Page 1

Liebert NX™

User Manual

50 and 60 Hz, 30-200kVA, 400V

AC Power

For Business-Critical Continuity

Page 2

Page 3

TABLE OF CONTENTS

1.0 SINGLE MODULE UPS INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 UPS Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.2 External Battery Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.1 System Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.2 30 to 40kVA UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.3 60-200kVA UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.4 Moving the Cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.5 Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.6 Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.7 Final Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.8 Floor Anchoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.9 Cable Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 External Protective Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.1 Rectifier and Bypass Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5.2 External Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5.3 UPS Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.6.1 Cable Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.7 Control Cables and Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.7.1 Monitor Board Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.8 Dry Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8.1 Input Dry Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8.2 Maintenance Bypass Cabinet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.8.3 External Circuit-Breaker Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.8.4 Output Dry Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.8.5 Emergency Power Off Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.8.6 External Bypass Switch Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.0 BATTERY INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Battery Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3.2 Temperature Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.4 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.5 Circuit Breaker Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.6 Moving the Battery Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.7 Cable Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.8 General Arrangement Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

i

Page 4

2.4 Battery Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.1 Connection Principles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.2 Fitting the Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.3 Connecting the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.4 Battery Room Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.5 Battery Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.6 Battery Circuit Breaker Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.6.1 Battery Temperature Sensor—Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.0 UPS MULTI-MODULE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.2 Paralleled UPS Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.2.1 Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.2.2 External Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.2.3 Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.2.4 Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3 Hot-Standby UPS Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3.1 Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3.2 External Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3.3 Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.4 Dual Bus System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.4.1 Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.4.2 External Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.4.3 Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.4.4 Control Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.4.5 Extended Dual Bus Synchronization Option (DBS Interface Box) . . . . . . . . . . . . . . . . . . . . . 51

4.0 EXTERNAL OPTIONAL CABINETS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.1 External Maintenance Bypass Cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.2 Interlock with UPS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.3 Isolation Transformer Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4 Top Cable Entry Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.0 INSTALLATION DRAWINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

6.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.1.1 Split-Bypass Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.1.2 Static Transfer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.1.3 Battery Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.1.4 Battery Temperature Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.1.5 Redundant Control Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.1.6 Socket Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.2 Multi Module UPS—1+N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.2.1 Features of NX Multi-Module UPS Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.2.2 Requirements for Paralleling of UPS Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

ii

Page 5

6.3 Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.3.1 Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.3.2 Battery Mode (Stored Energy Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.3.3 Auto-Restart Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.3.4 Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.3.5 Maintenance Mode (Manual Bypass) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.3.6 ECO Mode (Single UPS Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.3.7 Parallel Redundancy Mode (System Expansion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.3.8 Hot-Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.3.9 Frequency Converter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.3.10 Source Share Mode (Co-Generation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.4 Battery Management—Set During Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.4.1 Normal Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.4.2 Advanced Functions (Software Settings Performed by the Commissioning Engineer) . . . . . 80

6.5 Battery Protection (settings by commissioning engineer) . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.0 OPERATING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.2 Startup in Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.3 Startup into ECO Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.4 Battery Test Mode Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.4.1 Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.5 UPS Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.5.1 UPS Self-Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.6 Maintenance Bypass Procedure and UPS Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.7 Isolation of One Module in a Multi-Module System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.7.1 Multi-Module Systems With External Output CB1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.7.2 Multi-Module System Without External Output Circuit Breaker 1 . . . . . . . . . . . . . . . . . . . . 87

7.8 Insertion of One Module in a Multi-Module System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.9 Shutdown Procedure—Complete UPS and Load Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.10 Emergency Shutdown With EPO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.11 Reset After Shutdown for Emergency Stop (EPO Action) or Other Conditions . . . . . . . . . . 90

7.12 Auto Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.13 Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.14 Changing the Current Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.15 Command Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.0 OPERATOR CONTROL PANEL AND DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.1.1 Mimic Power Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.1.2 Audible Alarm (Buzzer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.1.3 Direct Access Push Buttons (Keys) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

8.1.4 LCD Monitor and Menu keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

8.1.5 Detailed Description of Menu Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.2 All Status and Event Messages Displayed on the UPS Front Panel. . . . . . . . . . . . . . . . . . . 98

iii

Page 6

8.3 Prompt (Pop-Up) Windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.4 Dynamic Energy Flow Chart and UPS Help Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.5 Default Screen Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.0 OPTIONS—FOR ASSEMBLY INSIDE THE UPS CABINET . . . . . . . . . . . . . . . . . . . . . . . . . .105

9.1 Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.1.1 Redundant Back-Feed Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.1.2 Seismic Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.1.3 Degree of Protection for the UPS Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.1.4 Battery Start Facility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.1.5 Bypass Current Sharing Inductors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9.1.6 Battery Ground Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.1.7 Replacing Dust Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.1.8 Redundant Fan for Power Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.2 Communication and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

9.2.1 OC Web Card - SNMP/HTTP Network Interface Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

9.2.2 Relay Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

9.2.3 Multiport-4 Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

9.2.4 OC485 Web Card – Modbus, Jbus, IGM Net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

9.2.5 Remote Alarm Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.0 TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

10.1 Conformity and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

iv

Page 7

FIGURES

Figure i Model number nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Figure 1 Residual current circuit breakers (RCCB) symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2 Monitoring board (U2) auxiliary terminal block detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3 Input dry contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 4 Output dry contacts and EPO wiring for firmware before M162 . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 5 EPO wiring for firmware M200 or later . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 6 Narrow battery cabinet with top and bottom cable entry locations . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 7 Narrow battery cabinet with top cable entry location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 8 Wide battery cabinet with top and bottom cable entry locations . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 9 Wide battery cabinet with bottom cable entry location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 10 Wide battery cabinet with fuse or optional circuit breaker locations . . . . . . . . . . . . . . . . . . . . . . 25

Figure 11 Large battery cabinet dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 12 Large battery cabinet with fuse or optional circuit breaker locations . . . . . . . . . . . . . . . . . . . . . . 27

Figure 13 SENXA0NBCN4LCB.eps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 14 SENXA0NBCN4LF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 15 SENXA0NBCN5LCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 16 SENXA0NBCN5LF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 17 SENXA0NBCWXX3LCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 18 SENXA0NBCWXX3LF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 19 SENXA0NBCWXX4LCB_2x4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 20 SENXA0NBCWXX4LCB_4x2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 21 SENXA0NBCWXX4LF_2x4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 22 SENXA0NBCWXX4LF_4x2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 23 Battery room design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 24 Battery circuit breaker box—30-120kVA and 140-200kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 25 Battery circuit breaker box connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 26 Single temperature sensor and monitor board—U2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 27 Multiple temperature sensors, battery circuit breaker box and UPS module. . . . . . . . . . . . . . . . 44

Figure 28 Emergency power off connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 29 Typical 1+N system block diagram with common input supply, with separate batteries

and optional output / bypass distribution panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 30 Dry contacts, multiple UPS modules with distribution panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 31 Connection of 1+N system parallel control cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 32 Hot standby configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 33 Typical dual bus system configuration with static transfer switch and Load Bus Synch . . . . . . 50

Figure 34 Connections of a typical dual bus system utilising Load Bus Synch . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 35 External maintenance bypass cabinet with separate bypass input. . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 36 Equipment arrangement—UPS, battery cabinet and top-entry Isolation Transformer

Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 37 Single input external isolation transformer cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 38 Dual input external isolation transformer cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 39 Output external isolation transformer cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 40 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 41 General arrangement—30-40kVA UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 42 Front view, door open30-40kVA NX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 43 Cable terminal layout—30-40kVA NX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 44 Location of parallel logic board M3 and options—30-40kVA NX . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 45 Internal battery layout and connections—30-40kVA NX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 46 General arrangement—60-80kVA NX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

v

Page 8

Figure 47 Front view doors open—60-80kVA NX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 48 Cable terminal layout—60-80kVA NX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 49 General arrangement—100-120kVA NX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 50 Front view, door open—100-120kVA NX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 51 Parallel logic board location—100-120kVA NX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 52 Cable terminal layout—100-120kVA NX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 53 General arrangement—140-200kVA NX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 54 Front view, door open—140-200kVA NX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 55 Parallel logic board location—140-200kVA NX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 56 Cable terminal layout—140-200kVA NX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 57 Optional external Maintenance Bypass Cabinet, 600mm wide . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 58 Optional external Maintenance Bypass Cabinet, 800mm wide . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 59 Optional External Maintenance Bypass Cabinet, 850mm wide . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 60 Cabling diagram, 30-200kVA, MBP-T cabinet, configuration 1.1.1. . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 61 Cabling diagram, 30-200kVA, MBP-T cabinet, configuration 1.1.3. . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 62 Cabling diagram, 30-200kVA, MBP-T cabinet, configuration 1.1.5. . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 63 Single unit block diagram with split-bypass input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 64 1+N multi-module UPS with external maintenance bypass switch . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 65 Example of configuration for single UPS with external Maintenance Bypass Cabinet . . . . . . . . 85

Figure 66 Typical 1+N system block diagram with common input supply, with separate batteries

and optional output / bypass distribution panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 67 UPS control and display panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 68 Graphic LCD monitor windows and keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 69 Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 70 Help screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 71 Default screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 72 Battery Start Option for UPS with external battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 73 Bypass current sharing inductances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 74 Battery ground fault detection set connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 75 Replacing the dust filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 76 Communication bays and cable location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 77 OC Web Card data summary window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 78 OC Web Card battery data summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 79 SiteNet MultiPort4 Intellislot pin configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 80 OC485 Web card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

vi

Page 9

TABLES

Table 1 Maximum steady state AC and DC currents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2 Distance from floor to connection point on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3 Input dry contacts at X3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4 Maintenance bypass cabinet interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5 External circuit-breaker interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 6 Output dry contact relays for firmware before M162 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7 EPO input contact relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 8 Dimensions and weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 9 UPS-circuit breaker configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 10 Battery circuit breaker box legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 11 Battery control label description (X102) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 12 UPS control and display panel components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Table 13 Rectifier indicator—1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 14 Battery indicator—2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 15 Bypass indicator—3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 16 Inverter indicator—4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 17 Load indicator—5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 18 Status (Alarm) indicator—6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 19 Audible alarm key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 20 Menu key Icons and their meaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 21 UPS system window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 22 Descriptions of UPS menus and data window items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 23 UPS messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 24 Prompt windows, meanings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 25 Seismic anchor sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 26 Bypass current sharing inductors-dimensions, values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 27 Dry contact fault alarm signal is available for remote monitoring . . . . . . . . . . . . . . . . . . . . . . . 108

Table 28 Relay Card pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 29 SiteNet MultiPort4 Intellislot pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table 30 NX communication options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 31 Compliance with European, international standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 32 Environmental characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 33 Efficiency, AC/AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 34 Mechanical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 35 Rectifier AC input (mains) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 36 Intermediate DC circuit, battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 37 Inverter output to critical load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 38 Bypass input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

. . . . . . . 117

vii

Page 10

Dear Customer:

Please allow us to congratulate you on choosing a Liebert manufactured Uninterruptible Power System.

If this is your first Liebert UPS, we cordially welcome you to a lifetime relationship of after-sales support

designed to keep your Liebert UPS and your systems permanently at their peak performance.

If you already own and use a Liebert UPS, then we are doubly honoured by your decision to continue this

valued relationship.

Our philosophy is reflected in our mission statement “Keeping Business in Business,” and with this we strive

to contribute to the growth & success of your business.

Please give us your valued feedback to help us realise our mission.

EMERSON NETWORK POWER

viii

Page 11

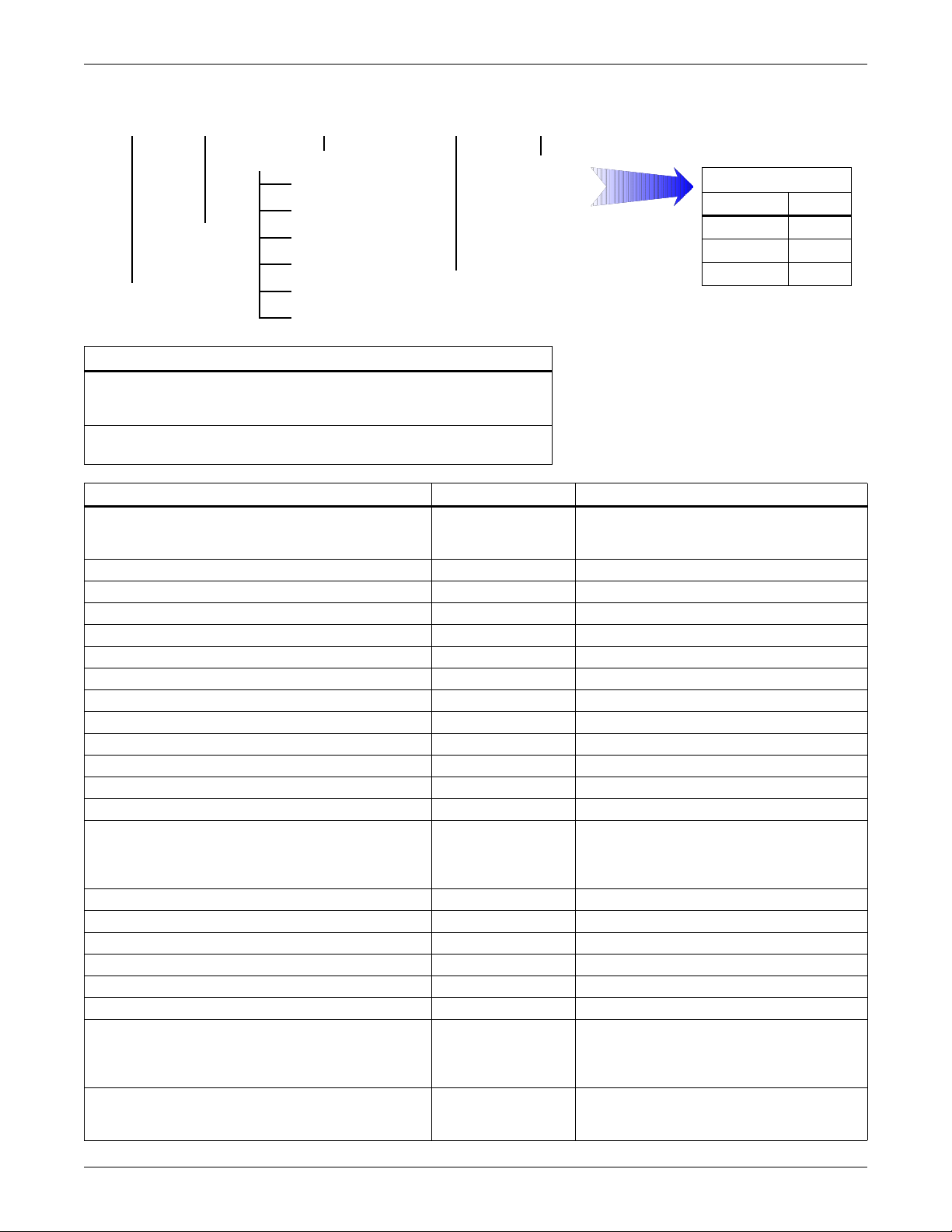

Figure i Model number nomenclature

NXa U

NX Product Line

Liebert NXa UPS module ratings:

30 & 40kVA (with internal battery)

60, 80, 100, 120, 140, 160, 200kVA (without internal battery)

Example:

0A0200

Feature Set for Region

A0 - EMEA

B0 - Aust/NZ

Revision

to Base

Unit

NXA0A0200U =

C0 - Japan

D0 - China

E0 - Latin Amer

F0 - Other

UPS Single Module

Output kVA

Input &

Output

Voltage

50/60Hz

Voltage Code

220/380 F

230/400 U

240/415 G

200kVA module for Europe and Middle East, 400V/230V output

Options Model Identification Note

Narrow battery cabinet NXA0BCN Specify: UPS kVA rating,

Wide battery cabinet NXA0BCW

Battery Circuit Breaker Box NXA0BCB Specify UPS kVA rating

Battery Start Kit NXA0UFXBB —

Battery Ground Fault detection kit NXA0UFXBGF —

Battery temperature probe (for external battery) NXA0UFXBTS —

Maintenance bypass cabinet (separate bypass input) NXA0MBX Specify total system kVA

