Page 1

OMNI X TDR-ZP

General Description

The OMNI X TDR-ZP is a fully

integrated cleaning, rinsing,

and drying system consisting

of an ultrasonic cleaning tank, a

two-stage cascade rinse tank,

a recirculated hot air dryer,

and TDR-ZP material handling

system. It’s specifically designed

to provide superior, precision

cleaning of small and medium

items in a variety of applica-

tions. When integrated

with the optional TDR-ZP

two-dimensional transport

system, the OMNI X becomes an

automatic high-throughput cleaning

system with precise PLC control.

Advanced-technology Cavitation Cleaning

OMNI X 1012 systems use ultrasonic cavitation to both

clean and rinse the parts. Cavitation is produced when

high-frequency, high-intensity sound is applied to a

liquid. The sound creates waves of high pressure and low

pressure that pass through the liquid. The low-pressure

OMNI Series

waves create microscopic vacuum bubbles, and when

the next high-pressure wave hits them, they implode

suddenly to create shock waves that blast the soil and

contaminants from even the tiniest holes and crevices.

The turbulence created by cavitation enhances the

action of cleaning chemistries by constantly exposing

surfaces to fresh chemistry. In the same way it improves

cleaning, ultrasonic cavitation also enhances rinsing.

Page 2

Ultrasonic Cleaning Tank

The basic wash tank is suitable for use with emulsifying chemistries. It’s constructed of

316 stainless steel, with stainless steel fill and drain connections and recirculating pump

and filter to ensure continuous removal of particulate matter. The cleaning tank is equipped

with Branson S8340 industrial 40 kHz ultrasonics as standard equipment, with other

frequencies optional. Cleaning tanks are heated and capable of maintaining 160°F.

