Page 1

Liebert NXLiebert NXr

8VHU0DQXDO

Page 2

Modular NXr UPS 30kVA ~ 200kVA (parallelable to 800kVA)

User Manual

Version V1.2 ENPAu

Revision date 2011 0401 (ENPAu 2011 1108)

BOM 31012244

Emerson Network Power provides customers with technical support. Users may contact the nearest

Emerson local sales office or service center.

Copyright © 2010 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Page 3

Safety Precaution

This manual covers the installation and use of Emerson NXr UPS.

Please read this manual before installation.

The NXr UPS must be commissioned and maintained by the engineers designated by the manufacturer or its

agent. Failure to observe this could result in personnel safety risk, equipment malfunction and invalidation of

warranty.

The NXr UPS is only used for commercial or industrial purpose and cannot be used as life support equipment.

This is a C2 type UPS product. In a domestic environment, this product may cause radio frequency interference,

in which case, the user may be required to take additional measures.

Conformity and standards

This product complies with CE 2006/95/EC (low voltage safety) and 2004/108/EC (EMC), EMC standards of Australia and

New Zealand (C-Tick), and the following UPS product standards:

* IEC62040-1-1-General and safety requirements for use in operator access area

* IEC/EN62040-2 EMC requirements CLASS C2

* IEC62040-3 Performance requirements and test methods

For more details, refer toChapter 8 Product Specifications.

Continued compliance requires installation in accordance with these instructions and the use of manufacturer approved

accessories only.

Warning: high earth leakage current

Earth connection is critical before connecting the input supply (including both mains supply and battery).

Earth leakage current exceeds 3.5mA and is less than 1000 mA.

Transient and steady state earth leakage currents, which may occur when the equipment is started, should be taken into

account in the selection of instantaneous residual current circuit breakers (RCCBs or residual current detector (RCD

devices.

Note also that the earth leakage currents of the load will be carried by the RCCBs or RCDs.

The equipment must be earthed in accordance with the local electrical authority codes of practices.

Warning: backfeeding protection

This UPS is fitted with a voltage-free contact closure signal for use with an external automatic disconnect device (supplied

by others), to protect against backfeeding voltage into the incoming termninal through the static bypass circuit. If this signal

is not used by the installer, a label must be added at the external incoming bypass supply disconnect device to warn service

personnel that the circuit is connected to a UPS.

The text has the following meaning or is equivalent to: Isolate the UPS before working on this circuit.

User serviceable components

All the equipment maintenance and servicing procedures involving internal access need special tools and should be carried

out only by trained personnel. The components that can only be accessed by opening the protective cover with tools cannot

be maintained by the user.

This UPS fully complies with the general and safety requirements for use in operator access area. Dangerous voltages are

present within the UPS and battery enclosure but out of reach of non-service personnel. Contact of these voltages is

minimized, because live parts are housed behind protective covers that require a tool for their removal. No risk exists if you

operate the equipment in the normal manner, following the recommended operating procedures in this manual.

Page 4

Battery voltage higher than 400Vdc

All the battery physical maintenance and servicing procedures need special tools or keys and should be carried out only by

trained personnel.

Take special care when working with the batteries associated with this UPS. When the batteries are connected together, the

battery terminal voltage exceeds 400vdc and is potentially leathal.

Battery manufacturers supply details of the necessary precautions to be observed in working on, or in the vicinity of, a large

bank of battery cells. These precautions should be followed implicitly at all times. Particular attention should be paid to the

recommendations concerning local environmental conditions and the provision of protective clothing, first aid and

fire-fighting facilities.

Page 5

Page 6

Contents

Chapter 1 Installation Of single UPS cubicle ....................................................................................................................... 1

1.1 Brief Introduction ................................................................................................................................................... 1

1.2 Initial Check .......................................................................................................................................................... 1

1.3 Location Selection ................................................................................................................................................. 2

1.3.1 UPS Room ................................................................................................................................................. 2

1.3.2 External Battery Room............................................................................................................................... 2

1.3.3 Storage ...................................................................................................................................................... 2

1.4 Positioning ............................................................................................................................................................ 3

1.4.1 System Cabinet ......................................................................................................................................... 3

1.4.2 Moving Cabinet .......................................................................................................................................... 3

1.4.3 Clearance .................................................................................................................................................. 3

1.4.4 Front Access .............................................................................................................................................. 3

1.4.5 Final Positioning And Fixing ...................................................................................................................... 3

1.4.6 Cable Entry ................................................................................................................................................ 5

1.5 External protective device ..................................................................................................................................... 5

1.5.1 Rectifier And Bypass Input ........................................................................................................................ 6

1.5.2 External Battery Circuit Breaker ................................................................................................................ 6

1.5.3 UPS Output ............................................................................................................................................... 6

1.6 Power Cables ....................................................................................................................................................... 6

1.6.1 Maximum Steady State AC And DC Currents Maximum steady state AC and DC currents ................... 6

1.6.2 Distance From Floor To Connection Point On The Equipment .................................................................. 7

1.6.3 Cable Connection ...................................................................................................................................... 7

1.7 Control Cables And Communication ................................................................................................................... 12

1.7.1 Input Dry Contact Port: Battery Environment (ventilation), Ground fault, Temperature ........................... 12

1.7.2 Battery Circuit-Breaker (BCB) Port .......................................................................................................... 13

1.7.3 Maintenance Switch And Output Switch State Port ................................................................................. 13

1.7.4 Backfeed protection Output Dry Contact Port .......................................................................................... 14

1.7.5 Remote Emergency Power Off (REPO) Input Port .................................................................................. 14

1.7.6 Relay and Network Interface Card ports, Service ports, .......................................................................... 15

Chapter 2 Battery .............................................................................................................................................................. 16

2.1 Brief Introduction ................................................................................................................................................. 16

2.2 Safety .................................................................................................................................................................. 17

2.3 Battery Power Cable ........................................................................................................................................... 18

2.3.1 Overview .................................................................................................................................................. 18

2.3.2 Battery Installation ................................................................................................................................... 18

2.3.3 Battery Connection .................................................................................................................................. 18

2.4 Battery Maintenance ........................................................................................................................................... 19

Page 7

2.5 Battery Recycling ................................................................................................................................................ 20

2.6 Connection Of External Battery Circuit-Breaker (BCB ........................................................................................ 20

Chapter 3 Installation Of Multiple UPS cubicles ................................................................................................................ 22

3.1 Overview ............................................................................................................................................................. 22

3.2 1 + N Parallel System ......................................................................................................................................... 22

3.2.1 Cabinet Installation .................................................................................................................................. 23

3.2.2 External protective device ........................................................................................................................ 24

3.2.3 Power Cable ............................................................................................................................................ 24

3.2.4 Auxiliary Control Wiring ........................................................................................................................... 25

3.2.5 Parallel Control Cables ............................................................................................................................ 25

3.3 Dual Bus System ................................................................................................................................................ 26

3.3.1 Cabinet Installation .................................................................................................................................. 26

3.3.2 External protective device ........................................................................................................................ 26

3.3.3 Power Cable ............................................................................................................................................ 26

3.3.4 Control Cable ........................................................................................................................................... 26

Chapter 4 System Description........................................................................................................................................... 28

4.1 Brief Introduction ................................................................................................................................................. 28

4.1.1 Operating Theory ..................................................................................................................................... 28

4.1.2 Static (bypass) Transfer Switch ............................................................................................................... 28

4.2 1 + N Parallel System ......................................................................................................................................... 29

4.2.1 Parallel System Features ......................................................................................................................... 29

4.2.2 Requirements For Paralleling Of UPS Modules ....................................................................................... 29

4.3 Operation Mode .................................................................................................................................................. 29

4.3.1 Normal Mode ........................................................................................................................................... 30

4.3.2 Battery Mode ........................................................................................................................................... 30

4.3.3 Automatic Restart Mode .......................................................................................................................... 30

4.3.4 Bypass Mode ........................................................................................................................................... 30

