Page 1

NGA 2000

Software Manual

CLD - Analyzer Module

Chemiluminescence - Measurement

(combined with NGA 2000 - Platform / MLT - Analyzer)

CLD Software V e rsion 2.3

(Platform / MLT Software Version 3.1.X)

1. Edition 04/98

Catalog No.: 90 003 749

90003749(1) [NGA-e (CLD-Software 2.3 / MLT-Software 3.1.X)] 04/98

Managing The Process Better

Page 2

This Operation Manual includes information about the operation of the instrument.

Information about the additional indications and notes regarding maintenance, troubleshooting and repair

are found in the accompanying Maintenance & Operation Manual.

T roubleshooting, component replacement and internal adjustments must be made by qualified

service personnel only.

Fisher-Rosemount GmbH & Co does not take responsibility for an y omissions or errors in this manual.

Any liability for direct or indirect damages, which might occur in connection with the deliv ery or the use of

this manual, is expressly e xcluded to the extend permitted by applicable law.

This instrument has left the works in good order according to safety regulations.

T o maintain this operating condition, the user must strictly follow the instructions and consider the warnings

in this manual or provided on the instrument.

Misprints and alterations reserved

©

1998 by FISHER-ROSEMOUNT GmbH & Co. (PAD)

1. Edition: 04/98

Read this operation manual carefully before attempting to operate the analyzer !

For expedient handling of reports of defects , please include the model and serial number which

can be read on the instrument identity plate.

Fisher - Rosemount GmbH & Co.

Industriestrasse 1

D - 63594 Hasselroth • Germany

Phone + 49 (6055) 884-0

Telefax + 49 (6055) 884-209

Internet: http://www.processanalytic.com

90003749(1) [NGA-e (CLD-Software 2.3 / MLT-Software 3.1.X)] 04/98

Page 3

Contents

1 Introduction 1 - 1

2 Structure of Menus 2 - 1

3 Display and Keyboard 3 - 1

3.1 Starting and Initializing...................................................................................3 - 1

3.2 Display and Function...................................................................................... 3 - 1

3.3 Operating Keys ..............................................................................................3 - 2

3.4 Lines...............................................................................................................3 - 2

3.5 Important Functions of the Softkeys...............................................................3 - 3

3.6 Entering/Changing of Variables......................................................................3 - 4

3.7 The STATUS Key...........................................................................................3 - 5

4 Basic Controls 4 - 1

4.1 Measurement 4 - 3

4.1.1 Multi Component Display: Change of Channel ..............................................4 - 3

4.1.2 Multi Component Display: Sequence Setup...................................................4 - 5

4.1.3 Range Setting ................................................................................................4 - 7

4.1.4 Range and Functional Control .......................................................................4 -11

4.1.5 Enable/Disable Ozonator Power....................................................................4 -15

4.1.6 Measurement Mode: NO ↔↔ NOx....................................................................4 -19

4.2 Calibration 4 -21

4.2.1 Zeroing...........................................................................................................4 -21

4.2.2 Spanning........................................................................................................ 4 -25

4.2.3 If It Won't Calibrate.........................................................................................4 -29

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

I

Page 4

5 Expert Controls and Set up 5 - 1

5.1 Analyzer Module Set up 5 - 3

5.1.1 Calibration/Calibration Gas List......................................................................5 - 4

5.1.2 Calibration Parameters...................................................................................5 - 9

5.1.3 Gas Measurement Parameters ......................................................................5 -11

5.1.4 Linearization Parameters................................................................................5 -12

5.1.5 Response Time/Delay Parameters.................................................................5 -14

5.1.6 Range Settings...............................................................................................5 -16

5.1.7 Units ...............................................................................................................5 -17

5.1.8 Linearization Functions...................................................................................5 -18

5.1.9 Analyzer Parameter List .................................................................................5 -23

5.1.10 Physical Measurement Parameters................................................................5 -26

5.1.11 Displayed Parameters ....................................................................................5 -28

5.2 Auxiliary Module Controls 5 -29

5.2.1 Local SIO Configuration Sections...................................................................5 -30

5.2.2 Set-up DIO Module(s).....................................................................................5 -39

5.3 Auxiliary Module Set up 5 -45

5.4 System Set up 5 -47

5.4.1 Front Panel Control ........................................................................................5 -48

5.4.2 Display Resolution..........................................................................................5 -50

5.4.3 Auxiliary Lines.................................................................................................5 -51

5.5 Expert Analyzer Controls 5 -53

5.5.1 Range Settings...............................................................................................5 -55

5.5.2 Zero/Span Calibration.....................................................................................5 -56

5.5.3 Physical Measurements..................................................................................5 -60

II

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 5

6 Technical Level Configuration 6 - 1

6.1 System Set up 6 - 3

6.1.1 Main Display Configuration ............................................................................6 - 4

6.1.2 Front Panel Control........................................................................................6 - 9

6.1.3 Date and Time Set up....................................................................................6 -11

6.1.4 Module Binding ..............................................................................................6 -12

6.1.5 System Reset.................................................................................................6 -14

6.1.6 Security Codes...............................................................................................6 -15

6.2 Service Menus 6 -17

6.2.1 Control Module Data......................................................................................6 -18

6.2.2 Analyzer Module Data.................................................................................... 6 -19

6.2.3 Control Module History...................................................................................6 -21

6.2.4 Analyzer Module History ................................................................................6 -23

6.3 Diagnostic Menus 6 -25

6.3.1 Control Module Diagnostics ...........................................................................6 -26

6.3.2 Analyzer Module Diagnostics.........................................................................6 -27

6.3.2.1 Power Supply Voltages ...................................................................6 -28

6.3.2.2 Primary Variable Parameters ..........................................................6 -29

6.3.2.3 Physical Measurements ..................................................................6 -33

6.3.2.4 Temperature Control.......................................................................6 -35

6.3.2.5 Flow Control Parameters.................................................................6 -36

6.3.2.6 Miscellaneous Control Parameters..................................................6 -38

6.3.2.7 Trend Display Control......................................................................6 -39

6.3.2.8 Software Diagnostics.......................................................................6 -41

6.3.2.9 Analyzer Start up............................................................................. 6 -42

6.3.2.10 NOx Converter Efficiency.................................................................6 -43

6.4 Other Module Diagnostic Menus 6 -44

6.5 Listing of all Modules 6 -45

Supplement: System Calibration

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

III

Page 6

IV

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 7

1 Introduction

This software manual describes step by step how to operate successfully with the ½ 19"

and 19" MLT analyzer module and analyzer of the NGA 2000 Series from .

Chapter two shows the structure of the software menus. Chapter three describes the

display and the keyboard of the analyzer. Chapter four describes the basic controls with

detailed illustrations. So you can easily compare the actual display of the analyzer module

with the illustrations of the manual.

Chapter five describes the expert controls and chapter six describes the technical level

configuration. The layout of both chapters is not as detailed as in chapter four. Normally,

the way to a certain software menu is described with the software catchwords, you have to

press to reach this menu. You will find the illustration of the corresponding LCD screen at

the end of the catchword listing. After that you can read the meaning of the functions and

variables of each expert or technical level menu.

Some contents of the expert controls are not important for every customer. It depends on

the configuration of your NGA 2000 system, relative to the following components:

♦ Control Module CM

♦ Analyzer Module AM

♦ Input/Output Modules I/O's (SIO, DIO)

You can distinguish the following system units and SIO/DIO configurations:

System Unit SIO/DIO-Configuration Corresponding Chapter

1

CLD analyzer module (AM):

• without front panel i.e.

⇒ Local I/O's are not existing

∗ ⁄⁄

without control unit

• can be combined with a

platform or an MLT analyzer

Platform (CM software):

• Control unit with front panel

• without measurement

channels

⇒ 1 SIO and up to 4 DIO's

can be installed in the

platform

⇒ SIO and DIO can be

∗ chapter 5.2

p. 29 to 44

configured for all channels

combined with the platform

MLT analyzer

(CM and MLT AM software):

• Analyzer with front panel

• CM and AM software in the

same analyzer,

i.e. all functions of the control

unit and of the AM are united

⇒ 1 SIO and 1 DIO can be

installed in the MLT

analyzer

⇒ SIO and DIO can be con-

figured for all channels

combined with the MLT

analyzer

∗ chapter 5.2

p. 29 to 44

in the same implement

1

The configuration of other analyzer modules like MLT modules is described in their own manuals !

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

1 - 1

Page 8

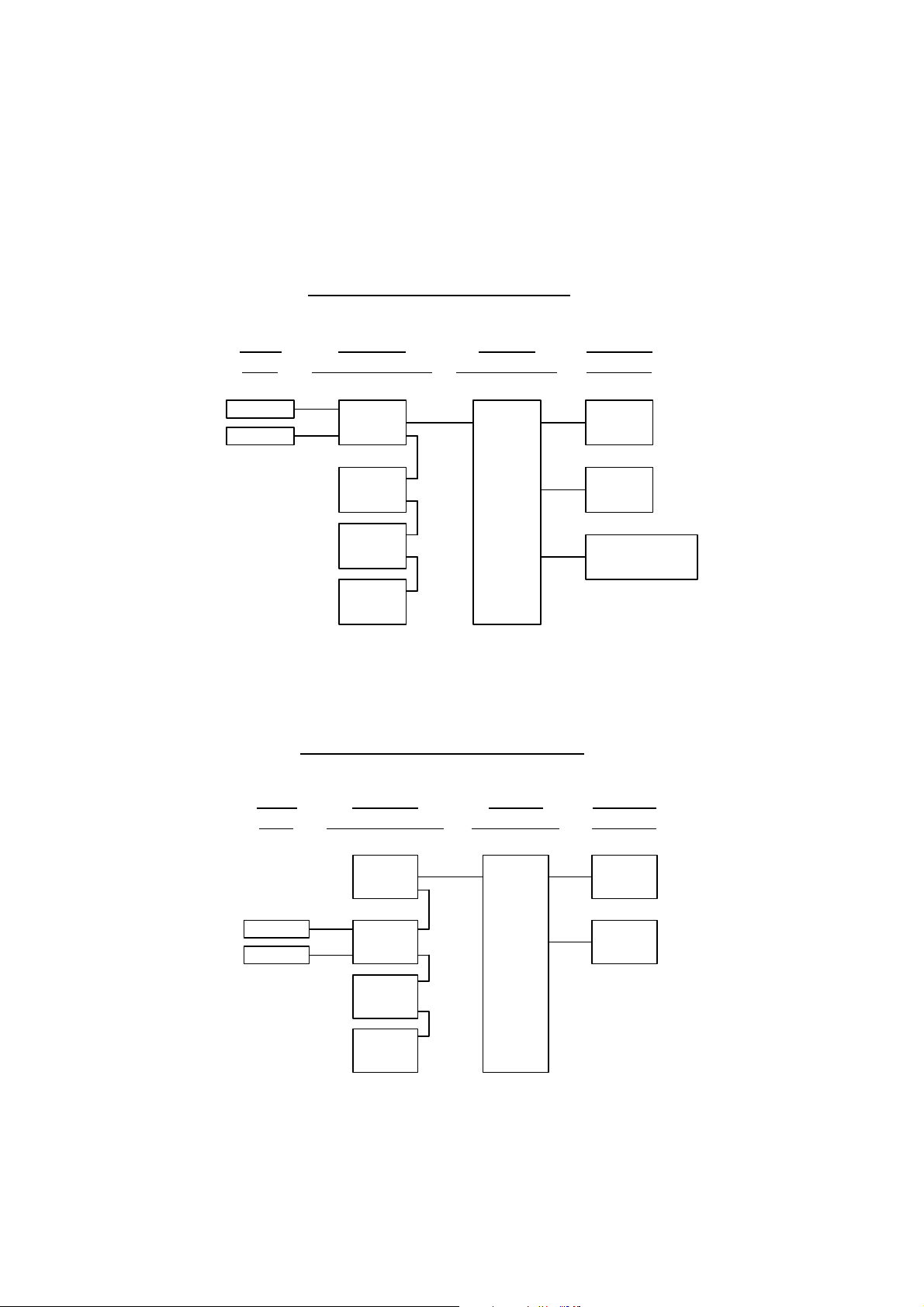

The following illustrations shall make plain the connection between the hardware configuration and the software setup of the modules:

NGA 2000 System via Platform

(see 5.1.17)

(see 5.1.18)

(other manuals)

(other manuals)

(other manuals)

Local

I/O's

SIO

DIO

Analyzer

Modules (AM's)

Control

Module (CM)

MLT

CLD

FID

Platform

PMD

NGA 2000 System via MLT Analyzer

Auxiliary

Modules

SIO

DIO

Other I/O´s

(see 5.2.1)

(see 5.2.2)

(other manuals)

Local

I/O's

(see 5.1/5.5)

SIO

DIO

Analyzer

Modules (AM's)

CLD

MLT

FID(other manuals)

PMD(other manuals)

Control

Modul (CM)

MLT Analyzer

Auxiliary

Modules

SIO

DIO

(see 5.2.1)

(see 5.2.2)

