Page 1

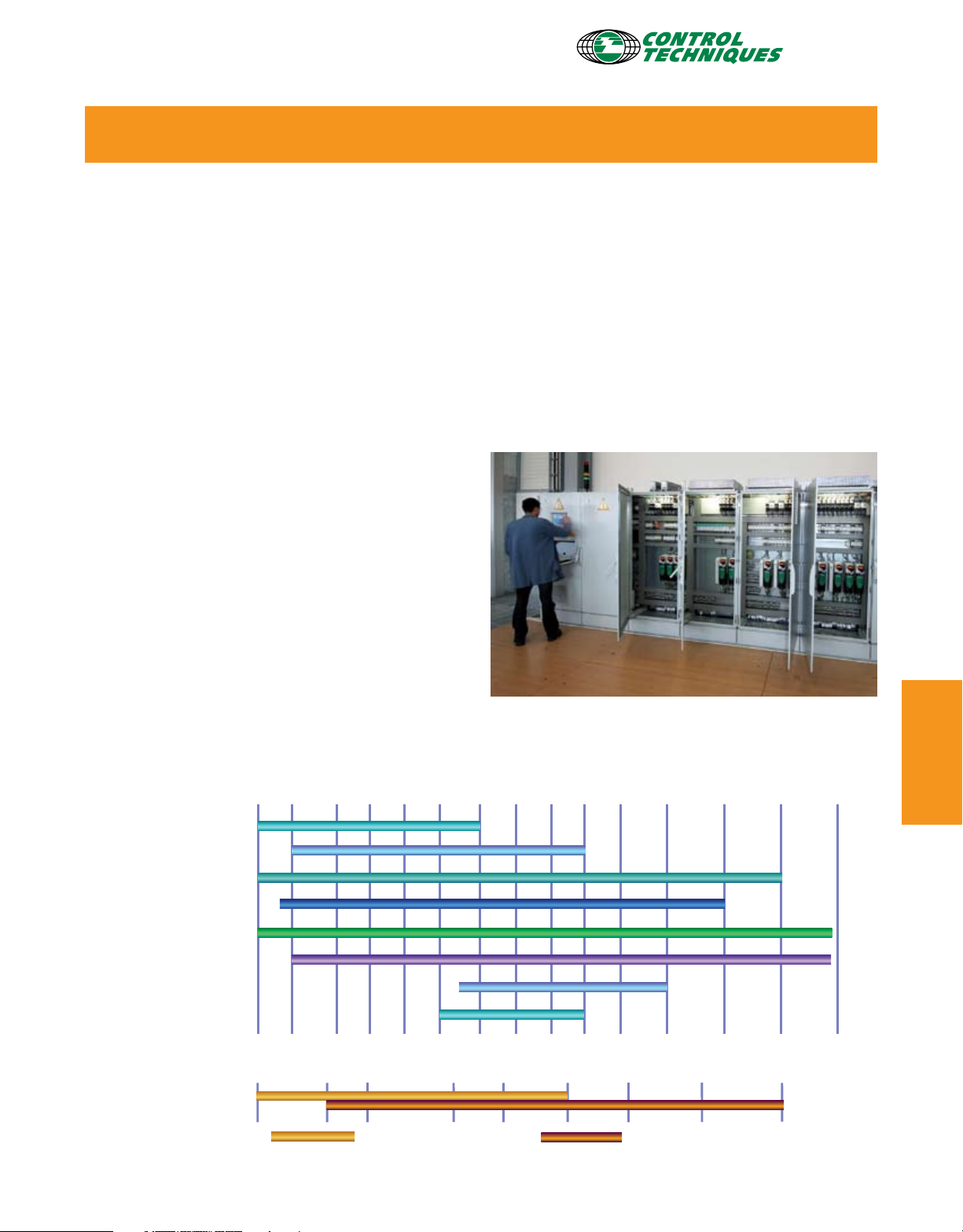

Packaged Drives

and Engineered Systems

Page 2

www.emersonct.com

AC RapidPak

DC RapidPak

AC CustomPak

DC CustomPak

AC Systems

DC Systems

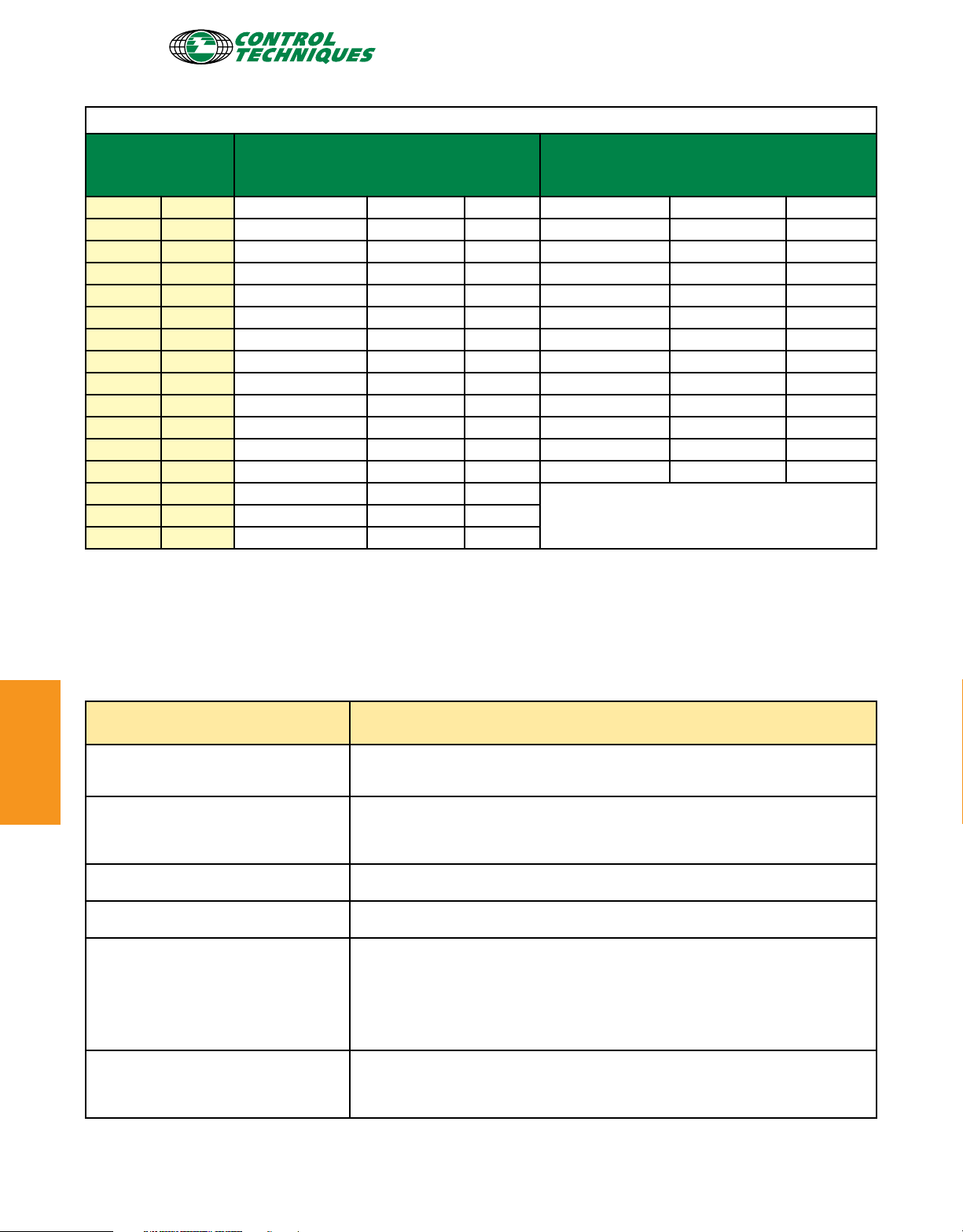

Unidrive SP (fs)*

Large Enclosed

*(fs) = Freestanding Drives

1 10 50 100 200 400 500 1000 1,500 2,000800300

5

20

3,000

Drive hp

Motion Control

Systems

Servo Drive lb-in 5 20 40 750 3,000 4,5001,500200150

with Brushless Servomotor

with AC Vector motor

800-893-2321

Packaged Drives and Engineered Systems

Control Techniques known worldwide for packaged

drives and engineered systems now offers an even wider

variety of enclosure, power, and control options.

From the simple to the complex, we offer six levels

of turn-key solutions to meet your requirements.

O AC RapidPaks

O DC StandardPaks

O AC & DC CustomPaks

O Unidrive SP Freestanding Drives

O Large Enclosed Drives

O Engineered Systems

Our engineered solutions are built with the quality

and reliability you expect from a leading world-wide

supplier and UL Certified shop. Our quick-turn custom

engineered packaged products allow us to respond to

the most demanding requirements with delivery lead

times among the shortest in the industry. Both packaged

products and system solutions are backed by formal

engineering documentation and drawings. Our refined

processes, combined with robust after-sale support

programs, result in a single-source solution, with single

source accountability.

Total Systems Solutions

When the requirement is for a total system solution,

our Engineered Systems group is ready to fulfill your

needs. Our team consists of industry experts who know

what is required for a successful drive application. Our

unparalleled technology coupled with the expertise of

our engineering, field installation and service teams have

made Control Techniques the choice for thousands of

engineered drive systems worldwide.

Packaged Drives and Engineered Systems Power Range (460 VAC)

Packaged Drives &

Engineered Systems

319

Page 3

RapidPaks and CustomPaks

www.emersonct.com

800-893-2321

RapidPaks

Think RapidPak, when you need a packaged drive fast.

The AC RapidPak has a one week standard lead time and

express lead time in as little as 24 hours. Designed to

be easily tailored to a multitude of applications, these

pre-engineered AC drive packages feature the most

popular choices for operator controls, keypads, fusing,

reactors and disconnects. The N12 (PPBF) or N3R

RapidPak enclosure will have you up and running fast.

AC RapidPaks are offered with the Commander SK,

Commander GP20 and the Unidrive SP. Voltages options

are 208V to 460V models. Horsepower extends up to

75 hp, and to 2,000 hp as a CustomPak.

Extensive RapidPak Options

With over 40 options available, customers have the

opportunity to create a RapidPak or CustomPak that

meets most single-drive control system needs.

Engineered Systems

Packaged Drives &

StandardPaks

DC StandardPaks are offered with the Mentor II and

Quantum III digital DC drive. Voltage options are 208V to

480V Models. Horsepower range 5 to 500 hp @ 480V,

5 to 200 hp @ 240V input. Standard lead time is one to

three weeks depending on options.

CustomPaks

Think CustomPak when you need custom configured AC

or DC drive package. CustomPaks are ideal when higher

horse powers and higher voltages are needed, and when

there are special needs. CustomPaks include 18 pulse—

low harmonic drives, stainless steel enclosures, enclosure

heating and air conditioning, lighting and outlets, all

built to your requirements, and fully documented.

These engineered packages are be tailored to meet the

needs of the most demanding applications. Lead time is

typically four to six weeks.

