Page 1

Application Note (Syllabus)

GFK-3167A

April 2020

PACMOTION VFD

APPLICATION NOTE (SYLLABUS)

Page 2

PACMotion VFD Syllabus

GFK-3167A April 2020

ii

Contents

Revision History .................................................................... iv

Introduction VFD Basic Setup ................................................. 1

Signal Wiring Example ............................................................................................. 1

IO Configuration ..................................................................................................... 2

Power Wiring Example ............................................................................................ 3

NOTE 1: Modbus/TCP Ethernet Demo (Demo Case with Modbus/TCP

Option Card) ...................................................................................... 4

Note 2: PROFINET Demo (Demo Case with PROFINET Option Card .......................... 4

NOTE 3: Modbus RTU Serial Demo (RS-485 2-wire) and Modbus/TCP Demo

5

NOTE 4: Modbus/TCP Ethernet Demo .......................................................... 5

NOTE 5: Modbus/TCP User Defined Function Block Examples ..................... 6

NOTE 6: PROFINET User Defined Function Block Examples ......................... 6

NOTE 7: Using Bluetooth USB or Serial Cable to PACMotion with VFD Suite:

7

NOTE 8: PACMotion Fieldbus Option Modules and Setup ........................... 7

NOTE 9: PACMotion VFD Fieldbus PDI/PDO Data Map and Addressing ...... 8

NOTE 10: PACMotion VFD Complete PDI/PDO Data Map and Addressing .. 8

NOTE 11: PACMotion VFD Demo Case Details ............................................. 9

Modbus/TCP Ethernet Demo (Note 1) ................................... 10

PROFINET Controller Demo (Note 2) ..................................... 13

VFD Settings ......................................................................................................... 13

VFD I/O Signals ...................................................................................................... 13

Option Module Details .......................................................................................... 14

Bus Specific Technical Data ................................................................................... 15

Hardware Insertion and Removal ........................................................................... 15

PROFINET Slave Module Settings ........................................................................... 15

Starting the system ............................................................................................... 15

Supporting Files .................................................................................................... 16

PROFINET Process Data Exchange.......................................................................... 16

Fieldbus Connection Timeout ................................................................................ 16

Page 3

PACMotion VFD Syllabus

GFK-3167A April 2020

iii

MODBUS RTU SERIAL DEMO (NOTE 3) ......................................... 17

Supporting Files .................................................................................................... 20

Modbus RTU Connection Timeout ......................................................................... 21

Drive Parameter Access ......................................................................................... 21

MODBUS/TCP DEMO (NOTE 4) .................................................. 22

Supporting Files .................................................................................................... 23

Modbus/TCP Connection Timeout......................................................................... 23

USER DEFINED FUNCTION BLOCK – MODBUS/TCP (NOTE 5) ............. 25

USER DEFINED FUNCTION BLOCK – PROFINET (NOTE 6) ................ 30

Setting Fieldbus Connection Timeout Preferences ................................................. 37

PROFINET Process Data Exchange Map .................................................................. 38

Supporting Files .................................................................................................... 39

Other Modbus/TCP UDFBs ..................................................................................... 40

Supporting Files .................................................................................................... 40

Modbus/TCP UDFB to VFD PME Projects ...................................................... 40

Modbus/TCP UDFB to VFD Toolchest Drawer .............................................. 41

Modbus/TCP UDFB to VFD XML Block Code ................................................. 41

BLUETOOTH USB AND SERIAL CABLE (NOTE 7) ............................... 42

Communications to the VFD ................................................................................. 42

Serial RS-485 Communications to the VFD ............................ 48

Supporting Files .......................................................................................... 49

PACMotion VFD Fieldbus Option Modules and Setup (NOTE 8)

50

MODBUS/TCP FIELDBUS OPTION MODULE ................................................................... 50

Bus Specific Technical Data ................................................................................... 50

IP Address Setup ................................................................................................... 51

Start-Up and Operation ......................................................................................... 51

LEDs 51

Network Status LED .................................................................................... 52

Module Status LED ...................................................................................... 52

Modbus TCP Data Exchange ........................................................................ 52

Modbus TCP Connection Timeout ............................................................... 53

Page 4

PACMotion VFD Syllabus

GFK-3167A April 2020

iv

Drive Parameter Access – Direct Address Method ....................................... 53

Drive Parameter Access – Indirect Address Method ..................................... 53

PROFINET FIELDBUS OPTION MODULE............................................................. 54

Bus Specific Technical Data ......................................................................... 54

Hardware Insertion and Removal ................................................................ 55

PDO/PDI Data Map and Addressing (Note 9) ......................... 56

Modbus/TCP PDO Data (or Built-in Modbus RTU Serial Port) . 56

Modbus/TCP or RTU PDI Data ................................................................................ 57

PROFINET PDO Data .............................................................................................. 59

PROFINET PDI Data ................................................................................................ 61

PACMotion VFD Data Map and Addressing (Note 10) ............ 63

Complete Address Mapping Modbus/TCP, Modbus RTU, PROFINET ....................... 63