Transformer cabinet NXA0TCX Specify UPS kVA & I/O Voltage

Fan Redundancy kit NXA0UFXRF Specify UPS kVA rating

Seismic Anchor kit NXA0UFXSAN —

Bypass current sharing inductance NXA0UFXBK —

Dual bus control cable 05-10-15 metr es NXA0UFXD Specify length in metres

Parallel control cable kit 05-10-15 metres NXA0UFXP Specify length in metres

Relay Card (On Bat, Bat Low, On Byp, Sum, UPS Fail)

Relay Card 4 (4 sets On Bat, bat Low)

Webbrowser/TCPIP/SNMP Card

Jbus/Modbus Card

RAM - Remote Alarm Monitor NXA0CFXRAM Requires RELAYCARD-INT

Modem card NXA0CFXMOD —

Large Battery Cabinet NXA0NBCL —

Maintenance bypass cabinet (separate bypass input) NXA0NMBX —

Transformer cabinet NXA0NTCX —

Air Filter (One Filter) NXA0UFXARF —

Dual Bus Extension Kit 50-150 Meters NXXXXMLBSKIT (XXX: 050 or 150)- 'Specify Length in metres.

Individual Battery Monitoring BDS 40 or BDS 256 Specify number of blocks. Consult Emerson

RELAYCARD-INT

MULTIPORT 4

OCWEB-LB

OC485CARD

3, 4 or 5-shelves

fuse or circuit breaker protection

Intellislot plug-in cards—3 slots available.

Used for extension in length or dual bus

arrangement between Nx and non-Nx

sources'

Network Power representatives for complete

configuration

ix

Page 12

x

Page 13

SAFETY PRECAUTIONS

This manual contains information concerning the installation and operation of this Emerson Network

Power Liebert NX Uninterruptible Power System (UPS).

This manual should be read before commencing installation.

The UPS must be commissioned and serviced by an engineer approved by the manufacturer (or

agent).

Failure to do so could result in personnel safety risk, equipment malfunction and invalidation of warranty.

The Liebert NX has been designed for Commercial/Industrial use only, and is not recommended for

use in life support applications.

This is a low emission CLASS A Uninterruptible Power System (UPS) product. In a residential environment, this product may nevertheless cause radio interference, in which case, the user may be

required to take additional measures.

Conformity and Standards

This equipment complies with CE directives 73/23 & 93/68 (LV Safety) and 89/336 (EMC), with Australia and New Zealand EMC Framework (C-Tick) and with the following product standards for Uninterruptible Power System (UPS).

• EN / IEC / AS 62040-1-1—General and safety requirements for use in operator access area

• EN / IEC / AS 62040-2—EMC requirements; Class A compliant

• EN / IEC / AS 62040-3—Performance requirements and test methods

For more details, see 10.0 - Technical Specifications

Continued compliance requires installation in accordance with these instructions and the use of manufacturer approved accessories only.

WARNING

!

High Leakage Current

EARTH CONNECTION IS ESSENTIAL BEFORE CONNECTING THE INPUT SUPPLY.

Earth leakage current exceeds 3.5 mA and is less than 1000 mA for 30-80kVA, less than

2000mA for 100-120kVA. models and less than 2500mA for 140-200kVA models.

Transient and steady-state earth leakage currents, which may occur when starting the

equipment, should be taken into account when selecting instantaneous RCCB or RCD devices.

Residual Current Circuit Breakers (RCCBs) must be selected sensitive to DC unidirectional

pulses (class A) and insensitive to transient current pulses.

Note also that the earth leakage currents of the load will be carried by this RCCB or RCD.

This equipment must be earthed in accordance with the local electrical code of practice.

WARNING

!

Back-Feed Protection Notice

This UPS is fitted with a voltage-free contact closure signal for use with an external

automatic disconnect device (supplied by others) to protect against back-feeding voltage into

the bypass input. If this signal is not used by the installer, a label must be added at the

external bypass input disconnect device to warn service personnel that the circuit is

connected to a UPS.

The text to use is the following or equivalent:

ISOLATE THE UNINTERRUPTIBLE POWER SYSTEM BEFORE WORKING ON THIS

CIRCUIT.

1

Page 14

User-Serviceable Parts

All equipment maintenance and servicing procedures involving internal access requires the use of a

tool and should be carried out only by trained personnel. There are no user-serviceable parts behind

covers requiring a tool for removal.

This UPS is fully compliant with safety regulations for equipment located in an operator accessible

area. Hazardous voltage is present within the UPS and battery enclosure but out of reach of non-service personnel. Contact with hazardous voltage is minimized by housing live parts behind safety panels that require a tool for their removal. No risk exists to any personnel when operating the

equipment in the normal manner, following the recommended operating procedures.

Battery Voltage Exceeds 400VDC

All physical battery maintenance and servicing requires the use of a tool or a key and should be carried out only by trained personnel.

WARNING

!

Special care should be taken when working with the batteries associated with this equipment.

When connected together, the battery terminal voltage will exceed 400VDC and is potentially

lethal.

Battery manufacturers supply details of the necessary precautions to be observed when working on,

or in the vicinity of, a large bank of battery cells. These precautions should be followed implicitly at all

times.

Attention should be paid to the recommendations concerning local environmental conditions and the

provision of protective clothing, first aid and fire-fighting facilities.

2

Page 15

1.0 SINGLE MODULE UPS INSTALLATION

1.1 Introduction

This following section describes the requirements that must be taken into account when planning the

positioning and cabling of the Liebert NX uninterruptible power supply and related equipment.

This chapter is a guide to general procedures and practices that should be observed by the installing

engineer. The particular conditions of each site will determine the applicability of such procedures.

WARNING

!

Professional Installation Required

Do not apply electrical power to the UPS equipment before being authorised to do so by the

commissioning engineer.

The UPS equipment shall be installed by a qualified electrical tradesperson in accordance

with the information contained in this manual. All equipment not referred to this manual is

shipped with details of its own mechanical and electrical installation.

NOTE

Three-phase, 4-wire input supply required.

The standard Liebert NX UPS is suitable for connection to 3-phase, 4-wire (+ Earth) TN, TT

and IT AC power distribution systems (IEC60364-3). Optional 3-wire to 4-wire conversion

transformers are available. If it is used in IT AC power distribution systems, a 4-pole circuit

breaker must be used on the input and refer to the relative IT Systems’ standard

Single Module UPS Installation

WARNING

!

Battery Hazards

Special care should be taken when working with the batteries associated with this equipment.

When connected together, the battery terminal voltage will exceed 400VDC and is hazardous.

Eye protection should be worn to prevent injury from accidental electrical arcs.

Remove rings, watches and all other metal objects.

Use only tools with insulated handles.

Wear rubber gloves.

If a battery leaks electrolyte or is otherwise physically damaged, it must be replaced, stored in

a container resistant to sulfuric acid and disposed of in accordance with local regulations.

If electrolyte comes into contact with the skin, the affected area should be washed

immediately with water.

1.2 Preliminary Checks

Before installing the UPS, please carry out the following preliminary checks:

1. Visually examine the UPS and battery equipment for transit damage, both internally and

externally. Report any damage to the shipper immediately.

2. Verify that the correct equipment is being installed. The equipment supplied has an identification

tag on the back of the main door reporting: the type, size and main calibration parameters of the

UPS.

3

Page 16

1.3 Location

1.3.1 UPS Room

The UPS and its internal battery is intended for indoor installation and should be located in an environment with clean air and with adequate ventilation to keep the ambient temperature within the

specified operating range (see Table 33).

