Page 1

MVME7100 Single Board Computer

Installation and Use

6806800E08A

November 2008

Page 2

©

Copyright 2008 Emerson

All rights reserved.

Trademarks

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service

marks of Emerson Electric Co.

All other product or service names are the property of their respective owners.

®

PICMG

PCI Industrial Computer Manufacturers Group.

, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the

©

2008 Emerson Electric Co.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Emerson assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Emerson reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Emerson to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded f or personal use , or referenced in another document as a URL to

a Emerson website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise altered

without the permission of Emerson,

It is possible that this publication may contain reference to or information about Emerson products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Emerson intends to announce such Emerson products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S . Go vernment, the f ollowing notice shall apply unless

otherwise agreed to in writing by Emerson.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in Technical

Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and Documentation clause

at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Emerson Network Power - Embedded Computing

2900 South Diablo Way, Suite 190

Tempe, AZ 85282

USA

Page 3

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.3 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.4 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.4.1 Supported Board Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.4.2 Board Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2 Hardware Preparation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2 Unpacking and Inspecting the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.3 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.3.1 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.3.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3.3 Thermal Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.4 Thermally Significant Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.5 Equipment Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4 Configuring the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4.1 SMT Configuration Switch, S1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.1.1 Safe Start Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.1.2 Boot Block B Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.1.3 Flash Bank Write Protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.1.4 JTAG Pass-Thru . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.1.5 Low Memory Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.1.6 PMC 133 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.1.7 Master WP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.4.2 Geographical Address Switch, S2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.4.3 VME System Controller Select, S2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.5 Installing Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.5.1 Transition Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.5.2 PMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.5.3 XMCspan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

MVME7100 Single Board Computer Installation and Use (6806800E08A)

3

Page 4

Contents

2.6 Installing and Removing the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.7 Completing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.8 Factory Installed Linux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3 Controls, LEDs, and Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.2 Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.3 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3.1 Reset/Abort Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3.2 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.3.3 Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.3.3.1 XMC Expansion Connector (J6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.3.3.2 Ethernet Connectors (J4A/J4B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.3.3.3 PCI Mezzanine Card (PMC) Connector s (J11 – J14, J21 – J23) . . . . . . . . . . 53

3.3.3.4 Serial Port Connector (COM1/J1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.3.3.5 VMEbus P1 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.3.3.6 VMEbus P2 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.3.3.7 MVME7216E PMC I/O Module (PIM) Connectors (J10, J14) . . . . . . . . . . . . 63

3.3.3.8 USB Connector (J2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.4 Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.4.1 Processor COP Header (P4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.4.2 Boundary Scan Header (P5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.3 Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.4 I2C Serial Interface and Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.5 System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.6 Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.7 Ethernet Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.8 Local Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.8.1 Flash Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.8.2 NVRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.8.3 Quad UART (QUART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.8.4 Control and Timers PLD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.9 DUART Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.10 PCI-E Port 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.10.1 VME Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.10.2 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.11 XMC Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.12 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.12.1 Power Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.12.2 Power Supply Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.12.3 Power Supply Filtering and Fusing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 5

Contents

4.13 Clock Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.13.1 System Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.13.2 Real Time Clock Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.13.3 Local Bus Controller Clock Divisor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.14 Reset Control Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.15 Real Time Clock Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5 Transition Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.2 Transition Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.4 SEEPROM Address Switch, S1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.5 Rear Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.6 PMC Input/Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6 MOTLoad Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.2 Implementation and Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.3 MOTLoad Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.3.1 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.3.2 Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6.3.3 Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.4 Using the Command Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.4.1 Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.4.2 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.5 Firmware Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.5.1 Default VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.5.2 Control Register/Control Status Register Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.5.3 Displaying VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.5.4 Editing VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.5.5 Deleting VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.5.6 Restoring Default VME Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.6 Remote Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.7 Boot Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.7.1 Checksum Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.7.2 Image Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.7.3 User Images. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.7.4 Alternate Boot Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.7.5 Alternate Boot Images and Safe Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.7.6 Boot Image Firmware Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.8 Startup Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

A Battery Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

A.1 Battery Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

MVME7100 Single Board Computer Installation and Use (6806800E08A)

5

Page 6

Contents

B Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

B.1 Emerson Network Power - Embedded Computing Documents . . . . . . . . . . . . . . . . . . . . . . . 101

B.2 Manufacturers’ Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

B.3 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 7

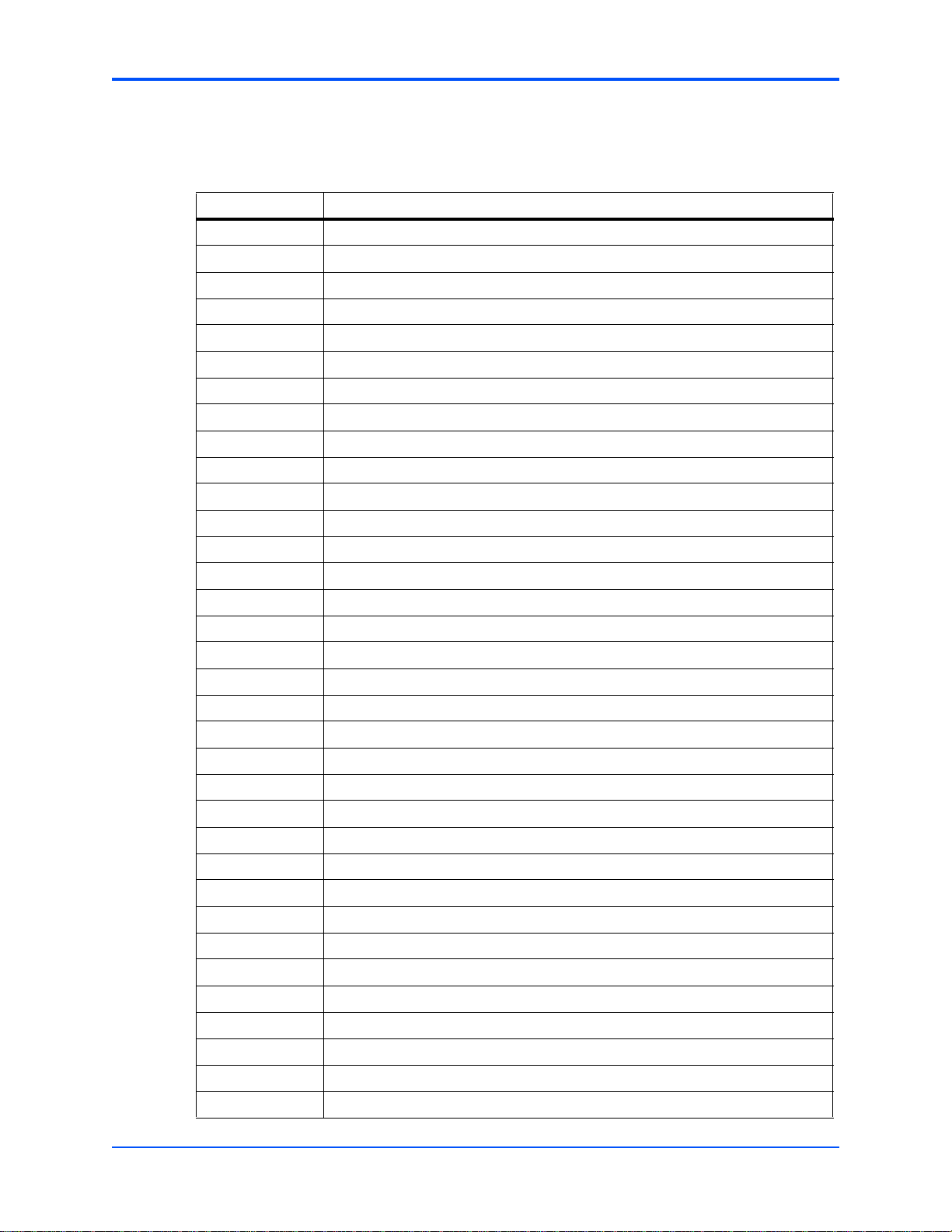

List of Tables

Table 1-1 Features List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 1-2 Board Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 1-3 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 1-4 Board Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 2-1 Startup Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 2-2 MVME7100 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 2-3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 2-4 Thermally Significant Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 2-5 Configuration Switch Settings (S1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 2-6 VME System Controller and GA Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 3-1 Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 3-2 Baseboard Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 3-3 XMC Expansion Connector (J6) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 3-4 Ethernet Connectors (J4A/J4B) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 3-5 PMC Slot 1 Connector (J11) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3-6 PMC Slot 1 Connector (J12) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 3-7 PMC Slot 1 Connector (J13) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 3-8 PMC Slot 1 Connector (J14) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 3-9 PMC Slot 2 Connector (J21) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 3-10 PMC Slot 2 Connector (J22) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 3-11 PMC Slot 2 Connector (J23) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 3-12 COM1 Port Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 3-13 VMEbus P1 Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 3-14 VME P2 Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 3-15 MVME721 Host I/O Connector (J10) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 3-16 USB Connector (J2) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 3-17 Processor COP Header (P4) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 3-18 Boundary Scan Header (P5) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 4-1 Clock Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 5-1 Transition Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 5-2 SEEPROM Address Switch Assignments (RTM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 5-3 Switch Settings and Device Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 5-4 Transition Module Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 5-5 Transition Module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 6-1 MOTLoad Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 6-2 MOTLoad Image Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table B-1 Emerson Network Power - Embedded Computing Publications . . . . . . . . . . . . . . . . 101

Table B-2 Manufacturer’s Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table B-3 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

MVME7100 Single Board Computer Installation and Use (6806800E08A)