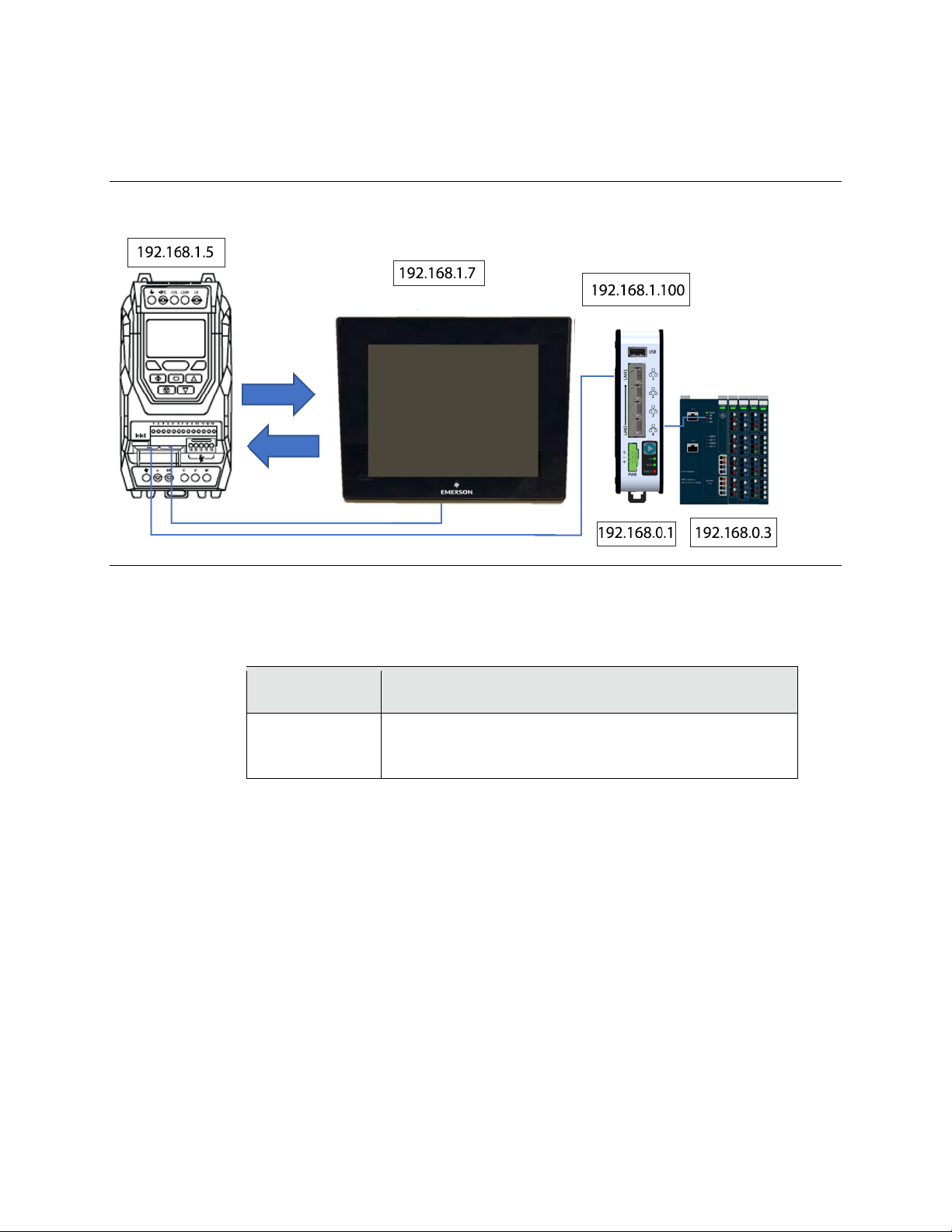

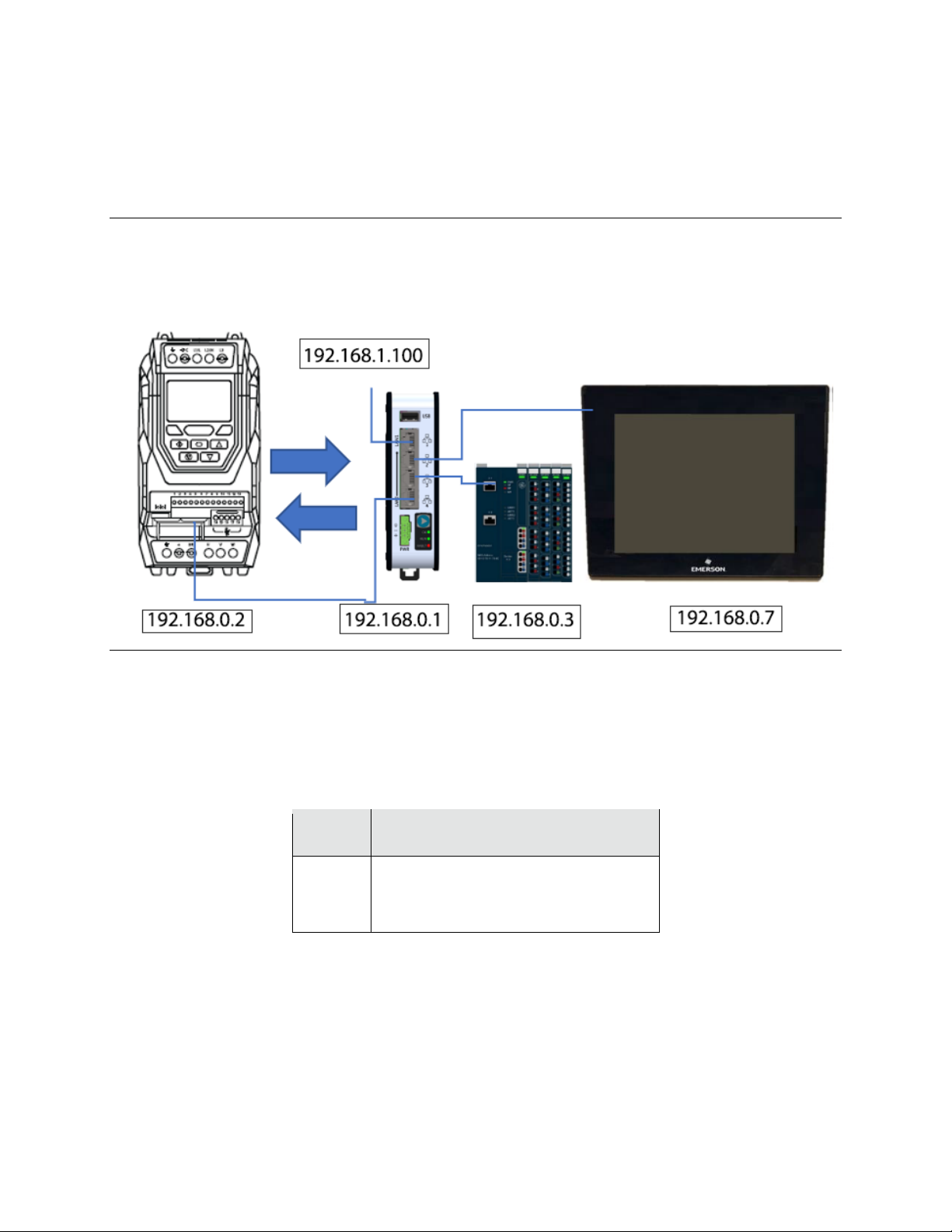

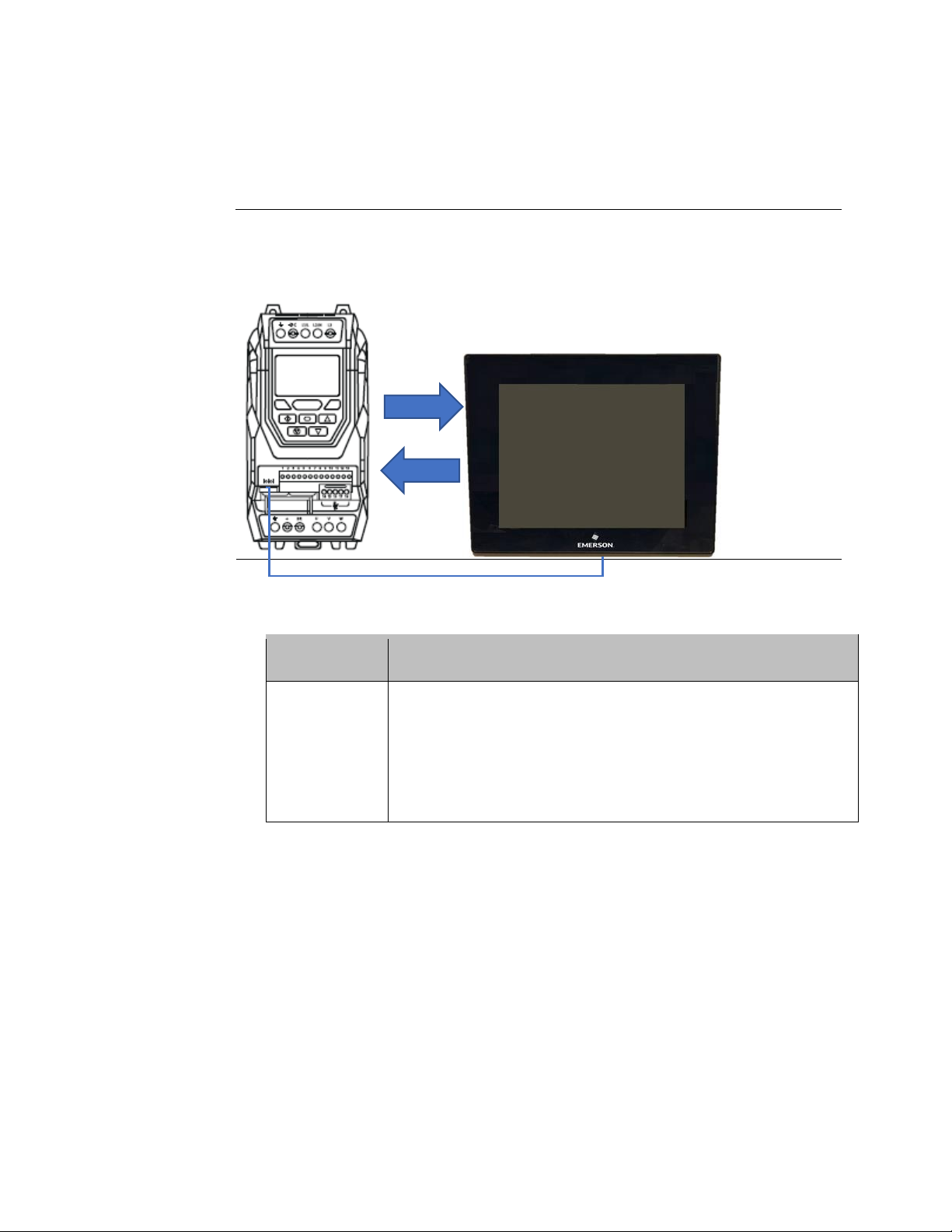

PACMotion VFD Demo Case Details (Note 11) ....................... 64

Quickpanel to CPE100 (Ethernet) and CPE100 to VFD (PROFINET) ......................... 64

Quickpanel to CPE100 (Ethernet) and CPE100 to VFD (PROFINET) ......................... 65

PACMotion VFD Demo Case and Factory Reset ...................................................... 67

General Contact Information ................................................................................. 68

Technical Support ................................................................................................. 68

Revision History

Revision

Date

Description

A

April 2020

Initial Release

Page 5

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 1

Introduction VFD Basic Setup

Basic overview for setup and operation of the PACMotion VFD.

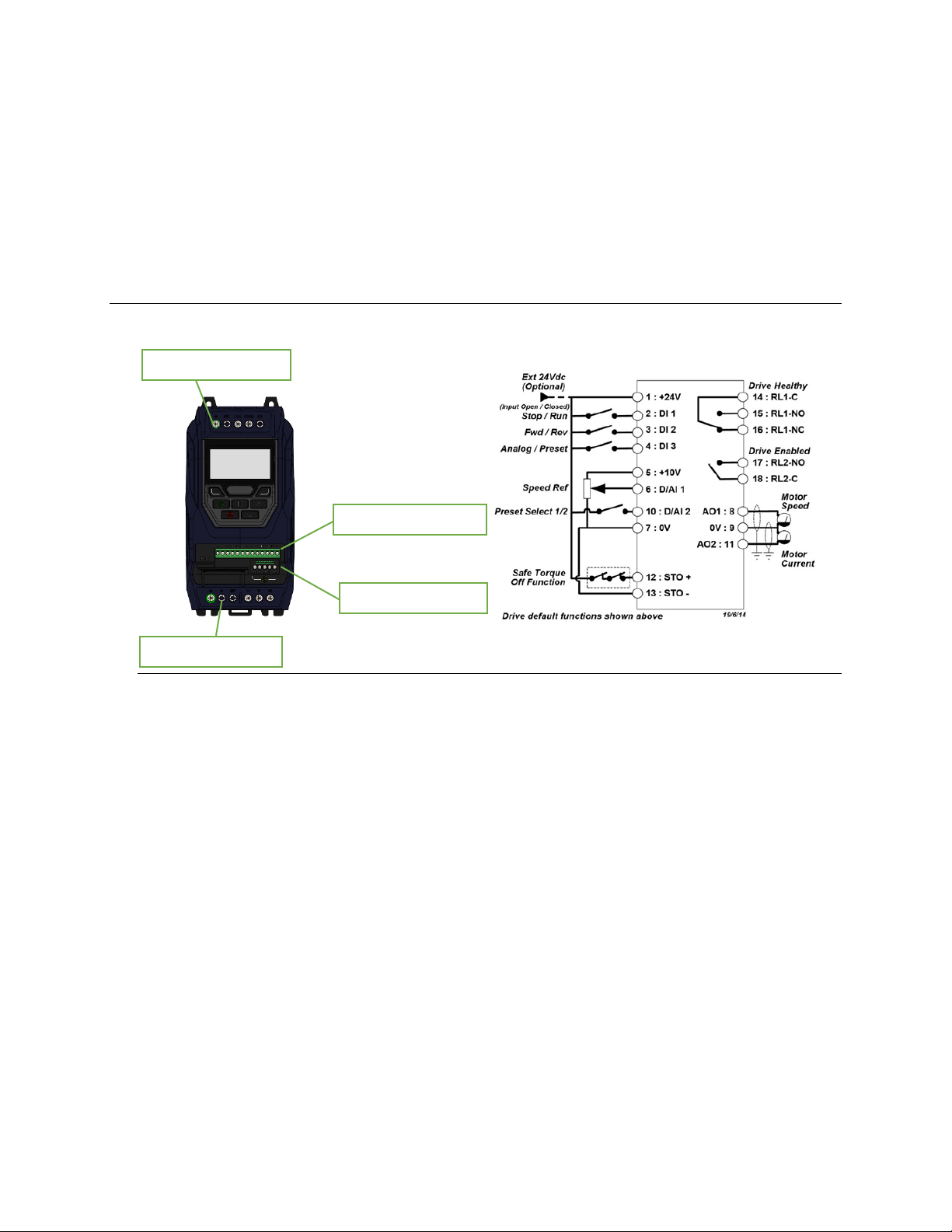

Signal Wiring Example

Figure 1: Signal Wiring Example

Terminals 1 - 13

Terminals 14 - 18

G, L1, L2, L3

G, +, BR, U, V, W

Page 6

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 2

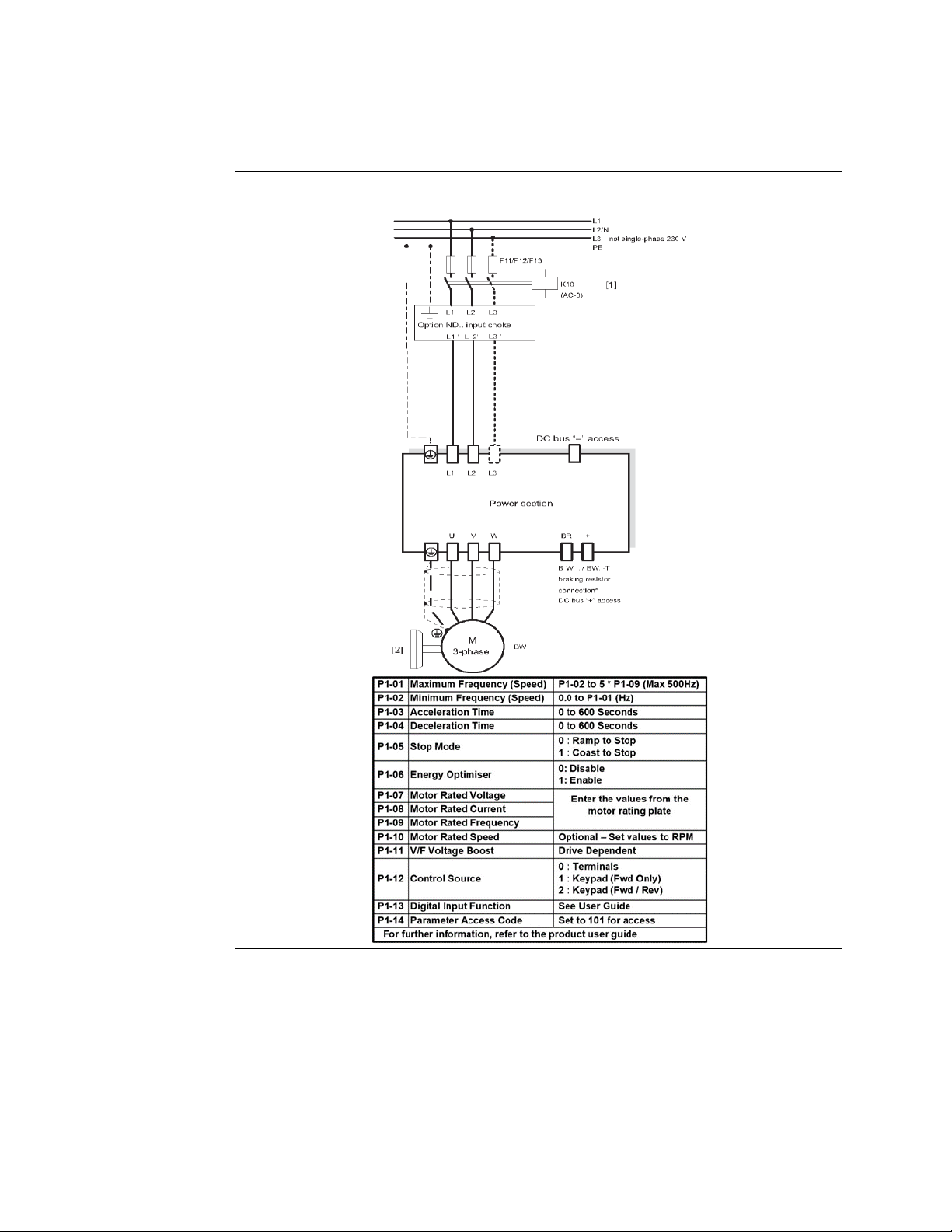

IO Configuration

Default configuration for I/O given here. Refer to GFK-3111 and GFK-3112 for details

Figure 2: IO Configuration (Pinout)

Page 7

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 3

Power Wiring Example

Figure 3: Power wiring and Group 1 Parameters Example (VFD/Motor Setup)

Related Documentation

For more details on wiring and setup refer to documents:

• GFK-3111 PACMotion VFD AC Variable Speed Drive User Guide

• GFK-3112 PACMotion VFD AC Variable Speed Drive Advanced User Guide.

