Instruction Manual

D104239X012

Service Manual for Multiport Flow

™

Selector

Valve

Multiport Flow Selector

January 2019

Contents

Introduction 1.................................

Specifications 3................................

Installation 4..................................

Field Technician Commissioning Activities 5.......

Reinstallation of the Actuator Assembly 5.....

Home Port Calibration 6....................

Electric Actuator Setup 6....................

Maintenance 7.................................

Disassembly 7.................................

Assembly 8....................................

Body 8......................................

Plug 8.......................................

Bonnet 9.....................................

Plug Seal Adjustment 10........................

Troubleshooting 11.............................

Drawing Assembly 12...........................

Parts List 15...................................

Maintenance Checklist Procedure 18..............

Multiport Electric Actuator 19....................

Figure 1. Fisher Multiport Flow Selector Valve

X1398

Introduction

Scope of Manual

This instruction manual includes installation, operation, and maintenance information for the Multiport Flow Selector.

Do not install, operate, or maintain a Multiport Flow Selector without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is

important to carefully read, understand, and follow all the contents of this manual, including all safety cautions and

warnings. If you have any questions about these instructions, contact your Emerson sales office

www.Fisher.com

before proceeding.

Multiport Flow Selector

January 2019

Instruction Manual

D104239X012

Description

The Multiport Flow Selector offers an efficient solution for oil well testing. This valve has eight inlets, one test outlet,

and one group outlet. Eight pipe lines can be connected to this valve and allows continuous flow while

sampling/testing individual oil wells.

Educational Services

For information on available courses for the Multiport Flow Selector valve, as well as a variety of other products,

contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

2

Instruction Manual

D104239X012

Multiport Flow Selector

January 2019

Specifications

The Multiport Flow Selector specifications are given in tables 1 through 5.

Table 1. Valve Specifications NPS 2x4 and 3x6

SPECIFICATIONS

ASME Class Rating

Weight, kg (lb) 91 (200) 91 (200) 363 (800) 553 (1220) 630 (1390) 658 (1450) 680 (1500) 968 (2135)

Inlet Ports NPS 2 NPS 3

Test Outlet Port NPS 2 NPS 3

Group Outlet Port NPS 4 NPS 6

End Connections Mates with raised-faced flanges per ASME B16.5

Temperature Range

Shutoff ANSI/FCI 70-2 Class IV

1. The pressure/temperature limits in this instruction manual and any applicable standard or code limitation should not be exceeded.

2. Standard O-ring material established upper and lower temperature limits.

(1)

CL300 CL600 CL900 CL150 CL300 CL600 CL900 CL1500

(2)

2 x 4 3 x 6

Table 2. Valve Specifications NPS 4x8, 4x10, and 6x16

SPECIFICATIONS

ASME Class Rating CL300 CL600 CL900 CL1500 CL300 CL600 CL900 CL1500 CL2500

Weight, kg (lb)

Inlet Ports NPS 4 NPS 4 NPS 6

Test Outlet Port NPS 4 NPS 4 NPS 6

Group Outlet Port NPS 8 NPS 10 NPS 16

End Connections Mates with raised-face flanges per ASME B16.5

Temperature Range

Shutoff ANSI/FCI 70-2 Class IV

1. The pressure/temperature limits in this instruction manual and any applicable standard or code limitation should not be exceeded.

2. Standard O-ring material established upper and lower temperature limits.

(1)

959

(2115)

4 x 8 4x10 6 x 16

975

(2150)

1134

(2500)

1742

(3840)

VALVE SIZE

-1 to 204°C (30 to 400°F)

VALVE SIZE

1810

(3990)

-1 to 204°C (30 to 400°F)

2018

(4450)

3590

(7915)

5343

(11780)

8704

(19190)

SPO

Compact

Flange

Table 3. Actuator Specifications

SPECIFICATIONS

Max Torque Output,

Nm (ftlbf)

Actuator Speed, RPM 1.0 0.5-1.0 0.5-1.0 0.5-1.0 0.3-0.5

Actuator Weight, kg (lb) 82 (180)

Plug Position Accuracy ± 1°

NPS 2 x 4

CL300/600/900

203 (150) 881 (650) 1085 (800) 1085 (800) 2034 (1500)

VALVE SIZE AND ASME CLASS RATING

NPS 3 x 6

CL150/300/

600/900/1500

NPS 4 x 8

CL300/600/900

NPS 4 x 10

CL1500

NPS 6 x 16

CL300/

600/900/

1500/2500

3

Multiport Flow Selector

January 2019

Instruction Manual

D104239X012

Installation

Minimum Tools Required

A torque wrench, socket wrench, and Allen head wrenches are required to install the Multiport Flow Selector Valve and

actuator assembly.