4.3.5 Maintenance Mode (Manual Bypass) ...................................................................................................... 30

4.3.6 Parallel Redundancy Mode (System Expansion) ..................................................................................... 30

4.4 Battery Management (Set During Commissioning) ............................................................................................. 30

4.4.1 Normal Function ...................................................................................................................................... 30

4.4.2 Advanced Function .................................................................................................................................. 31

4.5 Battery Protection (Set By Commissioning Engineer) ......................................................................................... 31

Chapter 5 Operator Control And Display Panel ................................................................................................................. 32

5.1 Introduction ......................................................................................................................................................... 32

5.1.1 Indicators ................................................................................................................................................. 32

5.1.2 Audible Alarm (Buzzer) ............................................................................................................................ 33

5.1.3 Control Keys ............................................................................................................................................ 33

5.1.4 LCD And Menu Keys ............................................................................................................................... 33

5.2 LCD Screen Type ............................................................................................................................................... 34

Page 8

5.2.1 Start Screen ............................................................................................................................................. 34

5.2.2 Primary Screen ........................................................................................................................................ 34

5.2.3 Default Screen ......................................................................................................................................... 35

5.3 Selecting Language ............................................................................................................................................ 35

5.4 Changing The Current Date And Time ................................................................................................................ 35

5.5 Control Password ................................................................................................................................................ 35

5.6 Detailed Description Of Menu Items ................................................................................................................... 35

5.7 Prompt Window ................................................................................................................................................... 37

5.8 Alarm List ............................................................................................................................................................ 38

Chapter 6 Operating Instructions ...................................................................................................................................... 41

6.1 Power Switches .................................................................................................................................................. 41

6.2 UPS Startup Procedures ..................................................................................................................................... 42

6.2.1 Procedures For Startup Into Normal Mode .............................................................................................. 43

6.2.2 Procedures For Startup In Battery Mode (Startup Without A.C. Input Supply) ........................................ 43

6.3 Procedures For Transfer Between Operation Modes .......................................................................................... 44

6.3.1 Transfer From Normal Mode To Battery Mode ........................................................................................ 44

6.3.2 Transfer From Normal Mode To Bypass Mode ........................................................................................ 44

6.3.3 Transfer From Bypass Mode To Normal Mode ........................................................................................ 44

6.3.4 Transfer From Normal Mode To Maintenance Mode ............................................................................... 44

6.4 Procedures For Completely Powering Down The UPS ....................................................................................... 45

6.5 Procedures For Completely Powering Down The UPS While Maintaining he Power Supply To The Load ........ 45

6.6 Isolation Procedures (Of One UPS In A Parallel System) ................................................................................... 45

6.7 Insertion Procedures (Of One UPS In A Parallel System) .................................................................................. 46

6.8 Emergency Power Off (EPO) Procedures ........................................................................................................... 46

6.9 Automatic Restart ............................................................................................................................................... 46

6.10 UPS Reset Procedures ..................................................................................................................................... 47

Chapter 7 Service ............................................................................................................................................................. 48

7.1 Service Procedures Of Power Module And Bypass Module ............................................................................... 48

7.1.1 Notes ....................................................................................................................................................... 48

7.1.2 Service Procedures Of Power Module ..................................................................................................... 48

7.1.3 Service Procedures Of Bypass Module ................................................................................................... 48

7.2 Replacement Procedures Of Air Filter ................................................................................................................ 49

Chapter 8 Product Specification.. ...................................................................................................................................... 51

8.1 Conformity And Standards .................................................................................................................................. 51

8.2 Environmental Characteristics ............................................................................................................................ 51

8.3 Mechanical Characteristics ................................................................................................................................. 51

8.4 Electrical Characteristics (Input Rectifier) ........................................................................................................... 52

8.5 Electrical Characteristics (Intermediate DC Circuit) ............................................................................................ 52

8.6 Electrical Characteristics (Inverter Output) ......................................................................................................... 53

8.7 Electrical Characteristics (Bypass Input) ............................................................................................................. 53

Page 9

8.8 Efficiency, Heat Losses And Air Exchange ......................................................................................................... 54

Appendix 1 Option List ...................................................................................................................................................... 55

Appendix 2 List Of Abbreviations ...................................................................................................................................... 56

Page 10

Chapter 1 Installation Of UPS Module 1

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

Chapter 1 Installation Of single UPS cubicle

This chapter introduces the installation of Emerson NXr 30kVA ~ 200kVA UPS (hereinafter referred to as UPS)

module, including the initial check, location selection, positioning, external protective device and cable connection.

1.1 Brief Introduction

This chapter briefs the relevant requirements that must be considered in the location selection and cabling of the UPS

and relevant equipment.

Because each site has its particular characteristics, this chapter does not provide detailed installation steps, it only

acts as a guide for the general procedures and practices that should be observed by the installing engineer, so that

they can properly handle the specific situation of the site.

Warning: professional installation required

1. Do not apply electrical power to the UPS without permission of the commissioning engineer.

2. The UPS should be installed by a qualified engineer in accordance with the information contained in this manual. All the

equipment not referred to in this manual is shipped with details of its own mechanical and electrical installation information.

Note: 3-phase 5-wire input power required

The standard UPS can be connected to TN, TT and IT AC distribution systems (IEC60364-3) of 3-phase 5-wire (A, B, C, N, PE).

Warning: battery hazards

1. Take special care when working with the batteries associated with the UPS. When the battery is connected, the battery terminal

voltage exceeds 400Vdc and is potentially lethal.

2. Wear eye protection to prevent injury from accidental electrical arcs.

3. Remove rings, watches and all metal objects.

4. Use tools with insulated handles only.

5. Wear rubber gloves.

6. If a battery leaks electrolyte, or is otherwise physically damaged, it must be replaced, stored in a container resistant to sulfuric

acid and disposed of in accordance with local regulations.

7. If electrolyte comes into contact with the skin, the affected area should be washed immediately with water.

1.2 Initial Check

Check the following items prior to UPS installation:

1. Visually examine if there is any damage inside and outside the UPS and battery due to transportation. Report any

such damage to the shipper immediately.

2. Verify the UPS label and confirm the correctness of the UPS. The UPS label is attached on the back of the door.

The UPS model, capacity and main parameters are marked on the label.

Page 11

2 Chapter 1 Installation Of UPS Module

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

1.3 Location Selection

1.3.1 UPS Room

The UPS is designed for indoor installation. It should be installed in a clean environment with adequate ventilation to

keep the environmental parameters within the specified operating range (see Table 8-2). For example, the UPS

should not be installed in an environment outside the specified operating range, like in thruway tunnels or outdoor

places without air-conditioning.

The UPS uses forced cooling by internal fans. Cooling air enters the UPS through the ventilation grills at the front of

the cabinet and exhausted through the ventilation grills in the rear of the cabinet. Do not obstruct the ventilation holes.

If necessary, install a system of extractor fans to aid cooling-air flow to avoid room temperature buildup. An air filter

should be used when the UPS is to operate in a dirty environment.

Note

The UPS should be installed on a cement surface or other surface that is not combustible.

1.3.2 External Battery Room

Batteries generate some amount of hydrogen and oxygen at the end of charge, so the fresh air volume of the battery

installation environment must meet the EN50272-2001 requirements.

The ambient temperature of the battery must be stable. Ambient temperature is a major factor in determining the

battery capacity and life. The nominal operating temperature of the battery is 20°C. Operation above this temperature

will reduce the battery life, and operation below this temperature will reduce the battery capacity. If the average

operating temperature of the battery rises from 20ºC to 30ºC, the service life of the battery will be reduced by 50%. If

the operating temperature of the battery is above 40ºC, the battery service life will be decreased in exponent rate. In

a normal installation, the battery temperature is maintained between 15°C and 25°C. Keep batteries away from heat

sources and ventilation holes.

If external battery is used, a battery protective device (for example, fuse or circuit breaker) shall be installed. The

battery protective device shall be installed as close to the battery as possible, and the cabling distance between the

battery protective device and the battery shall be minimized.