All models in the Liebert NX UPS range are air-cooled with the aid of internal fans. Cold air enters

through ventilation grilles at the front of the cabinet for NXa 30-120kVA and through ventilation

grilles located at the front and bottom of the cabinet for NXa 140-200kVA. Hot air is released through

grilles at the top. Do not cover the ventilation openings.

If necessary to avoid room temperature build-up, install a system of room extractor fans. Optional air

filters are available if the UPS is to operate in a dusty environment.

The UPS heat dissipation detailed in Table 34 can be used as a guide for air conditioning sizing,

depending on the selected mode of operation:

• Normal Mode (VFI SS 111 Double Conversion UPS)

• ECO Mode (VFD SS 311 Stand By UPS)

If in doubt use Normal Mode figures.

NOTE

The UPS is suitable for mounting on concrete or other non-combustible surface only.

Single Module UPS Installation

1.3.2 External Battery Room

Batteries should be mounted in an environment where the temperature is consistent and even over

the whole battery. Temperature is a major factor in determining the battery life and capacity. Typical

battery manufacturer performance data are quoted for an operating temperature between 20 and

25°C (68 and 77°F). Operating above this range will reduce the battery life while operation below this

range will reduce the battery capacity. In a normal installation the battery temperature is maintained between 15°C and 25°C (59 and 77°F). Keep batteries away from main heat sources or main air

inlets etc.

Where the batteries are located externally to the main UPS cabinet, a battery protection device

(e.g., fuses or circuit breakers) must be mounted as close as possible to the batteries themselves, and

connected using the most direct route possible.

1.3.3 Storage

Should the equipment not be installed immediately, it must be stored in a room for protection against

excessive humidity and or heat sources (see Table 33).

CAUTION

!

An unused battery must be recharged periodically per battery manufacturer

recommendation. Temporarily connecting the UPS to a suitable AC supply mains and

activating it for the time required for recharging the batteries can achieve this.

4

Page 17

1.4 Positioning

The cabinet is mounted on four casters for ease of positioning and for moving short distances. Jacking

feet are provided to prevent the UPS from moving once it has been wheeled to its final position.

For optimal design life, the place chosen must offer:

•Easy connection

• Enough space to easily work on the UPS

• Sufficient air exchange of enough to dispel heat produced by UPS

• Protection against atmospheric agents

• Protection against excessive humidity and very high heat sources

• Protection against dust

• Compliance with the current fire prevention requirements

• Operating environment temperature between 20°C and 25°C (68 and 77°F). The batteries are at

maximum efficiency in this temperature range (see Table 33).

The UPS cabinet is constructed around a steel chassis with removable panels. The top and side panels

are secured to the chassis by screws.

Access to the power terminals, auxiliary terminals blocks and power switches is from the front. Operational status and alarm information is provided through the front door operator control panel. Models 40kVA and below house both the power components and an internal battery. Cooling air enters in

the front of the NXa 30-120kVA and the front and bottom of NXa 140-200kVA; it is exhausted out the

top of each.

1.4.1 System Cabinets

A UPS may comprise a number of cabinets, depending on design requirements (e.g., UPS cabinet, external battery cabinet, external bypass cabinet). In general, all the Liebert cabinets used in a particular

installation are of the same height and designed to be positioned side-by-side to form a matching array.

Refer to 5.0 - Installation Drawings for assistance on positioning the cabinets described below.

Single Module UPS Installation

1.4.2 30 to 40kVA UPS

The UPS consist of a single cabinet, which uses typically forty (40) 12V battery blocks, fitted internally and connected in series to provide a nominal battery voltage.

the batteries fitted.

An extended battery option is available. This comprises a separate cabinet containing additional batteries that can be connected to the UPS to increase its battery run time. Battery cabinets and batteries are usually shipped separately.

1.4.3 60-200kVA UPS

The 60 to 200kVA consist of a single cabinet without any internal battery. Usually, with 60 to 200kVA

UPS installations, the batteries are contained in a purpose-built battery cabinet, which sits alongside

the main UPS equipment. Batteries are accessible in the external cabinet from the front, making it

unnecessary to allow for side access.

1.4.4 Moving the Cabinets

WARNING

!

Ensure that the UPS weight is within the designated surface weight loading of any handling equipment. See Table 35.

UPS and optional cabinets (battery cabinets, top cable entry cabinets, etc.) can be handled by means

of a forklift or similar equipment.

The UPS cabinet also can be moved short distances by its casters.

Ensure that any equipment used to move the UPS cabinet has sufficient lifting capacity.

The UPS is fitted with casters. Take care to prevent the NX from moving when unbolting the

unit from its shipping pallet. Ensure that adequate personnel and lifting aids are available

when removing the shipping pallet.

The UPS may be shipped without

NOTE

Care must be taken when maneuvering units fitted with batteries. Keep such moves to a

minimum.

5

Page 18

1.4.5 Clearances

The Liebert NX has no ventilation grilles at either side of the UPS. To enable routine tightening of

power terminations within the UPS, in addition to meeting any local regulations, Liebert recommends providing adequate clearance in the front of the equipment for unimpeded passage of personnel with the doors fully opened. It is important to leave 800mm (31.5") clearance above the UPS to

permit adequate circulation of air coming out of the unit.

1.4.6 Access

The component layout of the UPS supports front and top access while servicing, diagnosing and

repairing the UPS, thus reducing the space requirement for side and rear access.

1.4.7 Final Positioning

The UPS cabinets are fitted with casters on the base to allow ease of movement and positioning.

WARNING

!

Casters are strong enough for movement across even surfaces only. Caster failure could occur

if they are subjected to shock loading.

When the equipment has been finally positioned, ensure the adjustable feet are set so that the UPS

will remain stationary and stable.

1.4.8 Floor Anchoring

Single Module UPS Installation

Diagrams in 5.0 - Installation Drawings show the location of the holes in the base plate through

which the equipment may be bolted to the floor. If the equipment is to be installed on a raised floor it

should be mounted on a pedestal suitably designed to accept the equipment point loading.

1.4.9 Cable Entry

Cables can enter the Liebert NX UPS and battery cabinet from below. Cable entry is made possible by

removing a blanking piece fitted at the bottom of equipment to reveal the cable entry hole.

Top Cable Entry—Optional

Optionally a top cable entry extension may be used. The cabinet extends the overall width of the UPS

and permits connection of all incoming AC/DC power cables from above.

The top cable entry option is fitted on the side of the UPS cabinet and is supplied without side panels;

the side cover from the UPS being used.

The cabinet with cables coming in from the top for the 30-40 kVA UPS must be positioned on the left

side; the cabinet for the 60 to 200 kVA UPS can be positioned on either side.

This facilitates cable entry through the top metal panel after the appropriate cable entry holes have

been cut.

NOTE

The top cable entry also includes the power connection cables between the cabinet and the UPS.

1.5 External Protective Devices

Circuit breakers or other protective devices must be installed in the AC supply, external to the UPS.

This chapter provides guidelines for qualified installers who must have knowledge of local wiring

practices pertaining to the equipment to be installed.

6

Page 19

1.5.1 Rectifier and Bypass Input

Overcurrent protection must be installed at the distribution panel of the incoming main supply. The

protection must discriminate with the power cables current capacity and with the overload capacity of

the system (see Table 38). As a guideline, a thermomagnetic circuit breaker, with an IEC 60947-2

trip curve C (normal) for 125% of the current listed in Table 1 is suitable.

Split-Bypass—If a split-bypass is used, install separate protective devices for the rectifier and for

the bypass in the incoming mains distribution panel.

NOTE

Rectifier and bypass input sources must be referenced to the same neutral potential.

NOTE

Earth Leakage (RCD)

Any residual current detector (RCD) installed upstream of the UPS input supply must be:

For IT power systems, four-pole protective devices must be used, external to the UPS, both

upstream of the input distribution panel and downstream (toward the load).

• sensitive to DC unidirectional pulses (Class A)

• insensitive to transient current pulses, and

• must have an average sensitivity, adjustable between 0.3 and 1A.