Table 4. Socket Size for Multiport Bonnet Studs and Nuts

VALVE SIZE, NPS ASME CLASS RATING SOCKET SIZE (in)

CL300

2 x 4

3 x 6

4 x 8

4 x 10 CL1500 2-3/4

6 x 16

CL600

CL900

CL150

CL300

CL600

CL900

CL1500 2-3/8

CL300

CL600

CL900

CL300

CL600

CL900 3-1/8

CL1500 3-7/8

CL2500 5

1-5/8

2

2-3/16

2-9/16

Other socket sizes (inch) required: 7/16, 1/2, 9/16, 3/4, 7/8, and 1-1/8.

Allen key sizes (inch) required: 5/32, and 1/4

Table 5. Wrench Sizes (Inch) for Multiport Inlet and Outlet Flanges

FLANGE SIZE, NPS

2 - - - 1-1/16 1-1/16 1-7/16 - - - - - -

3 1-1/16 1-1/4 1-1/4 1-7/16 1-13/16 - - -

4 - - - 1-1/4 1-7/16 1-13/16 2 - - -

6 1-1/4 1-1/4 1-5/8 1-13/16 2-3/16 1-13/16

8 - - - 1-7/16 1-13/16 2-3/16 - - - - - -

10 - - - - - - - - - - - - 2-15/16 - - -

16 - - - 2 2-3/8 2-9/16 3-7/8 3-1/2

CL150 CL300 CL600 CL900 CL1500 CL2500

ASME CLASS RATING

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury. Check with your process or safety engineer for any additional measures that must be taken to protect against

process media.

Avoid personal injury and property damage by keeping hands, tools, and other objects away from the plug while operating

the valve.

Observe all WARNING decals and tags.