1.3.3 Storage

Should the UPS not be installed immediately, it must be stored in a room for protection against excessive humidity

and heat sources (see Table 8-2). The battery needs to be stored in a dry and cool place with good ventilation. The

most suitable storage temperature ranges from 20ºC to 25ºC.

Warning

During storage, periodically charge the battery according to the battery manufacturer instructions. In the charge process,

temporarily connect the UPS to the mains and activate the battery for the time required for recharging the battery.

Page 12

Chapter 1 Installation Of UPS Module 3

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

1.4 Positioning

To prolong the service life, the place chosen should offer:

convenient wiring

space for easy operation on UPS

sufficient air exchange to dispel heat produced by UPS

protection against atmospheric agents

protection against excessive humidity and heat sources

protection against dust

compliance with fire prevention requirements

operating environment temperature between 20°C and 25°C (the typical temperature range for max. battery life)

The UPS is of steel frame structure wrapped by removable panels. The top and side panels are fixed by screws.

Opening the UPS door reveals the power terminals, auxiliary terminal block and power switch. The UPS has an

operator control and display panel located on its front door, which provides the basic operating status and alarm

information. The UPS provides air inlet in the front and air outlet at the back.

1.4.1 System Cabinet

Depending on the design requirement of each UPS system, a UPS system may include certain equipment cabinets,

such as UPS cabinet, external battery cabinet, external bypass cabinet, and so on. All the cabinets should be

installed side by side to achieve an aesthetic effect.

1.4.2 Moving Cabinet

Warning

1. The lifting equipment for moving the UPS cabinet shall have enough lifting capacity. For the UPS weight, refer to Table 8-3.

2. Ensure that adequate personnel and lifting aids are available when removing the shipping pallet.

Note

Take special care when moving the battery cabinet fitted with batteries, in which case, the moving distance shall be minimized.

The UPS can be moved by means of a fork lift or similar equipment.

1.4.3 Clearance

As the UPS has no ventilation grills at either side, no clearances are required for either side.

To enable routine tightening of the power terminations within the UPS, it is recommended that clearance around the

front of the equipment should be sufficient to enable free passage of personnel with the door fully open. Meanwhile,

maintain, for full 200kVA applications a rear clearance of at least 350mm to permit adequate circulation of air coming

out of the UPS, and advisably more than 500mm to facilitate maintenance.

1.4.4 Front Access

The component layout of the UPS supports front access and top access for servicing, diagnosing and repairing the

UPS, thus reducing the space requirement for side and rear access.

