Page 1

Instruction Manual

HASXEE-IM-HS

10/2010

Gas Analyzer Series

Instruction Manual

www.EmersonProcess.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and

tests its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal specications.

The following instructions MUST be adhered to and integrated into your safety program

when installing, using and maintaining Emerson Process Management (Rosemount

Analytical) products. Failure to follow the proper instructions may cause any one of the

following situations to occur: Loss of life; personal injury; property damage; damage to

this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarication.

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specied in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualied personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualied people use replacement

parts specied by Emerson Process Management (Rosemount Analytical).

Unauthorized parts and procedures can affect the product’s performance, place the

safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike

substitutions may result in re, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place,

except when maintenance is being performed by qualied persons, to prevent

electrical shock and personal injury.

The information contained in this document is subject to change without notice.

X-STREAM and IntrinzX are marks of one of the Emerson group of companies.

All other marks are property of their respective owners.

2nd edition, 2010-10

Rosemount Analytical

Process Gas Analyzer Center of Excellence

Emerson Process Management GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T +49 6055 884 0

F +49 6055 884 209

Page 3

Instruction manual

HASXEE-IM-HS

10/2010

SHORT FORM GUIDE FOR THIS MANUAL

X-STREAM XE

To nd information about see chapter

Safety instructions S

The different instruments designs

1

The instruments technical data 2

Measuring principles characteristics 3

How to install the instruments

st

startup procedures,

1

4

checking the instrument´s setup 5

Software menu structure, how to navigate

and menu entries descriptions 6

Basic procedures (eg calibration) 7

Table of contents

TOC

Maintenance procedures 7

Status messages and troubleshooting

8

Modbus parameters 9

Service information

Dismounting and disposal of instruments

Block diagrams, terminals & connectors

Index

Emerson Process Management GmbH & Co. OHG TOC-1

I

10

11

A

Page 4

Instruction manual

X-STREAM XE

HASXEE-IM-HS

10/2010

Table of ConTenTs

Introduction S-1

Denitions S-1

Terms used in this instruction manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-2

Symbols used on and inside the unit

Symbols used in this manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-4

Safety instructions S-5

Intended use statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-5

General safety notice / Residual risk

Authorized personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-6

Disposal of batteries

Installing and connecting the unit

Operating and maintaining this unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-7

Chapter 1 Technical description 1-1

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.1.1 The Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2 Conguration of Gas Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.2.1 Materials Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.2.2 Safety Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.2.3 Gas Inlets and Outlets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.2.4 Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.2.5 Infallible Containments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.2.6 Optional Components for Gas Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.2.7 Alternative Congurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.3 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.3.1 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.3.2 Status Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.3.3 Modbus Interface, Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.3.4 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1.3.5 USB Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1.3.6 Optional Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1.4 Comparison of the Various X-STREAM Analyzer Models . . . . . . . . . . . . . . . . . . . . . . .1-13

1.5 X-STREAM XEGC: ½ 19 Inch Table-Top Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

1.6 X-STREAM XEGP: 19 inch table-top or rackmount design . . . . . . . . . . . . . . . . . . . . . .1-17

1.7 X-STREAM XEF/XDF: Field Housing With Single Or Dual Compartment. . . . . . . . . . .1-19

1.7.1 Field Housings for Installation in Hazardous Areas (Ex-Zones) . . . . . . . . . . . . . . . . .1-23

1.8 X-STREAM XEFD: Cast Aluminum Flameproof Housing . . . . . . . . . . . . . . . . . . . . . . .1-24

Emerson Process Management GmbH & Co. OHGTOC-2

Page 5

Instruction manual

HASXEE-IM-HS

10/2010

Table of Contents

X-STREAM XE

Chapter 2 Technical data 2-1

2.1 Common Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2 Model-Specic Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.1 X-STREAM XEGC: ½ 19 Inch Tabletop Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.2 X-STREAM XEGP: 19 Inch Tabletop and Rack-Mount Models . . . . . . . . . . . . . . . . .2-12

2.2.3 X-STREAM XEF/XDF: Single/Dual Compartment Field Housing . . . . . . . . . . . . . . . .2-15

2.2.4 X-STREAM XEFD: Flameproof Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2.3 Information on Name Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Chapter 3 Measuring Principles 3-1

3.1 Infrared Measurement (IR), Ultraviolet Measurement (UV) . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1 IntrinzX Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.2 NDIR Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.1.3 Technical Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.2 Oxygen Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.2.1 Paramagnetic Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.2.2 Electrochemical Measurement (I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.2.3 Special Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.3 Thermal Conductivity Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3.3.1 Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3.3.2 Technical Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.4 Measurement Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Table of contents

TOC

Chapter 4 Installation 4-1

4.1 Scope of Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.3 Gas Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.4 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.5 Analyzer Specic Instructions for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.5.1 X-STREAM XEGC, X-STREAM XEGP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.5.2 X-STREAM XEF, X-STREAM XDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4.6 Notes On Wiring Signal Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

4.6.1 Electrical Shielding of Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

4.6.2 Wiring Inductive Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

4.6.3 Driving High-Current Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

4.6.4 Driving Multiple Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

Chapter 5 Startup 5-1

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Symbols and Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.3 Front Panel Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Emerson Process Management GmbH & Co. OHG TOC-3

Page 6

Instruction manual

X-STREAM XE

Table of Contents

5.3.1 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.3.2 Status Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.3.3 Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.4 Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.4.1 Access Levels & Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.2 Special Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.5 Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.5.1 Boot Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.5.2 Measurement Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.6 Selecting the Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

5.7 Checking the Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5.7.1 Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5.7.2 Conguring the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5.7.3 Calibration Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

5.7.4 Setting the Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

5.7.5 Setting Concentration Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-23

5.7.6 Backup the Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

5.8 Perform a Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

HASXEE-IM-HS

10/2010

Chapter 6 User Interface and Software Menus 6-1

6.1 Symbols and Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 Menu System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2.1 Switching On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.2.2 Control Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.2.3 Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

6.2.4 Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-108

6.2.5 Info Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-122

6.2.6 Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-126

Chapter 7 Maintenance and other Procedures 7-1

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 General Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.3 Performing a Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.4 Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.4.1 Preparing Calibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

