Page 1

PCM-22

Rotary Knife Controller

Information furnished by EMERSON Motion Control is believed to be accurate and reliable. However,

no responsibility is assumed by EMERSON Motion Control for its use. EMERSON Motion Control

reserves the right to change the design or operation of the equipment described herein and any

associated motion products without notice. EMERSON Motion Control also assumes no responsibility

for any errors that may appear in this document. Information in this document is the property of

EMERSON Motion Control and is subject to change without notice.

P/N 400274-01

Rev.: A2

Date: December 7, 1998

© 1998 EMERSON Motion Control. All Rights Reserved.

Page 2

PCM-22 Rotary Knife Controller

© 1998 EMERSON Motion Control. All Rights Reserved.

Document Number: 400274-01

No part of this manual may be reproduced by any means without the written permission of EMERSON Motion

Control.

EMERSON Motion Control is a registered trademark of EMERSON ELECTRIC.

Printed in U.S.A.

December, 1998 Revision A2

This document has been prepared to conform to the current release version of the PCM-22 Rotary Knife

Controller. Because of our extensive developments and our desire to further improve and enhance the product,

inconsistencies may exist between the product and documentation in some instances. Call your customer

support representative if you encounter an inconsistency.

ii © EMERSON Motion Control

Page 3

Customer Services

EMERSON Motion Control offers a wide range of services to support our

customers’ needs. Listed below are some of these services.

Application Engineering (612) 474-1116

E-Mail: applengr@emersonemc.com

An experienced staff of factory application engineers provide complete

customer support for tough or complex applications. Our engineers offer

you a broad base of experience and knowledge of electronic motion

control applications.

EMERSON BBS (612) 474-8835

EMERSON Motion Control maintains a electronic Bulletin Board

System which provides you access to software updates, technical

information and services.

Communications protocol: 300 - 28,800 Baud, N, 8, 1.

FAX (612) 474-8711

Internet Access www.emersonemc.com

Order / Repair Status (612) 474-1116

Sales (800) FX-SERVO

E-Mail: sales@emersonemc.com

Service Support (612) 474-8833

E-Mail: service@emersonemc.com

EMERSON Motion Control’s products are backed by a team of

professionals who will service your installation wherever it may be. Our

customer service center in Minneapolis Minnesota is ready to help you

solve those occasional problems over the telephone. Our customer service

center is available 24 hours a day for emergency service to help speed

any problem solving. Also, hardware replacement parts, should they ever

be needed, are available through our customer service organization.

Need on-site help? EMERSON Motion Control provides on-site service,

in most cases, the next day. Just call EMERSON’s customer service

center when on-site service or maintenance is required.

See Service Support Check List on the following page.

Training Services (612) 474-1116

EMERSON Motion Control maintains a highly trained staff of

instructors to familiarize customers with EMERSON Motion Control

products and their applications. A number of courses are offered, many

of which can be taught in your plant upon request.

P/N 400274-01 Revision A7 iii

Page 4

PCM-22 Rotary Knife Controller

Service Support Check List

To ensure the most timely and efficient support possible, please have the

following items ready before calling for Service Support.

1. The model and serial number(s) of your FX Amplifier(s) and

manual(s).

2. The model and serial number(s) of your PCM(s).

3. The result (using Terminal Mode) of ID?; 0ID? (zero ID?) if axis ID’s

are used.

4. The result (using Terminal Mode) of ID1?; 0ID1? (zero ID1?) if axis

ID’s are used.

5. A description of the symptom(s) or issue(s) observed including any

fault status codes displayed on the LED Diagnostic Display.

6. Copies of the current uploaded program(s) that are in each of your

PCM(s).

7. The gear ratio, model number and type of reducer(s) used.

8. This manual.

iv © EMERSON Motion Control

Page 5

Table Of Contents

Introduction 1

Description ................................................................................................................... 1

Features ........................................................................................................................3

Terminology ................................................................................................................. 4

Master Cycle Length .............................................................................................. 4

Follower Cycle Length ........................................................................................... 4

Working Segment .................................................................................................. 5

Cycle Point............................................................................................................. 5

Working Offset....................................................................................................... 5

Variable Segment................................................................................................... 6

Cycle Drop Out Position.........................................................................................7

Working Ratio........................................................................................................ 7

Phase...................................................................................................................... 8

Average Length...................................................................................................... 8

Theory of Operation 11

General Running......................................................................................................... 11

Master Cycle Defined By Sensor Mode................................................................. 12

Master Cycle Not Defined By Sensor Mode.......................................................... 12

Resetting the Master Cycle Processing ........................................................................ 13

How the Master Cycle is Defined.......................................................................... 13

Automatically Resetting the Master Processing..................................................... 13

Manually Resetting the Master Processing............................................................ 14

Starting A Follower Cycle........................................................................................... 15

Homes and the Follower Zero Position ........................................................................ 16

Indexes and the Follower Zero Position....................................................................... 16

Cycle Inter-Relationships............................................................................................ 17

Operational Timing..................................................................................................... 18

Maximum Master Velocity.......................................................................................... 19

Sensors ....................................................................................................................... 20

Selection .............................................................................................................. 20

Sensors: When, Where and Why .......................................................................... 21

Installation Guidelines 23

Attaching the PCM-22 Module ................................................................................... 23

I/O Wiring.................................................................................................................. 23

P/N 400274-01 Revision A7 v

Input Wiring ........................................................................................................ 23

Output Wiring...................................................................................................... 23

Page 6

PCM-22 Rotary Knife Controller

PCM-22 Software Setup 25

Programming the PCM-22...........................................................................................25

Master Axis .................................................................................................................29

Master Cycles ..............................................................................................................37

Follower Cycles ...........................................................................................................42

Input Functions............................................................................................................52

Output Functions .........................................................................................................58

Programming ...............................................................................................................63

Description ...........................................................................................................29

Master Axis Setup.................................................................................................31

Master Cycle Number............................................................................................37

Master Cycle Length.............................................................................................37

Master Phase Distance ..........................................................................................40

Master Cycle Defined By Sensor ...........................................................................40

Cycle Number.......................................................................................................43

Follower Cycle Length..........................................................................................43

Cycle Defined by Registration Sensor....................................................................46

Phase Correction Limit .........................................................................................47

Phase Distance Error Limit (+) .............................................................................47

Phase Distance Error Limit (-) ..............................................................................47

Phase Correction Deadband...................................................................................48

Length Change Increment.....................................................................................48

Master Cycle Number............................................................................................48

Batch Count..........................................................................................................48

Cycle Count ..........................................................................................................49

Working Segment Width.......................................................................................49

Offset/Phase Fine Increment..................................................................................51

Offset/Phase Coarse Increment..............................................................................51

Description of Input Functions..............................................................................53

Typical Input Assignments....................................................................................57

Description Of Output Functions...........................................................................58

Recommended Output Assignments......................................................................62

Additional programming functions........................................................................63

Example program..................................................................................................64

Example Applications 67

Rotary Knife ................................................................................................................67

Seal and Cut Off Packages...........................................................................................68

Flexible Bag Maker......................................................................................................69

Pick and Place..............................................................................................................70

Imprinter .....................................................................................................................71

Maximizing Profile Performance 73

Commands Referenced.................................................................................................74

Minimizing Length Variation......................................................................................74

Minimizing Phase Variation........................................................................................76

vi © EMERSON Motion Control

Page 7

Tips and Troubleshooting 80

General Issues............................................................................................................. 80

Product Ranges and Limits.......................................................................................... 80

Follower Cycle Will Not Start ..................................................................................... 81

Verifying the Working Segment Position .................................................................... 81

Issues Maintaining Phase............................................................................................ 82

System Calibration Issues............................................................................................ 83

Synchronization Source Issues .................................................................................... 83

Running Into a Length Limit....................................................................................... 84

Missing Sensor Issues ................................................................................................. 85

Extra Sensor Issues ..................................................................................................... 86

Common Operation Issues........................................................................................... 87

Appendix A - Serial Commands 88

CI2 - Executing Master Cycle ..................................................................................... 88

CQ - Cycle Status Query ............................................................................................. 88

FF - Follower Cycle Flags........................................................................................... 91

FM7 - Master Phase Variation In User Units............................................................... 92

FM8 - Follower Phase Variation In User Units............................................................ 92

FM9 - Master Length Variation In Sync. Counts......................................................... 92

FM10 - Follower Length Variation In Resolver Counts ............................................... 93

FM11 - Master Axis Velocity...................................................................................... 93

FM12 - Average Master Length In User Units............................................................. 93

FM13 - Average Follower Length In User Units.......................................................... 93

FM14 - Computed Starting Master Distance In Master Steps ...................................... 93

FN1 - Follower Cycles Per Follower Sensor................................................................. 94

KC4 - Total Cycle Count............................................................................................. 94

MF - Master Cycle Flags............................................................................................. 94

ML11 - Current Master Length In Master Steps .......................................................... 95

PH4 - Minimum Master Velocity For I/O Profile Adjustments .................................... 95

TC5 - Working Ratio Change Increment..................................................................... 95

Appendix B - PCX Cycle Screens to FX Command Cross

Reference 96

PCM-22 Master Cycles Screen.................................................................................... 96

PCM-22 Follower Cycles Screen................................................................................. 97

Appendix C - Master Signal Components 98

Encoder Operation...................................................................................................... 98

Encoder to Drive Cables.............................................................................................. 99

Drive to Drive Cables.................................................................................................. 99

Index 100

P/N 400274-01 Revision A7 vii

Page 8

Page 9

This manual provides setup and programming information for the

PCM-22 Rotary Knife Controller Application Module.

It is important that you become familiar with the 230V FX Drives Setup

and Programming Operator's Manual (P/N 400282-00), 460V FX Drives

Setup and Programming Operator's Manual (P/N 400310-00) or 525

Programmable Motion Controller Installation and Operation Manual

(P/N 400276-01) as appropriate.

This manual should be read completely before installing the

PCM-22. It provides the background information needed to setup and

configure the PCM-22/FX amplifier combination using PCX 7.x software.

