Page 1

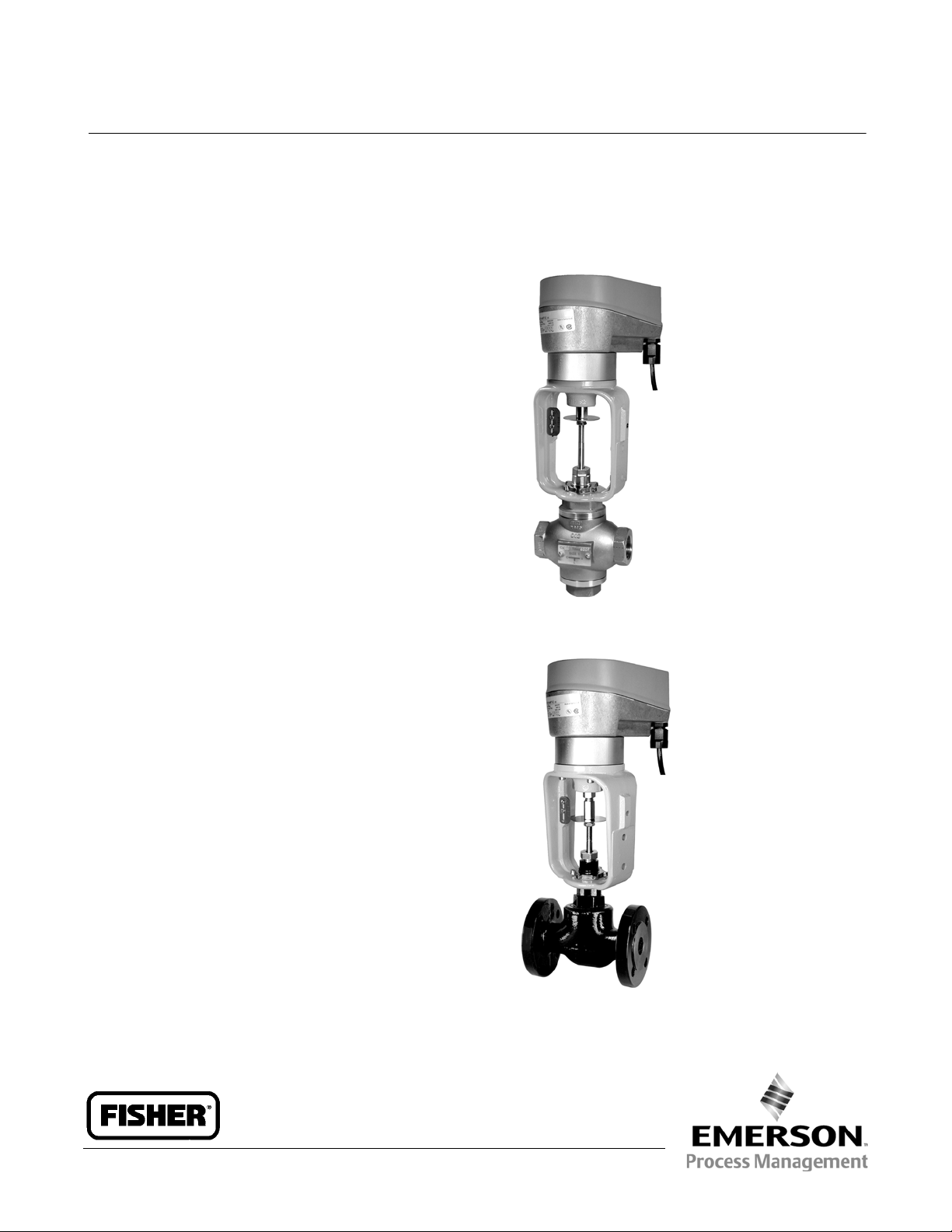

NV Electric Actuator

D103326X012

Baumannt NV Electric Actuator

with 24000 Control Valves

The Baumann NV electric control valve series is

specifically designed for Baumann sliding-stem control

valves. It is used for temperature and humidity control

for HVAC (hot and chilled water, steam, glycol, etc.),

semiconductor manufacturing (clean rooms, make-up

air handlers, recirculation air handlers, humidification,

chillers, jackets, and glycol systems) and for many

more industrial environments (textiles, food and

beverage, and tire manufacturing).

