Page 1

Instruction Manual

HASXEDE-IM-EX

03/2012

Gas Analyzer

X-STREAM Enhanced Series

Flameproof Variation

For Use in Zone 1 and Division 2 Hazardous Areas

Instruction Manual Addendum

www.EmersonProcess.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and

tests its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal specications.

The following instructions MUST be adhered to and integrated into your safety program

when installing, using and maintaining Emerson Process Management (Rosemount

Analytical) products. Failure to follow the proper instructions may cause any one of the

following situations to occur: Loss of life; personal injury; property damage; damage to

this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarication.

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specied in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualied personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualied people use replacement

parts specied by Emerson Process Management (Rosemount Analytical).

Unauthorized parts and procedures can affect the product’s performance, place the

safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike

substitutions may result in re, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place,

except when maintenance is being performed by qualied persons, to prevent

electrical shock and personal injury.

The information contained in this document is subject to change without notice.

5th edition 03/2012

Rosemount Analytical

Process Gas Analyzer Center of Excellence

Emerson Process Management GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T +49 6055 884 0

F +49 6055 884 209

Original Instruction Manual for the purpose

of the European Directive 94/9/EC.

Page 3

Instruction Manual

HASXEDE-IM-EX

03/2012

X-STREAM XEFD

Table of ConTenTs

Introduction S-1

Denitions S-1

Terms used in this instruction manual .......................................... S-2

Symbols used on and inside the unit ........................................... S-3

Symbols used in this manual ................................................. S-4

Safety Instructions S-5

Intended Use Statement..................................................... S-5

General safety notice / Residual risk ........................................... S-5

Special Conditions for Safe Use............................................... S-5

Authorized personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-6

Additional Literature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-6

Chapter 1 Technical Description 1-1

1.1 Overview .............................................................1-1

1.2 Design Features........................................................1-1

1.3 Protective Measures in Detail .............................................1-2

1.4 High Pressure Option / Purge Option .......................................1-3

1.5 Explosion Protection Compliances .........................................1-4

1.5.1 Special Conditions for Safe Use ..........................................1-5

1.6 Nameplate Label .......................................................1-6

1.7 Technical Data .........................................................1-7

1.8 Measurements Specications ..........................................1-15

1.9 Vapor Recovery Application (Simultaneous Measurement of CH4 and Non-CH4) .....1-19

Table of contents

TOC

Chapter 2 Installation 2-1

2.1 Scope of Supply........................................................2-1

2.2 Installing the Analyzer ...................................................2-2

2.3 Connecting Gas Lines ...................................................2-4

2.3.1 Special Conditions ....................................................2-5

2.3.2 Gas Conditioning...................................................2-7

2.4 Electrical Installation ....................................................2-8

2.4.1 Equipotential bonding conductor ........................................2-20

Chapter 3 Start up 3-1

3.1 Final Check ...........................................................3-1

3.2 Performing a Leak Test ..................................................3-2

3.3 Switching On ..........................................................3-3

3.4 Symbols and Typographical Conventions ....................................3-4

Emerson Process Management GmbH & Co. OHG TOC-1

Page 4

Instruction Manual

X-STREAM XEFD

Table of Contents

3.5 Front Panel Elements ...................................................3-5

3.5.1 Display..............................................................3-5

3.5.2 Status Line and Text message line ........................................3-5

3.5.3 Keys 3-6

3.6 Software..............................................................3-8

3.6.1 Access Levels & Codes................................................3-11

3.6.2 Special Messages ....................................................3-12

3.7 Start up .............................................................3-12

3.7.1 Boot Sequence ......................................................3-12

3.7.2 Measurement Display .................................................3-12

3.8 Language Settings .....................................................3-14

3.9 Checking the Settings ..................................................3-15

3.9.1 Installed Options .....................................................3-16

3.9.2 Conguring the Display ................................................3-17

3.9.3 Calibration Setup.....................................................3-18

3.9.4 Setting the Analog Outputs .............................................3-20

3.9.5 Setting Concentration Alarms ...........................................3-25

3.9.6 Backup the Settings ..................................................3-26

3.10 Web Browser .........................................................3-28

3.10.1 Connection via network ................................................3-28

3.10.2 Connection to single computer ..........................................3-29

HASXEDE-IM-EX

03/2012

Chapter 4 Service and Maintenance 4-1

4.1 Verications and Tests ...................................................4-3

4.1.1 Routine Tests.........................................................4-3

4.2 Replacement of Parts ...................................................4-6

4.3 Vapor Recovery Application - Special Information ..............................4-8

4.3.1 Determining the converter efciency .......................................4-9

4.3.2 Replacement Instructions ..............................................4-10

4.3.3 Failure Situation .....................................................4-14

4.4 Perform a Calibration...................................................4-15

4.4.1 Manual Zero Calibration ...............................................4-16

4.4.2 Manual Span Calibration ...............................................4-17

4.4.3 Manual Calibration for Vapor Recovery Applications..........................4-18

Chapter 5 Dismounting and Disposal 5-1

5.1 Dismounting and Diposal of the Analyzer ....................................5-1

Appendix A-1

A.1 EC Declaration of Conformity ............................................ A-2

A.2 ATEX EC Type Examination Certicate ..................................... A-3

Emerson Process Management GmbH & Co. OHGTOC-2

Page 5

Instruction Manual

HASXEDE-IM-EX

03/2012

Table of Figures

A.3 CSA Certicate of Compliance........................................... A-12

A.4 Block Diagram ....................................................... A-19

A.5 Assignment of Terminals and Sockets .................................... A-25

X-STREAM XEFD

Index of fIgures

Fig. 1-1: Frontal View ............................................................................................................1-1

Fig. 1-2: Bottom View ............................................................................................................1-2

Fig. 1-3: Nameplate Label Details (exemplary) ....................................................................1-6

Fig. 1-4: Dimensions .............................................................................................................1-7

Fig. 1-5: Signals Terminals ..................................................................................................1-13

Fig. 1-6: Power Terminals / Fuse Holders ...........................................................................1-14

Fig. 1-7: Vapor Recovery Gas Flow Diagram .....................................................................1-19

Table of contents

TOC

Fig. 2-1: Scope of Supply .....................................................................................................2-1

Fig. 2-2: Dimensions .............................................................................................................2-3

Fig. 2-3: Flame arrestor installed into instrument enclosure .................................................2-4

Fig. 2-4: Flame arrestor elements, considering as example FA 01 .......................................2-4

Fig. 2-5: Exemplary diagram for a single channel unit with purge option .............................2-5

Fig. 2-6: Exemplary diagram for a single channel instrument for high gas pressure ...........2-6

Fig. 2-7: Label with fastening torques, installed at the instrument .......................................2-6

Fig. 2-8: Allocation of terminals ..........................................................................................2-12

Fig. 2-9: Terminals block X1 - analog signals and relay outputs 1-4 .................................2-14

Fig. 2-10: Terminals block X1 - Modbus interface ................................................................2-15

Fig. 2-11: Modbus Interface - Ethernet connector ................................................................2-16

Fig. 2-12: Terminal blocks X4.1 and X4.2 - Digital inputs and outputs .................................2-17

Fig. 2-13: Terminal block X5 - analog inputs ........................................................................2-18

Fig. 2-14: Power terminals ....................................................................................................2-19

Fig. 2-15: Equipotential bonding conductor terminal ............................................................2-20

Fig. 3-1: Leak Testing with U-turn Manometer ......................................................................3-2

Fig. 3-2: Front panel .............................................................................................................3-5

Fig. 3-3: Arrangement of concentration thresholds .............................................................3-25

Fig. 3-4: Ethernet connectors .............................................................................................3-28

Fig. 3-5: Web browser logon screen ...................................................................................3-30

Fig. 3-6: Web browser measurements screen ....................................................................3-30

Emerson Process Management GmbH & Co. OHG TOC-3

Page 6

Instruction Manual

X-STREAM XEFD

Index of Figures / Index of Tables

Fig. 4-1: Leak Testing with U-tube Manometer (Flame arrestor) ..........................................4-5

Fig. 4-2: Pressure Drop Test .................................................................................................4-5

Fig. 4-3: Vapor recovery application setup............................................................................4-8

Fig. 4-4: Converter assembly ................................................................................................4-9

Fig. 4-5: Converter assembly details ....................................................................................4-9

Fig. 4-6: Heated jacket ........................................................................................................4-10

Fig. 4-7: Converter, laid open .............................................................................................4-10

Fig. 4-8: Converter lling sequence ....................................................................................4-11

Fig. 4-9: Jacket in converter assembly ..............................................................................4-12

Fig. 4-10: Heated jacket ........................................................................................................4-12

Fig. 4-11: Converter metallic cover .......................................................................................4-12

Fig. 4-12: Location of Overtemperature Protection Device ...................................................4-13

HASXEDE-IM-EX

03/2012

Index of Tables

Tab. 1-1: Generic Analyzer Data ...........................................................................................1-8

Tab. 1-2: Standard Interfaces Data .......................................................................................1-9

Tab. 1-3: Optional Interfaces Data ......................................................................................1-10

Tab. 1-4: Increased Pressure Data .....................................................................................1-12

Tab. 1-5: Purging Gas Data .................................................................................................1-12

Tab. 1-6: Gas Components and Measuring Ranges, examples ..........................................1-15

Tab. 1-7: IR, UV, VIS, TCD - Standard and Enhanced Measurement Performance

Specifications ......................................................................................................1-16

Tab. 1-8: Trace Moisture - Standard Measurement Performance Specifications ................1-16

Tab. 1-9: Oxygen - Standard and Enhanced Measurement Performance Specifications ...1-17

Tab. 1-10: Special Performance Specifications for Gas Purity Measurements .....................1-18

Tab. 3-1: Analog output signals settings and operational modes ........................................3-23

Emerson Process Management GmbH & Co. OHGTOC-4

Page 7

Instruction Manual

HASXEDE-IM-EX

03/2012

X-STREAM XEFD

INTRODUCTION

This instruction manual provides information about installing, operating and maintaining/

servicing X-STREAM series ame proof gas analyzers in hazardous (classied) areas and

shall be read in conjunction with the basic analyzer instruction manual only!

This instruction manual covers several X-STREAM series ame proof gas analyzer varia-

tions and therefore may describe congurations and/or options not part of your specic

analyzer.

DEFINITIONS

Safety Instructions

S

The following denitions apply to WARNINGS, CAUTIONS and NOTES found throughout

this publication.

HIGHLIGHTS AN OPERATION OR MAINTENANCE PROCEDURE,

PRACTICE, CONDITION, STATEMENT, ETC.

If not strictly observed, could result in injury, death, or long-term health

hazards of personnel.

HIGHLIGHTS AN OPERATION OR MAINTENANCE PROCEDURE,

PRACTICE, CONDITION, STATEMENT, ETC.

If not strictly observed, could result in damage to or destruction of equipment,

or loss of effectiveness.

NOTE!

Highlights an essential operating procedure, condition or statement.

Emerson Process Management GmbH & Co. OHG S-1

Page 8

X-STREAM XEFD

Terms Used In This Instruction Manual

Instruction Manual

HASXEDE-IM-EX

03/2012

ATEX

Directive 94/9/EC, commonly called the

ATEX („Atmosphères Explosibles“) directive,

dealing with equipment intended to be used

in potentially explosive atmospheres.

This directive is valid for equipment to be

sold into and/or installed and operated in the

European Union (EU).

Division 2

Where ignitable concentrations of ammable

gases are not likely to exist under normal

operating conditions (similiar to Zone 2).

Explosive Gas(es)

Flammable Gases and gas mixtures in a mixture with air within the explosive limits.

Flammable Gas(es)

Gases and gas mixtures are assigned to be

ammable if they might become ignitable

when in a mixture with air.

Infallible Containment

This term is derived from the standards of

explosion protection especially from the requirements for pressurized housings: thus an

infallible containment can be characterized

by no intended leakage into the gas paths

enabling gas to enter the inner compartment

of the analyzer housing.

