Il faut toujours connecter les câbles du

ransmetteur avant de l’allumer, puis

t

éteindre le transmetteur avant de les déconnecter. Cela limitera les risques de

choc électrique.

• Ne jamais allumer le transmetteur lorsque

quelqu’un touche le conducteur, le piquet de terre ou toute autre partie du

transmetteur. Eteignez le transmetteur avant

de toucher ses câbles ou tout conducteur

non isolé.

• N’utilisez pas ce matériel là ou il y a

risque d’entrer en contact avec des éléments sous haute tension. Ne jamais

connecter les câbles à des conducteurs

sous haute tension. Ce matériel n’offre

aucune protection ou isolation contre les

éléments sous haute tension.

• Ce matériel de localisation utilise des

champs magnétiques qui sont susceptibles aux déformations et au parasitage.

Il risque d’y avoir plusieurs circuits électriques dans les environs. Respectez les

consignes locales et contactez les services concer nés avant de creuser. Le

sondage d’un service souterrain est le seul

moyen de vérifier son existence, sa position

et sa profondeur.

• Evitez la circulation routière. Faites par-

ticulièrement attention à la circulation

des véhicules lorsque vous travaillez

sur ou à proximité de la chaussée. Portez

des vêtements visibles ou des vestes

réfléchissantes.

• Avant d’utiliser le localisateur de rupture

RIDGID A-Frame, familiarisez-vous avec le

mode d’emploi ci-présent et ceux de tout

autre matériel utilisé. Le non-respect de

l’ensemble des consignes et avertissement

qu’ils renferment pourrait occasionner des

dégâts matériels et/ou de graves blessures

corporelles.

• Utilisez ce manuel en conjonction avec

l’ensemble des procédés et règles établis par votre entreprise, les services

publics ou les lieux d’intervention. Fami-

liarisez-vous avec l’ensemble des consignes

d’intervention, et notamment les consignes

de sécurité, avant de pénétrer les lieux et d’utiliser ce matériel.

AVIS IMPORTANT

i la société Ridge Tool

N

Company, ses filiales ou ses fournisseurs ne

sauraient être tenu responsables de blessures

ou dégâts directs, indirects, fortuits ou consécutifs subis en raison de l’utilisation du localisateur de rupture A-Frame.

Coordonnées RIDGID

En cas de questions concernant ce produit

®

RIDGID

veuillez :

– Consulter le distributeur RIDGID le plus

proche ;

– Visiter le site www.RIDGID.com pour lo-

caliser le représentant RIDGID le plus

proche ;

– Consulter les services techniques RIDGID

par mail adressé à rtctechservices@emerson.com, ou bien en appelant le (800) 5193456 à partir des Etats-Unis ou du Canada.

Description

Le localisateur de rupture RIDGID®A-Frame

est compose d’un ensemble transmetteur/récepteur spécifiquement prévu pour détecter

et localiser les passages de fuite à la terre

(détection direct de fuite dite « DFF ») dans les

gaines d’isolation des conducteurs (câbles ou

fils électriques) souterrains. Ce système assure la localisation facile et précise des fuites à

la terre occasionnées par la rupture d’une

gaine d’isolation ou d’un câble, voire d’autres

causes.

Le transmetteur FT-103 est connecté à un

câble isolé pour établir un courant électrique

qui, ensuite, fuit à la terre via la rupture d’isolation, puis revient jusqu’au piquet de terre.

Le récepteur FR-30 détecte la fuite de courant

via la rupture d’isolation. Le récepteur assure

des indications auditives et visuelles à la fois

de l’intensité et de la direction du signal afin

d’aider à détecter et localiser la fuite. Pour

que le détecteur de fuite A-Frame puisse fonctionner, le conducteur électrique en question

doit être directement enterré – Il ne fonctionnera pas sur des conducteurs électriques

sous fourreaux.

999-995-095.10_REV. A

19

Page 22

ocalisateur de rupture A-Frame

L

e transmetteur peut également servir à appli-

L

quer un signal au conducteur électrique en

vue de sa localisation à l’aide d’autres types de

récepteurs, tels que ceux des localisateurs

RIDGID SeekTech

®

ou NaviTrack®. Cela peut se

faire par moyen de connexion directe ou inductive. De multiples fréquences et niveaux d’intensité sont prévus.