4

Instruction Manual

D104239X012

Multiport Flow Selector

January 2019

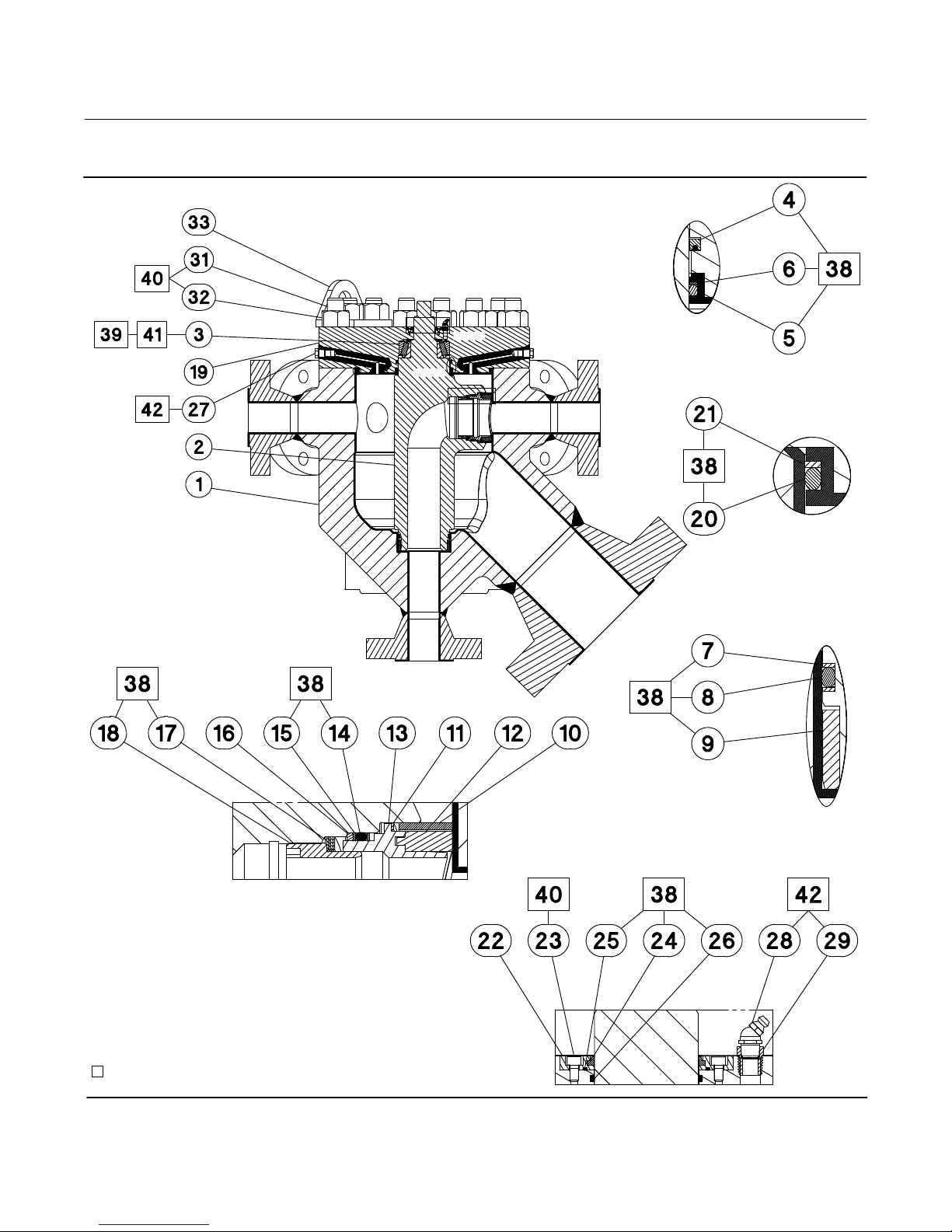

Key numbers in this procedure are shown in figure 2 and 3 unless otherwise indicated.

Before installing the unit, observe all warning tags and:

1. Check for external physical damage.

2. Check for any visible leakage of gear oil from the Multiport Electric Actuator (MPA).

3. Visually inspect the inside of the Multiport through the group outlet port checking for damage, rust, and/or debris.

4. Verify the voltage requirement of the MPA (AC/DC) and connect power supply and signal circuits to test the

operation of the electric actuator and plug. Check for proper plug alignment at each port.

5. Inspect connecting piplines to be certain they are free of foreign material such as pipe scale or weld slag that could

damage the sealing surfaces fo the Multiport Flow Selector valve.

6. Provide appropriate flange gaskets and install them between the pipe flanges and valve body flanges. Tighten

flange bolting in a star pattern to ensure uniform compression of the gaskets.

Note

To prevent seal damage when hydrotesting external piping, position the plug midway between two inlet ports in order to equalize

pressure between the plug and valve body.

The Multiport Flow Selector plug/port alignment is factory adjusted when supplied with an actuator and should not require further

adjustment.

Field Technician Commissioning Activities

Refer to the Multiport Actuator (MPA) O&M Manual — Supplied by Bettis (MPA-400-0711). See page 19 for detailed

commissioning activities.

CAUTION

Replace pipe plug with breather before operating unit. The valve body may be pressurized from hydrostatic testing. Do not

remove any bolts or flanges for inspection until after the unit has been depressurized.

Circuit boards are susceptible to damage from static discharge when touched. Ensure that you ground yourself before

touching the knobs on the electric actuator.