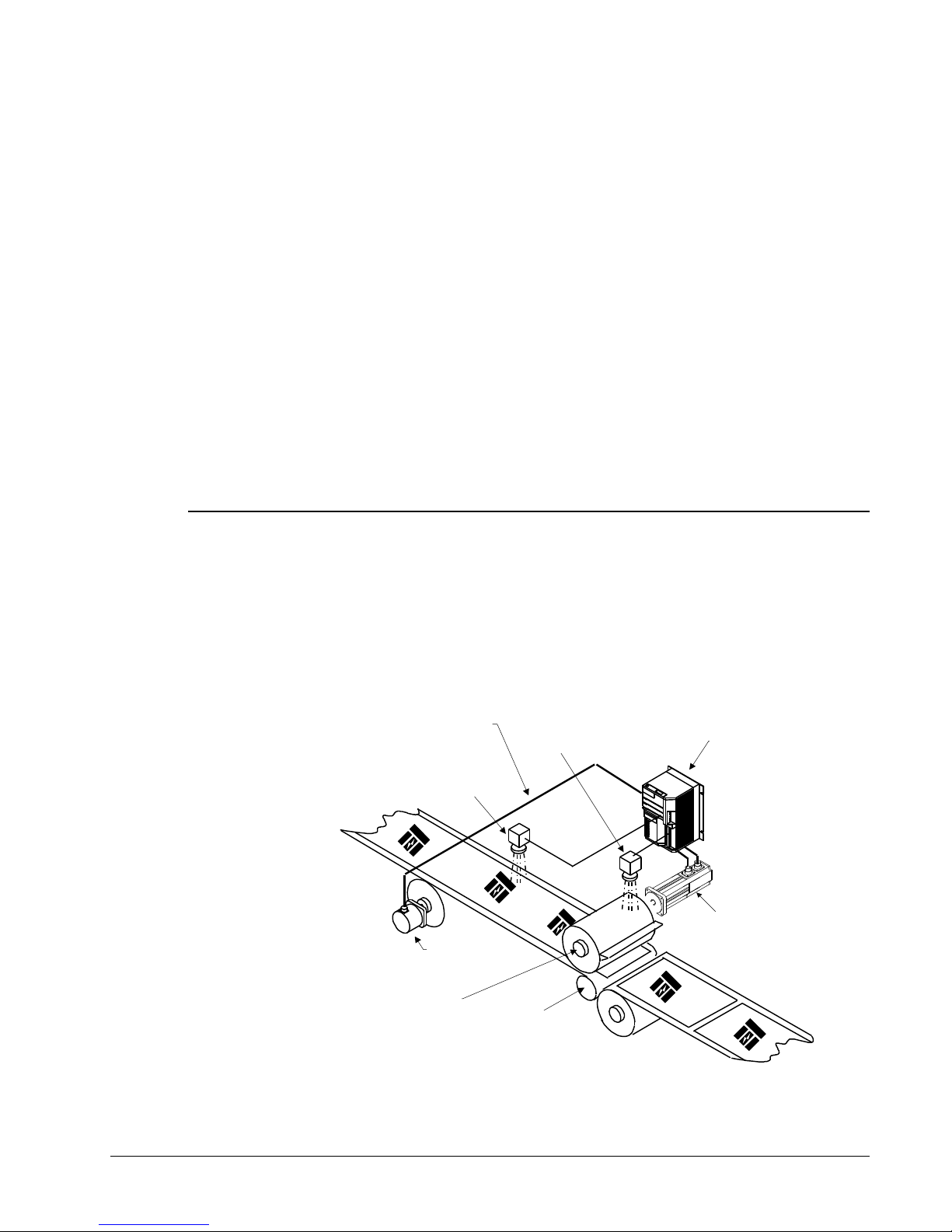

Description

The PCM-22 Rotary Knife Controller is an application module that

attaches to any EMERSON Motion Control FX positioning servo drive.

The PCM-22 enables a FX drive to automatically calculate and create

motion profiles using sensor information and/or user-defined parameters.

The PCM-22 is designed to maintain a phased relationship between the

motor axis (referred to as the Follower axis) and the motion of an

independent axis (referred to as the Master axis).

Introduction

MSC

CABLE

MASTER REGISTRATION

SENSOR

FOLLOWER

SENSOR

FX AMPLIFIER

WITH PCM-22

P/N 400274-01 Revision A7 1

SCS-4

ENCODER

KNIFE

AXIS

Figure 1 Typical Application - Rotary Cut-Off.

ANVIL

MOTOR

Page 10

PCM-22 Rotary Knife Controller

The PCM-22 accepts application data relating to the mechanical

dimensions of the system entered using PCX Software. These parameters

along with sensor and synchronization information allow the PCM-22 to

calculate the motion profile necessary to meet the user specified

positioning requirements of the application.

Many parameters relating to the PCM-22 application can be changed

using hardware inputs, PCX software or serial commands. Using these

new parameters, the PCM-22 will calculate the new motion

automatically, without stopping, to maintain continuous machine

operation.

If an axis uses a registration sensor, the PCM-22 can automatically

adjust parameters based on sensor information about that axis. It will,

within user-defined limits, automatically compensate for length changes

and detected mechanical inaccuracies.

For example:

If the distance between registration sensor inputs on the Follower axis

indicate that the length is 8.25 inches and not 8.30 inches as entered

using PCX. The PCM-22 will automatically make adjustments to

compensate for the difference in length.

These capabilities allow the PCM-22 to produce one or more cycles of

motion for every individual cycle of motion produced by the Master axis.

The PCM-22 will position the Follower axis to a corresponding position

and velocity relative to the Master axis while it is executing a cycle.

This type of motion profile is commonly used in cutting, sealing, printing

and perforating applications.

2 © EMERSON Motion Control

Page 11

Features

Introduction

The features of the PCM-22 Rotary Knife Controller include:

• Set up with easy-to-use PCX software.

• Works with all FX series drive products and 525 PMC products.

• Allows an FX drive to accurately position and match speed based on

data received from a Master axis.

• Drive setup parameters are stored in the PCM-22 module. This

allows the PCM-22 to be transferred to another FX drive of the same

size without losing any setup parameters.

• Calculates cycle profiles based on user-defined parameters

automatically.

• All parameters are in user-defined units.

• Most parameters can be changed automatically, without stopping.

• Two internal counters for each cycle: product cycle counter and

product batch counter.

• 100 programs (with a maximum of 512 steps total for all programs).

• 16 Master axis and 16 Follower axis motion profile definitions.

• 98 user-assignable I/O functions.

• 64 indexes.

• 2 homes.

• Expands I/O line capacity of FX drive with an additional eight

optically isolated input lines and four optically isolated output lines.

• Interactive cycle diagnostic capabilities.

• Always uses linear ramps for Homes, Indexes, Jogs and Follower

cycles for increased accuracy.

Note: Not all of the features available with the PCM-22 will be used in

every application.

For example:

There are 15 programming functions available with the PCM-22

however, a typical rotary knife program will use only a few of

them.

P/N 400274-01 Revision A7 3

Page 12

PCM-22 Rotary Knife Controller

Terminology

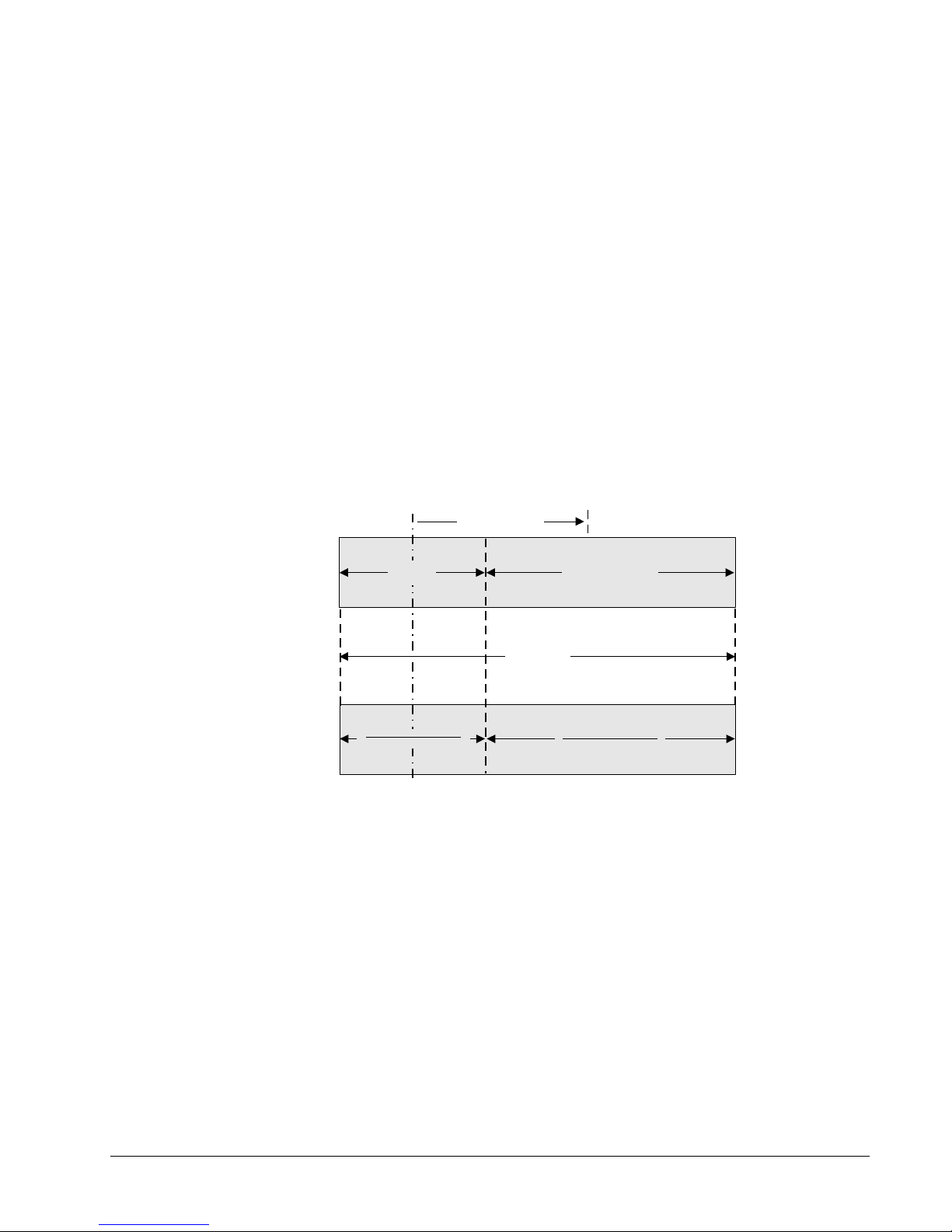

Master Cycle Length

The Master Cycle Length (also called the Master Length) is the

particular distance, in user units, that the Master axis (encoder or

upstream drive) moves during each Master cycle. It is the distance

between two Master Cycle zero positions. See Figures 2 and 3.