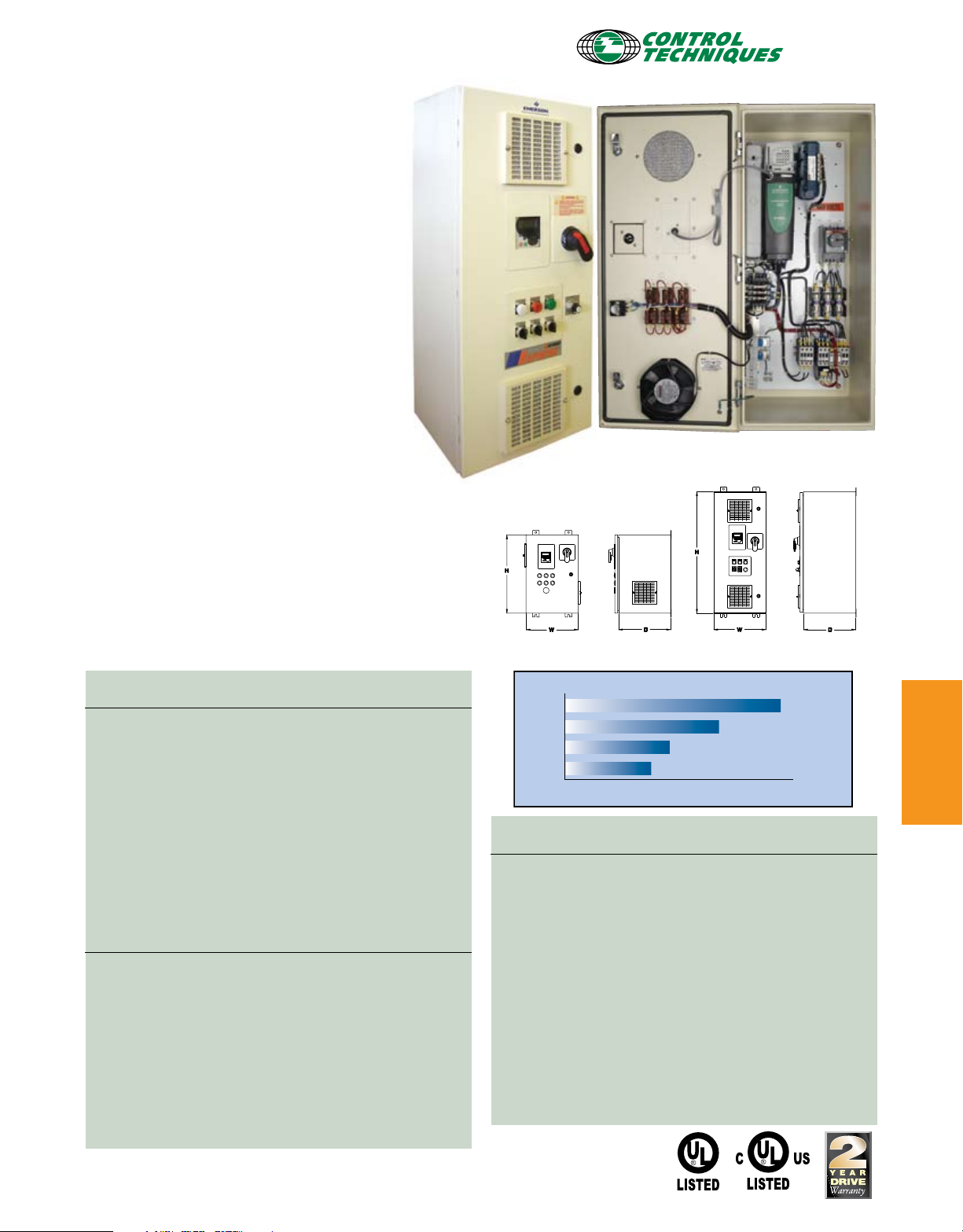

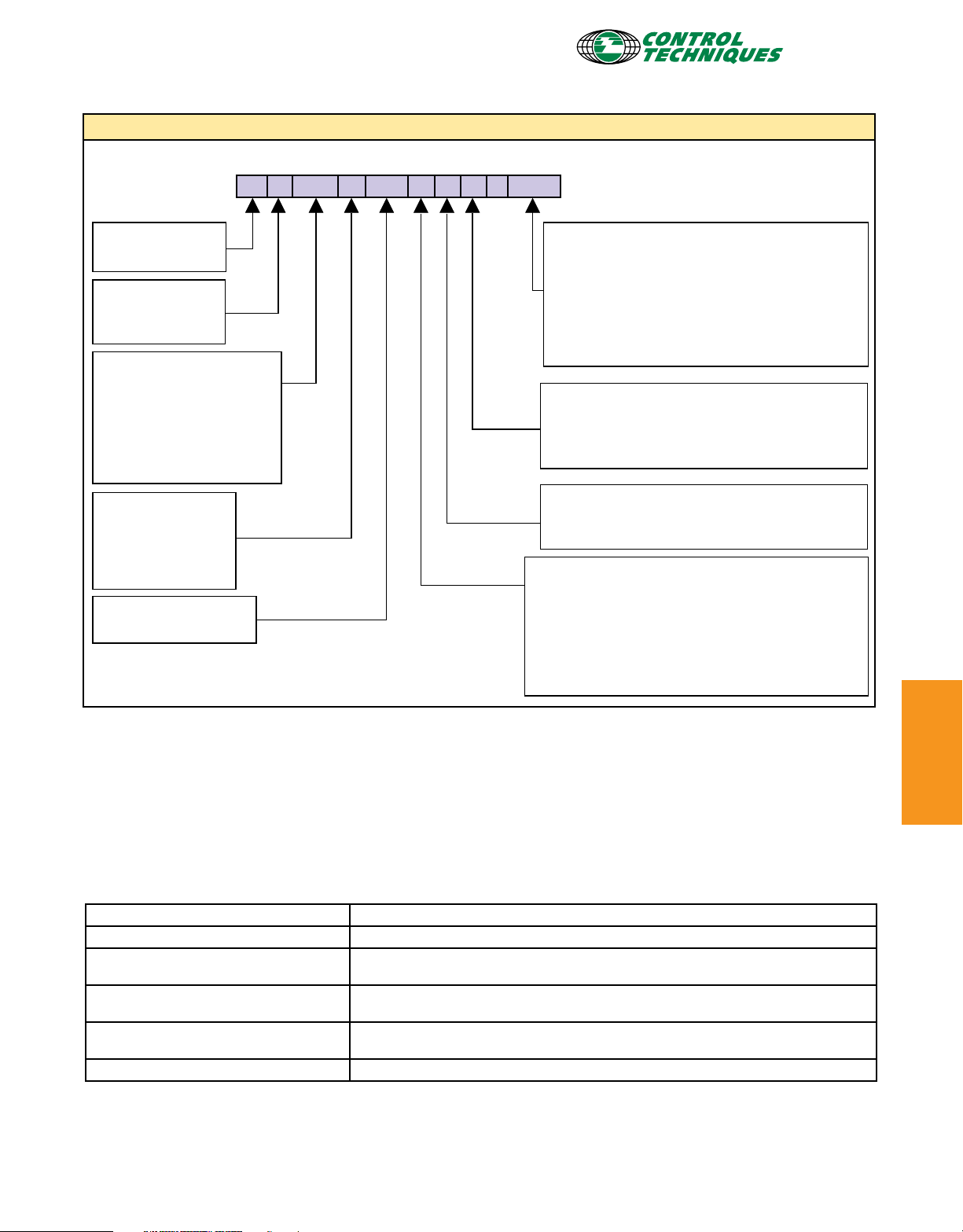

Large Enclosed Drives

Our large enclosed drives are a high-horsepower

NEMA12 Positive Pressure Blown and Filtered AC drive

system with all the state-of-the-art integration features

of the Unidrive SP. The robust Unidrive SPM technology

from Control Techniques gives users the power,

performance, and the ultimate in flexibility for all AC

applications from 100 hp to 500 hp.

320

See our Packaged Soft Starters including Crusher

Duty solutions to 1,500 hp in the Soft Starter Section.

This cost competitive, pre-engineered “AC In – AC

Out” solution is a perfect match for both highperformance, and standard drive applications, such as

fans, pumps and conveyors.

Unidrive SP Free Standing Drives

The Unidrive SP Free Standing AC drives extend the

power range of “the Benchmark” solution platform to

1000 hp, while providing users with the same integration

options as the standard, panel-mount Unidrive SP. Packaged in an IP21 or IP23 enclosure, these Free Standing

drives deliver maximum horsepower density for physical

size, and include rectifier, inverter and inductor. In addition, an “Incomer” enclosure is available with line power

bus bars included to integrate fuse switch/MCCB etc.

Page 4

www.emersonct.com

0

Voltage

Horsepower

230

1-40 HP

380

1-60 HP

208

.75-30 HP

460

1-200 HP

800-533-0031

AC RapidPak

With our RapidPak solutions, and one of the

shortest lead times in the industry, you will have

an expertly packaged complete drive solution

within days of placing your order. One week

lead time is standard with a 24 hour option

available.

Use the intuitive Order Code Configurator on

the following pages to customize the package

to your exact requirements. Choose between

the simple and flexible Commander SK, the

general purpose Commander GP20, and the

high performance Unidrive SP. Each of these

drives is available in either the space saving

“Cube” style or the option abundant “Slimline”

enclosure. A main disconnect, door-mounted

keypad, input and output reactors, and a

variety of door mounted operator’s are only

the beginning of the long list of options. Combine these

with an SM Solutions Module for fieldbus connectivity,

additional I/O, or a scalable PLC to solve the most difficult

applications. Please see the AC Drives Section for SM

Module options and drive compatibility.

Slimline, 460VAC, 15 HP, OP Stn #5, Keypad,

CB, Input reactor, 3 contactor Bypass

These UL508A approved drive packages come standard

with a 2 year Drive Warranty.

Standard Features

• Open or Closed Loop Vector, V/Hz,

Rotor Flux Control (RFC) performance

• Input Voltage 208-460 VAC, 50/60 Hz

• Cube or Slimline Enclosure, Nema -12 (PPBF), fully

gasketed, (PPBF) Positive Pressure Blown and Filtered

• AC Line Fusing

• Input Main lugs for customer termination

• Standard lead time in one week

• CT Soft WindowsTM-based programming tool

Enclosure Design

• Cube: smallest possible package drive and input

disconnect option.

• Slimline: compact packaging suitable for side-by side

mounting ( only ½” spacing required)

• Textured, beige powder coat

• Nema -12 (PPBF), fully gasketed, (PPBF) Positive

Pressure Blown and Filtered

• 14 gauge steel

Slimline StyleCube Style

Options

• Normal Duty rating (110% for 1 minute)

• Heavy Duty rating (150% for 1 minute)

• 3%, AC Line Reactor

• 3%, AC Output Reactor

• Auto or Manual 3-Contactor Bypass

• Blower motor starter with adjustable overload

• Nema 3R, Enclosure

• Door mounted operator devices.

• Circuit breaker or Non-fused disconnect switch

• Door mounted LCD (SM – Keypad Plus) with three

lines of text.

• SM-Modules not included in the Order Code

configurator, please consult with factory.