Features

Product Bulletin

52.1:NVACT

November 2012

Actuator

Multi-Function Technologyt (MFT) provides

standard auto calibration and signal select ability at

the factory or in the field

Valve failure modes available - close, open, and last

position

Choice of power supply: 24VAC or 24VDC

Stem position feedback transmitter available

Valve

High quality S21800 SST and S31600 SST internal

valvetrimpartsarestandard;S41600trimandPTFE

seating options are available

Dual stem and plug guiding provides increased

stability during plug travel

Available equal percentage and linear characterized

trims to match process loop dynamics

W9870

Baumann 24000 3-Way Little Scotty Valve with

NV Electric Actuator

W9871

Baumann 24000C Valve with NV Electric Actuator

www.Fisher.com

Page 2

Product Bulletin

52.1:NVACT

November 2012

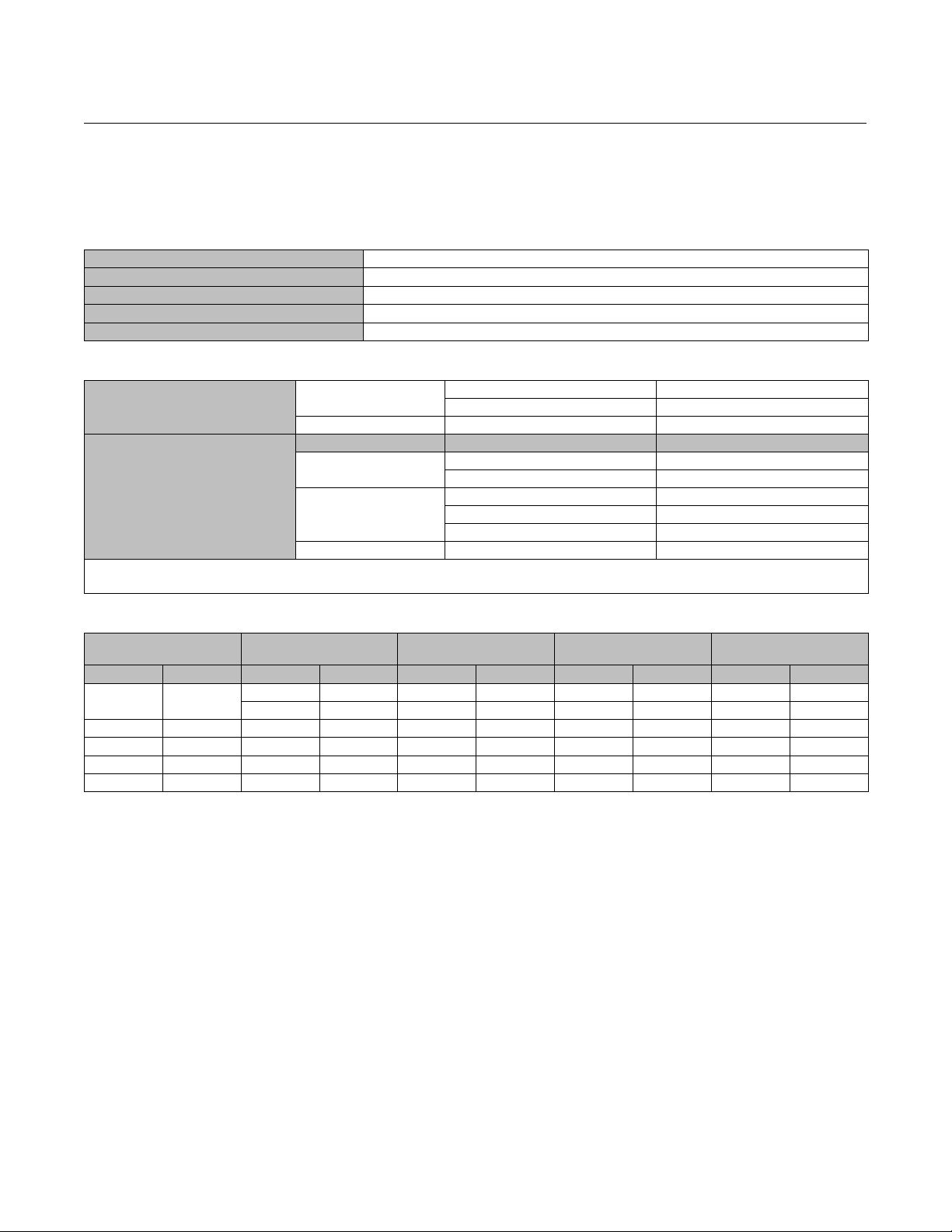

Specifications

Actuator specifications are shown in table 1. Valve

technicalspecificationsareshownintables3,5,7,10,

and 13.

