Page 1

A technical manual from the experts

in Business-Critical Continuity

™

NetSure™ -48V DC Power System

Installation Instructions

Section 5876 (Issue AT, April 26, 2013)

SPEC. NO. MODEL

802NLDB

582140000

802NLEB

802NL-B

Page 2

Business-Critical Continuity™, Emerson Network Power, and the Emerson Network

Power logo are trademarks and service marks of Emerson Electric Co.

Lorain

®

and Vortex® are registered trademarks of Emerson

Network Power, Energy Systems, North America, Inc.

NetSure™, NetSpan™, NetReach™, NetXtend™, and NetPerform™

are trademarks of Emerson Network Power, Energy Systems, North America, Inc.

All other trademarks are the property of their respective owners.

The products covered by this instruction manual are manufactured and/or

sold by Emerson Network Power, Energy Systems, North America, Inc.

The information contained in this document is subject to change without notice and may not be

suitable for all applications. While every precaution has been taken to ensure the accuracy and

completeness of this document, Emerson Network Power, Energy Systems, North America, Inc.

assumes no responsibility and disclaims all liability for damages resulting from use of this information

or for any errors or omissions. Refer to other local practices or building codes as applicable for the correct

methods, tools, and materials to be used in perf orming procedures not specifical ly des c ribed in this doc ument.

This document is the property of Emerson Network Power, Energy Systems, North America, Inc.

and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use or disclosure of it without the written permission

of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Copyright

©

2013, Emerson Network Power, Energy Systems, North America, Inc.

All rights reserved throughout the world.

Page 3

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

STATIC WARNING

The printed circuit cards used in this equipm ent contain static sensitive com ponents. The warnings l isted below

must be observed to pre vent damage to these components. D isregarding any of these warni ngs may result in

personal injury or damage to the equipment.

1. Strictly adhere to the procedures provided in this document.

2. Before touching any static sensitive component or printed circuit card containing such a component,

discharge all static electricity from yourself by wearing a wrist strap grounded through a one m egohm

resistor. Some wrist strap s, such as Emerson Network Power Part Number 631810600, have a b uilt-in

one megohm resistor; no external resistor is necessary. Read and follow wrist strap manufacturer’s

instructions outlining use of a specific wrist strap.

3. Do not touch the traces or components on a pr inted circuit card conta ining static sensitive com ponents.

Handle the printed circuit card only by the edges that do not have connector pads.

4. After removing a printed cir cuit c ard conta ining a st atic s ensitive component, place the printed circu it card

only on conductive or anti-static material such as conductive foam, conducti ve plastic, or aluminum foil.

Do not use ordinary Styrofoam or ordinary plastic.

5. Store and ship static sens itive devices or print ed circuit cards contain ing such com ponents only in static

shielding containers.

6. If necessary to repair a pr int ed circuit c ard c ontain ing a static s ensitiv e com ponent , wear an appropr iate ly

grounded wrist strap , work on a conductive surfac e, use a grounded soldering iron, a nd use grounded

test equipment.

Static Warning Page 1 of 2

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 4

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

This Page Intentionally Left Blank

Page 2 of 2 Static Warning

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 5

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

FCC INFORMATION

The MCA Interface Modem Option (if installed) has been granted a registration number by the Federal

Communications Comm iss ion, under Part 68 rules a nd regu lations f or direct c onnection to the te lephone lin es. In

order to comply with these FCC rules, the following instructions m ust be carefully read and applicable portions

followed completely:

a) Direct connection to the telephone lines may be made only through the standard plug- ended cord

furnished to the utilit y-installed jack . No connection m ay be made to party or c oin phone lines. Pri or to

connecting the device to the telephone lines, you must:

b) Call your telephone company and inform them you have an FC C regis tered dev ice you des ire to c onnect

to their telephone l ines. Give them the num ber(s) of the line(s ) to be used, the m ake and model of the

device, the FCC registr atio n num ber and ringer equi valenc e. T his information will b e found o n the de vice

or enclosed with instructions as well as the jack suitable for your device.

c) After the telephone compan y has been advised of the above you ma y connect your device if the jack is

available, or after the telephone company has made the installation.

d) Repairs may be made only by the manufacturer or his author ized service agenc y. Unauthorized repairs

void registration and warr anty. Contact seller or manufac turer for details of permissible user perf ormed

routine repairs, and where and how to have other than routine repairs.

e) If, through abnormal circumstances, har m to the te lephone lines is caus ed, it sh ould be unpl ugged unti l it

can be determined if your device or the telephone line is the source. If your device is the source, it should

not be reconnected until necessary repairs are effected.

f) Should the telephone company notify you that your device is causing harm, the device should be

unplugged. The teleph one company wil l, where practi cable, notif y you, that tem porary disc ontinuance of

service may be require d. However, where prior notice is not pract icable, the telephone company ma y

temporarily discontinue service, if such action is reasonably necessary, in such cases the telephone

company must (A) Promptly notify you of such tempor ary discontinuance, (B) Afford you the opportunity

to correct the condition and (C) Inform you of your rights to bring a complaint to the FCC under their rules.

g) The telephone company may make changes in its communications facilities, equipment, operations or

procedures, where such action is reasonably required in the operation of its business and is not

inconsistent with FCC rules. If such changes can be reasonably expected to render any customer’s

devices incompatib le with telepho ne compan y facilities , or require m odification o r alteration, or otherwise

materially affect its performance, written notification must be given to the user, to allow uninterrupted

service.

The following inform ation is provided here and on a label attach ed to the outside of the MCA Interfac e Modem

Option (if installed).

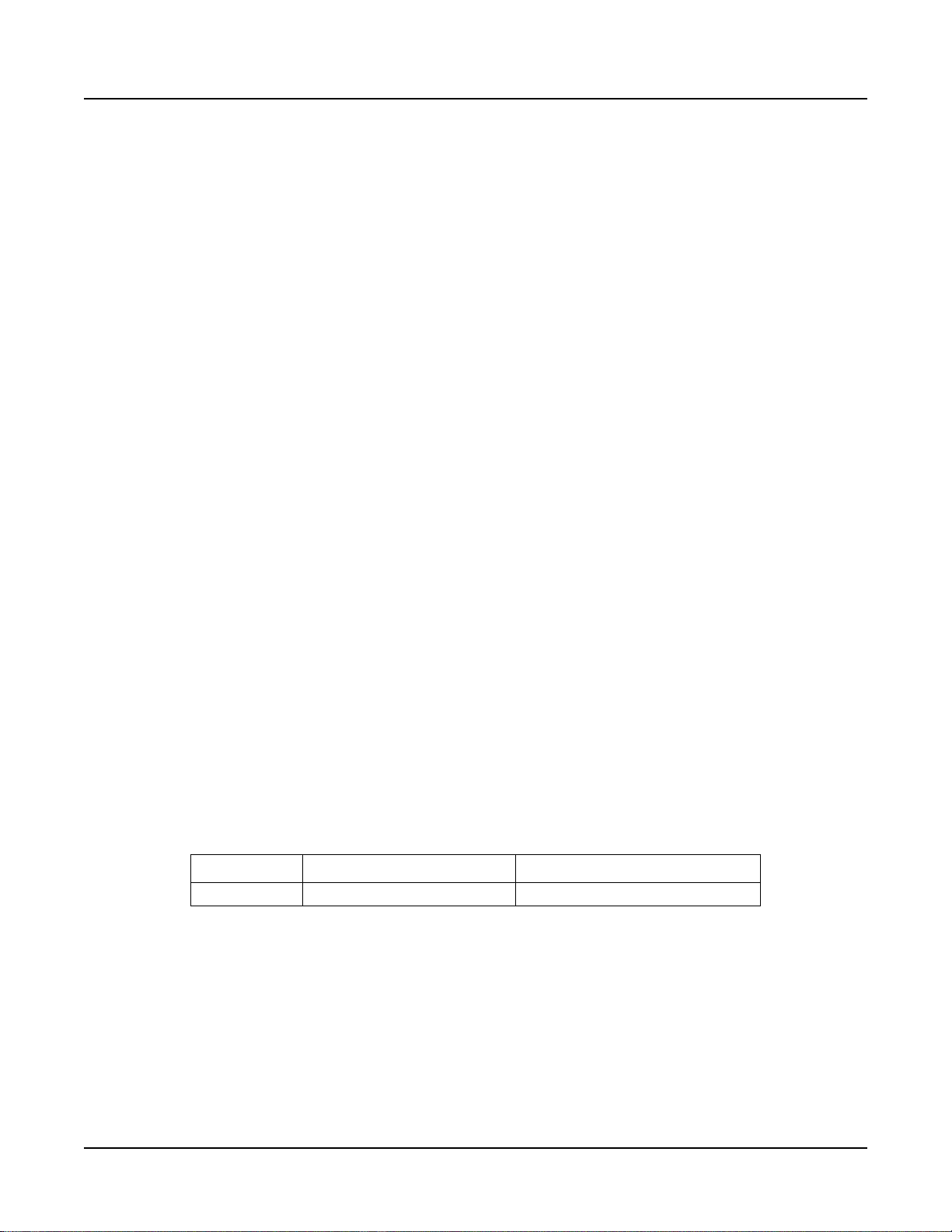

JACK RINGER EQUIVALENCE FCC REGISTRATION NUMBER

RJ-11 0.2A B46USA-22429-MM-E

FCC Information Page 1 of 2

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohib ited.

Page 6

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

This Page Intentionally Left Blank

Page 2 of 2 FCC Information

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 7

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

TABLE OF CONTENTS

CONTENTS

PAGE

CHAPTER 1 GENERAL INFORMATION AND INSTALLATION CHECKLIST ..................... 1-1

Preface ............................................................................................................................................................. 1-1

Installation Acceptance Checklist .................................................................................................................... 1-1

CHAPTER 2 PLACING THE BAYS AND INST ALLING

INTERNAL/EXTERNAL BUSBARS....................................................................................... 2-1

General Requirements ..................................................................................................................................... 2-2

Placing and Securing List 1 and List 11 Power/Dis tri but ion Bays (without PDSC) ......................................... 2-3

Placing and Securing List 2 and List 12 Power/Distribution Bays (with PDSC) .............................................. 2-5

Placing and Securing List 3, 4, 5, 13, 14, and 15 Power Only Bays ............................................................... 2-7

Placing and Securing List 16 Distribution Only Bays ....................................................................................... 2-9

Installing Power/Distribution Bay to Power/Distribution Bay Negative and Positive Busbar Links ................ 2-19

Installing Power/Distribution Bay to Power/Distribution Bay Negative and Positive Busbar Links

(Newer Style Bay to an Existing Older Style Bay) ......................................................................................... 2-22

Connecting Power/Distribution Bay Rectifier Mounting Position AC Input Connectors to PDSC (Lists 2

and 12 Only) ................................................................................................................................................... 2-24

Installing Power/Distribution Bay External Top-Mount Horizont al Bat tery Input Busbar Assembl y, P/N

554873 (if furnished) ...................................................................................................................................... 2-25

Installing Optional Power/Distribution Bay Busbar Shield Kit, P/N 528482 (if furnished) .............................. 2-34