7.4.2 Manual Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

7.4.3 Advanced Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

7.4.4 Remote Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32

7.4.5 Unattended Automatic Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-36

7.4.6 Verifying a Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-39

Emerson Process Management GmbH & Co. OHGTOC-4

Page 7

Instruction manual

HASXEE-IM-HS

10/2010

Table of Contents

7.4.8 Restoring a Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-40

7.4.7 Cancelling an Ongoing Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-40

7.5 Replacing the Electrochemical Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-41

7.5.1 General Hints on Handling the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-44

7.5.2 Opening X-STREAM Analyzers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-45

7.5.3 Locating the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-47

7.5.4 Disassembling the Sensor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-48

7.5.5 Adjusting the Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-49

7.5.6 Finalizing the Sensor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-50

7.6 Cleaning the Instrument´s Outside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-51

7.7 Save / Restore Conguration Data Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-52

7.7.1 Local Backup - Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-54

7.7.2 Local Backup - Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-55

7.7.3 Factory Defaults - Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-56

7.7.4 USB Backup - Save. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-57

7.7.5 USB Backup - Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-60

7.7.6 Undo Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-61

7.8 Handling Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-62

7.8.1 Conguring Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-62

7.8.2 Exporting Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-63

7.8.3 Log Files Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-65

7.9 Files on USB Memory Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-66

7.9.1 autorun.inf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-66

7.9.2 xe_win_tools.zip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-67

7.10 Web Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-68

X-STREAM XE

Table of contents

TOC

Chapter 8 Troubleshooting 8-1

8.1 Abstract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.2 Solving Problems Indicated by NAMUR Status Messages . . . . . . . . . . . . . . . . . . . . . . .8-2

8.2.1 Analyzer Related NAMUR Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.2.2 Channel Related Messages (preceded by Channel Tag, e.g. CO2.1) . . . . . . . . . . . . .8-8

8.3 Solving Problems Not Indicated by Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . .8-12

8.4 Troubleshooting on Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-18

8.4.1 Opening X-STREAM Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

8.4.2 Signal Connectors on XSP Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-22

8.4.3 Sample Pump: Replacement of Diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-23

8.4.4 Paramagnetic Oxygen Cell for Standard Applications: Adjustment of Physical Zero .8-34

8.4.5 Thermal Conductivity Cell: Adjustment of Output Signal. . . . . . . . . . . . . . . . . . . . . . .8-37

Emerson Process Management GmbH & Co. OHG TOC-5

Page 8

Instruction manual

X-STREAM XE

Table of Contents

HASXEE-IM-HS

10/2010

Chapter 9 Modbus Functions 9-1

9.1 Abstract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.1.1 Modbus TCP/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.2 Supported Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.3 List of Parameters and Registers - Sorted by Tag Name. . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.4 List of Parameters and Registers - Sorted by Daniel Registers. . . . . . . . . . . . . . . . . . .9-31

Chapter 10 Service Information 10-1

10.1 Return of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

10.2 Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

10.3 Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Chapter 11 Dismounting and Disposal 11-1

11.1 Dismounting and Diposal of the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Appendix A-1

A.1 Modbus Specication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.2 EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

A.3 CSA Certicate of Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

A.4 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

A.5 Water Vapor: Relationship of Dewpoint, Vol.-% and g/Nm³ . . . . . . . . . . . . . . . . . . . . . A-34

A.6 Declaration of Decontamination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-35

A.7 PLC Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-36

A.8 Assignment of Terminals and Sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-43

A.8.1 Tabletop & Rack Mount Analyzers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-43

A.8.2 Field Housings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-44

Emerson Process Management GmbH & Co. OHGTOC-6

Page 9

Instruction manual

HASXEE-IM-HS

10/2010

X-STREAM XE

Index of Tables

Tab. 3-1: Standard paramagnetic sensor -

Tab. 3-2: Solvent resistant paramagnetic sensor - approved solvents ....................................3-7

Tab. 3-3: Solvent resistant paramagnetic sensor - medium affected materials ......................3-7

Tab. 3-4: Solvent resistant paramagnetic sensor Tab. 3-5: Electrochemical oxygen measurement -

Tab. 3-6: Examples of specific thermal conductivities ...........................................................3-11

Tab. 3-7: Gas Components and Measuring Ranges, examples

Tab. 3-8: General Measurement Performance Specifications ...............................................3-14

Tab. 3-9: Special Performance Specifications for Gas Purity Measurements .......................3-15

Tab. 5-1: Analog output signals settings and operation modes

Tab. 6-1: Analog output failure modes

Tab. 7-1: Digital Inputs Priorities ............................................................................................7-31

cross interference by accompanying gases ............. 3-6

cross interference by gases ......................... 3-7

cross interference by gases ......................3-10

............................................3-13

.............................................5-21

...................................................................................6-61

Table of contents

TOC

Emerson Process Management GmbH & Co. OHG TOC-7

Page 10

Instruction manual

X-STREAM XE

HASXEE-IM-HS

10/2010

Index of fIgures

Fig. 1-1: X-STREAM front panel (here the X-STREAM XEGP) ............................................1-3

Fig. 1-2: Optional heated area ..............................................................................................1-8

Fig. 1-3: Gas ow diagram: single channel or in series ........................................................1-9

Fig. 1-4: Serial Interface Marking ........................................................................................1-11

Fig. 1-5: X-STREAM XEGC - views ....................................................................................1-16

Fig. 1-6: X-STREAM XEGP - Details ..................................................................................1-18

Fig. 1-7: X-STREAM XEF / XDF- Front views ....................................................................1-20

Fig. 1-8: X-STREAM XEF - right side and bottom view ......................................................1-21

Fig. 1-9: X-STREAM XEF - power supply and signal terminals ..........................................1-22

Fig. 1-10: X-STREAM XEFD - Front view ............................................................................1-25

Fig. 1-11: X-STREAM XEFD - Bottom view ..........................................................................1-26

Fig. 1-12: X-STREAM XEFD - terminals ...............................................................................1-27

Fig. 2-1: X-STREAM XEGC - dimensions ............................................................................2-6

Fig. 2-2: X-STREAM XEGC - connectors and Fuse .............................................................2-6

Fig. 2-3: X-STREAM XEGC - Rack mounting options ..........................................................2-7

Fig. 2-4: UPS 01 tabletop power supply unit ........................................................................2-9

Fig. 2-5: UPS 01 power supply unit for rack installation .....................................................2-10

Fig. 2-6: 10 A tabletop PSU ................................................................................................2-11

Fig. 2-7: X-STREAM XEGP - dimensions ...........................................................................2-12

Fig. 2-8: X-STREAM XEGP - Power supply and signal connections ..................................2-14

Fig. 2-9: X-STREAM XEGP - Signal connections with screw-type terminal adapters ........2-14

Fig. 2-10: X-STREAM XEF - dimensions ..............................................................................2-15

Fig. 2-11: X-STREAM XDF - dimensions .............................................................................2-16

Fig. 2-12: X-STREAM XE Field housing - power supply terminals / fuse holders ..............2-18

Fig. 2-13: X-STREAM XE Field housing - signal terminals ...................................................2-18

Fig. 2-14: X-STREAM XEFD - dimensions ...........................................................................2-19

Fig. 2-15: X-STREAM XEFD - Power supply terminals / fuse holders .................................2-21

Fig. 2-16: X-STREAM XEFD - signal terminals ....................................................................2-21

Fig. 2-17: Analyzer name plate (examples) ..........................................................................2-22

Fig. 3-1: IntrinzX signal forms ...............................................................................................3-2

Fig. 3-2: Gas detector design principle .................................................................................3-3