If the Master Cycle Defined By Sensor is “Yes”; when the Zero Master

Cycle sensor detects a target on the Master axis, that is the Master zero

position. The distance between two Zero Master Cycle positions is the

Master Cycle Length.

If the Master Cycle Defined By Sensor is “No”; when the first Zero

Master Cycle input is received, that is the initial Master zero position.

This will be the only Zero Master Cycle input required for all Master

cycles following. When the Master axis has moved the user entered

Master Cycle Length, it has moved the distance between two Master zero

positions.

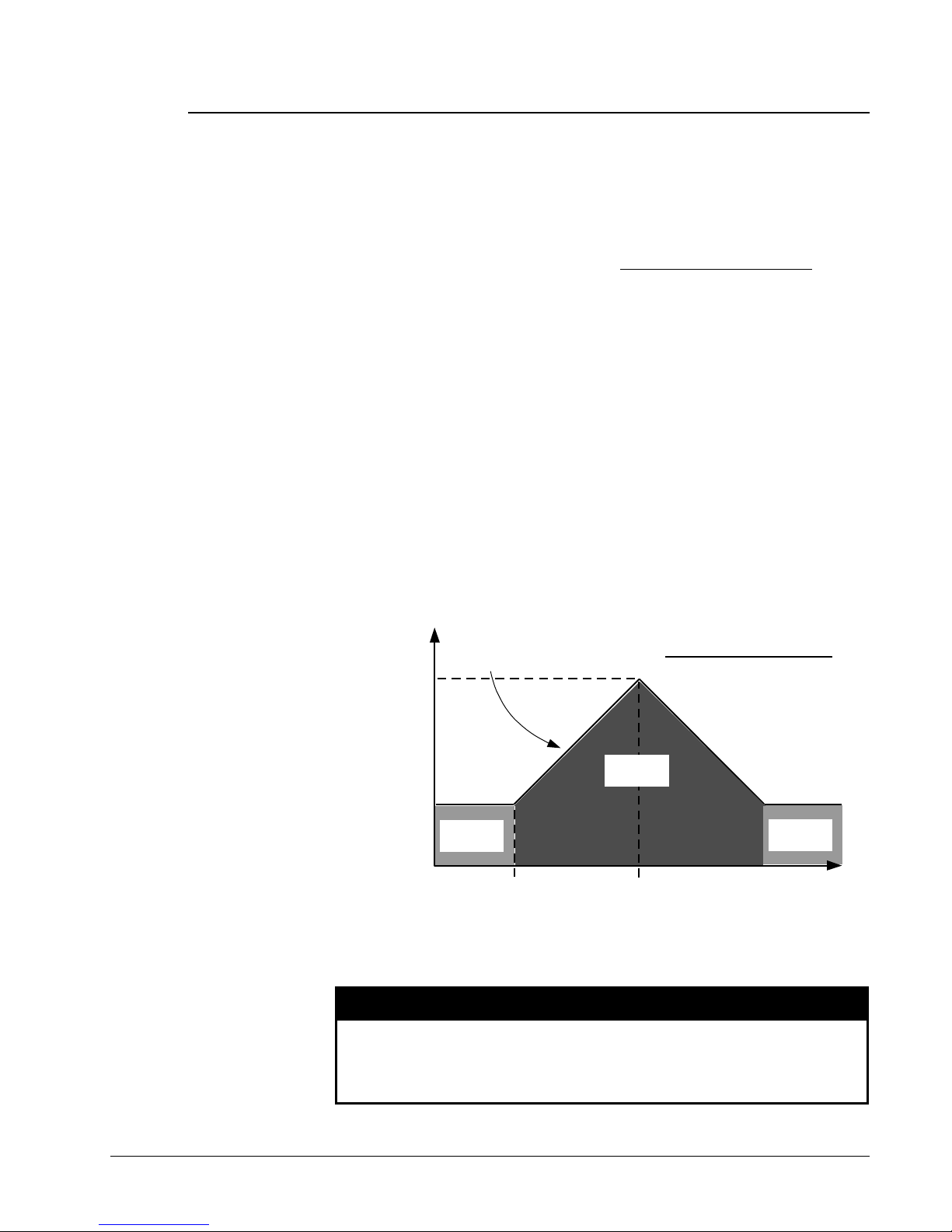

CIRCUMFERENCE OF

ROTARY KNIFE EQUALS

FOLLOWER LENGTH

WORKING SEGMENT

PRODUCT

MOVEMENT

Figure 2 Typical Rotary Knife System Component Locations

Follower Cycle Length

The Follower Cycle Length (also called the Follower Length) is the

distance, in user units, that the Follower axis (PCM-22/FX drive) moves

during each Follower cycle. It is the distance between two Follower cycle

zero positions. See Figures 2 and 3.

If the Follower Cycle Defined By Sensor is “Yes”; when the Zero Follower

Cycle sensor detects a target on the Follower axis, that is the Follower

zero position. The distance between two Zero Follower Cycle positions is

the Follower Cycle Length.

ZERO

MASTER

SENSOR

MASTER PHASE

DISTANCE

PHASE

MASTER

LENGTH

ZERO

FOLLOWER

T

A

O

T

I

R

O

N

CYCLE

POINT

SENSOR

WORKING

OFFSET

4 © EMERSON Motion Control

Page 13

Introduction

FOLLOWER LENGTH

ONE

CYCLE

MASTER LENGTH

ONE TO ONE RELATIONSHIP (IGNORING SCALE) BETWEEN

MASTER LENGTH AND FOLLOWER LENGTH.

Figure 3 Relationship Between the Master Cycle Length and the Follower Cycle Length

If the Follower Cycle Defined By Sensor is “No”; when the Follower cycle

starts, it is at the Follower zero position. When the Follower axis has

moved the user entered Follower Cycle Length, it has moved the distance

between two Follower zero positions. See Homes and the Follower Zero

Position.

Working Segment

This is called Working Segment Width on the Follower Cycles screen. It

is the constant velocity portion of the cycle, usually when the Follower is

in contact with the product. The Follower moves at the Working Ratio

velocity relative to the Master velocity during this distance. See Figures

4, 5, and Cycle Inter-Relationships, Maximum Product Velocity and

Variable Segment.

Note: The Master Length also has a Working Segment. It is not

directly user adjustable, it is computed from the Follower

Cycles Working Segment divided by the Working Ratio. See

Figure 6.

Cycle Point

The Cycle Point is at the center of the Working Segment. It is the

beginning and the end of every cycle. See Operational Timing.

Working Offset

The Working Offset is the distance from the Cycle Point to the Follower

zero position, in the direction of Follower rotation. The Follower zero

position is the same position as the Zero Follower Sensor if used. See

Figures 4, 5, Cycle Inter-Relationships, Homes and the Follower Zero

Position.

P/N 400274-01 Revision A7 5

Page 14

PCM-22 Rotary Knife Controller

CYCLE POINT

WORKING

SEGMENT

WORKING OFFSET

FOLLOWER

ZERO POSITION

VARIABLE SEGMENT

ONE

CYCLE

ONE TO ONE RELATIONSHIP (IGNORING SCALE) BETWEEN

MASTER LENGTH AND FOLLOWER LENGTH.

Figure 4 Follower Terminology Relationships

B

G

A

FOLLOWER

LENGTH

MASTER

LENGTH

DIRECTION

D

FOLLOWER

ROTATION

C

Figure 5 Circular View of Follower Terminology Relationships

Variable Segment

This is a computed parameter. It is the Follower Cycle Length minus the

Working Segment. This is where all cycle adjustments occur. See Figures

4, 5, 6 and Cycle Inter-Relationships.

When designing a PCM-22 system, the peak acceleration and the peak

velocity required during the Variable Segment must be calculated at

the maximum process speed with the shortest Master Length

spacing. This is necessary to determine the required motor size.

See Maximum Product Velocity.

OF

F

A: FOLLOWER CYCLE LENGTH

B: FOLLOWER ZERO POSITION

C: WORKING SEGMENT

D: VARIABLE SEGMENT

E: WORKING OFFSET

E

F: CYCLE POINT

(CENTER OF WORKING SEGMENT)

G: CYCLE DROPOUT POSITION

WARNING!

6 © EMERSON Motion Control

Page 15

Cycle Drop Out Position

The Cycle Drop Out Position is the position exactly opposite the Cycle

Point. While Cycle Drop Out input function is active, the Follower will

complete its current cycle and decelerate to this position and hold there.

See Figure 5, the Cycle Drop Out input function, Cycle

Inter-Relationships, Homes and the Follower Zero Position.

Working Ratio

The Working Ratio defines the relationship between the Follower

velocity and the Master velocity during the Working Segment.

For example:

If the Follower is to move the same speed as the Master during the

Working Segment, then the Working Ratio would be 1.00000. This is

common in many applications.

If the Follower is to move 5 percent faster than the Master velocity

during the Working Segment, then the Working Ratio would be 1.05000.

The range is from 0 to 9.99999.

CYCLE POINT

WORKING OFFSET

FOLLOWER

ZERO POSITION

Introduction

WORKING

SEGMENT

VARIABLE SEGMENT

FOLLOWER

ONE

CYCLE

WORKING SEGMENT

WORKING RATIO

ONE TO ONE RELATIONSHIP (IGNORING SCALE) BETWEEN

MASTER LENGTH AND FOLLOWER LENGTH.

