Page 1

Product Bulletin

51.1:GX 3--Way

D103305X012

August 2011

GX 3--Way Valve and Actuator

Fisherr GX 3-Way

Control Valve and Actuator System

The Fisher GX 3-Way is a compact, state-of-the-art

control valve and actuator system, designed to

accurately control water, oils, steam, and other

industrial fluids. The robust GX 3-way valve package

is perfectly suited to address the space limitations of

the OEM industry.

The GX 3-Way is rugged, reliable, and easy to

select. The internal valve trim is designed to ensure

long service life and avoiding unnecessary

maintenance. The same construction may be used

for both converging and diverging applications.

The GX 3-Way meets the requirements of both EN

and ASME standards. It is available with a complete

accessory package, including the FIELDVUEt

DVC2000 integrated digital valve controller.

The GX 3-Way trim characteristics are designed for

accurate temperature control in heat exchanger

applications.

D Side-Port Common (SPC)----The side flange is

the common pipe connection for general converging

(flow-mixing) and diverging (flow-splitting) service

(see figure 5). Utilizes an unbalanced plug design.

D Bottom-Port Common (BPC)----A balanced

design used for high nP applications. The bottom

flange is the common pipe connection for both

converging and diverging service (see figure 9).

D High--Temperature Side--Port Common

(SPC)-- -- The side flange is the common pipe

connection for general converging (flow-mixing) and

diverging (flow-splitting) service (see figure 3).

Utilizes an unbalanced plug design, a stem

extension, a yoke extension, and includes

live--loaded ULF graphite packing and a hard--faced

seat ring.

W9557

www.Fisher.com

GE49204

X0176

GX 3--WAY

Figure 1. Fisher GX 3-Way Control Valve, Actuator, and FIELDVUE DVC2000 Digital Valve Controller

GX 3--WAY HIGH--TEMPERATURE

Page 2

GX 3--Way Valve and Actuator

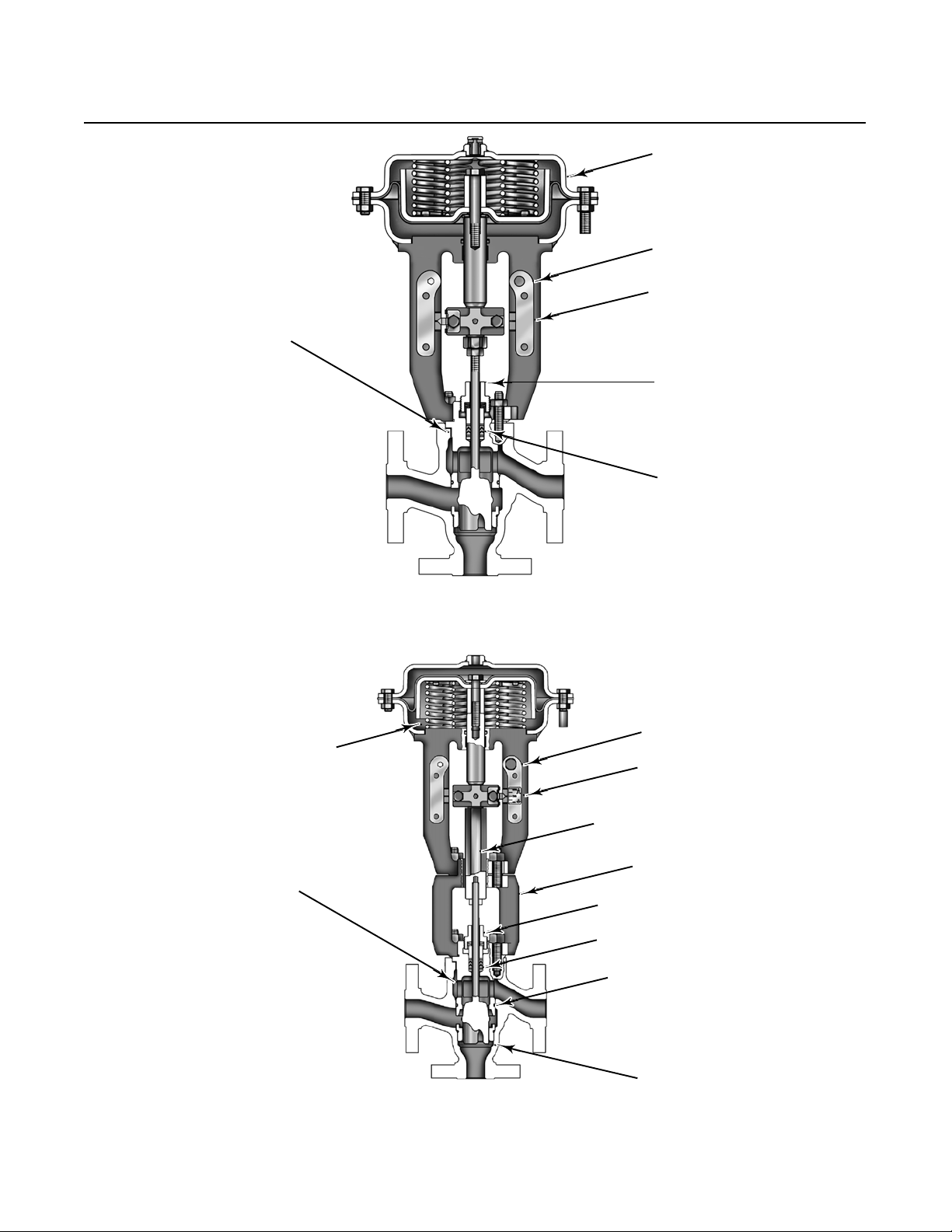

CLAMPED BONNET DESIGN

Product Bulletin

51.1:GX 3--Way

August 2011

COMPACT FIELD-REVERSIBLE

MULTI-SPRING ACTUATOR

INTEGRATED POSITIONER

MOUNTING

NAMUR POSITIONER

MOUNTING CAPABILITY

ONE-PIECE SCREWED

PACKING FOLLOWER

STANDARD LIVE-LOADED

PACKING

W9578-1

Figure 2. Fisher GX 3-Way Control Valve Assembly with Port-Guided Contoured Plug (Side Port Common)

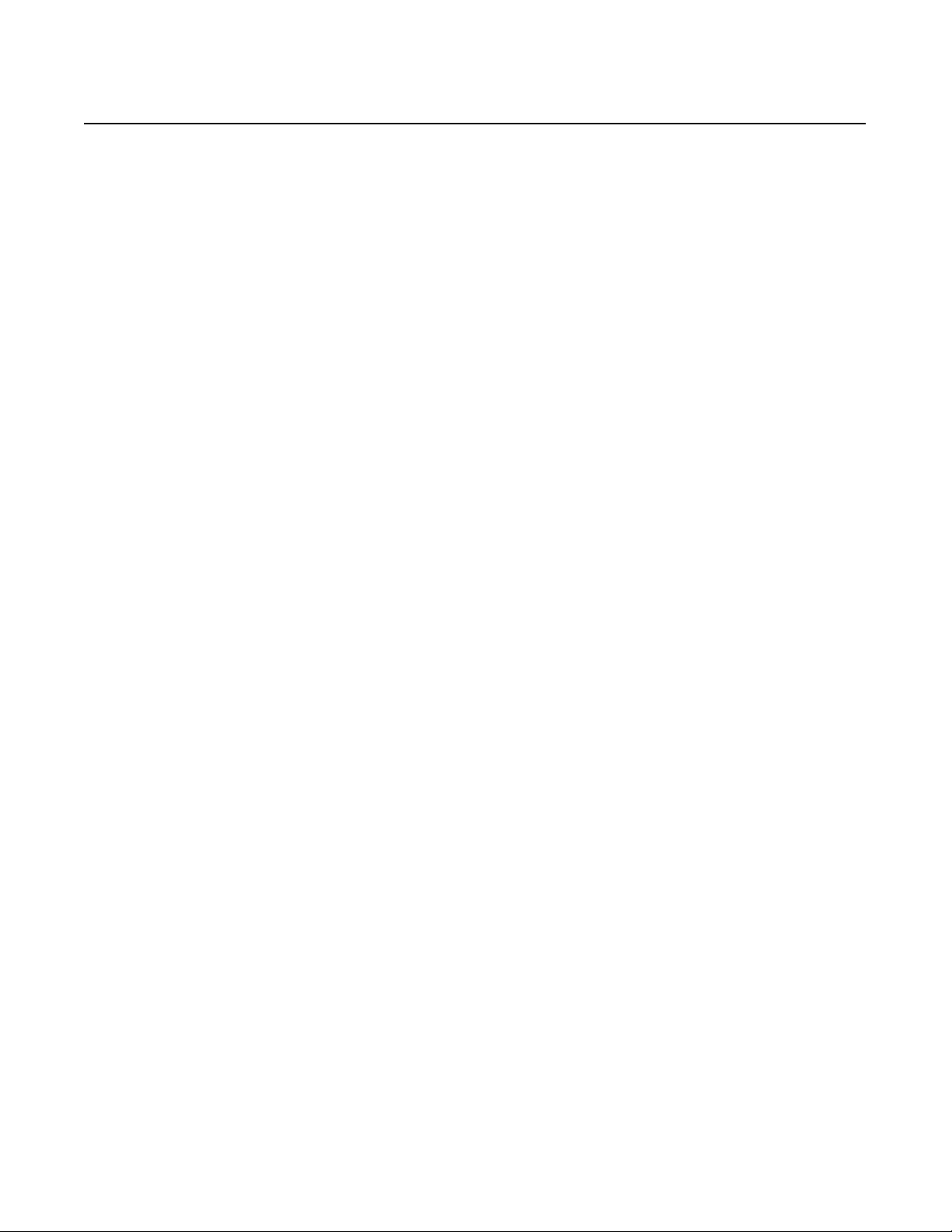

COMPACT FIELD-REVERSIBLE

MULTI-SPRING ACTUATOR

CLAMPED BONNET DESIGN

INTEGRATED POSITIONER

MOUNTING

NAMUR POSITIONER

MOUNTING CAPABILITY

STEM EXTENSION

YOKE EXTENSION

ONE-PIECE SCREWED

PACKING FOLLOWER

STANDARD GRAPHITE ULF

LIVE-LOADED PACKING

GRAPHITE SEAL RING

X0094--1

HARD--FACED SEAT AND GUIDE

SURFACES ON SEAT RING

Figure 3. Fisher GX 3-Way High--Temperature Control Valve Assembly with Port-Guided Contoured Plug (Side Port Common)

2

Page 3

Product Bulletin

51.1:GX 3--Way

August 2011

GX 3--Way Valve and Actuator

Contents

Features 3.................................

Principle of Operation 10.....................

GX 3-Way Control Valve Specifications

and Materials of Construction 11...........

The GX 3-Way Diaphragm Actuator 14........

Valve-Actuator Dimensions and Weights 17....

GX 3-Way Actuator Accessories 19...........

The FIELDVUE DVC2000

Digital Valve Controller 19.................

Optional Positioners and Instruments 20.......

Coefficients 21.............................