Intrinsically Safe Cell (IS Cell)

Cells supplied with an intrinsically safe power

signal, approved by a Test Institute, to operate

with explosive gases.

The design ensures the IS cells remains safe

even in case of failure and explosive gases

are not ignited.

Lower Explosion Limit (LEL)

Volume ratio of ammable gas in air below

which an explosive gas atmosphere will not

be formed: the mixture of gas and air lacks

sufcient fuel (gas) to burn.

Protection Class IP66 / NEMA 4X

Both terms are used to specify conditions for

equipment to be installed outdoor.

IP stands for Ingress Protection, the rst num-

ber species protection against solid objects

(6. = dust tight) while the second number

species the degree of protection against

liquids (.6 = heavy seas).

NEMA stands for National Electrical Manuf-

acturers Association. 4X species a degree

of protection to personnel against incidental

contact with the enclosed equipment; to provide a degree of protection against falling dirt,

rain, sleet, snow, windblown dust, splashing

water, and hose-directed water; and that will

be undamaged by the external formation of

ice on the enclosure

Upper Explosion Limit (UEL)

Volume ratio of ammable gas in air above

which an explosive gas atmosphere will not

be formed: the mixture of gas and air is too

rich in fuel (decient in oxygen) to burn.

Zone 1

Where ignitable concentrations of ammable

gases can exist some of the time under normal operating conditions.

(A guideline value [not part of a standard ] is

10 to 1.000 hours per year.)

Zone 2

Where ignitable concentrations of ammable

gases are not likely to exist under normal

operating conditions.

(A guideline value [not part of a standard ] is

less than 10 hours per year.)

Emerson Process Management GmbH & Co. OHGS-2

Page 9

Instruction Manual

HASXEDE-IM-EX

03/2012

X-STREAM XEFD

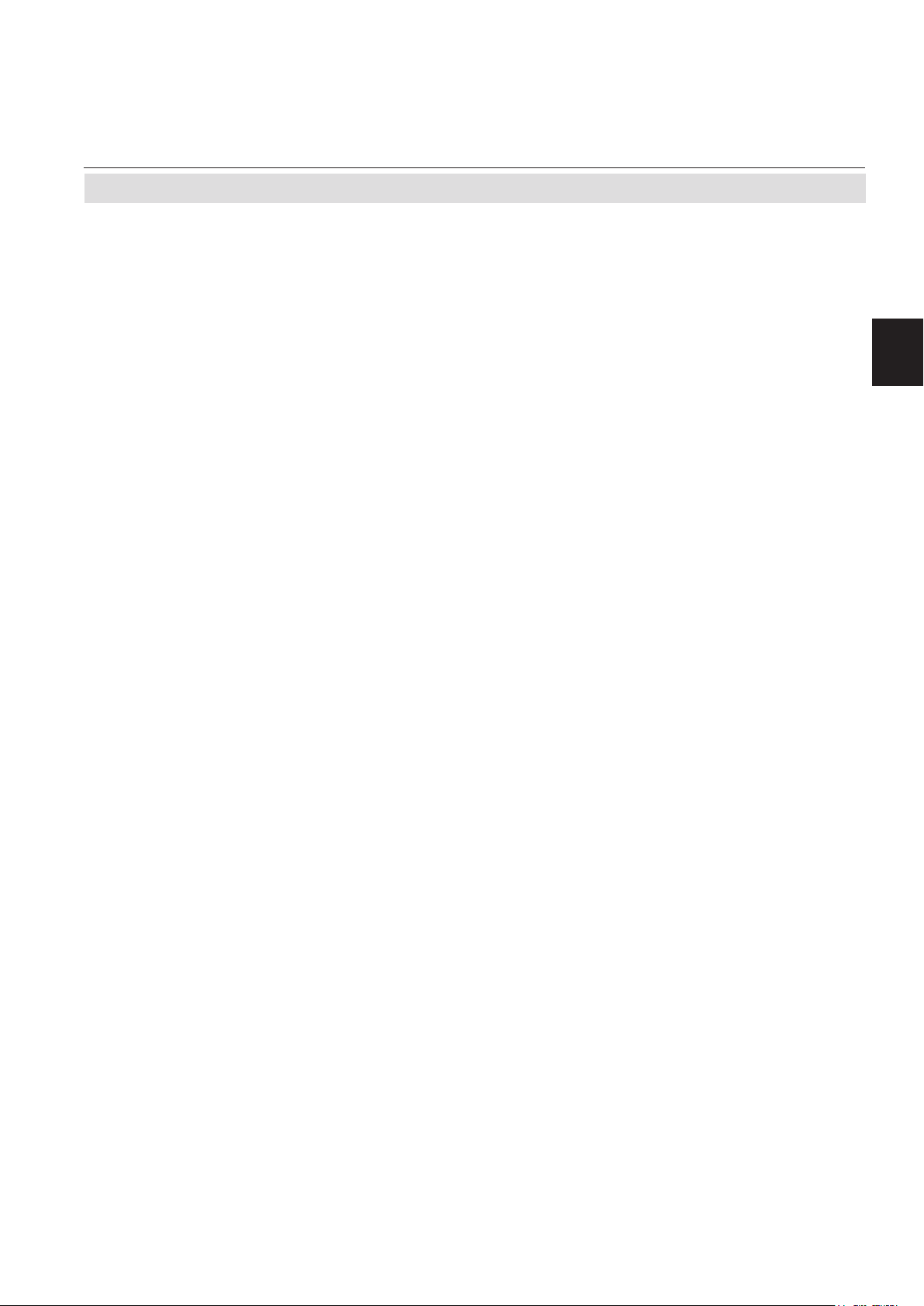

Symbols Used On And Inside The Unit

Wherever one or more of the following symbols appear on or inside the instrument, be careful

and read the instructions given in the accompanying manuals!

Strictly observe the given warnings, instructions and information to minimize hazards!

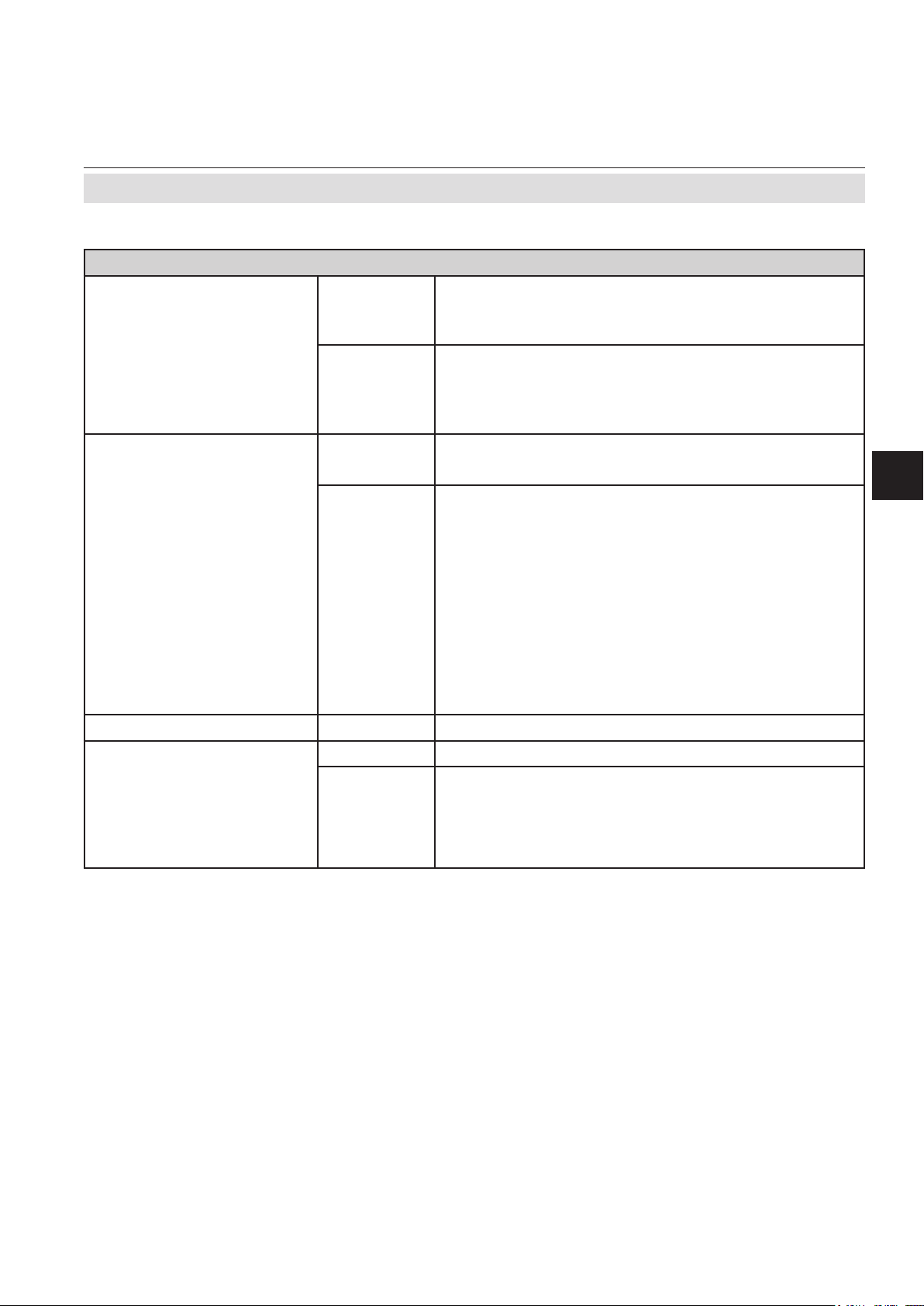

This symbol at the instrument ... ... means

dangerous voltages may be accessible. Remo-

ving covers is permitted only, if the instrument is

disconnected from power - and even in this case

by qualied personnel only!

hot surfaces may be accessible. Removing

covers by qualied personnel is permitted only,

if the instrument is disconnected from power.

Nevertheless several surfaces may remain hot

for a limited time.

more detailled information available: see in-

struction manual before proceeding!

more detailled information available: see in-

struction manual before proceeding!

Safety Instructions

S

Emerson Process Management GmbH & Co. OHG S-3

Page 10

Instruction Manual

X-STREAM XEFD

HASXEDE-IM-EX

03/2012

Symbols Used In This Manual

Where one or more of the following symbols appear within this manual, carefully read the related information and instructions!

Strictly observe the given warnings, instructions and information to minimize hazards!

