Page 1

Precision Cooling

For Business-Critical Continuity™

Liebert® iCOM

User Manual - Intelligent Communications & Monitoring

™

Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 LIEBERT ICOM DISPLAY COMPONENTS AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Navigating Through the Liebert iCOM Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Control Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.2 Accessing Submenus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.3 Entering a Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.4 Viewing Multiple Units with a Networked Large Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.1 Single Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Unit/Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Chilled Water Units with Variable Speed Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 General Compressor Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.4 Compressor Timing—Units With Two Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.5 Compressor Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Motorized Ball Valve in Digital Scroll Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.1 MBV Operation After Compressor is Turned Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.2 Service Offset—Changing System Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Temperature Control—Single Source Cooling (No Extra Cooling Coil) . . . . . . . . . . . . . . . . 17

3.3.1 Temperature Proportional Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.2 Compressor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.3 Chilled Water Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4 Temperature Control—Second Cooling Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4.1 Differential Temperatures / Controls (Comparator Circuit) . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 Temperature Control—Reheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.1 Three-Stage Electric, Hot Gas and Hot Water Reheat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.2 SCR Reheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.6 Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.6.1 Humidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.6.2 Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.7 Control Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.7.1 Temperature and Humidity Control Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.7.2 Humidity Sensor Reading Control Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.7.3 Supply Limit—Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.7.4 High and Low, Temperature and Humidity Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.7.5 User Inputs / Customer Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.7.6 Event Types and Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.8 Possible Event Notifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

i

Page 4

3.9 Next Maintenance Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.9.1 Calculation of Next Maintenance and Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.0 TEAMWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.1 Teamwork Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1.1 Application of Teamwork Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1.2 No Teamwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1.3 Teamwork Mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1.4 Teamwork Mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1.5 Standby – Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.0 INSTALLING A LIEBERT ICOM UNIT-TO-UNIT NETWORK. . . . . . . . . . . . . . . . . . . . . . . . . . .42

5.1 Placement of Cooling Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2 U2U Hardware: Cables and Network Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3 Wiring for Unit-to-Unit Communications—U2U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.3.1 Wiring a Liebert iCOM U2U Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4 External Communications—Building Management Systems, Liebert SiteScan

® . . . . . . . . . . . 48

6.0 MOUNTING A LARGE DISPLAY ON A WALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.0.1 Location Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.0 USER MENU PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

8.0 SERVICE MENU PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ii

Page 5

FIGURES

Figure 1 Liebert iCOM components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

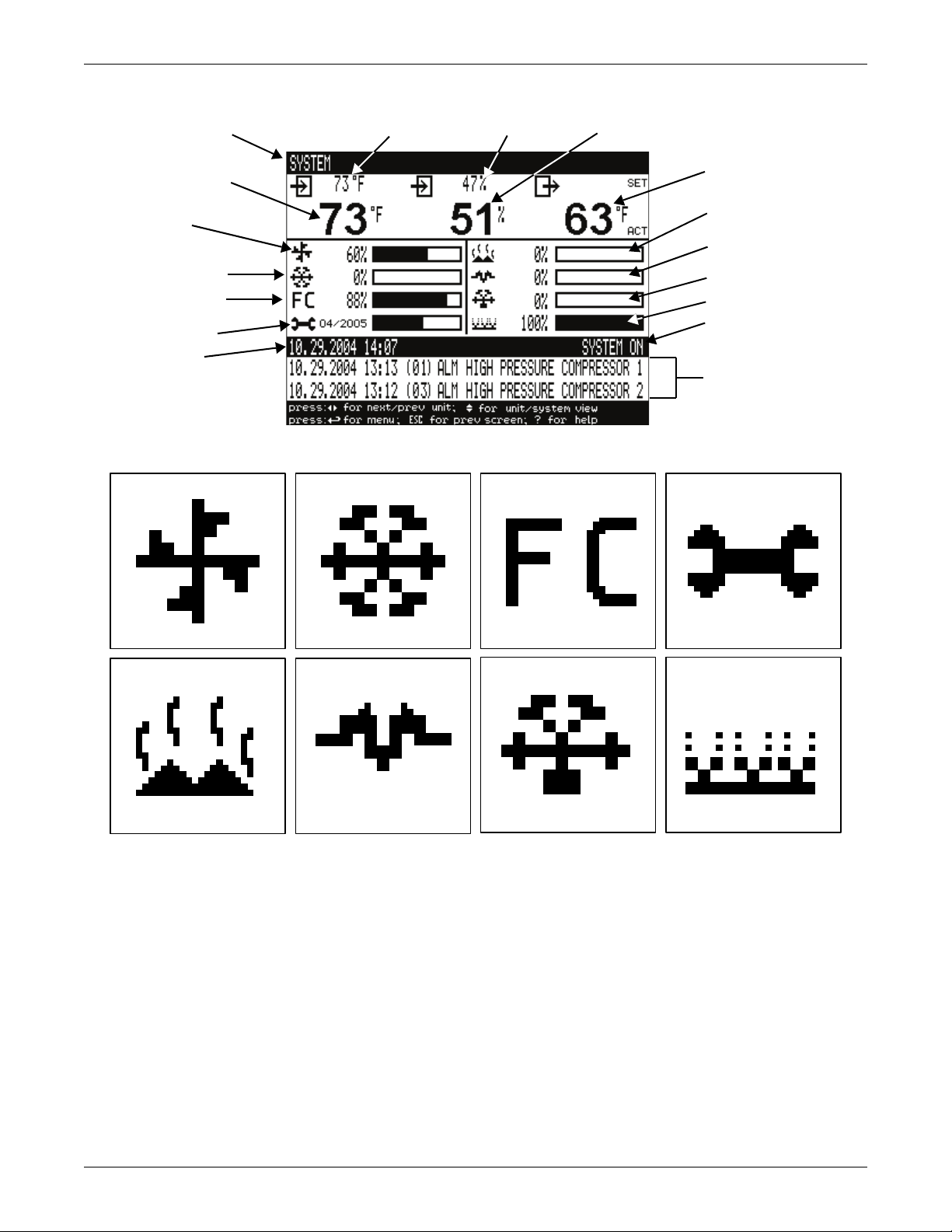

Figure 2 Liebert iCOM display components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 3 Status menu, large display, graphical view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4 Liebert iCOM default screen symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

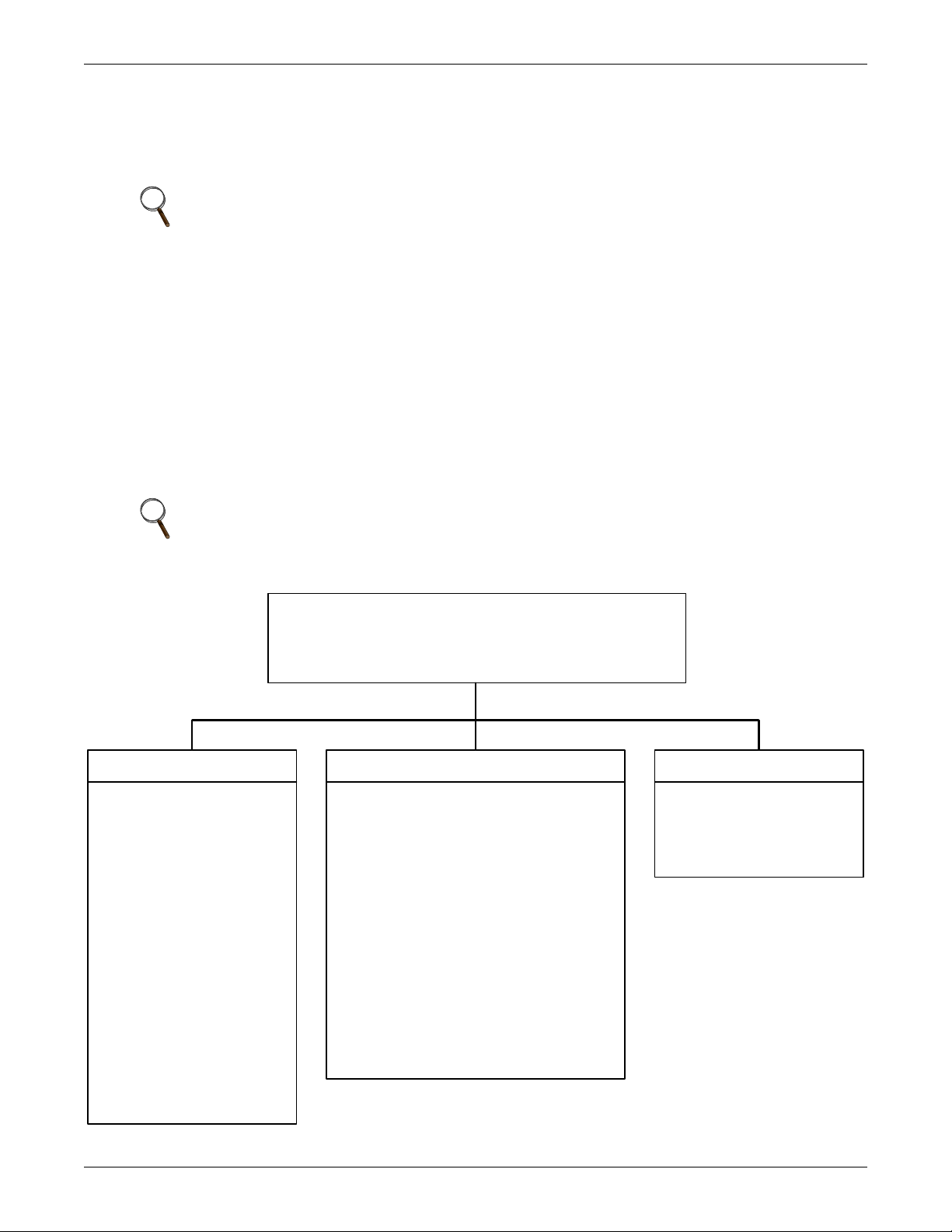

Figure 5 Menu tree—Small display, stand-alone or networked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

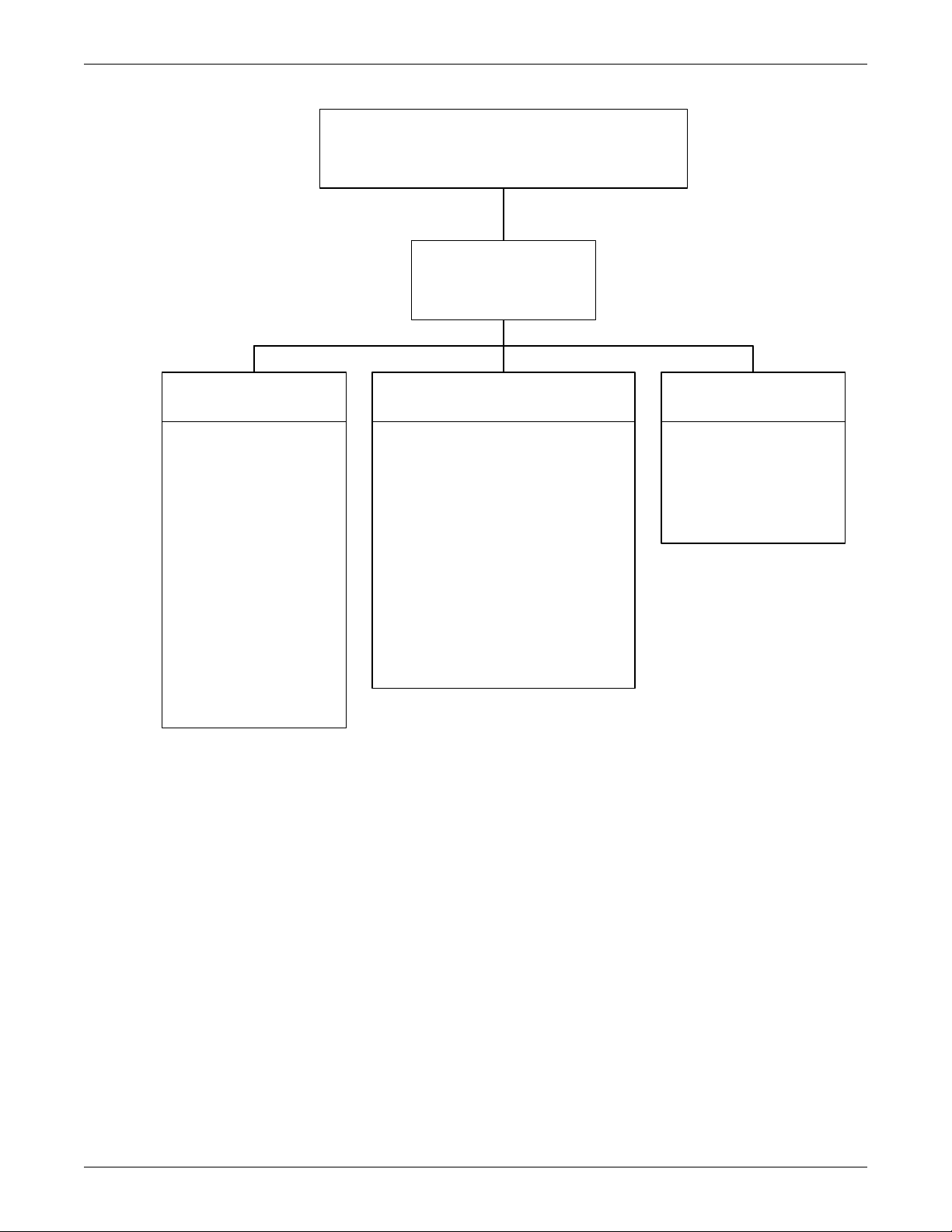

Figure 6 Menu tree—Large display, stand-alone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