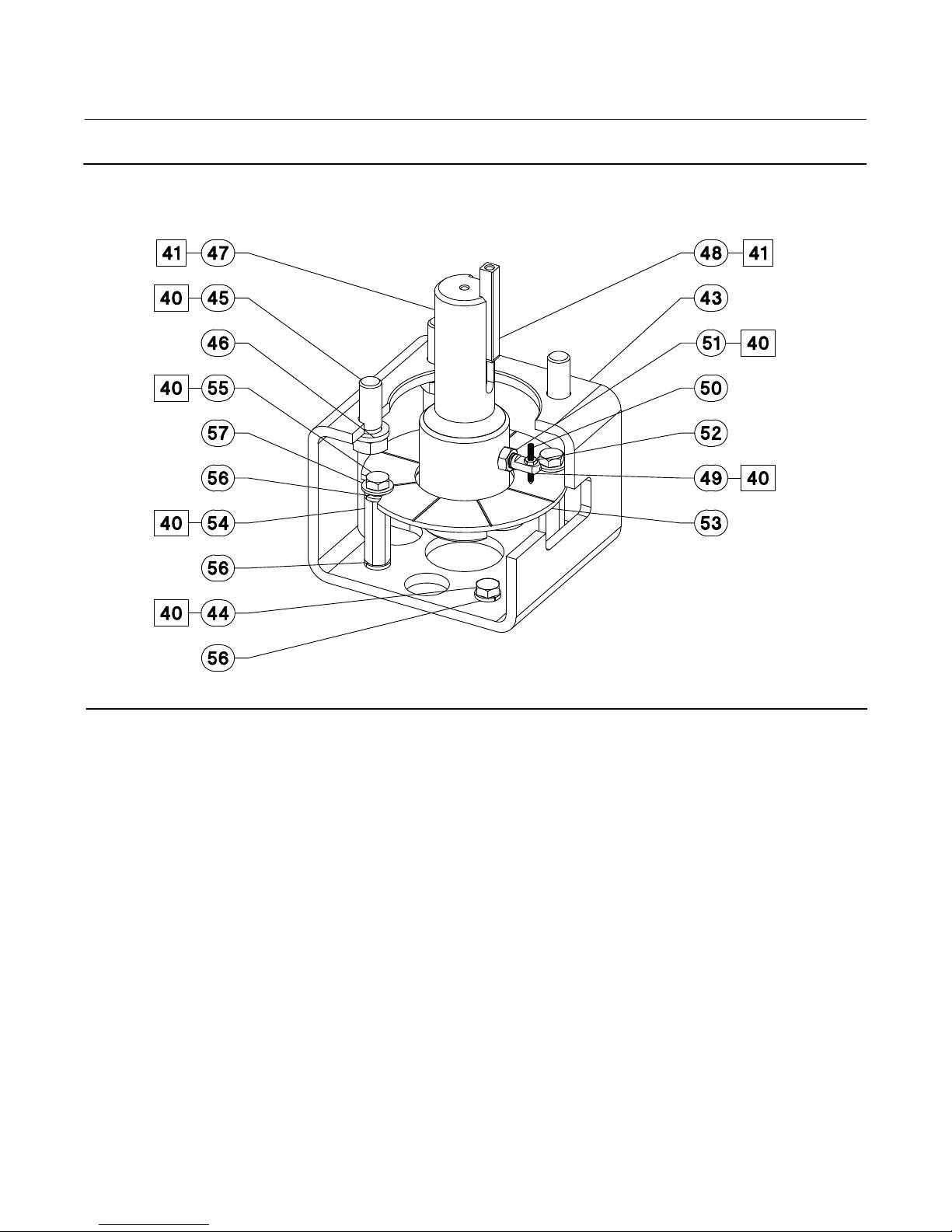

Reinstallation of the Actuator Assembly

1. Using a manual wrench, rotate the plug (key 2) a few revolutions to verify it turns freely. Initial effort required to

rotate the plug could be high if the plug has not been rotated for an extended period of time.

2. Secure the actuator mounting bracket (key 43) to the bonnet using two cap screws (key 44), two travel indicator

studs (key 54), and four lock washers (key 56). For the NPS 2x4 construction, secure the lower plate to the bonnet

using two cap screws, two travel indicator studs and nuts, and four lock washers.

Regardless of size, apply an anti-seize lubricant (key 40) to the threaded portion of the fasteners. The cap screws

should be spaced 180 degrees apart from one another and 90 degrees apart from the travel indicator studs.

3. Secure the travel indicator plate to the travel indicator studs by tightening two cap screws (key 55). Proper

assembly has occurred if the lock washers have been placed between the travel indicator studs and travel indicator

plate and if flat washers (key 57) have been placed between the cap screws and travel indicator plate. For the 2x4

construction, place travel indicator spacers over the travel indicator studs and secure the travel indicator plate

5

Multiport Flow Selector

January 2019

down by tightening the nuts. Proper assembly has occurred if there are flat washers between the travel indicator

spacers and travel indicator plate and travel indicator plate and nuts.

Instruction Manual

D104239X012

Regardless of size, an anti-seize lubricant (key 40) shall be applied to the threaded portion of the fasteners and nuts

4. To complete the assembly of the mounting kit for the NPS 2x4 construction, thread four spacer studs into the lower

plate and secure the upper plate to the spacer studs using four cap screws. Proper assembly has occurred if there

are lock washers between the lower plate and spacer studs and spacer studs and upper plate. An anti-seize lubricant

(key 40) shall be applied to the threaded portion of the studs and fasteners.

5. Apply grease (key 41) to the surfaces on the key slot(s) found on the shaft coupler (key 47). Insert key(s) (key 48)

into the shaft coupler key slot(s). Insert the shaft coupler with key(s) into the bottom of the Multiport Electric

Actuator and hold in place by hand.

6. Slowly lower the actuator with shaft coupler (key 47) onto the mounting bracket (key 43). Align the shaft coupler

with the square end of the plug (key 2). Position the shaft coupler such that the reference mark on the square end of

the plug remains visible between the flats of the shaft coupler. This reference mark indicates the location of the seal

assembly relative to the inlet ports of the body.

7. Attach the actuator to the mounting bracket (key 43) using four cap screws (key 45) and four lock washers (key 46).

Tighten these fasteners finger tight only.

8.

Apply an anti-seize lubricant (key 40) to the travel indicator holder (key 49) and thread on the jam nut (key 51), as

well as the travel indicator pointer (key 50) and nut (key 52). Thread this assembly into the shaft coupler (key 47).

The travel indicator pointer shall be on the same side as the reference mark found on the square end of the plug and

shall be positioned such that it will not contact any parts of the travel indicator assembly while rotating.

9. Using the electric actuator, rotate the plug (key 2) a few revolutions to establish proper alignment between the

shaft coupler (key 47) and plug. Visually check for any binding and adjust the position of the actuator as necessary.

Once the proper alignment has been established, secure the actuator to the mounting bracket (key 43) by

tightening the cap screws (key 46).

Home Port Calibration

.

Refer to the Multiport Electric Actuator (MPA) O&M Manual — Supplied by Bettis (MPA-400-0711) for detailed

instructions on how to calibrate the home port position.