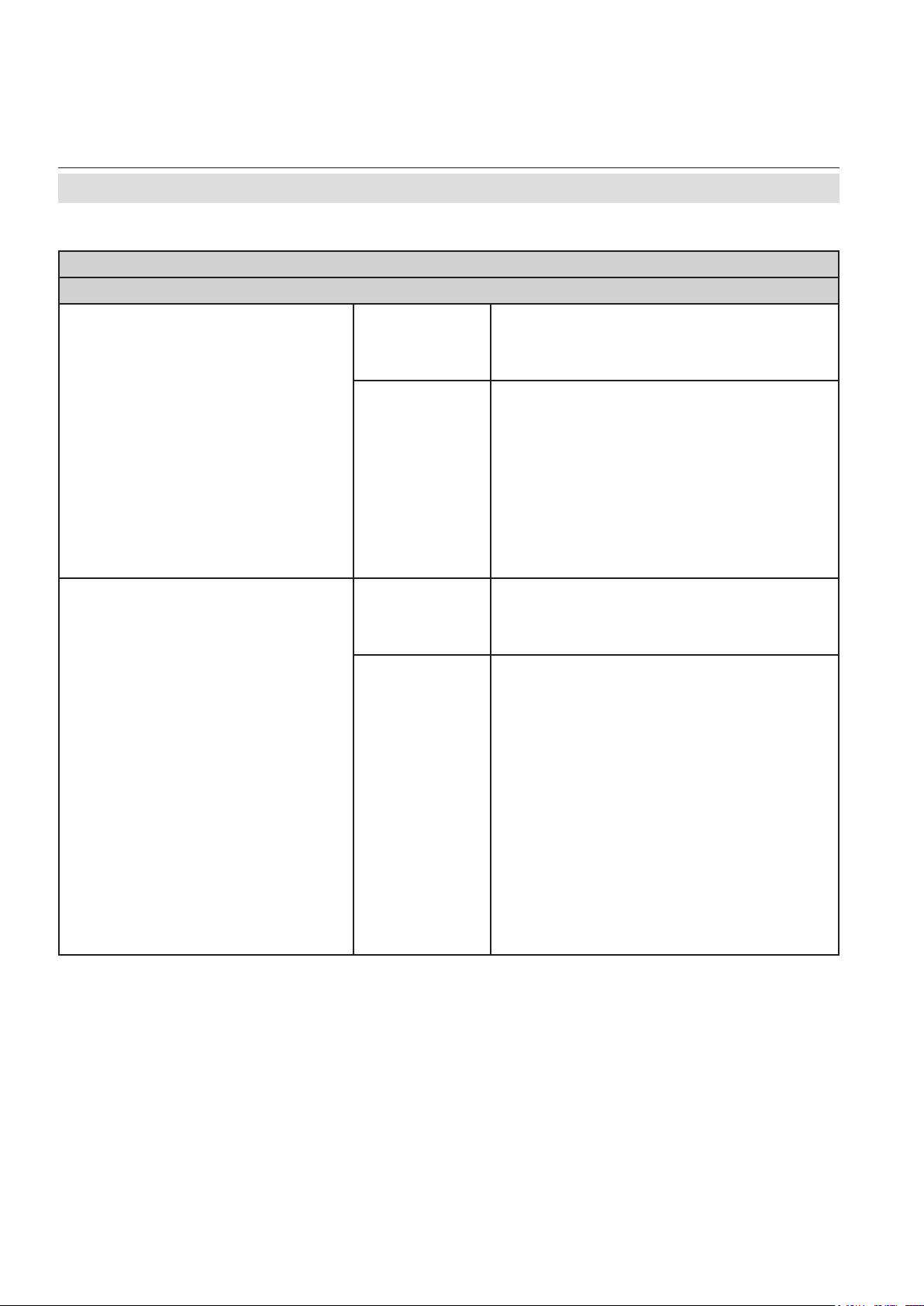

This symbol used in the manual ... ... means

dangerous voltages may be exposed

hot surfaces may be exposed

possible danger of explosion

toxic substances may be present

substances harmful to health may be present

indicates notes relating to heavy instruments

electrical components may be destroyed by

electrostatic discharges

units must be disconnected from the power

source

indicates special instructions or information for

operation at low temperatures.

indicates basic conditions or procedures are

being described.

This symbol may also indicate information impor-

tant for achieving accurate measurements.

Emerson Process Management GmbH & Co. OHGS-4

Page 11

Instruction Manual

HASXEDE-IM-EX

03/2012

X-STREAM XEFD

SAFETY INSTRUCTIONS

Intended Use Statement

X-STREAM XE series gas analyzers are intended to be used as analyzers for industrial purposes.

They must not be used in medical, diagnostic or life support applications.

Using X-STREAM XE analyzers as safety devices is prohibited where redundancy and/or SIL

classication or equivalent is needed.

No independent agency certications or approvals are to be implied as covering such applications!

Safety Instructions

General Safety Notice / Residual Risk

If this equipment is used in a manner not specied in these instructions, protective systems may

be impaired.

Despite of incoming goods inspections, production control, routine tests and application of state-

of-the-art measuring and test methods, an element of risk remains when operating a gas analyzer!

Even when operated as intended and observing all applicable safety instructions, some residual

risks remain, including, but not limited to, the following:

• An interruption of the protective earth line, e.g. in an extension cable, may result in risk to

the user.

• Live parts are accessible when operating the instrument with doors open or covers removed.

• The emission of gases hazardous to health may even be possible when all gas connections

have been correctly made.

Avoid exposure to the dangers of these residual risks by taking particular care when installing,

operating, maintaining and servicing the analyzer.

SPECIAL CONDITIONS FOR SAFE USE

• Only specied screws M16x45 ISO 4762

A2-70 as specied in the maintenance

section of this manual shall be used (spare

part # 42716945).

• Vapor recovery application:

Pressure of gases not to exceed 1100 hPa.

Concentrations of gases must be below

25 % LEL.

S

• The ame joints correspond to the drawing

No. 4.271-7112/1 and do not comply with

the dimensions mentioned into the Tab. 1

and Tab. 2 of EN 60079-1 ed.2.

• The gas path for the sample gas shall be

equipped with additional appropriate ame

arrestors in case of gas pressure above

1100 hPa to 1500 hPa.

• Appropriate certied cable glands shall be

used in accordance with IEC/EN 60079-14

Emerson Process Management GmbH & Co. OHG S-5

• Depending on the particular application all

approbriate safety instructions mentioned

in this instruction manual on hand must

be considered!

• Take special care of formation of ammable gas at the outlet of breathing and/or

purging devices, if the sample gas con-

centration is above 25% LEL! If need be,

such outlets have to end in a safe area!

Page 12

Instruction Manual

X-STREAM XEFD

Safety Instructions

HASXEDE-IM-EX

03/2012

Authorized Personnel

In-depth specialist knowledge is an absolutely necessary condition for working with and on the

analyzer.

Authorized personnel for installing, operating, servicing and maintaining the analyzer are instructed

and trained qualied personnel of the operating company and the manufacturer.

It is the responsibility of the operating company to

• train staff,

• observe safety regulations,

• follow the instruction manual.

Operators must

• have been trained,

• have read and understood all relevant sections of the instruction manual before commencing

work,

• know the safety mechanisms and regulations.

To avoid personal injury and loss of property, do not install, operate, maintain or service this instru-

ment before reading and understanding this instruction manual and receiving appropriate training.

Additional Literature

This manual covers aspects specic for using ameproof X-STREAM XEFD gas analyzers

in hazardous (classied) areas, only.

For comprehensive information on operating and maintain/service the instrument in a

safe manner it is MANDATORY to read all additional instruction manuals, if not provided

as printed version, see the accompanying USB stick for an electronic version (PDF)!

The following instruction manuals are available and/or referenced within this manual at hand:

HASXEE-IM-HS X-STREAM XE series instruction manual

HASICx-IM-H Infallible Containment

The original manufacturer's cable gland or conduit instruction manual, depending on what is used.

Contact your local service center or sales ofce when missing documents.

SAVE ALL INSTRUCTIONS FOR FUTURE USE!

Emerson Process Management GmbH & Co. OHGS-6

Page 13

Instruction Manual

HASXEDE-IM-EX

03/2012

Consider the waiting time statement on the front door label before opening,

if the analyzer is congured with selected measurement principles!

Do not open instrument when energized.

Ensure that external circuitry is disconnected or de-energized before

opening the instrument.

Ensure that all gas connections are made as labeled and are leak free.

Improper gas connections could result in explosion and death.

X-STREAM XEFD

Safety Instructions

EXPLOSION HAZARD BY CONNECTIONS

Safety Instructions

S

EXPLOSION HAZARD BY MODIFICATION

Any addition, substitution, or replacement of components installed on or

in this device, must be certied to meet the hazardous area classication

that the device was certied to prior to any such component addition,

substitution, or replacement. In addition, the installation of such device or

devices must meet the requirements specied and dened by the hazardous

area classication of the unmodied device.

Any modications to the device not meeting these requirements, will void

the product certication(s).

Contact Emerson Process Management‘s customer service center for return

authorization.

EXPLOSION HAZARD BY SAMPLE HANDLING

The X-STREAM analyzer may utilize not only sample gas but one or more

pressurized carrier gases and/or calibration gases.

If an external owmeter is required for ow control, legislative requirements

and instructions for installation in hazardous (classied) areas must be

considered.

Emerson Process Management GmbH & Co. OHG S-7

Page 14

X-STREAM XEFD

Installation, and connecting mains and signal cables are subject to qualied

personnel only, taking into account all applicable standards and legislative

requirements!

Failure to follow may cause warranty invalidation, property damage and/or

personal injury or death! Connecting mains and signal cables to internal

srew terminals requires working at open housing near life parts!

Installation of this instrument is subject to qualied personnel only, familiar

with the resulting potential risks!

The gas analyzers do not provide a mains power switch and are operable

when connected to power.

Instruction Manual

HASXEDE-IM-EX

03/2012

Safety Instructions

ELECTRICAL SHOCK HAZARD

The gas analyzers do not provide a mains switch! A mains switch or circuit

breaker (to comply with IEC 60947-1 /-3) has to be provided in the building

installation. This switch has to be installed near by analyzer, must be

easily operator accessible and has to be assigned as disconnector for the

analyzer.

EXPLOSION and ELECTRICAL SHOCK HAZARD BY INSTALLATION

These instruments provide a protective earth terminal. To prevent electrical

shock and explosion hazards, the instrument must be connected to a

protective earth.

Therefore the instrument has to be connected to mains by using a three

wire mains cable with earth conductor!

Any interruption of the earth connector inside or outside the instrument

or disconnecting the earth terminal may cause potential electrical shock

hazard!

Intended interruption of protective earth connections is not permitted!

Emerson Process Management GmbH & Co. OHGS-8

Page 15

Instruction Manual

HASXEDE-IM-EX

03/2012

Take care to not damage the housing nor threads, and to not produce

scratches on the ange, as threads and ange function as ame paths!

Violation may result in explosion and personal injury!

Before connecting the analyzer to mains power, please read the chapter on

safety warnings and the following instructions carefully.

X-STREAM XEFD

Safety Instructions

EXPLOSION HAZARD BY DAMAGED FLAME PATHS

Safety Instructions

S

ELECTRICAL SHOCK HAZARD WHEN CONNECTING TO MAINS

ELECTRICAL SHOCK HAZARD WHEN OPERATED OPENED

Do not operate without covers secure. Do not open while energized.

Installation requires access to live parts which can cause death or serious

injury.

For safety and proper performace this instrument must be connected to a

properly grounded three-wire source of power.

Violation may cause explosion and personnel injury!

EXPLOSION HAZARD WHEN OPEN

Do NOT operate the instrument with doors or covers open! This is permitted

only when no hazardous atmosphere is present! Depending on the local

regulation, this may require a competent hot work supervisor to issue a

hot work permit.

Use ALL 20 screws to x the cover!

Violation may cause an explosion hazard!

Emerson Process Management GmbH & Co. OHG S-9

Page 16

X-STREAM XEFD

Risk of internal overpressure under leakage conditions!

For the purge or high sample gas option, take care to limit the total of purge

gas ow and highest ow of sample gas lines into the instrument to max.

2 l/min!

Take care of special conditions for safe use, and gas parameter specications

( S-11 and 1-12 )!

Instruction Manual

HASXEDE-IM-EX

03/2012

Safety Instructions

EXPLOSION HAZARD BY HIGH PRESSURE

EXPLOSION AND ELECTRICAL SHOCK HAZARD

All cables (power and signal) must end (be connected) in either a safe (nonhazardous) area or in a protecting enclosure (e.g. Ex e junction box)!

The power and signal cables must be separated by a distance of minimum

1 cm (0.4 in) inside and outside the analyzer!

EXPLOSION HAZARD

Startup, operation and service must not be performed, before reading and

understanding all instructions!

Especially all warnings in this and the associated manuals have to be

considered! Inspection, maintenance and service must be carried out

considering all related standards e.g. for „Inspection and maintenance of

electrical installations in hazardous areas“ or „Equipment repair, overhaul

and reclamation“.

Emerson Process Management GmbH & Co. OHGS-10

Page 17

Instruction Manual

HASXEDE-IM-EX

03/2012

Consider the waiting time statement on the front door label before opening!

X-STREAM XEFD

Safety Instructions

EXPLOSION HAZARD: VAPOR RECOVERY APPLICATION

Disregarding the waiting time statement may result in explosion!

Temperatures of components for this application installed into the analyzer

exceed the analyzer's temperature classication for hazardous areas!

HEAVY INSTRUMENT HAZARD

X-STREAM XEFD analyzers, to which this manual relates, intended

to be wall mounted and/or outdoor installed, weigh up to approx. 63 kg

(139 lbs), depending on included options!