Single Module UPS Installation

Figure 1 Residual current circuit breakers (RCCB) symbols

To avoid false alarms, earth leakage monitoring devices when used in systems with split-bypass input

or when used in paralleled UPS configurations, must be located upstream of the common neutral

sinking point. Alternatively, the device must monitor the combined four-wire rectifier and splitbypass input currents.

The residual earth current introduced by the RFI suppression filter inside the UPS is greater than

3.5mA, 1000mA for 30-80kVA, 2000mA for 100-120kVA models and less than 2500mA for

140-200kVA models. Liebert recommends verifying the selectivity with all other differential devices

both upstream of the input distribution board and downstream (toward the load).

1.5.2 External Battery

The UPS and its associated batteries are protected against overcurrents through a DC compatible disconnect device.

1.5.3 UPS Output

Any external distribution board used for load distribution shall be fitted with protective devices that

discriminate with those used at the bypass input to the UPS and with the UPS overload characteristics (see Table 38).

7

Page 20

1.6 Power Cables

The cable design must comply with the voltages and currents provided in this section, follow local wiring practices and take into consideration the environmental conditions (temperature and physical

support media).

For cable entry terminal, refer to Figures 43, 48, 52 and 56.

WARNING

!

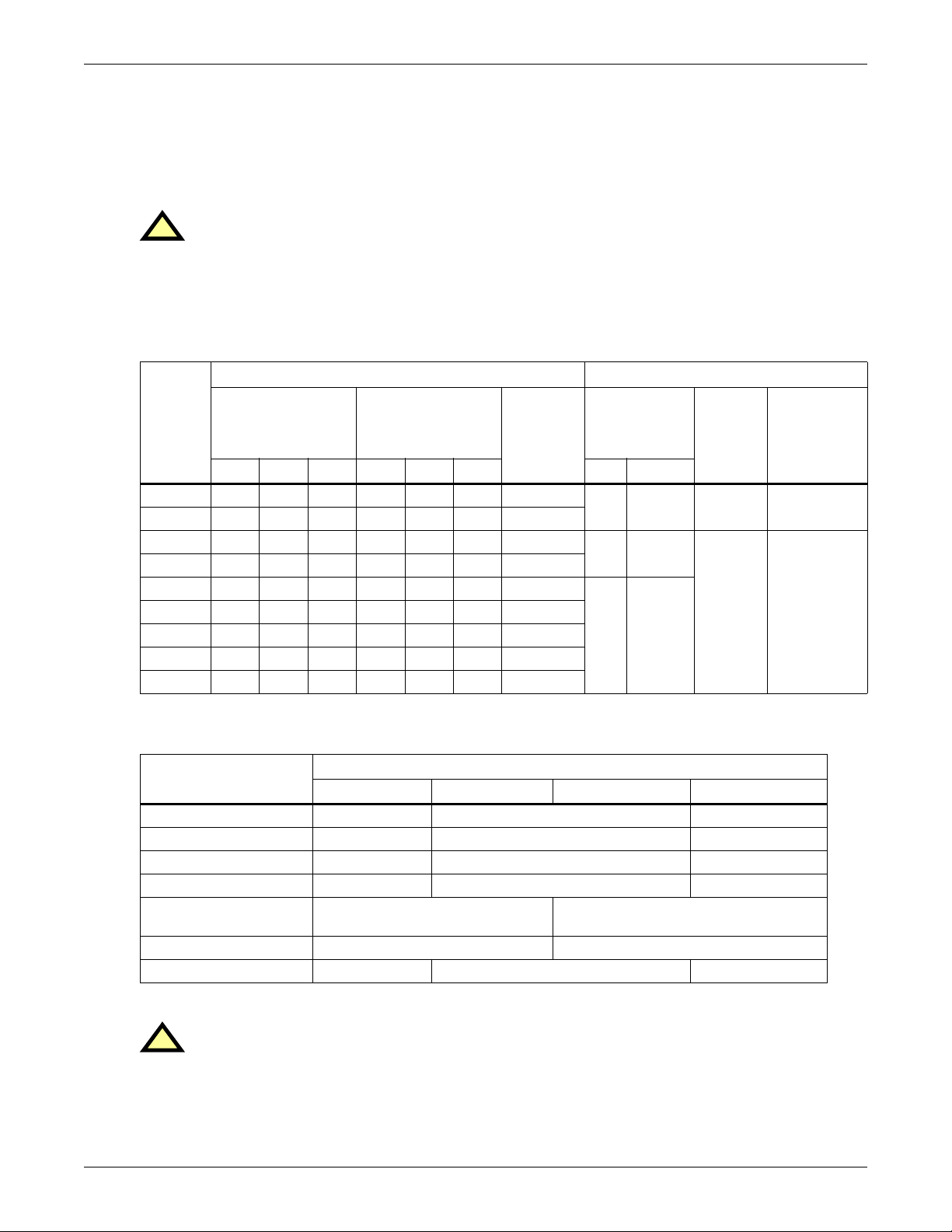

Table 1 Maximum steady state AC and DC currents

RATING

Before starting the UPS, ensure that you are aware of the location and operation of the

external isolators that connect the ups input/bypass supply to the mains distribution panel.

Check that these supplies are electrically isolated and post any necessary warning signs to

prevent their inadvertent operation.

Input Mains

with full battery

UPS

(kVA)

recharge

3ph + N

Single Module UPS Installation

NOMINAL CURRENT: Amps BUSBAR STUD SIZE

Bypass/Output

at full load

3ph + N

Battery at

minimum

battery

voltage

(400VDC)

Input/Output/

Bypass

Cables

Battery

Cables

(Bolts)

Torque

Load, Nm

(lb/ft)380V 400V 415V 380V 400V 415V Bolt Ø holes

30 50 47 45 46 43 42 64

40 65 62 60 61 58 56 85

60 97 92 88 91 86 83 128

80 128 122 117 121 115 111 170

100 160 152 146 152 145 139 213

120 191 181 175 182 174 167 255

140 222 211 204 212 201 194 298

160 254 241 232 242 230 222 340

200 317 301 290 303 288 277 426

For terminal location – refer to 5.0 - Installation Drawings

M6 7 - 5 (1.12)

M8 9

M10 Ø11

M10 11

Table 2 Distance from floor to connection point on the equipment

Minimum Distance, mm (in)

UPS

Rectifier AC Input supply 350 (13.8) 305 (12) 324 (12.8)

Bypass AC Input supply 300 (11.8) 250 (9.8) 310 (12.2)

UPS Output AC 260 (10.2) 250 (9.8) 310 (12.2)

Battery Power 1030 (40.5) 230 (9) 360 (14.2)

Auxiliary cables:

Monitor board (U2)

Communications 1070(42.1) 1250(49.2)

Earth 350 (13.8) 275 (10.8) 338 (13.3)

UPS 30/40 kVA UPS 60-80 kVA UPS 100-120 kVA UPS 140-200 kVA

1320(52) 1500 (59)

M8: 13 (2.9)

M10: 26 (5.8)

WARNING

!

Failure to follow adequate earthing procedures may result in electromagnetic interference or

in hazards involving electric shock and fire.

8

Page 21

1.6.1 Cable Termination

NOTE

Once the equipment has been finally positioned and secured, connect the power cables as described in

the following procedure.

Refer to the appropriate cable connection drawing in 5.0 - Installation Drawings.

1. Verify that the UPS equipment is isolated from its external power source and all the UPS power

2. Open the door to the UPS cabinet and remove one of the two protective cover to gain access to the

3. Connect the safety earth and any necessary bonding earth cables to the copper earth busbar

The operations described in this section must be performed by authorised electricians or

qualified technical personnel. If you have any difficulties, do not hesitate to contact our

Customer Service and Support Department. See the back page of this manual for contact

information.

isolators are open. Check that these supplies are electrically isolated and post any necessary

warning signs to prevent their inadvertent operation.

desired connection bars.

• the lower protective cover houses the 60-200kVA connection bars

• the left protective cover houses the 30-40kVA connection bars

The protective cover on the UPS cabinet of 60 to 200kVA models must be removed after the

handles on the power isolators have been removed.

located on the floor of the equipment below the power connections. All cabinets in the UPS must

be connected to the user’s ground connection.