Page 8

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 4

PACMotion VFD Syllabus

A collection of technical Application Notes and Data

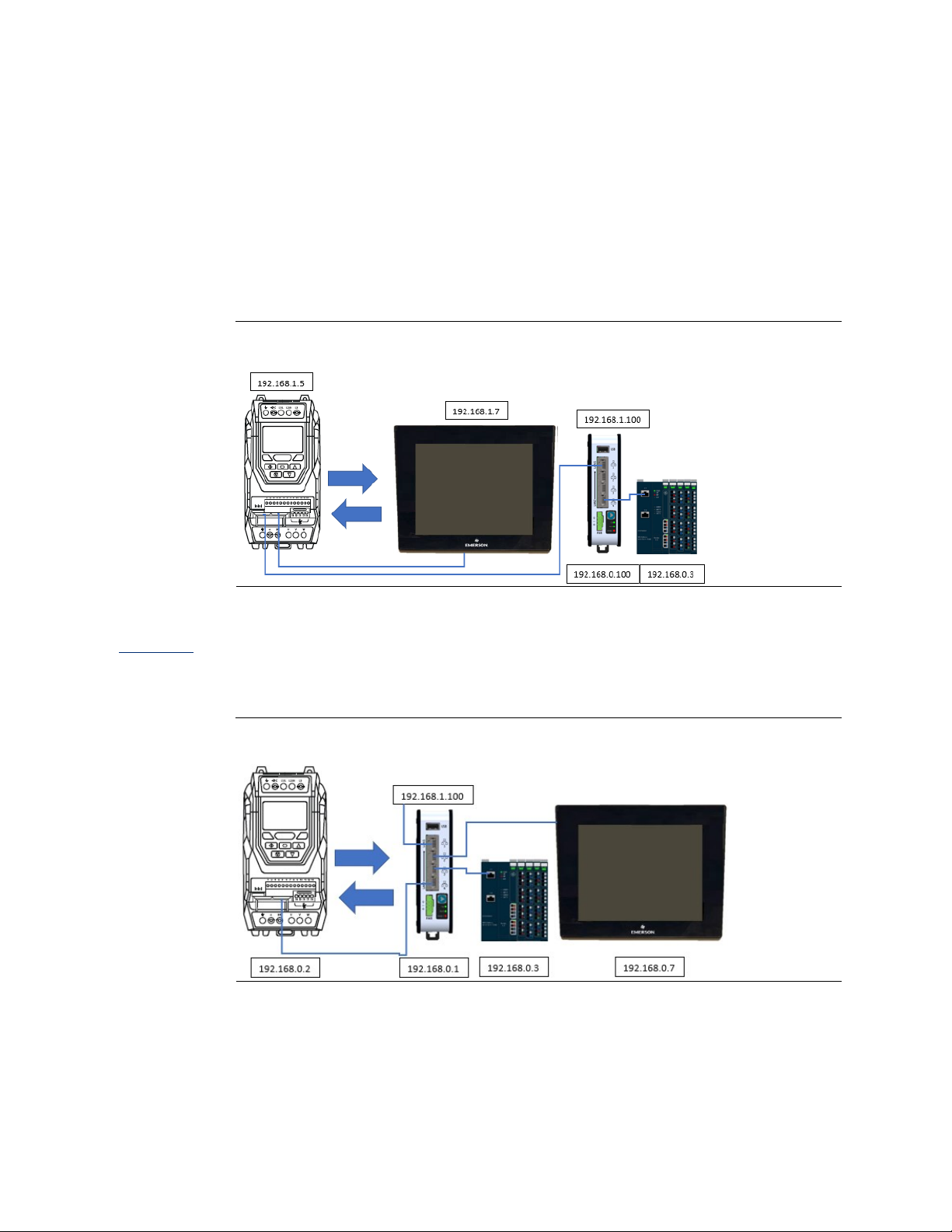

NOTE 1: Modbus/TCP Ethernet Demo (Demo Case with Modbus/TCP Option Card)

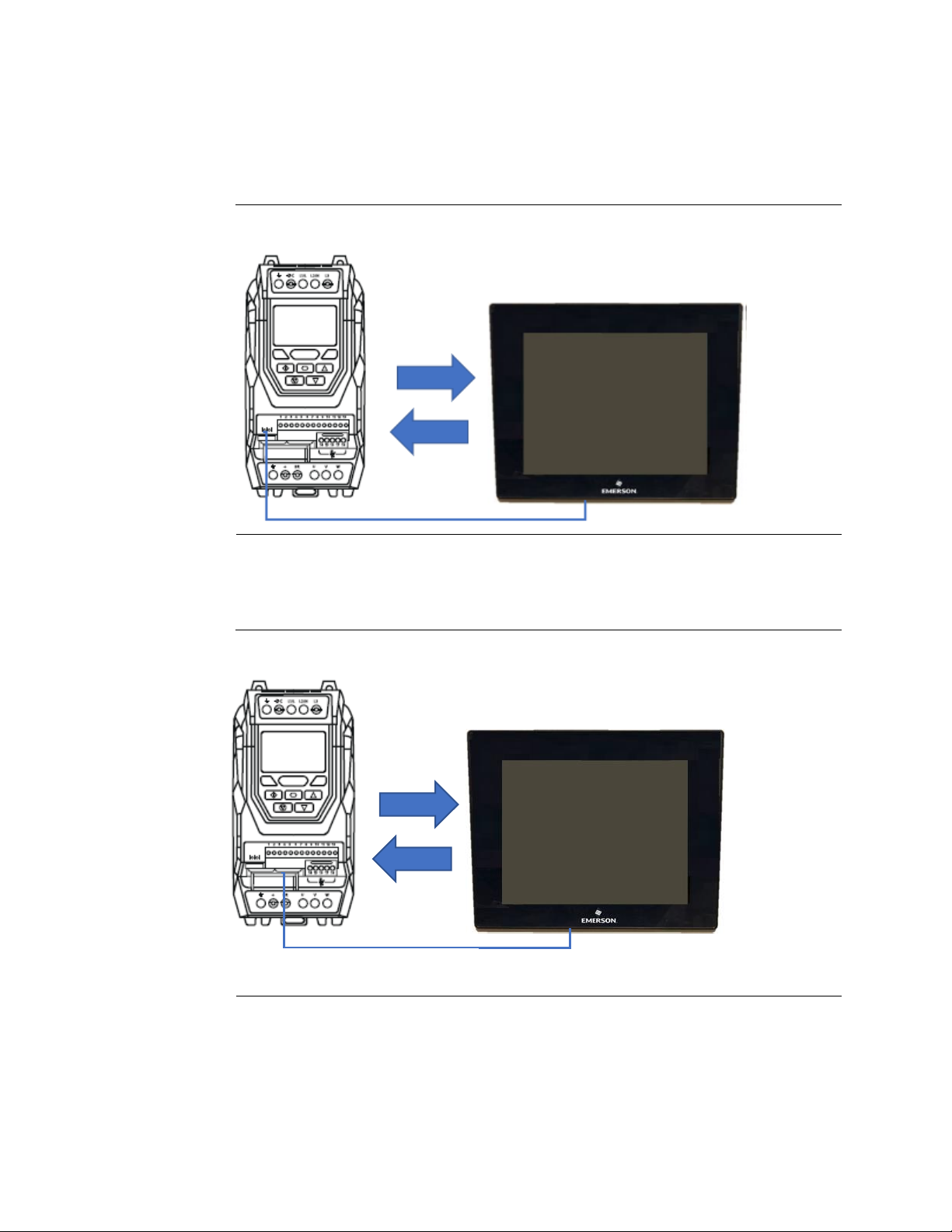

Figure 4: CPE100 TO VFD VIA MODBUS/TCP OPTION MODULE WITH QUICKPANEL

Note 2: PROFINET Demo (Demo Case with PROFINET Option

Card

Figure 5: CPE100 TO VFD VIA PROFINET OPTION MODULE WITH QUICKPANEL

Page 9

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 5

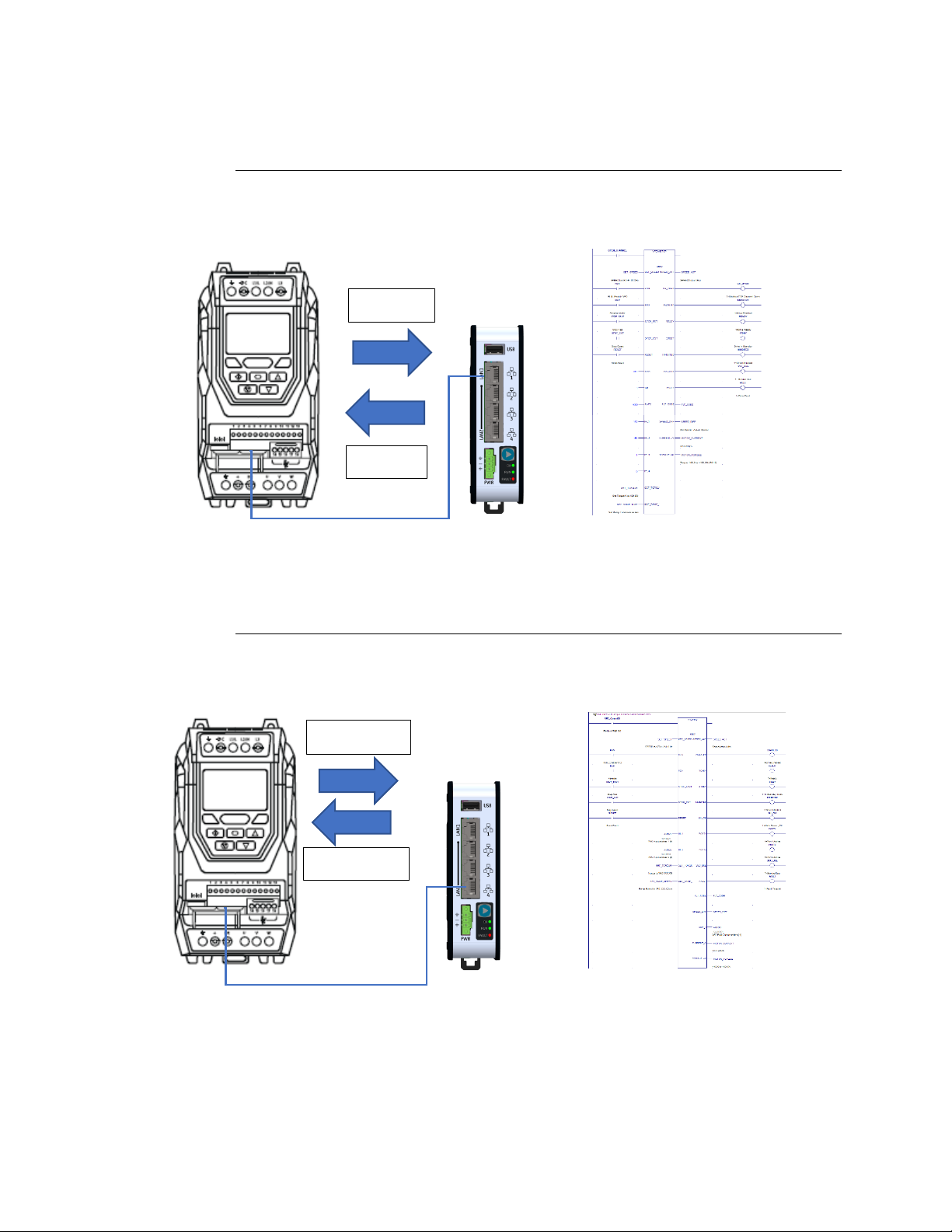

NOTE 3: Modbus RTU Serial Demo (RS-485 2-wire) and Modbus/TCP Demo

Figure 6: Quickpanel Plus or pc w/PME simulator to VFD Built-in Serial Port

NOTE 4: Modbus/TCP Ethernet Demo

Figure 7: Quickpanel Plus or pc w/PME simulator to VFD Modbus/TCP Option Module

Page 10

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 6

NOTE 5: Modbus/TCP User Defined Function Block Examples

Figure 8: CPE100 to VFD Modbus/TCP Option Module

NOTE 6: PROFINET User Defined Function Block Examples

Figure 9: CPE100 to VFD PROFINET Option Module

PDO1 - 4

PDI1 - 4

%AI1 to 8

%AQ1 to 4

Page 11

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 7

NOTE 7: Using Bluetooth USB or Serial Cable to PACMotion with VFD Suite:

Figure 10: Bluetooth BLE USB Stick

NOTE 8: PACMotion Fieldbus Option Modules and Setup

Figure 11: Fieldbus Option Module

Page 12

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 8

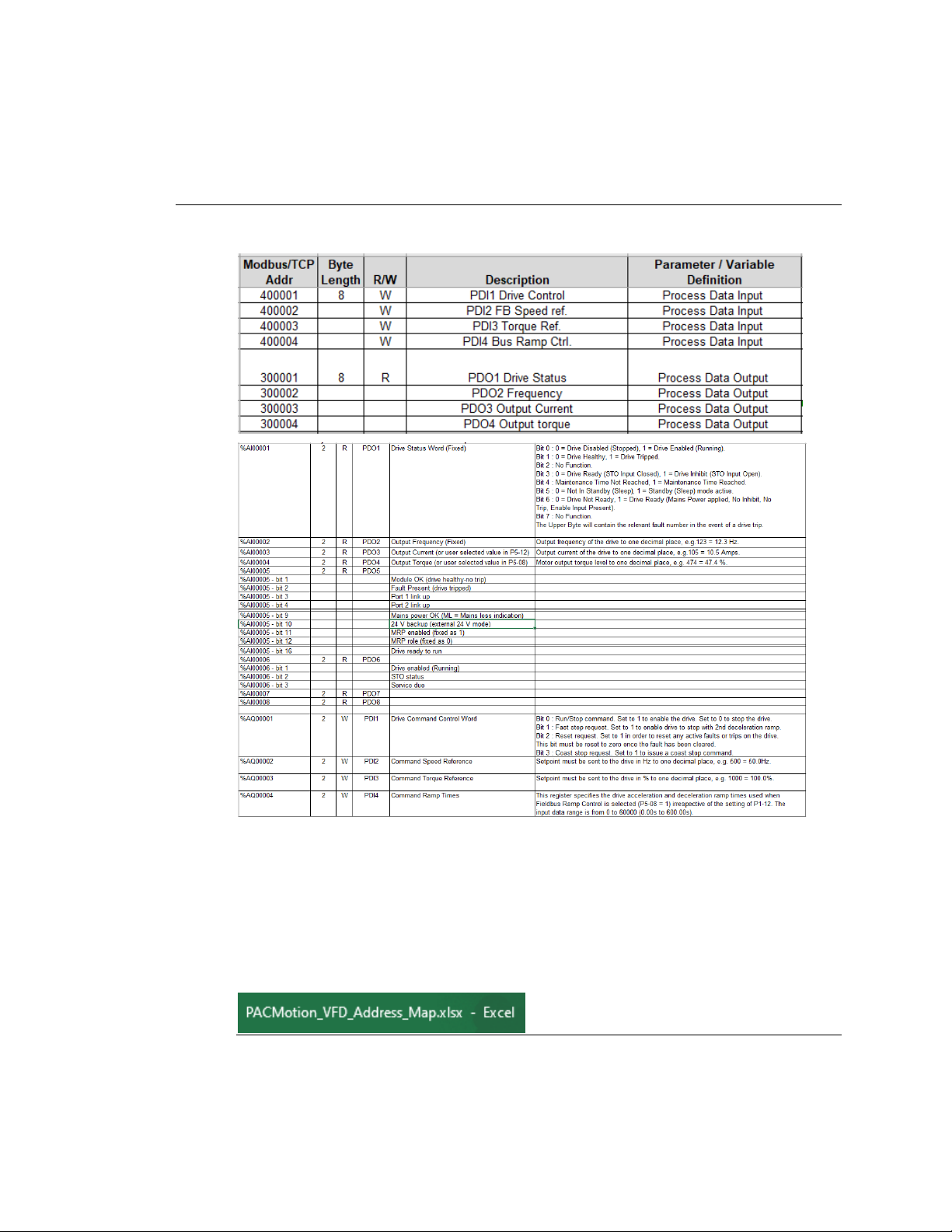

NOTE 9: PACMotion VFD Fieldbus PDI/PDO Data Map and Addressing

Figure 12:

PACM

OTION

VFD F

IELDBUS

PDI/PDO D

ATA MAP AND ADDRESSING

NOTE 10: PACMotion VFD Complete PDI/PDO Data Map and Addressing

Page 13

PACMotion VFD Syllabus

GFK-3167A April 2020

PACMotion VFD Syllabus 9

NOTE 11: PACMotion VFD Demo Case Details

Page 14

PACMotion VFD Syllabus Section 2

GFK-3167A April 2020

Modbus/TCP Ethernet Demo 10

Modbus/TCP Ethernet Demo (Note 1)

Figure 13: Modbus/TCP Ethernet Configuration

This Demo uses the CPE100 as the Initiating device for Modbus/TCP communications.

VFD Parameters

1. Set to the following VFD parameter values:

Parameter

Value and Description

P1-12

P1-14

P5-05

4 (Fieldbus)

201 (Extended Menu Access)

0.0 (Disable communication loss timeout)

QuickPanel Plus Ethernet Settings

2. Set the following IP Address/Mask:

IP address = 192.168.1.7

Subnet mask = 255.255.255.0

VFD Modbus/TCP Option Module settings

3. Use a DHCP server or the HMS IPConfig software to set the IP address of the

Modbus/TCP module. Use the following settings:

IP address = 192.168.1.5

Subnet mask = 255.255.255.0

Page 15

PACMotion VFD Syllabus Section 2

GFK-3167A April 2020

Modbus/TCP Ethernet Demo 11

Starting the system

4. As shown in the picture above, connect one ethernet port of the VFD

Modbus/TCP option module to the QuickPanel and connect the other ethernet

port of the VFD Modbus/TCP option module to the top port of CPE100.

5. Power up the devices.

6. Using a laptop PC with PAC Machine Edition, load in the PAC Machine Edition

project:

“VFD_DEMOCASE_MBTCP_Vx” and Download/Run the CPE100 and QuickPanel

targets. This will use the CPE100 as a Modbus/TCP Master.

7. The QuickPanel Screen should show live PDI/PDO Data. Information on this data

is given below.

Modbus/TCP Process Data Exchange

The mapping of Process Data Output/Input to Modbus/TCP Registers is shown below.

Process Data Word

Modbus/TCP Register1 *

PDO1

300001

PDO2

300002

PDO3

300003

PDO4

300004

PDI1

400001

PDI2

400002

PDI3

400003

PDI4

400004

Modbus/TCP Connection Timeout

The VFD Modbus/TCP interface allows the user to set the “Communication Loss Timeout”

and “Communication Loss Action” values. These parameters are at addresses P5-05 and

P5-06 respectively. The Timeout units are 1 = 0.1 sec and the range is from 0.0 (disable) to

5.0 seconds. A setting of 0.0 seconds will allow the VFD to continue running if

communications is lost.

1

Modbus Clients may address the first Modbus register as register 300001/400001. This assumes an address offset starting at 1. For

Clients that use zero based addressing just subtract 1.

Page 16

PACMotion VFD Syllabus Section 2

GFK-3167A April 2020

Modbus/TCP Ethernet Demo 12

Drive Parameter Access

The Modbus/TCP Interface allows the user to read/write the drive parameters. To perform

this function, the user can directly access the parameter. Simply add the parameter

number to the Modbus offset of 400000.

For example:

Read parameter P1-01 (Maximum Frequency), perform the following

Read Modbus/TCP Address 400101 value (scaling in 0.1 Hz).

Write parameter P1-01 (Maximum Frequency) = 60.0 Hz, perform the following

Write to Modbus/TCP Address 400101 value = 600 (scaling in 0.1 Hz)

Supporting Files

Figure 14: VFD Demo Case file

VFD_DEMOCASE_MBTCP_V2. zip

Right-click the icon to Copy the file.

Page 17

PACMotion VFD Syllabus Section 3

GFK-3167A April 2020

CPE100 to VFD PROFINET Demo 13

PROFINET Controller Demo (Note 2)

Figure 15: CPE100 (PROFINET Controller) to VFD PROFINET Slave Demo

VFD Settings

1. VFD Parameters must be set to the following values:

For help on changing parameters Refer to Manual GFK-3111.

Parameter

Value and Description

P1-12

P1-14

P5-05

4 (Fieldbus)

201 (Extended parameter description)

0.0 (Disable communication loss timeout)

VFD I/O Signals

Digital

By default, the VFD signals Digital Input 1 (DI1) and Safe Torque Off (STO) must be

energized to allow the VFD to Run. These signals are wired to and powered by the demo

RSTi-EP outputs. The outputs are set automatically when a certain screen is used on the

QuickPanel.

Page 18

PACMotion VFD Syllabus Section 3

GFK-3167A April 2020

CPE100 to VFD PROFINET Demo 14

Analog

The Analog I/O of the RSTi-EP module allow various analog signals to control/monitor the

VFD.

The following is a default map of the I/O points used in the Demo unit:

CPE100

PACMotion VFD

Signal

%Q00001

DI1

Enable Drive

%Q00002

DI2

Reverse

%Q00003

DI3

Set Point 1

%I00001

DI1

Drive Enabled

%AQ00001

AI1

Speed (reference)

%AI00001

AO1

Speed (actual)

24VDC

STO +

Safe Torque +

0VDC

STO -

Safe Torque -

Option Module Details

1. To use PROFINET with the VFD a PROFINET Option Module must be installed.

The PROFINET option card permits the PACMotion VFD Drive to connect to a PROFINET

network.

IC866-OC-P PROFINET Option Card for VFD

PROFINET Option Card

RJ45 Connectors & Network Activity LEDs,

PROFINET Option Card

[1]

LED: NS

[A]

LED: Activity

[2]

RJ45: P1

[B]

LED: Link

[3]

Labeling: PROFINET I/O

[4]

RJ45: P2

[5]

LED: MS

Page 19

PACMotion VFD Syllabus Section 3

GFK-3167A April 2020

CPE100 to VFD PROFINET Demo 15

Bus Specific Technical Data

Baud rate

10/100 Mbaud in full duplex mode

Connection technology

2 × RJ45

Hardware Insertion and Removal

Remove power from the VFD. Using a T9 driver bit, backout the 2 option module screws

approximately 4 or 5 turns each. This should allow the locking tabs to retract to a flat

position. Insert the module into the VFD fieldbus option module cage and gently press it

into place. Secure the T9 screws until they touch the module. This will engage the locking

tabs to hold it in place. Do not over tighten.

(Note: If the T9 screws are not backed out first the module will not insert or remove

properly.)

To remove the option module remove power from the VFD. Using a T9 driver bit backout

the option module 2 screws approximately 4 or 5 turns each. Gently pull the module out

by pulling on the screws.

PROFINET Slave Module Settings

1. With the PROFINET option module installed power up the VFD.

Using the PROFINET DCP tool, which is part of the PAC Machine Edition Utilities, set the

following VFD PROFINET Slave values example:

Device Name

IP Address

vfd-1

192.168.0.2

2. The QuickPanel Plus Ethernet Settings must be set to the following values:

IP address = 192.168.0.7

Subnet mask = 255.255.255.0

Starting the system

3. Connect the VFD PROFINET option module to an available PROFINET port on the

CPE100 (the lower 3 ports) and the QuickPanel to the top ethernet port on the CPE100

and power up the devices.

This is done inside the official PACMotion VFD Demo case.

4. Using a laptop PC with PAC Machine Edition, load in the PAC Machine Edition project:

“VFD_DEMOCASE_PN_Vx” and Download/Run the QuickPanel and CPE100 targets

through the front panel ports labeled “PROFINET/HMI” and “PLC”.

Page 20

PACMotion VFD Syllabus Section 3

GFK-3167A April 2020

CPE100 to VFD PROFINET Demo 16

Supporting Files

Figure 16: VFD Demo Case file

VFD_DEMOCASE_PN_V6.zip

Right-click the icon to Copy the file.

PROFINET Process Data Exchange

The mapping of Process Data Output/Input to Modbus RTU Registers is shown below.