1 - 2

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 9

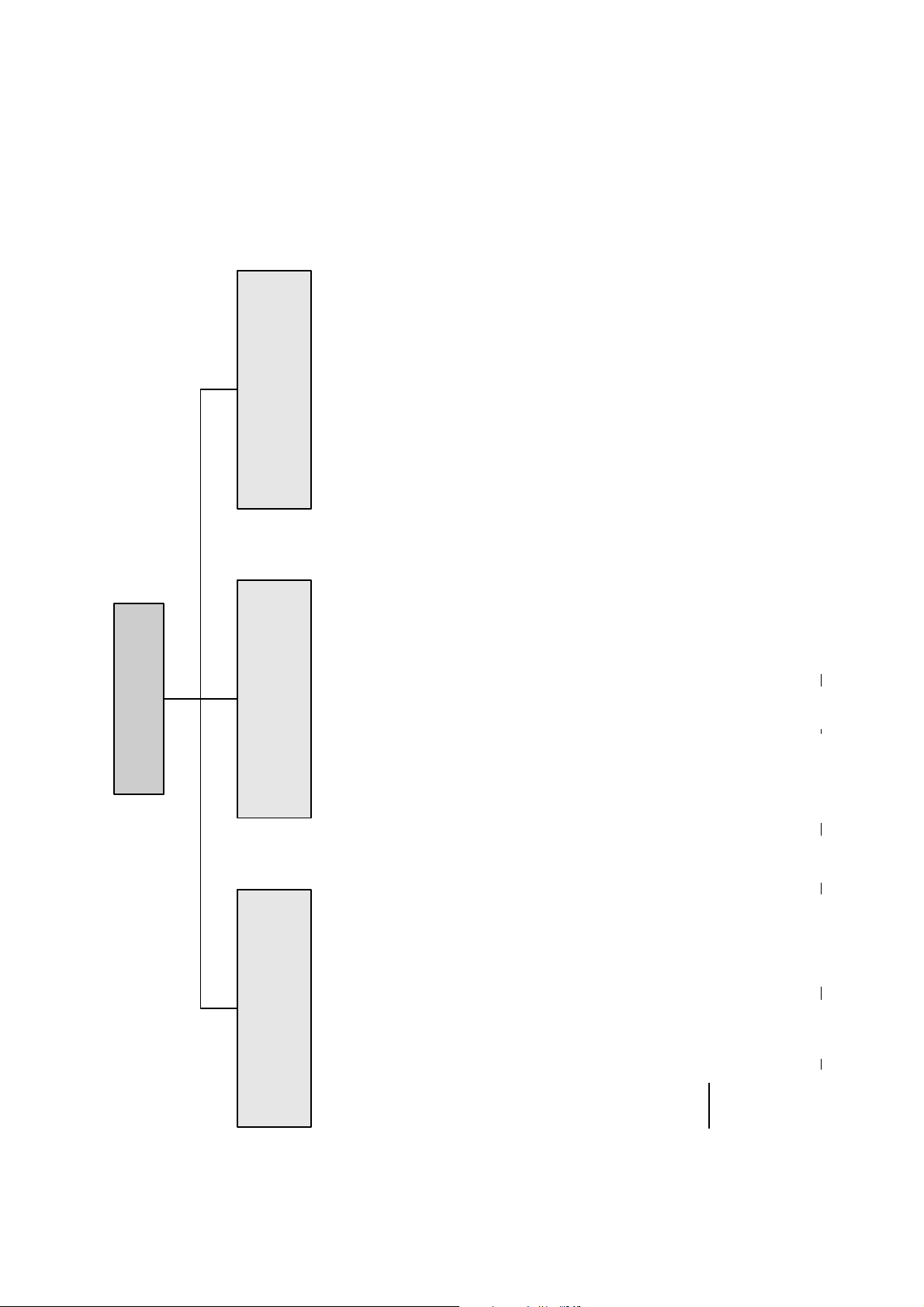

Notes:

*

In the menu structure shown above, you will find the most important ramifications of the MLT software 3.1.X for the

MLT platform and analyzer versions. The menu points related to the CLD analyzer module are marked with

They belong to the CLD software revision number 2.3.

*

At each menu point of the "Expert controls" and "Technical level" you can find which functionality will be set up:

odule), CM (

odule), I/O (

utput Module).

*

Menu lines ending with three points (...) are followed by submenus with further functions and set-ups.

-

-

-

-

-

Technical level

configuration...

2 Structure of Menus

"AM".

Main Menu

(CM)

- System set up...

and set up...

Expert controls

controls...

- Expert analyzer

(AM, CM, I/O's:

SIO, DIO and other I/O's)

- Service menus...

(AM)

controls...

- Auxiliary module

(AM, CM, I/O's:

SIO, DIO and other I/O's)

- Diagnostic menus...

(I/O's: SIO, DIO)

(CM)

- System set up...

diagnostic menus...

(Other I/O's)

- Other module

(AM)

- Analyzer module set up...

(AM, CM, I/O's:

SIO, DIO and other I/O's)

- Listing of all modules...

(Other I/O's)

- Auxiliary module set up...

(CM)

- System calibration...

Input-/O

Control M

Basic controls... (AM)

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Range set-up

Range and

functional control

Ozonator power

enable/disable

NGA 2000

Measurement mode

selection: NO/NOx-Zeroing...

Spanning...

AM (Analyzer M

2 - 1

Page 10

2 - 2

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X] 04/98

Page 11

3 Display and Keyboard

3.1 Starting and Initializing

After switching on the CLD analyzer module (in a platform or part of a NGA network), the

initialization procedure will be performed. A self control of the analyzer modules or the

analyzer(s) is running. You can see a sequence of several displays. They show the status

of initialization, revision notes of the MLT software and the tag. At the end

of this procedure you can see the single component display of channel one. It is the origin

to all the other channels, menus and submenus.

The instructions of the basic controls (chapter four) are all beginning with the single component display. The actual display might differ from the shown one because the customer

can configure it according to his requirements.

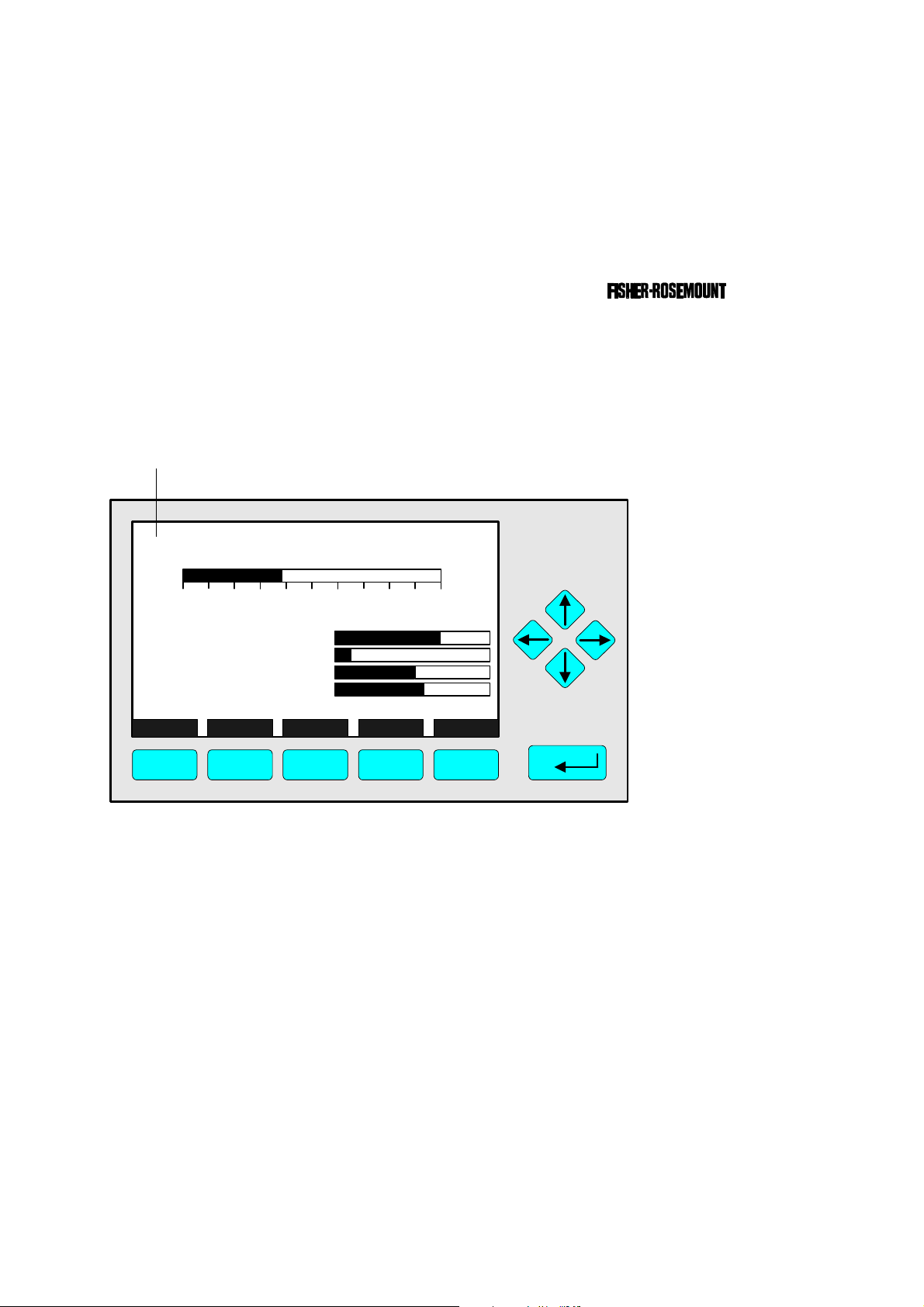

TAG

here e.g.: CLD Analyzer Module

CLD

95.00 ppm NOx

0 250

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

Typical starting menu after switching on

Range: 4

340 hPa

0.5 C

51.5 C

360 C

3.2 Display and Function

The LCD-screen shows all measurement values of the analyzer and all customer instructions. You can operate with five function keys, four arrow keys (cursors) and the enter key.

The function of each key depends on:

♦ the type of analyzer/analyzer module used

♦ the optional auxiliary modules (e.g. I/O boards) used

♦ the individual menu displayed

In case of power failure all customer specific module parameters are saved by a batterypowered buffer.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

3 - 1

Page 12

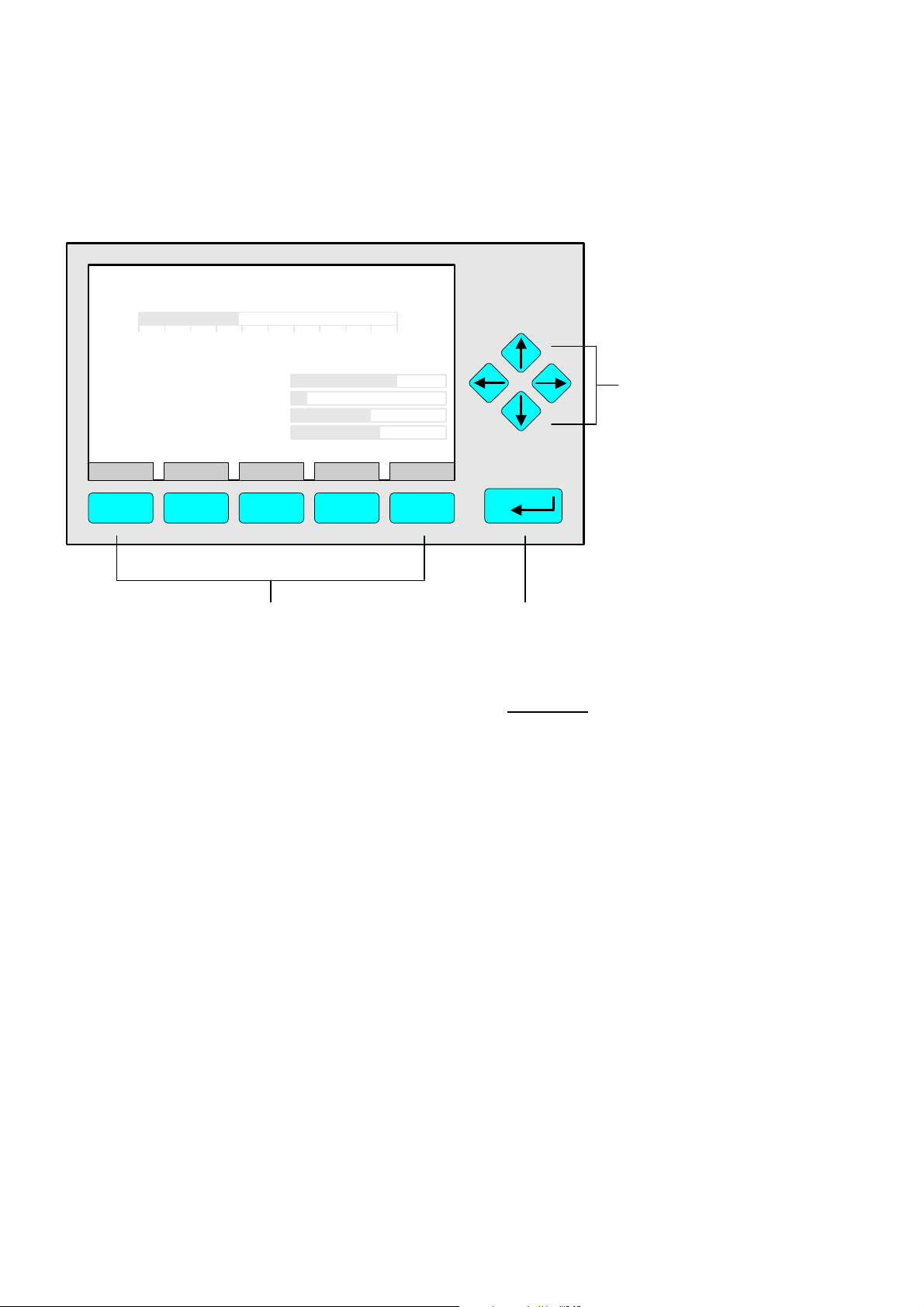

3.3 Operating Keys

CLD

95.00 ppm NOx

0 250

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

Range: 4

340 hPa

0.5 C

51.5 C

360 C

Function Keys:

♦ Keys without defined functions

♦ The current function depends on

the menu selected

♦ The softkey legend is shown on

the display above the key

3.4 Lines

Cursor keys:

↑↑ -key / ↓↓ -key:

♦ Line up / line down

within the same menu

♦ Alteration of numbers,

variables or digits

←← -key/ →→ -key:

♦ Moving back/forwards

between the pages of

a menu

♦ Selection of digits

Enter Key:

♦ To confirm a previously entered value

(variable)

♦ To start a selected function

(Alternative: →→ -key)

♦ To go into a menu (via menu line)