Single Module UPS Installation

NOTE

The earthing and neutral bonding arrangement must be in accordance with local and national

codes of practice.

Identify and make power connections for incoming cables according to one of the two procedures

below, depending on the type of installation.

Common Input Connections

4. For common bypass and rectifier inputs, connect the AC input supply cables between the mains

distribution panel and the UPS input (U1-V1-W1-N terminals) and tighten the connections to

5Nm for M6 bolts, to 13Nm for M8 bolts or to 26Nm for M10 bolts. Ensure correct phase rotation.

Split-Bypass Connections

5. If a split-bypass configuration is used, connect the AC input supply cables to the rectifier input

busbars (U1-V1-W1-N terminals) and the AC bypass supply cables to the bypass input

(U3-V3-W3-N terminals) and tighten the connections to 5Nm for M6 bolts, to 13Nm for M8 bolts

or to 26Nm (M10 bolt). Ensure correct phase rotation.

NOTE

For split-bypass operation, ensure that the linking busbars between bypass and rectifier input

are removed.

The AC input and the AC bypass supplies must be referenced to the same neutral point.

Frequency Converter Mode

If a frequency converter configuration is used, connect the AC input supply cables to the rectifier

input busbars (U1-V1-W1-N terminals). Torque to 5Nm for M6 bolts, to 13Nm for M8 bolts or to

26Nm (M10 bolt). Ensure correct phase rotation. There will not be any AC bypass supply cables to the

bypass input (U3-V3-W3-N terminals) and tighten the connections.

NOTE

For frequency converter operation, ensure that the linking busbars between bypass and rectifier

input are removed.

9

Page 22

Single Module UPS Installation

Output System Connections

6. Connect the system output cables between the UPS output (U2-V2-W2-N terminals) and the

critical load and tighten the connections to 5Nm for M6 bolts, to 13Nm for M8 bolts or to 26Nm for

M10 bolts. Ensure correct phase rotation.

External UPS Battery Connection (60kVA Models and Above, Option for 30-40kVA Models)

Connect the battery cables between the UPS terminals (+\-) and its associated battery circuit

breaker. Observe the battery cable polarity.

NOTE

When connecting the cables between the battery extremities to the circuit breaker always

connect the circuit breaker end of the cable first.

WARNING

!

If the load equipment will not be ready to accept power on the arrival of the commissioning

engineer, ensure that the system output cables are safely isolated at their ends.

Internal UPS Battery Connection (30/40kVA only)

7. The battery consists of a series string connection of 5 x 8 (or 10) x 12V 6-cell battery blocks.

a. Ensure that the eight (or 10) battery blocks in each tier (tray) are interconnected.

b. Connect the positive and negative cables to the UPS terminals.

c. Plug in the cables between the tiers.

d. Ensure correct polarity battery string series connections (i.e., intertier and

interblock connections are from positive to negative terminals.

WARNING

!

Hazardous Battery Terminal Voltage 480VDC

Ensure correct polarity of string end connections to the UPS terminals, i.e., positive to

positive and negative to negative, but leave these UPS terminal cables disconnected until

connection is authorised by the commissioning engineer.

Ensure correct polarity of string end connections to the battery circuit breaker and from the

battery circuit breaker to the UPS terminals, i.e., positive to positive and negative to negative,

but disconnect one or more battery cell links in each tier.

Do not reconnect these links and do not close the battery circuit breaker before authorised by

the commissioning engineer.

8. Refit all protective covers removed for cable installation.

10

Page 23

1.7 Control Cables and Communication

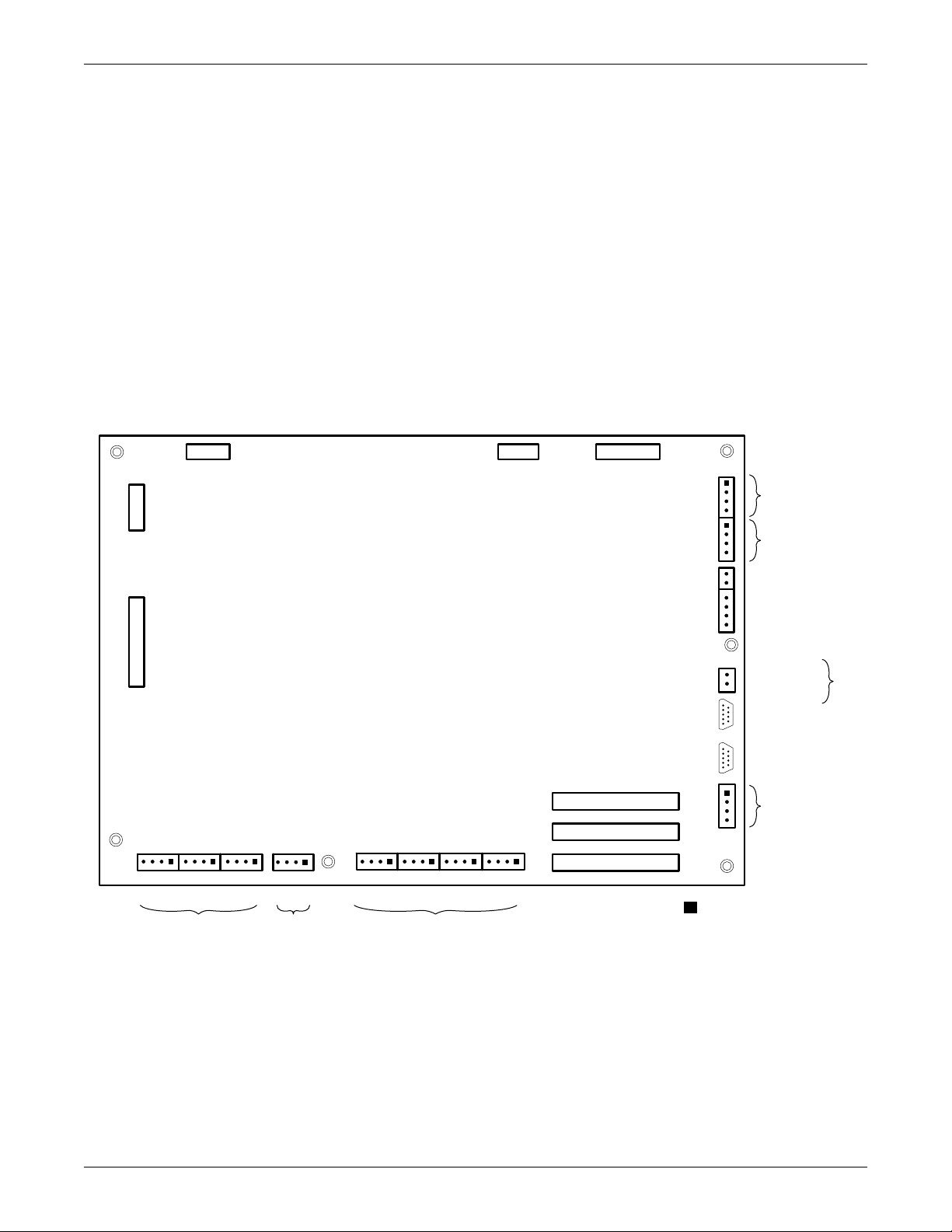

1.7.1 Monitor Board Features

Based on your site’s specific needs, the UPS may require auxiliary connections to manage the battery

system (external battery circuit breaker, battery temperature sensor), communicate with a personal

computer or provide alarm signaling to external devices or for Remote Emergency Power Off (REPO).

The monitor board, arranged for this purpose, is located on the rear of the operator access door. The

main features are:

• Input and Output dry contacts signal (one pair of contacts of relay)

• Emergency Power Off control (EPO)

• Environmental parameter input interface

• User communication (for data setting and user background monitor)

• Intellislot™ interface

• Modem interface

• Temperature detect interface

Figure 2 Monitoring board (U2) auxiliary terminal block detail

J8

LCD

Single Module UPS Installation

J1J3

J22

X7

J2

J13

BFP INV ACF

X1 X2 X3

EPO

J10J30J26J4J28J25J21

Dry In MBC BCB

J23

J12

J9

J15

J16

J17

Intellislot 2

Intellislot 1

Intellislot 3

The black square ( )

on each s lot indi cates P in 1.

X4

J24

X6

PWR

Modem

SNMP Card

X4

X5

11

Page 24

1.8 Dry Contacts

The UPS provides input dry contacts and output dry contacts.

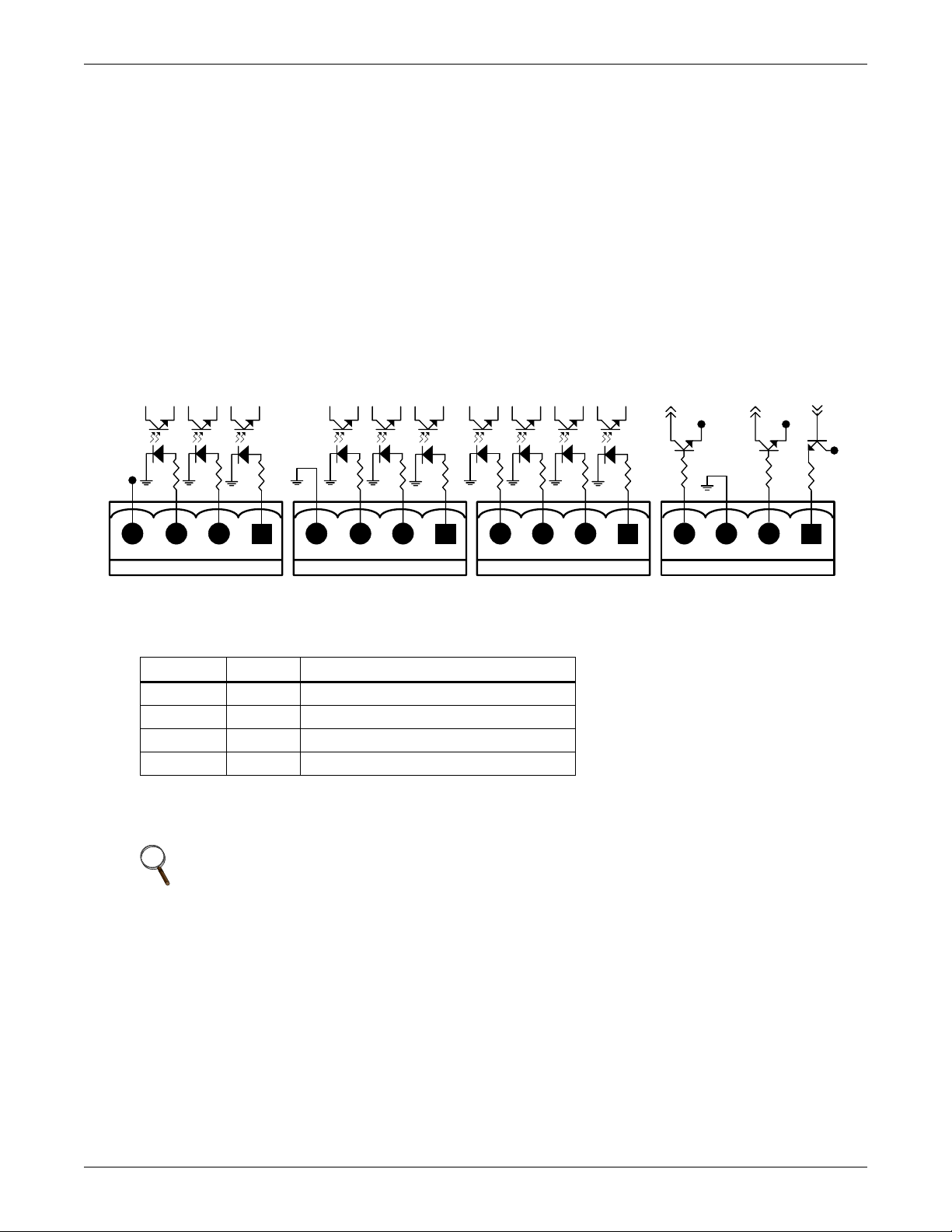

1.8.1 Input Dry Contacts

There are several input dry contacts at the X3 slot.

X3 Ancillary Control and Alarms

X3 IN DRY: Environmental, Battery Ground Fault and Generator Contacts

The UPS accepts external signalling from voltage-free (dry) contacts connected to finger-proof, pushin terminal X3 IN DRY. Subject to prior software programming, the signalling is accepted by the UPS

when connection between the relevant terminal and the +12V terminal is altered. Cables connected to

X3 IN DRY must be segregated from power circuits (for screening purposes), double insulated and of a

typical 0.5 to 1mm

respectively.

Figure 3 Input dry contacts

12V

2

cross-section area for maximum runs between 25 and 50 meters (82-164 ft),

Single Module UPS Installation

12V 12V

12V

X3

J4 J26 J30 J10

12V

BtG

GEN

ENV

12V

GND

T_IT

AUX_I

T_OT

AUX_O

FUSE

F_FAN

OL

GND

Table 3 Input dry contacts at X3

Position

J4.1 ENV

J4.2 BtG Battery Ground Fault Detection (NC)

J4.3 GEN

J4.4 +12V +12V Power

1 - Must be configured by configuration software before becoming active.

2 - When activated, the charger current can be limited, via software, to a percentage of the full charger current (0-100%).

3 - Activating this feature turns the battery charger off.

Name

Description

3

Battery Room Alarm (NC)

1,2

On Generator (NO)

NOTE

All auxiliary cables of terminal must be double-insulated. Wire should be 0.5-1.5mm

(16-20AWG) stranded for maximum runs between 25 and 50m (82-164 ft.) respectively.

FB

DRV

2

12

Page 25

1.8.2 Maintenance Bypass Cabinet Interface

J26 and J30 are the MBC interface.

Table 4 Maintenance bypass cabinet interface

Position

J26.1 T_IT

J26.2 AUX_I Reserved

J26.3 +12V +12V Power

J26.4 GND Power Ground

J30.1 FUSE Reserved

J30.2 F_FAN Fan Fail Alarm (NC)

J30.3 T_OT

J30.4 AUX_O Reserved

1

- Must be configured by software before becoming active

Name

Description

1

Input transformer overtemperature (NC)

1

Output Transformer Overtemperature (NC)

Single Module UPS Installation

NOTE

All auxiliary cables of terminal must be double-insulated. Wire should be 0.5-1.5mm

(16-20AWG) stranded for maximum runs between 25 and 50m (82-164 ft.) respectively.

1.8.3 External Circuit-Breaker Interface

J10 is the interface to any external battery circuit breaker (BCB).

Table 5

Position

J10.1 DRV BCB Driver Signal - Output (N.O.)

J10.2 FB BCB Contact State - Input (N.O.)

J10.3 GND Power Ground

J10.4 OL

External circuit-breaker interface

Name

NOTE

All auxiliary cables of terminal must be double insulated. Wire should be 0.5-1.5mm

(16-20AWG) stranded for maximum runs between 25 and 50 meters (82-164ft.) respectively.

Description

BCB On-Line - Input - This pin will become active when

BCB interface is connected. (N.O.)