Multiport Electric Actuator Set Up

Refer to the Multiport Electric Actuator (MPA) O&M Manual — Supplied by Bettis (MPA-400-0711) for detailed

instruction on:

1. Disabling port positions

2. Controller address

3. Control room MODBUS RTU operation

4. Installation and use of MPA software on laptop/PC

6

Instruction Manual

D104239X012

Multiport Flow Selector

January 2019

Maintenance

Refer to figure 2 and 3, typical Multiport assembly and mounting drawings.

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly rotate the plug.

D Use bypass valves or completely shut off the process to isolate the Multiport from process pressure. Relieve process

pressure from all parts of the valve. Drain the process media from all sides of the Multiport.

D Use lockout procedures to be sure the above measures stay in effect while you work on the equipment.

D Always wear protective gloves, clothing and eyewear when performing any maintenance operations to avoid personal

injury.

D The tapered roller bearing area may contain process fluids that are pressurized, even when the valve has been removed

from the pipeline. Process fluids may spray out under pressure when separating the bonnet from the plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

The Multiport Flow Selector valve is shipped completely greased and lubricated. Routine maintenance of this valve is

recommended, especially if it has been stored for an extended amount of time. Maintenance steps include:

1. Keeping the tapered roller bearing (key 3) greased. A high temperature silicone grease (key 39) can be injected into

the bearing housing through the lube fitting (key 28).

2. Confirming proper alignment between the plug and inlet ports.

D Verify the correct placement of the travel indicator pointer (key 50) onto the coupler (key 47).

D Align the plug (key 2) with one of the inlet ports. Confirm the travel indicator pointer is in alignment with the

selected inlet port.

3. Visual inspection of the seal insert (key 12). The sealing surface of this insert should be smooth and completely

intact.

D If the seal insert needs to be replaced, replace all o-rings (key 5, 7, 14, 20, 25, and 26), backup rings (key 6, 8, 15,

and 21), rod seal (key 4), plug bushing (key 9), and wiper seals (key 24).

4. Rotate the plug (key 2) one complete revolution using the electric actuator to confirm the assembly is functioning

properly. Check the local display unit on the electric actuator for any alarm codes.

Disassembly

Review warnings found in the Maintenance section of this manual.

Refer to figures 2 and 3 when disassembling the Multiport Flow Selector.

7

Multiport Flow Selector

January 2019

Note

The bonnet can be removed with the Multiport Electric Actuator still attached. If this is done, ensure proper orientation has been

maintained between the actuator and valve body once the bonnet has been re-installed onto the valve body. If this orientation has

not been maintained, recalibration of the actuator is required. One way to ensure proper orientation has been maintained is to

place alignment marks between the plug (key 2) and coupler (key 47) prior to removal of the bonnet (key 19).

1. Rotate the plug (key 2) to any unused inlet port. Remove the blind flange from this inlet port to gain access to the

seal assembly. Once the adjustment tool has been secured to the seal adjuster (key 18), rotate this tool clockwise

until it stops. This action unloads the wave springs (key 11, 17) and removes the forces generated between the seal

insert (key 12), valve body (key 1) and scraper (key 12)/valve body (key 1).

2. Remove the nuts (key 32) from the bonnet (key 19), lifting lugs (key 33), and the studs (key 31) from the body (key

31). Thread eye bolts into the jack screws holes provided in the bonnet. Raise the bonnet vertically until it clears the

plug (key 2) and move it to the side.

3. Remove the plug (key 2) from the valve body (key 1). The seal components should still be installed inside of the

plug.

4. Remove the seal assembly from the plug (key 2) using the adjustment tool as follows:

D Once the adjustment tool has been inserted into the seal adjuster (key 18) and secured, rotate the tool

counterclockwise until the seal adjuster disengages from the final thread on the plug.

Instruction Manual

D104239X012

D With the adjustment tool still secured to the seal adjuster (key 18), pull it out of the plug. All components that

make up the seal assembly are now outside of the plug.

5. Carefully remove the bearing cup (key 3) from the bonnet (key 19).

6. Inspect all components for damage. Replace any damaged parts and reassemble by following the Assembly

procedure in this manual.

Assembly

Refer to figures 2 and 3 when assembling the Multiport Flow Selector.

Ensure all parts are clean and in good condition before assembling the Multiport Flow Selector. Refer to figure 2 to

determine which components require lubrication.

Body (Key 1)

1. Visually inspect all internal and external surfaces and threads.

2. Install the plug bushing (key 9) into the lower section of the body.

Plug (Key 2)

1. Install the lower plug O-ring (key 8), with the correct number of backup rings (key 7). For ASME rated CL150, 300,

600, and 900 valves, install one backup ring above (on the side nearest to the bonnet) the O-ring. For CL1500 and

2500 rated Multiports, install two backup rings one on either side of the lower plug O-ring.