1.4.5 Final Positioning And Fixing

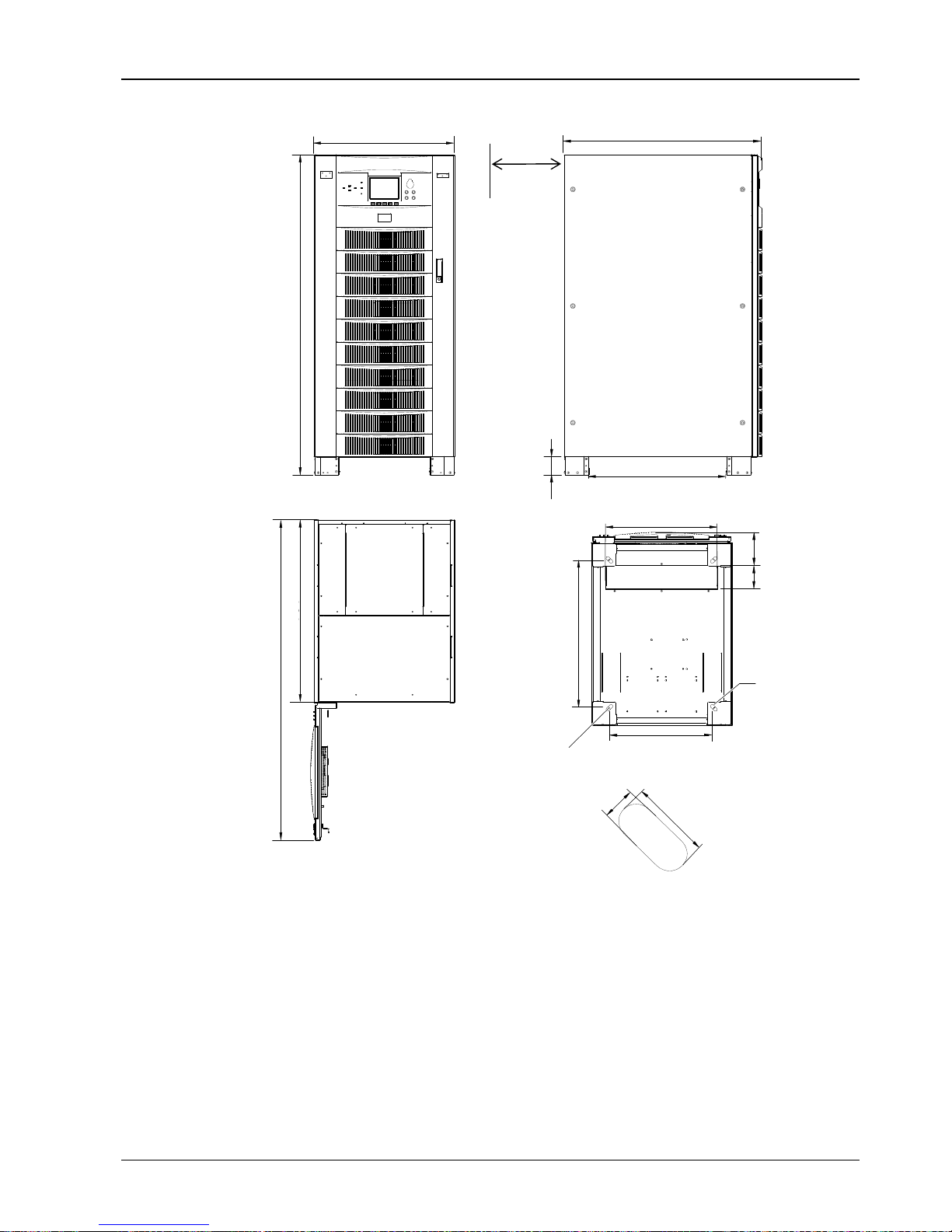

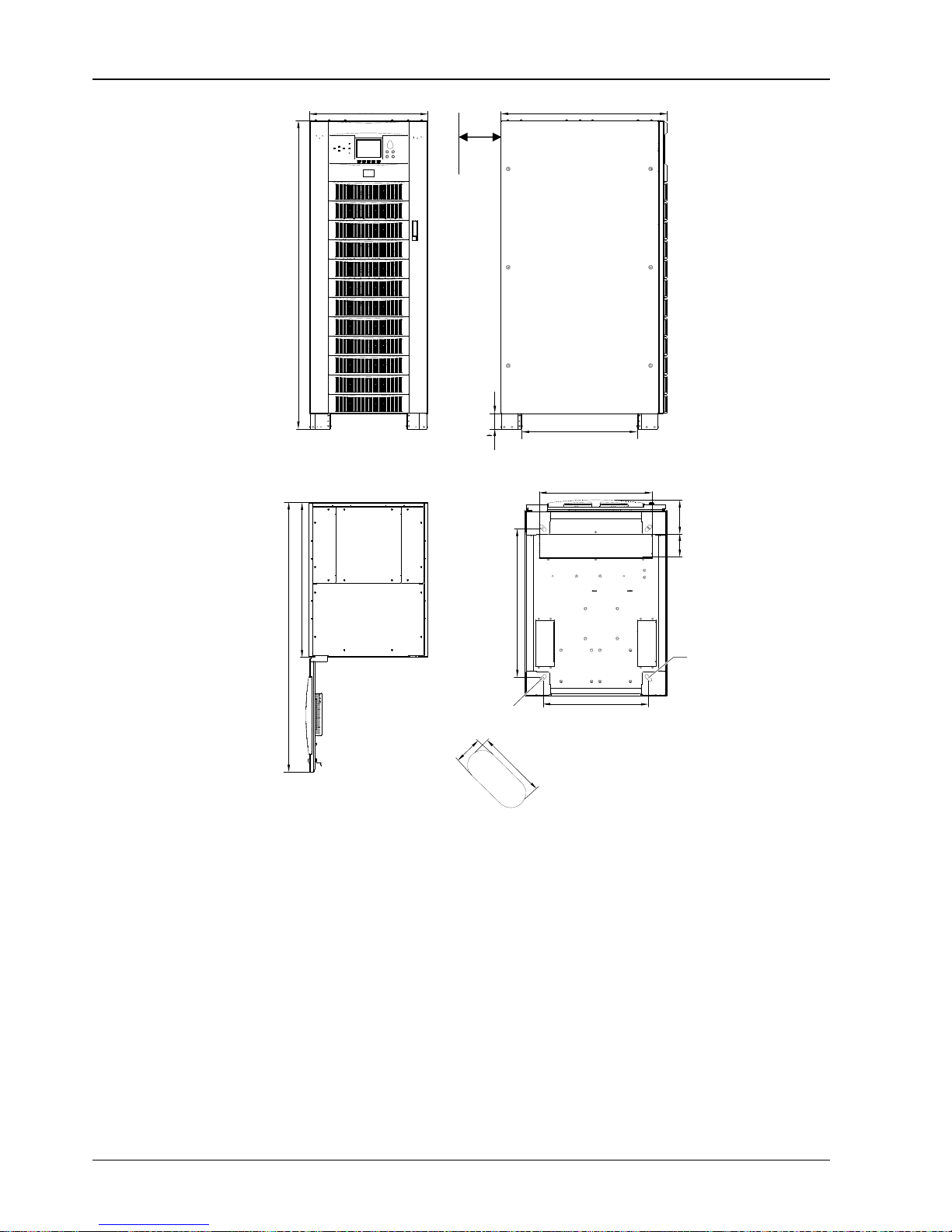

Figure 1-1 and Figure 1-2 provide the UPS installation dimensions. After final positioning, fix the UPS directly on the

installation surface through the anchor holes on the UPS base. If the UPS is mounted on raised floor, a suitable

pedestal should be designed, which should be able to bear the UPS weight. When designing the pedestal, refer to

the bottom view in Figure 1-1 and Figure 1-2.

Page 13

4 Chapter 1 Installation Of UPS Module

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

600

1396

843

80

586

794

1397

476

645

445

102

3

5

15

A amplified view

A

145

Anchor hole

Front view

Side view

Top view

Bottom view

1400

843

1400

800

100

Figure 1-1 30kVA

~

160kVA UPS installation dimensions (unit: mm)

350

Page 14

Chapter 1 Installation Of UPS Module 5

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

1598

600

843

80

586

1400

803

侧视图

474

645

445

146100

前视图

顶视图

1

5

3

5

A

600

843

1598

586

Front view

Side view

Top view

Anchor hole

Bottom view

A amplified view

1600

825

Figure 1-2 200kVA UPS installation dimensions (unit: mm)

1.4.6 Cable Entry

The UPS uses top cable entry and bottom cable entry.

1.5 External protective device

External circuit breakers or other protective devices must be fitted at the input AC supply of the UPS. This section

provides a general guide for qualified installation engineers. The installation engineers should have the knowledge of

the local wiring regulations on the equipment to be installed.

350

Page 15

6 Chapter 1 Installation Of UPS Module

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

1.5.1 Rectifier And Bypass Input

Over currents

Install suitable protective devices in the distribution of the incoming mains supply, considering the power cable

current-carrying capacity and overload capacity of the system (see Table 8-6). Generally, magnetic circuit breaker

with IEC60947-2 tripping curve C (normal) at 125% of the current listed in Table 1-1 is recommended.

Split bypass: In case a split bypass is used, separate protective devices should be installed for the rectifier input and

bypass input in the incoming mains distribution panel.

Note

1. The rectifier input and bypass input must use the same neutral line.

2. For IT power systems, four-pole protective devices must be used upstream of the input distribution panel and output distribution

panel, external to the UPS.

Earth leakage

The residual earth current introduced by the radio frequency interference (RFI) suppression filter inside the UPS is

greater than 3.5mA and less than 1000mA. It is recommended that the sensitivity of all differential devices be verified

upstream of the input distribution panel.

1.5.2 External Battery Circuit Breaker

The UPS and its associated battery are protected against the effect of overcurrents through a DC circuit breaker

provided by the external battery cabinet.

The rated voltage of the external battery overcurrent protective device is more than 500Vdc, and its DC breaking

current is more than 8kA.

1.5.3 UPS Output

The UPS output distribution shall be configured with a protective device. The protective device shall be different from

the input distribution protection switch and able to provide overload protection (refer to Table 8-6).

1.6 Power Cables

The cable design must comply with the instructions provided in this section, follow local wiring practices, take the

environmental conditions into consideration, and refer to IEC60950-1 Table 3B.

1.6.1 Maximum Steady State AC And DC Currents Maximum steady state AC and DC currents

UPS

rating

(kVA)

Rated current (A) Busbar stud size

Input mains

current

1,2

(at full

load with battery

recharging)

Output current

2

at full

load

Battery

discharge

current at

EOD

Main input,

output, bypass

input cables

Battery cables

380V 400V 415V 380V 400V 415V Bolt

To rq u e

(N.m)

Bolt Torque (N.m)

200 330 316 302 303 290 278 630

M8

15

M8

15

150, 160 280 265 255 225 215 205 525

120 224 212 204 180 172 164 420

90、100

168 159 153 135 129 123 315

60 112 106 102 90 86 82 210

40 75 71 68 60 57 55 140

30 56 53 51 45 43 41 105 M6 4.8

30-B 56 53 51 45 43 41 105 M6 4.8

Note:

1. Input mains current for common rectifier and bypass AC input.

Page 16

Chapter 1 Installation Of UPS Module 7

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

2. Non-linear loads (switch mode power supplies) affect the design of the output and bypass neutral cables. The current

circulating in the neutral cable may exceed that of the nominal phase current by up to 70%.

3. Values shown for 30 x 6-cell 12V blocks per battery string. Each string may contain from 30 to 40 x 6-cell 12V blocks. Inverse

proportional values apply with more blocks per battery string. E.g. The max discharge current from a 40 x 6-cell 12V battery applied

to a 30kVA NXr is 105A x (30/40) = 78A

1. Protective earth cable: Follow the most direct route possible to connect the earth cable to the cabinet. The earth

cable shall be sized in accordance with the AC supply fault rating, cable lengths and type of protection. E.g. typical

cross sectional area (CSA) is 70mm

2

(150kVA) according to AS/IEC60950-1 Table 2D.

2. When sizing the battery cables, a maximum volt drop of 4Vdc is permissible at the current ratings given in Table

1-1. The load equipment is generally connected to a distribution board containing individually protected busbars

rather than connected directly to the UPS output. The output cables from paralleled units to the parallel distribution

bus should be of the same length to optimise the sharing of current. Do not form coils, so as to minimize the

formation of electromagnetic interference.

3. For terminal location, refer to Figure 1-4 ~ Figure 1-6.

Warning

Failure to follow adequate earthing procedures may result in electromagnetic interference or in hazards involving electric shock

and fire.

1.6.2 Distance From Floor To Connection Point On The Equipment

Table 1-1 Distance from floor to connection point on the equipmen

UPS connection point Minimum distance (mm)

30kVA (NXr 30K-B) 30kVA (NXr 30K) ~ 160kVA 200kVA

Rectifier AC input supply 780 284 284

Bypass AC input supply 685 284 284

UPS AC output 530 369 251

Battery power 375 369 320

Auxiliary cable: to monitoring board (U2) 1104 1104 1304

1.6.3 Cable Connection

Important

The operations described in this section must be performed by authorised personnel. If you have any questions, please contact

the local customer service center of Emerson immediately.