Installing Power/Distribution Bay External Top-Mount Ground (Load Return) Busbar Assembly; P/N

514688, 514689, 514690, or 514691 (if furnished) ........................................................................................ 2-35

Installing Power/Distri bution Bay Load Return Lug Extension Busbar Assembly, P/N 514543 (if

furnished) ....................................................................................................................................................... 2-51

Installing Power/Distribution Bay External Top-Mount Vertical Battery Input Busbar Assembly, P/N

554874 (if furnished) ...................................................................................................................................... 2-60

CHAPTER 3 INSTALLING DISTRIBUTION DEVICES, MCA CIRCUIT CARDS, AND

LMS CIRCUIT CARDS ........................................................................................................... 3-1

Installing Distribution Fuses and Circuit Breakers ........................................................................................... 3-1

Installing 218 Circuit Breakers, TPL Fuseholders, and Bullet Nose-Type Device Mounting

Assemblies into Power/Distribution Bays .................................................................................................. 3-1

Installing 218 Circuit Breakers and TPL Fuseholders into Distribution Only Bays .................................... 3-2

Installing TPL Fuses .................................................................................................................................. 3-2

Installing TLS/TPS Fuses .......................................................................................................................... 3-3

Installing Bullet Nose-Type Circuit Breakers ............................................................................................. 3-3

Installing an Optional Bullet Nose-Type 10-Position GMT Fuse Module .................................................. 3-3

Storing Spare Fuses .................................................................................................................................. 3-3

Recording Fuse and Circuit Breaker Sizes ............................................................................................... 3-3

Installing MCA and LMS Circuit Cards ........................................................................................................... 3-18

Circuit Card Handling .............................................................................................................................. 3-18

Identifying the Circuit Cards .................................................................................................................... 3-18

Installing LMS Circuit Cards .................................................................................................................... 3-18

Installing MCA Customer Alarm Relay Circuit Card(s) and MCA I/O Circuit Card(s) ............................. 3-18

Table of Contents Page i

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 8

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

CHAPTER 4 MAKING ELECTRICAL CONNECTI ONS ......................................................... 4-1

Observe the Following Admonishments .......................................................................................................... 4-2

Wiring Considerations ...................................................................................................................................... 4-3

MCA Network Interconnections Between Bays ............................................................................................... 4-4

Distribution Only Bay BAT RTN Connection to System Monitoring and Control Section ................................ 4-7

MCA Battery Charge Digital Temperature Compensation Probe Connection ................................................. 4-7

MCA External CAN Bus Port Connectio n ........................................................................................................ 4-7

MCA External Alarm, Reference, and Control Connections and MCA I/O Circuit Card Connections ............. 4-9

Connections to Terminal Block TB1 on MCA Circuit Card P/N 509478 .................................................... 4-9

Connections to MCA Customer Alarm Relay Circuit Cards .................................................................... 4-10

Connections to MCA I/O Circuit Cards .................................................................................................... 4-10

LMS Connections (if LMS Furnished) ............................................................................................................ 4-22

LMS Local Port ........................................................................................................................................ 4-28

LMS Network Interconnections Between Bays and Optional LMS Expansion Assembly(s) ................... 4-29

Bay Frame Grounding Connections ............................................................................................................... 4-32

Load Connections .......................................................................................................................................... 4-34

Power/Distribution Ba y ............................................................................................................................ 4-34

Distribution Only Bay ............................................................................................................................... 4-38

AC Input and AC Input Ground Connections ................................................................................................. 4-43

Wiring Routing Guidelines ....................................................................................................................... 4-43

AC Input Connections to Lists 1 and 11 Bays (w/out PDSC) .................................................................. 4-44

AC Input Connections to Lists 2 and 12 Bays (with PDSC) .................................................................... 4-46

AC Input Connections to Lists 3 and 13 Bays ......................................................................................... 4-50

AC Input Connections to Lists 4 and 14 Bays ......................................................................................... 4-52

AC Input Connections to Lists 5 and 15 Bays ......................................................................................... 4-54

Battery Connections ....................................................................................................................................... 4-56

Power/Distribution Bay ............................................................................................................................ 4-56

Power Only Bay ....................................................................................................................................... 4-59

Distribution Only Bay ............................................................................................................................... 4-60

Re-Install Shields and Cover Panels ............................................................................................................. 4-61

MCA “Alternate Current Limit” Feature .......................................................................................................... 4-62

Admonishments ....................................................................................................................................... 4-62

MCA “Power Share” Feature.......................................................................................................................... 4-63

Admonishments ....................................................................................................................................... 4-63

Requirements and Conditions ................................................................................................................. 4-63

Paralleling the Existing and New Power Systems ................................................................................... 4-64

Operation ................................................................................................................................................. 4-66

Connecting the 582140000 System to Other Systems .................................................................................. 4-67

Connecting a 582140000 Main Power Bay to a 582121100 Power Bay and/or

582121900/582121901 Distribution Bay (MCA and LMS Interconnections) ........................................... 4-67

Connecting a 582140000 Main Power Bay to a Medium Vortex Power System when the MCA is

located in the PCU Intelligence Shelf (MCA Interconnections) ............................................................... 4-69

Connecting a 582140000 Main Power Bay to a Medium Vortex Power System when the MCA is

Located in the Distribution Cabinet (MCA and LMS Interconnections) ................................................... 4-71

Connecting a 582140000 Main Power Bay to a Legacy Power System (LMS Interconnections) .......... 4-73

Page ii Table of Contents

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 9

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

CHAPTER 5 INSTALLING THE RECTIF IERS AND INITIALLY STARTING THE

POWER SYSTEM .................................................................................................................. 5-1

Installing the Rectifiers ..................................................................................................................................... 5-2

Setting Switch S1 on the MCA Circuit Card in the Prim ary Power/Distribution or Power Only Bay ................ 5-3

Setting Jumper J4 on MCA Distribution Bus Monitoring Circuit Cards ............................................................ 5-3

Initially Starting, Configuring, and Checking System Operation ...................................................................... 5-7

Observe the Following Admonishment ...................................................................................................... 5-7

MCA (Meter, Control, Alarm Panel) ........................................................................................................... 5-7

Initial Startup Preparation ........................................................................................................................ 5-14

Initially Starting the System ..................................................................................................................... 5-14

MCA Initializa t io n ..................................................................................................................................... 5-14

Checking the Inventory and Setting the Number of PCU (Rectifier) Positions Available in the

System ..................................................................................................................................................... 5-18

Setting the Date and Time ....................................................................................................................... 5-19

Setting the Temperature Units (degrees C or degrees F) ....................................................................... 5-19

Setting and Testing MCA Customer Alarm Relays (and MCA Relay Function Channels) ..................... 5-20

Setting MCA I/O Circuit Card Parameters ............................................................................................... 5-22

Checking Manual Test/Equalize and Manually Initiated Timed Test/Equalize ........................................ 5-22

Checking High Voltage Shutdo wn ........................................................................................................... 5-25

Checking Remote High Voltage Shutdown and Rectifier Emergency Shutdown (ESTOP) Inputs ......... 5-25

Checking Remote High Voltage Shutdown ............................................................................................. 5-26

Checking Emergency Shut do wn and Fire Alarm Disconnect .................................................................. 5-27

Checking Remote Test/Equalize ............................................................................................................. 5-27

Checking MCA Audible Alarm and MCA Audible Alarm Cutoff ............................................................... 5-27

Checking AC Fail Alarm .......................................................................................................................... 5-28

Checking Rectifier Fail Alarm .................................................................................................................. 5-29

Checking System High Voltage Alarm 1 ................................................................................................. 5-29

Checking System High Voltage Alarm 2 ................................................................................................. 5-30

Checking System Battery Is On Discharge Alarm ................................................................................... 5-31

Checking Very Low Voltage Alarm .......................................................................................................... 5-32

Checking Total Distribution Load Alarm .................................................................................................. 5-33

Checking Distribution Group A Load Alarm ............................................................................................. 5-33

Checking Distribution Group B Load Alarm ............................................................................................. 5-34

Checking Fuse Alarm/Circuit Breaker Alarm ........................................................................................... 5-35

Checking Metering Functions .................................................................................................................. 5-36

Checking System Status ......................................................................................................................... 5-38

Checking and Configuring the LMS System ............................................................................................ 5-39

REVISION RECORD

Table of Contents Page iii

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 10

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

This Page Intentionally Left Blank

Page iv Table of Contents

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 11

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

CHAPTER 1 GENERAL INFORMATION AND INSTALLATION CHECKLIST

TABLE OF CONTENTS

Preface .................................................................................................................... 1-1

Installation Acceptance Checklist ............................................................................ 1-1

PREFACE

This document (Section 5876) provides Ins ta llati on Instructions for NetSure™ Power

System Model 802

(480V Input Power/Distribution and Power Only Bays) and 802

Bay); Spec. No. 582140000. For a condensed version of these instructions, refer to the

Installation Guide (Section 5957) located in the separate INSTALLATION MANUAL.

For User Instructions, refer to Section 5877 provided on the CD (Electronic

Documentation Package) furnished with your system.

NLDB (208V Input Power/Distribution and Power Only Bays), 802NLEB

NL-B (Distribution Only

Refer to SAG582140000 (System Application Guide) for additional information. The SAG

can be accessed via the CD (Electronic Documentation Package) furnished with your

system.

For a color MCA Menu Tree, refer to Section 5886. Section 5886 is provided in the

separate INSTAL LAT IO N MAN U AL and the CD CARRIER MANUAL (it is also provided

on the CD).

Your Power System may contain an optional LMS Monitoring System, refer to Section

5879 (LMS1000 Installation Instructions) and Section 5847 (LMS1000 User Instructions)

provided on the CD (Electronic Documentation Package) furnished with your system.

INSTALLATION ACCEPTANCE CHECKLIS T

Provided below is an Installation Acceptance Checklist. This checklist helps ensure

proper installation and initial operation of the system. As the procedures presented in

Chapters 2 through 5 of this document are completed, check the appropriate box on this

list. If the procedure is not required to be performed for your installation site, also check

the box in this list to indicate that the procedure was read. When installation is done,

ensure that each block in this list has been checked. Some of these procedures may

have been factory performed for you.

Note: The system is not powered up until the end of this checklist.

Note: Some of these procedures may have been performed at the factory for you.