2. Lubricate and install the seal adjuster (key 18) by turning it clockwise (i.e. viewing toward the plug centerline) until

solid. Follow with the correct number of wave springs (key 17). For NPS 2x4, 3x6, and 6x16 constructions, install

three wave springs. For NPS 4x8 and 4x10 constructions, install four wave springs. Ensure the wave springs are

properly aligned and seated on the seal adjuster.

Note

If the wave springs are not properly aligned and seated then the seal assembly may not function properly.

8

Instruction Manual

D104239X012

Multiport Flow Selector

January 2019

3. Install the back up plate (key 16) against the shoulder in the plug (key 2).

4. Install the O-ring (key 14) onto the seal carrier (key 13). Install the seal assembly into the plug. Hand force should

only be required for proper installation.

5. Install the correct number of wave springs (key 11) followed by the scraper (key 10) into the plug over the seal

assembly. For NPS 2x4 constructions, install two wave springs and for NPS 3x6, 4x8, 4x10, and 6x16 constructions,

install one wave spring.

Ensure the scraper fits freely into the plug. Check by pushing the scraper into the plug using

both hands then letting go to see if it returns to its original position.

6. Lower the plug (key 2) into the body ensuring that the seal insert (key 12) and scraper (key 10) clear the bore of the

body (key 1). When installed, the plug rests on top of the plug bushing (key 9).

7. Lubricate the tapered bearing cone and rollers (key 3) using a high temperature silicone grease (key 39) and install

onto the plug.

Bonnet (Key 19)

1. Lubricate and press fit the bearing cup (key 3) into the bonnet using a high temperature silicone grease (key 39).

Lubricate the bearing cup and press fit it into the bonnet.

2. Install the backup ring (key 6), O-ring (key 5), and rod seal (key 4) into the bonnet bore. Rod seal is not required for

NPS 2x4 or 3x6 CL300, 600, and 900 rated valves.

3. Install the bonnet O-ring (key 20) into the groove of the bonnet. For NPS 4x8, 4x10, and 6x16 constructions, install

the backup ring above this O-ring.

4. Install the wiper seal (key 24), lube fitting (key 28), and vent plug (key 27). For NPS 4x10 and 6x16 constructions,

install the wiper seal on an external wiper retainer (key 24) with two extra O-rings (key 25 and 26).

5. Using two eye bolts threaded into the jack screw holes found on the bonnet, slowly lower the bonnet onto the

body. Be careful not to damage any soft parts when feeding the plug through the bonnet. The bonnet has been

properly positioned onto the body when the following has been achieved:

D The bolt holes in the bonnet have been aligned with the stud holes in the body.

D The centerline of the bonnet vent port has been aligned with the centerline of the group outlet of the body.

Excessive force should not be required to properly seat the bonnet onto the body. For NPS 2x4, 3x6, and 4x8

constructions, use hoist rings or eye bolts with 1/2 UNC threads. For NPS 3x6 CL1500, 4x10, and 6x16

constructions, use hoist rings or eye bolts with 3/4 UNC threads.

6. Lubricate studs (key 31) with an anti-seize lubricant (key 40) and thread into valve body (key 1). Place the

appropriate number of lifting lugs (key 33) over these studs. The placement of these lifting lugs should be equally

spaced with one being located directly above the group outlet. The placement of these lifting lugs is as follows:

D For NPS 2x4, 3x6, 4x8, and 4x10 constructions, place two lifting lugs equally spaced with one being located

directly above the group outlet port.

D For NPS 6x16 CL300, 600, and 900 constructions, place three lifting lugs equally spaced with two of them

straddling the group outlet port.

D For NPS 6x16 CL1500 and 2500 constructions, place four lifting lugs equally spaced with two of them straddling

the group outlet port.

7. Lubricate the threads and the bottom surface of the nuts (key 32) with an anti-seize lubricant (key 40) paste prior to

threading them on to the studs (key 31). Once all nuts have been threaded hand tight, tighten two nuts spaced

180-degrees apart to the recommended torque values per table 6. Rotate the plug (key 2) one complete revolution

to ensure that it rotates with minimal resistance. If the plug rotates smoothly, then proceed to tighten the

remaining nuts using an appropriate tightening pattern.