Process Data Word

Typical CPE100 Address

PDO1

%AI00001

PDO2

%AI00002

PDO3

%AI00003

PDO4

%AI00004

PDI1

%AQ00001

PDI2

%AQ00002

PDI3

%AQ00003

PDI4

%AQ00004

Fieldbus Connection Timeout

The VFD interface allows the user to set the “Communication Loss Timeout” and

“Communication Loss Action” values. These parameters are at addresses P5-05 and P5-06

respectively. The Timeout units are 1 = 0.1 sec and the range is from 0.0 (disable) to 5.0

seconds. A setting of 0.0 seconds will allow the VFD to continue running if

communications is lost.

Page 21

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 17

MODBUS RTU SERIAL DEMO (NOTE 3)

Figure 17: Quickpanel Plus or PC w/PME simulator to VFD Built in Serial Port

1. VFD Parameters must be set to the following values:

Parameter

Value and Description

P1-12

P1-14

P5-01

P5-03

P5-04

P5-05

P5-16

4 (Fieldbus)

201 (Extended parameter description)

1 (Fieldbus address)

1 (Modbus RTU Baud rate 19.2Kbps)

0 (Modbus data format, no parity, 1 stop bit)

0.0 (Disable communication loss timeout)

0 (Extended Modbus drive address)

2. QuickPanel Plus with COM2 wiring (the 7 inch QuickPanel Plus does not have a COM2):

Note: To use a 7 inch QuickPanel Plus you would have to add a USB to RS-485/2-wire

serial port.

Page 22

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 18

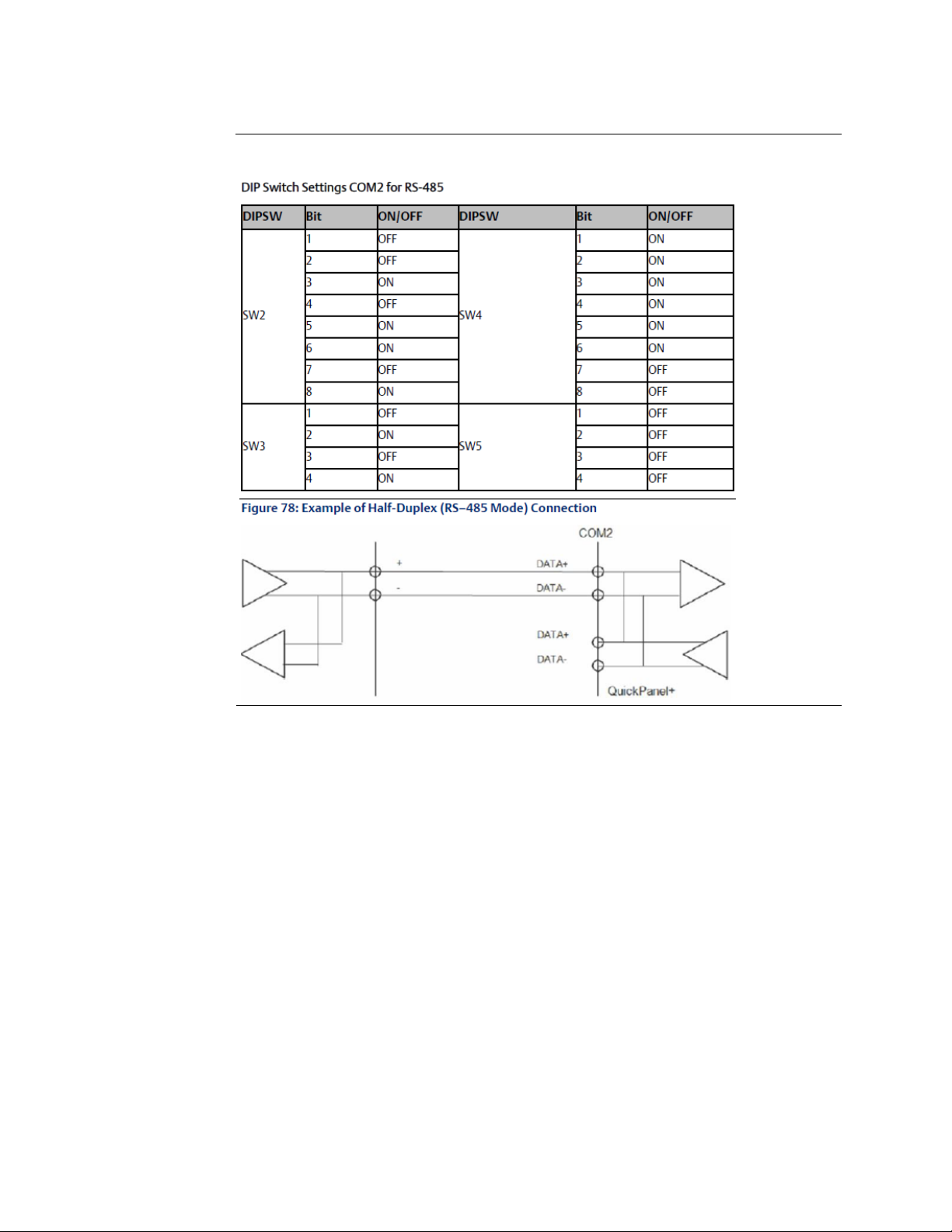

3. Set the QuickPanel Plus DIP switches for RS-485 2 wire operation.

Figure 18: RS-485 2 Wire Operation

Page 23

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 19

4. VFD to QuickPanel COM2 wiring Serial Cables

Make a serial cable with the following connections. Be sure to jumper the TXD+/RXD+ and

TXD-/RXD- on the QuickPanel for RS-485 two wire operation.

Figure 19: QuickPanel COM2 Port

Page 24

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 20

5. VFD to Laptop with RS-485 two wiring with a device such as USB Gearmo Model USA:482422

Figure 20: Serial connections PC to VFD

6. Connect the VFD to the Modbus Device and power up the devices.

7. Load in the example PAC Machine Edition project:

“VFD_Modbus_RTU_QPPlus12_VerX” and Download/Run the QuickPanel or the Laptop in

Simulate mode.

8. Set the required VFD terminal discrete signals properly to allow VFD operation.

DI1 = ON (Enabled) and STO = ON (Safe Torque ON)

Supporting Files

Figure19: Modbus RTU Serial Demo file

VFD_Modbus_RTU_QPPlus12_Ver2.zip

Right-click the icon to Copy the file.

Page 25

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 21

Modbus RTU Process Data Exchange

The mapping of Process Data Output/Input to Modbus RTU Registers is shown below.

Process Data Word

Modbus RTU Register2

PDO1

300001

PDO2

300002

PDO3

300003

PDO4

300004

PDI1

400001

PDI2

400002

PDI3

400003

PDI4

400004

Modbus RTU Connection Timeout

The VFD Modbus RTU interface allows the user to set the “Communication Loss Timeout”

and “Communication Loss Action” values. These parameters are at addresses P5-05 and

P5-06 respectively. The Timeout units are 1 = 0.1 sec and the valid range is from 0.0

(disable) to 5.0 seconds. A setting of 0.0 seconds will allow the VFD to continue running if

communications is lost.

Drive Parameter Access

The Modbus RTU Interface allows the user to read/write the drive parameters. To perform

this function, the user can directly access the parameter. Simply add the parameter

number to the Modbus offset of 400000.

For example:

Read parameter P1-01 (Maximum Frequency), perform the following

Read Modbus RTU Register 400101 value (scaling in 0.1 Hz).

Write parameter P1-01 (Maximum Frequency) = 60.0 Hz, perform the following

Write to Modbus RTU Register 400101 value = 600 (scaling in 0.1 Hz)

2

Modbus Clients may address the first Modbus register as register 300001/400001. This assumes an address offset starting at 1. For

Clients that use zero based addressing just subtract 1.

Page 26

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 22

MODBUS/TCP DEMO (NOTE 4)

Figure 20: Q

UICKPANEL PLUS OR PC W

/PME

SIMULATOR TO

VFD M

ODBUS

/TCP O

PTION MODULE

This Demo uses the Quick Panel Plus as the Initiating device for Modbus/TCP

communications.

1. VFD Parameters must be set to the following values:

Parameter

Value and Description

P1-12

P1-14

P5-01

P5-05

4 (Fieldbus)

201 (Extended parameter description)

1 (Fieldbus address)

0.0 (Disable communication loss timeout)

2. QuickPanel Plus Ethernet Settings

Set the following IP Address/Mask:

IP address = 192.168.1.7

Subnet mask = 255.255.255.0

3. VFD Modbus/TCP Option Module settings

Use a DHCP server or the HMS IPConfig software to set the IP address of the Modbus/TCP

module. Use the following settings:

IP address = 192.168.1.5

Subnet mask = 255.255.255.0

4. Connect the VFD to the Modbus/TCP Device and power up the devices.

192.168.1.

192.168.1.

Page 27

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 23

5. Load in the example PAC Machine Edition project:

“VFD_ModbusTCP_QPPlus12_VerX” and Download/Run the QuickPanel or the Laptop in

Simulate mode.

6. Set the required VFD terminal discrete signals properly to allow VFD operation.

DI1 = ON (Enabled) and STO = ON (Safe Torque ON)

Supporting Files

Figure 21: VFD Modbus TCP

VFD_ModbusTCP_QPPlus12_Ver2.zip

Right-click the icon to Copy the file.

Modbus/TCP Process Data Exchange

The mapping of Process Data Output/Input to Modbus/TCP Registers is shown below.

Process Data Word

Modbus RTU Register3

PDO1

300001

PDO2

300002

PDO3

300003

PDO4

300004

PDI1

400001

PDI2

400002

PDI3

400003

PDI4

400004

Modbus/TCP Connection Timeout

The VFD Fieldbus interface allows the user to set the “Communication Loss Timeout” and

“Communication Loss Action” values. These parameters are at addresses P5-05 and P5-06

respectively. The Timeout units are 1 = 0.1 sec and the valid range is from 0.0 (disable) to

5.0 seconds. A setting of 0.0 seconds will allow the VFD to continue running if

communications is lost.

3

Modbus/TCP Clients may address the first Modbus/TCP register as register 300001/400001. This assumes an address offset starting at

1. For Clients that use zero based addressing just subtract 1.

Page 28

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 24

Drive Parameter Access

The Modbus/TCP Interface allows the user to read/write the drive parameters. To perform

this function, the user can directly access the parameter. Simply add the parameter

number to the Modbus/TCP offset of 400000.

For example:

Read parameter P1-01 (Maximum Frequency), perform the following

Read Modbus/TCP Register 400101 value (scaling in 0.1 Hz).

Write parameter P1-01 (Maximum Frequency) = 60.0 Hz, perform the following

Write to Modbus/TCP Register 400101 value = 600 (scaling in 0.1 Hz)

Page 29

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 25

USER DEFINED FUNCTION BLOCK – MODBUS/TCP

(NOTE 5)

Figure 22: For Use with PACMotion VFD Modbus/TCP Option Module

1. Install the Modbus/TCP Option Module in your VFD.

Typical Part number IC866-OC-M.

2. The proper IP addresses must be set for your devices to communicate.

CPE100 = 192.168.1.100 (set with Proficy Machine Edition (PME)

VFD = 192.168.1.5 (set with a DHCP Server or IPCONFIG Tool from Anybus.Com)

3. Import the UDFB into PME.

The UDFB named “VFD_MBTCP” can be added to your PME project with the “Import Drawer”

function of the Toolchest, or the “Import Block From File” function of the Navigator Program Blocks.

Below is an example of the Navigator Import Block from File:

Figure 23: Import Block from File

PDI1 - 4

Page 30

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 26

Choose the XML file named “VFD_MBTCP.XML”

Figure 24: Select the XML File

4. Using the UDFB in your Logic.

Insert a CALL statement in your Logic and Double-Click on the CALL and choose the UDFB

“VFD_MBTCP”.

Figure 25: Insert a Call Statement

5. Assign the UDFB Instance name in your Logic.

You must assign an Instance name that is unique to the UDFB. Position the cursor on the block and

type in the Instance name where the question marks are.

Figure 26: Assign an Instance Name

Page 31

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 27

6. This Instance will have created a Structure with all variables needed for the PNS.

The Instance “VFD1” name is shown as an example below:

Figure 27: Instance Has Been Created

The Structure of points used in the Instance of this UDFB shown below:

Figure 28: Structure of Points used in Instance

Page 32

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 28

7. Assign input and output node variables.

This UDFB is an example of how the Modbus/TCP functions of the VFD can be controlled/monitored.