Chapter 2. Placing the Bays and Installing Internal/External Busbars

Bays (and PDSC if furnished) Bolted Together (if required) and Mounted to Floor

Bay-to-Bay Busbar Links Installed (if required)

PDSC (if furnished) AC Input Connectors Connected to Power/Distribution Bay

External Top-Mount Busbar Assemblies Installed (if furnished)

Chapter 1. General Information and Installation Checklist Page 1-1

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 12

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

Chapter 3. Installing Distribution Devices, MCA Relay Circuit Cards, MCA I/O Circuit Cards, and LMS Circuit Cards

NLDB, 802NLEB and 802NL-B)

Distribution Fuses and Circuit Breakers Installed

Distribution Lug Adapter Plates Installed

MCA Customer Alarm Relay Circuit Card(s) Installed (if required)

MCA I/O Circuit Card(s) Installed (if required)

LMS CPU Circuit Card Installed (if required)

LMS Modem Circuit Card Installed (if required)

LMS Four Input Analog Circuit Card Installed (if required)

after Making any Jumper Adjustment as Required

LMS Eight Input Analog Circuit Card Installed (if required)

LMS Twelve Input Analog Circuit Card Installed (if required)

LMS Four Input Binary Circuit Card Installed (if required)

LMS Eight Input Binary Circuit Card Installed (if required)

after Making any Jumper Adjustment as Required

LMS Four Output (Form-C) Relay Circuit Card Installed (if required)

after Making any Jumper Adjustment as Required

LMS Eight Input Temperature Circuit Card Installed (if required)

and Ground Lead Attached to Frame Ground

Chapter 4. Making Electrical Connectio n s

MCA Network Bay Interconnections Made

MCA Battery Charge Digital Temperature Compensation Probe Mounted and

Connected (if furnished)

MCA External Alarm, Reference, and Control Connections Made

Connections Made to all MCA I/O Circuit Cards Installed

External LMS CPU/Hardware Fail Alarm Connections Made (as required)

LMS Local Port Connections Made (if required)

LMS Ethernet Port Connections Made (if required)

LMS Modem Port Connections Made (if required)

LMS OEM (RS-485) Port Connections Made (if required)

Connections Made to all LMS Four Input Analog Circuit Cards Installed

Connections Made to all LMS Eight Input Analog Circuit Cards Installed

Connections Made to all LMS Twelve Input Analog Circuit Cards Installed

Connections Made to all LMS Four Input Binary Circuit Cards Installed

Connections Made to all LMS Eight Input Binary Circuit Cards Installed

Connections Made to all LMS Four Output (Form-C) Relay Circuit Cards Installed

Page 1-2 Chapter 1. General Information and Installation Checklist

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 13

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

Connections Made to all LMS Eight Input Temperature Circuit Cards Installed

LMS Energy Management Connections Made (as required)

LMS Sequential Start Connections Made (as required)

LMS Expansion Assembly(s) (if furnished) Interconnected to Customer Equipment

LMS Network Bay and Optional LMS Expansion Cabinet(s) and Assembly(s)

Interconnections Made (as required)

Frame Grounding Connections Made

Load Connections Made

AC Input and AC Input Ground Connections Made

Battery Connections Made

All Shields and Cover Panels in Re-Installed

MCA “Power Share” Connections Made (if required)

Connections to Other Systems Made (if required)

Chapter 5. Installing the Rectifiers and Initially Starting the Power System

Rectifiers Installed

Router Circuit Cards Switches Set

MCA Distribution Bus Monitor ing Circ uit Cards Jumper Set

System Started, Configured, and Checked

LMS Checked and Configured (as required)

Chapter 1. General Information and Installation Checklist Page 1-3

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 14

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

This Page Left Intentionally Blank

Page 1-4 Chapter 1. General Information and Installation Checklist

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 15

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

CHAPTER 2 PLACING THE BAYS AND INSTALLING INTERNAL/EXTERNAL BUSBARS

TABLE OF CONTENTS

General Requirements .................................................................................................... 2-2

Placing and Securing List 1 and List 11 Power/Distribution Bays (without PDSC) ......... 2-3

Placing and Securing List 2 and List 12 Power/Distribution Bays (with PDSC) .............. 2-5

Placing and Securing List 3, 4, 5, 13, 14, and 15 Power Only Bays ............................... 2-7

Placing and Securing List 16 Distribution Only Bays ...................................................... 2-9

Installing Power/Distribution Bay to Power/Distribution Bay Negative and Positive

Busbar Links .................................................................................................................. 2-19

Installing Power/Distribution Bay to Power/Distribution Bay Negative and Positive

Busbar Links (Newer Style Bay to an Existing Older Style Bay) ................................... 2-22

Connecting Power/Distribution Bay Rectifier Mounting Position AC Input

Connectors to PDSC (Lists 2 and 12 Only) ................................................................... 2-24

Installing Power/Distribution Bay External Top-Mount Horizont al Bat tery Input

Busbar Assembly, P/N 554873 (if furnished) ................................................................ 2-25

Installing Optional Power/Distribution Bay Busbar Shield Kit, P/N 528482 (if

furnished) ....................................................................................................................... 2-34

Installing Power/Distribution Bay External Top-Mount Ground (Load R etur n)

Busbar Assembly; P/N 514688, 514689, 514690, or 514691 (if furnished) .................. 2-35

Installing Power/Distribution Bay Load Return Lug Extension Busbar Assembly,

P/N 514543 (if furnished)............................................................................................... 2-51

Installing Power/Distribution Bay External Top-Mount Vertica l Battery Input

Busbar Assembly, P/N 554874 (if furnished) ................................................................ 2-60

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-1

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 16

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

GENERAL REQUIREMENTS

• The installer should be familiar with the installation requirements and techniques to

be used in securing the bay(s) to the floor.

• This product is intended only for installation in a Restricted Access Location on or

above a non-combustible surface.

• This product is intended for installation in Network Telecommunication Facilities (CO,

vault, hut, or other environmentally controlled electronic equipment enclosure).

• This product is intended to be connected to the common bonding network in a

Network Telecommunication Facility (CO, vault, hut, or other environmentally

controlled electronic equipment enclosure).

• Front and rear access is required for installation.

• Typical industry standards recommended minimum aisle space clearance is 2' 6" for

the front of the bay(s) and 2' for the rear of the bay(s). See also next paragraph.

• Rectifier ventilating openings must not be blocked and temperature of air entering

Rectifiers must not exceed rated Operating Ambient Temperature Range found in

System Application Guide SAG582140000. Distance from rear of a

Power/Distribution or Power Only Bay to a wall or other solid structure must not be

less than 6 inches. This assures proper airflow through the Rectifiers.

• The system consists of from 1 to 10 bays, depending upon your power requirements.

All bays that are designed to be bussed together must be placed in a line adjacent to

each other, with no space between bays. It is recommended to place the Primary

Power/Distribution or Power Only Bay on the far right or far left end of the bay lineup, and to expand the system to the left or right of the Prim ar y Power/Dist ri but ion or

Power Only Bay. This allows simple cable connections between bays, and a

consistent MCA Bay numbering scheme. The Primary Power/Distribution or Power

Only Bay is identified by the MCA as Bay #1. The other bays are numbered

consecutively, following the bay-to-bay cabling scheme. Thus, bays are numbered

#1-#10 from right to left or from left to right. The Primary Power/Distribution or Po w er

Only Bay may be placed in the middle of the bay line-up, expanding the system to the

left and right of the Primary Power/Distribution or Power Only Bay. In this

configuration, bay-to-bay cabling MUST start with the Primary Power/Distribution or

Power Only Bay, then each Secondary Power/Distribution or Power Only Bay and

Distribution On ly Ba ys are daisy-chained into the cabling string. Remember, the

Primary Power/Distribut ion or Power Only Bay is identified by the MCA as Bay #1,

the other bays are numbered consecutively following the bay-to-bay cabling scheme.

Page 2-2 Chapter 2. Placing the Bays and Installing Internal/Extern al Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 17

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

PLACING AND SECURING LIST 1 AND LIST 11 POWER/DISTRIBUTION B AYS (WI THO UT P DS C)

Note: If you are installing List 2 and List 12 bays (with List 30, 31, or 32 PDSC), skip this

procedure and refer to “Placing and Securing List 2 and List 12 Power/Distribution

Bays (with PDSC)".

• PDSC = AC Input 'Power Distribution Service Cabinet'.

• Refer to Figure 2-1 through Figure 2-9 as this procedure is performed. Figure 2-1

provides a floor hole drilling pattern.

• Bays are typically placed next to each other and bolted together. Refer to the

previous Section, GENERAL REQUIREMENTS, for bay line-up recommendations.

Procedure

Preparing the Bays

1) Remove all front Rectifier mounting position blank cover panels from each

Power/Distribution Bay to provide access to bay's floor mounting holes and

leveling feet. Cover panels will be re-installed in empty Rectifier mounting

positions after all Rectifiers are installed. To do so: Remove the screws and

ground washers securing the cover panel. Remove the cover panel.

2) Remove the three rear cover panels from each Power/Distribution Bay. These

cover panels will be re-installed after all mounting and electrical connection

procedures have been completed. To do so:

Top Panel: Loosen the screws

securing the cover panel. Lift the cover panel until the screw heads clear the

keyhole slots. Remove the cover panel.

Lower Panels:

Remove the screws and

ground washers securing the panel. Remove the panel.

3) Remove the side cover panels from each Power/Distribution Bay (two per side)

as follows, if equipped. Note that you may leave the side cover panels on the

"outside side" of the two end bays.

a) Remove the rear-most side cover panel as follows: Remove the screws

and ground washers securing the side cover panel. Screws are accessible

from the rear of the bay through holes in the side channels. After removing

screws, pivot rear edge of cover panel outward, then slide cover panel

toward rear of bay to disengage tabs at the front of the cover panel from slots

in the bay.

b) Remove the front-most side cover panel as follows: Open the bay's front

door. Remove the screws and ground washers securing the side cover

panel. Screws are accessible from the front of the bay through holes in the

side channels. After removing screws, pivot front edge of cover panel

outward, then slide cover panel toward front of bay to disengage tabs at the

rear of the cover panel from slots in the bay.

Placing and Securing the Bay(s)

1) Place bay(s) in position. Note that clearance holes for 1/4” bolts are provided in

the side rails of each bay. These holes are for bolting the bays together.

2) Level bay(s) as required, using leveling feet in base plate. Adjust leveling feet so

that all bays are even at top, and bolt holes in the side of each bay line up with

holes in the adjacent bay(s).

3) Bolt all bays together. Use 1/4” hardware, six places per pair of bays. Use a

ground washer in two locations with the 1/4" hard w are bolt i ng two bays together.

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-3

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 18

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

Note: A ground washer is an internal-external tooth, dish-type lock washer.

When installing ground washers, ensure that the ground washer is

oriented so that the teeth dig into the paint on the metal part the ground

washer is secured to (concave side faces the metal part).

4) Install shims between bottom of each bay and the floor as required to distribute

floor loading.

5) Secure bay(s) to floor using fastening hardware per site requirements.

Installing Side Cover Panels on End Bays

1) If the outside sides of the end bays do not have side cover panels, install them

now (two per side). Note that ground washers are used with each screw

securing the side cover panels.

a) Install the rear-most side cover panel as follows: Insert tabs at front of

cover panel into slots in bay. Pivot cover panel into position against side of

bay. Install the previously removed screws and ground washers into cover

panel from rear of bay.

b) Install the front-most side cover panel as follows: Open the bay's front

door. Insert tabs at rear of cover panel into slots in bay. Pivot cover panel

into position against side of bay. Install the previously removed screws and

ground washers into cover panel from front of bay.