VARIABLE SEGMENT

COMPUTED RATIO

Figure 6 Follower Component Relationships to the Master Cycle Length

MASTER

LENGTH

LENGTH

P/N 400274-01 Revision A7 7

Page 16

PCM-22 Rotary Knife Controller

(

Phase

A repeating pattern is called a cycle. When two repeating patterns are

synchronized there is an inherent position relationship between the two

patterns called phase. See Figure 7.

This means that:

There is a one-to-one positional profile relationship between the

two lengths (ignoring scale) and every point within the two

lengths.

CYCLE POINT

WORKING OFFSET

FOLLOWER

ZERO POSITION

WORKING

SEGMENT

PHASE

Figure 7 Phase Relationship Between Master and Follower Cycle Lengths

The PCM-22 maintains the phase relationship by automatically making

adjustments based on sensor inputs and applying user-defined

parameters. Figures 3, 4 and 6 show a phase relationship of zero.

Average Length

The PCM-22 uses continuous averaging when an axis is defined by

sensor. Continuous averaging provides increased stability by

incorporating every length into the average, starting from the initial

Follower Cycle Length or Initial Master Length. Average lengths are

generated from the following equation for the Master and the Follower

axes:

WORKING SEGMENT

WORKING RATIO

VARIABLE SEGMENT

ONE

CYCLE

VARIABLE SEGMENT

COMPUTED RATIO

FOLLOWER

LENGTH

MASTER

LENGTH

8 © EMERSON Motion Control

Average Length

=

Averaging

Current is equal to the current average length.

New is equal to the new measured length.

Averaging is entered by the user from 1-8.

Current *(Averaging - 1)) + New

Page 17

Introduction

(

For example:

If eight is entered here the new average Follower Length calculated by

the PCM would be:

Average Length

It takes at least three times the averaging number of cycles on an axis to

“learn” a change in length (e.g. if the averaging is set to eight, the PCM

will need to sense at least 24 cycles to completely adjust for the new

length). See Follower Length Correction Limit and Master Length

Correction Limit.

Therefore, the lower the average the faster length errors are corrected.

However, too low a value adversely affect the drive’s ability to quickly

correct for phase errors by causing overcompensation and instability. See

Maximizing Profile Performance and Theory of Operation.

The Average Master Cycle Length and the Average Follower Cycle

Length are the learned lengths which are used only when defined by

registration sensor.

Current *7) + New

=

Averaging

P/N 400274-01 Revision A7 9

Page 18

PCM-22 Rotary Knife Controller

10 © EMERSON Motion Control

Page 19

Theory of Operation

The operation of the PCM-22 is explained in the following sections.

This manual should be read completely before installing the

PCM-22.

General Running

The Master axis position is monitored by the PCM-22 using

synchronization signals. These signals, which come from an incremental

encoder driven by the Master axis or an upstream FX drive, provide the

positioning data to the PCM-22.

In order to maintain the proper phase relationship between the two axes,

the PCM-22 monitors the Zero Master Cycle and Zero Follower Cycle

sensors of both the Master and the Follower axes.

If the Follower axis does not use a sensor then the PCM-22 will use the

Follower Cycle Length parameter entered and only correct for Following

Error. Following Error is the difference between the motor’s

commanded position and it' actual position. No automatic length or

phase adjustments will be made for the Follower axis.

If the Master axis does not use a sensor, no corrections to the Follower

axis’ motion profile will be made for product differences or encoder

slippage.

If the Follower axis is not in phase synchronization with the Master axis,

the PCM-22 computes a correction which is applied in the next Follower

cycle. The Follower axis will speed up or slow down depending on what is

required for the length or phase correction. If both the Follower and the

Master axes are in phase synchronization, no correction is made.

The portion of the motion profile called the Variable Segment is where

all user changes or profile adjustments occur for each individual Master

Length. The remainder of the motion profile is called the Working

Segment. The Working Ratio will always be maintained during the

Working Segment.

Any changes made before the Cycle Point will take place during the next

cycle. If parameters are entered that cannot be accommodated while in

cycle, the Cycle Limit Reached (output function 41), if assigned, will be

activated until the cycle can be executed as defined. See Operational

Timing.

Product (master) positions are continuously tracked whether a Follower

cycle is executing or not. At power-up the PCM-22 is executing the

Master Cycle zero (0) definition. See the MF serial command.

P/N 400274-01 Revision A7 11

Page 20

PCM-22 Rotary Knife Controller

Master Cycle Defined By Sensor Mode

The PCM-22 handles the Master position information differently

depending on whether a product registration (master) sensor is used or

not. Each of the two ways of handling the Master position information

have different applications but operate similarly in the respect that

Mater position information is continuously tracked whether a Follower

Cycle is executing or not.

When a Zero Master Cycle sensor input occurs, the distance traveled

from the last product position will be checked to see if it is between the

Master Length Upper Limit and the Master Length Lower Limit. This

measured distance is factored into the Average Master Length starting

from the user entered Master Cycle Length. Any necessary corrections

will be made to the next Follower axis motion profile. See Average

Length, Master Cycles screen and Operational Timing.

FX AMPLIFIER WITH PCM-22

FOLLOWER

SENSOR

FOLLOWER

AXIS

MASTER AXIS (SYNC ENCODER)

REGISTRATION

MARKS

MASTER SENSOR

ROTARY KNIFE

Figure 8 PCM-22 Rotary Knife System Example

Master Cycle Not Defined By Sensor Mode

If the Master is Not Defined By Sensor, the user entered Master Cycle

Length will be used by the PCM-22. No corrections to the Follower axis’

motion profile will be made for product or encoder slippage in this mode.

12 © EMERSON Motion Control

Page 21

Theory of Operation

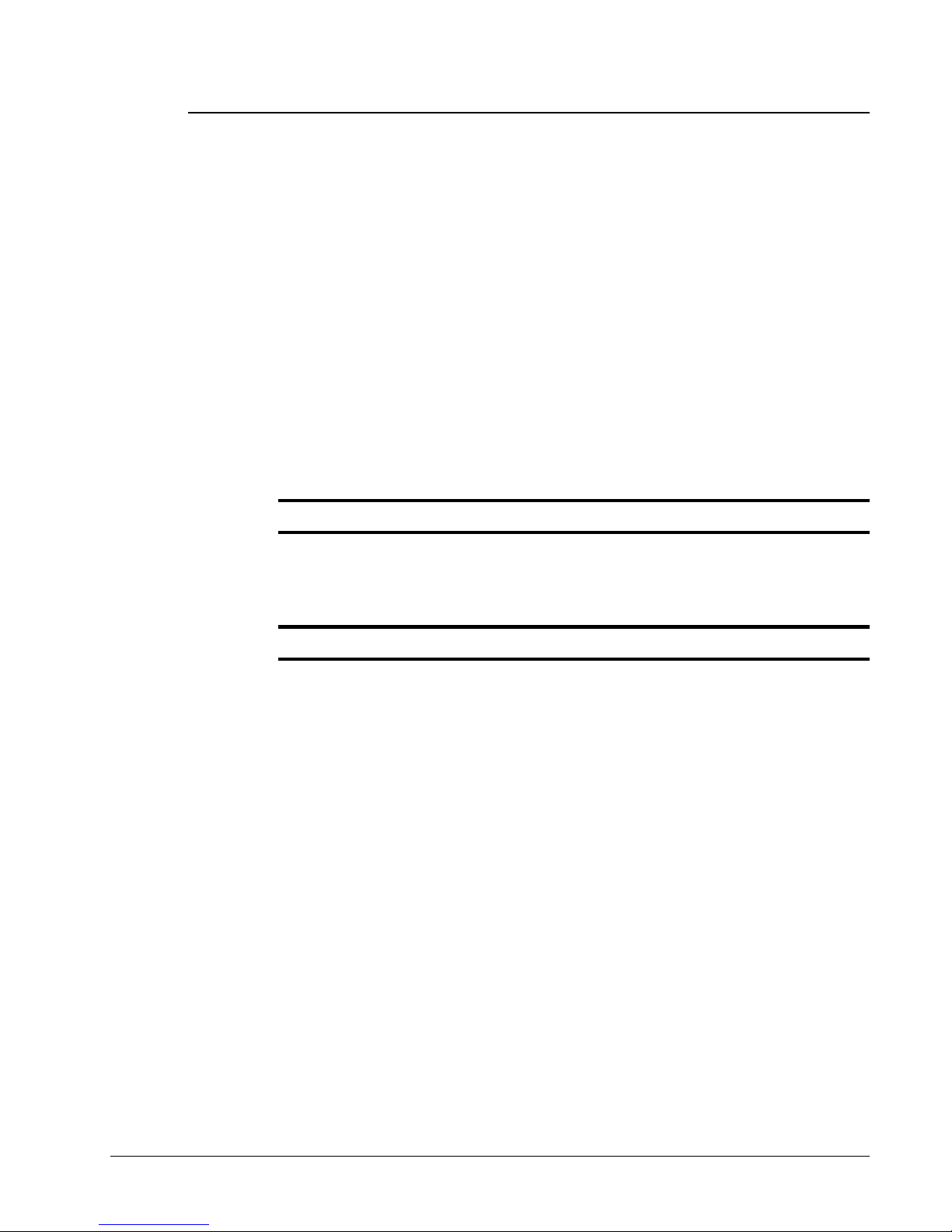

Resetting the Master Cycle Processing

Resetting the Master Cycle Processing on the PCM-22 involves reloading

the user-defined Master Cycle parameters. This overwrites all learned

and user-defined Master information currently in use. When the Master

processing is reset, the Master Cycle Defined output function is

deactivated until the Master Cycle is redefined. Resetting the Master

Cycle Processing usually happens automatically but may be induced. See

Automatically Resetting the Master Processing and Manually Resetting

the Master Processing.

Note: Resetting the Master Cycle Processing will only occur when a

Follower Cycle is not executing and the Follower axis is not

moving.

How the Master Cycle is Defined

After Resetting the Master Cycle Processing the Master cycle is

undefined and must be redefined before a Follower cycle may begin.

