Page 1

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

Getting Started

This is a brief document designed to quickly get you started setting up your valve manifold with an integrated

Numatics’ G2-2 series ControlNet communication node.

1) Initial Unpacking and Inspection

1) Examine exterior of package for signs of damage. Report any damage to shipping carrier.

2) Remove wrapped manifold assembly from box.

a) Remove manifold assembly from anti-static packaging

b) Retain documentation for installation and configuration

3) Examine manifold assembly for any shipping damage such as:

a) Bent pins or connectors

b) Report any damage to shipping carrier immediately

4) Examine manifold assembly for proper ordered configuration. (Valves, I/O, Protocol, etc.)

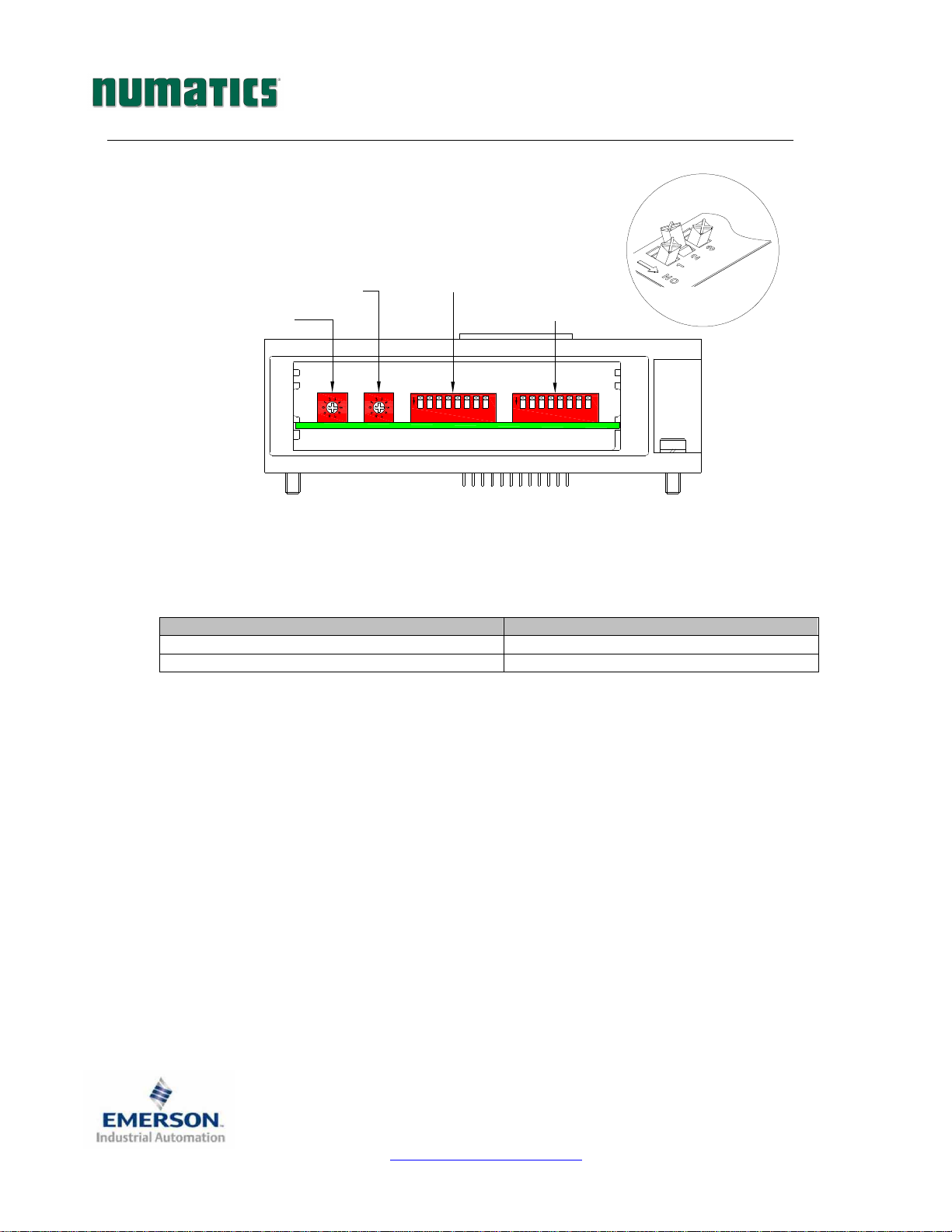

2) G2-2 Introduction

Below is an example of a 2012 series valve manifold. This fieldbus manifold series is capable of addressing a