Page 2-4 Chapter 2. Placing the Bays and Installing Internal/Extern al Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 19

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

PLACING AND SECURING LIST 2 AND LIST 12 POWER/DISTRIBUTION B AYS (WI TH P DS C)

Note: If you are installing List 1 and List 11 Bays (without List 30, 31, or 32 PDSC), skip

this procedure and refer to “Placing and Securing List 1 and List 11

Power/Distribution Bays (without PDSC)".

• PDSC = AC Input 'Power Distribution Service Cabinet'.

• Refer to Figure 2-1 through Figure 2-9 as this procedure is performed. Figure 2-2

provides a floor hole drilling pattern.

• Bays are typically placed next to each other and bolted together. Refer to the

previous Section, GENERAL REQUIREMENTS, for bay line-up recommendations.

PDSCs are located to the left (as viewed from the front) of each Power/Distribution

Bay.

Procedure

Preparing the Bays and PDSCs

1) Remove all front Rectifier mounting position blank cover panels from each

Power/Distribution Bay to provide access to bay's floor mounting holes and

leveling feet. Cover panels will be re-installed in empty Rectifier mounting

positions after all Rectifiers are installed. To do so: Remove the screws and

ground washers securing the cover panel. Remove the cover panel.

2) Remove the three rear cover panels from each Power/Distribution Bay. These

cover panels will be re-installed after all mounting and electrical connection

procedures have been completed. To do so:

Top Panel: Loosen the screws

securing the cover panel. Lift the cover panel until the screw heads clear the

keyhole slots. Remove the cover panel.

Lower Panels:

Remove the screws and

ground washers securing the panel. Remove the panel.

3) Remove the side cover panels from each Power/Distribution Bay (two per side)

as follows, if equipped. Note that you may leave the side cover panels on the

"outside side" of the right-most (as viewed from the front) end bay.

a) Remove the rear-most side cover panel as follows: Remove the screws

and ground washers securing the side cover panel. Screws are accessible

from the rear of the bay through holes in the side channels. After removing

screws, pivot rear edge of cover panel outward, then slide cover panel

toward rear of bay to disengage tabs at the front of the cover panel from slots

in the bay.

b) Remove the front-most side cover panel as follows: Open the bay's front

door. Remove the screws and ground washers securing the side cover

panel. Screws are accessible from the front of the bay through holes in the

side channels. After removing screws, pivot front edge of cover panel

outward, then slide cover panel toward front of bay to disengage tabs at the

rear of the cover panel from slots in the bay.

4) Remove the front cover panel from each PDSC. This cover panel will be reinstalled after all mounting and electrical connection procedures have been

completed. To do so: Remove the screws and ground washers securing the

cover panel. Remove the cover panel.

5) Remove the rear lower cover panel from each PDSC. This cover panel will be

re-installed after all mounting and electrical connection procedures have been

completed. To do so: Remove the screws and grou nd wash er s sec uring the

cover panel. Remove the cover panel.

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-5

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 20

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

6) Remove the rear upper cover panel from each PDSC. This cover panel will be

re-installed after all mounting and electrical connection procedures have been

completed.. To do so: Loosen the screws securing the cover panel. Lift the

cover panel until the screw heads clear the keyhole slots. Remove the cover

panel.

7) Remove the plug-button located on the left side (towards the front) of each

PDSC, except the end PDSC. This opening is provided for data communications

cable routing between bays.

Placing and Securing the Bay(s) and PDSCs

1) Place bay(s) and PDSC(s) in position. Note that PDSCs are placed to the left (as

viewed from the front) of each bay. Note that clearance holes for 1/4” bolts are

provided in the side rails of each bay and PDSC. These holes are for bolting the

bays and PDSCs together.

2) Level bay(s) and PDSC(s) as required, using leveling feet in base plate. Adjust

leveling feet so that all bays and PDSCs are even at top, and bolt holes in the

side of each bay and PDSC line up with holes in the adjacent cabinet(s).

3) Bolt all bays and PDSCs together. Use 1/4” hardware, five places per pair of

cabinets. Use a ground washer in two locations with the 1/4" hardware bolting

two cabinets together.

Note: A ground washer is an internal-external tooth, dish-type lock washer.

When installing ground washers, ensure that the ground washer is

oriented so that the teeth dig into the paint on the metal part the ground

washer is secured to (concave side faces the metal part).

4) Install shims between bottom of each bay and the floor as required to distribute

floor loading.

5) Secure Power/Distribution Bay(s) and PDSC(s) to floor using fastening hardware

per site requirements.

Installing Side Cover Panels on Right-Most End Bay

1) If the outside side of the right-most end bay does not have side cover panels,

install them now (two per side). Note that ground washers are used with each

screw securing the side cover panels.

a) Install the rear-most side cover panel as follows: Insert tabs at front of

cover panel into slots in bay. Pivot cover panel into position against side of

bay. Install the previously removed screws and ground washers into cover

panel from rear of bay.

b) Install the front-most side cover panel as follows: Open the bay's front

door. Insert tabs at rear of cover panel into slots in bay. Pivot cover panel

into position against side of bay. Install the previously removed screws and

ground washers into cover panel from front of bay.

Page 2-6 Chapter 2. Placing the Bays and Installing Internal/Extern al Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 21

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

PLACING AND SECURING LIST 3, 4, 5, 13, 14, AND 15 POWER ONLY BAYS

• Figure 2-1 provides a floor hole drilling pattern.

• Bays are typically placed next to each other and bolted together. Refer to the

previous Section, GENERAL REQUIREMENTS, for bay line-up recommendations.

Procedure

1) Remove all front Rectifier mounting position blank cover panels from each Power

Only Bay to provide access to bay's floor mounting holes and leveling feet.

Cover panels will be re-installed in empt y Rectifier mounti ng pos it ions after all

Rectifiers are installed. To do so: Remove the screws and ground washers

securing the cover panel. Remove the cover panel.

2) Remove the three rear cover panels from each Power Only Bay. These cover

panels will be re-installed after all mounting and electrical connection procedures

have been completed. To do so:

cover panel. Lift the cover panel until the screw heads clear the keyhole slots.

Remove the cover panel.

Lower Panels:

washers securing the panel. Remove the panel.

3) Remove the side cover panels from each Power Only Bay (two per side) as

follows, if equipped. Note that you may leave the side cover panels on the

"outside side" of the two end bays.

Top Panel: Loosen the screws securing the

Remove the screws and ground

a) Remove the rear-most side cover panel as follows: Remove the screws

and ground washers securing the side cover panel. Screws are accessible

from the rear of the bay through holes in the side channels. After removing

screws, pivot rear edge of cover panel outward, then slide cover panel

toward rear of bay to disengage tabs at the front of the cover panel from slots

in the bay.

b) Remove the front-most side cover panel as follows: Open the bay's front

door. Remove the screws and ground washers securing the side cover

panel. Screws are accessible from the front of the bay through holes in the

side channels. After removing screws, pivot front edge of cover panel

outward, then slide cover panel toward front of bay to disengage tabs at the

rear of the cover panel from slots in the bay.

4) Place bay(s) in position. Note that clearance holes for 1/4” bolts are provided in

the side rails of each bay. These holes are for bolting the bays together.

5) Level bay(s) as required, using leveling feet in base plate. Adjust leveling feet so

that all bays are even at top, and bolt holes in the side of each bay line up with

holes in the adjacent bay(s).

6) Bolt all bays together. Use 1/4” hardware, six places per pair of bays. Use a

ground washer in two locations with the 1/4" hardware bolting two bays together.

Note: A ground washer is an inter nal-external tooth, dish-type lock washer.

When installing ground washers, ensure that the ground washer is

oriented so that the teeth dig into the paint on the metal part the ground

washer is secured to (concave side faces the metal part).

7) Install shims between bottom of each bay and the floor as required to distribute

floor loading.

8) Secure bay(s) to floor using fastening hardware per site requirements.

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-7

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 22

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

9) If the outside sides of the end bays do not have side cover panels, install them

now (two per side). Note that ground washers are used with each screw

securing the side cover panels.

a) Install the rear-most side cover panel as follows: Insert tabs at front of

cover panel into slots in bay. Pivot cover panel into position against side of

bay. Install the previously removed screws and ground washers into cover

panel from rear of bay.

b) Install the front-most side cover panel as follows: Open the bay's front

door. Insert tabs at rear of cover panel into slots in bay. Pivot cover panel

into position against side of bay. Install the previously removed screws and

ground washers into cover panel from front of bay.

Page 2-8 Chapter 2. Placing the Bays and Installing Internal/Extern al Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 23

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

PLACING AND SECURING LIST 16 DISTRIBUTION ONLY BAYS

• Figure 2-3 provides List 16 Distribution Only Bay hole drilling patterns.

• Bays are typically placed next to each other and bolted together. Refer to the

previous Section, GENERAL REQUIREMENTS, for bay line-up recommendations.

Procedure

1) If bays are to be placed next to each other, remove the side cover panels from

the sides that will be placed next to another bay (leaving the side cover panels on

the "outside side" of the two end bays). Install side cover panels on end bays as

required.

2) Place bay(s) in position. Note that clearance holes for 1/4” bolts are provided in

the side rails of each bay. These holes are for bolting the bays together.

3) Remove the lower rear cover panel from each bay to provide access to bay's

floor mounting holes. These cover panels will be re-installed after all mounting

and electrical connection procedures have been completed.

4) Level bay(s) as required, using the leveling nut provided in base plate. Adjust

leveling bolts so that all bays are even at top, and bolt holes in the side of each

bay line up with holes in the adjacent bay(s).

5) Bolt all bays together. Use 1/4” hardware, seven places per pair of bays. Use a

ground washer in two locations with the 1/4" hardware bolting two bays together.

Note: A ground washer is an internal-external tooth, dish-type lock washer.

When installing ground washers, ensure that the ground washer is

oriented so that the teeth dig into the paint on the metal part the ground

washer is secured to (concave side faces the metal part).

6) Install shims between bottom of each bay and the floor as required to distribute

floor loading.

7) Secure bay(s) to floor using fastening hardware per site requirements.

8) If the outside sides of the end bays do not have side cover panels, install them

now (two per side). Note that ground washers are used with each screw

securing the side cover panels.