Fig. 3-3: Photometer assembly principle ..............................................................................3-4

Fig. 3-4: Paramagnetic oxygen sensor - assembly principle ................................................3-5

Fig. 3-5: Electrochemical sensor - design principle ..............................................................3-8

Fig. 3-6: Electrochemical sensor - assembly ........................................................................3-8

Fig. 3-7: Electrochemical reaction of oxygen sensor ...........................................................3-9

Emerson Process Management GmbH & Co. OHGTOC-8

Page 11

Instruction manual

HASXEE-IM-HS

10/2010

Index of Figures

Fig. 3-8: Wheatstone Bridge ...............................................................................................3-11

Fig. 3-9: TC cell, exterior view ,thermal isolation removed .................................................3-12

Fig. 3-10: TC cell, sectional view ..........................................................................................3-12

Fig. 4-1: X-STREAM XE Analyzers - scope of supply ..........................................................4-1

Fig. 4-2: Labelling of gas connectors (example) ...................................................................4-4

Fig. 4-3: Installation in bypass mode ....................................................................................4-5

Fig. 4-4: X-STREAM XEGC - table top version rear panel ...................................................4-8

Fig. 4-5: X-STREAM XEGP - table top version rear panel ...................................................4-9

Fig. 4-6: X-STREAM XEGP - Rear panel, model with terminal adapters and brackets ......4-10

Fig. 4-7: Socket X1 - Analog & Digital Outputs 1-4 ............................................................4-11

Fig. 4-8: Plug X2 - Modbus interface ..................................................................................4-12

Fig. 4-9: Conguration of XSTA terminal adapter ...............................................................4-13

Fig. 4-10: Sockets X4.1 and X4.2 - Pin conguration ..........................................................4-14

Fig. 4-11: Conguration of XSTD terminal adapter ...............................................................4-15

Fig. 4-12: Plug X5 - analog inputs ........................................................................................4-16

Fig. 4-13: Conguration of XSTI terminal adapter ................................................................4-17

Fig. 4-14: 24 V DC in connector, pin conguration ...............................................................4-18

Fig. 4-15: X-STREAM XEF - dimensions for installation .....................................................4-19

Fig. 4-16: X-STREAM XDF - dimensions for installation .....................................................4-20

Fig. 4-17: X-STREAM XE Field housing - terminals, cable glands and gas connectors ......4-21

Fig. 4-18: Terminal block X1 - analog signals and relay outputs 1-4 ...................................4-24

Fig. 4-19: Terminal block X1 - Modbus interface ..................................................................4-25

Fig. 4-20: X-STREAM XEF - Ethernet connector .................................................................4-26

Fig. 4-21: Terminal blocks for digital inputs and outputs .......................................................4-27

Fig. 4-22: Terminal block X5 - Analog input signals .............................................................4-28

Fig. 4-23: Power supply connections ....................................................................................4-29

Fig. 4-24: Shielded signal cable, shielding connected at both ends. ....................................4-31

Fig. 4-25: Shielded signal cable, shielding connected at one end. .......................................4-32

Fig. 4-26: Signal cable with double shielding, shieldings connected at alternate ends. .......4-32

Fig. 4-27: Shield connector terminal with cable ....................................................................4-33

Fig. 4-28: Suppressor diode for inductive loads. ..................................................................4-34

Fig. 4-29: Driving high-current loads .....................................................................................4-34

Fig. 4-30: Loads in series .....................................................................................................4-35

Fig. 4-31: Loads in parallel ...................................................................................................4-35

X-STREAM XE

Table of contents

TOC

Fig. 5-1: X-STREAM XE front panel .....................................................................................5-3

Fig. 5-2: Arrangement of concentration thresholds .............................................................5-23

Emerson Process Management GmbH & Co. OHG TOC-9

Page 12

Instruction manual

X-STREAM XE

HASXEE-IM-HS

10/2010

Index of Figures

Fig. 6-1: X-STREAM XE Software menu structure ...............................................................6-2

Fig. 6-2: Measurement display elements ............................................................................6-25

Fig. 6-3: Usage of labels and tags .....................................................................................6-31

Fig. 6-4: Measurement display with labels and tags (example) ..........................................6-93

Fig. 6-5: USB le system structure .....................................................................................6-98

Fig. 7-1: Leak Testing with U-turn Manometer ......................................................................7-2

Fig. 7-2: Calibration improvement by variable valve assignments ........................................7-8

Fig. 7-3: Internal valves assignments .................................................................................7-10

Fig. 7-4: Zero All Calibration Procedure Flow Diagram ......................................................7-21

Fig. 7-5: Span All Calibration Procedure Flow Diagram .....................................................7-24

Fig. 7-6: Zero&Span All Calibration Procedure Flow Diagram ............................................7-26

Fig. 7-7: Digital Inputs - Initializing Calibrations ..................................................................7-32

Fig. 7-8: Graphical Explanation of Interval Time Settings ...................................................7-36

Fig. 7-9: X-STREAM XEGP ................................................................................................7-44

Fig. 7-10: X-STREAM XEGC ................................................................................................7-44

Fig. 7-11: X-STREAM eld housings - Interior views(shown without front doors) ................7-45

Fig. 7-12: Location of the eO2 Sensor Unit ..........................................................................7-46

Fig. 7-13: Sensor Unit Design ...............................................................................................7-47

Fig. 7-14: OXS Board, top view ............................................................................................7-48

Fig. 7-15: Locking device details ..........................................................................................7-49

Fig. 7-16: Relations of supported data sets, and where to nd further information ..............7-52

Fig. 7-17: USB le system structure .....................................................................................7-59

Fig. 7-18: Subdirectory for log les .......................................................................................7-67

Fig. 7-19: Example of log le ................................................................................................7-68

Fig. 7-20: USB le system structure .....................................................................................7-69

Fig. 7-21: Autorun.inf template .............................................................................................7-69

Fig. 7-22: Ethernet connectors .............................................................................................7-71

Fig. 7-23: Web browser logon screen ...................................................................................7-72

Fig. 7-24: Web browser measurements screen ....................................................................7-72

Fig. 8-1: X-STREAM XEF, XDF and XEFD, opened with visible front panel ......................8-16

Fig. 8-2: X-STREAM XEGP ................................................................................................8-24

Fig. 8-3: X-STREAM XEGC ................................................................................................8-24

Fig. 8-4: X-STREAM eld housings - Interior views(shown without front doors) ................8-25

Fig. 8-5: XSP - Allocation of signal connectors ...................................................................8-26

Emerson Process Management GmbH & Co. OHGTOC-10

Page 13

Instruction Manual

HASXEE-IM-HS

04/2010

X-STREAM XE

INTRODUCTION

The instruction manual contains information about the component assembly, function,

installation, operation and maintenance of the X-STREAM® series gas analyzers.