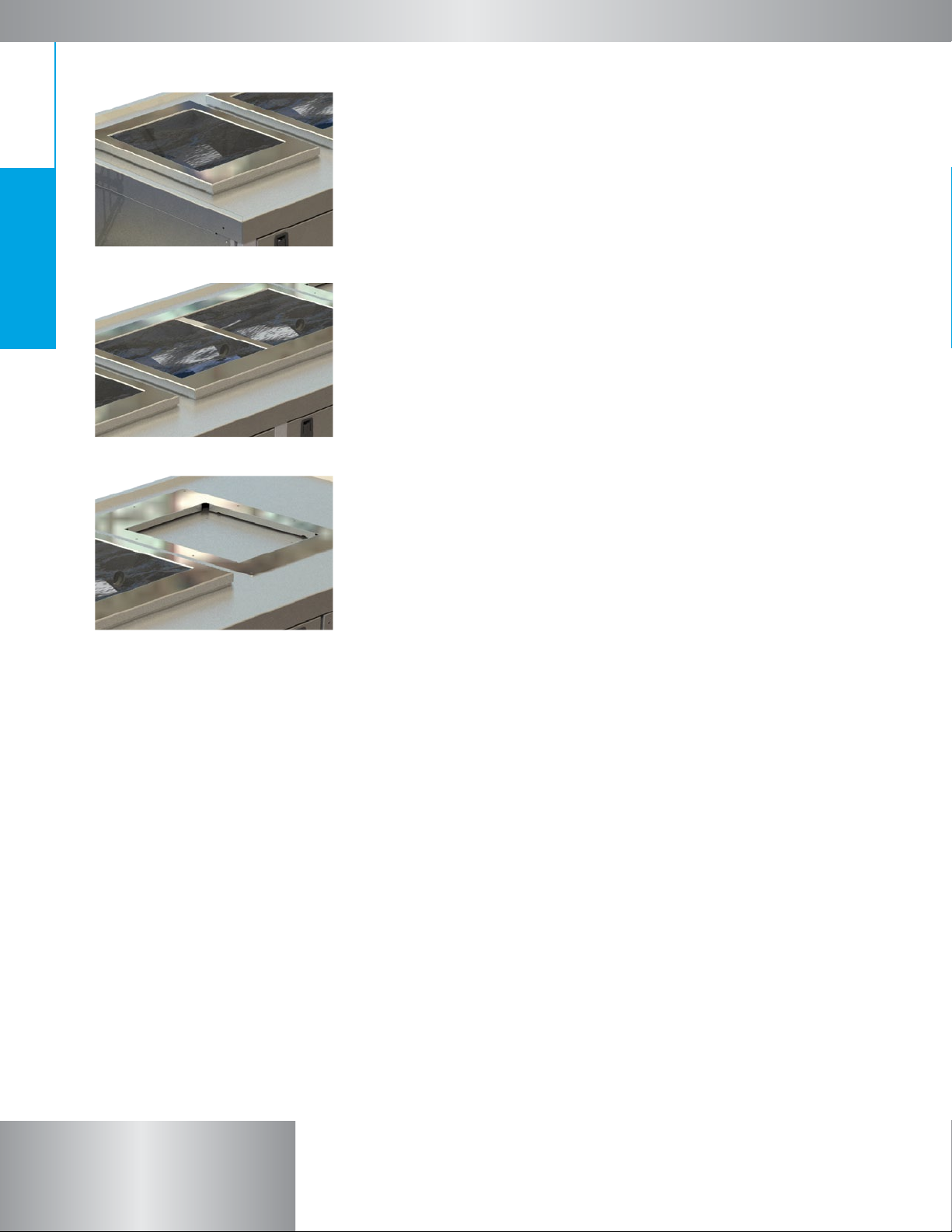

Tank 1

Tanks 2 & 3

Tank 4

Digital Controls

Heated Rinsing Tanks

The OMNI X employs two rinsing tanks in a counter-flow cascade arrangement from tank

#3 into tank #2 that provides excellent rinsing while substantially reducing water consump-

tion. A variety of cavitation technologies are also available on rinsing tank #2 to ensure that

all soils and cleaning chemistries are driven from blind holes and crevices before the drying

cycle. Rinsing tanks are heated to maintain the incoming water temperature. Options

include resistivity-controlled water make-up, pump and filter, a variety of ultrasonic fiters,

and rust-inhibitor configuration for tank #3.

Recirculating Hot Air Dryer

The hot air dryer utilizes both elevated temperature (up to 250°F) and rapid air movement

(up to 200 scfm) to thoroughly dry parts. The hot air is recirculated to provide the high

velocity required for rapid drying. Recirculation also reduces the amount of energy

required to maintain air temperature. A percentage of the air is continuously vented to

maintain low humidity in the dryer. Units are equipped with analog over-temperature

safety control and an air-flow safety switch to protect heaters. An optional power cover

is available on automated systems.

All functions on the OMNI X, including temperatures and times, are controlled by a PLC and a 6-inch diagonal, 3-color,

touchscreen operator interface. The touchscreen is angled for improved visibility, and a lockable power disconnect switch

and emergency stop switch are on the stainless steel control box.

Optional Automation with Load and Unload Shelves

Adding a TDR-ZP two-dimensional robot to the OMNI X provides precise process control and maximizes throughput. The robot

is fully integrated with the OMNI X at the factory and requires no additional set-up. It consists of a stepper-motor-powered hori-

zontal drive and pneumatic vertical lift for precise positioning. All drive components are located below the OMNI X countertop

to minimize the potential for contamination. Flex-sequence programming allows the user to process baskets through the tanks

in any sequence. Ten recipes of up to 16 steps each may be programmed by the user. All OMNI X functions may be controlled

automatically as recipe configurations. Optional load and unload platforms that include basket sensors may be mounted to the

OMNI X frame. Accumulating zero-pressure-load and -unload conveyors are also available.