AC RapidPak

321

Page 5

AC RapidPak

www.emersonct.com

800-533-0031

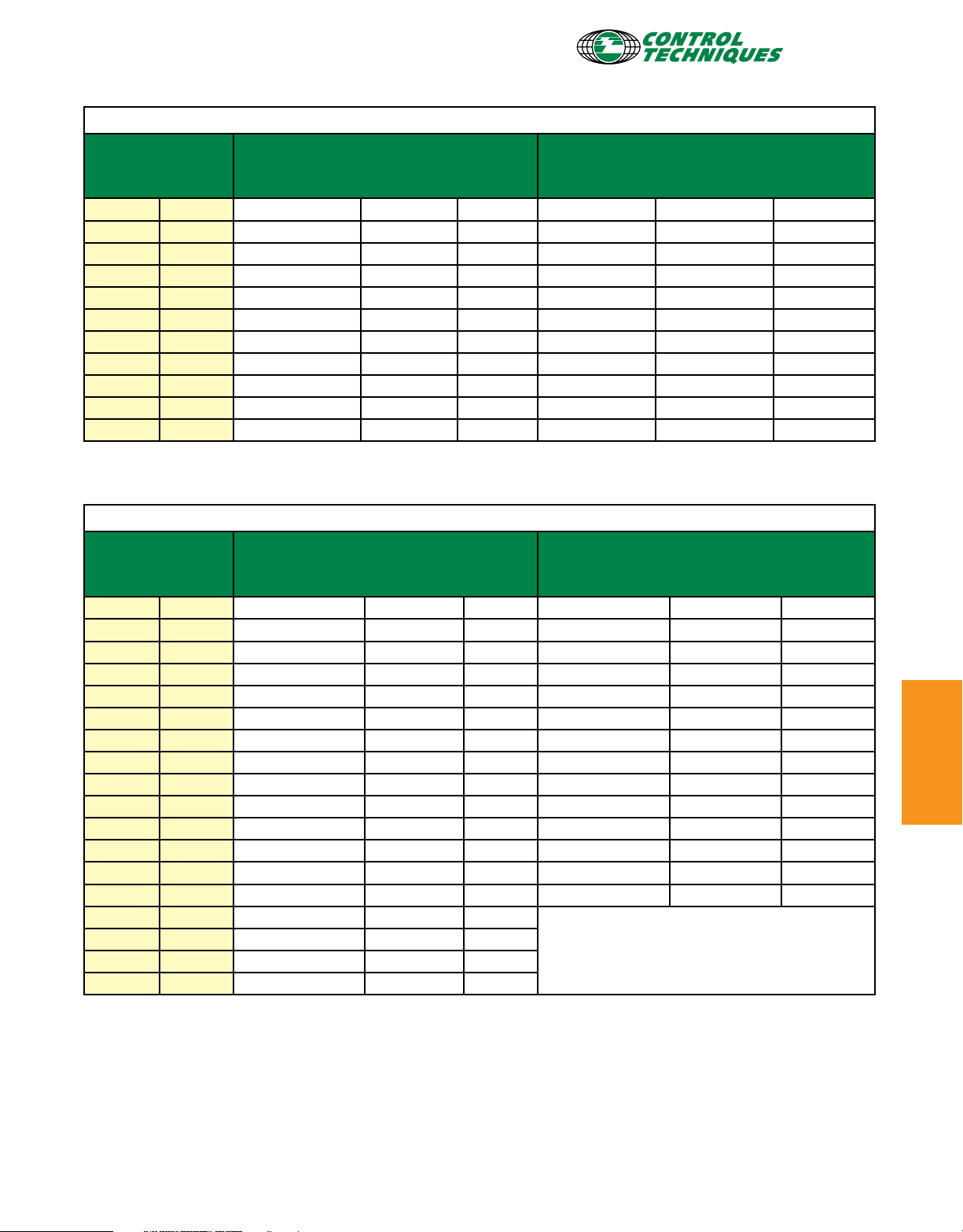

Normal Duty 208 VAC, 3-Phase Input and Output, 50/60 Hz Input

Normal Duty

110% for 1 minute

HP Amps

1 5.2 RSxxN8001xxx-x 38x16x16 135 RCxxN8001xxx-x 24x16x16 65

1.5 6.8 RSxxN81P5xxx-x 38x16x16 135 RCxxN81P5xxx-x 24x16x16 65

2 9.6 RSxxN8002xxx-x 38x16x16 135 RCxxN8002xxx-x 24x16x16 65

3 15.5 RSxxN8003xxx-x 38x16x16 140 RCxxN8003xxx-x 24x16x16 70

5 22 RSxxN8005xxx-x 38x16x16 140 RCxxN8005xxx-x 24x16x16 70

7.5 28 RSxxN87P5xxx-x 38x16x16 140 RCxxN87P5xxx-x 24x16x16 70

10 42 RSxxN8010xxx-x 56x16x16 210 RCxxN8010xxx-x 30x24x16 180

15 54 RSxxN8015xxx-x 56x16x16 210 RCxxN8015xxx-x 30x24x16 180

20 68 RSxxN8020xxx-x 72x21x16 240 RCxxN8020xxx-x 39x30x16 145

25 80 RSxxN8025xxx-x 72x21x16 300 RCxxN8025xxx-x 39x30x16 200

30 104 RSxxN8030xxx-x 72x21x16 300 RCxxN8030xxx-x 39x30x16 200

Order Code

Slim Enclosure Cube Enclosure

Dimensions

HxWxD (in)

Weight

(Ibs)

Order Code

Dimensions

HxWxD (in)

Heavy Duty 208 VAC, 3-Phase Input and Output, 50/60 Hz Input

Heavy Duty

110% for 1 minute

HP Amps

.75 4.3 RSxxH80P7xxx-x 38x16x16 135 RCxxH80P7xxx-x 24x16x16 65

1 5.8 RSxxH8001xxx-x 38x16x16 135 RCxxH8001xxx-x 24x16x16 65

1.5 7.5 RSxxH81P5xxx-x 38x16x16 135 RCxxH81P5xxx-x 24x16x16 65

2 10.6 RSxxH8002xxx-x 38x16x16 140 RCxxH8002xxx-x 24x16x16 70

3 17 RSxxH8003xxx-x 38x16x16 140 RCxxH8003xxx-x 24x16x16 70

5 25 RSxxH8005xxx-x 38x16x16 140 RCxxH8005xxx-x 24x16x16 70

7.5 31 RSxxH87P5xxx-x 56x16x16 140 RCxxH87P5xxx-x 30x24x16 70

10 42 RSxxH8010xxx-x 56x16x16 210 RCxxH8010xxx-x 30x24x16 145

15 56 RSxxH8015xxx-x 72x21x16 210 RCxxH8015xxx-x 39x30x16 145

20 68 RSxxH8020xxx-x 72x21x16 300 RCxxH8020xxx-x 39x30x16 200

25 80 RSxxH8025xxx-x 72x21x16 300 RCxxH8025xxx-x 39x30x16 200

Order Code

Slim Enclosure Cube Enclosure

Dimensions

HxWxD (in)

Weight

(Ibs)

Order Code

Dimensions

HxWxD (in)

Weight

(Ibs)

Weight

(Ibs)

322

Normal Duty 230 VAC, 3-Phase Input and Output, 50/60 Hz Input

Normal Duty

110% for 1 minute

HP Amps

1.5 5.2 RSxxN21P5xxx-x 38x16x16 135 RCxxN21P5xxx-x 24x16x16 65

2 6.8 RSxxN2002xxx-x 38x16x16 135 RCxxN2002xxx-x 24x16x16 65

3 9.6 RSxxN2003xxx-x 38x16x16 135 RCxxN2003xxx-x 24x16x16 65

5 15.5 RSxxN2005xxx-x 38x16x16 140 RCxxN2005xxx-x 24x16x16 70

7.5 22 RSxxN27P5xxx-x 38x16x16 140 RCxxN27P5xxx-x 24x16x16 70

10 28 RSxxN2010xxx-x 38x16x16 140 RCxxN2010xxx-x 24x16x16 70

15 42 RSxxN2015xxx-x 56x16x16 210 RCxxN2015xxx-x 30x24x16 180

20 54 RSxxN2020xxx-x 56x16x16 210 RCxxN2020xxx-x 30x24x16 180

25 68 RSxxN2025xxx-x 72x21x16 240 RCxxN2025xxx-x 39x30x16 145

30 80 RSxxN2030xxx-x 72x21x16 300 RCxxN2030xxx-x 39x30x16 200

40 104 RSxxN2040xxx-x 72x21x16 300 RCxxN2040xxx-x 39x30x16 200

Order Code

Order string: The base Order Code requires a minimum of 12 characters in sequence to create the order string.

Slim Enclosure Cube Enclosure

Dimensions

HxWxD (in)

Weight

(Ibs)

Order Code

Dimensions

HxWxD (in)

Weight

(Ibs)

Page 6

www.emersonct.com

800-533-0031

Heavy Duty 230 VAC, 3-Phase Input and Output, 50/60 Hz Input

Heavy Duty

150% for 1 minute

HP Amps

1 4.3 RSxxH2001xxx-x 38x16x16 135 RCxxH2001xxx-x 24x16x16 65

1.5 5.8 RSxxH21P5xxx-x 38x16x16 135 RCxxH21P5xxx-x 24x16x16 65

2 7.5 RSxxH2002xxx-x 38x16x16 135 RCxxH2002xxx-x 24x16x16 65

3 10.6 RSxxH2003xxx-x 38x16x16 140 RCxxH2003xxx-x 24x16x16 70

5 17 RSxxH2005xxx-x 38x16x16 140 RCxxH2005xxx-x 24x16x16 70

7.5 25 RSxxH27P5xxx-x 38x16x16 140 RCxxH27P5xxx-x 24x16x16 70

10 31 RSxxH2010xxx-x 56x16x16 140 RCxxH2010xxx-x 30x24x16 70

15 42 RSxxH2015xxx-x 56x16x16 210 RCxxH2015xxx-x 30x24x16 145

20 56 RSxxH2020xxx-x 72x21x16 210 RCxxH2020xxx-x 39x30x16 145

25 68 RSxxH2025xxx-x 72x21x16 300 RCxxH2025xxx-x 39x30x16 200

30 80 RSxxH2030xxx-x 72x21x16 300 RCxxH2030xxx-x 39x30x16 200

Order Code

Slim Enclosure Cube Enclosure

Dimensions

HxWxD (in)

Weight

(Ibs)

Order Code

Dimensions

HxWxD (in)

Weight

(Ibs)

Normal Duty 460 VAC, 3-Phase Input and Output, 50/60 Hz Input

Normal Duty

110% for 1 minute

HP Amps

1.5 2.8 RSxxN41P5xxx-x 38x16x16 135 RCxxN41P5xxx-x 24x16x16 70

2 3.8 RSxxN4002xxx-x 38x16x16 135 RCxxN4002xxx-x 24x16x16 70

3 5 RSxxN4003xxx-x 38x16x16 135 RCxxN4003xxx-x 24x16x16 70

5 8.8 RSxxN4005xxx-x 38x16x16 135 RCxxN4005xxx-x 24x16x16 70

7.5 11 RSxxN47P5xxx-x 38x16x16 135 RCxxN47P5xxx-x 24x16x16 70

10 15.3 RSxxN4010xxx-x 38x16x16 140 RCxxN4010xxx-x 24x16x16 70

15 21 RSxxN4015xxx-x 38x16x16 140 RCxxN4015xxx-x 24x16x16 70

20 29 RSxxN4020xxx-x 38x16x16 140 RCxxN4020xxx-x 24x16x16 70

25 35 RSxxN4025xxx-x 56x16x16 140 RCxxN4025xxx-x 30x24x16 150

30 43 RSxxN4030xxx-x 56x16x16 210 RCxxN4030xxx-x 30x24x16 150

40 56 RSxxN4040xxx-x 56x16x16 210 RCxxN4040xxx-x 30x24x16 250

50 68 RSxxN4050xxx-x 72x21x16 300 RCxxN4050xxx-x 39x30x16 280

60 83 RSxxN4060xxx-x 72x21x16 350 RCxxN4060xxx-x 39x30x16 280

75 104 RSxxN4075xxx-x 72x21x16 350 RCxxN4075xxx-x 39x30x16 280

100 138 RSxxN4100xxx-x 72x36x18 550

125 168 RSxxN4125xxx-x 72x36x18 550

150 202 RSxxN4150xxx-x 90x36x20 700

200 236 RSxxN4200xxx-x 90x36x20 700

Order Code

Slim Enclosure Cube Enclosure

Dimensions

HxWxD (in)

Weight

(Ibs)

Order Code

Dimensions

HxWxD (in)

n/a

Weight

(Ibs)

AC RapidPak

Note: Weight does not include options.

Order string: The base Order Code requires a minimum of 12 characters in sequence to create the order string.

323

Page 7

www.emersonct.com

800-533-0031

Heavy Duty 460 VAC, 3-Phase Input and Output, 50/60 Hz Input

Heavy Duty

150% for 1 minute

HP Amps

1 2.1 RSxxH4001xxx-x 38x16x16 135 RCxxH4001xxx-x 24x16x16 70

1.5 3 RSxxH41P5xxx-x 38x16x16 135 RCxxH41P5xxx-x 24x16x16 70

3 5.8 RSxxH4003xxx-x 38x16x16 135 RCxxH4003xxx-x 24x16x16 70

5 7.6 RSxxH4005xxx-x 38x16x16 135 RCxxH4005xxx-x 24x16x16 70

7.5 13 RSxxH47P5xxx-x 38x16x16 135 RCxxH47P5xxx-x 24x16x16 70

10 16.5 RSxxH4010xxx-x 38x16x16 140 RCxxH4010xxx-x 24x16x16 70

15 25 RSxxH4015xxx-x 38x16x16 140 RCxxH4015xxx-x 24x16x16 70

20 29 RSxxH4020xxx-x 38x16x16 140 RCxxH4020xxx-x 24x16x16 70

25 32 RSxxH4025xxx-x 56x16x16 140 RCxxH4025xxx-x 30x24x16 70

30 40 RSxxH4030xxx-x 56x16x16 210 RCxxH4030xxx-x 30x24x16 150

40 60 RSxxH4040xxx-x 72x21x16 210 RCxxH4040xxx-x 39x30x16 150

50 74 RSxxH4050xxx-x 72x21x16 300 RCxxH4050xxx-x 39x30x16 250

75 96 RSxxH4075xxx-x 72x21x16 300 RCxxH4075xxx-x 39x30x16 280

100 124 RSxxH4100xxx-x 72x36x18 550

150 180 RSxxH4150xxx-x 90x36x20 700

Order Code

Slim Enclosure Cube Enclosure

Dimensions

HxWxD (in)

Weight

(Ibs)

Order Code

Dimensions

HxWxD (in)

n/a125 156 RSxxH4125xxx-x 72x36x18 550

Weight

(Ibs)

AC RapidPak

Note: Weight does not include options.