The manual covers several X-STREAM analyzer models and so may contain information

about congurations and/or options not applicable to your analyzer.

The installation and operation of units for use in explosive (hazardous) environments is

not covered in this manual.

Analyzers intended to be used in such environments are supplied with further instruction

manuals, which should be consulted in addition to this.

DEFINITIONS

The following denitions apply to the terms WARNING, CAUTION and NOTE, and the symbol , as used in this manual.

Indicates an operational or maintenance procedure, a process, a condition,

an instruction, etc.

Failure to comply may result in injury, death or permanent health risk.

Safety Instructions

S

Indicates an operational or maintenance procedure, a process, a condition,

an instruction, etc.

Failure to comply may result in damage to or destruction of the instrument,

or impaired performance.

NOTE!

Indicates an imperative operational procedure, an important condition or instruction.

The symbol

refers to more information, provided on the indicated page or chapter.

Emerson Process Management GmbH & Co. OHG S-1

, together with a page number ( 6-5 ) or chapter headline ( Startup )

Page 14

X-STREAM XE

TERMS USED IN THIS INSTRUCTION MANUAL

Instruction Manual

HASXEE-IM-HS

04/2010

Explosive Gas(es)

Flammable Gases and gas mixtures in a mixture with air within the explosive limits.

Flammable Gas(es)

Gases and gas mixtures are assigned to be

ammable if they might become ignitable

when in a mixture with air.

Infallible Containment

This term is derived from the standards of

explosion protection especially from the requirements for pressurized housings: thus an

infallible containment can be characterized

by no intended leakage out of the gas paths

enabling gas to enter the inner compartment

of the analyzer housing.

Intrinsically Safe Cell (IS Cell)

Cells supplied with an intrinsically safe power

signal, approved by a Test Institute, to operate

with explosive gases.

The design ensures the IS cells remains safe

even in case of failure and explosive gases

are not ignited.

Protection Class IP66 / NEMA 4X

Both terms are used to specify conditions for

equipment to be installed outdoor.

IP stands for Ingress Protection, the rst number species protection against solid objects

(6. = dust tight) while the second number

species the degree of protection against

liquids (.6 = heavy seas).

NEMA stands for National Electrical Manufacturers Association. 4X species a degree

of protection to personnel against incidental

contact with the enclosed equipment; to provide a degree of protection against falling dirt,

rain, sleet, snow, windblown dust, splashing

water, and hose-directed water; and that will

be undamaged by the external formation of

ice on the enclosure

Upper Explosion Limit (UEL)

Volume ratio of ammable gas in air above

which an explosive gas atmosphere will not

be formed: the mixture of gas and air is too

rich in fuel (decient in oxygen) to burn.

Lower Explosion Limit (LEL)

Volume ratio of ammable gas in air below

which an explosive gas atmosphere will not

be formed: the mixture of gas and air lacks

sufcient fuel (gas) to burn.

NAMUR

NAMUR is an international user association of

automation technology in process industries.

This organisation has issued experience reports and working documents, called recommendations (NE) and worksheets (NA).

Emerson Process Management GmbH & Co. OHGS-2

Page 15

Instruction Manual

HASXEE-IM-HS

04/2010

SYMBOLS USED ON AND INSIDE THE UNIT

This symbol attached to the unit ... ... means

dangerous voltages may be exposed. Covers

may only be removed when power to the unit is

disconnected, and only be trained personnel.

hot surfaces may be exposed. Covers may

only be removed by trained personnel and when

power is disconnected. Certain surfaces may

remain hot.

further information and instructions are required: read the instruction manual.

X-STREAM XE

Safety Instructions

S

Emerson Process Management GmbH & Co. OHG S-3

Page 16

Instruction Manual

X-STREAM XE

HASXEE-IM-HS

04/2010

SYMBOLS USED IN THIS MANUAL

Wherever one or more of the following symbols are used in this instruction manual, read the

accompanying information and instructions carefully.

Follow these warnings and notes carefully

to minimize risk.

This symbol used in the manual ... ... means

dangerous voltages may be exposed

hot surfaces may be exposed

possible danger of explosion

toxic substances may be present

substances harmful to health may be present

indicates notes relating to heavy instruments

electrical components may be destroyed by

electrostatic discharges

units must be disconnected from the power

source

indicates basic conditions or procedures are

being described.

This symbol may also indicate information important for achieving accurate measurements.

Emerson Process Management GmbH & Co. OHGS-4

Page 17

Instruction Manual

HASXEE-IM-HS

04/2010

X-STREAM XE

SAFETY INSTRUCTIONS

INTENDED USE STATEMENT

X-STREAM series gas analyzers are intended to be used as analyzers for industrial purposes. They must not be used in medical, diagnostic or life support applications nor as

safety devices.

Using X-STREAM XE analyzers as safety devices, requiring redundant design or SIL classication, is also not permitted.

No independent agency certications or approvals are to be implied as covering such

applications!

GENERAL SAFETY NOTICE / RESIDUAL RISK

If this equipment is used in a manner not specied in these instructions, protective systems may be impaired.

Despite of incoming goods inspections, production control, routine tests and application

of state-of-the-art measuring and test methods, an element of risk remains when operating

a gas analyzer!

Even when operated as intended and observing all applicable safety instructions some

residual risks remain, including, but not limited to, the following:

Safety Instructions

S

• An interruption of the protective earth line, e.g. in an extension cable, may result in

risk to the user.

• Live parts are accessible when operating the instrument with doors open or covers

removed.

• The emission of gases hazardous to health may even be possible when all gas connections have been correctly made.

Avoid exposure to the dangers of these residual risks by taking particular care when installing, operating, maintaining and servicing the analyzer.

Emerson Process Management GmbH & Co. OHG S-5

Page 18

Instruction Manual

X-STREAM XE

Safety Instructions

HASXEE-IM-HS

04/2010

AUTHORIZED PERSONNEL

In-depth specialist knowledge is an absolutely necessary condition for working with and

on the analyzer.

Authorized personnel for installing, operating, servicing and maintaining the analyzer are

instructed and trained qualied personnel of the operating company and the manufacturer.

It is the responsibility of the operating company to

• train staff,

• observe safety regulations,

• follow the instruction manual.

Operators must

• have been trained,

• have read and understood all relevant sections of the instruction manual before

commencing work,

• know the safety mechanisms and regulations.

To avoid personal injury and loss of property, do not install, operate, maintain or service

this instrument before reading and understanding this instruction manual and receiving

appropriate training.

DISPOSAL OF BATTERIES

• This instrument contains a Li battery (button cell) of type CR 2032.

• The battery is soldered and usually does not need to be replaced during the

instrument´s lifetime.

• At the end of lifetime, the instrument must be disposed in compliance with the wast

regulations. The disposal specialist then has to disassemble the instrument and

dispose the battery in compliance with the regulations.