Use two people and/or suitable tools for transportation and lifting these

instruments!

Take care to use anchors and bolts specied to be used for the weight of

the units!

Take care the wall or stand the unit is intended to be installed at is solid

and stable to hold the units!

Safety Instructions

S

HIGH TEMPERATURES HAZARD

While working at internal components hot surfaces may be accessible, even

after the instrument has been disconnected from power!

HOW TO STAY IN COMPLIANCE WITH THE

EUROPEAN DIRECTIVE 94/9/EC ("ATEX") WHEN PERFORMING GAS

ANALYSIS WITHIN A FLAMEPROOF ENCLOSURE.

Special conditions apply to using a ameproof enclosure analyzer under the scope of the

"European Directive for Equipment used in Explosive Atmosphere" (Directive 94/9/EC;

ATEX). To stay compliant with the directive, consider the following clarication sheet released by the European ATEX Notied Body Group (see next page):

Emerson Process Management GmbH & Co. OHG S-11

Page 18

X-STREAM XEFD

Instruction Manual

HASXEDE-IM-EX

03/2012

Safety Instructions

Emerson Process Management GmbH & Co. OHGS-12

Page 19

Instruction Manual

HASXEDE-IM-EX

03/2012

This analyzer contains an internal battery!

X-STREAM XEFD

Safety Instructions

EXPLOSION HAZARD BY INTERNAL BATTERY

Safety Instructions

Do NOT OPEN the analyzer enclosure if explosive atmosphere may be

present!

Disregarding may cause explosion even if the analyzer is de-energized!

CRUSHING HAZARD

Take care of crushing hazard when closing the front door of analyzer eld

housings!

Keep out of the closing area between enclosure cover and base!

OPERATION AT LOW TEMPERATURES

When operating an instrument at temperatures below 0 °C (32 °F), do

NOT apply gas nor operate the internal pump before the warmup time has

elapsed!

S

Violation may result in condensation inside the gas paths or damaged

pump diaphragm!

HIGH TEMPERATURES

Hot parts may be exposed when working on photometers and/or

heated components in the unit.

Emerson Process Management GmbH & Co. OHG S-13

Page 20

X-STREAM XEFD

GENERAL OPERATING NOTES

HAZARD TO LIFE AND EXPLOSION HAZARD BY EXHAUST GASES

Exhaust gases may contain hydrocarbons and other toxic gases such as

carbon monoxide.

Faulty gas connections may lead to explosion and death.

Ensure that all gas connections are connected as labelled and airtight.

Instruction Manual

HASXEDE-IM-EX

03/2012

General Operating Notes

• The unit must be installed in a clean and dry area, protected from strong vibrations and frost

• The unit must not be exposed to direct sunlight and sources of heat. Admissible ambient

temperatures (see technical details) must be adhered to.

• Gas inlets and outlets must not be interchanged.All gases must be conditioned, before sup-

plied to the unit. When using this unit with corrosive sample gases, ensure that these gases

do not contain components harmful to the gas lines.

• Admissable pressure for all applied gases is 1500 hPa (consider special conditions for safe

use)!.

• Exhaust lines must be laid inclined downwards, depressurized, protected from frost and

according to applicable regulations.

• If it is necessary to disconnect the gas lines, the unit’s gas connectors must be sealed with

PVC caps to avoid polluting the internal gas lines with condensate, dust, etc.

• To ensure electromagnetic compatibility (EMC), only shielded cables (supplied by us on request, or of equivalent standard) may be used. The customer must ensure that the shielding

is correctly tted. Shielding must be electrically connected.

.

Emerson Process Management GmbH & Co. OHGS-14

Page 21

Instruction Manual

HASXEDE-IM-EX

03/2012

1.1 Overview

X-STREAM XEFD

Chapter 1

Technical Description

The new X-STREAM ameproof gas analyzers are designed to be used in hazardous

areas. The flameproof enclosure can be

installed at Zone 1 and Division 2 locations

without the need of any additional protective

measures, e.g. purge gas supply.

1.2 Design Features

Packaged into a cast aluminum enclosure,

the X-STREAM XEFD gas analyzer provides

all the measurement options available for general purpose instruments, but for installation

at locations, where explosive gas atmosphere

might be present frequently (Zone 1) or occasionally (Zone 2, Division 2).

The basic concept used to protect the surrounding atmosphere from being ignited, if an

internal failure results in high temperatures,

ames or even an explosion, is to keep the

explosion inside the enclosure and quench all

ames possibly passing through the ange.

To provide adequate explosion protection the

X-STREAM ameproof analyzer feature:

•

a cast aluminum enclosure, designed to

• withstand an internal explosion,

• quench ames resulting from an internal

explosion (thus preventing a surroun-

ding explosive atmoshere from being

ignited).

• ame arrestors avoiding ame transmissi-

on from the gas paths into the surrounding

atmosphere.

• approved cable glands (option: conduits),

protecting the cable inlets and outlets.

Techn. Description

1

3

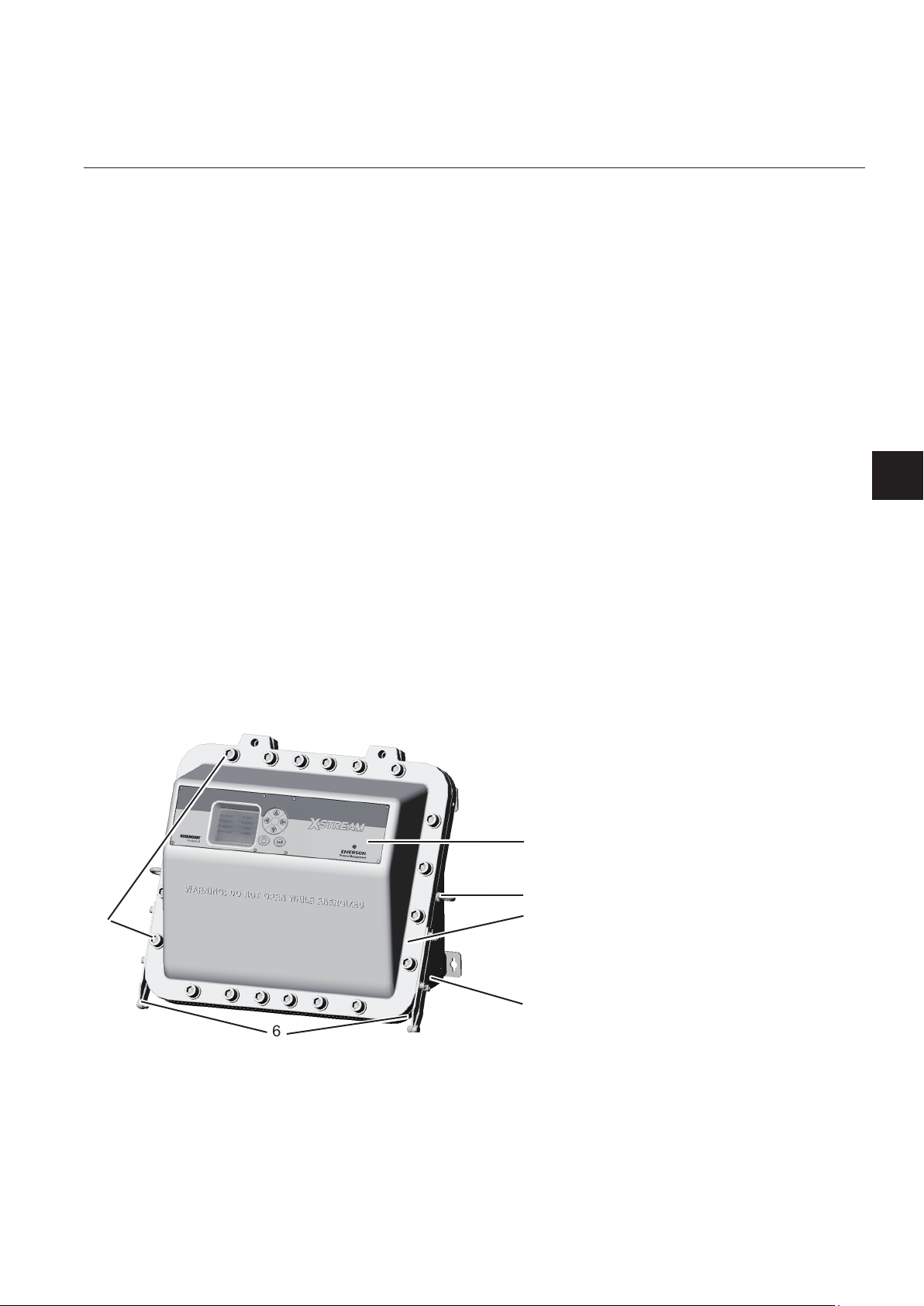

1: Enclosure base

2: Screws

5

3: Enclosure cover

4

2

6

Fig. 1-1: Frontal View

Emerson Process Management GmbH & Co. OHG 1-1

4: Flange

5: Eyebolts for lifting

6: Hinges

1

Page 22

X-STREAM XEFD

1.3 Protective Measures in Detail

1.3 Protective Measures in Detail

The cast aluminum enclosure consists of two

parts: base and cover, connected by hinges.

The area where the two parts are in contact

is designed to work as a ange, quenching

ames entering the small path between them.

When operated, the analyzer enclosure has to

be closed and secured by 20 screws evenly

arranged all over the ange. The ame path

between the ange parts is manufactured

with very low tolerances and best atness,

to ensure the function of quenching ames.

For this reason, it is of particular importance

to keep the anges surfaces free of scratches

and other damages!

The only openings penetrating the enclosure

are threads, to be used for gas and cable in-

and outlets:

Depending on the measurement application

the instrument provides up to 8 gas in- and

outlets, each protected by an approved ame

arrestor. These arrestors are installed into

threads at the bottom side of the enclosure

base. Two tting sizes are available for ex-

ternal connection of gas pipes with 3.18 mm

(1⁄8") or 6.35 mm (1⁄4") outer diameter (OD).

Instruction Manual

HASXEDE-IM-EX

03/2012

Optionally a clamping ring for 6 mm OD may

be used, replacing the 6.35 mm version.

Cables are fed into the enclosure utilizing up

to 4 cable glands, located at the enclosure`s

bottom right side. The approved glands ac-

cept 3 different internal elastomeric sealing

rings with different internal diameters, sup-

porting a wide range of cables.

For installation in North America cable glands

are replaced by a combination of conduits and

metric-to-NPT thread adapters.

All threads are designed to act as a ame

path of a length ensuring that possibly

entering flames are quenched before

exiting to the external atmosphere. For

this reason, avoid to damage the threads,

neither externally nor internally!

Unused threads must be closed with plugs

when the instrument is operated to ensure

explosion protection.

Note!

See the X-STREAM series instruction manuals for more information about common

gas analyzers features, and special features

of the X-STREAM XEFD.

Fig. 1-2: Bottom View

1 2 3 4

1: Plugged when not used

2: Gas tting (part of ame arrestor)

3: Plug

4: Cable gland (or conduits)

Emerson Process Management GmbH & Co. OHG1-2

Page 23

Instruction Manual

HASXEDE-IM-EX

03/2012

1.4 High Pressure Option / Purge Option

1.4 High Pressure Option / Purge Option

Normally ameproof housings are permitted

to operate under atmospheric conditions only,

that is within an ambient pressure range between 800 and 1100 hPa.

For analyzers this pressure range also applies

to the gas pressure within the containment

system. While the lower limit is not critical,

the higher is, because it lowers the permitted

sample gas (and calibration gases) pressures

by 400 hPa, compared to general purpose

analyzers. This results in higher requirements

for the sample handling system, as it has to

safely reduce the process gas pressure to the

permitted range.

Another aspect to take care for when ope-

rating ameproof analyzers is the option of

applying a purge gas to the enclosure when

measuring low concentrations of gases, being

constituent of the ambient air: The ambient air

inside the analyzer enclosure cross interfe-

rese with the sample gas and inuences the

measuring results. By purging the housing

with a gas free of the measured component,

this can be avoided, but could increase the

pressure inside the analyzer and so would

violate the atmospheric pressure condition.