Features

D Easy to size and select

D No actuator sizing required--selection is

automatic

D Engineered for easy maintenance

D Maximum part commonality across sizes

D Replaceable trim

D Low lifetime costs

D Robust, low-profile design

D Available with integrated, easy-to-calibrate

DVC2000 digital valve controller

D Valve body sizes DN 25 to DN 100

(NPS 1 through 4)

D Pressure Classes PN 10-40,

CL150 and 300

D High capacity design

D Valve body flow passage optimized for flow

stability

D Shutoff capabilities: Class IV metal to metal

D ISO 5210 F7 mounting available for use with

electric actuators

3

Page 4

GX 3--Way Valve and Actuator

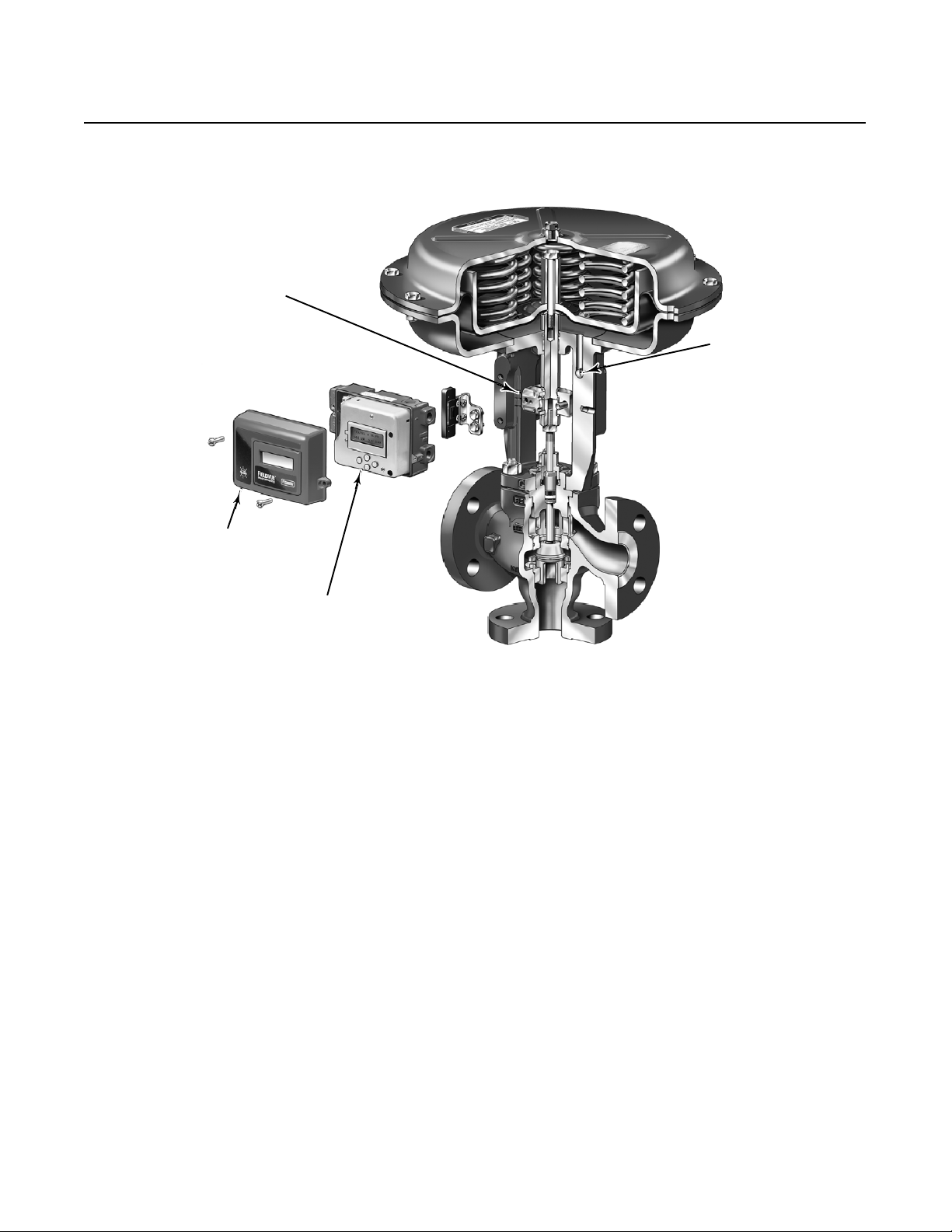

LINKAGE-LESS POSITION

FEEDBACK

Product Bulletin

51.1:GX 3--Way

August 2011

INTEGRAL PNEUMATIC

PASSAGEWAYS

DVC2000

COVER

PUSH-BUTTON INSTRUMENT

SETUP

Figure 4. Fisher GX 3-Way and FIELDVUE DVC2000 Digital Valve Controller

Optimized valve and actuator system. Product

simplicity and ease of selection form the foundation

of the GX 3-Way. Mounted with a digital or analog

positioner, the GX 3-Way provides high performance

control a cross a wide range of process applications.

Compact actuator design. The multi-spring GX

3-Way actuator is a compact robust design. The GX

3-Way design has been optimized to eliminate

complicated 3-way actuator sizing procedures - once

the valve body and port size are selected, the

actuator size is fixed.

Reliable Actuator Performance. Special actuator

diaphragm material helps reduce common problems

such as air o xidation, thermal aging, low

temperature embrittlement, and loss of retention.

The double-sided diaphragm within the a ctuator

helps eliminate mechanical wear-induced failure.

Modular design. The design architecture has been

optimized to maximize the use of common parts

across sizes. The actuator stem and stem connector

areusedacrossallGX3-Way sizes.

Low lifetime costs. Reduced product complexity,

low parts count, and part commonality all contribute

to reduced inventory and maintenance costs.

Stable flow control. The flow cavity of the GX

3-Way valve body has been engineered to provide

stable flow and reduce process variability. This linear

stability for both converging and diverging flow is

perfectly suited for temperature and pH control

applications.

Live-loaded packing. The GX 3-Way comes with

live-loaded PTFE V-ring packing as standard. The

live-loaded design helps to seal your process to

conserve valuable process fluid, while reducing

emissions to the environment. The long-life and high

reliability of the live-loaded system also reduces

maintenance costs and process downtime. ULF

(ultra low friction) graphite packing is also available

for all sizes and is standard on HT (high

temperature) construction.

4

Page 5

Product Bulletin

51.1:GX 3--Way

August 2011

GX 3--Way Valve and Actuator

Easy maintenance. The simple screwed seat-ring

and one -piece plug and stem design provide easy

maintenance. Design simplicity and parts

commonality contribute to reduced spares inventory.

The integrated DVC2000 digital valve controller

allows easy instrument removal, without a

requirement for tubing disconnection or replacement

(fail-down construction).

Digital valve controller. The GX 3-Wayisavailable

with the DVC2000 digital valve controller. The

DVC2000 is easy to use, compact, and designed for

easy mounting. It converts a 4-20 mA input signal

into a pneumatic output signal, which feeds the

control valve actuator. Instrument setup is performed

with a push button and liquid crystal display (LCD)

interface. This interface is protected from the

environment within a sealed enclosure. The interface

supports multiple languages, including German,

French, Italian, Spanish, Chinese, Japanese,

Portuguese, Russian, Polish, Czech, Arabic, and

English.

Intrinsic safety and non-incendive construction is

available to CSA, FM, ATEX, and IEC standards. An

optional module p rovides integrated limit switches

and a position transmitter.

Integrated mounting. The DVC2000 digital valve

controller integrally mounts to the GX 3-Way

actuator, eliminating the need for mounting brackets.

The DVC2000 transmits a pneumatic signal to the

actuator casing via an air passage in the yoke leg,

causing the valve to stroke (see figure 13). This

eliminates the need for positioner-to-actuator tubing

in the fail-down configuration.

The DVC2000 mounting interface is identical on both

sides of the actuator yoke for valve body sizes DN

25 through DN 100 (NPS 1 through 4). This

symmetrical design allows the DVC2000 to be easily

moved from one side of the valve to the other

without the need to rotate the actuator.

Linkage-less feedback. The DVC2000 digital valve

controller offers as standard a non-contacting valve

position feedback system. This is a true linkage-less

design, which uses no levers and no touching parts

between the valve stem and the positioner.

Additional Accessory selection. The GX 3-Way is

available with a variety of digital or analog

positioners besides the DVC2000, as well as

solenoid and limit switches. The actuator is also

compatible with the IEC 60534-6-1 (NAMUR)

positioner mounting standard.