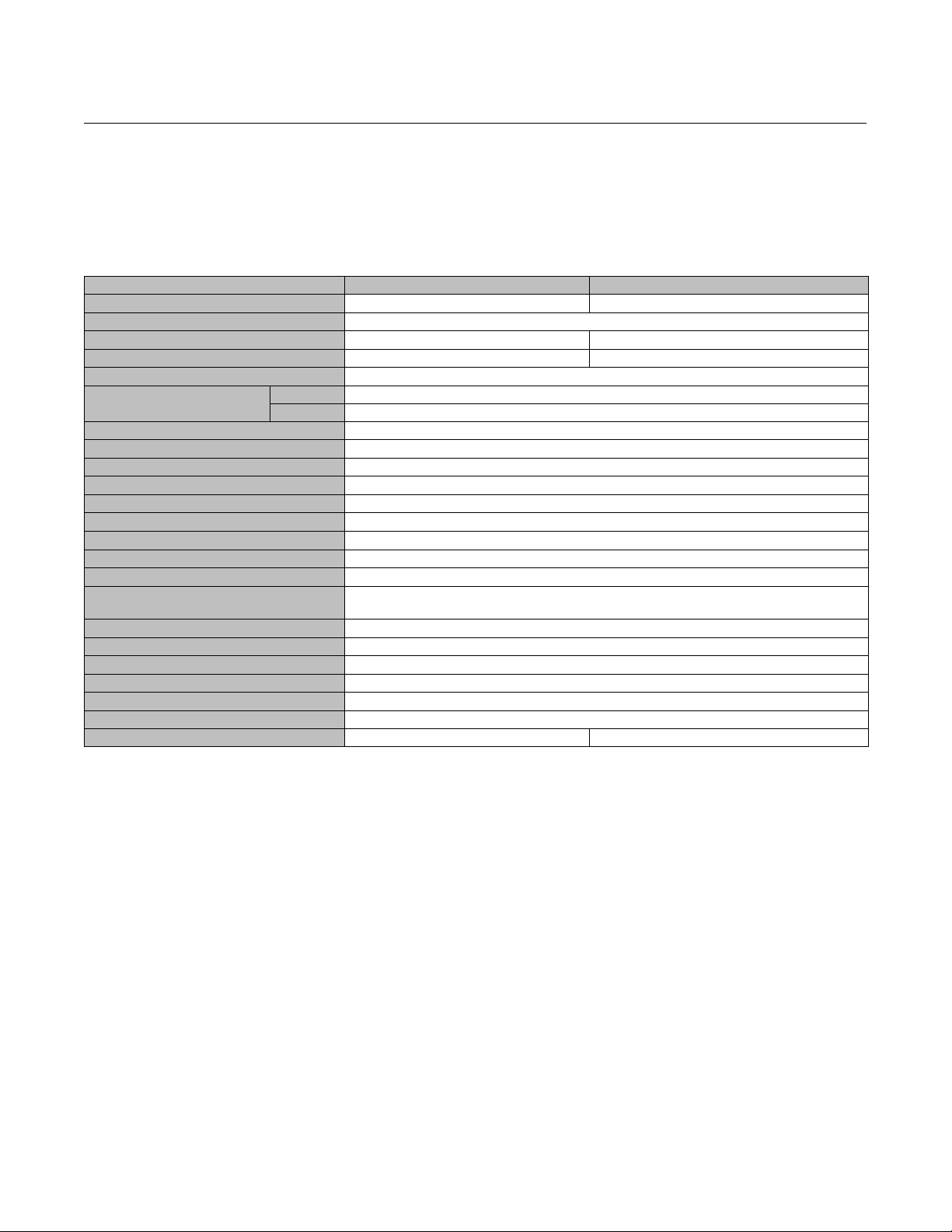

Table 1. Actuator Specifications

ACTUATOR TYPE NV24-MFT, Non Spring Return NVF24-MFT andNVF24-MFT-E, Spring Return

POWER FAILURE Lock in last position Lock inlast position/ Fail Open / Fail Closed

ACTION Direct or Reverse

POWER CONSUMPTION 5.0 W 5.5 W

TRANSFORMER SIZE 7VA(class2powersource) 10 VA (class 2 power source)

TRAVEL 12.7 and19.1 mm (0.50 and 0.75 inches)

MATERIAL

ENCLOSURE RATING NEMA 2 / IP 54 with cable entryfacing down

INPUT SIGNAL 2 - 10 VDC or 4 - 20 mA input signal

POWER SUPPLY 24 VAC or 24 VDC

ELECTRICAL CONNECTION 3 ft,18GA appliance cable, 0.5 inch conduit fitting

AMBIENT TEMPERATURE -30 to 50_C (-22 to 122_F)

RELATIVE HUMIDITY RANGE 5 to 95% RH, non-condensing

OUTPUT THRUST 800 N(180 lbf)

VALVE STEM POSITION FEEDBACK OUTPUT 2-10 VDC(2 mA maximum)

SHUTOFF CLASS Class IV or VI per ANSI/FCI 70-2 (Refer to Valve Technical Bulletin)

TRAVEL TIME

NOISE LEVEL Maximum 35 dB(A)

MANUAL OVERRIDE 5 mm(3/16 inch)Hex HeadScrewdriver

POSITION INDICATION Travel Indicator on Yoke

SPLIT RANGE CAPABILITY Yes

AGENCY APPROVALS CE (A), UL873, CSA 4813 02 (CE approval applies to actuator only)

QUALITY STANDARD ISO 9001

WEIGHT 1.5 kg(3.3 lbs) 1.8kg(4lbs)

HOUSING Polycarbon (ABS), UL94-5V flammability rating

YOKE Ductile Iron, Powder Epoxy-Coated

Maximum 150 seconds for 0.5 and 0.75 inch travel ranges (optional 75 second travel time for