total of 224 I/O. The manifold can be viewed as having two sections to it, the

. The

Side

Valve Side

supports a maximum of 32 solenoid coils and the

maximum of 6 modules totaling 192 Outputs, 96 Inputs, or various combinations. The communication

module has two BNC communication connectors. The power module has a 4-pin power connector. Pin-outs

for these, along with I/O connectors, are labeled on the side of the respective modules.

Module/

Network

Status LED's

Aux. Power

LED's

Valve Side

Discrete I/O Side

(Maximum of 32 Solenoids)

Chassis Ground

Connection

and the

supports a

Valve Side

Discrete I/O

Valve

End Plates

Valve

Valve Side

Sub-D Output

Module

Communications

Module

Power

Module

Manual

Override

Solenoid LED

Status Indicator

Subject to change without notice

Page 1

www.numatics.com/fieldbus

Page 2

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

3) MCM - Manual Configuration Module (for Self-Test Mode Function Only)

Rotary Switch

(SW3)

Rotary Switch

(SW4)

All DIP switches shown in the "OFF" position

DIP Switch

(SW2)

4

325 678

1

ON

DIP Switch

(SW1)

4

325

1

ON

6 7

8

The MCM is the module that allows the user to manually test the Numatics manifold using Self-Test mode.

The MCM consists of two DIP switch sets (SW1 and SW2) and two rotary switches (SW3 and SW4).

MCM Module Part Numbers

Description Part Number

Complete Module 239-1384

Replacement Board 256-684

Subject to change without notice

Page 2

www.numatics.com/fieldbus

Page 3

TDG2

2CNQS4

-0

1

/07

Testing

G2-2 Series ControlNet Quick Start Manual

4) Self-Test Mode

An internal diagnostic tool can also be enabled using the optional MCM module. This tool allows the user to

confirm that all of the Inputs and Outputs on the manifold are fully functional without needing a network

connection or controller. There are two test modes that the user can choose using SW2-8. The “Output” test

mode tests all the outputs by sequentially turning them ON one at a time. The “Input/Output” test mode

tests the inputs by causing all of the outputs to toggle between even and odd values when any input is made.

To use the Self-Test Mode, the user must first set some initial conditions using the MCM module. Follow

these steps to obtain the needed initial condition settings. Remember to remove power from the manifold

before making changes to the MCM when setting these initial conditions.

1) Disconnect power and air from the manifold!

2) Record current MCM settings.

3) Set the rotary switches to 99 (SW3 and SW4).

4) Make sure that SW1-5, SW2-1, and SW2-7 are in the “ON” position.

5) Select the desired test mode with SW2-8 (see table below)

Switch

SW2-8

6) Make sure that all of the other switches are in the “OFF” position.

The initial conditions are now set. To enable the Self-Test Mode, apply power to the manifold and make the

following changes within 5 to 10 seconds:

Self-Test Mode is terminated by removing power to the unit. Remember to return the MCM settings to their

original settings to return the communication node to normal operation.

!

Mode

Output Off Sequentially turns all the outputs ON and OFF.

Input/

Output

•

•

Setting

Causes all of the odd outputs to come on and stay on until an

On

1) Set SW2-6 to the “ON” position.

2) Set SW2-7 to the “OFF” position.

input is made. When an input is made, the outputs will toggle to

the even outputs.

Description

Air should be disconnected to the manifold when attempting to run the

Self-Test Mode to prevent unwanted motion.

Communication lines should be disconnected before attempting to run the

Self-Test Mode.