5

Page 6

GX 3--Way Valve and Actuator

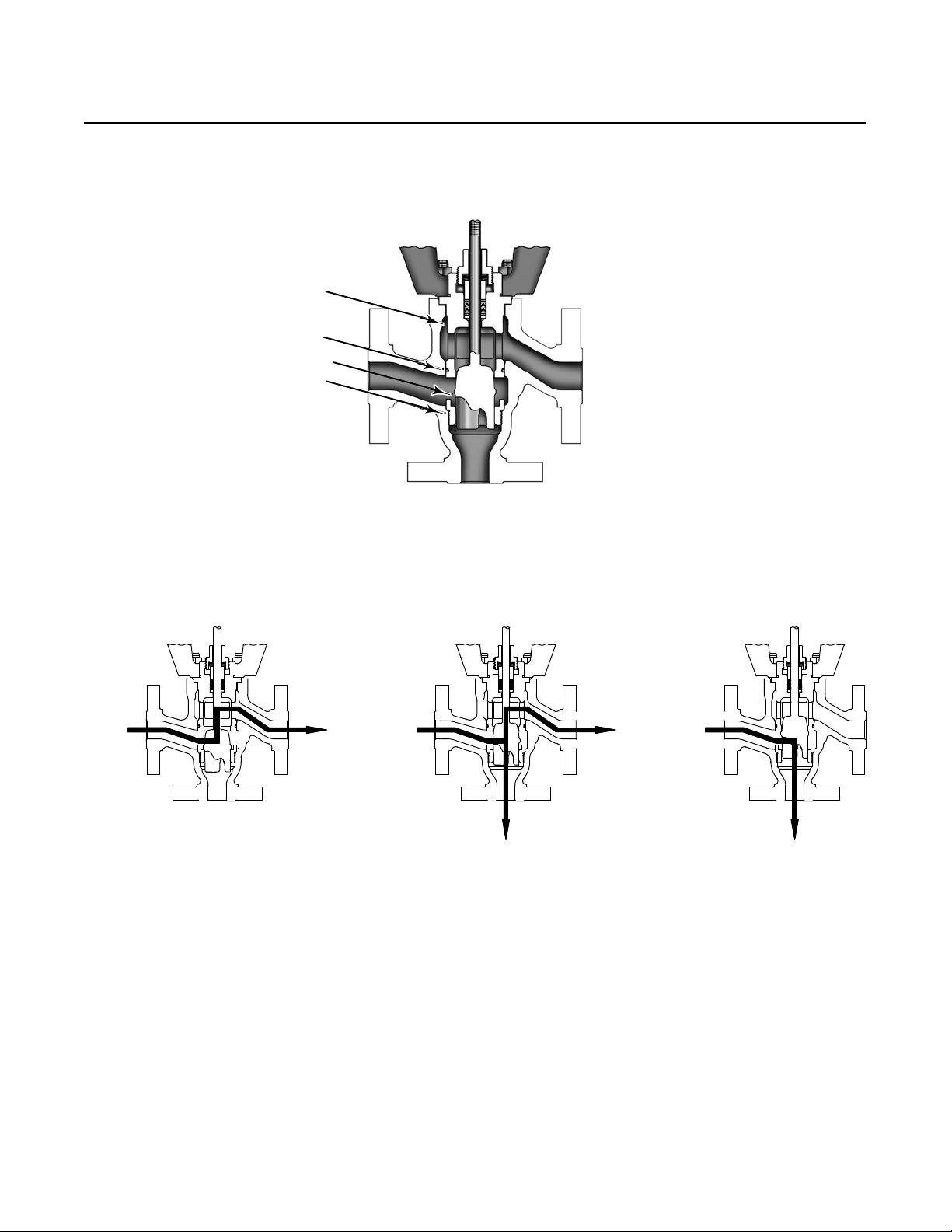

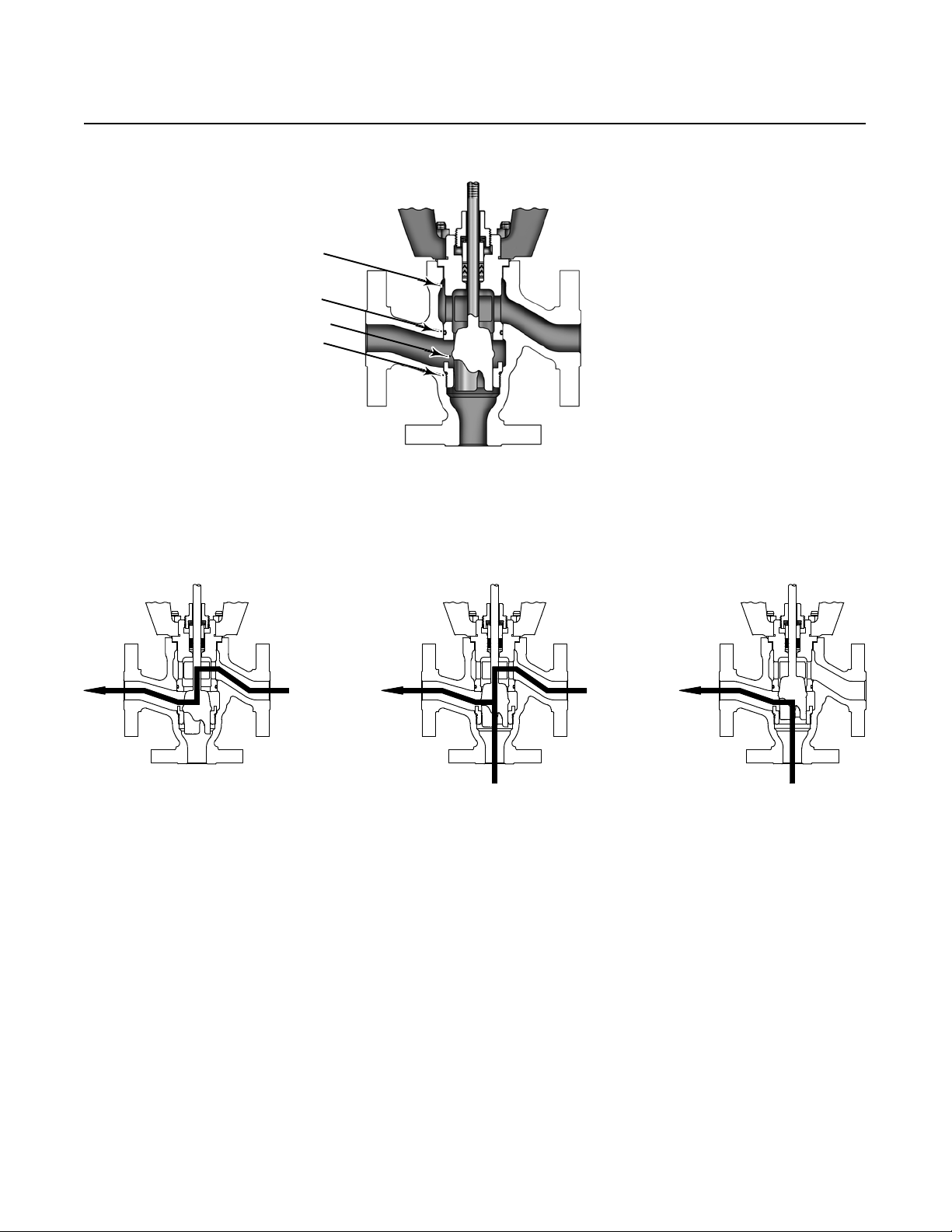

Flow Directions --- Side Port Common Constructions

See figures 5, 6, 7, and 8.

DIVERGING

BONNET

O-RING

LEFT PORT

(COMMON PORT)

W9580-1

VALVE PLUG

SEAT RING

BOTTOM PORT

Figure 5. Side Port Common Construction Details for Diverging Constructions

Product Bulletin

51.1:GX 3--Way

August 2011

RIGHT PORT

INLET

DIVERGING

PLUG DOWN (0% TRAVEL)

ALL FLOW PASSES

THROUGH FROM LEFT TO

RIGHT-HAND PORT

Figure 6. Fisher GX 3-Way Flow Directions for Side Port Common Diverging Constructions

PLUG MID TRAVEL (50% TRAVEL)

DIVERGING

INLET

FLOW IS DIVERTED EQUALLY

BETWEEN BOTTOM AND

RIGHT-HAND PORT

DIVERGING

PLUG UP (100% TRAVEL)

INLET

ALL FLOW PASSES

THROUGH FROM LEFT TO

BOTTOM PORT

6

Page 7

Product Bulletin

51.1:GX 3--Way

August 2011

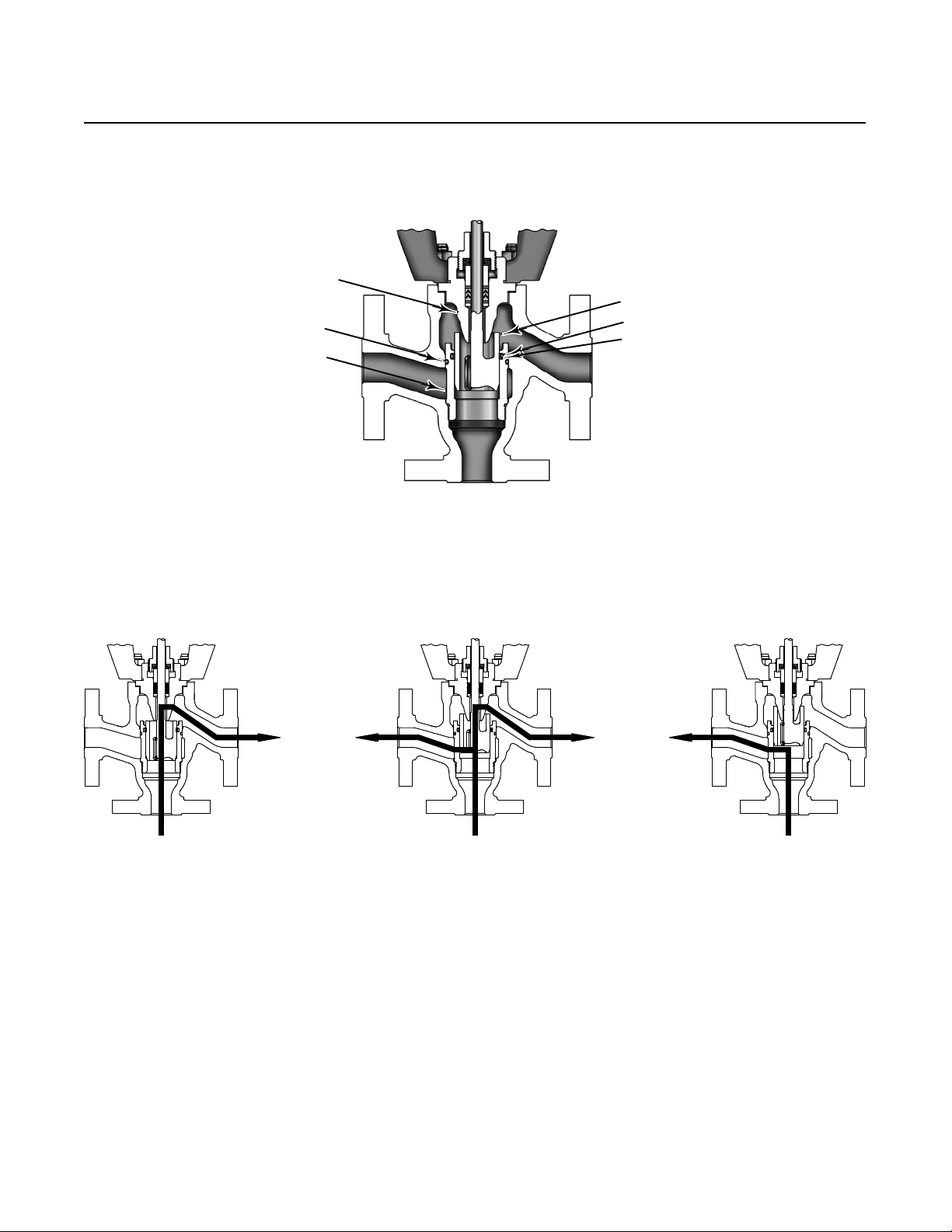

CONVERGING

LEFT PORT

(COMMON PORT)

BONNET

O-RING

VALVE PLUG

SEAT RING

GX 3--Way Valve and Actuator

RIGHT PORT

W9580-1

Figure 7. Side Port Common Construction Details for Converging Constructions

CONVERGING

PLUG DOWN (0% TRAVEL)

BOTTOM PORT FLOW IS SHUT-

OFF. ALL RIGHT-HAND FLOW

EXITS LEFT-HAND PORT

Figure 8. Fisher GX 3-Way Flow Directions for Side Port Common Converging Constructions

BOTTOM PORT

CONVERGING

PLUG MID TRAVEL (50% TRAVEL)

INLET INLET

INLET

FLOW IS MIXED EQUALLY FROM

BOTTOM AND RIGHT-HAND

PORTS

CONVERGING

PLUG UP (100% TRAVEL)

INLET

RIGHT-HAND FLOW IS SHUTOFF.

ALL BOTTOM PORT FLOW EXITS

THROUGH LEFT-HAND PORT

7

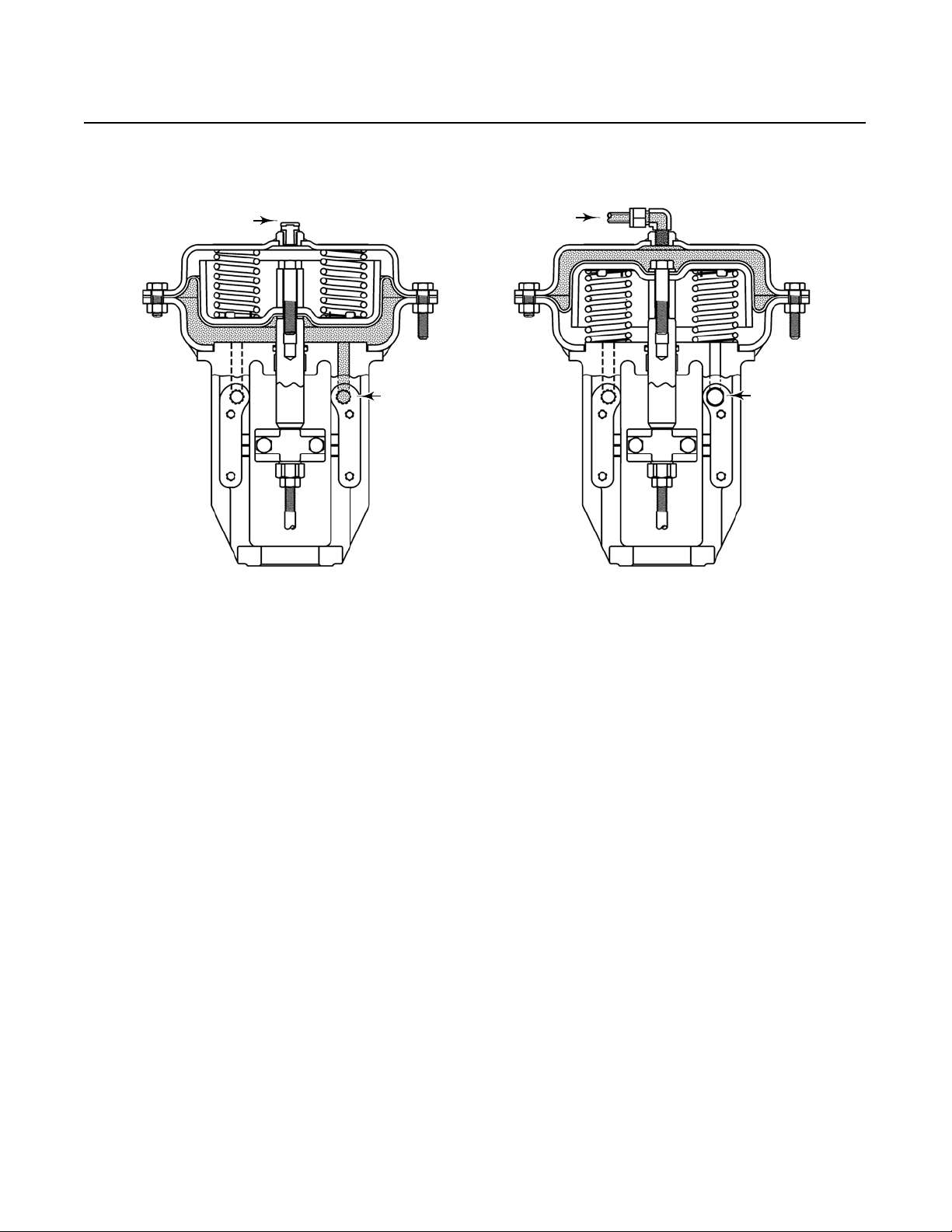

Page 8

GX 3--Way Valve and Actuator

Flow Directions --- Bottom Port Common Constructions

See figures 9, 10, 11, and 12.

DIVERGING

BONNET

O-RING

LEFT PORT

LOWER

SEAT / CAGE

Product Bulletin

51.1:GX 3--Way

August 2011

VALVE PLUG

SEAL RING

BACKUP RING

RIGHT PORT

W9579-1

DIVERGING

PLUG DOWN (0% TRAVEL)

INLET

ALL FLOW EXITING

RIGHT-HAND PORT

Figure 10. Fisher GX 3-Way Flow Directions for Bottom Port Common Diverging Constructions

BOTTOM PORT (COMMON PORT)

Figure 9. Bottom Port Common Construction Details for Diverging Constructions

DIVERGING

PLUG MID TRAVEL (50% TRAVEL)

INLET

FLOW IS DIVERTED EQUALLY

BETWEEN BOTH SIDE PORTS

DIVERGING

PLUG UP (100% TRAVEL)

INLET

ALL FLOW IS EXITING THE

LEFT-HAND PORT

8

Page 9

Product Bulletin

51.1:GX 3--Way

August 2011

GX 3--Way Valve and Actuator

CONVERGING

LEFT PORT

W9579-1

CONVERGING

PLUG DOWN (0% TRAVEL)

BONNET

VALVE PLUG

O-RING

LOWER

SEAT / CAGE

BOTTOM PORT (COMMON PORT)

SEAL RING

BACKUP RING

RIGHT PORT

Figure 11. Bottom Port Common Construction Details for Converging Constructions

PLUG MID TRAVEL (50% TRAVEL)

CONVERGING

CONVERGING

PLUG UP (100% TRAVEL)

LEFT-HAND FLOW IS SHUTOFF.

ALL RIGHT-HAND FLOW EXITS

THROUGH THE BOTTOM

Figure 12. Fisher GX 3-Way Flow Directions for Bottom Port Common Converging Constructions

INLET

INLET INLET

FLOW IS MIXED EQUALLY FROM

BOTH SIDE PORTS

INLET

RIGHT-HAND FLOW IS SHUTOFF.

ALL LEFT-HAND FLOW EXITS

THROUGH THE BOTTOM PORT

9

Page 10

GX 3--Way Valve and Actuator

Principle of Operation - GX 3-Way Actuator

Product Bulletin

51.1:GX 3--Way

August 2011

E0896-3

AIR VENT

FAIL-DOWN

(STANDARD CONFIGURATION)

Figure 13. Fisher GX 3-Way Principle of Operation--Actuator Fail Position

AIR SUPPLY

AIR SUPPLY

AIR VENT

FAIL-UP

(OPTIONAL CONFIGURATION)

Integrated Air Supply. When mounted with the

DVC2000 digital valve controller, the GX 3-Way uses

an integrated actuator air supply system. In the

fail-down configuration, air is supplied to the lower

actuator casing via a port on the actuator yoke face

-- no tubing is required. In the fail-up configuration,

air is supplied to the upper casing via tubing.

10

Page 11

Product Bulletin

51.1:GX 3--Way

August 2011

GX 3--Way Valve and Actuator

GX 3-Way Control Valve Specifications and Materials of Construction

See tables 1 and 2.

Table 1. Fisher GX 3-Way Valve Specifications

Specifications EN ASME

Va lve Body Size DN 25, 40, 50, 80, 100 NPS 1, 1--1/2, 2, 3, 4

Pressure Rating

End Connections

Va lve Body Materials

Bonnet Materials

PN 10 / 16 / 25 / 40 per EN 1092-1

Flanged raised face per EN 1092-1

1.0619 steel ASME SA216 WCC steel

1.4409 stainless steel ASME SA351 CF3M stainless steel

1.4409 stainless steel / CoCr-A SA351 CF3M SST / CoCr-A

Face-to-Face Dimensions

Shutoff per IEC 60534-4

and ANSI/FCI 70-2

Flow Direction Converging and Diverging

Trim Style

Side Port Common All sizes

Bottom Port Common All sizes

1. Stainless steel valve body is recommended for steam service when the high temperature (HT) construction is selected.

(1)

CL150 / 300 per ASME B16.34

Flanged raised face per ASME B16.5

Screwed (NPS 1, 1--1/2, and 2)

Seetable10

Metal seat - Class IV (standard)

SPC HT construction: Metal seat -- Class IV for bottom seat, Class II for upper seat

Type Plug Sizes Description

Unbalanced Port-guided

Balanced Cage-guided

Table 2. Materials (Other Valve Components)

Component Material

Packing Follower S21800 SST screwed follower

Body/Bonnet

Bolting and Nuts

Packing

Bonnet Gasket Graphite laminate

Bottom Port

Common Trim

(all sizes)

O-ring

(not used with

GX 3--Way HT)

Seal Ring

(GX 3--Way HT)

Stem Extension

(GX 3--Way HT)

SA193-B7 studs / SA194-2H nuts with NCF2 coating for carbon steel and stainless steel constructions

Live-loaded PTFE V-ring (standard) with N07718 Belleville springs

Live-loaded Graphite ULF (optional) with N07718 Belleville springs, (standard) on HT construction.

Carbon-Filled PTFE Seal Ring

NBR (Standard) --46 to 82_C (--50 to 180_F)

Ethylene Propylene [EPDM] (Optional): --46 to 232_C (--50 to 450_F) in steam and hot water;

Back-up Rings

NBR (Standard) --46 to 82_C (--50 to 180_F)

Ethylene Propylene [EPDM] (Optional): --46 to 232_C (--50 to 450_F) in steam and hot water;

--46 to 121_C (--50 to 250_F) in air (EPDM is not recommended for use in hydrocarbons)

FKM Fluorocarbon (Optional): --18 to 204_C(0to400_F) (Applicable in a wide variety of solvents, chemicals, and

hydrocarbons. Avoid use with steam, ammonia, or hot water over 82_C [180_F])

Graphite (FMS 17F27) --46 to 371_C (--50 to 700_F)

Stainless steel

--46 to 121_C (--50 to 250_F) in air (EPDM is not recommended for use in hydrocarbons)

FKM Fluorocarbon (Optional): --18 to 204_C(0to400_F) (Applicable in a wide variety of solvents,

chemicals, and hydrocarbons. Avoid use with steam, ammonia, or hot water over 82_C [180_F])

11

Page 12

GX 3--Way Valve and Actuator

Table 3. Trim Materials (all sizes)

Valve Body

Construction

Carbon steel (1.0619 /

WCC)

Stainless steel

(1.4409 / CF3M)

1. HT construction includes CF3M/CoCr--A lower seating. Seat and guide surfaces are hard--faced.

Trim Type Stem Plug Upper Seat Lower Seat/Cage

Bottom Port Common S31603 strain hardened

Side Port Common S31603 strain hardened CF3M

Bottom Port Common S31603 strain hardened

Side Port Common S31603 strain hardened CF3M

CF3M Chrome-plated CF3M/CoCr-A

CF3M/CoCr-A

CF3M Chrome-plated CF3M/CoCr-A

CF3M/CoCr-A

Product Bulletin

51.1:GX 3--Way

August 2011

(1)

CF3M

CF3M

CF3M

CF3M

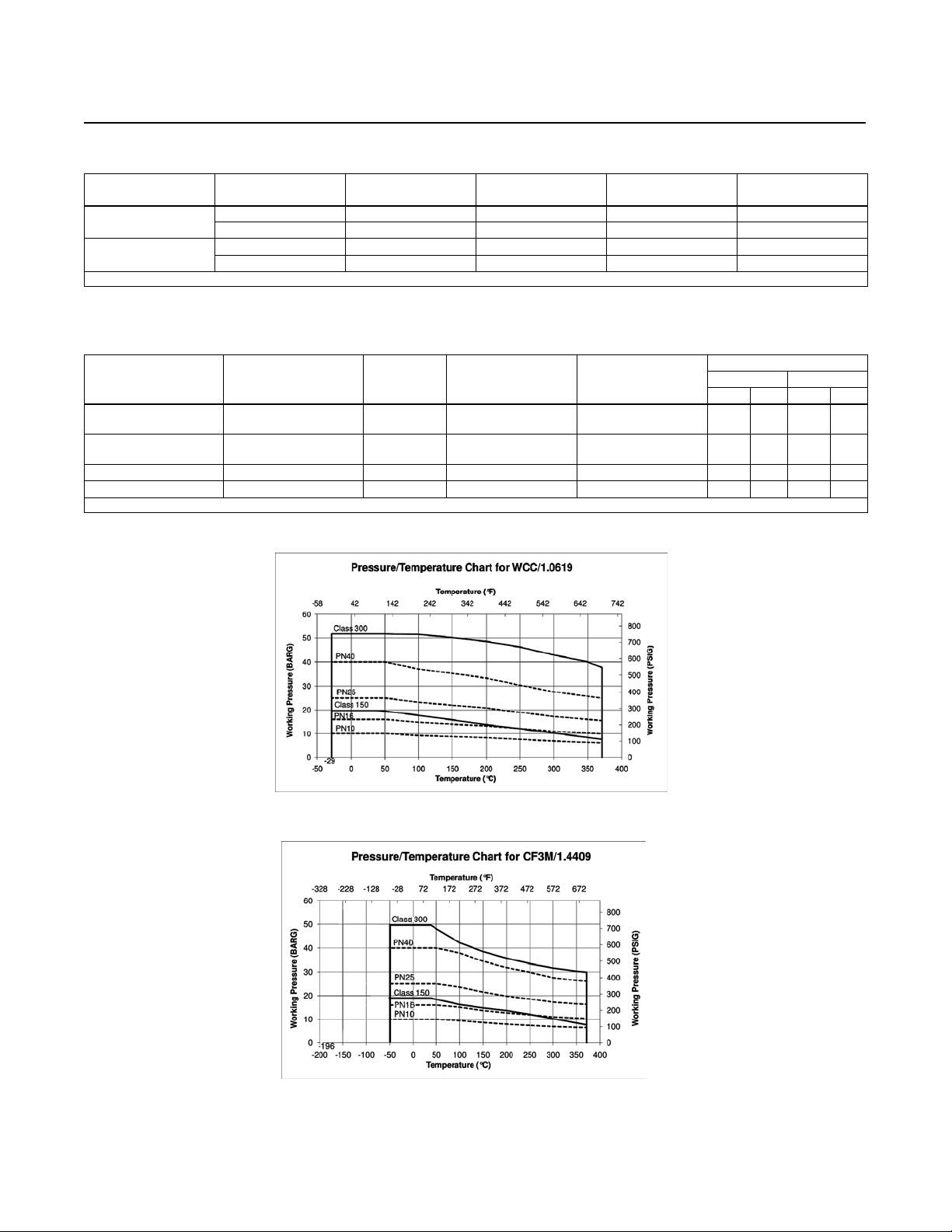

Table 4. Allowable Temperature Ranges for Valve Body, Bonnet and Trim

VALVE BODY / BONNET

MATERIAL

1.0619/SA216 WCC Steel Standard

1.4409/SA351 CF3M SST Standard

1.0619/SA216 WCC Steel HT Construction Graphite ULF Graphite laminate Side Port Common -- 29 371 -- 20 700

1.4409/SA351 CF3M SST HT Construction Graphite ULF Graphite laminate Side Port Common -- 4 6 371 -- 5 0 700

1. Bonnet O-ring and back-up ring materials used on BPC trim may be limited by temperature and application.

BONNET STYLE PACKING GASKET TRIM STYLE

PTFE or

Graphite ULF

PTFE or

Graphite ULF

Graphite laminate

Graphite laminate

(1)

TEMPERATURE

_C _F

Min Max Min Max

Bottom Port Common,

Side Port Common

Bottom Port Common,

Side Port Common

-- 29 232 -- 20 450

-- 46 232 -- 50 450

12

Figure 14. Material Pressure/Temperature Curves

Page 13

Product Bulletin

51.1:GX 3--Way

August 2011

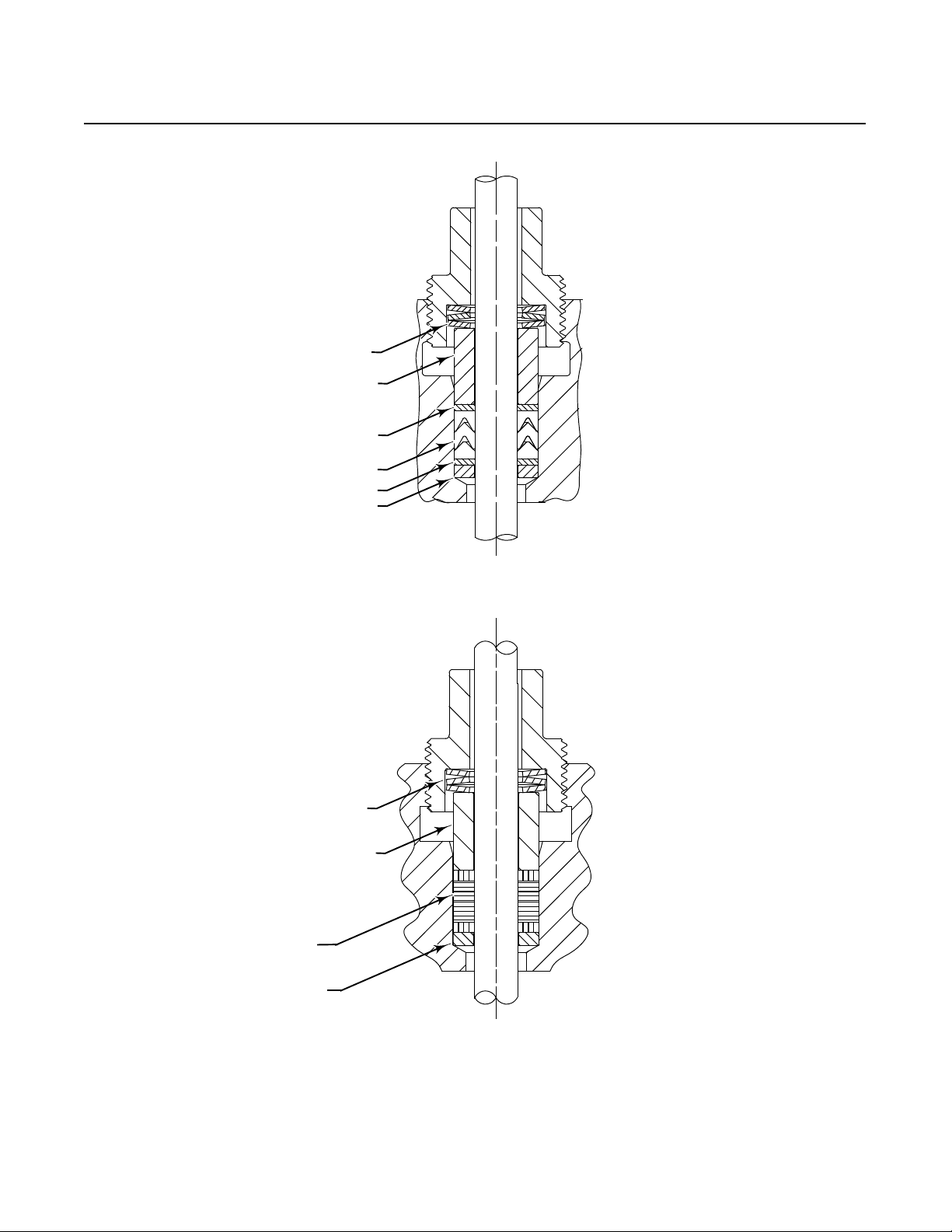

BELLEVILLE

SPRING PACK

PACKING SPACER

ANTI-EXTRUSION

WASHER

PACKING SET

ANTI-EXTRUSION

WASHER

PACKING

BOX RING

E0897/IL

GX 3--Way Valve and Actuator

STANDARD BONNET WITH PTFE PACKING SET

DN 25 through DN 100 (NPS 1 through 4)

BELLEVILLE

SPRING PACK

PACKING SPACER

PACKING

RINGS

PACKING

BOX RING

GE38594_ULF

STANDARD BONNET WITH OPTIONAL GRAPHITE ULF PACKING SET

(STANDARD ON HT CONSTRUCTION)

DN 25 through DN 100 (NPS 1 through 4)

Figure 15. Fisher GX 3-Way Packing

13

Page 14

GX 3--Way Valve and Actuator

Product Bulletin

51.1:GX 3--Way

August 2011

The GX 3-Way Diaphragm Actuator

The GX 3-Wayusesamulti-spring, pneumatic

diaphragm actuator (see figure 16). It is capable of

air supply pressures up to 5.0 barg (72 psig),

allowing valve shutoff at high pressure drops (see

table 8).

The GX 3-Way product selection system

automatically matches the actuator to the valve,

eliminating the need for complex actuator sizing

procedures.

The multiple spring design provides the preload,

eliminating the need for bench set adjustment. The

actuator is available in fail-down and fail-up

configurations.

The GX 3-Wayactuatorcanbeusedforthrottlingor

on-off service.

W8487-3/IL

The GX 3-Way is available with the integrated

DVC2000 digital valve controller. Other digital and

analog positioners are available, as well as optional

Figure 16. Fisher GX 3-Way Actuator

Table 5. Actuator Specifications

Description

Operating Principle

Operating Pressure Ranges See tables 8 and 9

Ambient Temperature

Pressure Connection (Fail-Up Construction)

Finish Powder coat polyester

solenoids and limit switches.

Pneumatic spring-return diaphragm actuator

Fail-down (standard configuration)

Fail-up (optional configuration)

--46 to 82_C (--50 to 180_F)

G 1/4 internal casing connection

Table 6. Materials of Construction

Part

Upper and Lower Casings AISI 1010 stamped carbon steel

Springs Steel

Diaphragm NBR and nylon

Diaphragm Plate AISI 1010 stamped carbon steel

Yoke and Y oke Extension on HT Construction Carbon steel

Casing Fasteners

Actuator Rod Stainless steel

Stem Connector CF3M

Stem Connector Fasteners

Stem Bushing

Stem Seal NBR

14

A2-70 stainless steel bolts and nuts

SA193-B7 bolts with NCF2 coating

High-density polyethylene (HDPE)

Material

Page 15

Product Bulletin

51.1:GX 3--Way

August 2011

GX 3--Way Valve and Actuator

Actuator Selection

GX ISO 5210 Electric Actuator

Mounting

With the GX 3-Way, actuator selection has never

been easier. Once the valve size has been

determined, the actuator is automatically selected.

The following tables provide the maximum allowable

pressure drops for the GX 3-Way.Seetable8for

Side Port Common construction and table 9 for

Bottom Port Common construction. For optimal

performance, the GX 3-Way should be operated with

a FIELDVUE digital valve controller.

Table 7. Fisher GX 3--Way Maximum Allowable Thrust for use with ISO 5210 Electric Actuators

(THRUST LIMITATIONS APPLY IN BOTH TRAVEL DIRECTIONS)

VALV E SI ZE

DN25--DN40

(NPS1to1--1/2)

DN50 (NPS 2) 14 19 S31603 14000 3150

DN80--DN100

(NPS3to4)

STEM DIAMETER TRAVEL

mm mm N lbf

10 19 S31603 6900 1550

14 38 S31603 14000 3150

Electric actuator mounting is available for any

manufacturing models that comply with ISO 5210,

Flange type F7. The mounting offering includes a

GX yoke, actuator rod adaptor, spacer, and bolting.

Thrust limitations apply when sizing electric

actuators (see table 7).

Mounting offering can be engineered if not already

available for a selected actuator. For additional

information, contact your Emerson Process

Management sales office.

STEM MATERIAL

MAXIMUM THRUST

15

Page 16

GX 3--Way Valve and Actuator

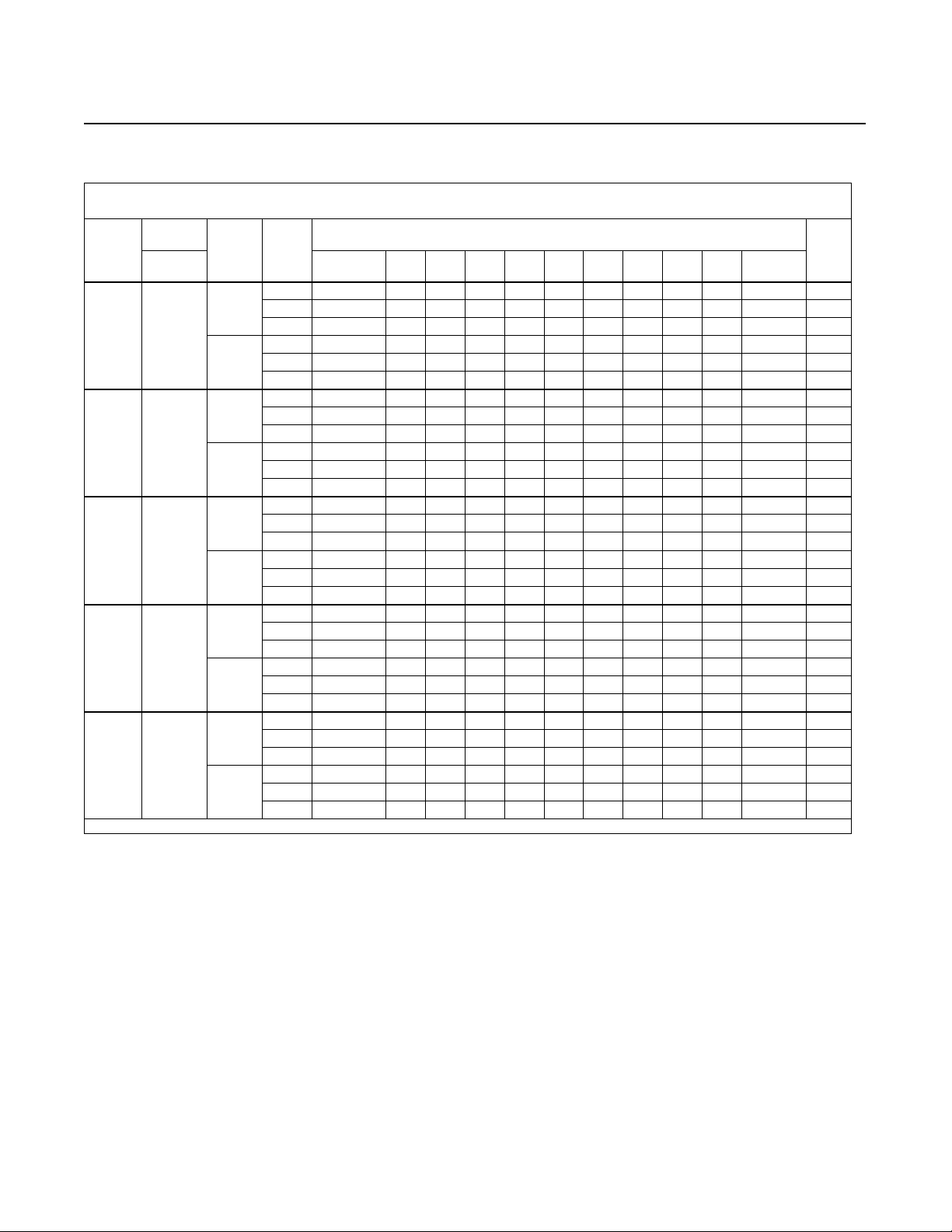

Table 8. Maximum Allowable Pressure Drop (Side Port Common)

FAIL-DOWN FAIL-UP

VALV E

DN100 750

ACTUATOR

SIZE

DN25 225

DN40 225

DN50 750

DN80 750

SIZE

FLOW

DIRECTION

Converging

Diverging

Converging

Diverging

Converging

Diverging

Converging

Diverging

Converging

Diverging

PACKING

PTFE 18.1 21.7 21.7 21.7 21.7 bar @ 5.0 bar 19.7 20.2 20.2 20.2 20.2 bar @ 5.0 bar

ULF 12.2 16.2 16.2 16.2 16.2 bar @ 5.0 bar 14.2 14.3 14.3 14.3 14.3 bar @ 5.0 bar

PTFE 14.0 14.0 14.0 14.0 14.0 bar @ 5.0 bar 14.0 14.0 14.0 14.0 14.0 bar @ 5.0 bar

ULF 14.0 14.0 14.0 14.0 14.0 bar @ 5.0 bar 14.0 14.0 14.0 14.0 14.0 bar @ 5.0 bar

PTFE 18.1 21.7 21.7 21.7 21.7 bar @ 5.0 bar 19.7 20.2 20.2 20.2 20.2 bar @ 5.0 bar

ULF 12.2 16.2 16.2 16.2 16.2 bar @ 5.0 bar 14.2 14.3 14.3 14.3 14.3 bar @ 5.0 bar

PTFE 14.0 14.0 14.0 14.0 14.0 bar @ 5.0 bar 14.0 14.0 14.0 14.0 14.0 bar @ 5.0 bar

ULF 14.0 14.0 14.0 14.0 14.0 bar @ 5.0 bar 14.0 14.0 14.0 14.0 14.0 bar @ 5.0 bar

PTFE 29.0 48.4 48.4

ULF 25.8 45.5 45.5

PTFE 30.0 30.0 30.0

ULF 30.0 30.0 30.0

PTFE 10.5 19.0 24.2

ULF 9.2 17.7 23.0

PTFE 16.0 16.0 16.0

ULF 16.0 16.0 16.0

PTFE 6.3 11.3 14.7

ULF 5.5 10.5 13.9

PTFE 10.0 10.0 10.0

ULF 10.0 10.0 10.0

Operating Pressure

3

3.44

bar

bar4bar5bar

MAXDP@

Maximum Supply

Pressure

48.4 bar @ 4.0 bar 35.4 44.9 44.9

---

45.5 bar @ 4.0 bar 32.6 41.7 41.7

---

30.0 bar @ 4.0 bar 30.0 30.0 30.0

---

30.0 bar @ 4.0 bar 30.0 30.0 30.0

---

24.2 bar @ 4.0 bar 12.0 20.2 24.2

---

23.0 bar @ 4.0 bar 10.7 19.0 22.9

---

16.0 bar @ 4.0 bar 16.0 16.0 16.0

---

16.0 bar @ 4.0 bar 16.0 16.0 16.0

---

14.7 bar @ 4.0 bar 7.2 12.2 14.4

---

13.9 bar @ 4.0 bar 6.5 11. 5 13.6

---

10.0 bar @ 4.0 bar 10.0 10.0 10.0

---

10.0 bar @ 4.0 bar 10.0 10.0 10.0

---

3

bar

Operating Pressure

3.44

bar4bar5bar

Product Bulletin

51.1:GX 3--Way

August 2011

MAXDP@

Maximum Supply

Pressure

44.9 bar @ 4.0 bar

---

41.7 bar @ 4.0 bar

---

30.0 bar @ 4.0 bar

---

30.0 bar @ 4.0 bar

---

24.2 bar @ 4.0 bar

---

22.9 bar @ 4.0 bar

---

16.0 bar @ 4.0 bar

---

16.0 bar @ 4.0 bar

---

14.4 bar @ 4.0 bar

---

13.6 bar @ 4.0 bar

---

10.0 bar @ 4.0 bar

---

10.0 bar @ 4.0 bar

---

Table 9. Maximum Allowable Pressure Drop (Bottom Port Common)

FAIL-DOWN FAIL-UP

VALV E

DN100 750

ACTUATOR

SIZE

DN25 225

DN40 225

DN50 750

DN80 750

SIZE

FLOW

DIRECTION

Converging

Diverging

Converging

Diverging

Converging

Diverging

Converging

Diverging

Converging

Diverging

PACKING

PTFE 32.4 50.1 51.7 51.7 51.7 bar @ 5.0 bar 36.2 36.2 36.2 36.2 36.2 bar @ 5.0 bar

ULF 21.7 39.4 51.7 51.7 51.7 bar @ 5.0 bar 25.6 25.6 25.6 25.6 25.6 bar @ 5.0 bar

PTFE 28.0 28.0 28.0 28.0 28.0 bar @ 5.0 bar 28.0 28.0 28.0 28.0 28.0 bar @ 5.0 bar

ULF 28.0 28.0 28.0 28.0 28.0 bar @ 5.0 bar 28.0 28.0 28.0 28.0 28.0 bar @ 5.0 bar

PTFE 25.0 38.7 51.7 51.7 51.7 bar @ 5.0 bar 27.9 27.9 27.9 27.9 27.9 bar @ 5.0 bar

ULF 16.8 30.5 47.9 51.7 51.7 bar @ 5.0 bar 19.7 19.7 19.7 19.7 19.7 bar @ 5.0 bar

PTFE 22.0 22.0 22.0 22.0 22.0 bar @ 5.0 bar 22.0 22.0 22.0 22.0 22.0 bar @ 5.0 bar

ULF 22.0 22.0 22.0 22.0 22.0 bar @ 5.0 bar 22.0 22.0 22.0 22.0 22.0 bar @ 5.0 bar

PTFE 35.2 51.7 51.7

ULF 31.4 51.7 51.7

PTFE 30.0 30.0 30.0

ULF 30.0 30.0 30.0

PTFE 19.5 35.2 51.7

ULF 17.1 32.8 51.7

PTFE 25.0 25.0 25.0

ULF 25.0 25.0 25.0

PTFE 19.5 35.2 51.7

ULF 17.1 32.8 51.7

PTFE 25.0 25.0 25.0

ULF 25.0 25.0 25.0

Operating Pressure

3

3.44

bar

bar4bar5bar

---

---

---

---

---

---

---

---

---

---

---

---

MAXDP@

Maximum Supply

Pressure

51.7 bar @ 4.0 bar 51.7 51.7 51.7

51.7 bar @ 4.0 bar 50.7 50.7 50.7

30.0 bar @ 4.0 bar 30.0 30.0 30.0

30.0 bar @ 4.0 bar 30.0 30.0 30.0

51.7 bar @ 4.0 bar 45.0 45.0 45.0

51.7 bar @ 4.0 bar 42.6 42.6 42.6

25.0 bar @ 4.0 bar 25.0 25.0 25.0

25.0 bar @ 4.0 bar 25.0 25.0 25.0

51.7 bar @ 4.0 bar 45.0 45.0 45.0

51.7 bar @ 4.0 bar 42.6 42.6 42.6

25.0 bar @ 4.0 bar 25.0 25.0 25.0

25.0 bar @ 4.0 bar 25.0 25.0 25.0

Operating Pressure

3

3.44

bar

bar4bar5bar

Maximum Supply

51.7 bar @ 4.0 bar

---

50.7 bar @ 4.0 bar

---

30.0 bar @ 4.0 bar

---

30.0 bar @ 4.0 bar

---

45.0 bar @ 4.0 bar

---

42.6 bar @ 4.0 bar

---

25.0 bar @ 4.0 bar

---

25.0 bar @ 4.0 bar

---

45.0 bar @ 4.0 bar

---

42.6 bar @ 4.0 bar

---

25.0 bar @ 4.0 bar

---

25.0 bar @ 4.0 bar

---

MAXDP@

Pressure

16

Page 17

Product Bulletin

51.1:GX 3--Way

August 2011

GX 3--Way Valve and Actuator

Valve-Actuator Dimensions and Weights

See figure 17, table 10, and table 11.

Table 10. Fisher GX 3-Way Dimensions and Weights (Standard and HT Constructions)

VALV E

SIZE

DN 25/

NPS 1

DN 40/

NPS

1-1/2

DN 50/

NPS 2

DN 80/

NPS 3

DN 100/

NPS 4

PORT DIA

TYPE

BPC 29 36

SPC 36 36

BPC 39 46

SPC 36 36

BPC 61 70

SPC 46 46

BPC 78 90

SPC 70 70

BPC 78 90

SPC 90 90

Upper Lower

mm mm mm mm mm mm mm mm mm mm

ACTUATOR

SIZE

225 19 197 184 197 98.5 92 98.5 73

225 19 235 222 235 117.5 111 117.5 76

750 19 267 254 267 133.5 127 133.5 95

750 38 318 298 318 159 149 159 119

750 38 368 352 368 184 176 184 119

TRAVEL

PN10 -

PN40

Table 11. Fisher GX 3-Way Dimensions and Weights

D (Actuator Height) E F (AR) TOTAL WEIGHT

VALV E SI ZE

DN 25/ NPS 1 313 418 270 115 26 30

DN 40/ NPS 1-1/2

DN 50/ NPS 2 342 485 430 120 66 74

DN 80/ NPS 3 395 585 430 145 97 112

DN 100/ NPS 4 395 585 430 145 123 138

1. Clearance required for removing actuator from installed valve body.

Std Construction HT Construction Casing Dia

mm mm mm mm kg kg

313 422 270 11 5 28 32

A B C

CL150 CL300

Removal Height

PN10 -

PN40

(1)

CL150 CL300 Bonnet

Std Construction HT Construction

AR

AR

E

D

F

C

B

A/2

A

GE54802

D

F

F

C

B

A/2

E

A

STANDARD CONSTRUCTION HT (HIGH TEMPERATURE) CONSTRUCTION

Figure 17. Fisher GX 3-Way Dimensions (also see tables 10 and 11)

17

Page 18

Product Bulletin

GX 3--Way Valve and Actuator

Table 12. Fisher GX 3-Way Electric Actuator Mounting Dimensions and Weights

G H

VALV E SI ZE

DN 25/ NPS 1 202 176 17 21

DN 40/ NPS 1-1/2

DN 50/ NPS 2 202 176 29 37

DN 80/ NPS 3 222 176 57 72

DN 100/ NPS 4 226 176 83 98

Electric Actuator Yoke Height

ISO 5210

mm mm kg kg

202 176 19 23

G

Yoke Diameter Std Construction HT Construction

H

GX ELECTRIC ACTUATOR MOUNTING ASSEMBLY

TOTAL WEIGHT,

51.1:GX 3--Way

August 2011

18

GE54756_1

Figure 18. Fisher GX 3-Way Electric Actuator Mounting Dimensions (also see table 12)

Page 19

Product Bulletin

51.1:GX 3--Way

August 2011

Table 13. Positioner Selection Guidelines

Type Digital I/P

DVC2000 X X X

DVC6200 X X X X

3661 X X X

3660 X

1. Digital I/P - microprocessor based electro-pneumatic with HART communication.

2. I/P - electro-pneumatic

3. P/P - pneumatic

4. Refer to Fisher bulletin 9.2:001 for instrument hazardous area classification details.

(1)

I/P

(2)

P/P

GX 3--Way Valve and Actuator

(3)

Intrinsic

(4)

Safety

Flameproof /

Explosion Proof

(4)

Incendive

GX 3-Way Actuator Accessories

The GX 3-Way is available with a variety of

pneumatic (P/P), electro-pneumatic (I/P), and digital

valve positioners, as well as limit switches and

solenoids. Table 13 provides the basic features of

the positioners offered with the GX 3-Way actuator.