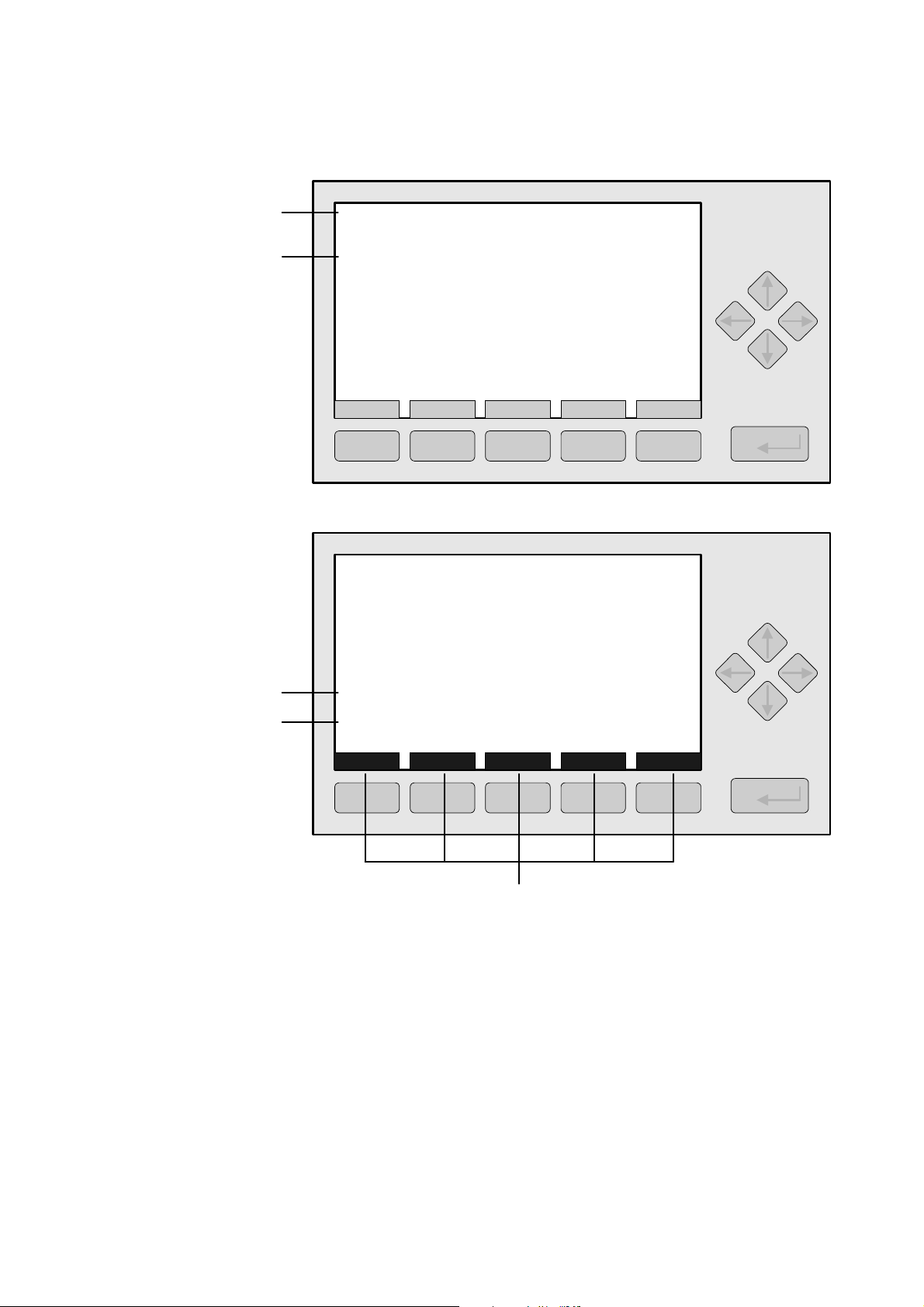

Lines can be selected by the ↓↓ -key or the ↑↑ -key. The selected line is displayed white on

black. You have four different types of lines in the menu:

Menu line...

♦ Line ending with three dots.

♦ You will go to a submenu by pressing the ENTER key or the →→ -key in such a line.

Function line !

♦ Line ending with an exclamation-mark.

♦ You will start a function (e.g. NO/NO

-toggle) by pressing the ENTER key or

x

the →→ -key in such a line.

Line of variables:

♦ Line ending with a colon.

♦ Display of module parameters (variables).

♦ Some parameters can be changed (e.g. range number), some parameters display only

a status (e.g. calibration status) and cannot be changed.

Text line

♦ Line without any punctuation marks.

♦ Only display of informations (e.g. analyzer module tag).

3 - 2

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 13

3 Display and Keyboard

Text Line

Line of Variables

Function Line

Menu Line

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

Zero/span calibration

Measurement range number: 3

Zero gas concentration: 0.0 ppm

Span gas concentration: 100.0 ppm

Sample flow: 1100 ml/min

Raw measurement signal: 521590

Measurement gas: NOx

NO/NOx toggle!

Status: READY

Result...

Calibration adjustment limits: Disabled

HOME FACTORS ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

Function Key Legend

3.5 Important Functions of the Softkeys

DISPLAY

♦ Change from the single component display to the multi component display.

MEASURE

♦ Change from the main menu to the single component display.

STATUS (see 3.7!)

♦ Change to the status report: Display of the most important parameters and

status informations of the CLD module or of the current channel.

♦ If available, this command is always assigned to the F2 key.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

3 - 3

Page 14

MENU

♦ Change from the single component display to the main menu or from several submenus

to higher menus.

ESCAPE or <<<

♦ Changing back to the last menu page selected.

♦ Reset of a changed but not confirmed parameter to the former value resp. to zero.

BACK

♦ Reset of a changed but not confirmed parameter to the former value.

LOCK

♦ Lock of any operation level, if activated. Each of the three operation levels has to be

activated separately.

♦ F4 key of the main menu.

NEXT

♦ Change of the channel in the same menu. This will only be possible, if several channels

of an analyzer or of combined analyzers are existing. Then, all available channels can

be selected one after another.

♦ In the main menu you can move among all channels of the connected analyzers and

analyzer modules. In the submenus you can only move among the channels of the

current analyzer or analyzer module.

INFO

♦ Change to menus containing status or help informations of the actual menu.

♦ If available, this function is always assigned to the F5 key.

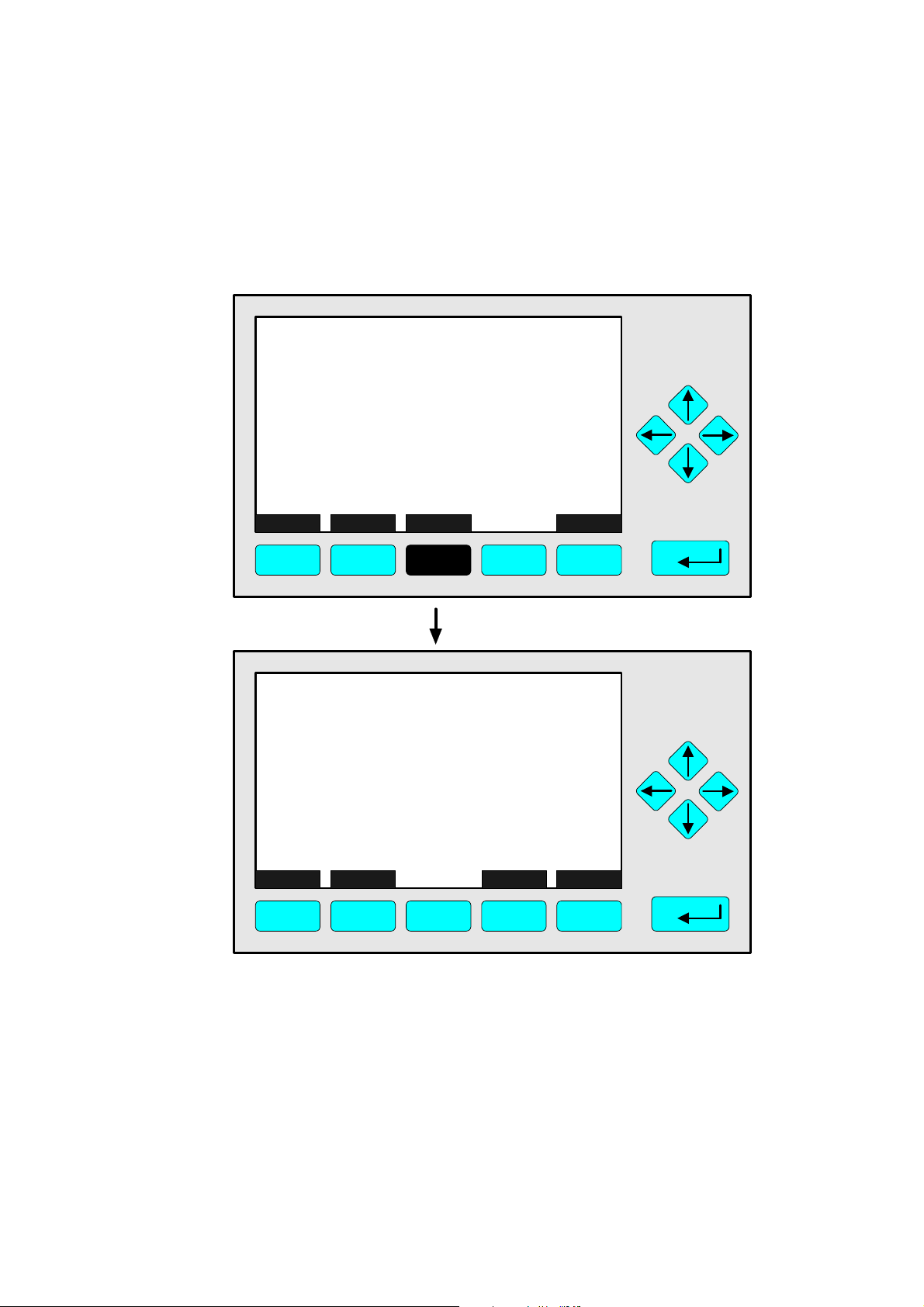

3.6 Entering/Changing of Variables

ENTER Key

♦ If you will press this key in a line of variables, the parameter will be displayed white on

black and can be changed. After you will have set up a new value, you can confirm it by

pressing the ENTER key again.

↑↑ -key / ↓↓ -key

♦ Function will depend on the variable selected: - Changing of the parameter values

- Scrolling among variables selected

- Changing of digits or characters

♦ Numbers consisting of several digits will increase/decrease totally, not digit by digit.

←← -key / →→ -key

♦ Selection of digits within a parameter.

♦ For some variables you can change the quantity of digits or characters.

3 - 4

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 15

3 Display and Keyboard

3.7 The STATUS Key

From the single component display or from the main menu you can change with the F2

key (STATUS) to the menu "Current measurement parameters":

CLD

Current measurement parameters

Analyzer gas measured: NOx

Measurement range number: 3

Range change control: LOCAL

Linearization mode: Disabled

Analyzer operational state: STANDBY

Analyzer alarm state: NORMAL

Alarms reported: FAILURE

HOME ESCAPE MORE INFO

F1 F2 F3 F4 F5

CLD

Current measurement parameters

Response time: 3.0 s

Bypass flow: 1100 ml/min

Capillary pressure: 340 hPa

Detector temperature: 0.5 C

95.0 ppm

95.0 ppm

HOME ESCAPE MORE INFO

F1 F2 F3 F4 F5

In the menu "Current measurement parameters" you can control the status of the CLD

analyzer module. With the F3 key (MORE) you can change to a further menu page of this

menu. With the F2 key (ESCAPE) you can always go back to the main menu. From the

second menu page you can return to the first with the F4 key (MORE) or the ←← -key.

In the menu "Current measurement parameters" you will only find status informations. You

cannot change the setups there. If you want to modify some parameters, you have to

change to the menu "Basic Controls" (see chapter 4) or to the menu "Analyzer module set

up" (see chapter 5.1) resp. "Expert analyzer controls" (see chapter 5.5).

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

3 - 5

Page 16

3 - 6

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 17

4 Basic Controls

In the chapter "Basic Controls" you will find the most important functions to set up your

CLD analyzer module via an NGA front panel:

1) Measurement p. 4 - 3pp (Chapter 4.1.1 and 4.1.2, p. 4-3 to 4-6, are only important

for systems with several channels.)

2) Calibration p. 4 - 21pp

All steps are figured with detailed illustrations and operation instructions. In the left column

you can see display and keyboard of the NGA front panel. In the right column you can

read the instructions and notes. All instructions will begin with any single component

display and will end with the corresponding single component display after the setups are

done. The keys you have to press are illustrated in black. The instructions are completed

with notes and further informations.

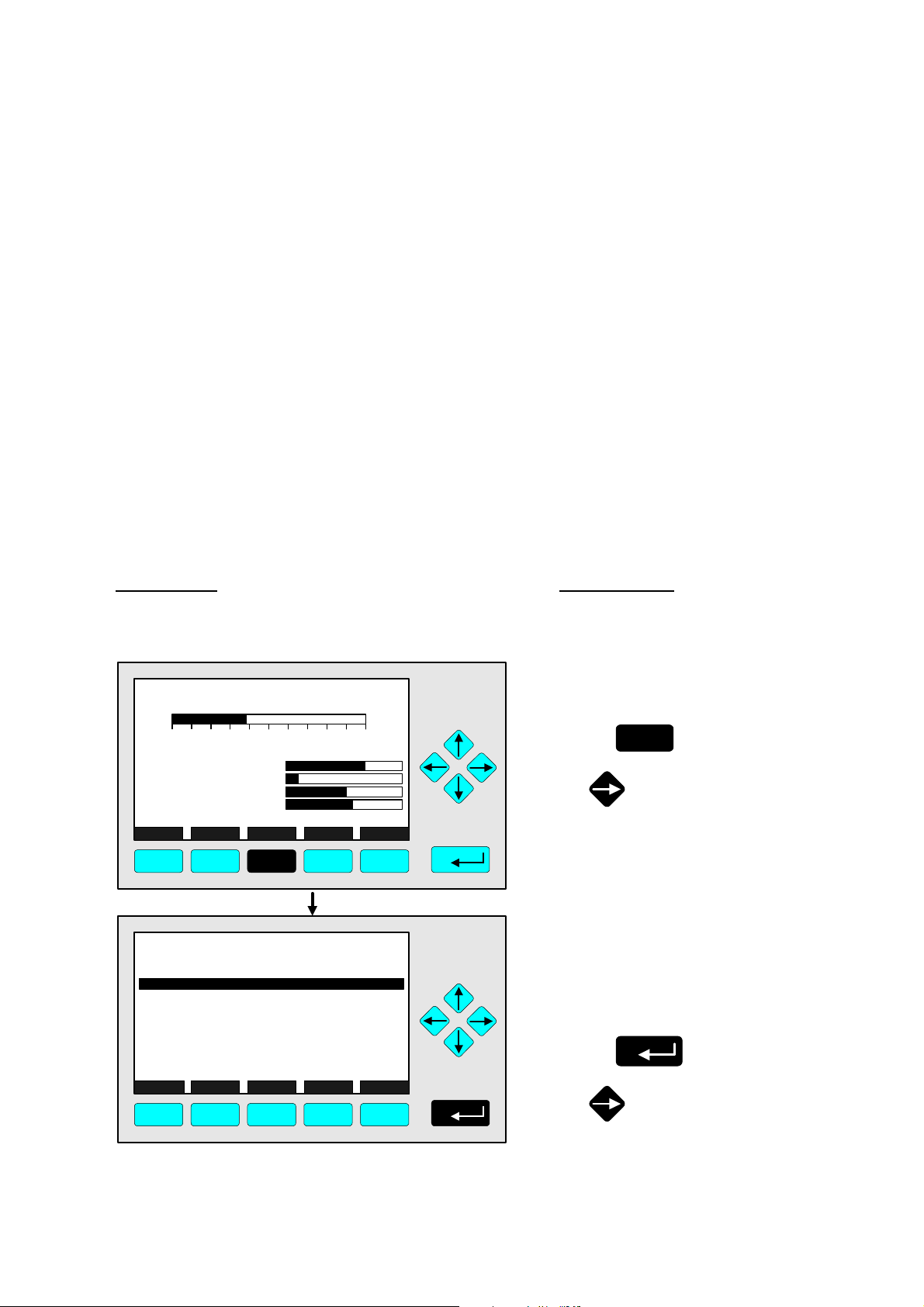

Example: You want to change from the single component display of NOx to the main menu

• Picture one shows the starting situation: single component display of NO

.

x

• If you press the F3 key you will change to menu page shown in picture 2: Main Menu.