Subject to change without notice

Page 3

www.numatics.com/fieldbus

Page 4

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

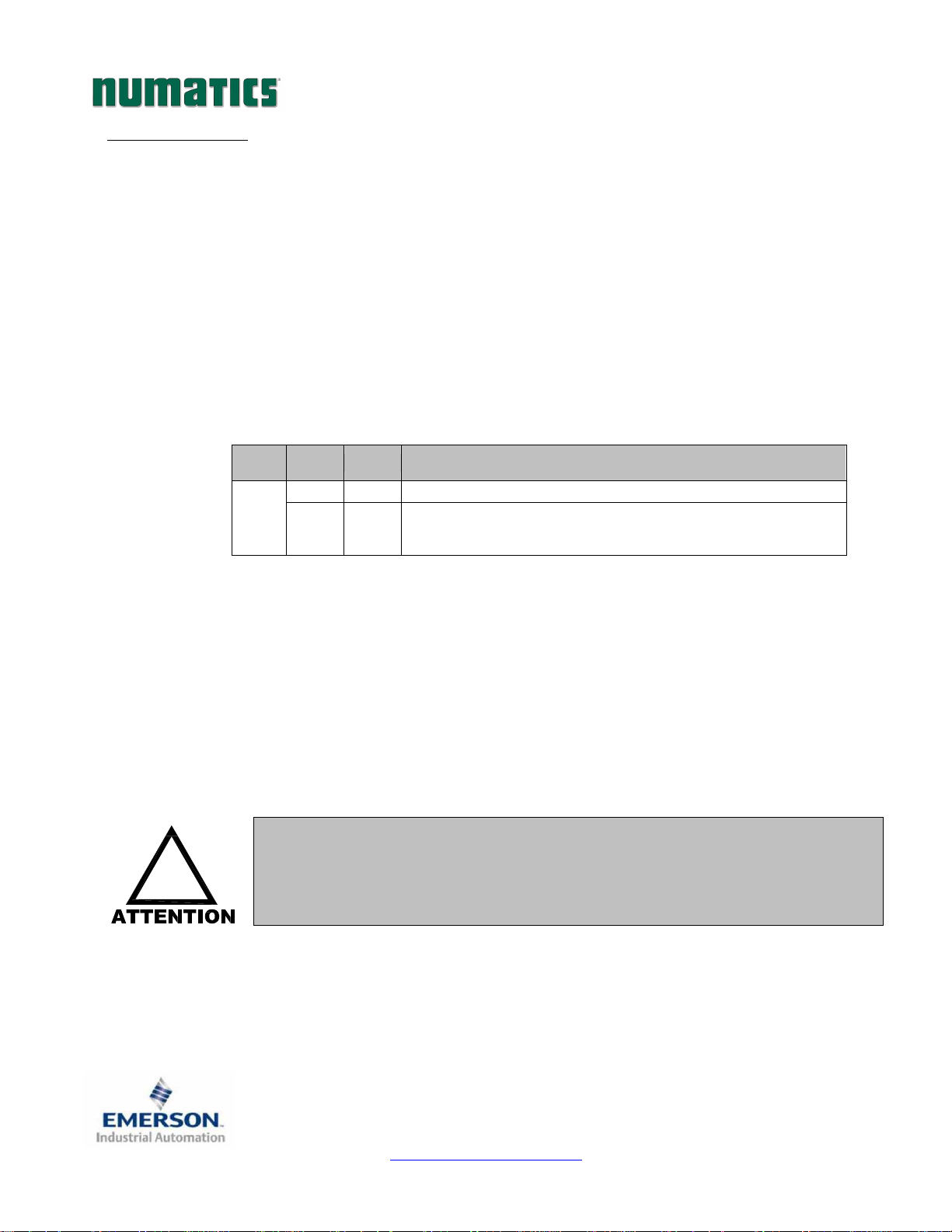

5) Communication Module Rotary Switches

The Rotary switches allow the user to set the node address.

Rotary Switch Settings

Network Address:

Switch

NA 01 Sets the Ones Digits

NA 10 Sets the Tens Digits

•

•

!

Description

Address is set to a default setting of 00 prior to shipment.

Rotary switch settings do not take effect until power is cycled (turned

OFF and ON).

Subject to change without notice

Page 4

www.numatics.com/fieldbus

Page 5

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

6) I/O Mapping Example

Example:

Assumed Settings

- Single Z-Boards

- Double Z-Boards

valves

- Run Idle Header (Overhead) will always take up

the first two Input words of the Input Map.

TM

used with single solenoid valves

TM

used with double solenoid

Discrete I/O Configuration

Pos

No.