AC RapidPaks are available with Commander SK, Commander GP20 and Unidrive SP

Definition - RapidPak AC Order Code Configurator

Item Description

Enclosure Style

C = Cube enclosure

S = Slimline enclosure

Drive Type

SKN = SK Normal Duty, SKH = SK Heavy Duty,

CGN = GP20 Normal Duty, CGH = GP20 Heavy Duty,

SPN = SP Normal Duty, SPH = SP Heavy Duty,

Voltage Rating

8=208 VAC, 2=230 VAC, 3=380 VAC, 4=460 VAC AC Input line voltage, 3 hp, 50/60 Hz, equals AC output rating for motor.

HP Rating Motor hp ratings are based on typical motor current ratings. Actual motor currents and the type of applications

Door Mounted Operator Station

0 = Blank

1 = Stop PB, Start PB, Fault Light, Pot.

2 = # 1 & Jog PB, Fwd/Rev SS

3 = # 2 & Power On Light

4 = HOA SS, Pot, Power On, VFD Run, Fault Light

5 = HOA SS, Plus Bypass

Input Power

0 = Main Lugs with Input Fusing

1 = Circuit breaker (CB)

2 = Non-fused disconnect (NFD)

Cube enclosure option allows only the circuit breaker, non-fused disconnect switch and door operator devices.

The Slimline enclosure allows all the options unless bypass is selected, then there is a limit of either an input or

output reactor.

Three drive models: Commander SK, Commander GP20 & Unidrive SP, AC drives with a Normal duty, current

overload rating of 110% for 60 seconds. Heavy duty, current overloads rating of 150% for 1 minute.

should be reviewed before selecting drive size.

The blank option defines that the devices are remote mounted. Selection #1 to #5 defines that the devices are

door mounted and wired to the drive terminals.

0 = Input Main lugs for customer termination with input fusing standard.

1 = CB with through the door operator, Thermal-magnetic overload protection and main circuit disconnect.

Includes drive input semiconductor fuses.

2 = NFD with through the door operator, main circuit disconnect. Includes drive fusing.

324

Page 8

www.emersonct.com

800-533-0031

AC RapidPak Order Code Configurator

Order String

R x xxx x xxx x x x - xxxxx

Product

R = RapidPak

Enclosure Style

S = Slimline2

C = Cube1

Drive Model

SKN = SK Normal Duty

SKH = SK Heavy Duty

CGN = GP20 Normal Duty

CGH = GP20 Heavy Duty

SPN = SP Normal Duty

SPH = SP Heavy Duty

Voltage Rating

8 = 208 V / 3 / 60

2 = 230 V / 3 / 60

3 = 380 V / 3 / 60

4 = 460 V / 3 / 60

Horsepower

see Order Code tables

1 Cube Enclosure Style does not allow for additional options (insufficient space)

2 Smallest Slimline Enclosure Style allows all the options unless bypass is selected,

then there is a limit of either an input or output reactor.

3 Abbreviation Key: PB = Push button; SS = Selector Switch; HOA = Hand-Off-Auto

Additional Options (if required)

1 = AC Input Reactor

2 = AC Output Reactor

4 = Auto 3-Contactor Bypass

5 = Blower Motor Starter

A = Manual Three-Contactor Bypass

F = NEMA-3R Enclosure

Input Power

0 = Main Lugs with Input Fusing

1 = Thru-Door Disconnect C/B

2 = Thru-Door Disconnect Switch

Keypad

N = Keypad on Drive

K = Keypad on Door

Door Mounted Operator Station

3

0 = Blank

1 = Stop PB, Start PB, Fault Light, Pot

2 = #1 + JOG PB, Fwd/Rev SS

3 = #2 + Power On Light

4 = HOA SS, Power On, VFD Run, Fault Light, Pot

5 = HOA SS plus Bypass

Order string: The base Order Code requires a minimum of 12 characters in sequence to create the order string.

Additional Order Code

AC Input Reactor 3% impedance input line reactor. Reduces harmonics to line. Slimline only

AC Output Reactor 3% impedance output line reactor. Increases motor insulation life by reducing dV/dt. Slimline only

Auto Three-Contactor Bypass Used in applications where full speed operation is required if drive becomes inoperable. Automatically switches

upon drive fault. Requires Operator Station #5. Slimline only

Blower Motor Starter Controls separately powered motor blower on TEBC and DPFV motors used for wide speed range applications.

Not available with Bypass Options. Slimline only

Manual Three-Contactor Bypass Used in applications where full speed operation is required if drive becomes inoperable. Manual (operator)

activated via Operator Station #5. Slimline only

Nema 3R Enclosure Enclosure intended for outdoor use. Provides a degree of protection against falling rain, sleet, and external ice.

For options not included in the Order Code configurator, please consult factory.

AC RapidPak

325

Page 9

AC CustomPak

575

0

Voltage

Horsepower

3-2000 HP

460

230

1-2000 HP

1-1000 HP

In addition to our pre-engineered AC RapidPak solutions,

we offer the AC CustomPak solution, when the stand

alone module or packaged drives can’t answer the

need. Available with the full range of Emerson / Control

Techniques products, this engineered product can

be customized to meet a wide variety of power and

control configurations. With power ranges up to 2000

hp and voltages ranging from 208V to 575V. We can

deliver a comprehensive and cost–effective design that

meets the needs of the most exotic packaged drive

configuration. It features Non-Regenerative AC drives,

fieldbus communication & coprocessor accessories for

the demanding applications. This package solution has

several optional features including; AC line contactor, AC

line fusing, Input and Output reactors, 12, 18 or 24 pulse

operation for harmonic reduction.

www.emersonct.com

800-533-0031

UL1, Ventilated Encl., SPM, 600 hp, 460VAC

AC CustomPak

Standard Features

• Input Voltage 208-460-575 VAC, 50/60 HZ

• Standard Enclosure, NEMA-12 (PPBF), Fully Gasketed,

(PPBF) Positive Pressure Blown and Filtered.

• CT Soft Windows™ based Programming Tool

Enclosure Design

• NEMA 3R, Enclosure, Fully Gasketed, (PPBF) Positive

Pressure Blown and Filtered

• N4, N4X or N12, (TENV) Enclosure, with or without

Air Conditioner Depending on Size of the Drive.

• 14 Gauge Steel

Options

• Normal Duty Rating (110% for 1 minute)

• Heavy Duty Rating (150% for 1 minute)

• 3%, AC Line Reactors

• 3%, AC Output Reactor

• Auto or Manual 3-Contactor Bypass

• Blower Motor Starter with Adjustable Overload

• Door Mounted Operator Devices.

• Circuit Breaker or Non-fused Disconnect Switch

• Input Main Lugs with Input Fusing

• Door Mounted LCD (SM – Keypad Plus) with Three

Lines of Text.

• SM-Modules

• Air Conditioner

• Space Heater

• 18 Pulse Operation

326

Page 10

www.emersonct.com

480

240

0

Voltage

Horsepower

5-500 HP

5-200 HP

800-533-0031

DC StandardPak

The DC StandardPak is a highly reliable, superior

performing DC drive package. Featuring the Mentor

II and Quantum III DC drive (depending on the options

selected), this package is fully equipped with everything

you would need to power and precisely control a DC

motor. It features non-regenerative or regenerative

operation, high speed fusing, field power supply, DC or

AC contactor and control power. It also offers optional

fieldbus communications & coprocessor accessories for

demanding applications. This packaged solution has

several optional features including; a circuit breaker,

non-fused disconnect switch, fused blower motor starter,

door mounted devices and remote mount dynamic

braking resistor.

The DC StandardPak has one of the shortest lead times

in the industry and can provide an expertly packaged,

DC drive solution within days of placing your order.

Standard lead time for the DC StandardPak is 1-3 weeks

depending on options.

MentorPak PN: DEN4255AN1A0-E

Nema -12 (PPBF), Ventilated Encl., 150 hp, 460 VAC,

Non-Regen, Circuit Breaker, AC Contactor, BMS

Standard Features

• Input Voltage 208-480 VAC

• Enclosure or Panel

• 120 VAC Control Logic

• AC Line semiconductor Fuse

• DC Output Fuse for Regenerative Drives.

• Standard field voltage - 240 VAC = 150 VDC

480 VAC = 300 VDC

• CT Soft Windows™-based Programming Tool

QuantumPak

• DC Contactor with DB pole (5-100 hp @ 500 VDC)

• DC/AC or Encoder Feedback

• 55˚C Drive Ambient

MentorPak

• AC Contactor (125-500 hp @ 500 VDC)

• DC or Encoder Feedback

• 40˚C Drive Ambient

Enclosure Design

• Standard Enclosure N12 (PPBF), Fully Gasketed,

(PPBF), Positive Pressure Blown and Filtered

• Painted with ANSI-61 Grey Paint

• Panel Design is with all the Standard Features

and Options on a Back Panel

• 14 Gauge Steel

Options

• Door Mounted Operator Devices

• Circuit Breaker or Non-fused Disconnect Switch

• Fused Blower Motor Starter

• Non-Standard 240 VDC Field Supply

• 20 Amp Field Regulator

• Dynamic Braking Resistor (shipped loose)

• Door Mounted Keypad

Approvals

• UL508A

DC RapidPak

327

Page 11

www.emersonct.com

Non-Regenerative 208-240-380-480 VAC, 3-Phase Input, 50/60 Hz

QuantumPak: Panel or N12 (PPBF) Enclosure, DC Drive, 120 VAC CPT, DC contactor with DB contact, Input fusing.

HP

240 VDC

3-10 5-20

15 25-30 55 DPNx055B0-x DENx055B0-x

20-30 40-60 106 DPNx106B0-x DENx106B0-x

40-50 75-100 172 DPNx172B0-x DENx172B0-x

MentorPak: Panel or N12 (PPBF) Enclosure, DC Drive, 120VAC CPT, AC Input contactor without DB contact, Input fusing.

HP

240 VDC

60 125 210

75 150 255

100 200 350 DPNx350A0-x DENx350A0-x

125 250 420 DPNx420A0-x DENx420A0-x

150 300 550 DPNx550A0-x DENx550A0-x

200 400 700 DPNx700A0-x DENx700A0-x

HP

500 VDC

HP

500 VDC

500 825 DPNx825A0-x DENx825A0-x

Armature Amps @

40 ˚ C 55 ˚ C

38

n/a

Armature Amps @

40 ˚ C 55 ˚ C

Call

Factory

Field Amps

Max 8A

Field Current

Regulator

Field Amps

Max 8A Field

Current Regulator

Max 10A

Fixed Field

Supply

Panel

Order Code

DPNx038B0-x DENx038B0-x

Order Code

Panel

Order Code

DPNx210A0-x DENx210A0-x

DPNx255A0-x DENx255A0-x

Order Code

800-533-0031

Enclosure

Enclosure

DC RapidPak

328

Regenerative 208-240-380-480 VAC, 3-Phase Input, 50/60 Hz

QuantumPak: Panel or N12 (PPBF) Enclosure, DC Drive, 120 VAC CPT, DC contactor with DB contact, Input fusing.

HP

240 VDC

3-10 15-20

15 25-30 55 DPRx055B0-x DERx055B0-x

20-30 40-60 106 DPRx106B0-x DERx106B0-x

40-50 100 172 DPRx172B0-x DERx172B0-x

MentorPak: Panel or N12 (PPBF) Enclosure, DC Drive, 120 VAC cntrl logic, AC Input contactor without DB contact, Input fusing.

HP

240 VDC

60 125 210

75 150 255

100 200 350 DPRx350A0-x DERx350A0-x

125 250 420 DPRx420A0-x DERx420A0-x

150 300 550 DPRx550A0-x DERx550A0-x

200 400 700 DPRx700A0-x DERx700A0-x

Notes:

1) HP rating is a guide, please verify the motor armature amps at 40° or 55° C, then select the drive amps to be equal or greater then the motor amps.

2) The voltage code suffix is the 4th digit in the order string.