non-spring return) Spring fail time: 30 seconds for full travel

NV Electric Actuator

D103326X012

2

Page 3

NV Electric Actuator

D103326X012

Product Bulletin

52.1:NVACT

November 2012

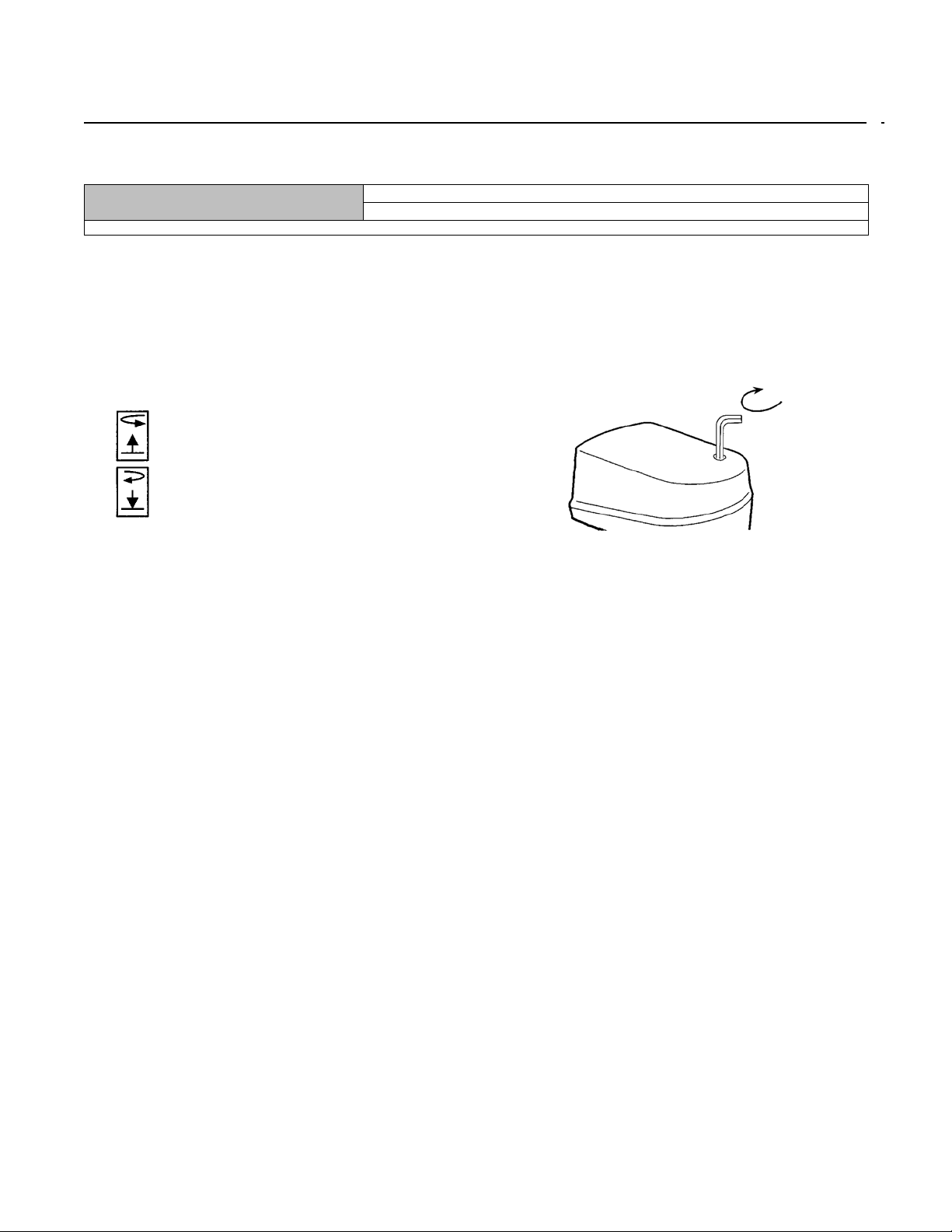

Table 2. Optional Accessories

VALVE STEM POSITION SWITCHES

1. Unit can be field wired for on-off control; referto instruction manual.

(1)

18CX10 Valve Stem Position Transmitter, Explosion Proof, 4-20mA output signal

Manual Override

The valve stem position can be adjusted by inserting a

5mm or 3/16 inch hex head screwdriver into the

housing cover. See figure 1.

Figure 1. Manual Override

TURN MANUAL OVERRIDE COUNTER-CLOCKWISE:

ACTUATOR PLUNGER RETRACTS.

TURN MANUAL OVERRIDE CLOCKWISE:

ACTUATOR PLUNGER EXTENDS.

E1348

11CX12 Limit Switch,Explosion P roof (2 SPDTswitches)

5mm OR 3/16 INCH

E1349

3

Page 4

Product Bulletin

52.1:NVACT

November 2012

NV Electric Actuator

Baumann 24000 Bronze

Control Valve

Table 3. Technical Specifications

NOMINAL SIZE NPS1/2,3/4,1,1-1/2,and2

VALVE BODY MATERIAL ASTM B62 Grade C83600Bronze (meetsor exceedsASME B16.15)

CONNECTIONS Screwed NPT

NOMINAL PRESSURE 400 psi@ 150_F/250 psi @ 400_F(ASME B16.15 CL250)