X-STREAM ameproof analyzers have been

subjected to additional tests to support both

situations:

X-STREAM XEFD

Higher gas pressure is specied to be within

the range of 1100 hPa to 1500 hPa. The maxi-

mum permitted ow is 1,5 l/min, depending on

the installed measurement system lower limits

may apply.

The gas paths need additionally to be protected

by suitable inline ame arrestors, designed and

approved for the applied higher gas pressure

and for the area of installation. These ame arrestors need to be installed outside the analyzer

and in addition to the ame arrestors provided

by the analyzer.

Note!

The external inline flame arrestors are not

subject of the analyzer certication and may

be provided by the customer, or optionally by

EMERSON PROCESS MANAGEMENT.

A separate analyzer ame arrestor has to be

installed, operating as a breathing device and

so limiting the increase of pressure in the enclosure in case of internal leakage.

Purging the housing with clean gas when

measuring low concentrations

The maximum permitted gas ow is 2 l/min. The

gas must be supplied via a separate ame arrestor. Another ame arrestor must be installed,

operating as a breathing device and so limiting

the increase of pressure in the enclosure.

Techn. Description

1

• higher sample and calibration gas pres-

sures

as well as

• purging the housing with a gas for best

measuring results at low concentrations.

To permit this, special additional conditions

must be taken into account:

High sample and calibration gas pressures

Emerson Process Management GmbH & Co. OHG 1-3

When making use of any of above

mentioned options, take care

of the special conditions given

in the technical data section,

and in chapter 2 (installation

instructions)!

EXPLOSION HAZARD

Page 24

X-STREAM XEFD

1.5 Compliances

1.5 Explosion Protection Compliances

Instruction Manual

HASXEDE-IM-EX

03/2012

These products are available in two different

variations, separately certied by agencies

for the use in hazardous (classied) areas:

The one variation, to be equipped with cable

glands, is certied by Fyzikálně technický

zkušební ústav, s.p (FTZÚ), an European

Notied Body under the Directive 94/9/EC

(„ATEX“) and conforms to the provisions of

EN 60079-0 and EN 60079-1. See appendix for a copy of the EC type examination

certicate.

The second variation, to be equipped with

metric-to-NPT adapters and conduits (these

components are not part of the instrument

certication), is certied by the Canadian

Standards Association, an „OSHA Nationally

Recognized Testing Laboratory“ (NRTL), for

Canada and USA and conforms to the provisions of CAN/CSA-E60079-0:02 (R2006),

CAN/CSA-E60079-1:02 (R2006), ANSI/

ISA-12.00.01-2002 (IEC 60079-0 Mod), ANSI/

ISA-12.22.01-2002 (IEC 60079-1 Mod). Furthermore, these X-STREAM X2FD analyzers

are certied for use in Class I, Division 2,

Group BCD T3 areas.

See appendix for a copy of the CSA Certicate

of Compliance.

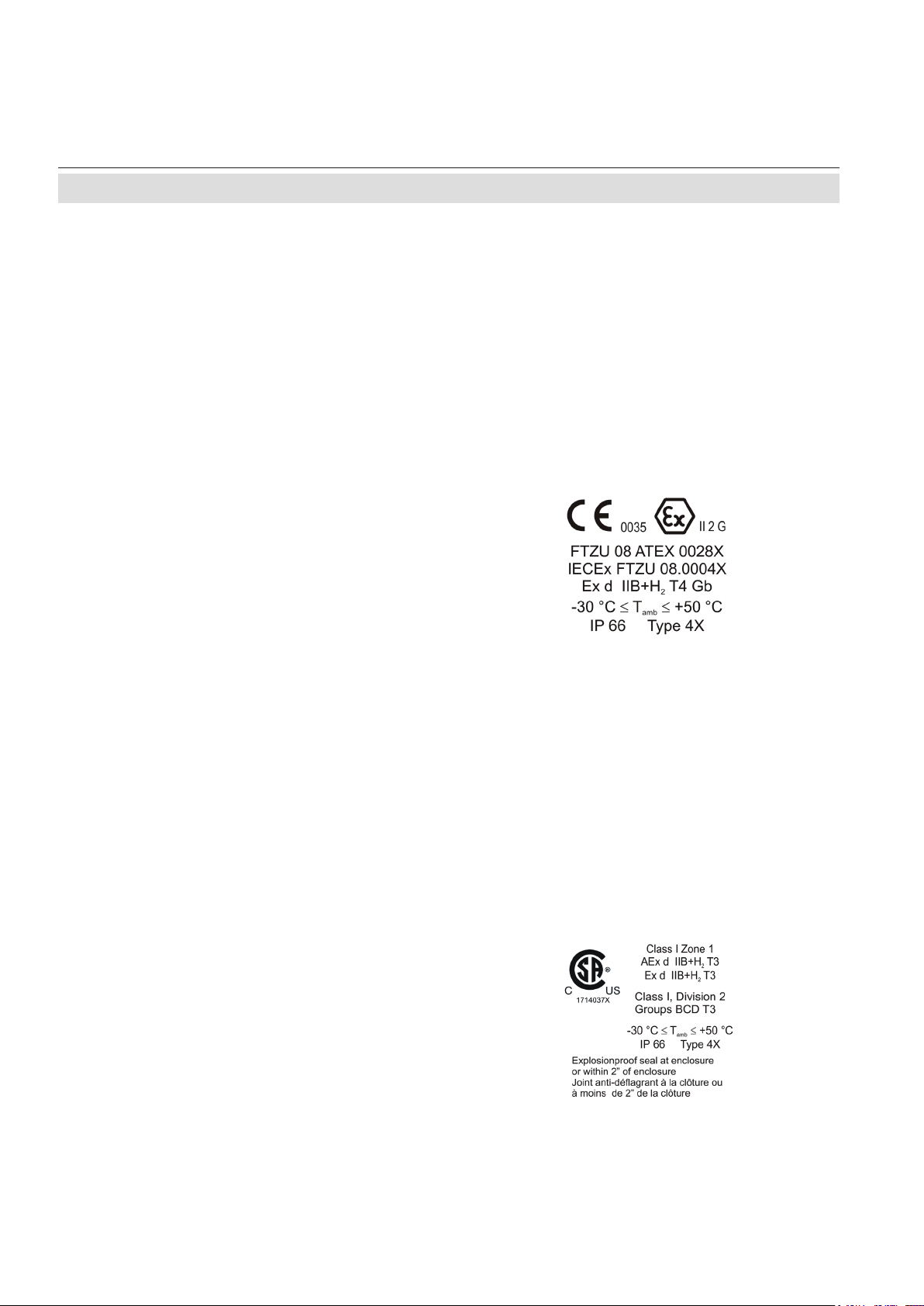

The following certication markings apply to

the products:

European Union (EU, ATEX)

Category 2, Zone 1:

Ex d IIB+H2 T4 Gb

EC ATEX Type Examination Certicate:

FTZU 08 ATEX 0028 X.

IECEx

Ex d IIB+H2 T4 Gb

Conforms to the provisions of the „Equipment

intended for use in Potentially Explosive At-

mospheres (ATEX)“ Directive 94/9/EC, EMC

Directive 2004/108/EC and CE Directive

93/68/EEC.

USA

Class I, Zone 1, AEx d IIB+H2 T3

Class I, Division 2, Group BCD T3

IECEx certication enables worldwide approvals with minimized need of testing.

Canada

Class I, Zone 1, Ex d IIB+H2 T3

Certicate of Compliance 1714037X

Emerson Process Management GmbH & Co. OHG1-4

Page 25

Instruction Manual

HASXEDE-IM-EX

03/2012

1.5 Compliances

1.5.1 Special Conditions for Safe Use

X-STREAM XEFD

• Only screws M16x45 ISO 4762 A2-70 as

specied in the maintenance section of

this manual shall be used (spare part #

42716945).

• The ame joints correspond to the drawing

No. 4.271-7112/1 and do not comply with

the dimensions mentioned into the Tab. 1

and Tab. 2 of EN 60079-1 ed.2.

• The gas path for the sample gas shall be

equipped with additional appropriate ame

arrestors in case of gas pressure above

1100 hPa to 1500 hPa.

• Appropriate certied cable glands shall be

used in accordance with IEC/EN 60079-14.

• Vapor Recovery application:

Pressure of gases not to exceed 1100 hPa.

Concentration of gases must be below

25 % LEL.

• Depending on the particular application all

approbriate safety instructions mentioned

in this instruction manual on hand must

be considered!

• Take special care of formation of ammable gas at the outlet of breathing and/or

purging devices, if the sample gas con-

centration is above 25% LEL! If need be,

such outlets have to end in a safe area!

Techn. Description

1

Emerson Process Management GmbH & Co. OHG 1-5

Page 26

Instruction Manual

X-STREAM XEFD

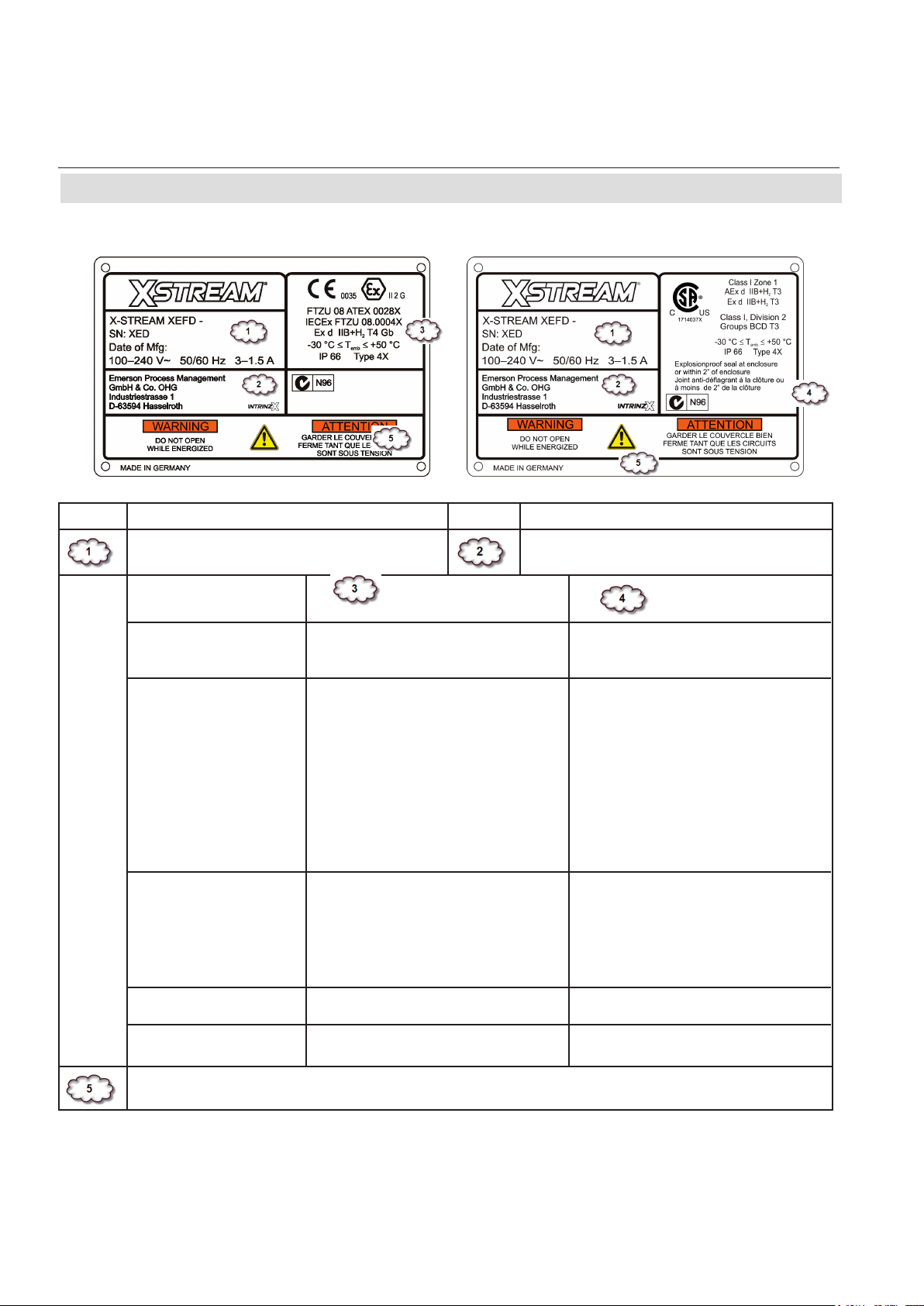

1.6 Nameplate Label

1.6 Nameplate Label

CSA-C/US versionATEX version

Area Description Area Description

The analyzer´s electrical data, manufac-

turing data and serial number

Manufacturer address

HASXEDE-IM-EX

03/2012

Certication Data

Area classication

Protection concepts

Additional Division

Marking, if applicable

Certicate numbers

Other

IECEx /

EU (ATEX)