HP

500 VDC

HP

500 VDC

500 825 DPRx825A0-x DERx825A0-x

Armature Amps @

40 ˚ C 55 ˚ C

38

n/a

Armature Amps @

40 ˚ C 55 ˚ C

Call

Factory

Field Amps

Max 8A

Field Current

Regulator

Field Amps

Max 8A Field

Current Regulator

Max 10A

Fixed Field

Supply

Panel

Order Code

DPRx038B0-x DERx038B0-x

Panel

Order Code

DPRx210A0-x DERx210A0-x

DPRx255A0-x DERx255A0-x

Enclosure

Order Code

Enclosure

Order Code

Dimensions & Weights

Armature

Amps @

40˚ C 55˚ C

38

n/a

210

255

350

420

550

700

825

Note: Package Size 2, when adding the FXM5 option to the panel or enclosure the package size changes to Size 3.

55

106

172

Call

Factory

Panel Enclosure Panel Enclosure

33x27x13 36x30x16 75 170

45x33x12 48x36x16 125 400

60x32x14

Dimensions

H x W x D (inches)

72x36x18 or

90x36x20 with NFD

Weights

(lbs)

210 600

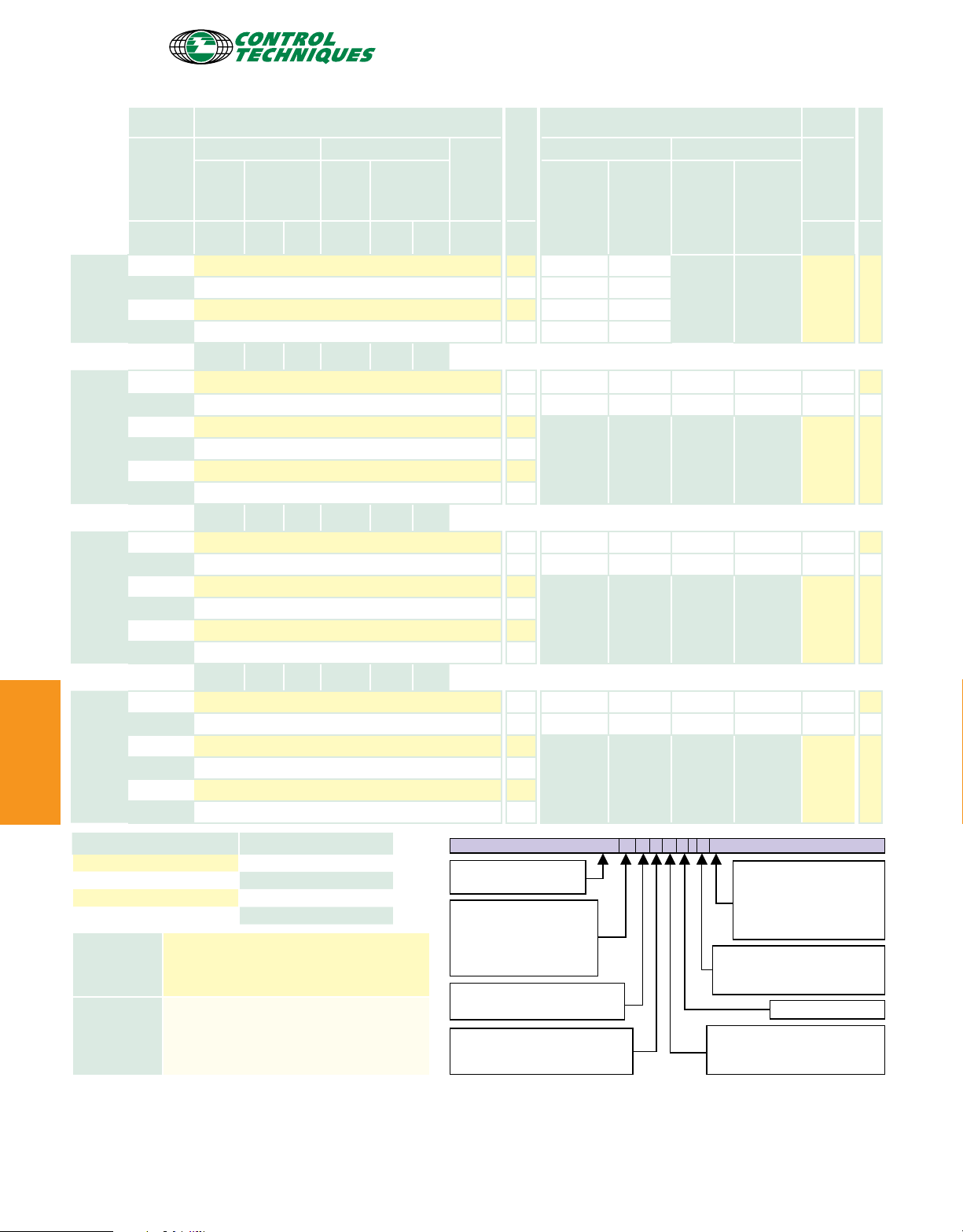

Page 12

www.emersonct.com

8

139 10 11 12 14 15

16 17

SHUNT FIELD

DC MOTOR

120 VAC

208-480 VAC

FU1-2-3

FU4DRIVE

208-480 VAC

CB

STANDARD FEATURES

STANDARD FEATURES WITH CB & AC & DB CONTACTOR OPTION

UN-REGULATED

XFMR

120 VAC

XFMR

FU1-2-3

UN-REGULATED

DRIVE

DB

FU4

DB RESISTOR

DC MOTOR

SHUNT FIELD

DBR

LC

LC

STANDARD FEATURES WITH CB & DC & DB CONTACTOR OPTION

120 VAC

208-480 VAC

XFMR

FU1-2-3

DRIVE

DC

FU4

DB

UN-REGULATED

SHUNT FIELD

DC MOTOR

DB RESISTOR

DBR

8

139 10 11 12 14 15

16 17

SHUNT FIELD

DC MOTOR

120 VAC

208-480 VAC

FU1-2-3

FU4DRIVE

STANDARD FEATURES

UN-REGULATED

XFMR

LC

800-533-0031

DB Braking Resistor

240 VDC 500 VDC

1

Motor HP

DB Resistor for 240 VDC

Order Code

DB Resistor for 500 VDC

Order Code

5 7.5 005-4301 005-4351

7.5 10 005-4302 005-4352

10 15 005-4303 005-4353

15 20 005-4304 005-4354

20 25 005-4305 005-4355

25 30 005-4306 005-4356

30 40 005-4307 005-4357

40 50 005-4308 005-4358

50 60 005-4309 005-4359

75 005-4360

100 005-4361

60 125 005-4310 005-4362

75 150 005-4311 005-4363

100 200 005-4312 005-4364

125 250 call factory 005-4365

150 300 call factory 005-4366

200 400 call factory 005-4367

(1) The Nema 1 DB resistor is shipped loose and is to be mounted externally to the StandardPak by the customer to meet UL508A.

Power One Line Diagram

QuantumPak

DC Contactor with DB pole

MentorPak

AC Input Line Contactor

DC RapidPak

329

Page 13

DC StandardPak Order Code Configurator

www.emersonct.com

800-533-0031

DC RapidPak

Order String

Product

D x x x xxx x x - xxxxxxxx

D = DC SandardPak

Enclosure Style

P = Panel

E = Enclosure

Drive Model

N = Non-Regenerative

R = Regenerative

Voltage Rating

8 = 208 VAC

2 = 240 VAC

3 = 380 VAC

4 = 480 VAC

Amp Rating

Amps are based on drive size

Dynamic Braking

A = AC Input Contactor

B = DC Contactor with DB pole

1

Input Power

0 = None (default)

1 = Circuit Breaker (C/B)

2 = Non Fused Disconnect Switch (NFD)

(1) E-Stop Braking option requires a DB contactor and an external DB resistor.

Consult factory for DC contactor for DC drives rated 210 Amps and up.

(2) Drives 255A and greater have fixed voltage field supply.

A field current regulator is required to operate above base motor speed.

(3) For 240 VAC application requiring 240 VDC armature and 240VDC Field Voltage.

(4) To meet UL508A for industrial applications the E-Stop PB is required when door mounted devices are selected.

(5) The Fwd/Rev Selector Switch applies to regenerative drives only.

(6) Encoder feedback requires DB9 connector at drive. This option includes cable from DB9 connector to a terminal block.

Additional Options (if required)

Fused Bower Motor Starter

1 = Range 0.4-0.65A

2 = Range 0.6 - 1.1A

3 = Range 1.0 -1.5A

4 = Range 1.3-1.9A

5 = Range 1.8-2.7A

6 = Range 2.5-4.1A

7 = Range 4.0-6.3A

Field Supply Options

A = 20A FXM-5 Field Current Regulator

B = 240 VDC @ 2A

C = 240 VDC @ 8A

D = 240 VDC @ 20A

Door Mounted Devices

E = E-Stop, Start PB, Stop PB, Speed Pot

F = Fwd/Rev Switch

3

3

3

4

5

H = HOA Selector Switch

J = Jog PB

K = Keypad (CTVue-303)

P = Drive Power “ON” PL

R = Reset PB

V = Analog Armature Ammeter & Voltmeter

W = Analog Field Ammeter & Voltmeter

Encoder Cable

6

Y = DB9 Encoder Cable to Terminal Block

2

330

Standard Enclosure is UL1 rated (NEMA 12 - PPBF (Positive Pressure Blown and Filtered))

Order String requires a minimum of 9 characters.

Examples:

Standard Order Code for Non-Regen: 200 hp @ 480 VAC, N12-(PPBF) enclosure, at 40˚ C

PN = DEN4350A0

Standard Order Code as above with the following options: Circuit Breaker, Fused Blower Motor Starter,

Field Regulator, Start/Stop PB, Reset PB, Armature Ammeter, Field Ammeter, Encoder Cable.

PN = DEN4350A1-4ARVWY

Page 14

www.emersonct.com

800-533-0031

Definition - DC StandardPak Order Code Configurator

Item Description

Enclosure Style

P = Panel

E = Enclosure

Drive Type

N = Non-regenerative

R = Regenerative

Voltage Rating

8 = 208 VAC

2 = 240 VAC

3 = 380 VAC

4 = 480 VAC

Drive Amp Rating - Armature Motor hp ratings are based on typical motor current ratings. Actual motor currents and the type of applications should

Dynamic Braking (DB)

A = AC Input Contactor

B = DC Contactor with DB pole

Input Power Disconnect

0 = None

1 = Circuit breaker (CB)

2 = Non-fused disconnect (NFD)

P = Panel allows additional options to be added to the Quantum III module.

E = The enclosure option is a UL1 rated, ventilated Nema -12 (PPBF), positive pressure blown and filtered.

14 gauge steel enclosure.

N for Non-regenerative DC drive or R for Regenerative DC drive. Regenerative provides FWD and REV direction with a

controlled braking action. Non-Regenerative is unidirectional and will have a coast to a stop action,

unless dynamic braking is used.

240 VAC for 240 VDC motor armature.

480 VAC for 500 VDC motor armature.

be reviewed before selecting drive size.

QuantumPak supplied with DC contactor (B), MentorPak supplied with AC contactor (A) as standard. Consult Factory

for drives 210A or above with DC contactor.

A = AC Input Contactor (210-825A)

B = DC Contactor with DB pole (38-172A)

1 – CB with through the door operator, Thermal-magnetic overload protection and main circuit disconnect.

Includes drive input semiconductor fuses.

2 – NFD with through the door operator, main circuit disconnect. Includes drive input

semiconductor fuses.

ADDITIONAL OPTIONS

Item Description

Blower Motor Starter

1 to 7

Door Mounted Devices

E = E-Stop, Start PB, Stop PB, Speed Pot

F = Fwd/Rev Switch

H = HOA Selector Switch

J = Jog PB

K = Keypad (CTVue-303)

P = Drive Power “ON” PL

R = Reset PB

V = Analog Armature Ammeter & Voltmeter

W = Analog Field Ammeter & Voltmeter

Encoder Cable

Y = Encoder cable

5

Select the correct blower motor amps. The value must be selected to complete

the Order Code for order entry.

To meet UL508A for industrial locations the E-Stop push button is required with door mounted devices.

E = E-Stop, Start, & Stop Push buttons, Speed Potentiometer

F = Forward / Reverse Switch - FWD/REV Selector Switch applies to regenerative drives only.

H = Hand (Manual) - Off - Automatic Switch

J = Jog Push button

K – Keypad (CTVUE-303 with standard program, mounted and wired on the door)

P = Drive Power “ON” pilot light indicates drive running.