Warning

1. Before cable connection, ensure that you are aware of the location and state of the breaker that connects the UPS input to the

mains distribution panel. Check that this breaker is off, and post any necessary warning sign to prevent inadvertent operation of

the breaker.

2. The power cables should be routed through cable tunnel or metallic cable trough to avoid being damaged under mechanical

stress and reduce electromagnetic interference to the environment.

Once the equipment has been finally positioned and secured, refer to Figure 1-3 to connect the power cables as

described in the following procedures:

Page 17

8 Chapter 1 Installation Of UPS Module

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

J9

J10

J5

J6

mA

J9

J10

mC

mB

mN

bA

bC

bB

bN

oA

oC

oB

oN

1

2

3

4

12 34

J8

324

J7

1

2

3

4

To user safety earth

Power cable

PE

Bypass module

UPS

External EPO

Input

Output

BFP_O

BFP_S

BFP_C

BPS

ENV

BIG

12V

EXT_Q3

EXT_OUT

IN_S

GND

EPO_NC

12V

12V

EPO_NO

DRV

FBOLGND

+12V

BAT_OUT

GND

N

BAT+

BAT-

Battery input

1

2

3

4

1

2

3

4

UPS output

Main input

Bypass input

BAT

EXT

Figure 1-3 UPS electrical connection

1. Verify that the UPS equipment is isolated from its external power source and all the UPS power isolators are open.

Check that these supplies are electrically isolated and post any necessary warning signs to prevent their inadvertent

operation.

2. Open the UPS door and remove the protective cover at the lower part in the front to gain access to the power

terminals, as shown in Figure 1-4 to Figure 1-6.

Page 18

Chapter 1 Installation Of UPS Module 9

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

Figure 1-4 30kVA (NXr 30K-B) UPS power terminals

Page 19

10 Chapter 1 Installation Of UPS Module

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

mNmCmBmA

BAT+ BAT N BAT-

PE

bA bB bC

mN

oN

oA

oB oC

Note:

1. Main input: mA, mB, mC, mN

2. Bypass input: bA, bB, bC, mN

3. UPS output: oA, oB, oC, oN

4. Battery input: BAT+, BAT-, BAT N

5. Earth: PE

Figure 1-5 30kVA (NXr 30K) ~ 160kVA UPS power terminals

mN

mA

mB

mC

oN bA

bB

bC

oA

oB

oC

+

-

N

PE

Note:

1. Main input: mA, mB, mC, mN

2. Bypass input: bA, bB, bC, mN

3. UPS output: oA, oB, oC, oN

4. Battery input: + , - , N

5. Earth: PE

Figure 1-6 200kVA UPS power terminals

Page 20

Chapter 1 Installation Of UPS Module 11

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

3. Connect the protective earth cable and all other necessary earth cables to the earth terminals (PE).

Note

The earth cables and neutral line connection must be in accordance with local and national codes of practice.

4. Identify and make power connections for the input cables according to one of the following two procedures,

depending on the type of installation.

Common input connections

1) In common bypass and rectifier input configuration, for 30kVA ~ 160kVA UPS, connect the AC input cables to the

main input terminals (mA-mB-mC-mN); for 200kVA UPS, connect the AC input cables to the bypass input terminals

(bA-bB-bC-mN). Refer to Table 1-1 for the torque. Ensure correct phase rotation.

Split bypass connections

2) If a split bypass configuration is used, connect the main input cables to the main input terminals (mA-mB-mC-mN),

and connect the bypass input cables to the bypass input terminals (bA-bB-bC-mN). Refer to Table 1-1 for the torque.

Ensure correct phase rotation.

Warning

For split bypass operation, ensure that the linking busbars between the bypass input and maiin input are removed. The main

input and bypass input must be referenced to the same neutral point.

System output connection

5. Connect the system output cables between the UPS output terminals (oA-oB-oC-oN) and the critical load. Refer to

Table 1-1 for the torque. Ensure correct phase rotation.

Warning

If the load equipment will not be ready to accept power on the arrival of the commissioning engineer then ensure that the system

output cables are safetly isolated at their ends.

Warning: hazardous battery terminal voltage 400Vdc

1. Ensure correct polarity of batter string end connections to the UPS terminals, that is, (+) to (+), (–) to (–) and (N) to (N). But do

not make these connections before authorized by the commissioning engineer.

2. Ensure correct polarity of battery string end connections to the battery circuit breaker (BCB) and from the BCB to the UPS

terminals, that is, (+) to (+) and (–) to (–), but disconnect one or more battery cell links in each tier. Do not reconnect these links

and do not close the BCB before authorized by the commissioning engineer.

6. For frequency converter applications ensure the bypass links are removed.

7. Replace the protective cover.

Page 21

12 Chapter 1 Installation Of UPS Module

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

1.7 Control Cables And Communication

As shown in Figure 1-7, the bypass module provides dry contact ports (J5 ~ J10), service and communication ports

(RS485 port, RS232 port and three Intellislot (Network Interface/Relay ports) on the front panel.

J8 J5

J10 J7

J6

J9

12

RS232 Intellislot 1RS485

Intellislot 2

Intellislot 3

Figure 1-7 Dry contact ports and communication ports

The UPS accepts external signalling from voltage-free (dry) contacts connected to push-in input dry contact terminal.

Subject to prior software programming, the signalling is accepted by the UPS when relevant terminals and the +12V

terminals are shorted. All control cables must be routed separately from the power cables and parallel cables,

double-insulated and of a typical 0.5mm

2

to 1.5mm2 CSA for maximum runs between 20m and 30m respectively.

1.7.1 Input Dry Contact Port: Battery Environment (ventilation), Ground fault, Temperature

The input dry contact ports J7 and J8 provide environmental and battery ground and temperature fault contacts. The

ports are shown in Figure 1-8 and described in Table 1-2.

12 V

BtG

ENV

J7

+12V

J8

GND

BAT_OUT

12V

BAT_IN

Figure 1-8 Input dry contact ports J7 and J8

Table 1-2 Description of input dry contact ports J7 and J8

Position Name Description

J7.1 ENV* Battery room environment detection (normally closed)

J7.2 BtG Battery ground fault

J74 +12V +12V power

J8.1 BAT_IN

Internal battery temperature detection

J8.2 +12V +12V power

J8.3 BAT_OUT External battery temperature detection

J8.4 GND Power ground

Note*: Activating this feature turns off the battery charger

J2

J3

J4

Page 22

Chapter 1 Installation Of UPS Module 13

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

1.7.2 Battery Circuit-Breaker (BCB) Port

J6 is the BCB port. The port is shown in Figure 1-9 and described in Table 1-3.

12V

OL

GND

FB

DRV

J6

12V

12V

Figure 1-9 BCB port

Table 1-3 BCB port description

Position Name Description

J6.1 DRV BCB driver signal – for BCB UV coil when used

J6.2 FB BCB aux contact closed to J6.3 when BCB is open

J6.3 GND Power ground

J6.4 OL BCB on line – enables J6.1 and J6.2 (when J6.4 is closed to J6.3)

The connection between the BCB port and BCB is shown in Figure 1-10.

电池开关

BCB

J10

OL

GND

FB

DRV

Aux-N.O.

Aux-N.O.

J6

Aux_N.O.

Aux_N.O.

BCB

Figure 1-10 Connection between BCB port and BCB

1.7.3 Maintenance Switch And Output Switch State Port

J9 is the maintenance switch and output switch state port. The port is shown in Figure 1-11 and described in Table

1-4.

EXT-S

CAB-S

CAB-S

J9

EXT_Q3

IN_S

GND

EXT_OUT

Figure 1-11 Maintenance switch and output switch state port

Table 1-4 Description of maintenance switch and output switch state port

Position Name Description

J9.1 EXT_Q3 External maintenance bypass (EBP) switch – Aux Contact closed to J9.4 when

EBP is open.

J9.2 IN_S J9.2 shorted to J9.4 when Internal maintenance switch is closed

J9.3 EXT_OUT

External output isolator (EOI) Aux Contact closed to J9.4 when EOI is closed.

J9.4 GND Power ground

Aux contact is open

when BCB is closed

Page 23

14 Chapter 1 Installation Of UPS Module

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

1.7.4 Backfeed protection Output Dry Contact Port

J5 is the output dry contact port, providing two relay output dry contact signals. The port is shown in Figure 1-12 and

described in Table 1-5. The shunt trip coil of the external circuit breaker can be driven directly through this dry

contact rated for 24Vdc/5A.

J5

BFP_C

BFP_S

BFP_O

Figure 1-12 Output dry contact port

Table 1-5 Description of output dry contact port

Position Name Description

J5.2 BFP_O

Bypass feedback protection relay (normally open), closed when bypass

silicon-controlled rectifier (SCR) is shorted

J5.3 BFP_S Bypass feedback protection relay center

J5.4 BFP_C

Bypass feedback protection relay (normally closed), open when bypass SCR is

shorted

1.7.5 Remote Emergency Power Off (REPO) Input Port

The UPS has an EPO function that operates by a button on the operator control and display panel of the UPS or by a

remote contact provided by the user. The EPO switch is under a hinged, plastic shield.

J10 is the remote EPO input port. The port is shown in Figure 1-13 and described in Table 1-6.

J10

+12V

EPO_NO

+12V

+12V

EPO_NC

Figure 1-13 Remote EPO input port

Table 1-6 Description of remote EPO input port

Position Name Description

J10.1 EPO_NC

EPO activate when J10.1 and J10.2 are open

J10.2 +12V

J10.3 +12V

EPO activate when J10.1 and J10.4 are closed

J10.4 EPO_NO

Notes

1. The UPS EPO action disables the UPS a.c. output by shuting down the rectifiers, inverters and static bypass.

2. The UPS EPO action does not disconnect any input power supply. To disconnect all power from the UPS, open the

upstream input breaker(s) and the battery breaker when EPO is activated.

3. Pins 1 and 2 of J10 are supplied factory-shorted.

4. If the UPS EPO function is not used, pins 1 and 2 of J10 must remain shorted and pins 3 and 4 of J10 must remain

open .

Page 24

Chapter 1 Installation Of UPS Module 15

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

1.7.6 Relay and Network Interface Card ports, Service ports,

Optional Intellislot cards

a) with Global Velocity Protocol

(On UPS display, select Protocol Velocity in “Settings”)

b) with Asia-Pacific YDN23 Protocol

(in use prior to 2012 - On UPS display, select Protocol YDN23 in “Settings”)

For details, refer to the user manuals of the each specific network interface card.

Service ports

J2 and J3: Parallel connection ports - used for control of two or more NXr UPS cabinets operating in

parallel.

J4: Load Bus Synch (LBS) interface - used to synchronize the outputs of two NXr UPS systems operating in

dual bus mode.

RS232 / RS485: maintenance ports - used for programming, commissioning and investigation by service

engineers.

ModBus Card p/n IS-485L

(preferred location: port 3)

SNMP/WebBrowser Card

p/n IS-WEBL (preferred loc: port 2)

Relay Card p/n IS-Relay

(preferred location: port 1)

Relay Card p/n 02351874

(preferred location: port 1)

SNMP/Web SIC (Site Interface Card)

p/n 02351817 2, (preferred loc: port 2)

ModBus Card p/n 02354066

(preferred location: port 3)

Page 25

16 Chapter 2 Battery

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

Chapter 2 Battery

This chapter introduces the relevant information of the battery, including the brief introduction, battery safety, battery

power cables, battery maintenance and recycling, reference current and connection of external BCB.

2.1 Brief Introduction

The UPS battery string consists of battery cells (or blocks) connected in series to provide a d.c. input voltage for the

UPS inverter to operate. The required battery backup time (that is, the time during which the battery can maintain

supply to the load in the event of a mains failure) is subject to the ampere-hour capacity of the battery. To achieve the

capacity required, subject to recommendation from the battery manufacturer, several battery strings may be

connected in parallel. Batteries of different brand, model and age should nottbe used together.

Except for the NXr 30K-B model that contains internal batteries, all UPS batteries are located external to the UPS

cabinet and is normally housed in a battery cabinet or located on stands/racks.

The NXr 30K-B UPS provides a battery compartment to accommodate internal batteries. Up to 40 x 24Ah/12V battery

blocks can be accommodated.

Page 26

Chapter 2 Battery 17

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

2.2 Safety

Take special care when working with the batteries associated with the UPS. When all the cells are connected together,

the battery string voltage can be up to 576Vdc and is potentially lethal. Please follow the precautions for high voltage

operation. Only qualified personnel are allowed to install and maintain the battery. To ensure the safety, the external

batteries shall be installed inside a key-lockable cabinet or in a purpose-designed, dedicated battery room, so that

they are segregated from all but qualified maintenance personnel.

During battery maintenance, pay attention to the following items:

Place the maintenance switch in the ON position

The battery cell number setting in the background software must be consistent with the actual battery cell

number

Note

Full safety instructions concerning the use and maintenance of UPS batteries are provided in the appropriate battery

manufacturers manuals. The battery safety inforamtion contained in this section relates to key considerations that must be taken

into account during the installation design process and might affect the design outcome depending on localised conditions.

Warning: hazardous battery voltage present behind covers

1. No user-serviceable parts are located behind covers that require a tool for their removal. Only qualified service personnel are

authorised to remove such covers.

2. Before operating the copper bars connected with the external battery, please disenergize the copper bars.

3. Observe the following safety precautions when working on the batteries:

1) The battery shall be firmly and reliably connected. After the connection is completed, all connections between the terminals and

the batteries shall be calibrated. The requirements on torque specified in the instructions or user manual provided by the battery

manufacturer shall be satisfied. All connections between the terminals and the batteries shall be inspected and tightened at least

once a year. Failure to observe this may cause fire!

2) Inspect the battery appearance before accepting and using the battery. If there exist any package damage, dirty battery

terminal, terminal erosion, rust, or enclosure crack, deformation or electrolyte leakage, replace it with new product. Otherwise,

battery capacity reduction, electrolyte leakage or fire may be caused.

3) The battery is very heavy. Please use proper method to move and hoist the battery, so as to prevent any damage to human

being or the battery terminals. Severe damage to the battery may cause fire.

4) The battery terminals shall not be subject to any force, such as the pulling force or twisting force of the cable. Otherwise, the

internal connection of the battery may be damaged, and severe damage may cause fire.

5) The battery shall be installed and stored in a clean, cool and dry environment. Do not install the battery in a sealed battery

chamber or a sealed room. The battery room ventilation shall at least meet the requirement of EN50272-2001. Otherwise, battery

bulging, fire or even personal may be caused.

6) The battery shall be kept away from heat sources like transformers, or fire sources. Do not burn the battery or the battery in fire,

otherwise, electrolyte leakage, battery bulge, fire or explosion may be caused.

7) Do not directly connect any conductor between the positive and negative terminals of the battery. Remove finger rings,

watches, necklaces, bracelets and other metal objects before operating the battery, and ensure that the tools (for example,

wrench) are wrapped with insulating material. Otherwise, battery burning, explosion, human death or injury may be caused.

8) Do not disassemble, modify or damage the battery. Otherwise, battery short circuit, electrolyte leakage or even personal may

be caused.

9) Clean the battery enclosure with wringed wet cloth. To avoid any static or arcing, do not use dry cloth or duster to clean the

battery. Do not use the organic solvent, such as thinner, gasoline,

volatile oil

, to clean the battery. Otherwise, the battery enclosure

may be cracked. In worst case, fire may be caused.