Page 3

Key Standard

Features

• 40 kHz ultrasonic wash tank with

S8340 series power supply

• Recirculating pump and filter on

the wash tank

• 40 kHz ultrasonics on the first

rinse stage (tank #2)

• Non-ultrasonic 2nd rinse stage

cascading into the first rinse tank

• Recirculating hot air dryer

• Manual sliding cover on the dryer

• PLC controls with 3-color touchscreen

operator interface

• PLC-controlled dwell timers for

each tank

• Brush-finished 304 stainless steel

skirts, doors, and control enclosure

— no paint

• Aluminum extrusion frame

• 316 bright annealed stainless

steel process tanks

• Drop-in tanks for easy replacement

• Maintenance items such as valves and

filters accessible from the front of unit

• Small footprint to minimize floor space

A Variety of Options

Automation Options

Specifications

OMNI X TDR-ZP

Dimensions

• Sparged overflow wash tank for optional

floating oil or particulate removal

• 25 kHz, 80 kHz, 120 kHz or 170 kHz

ultrasonics in wash tank

• 25 kHz, 80 kHz, 120 kHz or 170 kHz

ultrasonics in first rinse tank #2

• Recirculating pump and filter on

the rinse tank #2 or #3

• TDR-ZP PLC-controlled, two-dimensional

robot with stepper motor horizontal

drive and pneumatic vertical actuator;

10-recipe capability with up to 16 steps

per recipe; user-programmable

sequencing; power dryer cover

• 25 kHz, 40 kHz, 80 kHz, 120 kHz or

170 kHz ultrasonics in final rinse tank #3

• HEPA filtration for the dryer

• Resistivity-controlled DI rinse water

make-up

• Rust inhibit for the final rinse tank

• Low-liquid-level safety switches for all

wet tanks

• Load and unload shelves with

proximity switches

OMNI X TDR-ZP

Page 4

OMNI Series

Standard System Specifications

Cleaning Tank

Constructed of 316 stainless steel

bright annealed interior surfaces

Internal working dimensions:

10" L x 12" W x 10" liquid depth

Stainless steel fill and drain

connections (1/2" NPT )

• Ultrasonics

- Piezoelectric transducer elements

bonded to tank bottom

- Standard operating frequency:

40 kHz

• Heat

- 1,600 Watts

- PLC-controlled, externally

mounted heaters

• Shielded by stainless steel covers

• Recirculating pump and filter

• Ryton magnetic-drive,

seal-less pump

• Stainless steel plumbing

• 10", 10-micron retention filter

• 1-3 GPM recirculation rate

Cascade Rinsing Tanks

• Constructed of 316 stainless steel,

bright annealed interior surfaces

• Internal working dimensions:

10" L x 12" W x 10" liquid depth

• Counter-flow feature provides

rinse water to cascade from

tank #3 to tank #2, minimizing

the use of water

• Stainless steel fill and drain

connections (1/2" NPT )

• Heat

- 800 Watts per stage

- Digitally-controlled,

externally mounted heaters

Note: Heat provided to maintain

operating temperature at specified

flow rate. Rinse water should be

pre-heated prior to entering system

• Ultrasonics standard in first rinse

stage (tank #2)

- Piezoelectric transducer

elements bonded to tank

bottom

- Standard operating frequency:

40 kHz

Recirculating Hot Air Dryer

• Constructed of 316 stainless steel

• Internal working dimensions:

10" L x 12" W x 12.7"

maximum depth

• 2000 Watts of heat

• Operator interface displays set-

point and actual dryer temperature

• Heating up to 250°F

• Manual sliding cover

• Approximate air flow: 200 scfm

• Duct connection to facilitate

moist air removal

• Stainless steel drain connection

Americas

Branson Ultrasonics Corp.

41 Eagle Road

Danbury, CT 06810, USA

T: 203-796-0400

F: 203-796-0450

www.bransonultrasonics.com

Europe

Branson Ultraschall

Niederlassung der Emerson

Technologies GmbH & Co. OHG

Waldstrasse 53-55

T: +49-6074-497-0

F: +49-6074-497-199

www.branson.eu

Asia/Pacific

Branson Ultrasonics (Shanghai)

Co., Ltd. (China H.Q.)

758 Rong Le Dong Road

Song Jiang, Shanghai, PRC, 201613

T: 86-21-3781-0588

F: 86-21-5774-5100

www.branson.com.cn

© Branson Ultrasonics Corporation 2013.

The Emerson logo is a trademark and service mark

of Emerson Electric Co.

Printed in the U.S.A.

BCL-0005-13

Loading...

Loading...