II other than mines

2 Category 2 Equipm. (Zone 1)

G for explosive Gas atmosphere

Ex Explosion protected

d ameproof

IIB+H

Group II, Gas Group B

2

plus Hydrogen

T4 Temperature Class (135 °C)

Gb Equipment Protection Level

Ambient Temperature Range

T

amb

IP66, Type 4X Enclosure Rating

(outdoor use)

--

IECEx FTZU 08.0004X

FTZU 08 ATEX 0028 X

CE mark, number of Notied

Body for Quality assessment

North America (CSA)

Class I Flammable gases,

vapors or liquids

Zone 1 Zone 1 areas

AEx Explosion protected (US)

Ex Explosion protected (CAN)

d ameproof

IIB+H

Group II, Gas Group B

2

plus Hydrogen

T3 Temperature Class (200 °C)

Ambient Temperature Range

T

amb

IP66, Type 4X Enclosure Rating

(outdoor use)

Class I Flammable gases,

vapors or liquids

Division 2 Division 2 areas

Groups BCD all Gases, except

Acetylene

T3 Temperature Class (200 °C)

1714037X

Instruction note where to install

the explosion proof seal

Additional warning: Do not open the instrument while energized. Consult manual!

Fig. 1-3: Nameplate Label Details (exemplary)

Emerson Process Management GmbH & Co. OHG1-6

Page 27

Instruction Manual

HASXEDE-IM-EX

03/2012

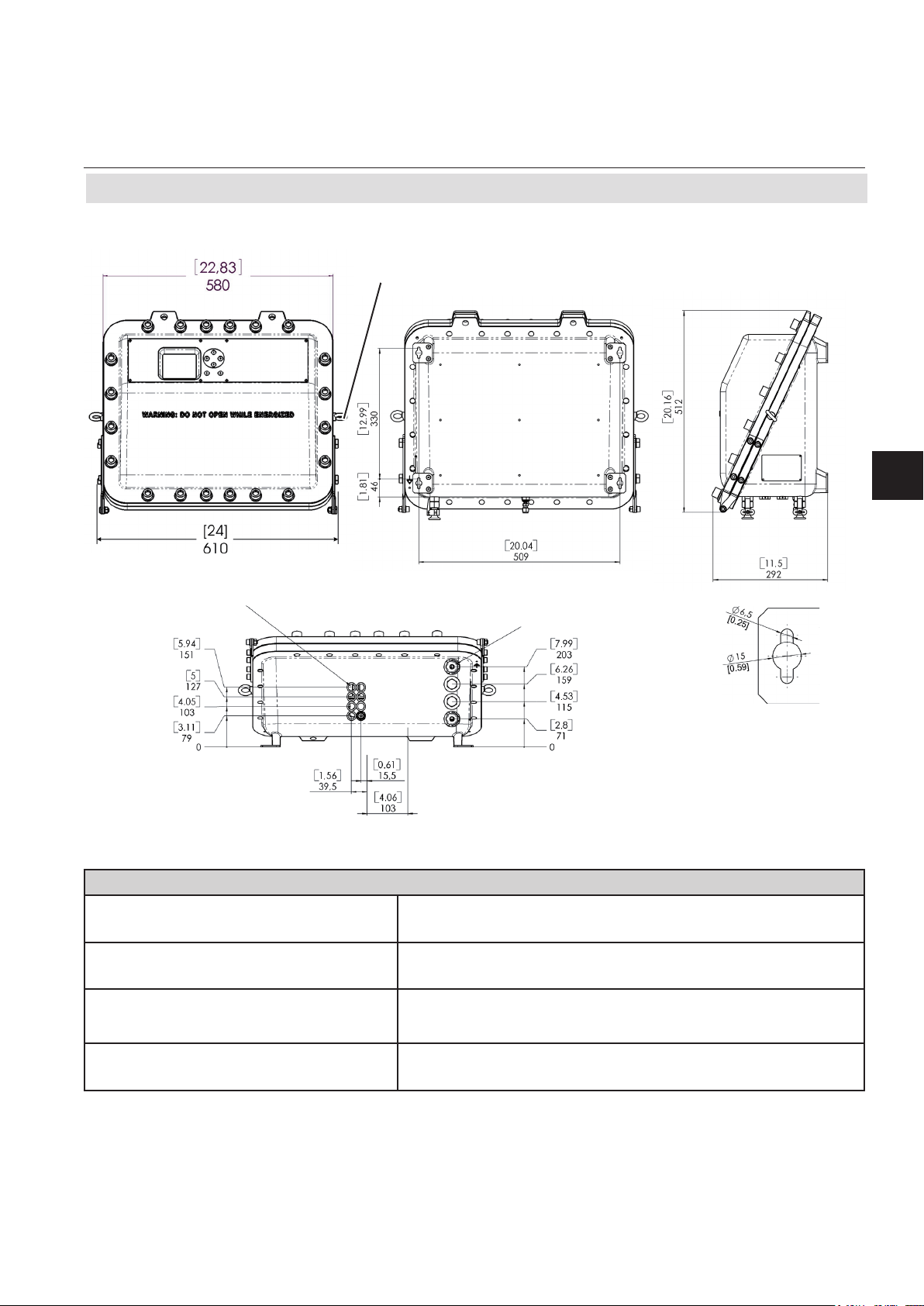

1.7 Technical Data

X-STREAM XEFD

1.7 Technical Data

Transport lugs to be removed after installation

Techn. Description

1

Flame arrestors with gas ttings

(enclosure threads: M18 x 1.5)

Fig. 1-4: Dimensions

Housing

Permissible operating ambient temperature range

Permissible storing ambient temperature range

Weight

Cable inlets

(enclosure threads; M20 x 1.5)

Eyebolt detail

All dimensions in mm

[inches in brackets]

-30 °C to +50 °C (-22 °F to +122 °F)

-30 °C to +70 °C (-22 °F to +158 °F)

approx. up to 63 kg (139 lbs),

(depending on analyzer conguration)

Protection class

Emerson Process Management GmbH & Co. OHG 1-7

IP 66 (EN 60529) / Type 4X for outdoor installation.

Analyzer must not be exposed to direct sun light

Page 28

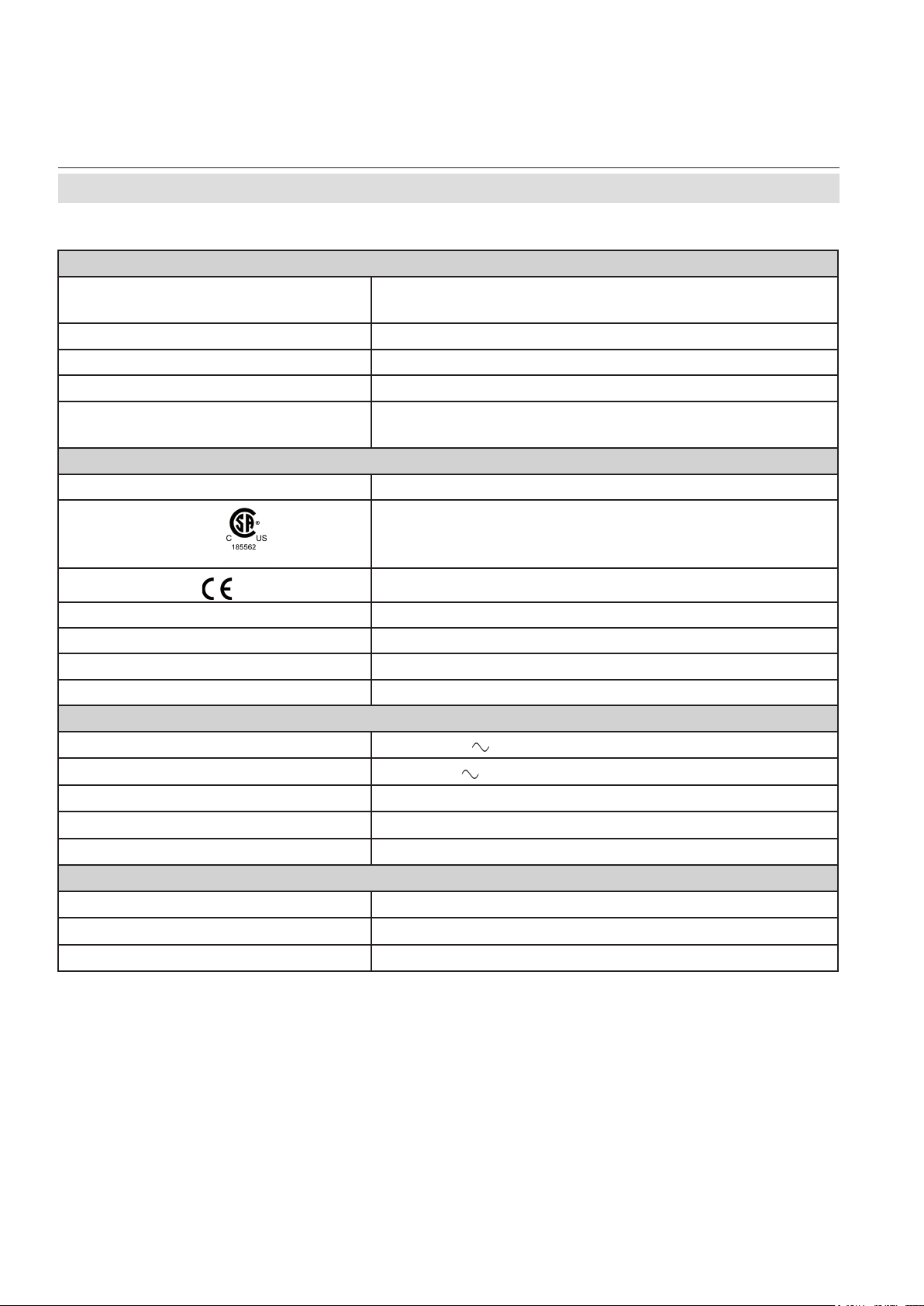

X-STREAM XEFD

1.7 Technical Data

Site of installation

Humidity

(non-consending)

Pollution degree 2

Installation category II

Altitude 0 to 6560 ft (2000 m) above sea level

Sourrounding atmosphere

General Purpose Compliances

Electrical safety

Canada / USA

< 90 % r.h. at +20 °C (68 °F)

< 70 % r.h. at +40 °C (104 °F)

Analyzers must not be operated in

corrosive atmosphere

CSA-C/US, based on

CAN/CSA-C22.2 No. 61010-1-04 /

UL 61010-1, 2nd Edition

Instruction Manual

HASXEDE-IM-EX

03/2012

Europe

CE, based on EN 61010-1

Electromagnetic compatibility

Europe CE, based on EN 61326

Australia C-Tick

others NAMUR

Power supply

Rated input voltage

100 - 240 V 50 / 60 Hz

Input voltage range 85 - 264 V 47 - 63 Hz

Nominal input current

standard 1.3 - 0,7 A

with temperature control 3 - 1.5 A

Gas connections

Quantity max. 8

Specication

ame arrestors with ttings

Sizes connections: 6/4 mm or 1⁄4“, stainless steel

Tab. 1-1: Generic Analyzer Data

Emerson Process Management GmbH & Co. OHG1-8

Page 29

Instruction Manual

HASXEDE-IM-EX

03/2012

1.7 Technical Data

Standard interfaces

electrical

up to 5 analog outputs

(standard: 1 analog output

per channel)