Emerson Process Management GmbH & Co. OHGS-6

Page 19

Instruction Manual

HASXEE-IM-HS

04/2010

Safety Instructions

X-STREAM XE

INSTALLING AND CONNECTING THE UNIT

The following notices should be carefollowed to ensure compliance with the low voltage directive

(Europe) and other applicable regulations.

1.

Suitable grounding connections should be made at all connectors provided for this purpose.

2. All safety covers and grounding connections must be properly reinstated after maintenance

work or troubleshooting.

3. A fuse should be provided at the installation site which will completely disconnect the unit

in case of failure. Installing an isolating switch may also be benecial. In either case, these

components must be constructed to conform to recognised norms.

Safety Instructions

S

OPERATING AND MAINTAINING THIS UNIT

On leaving our factory, this instrument conformed to all applicable safety directives.

In order to preserve this state of affairs, the

operator must take care to follow all the instructions and notes given in this manual and

on the unit.

Before switching on the unit, ensure that the

local nominal mains voltage corresponds to

the factory-set operational voltage of this

unit.

Any interruption of the protective earth connections, whether inside or outside of the unit,

may result in exposure to the risk of electricity.

Deliberately disconnected the protective earth

is therefore strictly forbidden.

Removing covers may expose components

conducting electric current. Connectors may

also be energised. The unit should therefore

be disconnected from the power supply before

any kind of maintenance, repair or calibration

work requiring access to the inside of the

unit.

Only trained personnel who are aware of

the risk involved may work on an open and

energized unit.

Fuses may only be replaced by fuses of an

identical type and with identical ratings. It is

forbidden to use repair fuses or to bypass

fuses.

Take note of all applicable regulations when

using this unit with an autotransformer or a

variable transformer.

Substances hazardous to health may escape

from the unit’s gas outlet. This may require

additional steps to be taken to guarantee the

safety of operating staff.

Emerson Process Management GmbH & Co. OHG S-7

Page 20

X-STREAM XE

The units described in this manual may not be used in explosive atmospheres

without additional safety measures.

Instruction Manual

HASXEE-IM-HS

04/2010

Safety Instructions

EXPLOSION HAZARD

ELECTRICAL SHOCK HAZARD

Do not operate without covers secure. Do not open while energized.

Installation requires access to live parts which can cause death or serious

injury.

For safety and proper performace this instrument must be connected to a

properly grounded three-wire source of power.

TOXIC GASES

This unit’s exhaust may contain toxic gases such as (but not limited to)

e.g. sulfur dioxide. These gases can cause serious injuries.

Avoid inhaling exhaust gases.

Connect the exhaust pipe to a suitable ue and inspect the pipes regularly

for leaks.

All connections must be airtight to avoid leaks;

7-4 for instructions on

performing a leak test.

Emerson Process Management GmbH & Co. OHGS-8

Page 21

Instruction Manual

HASXEE-IM-HS

04/2010

The models intended for outside and wall mounted use (X-STREAM XEF,

XDF and XEFD) weigh between 26 kg (57 lb) and 63 kg (139 lb) depending

on options installed.

X-STREAM XE

Safety Instructions

HEAVY INSTRUMENT

Safety Instructions

Two people and/or lifting equipment is required to lift and carry these

units.

Take care to use anchors and bolts specied to be used for the weight of

the units!

Take care the wall or stand the unit is intended to be installed at is solid

and stable to support the weight!

CRUSHING HAZARD

Take care of crushing hazard when closing the front door of analyzer eld

housings!

Keep out of the closing area between enclosure cover and base!

OPERATION AT LOW TEMPERATURES

When operating an instrument at temperatures below 0 °C (32 °F), do

NOT apply gas nor operate the internal pump before the warmup time has

elapsed!

S

Violation may result in condensation inside the gas paths or damaged

pump diaphragm!

HIGH TEMPERATURES

Hot parts may be exposed when working on photometers and/or

heated components in the unit.

Emerson Process Management GmbH & Co. OHG S-9

Page 22

X-STREAM XE

Safety Instructions

GASES AND PREPARATION OF GASES

GASES HAZARDOUS TO HEALTH

Follow the safety precautions for all gases (sample and span gases) and

gas cylinders.

Before opening the gas lines, they must be purged with air or neutral gas

(N2) to avoid danger from escaping toxic, ammable, exposive or hazardous

gases.

Instruction Manual

HASXEE-IM-HS

04/2010

FLAMMABLE OR EXPLOSIVE GASES

When supplying explosive gases or ammable gases with concentrations of

more than 25 % of the lower explosion limit, we RECOMMEND implementing

one or more additional safety measures:

• purging the unit with inert gas

• stainless steel internal pipes

• ame arrestors on gas inlets and outlets

• infallible measuring cells.

Emerson Process Management GmbH & Co. OHGS-10

Page 23

Instruction Manual

HASXEE-IM-HS

04/2010

POWER SUPPLY

Only qualied personnel following all applicable and legal regulations may

install the unit and connect it to power and signal cables. Failure to comply

may invalidate the unit’s warranty and cause exposure to the risk of damage,

injury or death.

This unit may only be installed by qualied personnel familiar with the

possible risks.

Working on units equipped with screw-type terminals for electrical

connections may require the exposure of energized components.

X-STREAM XE

Safety Instructions

CONNECTING UNITS FOR PERMANENT INSTALLATION

Safety Instructions

S

Wall-mounted units have no power switch and are operational when

connected to a power supply. The operating company is therefore required

to have a power switch or circuit breaker (as per IEC 60947-1/-3) available

on the premises. This must be installed near the unit, easily accessible to

operators and labelled as a power cut-off for the analyzer.

HAZARD FROM WRONG SUPPLY VOLTAGE

Ensure that the local power voltage where the unit is to be installed,

corresponds to the unit’s nominal voltage as given on the name plate

label.

ADDITIONAL NOTES FOR UNITS WITH SCREW-TYPE TERMINALS

Cables for external data processing must be double-insulated against mains

power.

If this is not possible, cables must be laid in such a way as to guarantee

a clearance of at least 5 mm from power cables. This clearance must be

permanently secured (e.g. with cable ties).

Emerson Process Management GmbH & Co. OHG S-11

Page 24

Instruction Manual

X-STREAM XE

HASXEE-IM-HS

04/2010

General Operational Notes

GENERAL OPERATING NOTES

EXPLOSION HAZARD

Exhaust gases may contain hydrocarbons and other toxic gases such as

carbon monoxide. Carbon monoxide is toxic.

Faulty gas connections may lead to explosion and death.

Ensure that all gas connections are connected as labelled and airtight.

• The unit must be installed in a clean and dry area protected from strong vibrations and

frost

.

• The unit must not be exposed to direct sunlight and sources of heat. Admissable ambient

temperatures (see technical details) must be adhered to.