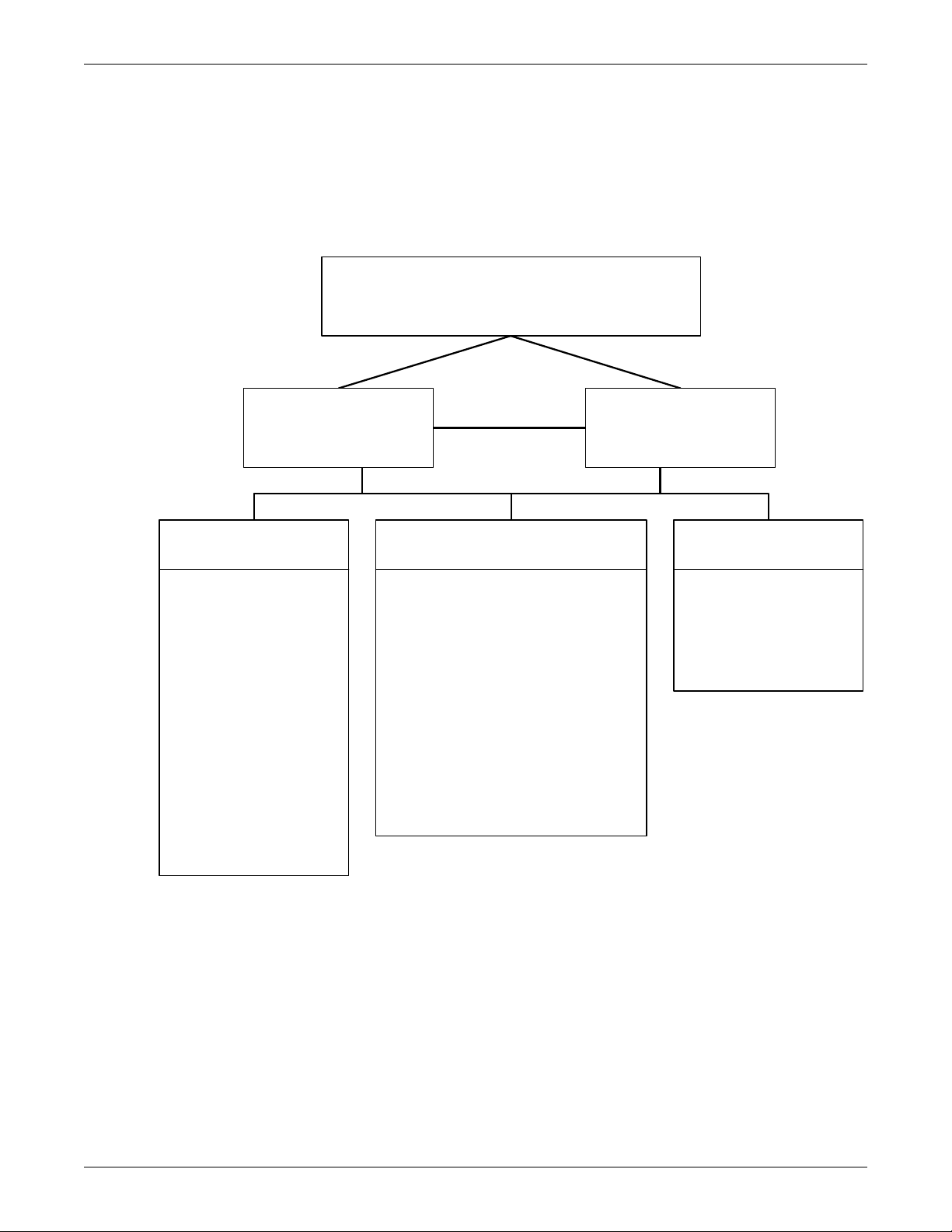

Figure 7 Menu tree—Large display, networked. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