4 relay outputs

2 Modbus interfaces Ethernet (RJ45 sockets), 10/100 MBit

specication

function

electrical

specication

function

specication USB 1.0

4 (0)–20 mA (RB ≤ 500 Ω)

optically isolated from each other and from analy-

zer electronics

user-congurable activation and deactivation of

concentration levels

support for NAMUR NE 43 operation modes, con-

gurable via keypad and Modbus

dry contacts

max. load. 30 V; 1 A; 30 W resistive

Each output can be congured to provide any of

the functions listed in chapter 6 of the X-STREAM

XE instruction manual. These functions include,

but are not limited to

NAMUR NE 107 status signals 'Failure', 'Main-

tenance request', 'Out of specication', 'Function

check',

concentration alarms,

control signals for external valves or pumps,

and many more

X-STREAM XEFD

Techn. Description

1

1 USB connector type A,

2 USB ports

function

Tab. 1-2: Standard Interfaces Data

Emerson Process Management GmbH & Co. OHG 1-9

for connecting external storage devices

1 USB connector type mini AB,

for connecting external computers

Page 30

X-STREAM XEFD

Optional interfaces

Digital I/O board

7 or 14 digital inputs

9 or 18 additional relay outputs

1.7 Technical Data

max. 30 V, internally limited to 2.3 mA

electrical

specication

HIGH: min. 4 V; LOW: max. 3 V

common GND

Each input can be congured to any of

the functions listed in chapter 6 of the

X-STREAM XE instruction manual, e. g.

function

Dry relay change-over contacts can be

electrical

used as NO or NC

specication

max. load. 30 V; 1 A; 30 W resistive

Each output can be congured to provi-

de any of the functions listed in chapter

6 of the X-STREAM XE instruction manual

These functions include, but are not limited to

function

NAMUR NE 107 status signals 'Failure',

'Maintenance request', 'Out of specication', 'Function check',

concentration alarms,

control signals for external valves or

pumps,

and many more

Instruction Manual

HASXEDE-IM-EX

03/2012

Open valve

Activate sample gas pump

Zero calibrate all channels

Span calibrate all channels

Zero and span calibrate all channels

Abort calibration

.

Tab. 1-3: Optional Interfaces Data

Emerson Process Management GmbH & Co. OHG1-10

Page 31

Instruction Manual

HASXEDE-IM-EX

03/2012

Optional interfaces

2 Analog inputs

1 Interface

1 Service interface

X-STREAM XEFD

1.7 Technical Data

0–1 V, 0–10 V (software selectable)

Rin = 100 kΩ

optional (requires to t wire bridges,

electrical

specication

function

electrical

specication

function RS232C, RS485 or Modbus

electrical

specication

function Only to be used by Emerson personnel

Chapter 2 'Installation'):

4 (0)–20 mA ; Rin = 50Ω

optically isolated from analyzer GND

protected against overload up to ±15 V

or ±20 mA

Input analog signals from external devices, such as e.g.

pressure transmitters,

ow sensors,

analyzers, etc.

for compensation or other purposes

9-pin,optically isolated from analyzer elec-

tronics

RS232C,

NOT optically isolated from analyzer

electronics

Techn. Description

1

Tab. 1-3: Optional Interfaces Data (cont‘d)

Emerson Process Management GmbH & Co. OHG 1-11

Page 32

X-STREAM XEFD

1.7 Technical Data

Increased sample and calibration gas pressure

Increased gas pressure

Maximum ow 1.5 l/min.

Special conditions

Connection of breathing

device

Above 1100 hPa to max. 1500 hPa (take

care

of the measurement principles limits!)

The gas paths need additionally to be protected by suitable inline

ame arrestors, designed and approved for the applied higher gas

pressure. These inline ame arrestors need to be installed outside

the analyzer and in addition to the ame arrestors provided by the

analyzer. A seperate analyzer ame arrestor has to be installed,

operating as a breathing device.

The external output of the breathing device (exhaust) can be open

to the ambience of the analyzer, if the measured gas concentration

is below 25 % V-V LEL. Otherwise it must end in safe area.

Instruction Manual

HASXEDE-IM-EX

03/2012

Consider the special conditions for safe use (

Tab. 1-4: Increased Pressure Data

Purging the housing to reduce cross-interference

Maximum gas ow 2 l/min

Inert gas or air. Dry, clean, free of corrosives or components contai-

Permitted purge medium

ningsolvents, and free of components to be measured. Its temperature must correspond to the ambient temperature of the analyzer,

but be at least within the range 20-35 °C (68-95 °F)

Special conditions

The medium must be supplied via a separate ame arrestor. Another

ame arrestor must be installed, operating as a breathing device.

The external output of the breathing device (exhaust) can be open to

Connection of breathing

device

the ambience of the analyzer, if inert gas is used as purge medium.

If air is used, the output must end in a safe area, if the measured

gas concentration is above 25% V-V LEL.

Consider the special conditions for safe use (

1-5 )

1-5 )

Tab. 1-5: Purging Gas Data

Emerson Process Management GmbH & Co. OHG1-12

Page 33

Instruction Manual

HASXEDE-IM-EX

03/2012

Signal inputs and outputs

Signal connections

Analog and digital I/O

Other

Cable glands

Types

Permissible outer cable diameter

X-STREAM XEFD

1.7 Technical Data

screw terminals max. 1.5 mm² (14 AWG);

end sleeves not required

Ethernet: RJ45 sockets; USB-connections

Cable entry via, IP 68, or conduits with metric-to-NPT adaptor

3…13 mm (0.11 to 0.5 inch),

see cable gland / conduit specication

*)

Techn. Description

1

Detailed terminals conguration 2 Installation

1 Ethernet & USB

2 Analog & digital I/O terminal strips

3 Max. 3 signal cables entries

1 2 3

Note!

Depending on the actual analyzer conguration

not all shown, or different terminals may be provided!

Fig. 1-5: Signals Terminals

Emerson Process Management GmbH & Co. OHG 1-13

Page 34

X-STREAM XEFD

1.7 Technical Data

Power Connection

Power connections

Power supply

Power supply fuses

Fuse ratings AC 230 V / T 4 A / 5x20 mm

Cable glands

Types

Connection via internal screw terminals near cable entries,

max 4mm² (10 AWG), end sleeves not required.

Cable gland, classied IP 68 or suitable conduit with metric-

to-NPT adaptor

Instruction Manual

HASXEDE-IM-EX

03/2012

Permissible outer cable diameter

1 Power terminals with integrated

fuse holders

2 Protective earth terminal (PE)

3 Power cable entry

4 EMI power supply lter

3…13 mm (0.11 to 0.5 inch),

see cable gland / conduit specication

1

4

3

2

Fig. 1-6: Power Terminals / Fuse Holders

Emerson Process Management GmbH & Co. OHG1-14

Page 35

Instruction Manual

HASXEDE-IM-EX

03/2012

X-STREAM XEFD

1.8 Measurements Specications

1.8 Measurements Specications

Sample gas components and measuring ranges (standard congurations)

In total, more than 60 gases are detectable, so the following table gives an overview only.

Consult with Emerson for gases / congurations not listed.

Not all data is applicable to all analyzer variations. The sample gas(es) and measuring ranges

for your specic analyzer are given by the order acknowledgement and on the analyzer's name

plate label.

Special Specs

or Conditions

Gas component Principle

Acetone

Acetone

1

1

CH3COCH

CH3COCH

Acetylene C2H

Ammonia NH

3

3

2

3

UV 0–400 ppm 0–800 ppm 0–3 %

IR 0–500 ppm 0–1000 ppm 0–3 %

IR 0–3 % 0–6 % 0–100 %

IR 0–100 ppm 0–200 ppm 0–100 %

Lowest

Range

Argon Ar TCD 0–50 % 0–100 % 0–100 %

Carbon dioxide CO

2

IR 0–5 ppm

Carbon monoxide CO IR 0–10 ppm 50–50 ppm 0–100 ppm 0–100 %

Chlorine Cl

Ethane C2H

Ethanol

1

C2H5OH IR 0–1000 ppm 0–2000 ppm 0–10 %

Ethylene C2H

2

6

4

UV 0–300 ppm 0–600 ppm 0–100 %

IR 0–1000 ppm 0–2000 ppm 0–100 %

IR 0–400 ppm 0–800 ppm 0–100 %

Helium He TCD 0–10 % 0–20 % 0–100 %

Hexane

Hydrogen

1

4

C6H

H

14

2

IR 0–100 ppm 0–200 ppm 0–10 %

TCD 0–1 %

Hydrogen Sulde H2S UV 0–2 % 0–4 % 0–10 %

Hydrogen Sulde H2S IR 0–10 % 0–20 % 0–100 %

Methane CH

Methanol

1

CH3OH IR 0–1000 ppm 0–2000 ppm 0–10 %

n–Butane C4H

Nitrogen dioxide

1

NO

4

10

2

IR 0–100 ppm 0–200 ppm 0–100 %

IR 0–800 ppm 0–1600 ppm 0–100 %

UV 0–25 ppm 30–50 ppm 0–100 ppm 0–10 %

Nitrogen monoxide NO IR 0–100 ppm 0–200 ppm 0–100 %

Nitrous oxide N2O IR 0–100 ppm 0–200 ppm 0–100 %

Oxygen O

Oxygen O

Oxygen, Trace O

Propane C3H

Propylene C3H

Sulfur dioxide SO

Sulfur dioxide SO

Sulfur hexauoride SF

Toluene

1

C7H

electrochem. 0–5 % – 0–25 %

2

2

2

6

paramagn. 0–1 % 0–2 % 0–100 %

electrochem. 0–10 ppm – 0–10 000 ppm

8

6

2

2

IR 0–1000 ppm 0–2000 ppm 0–100 %

IR 0–400 ppm 0–800 ppm 0–100 %

UV 0–25 ppm 30–50 ppm 0–130 ppm 0–1 %

IR 0–1 % 0–2 % 0–100 %

IR 0–5 ppm

8

UV 0–300 ppm 0–600 ppm 0–5 %

Vinyl chloride C2H3Cl IR 0–1000 ppm 0–2000 ppm 0–2 %

Water vapor

Water vapor, Trace

1

Dew point below ambient

temperature

1

H2O IR 0–1000 ppm 0–2000 ppm 0–8 %

1

H2O capacitive 0–100 ppm – 0–3000 ppm

2

Higher concentrations

decrease sensor lifetime

3

Daily zero calibration re- quired for ranges below lowest

standard specs range

Tab. 1-6: Gas Components and Measuring Ranges, examples

Standard Specs

(see Tab. 1-7 – 1-9)

Lowest

Range

5

0–50 ppm 0–100 ppm 0–100 %

Enhanced Specs

(see Tab. 1-7 & 1-9)

Lowest

Range

0–2 %

3

0–20 ppm 0–50 ppm 0–2 %

4

Special "renery" application with 0–1% H2 in N2

available

Highest

Range

0–100 %

5

see Tab. 1-10

6

standard specs only

2 6

6

Techn. Description

1

6

Emerson Process Management GmbH & Co. OHG 1-15

Page 36

Instruction Manual

X-STREAM XEFD

1.8 Measurements Specications

Standard and Enhanced Performance Specications

NDIR/UV/VIS Thermal Conductivity (TCD)

Detection limit (4 σ)

Linearity

1 4

Zero-point drift

Span (sensitivity) drift

Repeatability

1 4

1 4

1 4

1 4

Response time (t90) 3 4 s ≤ t90 ≤ 7 s

Permissible gas ow 0.2–1.5 l/min. 0.2–1.5 l/min.