Each Instance of the UDFB must have a different and unique Instance Name (VFD1 below). Various

node names are given to reflect the function they represent.

Figure 29: Assign Input and Output Node Variables

Page 33

PACMotion VFD Syllabus Section 5

GFK-3167A April 2020

Modbus/TCP Demo 29

8. Starting the system

Be sure to set your VFD Parameter P1-12 to 4 for Fieldbus Control.

Download the project to your PACSystems Controller.

Connect the top Ethernet Port of the CPE100 to the VFD Modbus/TCP option module. Power up the

devices and test functionality.

9. Setting Fieldbus Connection Timeout Preferences

The VFD interface allows the user to set the “Communication Loss Timeout” and “Communication

Loss Action” values. These parameters are at addresses P5-05 and P5-06 respectively. The Timeout

units are 1 = 0.1 sec and the range is from 0.0 (disable) to 5.0 seconds. Set these appropriately. A

setting of 0.0 seconds will allow the VFD to continue running if communications is lost.

Page 34

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 30

USER DEFINED FUNCTION BLOCK – PROFINET

(NOTE 6)

Figure 30: For Use with PACMotion VFD PROFINET Option Module

1. Install the PROFINET Slave Option Module in your VFD.

Typical Part number IC866-OC-P.

2. The proper GSDML file for this device must be added to your PROFINET Controller in

PAC Machine Edition (PME). The VFD will become a PROFINET Slave (PNS).

Typical file name: GSDML-V2.31-Intelligent Platforms, LLC-PACmotionVFD-

20200113.xml

Page 35

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 31

3. The unique PROFINET Name and IP address should be set for each PNS.

Be sure your IP address is in the PROFINET Controller (PNC) range and to assign a

Reference Variable to each (PNS & PNC) for PNIO_DEV_COMM use later, typical PNS

settings are shown below:

Figure 31: PNS Settings

4. The PNS will have 4 slots autoconfigured:

Slots 1,2,3 must be addressed. Double-click on the slots and configure them.

Figure 32: Configured Slots

Page 36

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 32

5. PROFINET PNS Configuration in PME:

3 address ranges must be entered for the PNS with similar values to the example

below:

• %AQ00001 Length 4 Words (slot 1)

• %AI00001 Length 4 Words (slot 2)

• %AI00005 Length 4 Words (slot 3)

Figure 33: PROFINET PNS Configurations

Page 37

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 33

6. Import the UDFB into PME.

The UDFB named “VFD_PNS” can be added to your PME project with the “Import Drawer”

function of the Toolchest, or the “Import Block From File” function of the Navigator

Program Blocks. Below is an example of the Navigator Import Block from File:

Figure 34: Import the UDFB into PME

7. Choose the XML file named “VFD_PNS.XML”.

Figure 35: Choose the XML File

8. Using the UDFB in your Logic.

Insert a CALL statement in your Logic and Double-Click on the CALL and choose the

UDFB “VFD_PNS”.

Figure 36: UDFB Logic

Page 38

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 34

9. Assign the UDFB Instance name in your Logic.

You must assign an Instance name that is unique to the UDFB. Position the cursor on

the block and type in the Instance name where the question marks are.

Figure 37: Assigning Instance Name

10. This Instance will have created a Structure with all variables needed for the PNS.

The Instance “VFD_Inst1” name is shown as an example below:

Figure 38: Instance-Created Structure

Page 39

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 35

11. The Structure of points used in the Instance of this UDFB shown below:

Figure 39: Structure of Points in Instance

Page 40

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 36

12. Assign input and output node variables.

This UDFB is an example of how the PROFINET functions of the VFD can be

controlled/monitored. Each Instance of the UDFB must have a different and unique

Instance Name (VFD1 below). Various node names are given to reflect the function they

represent.

Figure 40: Assign IO Node Variables

Page 41

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 37

13. Starting the system

Be sure to set your VFD Parameter P1-12 to 4 for Fieldbus Control. You may wish to insert a

PNIO_DEV_COMM block (similar to below) to assure your PROFINET Controller and PNS

are communicating without issue. The Reference Variables names created in step 3 can be

used for the PNIO_DEV_COMM. The output of the PNIO_DEV_COMM can be used to

power the UDFB.

Figure 41: Check the Status of the PNS Connection

14. Download the project to your PACSystems Controller.

Connect the PROFINET Controller to the VFD PROFINET option module. Power up the

devices and test functionality.

Setting Fieldbus Connection Timeout Preferences

The VFD interface allows the user to set the “Communication Loss Timeout” and

“Communication Loss Action” values. These parameters are at addresses P5-05 and P5-06

respectively. The Timeout units are 1 = 0.1 sec and the range is from 0.0 (disable) to 5.0

seconds. Set these appropriately. A setting of 0.0 seconds will allow the VFD to continue

running if communications is lost.

Page 42

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 38

PROFINET Process Data Exchange Map

The typical mapping of VFD Process Data Output (PDO)/Process Data Input (PDI) to

PROFINET Slave Addresses is shown below.

Process Data Word

Typical CPE Address

PDO1

%AI00001

PDO2

%AI00002

PDO3

%AI00003

PDO4

%AI00004

Additional Word 5

%AI00005

Additional Word 6

%AI00006

Additional Word 7

%AI00007

Additional Word 8

%AI00008

PDI1

%AQ00001

PDI2

%AQ00002

PDI3

%AQ00003

PDI4

%AQ00004

Page 43

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

User Defined Function Block UDFB 39

Supporting Files

Figure 42: VFD UDFB

VFD_CPE100_PN_UDFB.zip

Right-click the icon to Copy the file.

Figure 43: PROFINET UDFB to VFD Toolchest:

VF D_UDFBs.ZDRW

This Drawer also contains Modbus/TCP UDFB blocks)

Right-click the icon to Copy the file.

Figure 44: PROFINET UDFB to VFD XML Block Code

VFD_PNS.xml

Right-click the icon to Copy the file.

Page 44

PACMotion VFD Syllabus Section 6

GFK-3167A April 2020

User Defined Function Block UDFB 40

Other Modbus/TCP UDFBs

These UDFBs can be used similarly to the above UDFB. Nodes will change based on the

function.

VFD_RD_PARM

Used to Read 1 Parameter from the VFD.

VFD_WR_PARM

Used to Write 1 Parameter to the VFD.

VFD_RD_G1

Used to Read all Group 1 Parameters from the VFD.

Supporting Files

Modbus/TCP UDFB to VFD PME Projects

Figure 45: VFD PME Projects with Modbus/TCP UDFB

VFD_MBTCP_UDFB_V1.zip

VFD_MBTCP_UDFB_WR_PARM_V1.zip

VFD_MBTCP_UDFB_RD_PARM_V1.zip

VFD_MBTCP_UDFB_RD_G1_V1.zip

Right-click the icon to Copy the file.

Page 45

PACMotion VFD Syllabus Section 6

GFK-3167A April 2020

User Defined Function Block UDFB 41

Modbus/TCP UDFB to VFD Toolchest Drawer

(This Drawer also contains PROFINET UDFB blocks)

Figure 46:VFD Toolchest Drawer with Modbus/TCP UDFB

VF D_U DFBs.ZDRW

Right-click the icon to Copy the file.

Modbus/TCP UDFB to VFD XML Block Code

Figure 47: VFD XML Block Code for Modbus/TCP UDFBs

VFD_MBTCP.xml

VFD_RD_PARM.xml

VFD_WR_PARM.xml

VFD_RD_G1.xml

Right-click the icon to Copy the file.

Page 46

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

Bluetooth USB and Serial Cable 42

BLUETOOTH USB AND SERIAL CABLE (NOTE 7)

Communications to the VFD

Bluetooth BLE Connection

You can use the internal (built in) or external (USB) type Bluetooth BLE ports for your PC.

1. On the VFD plug the Bluetooth BLE USB Stick (typical part number IC866-BLUE) into the

Serial port (not the RJ-45 LAN network port) and turn on power to the VFD.

After a few seconds you should see the green, red, and blue LEDs similar to the picture

below:

Figure 48: Bluetooth BLE USB Stick

2. Start the Emerson PACMotion VFD Studio program.

3. Go to Tools-Select Communications Device menu.

4. Select the connection type = BluetoothStick (BLE).

Page 47

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

Bluetooth USB and Serial Cable 43

5. Select the BLE Interface = Integrated Bluetooth LE.

• This will be the typical built-in “Integrated Bluetooth LE” Bluetooth of your laptop.

Figure 49: Communication Settings

6. If you need to install an external Bluetooth device such as Bluetooth BLE USB Dongle be

sure to use a “BLE” (Bluetooth Low Energy) device. A regular Bluetooth device will not

work. One BLE tested device would be a BlueGiga part number BLED112-V1. When the

driver for this USB device is installed it should be assigned to an available COM port and be

selectable as seen below:

Figure 50: BLE Option

Page 48

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

Bluetooth USB and Serial Cable 44

7. Click the Scan button.

You should see the VFD “BluetoothStick” USB device in the list such as below:

Figure 51: VFD BlutoothStick Displayed in List

8. Click the small box to Select the VFD BluetoothStick device for connection.

9. Click the Connect button to connect to the Bluetooth Device.

10. Click the “Scan Drive Network” button (Allow a few seconds for the scan to complete).

This should find the VFD and transfer parameters from the VFD to the Studio.

In factory default mode you will only see Group 1 Tab with parameters (rows) for the VFD.

Figure 52: Group 1 Tab

11. Click on the variable number in the “Value” Column for P1-14 Extended Menu Access

Code.

12. Change the value to 201 and then press enter to accept the value.

You should see more Parameter tabs now (Group 0 to Group 9).

Page 49

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

Bluetooth USB and Serial Cable 45

Figure 53: Parameter Tabs

13. Save these parameters to your PC for future use by clicking “File-Save Parameter Set As….”

14. Press and hold the Red Lock button on the USB for aprox 3 seconds (until the yellow LEDs

stop flashing).

This will unlock the USB.

After a few seconds you should see the green, (no red), and blue LEDs similar to the picture

below:

Figure 54: Bluetooth BLE LEDs

Notice on the USB the 2 Green arrows (R/W) appear and the Red Lock disappears.

15. Select Parameters-Transfer Parameter Set to Drive

Allow a few seconds for the data to finish transferring from PC to VFD.

On the VFD Display you will see: “Parameters Written Successfully” for a few seconds.

This is how you would restore parameters in the VFD.

VFD Faceplate Parameter Access

Page 50

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

Bluetooth USB and Serial Cable 46

16. Call up the VFD Parameter list with the VFD keypad.

Press and hold the Navigate key > 2 seconds.

Figure 55: Navigate Key

You should see the parameters on the VFD faceplate display.

You can press the up and down Arrow Buttons to look at the various parameters.

Press the Navigate key once quickly to see the value of the parameter selected.

VFD Suite Real-Time Edit and Drive Monitor Tool

17. Click Real-Time Edit Mode button to enable Real-Time mode.

18. Scroll down to the Parameter P0-65 “Drive Life Time” row and select the box in the Refresh

Column.

You should see dynamic data updating in the Value Column.

19. Choose File-Save Parameter Set as your backup copy of the Real-Time parameters.

To select the Drive Monitor Tool, you must briefly leave the Real-Time Edit mode.

20. Click Disable Real-Time Edit.

21. Click Tools-Drive Monitor Tool.

22. Click the Enable Real-Time Monitor button.

23. In the “Local” column select the box for the VFD on your list.

You should see Live data on the Monitor Screen.

Figure 56: Local Column

24. Start the Drive by pressing the green “Start The Motor” button (motor will RUN if

permissives are true).

25. Enter a “Target Motor Speed” to Run the Drive.

26. Press the button again to Reverse the Motor.

27. Stop the Motor when finished.

Page 51

PACMotion VFD Syllabus Section 7

GFK-3167A April 2020

Bluetooth USB and Serial Cable 47

28. Disable the Real-Time Monitor when finished.

VFD Real-Time Edit and Drive Monitor Tool

To use the Scope and Data Logging Tool you must leave the Real-Time Edit mode.