1 MCM 239-1384 -- --

2

3

4

5

Manifold I/O Configuration

Outputs and Mapping Location

Valve Outputs = 12 Word 0; Bits 0-11

Allocated Unused

Valve Outputs = 20

Discrete

Outputs = 24

Total Outputs = 56

Inputs and Mapping Location

Discrete Inputs = 12 Word 5; Bits 0-3, 8-15

Allocated and

Reserved Inputs = 4

Total Inputs = 16

Module Type Part No.

8O Sourcing

(PNP)

16O Sourcing

(PNP)

4I Sinking

(NPN)

8I Sinking

(NPN)

239-1315 1 1

239-1319 1 2

239-1304 1 0

239-1308 1 0

Word 0; Bits 12-15

Word 1; Bits 0-15

Word 2; Bits 0-15

Word 5; Bits 4-7

In Out

Bytes

-7

Subject to change without notice

Page 5

www.numatics.com/fieldbus

Page 6

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

I/O Mapping Table Example Continued

Output Table

WORD BYTE

0

0

1

2

1

3

4

2

5

3 6

WORD BYTE

0

0

1

2

1

3

4

2

5

6

3

7

8

4

9

10

5

11

7 15 6 14 5 13 4 12 3 11 2 10 1 9 0 8

Valve Coil

No. 8

Allocated &

Reserved

Allocated &

Reserved

Allocated &

Reserved

Discrete

Output No. 7

Discrete

Output No. 7

Discrete

Output No. 15

Valve Coil

No. 7

Allocated &

Reserved

Allocated &

Reserved

Allocated &

Reserved

Discrete

Output No. 6

Discrete

Output No. 6

Discrete

Output No. 14

Valve Coil

No. 6

Allocated &

Reserved

Allocated &

Reserved

Allocated &

Reserved

Discrete

Output No. 5

Discrete

Output No. 5

Discrete

Output No. 13

Valve Coil

No. 5

Allocated &

Reserved

Allocated &

Reserved

Allocated &

Reserved

Discrete

Output No. 4

Discrete

Output No. 4

Discrete

Output No. 12

Input Table

7 15 6 14 5 13 4 12 3 11 2 10 1 9 0 8

Run Idle

Header

Run Idle

Header

Run Idle

Header

Run Idle

Header

Coil No. 8

Status

Coil No. 16

Status

Coil No. 24

Status

Coil No. 32

Status

Allocated &

Reserved

Allocated &

Reserved

Allocated &

Reserved

Discrete

Input No. 7

Run Idle

Header

Run Idle

Header

Run Idle

Header

Run Idle

Header

Coil No. 7

Status

Coil No. 15

Status

Coil No. 23

Status

Coil No. 31

Status

Allocated &

Reserved

Allocated &

Reserved

Allocated &

Reserved

Discrete

Input No. 6

Run Idle

Header

Run Idle

Header

Run Idle

Header

Run Idle

Header

Coil No. 6

Status

Coil No. 14

Status

Coil No. 22

Status

Coil No. 30

Status

Allocated &

Reserved

Allocated &

Reserved

Allocated &

Reserved

Discrete

Input No. 5

Run Idle

Header

Run Idle

Header

Run Idle

Header

Run Idle

Header

Coil No. 5

Status

Coil No. 13

Status

Coil No. 21

Status

Coil No. 29

Status

Allocated &

Reserved

Allocated &

Reserved

Allocated &

Reserved

Discrete

Input No. 4

BIT

BIT

Valve Coil

No. 4

Valve Coil

No. 12

Allocated &

Reserved

Allocated &

Reserved

Discrete

Output No. 3

Discrete

Output No. 3

Discrete

Output No. 11

Run Idle

Header

Run Idle

Header

Run Idle

Header

Run Idle

Header

Coil No. 4

Status

Coil No. 12

Status

Coil No. 20

Status

Coil No. 28

Status

Allocated &

Reserved

Status for

Discrete

Outputs

No.12-15

Discrete

Input No. 3

Discrete

Input No. 3

Valve Coil

No. 3

Valve Coil

No. 11

Allocated &

Reserved

Allocated &

Reserved

Discrete

Output No. 2

Discrete

Output No. 2

Discrete

Output No. 10

Run Idle

Header

Run Idle

Header

Run Idle

Header

Run Idle

Header

Coil No. 3

Status

Coil No. 11

Status

Coil No. 19

Status

Coil No. 27

Status

Allocated &

Reserved

Status for

Discrete

Outputs

No. 8-11

Discrete

Input No. 2

Discrete

Input No. 2

Valve Coil

No. 2

Valve Coil

No. 10

Allocated &

Reserved

Allocated &

Reserved

Discrete

Output No. 1

Discrete

Output No. 1

Discrete

Output No. 9

Run Idle

Header

Run Idle

Header

Run Idle

Header

Run Idle

Header

Coil No. 2

Status

Coil No. 10

Status

Coil No. 18

Status

Coil No. 26

Status

Status for

Discrete

Outputs

No. 4-7

Status for

Discrete

Outputs

No. 4-7

Discrete

Input No. 1

Discrete

Input No. 1

Valve Coil

No. 1

Valve Coil

No. 9

Allocated &

Reserved

Allocated &

Reserved

Discrete

Output No. 0

Discrete

Output No. 0

Discrete

Output No. 8

Run Idle

Header

Run Idle

Header

Run Idle

Header

Run Idle

Header

Coil No. 1

Status

Coil No. 9

Status

Coil No. 17

Status

Coil No. 25

Status

Status for

Discrete

Outputs

No. 0-3

Status for

Discrete

Outputs

No. 0-3

Discrete

Input No. 0

Discrete

Input No. 0

1 Byte = 8 Bits

1 Word = 2 Bytes or 16 Bits

Subject to change without notice

Page 6

www.numatics.com/fieldbus

Page 7

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

7) Output Short Circuit Protection (Status Input Bits)

Status Input Bits report the integrity of the load being driven by the output driver. They must be mapped to the

scanner as part of the Input Size Value. Please refer to the table below for Status Input Bit action during fault

condition:

Output Type Output State Fault Condition Status Bit

Valve Solenoid Coil Driver or

Sinking (NPN)