• Gas inlets and outlets must not be interchanged.All gases must be supplied to the unit already

processed. When using this unit with corrosive sample gases, ensure that these gases do

not contain components harmful to the gas lines.

• Admissable gas pressure for sample and test gases is 1,500 hPa.

• Exhaust lines must be laid inclined downwards, depressurized, protected from frost and

according to applicable regulations.

• If it is necessary to disconnect the gas lines, the unit’s gas connectors must be sealed with

PVC caps to avoid polluting the internal gas lines with condensate, dust, etc.

• To ensure electromagnetic compatibility (EMC), only shielded cables (supplied by us on request, or of equivalent standard) may be used. The customer must ensure that the shielding

is correctly tted. Shielding and terminal housing must be electrically connected; submin-D

plugs and sockets must be screwed to the unit.

• When using optional external adapters (submin-D to screw-type terminal), protection from

electromagnetic interference can no longer be guaranteed (CE compliance pursuant to EMC

guidelines). In this case the customer or operating company functions as a system builder

and must therefore ensure and declare compliance with EMC guidelines.

Emerson Process Management GmbH & Co. OHGS-12

Page 25

Instruction Manual

HASXEE-IM-HS

04/2010

X-STREAM XE

Chapter 1

Technical Description

The following are the main features of the new

Emerson Process Management X-STREAM

gas analyzers in brief:

• compact design with easily accessible

internal components

• customizable for a wide range of applications: different housings are available

while internal construction remains largely

identical

• a highly integrated mainboard contains

all interfaces and basic functions for the

operation of the unit

• multilingual microprocessor-controlled

user interface with liquid crystal (LCD) to

indicate measurement value and status

messages

• units for outdoor use are optionally supplied with an impact tested front panel

• widerange power supply unit for worldwide

use without modication (1⁄2 19in units with

external PSUs)

The new X-STREAM gas analyzers can

measure up to ve different gas components using any combination of the following

analyzing techniques (restrictions apply to

1

⁄2 19in units):

IR = non-dispersive infrared analysis

Modied resistant measuring cells are available for use with corrosive gases and/or

gases containing solvents.

Special congurations (e.g. intrinsically safe

or infallible measuring cells) for the analysis

of combustible gases are also available.

Chapter 3 gives a detailed description of

the various measuring techniques.

Standard applications

Different housings allow X-STREAM analyzers to be tailored to the many different

applications:

• Tabletop units in 1⁄2 19in modular design,

with IP 20 protection class

• Tabletop and rack mountable units in 19in

modular design, with IP 20 protection

class

• Stainless steel wall mountable field

housing with IP 66 / NEMA 4X protection

class for outdoor use (operating temperature -20°C to +50°C).

• Cast aluminium wall mountable field

housing with IP 66 / NEMA 4X protection

class for outdoor use (operating temperature -20 °C to +50 °C).

The various analyzer types are described in

more detail beginning with 1-13.

Technical Description

1

UV = ultraviolet analysis

pO2 =

eO2 =

TC = thermal conductivity analysis

Emerson Process Management GmbH & Co. OHG 1-1

paramagnetic oxygen analysis

electrochemical oxygen analysis

Installation in hazardous areas

X-STREAM analyzers in eld housings, when

tted with various protective devices, can also

be installed and operated in hazardous areas.

Available options are:

• Pressurized enclosure conforming to

ATEX directive 94/9/EC, for installation

in Zone 2.

Page 26

X-STREAM XE

1 Technical Description

• Non-incendive assembly for installation in

Zone 2 and Div 2 for the measurement of

non-ammable gases.

• Simplified purge system (Z-purge) for

installation in North American Div 2 environments.

The cast aluminium eld housing is designed

to withstand an explosion and intended to be

used in hazardous areas of Zone 1.

More information about EXanalyzers can be obtained from

your Emerson Process Management sales ofce.

Instruction Manual

HASXEE-IM-HS

04/2010

Note!

These instructions do not detail the installati-

on nor operation of X-STREAM analyzers in

hazardous areas. If you intend to use your

analyzer for such purposes, pay attention to the separate instruction manuals

supplied with analyzers to be used in hazardous areas.

Emerson Process Management GmbH & Co. OHG1-2

Page 27

Instruction Manual

HASXEE-IM-HS

04/2010

1.1 Overview

X-STREAM XE

1.1 Overview

All X-STREAM gas analyzers feature an

easy-to-use graphical user interface, which

displays measurement values, status and

error messages, and menus for the input of

parameters.