10) The battery contains diluted sulfuric acid. In normal use, the diluted sulfuric acid is absorbed to the baffle plate and polar plate

of the battery. However, if the battery is damaged, the acid may leak from the battery. Therefore, use personal protective

equipment, such as, goggles, rubber gloves and apron, when operating the battery. Otherwise, if the diluted sulfuric acid enters

the eyes, blindness may be caused; if it contacts the skin, the skin may be burnt.

11) The battery may have short circuit, electrolyte dry-up or positive-pole plate erosion at the end of its life. If it is still used in this

state, the battery thermorunaway, bulging or electrolyte leakage may occur. Please replace the battery before it enters this state.

12) Before connecting or disconnecting the battery connection cables, please cut off the charging power.

13) Check if the battery has been unexpectedly earthed. If yes, remove the earth power. Contact with any part of the earthed

battery may cause electric shock.

Page 27

18 Chapter 2 Battery

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

2.3 Battery Power Cable

2.3.1 Overview

Please install and connect the batteries according to the following description and graphic presentation.

2.3.2 Battery Installation

1. Before installation, check the battery appearance to ensure that there is no damage, inspect and count the

accessories, and carefully read this manual and the user manual or installation instruction provided by the battery

manufacturer.

2. There shall be a clearance of 10mm between the vertical sides of the batteries for the smooth flow of the air

around the batteries.

3. Certain clearance shall be maintained between the battery top and the underside of the layer above it to facilitate

battery monitoring and maintenance.

4. The batteries shall be installed from the bottom layer upwards to avoid high gravity center. The battery shall be

properly installed and protected from vibration or shock.

5. Measure the battery voltage, and calibrate the battery voltage after UPS startup.

2.3.3 Battery Connection

1. When the battery cabinet is installed on a raised floor, the battery power cables and optional BCB control cables

can enter the UPS cabinet through the cabinet bottom. If the UPS and battery cabinet are installed side by side on a

solid floor, these cables can be led into the UPS cabinet through the cable entry holes on the lower part of the battery

cabinet.

2. When multiple battery strings are used, they shall be connected in series and then in parallel. Before applying load

and power-up, be sure to measure the total voltage of the battery strings and make sure that it is correct. The

negative and positive terminals of the battery must be connected to the corresponding negative and positive battery

terminals of the UPS according to the labels on the battery and UPS. Reverse battery connection may cause

explosion, fire, battery damage, UPS damage, and personal injury.

3. After connecting the battery cables, install an insulating shroud for each terminal.

4. When connecting the cables between the battery terminals and the BCB, connect from the BCB side first.

5. The bending radius of the cable shall be larger than 10D, where D is the outer diameter of the cable.

6. After cable connection, it is prohibited to pull the battery cables or the cable terminals.

7. Do not cross the battery cables during connection, and do not tie the battery cables together.

8. Refer to Figure 2-1 and Figure 2-2 for the battery cable connection.

9. For NXr 30K-B UPS, it is required to install the factory supplied separators between the two rows of batteries on

each layer of the battery compartment, as shown in Figure 2-2.

Page 28

Chapter 2 Battery 19

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

Figure 2-1 External battery cable connection

40

46.7

46.746.7

46.7

126.5

384

Battery

Battery

Battery

Battery

Battery

Battery

Battery

Battery

Battery

Battery

Battery

Battery

Battery

Battery Battery

Lead out the battery neutral

cable from here on the third layer

Separator

Red

Battery

compartment

Black

Blue

Red

Black

Blue

Figure 2-2 Internal battery cable connection (NXr 30K-B)

2.4 Battery Maintenance

The battery supplied by Emerson complies with the safety requirements of IEC 62040-1:2008. For the battery

maintenance and maintenance precautions, refer to the relevant manual provided by the battery manufacturer and

observe applicable local regulation e.g. AS2676:1993, IEEE-Std-1188-2005.

Note

1. Periodically check the screws of the battery terminals for loose connection. If there is any loose screw, tighten it immediately.

2. Check that all safety devices are present and that their functions are normal. Check that the battery management parameters

are set correctly.

3. Measure and record the air temperature inside the battery room.

4. Check the battery terminals for damage and heating. Check the battery enclosure and terminal covers for damage.

Page 29

20 Chapter 2 Battery

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

2.5 Battery Recycling

If the battery leaks electrolyte, or is otherwise physically damaged, it should be placed in a container resistant to

sulfuric acid and disposed of in accordance with local regulations.

Disused lead-acid storage battery belongs to dangerous waste, and it is a key item for disused battery pollution

control. The storage, transportation, use and disposal of the battery shall comply with the national and local laws and

regulations on dangerous waste and disused battery pollution prevention and other standards.

According to the relevant national regulations, the disused lead-acid storage battery must be recycled and shall not

be disposed of with other methods. Random discard or any other improper disposal of the disused lead-acid storage

battery may cause severe environment pollution and the relevant person will be investigated of corresponding legal

responsibilities.

As a lead-acid storage battery supplier, Emerson has built a perfect service network and disused battery recycling

system to help the customer legally and properly dispose of the lead-acid storage battery. For detailed information

about the disused battery recycling system of Emerson, please consult the local customer service center or sales

office of Emerson. If the customer refuses to accept this special note or does not use the disused battery recycling

system of Emerson. Emerson will not undertake any environment responsibility caused by the improper disposal of

the disused battery products.

2.6 Connection Of External Battery Circuit-Breaker (BCB

Table 2-1 provides recommended BCB rated current and minimum connection cable Cross Sectional Area (CSA).

Table 2-7 Reference table for selection of BCB rated current and connection cable CSA (minimum recommended)

Note: the minimum CSA is adequate for batteries located up to 5 meters from the UPS. For longer cable runs, the CSA shall be increased so

that the voltage drop remains less than 1% in order not to affect the battery run time significantly.

Item Unit UPS rating (kVA)

30 40 60 90, 100 120 150, 160 200

30-cell

battery

Maximum battery discharge

current at full load

A 105 140 210 315 420 525 630

Reference rated current of BCB A 150 175 250 350 450 550 700

Connection cable CSA mm

2

35 50 70 120 150 185 240

32-cell

battery

Maximum battery discharge

current at full load

A 100 133 200 300 400 500 590

Reference rated current of BCB A 150 150 250 350 450 550 630

Connection cable CSA mm

2

35 50 70 120 150 185 240

34-cell

battery

Maximum battery discharge

current at full load

A 94 125 186 282 376 470 556

Reference rated current of BCB A 100 150 200 300 400 500 630

Connection cable CSA mm

2

35 50 70 95 120 185 200

36-cell

battery

Maximum battery discharge

current at full load

A 88 118 176 264 352 440 525

Reference rated current of BCB

A 100 125 200 320 400 500 550

Connection cable CSA

mm

2

25 35 50 95 120 150 200

38-cell

battery

Maximum battery discharge

current at full load

A 84 112 168 252 336 420 498

Reference rated current of BCB A 100 125 200 260 350 450 550

Connection cable CSA mm

2

25 35 50 95 120 150 200

40-cell

battery

Maximum battery discharge

current at full load

A 80 106 160 240 320 400 473

Reference rated current of BCB

A 100 125 200 250 320 400 500

Connection cable CSA

mm

2

16 25 35 70 95 120 180

Note:

-It is recommended to use a DC moulded-case circuit breaker (MCCB) appropriately rated to open the kA fault current of the

battery at the nominal battery voltage. Applicable connections between the battery, BCB and UPS are shown in Figure 2-3, 2-4

and 2-5.

Page 30

Chapter 2 Battery 21

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

N

N

N

UPS

+

N

N

-

UPS

N

+

-

Figure 2-3 Connections between battery, 4-pole BCB and UPS (4 wires at battery side)

UPS

N

N

N

N

UPS

Figure 2-4 Connections between battery, 3-pole BCB and UPS (3 wires at battery side,

N

N

UPS

+

N

-

UPS

N

+

-

Figure 2-5 Connections between battery, 4-pole BCB and UPS (3 wire at battery side

Figure 2-6 below shows connections to be carried out when using the UV trip controlled BCB box (containing a BCB

and a BCB control board) made by Emerson Network Power.