Left column: Right column:

LCD and keyboard Instructions and notes

CLD

95.00 ppm NOx

0 250

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

CLD

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

F1 F2 F3 F4 F5

Range: 4

340 hPa

0.5 C

51.5 C

360 C

95.0 ppm

Main Menu

⇒ ⇒ Change to the

Main Menu

F3

Press

or

⇒ ⇒ Next instruction

or step,

here e.g.:

Change to the

Basic Controls:

Press

or

90003479(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 1

Page 18

4 - 2

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 19

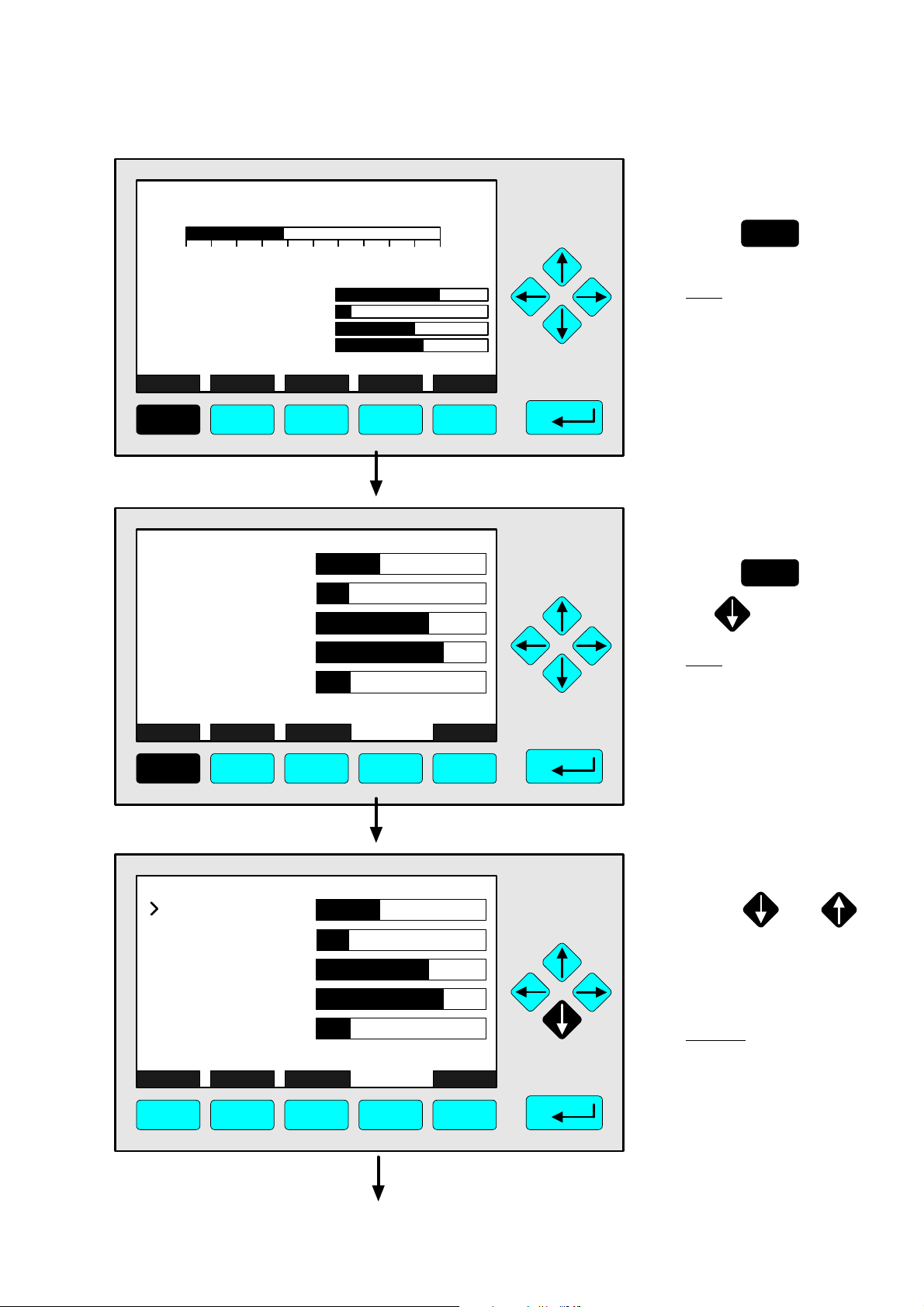

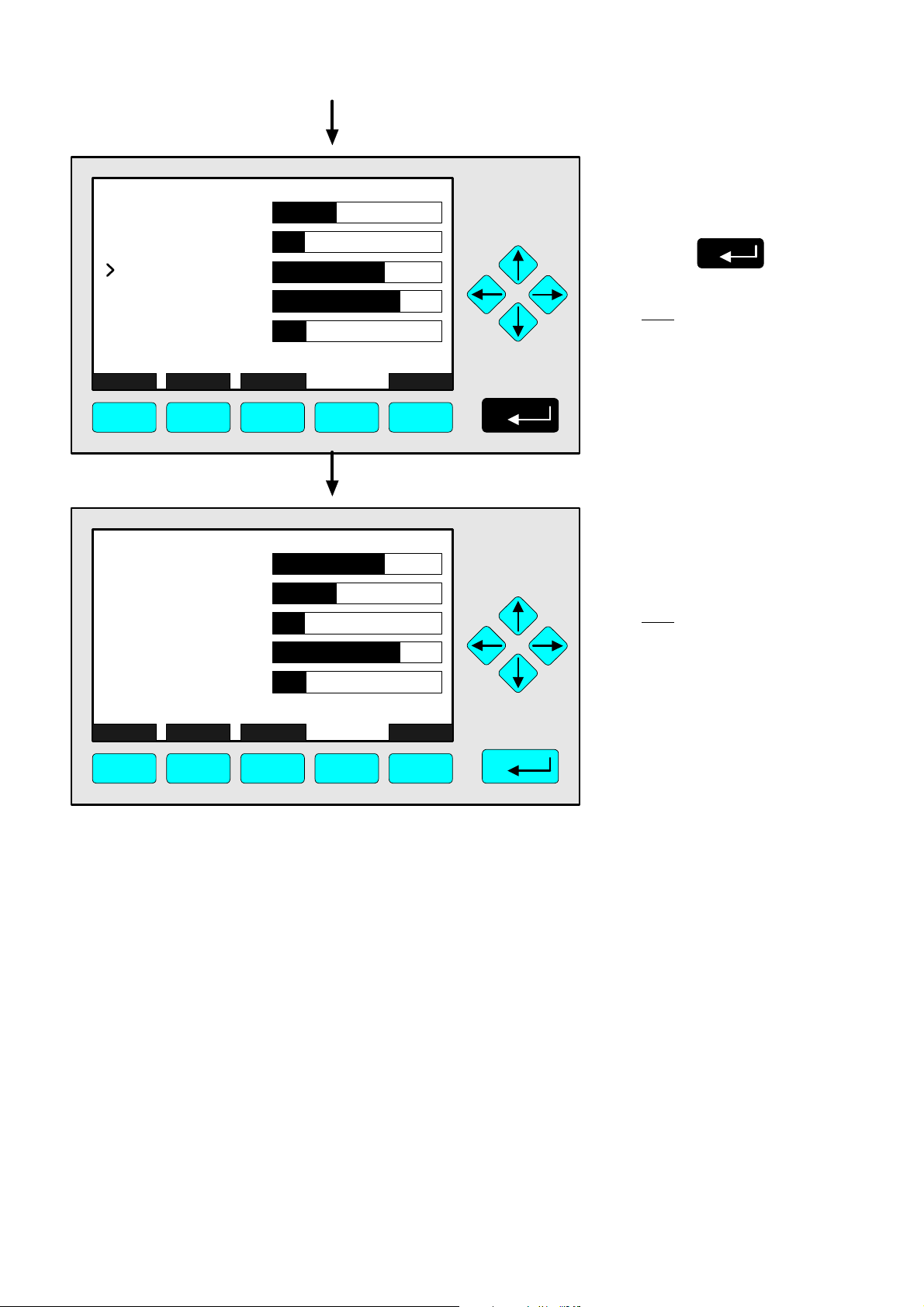

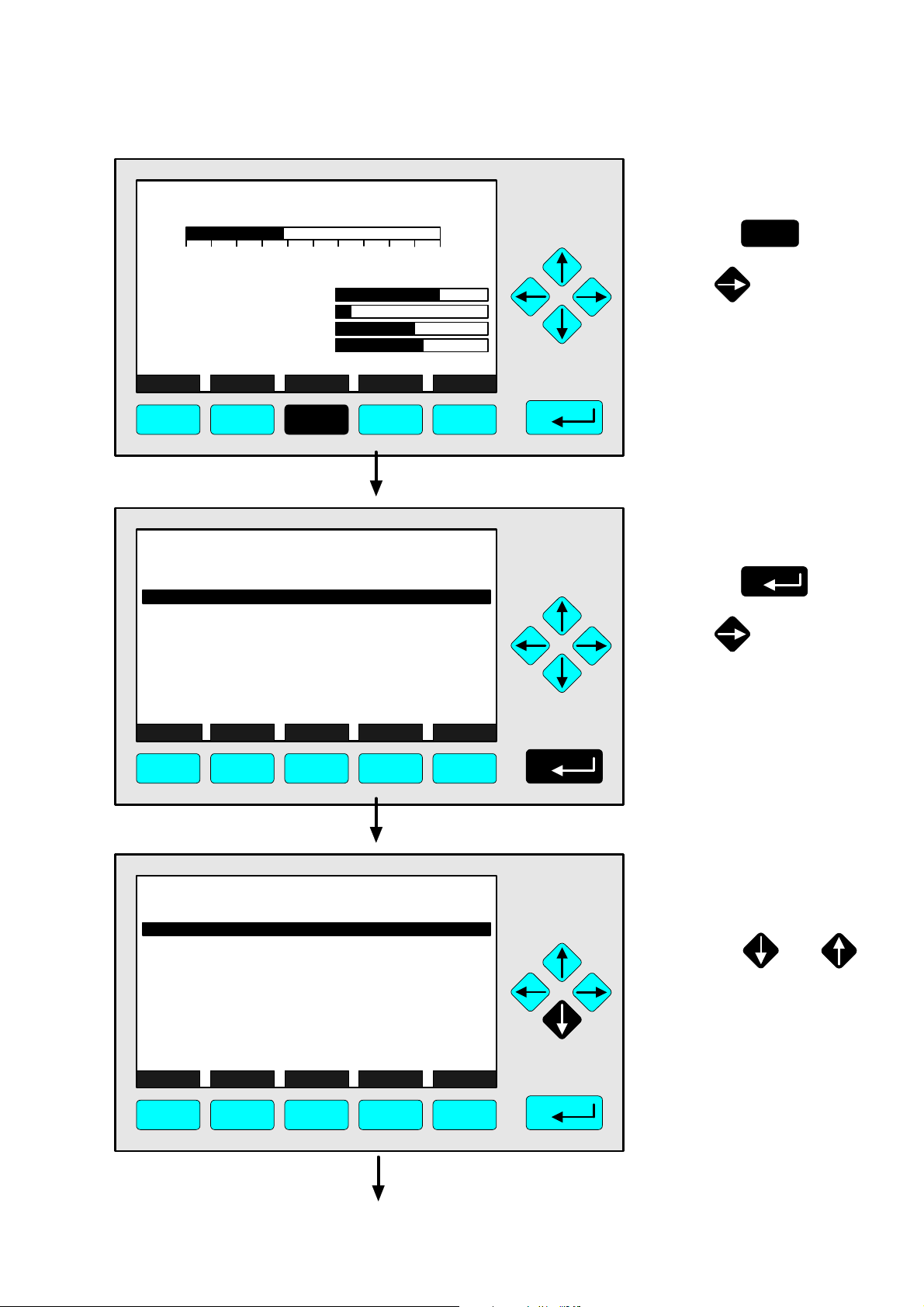

4.1.1 Measurement - Multi Component Display:

CLD

95.00 ppm NOx

0 250

Range: 4

Change of Channel

⇒ ⇒ Change to the multi

component display

F1

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

CLD

95.00

45.00

333.0

150.0

20.00

SELECT STATUS TAGS OFF

F1 F2 F3 F4 F5

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

340 hPa

0.5 C

51.5 C

360 C

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

INFO

Note:

You can change to the

multi component display

from each single

component display.