SEAT PLUG SEALING Metal to Metal or PTFE Soft Seat

CHARACTERISTIC Equal Percentage or Linear

TEMPERATURE RANGE

1. See pressure-temperaturerating chart for specific valve body material rating.

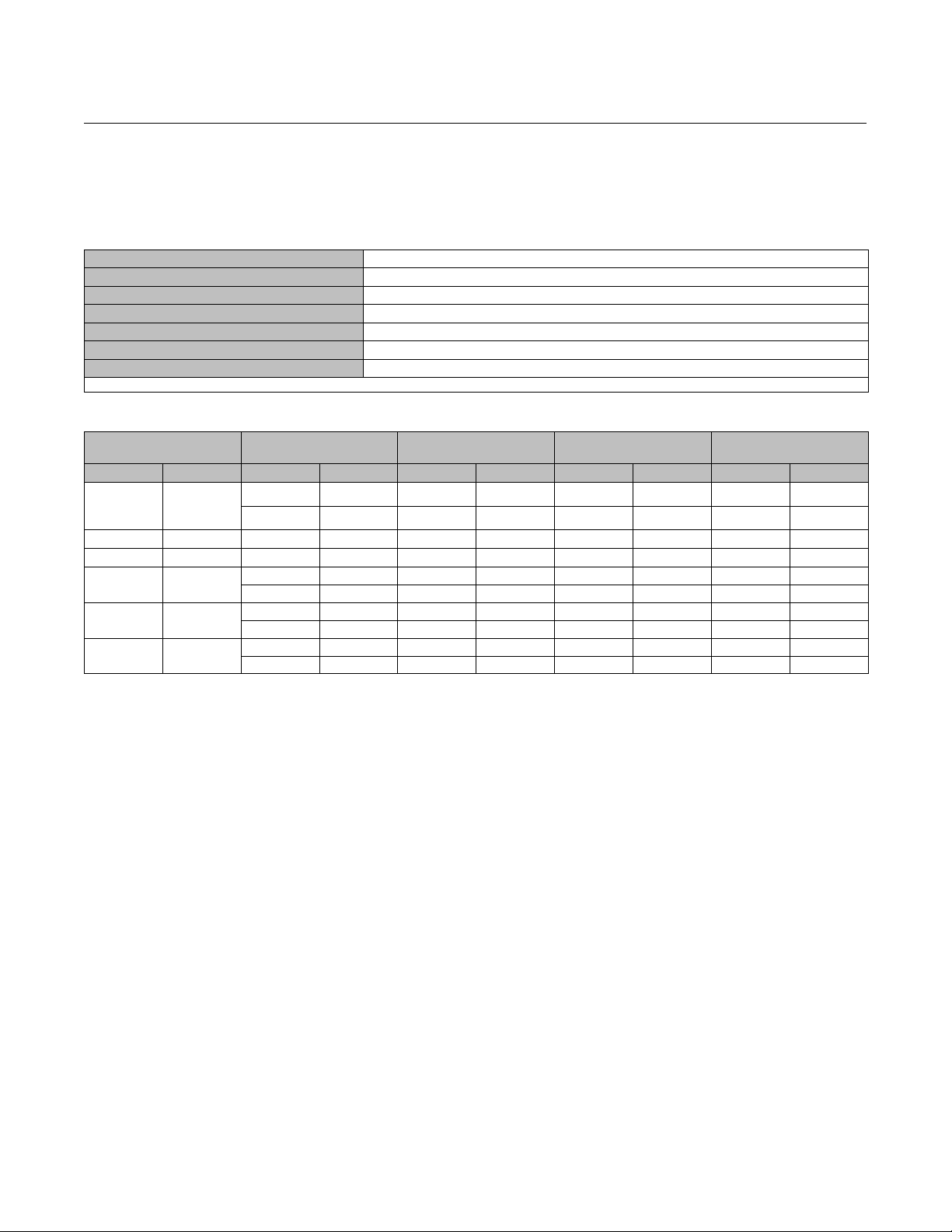

Table 4. Maximum Allowable Pressure Drops

VALVE SIZE ORIFICE DIAMETER PLUG TRAVEL

DN NPS mm in mm in bar psi bar psi

15

20

25

15 1/2 20.6 0.8125 12.7 0.50 17 250 17 250

20 3/4 20.6 0.8125 12.7 0.50 17 250 17 250

25 1

40 1-1/2

50 2

1/2

3/4

1

(1)

6.3 0.25 12.7 0.50 17 250 17 250

9.5 0.375 12.7 0.50 17 250 17 250

20.6 0.8125 12.7 0.50 17 250 17 250

26.9 1.0625 12.7 0.50 14 203 9.1 133

32 1.25 19.1 0.75 10 147 5.3 77

38.1 1.50 19.1 0.75 7.0 102 2.2 32

38.1 1.50 19.1 0.75 7.0 102 2.2 32

50.8 2.00 19.1 0.75 3.9 57 --- ---

-29 to204_C (-20 to 400_F)

SHUTOFF

Metal Seat CL IV

Soft Seat CL VI

D103326X012

SHUTOFF

4

Page 5

Product Bulletin

NV Electric Actuator

D103326X012

November 2012

Baumann 24000C Carbon

Steel Control Valve

Table 5. Technical Specifications

VALVE TYPE EN ASME

NOMINAL SIZE DN 15,20, 25, 40, & 50 NPS1/2,3/4,1,1-1/2,and2

VALVE BODY PRESSURE RATING PN 40per EN 1092-2 ASME CL150 per ASME B16.34

END CONNECTIONS

FLANGE FINISH EN 500to 300 Ra circular lay ANSI 250 to 125 Ra circular lay

FACE-TO-FACE DIMENSIONS Consistent with EN558-1

TEMPERATURE RANGE

CHARACTERISTIC Equal Percentage or Linear Equal Percentage or Linear

1. See pressure-temperaturerating chart for specific valve body material rating.

(1)

Mates with EN10-40 Flanges perEN

1092-2

-29 to232_C (-20 to 450_F) -29 to 232_C (-20to 450_F)