X104

X105

X106

OUT

-P

OUT-N

AUX1

AUX2

X101

X108

X102

X103

X100

UV

220VDC

BCB

Battery

+

-

+12V

+12V

BAT-T

BAT-

T

GND GND2

USE

GND1

AUX

DRV

OL

GND

FB

DRV

NC

12V

OUT

GND

TPM2

+

N

-

Temp sensor

W3

W2

W3

BCB control board

Bypass module

J8J6

Auxiliary

contactor

UPS

UHW241C2

Figure 2-6 Connections between UPS, BCB and BCB control board (option)

Page 31

22 Chapter 3 Installation Of Parallel System

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

Chapter 3 Installation Of Multiple UPS cubicles

This chapter details the installation and wiring of a system containing more than one UPS cubicles installed in either

parallel and / or dual bus configuration.

3.1 Overview

Up to four UPS units can be connected in parallel to form a parallel system. Further, single or parallel configurations

can form systems with independent output buses (“dual bus systems”). The parallel and dual bus system installation

shall be carried out according to the installation procedures contained in chapter 1 for the single UPS cubicle and to

the applicable requirements of this chapter.

In addition to the Emergency Power Off (EPO switch provided on the operator control and display panel of each UPS

module for controlling the EPO of each module respectively, the parallel system also provides remote EPO function

for controlling all UPS modules to shut down simultaneously from a remote terminal, as shown in Figure 3-1.

Note

1. The remote EPO switch must provide dry contact signal, which is normally open or closed.

2. The open circuit voltage provided is 5Vdc, <20mA.

3. The external EPO device can be composed of another control system which can disconnect the UPS mains supply or the

bypass input.

4. Pins 1 and 2 of the normally closed EPO-J10 port on the bypass module have been linked in factory.

UPS 1

J10: 3

J10: 4

J10: 3

J10: 4

UPS 2

UPS 1

Bypass module

Bypass module

J10: 3

J10: 4

Bypass module

Figure 3-1 EPO circuit diagram (single and parallel UPS)

3.2 1 + N Parallel System

The basic installation steps of parallel system are the same as those of the single UPS cubicle. The following sections

describe the differences between the parallel system installation and single UPS installation.

Page 32

Chapter 3 Installation Of Parallel System 23

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

3.2.1 Cabinet Installation

Position the UPS cubicles side by side and make connection as shown in Figure 3-2. The output distribution

consisting of external UPS output switches and maintenance bypass must be installed, as shown in Figure 3-2, to

facilitate maintenance and system testing.

Figure 3-2 Typical “1+N” system schematic diagram (with common input, separate battery and output/bypass distribution cabinet)

Page 33

24 Chapter 3 Installation Of Parallel System

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

Qout of all UPSs

Rectifier

Inverter

Mains input

L1, L2, L3, N

Qout UPS 1

Supplied by others

Qin UPS 1

STS

Qout UPS 2

Qout UPS 3

Output distribution

Qout Byp

Bypass input

L1, L2, L3, N

Mains input L1,

L2, L3, N

Bypass input

L1, L2, L3, N

Mains input L1,

L2, L3, N

Bypass input

L1, L2, L3, N

L1, L2, L3

Rectifier

STS

Inverte r

UPS 1 output

UPS 2 output

L1, L2, L3, N

L1, L2, L3, N

L1, L2, L3, N UPS 3 output

STS

Rectifier

Inverter

Qin UPS 2 Qin UPS 3

Qin Ext

Byp

Figure 3-3 1 + N UPS system with external maintenance switch

Note

For 1+N installations an external bypass rated for the total system load must be installed and the UPS internal maintenance

bypass must be locked off to prevent operation.

1. For parallel systems designed for redundancy with 3 or more UPSs, it is recommended to install bypass load

sharing inductors to optimize current sharing during static bypass operation.

2. For parallel systems designed for capacity, with 2 or more UPSs, it is recommended to install bypass load

sharing inductors to optimize current sharing during static bypass operation.

3.2.2 External protective device

Refer to Chapter 1 Installation Of single UPS cubicle .

3.2.3 Power Cable

The wiring of the power cable is similar to that of UPS module. The bypass and main input supplies must use the

same neutral line input terminal. If the input has a current leakage protective device, the current leakage protective

device must be fitted upstream of the common neutral sinking point. Refer to Chapter 1 Installation Of single UPS

cubicle .

Note

The length and specification of power cables including the bypass input cables and UPS output cables should be the same. This

facilitates load sharing in bypass mode.

Page 34

Chapter 3 Installation Of Parallel System 25

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

3.2.4 Auxiliary Control Wiring

Auxiliary wiring must be installed as shown in Figure 3-4 to protect the system and enable a single UPS to be isolated

and tested during service. Refer to 1.7.3 Maintenance Switch And Output Sw itch State Port for auxiliary contact

details.

Input dist ribution

UPS 3

J9

143

UPS 2

J9

143

UPS 1

J9

143

Q1Ext

Q2Ext

QByp

QUPS

Q2Ext

Dis tribut ion panel

To load

Figure 3-4 Auxiliary control wiring

3.2.5 Parallel Control Cables

Shielded and double-insulated parallel control cables available in lengths 5m, 10m and 15m must be interconnected

in a ring configuration between the UPS modules, as shown in Figure 3-5. The parallel ports J2 and J3 are provided

on the front panel of the bypass module, as shown in Figure 3-6. The ring connection ensures the reliability of the

control of the parallel system. Be sure to verify the reliable cable connection before starting up the system.

J2

J3

UPS 1

J2

J3

UPS 2

J2

J3

UPS 3

J2

J3

UPS 4

Figure 3-5 Connection of parallel control cables of 1+N parallel system

Page 35

26 Chapter 3 Installation Of Parallel System

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

J2

J3

J4

Figure 3-6 Locations of ports J2, J3 and J4 on bypass module

3.3 Dual Bus System

3.3.1 Cabinet Installation

A dual bus system consists of two independent UPS systems, each containing one or more (maximally 4) parallel

UPS modules, as shown in Figure 3-7. The dual bus system has high reliability and is suitable for load with multiple

input terminals. For single-input load, an optional static transfer switch can be fitted to start the load bus synchronizer

(LBS supplied in standard configuration.

UPS 1

Bypass

UPS 1

LBS

To load

Main input

UPS4 UPS4

Main input Main inputMain input

Parallel

control

cable

Parallel

control

cable

Bypass

STS

Figure 3-7 Typical dual bus system (with static transfer switch and LBS)

The dual bus system uses the LBS to keep the output of the two independent UPS systems (or parallel systems) in

synchronization. One system is designated as the master, the other is designated as the slave. The operation modes

of the parallel system comprise master and/or slave operation in normal or bypass mode.

Place the UPS modules side by side and interconnect the UPS modules according to the following instructions.

3.3.2 External protective device

Refer to Chapter 1 Installation Of single UPS cubicle .

3.3.3 Power Cable

The wiring of power cables is similar to that of single module system. The bypass and the main input sources must be

referenced to the same neutral potential and input earth leakage monitoring devices, if installed, must be located

upstream of the common neutral sinking point. Refer to Chapter 1 Installation Of singl e UPS cubicle .

3.3.4 Control Cable

For NXr-to-NXr dual bus system, connect the optional LBS cables between the LBS ports (J4) of the two parallel

systems, as shown in Figure 3-8. The LBS port (J4) is provided on the front panel of the bypass module, as shown in

Figure 3-6.

Page 36

Chapter 3 Installation Of Parallel System 27

NXr UPS Module And Parallel System 30kVA ~ 200kVA User Manual

UPS 1

Bypass module

LBS cable

UPS 3 UPS 4

J2

J3

J4

J2

J3

J4

J2

J3

J4

J2

J3

J4

Bypass module Bypass module Bypass module

UPS 2

LBS cable