Master Cycle Defined By Sensor Mode

When the first Zero Master Cycle sensor input is received, the product is

at the initial Master zero position. When the second Zero Master Cycle

sensor input is received, the Master Cycle Length will be defined and the

Master Cycle Defined output function will activate.

Master Cycle Not Defined By Sensor Mode

When the first Zero Master Cycle input is received, the product is at the

initial Master zero position. The Master Cycle Length will be defined at

this point and the Master Cycle Defined output function will activate.

This will be the only Zero Master Cycle sensor input required for all

master cycles following.

Note: For situations where there is no need for any master axis

alignment, you can wire the Follower Cycle Defined output to

the Zero Master Cycle input to define the Master Cycle position

automatically.

Automatically Resetting the Master Processing

• If the PCM-22 has been powered-up but has not yet executed a

Follower cycle, it is executing the Master Cycle 0 data definition. The

first time after power-up the Y Execute Follower Cycle program step

is executed in a PCX program, the Master processing will be reset.

See the MF serial command.

• When the Y Execute Follower Cycle program step is executed in a

PCX program and the Master Cycle definition specified in the

Follower Cycle screen, is not the same as the currently executing

Master Cycle definition then the Master processing will be reset. See

the CI2 serial command.

P/N 400274-01 Revision A7 13

Page 22

PCM-22 Rotary Knife Controller

Manually Resetting the Master Processing

• Setting the Force Reset Master Processing bit using the FF serial

command will automatically cause a Reset of the Master processing

every time a Y Execute Follower Cycle program step is executed in a

PCX program. See Starting A Follower Cycle.

Manually Resetting the Master Cycle Processing is particularly useful for

troubleshooting product handling (slippage or registration) issues.

The PCM-22 provides two ways for resetting the Master processing

manually by:

• Writing the MF serial command.

• Reset Master input function 115.

These methods allow the user to reset the Master processing as the

application requires. The result is the same as selecting a different

Master Cycle definition for the same Follower cycle on demand.

14 © EMERSON Motion Control

Page 23

Starting A Follower Cycle

An initial Home or Index is required to move the Follower axis to the

Follower zero position before the Y Execute Follower Cycle statement is

executed. This will determine, using the Working Offset, the position of

the Cycle Point on the product. When the Y Execute Follower Cycle

statement is executed, the Follower Cycle Defined output function will

activate and if the Master cycle is defined, the Follower cycle will start.

When the PCM-22 axis starts moving from the Follower zero position,

Home position or the Cycle Drop Out Position, a linear acceleration is

used to get to the correct velocity at the beginning of the Working

Segment. The PCM-22 checks the first product’s (Cycle Point) position to

see if it can reach the correct velocity (Working Ratio * Master velocity)

in the distance it would travel from the Follower zero position to the

beginning of the first product’s Working Segment. If this is not possible

(i.e., the start-up distance is longer than the first product position), the

PCM-22 will check the second product position. If it can not make the

second product position, it will check the third and so on, until the

PCM-22 finds a product position that will allow the Follower axis to

reach the product’s Working Ratio velocity at the beginning of its

Working Segment. The Follower axis is not moving while it is

determining which product position to try for. See Figure 9 and Master

Phase Distance.

Theory of Operation

DIRECTION OF FOLLOWER ROTATION

ZERO

MASTER

SENSOR

MASTER PHASE DISTANCE

PRODUCT MOVEMENT

Figure 9 PCM-22 Starting Cycle Ramp

WS

ZERO FOLLOWER

SENSOR

WORKING

OFFSET

When the Follower has passed the first Cycle Point after the Master has

moved the Master Phase Distance, the In Phase output function will

activate.

In Master Cycle Defined By Sensor mode, it is possible for the start-up

distance to be greater than the Master Phase Distance. If this is the case

it will generate product positions to target before the sensor using the

Average Master Length. Please note that the entered Master Cycle

Length is only equal to the Average Master Length just after the Master

processing is reset.

The Follower will start executing the computed starting ramp distance to

the targeted product position. Any products that pass the Cycle Point

before the Follower has completed the initial acceleration will be ignored.

See Figure 10, Average Length, and Resetting the Master Processing.

P/N 400274-01 Revision A7 15

Page 24

PCM-22 Rotary Knife Controller

DIRECTION

ZERO MASTER

SENSOR

CAN

MAKE

IT

AVERAGE

MASTER

LENGTH

Figure 10 When the Follower Start-up Ramp Exceeds the Master Sensor Distance

CAN NOT

MAKE IT

PRODUCT MOVEMENT

OF ROTATION

ZERO FOLLOWER

WORKING

WS

OFFSET

SENSOR

Homes and the Follower Zero Position

In order to obtain the highest accuracy, certain types of homes are

recommended for use with the PCM-22: Resolver Offset and

Feed On/Off. Make sure the “On” move is in the direction of travel and

the “Off” move is much slower in the opposite direction. The goal of this

is to have the Follower’s starting position be the same as the Follower

zero position when the cycle is running. A reducer’s backlash is minimal

compared to an inaccurate initial reference position during the first

several cycles.

Ensuring a correct starting position goes far in eliminating length and

phase variations when the Follower is executing its first several cycles

and learning its length the fastest.

It is not recommended, but it is possible, once the home is completed, to

move to a different location which will be the Follower zero position. It is

from this point that the Follower cycle will start. If this is not the actual

Follower zero position and the Follower cycle is defined by sensor, the

PCM-22 will perceive this as an error and correct for it.

Indexes and the Follower Zero Position

An index may be used instead of a home to move the Follower axis to

the Follower zero reference position. It behaves the same as a home but

there are more options for positioning the Follower axis before actually

starting the cycle.

For example:

• A Registration index.

• A Feed to Sensor index.

• A home followed by an Incremental index.

The index must not be compounded and must finish before the Follower

cycle begins.

Ensuring a correct starting position goes far in eliminating length and

phase variations when the Follower is executing its first several cycles

and learning its length the fastest.

16 © EMERSON Motion Control

Page 25

Cycle Inter-Relationships

Every cycle has certain relationships pertaining to the Working Segment.

These relationships must be maintained for the PCM-22 to execute the

motion profile required by the Follower axis for each product on the

Master axis. Please refer to the Terminology section for clarification of

terms.

The following relationships are considered the rules for cycle

operation.

1) The Working Segment must be less than the Follower Cycle Length.

2) The Working Segment divided by the Working Ratio must be less

than Master Length Lower Limit.

3) The Working Segment must be less than the Upper Working Segment

Limit.

4) The Working Segment must be greater than the Lower Working

Segment Limit.

5) The Working Segment must not overlap the Follower Zero Position.

A) The Working Offset must be less than the Follower Cycle Length

minus one half of the Working Segment.

B) The Working Offset must be greater than one half of the

Working Segment.

This means that the follower sensor must not be inside the Working

Segment.

The above Cycle Inter-Relationship cross-checks are performed against

the following cycle parameters every time a cycle is started and every

time one of these parameters is changed while the Follower is in cycle:

• Working Segment.

• Working Offset.

• Follower Cycle Length.

• Master Length Lower Limit.

If the profile is determined invalid due to one of these cross-checks when

the cycle is started, the cycle will exit and Cycle Error (output

function 66) will be activated. The Follower Cycle will not start and the

CQ serial command will have flags set indicating where the problem is.

If the profile is determined invalid due to one of these cross-checks while

the cycle is running due to a user change, the requested change will be

ignored. The CQ serial command will have flags set indicating where the

problem is and Cycle Limit (output function 41) will be activated.

If the Working Segment flag is set within the CQ serial command

response then additional flags will be set indicating where the conflict is:

Working Offset, Follower Cycle Length or Master Cycle Length.

