Page 1

Emerson Deepwater Offshore Solutions

Proven Fisher® technology to mitigate risks and meet production targets

Page 2

2 | Offshore Solutions

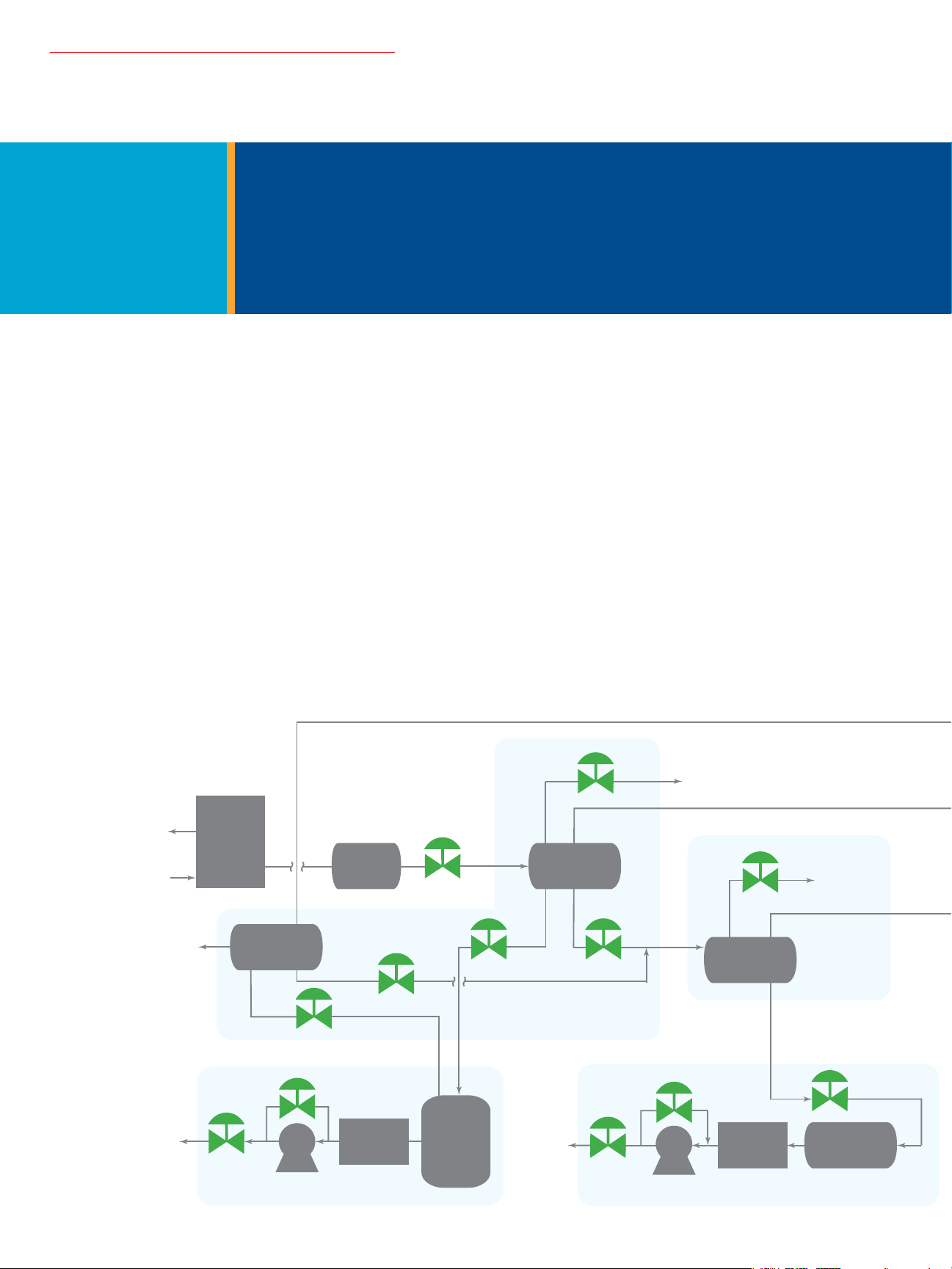

HIGH PRESSURE COMPRESSION SYSTEM

LOW PRESSURE COMPRESSION SYSTEM

“Unplanned maintenance or shutdowns put my

personnel and process at risk. High operating costs

and declining production prevent me from reaching

the target return on our production assets.”

As offshore exploration activities continue to increase and drilling deepens, the risks to your assets

compound. If your equipment isn’t running at its best in remote and extreme environments, you put

your personnel at risk. Common process upsets caused by inefficient control valves can negatively

impact your production uptime, increasing operational costs and the chances of a safety incident.

What if you could...

+ MAXIMIZE PRODUCTION with proven technology, durable equipment, and application expertise? pages 4-7

+ REDUCE OPERATIONAL COSTS and risks to your personnel with proven-reliable technology? pages 8-10

+ INCREASE UPTIME by having access to reliable control valve service and support? page 11

Mitigate risks and meet production targets with proven Fisher® technology for your critical valve applications:

GAS/WATER

INJECTION

TO WELL

FROM WELL

GAS SCRUBBERS

AND COMPRESSION

WELL

HEAD

TEST

SEPARATOR

SLUG

CATCHER

2

1

HIGH PRESSURE

SEPARATOR

1

1

1

GAS TO

FLARE

LOW PRESSURE

SEPARATOR

2

GAS TO

FLARE

LOW PRESSURE

SEPARATION

SYSTEM

OVERBOARD

OR INJECTION

6/7

1

5

MAIN

PUMP

WATER INJECTION SYSTEM

FLOATATION

CELL

FREE

WATER

KNOCKOUT

HIGH PRESSURE

SEPARATION SYSTEM

PIPELINE

1

BULK

TREATER

MAIN

PUMP

3

DRY OIL

TANK

OIL TREATMENT SYSTEM

4

Page 3

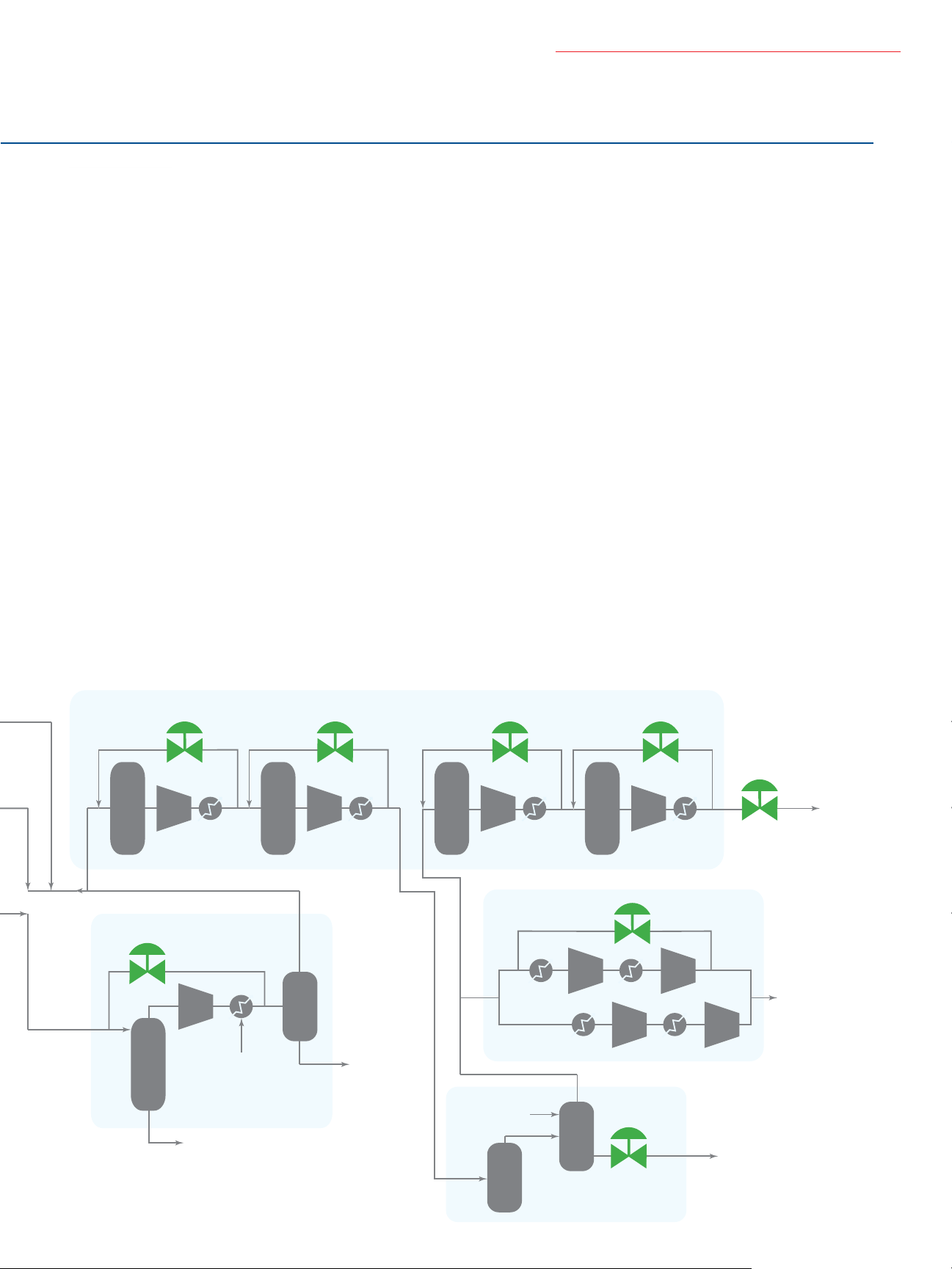

1 2 3 4 5

Offshore Solutions | 3

Level Control Valve

► more on pages 6 & 7

Gas to Flare Valve

► more on page 4

Oil Pump

Recirculation Valve

Oil Pump Discharge Valve Water Injection Pump

6 7 8 9 10

Water Injection Valve

► more on page 5

HIGH PRESSURE COMPRESSION SYSTEM

Water Overboard

Valve

Compressor Antisurge Valve

► more on page 9

Gas Injection Valve

► more on page 6

8 8 8 8

Recirculation Valve

► more on page 5

Glycol Contactor Level

Control Valve

► more on page 6

LOW PRESSURE COMPRESSION SYSTEM

8

INPUT FROM

LOW PRESSURE

DISCHARGE

SUCTION SCRUBBER

9

FUEL GAS SYSTEM

8

FUEL

GAS

SYSTEM

COMPRESSION

DISCHARGE

SCRUBBER

GAS DEHYDRATION

SYSTEM

10

Page 4

4 | Offshore Solutions

MAXIMIZE PRODUCTION

A lot goes into the sizing and selection of a control valve.

A procedure based on sound engineering principles,

coupled with real-world knowledge of your process,

helps determine the valve selections that are most

appropriate for your production requirements. Total

comprehension of this procedure, your process, and

the engineered specifications of your applications are

critical to helping you reach your production targets.

By partnering with Emerson, you can work alongside

a team of application experts who are dedicated

to solving your toughest offshore challenges. Our

engineers carry out the sizing and selection of your

control valve equipment with precision for detail.

This helps you reach your production targets and gain

confidence in your process.

Fisher HP control valve with Whisper trim™

(often used in gas-to-flare applications)

Reduce Noise and Improve Output

Gas-to-flare systems are an integral part of many

deepwater offshore assets. They safeguard against the

overpressure of critical equipment and are vital to the

start-up, shut-down, and short-duration upsets of your

offshore production platform.

Like any critical application, the gas-to-flare application

comes with its challenges. Significant pressure drops

and high flow rates across the valve are the primary

concerns. If these issues are not taken into account

during the valve sizing and selection process, excessive

noise levels and even damaging vibration can occur,

resulting in production interruptions, safety incidents,

or environmental fines.

Emerson engineers use aerodynamic noise modeling

and prediction technology to account for independent

trim and valve body noise, leaving you with a

customized valve solution that best fits your large

pressure drop applications. This comprehensive

approach incorporates field-proven, noise-attenuating

valve trims, like Fisher Whisper III trim, to reduce noise

and prevent damaging vibration. When you’re able

to control noise effectively, you can keep production

running smoothly and safely.

Laser shadowgraphs show jet independence from three

properly spaced holes (left). The same three holes spaced too

closely (right) show jet interaction, which leads to additional

noise. Being able to predict and control jet interaction can

reduce the noise produced by up to 40 dBA.

A top-down look at flow through Fisher WhisperFlo™ trim (left) using

computational fluid dynamics illustrates the independence of fluid

jets as they exit the cage. In contrast, the exit jets of some tortuous

path trims (right) impinge upon one another in pairs, creating an

additional noise source.

Page 5

Combat Corrosion, Mitigate Erosion, and Increase Recovery

Offshore Solutions | 5

Water injection systems can be one of the most difficult applications on your

offshore asset. Because they serve to significantly increase extraction, these

systems are essential to meeting production targets. High-pressure water

is injected into the well to dispose of water recovered from processing or

to help facilitate product flow by maintaining reservoir pressure. While sea

water is often the most convenient source for this system, it also presents its

own unique set of challenges unlike those that exist onshore.

The pressures at the bottom of the ocean and down the wellbore are much

greater than those on the surface. However, the inherently corrosive nature

of seawater could be the most difficult characteristic to combat. Its alkalinity,

or pH, can cause a chemical reaction that quickly degrades your control valve

equipment. Sand, microorganisms, and other particulates, combined with

the high pressure drops can shorten control valve life by plugging the cage

and causing material erosion or corrosion of the plug, cage, and seat. Damage

to the control valve body may also occur. These issues compromise your

production efforts and may shutdown your process.

With a variety of valve materials suited for corrosion resistance, Emerson

engineers can help you select a valve construction that will endure even

the harshest conditions. Designed specifically for dirty service applications,

Fisher dirty service trim technologies allow particulate to pass, while

resisting or eliminating cavitation or process particulate damage. The

use of corrosion-resistant alloys, such as super duplex steel in trim

components, can help reduce chloride pitting and stress corrosion cracking

to promote longer service life and tighter shutoff.

MATERIALS

MATTER.

We’ve got you

covered:

Tungsten Carbide

Super Duplex

Duplex

Ceramic

Ferrallium

Inconel

Aluminum Bronze

Monel

254 SMO

Superaustenitic

WCC

316sst

440C

Scan this QR code to learn

more about solutions for

cavitation control.

PROVEN RESULTS

APPLICATION: The water injection system of an offshore platform in the Gulf of Mexico

CHALLENGE : Subjected to pressure drops as high as 10,000 psi (689.5 bar) and abrasive sea water,

valves in this application are prone to clogging, severe cavitation damage, and corrosion.

Valve failures were costing the facility 3000 barrels in lost production per day.

SOLUTION: Using Fisher HP valves fitted with Cavitrol

opposed to containment—the platform was able to increase runtime of the waterflood

system by nearly 80%. With Fisher Lifecycle Services’ Quick Ship delivery, the application was

restarted 15 weeks sooner than planned, saving the platform more than $300,000 USD per day.

™

trim—designed to eliminate cavitation, as

Titanium

Fisher forged-block

HP control valve with

Cavitrol IV trim

Page 6

6 | Offshore Solutions

MAXIMIZE PRODUCTION

Full Range Equipment for Variable Pressures

Like water injection, gas lift and gas injection are methods used

to increase production as the well ages. In this application, gas

injection may also be used as a way to dispose of unwanted

gas production. In either case, the valves are subjected to

high pressures and large pressure drops and must be able to

maintain sufficient uptime. With little opportunity to change

out the valve—not to mention the high cost of doing so—proper

engineering and configuration up front is critical.

Emerson engineers understand that the success of the gas lift

and gas injection methods are directly tied to the initial design of

the control valve. When you require thorough engineering and

high quality standard design, Fisher high pressure control valves

(HP series) provide a thicker valve body wall for extra protection

against erosion and corrosion.

Fisher valves are factory-tested beyond

standard requirements for tight shutoff

and endurance to extend service life and

ensure you achieve optimum production.

Scan the QR code to learn more about

Fisher solutions for noise abatement.

Identifying application challenges during the engineering

of a valve is crucial to ensuring valve reliability and more

importantly, ensuring the safety of your personnel.

Optimized Level Control

Carefully managing the levels of oil, water, and

glycol is critical to ensuring you get the highest

quality product. Level control valves and

controllers are integral in separating water, gas,

and other constituents from the oil before it is

shipped from the offshore production asset.

The erosive qualities associated with deep

water extraction, like sand and salt particulates,

put these valves under a lot of stress. Flashing,

erosion, and high vibration only add to what is

already a critical application.

With these issues in mind, Emerson has a

variety of Fisher valves, trims, and materials

to handle the challenging level control

applications found on your offshore asset.

Page 7

Dependable Performance Across the Board

Emerson uses innovative engineering practices to give you highperforming, reliable solutions specifically for precise level control.

™

The rugged Fisher easy-e

extensive flow testing and evaluation, yielding a robust control

valve that is the industry standard for dependability and longevity.

And, with interchangeable trim parts, the easy-e valve allows you

to minimize your valve investment while maximizing your control

options. You’ll quickly understand why over a million units have been

installed globally in a broad range of applications.

Also available, the Fisher Vee-Ball

V-notch ball provides positive shearing action and a nearly equal

percentage flow characteristic. It is essential to the accuracy and

controllability of your system and provides non-clogging, high

capacity flow control of your gas, steam, and clean or dirty fluids.

Extensive flow loop testing has demonstrated the Vee-Ball valve’s low

friction performance advantage in controlling process variability.

Both the easy-e valve and the Vee-Ball valve can be coupled with a

full range of Fisher actuators and FIELDVUE

to yield compact, easy-to-handle control valve assemblies. All

components are engineered to work together to deliver dynamic

performance and reliability.

sliding-stem control valve has undergone

™

rotary control valve with its

™

digital valve controllers

Offshore Solutions | 7

EXCEEDING EXPECTATIONS

Every Fisher control valve design

received Lloyd’s Register’s Marine Type

Approval for process applications within

the offshore oil and gas production

industry, including those high integrity

control valve applications that could

potentially affect the safe operation of

the offshore installation. In fact, all Fisher

products have been thoroughly tested

per Lloyd’s Register requirements to

confirm compliance with marine industry

standards. All product designs have been

certified to meet rigorous offshore codes

and standards.

Fisher control valve assemblies are subjected to

in-line dynamic performance testing to evaluate

their ability to reduce process variability.

In addition to Marine Type Approval,

Emerson facilities in all world areas have

been approved to manufacture products

certified to Lloyd’s Register Marine rules.

And one more thing—no other control valve

supplier in the world can say the same.

Scan the code to learn more about what

the Lloyd’s approval could mean for

maximizing your production efforts.

Page 8

8 |Offshore Solutions

REDUCE OPERATIONAL COSTS

For years, reactive and routine maintenance has been the

standard approach to valve and instrument care in the oil &

gas industry. “Run-to-fail” often seemed like the most costeffective option. A traditional alternative to the run-to-fail

strategy is schedule-based maintenance where inspections and

refurbishments are performed to a schedule—whether they are

necessary or not. As offshore production grows and technology

expectations increase, it’s evident that reactive and schedulebased maintenance is not a sustainable strategy.

By implementing field-proven control valves and instruments

from the very start of your planning and designing process,

you can optimize your maintenance program, streamline your

process, improve your performance, and protect your personnel.

Using a valve signature series test, you can easily track

the operating health of your control valve without

removing it from the line.

The Control Valve You Choose Matters

When you buy Fisher control valves, you get the application expertise that comes from

more than a century of oil & gas production experience. Plus you benefit from millions of

dollars of research invested in reliability-centric testing of Fisher control valve technologies.

Fisher product specifications are, in many cases, more stringent than the industry accepted

standards set by regulatory agencies. Our attention to and evaluation of product quality is

necessary to bring you Fisher technologies of the highest reliability and performance. Fisher

technology development capabilities extend worldwide with engineers and labs in North

America, Europe, and Asia.

Using Fisher technology can help you achieve efficient, productive, and reliable plant

operation. Want to see for yourself? Visit the Emerson Innovation Center for Fisher

Technology in Marshalltown, Iowa, USA. To schedule a visit, please contact your local

Emerson sales office.

Scan the code to watch how

Fisher products are rigorously

tested to meet safety and

performance standards.

Page 9

By moving the compressor’s

operating point closer to

the surge limit line, you can

operate more efficiently.

Offshore Solutions | 9

Safely Operate Closer to Compressor Limits

Compressors can be the most critical and expensive

components on your offshore asset. To minimize unplanned

downtime, equipment damage, and risks to personnel

safety, it’s critical to have a system and valve that recognize

an impending surge condition and take immediate action to

prevent it.

Typical methods for maintaining surge control include either

a blow-off to atmosphere or recirculation from the outlet to

the inlet of the compressor. The anti-surge control strategy is

tightly integrated with the compressor load control strategy.

The control strategy requires not only a fast-acting controller,

but a fast-acting valve with properly selected noise-attenuating

and vibration-reducing trim to release or recirculate the flow.

Fisher optimized digital valves (ODV) and the predictive

diagnostic capability of the FIELDVUE digital valve controller

make it easier for operators to protect the compressor and

ensure valves are working properly. Using the FIELDVUE

digital valve controller, you can remotely check for valve

packing friction, air leaks, stuck valves, and even analyze valve

health while in-service or offline. With an antisurge valve that

moves with greater speed, precision, and control, you can

push the compressor’s operating point closer to the surge

limit—increasing efficiency, while avoiding process upsets

and compressor failure. Fisher control valves and instruments

exhibit industry-leading dynamic performance.

The FIELDVUE digital valve controller offers

antisurge-specific tuning capability that is an

integral part of the Fisher ODV package.

Scan the code to learn more about the

FIELDVUE DVC6200 digital valve controller

with stainless steel housing to handle

abrasive offshore environments.

Page 10

10 | Offshore Solutions

REDUCE OPERATIONAL COSTS

Flow Stability Means Improved Uptime

Extreme water depths mean extreme conditions, like frigid

temperatures, high pressures, and corrosion. Such severe

temperatures, pressures, and pressure drops can result in the

formation of ice-like structures, called hydrates. Hydrates

can cause large plugs that block piping and other equipment,

causing them to become inoperable. High pressure and low flow

rates can also cause erosion, often requiring increased valve

maintenance or costly downtime.

Mono-ethylene glycol (MEG) is used as a freeze-protectant to

help inhibit the formation of hydrates. MEG injection control

valves regulate the flow of MEG and are critical to providing

precise and continuous MEG dosage, as even the smallest

percentage loss of MEG dosage can lead to hydrate formation.

Fisher HP control valve with Cavitrol III micro-flat trim

(often used in MEG injection applications)

Tested to the highest requirements, including seat leakage,

packing emission, cavitation, and erosion, Fisher control valves

and instruments used in MEG injection applications are designed

to prevent erosion damage to the seat and plug to maintain

integrity for tight shutoff and precise, continuous flow control.

The valve plug and seat ring are uniquely matched to regulate

flow during very low flow and high pressures. A valve with

built-in reliability means preventing hydrates from the start,

so you can meet the flow requirement and attain the highest

performance from your process.

Fisher control valves shown in an offshore environment.

Page 11

Offshore Solutions | 11

INCREASE UPTIME

Improved Availability and Dependable Support

The way you manage key production assets like control valves directly affects your plant’s

efficiency, reliability, and profitability. Emerson Process Management’s Fisher Services provides

trusted expertise for control valve maintenance and repair.

Whether you’re starting or commissioning a process, scheduling diagnostics and repair, or

planning a turnaround with upgrades to optimize and extend your plant’s lifecycle, our network of

owned and authorized service centers around the world provide effective maintenance through a

network of experienced, highly skilled technicians when and where you need them.

To help you maintain your plant’s efficiency and reliability, Fisher Services uses only certified OEM

parts and assemblies sourced through local inventories, regional parts distribution centers, and

Quick Ship facilities to deliver unmatched response to customer needs.

Page 12

To learn more, visit Fisher.com/OilandGas or contact

your local Emerson sales office. Take advantage of

the many benefits of Fisher solutions today.

http://www.Facebook.com/FisherValves

http://www.Twitter.com/FisherValves

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

D352312X012 / MAA17 / Nov14

http://www.YouTube.com/user/FisherControlValve

http://www.LinkedIn.com/groups/Fisher-3941826

© 2014 Fisher Controls International LLC. All rights reserved.

Fisher, Whisper Trim, WhisperFlo, Cavitrol, easy-e, Vee-Ball, and FIELDVUE are marks owned by one of the

companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All

other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has

been made to ensure their accuracy, nothing herein is to be construed as a warranty or guarantee, express

or implied, regarding the products or services described herein or their use, performance, merchantability

or tness for a particular purpose. Individual results may vary. All sales are governed by our terms and

conditions, which are available upon request. We reserve the right to modify or improve the designs or

specications of our products at any time without notice. Responsibility for proper selection, use and

maintenance of any product or service remains solely with the purchaser and end user.

Loading...

Loading...