8. Using the lube fitting (key 28), fill the bearing bore with grease.

9

Multiport Flow Selector

January 2019

Instruction Manual

D104239X012

Table 6. Bonnet Bolting Torque

VALVE SIZE,

NPS

2 x 4

3 x 6

4 x 8

4 x 10 1500 44.5 1-3/4 1356 1000

6 x 16

ASME

CLASS RATING

300

600

900

150

300

600

900

1500 38.1 1-1/2 814 600

300

600

900

300

600

900 50.8 2 2034 1500

1500 63.5 2-1/2 4203 3100

2500 82.6 3-1/4 10170 7500

STUD SIZE TORQUE

mm Inch Nm ftlbf

25.4 1 217 160

31.8 1-1/4 441 325

34.9 1-3/8 651 480

41.3 1-5/8 1085 800

Plug Seal Adjustment

1. Prior to adjusting the seal assembly (key 12 and 13), align the plug (key 2) with an open inlet port and insert the

supplied adjustment tool. Once this tool has been secured to the seal adjuster (key 18), rotate this tool counter

clockwise until the scraper (key 10) touches the inside surface of the body (key 1). The resistance to rotate the

adjustment tool will increase once the scraper contacts the body. Remove the adjustment tool.

2. Rotate the plug (key 2) a few revolutions to check for binding or excessive turning torque. If the plug rotates

smoothly, then insert, secure, and rotate the adjustment tool counter clockwise to tighten the seal adjuster (key

18) to the appropriate torque value listed in table 7.

Note

Do not exceed the torque values listed in table 7. Exceeding these values may cause the valve to not function as intended.

Table 7. Plug Seal Torque

VALVE SIZE, NPS ASME CLASS RATING

2 x 4

3 x 6

4 x 8

4 x 10 1500 54 40

6 x 16

10

Nm ftlbs

300

600

900

150

300

600

900

1500

300

600

900

300

600

900

1500

2500

TORQUE

41 30

48 35

41 30

54 40

95 70

Instruction Manual

D104239X012

3. Rotate the plug (key 2) a few revolutions while checking for smooth movement. If the seal assembly is binding

during rotation, then the seal assembly or the wave springs (key 17) are not in their proper position(s). See

disassembly procedure, if required.

4. Install the appropriate amount of pipe plugs (key 27).

5. Perform any required functionality test(s).

Multiport Flow Selector

January 2019

Troubleshooting

Actuator Does Not Align Plug to Inlet Port

1. Check the shaft coupler for looseness.

2. Check the motor for stalling or overload.

3. Check the visual leakage or noisy gear.

4. Refer to the Multiport Electric Actuator (MPA) O&M Manual — Supplied by Bettis (MPA-400-0711

calibration procedures and troubleshooting.

Seal Leakage

1. Check the travel indicator plate (key 53) and travel indicator pin (key 50) to ensure the plug (key 2) is properly

aligned with the inlet ports.

2. Check the seal insert (key 12) for damage. To visually inspect the seal insert, the blind flange from an unused inlet

port needs to be removed. Prior to removing this flange, verify the Multiport Flow Selector valve has been

depressurized to a value of zero. With the blind flange removed, rotate the plug until visual inspection of the seal

insert can occur. The sealing surface of the seal insert should be smooth, completely intact, and free of deep groove

marks.

) for port

WARNING

Ensure that all pressures in the Multiport body, group outlet, and test port are ZERO before visually checking the seal.

3. If more information is required, please contact your Emerson sales office.

11

Multiport Flow Selector

January 2019

Figure 2. Multiport Drawing Assembly

Instruction Manual

D104239X012

VIEW C

VIEW D

VIEW B

VIEW E

VIEW B

SCALE 2:1

VIEW A

VIEW D

SCALE 2:1

VIEW E

SCALE 3:1

VIEW A

SCALE 2:1

GE99805

APPLY LUB/SEALANT

PARTS NOT SHOWN: 30, 34, 35, 36, AND 37.

12

VIEW C

SCALE 2:1

Instruction Manual

D104239X012

Figure 3. Multiport Mounting Assembly for NPS 3x6, 4x8, and 6x16 Constructions

Multiport Flow Selector

January 2019

GE99891

13

Multiport Flow Selector

January 2019

Parts Kits

Recommend Seal Kits

MAJOR REPAIR KIT, AFLAS FOR 2x4 MPFS RVAE0-960-952

MAJOR REPAIR KIT, AFLAS FOR 3x6 MPFS RVAE0-960-953

MAJOR REPAIR KIT, AFLAS FOR 4x8 MPFS RVAE0-960-954

MAJOR REPAIR KIT, AFLAS/FLEXISEAL FOR 2x4 MPFS RVAE0-960-957

MAJOR REPAIR KIT, AFLAS/KALREZ FOR 3x6 MPFS RVAE0-960-959

HIGH DIFFERENTIAL PLUG UPGRADE, AFLAS FOR 2x4 MPFS RVAE0-960-972

HIGH DIFFERENTIAL PLUG UPGRADE, AFLAS FOR 3x6 MPFS RVAE0-960-973

HIGH DIFFERENTIAL PLUG UPGRADE, AFLAS FOR 4x8 MPFS RVAE0-960-974

HIGH DIFFERENTIAL PLUG UPGRADE, AFLAS/FLEXISEAL FOR 2x4 MPFS RVAE0-960-975

HIGH DIFFERENTIAL PLUG UPGRADE, AFLAS/KALREZ FOR 3x6 MPFS RVAE0-960-976

MINOR REPAIR KIT, AFLAS FOR 3x6 MPFS RVAE0-960-987

MINOR REPAIR KIT, AFLAS/VITON FOR 4x8 MPFS RVAE0-960-988

MINOR REPAIR KIT, AFLAS FOR 2x4 MPFS RVAE0-960-992

MINOR REPAIR KIT, AFLAS/FLEXISEAL FOR 2x4 MPFS RVAE0-960-994

MINOR REPAIR KIT, AFLAS/KALREZ FOR 3x6 MPFS RVAE0-960-997

Instruction Manual

D104239X012

PART NUMBER

Adjustment Tool Kits

DESCRIPTION PART NUMBER

ADJUSTMENT TOOL 2x4 CL 300, 600, and 900 RMP20409X012

ADJUSTMENT TOOL 3x6 CL 150, 300, 600, and 900 RMP30609X012

ADJUSTMENT TOOL 3x6 CL 1500 RMP30615X012

ADJUSTMENT TOOL 4x8 CL 300, 600, and 900 RMP41015X012

ADJUSTMENT TOOL 4x10 CL 1500 RMP41015X012

ADJUSTMENT TOOL 6x16 CL 300, 600, and 900 RMP61609X012

ADJUSTMENT TOOL 6x16 CL 1500 and 2500 RMP61625X012

14

Instruction Manual

D104239X012

Multiport Flow Selector

January 2019

Parts List

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Key Description

Note

Contact your Emerson sales office

for part ordering information.

Multiport Assembly

(see figure 2 and 3)

Key Description

1 Valve Body

2 Plug

3 Bearing

4 Rod Seal

5 O-Ring, upper plug

6 Back up Ring, upper plug

7 O-Ring, lower plug

8 Back up Ring, lower plug

9 Plug Bushing

10 Scraper

11 Wave Spring Scraper

12 Seal Insert

13 Seal Carrier

14 O-Ring

15 Back up Ring

16 Back up Plate

17 Wave Spring

18 Seal Adjuster

19 Bonnet

20 O-Ring

21 Back up Ring

22 Wiper Retainer

23 Cap Screw, Wiper Retainer

24 Wiper Seal

25 O-Ring, Wiper Retainer

26 O-Ring, Shaft

27 Pipe Plug

28 Lube Fitting

29 Pipe Bushing

30 Set Screw

31 Stud

32 Nut

33 Lifting Lug

38 White Petrolatum

39 High temperature silicone grease

40 Anti-seize lubricant

41 Grease

42 Thread sealant paste

43 Mounting Bracket

44 Cap Screw

45 Cap Screw

46 Lock Washer

47 Coupler

48 Key

49 Travel Indicator Holder

50 Travel Indicator Pointer

51 Jam Nut

52 Nut

53 Travel Indicator Plate

54 Travel Indicator Stud

55 Cap Screw

56 Lock Washer

57 Washer

15

Multiport Flow Selector

January 2019

Figure 4. Typical Multiport Seal Components

Instruction Manual

D104239X012

PLUG SEAL

WAVE SPRINGS

SCRAPER

X1581

SEAL

ADJUST

MENT

NUT

X1582

SEAL

ADJUSTMENT NUT

SCRAPER WAVE

SPRING

PLUG SEAL COMPONENTS

ASSEMBLY

SEAL WAVE

SPRINGS

SEAT RING/

PLATE/

O-RING/

SEAL INSERT

HIGH DIFFERENTIAL SEAL

BEARING

DIFFERENTIAL SEAL

SCRAPER

WAVE

SPRINGS

HIGH

SCRAPER

X1584

BACKUP

PLATE

X1583

O-RING

SEAT

RING

HIGH DIFFERENTIAL

SEAL ASSEMBLY

SEAL ADJUSTMENT TOOL

SEAL

INSERT

ASSEMBLY

NOTE:

1

PLUG SEAL ADJUSTMENT TOOL SHOWN WITH BASE PARALLEL TO SHANK FOR INSERTION, BASE PERPENDICULAR TO SHANK, AND ENGAGED IN SEAL ADUSTMENT NUT.

16

Instruction Manual

D104239X012

Figure 5. Typical Multiport Seal Components

Multiport Flow Selector

January 2019

PLUG

E-60681009

NOTE:

1

PLUG (INDEX MARK CAN BE FOUND ON THE STEM FLAT THAT FACES THE SAME WAY AS THE PLUG SEAL OPENING.) PLUG SEAL ADJUSTMENT TOOL IN PLUG.

SEAL ADJUSTMENT TOOL

17

Loading...

Loading...