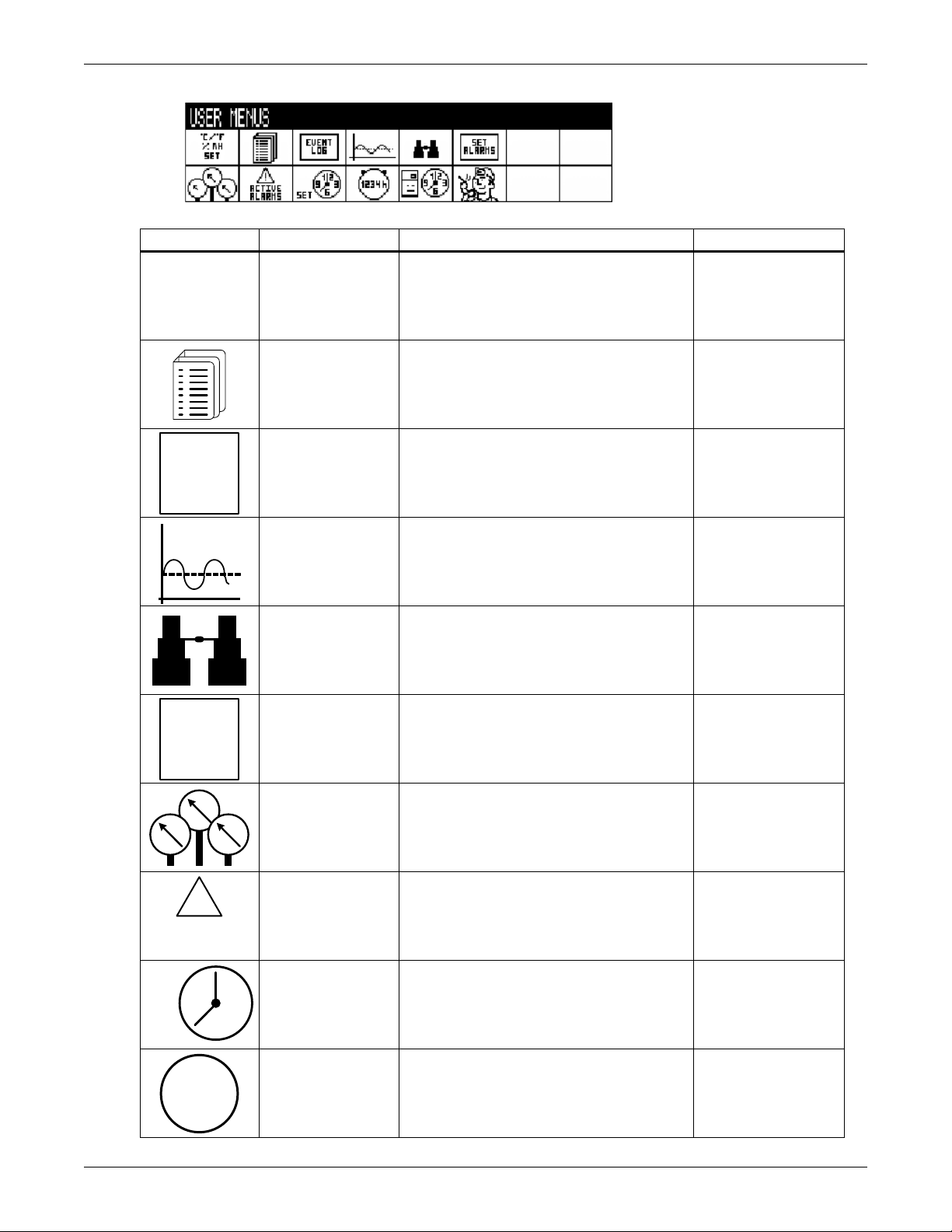

Figure 8 User menu icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

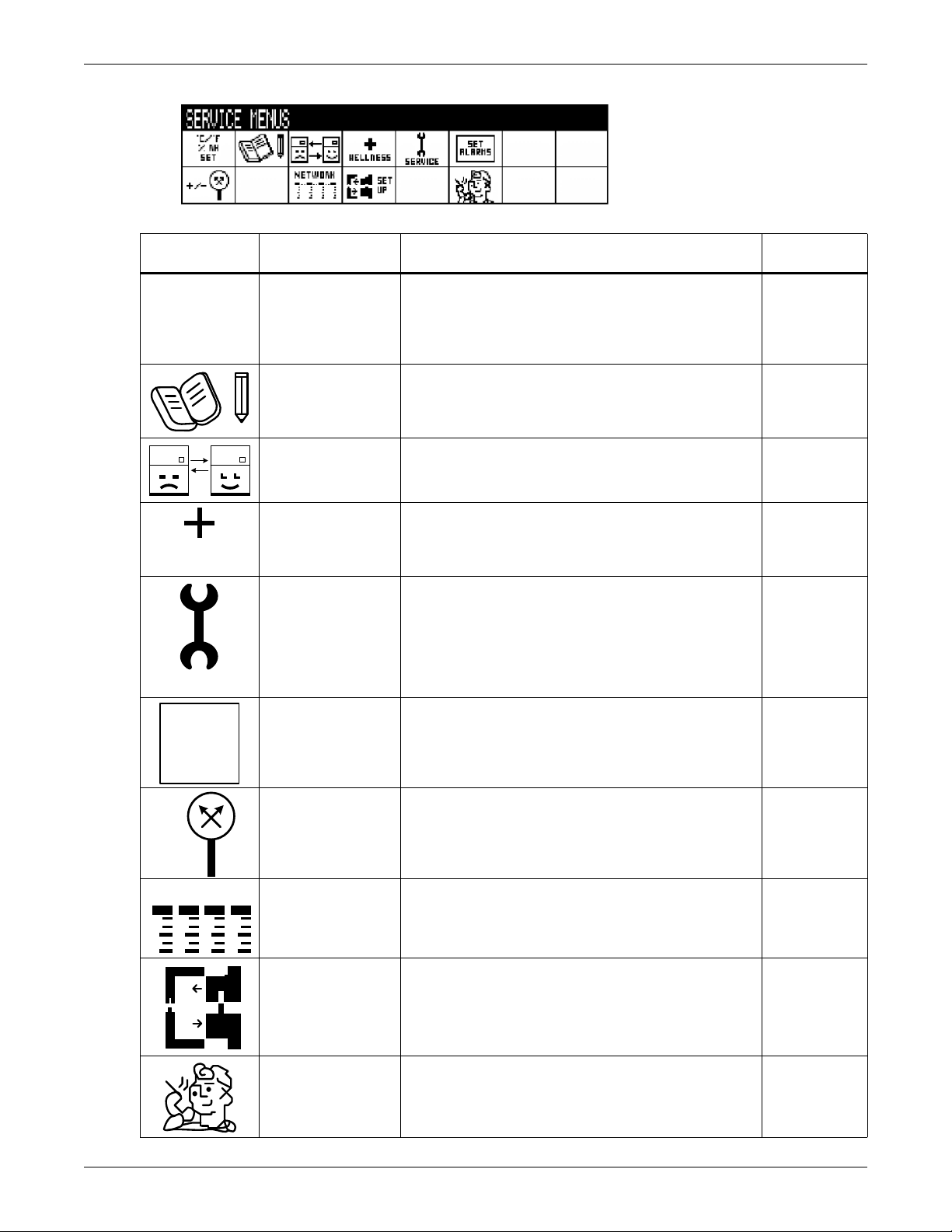

Figure 9 Service menu icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

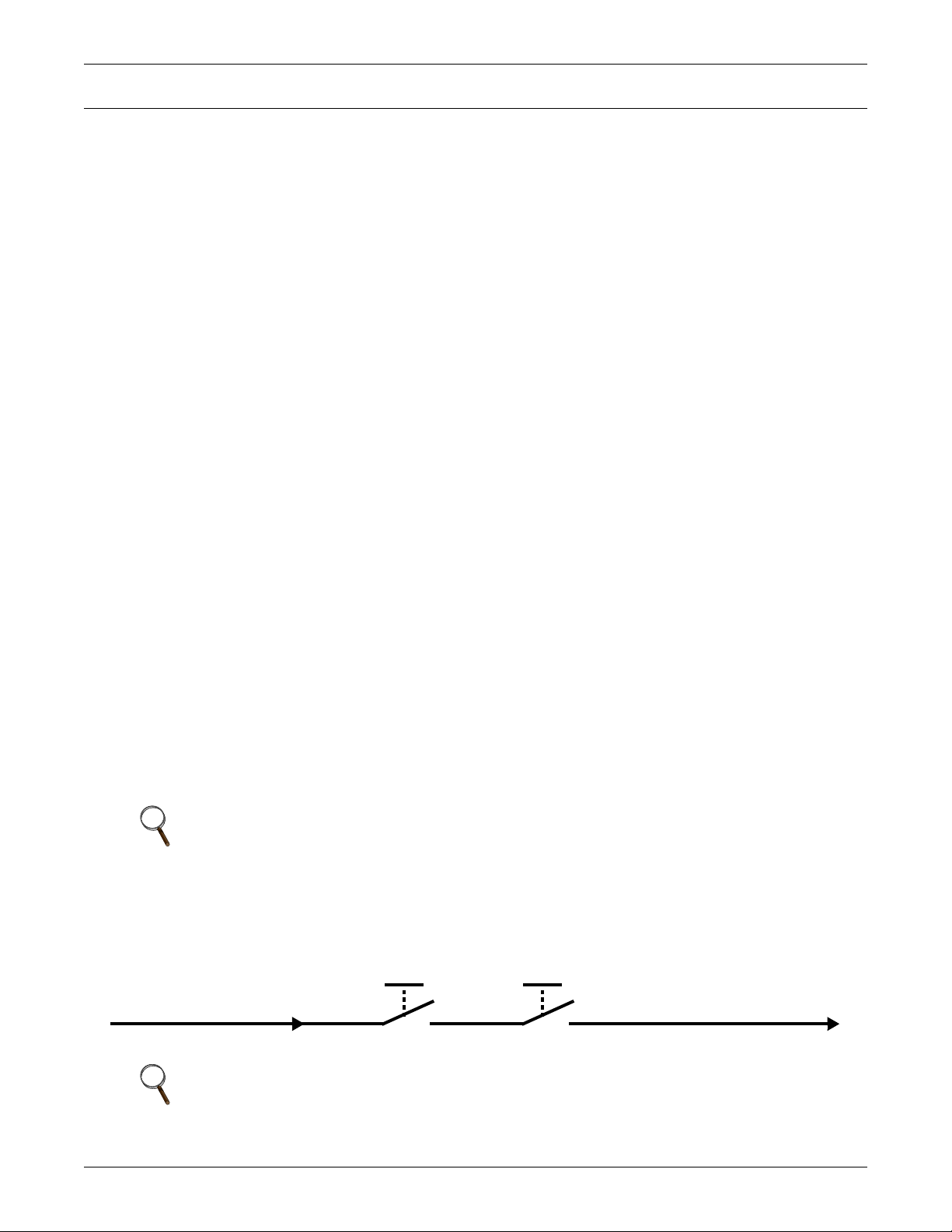

Figure 10 Start-stop priority switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

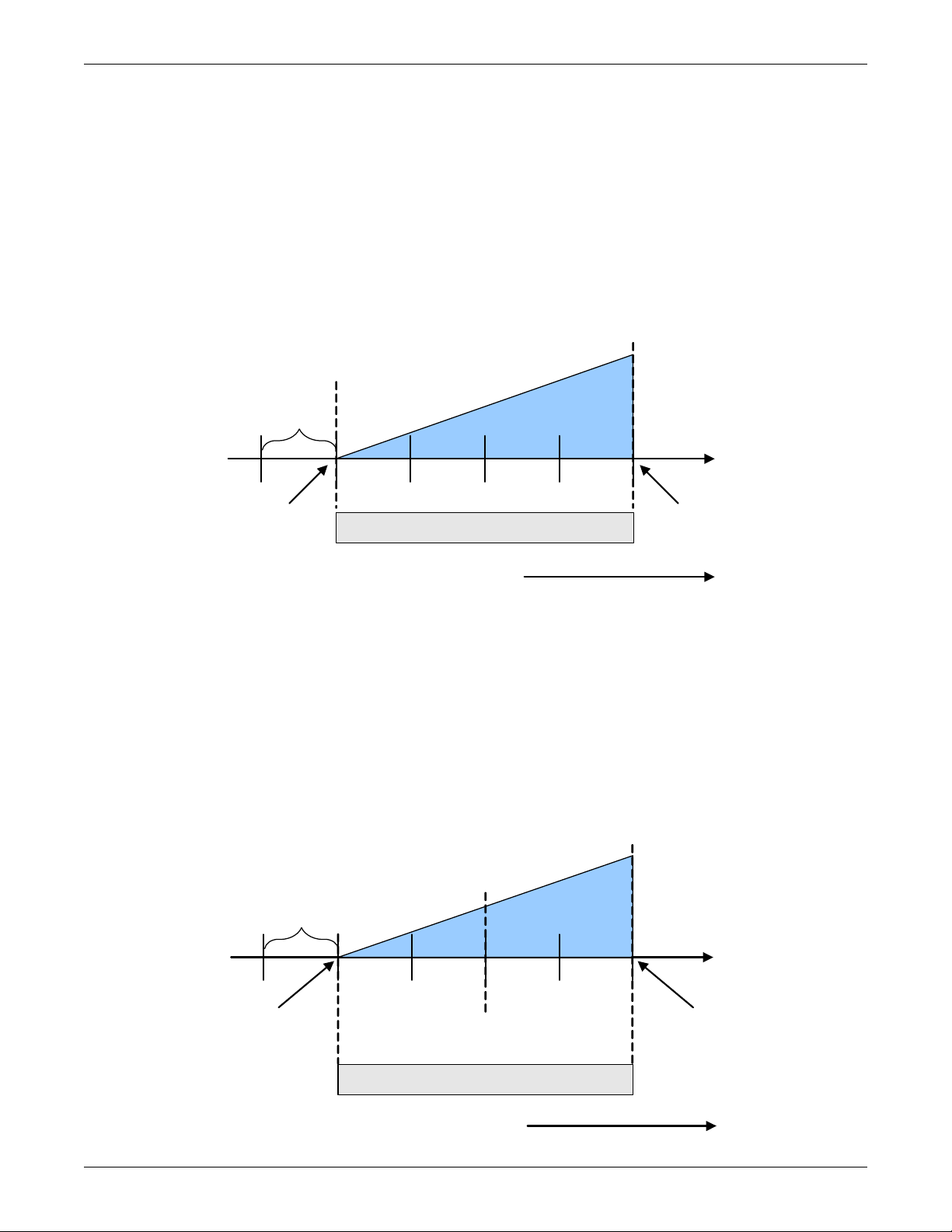

Figure 11 Temperature proportional band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 12 One single-step compressor without unloaders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 13 Two single-step compressors without unloaders or one compressor with an unloader

(two-step) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

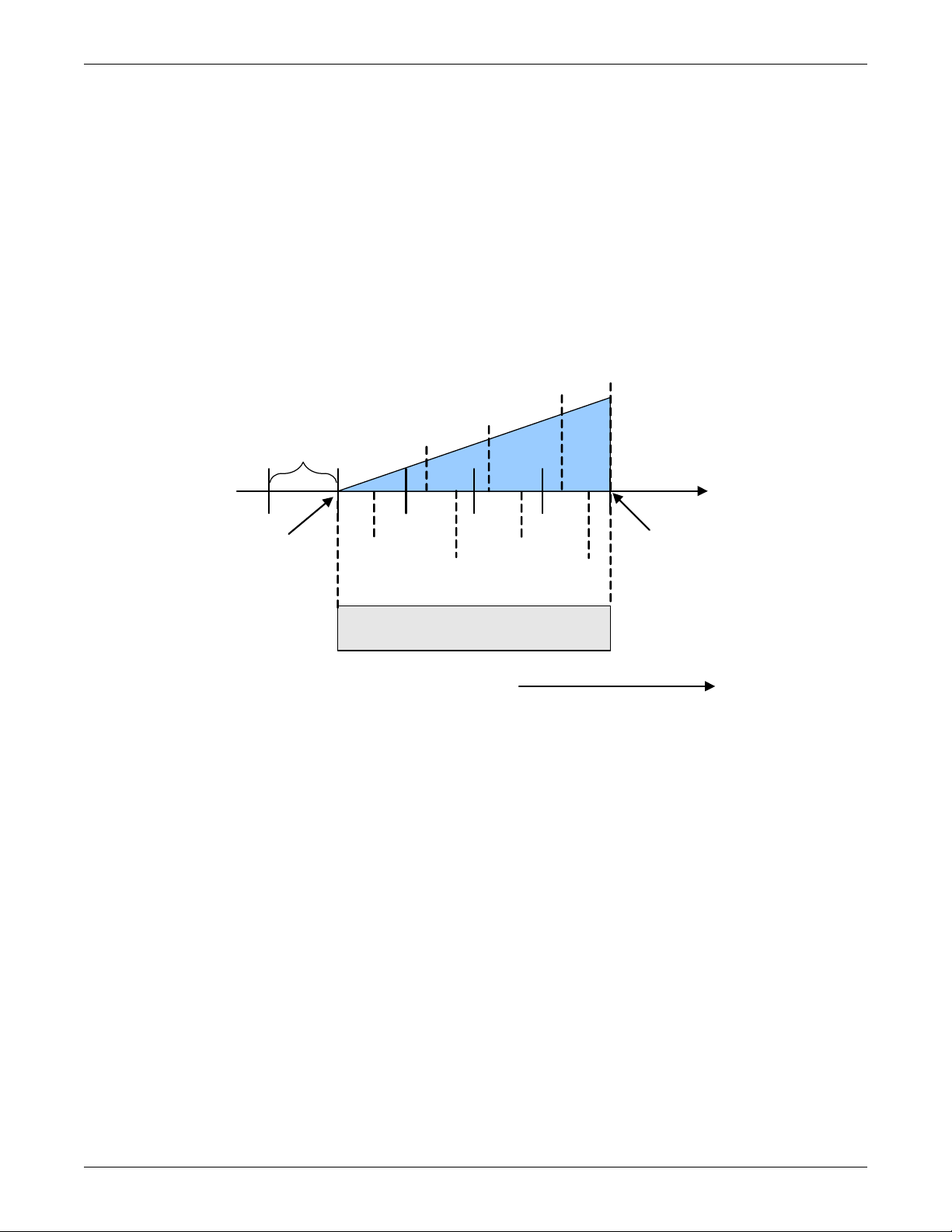

Figure 14 Two compressors with unloaders (four-step) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 15 Digital scroll capacity modulation, 10-100% variable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 16 Single and dual digital scroll compressor activation points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 17 Three-point actuator control (example: cooling) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 18 Second cooling source and compressorized cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 19 Three-stage heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