Discrete Outputs

Discrete Outputs

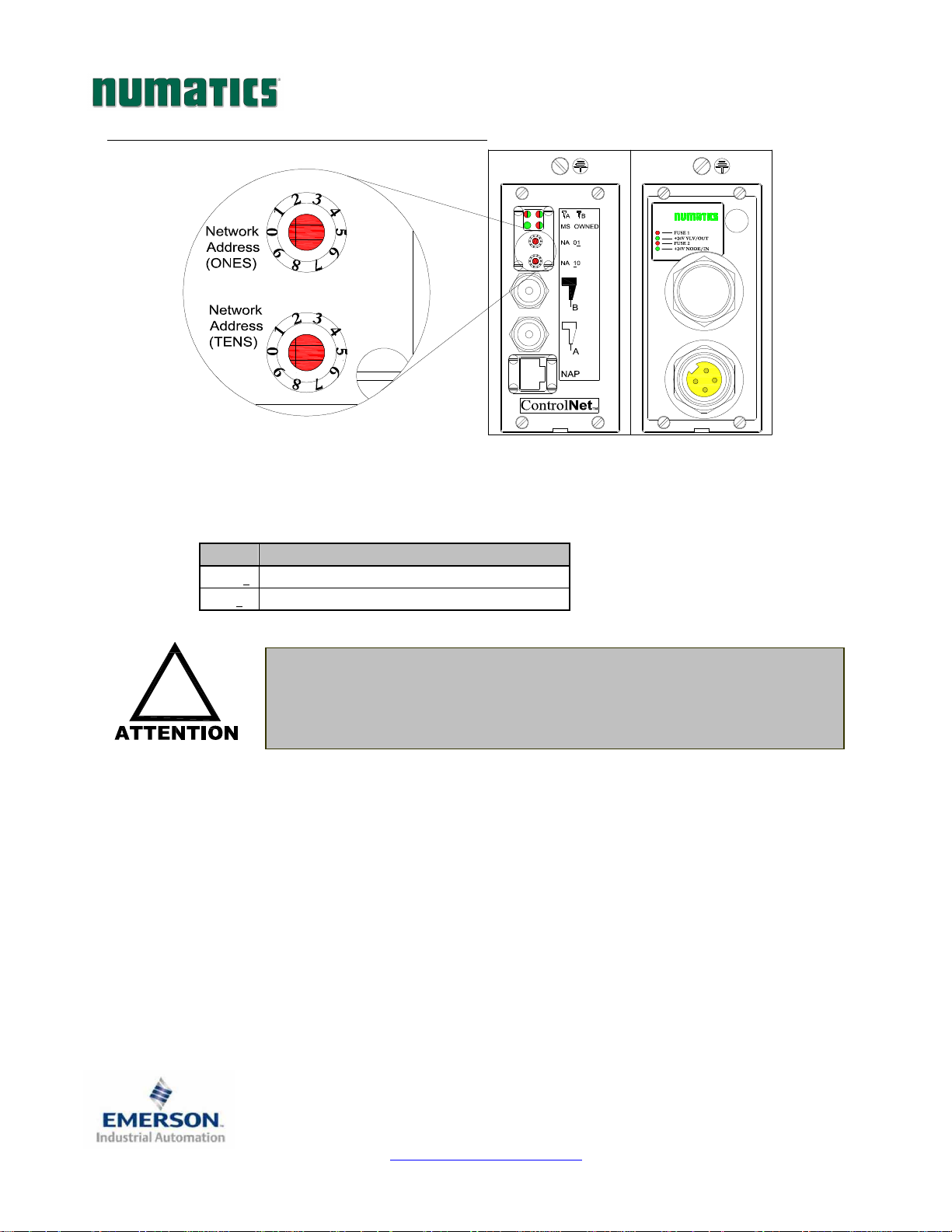

8) Ground Wiring

All Numatics Inc. communication nodes should be grounded during the installation process. These grounding

guidelines can be found in National Electrical code IEC 60204-1 or EN 60204-1. There also is a,

“ATTENTION: CONNECT TO EARTH GROUND FOR PROPER GROUNDING OF UNIT”, label

attached to the chassis ground connection point on the G2-2 series communication node housing. This label

also points out where the grounding guidelines can be found.

!

ON

OFF

ON

•

Proper grounding will alleviate and prevent many intermittent problems

with network communication.

•

When grounding to a machine frame, please ensure that the machine frame

itself is already properly grounded.

•

Better grounding can be achieved when larger diameter (lower gauge) wire

is used.

No Fault

Fault No Fault

Fault No Fault 0 Sourcing (PNP)

Fault -

Short Circuit, Over Temp/Over Current

Open Load

1

Short Circuit, Over Temp/Over Current

1

1

0

0

Subject to change without notice

Page 7

www.numatics.com/fieldbus

Page 8

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

9) Auxiliary Power Connector Pin-Out

Pin No. Function Description

1

2 Earth Ground Protective Earth (Case Ground)

3 0VDC Common 0VDC Common, for Valves, I/O, and Node Power

4

+24VDC

(Valves and Outputs)

+24VDC

(Node and Inputs)

•

Maximum current capacity on the 0VDC common pin of the auxiliary

power connector is 8 Amps. The combined draw of the +24VDC Valves and

Outputs and +24VDC Node and Inputs pins cannot exceed 8 Amps, at any