Inuence of gas ow

Maximum gas pressure

Inuence of pressure

1 4

8 9

2

– At constant temperature ≤ 0.10 % per hPa ≤ 0.10 % per hPa

– With pressure compensation

Permissible ambient temperature

Inuence of temperature

1 14

(at constant pressure)

– On zero point ≤ 1 % per 10 K ≤ 0.5 % per 10 K ≤ 1 % per 10 K ≤ 0.5 % per 10 K

– On span (sensitivity) ≤ 5 % (0 to +50 °C / 32 to 122 °F) ≤ 1 % per 10 K

Thermostat control

Warm-up time

1

Related to full scale

2

Related to measuring value

3

From gas analyzer inlet at gas ow of 1.0 l/min

(electronic damping = 0 s)

4

Constant pressure and temperature

5

Dependent on integrated photometer bench

6 13

6

Standard Spec Enhanced Spec Standard Spec Enhanced Spec

≤ 1 % ≤ 0.5 % ≤ 1 % ≤ 0.5 %

≤ 1 % ≤ 1 %

≤ 2 % per week ≤ 1 % per week ≤ 2 % per week ≤ 1 % per week

≤ 0.5 % per week ≤ 1 % per month ≤ 1 % per week

≤ 0.5 % ≤ 0.5 %

5

≤ 0.5 % ≤ 1 %

15 s ≤ t90 ≤ 30 s

12

≤ 1500 hPa abs. (≤ 7 psig) ≤ 1500 hPa abs. (≤ 7 psig)

7

10

0 (-20) to +50 °C (32 (-4) to 122 °F) 0 (-20) to +50 °C (32 (-4) to 122 °F)

≤ 0.01 % per hPa ≤ 0.01 % per hPa

none / 60 °C (140 °F) 5 none / 60 °C (140 °F) 11

15 to 50 minutes

5

approx. 50 minutes

Note! 1 psi = 68.95 hPa

6

Depending on measuring range

7

Pressure sensor is required

8

Special conditions for > 1.100 hPa abs.

9

Limited to atmospheric if internal sample pump

10

Temperatures below 0 °C (-4 °F) with thermostat

control only

11

Thermost. controlled sensor: 75 °C (167 °F)

12

Flow variation within ± 0.1 l/min

13

Optional thermostatically controlled box with

temperature 60 °C (140 °F)

14

Temperature variation: ≤ 10 K per hour

HASXEDE-IM-EX

03/2012

6

12

Tab. 1-7: IR, UV, VIS, TCD - Standard and Enhanced Measurement Performance Specications

Trace Moisture (tH2O)

Measurement range -100 to -10 °C dew point (0–100…3000 ppm)

Measurement accuracy ±2 °C dew point

Repeatability 0.5 °C dew point

Response time (t95) 5 min (dry to wet)

Operating humidity 0 to 100 % r.h.

Sensor operating temperature -40 to +60 °C

Temperature coefcient Temperature compensated across operating temperature range

Operating pressure

2

Flow rate

1

If installed in series to another measurement system, e. g. IR channel

2

Special conditions apply to pressures above 1100 hPa

Depending on sequential measurement system, see analyzer specication

max. 1500 hPa abs / 7 psig

Depending on sequential measurement system, see analyzer specication

0.2 to 1.5 Nl/min

Note! 1 psi = 68.95 hPa

(1.5 psig) up to 1500 hPa (7 psig)

Note! Do not calibrate, see special calibration notes in the X-STREAM Enhanced instruction manual!

Tab. 1-8: Trace Moisture - Standard Measurement Performance Specications

Emerson Process Management GmbH & Co. OHG1-16

1

1

Page 37

Instruction Manual

HASXEDE-IM-EX

03/2012

X-STREAM XEFD

1.8 Measurements Specications

Oxygen Sensors

Paramagnetic (pO2) Electrochemical (eO2) Trace (tO2)

Detection limit (4 σ)

Linearity

1 4

Zero-point drift

Span (sensitivity) drift

Repeatability

Response time (t90)

1 4

1 4

1 4

1 4

3

Permissible gas ow 0.2–1.5 l/min 0.2–1.5 l/min. 0.2–1.5 l/min.

Inuence of gas ow 1

Maximum gas pressure

Inuence of pressure

4

7 8

2

– At constant temperature ≤ 0.10 % per hPa ≤ 0.10 % per hPa ≤ 0.10 % per hPa

– With pressure compensation

Permissible ambient temperature 90(-20) to +50 °C (32 (4) to 122 °F) 5 to +45 °C (41 to 113 °F) 5 to +45 °C (41 to 113 °F)

Inuence of temperature

1 13

(at constant pressure)

– On zero point ≤ 1 % per 10 K ≤ 0.5 % per 10 K ≤ 1 % per 10 K ≤ 1 % per 10 K

– On span (sensitivity) ≤ 1 % per 10 K ≤ 1 % per 10 K ≤ 1 % per 10 K

Thermostat control 60 °C (140 °F) 12 none none

Warm-up time Approx. 50 minutes - Approx. 50 minutes

1

Related to full scale

2

Related to measuring value

3

From gas analyzer inlet at gas ow of 1.0 l/min

(electronic damping = 0 s)

4

Constant pressure and temperature

5

Range 0–10…200 ppm: ≤ 5 % (5 to 45 °C /

41 to 113 °F)

6

Pressure sensor is required

Note! Take care of the tO2 sensor‘s documentation, providing important calibration instructions!

Tab. 1-9: Oxygen - Standard and Enhanced Measurement Performance Specications

Standard Spec Enhanced Spec

≤ 1 % ≤ 0.5 % ≤ 1 % ≤ 1 %

≤ 1 % ≤ 1 % ≤ 1 %

≤ 2 % per week ≤ 1 % per week ≤ 2 % per week ≤ 1 % per week

≤ 1 % per week ≤ 0.5 % per week ≤ 1 % per week ≤ 1 % per week

≤ 0.5 % ≤ 1 % ≤ 1 %

< 5 s approx. 12 s 20 to 80 s

11

≤ 2 %

≤ 1500 hPa abs. (≤ 7 psig)

6

≤ 0.01 % per hPa ≤ 0.01 % per hPa ≤ 0.01 % per hPa

14

≤ 1500 hPa abs. (≤ 7 psig) ≤ 1500 hPa abs. (≤ 7 psig)

≤ 2 % ≤ 2 %

Note! 1 psi = 68.95 hPa

7

Special conditions for > 1100 hPa abs. (1.5 psig)

8

Limited to atmospheric if internal sample pump

9

Temperatures below 0 °C (-4 °F) with thermostat

control only

10

Thermost. controlled sensor: 35 °C (95 °F)

11

For ranges 0–5…100 % and ow 0.5…1.5 l/min

12

Optional thermostatically controlled sensor with

temperature 60 °C (140 °F)

13

Temperature variation: ≤ 10 K per hour

14

No sudden pressure surge allowed

5

5

10

Techn. Description

1

Note 1!

Not all data listed are applicable to all analyzer versions (e.g. 60 °C thermostatically controlled

box is not available for electrochemical and trace oxygen).

Note 2!

For NDIR/UV/VIS measurements, take into account that

• sample gas may diffuse or be released by leakages into the analyzer enclosure

• if existent in the analyzer surroundings, the component to be measured may enter the enclosure.

Concentrations then may increase inside the enclosure. High concentrations of the component

to be measured inside the enclosure may inuence the measurement by unintended absorption,

which could cause drift of the measurement.

A remedy for this issue is to purge the housing with gas not containing the component of interest.

Emerson Process Management GmbH & Co. OHG 1-17

Page 38

Instruction Manual

X-STREAM XEFD

HASXEDE-IM-EX

1.8 Measurements Specications

Special Performance Specications for Gas Purity Measurements (ULCO & ULCO2)

0–10…< 50 ppm CO

Detection limit (4 σ)

Linearity

Zero-point drift

1 2

1 2 3

Span (sensitivity) drift

Repeatability

1 2

Response time (t90)

Permissible gas ow 0.2–1.5 l/min.

Inuence of gas ow

Maximum gas pressure

Inuence of pressure

– At constant temperature ≤ 0.1 % per hPa

– With pressure compensation

Permissible ambient temperature +15 to +35 °C (59 to 95 °F) +5 to +40 °C (41 to 104 °F)

Inuence of temperature 6

(at constant pressure)

– On zero point < 2 % per 10 K resp. < 0.2 ppm per 10 K

– On span (sensitivity) < 2 % per 10 K resp. < 0.2 ppm per 10 K

Thermostat control none 60 °C (140 °F)

1

Related to full scale

2

Constant pressure and temperature

3

Within 24 h; daily zero calibration requested

4

Within 24 h; daily span calibration recommended

1 2

1 2 4

7

1 2

10 11

≤ 1500 hPa abs. (≤ 7 psig)

5

8

5

Related to measuring value

6

Temperature variation: ≤ 10 K per hour

7

From gas analyzer inlet at gas ow of 1.0 l/min

8

Barometric pressure sensor is required

0–5…< 50 ppm CO

< 2 %

< 1 %

< 2 % resp. < 0.2 ppm

< 2 % resp. < 0.2 ppm

< 2 % resp. < 0.2 ppm 9

< 10 s

< 2%

≤ 0.01 % per hPa

Note! 1 psi = 68.95 hPa

2

9

9

9

9

9

Whichever value is higher

10

Limited to atmospheric if internal sample pump

Special conditions apply to pressures above

11

1100 hPa

(1.5 psig) up to 1500 hPa (7 psig)

03/2012

Tab. 1-10: Special Performance Specications for Gas Purity Measurements

Emerson Process Management GmbH & Co. OHG1-18

Page 39

Instruction Manual

HASXEDE-IM-EX

03/2012

X-STREAM XEFD

1.9 Vapor Recovery Application

1.9 Vapor Recovery Application (Simultaneous Measurement of CH4 and Non-CH4)

This application is served by a special conguration of the X-STREAM XEFD ameproof

analyzer.

EXPLOSION HAZARD BY HOT COMPONENTS

Temperatures inside an analyzer for VAPOR RECOVERY applications exceed

the analyzer‘s temperature classication for hazardous areas!

Special conditions apply to handling this analyzer, consider the safety

instructions at the beginning of this manual and the special conditions for

safe use

(

1-5 )!

Consider the waiting time statement on the front door label before opening!

Principle of measurement

The sample gas is taken towards a converter.

At it‘s inlet the gas stream is divided into two:

one is directly fed to a non-CH4 measurement.

The other is supplied to a solenoid valve,

normally forwarding the gas to the converter.

Within the converter, hydrocarbons higher

than CH4 are converted into H2O and CO2.

The converter outlet is connected to a second

IR measurement system, analyzing the re-

maing amount of hydrocarbons (mainly CH4)

in the sample gas.

The conguration consists of a dual channel

IR measurement, connected to the inlet and

outlet of a converter. This converter is installed inside the X-STREAM analyzer and is

heated to about 280 °C (536 °F).

&+&+

CH2: non-CH

&+&+

CH1: CH

7

)

)$ )$ )$

9

Converter

&XWWHU

4

4

Techn. Description

1

After switching power on, wait

about 50 min. for the converter

to reach its operating temperature before applying gases!

Fig. 1-7: Vapor Recovery Gas Flow Diagram

Emerson Process Management GmbH & Co. OHG 1-19

FA1: Analyzer‘s inlet ame arrestor

FA2...3: Analyzer‘s outlet ame arrestors

F1: Filter

T1: Throttle

V1: Valve

Page 40

X-STREAM XEFD

1.9 Vapor Recovery Application

Converter efciency

The measurement accuracy is highly depen-

dent on the converter efciency: If this is too

low, the converter material needs replacement.

To measure the converter efciency, one

has to compare the measurement values of

CH1 with and without having the gas owing

through the converter. This requires activating

the valve V1.

For the ease of use, special PLC and calculator programs are provided with analyzers

for vapor recovery applications, automatically

calculating the efciency each time after a calibration has been performed. The calculated

value shows up as a measurement result on

the measurement display.

To calculate the efciency without a preceding calibration, you can also start the PLC

program manually from the webbrowser

interface.

4 Maintenance section of this manual for

instructions about when and how to replace

the converter material. The appendix contains