Theory of Operation

P/N 400274-01 Revision A7 17

Page 26

PCM-22 Rotary Knife Controller

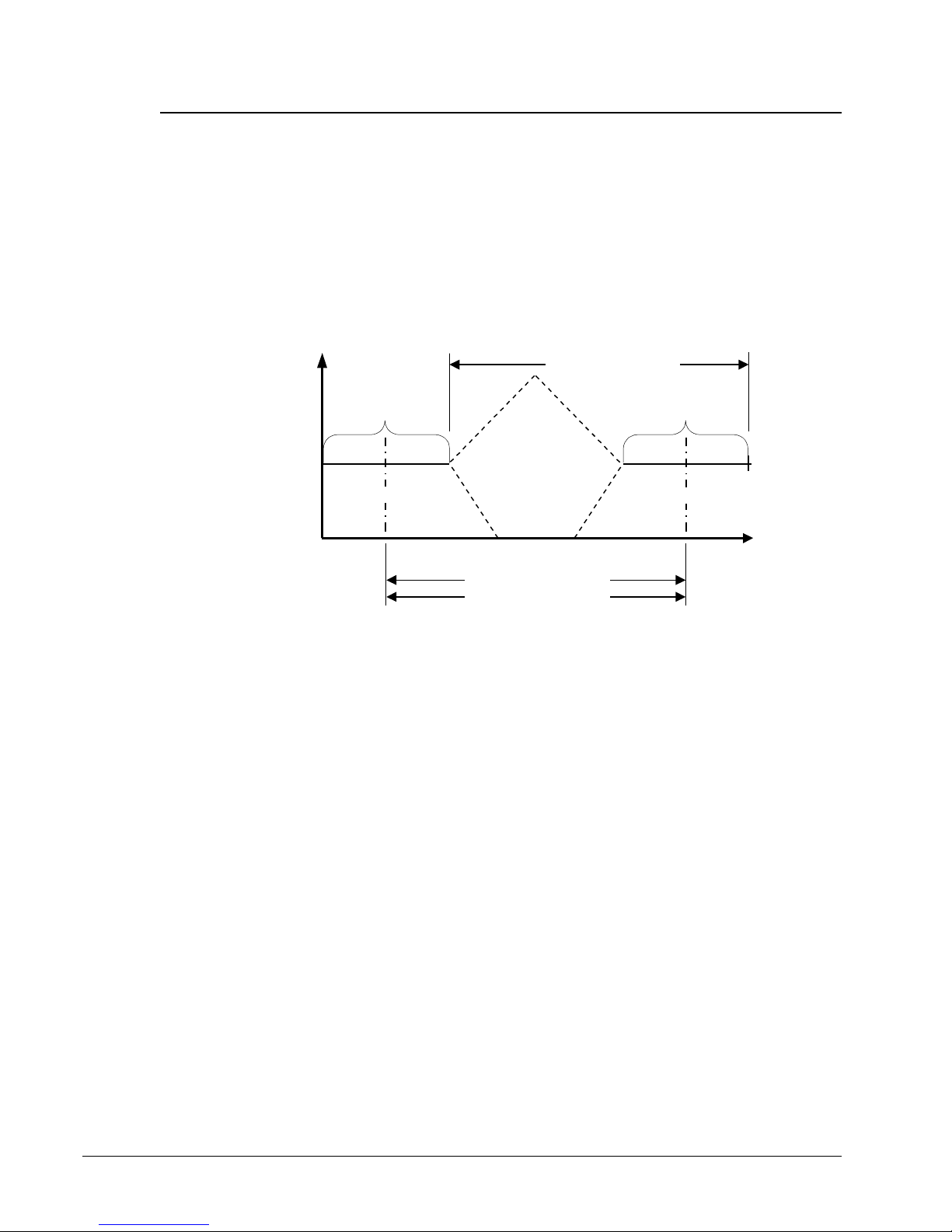

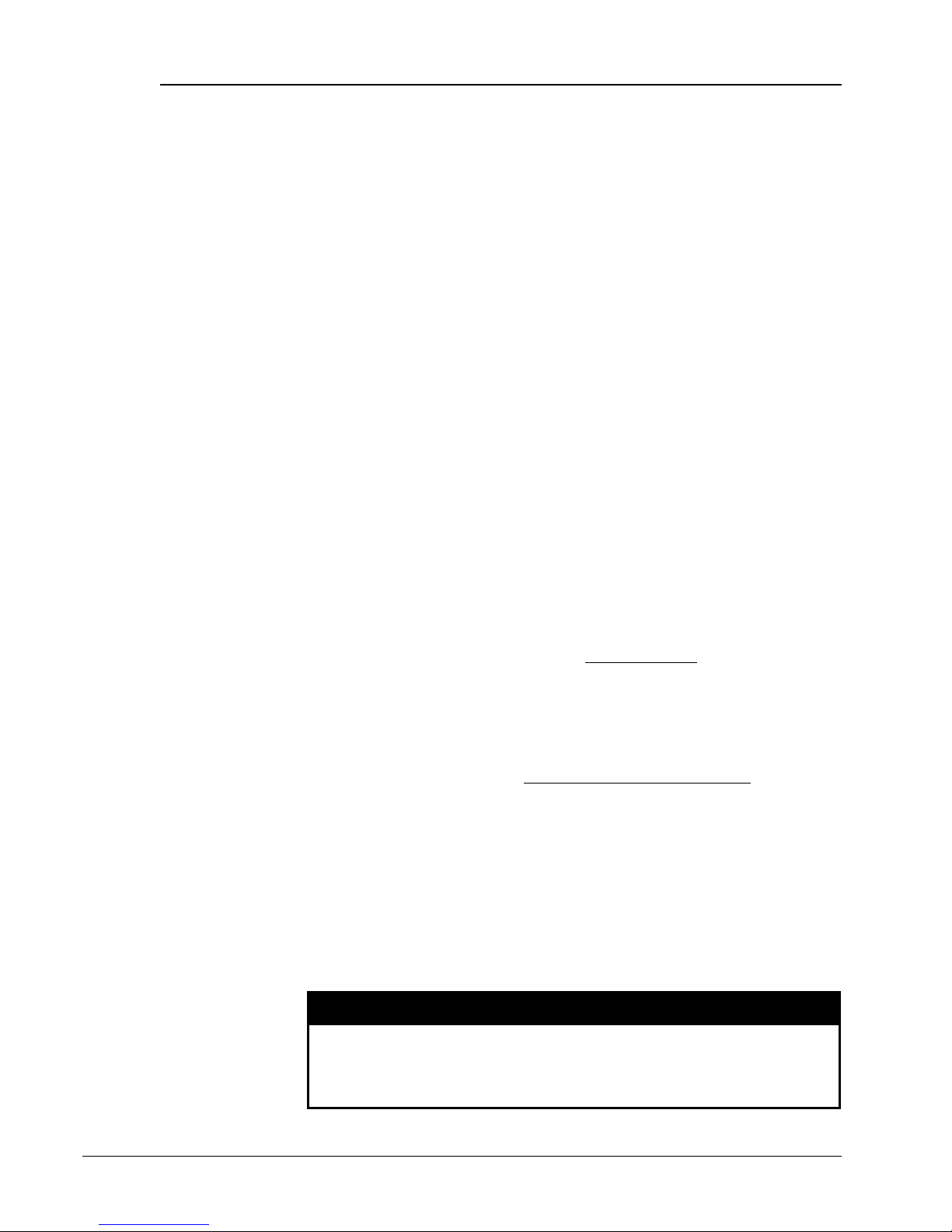

Operational Timing

FOLLOWER VELOCITY

For every cycle, there is a one-to-one positional profile

relationship (ignoring scale) between the Master cycle and the

Follower cycle.

The PCM-22 may adjust the motion profile because of:

• User requested changes using I/O or serial commands.

• Learned length and/or phase variation changes if an axis is defined

by sensor.

MACHINE CYCLE

WORKING SEGMENTWORKING SEGMENT

WORKING

RATIO

VELOCITY

ZERO

VARIABLE SEGMENT

CALCULATED BY

CYCLE POINT

THE PCM

CYCLE POINT

MASTER

POSITION

MASTER CYCLE

FOLLOWER CYCLE

Figure 11 PCM-22 Motion Profile

In both cases, all motion profile changes (user requested changes,

learned length and/or phase variations) occurring before the Cycle Point

will be applied when the PCM-22 calculates the next Working Segment

location.

When the Follower reaches the end of the current Working Segment, the

new motion profile is used to move to the next Working Segment. See

Figure 11. This new motion profile is the typical machine cycle which

starts when the Follower axis leaves the Working Segment and gets clear

of the product (e.g. the rotary knife comes out of the product).

18 © EMERSON Motion Control

Page 27

Maximum Master Velocity

For every set of Master and Follower cycle parameters, the user must

limit the maximum velocity of the Master so that the maximum velocity

of the Follower is not exceeded. This is critical for product lengths

shorter than the Follower Cycle Length.

Theory of Operation

Maximum Master Velocity

=

FVS / MVS *2 - WR

( )

MAV

Where:

MAV =Maximum Allowable Velocity of the Follower from the Limits

screen.

WR = Working Ratio.

FVS = Follower Variable Segment =

Follower Cycle Length - Working Segment.

MVS = Master Variable Segment =

Master Cycle Length - (Working Segment / Working Ratio).

Note: The above equation reflects ideal conditions and the user must

reduce the calculated Maximum Master Velocity due to the

effects of inertia, friction, encoder slippage, sensor, mechanical

issues to allow enough velocity headroom for any motion

corrections. Usually, this velocity reduction needs to be

approximately 20 percent.

V

-

V

Peak

V

Peak

T

Peak

Follower Acceleration =

Working Ratio

-

T

Working Segment End

Velocity

VARIABLE

SEGMENT

V

Working Ratio

WORKING

SEGMENT

WORKING

SEGMENT

0

T

Working Segment End

Figure 12 Variable Segment Acceleration

At the Maximum Master Velocity, VPeak = MAV.

T

Peak

Time

WARNING!

When sizing a system, keep in mind the velocity and acceleration of

the Follower during the variable segment for the shortest product

length because the Follower acceleration and deceleration rates are

not controlled by PCX Limits.

P/N 400274-01 Revision A7 19

Page 28

PCM-22 Rotary Knife Controller

Sensors

Selection

In a typical rotary knife system, the rotary knife will be designated as

the Follower axis and the product or material conveyor as the Master

axis. A sensor on the knife (or Follower axis) is strongly recommended

since the exact position of the blade typically changes due to mechanical

imperfections.

The Zero Master Cycle and Zero Follower Cycle, input functions

45 and 46 respectively, must be assigned to separate FX drive high

speed inputs 1 and 2.

The PCM-22 reacts to learned sensor information by adjusting the

motion of the Follower to match the Master axis. If the sensor

information is inaccurate or not consistent, it will be reflected in the

accuracy of the Follower positioning.

The general guidelines when selecting a sensor are related to machine

issues such as the type of material being detected and the rate of input

occurrences.

The sensor type is dependent on what the sensor detects, called the

target. The surface area of the target should be as large as the sensing

face of the sensor to minimize hysteresis effects as defined by the sensor

type. This determines how consistently the sensor can be activated by

the target.

For a target larger than the sensor moving at a constant velocity, the

sensor should be selected be selected so the following equation is true:

Response Time

As the target becomes smaller approaching the size of the sensors’

detection field, at a constant velocity, the sensor should be selected be

selected so the following equation is true:

Response Time

The response time of a sensor is defined as the elapsed time from when

the target is detected until the signal appears on the sensor output. The

response time of the sensor will have a direct impact on the system

performance and accuracy. The response time of the sensor is part of the

switching frequency of the sensor.

The switching frequency is the minimum time from when a sensor is

triggered until it can be triggered again. Which is the time between

successive sensor triggers. Both of these parameters should be fast

enough for the application.

Width of target - Detection field size

≤

Width of target

≤

Velocity of target

Velocity of target

WARNING!

If the sensor switching frequency or response time is too slow for

the application, poor system performance will result and can cause

the Follower axis’ position to appear to shift phase as the system

speed is increased (i.e. the Cycle Point is in the wrong position).

20 © EMERSON Motion Control

Page 29

For example:

The target is moving at 48 inches/second and is 0.1 inches wide. The

detection field of the sensor is 0.062 inches wide. The response time of

the sensor would need to be faster than 1264 Hz.

Sensors selected, should have a directed detection field such as a D.C.

shielded inductive proximity sensor or a focused contrast/registration

photo sensor.