given moment in time.

!

•

The auxiliary power +24VDC Node and Inputs pin supplies power to the

node electronics. This pin must be powered at all times for communication

node to be functional.

Voltage Used to Power Outputs

(Valve Coils and Discrete Outputs)

Voltage Used to Power Discrete Inputs and Node Electronics

4

1 3

2

Subject to change without notice

Page 8

www.numatics.com/fieldbus

Page 9

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

10) LED Functions

Upon power up, the LEDs indicate the status of the unit. The Power Module of the G2-2 ControlNet node has

four LEDs; two for internal fuse integrity and two for Aux. Power status. The Communication module also

has four status LEDs which are described below.

Communication Module

LED Name Color Status Description

Green Red FLASHING Self test of bus controller

Green Red FLASHING Incorrect network configuration

MS

(Module Status)

(Module Owned)

Power Module

LED Name Color Status Description

FUSE 1 Red

+24V VLV/OUT Green

FUSE 2 Red

+24V NODE/IN Green

Off OFF Module is not initialized

Red

Off OFF Channel is disabled, depending on the network configuration

Green

Red FLASHING Media Fault or no other nodes on the network

Green

Red

Green

ON Faulted unit, must be restarted

FLASHING Incorrect node configuration; i.e. duplicate MAC ID

ON Normal operation of channel

FLASHING

ON Module is initialized

FLASHING Module is waiting for initialization

ON Major fault, module must be restarted

FLASHING Minor fault, MAC ID has been changed after initialization, etc.