R = Drive can be reset by means of the door mounted push button (PB), Remote (PB) or (PB) on the cover of the drive.

V = Analog Armature Ammeter (150%) & Voltmeter (100%).

W = Analog Field Ammeter (100%) & Voltmeter (100%)

The drive has a DB9 connector for encoder feedback. The encoder cable is supplied with the DB9 connector wired to a

terminal block.

DC MentorPak

For options not included in the Order Code configurator, please consult factory.

331

Page 15

660

575

0

Voltage

Horsepower

200-1500 HP

150-1250 HP

480

240

5-1000 HP

3-500 HP

DC CustomPak

In addition to our pre-engineered DC StanardPak

solutions, we offer a DC CustomPak solution. Featuring

the Mentor II or the Quantum III DC drive, this engineered

product can be customized to meet a wide variety of

power and control configurations. With power ranges

up to 1500 hp and voltages ranging from 240V to

660V, our custom engineered DC packaged solution

can meet the needs of the most demanding packaged

drive configuration. It features non-regenerative or

regenerative operation, high speed fusing, field power

supply regulated and unregulated, DC or AC contactor

and control power. It also offers optional fieldbus

communications & coprocessor accessories for

demanding applications.

This packaged solution has several optional features

including; a circuit breaker, AC line contactor, DC/DB

contactor, fused blower motor starter, door mounted

devices, line reactors, 12 pulse operation for harmonic

reduction, and higher horsepower range.

www.emersonct.com

800-533-0031

Nema -12 (PPBF), Ventilated Encl., 500 hp, 460 VAC,

Non-Regen, Circuit Breaker, DC Contactor, Field Regulator

DC CustomPak

332

Standard Features

• Input Voltage 208-240-380-480-575-660 VAC

• Enclosure or Panel

• 120 VAC control logic

• AC Line semiconductor fuse

• DC output fuse for regenerative drives

• AC, DC, DB contactor

• 2, 8 amp field regulator

• 10, 20A field supply

• DC, AC Tach or Encoder feedback

• Standard field voltage - 240 VAC = 150 VDC

480 VAC = 300 VDC

• CT Soft Windows™ based programming tool

Approvals

• UL508A up to 150 hp @ 240 VAC,

500 hp @ 480 VAC, 40˚ C

Options

• Door mounted operator devices and meters

• Circuit Breaker or Non-fused disconnect

• Fused blower motor starter

• Non-Standard field volts

• 20, 50, 90 Amp field regulator

• Line Reactor

• DC Choke

• 12 Pulse

• Dynamic braking resistor

• Air conditioner

• Door mounted keypad

Enclosure Design

• Standard Enclosure is (Nema 12 –PPBF) positive

pressure blower and filter

• ANSI-61 grey paint

• 14 gauge steel

• Nema 3R, fully gasketed, (PPBF), Positive Pressure

Blown and Filtered

Page 16

www.emersonct.com

800-893-2321

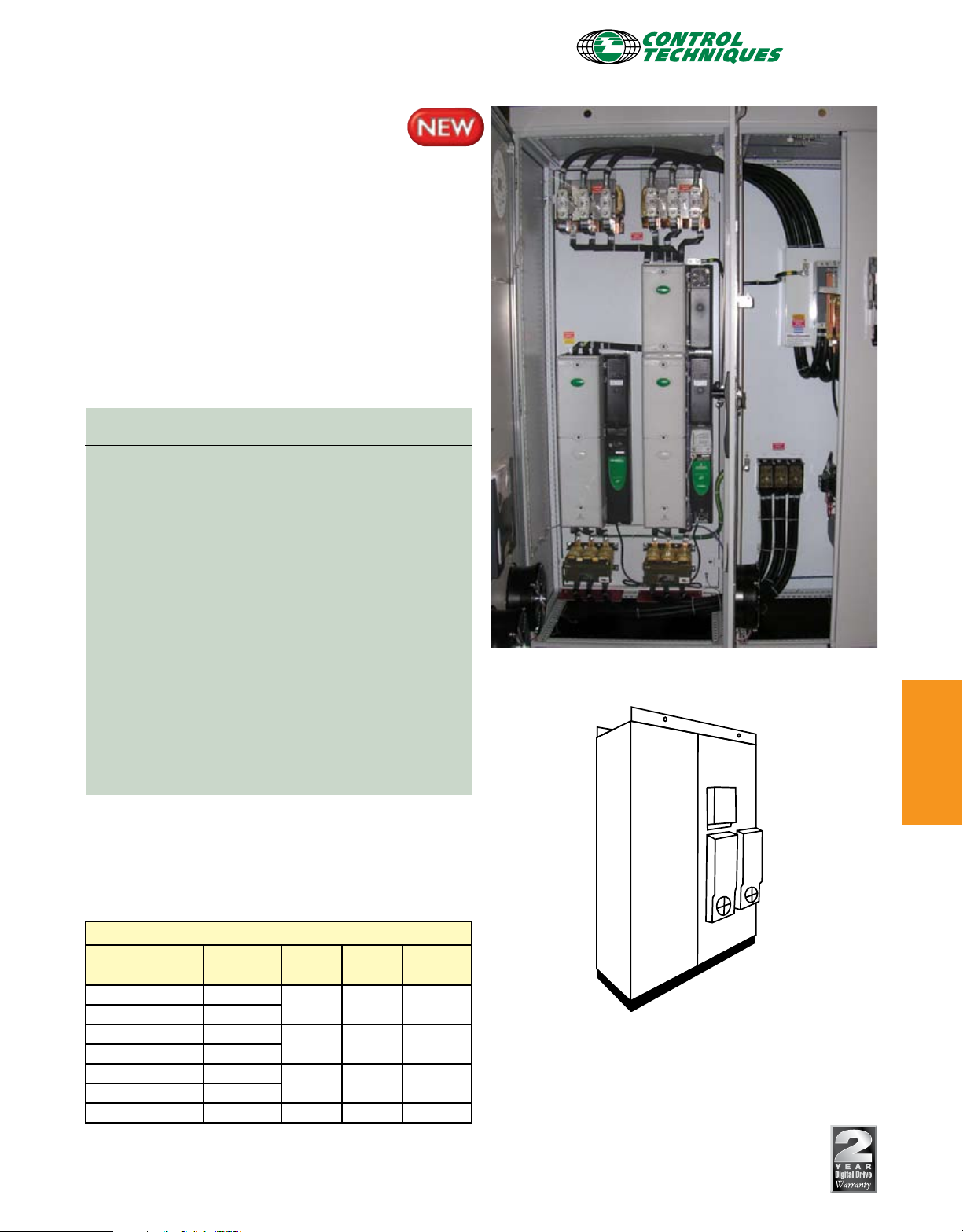

Large Enclosed

AC Drives

Users requiring quick delivery of a high-horsepower

NEMA 12 Positive Pressure Blown and Filtered AC drive

system, now have an Emerson Solution.

Robust Unidrive SPM technology from Control

Techniques gives users the power, performance, and

the ultimate in flexibility for all AC applications from

100 hp to 500 hp. For custom built higher horsepower

configurations please consult your sales representative.

Features

• All the state-of-the-art integration features of

the Unidrive SP

• A cost competitive, pre-engineered

“AC In – AC Out” solution

• A perfect match for both high-performance,

and standard drive applications, such as fans,

pumps and conveyors

• Industry standard NEMA 12 filtered

and ventilated enclosures

• Simplicity in ordering, installing and configuring

• An extensive array of options, including...

- Circuit Breaker Disconnect

- Line / Load Reactors

- Door Mounted Operator Controls

- Door Mounted Keypad

Dimensions

Cabinet Dimensions (inches)

460V

Horsepower

100–125 hp Normal

100–125 hp Heavy

150–250 hp Normal

150–250 hp Heavy

300–500 hp Normal

300–450 hp Heavy

500 hp Heavy 78.75 63 27.5

Duty Height Width Depth

78.75 23.6 23.6

78.75 31.5 27.5

78.75 55.1 27.5

Note: Depth dimensions for the cabinets in the table

include through-panel heatsinks and blowers on the

back of the cabinet.

Packaged Drives &

Engineered Systems

333

Page 17

www.emersonct.com

800-893-2321

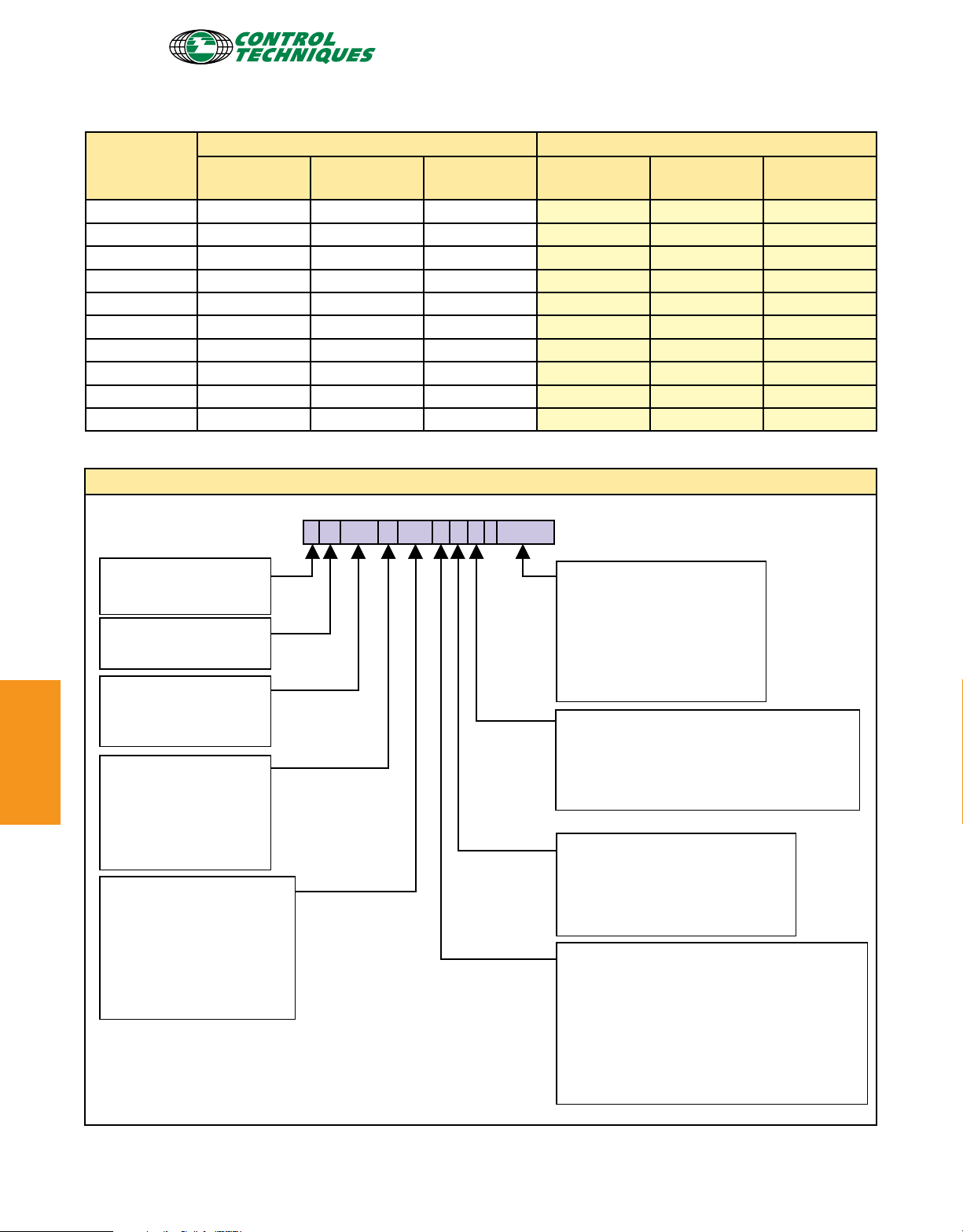

460 VAC Large Enclosed Drives Horsepower Ratings

Normal Duty Rating (110%) Heavy Duty Rating (150%)

Model

LESPx4100 100 138 151 100 124 217

LESPx4125 125 168 184 125 156 273

LESPx4150 150 205 226 150 210 315

LESPx4200 200 236 260 200 246 369

LESPx4250 250 290 319 250 290 435

LESPx4300 300 335 369 300 342 513

LESPx4350 350 448 492 350 399 599

LESPx4400 400 470 517 400 470 682

LESPx4450 450 551 606 450 551 827

LESPx4500 500 637 701 500 599 898

Maximum permissible current output @ 40°C and 3kHz switching frequency. Consult factory for higher horsepower drives.