⇒ ⇒ Enable the selecting:

">"

F1

Press

or

Note:

If no channels of other

analyzer modules are

combined to the CLD,

only the bargraph of the

CLD module will be displayed.

Then, a change of channel

will not be possible !

CLD

95.00

45.00

333.0

150.0

20.00

SELECT STATUS TAGS OFF

F1 F2 F3 F4 F5

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

INFO

NGA 2000

⇒ ⇒ Select any channel

Press or

as often as necessary to

put the > - mark into the

selected line.

Example:

Change from

NOX (CLD) to

CO (MLT channel 1)

4 - 3

Page 20

CLD

95.00

45.00

333.0

150.0

20.00

CLD

ppm NOx

MLT25/CH1/R2

ppm CO

MLT25/CH2/R2

ppm SO2

MLT25/CH3/R2

ppm NO

MLT25/CH4/R2

%O2

⇒ ⇒ Change to the single

component display

of the channel

selected

F1

Press

SELECT STATUS TAGS OFF

INFO

F1 F2 F3 F4 F5

MLT25/CH1/R2

45.00 ppm CO

0 250

Temperature:

Function Control:

Maintenance Request:

Failure:

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

Range: 2

25.0 C

No

No

No

⇒ ⇒ Single component

display of the

channel selected

will appear

4 - 4

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 21

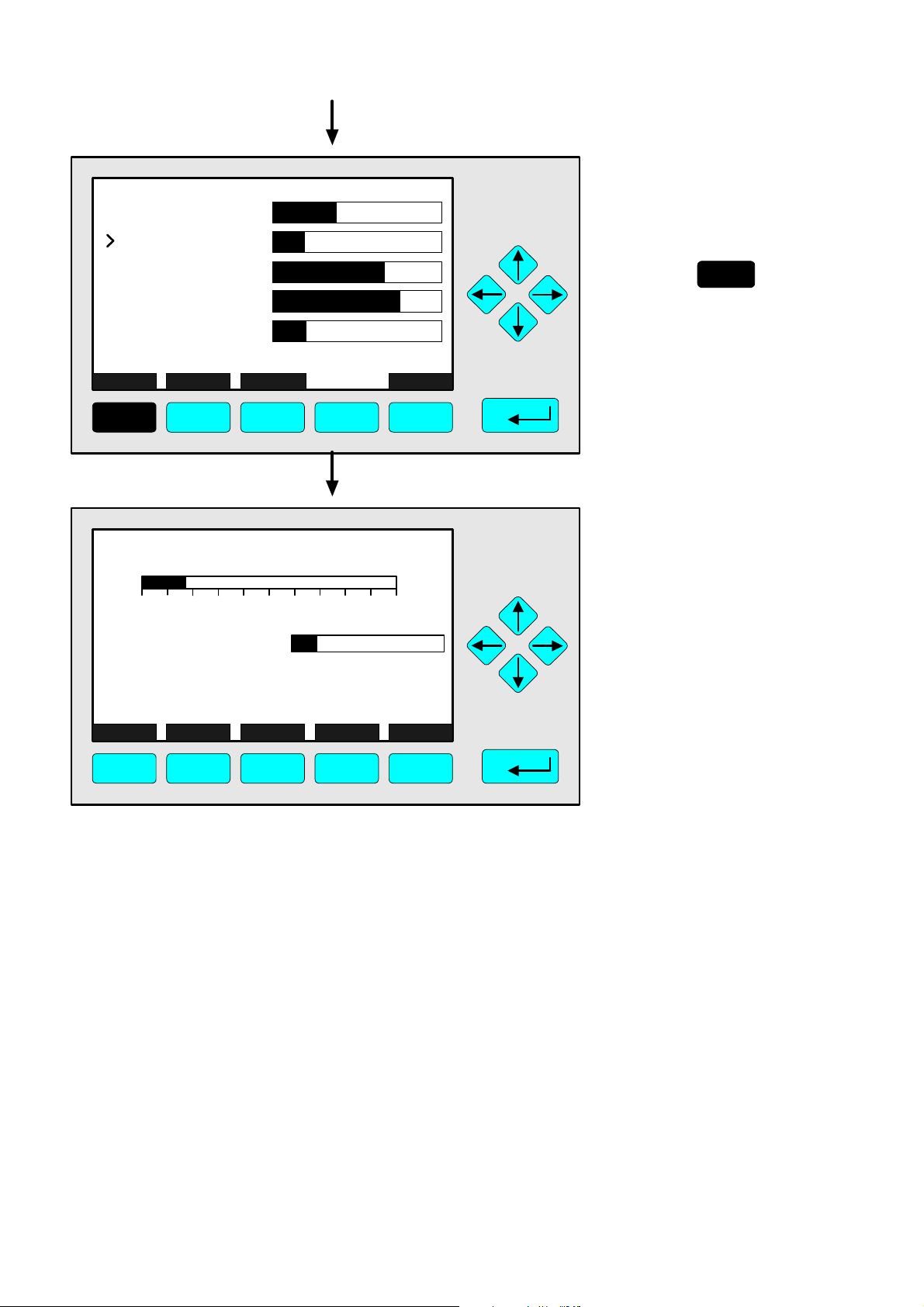

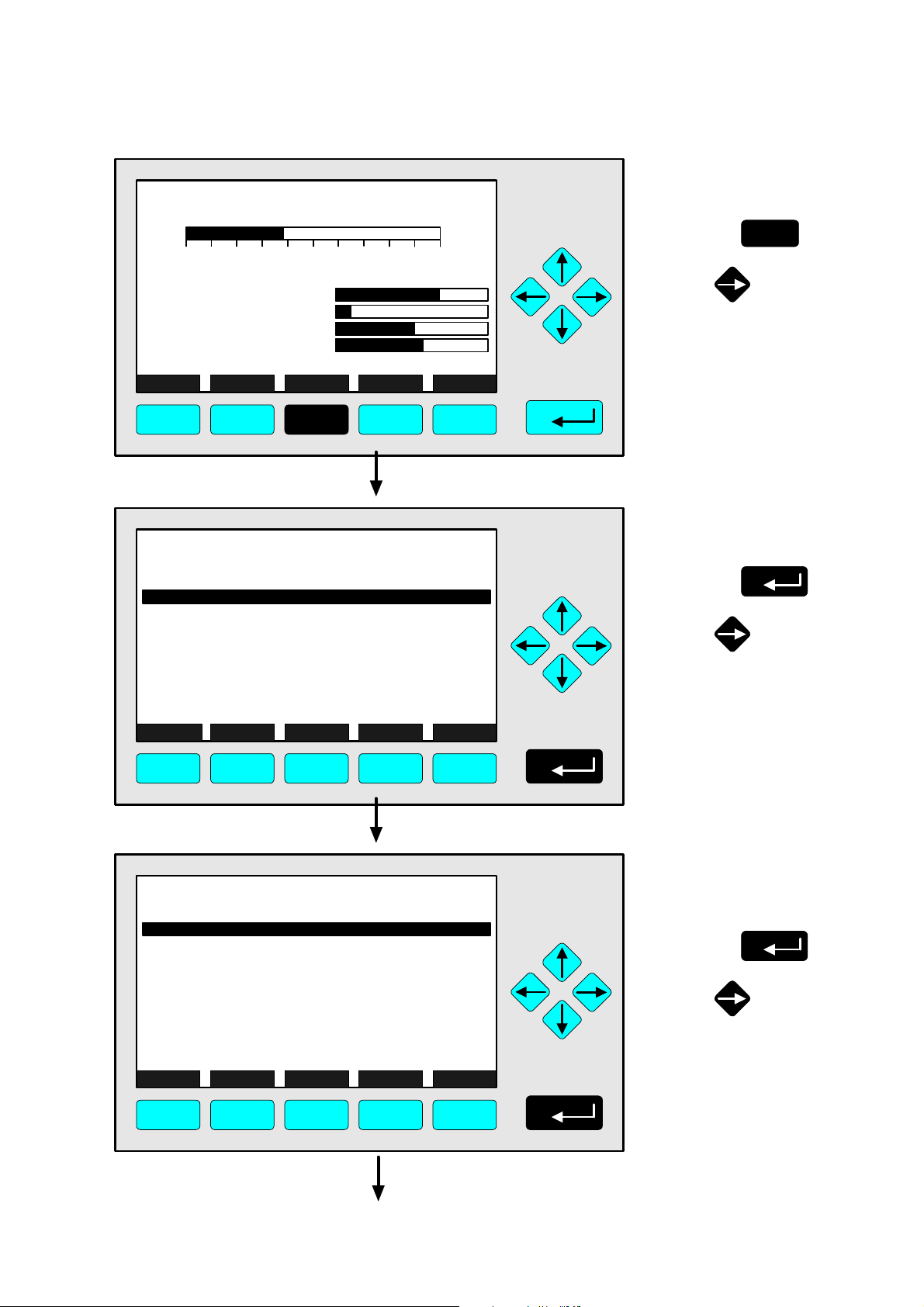

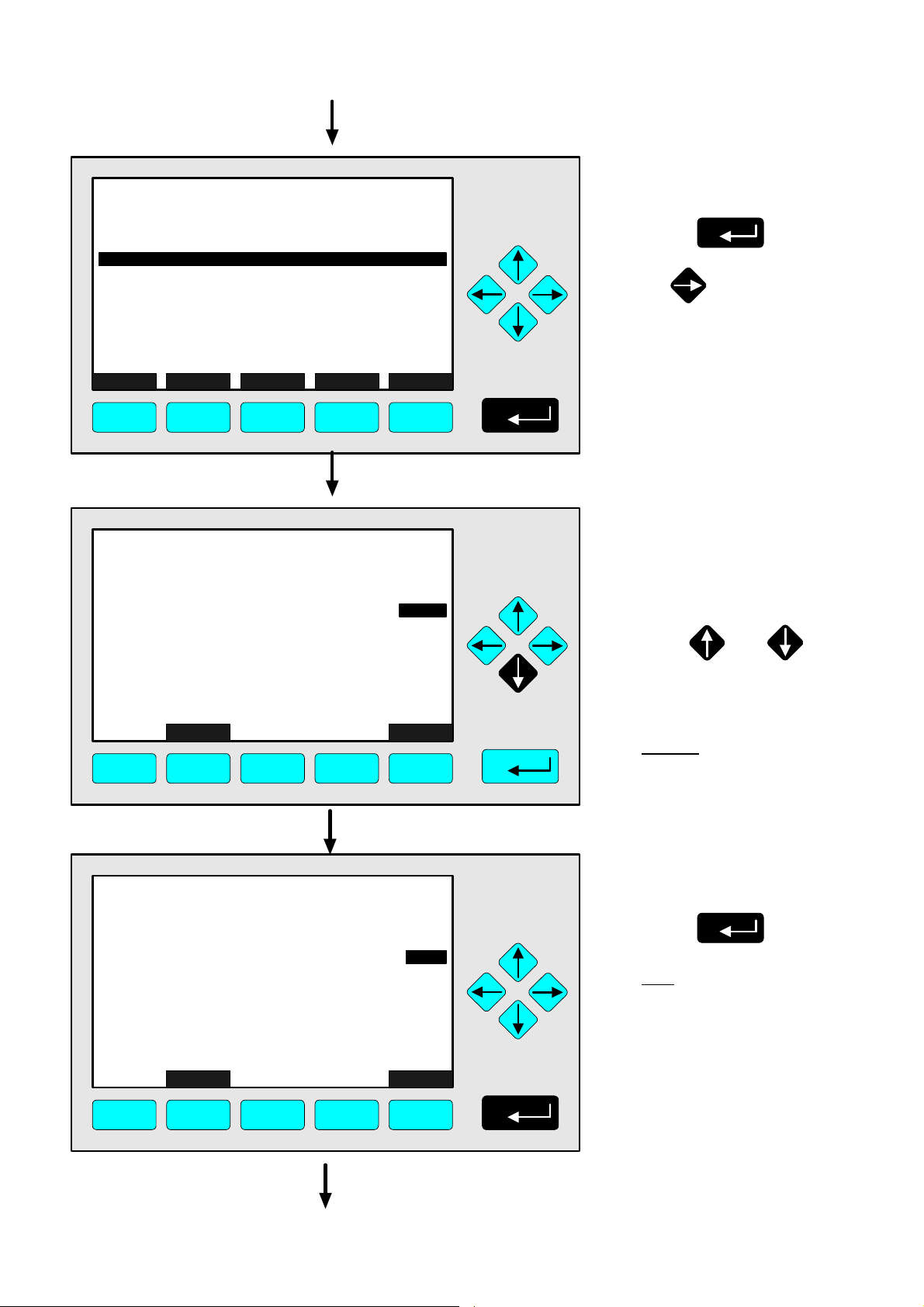

4.1.2 Measurement - Multi Component Display:

CLD

95.00 ppm NOx

0 250

Range: 4

Sequence setup

⇒ ⇒ Change to the multi

component display

F1

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

CLD

95.00

45.00

333.0

150.0

20.00

SELECT STATUS TAGS OFF

F1 F2 F3 F4 F5

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

340 hPa

0.5 C

51.5 C

360 C

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

INFO

⇒ ⇒ Enable the selecting:

">"

F1

Press

or

Note:

If no channels of other

analyzer modules are

combined to the CLD,

only the bargraph of the

CLD module will be displayed.

Then, the sequence setup

will not be possible !

CLD

95.00

45.00

333.0

150.0

20.00

SELECT STATUS TAGS OFF

F1 F2 F3 F4 F5

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

INFO

NGA 2000

⇒ ⇒ Select the channel

for position one

Press or

as often as necessary to

put the > - mark into the

selected line.

Example:

MLT channel 2 (SO2) shall

appear at position one of the

multi component display.