Note: Electrostatic Discharge (ESD) sensors, such as spark gap

sensors, should never be used with FX products because the

intense electrical noise they generate can affect the electronics

in the FX amplifier.

Refer to manufacturer’s information concerning sensor selection,

application and installation.

Sensors: When, Where and Why

Master Sensor

A Master sensor should be used for any of the following situations:

• When the products are randomly spaced and an average product

length is desired.

• When we need to stay in phase with registration marks or products

outside of a Follower cycle.

The Master sensor, ideally, should be positioned between one and two

Average Master Lengths away from the Cycle Point to minimize the

effects of product slippage and to allow the PCM-22 to correct for any

phase variation on that product. See Operational Timing.

Follower Sensor

A Follower sensor must be used if the Follower Cycle Length is not an

exact number of motor steps (i.e., no fractions of steps). If the Follower

Length is not an exact number of steps, the Follower can drift out of

position due to rounding. The precision of the data entered in the PCX

software is the most common cause of drifting.

The recommended solution is to use a Follower sensor to let the PCM-22

determine the real Follower Length and allow it to compensate for any

discrepancies.

Stable sensor characteristics are especially important for the Follower

axis because the Follower sensor is in the Variable Segment which is

always accelerating or decelerating.

The Follower sensor should be positioned so that it does not interfere

with machine operation and so that the acceleration/deceleration is

minimal. See Maintaining Phase Issues. Ideally, the sensor should be

placed so it would be activated at areas of the Variable Segment where

the change in velocity is low (i.e., the beginning or middle of the Variable

Segment).

Theory of Operation

P/N 400274-01 Revision A7 21

Note: Typically, if the Master cycle is defined by sensor then the

Follower should also be defined by sensor for the greatest

accuracy.

Page 30

PCM-22 Rotary Knife Controller

For example:

The Follower axis is moving at a specific acceleration and its sensor has

a response time (R.T.) of 1000 Hz (0.001 seconds). The acceleration and

response time effects on sensor accuracy are shown in the following

table.

Working

Segment

Velocity

(W.S.V.)

10 in/sec 0 in/sec

10 in/sec 10 in/sec

10 in/sec 20 in/sec

Follower

Acceleration

(F.A.)

See Figure 12

Time

Factor

(T.F.)

= W.S.V.

F.A.

2

2

2

0 sec 0.010 in

1 sec 0.020 in

2 sec 0.030 in

Sensor Accuracy

W.S.V.

= * T.F. + 1

( )

R.T.

22 © EMERSON Motion Control

Page 31

Installation

Guidelines

Attaching the PCM-22 Module

PCM modules attach to the front of any FX amplifier with two locking

arms. All electrical connections (except I/O) are made using the 48 pin

connector.

All PCM modules are equipped with eight input lines and four output

lines, doubling the I/O capability of the standard FX drive. All inputs

and outputs are optically isolated for +10.5 to +30 VDC operation. Each

input and output line has two screw terminals associated with it to

provide for either current sinking or current sourcing operation.

The first eight pairs of terminals (numbered 13 - 20) are inputs and the

last four pairs of terminals (numbered 21 - 24) are outputs. The outputs

are capable of sinking or sourcing 200 mA. You must limit the output

current to 200 mA per output or less.

Installation Guidelines

I/O Wiring

Input Wiring

Inputs require an external voltage source for operation. This voltage

source must be in the range of 10.5 to 30 VDC. The negative (-) lead of

the external power supply must be connected to the enclosure or safety

ground. See Figure 13.

Output Wiring

Outputs are similar to inputs in that they can be connected to either

sinking or sourcing type loads. Outputs require an external isolated

supply voltage, usually the same supply as the inputs. Each output can

sink or source 0.2 amps DC. The negative (-) lead of the external power

supply must be connected to enclosure or safety ground. See Figure 13.

P/N 400274-01 Revision A7 23

Page 32

PCM-22 Rotary Knife Controller

EXAMPLE A: SOURCING INPUT

EXTERNAL

SUPPLY(10.5 to

POWER

30)VDC

+

INPUT

SWITCH

-

EXAMPLE B: SINKING INPUT

EXTERNAL

SUPPLY(10.5 to

POWER

30)VDC

+

-

INPUT

SWITCH

EXAMPLE A: SOURCING OUTPUT

EXTERNAL

SUPPLY(10.5 to

POWER

30)VDC

+

LOA

D

-

EXAMPLE B: SINKING OUTPUT

EXTERNAL

SUPPLY(10.5 to

POWER

30)VDC

EXAMPLE C: SINKING OUTPUT WITH INDUCTIVE LOAD

EXTERNAL

SUPPLY(10.5 to

POWER

30)VDC

LOA

+

-

+

-

D

DIODE

SUPPRESSOR

Figure 13 Installing the PCM Module

INPUTS

OUTPUTS

PCM MODULE

INPUTS/OUTPUTS

13

14

15

16

17

18

19

20

21

22

23

24

WARNING!

48 PIN CONNECTOR

FX DRIVE WITH AN

PCM APPLICATION MODULE

Do not install or remove the PCM module when there is power

applied to the FX drive or 525 PMC because damage will occur to

one or both.

24 © EMERSON Motion Control

Page 33

PCM-22

Software Setup

This manual should be read completely before installing the

PCM-22. It provides the background information needed to setup and

configure the PCM-22/FX amplifier combination using PCX 7.x software.

Programming the PCM-22

The first step in programming your FX drive with a PCM-22 is to

configure the drive using the 5 (7 for 525 PMC) menu options in the

Drive Configuration screen. The Drive Parameters, Limits, Inputs and

Outputs screens are explained in the Software Setup and Operation

section of the 230V FX Drives Setup and Programming Operator’s

Manual, 460V FX Drives Setup and Programming Operator’s Manual or

525 Programmable Motion Controller Installation and Operation manual

as appropriate.

The Master Axis screen is where you identify the signal source of the

Master axis and set up synchronization parameters.

The next step is to define the motion parameters in the Define Motion

screen. The first three menu selections; Jog, Homes and Indexes, are

explained in the Software Setup and Operation section of the 230V/460V

FX Drives Setup and Programming Operator’s Manual or 525

Programmable Motion Controller Installation and Operation manual as

appropriate. The next two selections, Master Cycles and Follower Cycles,

define the relationship between the Master and Follower axes.

The last step is to create a program (or programs) that use the

Y Execute Follower Cycle command with other programming functions

as logical steps within a program.

The shaded boxes in the PCX menu hierarchy charts, in Figures 14 and

15, show the menus in the that are added or changed in PCX 7 software

when a PCM-22 module is employed with an FX drive or 525 PMC.

P/N 400274-01 Revision A7 25

Page 34

PCM-22 Rotary Knife Controller

Drive

Setup

Define

Motion

Programming

Jog

Homes

Indexes

Master

Cycles

Follower

Cycles

Suspend

Figure 14 PCX Hierarchy Diagram #1

Initialize

Memory

Operations

Drive

Configuration

Drive

Parameters

Master

Axis

Limits

Input

Functions

Output

Functions

Entire

Memory

Program

Data

Index Data

Input/Output

Data

Gain Setup

Analog

Setup

Limit Setup

Cycle/Infeed

Data

Figure 15 PCX Hierarchy Diagram #2

26 © EMERSON Motion Control

Page 35

PCM-22 Software Setup

The PCX features necessary to run a Cycle Profile are listed below in the

order in which they should be addressed. Each feature listed must be set

up before you use them in a Cycle Profile application.

Individual setup information for each feature is covered on the following

pages and in the 230V/460V FX Drives Setup and Programming

Operator’s Manual or 525 Programmable Motion Controller Installation

and Operation manual as appropriate.

1. Drive Parameters:

The first step in setting up the PCM-22 is to define the parameters in

the Drive Parameters screen. A description of the parameters in this

screen can be found in the Software Setup and Operation section of

the 230V/460V FX Drives Setup and Programming Operator’s

Manual or 525 Programmable Motion Controller Installation and

Operation manual as appropriate. The Drive Parameters screen can

be found by selecting Drive Setup, Drive Configuration then Drive

Parameters from the PCX menu.

2. Master Axis (Signal Source):

Specify the signal source of the Master axis. In this screen, only the

following parameters are used by the PCM-22 when running Cycle

Profiles:

Signal Source

Encoder Count Per Revolution

User Distance Per Revolution

Signal Polarity

Signal Interpretation

Sync Output Signal from

In addition to running Cycle Profiles, the PCM-22 also has the ability

to run synchronized Indexes and Homes. This is what the remaining

parameters on this screen are used for. The Master Axis screen is

found by selecting Drive Setup, Drive Configuration then Master

Axis from the PCX menu.

3. Master Cycle:

Define the parameters of the Master Cycle screen. The Master Cycles

screen is found by selecting Drive Setup, Define Motion then Master

Cycles from the PCX menu.

4. Follower Cycle:

Define the parameters of the Follower Cycle screen. The Follower

Cycles screen is found by selecting Drive Setup, Define Motion then

Follower Cycles from the PCX menu.

5. Input and Output lines:

Assign the input and output functions to the I/O lines on the FX

amplifier and the PCM-22 module. There are several input and

output functions used specifically for Cycle Profiles. The Input and

Output Function screens can be found by selecting Drive Setup,

Drive Configuration then either Input Functions or Output

Functions from the PCX menu. For a list of basic I/O functions see

Input and Output functions in your FX drive or 525 PMC manual.

See Typical Input Assignments and Recommended Output

Assignments.

P/N 400274-01 Revision A7 27

Page 36

PCM-22 Rotary Knife Controller

6. Homes and Indexes:

Determine the type of Home or Index reference move and other

motion operations as needed. See Homes and the Follower Zero

Position and Homes and the Follower Zero Position.. The Homes and

Indexes screens are found by selecting Drive Setup then Define

Motion from the PCX menu.

7. Cycle Profile Programs:

Create a program using the “Y Execute Cycle Profile” programming

function. The program typically contains motion statements before

and after the Y Execute Follower Cycle statement.

28 © EMERSON Motion Control

Page 37

Master Axis

Description

With synchronized moves, an external Master axis becomes the time

base for the motion of the Follower axis (your FX drive equipped with a

PCM-22). Operation is determined by the relationship of the Master axis

signal source (encoder or upstream drive) to the Follower axis motor.

The Master axis is typically an EMERSON SCS series encoder, upstream

drive, EMERSON Master Frequency Generator or a customer supplied

encoder of any line density yielding the appropriate steps per revolution.

In this screen, only the following parameters are used by the PCM-22

when running cycle profiles:

In addition to running Cycle Profiles, the PCM-22 also has the ability to

run synchronized Homes, Indexes and Jogs. The remaining parameters

on this screen are listed below and used for these synchronized

operations.

PCM-22 Software Setup

Signal Source

Encoder Count Per Revolution

User Distance Per Revolution

Signal Polarity

Signal Interpretation

Sync Output Signal from

Master Maximum Velocity

Sync Velocity User Units

Sync Velocity Scaling

External Mode Override.

Encoder selection should be based-on the accuracy desired for the

application.

For example:

If your encoder delivers 12,000 counts per revolution and the distance

per revolution is 12.000 inches, then the distance per count is 0.001

inches.

For highest system performance and accuracy, the number of resolver

steps per Follower Cycle Length should ideally be no more than two

times the number of synchronization steps for the shortest Master Cycle

Length.

For example:

If the Follower Cycle Length is 20,480 resolver steps long, then the

shortest a Master Cycle Length should be is 10,240 synchronization

steps.

Note: If a high mismatch between Follower and Master steps exist, it

will cause poor system performance and may cause machine

damage.

WARNING!

P/N 400274-01 Revision A7 29

Page 38

PCM-22 Rotary Knife Controller

WARNING!

The maximum Master axis frequency into the PCM-22 module must

not exceed 210 kHz (210,000 steps/second).

30 © EMERSON Motion Control

Page 39

Master Axis Setup

To set up a relationship between the Master axis and the Follower axis,

select the Master Axis option from the Drive Configuration screen.

Signal Source

Select the origin of the synchronization (also referred to as “sync”) signal

(Drive or Encoder) used for Master axis positional information. When

Drive is selected, the Follower axis (PCM-22) is receiving its

synchronization source from a FX/DX upstream drive, the Counts Per

Revolution becomes 4096 counts per revolution.

If you select Drive for your signal source, the Encoder Counts Per

Revolution parameter will not appear (shown below).

PCM-22 Software Setup

Figure 16 Master Axis Screen for an Upstream Drive

If your Master axis is an Encoder, there will be up to seven parameters

that you need to set up that pertain to the signal source (see Master Axis

screen below).

P/N 400274-01 Revision A7 31

Page 40

PCM-22 Rotary Knife Controller

Figure 17 Master Axis Screen for an Encoder

32 © EMERSON Motion Control

Page 41

PCM-22 Software Setup

Encoder Counts Per Revolution

This parameter is not available if the Signal Source is set to Drive.

The Encoder Counts Per Revolution parameter sets the number of

encoder steps per revolution of the synchronization encoder. The default

value is 4000 steps per revolution. The minimum value is 1 and

maximum value is 65,535.

User Distance Per Revolution

The default value for this parameter is 4000 "user units" per revolution

of the sync source. See definition of user units in the PCX section of the

230V and 460V FX Drives Setup and Programming Operator’s Manual

or 525 Programmable Motion Controller Installation and Operation

manual as appropriate. The minimum value is 1 and maximum value is

65,535.

Signal Polarity

This feature defines the direction of the synchronization source that

corresponds to a positive Master axis position change. Clockwise is

indicated with a (+); counterclockwise is indicated with a (-). CW and

CCW motion of the Master axis is defined while facing the encoder shaft.

WARNING!

The Signal Source must count upwards for cycle operation. If the

count is going the wrong way, change the signal polarity in PCX to

correct this.

Figure 18 CW Encoder Rotation.

Signal Interpretation

The signal interpretation feature allows you to define how the Follower

reacts to clockwise and counterclockwise motion of the synchronization

source.

P/N 400274-01 Revision A7 33

WARNING!

The COMP+ mode must be used when running Follower Cycles on

the PCM-22.

Page 42

PCM-22 Rotary Knife Controller

Maximum Velocity

The following signal interpretation modes apply to all the

synchronization modes of operation.

Mode 1 (+ and -): When the Master axis moves either CW or CCW, the

Follower axis will move in its commanded direction. If the Master axis

changes direction the Follower axis will continue in the original

commanded direction. The Follower axis will not reverse direction.

Mode 2 (+): The Follower will only react to synchronization pulses when

the Master axis runs in the CW direction. CCW Master axis pulses are

ignored.

Mode 3 (-): The Follower will only react to synchronization pulses when

the Master axis runs in the CCW direction. CW Master axis pulses are

ignored.

Mode 4 (COMP +): The Follower will only react to synchronization pulses

when the Master axis runs in the CW direction. The drive counts the

pulses received in the CCW direction and ignores that exact number of

CW pulses before Follower motion in the CW direction occurs.

This feature compensates for Master axis motion in the opposite (CCW)

direction. For example, the Master stops, then inadvertently backs up

due to conveyer slack, etc.

Mode 5 (COMP -): The Follower axis will only react to synchronization

pulses when the Master axis runs in the CCW direction. The drive

counts the pulses received in the CW direction and ignores that exact

number of CCW pulses before Follower motion in the CCW direction

occurs. This feature compensates for Master axis motion in the opposite

(CW) direction.

The Master maximum velocity is the maximum frequency that the

Master axis signal source is expected to produce when running at its’ full

speed. To calculate the Master maximum velocity, use the following

formula:

MV MS

Master MaxVelocity

MV = Master Axis Maximum Velocity (RPM's)

MS = Master Steps/Rev

If encoder is master: MS = (Encoder Line Density)*(4)

If drive is master: MS = 4096

For example: The Master axis is a 1000 line encoder and rotates at a

maximum speed of 3000 rpm, and, when quadratured, produces 4000

steps per revolution. Then:

( )(

3000 4000

RPM Steps

Re )

v

60

This value is the Master encoder velocity at which synchronized time

base and real time base are equal. This parameter is used to calculate

actual Follower velocity while running in synchronized time base.

/

Sec Min

( )( )

=

Sec Min

,

200 000

/60

StepsPer Second=

34 © EMERSON Motion Control

Page 43

PCM-22 Software Setup

WARNING!

The maximum frequency into the PCM-22 module must not exceed

210 kHz (210,000 steps/second).

Sync Velocity User Units

This parameter sets the units to be associated with all sync velocities.

User units can be any three letter combination, such as IPS (inches per

second), RPM (revolutions per minute), FPM (feet per minute), etc.

Sync Velocity Scaling (Max RPM Equals)

This parameter sets the sync velocity entry that will produce maximum

velocity of the drive when the Master axis signal source is at maximum

velocity. For example, when an Index is running in sync time base, the

velocity is specified in user units.

The default value is 1.000. In this case a setting of 0.500 in an Index

velocity when in synchronized time means the drive will accel to half of

maximum velocity.

Sync Output Signal from

If you select Motor, your FX drive will output the sync signal to the next

FX drive based on the motion of its own motor. If you select Upstream

Drive, your FX drive will output the signal that comes from the

preceding PCM/Drive. The Signal Source of the next FX drive and PCM22 in the synchronization chain must be set to Drive in order to operate

with this signal.

Encoder pulses are passed to all amplifiers in the synchronization signal

chain. How you answer this question has no effect on the integrity of the

encoder signal.

External Mode Override

External mode override works in conjunction with input function 38 to

override the current mode of operation. When input function 38 is

assigned and active, the drive will exit its current operating mode and

default to the mode selected with this parameter. This is operable

outside of a program only.

There are three modes of operation: Analog Velocity, Analog Torque and

Bipolar Sync.

Analog Velocity/Torque

When set to analog velocity or torque mode, the drive will respond to a

conventional 10 VDC signal. In either of the two analog modes a 10 VDC

signal is equated to either (CW) or (CCW) maximum programmed

velocity or maximum full peak torque rating.

If there is no physical resistance to the torque at the motor shaft, the

motor will very quickly accelerate to maximum speed.

If you enable analog torque mode and apply a voltage between 0 and 10

VDC to the command connector, the FX drive will attempt to produce

torque equal to:

WARNING!

P/N 400274-01 Revision A7 35

Page 44

PCM-22 Rotary Knife Controller

Actual Torque Max Torque=

Applied Voltage

10 VDC

Bipolar Sync

When set to Bipolar Sync, this parameter allows for direct movement of

the FX drive motor ratioed to the sync encoder. This mode moves the

motor shaft in direct response to encoder or drive signals. This means

immediate velocity without ramping in your FX drive. If the Master axis

accelerates very quickly, your FX drive (Follower axis) will try to follow

just as quickly. Too fast an acceleration by the Master axis could result

in “F” (Following Error) faults for the Follower axis.

Bipolar Sync Ratio(Motor)

This parameter is the relationship of the Follower axis position to the

Master axis position.

For example:

If you set it to three, for every revolution of the Master axis there will be

three revolutions of the Follower axis. Thus, the bipolar sync ratio would

be 3:1.

36 © EMERSON Motion Control

Page 45

Master Cycles

A Master Cycle Length is defined as the distance between successive

Master zero positions. The FX drive, with the PCM-22 acting as the

Follower axis, will produce one or more cycles of motion for every cycle

produced by an independent (Master) axis while maintaining a phase

relationship. All values are in user units of the amplifier as defined in

the Drive Parameters screen (i.e., inch, millimeters, etc.) from the PCX

menu.

PCM-22 Software Setup

Figure 19 Master Cycles Screen.

The Master Cycles screen is found by selecting Drive Setup, Define

Motion then Master Cycles from the PCX menu.

Note: The Master Cycle must be defined before a Follower Cycle may

start. See Resetting the Master Cycle Processing for details on

Master Cycle definition.

Master Cycle Number

This parameter identifies the Master Cycle currently being defined. Up

to 16 different Master cycles can be defined (0 to 15). Any Master Cycle

can be used with any Follower cycle.

Master Cycle Length