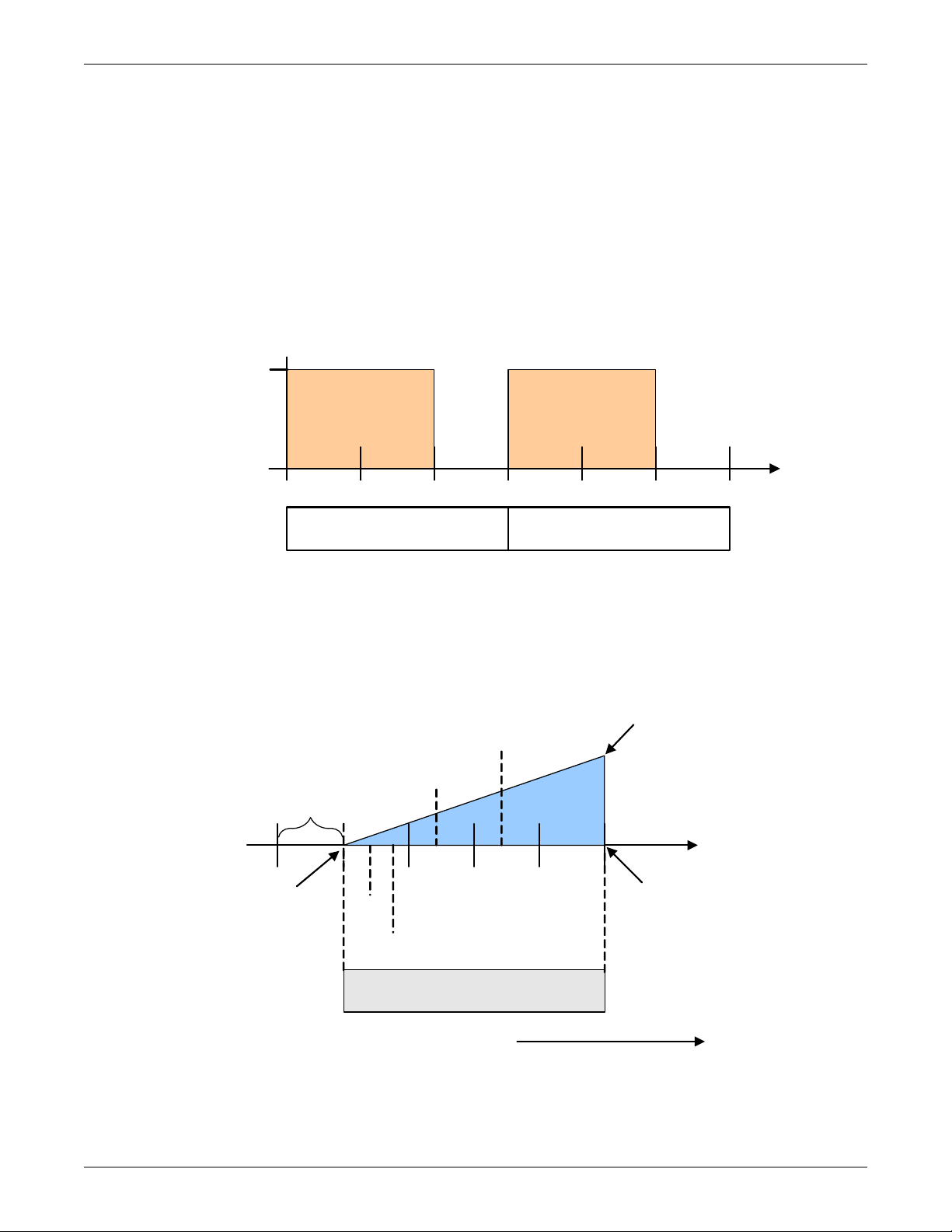

Figure 20 Two single-step compressors with SCR reheat set to Tight mode . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 21 Two single-step compressors with SCR reheat set to Standard mode . . . . . . . . . . . . . . . . . . . . . . 26

Figure 22 Humidity proportional band. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 23 Teamwork Mode 1 with two cooling units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 24 Connecting two cooling units, each with a small display using a crossover Ethernet cable . . . . 44

Figure 25 Wiring a small display for stand-alone operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 26 Wiring a small display for U2U network operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 27 Wiring a large display for stand-alone operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 28 Wiring a large display for U2U network operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 29 Liebert iCOM input-output control board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 30 Liebert vNSA with optional remote large display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 31 Liebert iCOM display dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

iii

Page 6

TABL ES

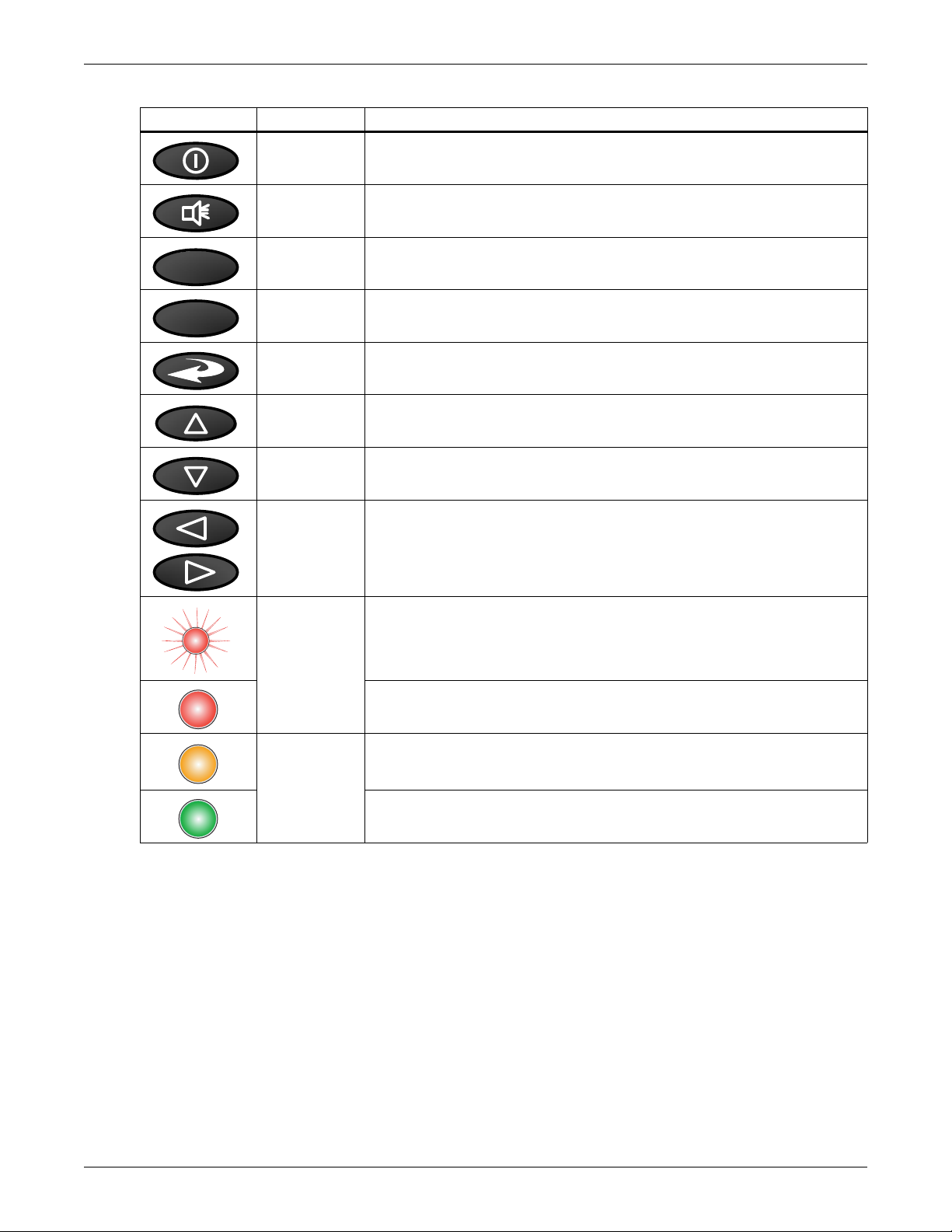

Table 1 Keyboard icons and functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2 User menu icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3 Service menu icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4 Reheat configuration types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 5 Parameters for infrared humidifier control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 6 Dehumidification With Comp settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 7 Customer inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 8 Possible event settings—some events not available in all units . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 9 Event notifications—large or small display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 10 Sample Liebert iCOM network configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 11 Ports available for connecting Liebert iCOM control devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 12 Setpoints parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 13 Spare part list parameters—large display only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 14 Event log parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 15 View network parameters—large display only* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 16 Sensor data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 17 Set alarms parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 18 Active alarms parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 19 Display setup parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 20 Timer parameters—Sleep Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 21 Total run hours parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 22 Service contacts parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 23 Setpoints parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 24 Unit diary parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 25 Maintenance / wellness settings parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 26 Standby settings / lead-lag parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 27 Diagnostics / service mode parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 28 Set alarms parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 29 Sensor calibration / setup parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 30 System / network setup parameters—large display only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 31 Network setup parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 32 Options setup parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 33 Service contact info parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

iv

Page 7

1.0 INTRODUCTION

Wall Mount Large Display

Direct Panel Mount

Small Display and Bezel

Direct Panel Mount Large Display and Bezel

Liebert iCOM Input/Output Board

The Liebert iCOM™ control offers the highest capabilities in unit control, communication and monitoring of Liebert mission-critical cooling units.

Liebert iCOM may be used to combine multiple cooling units into a team that operates as a single

entity, enhancing the already-high performance and efficiency of Liebert’s units.

Liebert iCOM is available as a factory-installed assembly or may be retrofitted on existing products

with SM, AM or AG controls. Large graphic display wall-mount versions of the control are available

for remote operation and monitoring of cooling units.

1.1 Features

Large and Small Displays

The Liebert iCOM control is available with either a large or small liquid crystal display.

•The Liebert iCOM with small display has a 128 x 64 dot matrix screen that simultaneously

shows two menu icons, along with descriptive text. This display is capable of controlling only the

unit it is directly connected to.

•The Liebert iCOM with large display has a 320 x 240 dot matrix screen that shows up to 16

menu icons at a time, as well as descriptive text. This display can be used to control a single cooling unit or any cooling unit on a network, regardless of how it is connected—either integrated into

a cooling unit or simply connected to the network and mounted remotely.

Introduction

Liebert iCOM’s menu-driven display is used for all programming functions on each connected cooling

unit. The Status menu shows the status of the conditioned space, such as room temperature and

humidity, temperature and humidity setpoints, alarm status and settings, event histories and the

current time.

Figure 1 Liebert iCOM components

1

Page 8

Liebert iCOM Display Components and Functions

ESC

?

Liquid Crystal Display

Keypad

Large Liebert iCOM Display

shown - Keypad and LEDs are

identical on all displays.

LED Status Indicators

(top LED is red or

flashing red; bottom

LED is green or amber)

ESC

?

On/Off Key

Escape Key Down Arrow Key

Up Arrow Key

Left Arrow Key Right Arrow KeyEnter Key

Alarm Key

Help Key

2.0 LIEBERT ICOM DISPLAY COMPONENTS AND FUNCTIONS

The small and the large display have a common key layout, as shown in Figure 2.

Figure 2 Liebert iCOM display components

NOTE

The Help key may be pressed at any time for a brief explanation of what is being viewed.

2

Page 9

Table 1 Keyboard icons and functions

?

ESC

Icon Key Name Function

On/Off Key Controls the operational state of the cooling unit.

Alarm Key Silences an alarm.

Help Key Accesses integrated help menus.

ESCape Key Returns to the previous display view.

Enter Key Confirms all selections and selects icons or text.

Liebert iCOM Display Components and Functions

Increase Key

(Up Arrow)

Decrease Key

(Down Arrow)

Left and Right

Arrow Keys

Upper LED

Lower LED

Moves upward in a menu or increases the value of a selected parameter.

Moves downward in a menu or reduces the value of a selected parameter.

Navigates through text and sections of the display.

Blinking Red—Active, unacknowledged alarm exists

Solid Red—Active, acknowledged alarm exists

Amber—Power is available to the unit, unit is NOT operating

Green—Power is available to the unit, unit is operating

3

Page 10

Figure 3 Status menu, large display, graphical view

Evaporator

Fan Speed

Temperature

Setpoint

Humidity

Setpoint

Humidity

Sensor

Reading

Supply

Air Temperature

Percent Hot Water

Heating

Percent Electric

Heating

Percent Dehumidifying

Percent Humidifying

System (or Unit) On/Off

Most Recent Alarms

(Date, Time, Unit,

Description)

System or

Unit # view

Temperature Sensor

Reading

Percent Cooling

Free-Cooling

Percentage

Next Maintenance

Date and Time

fan

cooling

maintenance

hot water

electric heat

dehumidification humidification

freecooling

Figure 4 Liebert iCOM default screen symbols

Liebert iCOM Display Components and Functions

4

Page 11

2.1 Navigating Through the Liebert iCOM Menus

Liebert iCOM shows icons and text for monitoring and controlling your Liebert cooling units or network of cooling units. The number of icons and amount of text shown depends on the display size.

