Emerson PAC8000 Datasheet

PAC8000 Remote I/O

00813-0100-0108

PAC8000 Remote I/O

The Control Solution for Process Industries

PAC8000 Remote I/O is a completely modular I/O

solution for both general purpose and hazardous

area applications. Based upon a carrier system,

PAC8000 supports a wide range of modules and

I/O functions, including intrinsic safety signals.

An open architecture allows communication

with a variety of different fieldbuses by selecting

the appropriate type of Bus Interface Module

(BIM).

Designed to resist extreme temperatures,

humidity, corrosive materials, shocks, and

vibration, PAC8000 delivers full specification

performance in even the harshest environments.

In ATEX environments PAC8000 excels – all

components can be mounted and live worked in

Zone 2 / Division 2 and ATEX Zone 1 hazardous

areas. The I/O includes types that can be

connected directly to intrinsically safe (Exi)

or increased safety (Exe) field wiring.

PAC8000 Remote I/O integrates seamlessly with

PACSystems solutions and is connected via

PROFINET or Modbus TCP to RX3i and RSTi-EP

controllers.

Harsh & Hazardous Area Operation

PAC8000 can go where other products cannot. They can be

eld mounted and subjected to the following:

n -40°C to +70°C operating range

n ISA Level G3 corrosion

n 30g shocks and 5g vibration

n Operation in Class I, Division 2 and Zone 2 hazardous areas

with I/O module eld wiring including intrinsically safe (Exi)

and increased safety (Exe) options

n Supports UL HAZLOC C1D1 and ATEX Zone 1 hazardous areas

with I/O module eld wiring including intrinsically safe (Exi)

and increased safety (Exe) options

High Availability

PAC8000 supports PROFINET System Redundancy (PNSR),

enabling synchronized independent controllers to service the

I/O and transition from active to back-up controller without

interruption. With controllers separated up to 10 kilometers

from each other, processes will be resilient from physical

disruption. Consider unplanned downtime a thing of the past.

Variety of IO Modules

Beyond just analog and digital I/O, a broad range of PAC8000

I/O modules are available, including options for low-level

instrumentation, AC mains, and intrinsically safe signals.

4, 8, 16, and 32 eld channels modules are available, and

all modules provide comprehensive diagnostic information.

Easy Troubleshooting and

Machine Setup

Using integrated PAC Machine Edition (PME) software, you can

easily congure PAC8000 I/O. If you are using PROFINET then it

is even easier using the GSDML le. PME is the same software

as all PACSystems CPUs so you only need a single tool from

small to large applications. This approach utilizes the same

hardware conguration, network conguration, and

programming editors. HMI development is also streamlined

with a single tag database for QuickPanel+ HMIs.

Data Sheet

March 2021

PAC8000 Remote I/O

HART Support

PAC8000 Modbus EBIM can provide HART data directly to

Emerson’s Asset Management System (AMS), allowing remote

conguration and access to eld instrument diagnostic

information. PAC8000 can also acquire HART data for use in

the process controlapplication. HART devices may be selected

for regular status monitoring and alerts can be issued if the

status changes. This allows for reduced commissioning time,

reduced downtime, and reduced maintenance costs.

Specifications

Mounting Format

n DIN Rail

Network Interfaces

n PROFINET

n Modbus/TCP

Gateways / Bridges

n HART

Network Redundancy

n MRP

n Dual LAN

System Redundancy

n PNSR or Modbus/TCP

I/O Redundancy

n Dual

March 2021

Specialty Modules

n Pulse Test (24 VDC)