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-9

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 24

Section 5876 Installation Instructions

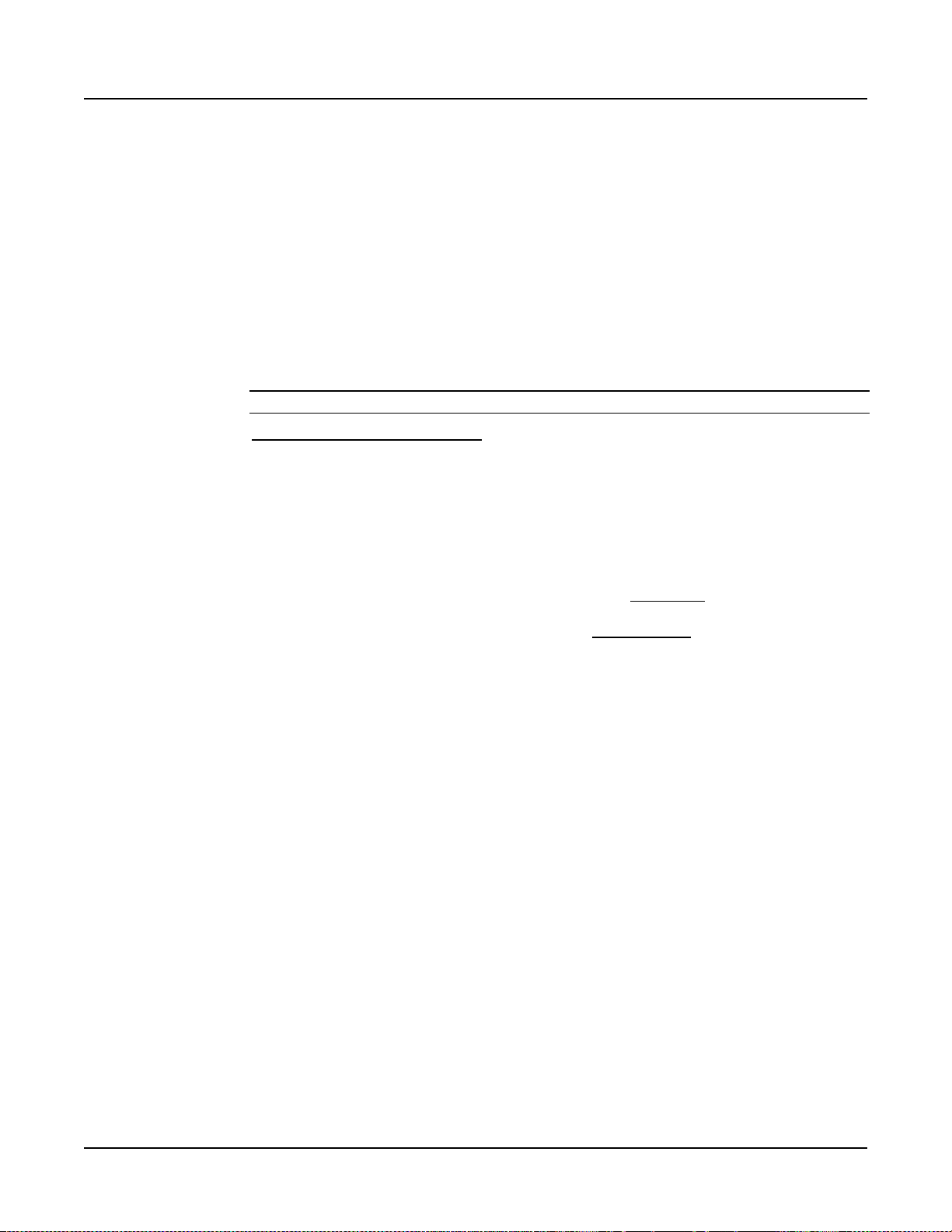

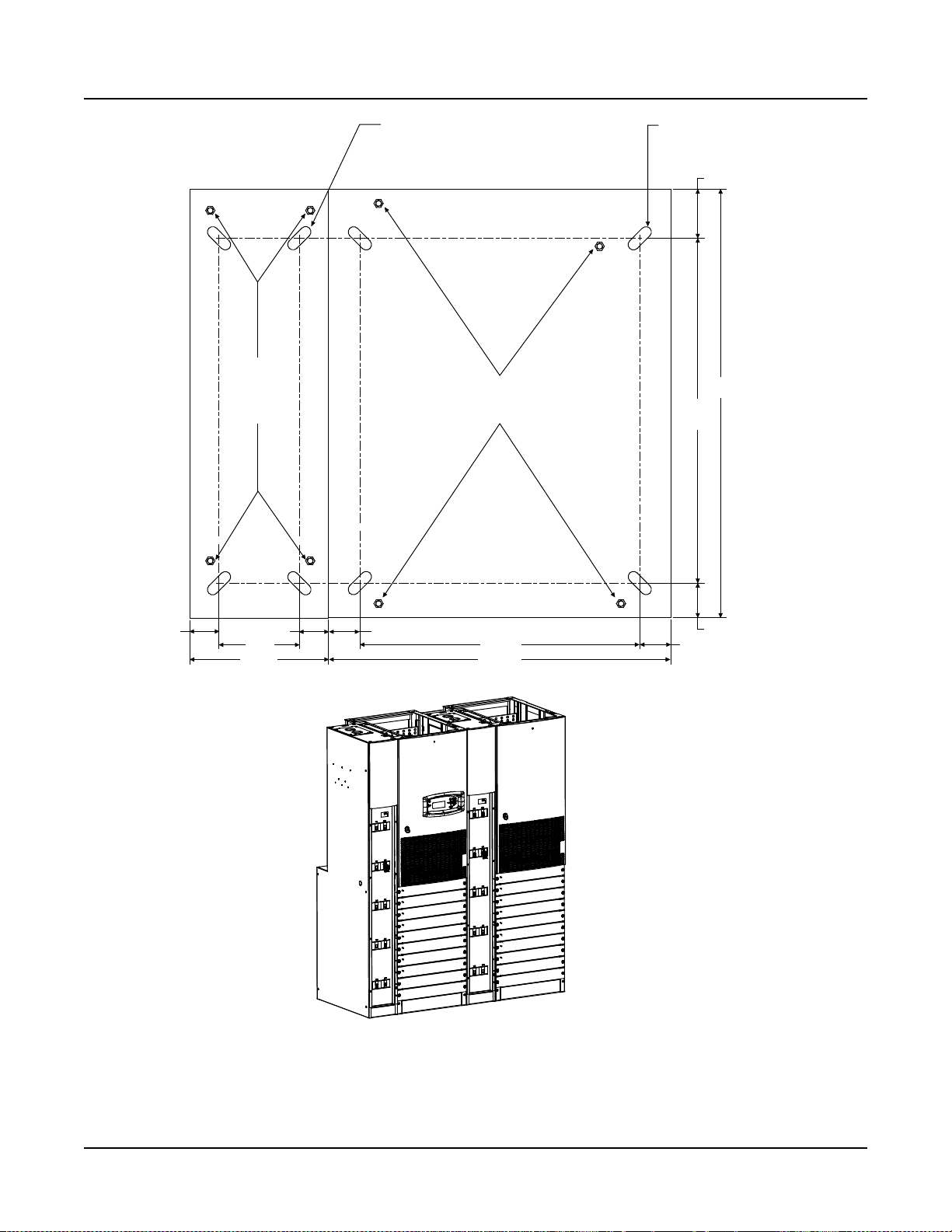

0.750 X 2.000 SLOT

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

2.19

FRONT

(4 PLACES)

3/8-16 Floor

Leveling Bolts

19.62

24.00

3.44

30.00

24.12

2.44

2.19

Floor Hole Drilling Pattern

Power/Distribution Bay

Figure 2-1

Floor Mounting Hole Dimensions

(Primary and Secondary Power/Distribution Bays without PDSC)

(Power Only Bays Have the Same Hole Pattern)

(all dimensions in inches)

Page 2-10 Chapter 2. Placing the Bays and Installing Internal/External Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 25

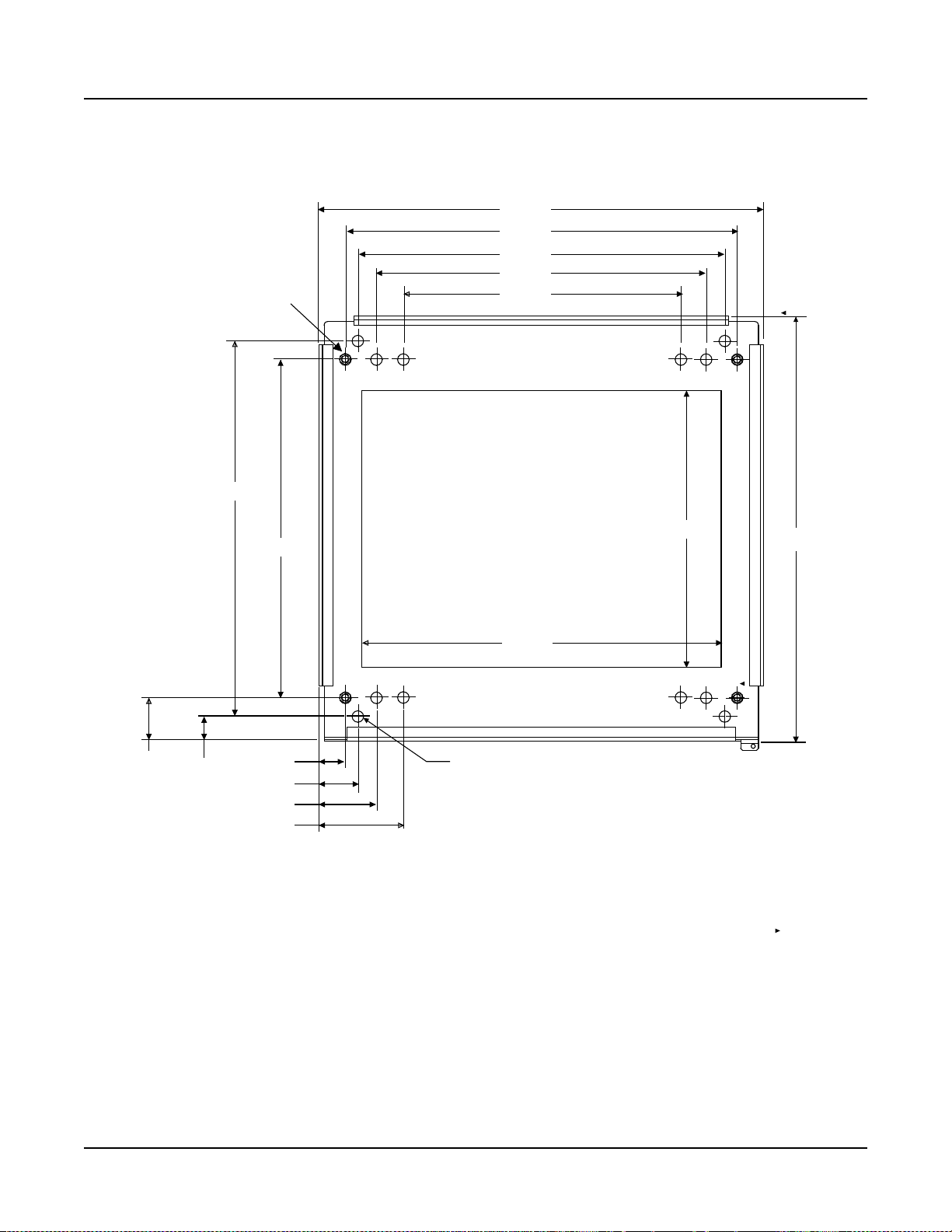

Installation Instructions Section 5876

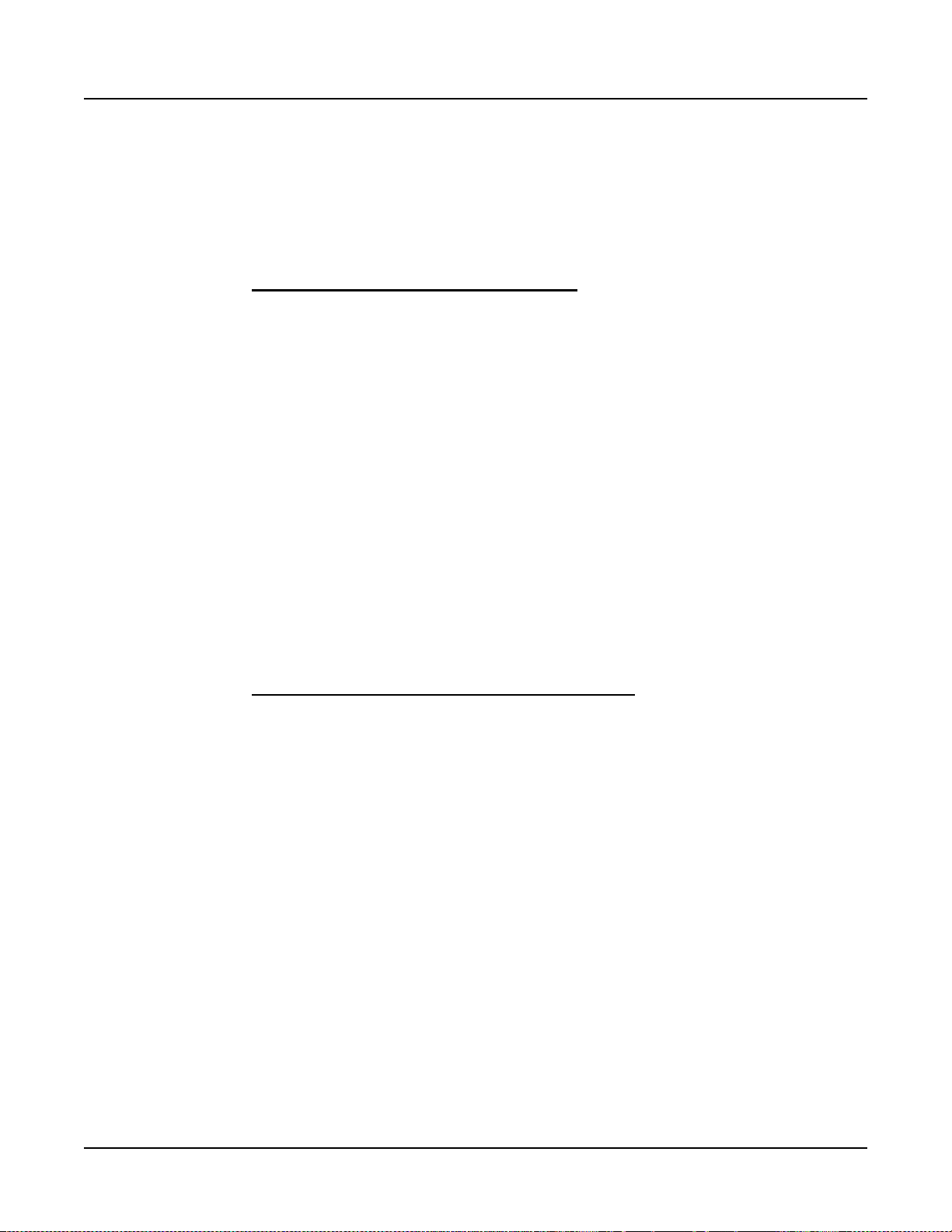

3/8-16 Floor

Leveling Bolts

FRONT

19.62

24.00

2.19

24.12

30.00

2.44

3.44

0.750 X 2.000 SLOT

(4 PLACES)

2.19

9.85

5.63

2.11

2.11

POWER/

DISTRIBUTION BAY

AC POWER

DISTRIBUTION

SERVICE CABINET

0.750 X 2.000 SLOT

(4 PLACES)

3/8-16

Floor

Leveling

Bolts

Floor Hole Drilling Pattern

Power/Distribution Bay

and PDSC

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

Figure 2-2

Floor Mounting Hole Dimensions

Primary and Secondary Power/ Distr i but ion Bays with PDSC

(all dimensions in inches)

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-11

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 26

Section 5876 Installation Instructions

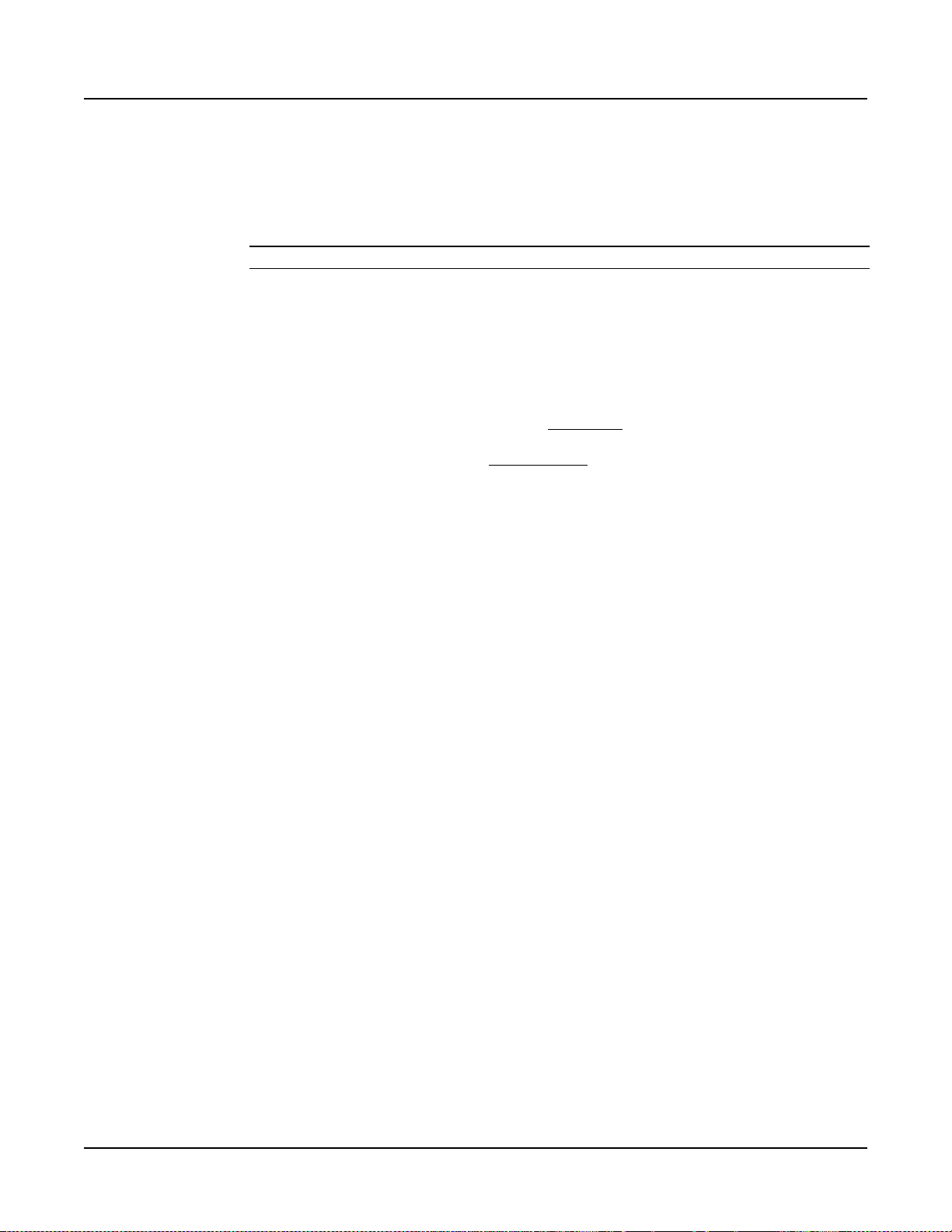

Front

3/8-16

Welded Nut (4)

0.812 Dia.

(8 PLACES)

25.875

23.250

27.625

25.375

19.500

26.625

24.000

3.063

1.750

1.875

2.750

4.063

30.000

31.375

19.500

5.937

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

Figure 2-3

Floor Mounting Hole Dimensions - Distribution Only Bay

(all dimensions in inches)

Page 2-12 Chapter 2. Placing the Bays and Installing Internal/External Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