29. Click Disable Real-Time Edit.

30. Click Tools-Scope/Data Logger

Figure 57: Scope/Data Logger

31. Choose the Channel 1 and 2 data similar to below and then Click the START Button to

Capture Data.

(Fieldbus Speed Ref (Hz) and Master Speed Ref (Hz))

32. Click the STOP Button to stop the capture.

33. Choose File-Save Scope Data to keep the Captured information.

This can also be saved as a CSV file type for analysis.

Page 52

PACMotion VFD Syllabus Section 8

GFK-3167A April 2020

Serial RS-485 Communication to the VFD 48

Serial RS-485 Communications to the VFD

1. Make sure your PC supports an open USB port and plug in the USB-to-Serial device

(typical part number IC855-CABL-USB485).

This is wired to connect to the Optibus pins (4 and 5) of the VFD serial.

Figure 58: USB-to-Serial Devices

Your PC should recognize the USB device and assign a COM port.

Page 53

PACMotion VFD Syllabus Section 8

GFK-3167A April 2020

Serial RS-485 Communication to the VFD 49

2. Click Tools – Select Communications Device.

Figure 59: Select Communication Device

3. Choose the “Wired Serial Interface (RS485/RS232)” and the appropriate COMx port

number.

Figure 60: Connection Type

4. Click the “Connect” Button.

You should be able to Scan the Drive Network now and perform any of the functions in the

above document as you did with the Bluetooth USB device.

Supporting Files

Figure 61: VFD Demo Case

VFD_S2_230V_0.75k

W_V2.50_DemoCase.ptl

Right-click the icon to Copy the file.

Page 54

PACMotion VFD Syllabus Section 9

GFK-3167A April 2020

PACMotion VFD Fieldbus Option Modules/Setup 50

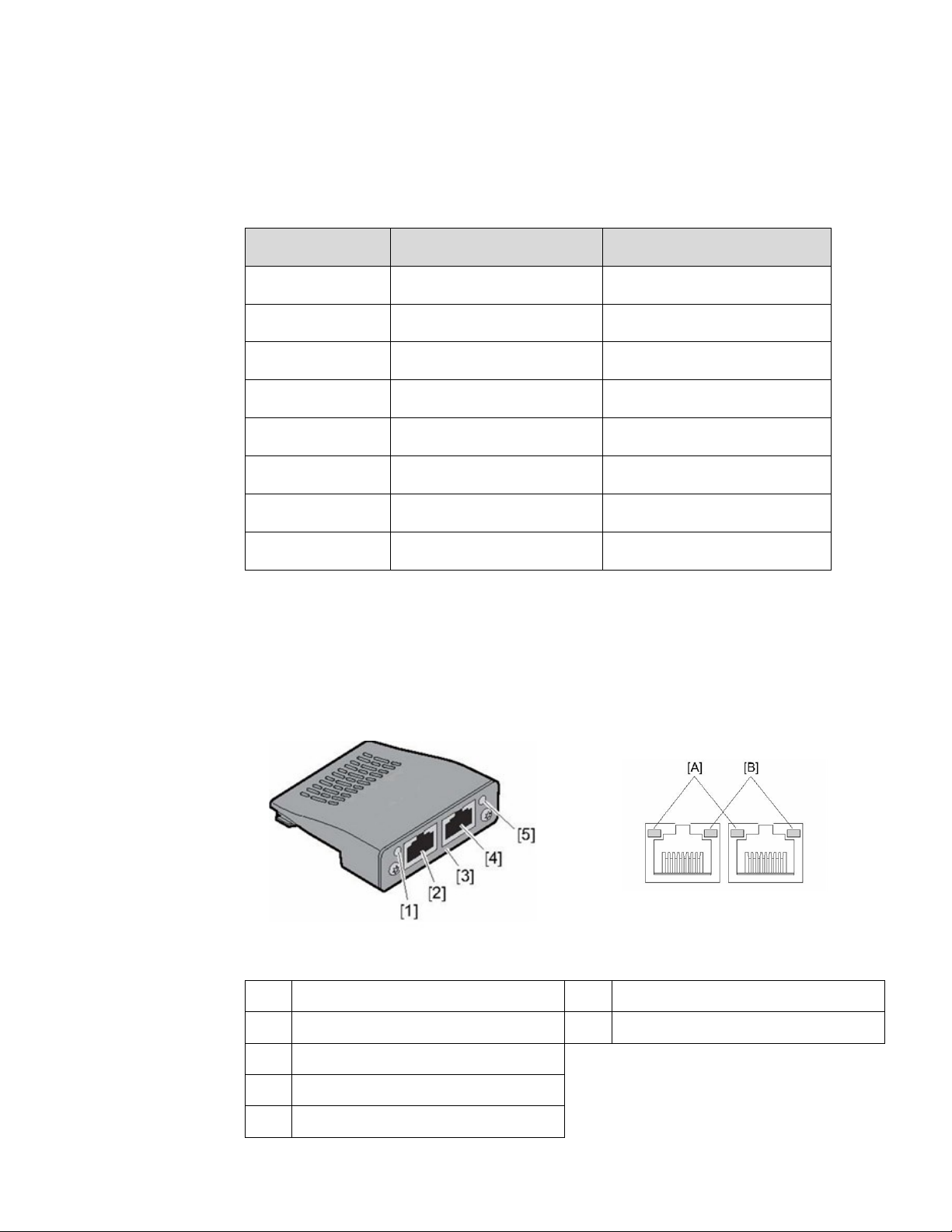

PACMotion VFD Fieldbus Option Modules and Setup (NOTE 8)

MODBUS/TCP FIELDBUS OPTION MODULE

Option

Module

IC866OC-M

Modbus TCP Option

Card for VFD

The Modbus/TCP option card permits the PACMotion Drive to connect to a Modbus/TCP

network.

Figure 62: Modbus/TCP Option Card

Figure 63: RJ45 Connectors &

Network Activity LEDs,

Modbus/TCP Option Card

[1]

LED: NS

[A]

LED: Activity

[2]

RJ45: P1

[B]

LED: Link

[3]

Labeling: Modbus/TCP

[4]

RJ45: P2

[5]

LED: MS

Bus Specific Technical Data

Baud rate

10/100 Mbaud in full duplex mode

Connection technology

2 × RJ45

Page 55

PACMotion VFD Syllabus Section 9

GFK-3167A April 2020

PACMotion VFD Fieldbus Option Modules/Setup 51

Hardware Insertion and Removal

Remove power from the VFD. Using a T09 driver bit, backout the option module 2 screws

approximately 4 or 5 turns each. This should allow the locking tabs to retract to a flat

position. Insert the module into the VFD fieldbus option module cage and gently press it

into place. Secure the T09 screws until they touch the module. . This will engage the

locking tabs to hold it in place. Do not over tighten .

Note: If the T09 screws are not backed out first the module will not insert/remove

properly.

To remove the option module remove power from the VFD. Using a T09 driver bit backout

the option module 2 screws approximately 4 or 5 turns each. Gently pull the module out

by pulling on teh 2 screws.

IP Address Setup

The IP address of the Modbus/TCP module is set with a DHCP Server or with the

IPCONFIGTOOL software from Anybus.

Start-Up and Operation

Modbus/TCP

Parameter setting

P1-12 = 4 (Fieldbus)

P1-14 = 101 (Extended parameter description)

IP address

The basic setting of the option card is the DHC protocol. To establish

communication with the network, set the IP address using the

"Anybus IPconfig" software. The freeware is available at

www.anybus.com.

Bus structure

You can use the integrated Ethernet switch to achieve line topologies

known from the fieldbus technology. Other bus topologies, such as

star or tree, are also possible. Ring topologies are not supported.

LEDs

The Modbus/TCP option card has two LEDs, designated per Figure 62 as:

• NS for Network Status and

• MS for Module Status.

Page 56

PACMotion VFD Syllabus Section 9

GFK-3167A April 2020

PACMotion VFD Fieldbus Option Modules/Setup 52

Network Status LED

Status

Explanation

Off

No supply voltage available.

Lights up green

Connection established, communication available.

Flashing green

Connection established, communication not available.

Lights up red

IP address is set to 0.0.0.0.

Flashing red

Communication timeout.

Module Status LED

Status

Explanation

Off

No supply voltage available.

Lights up green

Ethernet connection established, communication not

available.

Lights up red

Option card fault.

Flashing red

IP conflict.

Modbus TCP Data Exchange

Modbus TCP process data is exchange utilizing the same format as described in section

9.1.1 Structure and Settings of Process Data Words. The mapping to Modbus TCP

Registers is shown below.

Reference Word

Modbus TCP Register4

PO1

300001

PO2

300002

PO3

300003

PO4

300004

PI1

400001

PI2

400002

PI3

400003

PI4

400004

4

Modbus Clients may address the first Modbus register as register 300001/400001. This assumes an address offset starting at 1. For

Clients that use zero based addressing just subtract 1.

Page 57

PACMotion VFD Syllabus Section 9

GFK-3167A April 2020

PACMotion VFD Fieldbus Option Modules/Setup 53

Modbus TCP Connection Timeout

The VFD Modbus TCP interface allows the user to set the “Communication Loss Timeout”

and “Communication Loss Action” values. These parameters are at addresses P5-05 and

P5-06 respectively. The Timeout units are 1 = 0.1 sec and the range is from 0.0 (disable) to

5.0 seconds.

Drive Parameter Access – Direct Address Method

The Modbus Interface allows the user to read/write directly the drive parameters. To

perform this function, the user can directly access the parameter. Simply add the 3-digit

parameter number to the Modbus offset of 400000.

For example:

Read parameter P1-01 (Maximum Frequency), perform the following

Read Modbus TCP Register 400101 value (scaling in 0.1 Hz).

Write parameter P1-01 (Maximum Frequency) = 60.0 Hz, perform the following

Write to Modbus TCP Register 400101 value = 600 (scaling in 0.1 Hz)

Drive Parameter Access – Indirect Address Method

The Modbus Interface allows the user to read/write indirectly the drive parameters. To do

this you must use an Index number (Pointer) to point to the Parameter (Value) you want to

access. The Index is at Modbus Address 404131. You must also use the next address

404132 to Read or Write the data desired.

EXAMPLE: Given that the Index pointer = Addr. 404131 and Index Value = Addr. 404132

Read parameter P1-01 (Maximum Speed), perform the following:

Write to Modbus TCP Register 404131 a value = 101 <- Code for P1-01 (reference table)

*Read from Modbus TCP Register 404132 value = Parameter Value in P1-01

*P2-39 Lock/Unlock = will not affect this R/W of Parameters

To Write to P1-01 01 (Maximum Speed) and set it to 1800 rpm, perform the following:

Write to Modbus TCP Register 404131 value = 101 (This moves P1-01 current value into

404132)

**Write to Modbus TCP Register 404132 with the New value = 3600 (scaling in .5 rpm)

eg. 6 = 0.1Hz

**P1-12 must be = 4 for Write capability into a Parameter. This could be done on the VFD

faceplate or with the PACMotion VFD Suite.

Page 58

PACMotion VFD Syllabus Section 9

GFK-3167A April 2020

PACMotion VFD Fieldbus Option Modules/Setup 54

PROFINET FIELDBUS OPTION MODULE

Option Module Details: PROFINET Option Card for VFD Part Number: IC866-OC-P

The PROFINET option card permits the PACMotion VFD Drive to connect to a PROFINET

network.

PROFINET Option Card

RJ45 Connectors & Network

Activity LEDs, PROFINET Option

Card

[1]

LED: NS

[A]

LED: Activity

[2]

RJ45: P1

[B]

LED: Link

[3]

Labeling: PROFINET I/O

[4]

RJ45: P2

[5]

LED: MS

Bus Specific Technical Data

Baud rate

10/100 Mbaud in full duplex mode

Connection technology

2 × RJ45

Page 59

PACMotion VFD Syllabus Section 9

GFK-3167A April 2020

PACMotion VFD Fieldbus Option Modules/Setup 55

Hardware Insertion and Removal

Remove power from the VFD. Using a T09 driver bit, backout the option module 2 screws

approximately 4 or 5 turns each. This should allow the locking tabs to retract to a flat

position. Insert the module into the VFD fieldbus option module cage and gently press it

into place. Secure the T09 screws until they touch the module. This will engage the locking

tabs to hold it in place. Do not over tighten.

Note: If the T09 screws are not backed out first the module will not insert/remove

properly.