7

Page 8

List of Tables

8

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 9

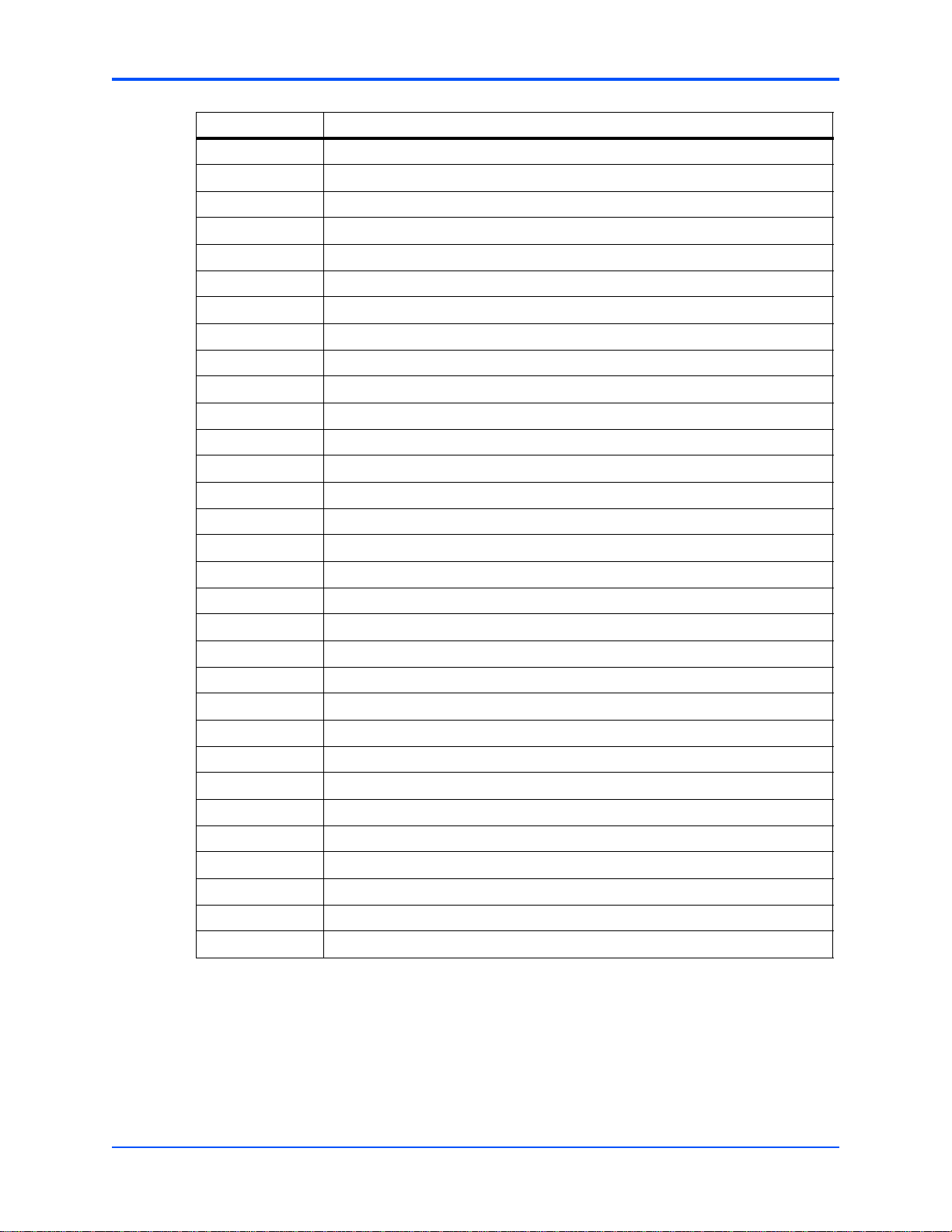

List of Figures

Figure 2-1 Primary Side Thermally Significant Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 2-2 Secondary Side Thermally Significant Components . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 2-3 Switch Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 2-4 SMT Configuration Switch Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 2-5 Geographical Address Switch Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 2-6 Typical Placement of a PMC Module on a VME Module . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 3-1 Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 3-2 Front P anel LEDs, Connectors, Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 4-1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 5-1 Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 5-2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 5-3 S1 Switch Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 5-4 Rear Panel Connectors and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 5-5 Installing the PIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure A-1 Battery Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

MVME7100 Single Board Computer Installation and Use (6806800E08A)

9

Page 10

List of Figures

10

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 11

About this Manual

Overview of Contents

This manual provides the information required to install and configure an MVME7100 Single

Board Computer. Additionally, this manual provides specific preparation and installation

information and data applicable to the board.

The MVME7100 is a high-performance, dual core processor board featuring the Freescale

8641D with a dedicated bridge to each processor.

This manual is divided into the f ollowing chapters and appendices:

Safety Notes, contains the cautions and warnings applicable to the use of this product.

Sicherheitshinweise, contains the cautions and warnings applicable to the use of this product

translated to the German language.

Chapter 1, Introduction, lists the f eatures of the MVME7100 baseboard, standard compliances,

and model numbers for boards and accessories.

Chapter 2, Hardware Preparation and Installation, includes a description of the MVME7100,

unpacking instructions, environmental, thermal, and power requirements, and how to prepare

and install the baseboard, transition module, and PMC module.

Chapter 3, Controls, LEDs, and Connectors, provides an illustration of the board components

and front panel details. This chapter also gives descriptions for the onboard and front panel

LEDs and connectors.

Chapter 4, Functional Description, describes the major featur es of the MVME7100 baseboard .

These descriptions include both programming and hardware characteristics of major

components.

Chapter 5, Transition Module, describes the MVME7216E transition module used with the

MVME7100.

Chapter 6, MOTLoad Firmware, describes the role, process and commands employed by the

MVME7100 diagnostic and initialization firmware MO TLoad. This chapter also briefly describes

how to use the debugger commands.

Appendix A, Battery Exchange, describes the procedure for replacing a battery.

Appendix B, Related Documentation, provides listings for publications, manufacturer’s

documents and related industry specification for this product.

MVME7100 Single Board Computer Installation and Use (6806800E08A)

11

Page 12

About this Manual

Abbreviations

This document uses the following abbreviations:

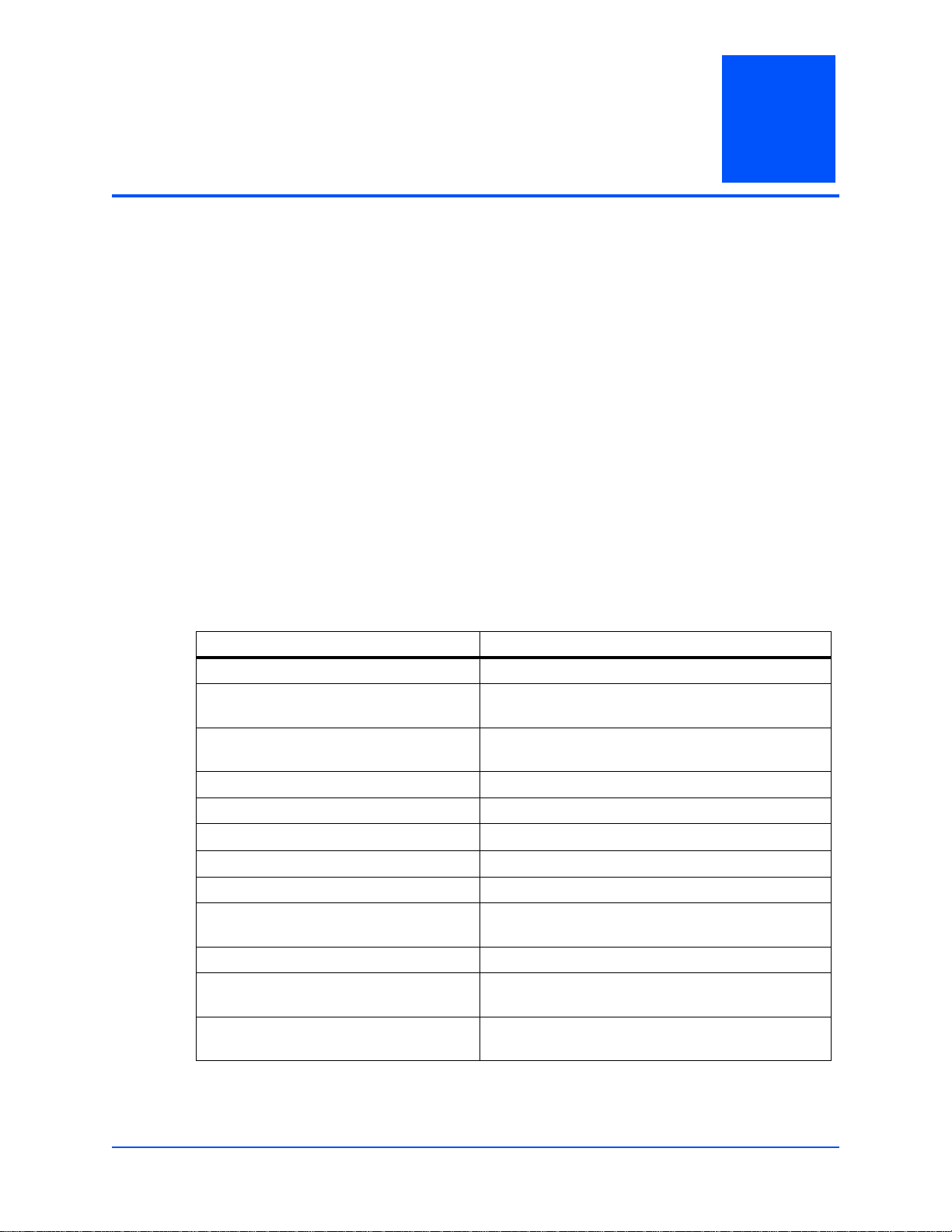

TERM MEANING

AAmps

A/D Analog/Digital

ANSI American National Standard Institute

ASIC Application Specific Integrated Circuit

BGA Ball Grid Array

BLT Block Transf er

CCB Core Complex Bus

CE Chip Enable

CFM Cubic Feet per Minute

CHRP (PowerPC) Common Hardware Reference Platform

CMC Common Mezzanine Card

COM Communications

COP Common On-chip Processor

COTS Commercial-Off-the-Shelf

CPU Central Processing Unit

CRC Cyclic Redundancy Check

DDR Dou ble Data Rate

oC Degrees Celsius

DLL Delay-Locked Loop

DMA Direct Memory Access

DRAM Dynamic Random Access Memory

DUART Dual Universal Asynchronous Receiver/Transmitter

ECC Error Correction Code

EEPROM Electrically Erasable Programmable Read-Only Memory

EPROM Erasable Programmable Read-Only Memory

FCC Federal Communications Commission

FEC Fast Ethernet Controller

FIFO First In First Out

12

F/W Firmware

fpBGA Flip chip Plastic Ball Grid Array

GB Gigabytes

Gbit Gigabit

Gbps Gigabits Per Second

GMII Gigabit Media Independent Interface

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 13

TERM MEANING

GPCM General Purpose Chip select Machine

GPR General Purpose Register

H/W Hardware

ID Identification

IDMA Independent Direct Memory Access

I/O Input/Output

IEEE Institute of Electrical and Electronics Engineers

I2C Inter IC

JTAG Joint Test Access Group

KB Kilobytes

KBAUD Kilo Baud

LBC Local Bus Controller

LCD Liquid Crystal Display

LED Light Emitting Diode

LSB Least Significant Byte

About this Manual

MB Megabytes

Mbit Megabit

MBLT Multiplexed Block Transfer

Mbps Megabits Per Second

MHz Megahertz

MII Media Independent Interface

MSB Most Significant Byte

Msb Most Significant Bit

MTBF Mean Time Between Failure

NAND (Not and) Flash that is used for storage

NOR (Not or) Flash that is used for executing code

OS Operating System

PBGA Plastic Ball Grid Array

PCI Peripheral Component Interconnect

PCI-X Peripheral Component Interconnect -X

PIC Programmable Interrupt Controller

PIM PCI Mezzanine Card In put/Output Module

PMC PCI Mezzanine Card (IEEE P1386.1)

PLD Programmable Logic Device

PLL Phase-Locked Loop

POR Power-On Reset

Ppm Parts Per Million

MVME7100 Single Board Computer Installation and Use (6806800E08A)

13

Page 14

About this Manual

TERM MEANING

PRD Product Requirements Document

PReP PowerPC Reference Platform

PrPMC Processor PCI Mezzanine Card

QUAR T Quad Universal Asynchronous Receiver/Transmitter

RAM Random Access Memory

Rcv Receive

RGMII Reduced Gigabit Media Independent Interface

ROM Read-Only Memory

RTBI Reduced Ten Bit Interface

RTC Real-Time Clock

RTM Rear Transition Module

sATA Serial AT Attachment

SBC Single Board Computer

SDRAM Synchro nous Dynamic Random Access Memory

SMT Surface Mount Technology

SODIMM Small-Outline Dual In-line Memory Module

SPD Serial Presence Detect

SRAM Static Random Access Memory

S/W Software

TBI Ten Bit Interface

TSEC Three-Speed Ethernet Controller

2eSST Two edge Source Synchronous T ransfer

UART Universal Asynchronous Receiver/Transmitter

USB Universal Serial Bus

VVolts

VIO Input/Output Voltage

VITA VMEbus International Trade Association

VME VMEbus (Versa Module Eurocard)

VPD Vital Product Data

WWatts

Xmit Transmit

14

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 15

Conventions

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related

Courier + Bold Used to characterize user input and to

Reference Used for references and for table and figure

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

About this Manual

(digits are 0 through F), for example used for

addresses and offsets

elements or commands in body text

separate it from system output

descriptions

[text] Notation for software buttons to click on the

screen and parameter description

... Repeated item for example node 1, node 2,

..., node 12

.

.

.

.. Ranges, for example: 0..4 means one of the

| Logical OR

Omission of information from

example/command that is not necessary at

the time being

integers 0,1,2,3, and 4 (used in registers)

Indicates a hazardous situation which, if not

avoided, could result in death or serious

injury

Indicates a hazardous situation which, if not

avoided, may result in minor or moderate

injury

Indicates a property damage message

No danger encountered. Pay attention to

important information

MVME7100 Single Board Computer Installation and Use (6806800E08A)

15

Page 16

About this Manual

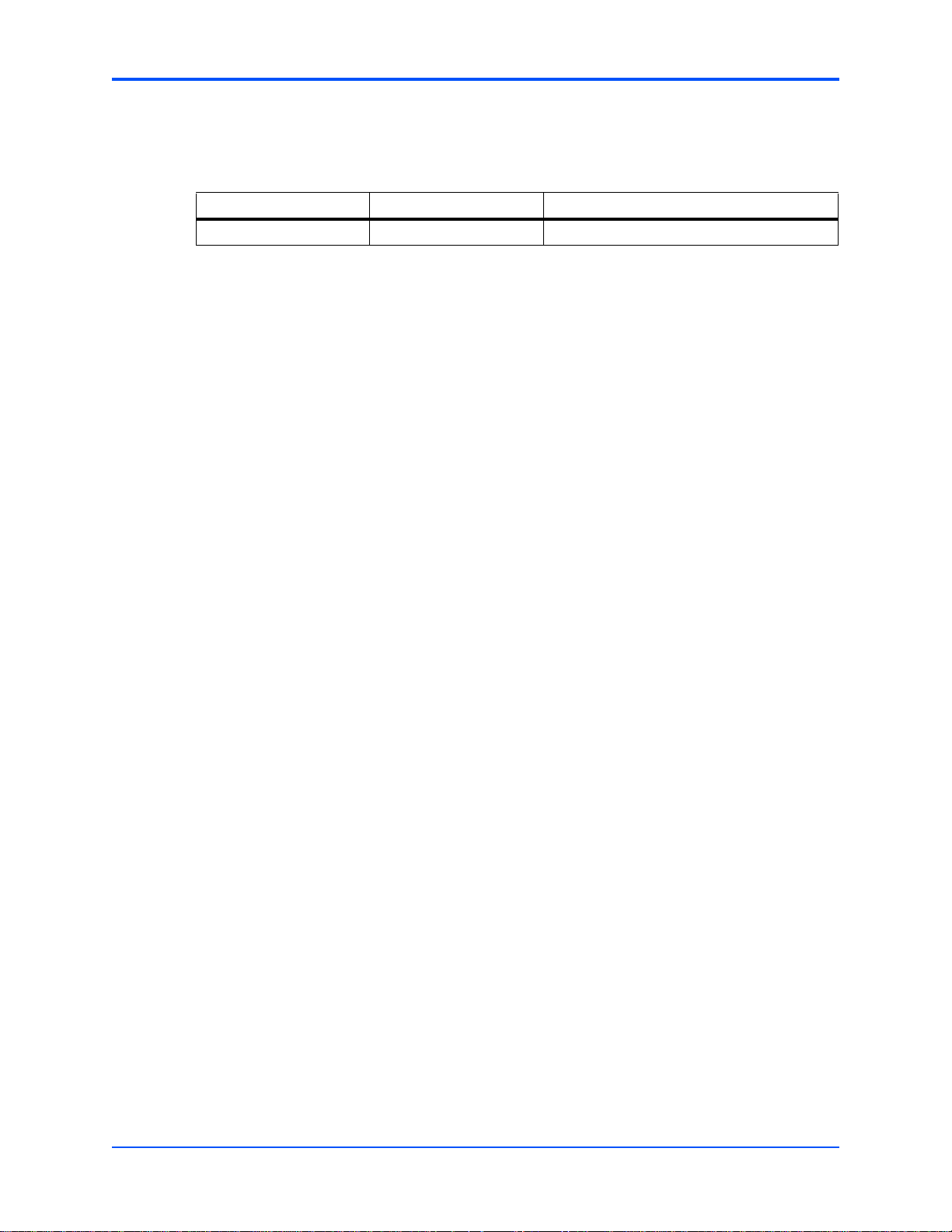

Summary of Changes

This is the first edition of the MVME7100 Single Board Computer Installation and Use.

Part Number Publication Date Description

6806800E08A November 2008 First edition

Comments and Suggestions

We welcome and appreciat e your comments on our do cumentation. W e want to know what y ou

think about our manuals and how we can make them better.

Mail comments to us by filling out the following online form:

http://www.emersonnetworkpowerembeddedcomputing.com/ > Contact Us > Online For m

In “Area of Interest” select “Technical Docume ntation". Be sure to include the ti tle, part number ,

and revision of the manual and tell us how you used it.

16

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 17

Safety Notes

This section provides warnings that precede potentially dangerous procedures

throughout this manual. Instructions containe d in the warnings must be f ollowed during

all phases of operation, service, and repair of this equipment. You should also employ

all other safety precautions necessary for the operation of the equipment in your

operating env ironment. Failure to comply with these precautions or with specific

warnings elsewhere in this manual could result in personal injury or damage to the

equipment.

Emerson intends to provide all necessary information to install and handle the product

in this manual. Because of the complexity of t his product and its v arious uses, we do not

guarantee that the given informa tion is complete. If you need a dditional information , ask

your Emerson representative.

EMC

The product has been designed to meet the standard industrial safety requirements. It

must not be used except in its specific area of office telecommunication industry and

industrial control.

Only personnel trained by Emerson or persons qualified in electronics or electrical

engineering are authorized to install, remove or maintain the product.

The information give n in this man ual is meant to complete th e knowledge of a specialist

and must not be used as replacement for qualified personnel.

Keep away from live circuits inside the equipment. Operating personnel must not

remove equipment co vers. Only F actory Authorized Service P ersonnel or other qualif ied

service personnel may remove equipment covers for internal subassembly or

component replacement or any internal adjust ment.

Do not install substitute parts or perform any unauthorized modification of the

equipment or the warranty may be v oided. Contact your local Emer son representative for

service and repair to make sure that all safety features are maintained.

This equipment has been tested and f ound to comply with th e limits for a Class A digi tal

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interf erence when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be require d to correct the interference at his own expense.

Changes or modifications not expressly approved by Emerson Network Power could

void the user's authority to operate the equipment. Board products are tested in a

MVME7100 Single Board Computer Installation and Use (6806800E08A)

17

Page 18

Safety Notes

representative system to show compl iance with the above mentioned requirements. A

proper installation in a compliant system will maintain the required performance. Use

only shielded cables when connecting peripherals to assure that appropriate radio

frequency emissions compliance is maintain ed.