Table 6. Maximum Allowable Pressure Drops

VALVE SIZE ORIFICE DIAMETER PLUG TRAVEL

DN NPS mm in mm in bar psi bar psi

15

20

25

15 1/2 20.6 0.8125 12.7 0.50 20 290 19 277

20 3/4 20.6 0.8125 12.7 0.50 20 290 19 277

25 1

40 1-1/2

50 2

1/2

3/4

6.3 0.25 12.7 0.50 20 290 20 290

1

9.5 0.375 12.7 0.50 20 290 20 290

20.6 0.8125 12.7 0.50 20 290 19 277

27.0 1.0625 12.7 0.50 14 203 9.1 133

31.8 1.25 19.1 0.75 10 147 5.3 77

38.1 1.50 19.1 0.75 7.0 102 2.2 32

38.1 1.50 19.1 0.75 7.0 102 2.2 32

50.8 2.00 19.1 0.75 3.9 57 --- ---

SHUTOFF

Metal Seat CL IV

MateswithASMECL150RFFlangesper

ASME B16.5

Consistent with EN588-2 (same asISA

S75.03)

Soft Seat CL VI

52.1:NVACT

SHUTOFF

5

Page 6

Product Bulletin

52.1:NVACT

November 2012

Baumann 24000S Stainless

Steel Control Valves

Table 7. Technical Specifications

NOMINAL SIZE DN15, 25, 40, 50 &80 / NPS 1/2, 1, 1-1/2, 2 and 3

VALVEBODYPRESSURERATING CL300 (CL150 forNPS 3 per ASME B16.34)

VALVE BODY MATERIAL ASTM A351,GR, CF8M

END CONNECTIONS Screwed (NPT) (except for NPS 3, flangeless only) / Flangeless / Buttweld

CHARACTERISTIC Equal Percentage or Linear

NV Electric Actuator

D103326X012

Table 8. Temperature Ratings for Packing and Seat Material

SEATING MATERIAL

PACKING AND BONNET

COMBINATIONS

1. Temperature limitsapply to seating orpacking arrangements only. Complete valve assemblytemperature limitsmay differ, referto appropriate pressure/temperatureratings. For more

information on packing selection, reference Fisher Sliding-Stem Packing SelectionGuidelines (Bulletin 59.1:062,D101986X012).

2. PTFE packing can beused in cryogenic servicebut becomes stiff.

PTFE Soft Seat

Metal Seat 102, 548,588, 648, 688 Trim -195 to 537_C (-320 to 1000_F)

BONNET STYLE PACKING TEMPERATURE LIMIT

Standard Bonnet

Extension Bonnet

Bellows NOLEEK Bellows -195 to 399_C (-320 to 750_F)

(2)

(1)

151 Trim -29to 177_C(-20to350_F)

177, 577, 677 Trim -73 to232_C (-100 to 450_F)

Spring Loaded PTFE Packing -73 to232_C (-100 to 450_F)

Graphite -73to 232_C (-100 to 450_F)

Spring Loaded PTFE Packing -195 to 537_C (-320 to 1000_F)

ENVIRO-SEALt -45 to232_C(-50to450_F)

Graphite -195 to537_C (-320 to 1000_F)

Table 9. Maximum Allowable Pressure Drops

VALVE SIZE ORIFICE DIAMETER PLUG TRAVEL

DN NPS mm in mm in bar psi bar psi

15

25

25 1 20.6 0.8125 12.7 0.50 24 347 19 277

40 1-1/2 31.8 1.25 19.1 0.75 10 147 5.3 77

50 2 38.1 1.50 19.1 0.75 7.0 102 2.2 32

80 3 50.8 2.00 19.1 0.75 3.9 57 --- ---

1/2

1

6.3 0.25 12.7 0.50 50 720 50 720

9.5 0.375 12.7 0.50 50 720 50 720

SHUTOFF

Metal Seat CL IV

SHUTOFF

Soft Seat CL VI

6

Page 7

NV Electric Actuator

D103326X012

Baumann 24000CVF/SVF

Carbon Steel and Stainless

Steel Flanged Control

Valve

Table 10. Technical Specifications

VALVE TYPE ASME EN

NOMINAL SIZE NPS 1/2, 3/4, 1, 1-1/2, and 2 DN 15, 20, 25, 40, & 50

VALVE BODY PRESSURE RATING ASME CL150 / CL300per ASMEB16.34 PN 40 per EN 1092

END CONNECTIONS

FLANGE FINISH ASME 250 to 125 Ra circular lay EN 500to 300 Ra circular lay

FACE-TO-FACE DIMENSIONS

Mates with ASME CL150 or 300RFFlanges

per ASME B16.5

Consistent with EN588-2 (same as ISA

S75.03)

Product Bulletin

52.1:NVACT

November 2012

EN10-40 Flanges per EN1092

Consistent with EN558-1

Table 11. Temperature Ratings for Packing and Seat Material

SEATING MATERIAL

PACKING AND BONNET

COMBINATIONS

CHARACTERISTIC Equal Percentage or Linear

1. Temperature limitsapply to seating orpacking arrangements only. Complete valve assemblytemperature limitsmay differ, referto appropriate pressure/temperatureratings. For more

information on packing selection, reference Fisher Packing Selection Guidelines for Sliding-Stem Valves,(Bulletin 59.1:062, D101986X012.