For ease of use, the operator can select one

of three languages for the display: By default

any analyzer is congured with English and

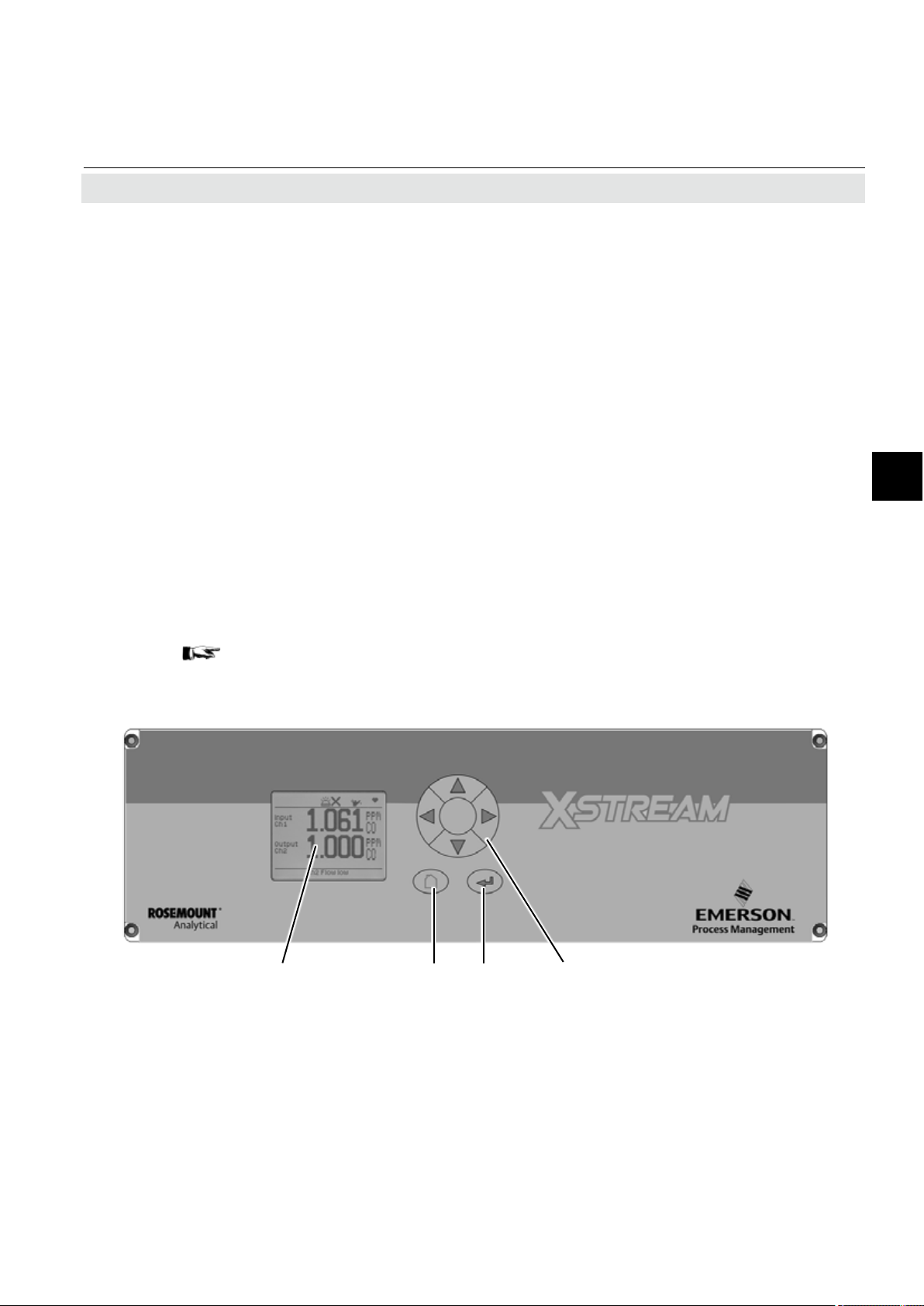

1.1.1 The Front Panel

The graphic LCD shows measurement and

status information with plain text and symbols.

The symbols are designed to indicate the different status 'Failure', 'Function check', 'Out

of specication' and 'Maintenance request' as

specied by the NE 107 standard. For further

information,

chapter 8.

German language sets, while a third can

optionally be added. Currently available:

French, Italian, Portuguese and Spanish..

Technical Description

1

The analyzer software is operated by means

of only six keys.

Depending on the analyzer model, the display

is protected with an impact tested glass panel,

to withstand even harsher conditions and to

provide a higher IP protection class of up to

IP66 / NEMA Type 4X.

1 3 42

1 Graphic display

2 “Measure“ key

3 “Enter” key

4 4 keys for settings and menu navigation

Fig. 1-1: X-STREAM Front Panel (here the X-STREAM XEGP)

Emerson Process Management GmbH & Co. OHG 1-3

Page 28

X-STREAM XE

Instruction Manual

HASXEE-IM-HS

04/2010

1.1 Overview

Further analyzer features include (some of

them optional):

• Congurable measurement display:

• gas measurements results and/or se-

condary results (e.g. ow)

• one or two independently congurable

pages

• Congurable measurement units

• user congurable units and conversion

factors from ppm to user unit

• 3 software access levels with individual

password protection, and administrator

selectable activation

• protection against unauthorized con-

guration changes

• Unattended zero and span calibrations

• enables operation without user inter-

action

• Communication via serial interface and

Ethernet

• enables remote operation

• Web browser interface

• for remote operation with full analyzer

control

• Realtime clock (supports time server synchronization)

• enables time controlled operation

• Data logger with configurable logging

periods

• for legislative and quality documenta-

tion

• Event logger with configurable events

list

• keep monitoring the analyzer, even

when not present

• Log les sizes only limited by free memory

on an internal SD card

• up to 2 GB for up to 1 year logging wi-

thout storage problems

• replaceable (not by operator, as the

card is also used for storage of analyzer

operating software les)

• Export of log les via USB, ethernet and

webbrowser

• export to text les

• enables external data analysis

• Save and load analyzer conguration to/

from an internal protected memory area

and USB stick

• save a functional conguration to protect

it against changes or for reference

• restore a functional setup in case of

misconguration or crashes

• Calculator for 'virtual' channels or measurement calculations

• setup a virtual measurement channel

by calculating results of existing real

channels (e.g. summarize NO and NO2

to show NOx)

• PLC (programmable logic controller) for

enhanced functionality

• no need to add an external PLC to con-

trol external valves, pumpes, etc.

• supports uploading externally written

PLC text les into the analyzer

See the related sections in this manual for

more detailled information on these features.

Emerson Process Management GmbH & Co. OHG1-4

Page 29

Instruction Manual

HASXEE-IM-HS

04/2010

1.2 Conguration of Gas Lines

1.2 Conguration of Gas Lines

X-STREAM XE

Various materials are available to allow the

analyzer to be customized to your needs.

The materials used are selected based on

the characteristics of the sample gas, e.g.

diffusion rate, corrosiveness, temperature

and pressure.

1.2.1 Materials Used

The physical and chemical properties of the

sample gas as well as the conditions under

which measurement takes place inuence the

choice of materials. Among those available

are Viton

®

, PFA and stainless steel.

1.2.2 Safety Filter

The analyzers are generally tted with an

internal stainless-steel lter. This lter is not

a replacement for any dust lter in the preparation of the gas, but represents a last line of

defence.

1.2.3

Gas Inlets and Outlets

Rackmounted and tabletop devices are tted

with PVDF inlets and outlets (ø 6/4 mm) as

standard. Alternatively, Swagelok™ or stainless steel ttings (ø 6/4 mm or

1

⁄4 in).

Wall-mounted eld housings are supplied

with Swagelok™ or stainless steel ttings (ø

6/4 mm or 1⁄4 in).

Other materials available on request.

X-STREAM XEFD units are always supplied

with ame arrestors and stainless steel ttings

(ø 6/4 mm or

1

⁄4 in).

1.2.5 Infallible Containments

Infallible containments are gas lines which,

due to their design, can be regarded as permanently technically tight. This is achieved

by, for example, welded joints, or metallically

sealing joints (e.g. tap connectors and binders), providing they are seldom disconnected. Gas lines congured in this manner can

be used for measuring noxious, ammable

and explosive gases. At the time of going to

press, infallible containments are available

for thermal conductivity analysis (TC) only.

Further information about infallible containments can be found in the separate instruction

manual supplied with these units.

Infallible containments do not

render it unnecessary to test for

leaks regularly, e.g. following

lengthy breaks in service, substantial alterations, repairs and

modications.

Read the separate instruction

manual giving detailed instructions on the conguration, operation and maintenance of units

fitted with infallible containments.

Technical Description

1

1.2.4 Tubing

Unless otherwise specied, the analyzers

are supplied with Viton

®

or PVDF piping

(ø 6/4 mm or 1⁄4 in). Other materials (e.g.

stainless steel) can be used, depending on

the application.