n Pulse Input

n Sequence of Events (SoE) Inputs

n ASH Detector

Isolation

n Galvanic Isolation

n DI, DO, AI, AO

Hot Swap

n Yes

Environmentals

n IP20

n-40˚C to 70˚C

n Conformal Coat

n ISA Level G3 corrosion

n 30g shock

n 5g vibration

Media Support

n Copper & MM Fiber

Media Connector

n 2x RJ45 or 2x SFP

I/O Types

n 24 VDC,

n 115/230 VAC in

n 2-60 VDC,

n 20 - 265 VAC out

n Analog, RTD, Thermocouple

Agency Approvals

n UL

n UL HAZLOC C1D1

n CE

n ATEX Zone 1

n Intrinsically Safe

Marine

n Lloyd’s Register

www.Emerson.com2

March 2021

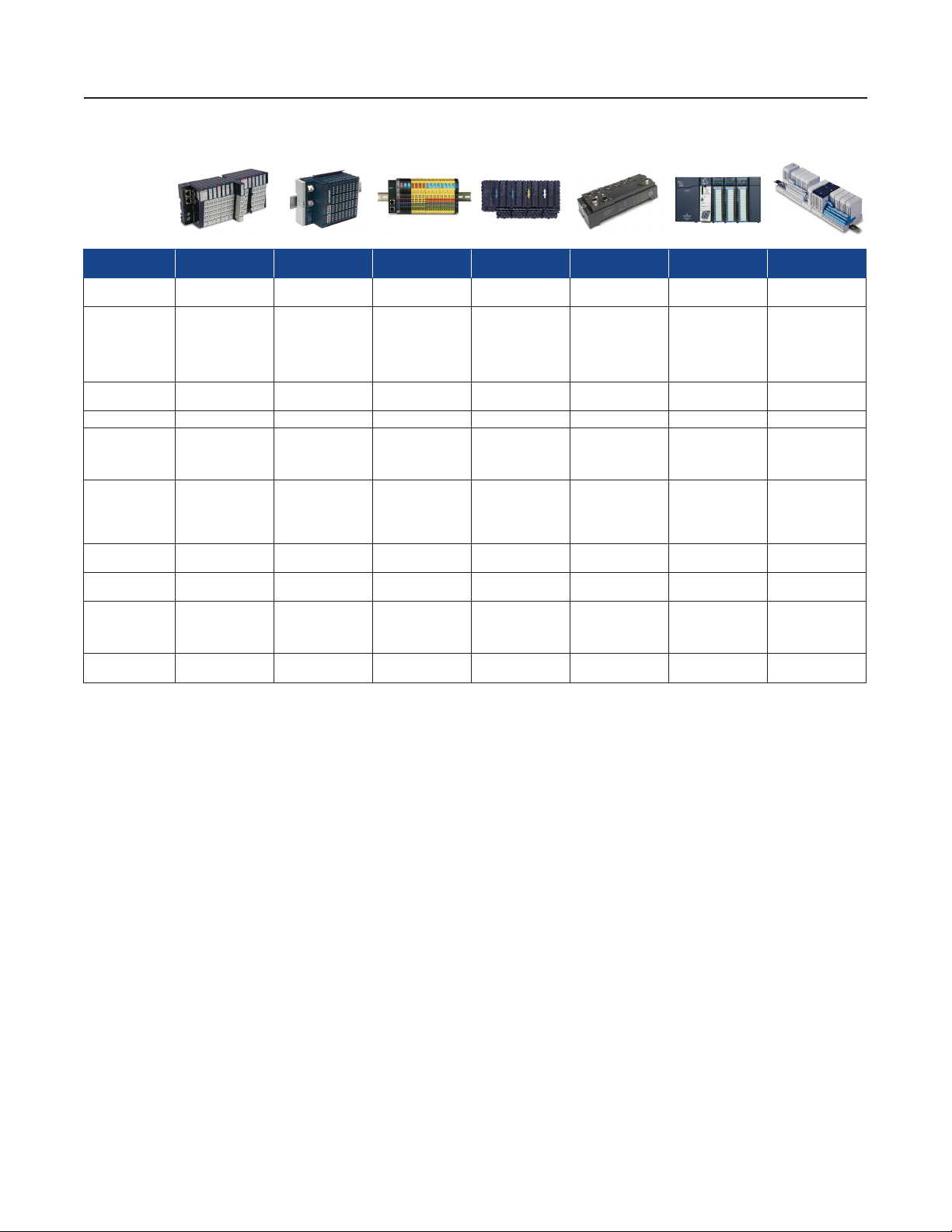

I/O Family Comparison

PAC8000 Remote I/O

Product

Typ e Distributed Slice Distributed Slice Distributed Slice Chassis Based

Network

Interfaces

System

Redundancy

Hot Swap No Yes No Yes No Yes Ye s

Environmentals

Agency

Approvals

Marine - DNV GL -

I/O Module Size

(W x H x D)

Typical

Applications

Level of

Diagnostics

PACSystems

RSTi

PROFINET

PROFIBUS DP

Modbus/TCP

Modbus/RTU

DeviceNet

- PNSR -

IP20

0˚C to 55˚C (UL)

0˚C to 60˚C (non-UL)

UL

UL HazLoc C1D2CE

ATEX Zone 2

12 x 99 x 70 mm 11.5 x 120 x 76mm 12 x 120 x 70 mm 66.8 x 163.5 x 70 mm 70 x 178 x 49.3 mm 34 x 145 x 140 mm 42 x 110 x 106 mm

Basic Machine

Good Better Best Better Good Best Best

PACSystems

RSTi-EP

PROFINET

PROFIBUS DP

Modbus/TCP

EtherCAT

Ethernet/IP

IP20

-20˚C to 60˚C

UL

UL HazLoc C1D2

CE

ATEX Zone 2

Machine Control

Light Process Control

General Automation

VersaPoint

/VersaSafe

PROFINET

PROFIBUS DP

Modbus/TCP

DeviceNet

IP20

-20˚C to 55˚C

UL

UL HazLoc C1D2

CE

ATEX Zone 2

TUV SIL3

Functional Safety

VersaMax

Modular

PROFINET

PROFIBUS DP

Modbus/TCP

EGD

DeviceNet

GENIUS

PNSR, EGD or

GENIUS

IP20

0˚C to 60˚C

-40˚C to 60˚C (opt.)

Conformal Coat (opt.)

UL

UL HazLoc C1D2

CE

ATEX Zone 2

ABS, BV, DNV GL, LR

(only select models)

Machine and Light

Process Control

General Automation

VersaMax/IP

On-machine

Distributed

PROFINET

PROFIBUS DP

- PNSR or EGD

IP67

-20˚C to 60˚C

UL

UL HazLoc C1D2

CE

-

On-machine

Cabinetless I/O

PACSystems

RX3i

Chassis Based Intrinsically Safe

PROFINET

PROFIBUS DP

Modbus/TCP

EGD

CMX

IP20

0˚C to 60˚C

-40˚C to 60˚C (opt.)

Conformal Coat (opt.)

UL

UL HazLoc C1D2

CE

ATEX Zone 2

ABS, BV, DNV GL

(only select models)

Complex Machine

Process Control

Motion Control

General Automation

PAC8000

PROFINET

Modbus/TCP

PNSR or Modbus/

TCP

IP20

-40˚C to 70˚C

Conformal Coat (G3)

UL

UL HazLoc C1D1

CE

ATEX Zone 1

Intrinsically Safe

LR

Harsh Environment

Process Control

3www.Emerson.com

Loading...

Loading...