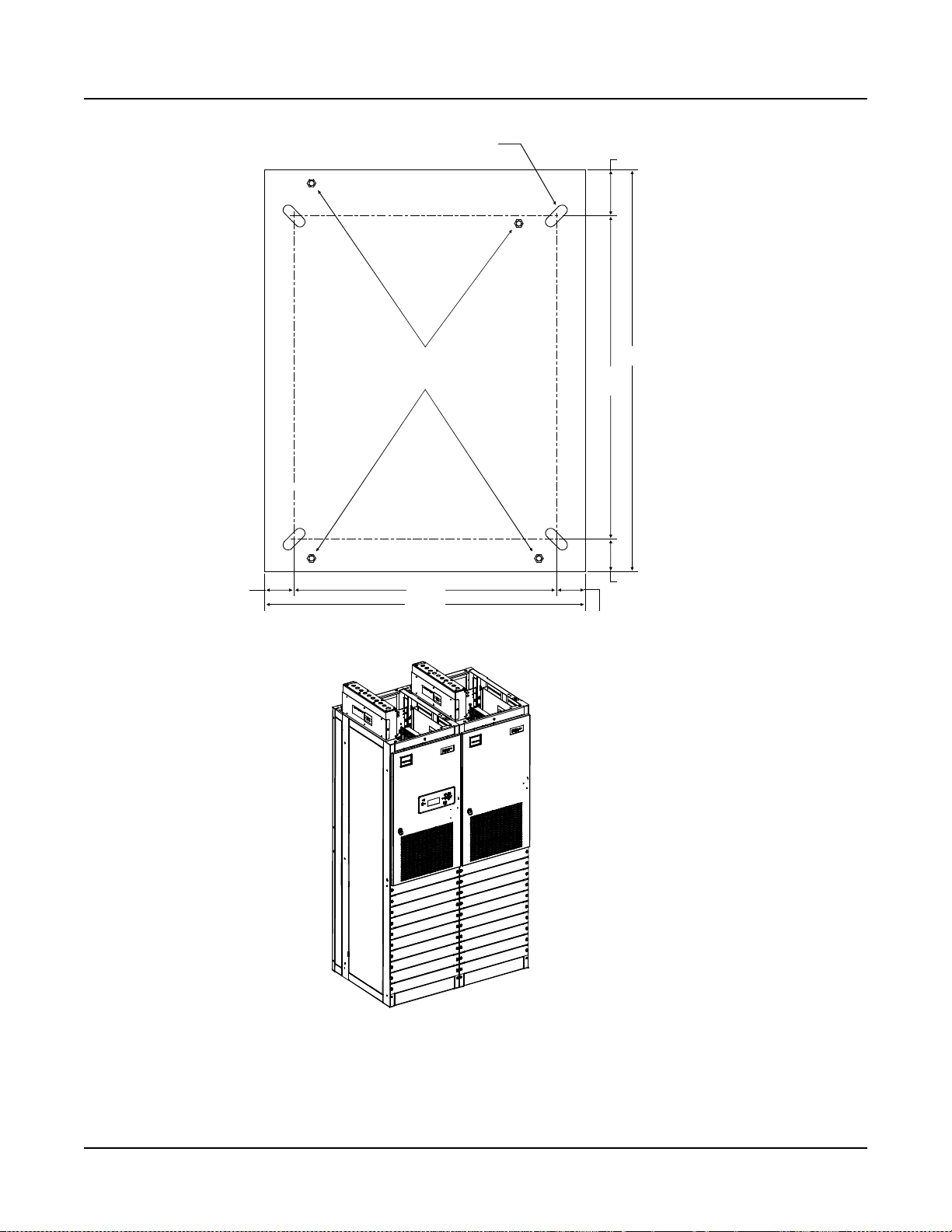

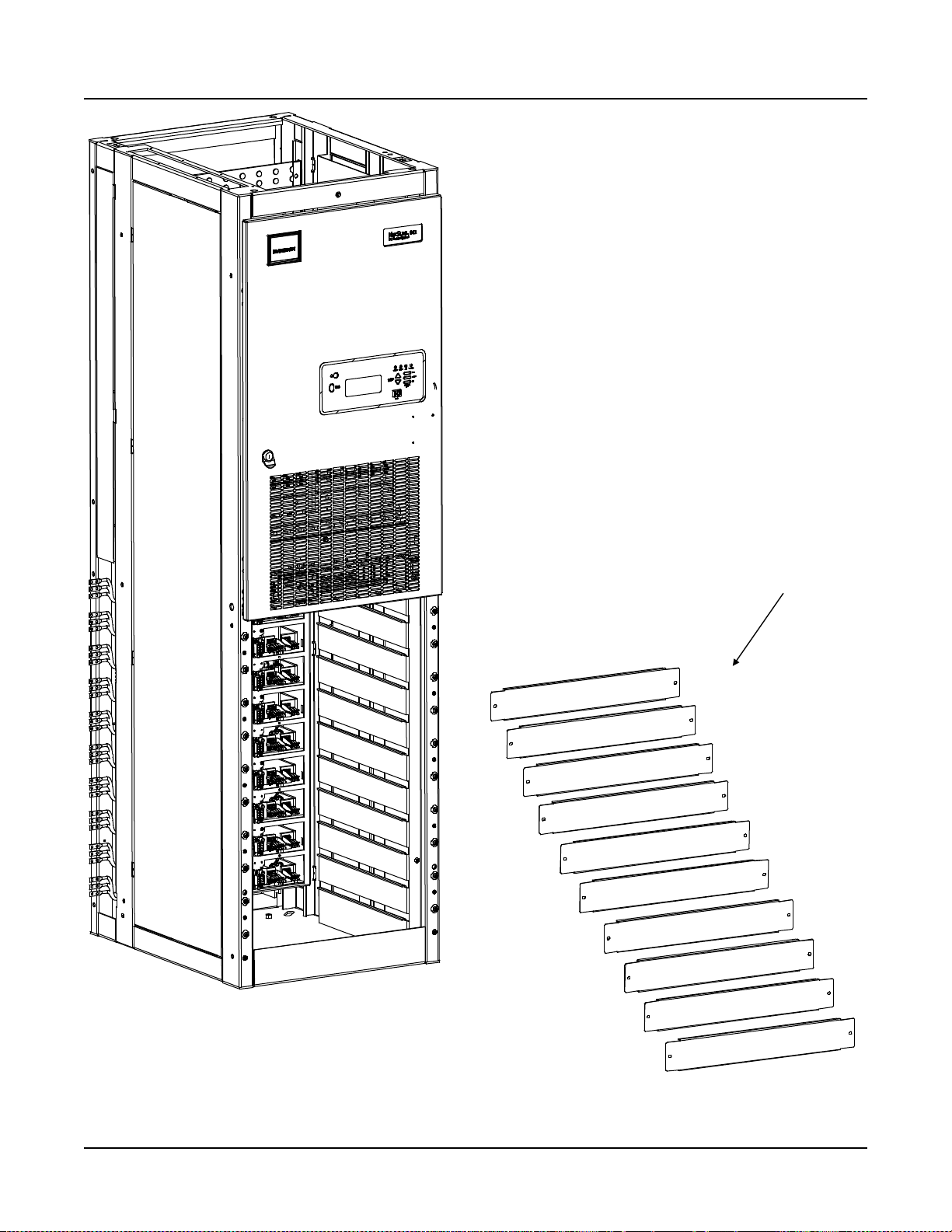

Page 27

Installation Instructions Section 5876

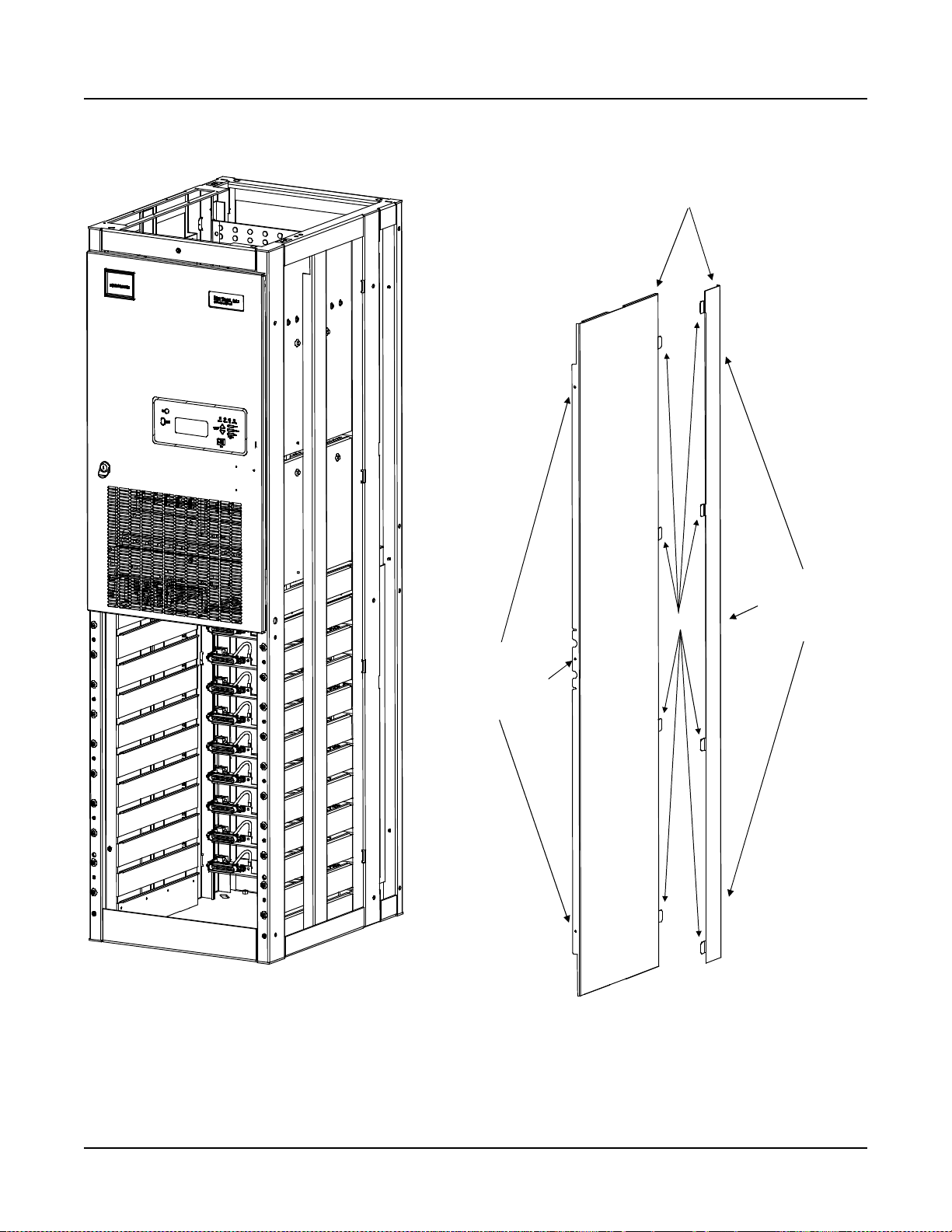

PCU Mounting Posi

tion

Blank Cover Panels

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

Figure 2-4

Removing Rectifier Mounting Position Blank Cover Panels from Power/Distribution Bay

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-13

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

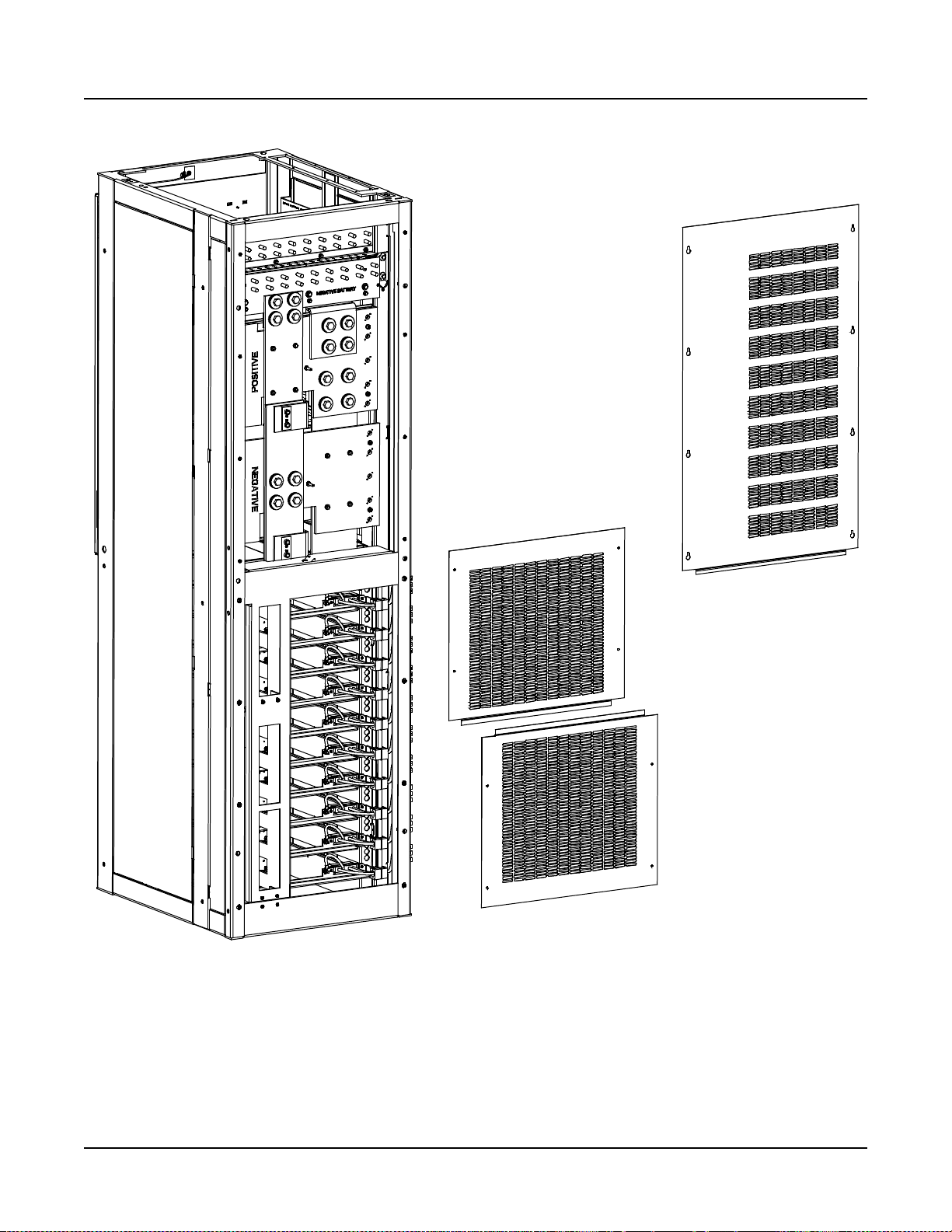

Page 28

Section 5876 Installation Instructions

Rear

Cover

Panels

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

Figure 2-5

Removing Rear Cover Panels from Power/Distribution Bay

Page 2-14 Chapter 2. Placing the Bays and Installing Internal/External Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 29

Installation Instructions Section 5876

Remove/Install

Screws through

Rear of Bay at

these Points

Side

Cover

Panels

TABS

Remove/Install

Screws through

Front of Bay at

these Points

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

Figure 2-6

Removing Side Cover Panels from Po wer /Distributio n Bay

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-15

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 30

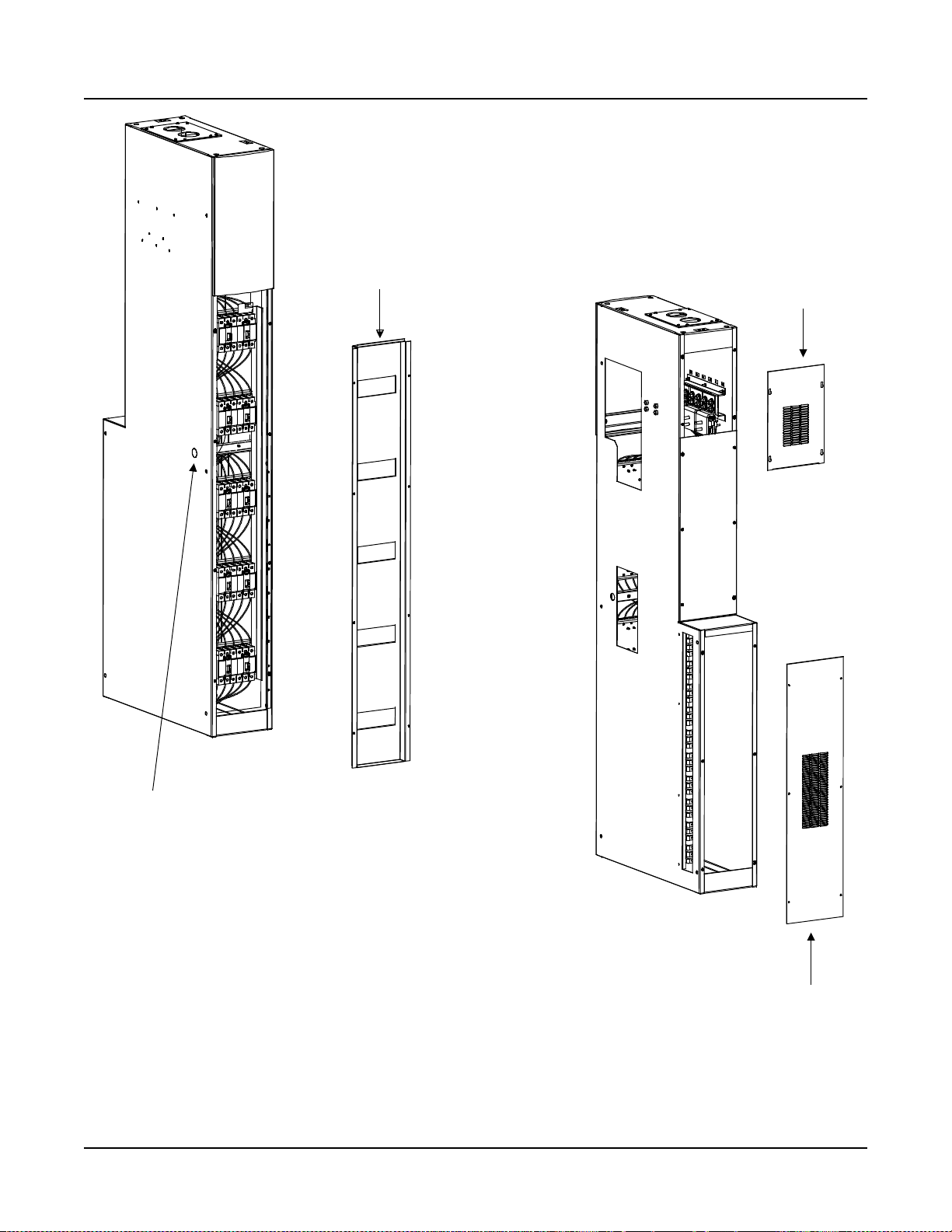

Section 5876 Installation Instructions

Front

Cover

Panel Rear Upper

Cover Panel

Rear Lower

Cover Panel

Remove Plug-Button

on all but End Cabinet

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

Page 2-16 Chapter 2. Placing the Bays and Installing Internal/External Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 2-7

Removing Front and Rear Cover Panels, and Plug-Button

from PDSC (AC Input 'Power Distribution Service Cabinet')

Page 31

Installation Instructions Section 5876

Hardware Build-Up: (use ground washers

in ce

nter tie points each side)

Bolt

, Ground Washer, Bay/Cabinet

Sides,

Ground Washer, Nut

Hardware Build-Up: (use in remain

ing connection points)

Bolt, L

ock Washer, Flat Washer, Bay/C

abinet Sides,

Flat Washer, Lo

ck Washer, Nut

Bay/Cabinet S

ides Bay/Cabinet Sides

Holes for Bolting

Power/Distribution

Bays a

nd PDSCs

Togethrer

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-17

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 2-8

Bolting Power/Distribut ion Bay to PDSC Cabinet

Page 32

Section 5876 Installation Instructions

Hardware Build-Up: (use ground washers

in center tie points each side)

Bolt, Ground Washer, Bay/Cabinet Sides,

Ground Washer, Nut

Hardware Build-Up: (use in remaining connection points)

Bolt, Lock Washer,Flat Washer, Bay/Cabinet Sides,

Flat Washer, Lock Washer, Nut

Bay/Bay Sides Bay/Bay Sides

Holes for Bolting

Power/Distribution

Bays Togethrer

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

Figure 2-9

Bolting Power/Distribut ion Bay to Power/Distribution Bay

Page 2-18 Chapter 2. Placing the Bays and Installing Internal/External Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 33

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

INSTALLING POWER/DISTRIBUTION BAY TO POWER/DISTRIBUTION B AY NEGATIVE AND POSITIVE BUSBAR LINKS

Note: Refer to the next procedure to connect the newer style bay to an existing older

style bay.

Note: Apply electrical anti-oxidation compound to mating surfaces of busbars before

connecting together.

Procedure

1) Refer to Figure 2-10 or Figure 2-11 and install the "Negative Busbar Link"

between the "Negative Side" of one bay and the "Negative Side" of the adjacent

bay. Use the supplied 3/8-16 x 1-1/2" bolts and hardware. Hardware build-up is :

Bolt, Belleville Lock Washer, Belleville Lock Washer (concave side of Belleville

lock washers face each other), Hardened Flat Washer. Torque to 180 in-lbs.

2) Refer to Figure 2-10 or Figure 2-11 and install the "Positive Busbar Link "

between the "Positive Side" of one bay and the "Positive Side" of the adjacent

bay. Use the supplied 3/8-16 x 1-1/2" bolts and hardware. Hardware build-up is :

Bolt, Belleville Lock Washer, Belleville Lock Washer (concave side of Belleville

lock washers face each other), Hardened Flat Washer. Torque to 180 in-lbs.

3) For bays with PDSCs, the busbar link cover shield is installed after all mounting

and electrical connection procedures are completed.

4) Repeat these steps for each adjacent bay.

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-19

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 34

Section 5876 Installation Instructions

3/8-16 x 1-1/2" Bolt

3/8" Belleville Lock Washer

3/8" Belleville Lock Washer

(concave side of Belleville

Lock Washers face each other)

3/8” Hardened Flat Washer

(10 Places per Busbar)

POSITIVE

BUSBAR LINK

NEGATIVE

BUSBAR LINK

Slide Busbar Links Under

Bays' Upright Channels.

Use Bolt Holes as Shown

in Illustration.

Torque to 180 in-lbs.

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

Figure 2-10

Installing Power/Distribution Bay to Power/Distribution Bay Negative and Positive Busbar Links

(Lists 1 and 11)

Page 2-20 Chapter 2. Placing the Bays and Installing Internal/External Busbars

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 35

Installation Instructions Section 5876

Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B) Issue AT, April 26, 2013

POSITIVE

BUSBAR LINK

3/8-16 x 1-1/2" Bolt

3/8" Belleville Lock Washer

3/8" Belleville Lock Washer

(concave side of Belleville

Lock Washers face each other)

3/8” Hardened Flat Washer

(10 Places per Busbar)

NEGATIVE

BUSBAR LINK

Slide Busbar Links Under

Bays' Upright Channels.

Use Bolt Holes as Shown

in Illustration.

Torque to 180 in-lbs.

(installed after

and electrical

are completed)

Busbar Link

Cover Shield

all mounting

connection

procedures

Figure 2-11

Installing Power/Distribution Bay to Power/Distribution Bay Negative and Positive Busbar Links

(Lists 2 and 12, w/ List 30 or 31)

Chapter 2. Placing the Bays and Installing Internal/External Busbars Page 2-21

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 36

Section 5876 Installation Instructions

Issue AT, April 26, 2013 Spec. No. 582140000 (Models 802

NLDB, 802NLEB and 802NL-B)

INSTALLING POWER/DISTRIBUTION BAY TO POWER/DISTRIBUTION B AY NEGATIVE AND POSITIVE BUSBAR LINKS (NEWER STYLE BAY TO AN EXISTING OLDER STYLE BAY)

Note: Apply electrical anti-oxidation compound to mating surfaces of busbars before

connecting together.

Procedure

1) Refer to Figure 2-12 and install the "Negati ve Busbar Link " betwee n the

"Negative Side" of one bay and the "Negative Side" of the adjacent bay. Use the

supplied 3/8-16 x 1-1/2" bolts and hardware. Hardware build-up is: Bolt,

Belleville Lock Washer, Belleville Lock Washer (concave side of Belleville lock

washers face each other), Hardened Flat Washer. Torque to 180 in-lbs.

2) Refer to Figure 2-12 and install the "Positive Busbar Link " between the "P os itive

Side" of one bay and the "Positive Side" of the adjacent bay. Use the supplied

3/8-16 x 1-1/2" bolts and hardware. Hardware build-up is: Bolt, Belleville Lock