4 - 5

Page 22

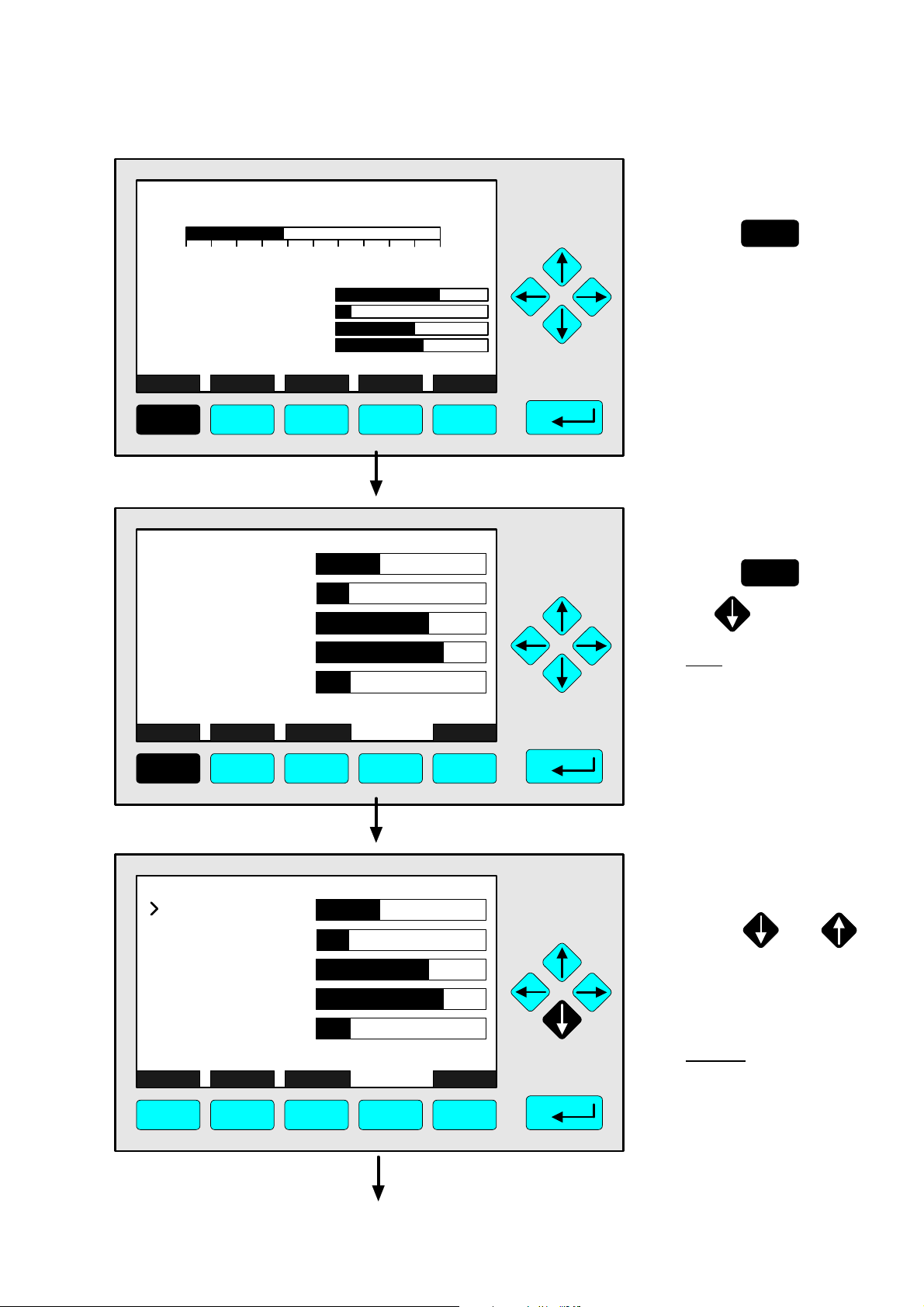

CLD

95.00

45.00

333.0

150.0

20.00

SELECT STATUS TAGS OFF

F1 F2 F3 F4 F5

MLT25/CH2/R2

333.0

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

MLT25/CH2/R2

95.00

45.00

150.0

20.00

SELECT STATUS TAGS OFF

MLT25/CH1/R2

MLT25/CH3/R2

MLT25/CH4/R2

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

ppm SO2

CLD

ppm NOx

ppm CO

ppm NO

%O2

INFO

INFO

⇒ ⇒ Assignation of the

channel selected to

position one

Press

Note:

The channel selected will

appear at position one.

All the other channels will

automatically appear one

line below their last position.

⇒ ⇒ Multi component

display will appear

with the changed

sequence

Note:

Now, you can change

to any available single

component display.

The method is described in

the last chapter (4.1.1).

F1 F2 F3 F4 F5

4 - 6

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 23

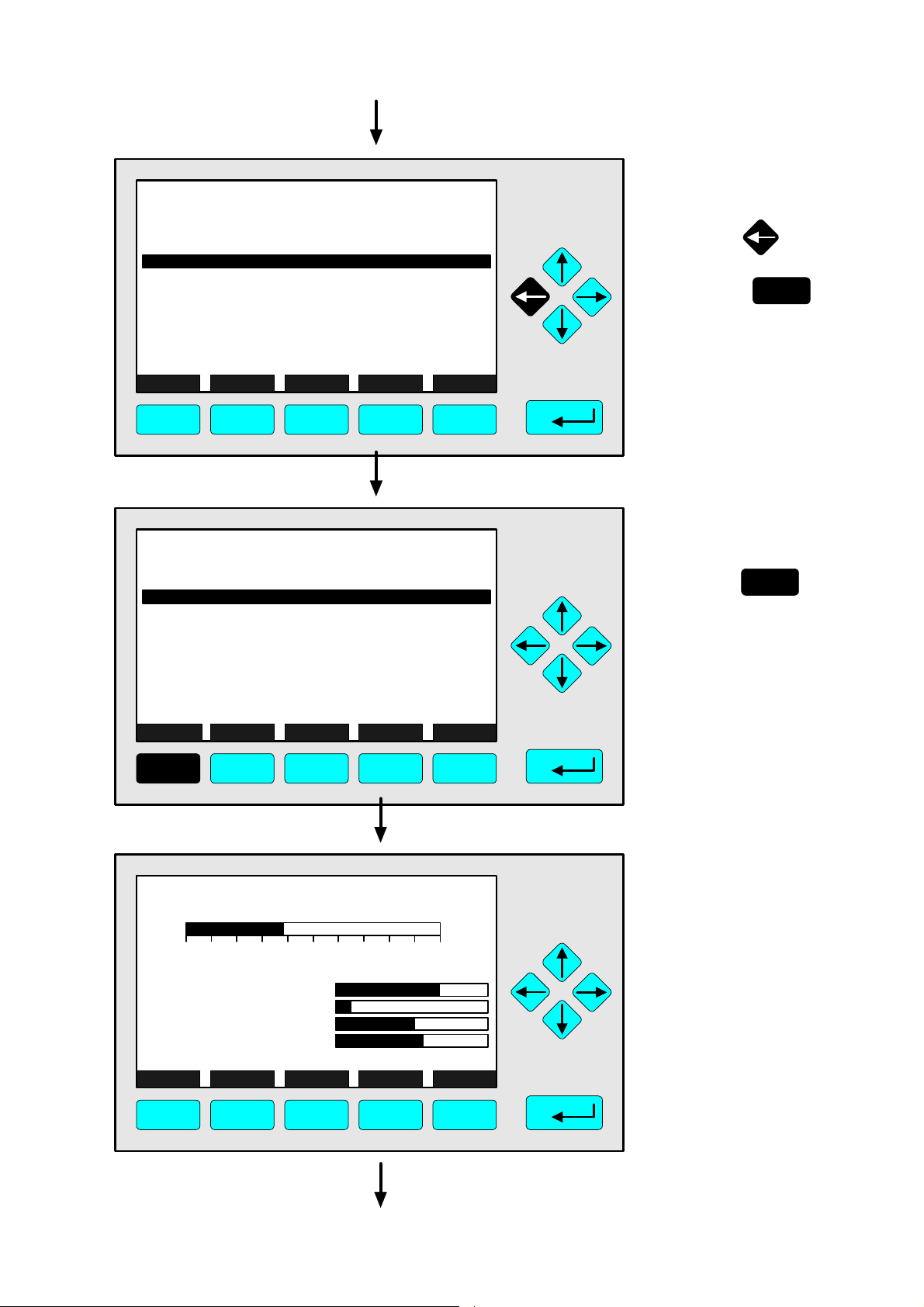

CLD

95.00 ppm NOx

0 250

Range: 4

4.1.3 Measurement - Range Setting

⇒ ⇒ Change to the

main menu

F3

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

or

⇒ ⇒ Change to the

basic controls

Press

or

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Choose the

measurement

range number

Press

or

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 7

Page 24

CLD

Basic Controls

Measurement range number:

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

4

ESCAPE INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number:

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

4

ESCAPE INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Select the

range number

4

Press or

as often as necessary

to select another range

number.

Example:

Change from

range 4 (250 ppm) to

range 3 (100 ppm)

⇒ ⇒ Confirm the

range selected

3

Press

Note:

If you don't want to set the

new range number, you

can reactivate the former

selection:

Press F2 (ESCAPE) and

confirm it with ENTER.

CLD

Basic Controls

Measurement range number: 3

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

F1 F2 F3 F4 F5

4 - 8

95.0 ppm

NGA 2000

⇒ ⇒ Change to the

main menu

Press or

F1

2 times

Note:

The range upper limit (line 2)

of the range selected will be

set up automatically after the

range setting is confirmed.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 25

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

F1 F2 F3 F4 F5

4.1.3 Measurement - Range Setting

⇒ ⇒ Change to the single

component display

F1

Press

CLD

95.00 ppm NOx

0 100

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

Range: 3

340 hPa

0.5 C

51.5 C

360 C

⇒ ⇒ Single component

display will appear

with the new range

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 9

Page 26

4 - 10

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 27

4.1.4 Measurement - Range and Functional Control

CLD

95.00 ppm NOx

0 250

Range: 4

⇒ ⇒ Change to the

main menu

F3

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

or

⇒ ⇒ Cahnge to the

basic controls

Press

or

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the

line "Range and

functional control"

Press or

as often as necessary

until the line "Range and

functional control" will

appear white on black.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 11

Page 28

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control:

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

LOCAL

ESCAPE INFO

95.0 ppm

LOCAL

F1 F2 F3 F4 F5

⇒ ⇒ Choose the

parameter

Press

or

⇒ ⇒ Set up the range

and functional

control you want

++ Pay attention to

the note at p. 4-14 !

Press or

as often as necessary

to select the parameter

you want.

Options:

LOCAL, AUTO, REMOTE

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control:

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

LOCAL

ESCAPE INFO

F1 F2 F3 F4 F5

4 - 12

95.0 ppm

AUTO

NGA 2000

⇒ ⇒ Confirm the

parameter selected

Press

Note:

If you don't want to set the

new parameter, you can

reactivate the former

selection:

Press F2 (ESCAPE) and

confirm it with ENTER.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 29

4.1.4 Measurement - Range and Functional Control

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: AUTO

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

F1 F2 F3 F4 F5

95.0 ppm

⇒ ⇒ Change to the

main menu

Press or

F1

2 times

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

95.00 ppm NOx

0 250

Range: 4

⇒ ⇒ Change to the single

component display

F1

Press

⇒ ⇒ Single component

display will appear

after the changing

of the range and

functional control

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 13

Page 30

⇒ ⇒ Range and functional control – Options:

• LOCAL:

The platform will be controlled via the display.

• AUTO:

The range will be selected automatically ("auto range"). This

function will only be available with an I/O board with 3 alarms

(PIN 70 656 193), because the auto ranging parameters are

located on the I/O board (see its own manual)!

• REMOTE:

The range selection will be controlled by digital inputs, e.g. via

a DIO board or I/O board with 3 alarms.

4 - 14

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 31

4.1.5 Measurement - Enable/Disable Ozonator Power

CLD

95.00 ppm NOx

0 250

Range: 4

⇒ ⇒ Change to the

main menu

F3

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

or

⇒ ⇒ Change to the

basic controls

Press

or

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the line

"Ozonator power"

Press or

as often as necessary

until the line "Ozonator

power" will appear white

on black.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 15

Page 32

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

Enabled

ESCAPE INFO

95.0 ppm

Enabled

⇒ ⇒ Choose the

parameter

Press

or

⇒ ⇒ Select the ozonator

power status you

want

Press or

to select "Enabled" or

"Disabled".

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

Enabled

ESCAPE INFO

95.0 ppm

Disabled

F1 F2 F3 F4 F5

⇒ ⇒ Confirm the setup

Press

Note:

If you don't want to confirm

the new selection, you

can reactivate the former

one:

Press F2 (ESCAPE) and

confirm it with ENTER.

4 - 16

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 33

4.1.5 Measurement - Enable/Disable Ozonator Power

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: OFF - DISABLED

Ozonator power: Disabled

HOME NO/NOx ZERO SPAN INFO

F1 F2 F3 F4 F5

95.0 ppm

⇒ ⇒ Change to the

main menu

Press or

F1

2 times

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

95.00 ppm NOx

0 250

Range: 4

⇒ ⇒ Change to the single

component display

F1

Press

⇒ ⇒ Single component

display will appear

after the setup of

the ozonator power

status

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 17

Page 34

4 - 18

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 35

4.1.6 Measurement - Measurement Mode: NO ↔↔ NO

CLD

95.00 ppm NOx

0 250

Range: 4

x

⇒ ⇒ Change to the

main menu

F3

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

or

⇒ ⇒ Change to the

basic controls

Press

or

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Select NO ↔↔ NO

x

F2

Press

to select the

measurement mode

you want.

The current selection will

be displayed in the line

"Measurement mode".