To remove the option module remove power from the VFD. Using a T09 driver bit backout

the option module 2 screws approximately 4 or 5 turns each. Gently pull the module out.

Page 60

PACMotion VFD Syllabus Section 10

GFK-3167A April 2020

PDO/PDI Data Map and Addressing Modbus/TCP PDO Data 56

PDO/PDI Data Map and Addressing (Note 9)

VFD Process Data Output (PDO1 - 4) From VFD to Client (Master)

The Client will initiate communications and READ this data from the VFD.

Figure 64: Modbus/TCP Client (Master)

Modbus/TCP PDO Data (or Built-in Modbus RTU Serial Port)

PDO1 (Drive Status Word - Fixed)

Modbus/TCP address: 300001

Bit 0

0 = Drive Disabled (Stopped), 1 = Drive Enabled (Running)

Bit 1

0 = Drive Healthy, 1 = Drive Tripped

Bit 2

No Function

Bit 3

0 = Drive Ready (STO Closed), 1 = Drive Inhibit (STO Open)

Bit 4

0 = Maintenance Time Not Reached, 1 = Maintenance Time Reached

Bit 5

0 = Not in Standby (Sleep), 1 = Standby (Sleep) mode Active

Bit 6

0 = Drive Not Ready, 1 = Drive Ready (Mains Power Applied, No Inhibit,

No Trip, Enable Input Present)

Bit 7

No Function

Bits 8-15

Fault Number in the event of a Drive Trip

Page 61

PACMotion VFD Syllabus Section 10

GFK-3167A April 2020

PDO/PDI Data Map and Addressing Modbus/TCP PDO Data 57

PDO2 (Output Frequency - Fixed)

Modbus/TCP address: 300002

123 = 12.3 Hz

PDO3 (Output Current or P5-12 select)

Modbus/TCP address: 300003

105 = 10.5 A

PDO4 (Output Torque or P5-08 select)

Modbus/TCP address: 300004

33 = 3.3 %

Modbus/TCP or RTU PDI Data

VFD Process Data Input (PDI1 - 4) From Client (Master) To Server (Slave)

The Client will initiate communications and WRITE this data to the VFD.

Figure 65: Modbus/TCP Client (Master)

PDI1 (Drive Control Word)

Modbus/TCP address: 400001

Bit 0

0 = Stop the Drive (Disable), 1 = Run the Drive (Enable)

Bit 1

0 = Allow Drive to Run, 1 = Enable Drive to Stop with 2nd deceleration ramp

(Fast stop request.)

Bit 2

0 = No Fault Reset, 1 = reset any active faults or trips on the drive (Reset

request).

This bit must be reset to zero once the fault has been cleared.

Bit 3

0 = Allow Drive to Run. Set to 1 to issue a coast stop command (Coast stop

request).

Bit 4-7

No Function

Page 62

PACMotion VFD Syllabus Section 10

GFK-3167A April 2020

PDO/PDI Data Map and Addressing Modbus/TCP PDO Data 58

PDI2 (Frequency Reference)

Modbus/TCP address: 400002

500 = 50.0Hz

PDI3 (Torque Reference or P5-14 select)

Modbus/TCP address: 400003

1000 = 100.0%

PDI4 (Fieldbus Ramp or P5-13 to select, P5-07 to Enable)

Modbus/TCP address: 400004

60000 = 600.00s

Page 63

PACMotion VFD Syllabus Section 10

GFK-3167A April 2020

PDO/PDI Data Map and Addressing Modbus/TCP PDO Data 59

PROFINET PDO Data

VFD Process Data Output (PDO1 - 4) From VFD to PROFINET Controller

The PROFINET Controller will RECEIVE this data from the VFD.

Figure 66: PROFINET PDO Data

PDO1 (Drive Status Word - Fixed)

PROFINET Slave assigned address: %AI00001 (Typical)

PDO2 (Output Frequency - Fixed)

PROFINET Slave assigned address: %AI00002 (Typical)

123 = 12.3 Hz

PDO3 (Output Current or P5-12 select)

Bit 0

0 = Drive Disabled (Stopped), 1 = Drive Enabled (Running)

Bit 1

0 = Drive Healthy, 1 = Drive Tripped

Bit 2

No Function

Bit 3

0 = Drive Ready (STO Closed), 1 = Drive Inhibit (STO Open)

Bit 4

0 = Maintenance Time Not Reached, 1 = Maintenance Time Reached

Bit 5

0 = Not in Standby (Sleep), 1 = Standby (Sleep) mode Active

Bit 6

0 = Drive Not Ready, 1 = Drive Ready (Mains Power Applied, No Inhibit, No Trip, Enable Input

Present)

Bit 7

No Function

Bits 8-15

Fault Number in the event of a Drive Trip

Page 64

PACMotion VFD Syllabus Section 10

GFK-3167A April 2020

PDO/PDI Data Map and Addressing Modbus/TCP PDO Data 60

PROFINET Slave assigned address: %AI00003 (Typical)

105 = 10.5 A

PDO4 (Output Torque or P5-08 select)

PROFINET Slave assigned address: %AI00004 (Typical)

33 = 3.3 %

VFD Data Output (PDO5 - 8) From VFD to PROFINET Controller – Additional to PDO

PROFINET Slave assigned address: WORD 5 = %AI00005 (Typical)

PROFINET Slave assigned address: WORD 6 = %AI00006 (Typical)

PROFINET Slave assigned address: WORD 7 = %AI00007 (Typical)

Not Defined

Bit 0

1 = Module OK (drive Healthy No Trip)

Bit 1

0 = Drive Healthy, 1 = Fault Present, Drive Tripped

Bit 2

0 = Port 1 Link Down, 1 = Port 1 Link Up

Bit 3

0 = Port 2 Link Down, 1 = Port 2 Link Up

Bit 4

Not Defined

Bit 5

Not Defined

Bit 6

Not Defined

Bit 7

Not Defined

Bit 8

0 = Mains Power Loss (“ML” indication), 1 = Mains power OK

Bit 9

1 = 24 V backup (external 24 V mode)

Bit 10

MRP enabled (fixed as 1)

Bit 11

MRP role (fixed as 0)

Bits 12-14

Not Defined

Bit 15

1 = Drive Ready to Run

Bit 0

0 = Drive Disabled (Stopped), 1 = Drive Enabled (Running)

Bit 1

0 = STO Open/OFF (Fault), 1 = STO Closed/ON (Good)

Bit 2

0 = No Service Due, 1 = Service Due

Page 65

PACMotion VFD Syllabus Section 10

GFK-3167A April 2020

PDO/PDI Data Map and Addressing Modbus/TCP PDO Data 61

PROFINET Slave assigned address: WORD 8 = %AI00008 (Typical)

Not Defined

PROFINET PDI Data

VFD Process Data Input (PDI1 - 4) From PROFINET Controller to VFD

The PROFINET Controller will SEND this data to the VFD.

Figure 67: PROFINET PDI Data

PDI1 (Drive Control Word)

PROFINET Slave assigned address: %AQ00001 (Typical)

Bit 0

0 = Stop the Drive (Disable), 1 = Run the Drive (Enable)

Bit 1

0 = Allow Drive to Run, 1 = Enable Drive to Stop with 2nd deceleration

ramp (Fast stop request.)

Bit 2

0 = No Fault Reset, 1 = reset any active faults or trips on the drive (Reset

request).

This bit must be reset to zero once the fault has been cleared.

Bit 3

0 = Allow Drive to Run. Set to 1 to issue a coast stop command (Coast

stop request).

Bit 4-7

No Function

Page 66

PACMotion VFD Syllabus Section 10

GFK-3167A April 2020

PDO/PDI Data Map and Addressing Modbus/TCP PDO Data 62

PDI2 (Frequency Reference)

PROFINET Slave assigned address: %AQ00002 (Typical)

500 = 50.0Hz

PDI3 (Torque Reference or P5-14 select)

PROFINET Slave assigned address: %AQ00003 (Typical)

1000 = 100.0%

PDI4 (Fieldbus Ramp or P5-13 to select, P5-07 to Enable)

PROFINET Slave assigned address: %AQ00004 (Typical)

60000 = 600.00s

Page 67

PACMotion VFD Syllabus Section 12

GFK-3167A April 2020

PACMotion VFD Data Map and Addressing 63

PACMotion VFD Data Map and Addressing (Note 10)

Complete Address Mapping Modbus/TCP, Modbus RTU, PROFINET

Figure 68: Excel Spreadsheets for all addresses

PACMotion_VFD_A

ddress_Map.xlsx

Right-click the icon to Copy the file. Double-click to Open in Excel.

Page 68

PACMotion VFD Syllabus Section 13

GFK-3167A April 2020

PACMotion VFD Demo Case Details 64

PACMotion VFD Demo Case Details (Note 11)

Quickpanel to CPE100 (Ethernet) and CPE100 to VFD (PROFINET)

Page 69

PACMotion VFD Syllabus Section 13

GFK-3167A April 2020

PACMotion VFD Demo Case Details 65

Quickpanel to CPE100 (Ethernet) and CPE100 to VFD (PROFINET)

Signal Wiring, Interconnection and Addressing

Figure 69: Signal Wiring

Address

RSTi-EP I/O Module

To VFD Terminal Strip

%I00001

EP-1218

DI1 - Monitor Enabled State

%Q00001

EP-2218

DI1 - Enable

%Q00002

EP-2218

DI2 - Reverse

%Q00003

EP-2218

DI3 - Set Speed to SP1

%AI00001

EP-3164

AQ1 – Speed Feedback for Terminal Strip

operation

%AQ00001

EP-4164

AI1 – Speed Reference for Terminal Strip

operation

Page 70

PACMotion VFD Syllabus Section 13

GFK-3167A April 2020

PACMotion VFD Demo Case Details 66

Figure 70: Interconnection and Addressing

Page 71

PACMotion VFD Syllabus Section 13

GFK-3167A April 2020

PACMotion VFD Demo Case Details 67

PACMotion VFD Demo Case and Factory Reset

Resetting the PACMotion VFD to Factory defaults

1. If necessary, you can reset the parameters VFD to factory defaults

Figure 71: Reset Parameters to Factory Defaults

Setting the following PACMotion VFD Parameters for PROFINET Demo Case Operation

2. Set the following Parameters for PROFINET Operation:

A file containing these settings can be found in Application Note 7.

They can be downloaded using the PACMotion VFD Studio. The file name is:

VFD_S2_230V_0.75kW_V2.50_DemoCase.ptl

Parameter

Value

Definition

P1-14

201

Extended menu access (201=all parameters)

P4-02

1

Autotune (1=enable, VFD will set back to 0)

P1-07

230

Motor rated voltage (AC Volts)

P1-08

0.4

Motor rated current (Amps)

P1-09

60

Motor rated frequency (Hz)

P1-10

1600

Motor rated speed (RPM)

P1-12

4

Primary command source (4 = Fieldbus)

P2-13

0

AO2 Output 2 function (DO2 = 24VDC)

Page 72

General Contact Information

Home link: http://www.emerson.com/industrial-automation-controls

Knowledge Base: https://www.emerson.com/industrial-automation-controls/support

Technical Support

Americas

Phone: 1-888-565-4155

1-434-214-8532 (If toll free option is unavailable)

Customer Care (Quotes/Orders/Returns): customercare.mas@emerson.com

Technical Support: support.mas@emerson.com

Europe

Phone: +800-4444-8001

+420-225-379-328 (If toll free option is unavailable)

Customer Care (Quotes/Orders/Returns): customercare.emea.mas@emerson.com

Technical Support: support.mas.emea@emerson.com

Asia

Phone: +86-400-842-8599

+65-6955-9413 (All other Countries)

Customer Care (Quotes/Orders/Returns): customercare.cn.mas@emerson.com

Technical Support: support.mas.apac@emerson.com

Any escalation request should be sent to: mas.sfdcescalation@emerson.com

Note: If the product is purchased through an Authorized Channel Partner, please contact the seller directly

for any support.

Emerson reserves the right to modify or improve the designs or specifications of the products mentioned in

this manual at any time without notice. Emerson does not assume responsibility for the selection, use or

maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson product

remains solely with the purchaser.

© 2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a trademark and

service mark of Emerson Electric Co. All other marks are the property of their respective owners.

Loading...

Loading...