2.1.1 Control Interface

When the buttons on the Liebert iCOM control have not been pressed for a short period, the display

backlight turns off. Pressing any key will turn the backlight on (wake up the screen) and display the

Status menu of the last cooling unit viewed. The Status menu will show the cooling unit’s operational

mode(s), return air temperature and humidity readings, temperature and humidity setpoints and any

active alarm conditions.

If the cooling unit has a large display and is not on a network, or if the unit has a small display,

whether it is networked or stand-alone, the Status menu will display only that cooling unit’s information. Any large display that is connected to a network can be used to view any cooling unit on the network or show an average view of the entire system of cooling units.

The Liebert iCOM control has three main menus; User, Service and Advanced.

The User menu contains the most frequently used features, settings and status information. The Service menu contains settings and features used to set up unit communications and for unit maintenance. The Advanced menu contains settings used to set up the unit at the factory.

NOTE

Menu settings may be viewed without a password, but changing settings requires a password.

If a password is required, Liebert iCOM shows a prompt to enter the password. The password

for the User menu is 1490. The password for Service menu is 5010. For details on entering a

password, see Entering a Password on page 6

Liebert iCOM Display Components and Functions

2.1.2 Accessing Submenus

To access the User, Service or Advanced menu, press the Enter or down arrow key while viewing the

Status menu of the unit you wish to access. The User menu will be displayed first. To view the Service

or Advanced menus, press the right arrow key.

Accessing Submenus on Small Displays

While viewing the menu you wish to access (User, Service or Advanced), use the up and down arrow

keys to scroll through the icons page-by-page. To scroll through the icons one-by-one, press the enter

key and then use the up and down arrow keys. With the desired icon highlighted, press the enter key

to enter that submenu. Once in a Submenu, a list of parameters is displayed.

Press the enter key and use the up and down arrow keys to scroll through the parameters one-by-one.

Pressing the Esc key will go back a level. Figure 5 shows the Liebert iCOM control menus for a small

display.

Accessing Submenus on Large Displays

While viewing the menu you wish to access (User, Service or Advanced), press the enter key to highlight the first icon. Use the arrow keys to navigate through the icons. With the desired icon highlighted, press the enter key to enter that submenu. Once in a Submenu, a list of parameters will be

displayed.

The up and down arrow keys may be used to scroll through the parameters page-by-page if the submenu has multiple pages. To scroll item-by-item, press the Enter key and then use the up and down

arrow keys. Using the right or left arrow keys on large displays attached to a network will change the

unit being viewed. Pressing the Esc key will go back a level. Figures 6 and 7 show the Liebert iCOM

control menus for a stand-alone large display and for a networked large display, respectively.

NOTE

Settings are readable without a password, but changing settings requires a password.

5

Page 12

2.1.3 Entering a Password

Status Menu

Unit 1 View

User Menu

Password

Setpoints

Event Log

Graphics

Set Alarms

Sensor Data

Display Setup

Total Run Hours

Sleep Mode

Service Info

Active Alarms

Service Menu

Password

Setpoints

Standby

Wellness

Diagnostics

Set Alarms

Calibration

Network Setup

Options Setup

Service Info

Advanced Menu

Password

Factory Settings

Access Passwords

To change the value of a parameter in a menu, you must first enter the password for that menu. The

User, Service and Advanced menus each has a unique password to prevent unauthorized changes.

The User menu password is 1490; the Service menu password is 5010.

NOTE

Entering the Service menu password permits access to both the User and Service menus.

To enter a password:

1. Navigate to the menu that contains the parameter to be changed.

2. Select Password in the submenu by pressing the Enter key

3. Press the Enter key to move your cursor to the right side of the screen to select the question

marks.

4. Use the arrow keys to enter the numeral for the password’s first digit (the up arrow key moves

from 1 to the next digit).

5. Use the right arrow key to move to the next question mark and repeat Step 4 to enter all digits in

the password.

6. After entering the password, press enter.

If the password is correct, the Actual Level shown to the right of Password will change

from 0 to 1 or 2. The menu will remain locked if the password was incorrect.

Liebert iCOM Display Components and Functions

Figure 5 Menu tree—Small display, stand-alone or networked

NOTE

Returning to the Status menu will require re-entering a password to make changes.

6

Page 13

Figure 6 Menu tree—Large display, stand-alone

Status Menu – System View

Status Menu

Unit 1 View

User Menu

Unit 1

Password

Setpoints

Spare Part List

Event Log

Graphics

View Network

Set Alarms

Sensor Data

Active Alarms

Display Setup

Total Run Hours

Sleep Mode

Service Contact Info

Service Menu

Unit 1

Password

Setpoints

Unit Diary

Standby Settings/Lead-Lag

Maintenance/Wellness Settings

Diagnostics / Service Mode

Set Alarms

Sensor Calibration/Setup

System/Network Setup

Options Setup

Service Contact Info

Advanced Menu

Unit 1

Password

Factory Settings

Compressor Info

Access Passwords

Unit 1 will be displayed

in the top left corner of

the screen.

Liebert iCOM Display Components and Functions

7

Page 14

Liebert iCOM Display Components and Functions

Status Menu – System View

(Networked Large Display Only)

Status Menu

Unit 1 View

Status Menu

Unit 2, 3, 4...

User Menu

Unit #

Password

Setpoints

Spare Part List

Event Log

Graphics

View Network

Set Alarms

Sensor Data

Active Alarms

Display Setup

Total Run Hours

Sleep Mode

Service Contact Info

Service Menu

Unit #

Password

Setpoints

Unit Diary

Standby Settings/Lead-Lag

Maintenance/Wellness Settings

Diagnostics / Service Mode

Set Alarms

Sensor Calibration/Setup

System/Network Setup

Options Setup

Servi ce Contact Info

Advanced Menu

Unit #

Password

Factory Settings

Compressor Info

Access Passwords

Unit # or System will be

displayed in the top left

corner of the screen.

2.1.4 Viewing Multiple Units with a Networked Large Display

When you first wake up the control, press the Esc key to return to the System view Status menu. This

view shows an average of all the units on the network and any alarms present. To view a specific unit

on the network, press either the enter key or down arrow key. When you do this, you will see the word

System in the top left of the screen change to a unit number. Using the left and right arrow keys you

can toggle through the various units on the network. To go back to the System view, or back one level

from any menu in the control, press the Esc key.

Figure 7 Menu tree—Large display, networked

8

Page 15

Figure 8 User menu icons

User Menu password: 1490

°C / °F

% RH

SET

EVENT

LOG

SET

ALARMS

!

ACTIVE

ALARMS

1 2

39

6

SET

1234h

Table 2 User menu icons

Icon Name

Description

Liebert iCOM Display Components and Functions

Available On Display

Setpoints

Spare Part List

Event Log Contains last 400 events Small & Large

Graphics Displays temperature and humidity graphs Small & Large

View Network Shows status of all connected units Large

Set Alarms Allows enable, disable and settings for alarms Small & Large

View and change temperature and humidity

setpoints

Displays the various part numbers of the

components/parts in the cooling unit

Small & Large

Large

Sensor Data

Active Alarms

Display Setup

Total Run Hours

Shows readings of standard and optional

sensors

Allows the user to view all current active

alarms

Change settings for display: language, time,

simple or graphic view

Records the run time of all components and

allows setting of limits on run time

9

Small & Large

Small & Large

Small & Large

Small & Large

Page 16

Table 2 User menu icons (continued)

1 2

39

6

Icon Name

Description

Liebert iCOM Display Components and Functions

Available On Display

Sleep Mode

Service Contact Info

Allows setback settings for non-peak

operation

Contains key contact information for local

service, including names and phone numbers

Small & Large

Small & Large

10

Page 17

Figure 9 Service menu icons

Service Menu password: 5010

°C / °F

% RH

SET

WELLNESS

SERVICE

SET

ALARMS

+ / -

NETWORK

Table 3 Service menu icons

Icon Name

Setpoints To view and change temperature and humidity setpoints Small & large

Description

Liebert iCOM Display Components and Functions

Available On

Display

Unit Diary

Standby Settings/

Lead-Lag

Maintenance/

Wellness Settings

Diagnostics/

Service Mode

Set Alarms Allows enable, disable and settings for alarms Small & large

Sensor

Calibration/Setup

Shows all entered program changes and maintenance

performed on the unit

Allows lead/lag setup when multiple units are connected Small & large

Allows setting maintenance interval reminder,

maintenance message, number of unit starts and stops,

and time since last maintenance

Allows troubleshooting, manual mode, read analog and

digital inputs

Allows calibration of sensors Small & large

Large

Small & large

Small & large

System/Network

Setup

Options Setup Allows setup of component operation Small & large

Service Contact Info

Allows setup and U2U communication for multiple units Large

Contains key contact information for local service,

including names and phone numbers

11

Small & large

Page 18

3.0 OPERATION

Remote On / Off

Display On / Off

The Liebert iCOM display for your Liebert cooling unit features an easy-to-use, menu-driven liquid

crystal display (LCD). All unit settings and parameters can be viewed and adjusted through three

menus: User, Service and Advanced. All active alarms are displayed on the LCD and annunciated.

The control is shipped from the factory with default selections for all necessary settings. Adjustments

can be made if the defaults do not meet your requirements.

References to menu items in this manual are followed by the main menu and the submenu where they

can be found.

For example:

• Temperature Setpoint (User Menu, Setpoints) - The Temperature Setpoint parameter is

located in the User menu under the Setpoints submenu.

• High Return Humidity (Service Menu, Set Alarms) - The High Return Humidity alarm is

located in the Service menu under the Set Alarms submenu.

3.1 Single Unit Functions

3.1.1 Unit/Fan Control

Start - Stop

Operation

Unit on means the fan output is activated. The unit can be switched On and Off from two inputs:

1. Remote on/off input

2. Display button

Pressing the On/Off key on a small display will control only the cooling unit it is connected to regardless, of whether the cooling unit is a stand-alone unit or part of a network.

Pressing the On/Off key on a large display of a stand-alone cooling unit will control only that unit.

The effect of pressing the On/Off key on a large display connected to a network depends on the view:

System or Unit.

• In System view, pressing the On/Off key shows a warning asking for confirmation to shut down

the entire system.

• In Unit view, pressing the On/Off key affects only the unit being viewed, without a confirmation

request.

Each time a unit is powered on or off, an event is added to the Event Log in the User menu.

NOTE

Customer switches: remote On/Off (if used) and display On/Off switches are in series. A

cooling unit will start only if both switches are On; if one of these switches is Off, the unit will

stop. Safety devices within the unit are also in series and will shut the unit down if required.

Figure 10 Start-stop priority switches

NOTE

If Remote On/Off is not used, a jumper is inserted to bypass the switch.

12

Page 19

Operation

Autorestart

When there is a loss of power to the cooling unit and power comes back, the unit will return to its previous operating status—on if it was on before the power off, off if it was off.

When power returns, the autorestart time—time-selectable: Single Unit Auto Restart (Service Menu,

Options Setup)—controls the start of the unit. The autorestart time runs in a loop, starting the next

unit each time when elapsed, starting with Unit # 1.

Loss of Power Alarm

A Loss of Power Alarm is activated when power is restored after an interruption. If acknowledged, the

alarm resets automatically after 30 minutes. This alarm can be set to different event types (Message,

Alarm or Warning) and can be disabled under menu item Loss of Power (Service Menu, Set Alarms).

NOTE

Loss of power alarm will be activated only on units that had the fan on before power was lost.

Fan Alarm / Fan Protection Settings

The fan operation is protected by two digital devices: motor protection (optional) and a differential

pressure switch. The motor protection monitors for main fan overload and the differential pressure

switch ensures that the blower(s) are moving air. If either protection device triggers, an alarm will be

announced by a buzzer, alarm relay and event to monitoring after an adjustable time-delay (Main

Fan Overload and Loss Of Airflow in Service Menu, Set Alarms).

The time delay at the unit start is always five seconds shorter than the control delay (to avoid short

component starting when the fan is not working). During operation, the fan delay is fixed to

15 seconds.