2

2

13

Page 26

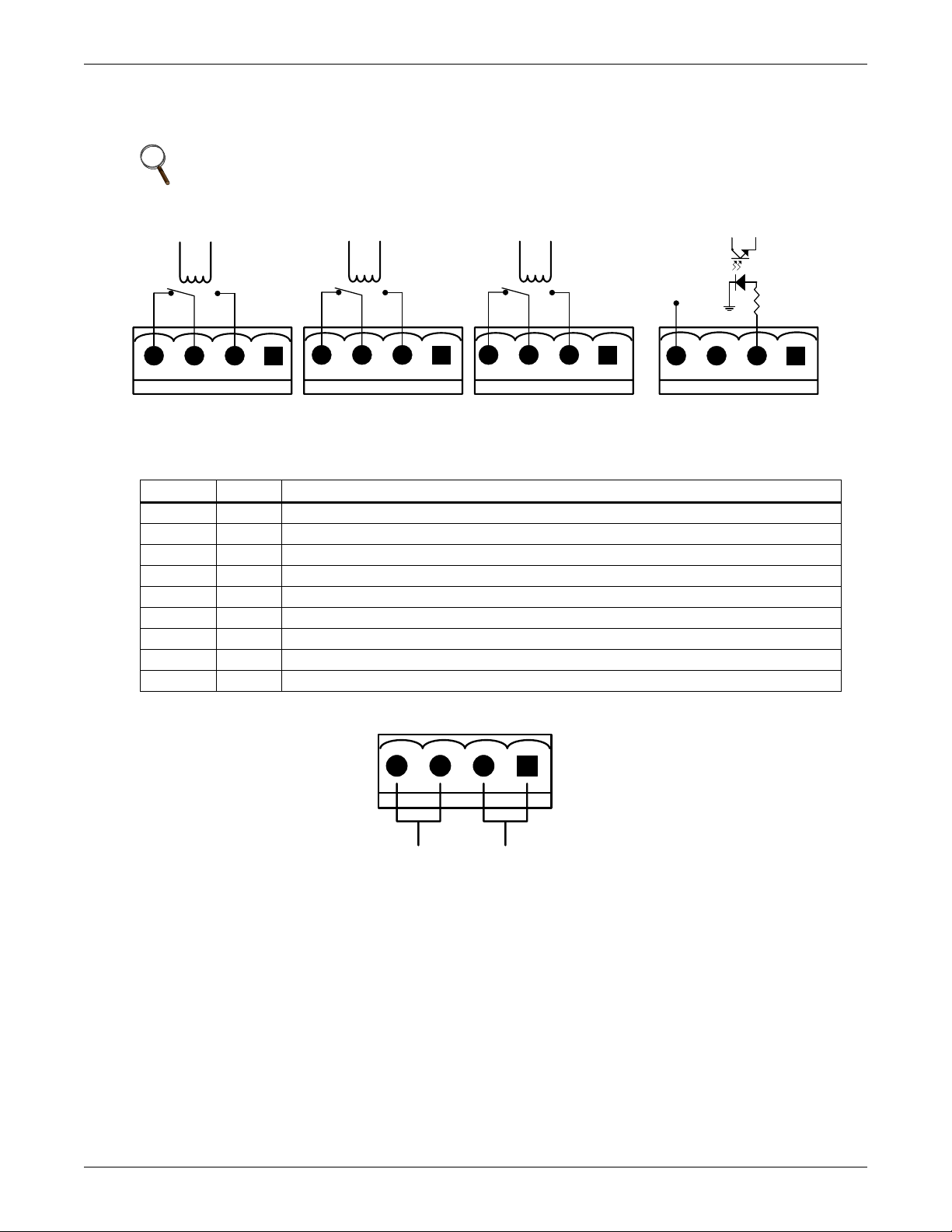

1.8.4 Output Dry Contacts

There are three output dry contact relays at the X1 slot (see Figure 4 and Table 6)

Single Module UPS Installation

NOTE

All auxiliary cables of terminal must be double-insulated. Wire should be 0.5-1.5mm

(16-20AWG) stranded for maximum runs between 25 and 50m (82-164 ft.) respectively.

Figure 4 Output dry contacts and EPO wiring for firmware before M162

J13

BFP_C

BFP_S

BFP_O

J21 J25 J25

INV_S

INV_C

INV_O

ACF_C

ACF_S

ACF_O

Table 6 Output dry contact relays for firmware before M162

Position Name

J13.2 BFP_O Bypass feedback protection relay; normally ope n. Closed when bypass SCR is shorted.

J13.3 BFP_S Bypass feedback protection relay center

J13.4 BFP_C Bypass feedback protection relay; normally closed. Open when bypass SCR is shorted.

J21.2 INV_O Inverter mode relay; normally open. Closed when UPS is in inverter mode.

J21.3 INV_S Inve rter mode relay center

J21.4 INV_C Inverter mode relay; normally closed. Open when UPS is in inverter mode.

J25.2 ACF_O Main input fault relay; normally open. Closed when main input is in fault.

J25.3 ACF_S Main input fault relay center

J25.4 ACF_C Main input fault relay; normally closed. Open when main input is in fault.

Description

2

+12V

X2X1

EPO-LEPO-H

Figure 5 EPO wiring for firmware M200 or later

J28

EPO-NO EPO-NC

1.8.5 Emergency Power Off Input

The UPS has an Emergency Power Off (EPO) function that operates by a button on the control panel

or by a remote contact provided by the user. The EPO button is under a hinged, clear plastic shield.

The X2 slot, shown in Figure 4, is the remote EPO input interface. The EPO has an NO/NC contact

point that becomes active when shorting terminals X2: 3 and 4 or open terminal connection X2: 2 and 1

If an external emergency stop facility is required, it is connected terminals X2: 1&2 or X2: 3&4 of the

auxiliary terminal block (X2). It also is connected to the normally open or normally closed remote stop

X2

14

Page 27

Single Module UPS Installation

switch between these two terminals using shielded cable (see Figure 4 and Table 7). If this function

is not used, terminals X2: 3&4 must be opened and X2: 1&2 must be closed.

Table 7 EPO input contact relays

Position Name

J28.1 EPO_NC EPO Activated when opened to J28.2

J28.2 EPO_NC EPO Activated when opened to J28.1

J28.3 EPO_NO EPO Activated when sh orted to J28.4

J28.4 EPO_NO EPO Activated when sh orted to J28.3

Description

NOTE

The emergency stop action within the UPS shuts down the rectifier, inverter and static bypass.

It does not internally disconnect the input power supply. To disconnect ALL power to the UPS,

open the upstream feeder breaker(s) when the remote EPO is activated.

NOTE

Normally closed EPO – X2: 1,2, these terminals are supplied factory-linked on the monitor

board and must remain installed if using NC contacts.

NOTE

All auxiliary cables of terminal must be double insulated. Wire should be 0.5-1.5mm

2

(16-20AWG) stranded for maximum runs between 25 and 50 meters (82-164ft.) respectively.

X5: Auxiliary DC Power Output

Auxiliary DC power for modem or external SNMP card. The voltage is between 9V to 12V. The maximum current is 500mA.

X6: Analog Input Interface

Two analog signal channels with an input range is from 0 to +12V. The precision of detection is ÷3%.

• X6 pin 1: Not used

• X6 pin 2: +12V

• X6 pin 3: ENV-T – environment temperature detection

• X6 pin 4: GND

X7: External Battery Temperature Detector Interface

Interface for TMP12Z temperature detector, normally connected to an external battery cabinet (see

Figure 26).

Pin reference:

• X7 pin 1: Not used

• X7 pin 2: +12V (Power supply for Temperature Monitoring Probe)

• X7 pin 3: BAT-T (Battery Temperature signal)

• X7 pin 4: GND

15

Page 28

Serial Ports RS232-1 and RS232-2

RS232-1 provides serial data and is intended for direct use with Liebert MultiLink monitoring and

server shutdown software.

RS232-2 provides serial data and is intended for use by authorized commissioning and service personnel.

These serial ports are shared with the optional Web browser, SNMP, ModBus and relay cards. Refer

to Table 31 regarding compatibility of simultaneous use.

Intellislot Web Browser, SNMP, ModBus and Relay Cards Interface

There are three interface slots available for optional Web browser, SNMP, ModBus and Relay cards

as illustrated in 9.0 - Options—For Assembly Inside the UPS Cabinet.

1.8.6 External Bypass Switch Interlock

EXT-Maint X3-1&2 on UPS Parallel Board M3 (leave open if no external bypass switch is used)

Provides external maintenance bypass interlock protection for the UPS. Short circuit means external

bypass closed.