2. Extension bonnetsand NOLEEK bellows bonnets are applicable for the 24000SVF stainless body assembly ONLY.

3. PTFE packing can beused in cryogenic servicebut becomes stiff.

PTFE Soft Seat

Metal Seat 102, 548, 588, 648, 688 Trim -195 to454_C (-320 to 1000_F)

BONNET STYLE PACKING TEMPERATURE LIMIT

Standard Bonnet

Extension Bonnet

Bellows

(2,3)

(2)

(1)

151 Trim -29 to 177_C (-20 to 350_F)

177, 577, 677 Trim -73 to232_C (-100 to 450_F)

Spring Loaded PTFE -73 to 232_C (-100 to 450_F)

ENVIRO-SEAL -46 to 232_C (-50to 450_F)

Graphite -73 to232_C (-100 to 450_F)

Spring Loaded PTFE -184 to 454_C(-320 to 1000_F)

ENVIRO-SEAL -46 to 232_C (-50to 450_F)

Graphite -184 to 454_C(-320 to 1000_F)

NOLEEK Bellows -195 to 399_C (-320 to 750_F)

Table12.MaximumAllowablePressureDrops

VALVE SIZE ORIFICE DIAMETER PLUG TRAVEL

DN NPS mm in mm in bar psi bar psi

15

20

25

15 1/2 20.6 0.8125 12.7 0.50 20 290 19 277

20 3/4 20.6 0.8125 12.7 0.50 20 290 19 277

25 1

40 1-1/2

50 2

1/2

3/4

6.3 0.25 12.7 0.50 50 720 50 720

1

9.5 0.375 12.7 0.50 50 720 50 720

20.6 0.8125 12.7 0.50 20 290 19 277

27.0 1.0625 12.7 0.50 14 203 9.1 133

31.8 1.25 19.1 0.75 10 147 5.3 77

38.1 1.5 19.1 0.75 7.0 102 2.2 32

38.1 1.5 19.1 0.75 7.0 107 2.2 32

50.8 2.0 19.1 0.75 3.9 57 --- ---

SHUTOFF

Metal Seat CL IV

SHUTOFF

Soft Seat CL VI

7

Page 8

Product Bulletin

52.1:NVACT

November 2012

NV Electric Actuator

Baumann 24003 3 Way

Control Valve

Table 13. Technical Specifications

NOMINAL SIZE NPS 1/2, 1, 1-1/2, and 2

VALVE BODY RATING 250 psi@ 400_F / 400 psi@ 150_F

CONNECTIONS Screwed NPT (Flanges available

SEAT PLUG SEALING Metal to Metal

CHARACTERISTIC Linear

SEAT LEAKAGE Class III

RANGEABILITY Exceeds 50:1

VALVE BODY MATERIAL BRONZE STAINLESSSTEEL

VALVE BODY RATING 400 psi@ 150_F / 250 psi @ 400_F 720 psi @ 150_F / 515 psi@ 400_F

TEMPERATURE LIMITS 32 to 400_F 32 to450_F

Table14.MaximumAllowablePressureDrops

VALVE SIZE ORIFICE DIAMETER PLUG TRAVEL

DN NPS mm in mm in bar psi

15 1/2

25 1 28.6 1.126 12.7 0.50 5.5 80

40 1-1/2 42.7 1.676 19.1 0.75 3.4 50

50 2 54.0 2.126 19.1 0.75 2.0 30

15.9 0.626 12.7 0.50 9.6 140

22.3 0.876 12.7 0.50 96 140

(1)

)

Metal Seat CL III

D103326X012

SHUTOFF

8

Page 9

NV Electric Actuator

D103326X012

Product Bulletin

52.1:NVACT

November 2012

Figure 2. Baumann MV-1020 Dimensions

DIVERGING

VALVE

COOL

WATER

E1350

C

L

U

HEAT

EXCHANGER

TEMPERED

WATER

Table 15. Application Port Table

Service Inlet Outlet

Diverging C UandL

Mixing UandL C

C = Common Port, U = Upper Port, L = Lower Port

HEATING WATER

MIXING

VALVE

B

U

C

L

RETURN

Figure 3. Baumann VA-1020 Dimensions

179 (7.0)

284

(11.2)

B

E1351

105 (4.2)

B

AA A

24000

125 (4.9)

24000S 24000C 24000 CVF & SVF 24003

B

B

B

A

B

C

A

9

Page 10

Product Bulletin

52.1:NVACT

November 2012

NV Electric Actuator

D103326X012

Valve Dimensions

Table 16. Baumann 24000

VALVE SIZE A B

DN NPS mm in mm in

15 1/2 89 3.5 78 3.1

20 3/4 89 3.5 78 3.1

25 1 109 4.3 83 3.3

40 1-1/2 135 5.3 98 3.9

50 2 168 6.6 104 4.1

Table 17. Baumann 24000C

VALVE SIZE

DN NPS mm in mm in mm in

15 1/2 130 5.1 184 7.25 80 3.2

20 3/4 150 5.9 184 7.25 80 3.2

25 1 160 6.3 184 7.25 83 3.3

40 1-1/2 200 7.9 222 8.75 99 3.9

50 2.0 230 9.1 254 10.0 107 4.2

EN 10-40 CL150 STANDARD

A B

Table 18. Baumann 24000S

VALVE SIZE

DN NPS mm in mm in mm in mm in mm in

15 1/2 7.9 3.1 365 14.38 61 2.4 198.1 7.8 208.3 82

25 1 102 4.0 381 15.00 61 2.4 198.1 7.8 208.3 82

40 1-1/2 114 4.5 387 15.25 78.7 3.1 215.9 8.5 2.134 8.4

50 2 124 4.9 394 15.50 78.7 3.1 215.9 8.5 2.134 8.4

80 3 165 6.5 337 13.25 78.7 3.9 215.9 9.3 213.4 8.4

Table 19. Baumann 24003

VALVE SIZE

DN NPS A B C

15 1/2 4.875 2.75 2.75 4.8125 2.75 2.75

25 1 4.875 2.75 2.75 5.00 2.75 2.75

40 1-1/2 5.75 3.8125 3.3125 6.125 3.375 3.125

50 2 6.50 4.00 3.625 6.50 3.75 3.625

1. For face-to-face dimension of CL150/300 RF flangedstainless steel valve body subassembly, consult your Emerson Process Managementsales office.

NPT (Except NPS 3) Buttweld Sched 40 Standard Extension NOLEEK

(1)

A B

VALVE BODY MATERIAL

Bronze, NPT Stainless Steel, NPT

1

A B C

1

Table 20. Baumann 24000CVF and SVF

VALVE SIZE

DN NPS mm in mm in mm in mm in mm in mm in

15 1/2 184 7.25 190 7.50 130 5.11 79 3.1 216 8.5 226 8.9

20 3/4 184 7.25 194 7.62 150 5.90 79 3.1 216 8.5 226 8.9

25 1 184 7.25 197 7.75 160 6.30 84 3.3 221 8.7 229 9.0

40 1-1/2 222 8.75 235 9.25 200 7.87 96 3.8 234 9.2 229 9.0

50 2 254 10.0 267 10.5 230 9.06 107 4.2 244 9.6 234 9.2

10

CL150 CL300 EN 10-40 Standard Single Extension NOLEEK

A B

Page 11

NV Electric Actuator

D103326X012

Product Bulletin

52.1:NVACT

November 2012

Valve Weights

Table 21. Baumann 24000

VALVE SIZE WEIGHT

DN NPS kg lbs

15 1/2 1.6 3.5

20 3/4 1.6 3.5

25 1 2.3 5.0

40 1-1/2 4.9 10.9

50 2 8.9 19.7

Table 22. Baumann 24000C

VALVE SIZE WEIGHT

DN NPS kg lbs

15 1/2 3.9 9

20 3/4 4.8 11

25 1 6.4 14

40 1-1/2 10 22

50 2 15 33

Table 23. Baumann 24003 3-Way

VALVE SIZE WEIGHT

DN NPS kg lbs

15 1/2 4 8

25 1 4 8

40 1-1/2 7 15

50 2 9 20

Table 24. Baumann 24000S

VALVE SIZE WEIGHT

DN NPS kg lbs

15 1/2 2.3 5

25 1 2.7 6

40 1-1/2 4.1 9

50 2 5.0 11

80 3 9.1 20

Table 25. Baumann 24000CVF and SVF

VALVE SIZE

DN NPS kg lbs kg lbs kg lbs

15 1/2 3.0 6.6 3.5 7.7 3.3 7.3

20 3/4 3.1 6.9 4.2 9.3 3.4 7.6

25 1 5.1 11.3 5.9 13.1 5.7 12.6

40 1-1/2 7.9 17.5 10.7 23.5 8.8 19.5

50 2 13.4 29.5 15.0 33.1 14.4 31.9

CL150 CL300 EN 10-40

WEIGHT

11

Page 12

Product Bulletin

52.1:NVACT

November 2012

Table 26. Model Numbering - Baumann 24000, 24000C, 24000S, 24000CVF & SVG, and 24003

24

ACTUATOR

TYPE

(1)

NV

(2)

NVF

(3)

NVFE

1. NV24-MFT = Non SpringReturn

2. NVF24-MFT = Spring Return - Fail Open

3. NVF24-MFT-E = Spring Return - Fail Closed

4. See appropriatevalve product bulletinfor available plug series and rated Cv.

TRAVEL

50 102 Linear / Metal Seat IV Omit Bronze - NPT

75 151 Modified Equal % /PTFE Seat VI C Carbon Steel - Flanged

VALVE

BODY

SERIES

PLUG

SERIES

(4)

177 Modified Equal% / PTFE Seat VI CVF Carbon Steel - Flanged

577 Equal % / PTFE Seat VI S Stainless Steel - NPT

548 Equal % / Metal Seat (S41600) IV SVF Stainless Steel - Flanged

588 Equal % / Metal Seat (S31600) IV

677 Linear / PTFE Seat VI

648 Linear / Metal Seat(S41600) IV

688 Linear / Metal Seat(S31600) IV

D1 Diverting - Port L Fails Closed III 3 3WayBronze

D2 Diverting - Port L Fails Open III 3S 3 Way Stainless Steel

D3 Diverting - Port L Fails Last III

M1 Mixing - Port L Fails Closed III

M2 Mixing - Port L Fails Open III

M3 Mixing - Port L Fails Last III

CHARACTERISTIC

SEAT

LEAKAGE

NV Electric Actuator

VALVE BODY MATERIAL /

D103326X012

END CONNECTION

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of anyproduct. Responsibility for proper selection, use, and maintenance of any product remains solelywith the purchaser and end user.

Baumann, Fisher, and ENVIRO-SEAL are marks ownedby one of the companies in the Emerson Process Management business unit of Emerson Electric Co.

Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property

of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are availableupon request. Wereserve the right tomodify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2009, 2012 Fisher ControlsInternational LLC. All rights reserved.

12

Loading...

Loading...