Transmetteur

ommandes de transmetteur :

C

9

1

2

4

5

6

Récepteur

Câble noir

(vers piquet

de terre)

Câble rouge

(vers conducteur)

Transmetteur

Piquet de terre

Figure 1 – Localisateur de rupture A-Frame

3

9

N° Icône Désignation

1. — Ecran LCD

2. Marche/Arrêt et touche de mode inductif

Alimentation générale – Appuyer momentanément pour

allumer ou éteindre l’appareil.

Appuyer longuement (5 secondes) pour activer le mode de

transmission par induction.

3. Sélection de fréquence

élection d’une fréquence de transmission à partir de

S

fréquences prédéterminées. Consultez la section

Caractéristiques techniquespour les fréquences disponibles.

4. — Plaque signalétique et avertissement

(au dos de l’appareil)

5. Prise de pince à induction

6. — Borne positive (vers conducteur électrique)

7. Borne négative (vers piquet de terre)

8. Réglage d’intensité du signal

Appuyez sur la touche d’intensité de signal pour naviguer

entre une intensité de signal faible, moyenne ou élevée.

9. — Décalcomanie de transmission par induction

(haut et bas)

Figure 2 – Commandes du transmetteur

7

8

20

999-995-095.10_REV. A

Page 23

Localisateur de rupture A-Frame

cran d’affichage du transmetteur

E

1

2

3

4

5

6

7

8

9

N° Icône Désignation

1–––kHz Fréquence. « dFF » (localisation de rupture) indiqué.

2 Intensité du signal. Le nombre de barres augmente avec l’augmentation d’intensité. Trois

3

–––

4 Avertissement « Sous tension » - Le transmetteur et connecté à un conducteur sous

niveaux – Faible, moyenne, élevée.

Détails du circuit – mA, V ou résistance en Ohms. Le transmetteur navigue d’un à l’autre à

2 secondes d’intervalle.

tension – risque de choc électrique. Ne pas toucher le transmetteur, ses câbles ou leurs

connexions. Appliquez les précautions « haute tension » pour débrancher.

5 Transmetteur en mode « localisation de rupture » (dFF affiché dans la zone Fréquence (1).

6 Transmetteur en mode « utilisation de pince à induction pour traçage de ligne (introduire la

fiche de la pince à induction dans la sortie).

7 Transmetteur en mode « connexion directe pour localisation de rupture ou traçage de ligne.

8 Transmetteur en mode « transmission inductive pour traçage de ligne.

9 Etat de charge des piles.

Figure 3 – Ecran d’affichage du transmetteur

Récepteur

Logement

de piles

Plaque

signalétique

Avertissement

Pointe

arrière

Figure 4 – Récepteur A-Frame

999-995-095.10_REV. A

Pointe

avant

Ecran

d’affichage

et

commandes

Commandes et écran du récepteur :

1

2

N° Icône Désignation

1 Touche de point de référence

Ref

Appuyez pour enregistrer et afficher l’intensité du signal

au point de départ.

2 Touche Marche/Arrêt

Alimentation générale – Appuyez pour allumer ou

éteindre l’appareil.

3 Flèches directionnelles

Indication de la direction de la rupture.

4

Intensité du signal

––

Affichage de l’intensité absolue du signal de 0 à 99.

5 Indicateur de faible charge des piles

Figure 5 – Commandes du récepteur

3

4

5

21

Page 24

ocalisateur de rupture A-Frame

L

Caractéristiques

techniques

Transmetteur FT-103 :

Fréquences

utilisées..............Localisation de rupture

directe :

797 Hz – « dFF » affiché

Traçage de ligne :

128 Hz, 1 kHz, 8 kHz, 33

kHz, 93 kHz

Connexion directe :

128 Hz, 1 kHz, 8 kHz, 33

kHz, 93 kHz

Pince à induction :

8 kHz, 33 kHz, 93 kHz

Transmission inductive :

33 kHz, 93 kHz

Charge ...............5 Ω à 2M Ω

Puissance

de sortie .............Jusqu’à 3 watts (intensité

faible, moyenne et élevée)

Tension de

sortie ..................5 volts à 600 volts

Alimentation .......8 piles type « C »

(R14) = 12 volts

Longévité

des piles.............En continue : jusqu’à 15

heures

Par intermittence : jusqu’à

60 heures (faible intensité

à 1000 ohms de charge)

Température

opérationnelle ....-4 °F à 133 °F

(-20 °C à 55 °C)

Température

de stockage........-13 °F à 140 °F

(-25 °C à 60 °C)

Protection IP.......IP54

Dimensions ........8,5" x 5,8" x 2,5"

(21 cm x 15 cm x 6 cm)

Poids..................2,2 livres (1 kg)

Test Lead

Sorties câbles ....0,16" (4mm) selon

IEC61010

Récepteur A-Frame FR-30 :

réquences

F

utilisées..............Localisation de rupture :

Localisation de ruptures –

Profondeur..........Jusqu’à 20 pieds (6 m)

...........................selon les conditions

Localisation de ruptures –

Distance.............Jusqu’à 3 miles (4,8 km)

Affichage............LCD noir et blanc

Indication

audio ..................Réponse piézo

Alimentation .......6 pilles « AA »

Longévité des

piles ....................En continue : jusqu’à 40

Température

opérationnelle ....-4°F à 133°F

Température

de stockage........-13°F à 140°F

Protection IP.......IP54

Dimensions ........30,3" x 30,4" x 1,5"

Poids..................3 livres (1,3 kg)

797 Hz – « dFF » affiché

selon les conditions

(LR6) = 9 volts

heures, Par intermittence :

jusqu’à 82 heures

(-20°C à 55°C)

(-25°C à 60°C)

(77 cm x 77 cm x 4 cm)

Equipements de base

L’ensemble Localisateur de rupture A-Frame

est composé des éléments suivants :

• Récepteur A-Frame FR-30

• Transmetteur FT-103

• Piquet de terre

• Câbles de connexion rouge et noir de 7,5

pieds (2,30 m) de long

• Mallette de transport

• Piles

• Mode d’emploi

AVIS IMPORTANT

sation des ruptures de conduit et au traçage

des câbles. Toute exploitation ou application

inappropriée risquerait de produire des résultats

inexacts ou imprécis. Il appartient à l’utilisateur d’établir et d’appliquer les méthodes de localisation appropriées en fonction des conditions existantes.

Ce matériel sert à la locali-

22

999-995-095.10_REV. A

Page 25

Localisateur de rupture A-Frame

Remplacement des

piles

AVERTISSEMENT

Eteignez l’appareil et déconnectez le

transmetteur/récepteur avant le remplacement des piles.

Les piles du localisateur de rupture A-Frame ne

sont pas installées à la livraison de l’appareil.

Retirez les piles avant le stockage de l’appareil afin d’éviter d’éventuelles fuites d’électrolyte. Lorsque l’indicateur de faible charge

apparait à l’écran du transmetteur ou du

récepteur , les piles doivent être remplacées.

AVIS IMPORTANT

identique. Ne mélangez pas différents types

de piles. Le mélange de piles peut provoquer

la surchauffe et la détérioration des piles.

Transmetteur :

1. Avec l’appareil éteint, retirez le couvercle

du logement de piles. Au besoin, retirez les

piles (Figure 6).

Utilisez des piles de type

Logement de piles

+

-

+

-

Couvercle du

logement de piles

igure 7 – Remplacement des piles du récepteur

F

Piles

2. Installez six nouvelles piles alcalines type

« AA » (LR6) en respectant la polarité indiquée sur le couvercle du logement de

piles.

3. Réinstallez le couvercle du logement de

piles.

Inspection préalable

AVERTISSEMENT

Au quotidien et avant chaque utilisation,

inspectez le localisateur de rupture AFrame et rectifiez toute anomalie éventuelle afin de limiter les risques de blessure grave (choc électrique, etc.) et éviter d’endommager le matériel.

+

-

Piles

Figure 6 – Remplacement des piles du

transmetteur

+

-

Couvercle

2. Installez huit nouvelles piles alcalines

type « C » (R14) en respectant la polarité

indiquée dans le logement de piles.

3. Réinstallez le couvercle du logement de

piles.

Récepteur A-Frame :

1. Avec l’appareil éteint, dévissez le couvercle du logement de piles en bout du tube

(Figure 7). Au besoin, retirez les piles.

999-995-095.10_REV. A