Order String

hp

460 VAC

Continuous

Amps

Peak Amps

hp

460 VAC

Continuous

Amps

Closed Loop

Peak Amps

Product

L = Large Enclosed Drive

Package Type

E = NEMA 12 Enclosure

Engineered Systems

Packaged Drives &

Drive Model

SPN= SP Normal Duty

SPH= SP Heavy Duty

Voltage Rating

8 = 208 VAC (future)

2 = 230 VAC (future)

3 = 380 VAC (future)

4 = 460 VAC

Horsepower Rating

100 = 100 hp 125 = 125 hp

150 = 150 hp 200 = 200 hp

250 = 250 hp 300 = 300 hp

350 = 350 hp 400 = 400 hp

450 = 450 hp 500 = 500 hp

L E XXX X XXX X X X - XXXXX

Options

0 = None

1 = AC Input Reactor (2)

2 = AC Output Reactor (3)

5 = Blower Motor Starter

F = Nema-3R Enclosure (future)

Input Power

0 = Main Lugs (1)

1 = Thru Door Disconnect Circuit Breaker(1)

2 = Thru Door Non-Fused Disconnect Switch(1)

Door Mounted Keypad

0 = LED Keypad on drive

K = LCD Keypad mounted on door

N = LCD Keypad on drive

Door Mounted Operator Station

0= No Operators

1 = Stop PB, Start PB, Fault Lamp, Potentiometer

2 = #1 + Jog PB, Fwd/Rev SS

3 = #2 + Power On Lamp

4 = HOA SS, Power On Lt, VFD Run,

Fault Lamp, Potentiometer

334

Ordering Notes:

(1) Drive line fuses are included as standard

(2) Input reactors are included on 200 hp HD, and all 250 to 500 hp drives

(3) Output reactors are included on all 300 to 500 hp drives

Page 18

www.emersonct.com

800-893-2321

Unidrive — 60 hp to 2900 hp

Modular drives ideal

for system integrators

and OEMs

The Unidrive SPM — Solution

Platform Modular systems give

integrators and OEMs added

flexibility to design and build

high power AC drives that meet

their exact requirements.

The Unidrive SPM platform

offers all of the standard and

optional features available

on the panel mount SP

drives and is integrated

using the same software

tools for commissioning and

programming.

The modular nature of the power circuit allows drive systems to be constructed in non-standard enclosures. For

example, it is possible to implement a drive system of between 60 and 2900 hp in an enclosure no taller than 36 in.

FEATURES BENEFITS

• Control high current motors by paralleling output

inverter modules

• Compact IP20 input and output power modules

• Utilize an existing DC supply

• Return braking energy to AC supply with standard

inverter modules

• Recycle energy between simultaneously motoring

and regenerating drives

• Enable a single AC power entry

• Minimize harmonics with 12-, 18- and 24-pulse

rectifier configurations

• Eliminate harmonics with an active front end

Build customized high power drives with standard

volume produced modules

Create a comprehensive range of custom power systems

Economic integration with existing plant

Reduce running cost

Ideal for unwinding / winding processes

Simplify installation and minimize cabling

Meet more demanding supply regulations

Comply with supply regulations

Unidrive SPMs

• IP54 heatsink with through panel mounting

Allows smaller enclosure size, reduces cooling

requirements

335

Page 19

Top of

SPMD

(inverter)

Bottom of

SPMC/U

(rectifier)

PE

busbar

+D

C

busbar

-D

C

busbar

SPM interface

bracket

SPMD

SM-Control

Master

SM-Control

Follower

Weight:

55kg (121lbs)

310mm

(12.2in)

796mm

(31.3in)

298mm

(11.7in)

w

w

w.

controltechniq

u

es.co

m

112mm

(4.4in

)

448mm

(17.6in

)

162mm

(6.4in)

Weight:

1.5kg (3.3lbs)

11

2mm

(4.4in

)

448mm

(17.6in)

79

m

m

(3.1

in

)

Weight:

1kg (2.2lbs)

SPMA

SPMD

Weight:

55kg (121lbs)

310mm

(12.2in)

796mm

(31.3in)

298mm

(11.7in)

Weight:

75kg (165.3lbs)

310mm

(12.2in

)

11

31mm

(44.5in)

298mm

(11.7in)

SPMD

Weight:

55kg (121lbs)

310mm

(12.2in)

796mm

(31.3in)

298mm

(11.7in)

SPMA

SPMD

SPMC/U

SM-Control

Master

SM-Control

Follower

310m

m

(12.2in)

425mm

(16.7in)

298mm

(11.7in)

Weight:

15kg (33lbs)

Weight:

55kg (121lbs)

310mm

(12.2in)

796mm

(31.3in)

298mm

(11.7in)

310mm

(12.2in

)

11

31mm

(44.5in)

298mm

(11.7in)

w

w

w.

controltechniq

u

es.co

m

112mm

(4.4in

)

448mm

(17.6in

)

162mm

(6.4in)

Weight:

1.5kg (3.3lbs)

11

2mm

(4.4in

)

448mm

(17.6in)

79

m

m

(3.1

in

)

Weight:

1kg (2.2lbs)

SM-Control

Follower

310mm

(12.2in)

796mm

(31.3in)

298mm

(11.7in)

11

2mm

(4.4in

)

448mm

(17.6in)

79

m

m

(3.1

in

)

Weight:

1kg (2.2lbs)

SPM MODULE DESCRIPTIONS

SPMA - Is a complete inverter drive (AC in, AC out) with

internal rectifier capable of being parallel connected

with SPMA modules of equal rating. DC connections are

present for regen and common bus applications.

SPMD - Inverter module (DC in, AC out) that requires a

DC power supply from either an SPMC/U or an existing

source.

SPMC - Controlled rectifier bridge module (AC in, DC

out) used as a front end power supply to the SPMD

inverter module.

SPMU - Uncontrolled rectifier bridge (AC in, DC out)

used as a front end power supply to the SPMD inverter

module. A separate soft start must be provided.

www.emersonct.com

800-893-2321

Docking kits are available that provide the necessary

hardware to directly mount the SPMC to an SPMD.

Input line reactors and output sharing chokes are

specified and available.

Unidrive SPMs

336

Page 20

www.emersonct.com

A

P

P

R

O

V

A

L

I

S

O

9

0

0

1

:

2

0

0

0

800-893-2321

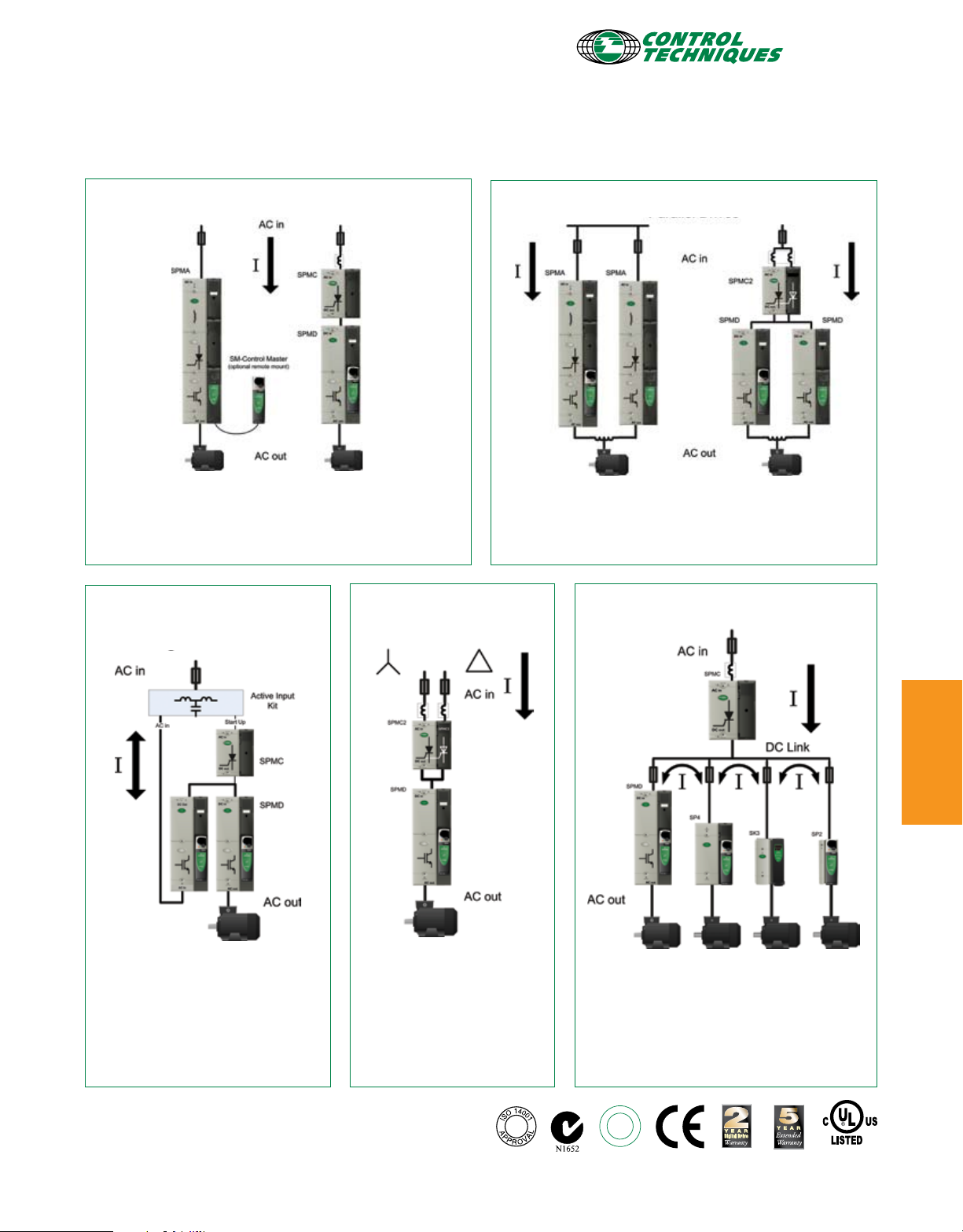

Basic Configurations

The examples below demonstrate the versatility of the Unidrive SPM in creating a wide range of High Power AC drives.

Single Drives

The SPMA solution will be lower cost but the SPMD solution

may give site standardization. The master control module

on the drive may be replaced by a follower module and the

master can be remotely mounted, as the application requires.

Active Input and

Regeneration

12 Pulse Input

Current

Parallel Drives

For higher currents multiple SPMAs or SPMDs may be

configured in parallel. The SPMA may give shorter installation

time with less interconnections but the SPMD may give lower

cost. Site standardization may also be a factor.

Common DC bus

Unidrive SPMs

Drives from the Unidrive and Commander families

Active inputs for harmonic elimination

and regenerating excess energy can

be configured with standard drive

modules, configured as motoring or

regenerating.

Multi-pulse rectifiers can be

configured (12, 18 and 24 etc.),

to minimise input harmonics

and help to meet local supply

authority regulations.

can be connected on a common DC bus system,

in order to circulate energy between drives with

opposing energy flow, supplied from a controlled

rectifier input (SPMC), an active input (SPMA or

SPMD) or an existing DC source.

337

Page 21

www.emersonct.com

800-893-2321

200240 VAC

+/- 10%

380480 VAC

+/- 10%

500575 VAC

+/- 10%

Unidrive SPMs

500690 VAC

+/- 10%

Drive

Order

Code

Output Module Selection

Normal Duty Heavy Duty

Max

Cont.

Current

A

Typical

Motor

Output

220V kW230V

hp

Max

Cont.