Emerson Process Management GmbH & Co. OHG 1-5

Page 30

X-STREAM XE

1.2 Conguration of Gas Lines

1.2.6 Optional Components for Gas Lines

Instruction Manual

HASXEE-IM-HS

04/2010

The analyzers can, as an option, be tted with

further components. Not all components are

available for all analyzer types:

• internal sample gas pump

• internal valve block

• internal ow sensors

• internal ow monitor switch

• internal barometric pressure sensor

• internal temperature sensors.

1.2.6.1 Internal Sample Gas Pump

An internal sample gas pump is used when

the sample gas is under insufcient pressure.

It ensures a constant ow of sample gas (max.

2.5 l/min through the analyzer).

When in internal pump is tted, the relevant

parameter in the software setup dialog is set

to Yes ( 6-88). The pump can be controlled either manually through a software

menu or optionally by a digital input.

Note!

Gas pressure is limited to atmospheric, if an

internal pump is used!

1.2.6.2 Internal Valve Block

An internal valve block allows all necessary

gas lines (zero gas, span gas, sample gas)

to remain permanently connected to the

analyzer. Valves are then activated automatically when required (e.g. during automatic

calibration).

When an internal valve block is tted, this

is shown in the relevant software setup

dialog as either Internal or Int+Ext (

6-88). The valves are controlled by either

a software menu, optionally by digital input, or automatically during autocalibration.

Depending on the model, up to two valve

bocks can be tted.

1.2.6.3 Internal Flow Sensor

Up to two internal ow sensors can measure

the ow of gas and, compared to the ow

monitor switch can provide a ow reading.

They also can activate an alarm signal in the

event of a failure.

The alarm level for ow sensors is operator

adjustable to up to 2000 ml/min. Depending

on the model, up to two sensors can be tted

and evaluated separately.

When a sensor is tted, the relevant parameter in the software setup dialog is set to Yes

(

6-90).

If the current ow rate is too low, a status

message is displayed and the parameter

under CHECK REQUESTS.. is set to Yes

(

Chapter 8 'Troubleshooting').

1.2.6.4 Internal Flow Monitor Switch

An internal ow switch monitors the gas ow

and activates an alarm signal in case it is

not sufcient. Compared to the ow sensore

it does not provide a ow reading, but only

indicates if the ow is sufcient, or not.

The alarm level for the internal ow switch is

xed and not operator adjustable. Additional

external switches may be used and connected

via digital inputs. All tted ow switches are

evaluated to share a common alarm.

When an internal ow switch is tted, the relevant parameter in the software setup dialog

is set to Yes (

If the current ow rate is too low, a status

6-85).

message is displayed and the parameter

under CHECK REQUESTS.. is set to Yes

(

Chapter 8 'Troubleshooting').

Emerson Process Management GmbH & Co. OHG1-6

Page 31

Instruction Manual

HASXEE-IM-HS

04/2010

1.2 Conguration of Gas Lines

1.2.6.6 Internal Barometric Pressure Sensor

X-STREAM XE

Varying atmospheric pressure has an inuence also on the density of the gases applied

to the measuring system: Higher density correlates with more molecules per volume and

thus inuences the measuring results.

To compensate such inuences. an internal

barometric pressure sensor can be installed.

It´s reading is used to electronically compen-

1.2.6.5 Internal Temperature Sensors

In the same way as pressure variations, varying temperatures inuence the measuring

results: Higher temperature results in lower

gas density and thus in less molecules per

volume. To compensate temperature inuence, internal temperature sensors can be

installed to electronically compensate temperature variations (

specication).

page 3-14 ,measurement

sate the atmospheric pressure variation (

measurement specication, page 3-14).

If such a sensor is installed in the unit, the

related menu shows the entry Internal (

6-91).

Depending on the conguration of the unit or

the demands of the application, temperature

sensors can measure the unit’s internal temperature or selected measurement channel

components.

If such sensors are installed in the unit, this

is indicated in the installed options menu

(

6-85).

Technical Description

1

Emerson Process Management GmbH & Co. OHG 1-7

Page 32

X-STREAM XE

1.2 Conguration of Gas Lines

1.2.6.7 Optional Heated Area

Instruction Manual

HASXEE-IM-HS

04/2010

The physical components can be optionally

separated from the electrical components

by means of a special box (not an option for

½ 19 in units). This can be done for one or

both of the following purposes:

Firstly, the box allows the physical components to be regulated to a temperature of

approx. 60 °C, avoiding condensation of

gases or minimizing the inuence of varying

environmental temperatures.

Secondly, the box can be purged with, for

example, inert gas. The purge gas is rst fed

through a separate tting, purges the electronic components, then oods the box and

leaves the instrument via another tting.

Purging in this manner can be useful when

measuring very low concentrations (e.g. of

CO or CO

): the expulsion of ambient air

2

avoids adulterant outside inuences.

Alternatively, purging can be used to secure

enhanced protection for electronic parts and

operators from corrosive or toxic gases: any

leaking gas is expelled from the housing and

does not escape into the vicinity of the unit or

come into contact with any electronic components located outside the box.

In either case, the purge gas outlet should be

connected to an exhaust gas line.

Insulating cover

Physical

components

(example)

The gure shows the heated

area with the insulating cover

removed.

Fig. 1-2: Optional Heated Area

Heated mounting panel

Cable support for

signal wires

Emerson Process Management GmbH & Co. OHG1-8

Page 33

Instruction Manual

HASXEE-IM-HS

04/2010

1.2 Conguration of Gas Lines

1.2.7 Alternative Congurations

Depending on the application and the selected

analyzer options, alternative gas line congurations are available, exemplied in the following diagram of a dual-channel analyzer:

X-STREAM XE

Technical Description

1

Fig. 1-3: Gas Flow Diagram: Single Channel Or in Series

Emerson Process Management GmbH & Co. OHG 1-9

Page 34

X-STREAM XE

1.3 Interfaces

Instruction Manual

HASXEE-IM-HS

04/2010

1.3 Interfaces

All analyzer types are tted with one analog

electrical output for each channel, four status

relays, 2 Ethernet interfaces and a serial service interface as standard.

As an option, further interfaces can be added.

1.3.1 Analog Outputs

By default each X-STREAM analyzer is tted with one output per channel, which can

transmit data on concentration levels to an

external data acquisition system. Up to four

analog outputs can be installed.

The analog outputs support several operation

modes, such as 4-20 mA, 0-20 mA, as well

as the NAMUR NE 43 specications (incl.

Live Zero). Operation modes can be set in a

software menu ( 6-63).

The factory setting for analog outputs is

4-20 mA.

Depending on the unit conguration, all interfaces are accessible via either SubminD

connectors or screw terminals

.

X-STREAM analyzers support up to four

analog outputs, which, however, do not always need to be assigned to measurement

channels which are physically present: If a

unit features less than four channels, the

remaining analog outputs can be used to

transmit concentration levels with a different

resolution; for example, a single-channel

analyzer could be set up as follows: