Page 1

HP Valve

D101635X012

Fisherr HP Series Control Valves

HP (Globe Valve)

HPA (Angle Valve)

Balanced High-Temperature Trim

Balanced Tight Shutoff Trim

Unbalanced Trim

Fisher HP Series control valves are single-port,

high-pressure, globe- or angle-style valves with metal

seats, cage guides, and push-down-to-close valve plug

action.

These valves are designed for high-pressure

applications in process control industries such as

power generation, hydrocarbon production, chemical

processing, and refining.

Product Bulletin

51.2:HP

October 2014

HP Series valves have NACE compliant materials

available. Extra valve body wall thickness provides a

safety margin of protection against erosion, as well as

extra protection against corrosion due to chemical

attack. Because these valves feature a thicker valve

body wall, they are available in higher intermediate

ratings with weld-end fittings.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002 and MR0103.

Balanced

High-Temperature Trim

HPD and HPAD

These valves use a balanced valve plug with graphite

piston rings and are well suited for general applications

with process temperatures in excess of 232_C(450_ F),

where extremely tight shutoff is not required.

X0183-1

FISHER HP VALVE WITH 667 ACTUATOR AND FIELDVUE™

DVC6200 DIGITAL VALVE CONTROLLER

Balanced Tight Shutoff

Trim

HPT and HPAT

These valves use a balanced valve plug and offer

excellent s hutoff with process temperatures below

232_C(450_F). The temperature limits of HPT can be

extended above 232_C(450_F) to 316_C(600_F) by

using PEEK (PolyEtherEtherKetone) anti-extrusion rings

in combination with a spring-loaded PTFE seal. The

PEEK anti-extrusion rings expand to help close off the

clearance gaps on the plug outside diameter and the

cage inside diameter where the PTFE seal may extrude

at high temperatures and pressures.

www.Fisher.com

Page 2

Product Bulletin

51.2:HP

October 2014

Specifications

HP Valve

D101635X012

Available Configurations

(1)

and Valve Sizes

See table 1

Common Characteristics: Designed according to:

ASME B16.34 Valve-Flanges, Threaded and Welding

End and

End Connections Styles

J ANSI/ISA-75.08.06

(1)

See table 1

Maximum Inlet Pressure and Temperature

(1,2)

Flanged, Socketwelding, or Buttwelding: Consistent

with CL900, 1500, and 2500 according to ASME

B16.34, unless limited by maximum pressure drop or

material temperature capabilities

In addition, both steel HP and HPA valves with BWE

and SWE connections have increased

pressure/temperature ratings as shown in table 3

Maximum Pressure Drop

(1)

Valve with Standard Cage: Seefigure12

Valve with Cavitrol™ III Cage: 149 bar (2160 psi) for

two-stage and 207 bar (3000 psi) for three-stage

cage. Consult Fisher Bulletin 80.2:030, Cavitrol III

One-,Two-,andThree-Stage trims, for more

information

Valve with Whisper Trim™ III Cage:

J 0.6 nP/P

J 0.75 nP/P

J 0.85 nP/P

J 0.99 nP/P

maximum for levels A1 and A3

1

maximum for levels B1 and B3

1

maximum for levels C1 and C3

1

maximum for levels D1 and D3

1

Valve with WhisperFlo™ Trim:

J Levels X, Y, and Z: 0.94 nP/P

greater than 0.94 nP/P

, consult your Emerson

1

maximum. If

1

Process Management sales office

Shutoff Classifications

See table 4

J

chrome-moly alloy,

CD3MWCuN stainless steel, and

J CF8M,CD3MN,and

J LCC for low

temperature service

Trim: See table 12

Other Parts: See table 7

Consult your Emerson Process Management sales

office for special trim and valve body material

availability.

Material Temperature Capabilities

(1)

HPD,HPAD,HPS,andHPAS:Up to 566_C (1050_F)

unless limited (see tables 7 or 12 and figure 12)

HPT and HPAT: Up to 232_C(450_F) unless limited

(see tables 7 or 12 and figure 12)

Flow Characteristics

Standard Cages: J Linear, J equal percentage,

J modified equal percentage

(4)

(5)

Cavitrol III and Whisper Trim III Cages: Linear

Micro-Flute: Equal percentage

Micro-Flat: Linear

Micro-Form:

J Equal percentage, J modified equal

percentage

Flow Direction

Standard Cage

J HPD, HPAD: Normally flow down

J HPS, HPAS: Normally flow up

J HPAS Micro

J HPS, HPAS Micro

J HPT, HPAT: Normally flow down

-

Flat: Flow down

-

Form: Flow up only

(6)

Cavitrol III Cage: Flow down

Whisper Trim III Cage: Flow up

Flow Coefficients

See table 2 and also Fisher Catalog 12

Noise Levels

See Fisher Catalog 12, Section 3 for noise prediction

methods

Construction Materials

Valve Body and Bonnet:

J WCC steel

2

(3)

, J WC9 Cr-Mo steel

(3)

, J C12A

Port Diameters, Valve Plug Travel, and

Stem Diameters

Seetables5,8,9,and11

- continued -

Page 3

HP Valve

D101635X012

Specifications (continued)

Product Bulletin

51.2:HP

October 2014

Bonnet Style and Mounting

(1)

J Standard Bonnet: Seefigure1

Yoke Temperature Limit: Standard bonnet with cast

iron yoke is limited to 537_C (1000_F)

J Optional Style 1–Extension Bonnet: Used for NPS

1 and 2 valves for CL900 or 1500, and NPS 1 valves for

CL2500 (see figures 14 and 15)

Yoke Boss Diameter for Actuator Mounting

See tables 5 and 10, and figures 13, 14, and 15

Approximate Weight

See table 6

Options

(1)

J Valves with weld-end fittings have increased

pressure/temperature ratings, called intermediate

(7),

Packing Arrangements

ratings

J Class V

316_C(600_F) using PEEK anti-extrusion rings

J Single, J Double, and J Leakoff standard

packing, or optional

J ENVIRO-SEAL™ and

J HIGH-SEAL packing systems. See figure 4. Also see

bulletin 59.1:061, ENVIRO-SEAL and HIGH-SEAL

Packing System for Sliding-Stem Valves

1. The pressure/temperaturelimits in this bulletin and any applicable standard limitationsshould not be exceeded.

2. EN (or other valvebody material) ratings and end connections can usuallybe supplied; consult your Emerson Process Managementsalesoffice.

3. SA-105 and SA-182-F22 areused for CL2500 HPA valves instead of WCC and WC9.

4. Special characterized cages areavailable. Contact your Emerson Process Management sales office.

5. Modified equal percentagecharacteristic is equal percentage for the first75% of travel, then opens quickly foradditional capacity.

6. HPS valvesmaybe used flow down for on-off service only. HPAS valves may be used forflow down in erosive service.

7. For more information contact your Emerson Process Management sales office.

8. Required for all boilerfeedwater applications.

Class V shutoff for HPD and HPAD to 593_C (1100_F)

using C-seal trim,

J expanded ends

6 valves (NPS 4 valves are available with NPS 6 ends,

andNPS6valvesareavailablewithNPS8ends),

lubricator or lubricator/isolating valve

(6)

shutoff for HPT and HPAT to

(7)

for NPS 4 and

(7)

(8)

, J

J

Table of Contents

Balanced High-Temperature Trim 1................

Balanced Tight Shutoff Trim 1....................

Specifications 2................................

Unbalanced Trim 4.............................

Expanded Ends 4...............................

Cavitrol, Whisper Trim

and WhisperFlo Cages 4.......................

Features 4.....................................

Material Selection Guidelines 7...................

Installation 7..................................

Packing 9.....................................

Trim Selection Guidelines 17.....................

Trim Material Combinations 19...................

Pressure/Temperature Limits for

Trim Material Combinations 22.................

Dimensions 23.................................

3

Page 4

Product Bulletin

51.2:HP

October 2014

HP Valve

D101635X012

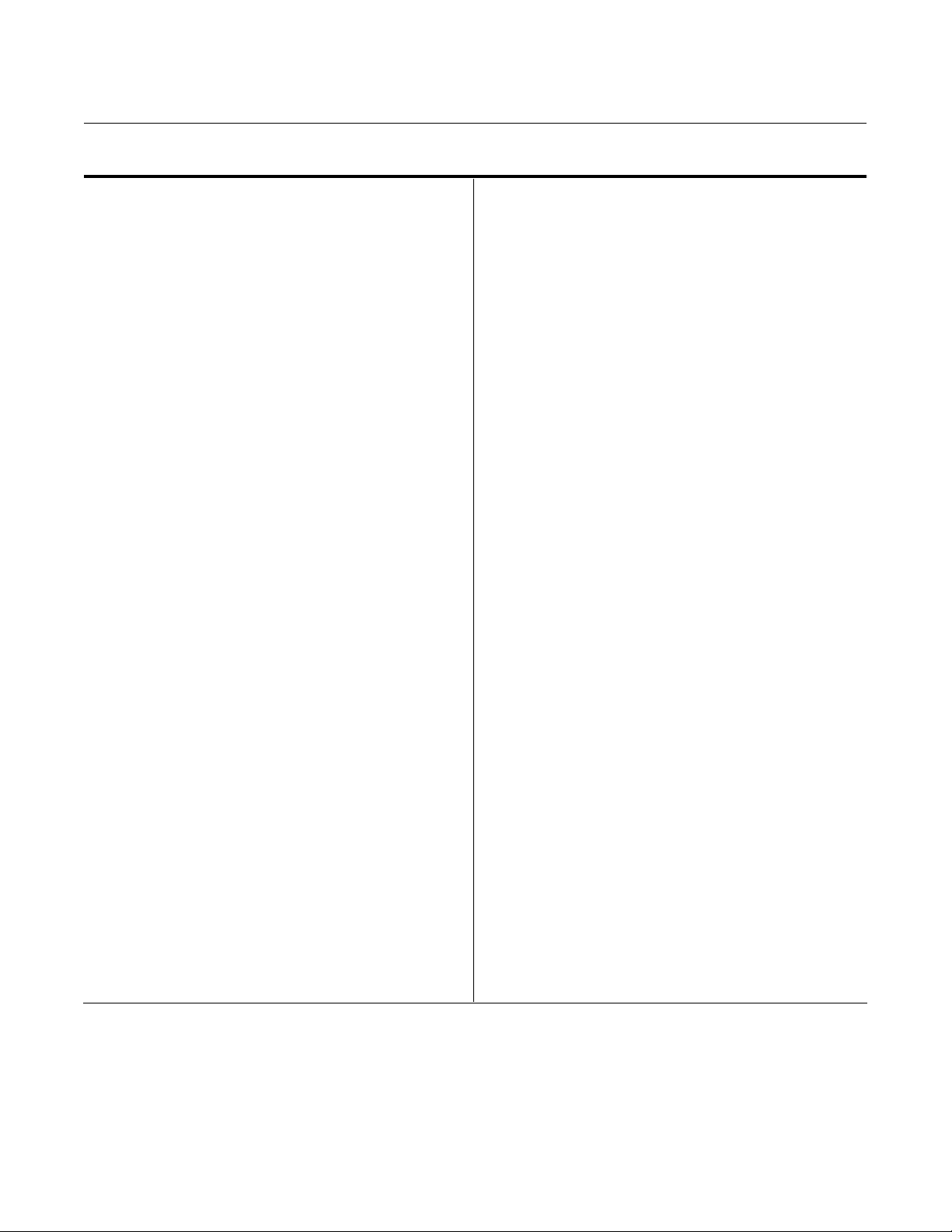

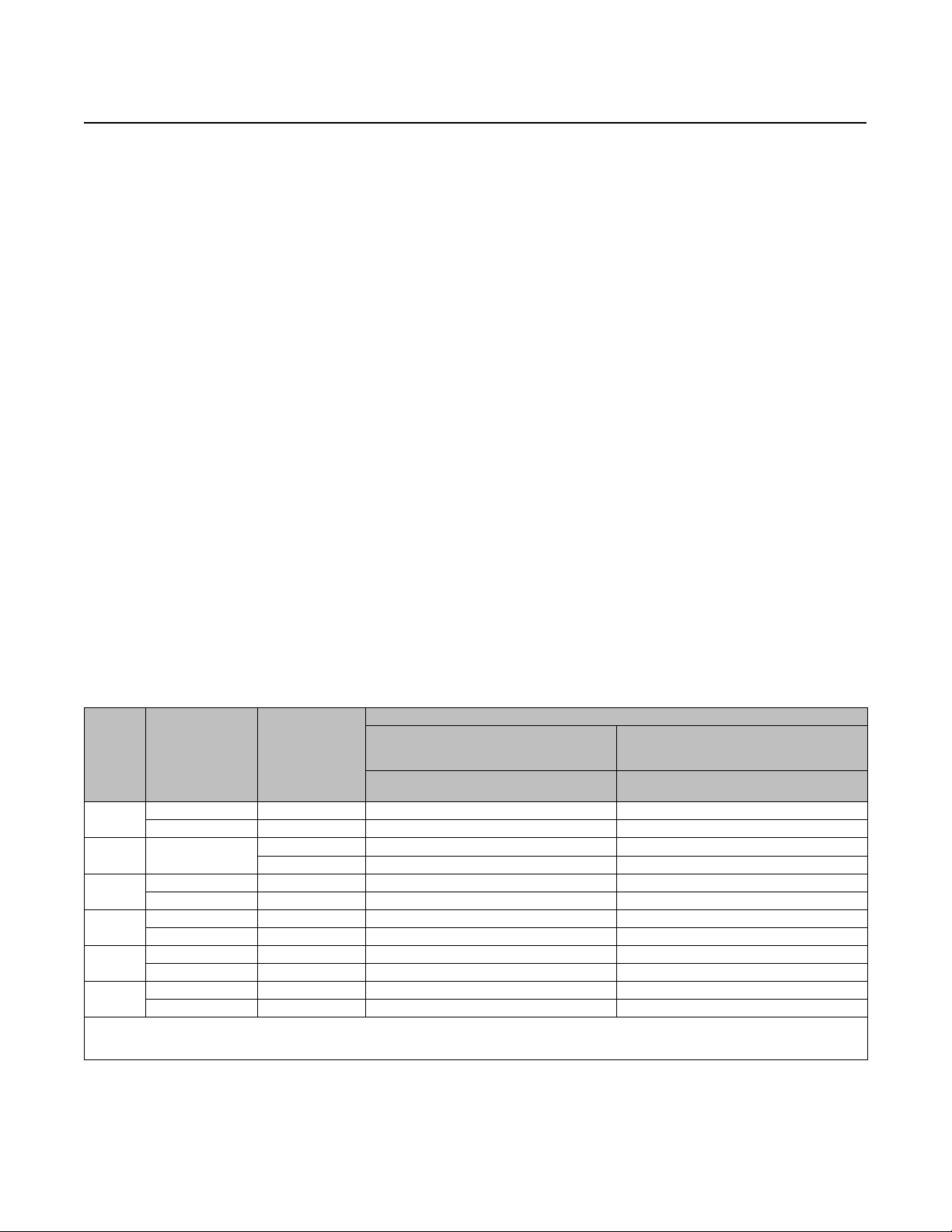

Figure 1. Fisher HPD Valve Assembly (NPS 2 to 6)

FLOW

W5815A-1

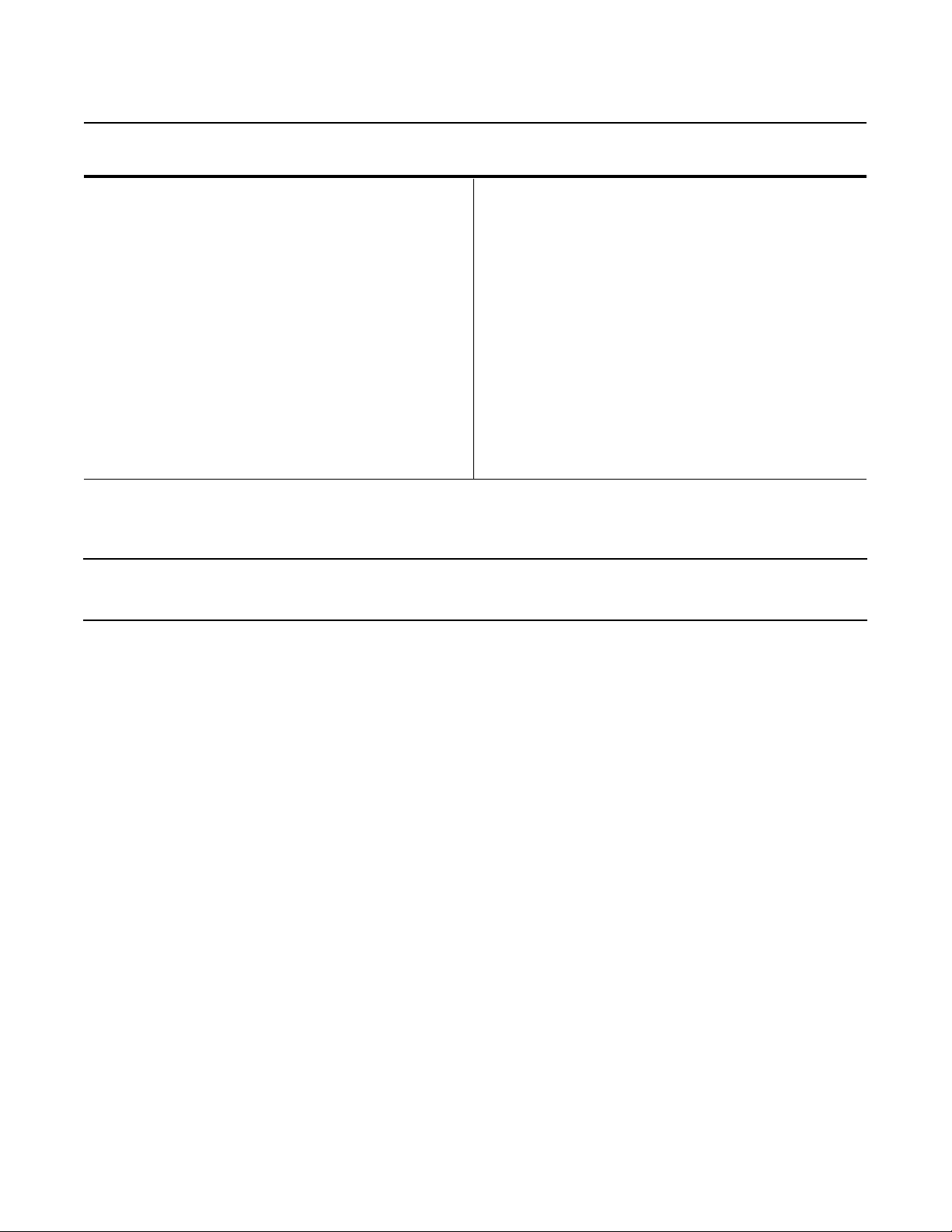

Figure 2. Typical WhisperFlo Trim Cut Section View

for Fisher HP Valve

Cavitrol III, Whisper Trim

III, and WhisperFlo Cages

To eliminate cavitation damage in a properly-sized

valve, a Cavitrol III cage is available with HPS, HPAS,

HPT, and HPAT control valves.

To help attenuate aerodynamic noise in gaseous

service, Whisper Trim III and WhisperFlo (figure 2)

cages are available with HPD, HPAD, HPS, HPAS, HPT,

and HPAT control valves. Contact your Emerson

Process Management sales office for more

information.

Features

Valve Plug Stability– Rugged cage guiding provides

increased valve plug stability, which reduces

vibration and mechanical noise.

Full Pressure Drop Capability–Rugged construction

allows full pressure drop capability in HP series

valves.

W7065

Unbalanced Trim

HPS and HPAS

These valves have an unbalanced plug and provide

excellent shutoff.

Expanded Ends

Expanded ends are available on the NPS 4 and 6 CL900

and 1500 HP valves. The NPS 4 HP valve body is offered

with NPS 6 ends. The NPS 6 valve body is offered with

NPS 8 ends. Both flanged and buttweld end valve

bodies are offered with expanded ends.

Spiral-Wound Gaskets for Excellent Sealing Under

All Service Conditions–Premium materials are used

in the construction of spiral-wound gaskets for HP

Series valves. These premium materials, which

make up the standard spiral-wound gaskets, are

N06600 (alloy 600)/graphite or N07750

(alloy X750)/graphite.

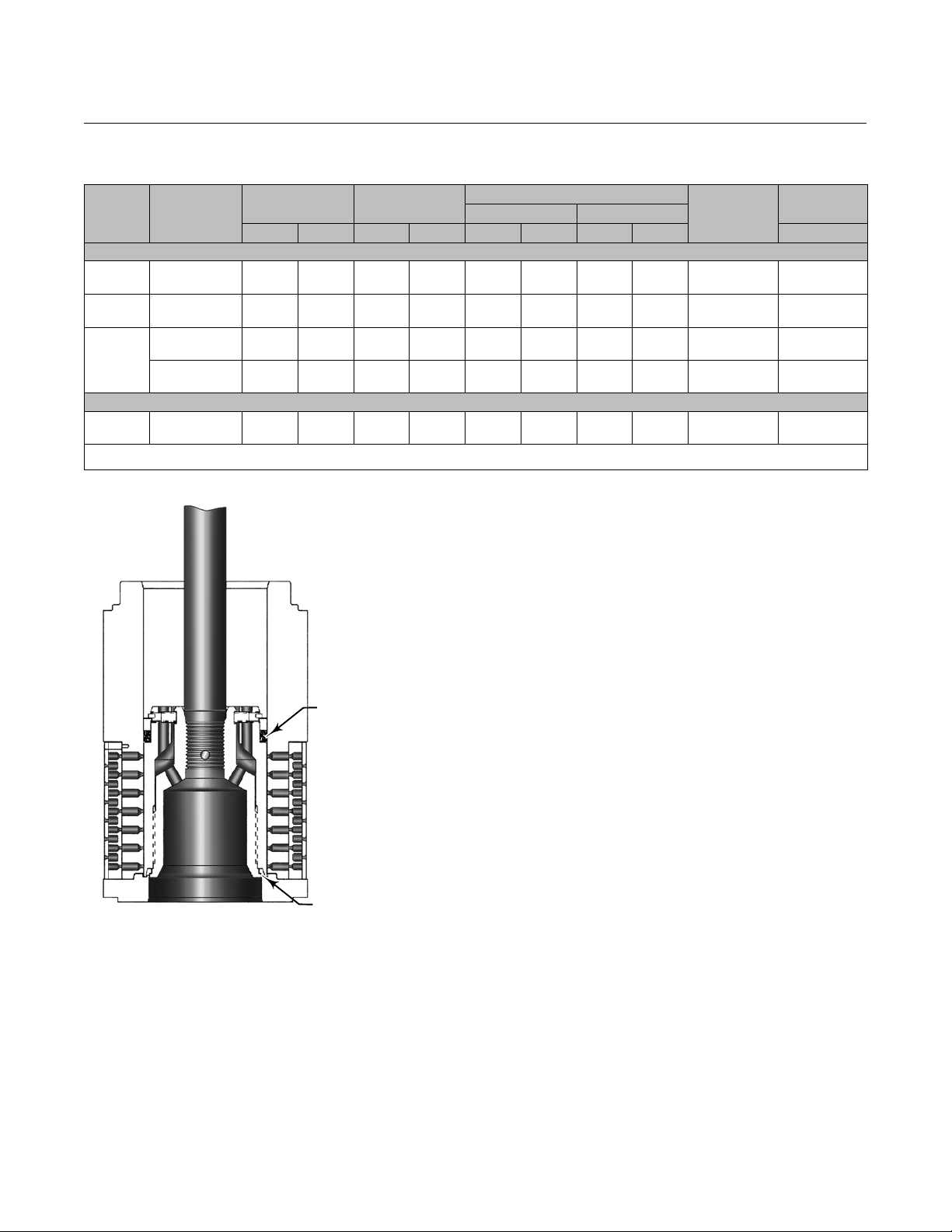

Compliance with the Clean Air Act–Optional

ENVIRO-SEAL packing systems (figure 4) provide an

improved stem seal to help prevent the loss of

valuable process fluid or emission of hazardous

process fluid. The ENVIRO-SEAL packing systems

featurePTFEorgraphiteULF.

Piping Economy–The availability of expanded end

connections on NPS 4 and 6 HP valves may

eliminate the need for line swages while

accommodating oversized piping arrangements.

Quick Change Trim–Maintenance is simple and can

easily be performed using common tools. Trim

components can be quickly removed and changed

with no need for special tools.

4

Page 5

HP Valve

D101635X012

Product Bulletin

51.2:HP

October 2014

Standard Hard Trim Materials–Thecage,valveplug,

and other trim parts are manufactured from

hardened materials. This standard feature provides

excellent wear resistance.

Control of Low Flow Rates/Tight

Shutoff–Micro-Flute and Micro-Form valve plugs

(figures 6 and 7, respectively) provide superb

rangeability in high-pressure, low-flow applications,

while maintaining tight shutoff (table 4). A choice of

several restricted port diameters helps to match

valve body capacity to required flow, to provide

necessary control with fulltravel,andtoprevent

throttling near the seat.

In low-flow applications where cavitation damage

may occur, the Micro-Flat valve plug can be used

with a special Cavitrol III cage. Contact your

Emerson Process Management sales office for more

information.

Increased Pressure/Temperature Ratings– HP Series

valves with weld-end fittings have increased

pressure/temperature ratings, called intermediate

ratings, as defined in ASME B16.34. The extra

strength of these valves allows ratings higher than

the standard CL900 or 1500 ratings specified in

B16.34. Contact your Emerson Process

Management sales office for further information on

intermediate ratings.

Trim Interchangeability–Cavitrol III, Whisper Trim

III, and WhisperFlo trims (figures 8, 9, and 10) are

interchangeable with standard trims.

Smooth Control at High Pressure Drops–Available

on NPS 2 through 6 valves, balanced trim provides

smooth control at high pressure drops.

High-Temperature Capability with Class V

Shutoff–Use of C-seal trim (see figure 5) permits

Class V shutoff up to 593_C (1100_F) for HPD

valves.

Sour Service Trims Available–Long-lasting, erosion-

and corrosion-resistant trims are available for

control of sour service. These trims are offered with

either a standard cage, a Cavitrol III cage, a Whisper

Trim III cage, or WhisperFlo trim. Spiral-wound

gasket construction is standard.

Table 1. Available Constructions

VALVE BODY MATERIAL AND END CONNECTION STYLE

WCC, WC9, LCC, C12A, CF8M, CD3MN, and

DESIGN

HPAD

HPAS 1to2

HPAT

HPD

HPS

HPT

X = Available Construction.

1. End connection styleabbreviations: RF - Raised Face, RTJ - Ring TypeJoint.

2. EN (or othervalvebody material) ratings and end connections canusually be supplied; consultyour Emerson Process Management sales office.

3. Socket Weld availableonNPS 1, 1-1/2, and 2 only.

VALVE SIZE,

NPS

2to8 CL900 and 1500 X ---

2 CL2500 --- X

2to8 CL900 and 1500 X ---

2 CL2500 --- X

2to6 CL900 and 1500 X ---

2 CL2500 X --1to3 CL900 and 1500 X --1to2 CL2500 X --2to6 CL900 and 1500 X ---

2 CL2500 X ---

PRESSURE RATING

CL900 and 1500 X ---

CL2500 --- X

CD3MWCuN Stainless Steel

Cast Valves

RF or RTJ Flanged,

Butt Weld, and Socket Weld

(3)

SA-105, SA-182-F22, SA-182-F316, S31803

F51, and S32760 F55 forged SST (for forged

(1, 2)

steel HPA CL2500 angle valves)

Socket Weld

5

Page 6

Product Bulletin

51.2:HP

October 2014

HP Valve

D101635X012

Table 2. Typic al Flow Coefficients

Valve Size,

NPS

1 HP CL1500

2 HP CL1500 Linear 52.2

3 HP CL1500 Linear 121

4 HP CL1500 Linear 201

6 HP CL1500 Linear 425

1 HPA CL1500

2 HPA CL1500 Linear 64.3

1 HPA CL2500

2 HPA CL2500 Linear 47.4

1. See the section titled Coefficients in thisbulletin and also Catalog 12 for a

complete listing of flow coefficients.

Valve Style Characteristic Maximum Cv

(1)

Modified Equal

Percentage

Modified Equal

Percentage

Modified Equal

Percentage

Table 3. Increased Pressure/Temperature Ratings for

Steel Valves with BWE and SWE Connections

17.1

19.5

14.3

Table 4. Shutoff Classifications per ANSI/FCI 70-2 and IEC 60534-4

Valve Design Port Diameter, mm (Inches) ANSI/FCI and IEC Leakage Class

47.6 (1.875) II

HPD, HPAD

Valve Size, NPS

HPD HPAD

3 4 73 (2.875)

HPD, HPAD

w/ C-seal trim

HPS, HPAS, HPT, HPAT All

HPS and HPT w/TSO

(Tight Shutoff trim)

HPT and HPAT w/PEEK

1. PEEK (PolyEtherEtherKetone), required forall boiler feedwater applications.

Rings

4 6

6 8

(1)

Anti-Extrusion

Port Diameter, mm (Inches) Cage Style ANSI/FCI and IEC Leakage Class

92.1 (3.625)

111.1 (4.375) Linear (Whisper III, D3)

136.5 (5.375)

47.6 (1.875) to 136.5 (5.375) All

58.7 (2.3125) to 92.1 (3.625)

111.1 (4.375) and larger

Linear (Whisper III, A1, B1)

73 (2.875) Linear (Whisper III, D3)

Linear (Whisper III, A1, B3, C3)

Linear (Whisper III, A1, B3, C3)

Cavitrol III andMicro-Flat V - Standard

Micro-Form, Micro-Flute, Eq. %,

Mod Eq. %, Linear, Whisper III

See table 5 See table 5

(1)

Valve Type

Globe Valves

1. Contact your Emerson Process Managementsalesoffi ce for further information on

intermediate ratings.

Eq.%,Mod.Eq.%,

Linear (std. cage),

Eq.%,Mod.Eq.%,

Linear (std. cage),

Eq.%,Mod.Eq.%,

Linear (std. cage),

Valve

Size,

NPS

1

2 CL900 and 1500 1694

3 CL1500 1578

4 CL1500 2017

6 CL1500 1876

Pressure Rating

CL900 and 1500 1675

CL2500 2800

II - Standard

III - Optional

III - Standard

IV - Optional

V - Standard

to 593_C (1100_F)

(for port diameters from 73 mm

[2.875 inch] through 136.5 mm [5.375

with optional C-seal trim)

IV - Optional

(for port diameters 73 mm [2.875

inch] through 136.5 mm [5.375 inch]

IV - Standard

V - Optional

TSO - Optional

TSO is not an ANSI/FCI or IEC leakage

Valves with TSO trim are factory tested

to a more stringent Fisher test

requirement of no leakage at time of

shipment.

Test medium is water.

Specify service Pwhenordering.

Test procedure is ANSI/FCI Class V test

procedure B

V - Standard (to 316_C [600_F])

IV - Optional (47.6 mm [1.875 inch]

136.5 mm [5.375 inch] ports)

Intermediate

Rating

(ASME

B16.34)

inch]

class.

through

6

Page 7

HP Valve

D101635X012

Product Bulletin

51.2:HP

October 2014

Material Selection

Guidelines

Usethefollowingstepsasaguidelinefortheselection

of materials:

1. Determine the pressure/temperature rating of the

valve body size and material required. Inlet pressure

and temperature must always be limited by the

applicable ASME pressure/temperature rating.

2. SelectthedesiredtrimstylefromtheAvailable

Configurations specification and from table 4, Shutoff

Classifications.

3. Select desired materials from tables 7, 8, 11, and 12

and figure 12. The temperature capabilities

determined from figure 12 may be further limited by

the temperature capabilities of materials selected

from tables 7 and 12. Refer to figure 12 to determine

pressure drop limits of the valve body-trim

combinations selected.

Installation

The valve must be installed so flow through the valve is

as indicated by the flow direction arrow on the valve

body. Consideration should be given to installing an

upstream strainer, especially if the valve uses a Cavitrol

III cage, Whisper Trim III, or WhisperFlo trim.

Overall dimensions are shown in figures 13, 14, and

15. Face-to-face dimensions are in compliance with

ANSI/ISA-75.08.06. Actual end connection dimensions

conform to ASME B16.25 for buttwelding ends and to

ASME B16.5 for flanged ends.

7

Page 8

Product Bulletin

51.2:HP

October 2014

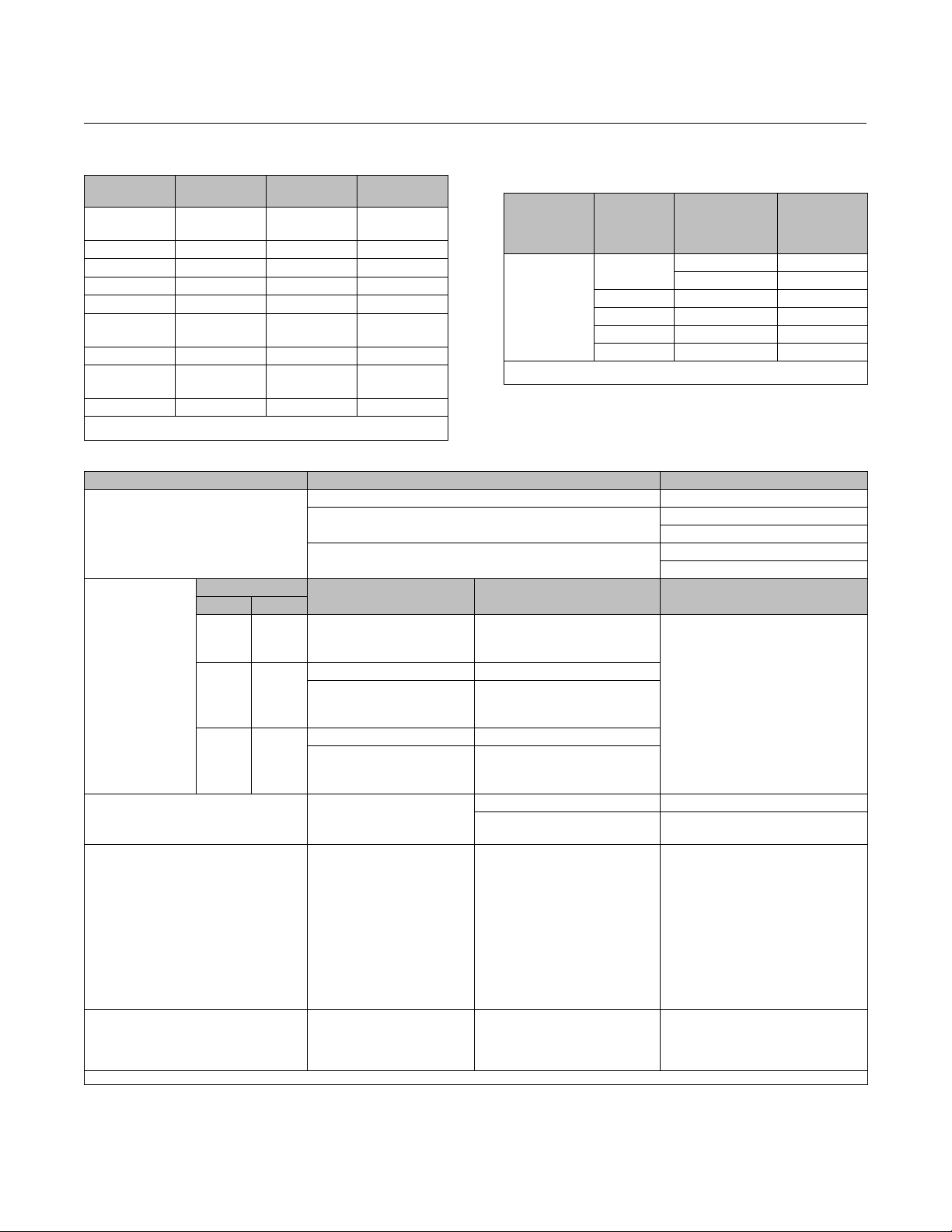

Table 5. Port Diameters, Valve Plug Travel, Yoke Boss Diameters for TSO (Tight Shutoff) Trim

VALVE

TYPE

HPT

(2)

NPS 3

HPT

NPS 4

HPT

NPS 6

HPS

NPS 2

1. This column lists the percent reduction ofpublished maximum CVof the trimlistedin the TRIM column.

2. Not available with 5-inch yoke boss.

TRIM

CAV III 3-Stage 63.5 2.5 90 3-9/16 47.6 1.875 42.9 1.6875 5% 0.031

CAV III 3-Stage 76.2 3

CAV III 3-Stage 102 4

Standard 76.2 3

CAV III 3-Stage 50.8 2 90 3-9/16 25.4 1 26.2 0.8125 0% 0.785

MAX TRAVEL YOKE BOSS SIZE

mm Inch mm Inch mm Inch mm Inch Inch

Balanced Plugs–Flow Down Only

90

127

127

127

3-9/16

5

90

3-9/16

5

90

3-9/16

5

Unbalanced Plugs–Flow Down Only

73.0 2.875 68.3 2.6875 2% 0.047

116 4.5625 111 4.375 0% 0.080

137 5.375 132 5.1875 4% 0.206

Figure 3. Typical Balanced TSO Trim

PORT DIAMETER

Nominal Actual TSO

C

V

REDUCTION

AT 100%

(1)

TRAVEL

HP Valve

D101635X012

UNBALANCE

AREA

2

W7020-1

VALVE PLUG

SEAL

TSO PROTECTED

SOFT SEAT SEAL

8

Page 9

HP Valve

D101635X012

Figure 4. ENVIRO-SEAL and HIGH-SEAL Packing Systems

Product Bulletin

51.2:HP

October 2014

SPRING

PACKING

W8533-1

PACKING

BOX

STUD

FOLLOWER

TYPICAL HIGH-SEAL PACKING SYSTEM

WITH GRAPHITE ULF PACKING

PACKING

BOX

STUD

SPRINGS

FOLLOWER

PACKING

W8532-1

TYPICAL ENVIRO-SEAL PACKING SYSTEM

WITH GRAPHITE ULF PACKING

PACKING

BOX

STUDS

SPRINGS

ANTIEXTRUSION

RING

LANTERN

RING

W5803-3

PACKING

RING

VALVE

BONNET

TYPICAL ENVIRO-SEAL PACKING SYSTEM

WITH PTFE PACKING

9

Page 10

Product Bulletin

51.2:HP

October 2014

Table 6. Approximate Weights (Valve and Bonnet Assemblies)

VALVE TYPE

Globe Valves

Angle Valves

1. Only SWE is availablefor CL2500.

VALVE SIZE,

NPS

1

1-1/2 x 2 CL2500 --- 34 --- 76

2

3

4

6

1

2

3 CL1500 123 78 272 173

4 CL1500 181 117 399 258

6 CL1500 357 202 788 445

8 CL1500 648 405 1428 893

PRESSURE RATING

CL900 and 1500 42 38 93 85

CL2500 45 34 100 76

CL900 and 1500 72 52 158 115

CL2500 104 74 229 164

CL900 125 --- 276 ---

CL1500 129 97 284 213

CL900 230 --- 507 ---

CL1500 249 201 548 444

CL900 511 --- 1127 ---

CL1500 557 455 1228 1003

CL900 and 1500 40 36 88 80

CL2500 --- 72

CL900 and 1500 69 50 153 110

CL2500 --- 109

Flg SWE, BWE Flg SWE, BWE

D101635X012

KILOGRAMS POUNDS

(1)

(1)

--- 160

--- 240

HP Valve

(1)

(1)

Figure 5. C-seal Trim

C-SEAL

METAL

PLUG

(1)

SEAL

FLOW DOWN FLOW UP

37B1399-A

Note:

1. Reverse the orientation of the C-seal plug seal for proper shutoff when valve is used in a process with different fluid flow direction.

C-SEAL

METAL

PLUG

(1)

SEAL

VIEW A

10

Page 11

Product Bulletin

HP Valve

D101635X012

Table 7. Construct ion Materials and Temperature Capabilities for Parts Other than Valve Body and Trim

PART MATERIAL

Valve plug stem

S20910 -198 to 593 -325 to 1100

S32760 -51 to 316 -60 to 600

Graphite (FMS 17F27)

HPD

piston ring

Graphite (FMS 17F39)

S41600 (416 SST) -29 to 427 -20 to 800

S31600 (316 SST) -198 to 593 -325 to 1100

S30200 (302 SST)

N07750 (NACE)

PEEK (PolyEtherEtherKetone) -73 to 316 -100 to 600

Spring-loaded

HPT or HPAT

valve plug seal

Backup ring

Retaining ring

Seal ring PTFE with N10276 Spring -73 to 232

Anti-extrusion

rings

Cage gasket N06600/Graphite -240 to 593 -400 to 1100

TSO protected soft seat seal Carbon-filled PTFE -73 to 232 -100 to 450

Seat ring gasket N06600/Graphite -240 to 593 -400 to 1100

Valve Body-tobonnet

(1)

bolting

Studs

Nuts

Studs

Nuts

Studs

Nuts

Studs

Nuts

Studs

Nuts

Studs

Nuts

Steel SA193-B7 (all valve body materials)

Steel SA194-2H (all valve body materials)

Steel SA193-B7Mforsourservice

Steel SA194-2HM for sour service

Steel SA193-B16 (WC9 and C12A valve body mat'ls)

Steel SA194-7

N07718 SST (SB637)

(3)

Steel SA194-7

S31600 stainless steel SA193-B8M (strain hardened)

(CF8M valve body mat'ls)

(4)

S31600 stainless steel SA194-8M (CF8M valve body mat'ls)

S20910 SST (SA479-XM-19)

(3)

(CF8M valve body mat'ls)

Steel SA194-7

(4)

PTFE V-ring -46 to 232 -50 to 450

Packing

Graphite ribbon filament (oxidizing service to 371_C [700_F]) -254 to 537 -425 to 1000

Graphite ribbon

(high-temperature oxidizing service)

Packing follower,

spring, or lanternring

S31600 stainless steel -254 to 593 -425 to 1100

Packing box ring S31600 stainless steel -254 to 593 -425 to 1100

Packing flange, studs, or nuts

1. Valve body materialswith which these bolting materials may beusedare shown in parentheses.

2. Steel studs andnuts with NCF (non-corrodingfinish)coatingareusedwithNPS4and6CF8Mvalvebodies.

3. These stud materialsare not listed in ASME B16.34.

4. For valve sizes upthrough NPS 3.

5. If used with PEEK anti-extrusion rings, PTFE/carbon seal ring may be used in temperatures upto 316_C (600_F) for non-oxidizing serviceorup to 260_C (500_F) for oxidizingservice.

Steel -29 to 427 -20 to 800

S31600 stainless steel -198 to 593 -325 to 1100

TEMPERATURE CAPABILITIES

_C _F

-46 to 427 (to 482

for nonoxidizing

-50 to 800 (to 900

for nonoxidizing

service)

-46 to 537 (to 593

for nonoxidizing

-50 to 1000 (to 1100

for nonoxidizing

service)

-254 to 593 -425 to 1100

(5)

-29 to 427

(WCC and WC9)

(WCC and WC9)

-46 to 371

(LCC)

-48 to 427

(316 CF8M)

-29 to 427 (WCC)

-46 to 371 (LCC)

(2)

-20 to 800 (WCC)

-50 to 700 (LCC)

-29 to 510 -20 to 950

-29 to 566 (WC9)

-29 to 593 (C12A)

-20 to 1050 (WC9)

-20 to 1100 (C12A)

-198 to 427 -325 to 800

-198 to 593 -325 to 1100

371 to 593 700 to 1100

51.2:HP

October 2014

service)

service)

-100 to 450

-20 to 800

-50 to 700

(LCC)

-55 to 800

(316 CF8M)

(5)

(2)

11

Page 12

Product Bulletin

51.2:HP

October 2014

Table 8. Additional Globe Valve Specifications

VALVE

SIZE,

NPS

1

2

3

FLOW

CHARACTERISTIC

Equal

percentage

Modified

equal percentage

Linear (cage style:

Cavitrol III, 2-stage)

Equal

percentage

Linear (cage style:

Std)

Linear (cage style:

Whisper Trim III,

level A1)

Modified

equal

percentage

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

Modified equal

percentage

Linear (cage style:

Std)

Linear (cage style:

Whisper Trim III, level

A1, B1)

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

VALVE BODY

DESIGN AND

PLUG STYLE

HPS w/Micro-Flute

HPS w/Micro-Form

HPS w/Micro-Form

HPS 22.2 0.875 38 1.5 12.7, 19.1 1/2, 3/4

HPS w/Micro-Form

HPS 47.6 1.875 29 1.125 12.7, 19.1, 25.4

HPS, HPD, HPT 47.6 1.875 38 1.5 12.7, 19.1, 25.4

HPS w/Micro-Form

HPS, HPD, HPT 47.6 1.875 38 1.5 12.7, 19.1, 25.4

HPT 44.5 1.75 51 2 12.7, 19.1 1/2, 3/4

HPS 25.4 1 51 2 19.1 3/4

HPD, HPT 73 2.875 51 2 12.7, 19.1, 25.4 1/2, 3/4, 1

HPT 63.5 2.5 64 2.5 12.7, 19.1, 25.4 1/2, 3/4, 1

HPT 47.6 1.875 64 2.5 12.7, 19.1, 25.4 1/2, 3/4, 1

HP Valve

D101635X012

PORT

DIAMETER

mm Inches mm Inches mm Inches

6.4

6.4

6.4

0.25

0.5

0.25

0.5

0.75

0.75

1

0.25

0.5

0.75

1

1.25

1.5

12.7

12.7

19.1

19.1

25.4

12.7

19.1

25.4

31.8

38.1

-continued-

VALVE PLUG

TRAVEL

19

19

19

19

19

29

29

19

19

19

29

29

38

0.75

0.75

0.75

0.75

0.75

1.125

1.125

0.75

0.75

0.75

1.125

1.125

1.5

VALVE STEM DIAMETER

12.7

12.7

12.7

12.7

12.7, 19.1

12.7, 19.1

12.7, 19.1

12.7

12.7

12.7, 19.1

(1)

(1)

12.7,19.1, 25.4

12.7, 19.1, 25.4

12.7, 19.1, 25.4

(1)

1/2

1/2

1/2

1/2

1/2, 3/4

1/2,3/4

1/2, 3/4

1/2

1/2

1/2, 3/4

1/2, 3/4, 1

1/2, 3/4, 1

1/2, 3/4, 1

1/2, 3/4, 1

1/2, 3/4, 1

1/2, 3/4, 1

(1)

(1)

(1)

12

Page 13

HP Valve

D101635X012

Table 8. Additional Globe Valve Specifications (Continued)

VALVE

SIZE,

NPS

Modified equal

percentage

Linear (cage style:

(Std)

Linear (cage style:

Whisper Trim III level

A1, A3, B3, C3)

4

Linear (cage style:

Whisper Trim III level

D3)

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

Modified equal percentage

Linear (cage style: Std)

Linear (cage style: Whisper

Trim III, level A1, B3, C3)

Linear (cage style: Whisper

6

Trim III, level D3)

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

1. Available only withHPS valve.

2. The first 75%isequal percentage.

FLOW

CHARACTERISTIC

(2)

VALVE BODY

DESIGN AND

PLUG STYLE

HPD, HPT 92.1 3.625 51 2 19.1, 25.4 3/4, 1

HPD, HPT 73 2.875 51 2 19.1, 25.4 3/4, 1

HPT 87.3 3.4375 76 3 19.1, 25.4 3/4, 1

HPT 73 2.875 76 3 19.1, 25.4 3/4, 1

HPD, HPT 136.5 5.375 76 3 19.1,25.4, 31.8 3/4, 1, 1-1/4

HPD, HPT 136.5 5.375 76 3 25.4, 31.8 1, 1-1/4

HPD, HPT 111.1 4.375 76 3 25.4, 31.8 1, 1-1/4

HPD, HPT 133.4 5.25 102 4 19.1, 25.4, 31.8 3/4, 1, 1-1/4

HPD, HPT 115.9 4.5625 102 4 19.1, 15.4, 31.8 3/4, 1, 1-1/4

mm Inches mm Inches mm Inches

PORT

DIAMETER

VALVE PLUG

TRAVEL

Product Bulletin

51.2:HP

October 2014

VALVE STEM DIAMETER

13

Page 14

Product Bulletin

51.2:HP

October 2014

Table 9. Valve Stem Travels for CL2500 Globe Valves

VALVE

SIZE,

NPS

1 HPS / Micro-Form or Micro-Flute

2

VALVE DESIGN / PLUG STYLE CHARACTERISTIC

Equal Percentage

Modified Equal Percentage

Equal Percentage

HPS / Micro-Form

HPS / Micro-Form

HPS

HPD, HPT

Modified Equal Percentage

Equal Percentage 38.1 1.5 28.6 1.125

Modified Equal Percentage 38.1 1.5 38.1 1.5

Linear

Equal Percentage

Modified Equal Percentage 47.6 1.875 28.6 1.125

Linear

Equal Percentage

Modified Equal Percentage 47.6 1.875 28.6 1.125

D101635X012

PORT DIAMETER MAXIMUM VALVE STEM TRAVEL

mm Inches mm Inches

6.4, 9.5, 12.7,

19.1, 25.4

6.4, 9.5, 12.7,

19.1, 25.4

6.4, 19.1, 25.4,

31.8

6.4, 19.1, 25.4,

31.8

47.6 1.875 25.4 1

47.6 1.875 25.4 1

0.25, 0.375, 0.5,

0.75, 1

0.25, 0.375, 0.5,

0.75, 1

0.25, 0.75, 1,

1.25

0.25, 0.75, 1,

1.25

19.1 0.75

25.4 1

19.1 0.75

28.6 1.125

HP Valve

71

127

(1)

0.5

1

Table 10. Globe and Angle Valve Yoke Boss and Valve Stem Diameter Combinations

VALVE

SIZE,

NPS

1 12.7 71 0.5 2-13/16 19.1 90 0.75 3-9/16

2

3 19.1 90 0.75 3-9/16

4 19.1 90 0.75 3-9/16 25.4 127 1 5

6

(2)

8

1.Seetables8,9,and11forvalvestemdiameters availableforspecificconstructions.

2. Angle valve construction only (HPAD,HPAT).

Stem Yoke Boss Stem Yoke Boss Stem Yoke Boss Stem Yoke Boss

12.7

19.1

25.4

31.8

25.4

31.8

STANDARD DIAMETERS OPTIONAL DIAMETERS

mm Inches mm Inches

71

90

127

127

127

127

0.5

0.75

1

1.25

1

1.25

2-13/16

3-9/16

5

5

5

5

25.4 127 1 5

12.7

25.4

19.1 71 0.75 3-9/16

19.1 71 0.75 3-9/16

2-13/16

5

14

Page 15

HP Valve

D101635X012

Table 1 1. Additional Angle Valve Specifications

VALVE

SIZE,

NPS

1

2

FLOW

CHARACTERISTIC

Equal

percentage

Modified

equal

percentage

Linear (cage

style: Std)

Linear (cage style:

Cavitrol III, 2-stage)

Equal

percentage

Modified equal

percentage

Linear (cage

style: std)

Linear (cage

style: std)

Linear (cage style:

Whisper III, level A1)

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

HPAS w/Micro-Flute Up

HPAS w/Micro-Form Up

HPAS, equal

percentage characterizedcage

HPAS w/Micro-Form Up

HPAS Down 19.1 0.75 29 1.125 19.1 3/4

HPAS w/ Micro-Flat Down

HPAS, HPAD Down 22.2 0.875 38 1.5 12.7, 19.1 1/2, 3/4

HPAS w/Micro-Flute Up

HPAS w/Micro-Form Up

HPAS, equal

percentage characterizedcage

HPAS Up 47.6 1.875 29 1.125 12.7, 19.1, 25.4 1/2, 3/4, 1

HPAT, HPAD Down 47.6 1.875 29 1.125 12.7, 19.1 1/2, 3/4

HPAS w/Micro-Form Up

HPAS, equal

percentage characterizedcage

HPAS Up 47.6 1.875 38 1.5 12.7, 19.1, 25.4 1/2, 3/4, 1

HPAT, HPAD Down 47.6 1.875 38 1.5 12.7, 19.1 1/2, 3/4

HPAS w/Micro-Flat Down 25.4 1 29 1.125 19.1 3/4

HPAS Up 47.6 1.875 38 1.5 12.7, 19.1, 25.4 1/2, 3/4, 1

HPAT, HPAD Down 47.6 1.875 38 1.5 12.7, 19.1 1/2, 3/4

HPAS, HPAT, HPAD Up 47.6 1.875 38 1.5 12.7, 19.1, 25.4

HPAT Down 44.5 1.75 51 2 12.7, 19.1 1/2, 3/4

HPAS Down 25.4 1 51 2 19.1 3/4

VALVE BODY

DESIGN AND

PLUG STYLE

Product Bulletin

October 2014

FLOW

DIRECTION

(2)

Down 19.1 0.75 19 0.75 19.1 3/4

(2)

Down

Down

-continued-

PORT

DIAMETER

mm Inches mm Inches mm Inches

6.4

9.5

0.375

12.7

6.4

12.7

19.1

12.7

19.1

25.4

9.5

0.375

12.7

19.1

6.4

9.5

0.375

12.7

6.4

12.7

19.1

25.4

19.1

25.4

31.8

38.1

25.4

31.8

38.1

19.1

25.4

31.8

38.1

0.25

0.5

0.25

0.5

0.75

0.5

0.75

1

0.5

0.75

0.25

0.5

0.25

0.5

0.75

1

0.75

1

1.25

1.5

1

1.25

1.5

0.75

1

1.25

1.5

VALVE PLUG

TRAVEL

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

29

1.125

29

1.125

29

1.125

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

19

0.75

29

1.125

29

1.125

29

1.125

38

1.5

29

1.125

29

1.125

29

1.125

38

1.5

VALVE STEM DIAMETER

12.7

12.7

12.7

12.7

12.7

12.7, 19.1

12.7

12.7, 19.1

12.7, 19.1

12.7

12.7

19.1

12.7

12.7

12.7

12.7

12.7

12.7, 19.1

12.7, 19.1, 25.4

19.1

19.1

25.4

25.4

12.7, 19.1, 25.4

12.7, 19.1, 25.4

12.7, 19.1, 25.4

19.1

19.1

25.4

25.4

(1)

1/2, 3/4, 1

51.2:HP

1/2

1/2

1/2

1/2

1/2

1/2, 3/4

1/2

1/2, 3/4

1/2, 3/4

1/2

1/2

3/4

1/2

1/2

1/2

1/2

1/2

1/2, 3/4

1/2, 3/4, 1

3/4

3/4

1

1

1/2, 3/4, 1

1/2, 3/4, 1

1/2, 3/4, 1

3/4

3/4

1

1

(1)

15

Page 16

Product Bulletin

51.2:HP

October 2014

Table 11. Additional Angle Valve Specifications (continued)

VALVE

SIZE,

NPS

3

4

6

8

1. Available onlywithHPAS valves.

2. Micro-Flutes (1 flute and0.5inch port 2 flute) may be used flow down inflashingand erosive service.

FLOW

CHARACTERISTIC

Equal percentage

Modified equal

percentage

Linear (cage style: Std) Down

Linear (cage style:

Whisper III, level A1)

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

Equal percentage

Modified equal

percentage

Linear (cage style: Std) Down

Linear (cage style:

Whisper III, level A1,

B1)

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

Equal percentage

Modified equal

percentage

Linear (cage style: Std) Down

Linear (cage style:

Whisper III, level A1,

A3, B3, C3)

Linear (cage style:

Whisper III, level D3)

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

Equal percentage

Modified equal

percentage

Linear (cage style: Std) Down

Linear (cage style:

Whisper III, level A1,

A3, B3, C3)

Linear (cage style:

Whisper III, level D3)

Linear (cage style:

Cavitrol III, 2-stage)

Linear (cage style:

Cavitrol III, 3-stage)

HPAT, HPAD

HPAT Down 44.5 1.75 51 2 12.7, 19.1 1/2, 3/4

HPAS Down 25.4 1 51 2 19.1 3/4

HPAT, HPAD

HPAT

HPAT, HPAD

HPAT

HPAT, HPAD

HPAT

VALVE BODY

DESIGN AND

PLUG STYLE

FLOW

DIRECTION

Down 47.6 1.875 29 1.125 12.7, 19.1 1/2, 3/4

Down 47.6 1.875 38 1.5 12.7, 19.1 1/2, 3/4

Up

Down 73 2.875 38 1.5 12.7, 19.1, 25.4 1/2, 3/4, 1

Down

Up

Down 64 2.5 64 2.5 12.7, 19.1, 25.4 1/2, 3/4, 1

Down 47.6 1.875 64 2.5 12.7, 19.1, 25.4 1/2, 3/4, 1

Down 92.1 3.625 38 1.5 19.1, 25.4 3/4, 1

Down

Up

Up 73 2.875 51 2 19.1, 25.4 3/4, 1

Down 87.3 3.4375 76 3 19.1, 25.4 3/4, 1

Down 73 2.875 76 3 19.1, 25.4 3/4, 1

Down

Down

Up 136 .5 5.375 76 3 25.4, 31.8 1, 1-1/4

Up 111 .1 4.375 76 3 25.4, 31.8 1, 1-1/4

Down 133.4 5.25 102 4 19.1, 25.4, 31.8 3/4, 1, 1-1/4

Down 115.9 4.5625 102 4 19.1, 25.4, 31.8 3/4, 1, 1-1/4

HP Valve

D101635X012

PORT

DIAMETER

mm Inches mm Inches mm Inches

47.6 1.875 38 1.5 12.7, 19.1 1/2, 3/4

73 2.875 51 2 12.7, 19.1, 25.4 1/2, 3/4, 1

92.1 3.625 51 2 19.1, 25.4 3/4, 1

5.375 64 2.5 19.1, 25.4, 31.8 3/4,1, 1-1/4

136.5

136.5 5.375 76 3 19.1, 25.4, 31.8 3/4, 1, 1-1/4

VALVE PLUG

TRAVEL

VALVE STEM DIAMETER

16

Page 17

HP Valve

D101635X012

Product Bulletin

51.2:HP

October 2014

Figure 6. Fisher HPS Trim with Micro-Flute Valve Plug

W5816-1

FLOW

Trim Selection Guidelines

Refer to the following descriptions as a guideline for

the selection of appropriate trims.

Trim 201A– Trim 201A is the standard trim for

carbon steel and alloy steel valve body materials.

This trim is recommended for general or severe

service applications up to 343_C(650_F) or 427_C

(800_F) depending on valve construction. Typical

applications for this trim include services in boiler

feedwater, water, nonsour hydrocarbons, and

steam.

Figure 7. Fisher HPS Trim with Micro-Form Valve Plug

W5817-1

FLOW

Trim 203– Trim 203 is the standard trim for

stainless steel valve body materials and should only

be used with stainless st eel valve body materials.

This trim meets the metallurgical requirements of

NACE MR0175-2002 and can be used in applications

up to 593_C (1100_F)

Trim 204– Trim 204 is used in sour or moderately

corrosive services. This trim meets the metallurgical

requirements of NACE MR01752002 and can be

used with carbon steel and alloy steel valve body

materials.

Trim 210– Provides a S31600 CoCr-A hardfaced

valve plug, which can be easily weld repaired. The

S17400 H1075 cage in this trim also allows it to be

usedinanHPTorHPATconstruction.

Trims 202 and 202H– Trims 202 and 202H are

designed for use in high temperature applications

up to 566_C (1050_F). Trim 202H includes special

tolerances required for larger sized HPD and HPAD

constructions, as indicated in table 12, at operating

temperatures above 343_C (650_F).

Trim 211– Trim 211 is the standard trim for C12A

valve body materials and should only be used with

C12A valve body materials. C12A should only be

used when the pressure and temperature

capabilities for WC9 valve body materials are not

acceptable.

17

Page 18

Product Bulletin

51.2:HP

October 2014

HP Valve

D101635X012

Figure 8. NPS 2 Fisher HPSTrim withCavitrolIII

3-Stage Cage

W5818-1

FLOW

Figure 9. Fisher HPT Trim with Whisper Trim III Level

A1 Cage (also available in HPD [NPS 2-6] and HPS

[NPS 2 and 3])

Figure 10. Fisher HPD Trim with Whisper Trim III

Level D Cage (also available in HPT and HPS)

W5951-1

FLOW

Figure 11. Fisher HPAS Trim with Micro-Flat Valve

Plug

W5952-1

FLOW

C-seal Trim Description

C-seal trim is available for HPD and HPAD valves with

port diameters from 2.875 inches through 5.375

inches.

With C-seal trim, a balanced valve can achieve

high-temperature, Class V shutoff. Because the C-seal

plug seal is formed from metal (N07718 nickel alloy)

rather than an elastomer, a valve equipped with the

C-seal trim can be applied in processes with a fluid

temperature of up to 593_C (1100_F).

18

W6021-1

FLOW

Fisher TSO (Tight Shutoff) Trim

Capabilities

TSO trim is available for HPS and HPT valves with port

diameters as defined in table 5. Also see figure 3 and

table 4.

TSO trim consists of a protected soft seat plus PEEK

anti-extrusion rings with a spring-loaded PTFE plug

seal. Used only in flow down applications, TSO trim

offers unparalleled shutoff integrity, resulting in longer

plug and seat life. For additional information contact

your Emerson Process Management sales office.

Page 19

HP Valve

D101635X012

Table 12. Trim Material Combinations

TRIM USAGE VALVE PLUG CAGE SEAT RING

With Standard Cage

S41600 heat-treated

201A

202

202H

203

(NACE

204

(NACE)

210

211

TC1

TC2

TC3

HP (NPS 1-6 CL900 &

1500 & NPS 1-2

HPA (NPS 1-8 CL900

&1500 &NPS 1-2

HPD & HPS only (NPS

1-6 CL900 & 1500 &

NPS 1 to 2 CL2500)

HPAD & HPAS only

(NPS 1-8 CL900 & 1500

&NPS 1-2 CL2500)

HPD NPS 6 CL900 &

(4)

HPAD NPS 8 CL900 &

HP (NPS 1-6 CL900 &

)(5)

1500 & NPS 1-2

HPA (NPS 1-8 CL900 &

1500 &NPS 1-2

(5)

HP (NPS 1-6 CL900 &

1500 & NPS 1-2

HPA (NPS 1-8 CL900 &

1500 &NPS 1-2

HPD & HPS only (NPS

1-6 CL900 & 1500 &

NPS 1 to 2 CL2500)

(9)

HPAD & HPAS only

(NPS 1-8 CL900 & 1500

&NPS 1-2 CL2500)

HPS & HPAS (NPS 1-2

(10)

CL900, 1500 & 2500)

HPS & HPAS (NPS 1-2

(10)

CL900, 1500 & 2500)

HPS & HPAS (NPS 1-2

(10)

CL900, 1500 & 2500)

CL2500)

CL2500)

1500,

1500 only

CL2500)

CL2500)

CL2500)

CL2500)

for HP, HPA,

Micro-Form (HPA), and

flow down HPAS)

or

S44004 (440C SST)

heat-treated for

Micro-Flute and

Micro-Flat (HPA only)

valve plugs

S31600 (316 stainless

steel) with CoCr-Aseat

and guide

S31600 (316 stainless

steel) with CoCr-Aseat

and guide

S31600 with CoCr-A

seat and guide

S31600 with CoCr-A

seat and guide

S31600 with CoCr-A

seat and guide

F91withCoCr-A

seat and guide

S17400/tungsten

carbide insert for seat

& contour (for Micro

trims)

(11)

S32550/tungsten

carbide insert for seat

& contour (for Micro

trims)

(11)

N07718/tungsten

carbide insert for seat

& contour (for Micro

trims)

(11)

S17400 (17-4SST)

H1075 heat-treated

F22 Cr-Mo alloy steel

nitrided

F22 Cr-Mo alloy steel

nitrided

S31600/hard

Cr coat

S17400 Double

H1150 heat-treated

S17400 H1075 S31600/CoCr-A

F91 ion nitrided F91 with CoCr-A C12A -29to 593 -20 to 1100

Alloy 6

Alloy 6

Alloy 6

S41600 heat-treated

HPA (S44004

heat-treated seat ring

for Micro-Flat

S44004 heat-treated

seat and liner)

S31600/CoCr-A

R30006 (Alloy 6) for

Micro-Flat valve plugs

R30006 seat, liner

S31600/CoCr-A

S31600/CoCr-A

R30006 (Alloy 6) for

Micro-Flat valve plugs

R30006 seat, liner

S31600/CoCr-A

R30006 (Alloy 6) for

Micro-Flat valve plugs

R30006 seat, liner

S17400/tungsten

carbide insert for seat

&bore

S32550/tungsten

carbide insert for seat

&bore

N07718/tungsten

carbide insert for seat

&bore

-continued-

Product Bulletin

51.2:HP

October 2014

VALVE BODY

MATERIAL

(1)

WCC -29 to 343

or

LCC -29 to 343 -20 to 650

WC9 -29 to 343

WCC -29 to 427 -20 to 800

or

LCC -46 to 343 -50 to 650

(3)

WC9 -29 to 566 -20 to 1050

WCC 260 to 427 500 to 800

LCC 260 to 343 500 to 650

WC9 260 to 566 500 to 1050

or

CF8M -198 to 593

(3)

or

WCC -29 to 427 -20 to 800

LCC -46 to 343 -50 to 650

(3)

WC9 -29 to 427 -20 to 800

WCC -29 to 427 -20 to 800

LCC -46 to 343 -50 to 650

WC9 -29 to 427 -20 to 800

WCC, WC9 -29 to 232 -20 to 450

CF8M, CD3MN,

CD3MWCuN

CW6MC -29 to 232 -20 to 450

OPERATING TEMPERATURE

RANGE

(2)

_C _F

(8)

-20 to 650

(8)

-20 to 650

(2)

-325 to 1100

-29 to 232 -20 to 450

(8)

(8)

(2)

19

Page 20

Product Bulletin

51.2:HP

October 2014

Table 12. Trim Material Combinations (continued)

TRIM USAGE VALVE PLUG CAGE SEAT RING

With Standard Cage

≤ 1/4inchPort:

Alloy 6

751

752

215A

215B

206

(NACE)

753

754

HP (NPS 1-6

CL900 & 1500)

HP (NPS 1-6

CL900 & 1500)

HP (NPS 1-6 CL900 &

1500 & NPS 1-2

HPA (NPS 1-8 CL900 &

1500 &NPS 1-2

HP (NPS 1-6 CL900 &

1500 & NPS 1-2

(6)

HPA (NPS 1-8 CL900 &

1500 &NPS 1-2

HP (NPS 1-6 CL900 &

1500 & NPS 1-2

(5)

HPA (NPS 1-8 CL900 &

1500 &NPS 1-2

HP (NPS 1-6

CL900 & 1500)

HP (NPS 1-6

CL900 & 1500)

CL2500)

CL2500)

CL2500)

CL2500)

CL2500)

CL2500)

>1/4inch,<3inch

Port: S31803 with

CoCr-Aseatandguide

≥ 3inchPort:

S31803/Ultimet

≤ 1/4inchPort:

Alloy 6

>1/4inch,<3inch

Port: S32760 with

CoCr-Aseatandguide

≥ 3inchPort:

S32760/Ultimet

S44004 heat-treated

S44004 heat-treated

S31600 with CoCr-A

seat and guide

≤ 1/4inchPort:

Alloy 6

>1/4inch,<3inch

Port: S31803 with

CoCr-Aseatandguide

≥ 3inchPort:

S31803/Ultimet

≤ 1/4inchPort:

Alloy 6

>1/4inch,<3inch

Port: S32760 with

CoCr-Aseatandguide

≥ 3inchPort:

S32760/Ultimet

S31803/Cr Pl S31 803/CoCr A CD3MN -51 to 316 -60 to 600

S32760/Cr Pl S32 760/CoCr A CD3MWCuN -51 to 316 -60 to 600

With Cavitrol IIICage

S42000

S17400

H1075 heat-treated

S17400

H1075 heat-treated

S17400 Double

H1150 heat-treated

S32760 S31803/CoCr A CD3MN -51 to 316 -60 to 600

S32760 S32760/CoCr A CD3MWCuN -51 to 316 -60 to 600

S44004 heat-treated

for CAV III Micro-Flat

S42000

S44004 heat-treated

for CAV III Micro-Flat

S31600/CoCr-A

-continued-

or

only

or

only

VALVE BODY

MATERIAL

(1)

WCC

LCC

WC9

WCC

LCC

WC9

WCC -29 to 232

LCC -46 to 232

WC9 -29 to 232

HP Valve

D101635X012

OPERATING TEMPERATURE

_C _F

-29 to 232

-29 to 232

RANGE

(7)

(7)

(7)

(7)

(7)

(2)

-20 to 450

-20 to 450

-20 to 450

-50 to 450

-20 to 450

(7)

(7)

(7)

(7)

(7)

20

Page 21

Product Bulletin

HP Valve

D101635X012

Table 12. Trim Material Combinations (continued)

TRIM USAGE VALVE PLUG CAGE SEAT RING

With Whisper Trim III Cage

HP (NPS 1-6 CL900 &

1500 & NPS 1-2

207A

207B

208

(4)

208H

209

(5)

(NACE)

(9)

212

751

752

1. If using valvebody/trim combinations other than those listed,consult your Emerson Process Management sales office.

2. Temperatures above 538_C (1000_F)require a non-standard CF8M body material (CF8M to FMS20B16).

3. For HPA valves.

4. Trims 202H and208Hhave valve plug tolerances for high temperatureservice and are used in place of trims 202 and208for the constructions listed when operating temperatures exceed

343_C (650_F).

5. NACE MR0175-2002.

6. Trim 215B hasaS31600 valve stem instead of the standardS20910material.

7. NPS 1 2 stageand NPS 2 3 stage HPS can be used at temperatures up to 343_C(650_F).

8.NPS1and2canbeusedattemperaturesupto427_C(800_F).

9. Trims 211 and212use S41000 stem instead of the standard S20910material. S41000 is limited to 538_C (1000_F). Fortemperaturesgreater than 538_C (1000_F), S42200 stem is used.

10. Trims TC1, TC2,TC3use S20910, S32550, and N07718 stem respectively. Use these trims for highly erosive applications.

11. Use with Micro-Form triminHPS, Micro-Form and Micro-Flat in HPAS valves.

CL2500)

HPA (NPS 1-8 CL900 &

1500 &NPS 1-2

CL2500)

HP (NPS 1-6 CL900 &

1500 & NPS 1-2

CL2500

HPD & HPS only (NPS

1-6 CL900 & 1500 &

NPS 1 to 2 CL2500)

HPAD&HPAS(NPS1-8

CL900 & 1500 &NPS

1-2 CL2500)

HPD (NPS 6 CL900 &

1500)

HPAD (NPS 8 CL900 &

1500 only)

HP (NPS 1-6 CL900 &

1500 & NPS 1-2

CL2500)

HPA (NPS 1-8 CL900 &

1500 &NPS 1-2

CL2500)

HPD & HPS only (NPS

1-6 CL900 & 1500 &

NPS 1 to 2 CL2500)

HPAD & HPAS only

(NPS 1-8 CL900 & 1500

&NPS 1-2 CL2500)

HP (NPS 1-6

CL900 & 1500)

HP (NPS 1-6

CL900 & 1500)

S41600 heat-treated

S41600 heat-treated

S31600 with CoCr-A

seat and guide

S31600 with CoCr-A

seat and guide

S31600 with CoCr-A

seat and guide

F91withCoCr-A

seat and guide

≤ 1/4inchPort:

Alloy 6

>1/4inch,<3inch

Port: S31803 with

CoCr-Aseatandguide

≥ 3inchPort:

S31803/Ultimet

≤ 1/4inchPort:

Alloy 6

>1/4inch,<3inch

Port: S32760 with

CoCr-Aseatandguide

≥ 3inchPort:

S32760/Ultimet

S17400

H1075 heat-treated

S17400

H1075 heat-treated

F22 steel

nitrided

F22 steel

nitrided

S17400 Double

H1150 heat-treated

F91 ion nitrided F91 with CoCr-A C12A -29to 593 -20 to 1100

S31803/Cr Pl S31 803/CoCr A CD3MN -51 to 316 -60 to 600

S32760/Cr Pl S32 760/CoCr A CD3MWCuN -51 to 316 -60 to 600

S41600

heat-treated

S31600/CoCr-A

S31600/CoCr-A

S31600/CoCr-A

S31600/CoCr-A

VALVE BODY

MATERIAL

(1)

WCC

LCC

WC9

WCC -29 to 427 -20 to 800

LCC -29 to 343 -20 to 650

WC9 -29 to 427 -20 to 800

WCC -29 to 427 -20 to 800

LCC -46 to 343 -50 to 650

WC9 -29 to 566 -20 to 1050

WCC -29 to 427 -20 to 800

LCC -46 to 343 -50 to 650

WC9 -29 to 566 -20 to 1050

WCC -29 to 343 -20 to 650

LCC -46 to 343 -50 to 650

WC9 -29 to 343 -20 to 650

OPERATING TEMPERATURE

RANGE

_C _F

-29 to 343

(8)

51.2:HP

October 2014

(2)

-20 to 650

(8)

21

Page 22

Product Bulletin

51.2:HP

October 2014

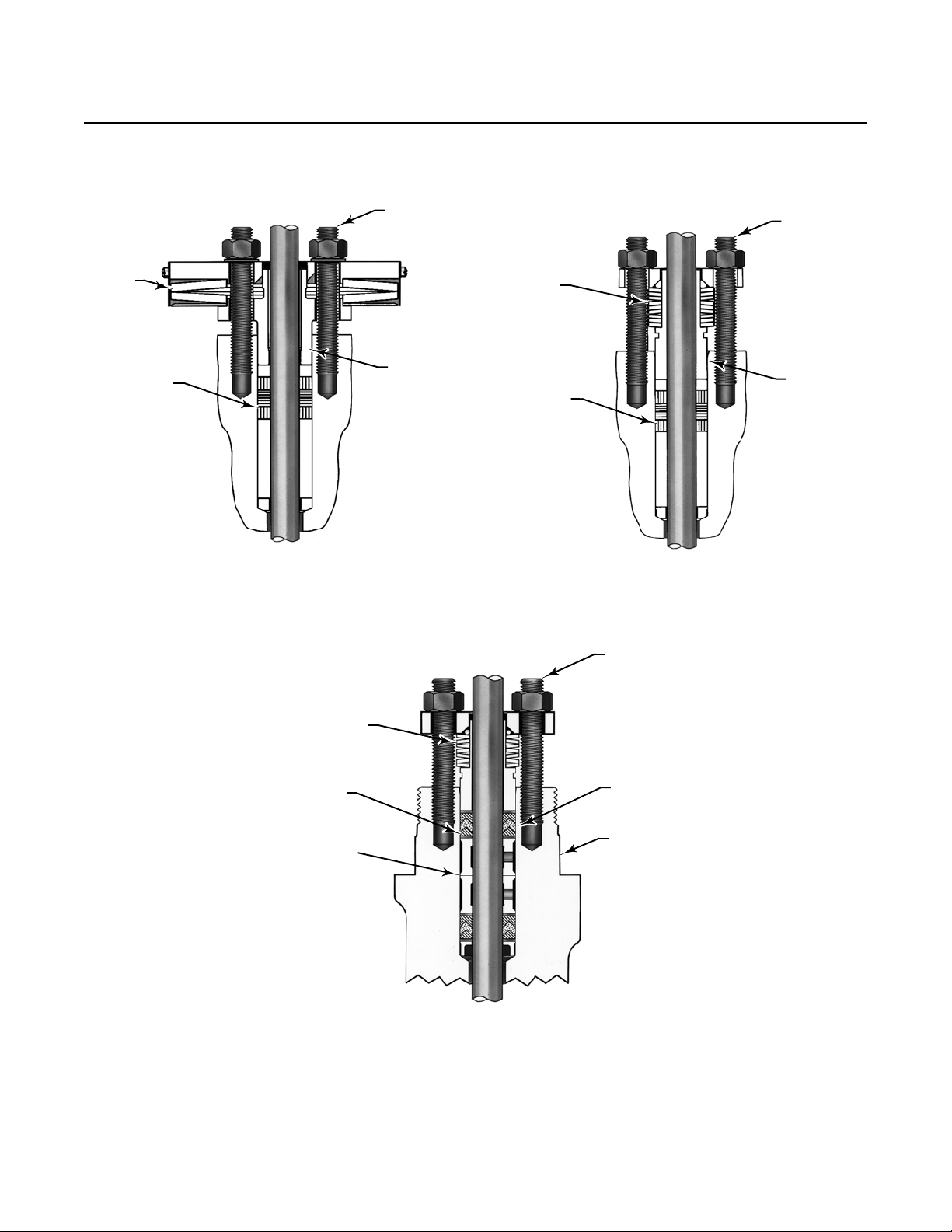

Table13.FlowingPressureDropLimitsforNPS6HPDandHPT Valves (Without Cavitrol III or Whisper Trim III

Cage)

FLOW

MEDIA

STEM

DIAMETER,

mm (INCHES)

Bar PSI

Flow Down Flow Up Flow Down Flow Up

19 (3/4) 103 --- 1500 ---

All except

boiler

feedwater

Boiler

feedwater

1. Requires 31.8 mm (1 -1/4 inch) S20910 stem with 52.8 mm (2-inch) plug-to-stem connection.

25.4 (1) 172 --- 2500 ---

31.8 (1-1/4) 259 --- 3750 ---

(2 x 1-1/4)

(1)

259 259 3750 3750

51.8 x 31.8

31.8 (1-1/4) 69 --- 1000 -- -

(2 x 1-1/4)

(1)

138 259 2000 3750

51.8 x 31.8

MAXIMUM FLOWING

PRESSURE DROP

D101635X012

HP Valve

Figure 12. Pressure-Temperature Limits for Trim Material Combinations

FLUID TEMPERATURE,

-40

_C

0 200 400 600

6000

5000

4000

3000

2000

PRESSURE DROP, PSI

1000

0

SOUR SERVICE APPLICATIONS (NACE)

204,

209

206

200

FLUID TEMPERATURE, _F

-29

6000

5000

4000

3000

2000

PRESSURE DROP, PSI

1000

0

800400-40

600 1000

FLUID TEMPERATURE,

_C

200 400 600

201, 207

800400-20

400

300

200

100

10

2

600 1000

6000

5000

4000

3000

2000

PRESSURE DROP, PSI

1000

PRESSURE DROP, BAR, DIFFERENTIAL

200

FLUID TEMPERATURE, _F

1200

400

300

200

100

1

10

1200

-40

0

PRESSURE DROP, BAR, DIFFERENTIAL

FLUID TEMPERATURE,

_C

0 200 400 600

210

206

215

200

FLUID TEMPERATURE, _F

6000

5000

4000

3000

2000

PRESSURE DROP, PSI

1000

LIMIT FOR

3-STAGE

LIMIT FOR

2-STAGE

800400-40

600 1000

FLUID TEMPERATURE,

-29

_C

00

202,208

0

200

FLUID TEMPERATURE, _F

400

300

200

4

100

10

1200

Notes:

Use trim 207B in NPS 3, 4, 6 HP and NPS 4, 6, 8 HPA above 343_C(650_F).

1

NACE MR0175-2002.

2

Be especiallycareful to specifyservicetemperature iftrim202 or 208 is selected, As differentthermal expansion rates

3

require special plug clearances.

4

The limit for 2-stage NPS 1 and 2 valves is 2160 psig. For NPS 3 to 6 valves the limit is 1800 psig.

C0746-5

200 400 600

202H,

208H

800400-20

600 1000

650

-73

FLUID TEMPERATURE,

_C

0

6000

5000

4000

3000

2000

PRESSURE DROP, PSI

1000

PRESSURE DROP, BAR, DIFFERENTIAL

0

200

-100

FLUID TEMPERATURE, _F

400

300

200

100

10

1200

PRESSURE DROP, BAR, DIFFERENTIAL

3

200 400 600

203

211

212

800400

600 1000

1200

400

300

200

100

10

PRESSURE DROP, BAR, DIFFERENTIAL

22

Page 23

HP Valve

D101635X012

Product Bulletin

51.2:HP

October 2014

Table 14. Globe Valve Dimensions with Standard

Bonnet

(1)

VALVE

SIZE,

NPS

1 292 292 292 292 292 292 269 277

2 375 378 375 375 375 378 344 360

3 442 445 460 --- 460 464 442 460

4x3 460 463 460 -- - 479 482 --- ---

4 511 514 530 --- 530 533 511 530

6x4 544 547 530 -- - 598 604 --- ---

6 714 718 768 --- 768 775 714 768

8x6 730 733 768 -- - 787 797 --- ---

1 --- --- 318 318 318 318 --- ---

2 --- --- 400 400 413 416 --- ---

1 11.50 11.50 11.50 11.50 11.50 11.50 10.58 10.90

2 14.75 14.88 14.75 14.75 14.75 14.88 13.56 14.18

3 17.38 17.50 18.12 --- 18.12 18.25 17.38 18.12

4x3 18.12 18.25 18.12 --- 18.88 19.00 --- ---

4 20.12 20.25 20.88 --- 20.88 21.00 20.12 20.88

6x4 21.44 21.56 20.88 --- 23.56 23.81 --- ---

6 28.12 28.25 30.25 --- 30.25 30.50 28.12 30.25

8x6 28.75 28.88 30.25 --- 31.00 31.38 --- ---

1 --- --- 12.50 12.50 12.50 12.50 --- --2 --- --- 15.75 15.75 16.25 16.38 --- ---

1. RF-raised-face flanges; RTJ-ring-type joint flanges; BWE -buttwelding ends;

SWE-socketweld ends.

CL900 CL1500

RF RTJ BWE SWE RF RTJ

CL2500

CL900 CL1500 PN160 PN250

CL2500

A

ASME EN

PN160 PN250

mm

Inches

Table 15. Globe Valve Dimensions with Standard

Bonnet

(1)

VALVE

SIZE,

NPS

1 146 146 146 146 146 146 134 138

2 187 189 187 187 187 189 172 180

(2)

3

(3)

3

4x3 212 214 209 --- 222 223 --- ---

4 229 230 238 --- 238 240 218 232

6x4 249 250 238 --- 276 279 --- ---

6 310 311 337 --- 337 340 298 316

8x6 317 319 336 --- 345 350 --- ---

1 --- --- 159 159 159 159 --- --2 --- --- 200 200 206 208 --- ---

1 5.75 5.75 5.75 5.75 5.75 5.75 5.29 5.45

2 7.38 7.44 7.38 7.38 7.38 7.44 6.78 7.09

(2)

3

(3)

3

4x3 8.38 8.44 8.25 --- 8.75 8.81 --- ---

4 9.00 9.06 9.38 --- 9.38 9.44 10.75 9.13

6x4 9.81 9.88 9.38 --- 10.88 11.00 --- ---

6 12.19 12.25 13.25 --- 13.25 13.38 11.72 12.43

8x6 12.5 12.56 13.25 --- 13.62 13.81 --- ---

1 --- --- 6.25 6.25 6.25 6.25 --- --2 --- --- 7.88 7.88 8.12 8.19 --- ---

1. RF-raised-face flanges; RTJ-ring-type joint flanges; BWE-buttwelding ends;

SWE-socketweld ends.

2. Manufactured in U.S.A.

3. Manufactured in Europeand Japan.

CL900 CL1500

RF RTJ BWE SWE RF RTJ

221 222 230 --- 230 232 --- --200 202 210 --- 210 211 192 202

CL2500

CL900 CL1500 PN160 PN250

8.69 8.75 9.06 --- 9.06 9.12 --- ---

7.88 7.94 8.25 --- 8.25 8.31 7.54 7.94

CL2500

B

ASME EN

PN160 PN250

mm

Inches

23

Page 24

Product Bulletin

51.2:HP

October 2014

HP Valve

D101635X012

Table 16. Globe Valve Dimensions with Standard

Bonnet

STANDARD BONNETS

VALVE

SIZE,

NPS

1 52 260 267 ---

2Std,

Whisper III,

Cavitrol III 3-Stage

2, Cavitrol III 2-Stage 77 279 286 344

Cavitrol III 3-Stage

2, Cavitrol III 2-Stage 84 320 320 40

Cavitrol III 3-Stage

2, Cavitrol III 2-Stage 3.06 11.00 11.25 13.56

Cavitrol III 3-Stage

2, Cavitrol III 2-Stage 3.31 12.59 12.59 14.53

1. Manufactured in U.S.A.

2. Manufactured in EuropeandJapan.

(1)

4x3, 3

(2)

3

6x4, 4 175 --- 300 368

8x6, 6 248 --- 365 402

1 63 35 35 ---

2Std,

Whisper III,

1 2.06 10 .25 10.50 -- -

2Std,

Whisper III,

(1)

4x3, 3

(2)

3

6x4, 4 6.88 --- 11.81 14.50

8x6, 6 9.75 --- 14.38 15.81

1 2.47 10 .07 10.07 -- -

2Std,

Whisper III,

Yoke Boss Diameters, mm (Inches)

G

71 (2-13/16) 90 (3-9/16)

mm

CL900 and 1500

77 261 267 331

121 322 311 370

141 289 278 337

CL2500

84 303 303 352

Inches

CL900 and 1500

3.06 10.31 10.56 13.06

4.75 12.69 12.25 14.56

5.56 11.38 10.94 13.25

CL2500

3.31 11.91 11.91 13.85

D

127

(5)

Table 17. Globe Valve Dimensions with Extension

Bonnet

EXTENSION BONNETS (CL900 AND 1500)

VALVE

SIZE,

NPS

1 52 384 400 ---

2Std,

Whisper III,

Cavitrol III 3-Stage

1 2.06 15.12 15.75 ---

2Std,

Whisper III,

Cavitrol III 3-Stage

2, Cavitrol III 2-Stage 3.06 17.62 18.25 20.38

2, Cavitrol III 2-Stage 77 448 464 518

Yoke Boss Diameters, mm (Inches)

G

71 (2-13/16) 90 (3-9/16)

mm

77 430 446 505

Inches

3.06 16.94 17.56 19.88

D

127

(5)

24

Page 25

HP Valve

D101635X012

Figure 13. Globe Valve Dimensions with Standard Bonnet (also see tables 14, 15, and 16)

Product Bulletin

51.2:HP

October 2014

FLANGED VALVE WITH 71 OR 90 mm

(2-13/16 OR 3-9/16 INCH)

A5700A-3

DIAMETER YOKE BOSS

MATCH LINE FOR

ACTUATOR

MATCH LINEFOR

ACTUATOR

MATCH LINE FOR

ACTUATOR

BUTTWELDING END VALVE WITH 71 OR 90 mm

(2-13/16 OR 3-9/16 INCH)

DIAMETER YOKE BOSS

TYPICAL NPS 1, 2, AND 3

MATCH LINE FOR

ACTUATOR

MATCH LINE FOR 585CSERIES

ACTUATORS AND TYPE 657,

667 SIZE 100 ACTUATORS

MATCH LINEFOR

ALL OTHER

ACTUATORS

25.4

(1.00)

mm

(INCHES)

127mm (5-INCH) DIAMETER YOKE BOSS

FOR USE WITH ALL

VALVES

MATCH LINE FOR 585C SERIES

ACTUATORS AND TYPE 657,

667 SIZE 100 ACTUATORS

FLANGED VALVE WITH 71 OR 90 mm

(2-13/16 OR 3-9/16 INCH)

DIAMETER YOKE BOSS

A2719A-4

Note:

For dimensions of valves with otherend connections, consult your Emerson Process Management sales office.

TYPICAL NPS 3 (EUROPE AND JAPAN MANUFACTURE), 4, AND 6

BUTTWELDING END VALVE WITH 71 OR 90 mm

(2-13/16 OR 3-9/16 INCH)

DIAMETER YOKE BOSS

MATCH LINE FOR

ALL OTHER

ACTUATORS

127mm (5-INCH) DIAMETER YOKE BOSS

FOR USE WITH FLANGEDOR

BUTTWELDING VALVE

25.4

(1.00)

mm

(INCHES)

25

Page 26

Product Bulletin

51.2:HP

October 2014

Table 18. Dimensions D for Style 1 Extension Bonnet

(A, B, and G Dimensions Listed in Figure 13 Do Not Change When Extension Bonnet is Used)

VALVE SIZE,

NPS

1(stdtrim) 383 390 ---

2 (std, Whisper III,

Cavitrol III, 3-stagetrim)

2(CavitrolIII

2-stage trim)

1(stdtrim) 15.09 15.34 ---

2 (std, Whisper III,

Cavitrol III 3-stage trim)

2(CavitrolIII

2-stage trim)

71 (2-13/16) 90 (3-9/16) 127 (5)

430 445 504

447 463 517

16.91 17.53 19.84

17.59 18.22 20.34

Yoke Boss Diameters, mm (Inches)

mm

Inches

D

Figure 14. Dimensions D for Style 1 Extension Bonnet (A, B, and G Dimensions Listed in Figure 13 Do Not Change

When Extension Bonnet is Used) (also see tables 17 and 18)

HP Valve

D101635X012

MATCH LINE

FOR ACTUATOR

D

G

B

A

FLANGED VALVE WITH STYLE 1

EXTENSION BONNET HAVING 71 OR 90 mm

(2-13/16 OR 3-9/16 INCH)

A5701A-2

DIAMETER YOKE BOSS

MATCH LINE FOR

585C SERIES ACTUATORS

MATCH LINE FOR ALL

OTHER ACTUATORS

D

25.4

(1.00)

127 mm (5-INCH) DIAMETER YOKE BOSS

FOR STYLE 1 EXTENSION BONNET

mm

(INCHES)

26

Page 27

HP Valve

D101635X012

Table 19. Angle Valve Dimensions with Standard Bonnet

STANDARD BONNETS

VALVE

SIZE,

NPS

1 230 204 238 210 --- ---

2Std,

Whisper III,

Cavitrol III 3-Stage

2

Cavitrol III 2-Stage

3 259 --- 265 --- 329 ---

4 289 --- 278 --- 337 ---

6 --- --- 300 --- 368 ---

8 --- --- 364 --- 401 ---

1 9.06 8.04 9.38 8.28 --- ---

2Std,

Whisper III,

Cavitrol III 3-Stage

2

Cavitrol III 2-Stage

3 10.19 --- 10.44 --- 12.94 ---

4 11.38 --- 10.94 --- 13.25 ---

6 --- --- 11.81 --- 14.50 ---

8 --- --- 14.34 --- 15.77 ---

VALVE

SIZE,

NPS

1 354 373 371 388 --- ---

2Std,

Whisper III,

Cavitrol III 3-Stage

2

Cavitrol III 2-Stage

1 13.94 14.67 14.62 15.28 --- ---

2Std,

Whisper III,

Cavitrol III 3-Stage

2

Cavitrol III 2-Stage

CL900 and 1500 CL2500 CL900 and 1500 CL2500 CL900 and 1500 CL2500

CL900 and 1500 CL2500 CL900 and 1500 CL2500 CL900 and 1500 CL2500

71 (2-13/16) 90 (3-9/16) 127 (5)

227 240 233 229 297 288

244 257 251 246 314 305

8.94 9.45 9.19 9.00 11.69 11.32

9.62 10.13 9.88 9.69 12.38 12.01

EXTENSION BONNETS

71 (2-13/16) 90 (3-9/16) 127 (5)

395 --- 411 --- 470 ---

413 --- 429 --- 487 ---

15.56 --- 16.19 --- 18.50 ---

16.25 --- 16.88 --- 19.19 ---

Product Bulletin

51.2:HP

October 2014

D

Yoke Boss Diameters, mm (Inches)

mm

Inches

D

Yoke Boss Diameters, mm (Inches)

mm

Inches

27

Page 28

Product Bulletin

51.2:HP

October 2014

HP Valve

D101635X012

Table 20. Angle Valve Dimensions with Standard Bonnet

VALVE

SIZE,

NPS

1 141 102 141 141 141 141 141 141 130 134

2 184 124 178 179 178 178 178 179 163 170

3 --- --- 226 227 235 --- 235 237 --- --4 --- --- 273 275 273 --- 273 275 --- ---

6 --- --- 325 327 353 --- 353 356 --- --8 --- --- 387 389 416 --- 416 421 --- ---

1 5.56 4.00 5.56 5.56 5.56 5.56 5.56 5.56 5.10 5.26

2 7.25 4.88 7.00 7.06 7.00 7.00 7.00 7.06 6.40 6.71

3 --- --- 8.88 8.94 9.25 --- 9.25 9.31 --- --4 --- --- 10.75 10.81 10.75 --- 10.75 10.81 --- --6 --- --- 12.81 12.88 13.88 --- 13.88 14.00 --- --8 --- --- 15.25 15.31 16.38 --- 16.38 16.56 --- ---

1. RF–raised-face flanges; RTJ–ring-type-joint flanges; BWE–buttwelding ends; SWE–socket-weld ends.

G A&G

ASME EN

CL2500 CL900 CL1500

SWE SWE RF RTJ BWE SWE RF RTJ

mm

Inches

(1)

PN160 PN250

Figure 15. Angle Valve Dimensions with Standard Bonnet (also see tables 19 and 20)

MATCH LINE

FOR ACTUATOR

MATCH LINE

FOR ACTUATOR

FLANGED VALVE WITH 71 OR 90

mm (2-13/16 OR 3-9/16 INCH)

DIAMETER YOKE BOSS

A6018A-1

1

For CL900 and 1500 valves, G = A. For CL2500 valves, see table 20 for theG dimension.

Note:

For dimensions of valves with otherend connections, consult your Emerson Process Management sales office.

FLANGED VALVE WITH STYLE 1 EXTENSION BONNET

HAVING 71 OR 90 mm

(2-13/16 OR 3-9/16 INCH) DIAMETER YOKE BOSS

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher, FIELDVUE, WhisperFlo, Cavitrol, Whisper Trim, and ENVIRO-SEAL aremarks owned by one of the companies in the Emerson Process Management

business unit of Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric

Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informationalpurposes only, and whileevery effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1991, 2014 Fisher Controls International LLC. All rights reserved.

28

Loading...

Loading...