18

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 19

Operation

Product Damage

High humidity and condensation on the board surface causes short circuits.

Do not operate the board outside the spec if ie d environmental limits.

Make sure the board is completely dry and there is no moisture on any surface before

applying power.

Damage of Circuits

Electrostatic discharge and incorrect installation and removal can damage circuits or

shorten their life.

Before touching the b oard or electr onic component s, make sure that y ou are w orking in

an ESD-safe environment.

Board Malfunction

Switches marked as “reserved” might carry production-related funct ions and can cause

the board to malfunction if their setting is changed.

Do not change settings of switc hes marked as “reserved”. The setting of s witches which

are not marked as “reserved” has to be checked and cha nged bef ore board installation.

Safety Notes

Installation

Data Loss

Powering down or removing a board before the operating system or other software

running on the board has been pr ope rl y shut do wn may cause corruption of data or file

systems.

Make sure all software is completely shut down before removing power from the board

or removing the board from the chassis.

Product Damage

Only use injector handles for board insertion to avoid damage to the front panel and/or

PCB. Deformation of the front panel can cause an electrical short or other board

malfunction.

Product Damage

Inserting or removing modules with power applied ma y result in damage to module

components.

Before installing or remo ving additional devices or modules, read the documentation

that came with the product.

MVME7100 Single Board Computer Installation and Use (6806800E08A)

19

Page 20

Safety Notes

Cabling and Connectors

Product Damage

RJ-45 connectors on modules are either twisted-pair Etherne t (TPE) or E1/T1/J1 network

interfaces. Connecting an E1/T1/J1 l ine to an Ethernet connector may damage your

system.

z Make sure that TPE connectors near your working area are clearly marked as

network connectors.

z Ve rify that the length of an electric cable connected to a TPE bushing does not

exceed 100 meters.

z Make sure the TPE bushing of the system is connected only to safety extra low

voltage circuits (SELV circuits).

If in doubt, ask your system administrator.

Battery

Board/System Damage

Incorrect exchange of lithium batteries can result in a hazardous explosion.

When exchanging the on-board lithium battery, make sure that the new and the old

battery are exactly the same battery models.

If the respective battery model is not available, contact your local Emerson sales

representative for the availability of alternative, officially approved battery models.

Data Loss

Exchanging the battery can result in loss of time settings. Backup power prevents the

loss of data during exchange.

Quickly replacing the battery may save time settings.

Data Loss

If the battery has low or insufficient power the RTC is initialized.

Exchange the battery before seven years of actual battery use have elapse d.

PCB and Battery Holder Damage

Removing the battery with a screw driver may damage the PCB or the battery holder. To

prevent damage, do not use a screw driver to remove the battery from its holder.

20

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 21

Sicherheitshinweise

Dieses Kapitel enthält Hinweise, di e potentiell gefährlichen Pr ozeduren innerhalb dieses

Handbuchs vorrangestellt sind. Beachten Sie unbedingt in allen Phasen des Betriebs,

der Wartung und der Reparatur des Systems die Anweisungen, die dies en Hinweisen

enthalten sind. Sie sollten außerdem alle anderen Vorsichtsmaßnahmen treffen, die für

den Betrieb des Produktes innerhalb Ihre r Betriebsumgebung notwendig sind. W enn Sie

diese Vorsichtsmaßnahmen oder Sicherheitshinweise, die an anderer Stelle diese

Handbuchs enthalten sind, nicht beachten, kann das Verletzungen oder Schäden am

Produkt zur Folge haben.

Emerson ist darauf bedacht, alle notwendigen Informationen zum Einbau und zum

Umgang mit dem Produkt in diesem Handbuch bereit zu stellen. Da es sich jedoch um

ein komplexes Produkt mit vielfältigen Einsatzmöglichkeiten handelt, können wir die

Vollständigkeit der im Handbuch enthaltenen Informat ionen nicht garantieren. Falls Sie

weitere Informationen be nötigen sollten, wenden Sie sich bitte an di e für Sie zuständige

Geschäftsstelle von Emerson.

EMV

Das System erfüllt die für die Industrie geforderten Sicherheitsvorschriften und darf

ausschließlich für Anwendungen in der Telekommunikationsindustrie und im

Zusammenhang mit Industriesteuerungen verwendet werden.

Einbau, Wartung und Betrieb dürfen nur von durch Emerson ausgebildetem oder im

Bereich Elektronik oder Elektr otechnik qualifiziertem Personal durchgeführt werden. Die

in diesem Handbuch enthalt enen Informationen dienen aussc hließlich dazu, das Wissen

von Fachpersonal zu ergänzen, können dieses jedoch nicht ersetzen.

Halten Sie sich von str omführenden Leitungen innerhalb des Pr oduktes fern. Entf ernen

Sie auf keinen Fall Abdeckungen am Produkt. Nur werksseitig zugelassenes

Wartungspersonal oder ander weitig qualifiziertes Wartungsper sonal darf Abdec kungen

entfernen, um Komponenten zu ersetzen oder andere Anpassungen vorzunehmen.

Installieren Sie keine Ersatzteile oder führen Sie keine unerlaubten Veränderungen am

Produkt durch, son st verfällt die Garantie. We nden Sie sich für W artung oder Reparatur

bitte an die für Sie zuständige Gesc häftss telle v on Emer son . So ste llen Sie s ich er, dass

alle sicherheitsrelevanten Aspekte beachtet werden .

Das Produkt wur de in einem Emerson Standar dsystem getestet. Es erfü llt die für digitale

Geräte der Klasse A gültigen Grenzwerte in einem solchen System gemäß den FCCRichtlinien Abschnitt 15 bzw. EN 55022 Klasse A. Diese Grenzwerte sollen einen

angemessenen Schutz vor Störstrahlung beim Betrieb des Produktes in Gewer be- sowie

Industriegebieten gewährleisten.

MVME7100 Single Board Computer Installation and Use (6806800E08A)

21

Page 22

Sicherheitshinweise

Das Produkt arbeitet im Hochfrequenzbereich und erzeugt Störstrahlung. Bei

unsachgemäßem Einbau und anderem als in diesem Handbuch beschriebenen Betrieb

können Störungen im Hochfrequenzbereich auftreten.

Wird das Produkt in einem Wohngebiet betrieben, so kann dies mit grosser

Wahrscheinlichkeit zu starken Störungen führen, welche dann auf Kosten des

Produktanwenders beseitigt werden müssen. Änderungen oder Modifikationen am

Produkt, welche ohne ausdrückliche Genehmigung von Emerson Network Power

durchgeführt werden, k önnen dazu führen, dass der Anwender die Genehmigung zum

Betrieb des Produktes verliert. Boar dprodukte wer den in einem repräsentativen System

getestet, um zu zeigen, dass das Board den oben aufgeführten EMV-Richtlinien

entspricht. Eine ordnungsgemässe Installation in einem System, welches die EMVRichtlinien erfüllt, stellt sicher , dass das Pr odukt gemäss den EMV -Richtlin ien betrieben

wird. V erwenden Sie nur abgesc hirmte Kabel zum Anschluss v on Zusatzmodulen. So ist

sichergestellt, dass sich die Aussendung von Hochfrequenzstrahlung im Rahmen der

erlaubten Grenzwerte bewegt.

Warnung! Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im

Wohnbereich Funkstörungen verursachen. In diesem Fall kann vom Betreiber verlangt

werden, angemessene Maßnahmen durchzuführen.

Betrieb

1 Beschädigung des Produktes

Hohe Luftfeuchtigkeit und Kondensat auf der Oberfläche des Produktes könne n zu

Kurzschlüssen führ en.

Betreiben Sie das Produkt nur innerhalb der angegebenen Grenzwerte für die relative

Luftfeuchtigkeit und Temperatur. Stellen Sie vor dem Einschalten des Stroms sicher,

dass sich auf dem Produkt kein Kondensat befindet.

Beschädigung von Schaltkreisen

Elektrostatische Entladung und unsachgemäßer Ein- und Ausbau des Produktes kann

Schaltkreise beschädigen oder ihre Lebensdauer verk ürzen.

Bevor Sie das Produkt oder elektronische Komponenten berühren, vergewissern Sie

sich, daß Sie in einem ESD-geschützten Bereich arbeiten.

Fehlfunktion des Produktes

Schalter, die mit 'Reserved' gekennzeichnet sind, können mit produktionsrelevanten

Funktionen belegt sein. Das Ändern dieser Schalter kann im normalen Betrieb

Störungen auslösen.

Ver stellen Sie n ur solche Schalte r, die nicht mit 'Reserved' gekennzeichnet sind. Prüf en

und ggf. ändern Sie die Einstellungen der nicht mit 'Reserved' gekennzeichneten

Schalter, bevor Sie das Produkt installieren.

22

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 23

Installation

Datenverlust

Das Herunterfahren oder die Deinstallation eines Boar ds bevor das Betriebssys tem oder

andere auf dem Board laufende Soft ware ordnungsmemäss beendet wurde, kann zu

partiellem Datenverlust sowie zu Schäden am Filesystem führen.

Stellen Sie sicher, dass sämtliche Software auf dem Board ordnungsgemäss beendet

wurde, bev or Sie das Boar d herunterfahren oder das Boa rd aus dem Cha ssis entfernen.

Beschädigung des Produktes

Fehlerhafte Installation des Produktes kann zu einer Beschädigung des Produktes

führen.

Verwenden Sie die Handles, um das Produkt zu installieren/deinstallieren. Auf diese

Weise vermeiden Sie, dass das F ace Plate oder die Platine def ormiert oder zerstört wird.

Beschädigung des Produktes und von Zusatzmodulen

Fehlerhafte Installation von Zusat zmodulen, kann zur Beschädigung des Pr oduktes und

der Zusatzmodule führen.

Lesen Sie daher vor der Ins tallation von Zusat zmodulen die zugehörige Dokumentation.

