Page 1

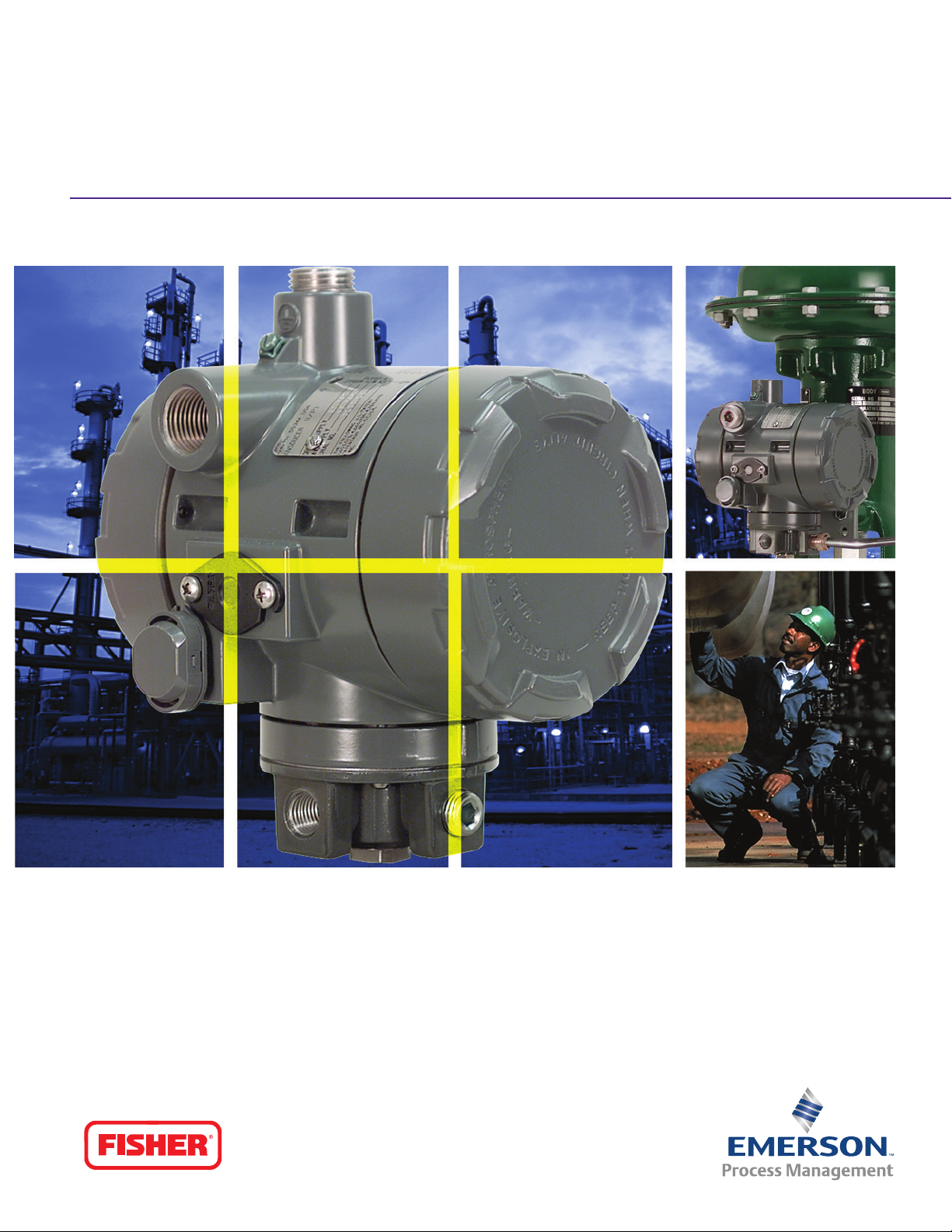

Fisher® i2P-100 Electro-Pneumatic Transducer

For Safer Operations and Improved Uptime

Page 2

i2P-100 Electro-Pneumatic Transducer

Fisher i2P-100

For safer operations and improved uptime

ElectroPneumatic

Transducer

he major issue with the design of electro-pneumatic

transducers is the balance between emissions and

T

uptime. If designed to minimize emissions, then the

device can be prone to plugging, especially if natural gas is

being used as the pneumatic supply.

The Fisher i2P-100 transducer is designed to meet

environmental concerns, but optimized to provide maximum

uptime. It features dual compartments with an “explosive-fluid

seal” to prevent natural gas from migrating to the electrical

conduit. Additional advantages offered by the i2P-100

transducer include corrosion resistance, tolerance to dirty

supply and vibration resistance.

These features give the i2P-100 transducer outstanding ability

to operate safer while improving uptime.

Installation

Each i2P-100 converts a millampere

input signal to a pneumatic signal

to operate a valve actuator,

damper drive or valve positioner.

It can be mounted directly to the

valve actuator case or to a

pipestand or surface.

Approved For Use With

Natural Gas

The i2P-100 transducer is ideal

when using natural gas as the

pneumatic supply, such as in gas

production facilities, compressor

stations and offshore platforms.

Corrosion Resistance

Converter module coils have a

corrosion resistant coating, and all

flexures are gold plated to provide

protection from hostile environments.

Dual compartment housing with an

“explosive-fluid seal” separates the

pneumatic and electronic components.

Page 3

The features, shown below, give the i2P-100 transducer

outstanding ability to operate safer while improving uptime.

Housing Assembly

The i2P-100 features an “explosive-

Plug-In Printed Wiring Board

Assembly

To keep water and harsh

atmosphere out of the i2P-100’s

electronic components, we’ve

encased them in a rugged shell.

Selectable dip switch settings enable

you to configure the output range

for 3-15, 6-30 or 3-30 psi (0.2-1.0,

0.4-2.0, or 0.2-2.0 bar). The switch

also allows you to set the input

range to 4-20, 4-12 or 12-20 mA dc

for a 3-15 psi (0.2-1.0 bar) output.

fluid seal” to meet Canadian

Standards Association, U.S. Factory

Mutual, ATEX and IEC approvals for

use with natural gas. And its NEMA

4X/IP66 housing is built to meet

explosion proof and intrinsically

safe requirements in the process

industry.

i2P-100 Electro-Pneumatic Transducer

Plug-In Converter

The corrosion resistant, rugged

i2P-100 uses a modular design that

allows for fast replacement of the

converter module.

Vent and

Pipe-Away Vent Capability

When the i2P-100 transducer

exhausts, air is released through

the vent to the atmosphere. When

not exhausting, the vent closes to

prevent water from entering the

instrument. If you need to pipe away

natural gas, simply remove the vent

and screw a 0.25 inch NPT pipe into

the housing.

Relay Assembly

The i2P-100 transducer can produce

output volume up to 8.0 normal

m3/hr (5.0 scfm). Pneumatic tubing

connects to a 0.25 inch NPT female

connection for output pressure.

Replaceable Filter and

Removable Primary Orifice

Particles in pneumatic supply

usually clog nozzles in low-bleed

transducers. This is not so with the

i2P-100. Its 5-micron filter helps

prevent clogging of the orifice,

thereby minimizing the need for

maintenance. The primary orifice

is easy to remove for service to

promote a longer operating life. The

filter and orifice can be accessed

from outside the device, without the

need for a complete strip down and

without removing the cover on the

electronics compartment.

Page 4

Contact your local Emerson Process Management sales office for

on dark backgroundson light backgrounds

standard

no gradients

watermark

stacked logo (for sharing only)

standard

no gradients

watermark

stacked logo (for sharing only)

more information or to make a purchase. They are ready to help

you take advantage of the many benefits of the Fisher i2P-100

transducer.

http://www.Facebook.com/FisherValves

http://www.Twitter.com/FisherValves

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

http://www.YouTube.com/user/FisherControlValve

http://www.LinkedIn.com/groups/Fisher-3941826

To nd the Fisher

sales contact in

your area, scan or

click the QR code.

© 2005, 2014 Fisher Controls International LLC. All rights reserved.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of

Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks

and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every

effort has been made to ensure their accuracy they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which are available upon

request. We reserve the right to modify or improve the designs or specifications of such products

at any time without notice. Neither Emerson, Emerson Process Management, nor any of their

affiliated entities assumes responsibility for the selection, use, or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the

purchaser and end user.

D351176X012 / MZ224 / Jan14

Loading...

Loading...