Non-

(4)

The FIELDVUE DVC2000 Digital Valve

Controller

The DVC2000 digital valve controller (figure 19) is

simple to use, compact, and designed for the GX

3-Way control valve. It converts a 4-20mA input

signal into a pneumatic output signal, which feeds

the control valve actuator. Instrument setup is

performed with a pushbutton and liquid crystal

display (LCD) interface. This interface is protected

from the environment within an IP66 enclosure.

Multiple languages are supported with the local

interface including German, French, Italian, Spanish,

Chinese, Japanese, Portuguese, Russian, Polish,

Czech, Arabic, and English. Additionally, HARTr

communication is supported over the 4-20mA loop

wiring.

The DVC2000 is designed to be integrally mounted

to the GX 3-Way actuator, avoiding the need for

mounting brackets. The DVC2000 mounts directly to

an interface pad on the actuator yoke leg with a

secure 3-point mounting. An internal passage inside

the yoke leg transmits the pneumatic signal to the

actuator casing, eliminating the need for e xternal

tubing (in the fail-down configuration).

W8755

Figure 19. FIELDVUE DVC2000 Digital Valve Controller

The high-performance linkage-less position feedback

system eliminates physical contact between the

valve stem and the digital valve controller or

instrument. There are no wearing parts so cycle life

is maximized. Additionally, the elimination of levers

and linkages reduces the number of mounting parts

and the mounting complexity. Digital valve controller

or instrument replacement and maintenance is

simplified because the feedback parts stay

connected to the actuator.

The DVC2000 is available with an optional module

which includes two (2) integral limit switches and a

stem position transmitter. The limit switches are

configurable for open and closed valve indication.

The position transmitter provides a 4-20mA signal for

valve position feedback verification. As an integral

component to the instrument, this option module

avoids the need for difficult-to-mount external

switches and transmitters.

Designed to meet intrinsic safety and non-incendive

requirements, this instrument delivers scalable

functionality and high performance in a small

package.

19

Page 20

GX 3--Way Valve and Actuator

Optional Positioners and Instruments

3660 and 3661 Valve Positioners

The 3660 pneumatic and 3661 electro-pneumatic

positioners are rugged, accurate, and feature low

steady-state air consumption. Designed to meet

intrinsic safety requirements, these positioners offer

simple functionality in a small package.

(See table 13.)

DVC6200 Digital Valve Controller

The DVC6200 digital valve controller is a

communicating, microprocessor-based

current--to--pneumatic instrument. Using HART or

OUNDATIONt fieldbus communication protocol,

F

access to critical instrument, valve, and process

conditions is provided. When used with ValveLinkt

software, valve diagnostic tests can be run while the

valve is in service to advise you of the performance

of the entire control valve assembly. Designed to

meet a broad range of hazardous area

classifications, this instrument offers maximum

functionality to improve your process performance.

(See figure 20 and table 13.)

Product Bulletin

51.1:GX 3--Way

August 2011

W9713

Figure 20. FIELDVUE DVC6200 Digital Valve Controller

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use, or maintenance of any

product. Responsibility f or the

selection, use, and maintenance of any

product remains with the purchaser

and end user.

20

Page 21

Product Bulletin

51.1:GX 3--Way

August 2011

Coefficients

Table 14. Fisher GX 3--Way , Side Port Common (SPC) Diverging, Linear

Side Port Common (SPC) Diverging

Maximum

Valve

Size

DN25/

NPS 1

DN40/

NPS

1--1/2

DN50/

NPS 2

DN80/

NPS 3

DN100/

NPS 4

1. At maximum flow.

Travel

mm

19

19

19

38

38

Exit Port

(see

figure 5)

Right

Bottom

Right

Bottom

Right

Bottom

Right

Bottom

Right

Bottom

Flow

Coeffi-

cient

Cv 16.1 15.0 14.2 13.5 12.6 11.1 9.35 7.21 5.27 2.89 0 0.919

Kv 14.0 13.0 12.3 11 .7 10.9 9.56 8.09 6.23 4.56 2.50 0 -- -- --

Xt 0.615 0.543 0.427 0.308 0.250 0.226 0.203 0.148 0.119 0.097 0 -- -- --

Cv 0 0.897 2.43 4.29 6.06 7.81 9.78 11.6 13.3 15.0 15.6 0.951

Kv 0 0.776 2.10 3.71 5.25 6.75 8.46 10.0 11. 5 13.0 13.5 -- -- --

Xt 0 0.899 0.687 0.654 0.698 0.673 0.622 0.700 0.706 0.702 0.758 -- -- --

Cv 25.4 22.4 20.5 17.7 15.8 14.2 11 .9 9.27 6.93 4.09 0 0.991

Kv 22.0 19.4 17.7 15.3 13.7 12.3 10.3 8.01 6.00 3.54 0 -- -- --

Xt 0.831 0.882 0.741 0.697 0.565 0.501 0.450 0.389 0.341 0.285 0 -- -- --

Cv 0 2.33 4.45 7.45 10.6 13.6 16.9 19.2 21.7 23.4 26.6 0.877

Kv 0 2.01 3.84 6.45 9.18 11.8 14.6 16.6 18.8 20.2 23.0 -- -- --

Xt 0 0.245 0.636 0.722 0.723 0.720 0.655 0.685 0.705 0.843 0.803 -- -- --

Cv 43.9 40.2 35.8 31.1 26.5 23.1 18.7 15.1 11. 1 6.78 0 0.973

Kv 38.0 34.7 30.9 26.9 22.9 20.0 16.2 13.1 9.63 5.87 0 -- -- --

Xt 0.864 0.817 0.767 0.656 0.598 0.533 0.536 0.429 0.333 0.215 0 -- -- --

Cv 0 2.66 7.61 13.2 18.1 23.5 29.3 34.9 41.6 48.1 52.2 0.831

Kv 0 2.30 6.58 11. 4 15.6 20.3 25.4 30.2 36.0 41.6 45.1 -- -- --

Xt 0 0.614 0.651 0.649 0.651 0.627 0.609 0.599 0.588 0.600 0.640 -- -- --

Cv 92.8 85.2 70.3 57.6 47.5 39.2 31.6 25.1 19.7 13.8 0 1.000

Kv 80.3 73.7 60.8 49.8 41.1 33.9 27.3 21.8 17.0 11.9 0 -- -- --

Xt 0.858 0.989 0.976 0.934 0.896 0.864 0.789 0.682 0.540 0.306 0 -- -- --

Cv 0 9.03 20.4 30.3 41.0 52.1 60.1 69.1 79.4 90.6 101.9 0.839

Kv 0 7.81 17.7 26.2 35.4 45.1 52.0 59.8 68.7 78.3 88.1 -- -- --

Xt 0 0.557 0.695 0.814 0.795 0.790 0.876 0.929 0.937 0.932 0.855 -- -- --

Cv 145.4 137.4 119.9 100.6 81.6 68.3 57.6 45.5 33.9 21.1 0 0.942

Kv 125.8 118.9 103.7 87.0 70.6 59.1 49.9 39.4 29.3 18.2 0 -- -- --

Xt 0.984 0.956 0.975 0.828 0.817 0.810 0.705 0.601 0.475 0.322 0 -- -- --

Cv 0 15.0 37.7 58.7 79.9 99.3 122.3 143.7 166.0 189.3 216.4 0.818

Kv 0 13.0 32.6 50.8 69.1 85.9 105.8 124.3 143.6 163.8 187.2 -- -- --

Xt 0 0.587 0.659 0.764 0.798 0.840 0.887 0.880 0.869 0.810 0.640 -- -- --

0

(Plug Down)

Valve Opening—Percent of Total Travel (see figure 6)

10 20 30 40 50 60 70 80 90

GX 3--Way Valve and Actuator

Linear

Characteristic

(1)

F

100

(Plug Up)

L

21

Page 22

GX 3--Way Valve and Actuator

Table 15. Fisher GX 3--Way, Side Port Common (SPC) Converging, Linear

Side Port Common (SPC) Converging

Maximum

Valve

Size

DN25/

NPS 1

DN40/

NPS

1--1/2

DN50/

NPS 2

DN80/

NPS 3

DN100/

NPS 4

1. At maximum flow.

Travel

mm

19

19

19

38

38

Inlet Port

(see

figure 7)

Right

Bottom

Right

Bottom

Right

Bottom

Right

Bottom

Right

Bottom

Flow

Coeffi-

cient

Cv 15.9 13.2 10.7 9.30 7.54 6.31 4.65 3.64 2.04 1.04 0 0.978

Kv 13.7 11. 4 9.28 8.04 6.52 5.46 4.02 3.15 1.77 0.898 0 -- -- --

Xt 0.658 0.866 0.758 0.657 0.723 0.669 0.739 0.728 0.909 0.898 0 -- -- --

Cv 0 0.562 1.72 3.28 4.90 6.51 8.74 10.3 12.9 14.3 16.3 0.949

Kv 0 0.486 1.49 2.84 4.24 5.63 7.56 8.89 11. 1 12.4 14.1 -- -- --

Xt 0 0.397 1.005 0.966 0.847 0.767 0.675 0.659 0.605 0.662 0.663 -- -- --

Cv 29.3 26.7 23.0 17.1 14.6 11.9 9.47 7.07 4.78 2.34 0 0.999

Kv 25.3 23.1 19.9 14.8 12.6 10.3 8.19 6.12 4.13 2.03 0 -- -- --

Xt 0.821 0.714 0.711 0.857 0.806 0.900 0.907 0.803 0.842 0.660 0 -- -- --

Cv 0 0.881 3.02 6.46 8.83 11. 7 15.9 18.3 20.9 24.3 28.4 0.978

Kv 0 0.762 2.61 5.58 7.64 10.1 13.7 15.8 18.1 21.1 24.5 -- -- --

Xt 0 -- -- -- 0.994 0.779 0.865 0.832 0.679 0.745 0.752 0.785 0.749 -- -- --

Cv 54.6 48.5 42.2 35.2 28.5 22.9 18.0 12.4 7.44 3.02 0 0.932

Kv 47.2 42.0 36.5 30.4 24.6 19.8 15.6 10.7 6.43 2.61 0 -- -- --

Xt 0.626 0.636 0.596 0.559 0.574 0.605 0.617 0.685 0.798 0.949 0 -- -- --

Cv 0 2.05 6.44 11. 0 15.8 20.9 25.6 32.2 41.6 47.6 52.0 0.958

Kv 0 1.78 5.57 9.50 13.7 18.1 22.2 27.9 36.0 41.2 45.0 -- -- --

Xt 0 0.888 0.919 0.958 0.895 0.844 0.859 0.804 0.735 0.745 0.785 -- -- --

Cv 111.9 101.0 87.8 72.7 59.2 48.3 38.5 28.5 18.9 9.87 0 1.000

Kv 96.8 87.4 75.9 62.9 51.2 41.8 33.3 24.7 16.4 8.53 0 -- -- --

Xt 0.811 0.757 0.669 0.704 0.755 0.765 0.745 0.723 0.725 0.716 0 -- -- --

Cv 0 6.84 16.1 26.4 40.0 55.0 70.4 85.7 100.8 113.1 127.8 0.965

Kv 0 5.91 13.9 22.8 34.6 47.6 60.9 74.1 87.2 97.8 110.6 -- -- --

Xt 0 0.989 0.967 0.994 0.876 0.800 0.773 0.759 0.752 0.767 0.752 -- -- --

Cv 163.4 153.0 137.0 115.0 92.0 74.0 57.8 43.5 28.3 12.8 0 0.869

Kv 141.4 132.3 118.5 99.4 79.6 64.0 50.0 37.7 24.5 11 .1 0 -- -- --

Xt 0.688 0.634 0.558 0.558 0.603 0.610 0.595 0.578 0.573 0.525 0 -- -- --

Cv 0 12.9 30.1 46.6 66.3 88.4 112.4 135.9 161.4 185.2 212.2 0.816

Kv 0 11 .2 26.0 40.3 57.3 76.4 97.2 117.5 139.7 160.2 183.6 -- -- --

Xt 0 0.920 0.949 0.826 0.789 0.737 0.683 0.660 0.625 0.629 0.589 -- -- --

0

(Plug Down)