Sicherheitshinweise

Kabel und Stecker

Beschädigung des Produktes

Bei den RJ-45-Steckern, die sich an dem Pr odukt befinden, handelt es sich entwe der um

Twisted-Pair-Ethernet (TPE) oder um E1/T1/J1-Stecker. Beachten Sie, dass ein

versehentliches Anschlie ßen e iner E1 /T1 /J1- Leit ung an eine n TPE-St ecker das Produkt

zerstören kann.

z Kennzeichnen Sie deshalb TPE-Anschlüsse in der Nähe Ihres Arbeitsplatzes

deutlich als Netzwerkanschlüsse.

z Stellen Sie sicher , dass die Län ge eines mit Ihrem Produkt verb undenen TPE-Kabels

100 m nicht überschreitet.

z Das Produkt darf über die TPE-Stecker nur mit einem Sicherheits-Kleinspannungs-

Stromkreis (SELV) verbunden werden.

Bei Fragen wenden Sie sich an Ihren Systemverwalter.

MVME7100 Single Board Computer Installation and Use (6806800E08A)

23

Page 24

Sicherheitshinweise

Batterie

Beschädigung des Blades

Ein unsachgemäßer Einbau der Batterie kann gefährliche Explosionen un d

Beschädigungen des Blades zur Folge haben.

Verwenden Sie deshalb nur den Batterietyp, der auch bereits eingesetzt wurde und

befolgen Sie die Installationsanleitung.

Datenverlust

Wenn Sie die Batterie austauschen, können die Zeiteinstellungen verloren gehen. Eine

Backupversorgung verhindert den Datenverlust während des Austauschs.

Wenn Sie die Batterie schnell austauschen, bleiben die Zeiteinstellungen

möglicherweise erhalten.

Datenverlust

Wenn die Batterie wenig oder unzureichend mit Spannung versorgt wird, wird der RTC

initialisiert.

Tauschen Sie die Batterie aus, bevor sieben Jahre tatsächlicher Nutzung vergangen

sind.

Schäden an der Platine oder dem Batterie h al te r

Wenn Sie die Batterie mit einem Schra ubendreher entfernen, können die Platine oder der

Batteriehalter beschädigt werden.

Um Schäden zu vermeiden, sollten Sie keinen Schraubendreher zum Ausbau der

Batterie verwenden.

Umweltschutz

Entsorgen Sie alte Batterien und/oder Blades/Systemkomponenten/RTMs stets gemäß

der in Ihrem Land gültigen Gesetzgebung, wenn möglich immer umweltfreundlich.

24

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 25

Introduction

1.1 Features

The MVME7100 Single Board Computer is a VMEbus board based on t he MC8640D and

MC8641D integrated PowerPC processors. It is a full 6U board and occupies a single VME card

slot with PMC cards installed. The MVME7100 is compliant with the VITA standards VMEbus,

2eSST, and PCI-X as listed in Appendix B, Related Documentation.

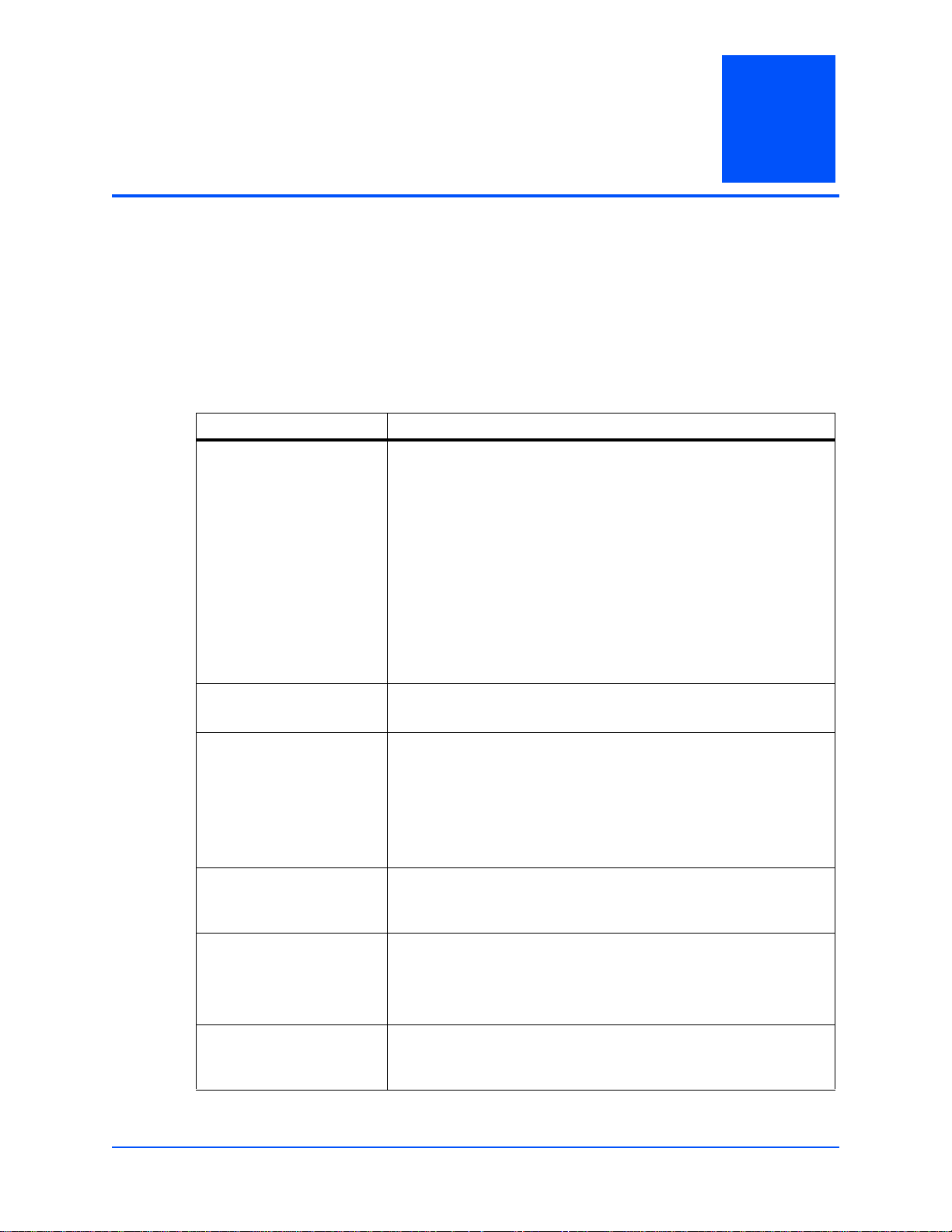

Table 1-1 Features List

Function Features

Processor / Host Controller /

Memory Controller

One MC864

Two e600 cores with integrated L2

Core frequency of 1.067 or 1.33 GHz

One integrated four channel DMA controller

Two integrated PCIE interfaces

Four integrated 10/100/1000 Ethernet controllers

One integrated DUART

Two integrated I

One integrated Programmable Interrupt Controller

One integrated Local Bus Controller

Two integrated DDR2 SDRAM controllers

xD Integrated Processor

2

C controllers

1

System Memory Two banks of DDR2 SDRAM with ECC

1GB, 2 GB, or 4 GB

2

I

C One 8 KB VPD serial EEPROM

Two 64 KB user configuration serial EEPROMs

One Real Time Clock (RTC) with removable battery

Dual temperature sensor

Two SPDs for memory

Connection to XMCspan and rear transition module

NOR Flash 128 MB soldered flash with two alternate 1 MB boot sectors selectable

via hardware switch

H/W switch or S/W bit write protection for entire logical bank

NAND Flash Up to two devices available:

z 4 GB - 1 device

z 8 GB - 1 device

z 16 GB - 2 devices

NVRAM One 512 KB MRAM extended temperature range (-40°C to

105°C/-40°F to 221°F)

Two 64 KB serial EEPROMs

MVME7100 Single Board Computer Installation and Use (6806800E08A)

25

Page 26

Introduction Features

Table 1-1 Features List (continued)

Function Features

PCI_E 8X Port to XMC Expansion

8X Port to 5 Port PCI Express switch

I/O One front panel mini DB-9 connector for front I/O: one serial channel

Two front panel RJ-45 connectors with integrated LEDs for front I/O:

two 10/100/1000 Ethernet channels

One front panel USB Type A upright receptacle for front I/O: one USB

2.0 channel

PMC site 1 front I/O and rear P2 I/O

PMC site 2 front I/O

USB One four-channel USB 2.0 controller: one channel for front panel I/O

Ethernet Four 10/100/1000 MC864

Ethernet connectors and two channels for rear P2 I/O

xD Ethernet channels: two front panel

Serial Interface One 16550-compatible, 9.6 to 115.2 Kbaud, MC864

serial channel: one channel for front panel I/O

One quad UART (QU AR T) controller to provide four 16550-compatible,

9.6 to 115.2 Kbaud, asynchronous serial channels: four channels for

rear P2 I/O

Timers Four 32-bit MC864

Four 32-bit timers in a PLD

Watchdog Timer One watchdog timer in PLD

VME Interface VME64 (ANSI/VITA 1-1994) compliant (3 row backplane 96-pin VME

connector)

VME64 Extensions (ANSI/VITA 1.1-1997) compliant (5 row backplane

160-pin VME connector)

2eSST (ANSI/VITA 1.5-2003) compliant

Two five-row P1 and P2 backplane connectors

One Tsi148 VMEbus controller

Form Factor Standard 6U VME, one slot

Miscellaneous One front panel RESET/ABORT switch

Six front panel status indicators:

z Two 10/100/1000 Ethernet link/speed and activity (4 total)

z Board fail

z User S/W controlled LED

Planar status indicators

One standard 16-pin JTAG/COP header

Boundary scan support

Switches for VME geographical addressing in a three-row backplane

Software Support VxWorks OS support

Linux OS support

xD timers

xD, asynchronous

26

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 27

Standard Compliances Introduction

1.2 Standard Compliances

The MVME7100 is designed to be CE compliant and to meet the following standard

requirements.

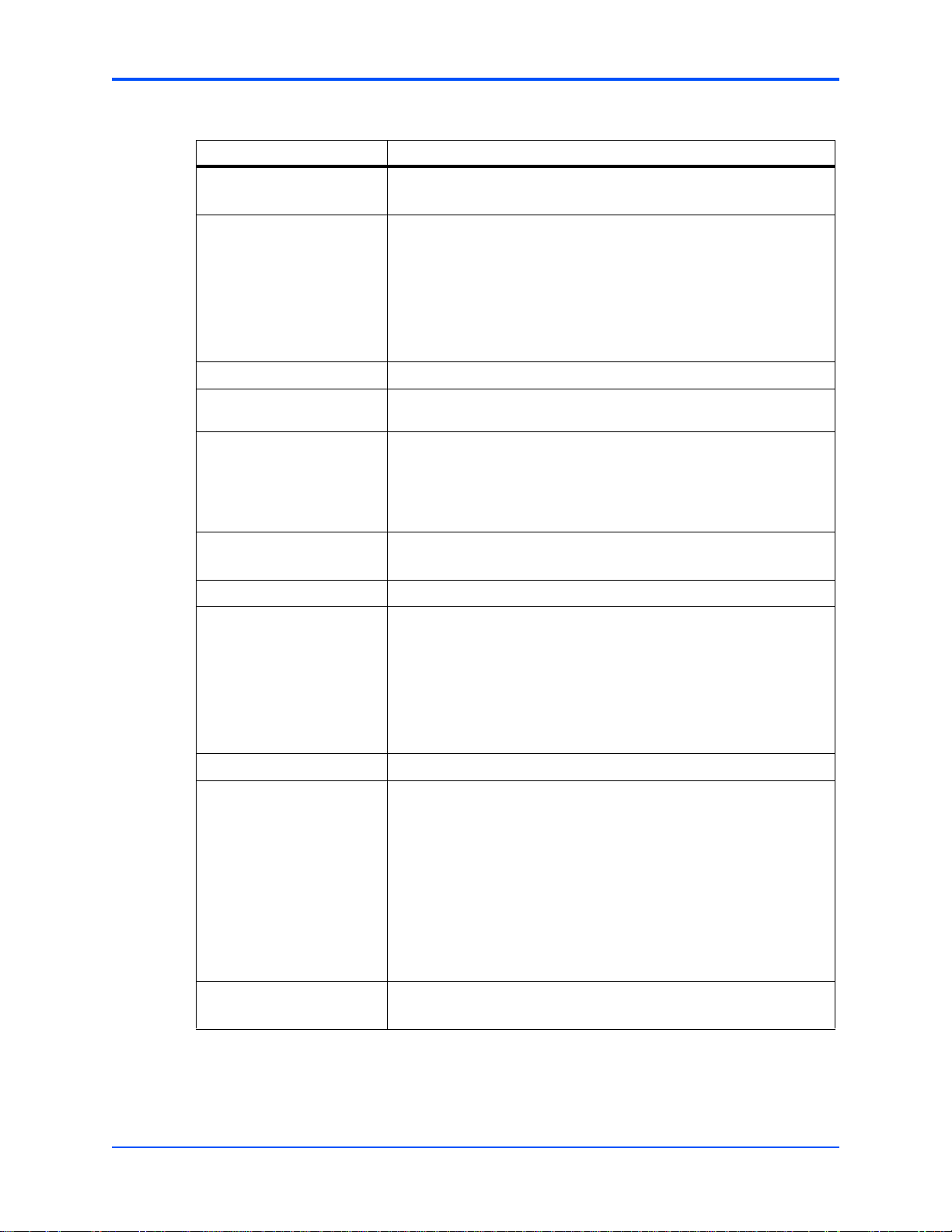

Table 1-2 Board Standard Compliances

Standard Description

UL 60950-1

EN 60950-1

IEC 60950-1

CAN/CSA C22.2 No 60950-1

CISPR 22

CISPR 24

EN 55022

EN 55024

FCC Part 15

Industry Canada ICES-003

VCCI Japan

AS/NZS CISPR 22

EN 300 386

NEBS Standard GR-1089 CORE

NEBS Standard GR-63-CORE

ETSI EN 300 019 series

Directive 2002/95/EC Directive on the restriction of the use of certain haza rd ous

1.3 Mechanical Data

Safety Requirements (legal)

EMC requirements (legal) on system level (predefined Emerson

system)

Environmental Requirements

substances in electrical and electronic equipment (RoHS)

This section provides details on the board’s mechanical data.

Table 1-3 Mechanical Data

Characteristic Value

Dimensions (D x W x H) 6U, 4HP wide, (233 mm x 160 mm x 20 mm)

Weight 0.680 kg

MVME7100 Single Board Computer Installation and Use (6806800E08A)

27

Page 28

Introduction Ordering Information

1.4 Ordering Information

When ordering board variants or board accessories, use the order numbers given in the

following tables.

1.4.1 Supported Board Models

At the time of publication of this ma nual, the MVME7100 Sin gle Board Computer is a va ilable in

the configurations shown below.

Table 1-4 Board Variants

Marketing # Processor

MVME7100-0161 MC8640D 1.067 GHz, 1 GB DDR, 4 GB NAND Flash, Scanbe handles

MVME7100-0163 MC8640D 1.067 GHz, 1 GB DDR, 4 GB NAND Flash, IEEE handles

MVME7100-0171 MC8641D 1.33 GHz, 2 GB DDR, 8 GB NAND Flash, Scanbe handles

MVME7100-0173 MC8641D 1.33 GHz, 2 GB DDR, 8 GB NAND Flash, IEEE handles

1.4.2 Board Accessories

This table lists the available expansion and transition modules for the MVME7100.

Model Number Description

MVME7216E-001 Transition module, 6E

XMCSPAN-001 XMC Expansion, IEEE handles

XMCSPAN-002 XMC Expansion, Scanbe handles

The IPMC712 and IPMC761 I/O modules are not supported on the MVME7100 SBC.

28

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 29

Hardware Preparation and Installation

2.1 Overview

This chapter provides startup and safety instructions related to this product, hardware

preparation instruction that includes default switch settings. System considerations and

installation instructions for the baseboard, PMC, and transition module are also described in

this chapter.

A fully implemented MVME7100 consists of the baseboard plus:

z Two single-wide or one double-wide PCI Mezzanine Card (PMC) slot for added versatility.

z One transition module f or support of the mapped I/O from the MVME7100 ba seboard to the

P2 connector.

2

z Up to two optional XMCspan cards.

The following table lists the things you will need to do before you can use this board and tells

you where to find the information you need to perform each step. Be sure to read this entire

chapter, including all Caution and Warning notes, before you begin.

Table 2-1 Startup Overview

T ask Page

Unpack the hardware. Unpacking and Inspecting the Board on page 30

Configure the hardware by setting jumpers

on the board and RTM.

Install the MVME7216E transition module in

the chassis.

Install PMC module (if required). Installing Accessories on page 40

Install XMCspan module (if required). XMCspan Installation and Use (6806800H03)

Install the MVME7100 in the chassis. Installing and Removing the Board on page 43

Attach cabling and apply power. Completing the Installation on page 45

Install PIM on transition module (if required). PMC Input/Output Module on page 79

Ensure that the firmware initializes the

MVME7100

Initialize the board Chapter 6, MOTLoad Firmware

Configuring the Board on page 36 and SEEPROM

Address Switch, S1 on page 76

Transition Module on page 40

Chapter 6, MOTLoad Firmware

Examine and/or change environmental

parameters.

Program the board as needed for your

applications.

MVME7100 Single Board Computer Installation and Use (6806800E08A)

MVME7100 Single Board Computer Programmer’s

Reference

MVME7100 Single Board Computer Programmer’s

Reference

29

Page 30

Hardware Preparation and Installation Unpacking and Inspecting the Board

2.2 Unpacking and Inspecting the Board

Read all notices and cautions prior to unpacking the product.

Damage of Circuits

Electrostatic disc harge and incorrect i nstallation and remov al can damage circ uits or

shorten their life.

Before touching the b oard or electr onic components, make sure that y ou are w orking

in an ESD-safe environment.

Shipment Inspection

To inspect the shipment, perform the following steps:

1. Verify that you have received all items of your shipment.

2. Check for damage and report any damage or differences to customer service.

3. Remove the desiccant bag shipped together with the board and dispose of it

according to your country’s legislation.

The product is thoroughly inspected before shipment. If any dama ge occurred during

transportation or any items are missi ng, contact customer service immediately.

30

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 31

Requirements Hardware Preparation and Installation

2.3 Requirements

Make sure that the board, when operated in your particular system configuration, meets the

requirements specified in the next sections.

2.3.1 Environmental Requirements

The following table lists the currently available specif ications for the environmental

characteristics of the MVME7100. A complete functional description of the MVME7100

baseboard appears in Chapter 4, Functional Description.

Operating temperatures refer t o the temperature o f the air cir culating ar ound the board

and not to the component temperature.

Table 2-2 MVME7100 Specifications

Characteristics Operating Nonoperating

Operating temperature 0°C to +55°C (32°F to 131°F) entry

air with forced-air cooling

Temperature change +/-0.5° C/min according to NEBS

Standard GR-63-CORE

Relative humidity 5% to 90% noncondensing 5% to 90% noncondesning

Vibration 1 G sine sweep, 5-100 Hz,

Shock 20 G peak (half sine) 11mSec

Free Fall 100 mm (unpackaged) per GR-63-

–40°C to +85° C (-40°F to 185°F)

horizontal and vertical (NEBS1)

CORE

Product Damage

High humidity and condensation on the board surface causes short circuits.

Do not operate the board outside the specified environmental limits.

Make sure the board is complete ly dry and there is no moi sture on any surfa ce before

applying power.

MVME7100 Single Board Computer Installation and Use (6806800E08A)

31

Page 32

Hardware Preparation and Installation Power Requirements

2.3.2 Power Requirements

The MVME7100 uses only +5.0 V from the VMEbus backplane. On board power supplies

generate the required voltages for the various ICs. The MVME 7100 connects the +12 V and 12 V supplies from the backplane to the PMC sites while the +3.3 V power supplied to the PMC

sites comes from the +5.0 V backplane po wer. A maximum of 10 A of +3.3 V powe r is av ailab le

to the PMC sites, however the 90 W +5.0 V limit must be observed as well as any cooling

limitations.

The next table provides an estimate of the typical and maximum power required.

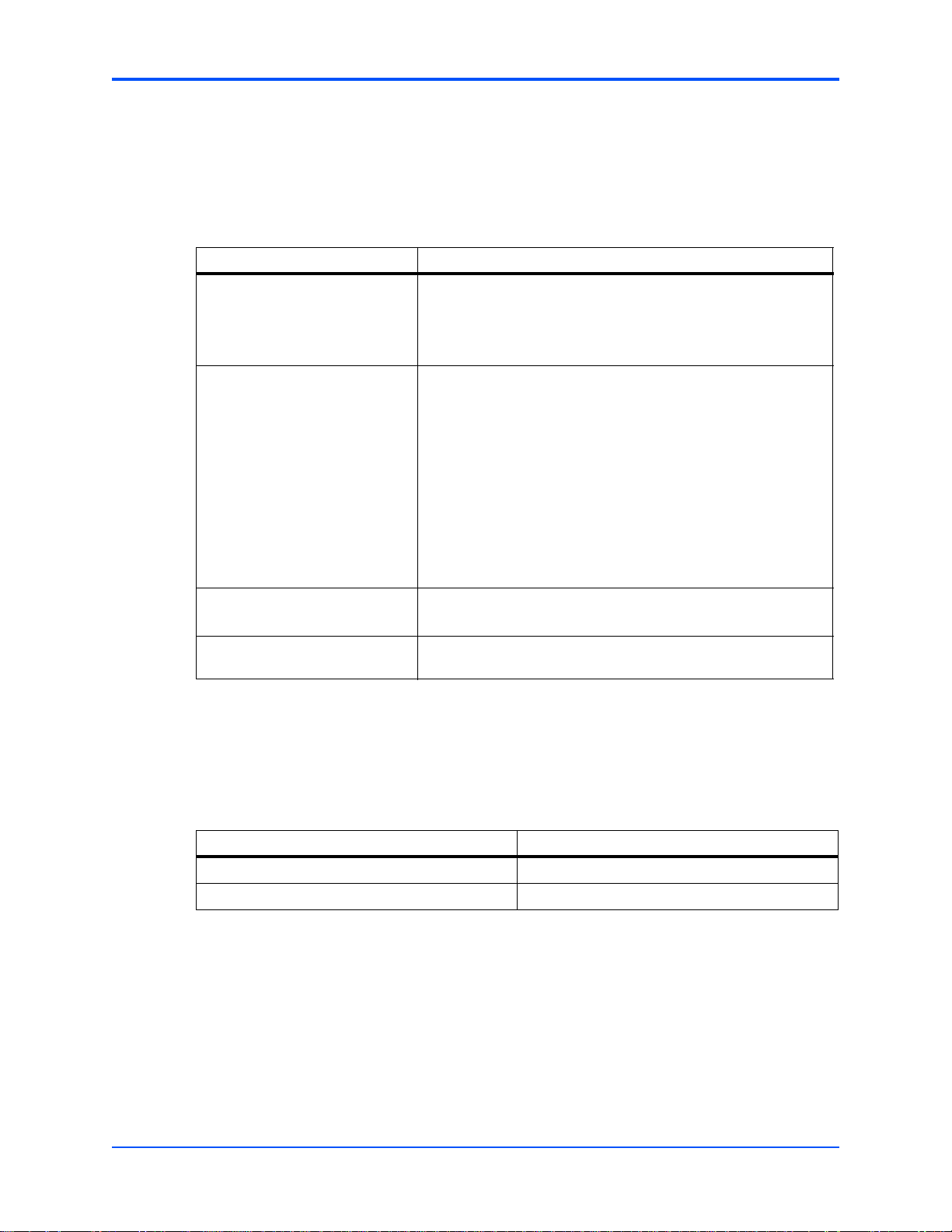

Table 2-3 Power Requirements

Board Variant Power

MVME7100-0161 Typical: 40 W @ +5 V

Maximum: 55 W @ +5 V

MVME7100-0163 Typical: 40 W @ +5 V

Maximum: 55 W @ +5 V

MVME7100-0171 Typical: 45 W @ +5 V

Maximum: 60 W @ +5 V

MVME7100-0173 Typical: 45 W @ +5 V

Maximum: 60 W @ +5 V

The following table shows the power available when the MVME7100 is installed in either a 3row or 5-row chassis and when PMCs are present.

Chassis Type Available Power Power With PMCs

3-Row 70 W maximum Below 70 W

5-Row 90 W maximum Below 90 W

1. Keep below power limit. Cooling limitations must be considered.

1

1

32

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 33

Thermal Requirements Hardware Preparation and Installation

2.3.3 Thermal Requirements

The MVME7100 module requires a minimum air flow of 10 CFM uniformly distributed across

the board, with the airflow traveling from the heat sink to the PMC2 site, when operating at a

55°C (131°F) ambient temperature.

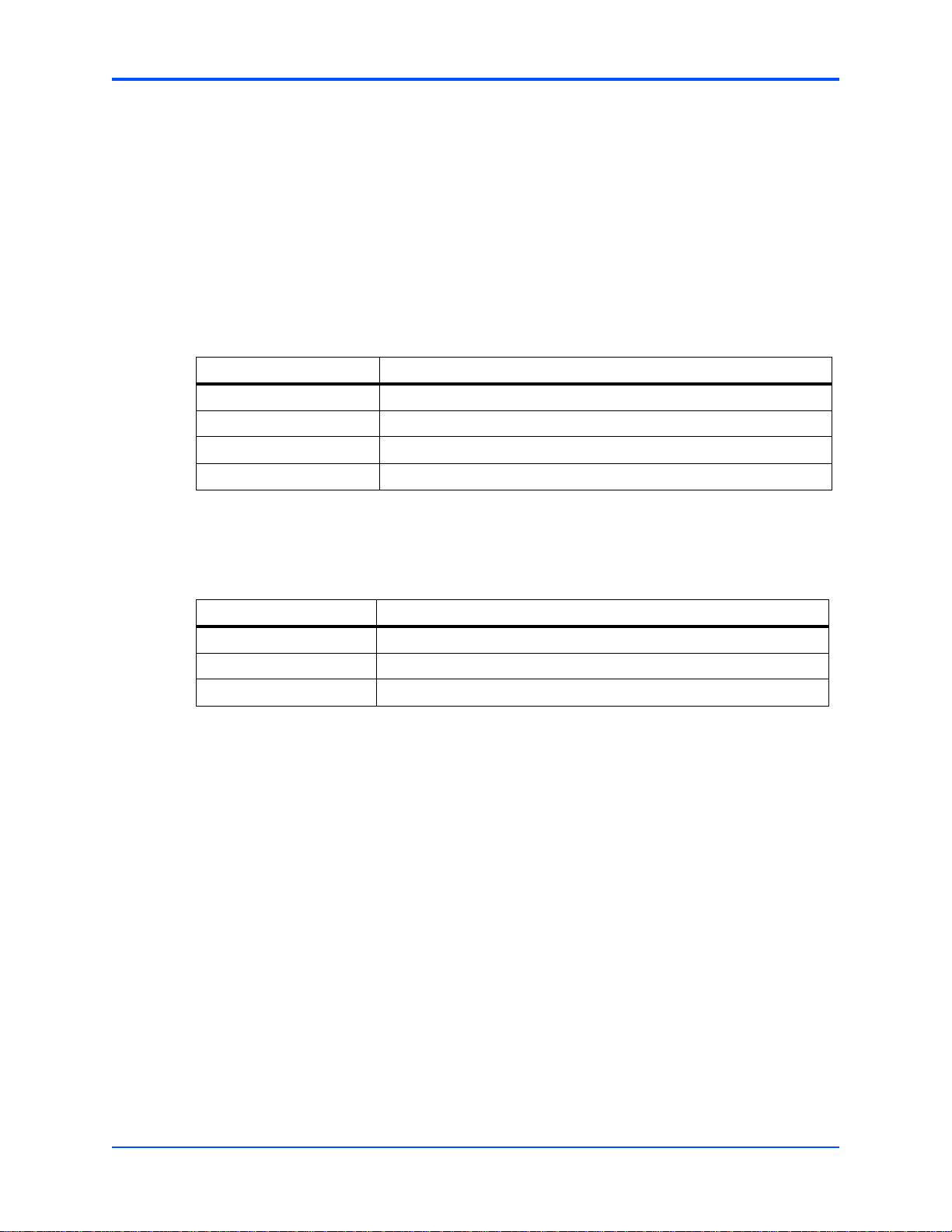

2.3.4 Thermally Significant Components

The following table summarizes components that exhibit significant temperature rises. These

are the components that should be monitored in order to assess thermal performance. The

table also supplies the component ref erence designator and the maximum allow abl e operating

temperature.

You can find components on the boar d by their reference designators as shown in Figure 2-1

and Figure 2-2 on the next page. Versions of the board that are not fully populated may not

contain some of these components.

The preferred measurement location for a component may be junction, case, or ambient as

specified in the table. Junction temperature refe rs to the te mpe rature measured by an on-chip

thermal device. Case temperature refers to the temperature at t he top, center surface of the

component. Air temperature refers to the ambient temperature near the component.