Current

A

Typical

Motor

Output

220V kW230V

hp

24 VDC

Input

[3]

DC Fuse Selection

A A A A

Input Module Selection

Controlled Uncontrolled

Single Dual

Single

[3]

Dual

[3]

24V DC

Input

[3]

SPMD1201 192 55 75 156 45 60 3.3 400 na na

SPMD1202 248 75 100 192 55 75 3.3 550 na na

SPMD1203 312 90 125 250 75 100 5.0 550 na na

[1]

[1]

SPMD1204 350

A

110

400V kW400V

[1]

150

290 90 125 5.0 550 na na

400V kW400V

A

hp

hp

SPMU1402 SPMU2402 3.0 400

SPMA1401 205 110 150 180 90 150 3.3 na na na na na na 315

SPMA1402 236 132 200 210 110 150 3.3 na na na na na na 350

SPMD1401 205 110 150 180 90 150 3.3 400

SPMD1402 246 132 200 210 110 150 3.3 560

SPMD1403 290 160 250 246 132 200 5.0 560

[1]

[1]

SPMD1404 350

SPMA1601

SPMA1602

SPMD1601

SPMD1602

SPMD1603

SPMD1604

[2]

[2]

[2]

[2]

[2]

[2]

200

575V kW575V

A

125 90 125 100 75 100 3.3 na na na na na na 200

144 110 150 125 90 125 3.3 na na na na na na 200

125 90 125 100 75 100 3.3 250

144 110 150 125 90 125 3.3 315

168 110 150 144 110 150 5.0 350

192 150 200 168 110 150 5.0 400

600V kW600V

A

[1]

300

290 160 250 5.0 560

575V kW575V

A

hp

hp

A

600V kW600V

hp

hp

SPMC1402 SPMC2402 SPMU1402 SPMU2402 3.0 400

SPMC1601 SPMC2601 SPMU1601 SPMU2601 3.0 250

SPMA1601 125 110 150 100 90 125 3.3 na na na na na na 200

SPMA1602 144 132 175 125 110 150 3.3 na na na na na na 200

SPMA1601 125 110 150 100 90 125 3.3 250

SPMA1602 144 132 175 125 110 150 3.3 315

SPMA1603 168 160 200 144 132 175 5.0 350

SPMC1601 SPMC2601 SPMU1601 SPMU2601 3.0 250

SPMA1604 192 185 250 168 160 200 5.0 400

AC Fuse Selection

Option Reference Order Code

SM-Control Master SM-Control Master

SM-Control Follower SM-Control Follower

24V DC Supply - 10A 8510-0000

SPM Docking Kit 3470-0012

Normal Duty Suitable for most applications, current overload

is set at 110% for 60 seconds. Where motor

rated current is less than the drive continuous

current, higher overloads are achieved.

Heavy Duty

(Rotor Flux

Control and

Closed Loop)

Notes:

[1] The full rating is only possible when the SPMD is mounted separately to the SMPC.

That is, a single module can deliver 350A with a separate airflow path for each module

and Tambient = <35°C. Otherwise the limit is 335A.

[2] The same model can be used on a 575V or a 690V supply and has two different output

ratings. e.g. At Normal Duty, SPMD1601 is suitable for a 90 kW output motor on a 575V

but is suitable for a 110 kW output motor on 690V.

338

[3] All SPM modules require a 24 VDC power supply for the cooling fans. The total

24 VDC current required can be assessed in the table and a 24 VDC supply chosen.

Suitable for demanding applications, current

overload is set at up to 150% for 60 seconds.

Where motor rated current is less than the

drive rated continuous current overloads

(200% or greater) are achieved.

SPM D 1 4 0 1 - 4 T

[4]

Modular power stages

for custom drive systems

Module Type (a)

A - AC in AC drive out put

D - DC in AC drive output

C - Controlled rectifier input

U - Uncontrolled rectifier input

Module Type (b)

1 - Single rectifier 2 - Dual rectifier

Voltage Rating

2 - 200V to 240V 4 - 380V to 480V

5 - 500V to 575V 6 - 500V to 690V

[4] For paralleling, the necessary interface cable that connects a follower to a master

or another follower is delivered with the follower module.

[5] A separate soft start must be provided for the DC link. Please contact your supplier.

[6] Input inductance may be incorporated in star-delta transformer.

[7] Only 400A AC and DC fuses are stocked by Control Techniques, as

these are used with other products.

[8] For more information, contact your supplier.

Top level code

Design requirement

T - 12 pulse S - Simple Install

L - Lowest Cost

R - Regen or Active Input

Top level code- Multiple modules

M - Single master S - Single follower

2-10 - Number of parallel drives

Current Rating Step

Configuration (SPMA and D only)

0 - Dynamic brake control

2 - No dynamic brake controls

Page 22

www.emersonct.com

800-893-2321

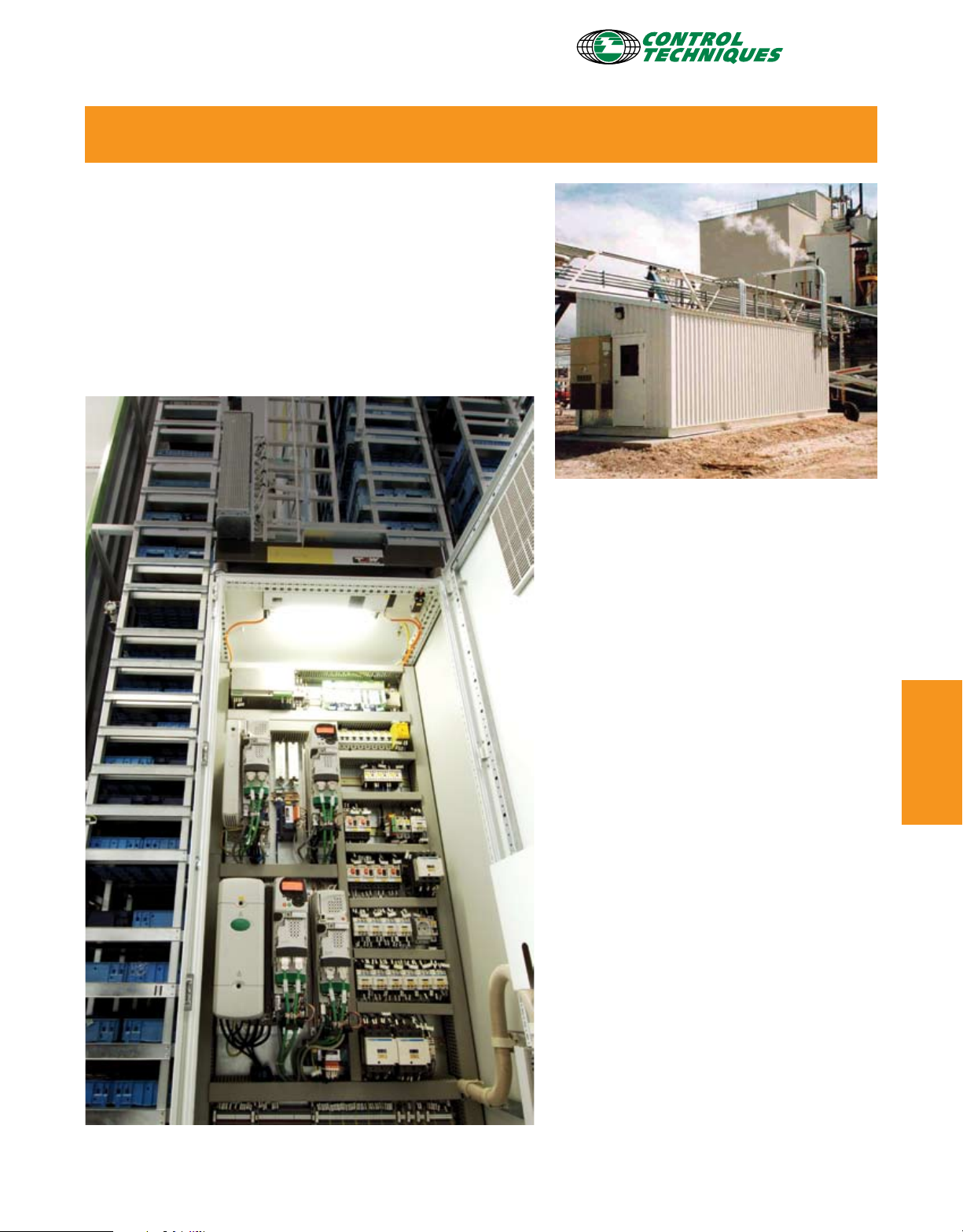

Engineered Systems

Total Systems Solutions

When your motion application demands more than panel mount,

free-standing, or packaged drives, our Drive Centers stand ready

to deliver a comprehensive and cost-effective design, build and

start up solution. Our more than 50 Drive Centers worldwide,

eight in the United States, provide an invaluable, industrial application knowledge base to apply to our customers’ needs. Forty years

of building electronic-based drive systems has given us the expertise to build solutions for nearly any application.

Control Techniques engineering and systems

centers are located around the country and are

staffed by engineers providing expertise to a

wide variety of industries:

O Automotive Assembly and Testing

O Mining and Aggregates

O Oil and Gas

O Metals Processing

O Glass

O Plastics and Rubber

O Heavy Moveable Structures

O Water/ Wastewater Pumping

O Web Handling

O Power Generation

O Converting

Packaged Drives &

Engineered Systems

O Packaging

O Printing

O Forestry

O Irrigation

O Ski Lifts

339

Page 23

SM-DeviceNet

SM-Applications Plus

SM-I/O Plus

SM-PROFIBUS-DP

SM-Ethernet

Section 1

I/O

Section 2

PC

Remote

Monitoring

Section

Master

Section

Master

Section 3

HMI

HMI

HMI

I/O

RS485

Modbus-RTU

(RS485)

Distributed Sectional Control — featuring CTNet and Ethernet communications

Programming

Machine Fieldbus Ethernet TCP/IP

Epsilon EP

reset

3 MIN

serial (J2)

L1

L2

PE

S

R

T

+

_

logic motor

digital i/o (J3)

J8

J6J5J10

EP204-I00-0000

9606XX-XX A1

SN 0610E014

DANGER CAUTION

High Voltage

This machine runs hot

DO NOT USE

COVER FOR LIFTING

DANGER CAUTION

High Voltage

This machine runs hot

DO NOT USE

COVER FOR LIFTING

DANGER CAUTION

High Voltage

This machine runs hot

DO NOT USE

COVER FOR LIFTING

+

SCADA

Remote I/O

To existing

remote PLC

+

+

Decentralized Control — featuring CTSync drive-to-drive synchronization with less than 250µsec jitter

Section 1

Section 2

Section 3

HMI

Flexible control architecture

Our drives systems are designed for any control architecture: centralized, distributed,

or fully decentralized. The options of scalable PLC functionality within the drive; high

speed, peer-to-peer networking; extended I/O capability, and support for all major fieldbuses, greatly simplifies system integration regardless of the control scheme.

www.emersonct.com

800-893-2321

Engineered Systems

Packaged Drives &

340

Page 24

www.emersonct.com

800-893-2321

Engineered Systems provides its customers with totally

integrated systems, which can include:

O Coordinated Drive/Servo Systems

O Four-quadrant Regenerative Systems

O 18-Pulse and 24-Pulse Drives

O PLC and PC-based Control Systems

O Switch gear, e.g., automatic transfer switches

O Custom Fabrication

O Climate Controlled MCC’s and E-Houses

O Electrical Control and Instrumentation

O Power Distribution

O Operator Interfaces (HMI)

O Industrial Communications Platforms

O Custom Enclosures

The typical engineered systems program consists of the

following components:

O Initial Applications Review

O Proposal and Review

O Order and Project Scheduling

O Hardware Design and Review

O Software Design and design review

O System Training

O Field Startup Assistance

Systems/Features AC Systems Motion Control Systems DC Systems

Control Technology

Power

AC Voltage

50/60Hz ± 10%

Motor Feedback

High Performance open loop and

closed loop vector, regen

.5 hp to 2900 hp

200V to 690V 3Ø 90V to 690V 1Ø, 3Ø 208-660V 3Ø

All major feedback devices supported.

Rotary and linear servo, and

AC Vector Servo

Servo: To 750 lb-in

Vector: To 4,500 lb-in

Digital open loop and closed

loop, regen and non-regen

5 hp to 2000 hp

Voltage Feedback (CEMF)

AC or DC Tachometer, Encoder

Packaged Drives &

Engineered Systems

Communication

Enclosures

Key Options

All major communication protocols supported.

NEMA 1, NEMA 3R, NEMA 4, NEMA 4X, NEMA 12, and NEMA 12–Positive Pressure, Custom

Operator control stations, Industrial CRT workstations, HMI programming, PLC’s, Switch gear,

Power distribution, Common DC bus, Speed reducers

341

Loading...

Loading...