Valve Opening—Percent of Total Travel (see figure 8)

10 20 30 40 50 60 70 80 90

Product Bulletin

51.1:GX 3--Way

August 2011

Linear

Characteristic

(1)

F

100

(Plug Up)

L

22

Page 23

Product Bulletin

51.1:GX 3--Way

August 2011

Table 16. Fisher GX 3--Way , Bottom Port Common (BPC) Diverging, Linear

GX 3--Way Valve and Actuator

Bottom Port Common (BPC) Diverging

Maximum

Valve

Size

DN25/

NPS 1

DN40/

NPS

1--1/2

DN50/

NPS 2

DN80/

NPS 3

DN100/

NPS 4

1. At maximum flow.

Travel

mm

19

19

19

38

38

Exit Port

(see

figure 9)

Right

Left

Right

Left

Right

Left

Right

Left

Right

Left

Flow

Coeffi-

cient

Cv 16.3 15.5 14.4 13.3 12.0 10.1 7.72 5.32 3.18 1.49 0 0.965

Kv 14.1 13.4 12.5 11 .5 10.4 8.70 6.68 4.61 2.75 1.29 0 -- -- --

Xt 0.661 0.670 0.691 0.655 0.608 0.577 0.523 0.556 0.533 0.474 0 -- -- --

Cv 0 1.67 3.03 4.58 6.32 8.41 10.6 12.0 13.7 14.7 15.5 0.886

Kv 0 1.45 2.62 3.96 5.46 7.27 9.18 10.4 11. 9 12.8 13.4 -- -- --

Xt 0 0.810 0.623 0.667 0.639 0.620 0.637 0.631 0.637 0.664 0.666 -- -- --

Cv 32.5 30.5 28.7 25.2 21.9 18.5 14.8 10.6 6.46 2.89 0 0.820

Kv 28.1 26.4 24.8 21.8 18.9 16.0 12.8 9.16 5.58 2.50 0 -- -- --

Xt 0.786 0.738 0.661 0.626 0.523 0.486 0.470 0.467 0.479 0.426 0 -- -- --

Cv 0 3.30 6.21 10.34 14.5 18.2 22.7 26.4 29.1 31.2 33.5 0.923

Kv 0 2.85 5.37 8.94 12.56 15.7 19.7 22.9 25.1 27.0 29.0 -- -- --

Xt 0 0.812 0.661 0.502 0.553 0.660 0.721 0.764 0.799 0.815 0.784 -- -- --

Cv 58.9 53.1 47.1 40.7 34.1 27.0 20.7 14.6 9.54 4.61 0 0.950

Kv 50.9 45.9 40.7 35.2 29.5 23.4 17.9 12.6 8.26 3.99 0 -- -- --

Xt 0.600 0.639 0.561 0.574 0.536 0.473 0.475 0.508 0.501 0.536 0 -- -- --

Cv 0 4.89 8.60 13.4 20.5 28.2 36.6 44.9 50.9 56.0 60.0 0.893

Kv 0 4.23 7.43 11. 6 17.8 24.4 31.7 38.8 44.0 48.4 51.9 -- -- --

Xt 0 0.553 0.674 0.610 0.575 0.599 0.598 0.607 0.632 0.647 0.619 -- -- --

Cv 155.9 151.9 139.6 126.6 108.8 90.8 69.0 49.0 30.8 15.1 0 0.935

Kv 134.9 131.4 120.7 109.5 94.1 78.5 59.7 42.4 26.6 13.1 0 -- -- --

Xt 0.640 0.595 0.578 0.532 0.500 0.451 0.453 0.462 0.471 0.465 0 -- -- --

Cv 0 12.0 27.7 47.9 68.3 87.7 104.5 120.0 136.5 154.7 170.3 0.862

Kv 0 10.4 24.0 41.4 59.1 75.8 90.4 103.8 118.1 133.8 147.3 -- -- --

Xt 0 0.605 0.556 0.596 0.650 0.680 0.706 0.719 0.713 0.664 0.642 -- -- --

Cv 166.3 152.9 139.7 121.1 98.0 77.1 60.3 42.9 27.0 13.0 0 0.901

Kv 143.9 132.3 120.8 104.8 84.8 66.7 52.2 37.1 23.3 11.2 0 -- -- --

Xt 0.675 0.631 0.533 0.510 0.530 0.526 0.503 0.520 0.520 0.542 0 -- -- --

Cv 0 11.3 26.9 46.1 63.8 82.2 102.0 121.1 137.6 153.2 169.1 0.866

Kv 0 9.8 23.2 39.9 55.2 71.1 88.2 104.8 119.0 132.5 146.3 -- -- --

Xt 0 0.657 0.583 0.615 0.704 0.727 0.716 0.696 0.723 0.703 0.669 -- -- --

0

(Plug Down)

Valve Opening—Percent of Total Travel (see figure 10)

10 20 30 40 50 60 70 80 90

Characteristic

100

(Plug Up)

Linear

(1)

F

L

23

Page 24

GX 3--Way Valve and Actuator

Table 17. Fisher GX 3--Way, Bottom Port Common (BPC) Converging, Linear

Bottom Port Common (BPC) Converging

Maximum

Valve

Size

DN25/

NPS 1

DN40/

NPS

1--1/2

DN50/

NPS 2

DN80/

NPS 3

DN100/

NPS 4

1. At maximum flow.

Travel

mm

19

19

19

38

38

Inlet Port

(see

figure 11)

Right

Left

Right

Left

Right

Left

Right

Left

Right

Left

Flow

Coeffi-

cient

Cv 16.4 14.4 12.8 11.7 10.7 9.64 8.58 6.27 3.80 1.08 0 0.973

Kv 14.2 12.4 11 .1 10.1 9.23 8.34 7.42 5.42 3.29 0.93 0 -- -- --

Xt 0.668 0.650 0.691 0.571 0.495 0.397 0.324 0.312 0.291 0.652 0 -- -- --

Cv 0 1.45 2.56 3.93 5.46 7.08 8.83 10.9 13.3 15.3 16.5 0.935

Kv 0 1.25 2.22 3.40 4.73 6.12 7.64 9.39 11. 5 13.2 14.3 -- -- --

Xt 0 0.702 0.784 0.725 0.720 0.710 0.722 0.717 0.678 0.609 0.597 -- -- --

Cv 36.8 32.3 25.6 21.3 17.5 12.5 10.3 8.22 4.63 2.34 0 0.804

Kv 31.9 28.0 22.1 18.4 15.1 10.8 8.94 7.11 4.00 2.02 0 -- -- --

Xt 0.540 0.538 0.675 0.661 0.613 0.723 0.690 0.575 0.595 0.634 0 -- -- --

Cv 0 3.36 5.99 9.42 13.3 17.4 22.4 27.4 33.8 37.5 41.5 0.878

Kv 0 2.91 5.18 8.15 11. 5 15.0 19.4 23.7 29.2 32.5 35.9 -- -- --

Xt 0 0.625 0.659 0.593 0.598 0.645 0.637 0.695 0.643 0.641 0.603 -- -- --

Cv 59.9 50.9 42.8 35.6 29.6 23.1 17.5 13.8 9.75 6.01 0 0.882

Kv 51.8 44.0 37.0 30.8 25.6 20.0 15.2 11 .9 8.43 5.20 0 -- -- --

Xt 0.560 0.569 0.609 0.634 0.611 0.613 0.571 0.490 0.387 0.256 0 -- -- --

Cv 0 4.84 8.90 14.2 19.2 25.4 32.8 40.0 47.1 53.4 57.8 0.935

Kv 0 4.19 7.70 12.3 16.6 21.9 28.4 34.6 40.7 46.2 50.0 -- -- --

Xt 0 0.504 0.575 0.549 0.641 0.692 0.696 0.693 0.707 0.722 0.723 -- -- --

Cv 158.7 142.5 125.3 102.8 80.3 61.0 45.8 33.1 20.8 10.6 0 0.813

Kv 137.2 123.3 108.4 88.9 69.5 52.8 39.6 28.7 18.0 9.18 0 -- -- --

Xt 0.558 0.578 0.553 0.549 0.600 0.663 0.665 0.653 0.714 0.705 0 -- -- --

Cv 0 12.1 25.7 43.8 63.1 83.1 102.7 120.4 135.7 151.1 164.9 0.931

Kv 0 10.5 22.2 37.9 54.6 71.9 88.9 104.1 117.4 130.7 142.6 -- -- --

Xt 0 0.525 0.579 0.619 0.660 0.658 0.676 0.685 0.701 0.691 0.670 -- -- --

Cv 155.9 145.0 127.4 107.6 85.9 66.4 49.4 35.6 23.6 12.2 0 0.810

Kv 134.9 125.4 110.2 93.0 74.3 57.5 42.7 30.8 20.4 10.5 0 -- -- --

Xt 0.564 0.550 0.518 0.504 0.545 0.593 0.628 0.621 0.601 0.553 0 -- -- --

Cv 0 13.5 28.9 48.9 69.5 90.6 111.1 129.2 145.4 159.9 174.4 0.830

Kv 0 11 .7 25.0 42.3 60.1 78.4 96.1 111.8 125.8 138.3 150.8 -- -- --

Xt 0 0.427 0.477 0.525 0.553 0.564 0.590 0.637 0.667 0.686 0.676 -- -- --

0

(Plug Down)

Valve Opening—Percent of Total Travel (see figure 12)

10 20 30 40 50 60 70 80 90

Product Bulletin

51.1:GX 3--Way

August 2011

Linear

Characteristic

(1)

F

100

(Plug Up)

L

Fisher, FIELDVUE, and ValveLink are marks owned by one of the companies in the Emerson Process Management business division of Emerson

Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. HART is

a mark owned by the HART Communications Foundation. F

the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they

are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the

designs or specifications of such products at any time without notice. Neither Emerson, Emerson Process Management, nor any of their affiliated

entities assumes responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of

any product remains solely with the purchaser and end user.

OUNDATION fieldbus is a mark owned by the Fieldbus Foundation. All other marks are

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

24

EFisher Controls International LLC 2008, 2011; All Rights Reserved

Loading...

Loading...