There are two selection possibilities for both, Loss Of Airflow and Main Fan Overload:

• Shutdown—stops the unit (intended for DX models).

• Disable—stops the humidifier, electrical heaters and dehumidification; allows cooling and

free-cooling only (intended for chilled water models / external cooling).

NOTE

When the Main Fan Overload alarm is active, the Loss of Airflow alarm is masked out.

3.1.2 Chilled Water Units with Variable Speed Motor

VSD Fan Speed (Auto or Manual VSD Fan Speed Control)

The parameter VSD Fan Speed (Service Menu, Setpoints) allows the cooling unit's fan motor speed to

be set for:

• Auto operation: when set to Auto, the speed of the VSD (variable speed drive) motor follows the

position of the chilled water valve based on predetermined logic for cooling and dehumidification

operation.

• Manual operation: when set to Manual, the speed of the VSD motor follows user input as set

either locally at the cooling unit's Liebert iCOM display (under VSD Setpoint in Service Menu,

Setpoints) or remotely using Modbus BMS signal with an optional Liebert IntelliSlot

VSD Setpoint (VSD Fan Speed Setting)

If the VSD Fan Speed Control (Service Menu, Setpoints) is set for Manual, the VSD Fan Speed Setpoint (Service Menu, Setpoints) may be set for the desired speed of the variable speed motor.

Depending on the product control design, there may be an internal minimum speed, as defined by

that specific product operation, while the customer input may be set for 0-100%:

• Fan speed may be set locally at the unit using the Liebert iCOM display.

• Fan speed may be set remotely via a BMS signal (sent via Modbus using an optional Liebert IntelliSlot 485 card), which then transmits to the unit local control.

®

485 card.

13

Page 20

3.1.3 General Compressor Requirements Low-Pressure Time Delay

When the compressor starts, the low-pressure input is ignored for a selected period of time based on

the setting of the Low Pressure Alarm Delay (Service Menu, Options Setup). This time is usually set

to 3 minutes on air-cooled units, and to 0 or 1 minute on water cooled units. When this time is

expired, a second timer starts to operate if the low-pressure input is active. This second timer is active

during normal compressor operation to avoid compressor trips due to bubbles in the refrigerant or

other influences creating short trips of the low-pressure switch. The low-pressure switch input is

enabled only if the compressor is operating. Exception: Pump Down (see Pump Down).

NOTE

Low-pressure condition could be read through contacts or through pressure transducers with

threshold setting.

Pump Down

The Pump Down operation is performed to protect the compressor oil from being diluted with liquid

refrigerant to ensure that the compressor is properly lubricated for the next startup. The Pump Down

operation operates in the following manner:

Whenever a compressor is turned Off and the low-pressure switch is closed (pressure OK), the compressor will be operated with the LLSV (liquid line solenoid valve) closed (de-energized) until the lowpressure switch opens (low-pressure condition, without giving alarm). When there is a call to turn off

a compressor the LLSV is closed. If the low suction pressure switch (LPS) does not open within a specified time, the LLSV is turned On then back Off (to try to unstick the LLSV). The control will then

wait a set period of time for the LPS to open. This will happen three times. If, after three times, the

low suction pressure switch does not open, the compressor and LLSV are locked off and an alarm

“Pump Down not completed” will appear.

Operation

There is a re-pump down if the LPS opens again after the compressor has been already stopped—a

maximum of six re-pump-down cycles per hour are allowed. At the seventh request of re-pump down

the alarm “Comp 1 Pumpdown Fail” or “Comp 2 Pumpdown Fail” will appear and the compressor will

be locked out.

Pump down is always performed loaded (for compressors with unloaders: unloaders off, digital scroll:

control solenoid valve disabled).

For digital scroll only: when pump down has finished successfully (LPS opened), pump down will be

continued for another half-second with the control solenoid valve energized.

High Pressure Alarm

When the compressor is initially activated, the system will be monitored for a high pressure situation.

When a high pressure situation is detected during the first 10 minutes of operation, the unit will

attempt to correct the problem several times without notification. If the unit is unsuccessful in correcting the problem, an alarm will occur and the affected compressor will be locked off. If high head

pressure alarm trips three times in a rolling 12 hour period, the affected compressor will be locked off.

After the compressor has been running for 10 minutes, if a high head pressure situation is detected,

an alarm will occur and the affected compressor will be immediately locked off without the unit trying

to correct the problem.

Once the compressor is locked off, it will not come back on until main power is reset, or until the

HP Alarm Counters (Service Menu, Diagnostics) are reset to 0. Setting the counter to 0 will auto-reset

the alarm without the need of pressing the reset button on the display. Even if the pressure in the

system drops below the alarm point, the compressor will remain off until the system is reset.

NOTE

If the unit is equipped with manual reset high head pressure switches, or if the auto reset high

head pressure switches don’t reset, the compressor will not be turned back on, but there will be

a 30-second delay from when the high head pressure situation occurs and when the alarm is

annunciated.

14

Page 21

Digital Scroll High Temperature

A protective maximum operating compressor temperature limit is imposed on units with digital scroll

compressor(s) with thermistor. Once the digital scroll temperature reaches the maximum temperature threshold, the compressor will be locked out for at least 30 minutes and an alarm will be annunciated. If after 30 minutes the temperature has cooled to a safe operating temperature, the

compressor will resume operation.

Each time a high-temperature alarm occurs, HT 1 Alarm Counter (Service Menu, Diagnostics) or

HT 2 Alarm Counter (Service Menu, Diagnostics) is increased by one. Once these counters reach five

occurrences in a rolling four-hour period, the compressor will be locked out. The alarm can be reset

once the temperature returns to a safe level by:

1. Setting the counter back to 0 from the display and pressing the alarm reset button.

2. Shutting off power to the control board by turning the cooling unit's main power disconnect switch

Off and On.

3.1.4 Compressor Timing—Units With Two Compressors

To help maximize the life of your compressor(s), there is a start-to-next start delay for each single

compressor.

A Minimum ON time and a Minimum Off time may be selected in the Advanced menu (minimum

three minutes for single phase compressors). Consult the factory on how to modify the Minimum ON

and OFF time settings.

Operation

3.1.5 Compressor Sequencing

Compressor Sequencing parameter (Service Menu, Options Setup) is intended to maintain equal run

times between compressors. This setting has three selection possibilities:

• Always use Compressor 1 as lead compressor

• Always use Compressor 2 as lead compressor

•Auto:

• First priority: if the safety timings are acceptable for only one compressor, then it is the next

to be started/stopped.

• If both compressors are off: the one with fewer working hours is the next to start.

• If both compressors are in operation: the one that has been operating longer since the last

start is the next to be stopped.

NOTE

The Auto setting attempts to maintain equal run times between compressors.

15

Page 22

3.2 Motorized Ball Valve in Digital Scroll Units

On digital scroll units, discharge pressure is controlled by a motorized ball valve. During unloaded

operation, pressure changes during each digital cycle could cause a pressure-controlled water regulating valve to open and close an excessive number of times.

The motorized ball valve is designed to maintain a consistent peak discharge pressure on Water/Glycol Cooled Digital Compressor Systems.

The control algorithm for the motorized ball valve uses an intelligent sampling rate and adjustable

pressure thresholds to reduce the number of times the valve opens and closes. The valve assembly

consists of the brass valve, linkage and actuator.

Each compressor has one motorized ball valve that is driven by the analog output of the Liebert iCOM

control board based on pressure. If there is a call for cooling, the compressor start is delayed by a 30second timer. During this delay, the motorized ball valve is set to 50% open. The compressor will start

after the 30-second timer elapses.

Motorized Ball Valve Manual Mode: (Service/Service) Manual operation can be selected to allow

service personnel to control the motorized ball valve from the Liebert iCOM control only when the

system is in manual mode.

When Auto BV Control is selected, the motorized ball valve functions as it would be during normal

system operation.

NOTE

Compressor operation will be delayed 30 seconds to allow the motorized ball valve to position

itself for initial startup.

Operation

When Manual BV Control is selected, the user must be careful in setting the analog output because

the ball valves will remain in the position set in the Service menu until the control is switched back to

Auto or until a technician changes the valves to another manual position (the motorized ball valve in

manual mode can be set in 1% increments from fully closed to fully open). Low- or high-discharge

pressure may occur during this mode, depending on environmental conditions and the position of the

motorized ball valve.

The motorized ball valve is driven by a 2-10VDC proportional control signal: the valve is closed at

2VDC, 50% open at 6VDC and fully open at 10 VDC.

3.2.1 MBV Operation After Compressor is Turned Off

Once a compressor has stopped, the MBV control will continue to change the MBV position to maintain system pressures for a maximum time of 10 minutes by following the auto control algorythm.

When the 10-minute delay has expired or the discharge pressure is below its minimum threshold the

motorized ball valve will close until the next compressor activation.

3.2.2 Service Offset—Changing System Pressure Settings

The MBV control is set to maintain a system pressure specific to the particular type of cooling unit. A

properly trained and qualified technician can increase or decrease the pressure through the Ball

Valve Setpoint Offset found in the Service/Options Setup menu. The range is 0 to 50 PSI; the default

is 30 PSI.

NOTE

Adjusting this parameter will increase or decrease the operating compressor discharge

pressure by changing the targeted range of control. The discharge pressure is the peak pressure

of the digital cycle.

16

Page 23

3.3 Temperature Control—Single Source Cooling (No Extra Cooling Coil)

0%

Setpoint

0%

Cooling

+ Temp

+ 100%

Cooling

½ Proportional Band

Dead -

band

-Temp

Heati ng

-100%

Heating

½ Proportional Band

CoolingHeati ng

-Temp + Temp

0%

Setpoint

+ 100%

Cooling

-100%

Heating

½ Proportional Band½ Proportional Band

With Deadband

Without D eadband

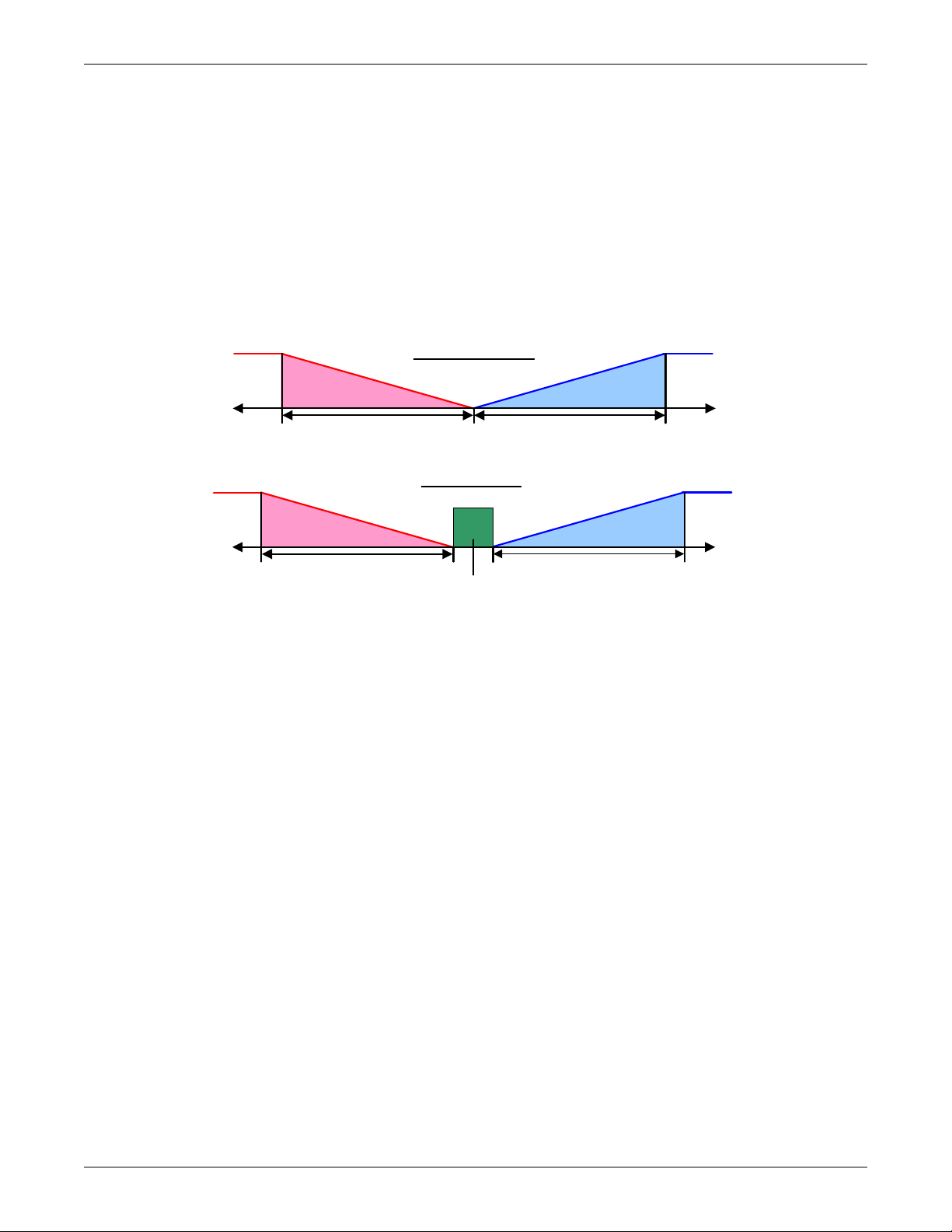

3.3.1 Temperature Proportional Band

The control uses the temperature proportional band to determine which operation to perform (cooling/heating) and how intensely to perform it. The Temperature Proportional Band is a user-defined

range that is divided into two equal parts for cooling and heating. The Temperature Setpoint is

between these two equal parts.