Table 2-4 Thermally Significant Components

Maximum Allowable

Reference

Designator Generic Description

U27, U4 Gb Ethernet Transceiver 0

U25, U26, U28 PCI-X/PCI-Express

Bridge

U22 PCI-Express Bridge -40

U24 VME Bridge 0

U10, U11, U12,

U13, U14, U56,

U57, U58, U59,

U6, U60, U61,

U62, U63, U64,

U7, U8, U9

U20 MPU 0

DDR2 SDRAM 0

Component Temperature

in Centigrade Measurement Location

-40

° to +70° Ambient

° to +85° Ambient

° to +85° Ambient

° to + 70° Ambient

° to +95° Case

° to +105° Junction

MVME7100 Single Board Computer Installation and Use (6806800E08A)

33

Page 34

U20

U28

U4

U6

U7

U8

U9

U10 U11 U12 U13 U14

U22

U25

U24

U26

U27

U56

U57

U58

U59

U60 U61 U62

U63 U64

Hardware Preparation and Installation Thermally Significant Components

Figure 2-1 Primary Side Thermally Significant Components

Figure 2-2 Secondary Side Thermally Signific an t Com p on e nt s

34

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 35

Equipment Requirements Hardware Preparation and Installati on

2.3.5 Equipment Requirements

The following equipment is recommended to complete an MVME7100 system:

z VMEbus system enclosure

z System console terminal

z Operating system (and/or applicat ion software)

z Transition module and connecting cables

MVME7100 Single Board Computer Installation and Use (6806800E08A)

35

Page 36

S1 S2

Hardware Preparation and Installation Configuring the Board

2.4 Configuring the Board

To produce the desired configur ation and ensure proper operat ion of the MVME7100, you m a y

need to carry out certain hardware modifications before installing the module.

The MVME7100 provides software cont rol over most options: by sett ing bits in control registers

after installing the module in a system, you can modify its configuration. The MVME7100 control

registers are described in the MVME7100 Programmer’s Reference.

Prior to installing PMC modules on the MVME7100 baseboard, ensure that all switches that are

user configurable are set properly. To do this, refer to Figure 2-3 or the board itself, for the

location of specific switches and set the switches according to the following descriptions.

Figure 2-3 Switch Locations

36

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 37

1

ON

1

2

3

4

5

6

7

8

Normal ENV

Boot Block A

WP Disabled

Normal Operation

PMC 133 MHz

Reserved

Master WP

Normal Operation

SMT Configuration Switch, S1 Hardware Preparation an d Install at ion

The following sections describe the on-board switches and their configurations for th e

MVME7100.

Board Malfunction

Switches marked as “reserved” might carry production-related functions and can

cause the board to malfunction if their setting is changed.

Do not change settings of switches marked as “reserved”. The setting of switches

which are not marked as “reserved” has to be checked and changed before board

installation.

2.4.1 SMT Configuration Switch, S1

An 8-position SMT configuration switch (S1) is located on the MVME7100 to control the flash

bank write-protect, select the flash boot image, and control the safe start ENV settings. The

default setting on all switch positions is OFF and is indicated by brackets in Table 2-5.

Figure 2-4 SMT Configuration Switch Position

Table 2-5 Configuration Switch Settings (S1)

Switch Description Setting Function

S1-1 Safe Start

MVME7100 Single Board Computer Installation and Use (6806800E08A)

S1-2 Boot Block B

Select

S1-3 Flash Bank WP [OFF]

S1-4 JTAG Pass Thru [OFF]

1

[OFF]

ON

[OFF]

ON

ON

ON

Use normal ENV

Use safe ENV

Flash memory map normal and boot block A selected

Boot block B selected, mapped to highest address

Entire flash not write-protected

Flash is write-protected

Normal operation

Pass-Thru mode

37

Page 38

Hardware Preparation and Installation SMT Configuration Switch, S1

Table 2-5 Configuration Switch Settings (S1) (continued)

Switch Description Setting Function

S1-5 CORE1 Low

Memory Offset

S1-6 PMC 133 MHz [OFF]

S1-7 Master WP [OFF]

S1-8 Reserved

1. Switch status is readable from System Status Register 1, bit 5.

[OFF]

ON

ON

ON

Normal operation

PMC 100 MHz maximum

PMC 133 MHz maximum

Master write protect disabled

Master write protect enabled

2.4.1.1 Safe Start Switch

When the SAFE_ST ART s witch is OFF, it indicates that the normal ENV setting should be used.

When the switch is set to ON , GEVs, VPD, and SPD settings are ignored and known, safe,

values are used.

2.4.1.2 Boot Block B Select

When the switch is OFF, the flash memory map is normal and block A is selected as shown in

Figure 3. When the switch is ON, block B is mapped to the highest address.

2.4.1.3 Flash Bank Write Protect

When the FLASH BANK WP switch is OFF, it indicates that the entire NOR flash is not writeprotected. NOR flash is used for executing code. When the switch is ON, it indicates that the

flash is write-protected and any writes to the flash devices are blocked by hardware.

2.4.1.4 JTAG Pass-Thru

The JTAG Pass-Thru switch is in the OFF position for normal operation. The switch is ON for

pass-through mode.

2.4.1.5 Low Memory Offset

The CORE1 Low Memory Offset switch is in the OFF position f or normal operat ion. The s witch

is ON for enabling this feature.

2.4.1.6 PMC 133 MHz

The PMC 133 MHz switch is OFF for normal operation. When the switch is ON, the maximum

frequency of operation f or the PMC sites is 133 MHz. 133 MHz operation should n ot be enabled

unless the PMC modules are designed to support 133 MHz operation. When the s witch is OFF,

the maximum frequency is 100 MHz.

38

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 39

Geographical Address Switch, S2 Hardware Preparation and Installat ion

2.4.1.7 Master WP

The Master Write Protect (WP) switch is OFF for normal operation. When this switch is ON,

writes to the NOR Flash, NAND Flash, MRAM and I

switch is OFF, writes to the non-volatile devices may be allowed depending on other switches

and control bits.

2.4.2 Geographical Address Switch, S2

The Tsi148 VMEbus Status Register pro vides the VMEbus geographical address of the

MVME7100. Applications not using the 5-row backplane can use the geographical address

switch to assign a geograp hical address per the f ollowin g diagram. Mor e info rmation regarding

GA address switch assignments can be found in the MVME7100 Single Board Computer

Programmer’s Reference.

Figure 2-5 Geographical Address Switch Position

2

C EEPROMs are disabled. When the

2.4.3 VME System Controller Select, S2

Positions 1 and 2 of S2 are used to select VME Syst em Co ntro ller selection. The default is for

automatic determination of SYSCON.

Table 2-6 VME System Controller and GA Switch Settings

Position Function Default

S2-1 VME SCON Auto

S2-2 VME SCON SEL

S2-3 GAP 1

S2-4 GA4 1

S2-5 GA3 1

S2-6 GA2 1

S2-7 GA1 1

MVME7100 Single Board Computer Installation and Use (6806800E08A)

1

2

Auto-SCON

Non-SCON

39

Page 40

Hardware Preparation and Installation Installing Accessories

Table 2-6 VME System Controller and GA Switch Settings (continued)

Position Function Default

S2-8 GA0 1

1. The VME SCON MAN switch is OFF to select Auto-SCON mode. The switch is ON to select manual SCON mode

which works in conjunction with the VME SCON SEL switch.

2. The VME SCON SEL switch is OFF to select non-SCON mode. The switch is ON to select always SCON mode.

This switch is only effective when the VME SCON MAN switch is ON.

If you are installing the optional MVME7216E transition module, refer to Transition Module on

page 40 for configuration switch settings.

2.5 Installing Accessories

This section describes the procedures for installing the MVME7216E transition module, PMCs,

and the XMCspan on the baseboard.

2.5.1 Transition Module

The MVME7216E does not support hot swap, You should remove power to the rear slot or

system before installing the module. Before installing the MVME7216E transition module, you

may need to manually configure the switch and install a PMC I/O Module (PIM). Refer to

Chapter 5, Transition Module, for switch settings and PIM installation.

Damage of Circuits

Electrostatic disc harge and incorrect i nstallation and remov al can damage circ uits or

shorten their life.

Before touching the b oard or electr onic components, make sure that y ou are w orking

in an ESD-safe environment.

Product Damage

Only use injector handles for board insertion to avoid damage to the front panel

and/or PCB. Deformation of the front panel can cause an electrical short or other

board malfunction.

Board Malfunction

Switches marked as “reserved” might carry production-related functions and can

cause the board to malfunction if their setting is changed.

Do not change settings of switches marked as “reserved”. The setting of switches

which are not marked as “reserved” has to be checked and changed before board

installation.

40

MVME7100 Single Board Computer Installation and Use (6806800E08A)

Page 41

PMC Hardware Preparation and Installation

Installation and Removal Procedure

To begin the installation of the transition module in a chassis, proceed as follows:

1. Turn all equipment power OFF and disconnect the pow er cable from the AC power

source.

2. Remove the chassis cover as instructed in the equipment user's manual.

3. Remove the filler panel(s) from the appropriate card slot(s) at the rear of the chassis

(if the chassis has a rear card cage).

4. Install the top and bottom edge of the transition module into the rear guides of the

chassis.

5. Ensure that the levers of the two injector/ejectors are in the outward position.

6. Slide the transition module into the chassis until resistance is felt.

7. Simultaneously move the injector/ejector levers in an inward direction.

8. V erify that the transition module is properly seated and secure it to the chassis using

the two screws located adjacent to the injector/ejector levers.

9. Connect the appropriate cables to the transition module.

To remove the transition module from the chassis, reverse the procedure and press the red

locking tabs (IEEE handles only) to extract the board.

2.5.2 PMC

The PMC connectors are placed to support two single-width PMCs or one double-width PMC.

PMC site 1 supports front PMC I/O and rear PMC I/O via the Jn4 connector . PMC 1 I/O is routed

to the VME P2 connector. PMC site 2 only supports front PMC I/O and does not have a Jn4

connector. The PMC 1 Jn4 user I/O signals only support low-current high-speed signals and

thus do not support current-bearing power supply usage.

In most cases, the PMCs are alrea dy in place on the baseb oard. The user-confi gured s witches

are accessible with the PMCs installed. The onb oard PMC sites are configured to support +3.3

V I/O PMC modules. The onboard PMC sites do not support +5.0 V I/O PMC modules.

Follow these steps to install a PMC onto the MVME7100 board.

MVME7100 Single Board Computer Installation and Use (6806800E08A)

41

Page 42

Hardware Preparation and Installation PMC

Installation Procedure

Read all notices and follow these steps to install a PMC on the baseboard.

Damage of Circuits

Electrostatic disc harge and incorrect i nstallation and remov al can damage circ uits or

shorten their life.