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 19

Page 36

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NO

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

13.8 ppm

⇒ ⇒ Change to the

main menu

Press or

F1

2 times

⇒ ⇒ Change to the single

component display

F1

Press

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

F1 F2 F3 F4 F5

CLD

13.75 ppm NO

0 250

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

Range: 4

340 hPa

0.5 C

51.5 C

360 C

⇒ ⇒ Single component

display will appear

with the measurement mode selected

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

4 - 20

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 37

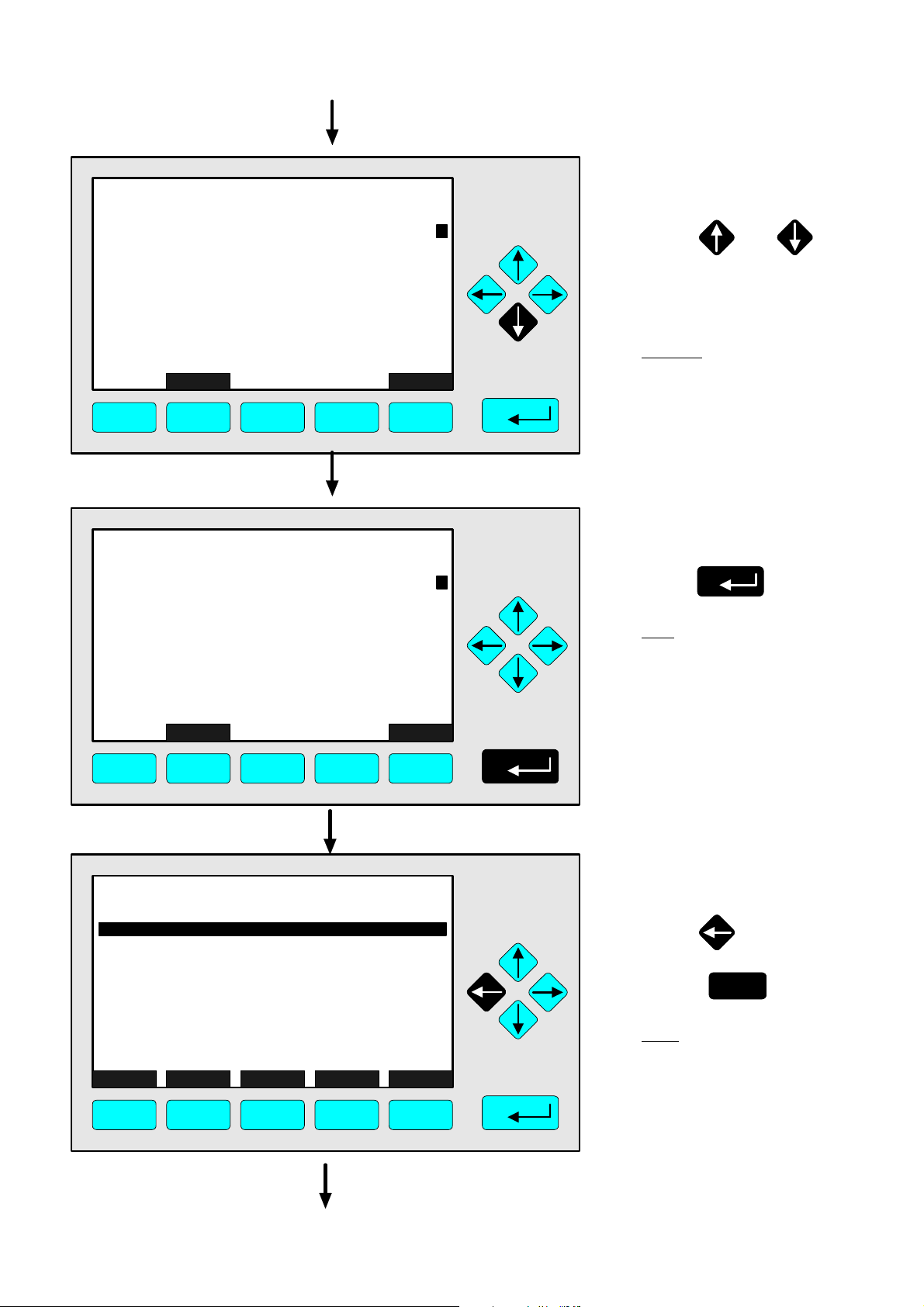

CLD

95.00 ppm NOx

0 250

Range: 4

4.2.1 Calibration - Zeroing

⇒ ⇒ Change to the

main menu

F3

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

or

⇒ ⇒ Change to the

basic controls

Press

or

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the

submenu

"Analyzer zero"

F3

Press

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 21

Page 38

CLD

Analyzer zero

Are you sure?

You must have zero gas flowing through the analyzer.

This control does NOT control any auto-calibration

module bound to this analyzer!

If you are sure, press ZERO again now.

Press the left arrow key when you are done.

Calibration status: READY

Error message for last zero: CAL OK

HOME ESCAPE ZERO INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

Analyzer zero

Are you sure?

You must have zero gas flowing through the analyzer.

This control does NOT control any auto-calibration

module bound to this analyzer!

If you are sure, press ZERO again now.

Press the left arrow key when you are done.

Calibration status: ZEROING - WAIT

Error message for last zero: CAL OK

ABORT

13.7 ppm

⇒ ⇒ Start Zeroing

++ Pay attention to

the note at p. 4-23 !

F3

Press

Caution:

You have to

• flow enough zero gas

through the analyzer

• look for a stabilized signal

before starting the zero gas

calibration.

Note:

You can go back to the

menu "Basic Controls"

with the F2 key.

⇒ ⇒ Zero gas calibration

is running

Note:

You can abort the

procedure at any time

with the F2 key.

F1 F2 F3 F4 F5

CLD

Analyzer zero

Are you sure?

You must have zero gas flowing through the analyzer.

This control does NOT control any auto-calibration

module bound to this analyzer!

If you are sure, press ZERO again now.

Press the left arrow key when you are done.

Calibration status: READY

Error message for last zero: CAL OK

HOME ESCAPE ZERO INFO

0.057 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the

main menu

F1

Press

Alternative:

If you want to continue with

the span gas calibration

after the zeroing is done,

you can go back to the

basic controls with the F2

key or the ←← -key.

(The spanning will be

described in the next

chapter: 4.2.2).

4 - 22

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 39

CLD

Main Menu

0.017 ppm

4.2.1 Calibration - Zeroing

⇒ ⇒ Change to the

single component

display

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

F1 F2 F3 F4 F5

CLD

0.017 ppm NOx

0 250

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

Range: 4

340 hPa

0.5 C

51.5 C

360 C

F1

Press

⇒ ⇒ Single component

display will appear

after the zero gas

calibration

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

⇒ ⇒ Notes for zero gas calibration:

• You can calibrate all ranges together or each range separately

with zero gas.

• You have to set up the parameter you want in the menu

"Calibration Parameters" (see chapter 5.1.2 S. 5-9).

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 23

Page 40

4 - 24

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 41

CLD

95.00 ppm NOx

0 250

Range: 4

4.2.2 Calibration - Spanning

⇒ ⇒ Change to the

main menu

F3

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

or

⇒ ⇒ Change to the

basic controls

Press

or

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the

submenu

"Analyzer span"

F4

Press

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 25

Page 42

CLD

Analyzer span

Are you sure?

You must have span gas flowing through the analyzer.

This control does NOT control any auto-calibration

module bound to this analyzer!

If you are sure, press SPAN again now.

Press the left arrow key when you are done.

Calibration status: READY

Error message for last span: CAL OK

HOME ESCAPE SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

Analyzer span

Are you sure?

You must have span gas flowing through the analyzer.

This control does NOT control any auto-calibration

module bound to this analyzer!

If you are sure, press SPAN again now.

Press the left arrow key when you are done.

Calibration status: SPANNING - WAIT

Error message for last span: CAL OK

ABORT

95.0 ppm

⇒ ⇒ Start Spanning

++ Pay attention to

the note at p. 4-27 !

F4

Press

Caution:

You have to

• flow enough span gas

through the analyzer

• look for a stable signal

before starting the span gas

calibration.

Note:

You can go back to the

menu "Basic Controls"

with the F2 key.

⇒ ⇒ Span gas calibration

is running

Note:

You can abort the

procedure at any time

with the F2 key.

F1 F2 F3 F4 F5

CLD

Analyzer span

Are you sure?

You must have span gas flowing through the analyzer.

This control does NOT control any auto-calibration

module bound to this analyzer!

If you are sure, press SPAN again now.

Press the left arrow key when you are done.

Calibration status: READY

Error message for last span: CAL OK

HOME ESCAPE SPAN INFO

225.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the

main menu

F1

Press

Alternative:

If you want to continue with

further setups of the basic

controls, you can go back to

the corresponding menu with

the F2 key or the ←← -key.

4 - 26

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 43

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

F1 F2 F3 F4 F5

225.0 ppm

4.2.2 Calibration - Spanning

⇒ ⇒ Change to the single

component display

F1

Press

⇒ ⇒ Single component

CLD

225.00 ppm NOx

display will appear

after the span gas

calibration

0 250

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

F1 F2 F3 F4 F5

Range: 4

340 hPa

0.5 C

51.5 C

360 C

⇒ ⇒ Notes for the span gas calibration:

• You can calibrate all ranges together or each range separately with span gas. You have to set up

the parameter you want in the menu "Calibration Parameters" (see chapter 5.1.2 p. 5-9).

• If it will not be possible to calibrate all ranges with the same span gas, you have to calibrate each

range separately!

• The desired value of span gas has to be (!) a value between 10% and 110% of each end of range.

Otherwise, no calibration will be running.

Example:

• End of range 1: 50 ppm → Potential span gas setpoints: 5 – 55 ppm

• End of range 2: 250 ppm → Potential span gas setpoints: 25 – 275 ppm

• End of range 3: 1000 ppm → Potential span gas setpoints: 100 – 1100 ppm

• End of range 4: 2500 ppm → Potential span gas setpoints: 250 – 2750 ppm

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 27

Page 44

4 - 28

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 45

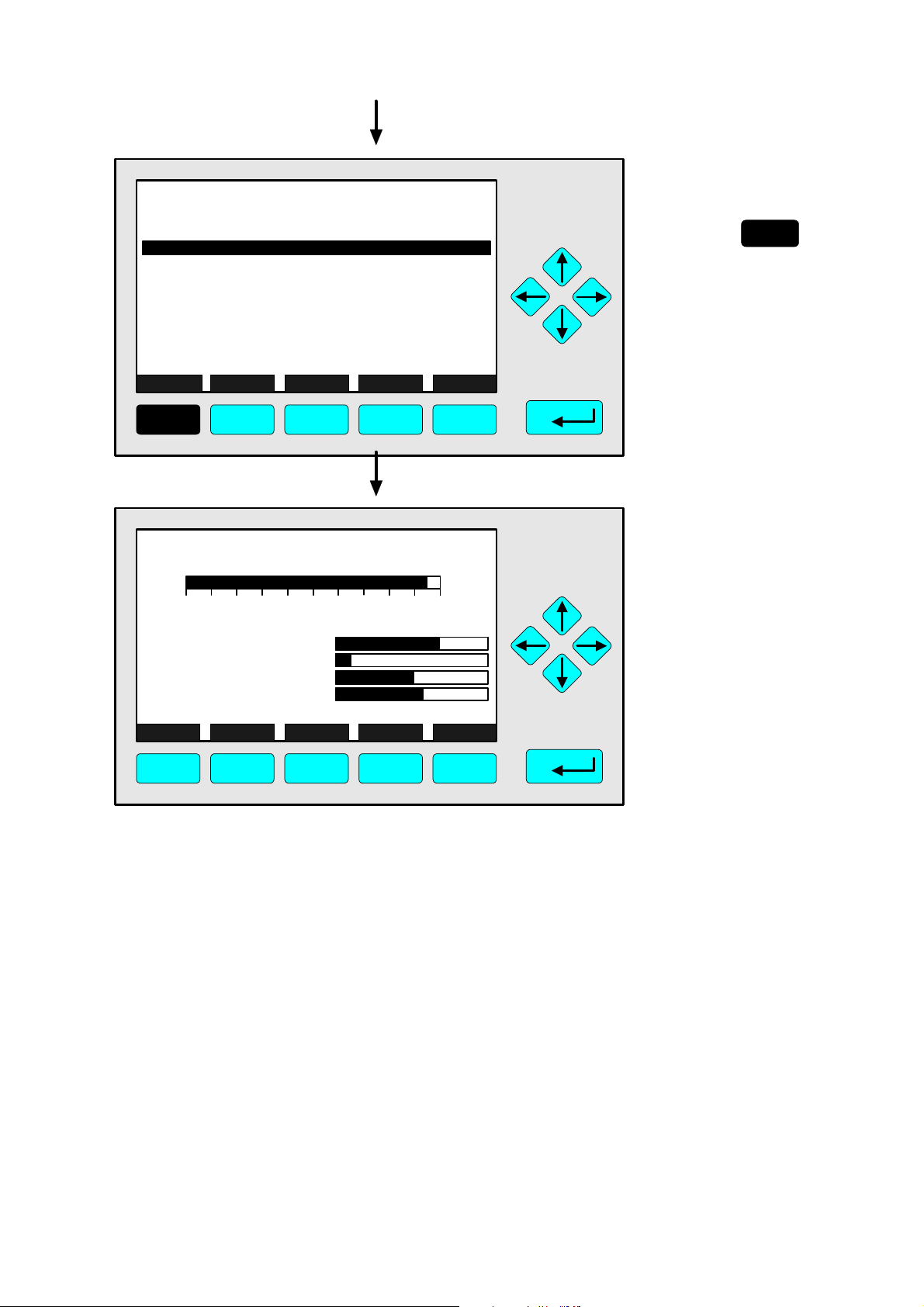

CLD

95.00 ppm NOx

0 250

Range: 4

4.2.3 Calibration - If It Won´t Calibrate

⇒ ⇒ Change to the

main menu

F3

Press

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

or

⇒ ⇒ Change to the

basic controls

Press

or

F1 F2 F3 F4 F5

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the line

"If it won´t calibrate..."

Press or

as often as necessary

until the line "If it won´t

calibrate..." will appear

white on black.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 29

Page 46

CLD

Basic Controls

Measurement range number: 4

Range upper limit: 250.0 ppm

Range and functional control: LOCAL

Ranges with valid calibration: 4

Calibration status: READY

If it won´t calibrate...

Status: STANDBY

Measurement mode: NOx

Ozonator status: On

Ozonator power: Enabled

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

F1 F2 F3 F4 F5

CLD

Check that you are flowing the correct gas, and the

gas concentration is what it is supposed to be.

Make sure that the reading is stable before starting.

If you have changed the range full scale value, or any

linearizer coefficients, or enabled or disabled it,

or done anything else that would affect how it

measures the gas, you may have made it hard for the

algorithm to get to a calibration.

In this case, manually adjust the coefficients

until the readings are close to correct, and try again.

HOME ESCAPE INFO

If it won´t calibrate...

95.0 ppm

⇒ ⇒ Change to the

menu page "If it

won´t calibrate..."

Press

Notes:

• Follow the instructions

on the screen

to calibrate succesfully!

• If you have further

questions, contact

your customer service,

please!

⇒ ⇒ Change to the

main menu

F1

Press

Alternative:

If you want to continue with

further setups of the basic

controls, you can go back to

the corresponding menu with

the F2 key or the ←← -key.

F1 F2 F3 F4 F5

CLD

Main Menu

Basic controls...

Expert controls and set up...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

MEASURE STATUS NEXT LOCK INFO

95.0 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the single

component display

F1

Press

4 - 30

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 47

CLD

95.00 ppm NOx

4.2.3 Calibration - If It Won´t Calibrate

⇒ ⇒ Single component

display will appear

0 250

Sample press.:

Detector temperature:

Block temperature:

Converter temp.:

DISPLAY STATUS MENU NEXT INFO

Range: 4

340 hPa

0.5 C

51.5 C

360 C

F1 F2 F3 F4 F5

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

4 - 31

Page 48

4 - 32

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 49

5 Expert Controls and Set up

If you press the ENTER key or the →→ -key in the line "Expert controls and set up..." of the

"Main Menu" you will change to the following display:

CLD

Expert controls and set up

Expert analyzer controls...

Auxiliary module controls...

System set up...

Analyzer module set up...

Auxiliary module set up...

System calibration...

MAIN

F1 F2 F3 F4 F5

<<<

NEXT INFO

95.0 ppm

From the menu "Expert controls and set up" you can change to several submenus to set

up parameters for the measurement and calibration of your analyzer and analyzer module.

Besides you can set up the configuration for auxiliary modules. Which part of these menus

are important for you depends on the configuration of your NGA 2000 system.

In the following table you will find a short overview about the contents of the menus and

where you will find the description in this manual:

Menu Important Contents Chapter in this manual

Expert analyzer

controls...

Auxiliary module

controls...

⇒ Zero/Span calibration

⇒ Range settings

⇒ Ozonator power

⇒ Configuration of the SIO and of

the DIO's installed in a platform

∗ 5.5 p. 53 to 60

∗ 5.2 p. 29 to 44

or in an MLT analyzer

System set up...

⇒ Front panel control

⇒ Set up of the

∗ 5.4 p. 47 to 52

single component display

⇒ Display resolution

Analyzer module set up...

⇒ Measurement/Calibration

∗ 5.1 p. 3 to 28

parameters set up

⇒ Linearizer parameters set up

⇒ Sensor/Converter/Block

parameters set up and

optimization

Auxiliary module set up...

⇒ Set up for micro processor

∗ 5.3 p. 45

controlled auxiliary I/O modules

System calibration...

⇒ Zero gas and span gas

∗ See Supplement!

calibration of all channel

automatically

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

5 - 1

Page 50

Structure of chapter five:

At the begin of any chapter you will find the way to a certain submenu of the MLT software

starting from the line "Expert controls and set up" in the "Main Menu". The way will be

described with the software catchwords that you have to enter one after another to reach

the corresponding submenu. At the end of the catchword listing you will find the illustration

of the LCD screen. After that you can read the set up instructions and explanations.

Sometimes the illustration will be completed by sketches or further menu pictures.

Example: You want to set up the zero/span gas concentrations for all ranges of the

analyzer module.

Main Menu — Expert controls and set up

↓↓

Analyzer module set up

↓↓

Calibration gas list

↓↓

CLD

Calibration Gas List

Zero gas - range 1: 0.00 ppm

NO Span gas - range 1: 2.00 ppm

NOx Span gas - range 1: 2.00 ppm

Zero gas - range 2: 0.00 ppm

NO Span gas - range 2: 25.00 ppm

NOx Span gas - range 2: 25.00 ppm

Calibration...

HOME ESCAPE MORE INFO

F1 F2 F3 F4 F5

95.0 ppm

In the menu "Calibration Gas List" you can set up the desired zero and span gas values

for all ranges. On the first menu page you will find the parameters of range 1 and 2, on the

second page you will find the parameters of range 3 and 4. You can reach the second

menu page with the F3 key (MORE)...

Further explanations and instructions to set up the parameters will follow!

5 - 2

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 51

5.1 Analyzer Module Set up

Main Menu — Expert controls and set up

↓↓

Analyzer module set up

↓↓

CLD

Analyzer module set up

Calibration gas list...

Calibration parameters...

Gas measurement parameters...

Analyzer parameter list...

Physical measurement parameters...

Displayed parameters...

Analyzer tag: CLD

HOME ESCAPE INFO

F1 F2 F3 F4 F5

95.0 ppm

From the menu "Analyzer module set up" you can change to several submenus, where

you can set up the measurement and calibration parameters of the CLD analyzer module.

Besides, you can go to those submenus where you can set up the parameters of the

single component display.

Caution:

Normally, you will find "CLD" as analyzer module tag in the line "analyzer tag".

If the CLD module is part of an analyzer network: You have to change the configuration of the programmable digital inputs and analog outputs, if you change the

identification tag ! Because, the parameters of the module source will change ! So,

the relations will disappear !

Set up parameters:

♦ Select the menu line you want or the line of variables "Analyzer tag" with

the ↓↓ -key or the ↑↑ -key.

♦ Select the variable or change to the submenu with the ENTER key or the →→ -key.

♦ Select any digit with the ←← -key or the →→ -key and adjust a new value with

the ↑↑ -key or the ↓↓ -key;

Maximum of digits: 30

Options: alphabet (capital and small letters), umlauts, letters from different languages,

0, 1, 2, ..., 9, +, -, *, /, =, ?, !, %, $ and many others.

♦ Confirm the new value with the ENTER key or cancel and go back to the last value with

the F2 key.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

5 - 3

Page 52

5.1.1 Analyzer Module Set up

Calibration/Calibration Gas List

Main Menu — Expert controls and set up

Analyzer module set up

Calibration gas list

↓↓

↓↓

↓↓

CLD

Calibration Gas List

Zero gas - range 1: 0.00 ppm

NO Span gas - range 1: 2.00 ppm

NOx Span gas - range 1: 2.00 ppm

Zero gas - range 2: 0.00 ppm

NO Span gas - range 2: 25.00 ppm

NOx Span gas - range 2: 25.00 ppm

Calibration...

HOME ESCAPE MORE INFO

F1 F2 F3 F4 F5

95.0 ppm

In the menu "Calibration Gas List" you can set up the desired zero and span gas values

for all ranges. On the first menu page you will find the parameters of range 1 and 2, on the

second page you will find the parameters of range 3 and 4. You can reach the second

menu page with the F3 key (MORE).

Via the menu line "Calibration..." you can change to the menu "Zero/span calibration",

where you can start zeroing and spanning (see next page).

Set up parameters:

♦ Select the line of variables you want or the menu line "Calibration..." with

the ↑↑ -key or the ↓↓ -key.

♦ Select the parameter or change to the menu "Zero/span calibration" with

the ENTER key or the →→ -key.

♦ Select any digit with the ←← -key or the →→ -key and adjust a new value with

the ↑↑ -key or the ↓↓ -key.

Options zero gas: 0.00 ppm up to the end of range value

Options span gas: 0.00 ppm up to 120% of the end of range value

You can set up the end of range values

in the menu "Range Settings" (see 5.1.6 p. 5-16).

♦ Confirm the new value with the ENTER key or cancel and go back to the last value

with the F2 key.

5 - 4

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 53

Span gas calibration notes:

♦ The span gas setpoint of NO and NO

have to be the same value, because both

x

components will be calibrated simultaneously!

♦ You can calibrate all ranges together or each range separately with span gas. You have

to set up the parameter you want in the menu "Calibration Parameters" (see chapter 5.1.2

p. 5-9).

♦ If it will not be possible to calibrate all ranges with the same span gas, you have to

calibrate each range separately!

♦ The desired value of span gas has to be (!) a value between 10% and 110% of each end

of range. Otherwise, no calibration will be running:

• Example:

End of range 1: 50 ppm → Potential span gas setpoints: 5 – 55 ppm

End of range 2: 250 ppm → Potential span gas setpoints: 25 – 275 ppm

End of range 3: 1000 ppm → Potential span gas setpoints: 100 – 1100 ppm

End of range 4: 2500 ppm → Potential span gas setpoints: 250 – 2750 ppm

How to calibrate:

Change to the menu "Zero/span calibration" via the menu line "Calibration...":

CLD

Zero/span calibration

Measurement range number: 3

Zero gas concentration: 0.0 ppm

Span gas concentration: 100.0 ppm

Sample flow: 1100 ml/min

Raw measurement signal: 521590

Measurement gas: NOx

NO/NOx toggle!

Status: READY

Result...

Calibration adjustment limits: Disabled

HOME FACTORS ZERO SPAN INFO

F1 F2 F3 F4 F5

95.0 ppm

1) Select the measurement range:

• Press the ENTER key or the →→ -key in the line "Measurement range number" to enter

the parameter. Select the range you want to calibrate with the ↑↑ -key or the ↓↓ -key and

confirm it with ENTER. The zero gas concentration and the span gas concentration of

the range selected will appear in the corresponding lines, automatically.

2) Select the gas component:

• Go to the line "NO/NOx toggle!" with the ↓↓ -key and select the gas component you

want with the ENTER key or the →→ -key. The component selected will appear in the

line "Measurement gas", automatically.

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

5 - 5

Page 54

3) Zeroing:

• Change to the submenu "Analyzer zero" with the F3 key (ZERO).

• Pay attention to the notes on the screen !

• Flow enough zero gas through the CLD.

• Wait for a stable signal (look at the headline of the display). Then, start the zero gas

calibration with the F3 key (ZERO). The running procedure will be the same as it is

described detailed in chapter 4.2.1 of the basic controls (p. 4-22pp).

• Go back to the menu "Zero/span calibration" with the F2 key or the ←← -key after the

zero gas calibration will be done (Messages on the display: READY/CAL OK).

4) Spanning:

• Change to the submenu "Analyzer span" with the F4 key (SPAN).

• Pay attention to the notes on the screen !

• Flow enough span gas through the CLD.

• Wait for a stable signal (look at the headline of the display). Then, start the span gas

calibration with the F4 key (SPAN). The running procedure will be the same as it is

described detailed in chapter 4.2.2 of the basic controls (p. 4-26pp).

• Go back to the menu "Zero/span calibration" with the F2 key or the ←← -key after the

span gas calibration will be done (Messages on the display: READY/CAL OK).

Alternative: Go back to the "Main Menu" with the F1 key (HOME).

5) Check the calibration results:

• You can change to the submenu "Zero/span diagnostic data" via the line "Result..." of

the menu "Zero/span calibration". There you can control the results of the last zero

and span calibration. You can go back to the menu "Zero/span calibration" with the F2

key or the ←← -key.

Manual input of calibration factors:

The calibration may be wrong because of a trouble in the gas flow. If a calibration was not

successful, you have to repeat it. It is possible that a new start of calibration will not solve

the problem, if the measured zero or span gas value will differ from normal signals largely.

In that case you have to put in the calibration factors manually:

♦ From the menu "Zero/span calibration" you can change to the submenu "Calibration

Factors" with the F2 key (FACTORS):

CLD

Calibration Factors

Only those factors appropriate for the current range

will affect the reading on the current range.

Make sure you are using the right ones!

Measurement range number: 3

Range 1 factors...

Range 2 factors...

Range 3 factors...

Range 4 factors...

HOME ESCAPE INFO

F1 F2 F3 F4 F5

95.0 ppm

5 - 6

NGA 2000

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

Page 55

♦ Select the range you want in the line "Measurement range number" and change via the

line "Range 1/2/3/4 factors..." to the corresponding submenu:

CLD

Range 3 Factors

Zero offset: 521580.6

Span factor: 0.002608716

Full scale range at calibration: 100.0 ppm

Measurement range number: 3

Raw measurement signal: 521660

HOME STORE NEXT HISTORY INFO

F1 F2 F3 F4 F5

95.0 ppm

Set up parameters:

♦ Press the ENTER key or the →→ -key in the line "Zero offset" to select the parameter and

set up "32700" resp. "524000" with the ↑↑ -key or the ↓↓ -key. You may select any digit

with the →→ -key or the ←← -key.

Note: The zero offset is about 32000 counts for the CLD software revision 2.2.1 (16 bit

D/A transformer) and about 520000 counts for the revision 2.3 (20 bit D/A transformer).

♦ Confirm your setup with the ENTER key.

♦ Go to the line "Span factor" with the ↓↓ -key.

♦ Press the ENTER key or the →→ -key to select the parameter and set up "0.00015" with

the arrow keys.

♦ Confirm your setup with the ENTER key.

Notes:

♦ You have to set up the factors for all ranges.

♦ With the parameter "Zero offset" you will fix the zero value. The changing of the zero

offset will influence the signal immediately (look at the headline).

♦ With the parameter "Span factor" you will fix the signal at the span gas setpoint. The

changing of the span factor will influence the signal immediately (look at the headline).

♦ Conditions for the manual input of factors:

• "Disabled" has to be set up in the line "Calibration adjustment limits" of the menu

"Zero/span calibration".

• "SEPARATELY" has to be set up in the lines "Zero ranges" and "Span ranges" of the

menu "Calibration Parameters" (see 5.1.2, p. 5-9).

♦ Attention:

After the calibration with factors you have to calibrate with zero gas and span gas in the

usual way!

90003749(1) [NGA-e (Software CLD 2.3/MLT 3.1.X)] 04/98

NGA 2000

5 - 7

Page 56

Saving the factors:

♦ You can store the actual zero offset and span factor with the F2 key (STORE) of the

menu "Range 1/2/3/4 Factors". You will find the stored settings on the second menu

page (see next illustration).

♦ You can change to the second menu page of the menu "Range 1/2/3/4 Factors" with

the F4 key (HISTORY):

CLD

Range 3 Factors

Zero offset: 0.000000

Span factor: 0.000000

Zero offset: 0.000000

Span factor: 0.000000

HOME NEXT RSTR MN RSTR ST INFO

F1 F2 F3 F4 F5

Manufacturer´s settings.