An optional Temperature Deadband range can be defined, which is equally divided on either side of

the setpoint and separates the two halves of the proportional band. Figure 11 illustrates how the

temperature proportional band is evenly divided on either side of the temperature setpoint, with and

without a deadband.

Figure 11 Temperature proportional band

Operation

When the return air temperature deviates from the setpoint it begins to penetrate one of the proportional band halves, cooling or heating. If the return air temperature increases, the control calls for 0%

(none) to 100% (full) cooling capacity based on how far the temperature penetrates the cooling portion

of the proportional band. If the return air temperature decreases, the control calls for 0% (none) to 100% (full) heating capacity based on how far the temperature penetrates the heating portion of the

proportional band.

When the return air temperature reaches the end of the proportional band, either 100% or -100%, full

cooling or full heating capacity is provided. No operation is performed when a 0% call is calculated.

The control varies the call for cooling and heating in 1% increments as the return air temperature

moves through the proportional band halves.

The deadband range is used to widen the setpoint. When the return air temperature falls within the

deadband, the control operates the same as if the temperature equaled the setpoint exactly. This setting helps maximize component life by preventing excessive component cycling. The Temperature

Proportional Band and Temperature Deadband parameters are in the Service menu under the Setpoints submenu. The Temperature Setpoint parameter is in both the User Menu and Service Menu

under Setpoints.

There is a parameter AutoSet Enable (Service Menu, Setpoints), which automatically sets the proportional bands for temperature and humidity, and both the integration time factors according to the

type of unit (Chilled Water, single or double compressor), with influence of the selected Teamwork

Mode. See 4.1 - Teamwork Modes for more on using this feature.

17

Page 24

3.3.2 Compressor Control

Temp Setpoint : 70°F

Proportional Band: 8°F

Deadband: 2°F

75

½ Proportional Band

0%

Cooling

+ 100 %

Cooling

71 72 73 7470

½ Dead-

band

Cool 1

Off

Cool 1

On

Increasing Temperature

Temp Setpoint: 70°F

Proportional Band: 8°F

Deadband : 2°F

75

1/2 Proportional Band

0%

Cooling

+ 100%

Cooling

71 72 73 7470

1/2 D ead -

band

Cool 1

On

Cool 2

On

Increasing Temperature

Cool 2

Off

Cool 1

Off

Depending on the type of Liebert air conditioning unit you have your unit may contain one or two

compressors with or without unloaders.

Compressor Proportional Bands

One Single-Step Compressor Without Unloaders—One-Step

One single-step compressor, Cool 1, is started at 100% call for cooling from the temperature proportional band and stopped at 0% (see Figure 12).

Figure 12 One single-step compressor without unloaders

Operation

Two Single-Step Compressors Without Unloaders—Two-Step

First single-step compressor, Cool 1, is started at 50% calculated output from the temperature proportional band, and stopped at 0%. The second compressor, Cool 2, starts at 100% and stops at 50% (see

Figure 13).

One Compressor With an Unloader—Two-Step

The two-step compressor is started unloaded at 50%, Cool 1, calculated output from the temperature

proportional band and stopped at 0%. At 100% the compressor starts fully loaded, Cool 2, and returns

to unload operation at 50% (see Figure 13).

Figure 13 Two single-step compressors without unloaders or one compressor with an unloader (two-step)

18

Page 25

Two Compressors With Unloaders—Four-Step

Cool 2

On

Temp Setpoint: 70°F

Proportional Band: 8°F

Deadband : 2°F

½ Dead-

band

Increasing Temperature

½ Proportional Band

757473727170

0%

Cooling

+ 100%

Cooling

Cool 4

Off

Cool 2

Off

Cool 1

Off

Cool 4

On

Cool 3

On

Cool 1

On

Cool 3

Off

The first two-step compressor is started unloaded at 33% calculated output from the temperature proportional band and stopped at 17%. At 80% Compressor 1 will be loaded, at 70% unloaded.

The second compressor starts unloaded at 63% and stops at 47%. At 100%, Compressor 2 will be

loaded, at 90% unloaded (see Figure 14).

The four stages of cooling are accomplished in the following manner:

• 1 stage: One compressor, unloaded - Cool 1

• 2 stages: Both compressors, unloaded - Cool 2

• 3 stages: One compressor, loaded and one compressor, unloaded - Cool 3

• 4 stages: Both compressors, loaded - Cool 4

Figure 14 Two compressors with unloaders (four-step)

Operation

19

Page 26

Digital Scroll Compressors

Call for Cooling: 66%

100% Loaded

0% Loaded

Solenoid

De-energized

Solenoid

De-energized

Solenoid

Energized

0 5 10 15 20 25 30

Solenoid

Energized

15-Second Capacity

Modulation Cycle

15-Second Capacity

Modulation Cycle

Temp Setpoint: 70°F

Proportional Band : 8°F

Deadband: 2°F

½ Dead-

band

Increasing Temperature

Comp 1

Off

½ Proportional Band

757473727170

0%

Cooling

+ 100 %

Cooling

Comp 2

Off

Comp 1 On Partially

Loaded

Comp 2 On Partially

Loaded

Comp 1 & 2 On

Fully Loaded

A compressor with a suction cutoff unloader can only modulate its capacity between two distinct levels: fully loaded and half loaded. A digital scroll compressor can modulate its capacity anywhere

between 10-100%. This variable capacity modulation allows cooling units to control an environment

more precisely.

Digital scroll capacity modulation is achieved by energizing and de-energizing a solenoid valve on the

compressor. When the solenoid valve is de-energized, the compressor capacity is 100%. When the solenoid valve is energized, the compressor capacity is zero. Therefore, the capacity of the compressor

depends on how long the solenoid is de-energized for. If the solenoid is de-energized for 10-seconds,

then energized for 5 seconds during a 15-second cycle, the resulting capacity will be 66% as shown in

Figure 15.

Figure 15 Digital scroll capacity modulation, 10-100% variable

Operation

On single and dual digital scroll compressor systems, the first compressor is started at 25% calculated

output from the temperature proportional band and stopped at 10%. On dual digital scroll compressor

systems, the second compressor is started at 35% and stopped at 20%, see Figure 16. When a compressor is started, the solenoid is energized longer than it is de-energized to match the call for cooling.

When the call for cooling increases to 100%, the solenoid is de-energized for the entire 15 second cycle.

Figure 16 Single and dual digital scroll compressor activation points

20

Page 27

3.3.3 Chilled Water Control

+ 100%

Cooling

Cooling

½ Proportional Band

0% - 3P Closed

Requested 3P Position

100% - 3P Fully Open

0%

Setpoint

+ Temp

The chilled water control valve is adjusted proportionally as the temperature control varies the

requirement for cooling from 0% to 100%. Units with the optional variable speed drive (VSD) control

the fan speed in a similar manner, except that the minimum fan speed is 60% when the cooling

requirement is less than 60%. Also, the fan is operated at 100% on a call for any heating and/or

humidification.

A three-point actuator is used for chilled water cooling, as well as free cooling, or heating, with either

valves or dampers. These actuators are driven through two digital outputs: Open and Close.

The Three-Point Actuator Running Time (Service Menu, Options Setup) defines the time needed to

move the valve or damper from closed to open. The Actuator Direction (Service Menu, Options Setup)

defines if the valve/damper works in direct or reverse mode (the controller outputs are exchanged;

Open becomes Close and Close becomes Open).

Any time the unit receives the Power On signal, the valve performs a 3P Reset: the Close command is

given continuously for a time of 110% of the 3P actuator run time. This calibrates the valve or damper

with the controller and ensures that it is closed. A 3P Reset is also performed if the fan is switched off

for any reason (timer off, unit off, etc.).

During normal operation the 3P actuator is driven in steps. After start of control (unit on or free-cooling / glycol cooling is enabled) the 3P actuator moves (without stepping) to the requested position,

after that the stepping starts.

Figure 17 Three-point actuator control (example: cooling)

Operation

3.4 Temperature Control—Second Cooling Source

3.4.1 Differential Temperatures / Controls (Comparator Circuit)

Certain cooling units are available with a second source of cooling within the unit. These typically are

compressorized models with an additional chilled water or free-cooling coil.

Delta T (Temperature Difference) Between Room and Glycol

The comparator circuit determines if the glycol / chilled water temperature of the second cooling

source is low enough to provide at least partial cooling capacity. The comparator circuit has three settings (DT Between Room / FC Type, [Service Menu, Setpoints]):

•No

•Contact

•Value

The No setting is for standard compressorized and chilled water units that do not have a second cooling source. The Contact setting is used when an external control is being used to determine when the

second cooling source is to be activated. The external control communicates to the Liebert unit via a

contact closure

• Closed = cooling enabled

• Open = cooling disabled.

21

Page 28

The Value setting is the factory default setting on free-cooling and dual cooling units. If the tempera-

7571 72 73 7470

Increasing Temperature

Cool 2

On

Cool 1

On

+ 100%

Cooling

Valve 100%

Open

Valve

Closed

½ Dead -

band

76 77 78 79

+ 200%

Cooling

0%

Cooling

2nd

Source

Comp

½ Proportional Band ½ Proportional Band

Band1: 2

nd

Source B and 2: Compressors

Temp Setpoint: 70°F

Proportional Band: 8°F

Deadband: 2°F

ture difference between the second source cooling fluid parameter, Free-cooling Fluid Temperature

(User Menu, Sensor Data) and room air is equal to or greater than the adjustable DT Between Room

Air / FC Fluid (Service Menu, Setpoints) value, then the second source cooling fluid will be used to

provide at least partial cooling (delta T between room and glycol = true).

Sensors used for this delta T are: room/local sensor or the return air sensor; and the glycol sensor.

If this delta T is true, the following actions will be performed:

1. The Free-Cooling Status indication will show “On” instead of “Off”.

2. The compressor band will be shifted to the right by 100%, and within the first 100% the freecooling valve band will take place (see Figure 18).

Figure 18 Second cooling source and compressorized cooling

Operation

Minimum Chilled Water Temperature—This feature permits the user to select the minimum

chilled water temperature that allows simultaneous operation of the second cooling source (chilled

water control) and compressor control. This feature is enabled in the Service menu under Setpoints,

parameter Minimum CW Temp.

Below this minimum chilled water setpoint, parameter Minimum CW Temp Value, (Service Menu,

Setpoints), the control will operate ONLY the second cooling source control, i.e., the compressor is

locked out. Above the minimum chilled water setpoint, assuming the fluid temperature is below the

return room air temperature (delta T between room and glycol = true), the control will operate the

second cooling source control and compressor control simultaneously if needed.

If the Minimum CW Temp is disabled, the second cooling source temperature is ignored, the control

will always operate the second cooling source and compressors simultaneously when the load requires

it.