OFF No connection is opened OWNED

ON A connection is opened to the module

OFF

ON

OFF No DC Power present at

ON DC Power applied to

OFF

ON

OFF No DC Power present at

ON DC Power applied to

Temporary errors (node will self correct) or node is not configured to

go online

Internal fuse

+24V

Internal fuse F1 is open; No power is internally provided to valves or

outputs. Communication NOT affected.

Internal fuse F2 is OK (valid only when power is applied to

+24V

Internal fuse F2 is open; No power is internally provided to node

electronics or inputs. Communication Node will not function.

VLV / OUT

NODE / IN

F1

is OK (valid only when power is applied to

pin on Aux. Power connector).

+24V

VLV / OUT

+24V

NODE / IN

VLV / OUT

NODE / IN

+24V

pin on Aux. Power connector.

+24V

pin on Aux. Power connector.

pin on Aux. Power Connector.

pin on Aux. Power connector.

pin on Aux. Power connector.

Subject to change without notice

Page 9

www.numatics.com/fieldbus

Page 10

TDG2

2CNQS4

-0

1

/07

. This is a

G2-2 Series ControlNet Quick Start Manual

11) Configuration with RSLOGIX 5000

When commissioning your ControlNet node, specific values must be entered in the “Connection Parameters”

section for the “Assembly Instance” column with regards to “Input Size”, “Output Size”, and

“Configuration”. The “Size” values are determined from the actual physical configuration of the manifold

(i.e. how many and which I/O modules are installed on the manifold). The size values are a minimum value;

higher values can be used if future manifold I/O expansion is required. Below is a sample screen shot taken

from Allen Bradley’s RSLogix 5000 programming software, it shows where the appropriate values for the

Node Address, Assembly Instance, Size

and

Configuration

must be entered.

Module Properties

Comm. Format:

Connection Parameters:

Description Data

Comm. Format “Data – INT”

Description

Input

Output

Configuration

Assembly Instance

Values

100 (Decimal) or

64 (Hexadecimal)

150 (Decimal) or

96 (Hexadecimal)

1 (Decimal) or

1 (Hexidecimal)

Size

(16 Bits=1 Word)

Total Input Size value (in words) from manifold

configuration (including status Input bits) + 2 Words

of ControlNet Run/Idle Header (overhead)

minimum value; larger values may be specified for

future expansion purposes.

Total Output Size value (in words) from manifold

configuration. This is a minimum value; larger values

may be specified for future expansion purposes.

0

Subject to change without notice

Page 10

www.numatics.com/fieldbus

Page 11

TDG2

2CNQS4

-0

1

/07

G2-2 Series ControlNet Quick Start Manual

12) Factory Default Settings

Unless otherwise requested, all standard G2-2 Series ControlNet manifolds ship with specific factory default

settings. Below is a list of the factory default settings:

Description Default Settings

Node Address 0

Baud Rate 5 Mbit/sec

Input Module Power Jumper

+24VDC Node and Inputs pin on the Aux. power connector)

Output Module Power Jumper

+24VDC Valves and Outputs pin on the Aux. power connector)

Valve Side Output Bytes 4 Bytes (32 Allocated Valve Coil Outputs)

Discrete I/O Side - I/O Bytes Self-Configuring

13) Technical Support

For technical support, contact your local Numatics distributor. If further information is required,

please call Numatics Inc. at (248) 887-4111 and ask for Technical Support.

Issues relating to network set-up, PLC programming, sequencing, software related functions, etc…

should be handled with the appropriate product vendor.

Information on device files, technical manuals, local distributors, and other Numatics, Inc. products

and support issues can be found on the Numatics, Inc’s WEB site at www.numatics.com

For general help or more information regarding the fieldbus you may access the ControlNet International

homepage found at www.controlnet.org

(Input sensor power supplied by

(Output module power supplied by

based on the I/O modules installed.

PU

SP

Subject to change without notice

Page 11

www.numatics.com/fieldbus

Loading...

Loading...