22

Page 29

Operation

GLYCOOL™ Cooling—Free-Cooling

When GLYCOOL cooling is available, the temperature control will calculate a total cooling requirement of 200% rather than 100%. Assuming that full GLYCOOL capacity is available, the GLYCOOL

valve opens proportionally as the requirement for cooling rises from 0 to 100%. If more than 100%

cooling is required, then the compressors are activated at 150% and 200% respectively (133%, 163%,

180% and 200% for a four-step system). If full GLYCOOL capacity is not available, then the GLYCOOL valve will be opened proportionally over a cooling requirement band equal to the available

GLYCOOL capacity. The compressors would be activated when the GLYCOOL capacity is exceeded.

For example, if the GLYCOOL capacity is 60%, then the GLYCOOL valve would be full open at 60%

cooling requirement and the compressors would activate at 110% and 160% cooling requirement. In

order to reduce compressor cycling and prevent hunting, GLYCOOL capacity first becomes available

when the entering glycol temperature is at least 8°F (4.4°C) (22% capacity) below the return air temperature, or 3°F (1.7°C) below the return air temperature for two hours. GLYCOOL capacity is 100%

when the glycol temperature is 25°F (13.9°C) below the return air temperature. The system will continue to operate in Econ-O-Cool mode as necessary as long as the entering glycol temperature

remains at least 3°F (1.7°C) (0% capacity) below the return air temperature. If GLYCOOL is not

available, the temperature control will operate the compressors in the same manner as a two-step or

four-step system without GLYCOOL.

Dual Cooling Source

If dual cooling is available, the sensible cooling system operates in the same manner as a GLYCOOL

system, except that it is assumed that 100% chilled water capacity is available any time the chilled

water temperature is 3°F (1.7°C) below the return air temperature.

3.5 Temperature Control—Reheat

If the room air temperature becomes too cold, the control will call for heating. Heating mode is controlled by the Temperature Proportional Band, explained in 3.3.1 - Temperature Proportional

Band.

3.5.1 Three-Stage Electric, Hot Gas and Hot Water Reheat

The Reheat Proportional Band is divided into three equal parts, each representing one reheat stage.

As the Temperature Proportional Band increases the call for heating from 0% to -100%, stages 1

through 3 are switched On, as shown in Figure 19. Your unit will have one of the nine reheat configuration types shown in Table 4.

Table 4 Reheat configuration types

Type A B C D E F G H I

Stage 1 Electric 1 Electric 1 Electric 1 Hot Gas Hot Gas Hot Gas Hot Water Hot Water Hot Water

Stage 2 - Electric 2 Electric 2 - Electric 1 Electric 1 - Electric 1 Electric 1

Stage 3 - - Electric 3 - - Electric 2 - - Electric 2

NOTE

1. Hot gas / hot water are not influenced by the setting of electric reheat during

dehumidification.

2. Hot gas output will be set only if the selected compressor is in operation.

23

Page 30

Figure 19 Three-stage heating

0%

Heating

65 70

Heat 3

On

½ Dead -

band

66 67 68 69

Heat 2

On

Heat 1

On

Heat 3

Off

Heat 2

Off

Heat 1

Off

-100 %

Heating

½ Proportional Band

Decreasing Temperature

Temp Setpoint: 70°F

Proportional Band: 8°F

Deadband : 2°F

Operation

24

Page 31

3.5.2 SCR Reheat

Temp Setpoint: 70°F

Proportional Band: 8°F

Deadband: 0°F

Cool 1

Off

-100 %

Heating

Cool 2

On

SCR On

Cool 1 On

Cool 2

Off

SCR

Off

-200%

Heati ng

100%

Cooling

0%

½ Proportional Band ½ Proportional Band ½ Proportional Band

7465 7066 67 68 69 71 72 73646362

Cooling 2 On

Cooling 1 On

SCR Reheat On

SCR reheat is a type of electric reheat that provides tighter temperature control than staged electric

reheat. SCR reheat capacity modulation is achieved by pulsing the reheat On and Off. Full capacity is

achieved by constantly energizing the reheat. Units equipped with SCR reheat can operate in Tight or

Standard mode. By default, cooling units with SCR reheat are factory-set to operate in Tight mode.

The mode of operation can be set by adjusting the SCR Control Type parameter (Service Menu, Setpoints).

Tight Mode

In Tight mode, the compressors and reheats are operated at the same time to provide maximum temperature control. The temperature deadband is set to zero at the factory. In a cooling unit with SCR

reheat and two single-step compressors, the first single-step compressor is started and full reheat

capacity is provided at 0% calculated output from the Temperature Proportional Band. As the call for

cooling increases from 0% to 100%, the reheat capacity is slowly reduced by pulsing the reheat. At

100% call for cooling, the reheat is deactivated and the second single-step compressor is started. As

the call for cooling is reduced, the reheat capacity is slowly increased. When the call for cooling

returns to 0%, the second single-step compressor is deactivated.

If the Temperature Proportional Band calculates a call for heating from 0% to -200%, the first single-step compressor remains activated and full reheat capacity is provided. Based on the factory

default settings, the first single-step compressor is deactivated when the control reaches -200% call

for heating. The compressor remains deactivated until the control calls for 0% heating. The compressor activation and deactivation points can be adjusted in the Service menu under Setpoints.

Figure 20 illustrates how a cooling unit with two single-step compressors and SCR reheat operates

when the SCR Control Type is set to Tight mode.

Operation

Figure 20 Two single-step compressors with SCR reheat set to Tight mode

NOTE

Some cooling units are not suited for a strict NO LOAD application. These cooling units

require a minimal load in the space. Consult factory for verification.

25

Page 32

Standard Mode

Temp Setpoint: 70°F

Proportional Band : 8°F

Deadband : 0°F

Cool 2

On

Cool 1

On

Cool 2

Off

Cool 1 Off

SCR Off

SCR

On

0%

100 %

Cooling

-100%

Heati ng

7471 72 7366 67 68 69 70

½ Proportional Band

Cooling 1 On

Cooling 2 On

½ Proportional Band

SCR On

In Standard mode, the SCR reheat operates only when the Temperature Proportional Band calls for

heating. SCR reheat output is adjusted proportionally as the Temperature Proportional Band varies

the requirement for heating from 0% to -100%. Compressors operate only when there is a call for cooling as described in 3.3.2 - Compressor Control.

Figure 21 illustrates how SCR reheat operates when SCR Control Type is set to Standard mode.

Figure 21 Two single-step compressors with SCR reheat set to Standard mode

Operation

26

Page 33

3.6 Humidity Control

0%

Setpoint

0%

+ 100%

Dehumidification

Dead-

band

Humidification

-Hum + Hum

0%

Setpoint

½ Proportional Band

Dehumidification

- 100%

Humidification

-100%

humidification

Without Deadband

With Deadband

Humidification

-Hum

+ 100%

Dehumidification

+ Hum

Dehumidification

½ Proportional Band

½ Proportional Band ½ Proportional Band

The control uses the humidity proportional band to determine which operation to perform (dehumidification/humidification) and how intensely to perform it. The Humidity Proportional Band is a user

defined range that is divided into two equal parts for dehumidifying and humidifying. The Humidity

Setpoint is located between these two equal parts.

An optional Humidity Deadband range can be defined, which is equally divided on either side of the

setpoint and separates the two halves of the proportional band. Figure 22 illustrates how the humidity proportional band is evenly divided on either side of the humidity setpoint, with and without a

deadband.

Figure 22 Humidity proportional band

Operation

When the return air humidity deviates from the setpoint, it begins to penetrate one of the proportional band halves, either dehumidification or humidification. If the return air humidity increases,

the control calls for 0% (none) to 100% (full) dehumidifying capacity, based on how far the humidity

penetrates the dehumidification portion of the proportional band. If the return air humidity

decreases, the control calls for 0% (none) to -100% (full) humidifying capacity based on how far the

humidity penetrates the humidification portion of the proportional band.

When the return air humidity reaches the end of the proportional band, either 100% or -100%, full

dehumidification or full humidification capacity is provided. No operation is performed when a 0%

call is calculated. The control varies the call for dehumidifying and humidifying in 1% increments as

the return air humidity moves through the proportional band halves.

The deadband range is used to widen the setpoint. When the return air humidity falls within the

deadband, the control operates the same as if the humidity equaled the setpoint exactly. This setting

helps maximize component life by preventing excessive component cycling. The Humidity Proportional Band and Humidity Deadband parameters are in the Service menu under the Setpoints submenu. The Humidity Setpoint parameter is in both the User menu and Service menu under

Setpoints.

27

Page 34

3.6.1 Humidification

Infrared Humidifier

There are two types of infrared humidifiers: small pan (IFS) and large pan (IFL). The operating mode

of each is similar, however, some of the variables or timings differ.

Infrared humidifiers are started at 100% humidification request, and stopped at 0%. Infrared humidifiers cannot be driven in proportional mode.

Table 5 Parameters for infrared humidifier control

Parameter IFS Default IFL Default

Humidity in Last xx Hours 15 hours 15 hours

Prefill Time 30 seconds 60 seconds

Fill Time 4 minutes 7 minutes

Humidifier On Time 8 or 10 minutes 10 minutes

Flush Rate 150% 150%

An autoflush system automatically controls a water makeup valve to maintain proper levels in the

infrared humidifier water pan during humidifier operation. If humidification is needed and 15 hours

have elapsed since the last time the humidifier was on, then the humidifier is not turned on until the

valve completes an initial fill of the humidifier pan. This pre-fill is about 30 seconds for a small pan

and 60 seconds for a large pan. The valve continues to fill and flush the pan for about 4-1/2 minutes

for a small pan or 7-1/2 minutes for a large pan. Pan size is selected based on unit specifications and

is preset at the factory.

Operation

During humidifier operation, with the flush rate set at the default of 150%, the valve is opened periodically to add water to the pan (about 45 seconds every 7 minutes of humidifier operation for a small

pan, or 80 seconds every 10 minutes of operation for a large pan). This adds enough water to the pan

to cause about a third of the total water used to be flushed out of the overflow standpipe located in the

humidifier pan. This action helps to remove solids from the pan. The flush rate is adjustable from

110% to 500% in 10% intervals. Default is 150%. If the water quality is poor, it may be desirable to

increase the water flushing action above the normal 150% rate. Also, if the supply water pressure is

low, the flush rate adjustment can be increased so that sufficient water level is maintained during

humidification. The flush rate parameter, Infrared Flush Rate (Service Menu, Options Setup), is

adjustable from 110%-500%.

External Humidifier Control—Optional

A factory-supplied option may be provided to allow a start-stop command to be sent to the control of a

remote-mounted humidifier.

28

Page 35

3.6.2 Dehumidification

The Dehumidification Enable parameter (Service Menu, Options Setup) allows for enabling/disabling

the dehumidification function.

A call for dehumidification is calculated in the same way as a cooling request. The components

(valves, compressors) will follow this dehumidification request as soon as it is higher than the request

for cooling.

Dehumidification Low Limit

Low Limit 1 and Low Limit 2 are used to avoid overcooling a room during dehumidification. When a

low limit is reached, a compressor or the liquid cooling source that is used for dehumidification is disabled. It is re-enabled when the return air temperature rises. The Low Limit 1 and 2 settings are in

the Service menu under Setpoints.

Low Limit 1: Low Limit 1 will disable one of two compressors for dehumidification. If only one compressor is set for dehumidification, or if the dehumidification source is chilled water, this limit will

not be visible and will be inactive.

Low Limit 2: Low Limit 2 will disable both compressors for dehumidification. This limit will also

stop dehumidification in single compressor units and in chilled water units.

The limits become active when the return air temperature drops below a temperature value equal to

the sum of the temperature setpoint plus the value set on Low Limit 1 and 2 (the Low Limit settings

are negative values).

Operation

A dehumidification source is deactivated if the return air temperature drops below the Deactivation

Temperature, as in this example:

Temperature Setpoint: 70°F

Low Limit Value: -7°F

Deactivation Temperature: 62°F

NOTE

If a cooling unit is equipped with SCR reheat and the SCR Control Type parameter is set to

Tight mode, then Low Limit 2 will be ignored, see 3.5 - Temperature Control—Reheat.

Dehumidification Compressor Quantity

Under Factory Settings in the Advanced menu there is an item called Dehumidification With Comp.

This item will be set to either 1, 2, 1 or 2, or BOTH. This setting determines which compressors are

used for dehumidification. It also determines if Low Limit 1 will be available and impacts how the

reheats will operate during dehumidification. The Dehumidification With Comp field is set when the

cooling unit is built and should not be adjusted without consulting the factory first. Table 6 outlines