Emerson Fisher G100, Fisher G105, Fisher G104, Fisher G102, Fisher G106 Instruction Manual

...Page 1

Instruction Manual

MCK-1095

September 2015

G100 Series Back Check Valves

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or re causing

property damage and personal injury or death.

Fisher® equipment must be installed, operated,

and maintained in accordance with federal,

state, and local codes and manufacturer’s

instructions. The installation in most states

must also comply with NFPA No. 58 or ANSI

K61.1 standards.

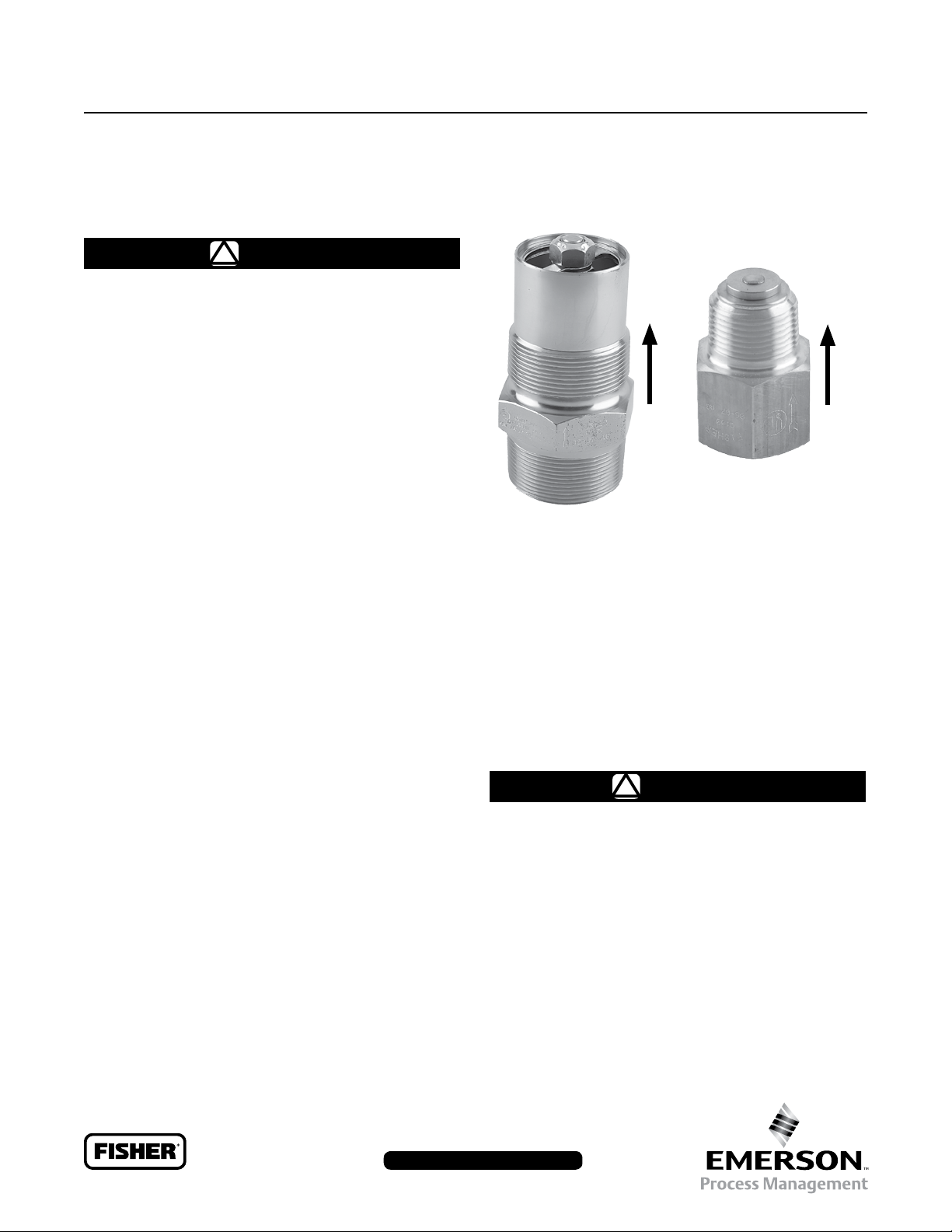

G100 Series

P1038

Only personnel trained in the proper

procedures, codes, standards, and regulations

of the LPG industry should install and service

this equipment.

Introduction

Scope of the Manual

This instruction manual covers installation and maintenance

for Fisher G100 Series Back Check Valves used on LPG

and anhydrous ammonia.

Description

Back check valves are normally closed valves that allow

ow in only one direction. When ow, in the direction

of the arrow starts, the valve poppet opens. When

ow stops or reverses, the valve poppet closes. Back

check valves are installed in liquid lling connections on

stationary storage tanks and bobtail delivery trucks, as

well as liquid transfer lines. The valves are frequently

used in conjunction with globe and angle valves or large

single-check ller valves.

Two styles of seat construction are available: soft

seat or metal-to-metal. The soft-seated construction is

intended for the lling connection on bobtail delivery

P1039

G105 SERIES

Figure 1. G100 Series Back Check Valves

(Arrow indicates direction of ow)

trucks. Because the valves give tight shutoff, piping on

the bobtail can be blown down easily for maintenance or

repair without experiencing leakage.

G100 SERIES

Installation

CAUTION

If the valve is to be used in service other than

LPG or anhydrous ammonia, contact the

factory to determine if the valve materials are

suitable for the particular service.

Flow through the back check valve must

be in the same direction as the flow arrow

stamped on the valve.

www.sherregulators.com

D450017T012

Page 2

G100 Series

Specifications

This section lists the specications for the G100 Series valve. Factory specications are stamped on the nameplate fastened on

the valve at the factory.

SEAT CONSTRUCTION

Metal-to-Metal

Soft Seat

OUTLET CONNECTION,

IN.

3/4 FNPT 3/4 MNPT 21 GPM / 79.5 l/min G100 - - - -

1-1/4 FNPT 1-1/4 MNPT 55 GPM / 208 l/min G101 - - - -

2 FNPT 2 MNPT 150 GPM / 568 l/min G102 G112

2 FNPT 2 FNPT 150 GPM / 568 l/min G109 - - - -

3 FNPT 3 MNPT 250 GPM / 946 l/min - - - - G104

2 MNPT and 1-1/4 FNPT 2 MNPT 137.5 GPM / 520 l/min - - - - G105

2 MNPT 3 FNPT 254 GPM / 961 l/min - - - - G106

3 MNPT and 2 FNPT 3 MNPT 254 GPM / 961 l/min - - - - G107

INLET CONNECTION,

IN.

Maximum Operating Pressure: 250 psig / 17.2 bar

1. Brass valves are not suitabe for NH

applications.

3

2. Manually operate the back check valve’s poppet

before installation to assure parts were not damaged in

shipment or blocked with dirt or foreign material.

3. Install valve so that arrow points in the direction of flow

through the valve.

4. Use pipe dope on the main threads of the valve or

the pipeline. Polytetrafluoroethylene (PTFE) tape or

PTFE pipe dope compound is recommended for the

male threads of the larger valves such as the 2 and

3 in. sizes.

5. Test the valve for proper operation after installation and

before placing the system into full service. To make the

test, pressure the system through the back check valve

and then quickly bleed pressure from the valve inlet

piping. Check for pressure build-up in the inlet piping.

On soft seated valves, there should be no build-up

in the inlet side. On metal-to-metal seated valves, a

slow pressure build-up is permissible. A rapid pressure

build-up on either valve style indicates that the valve

has malfunctioned.

PROPANE FLOW CAPACITY AT

10 psig / 0.69 bar

DIFFERENTIAL PRESSURE

!

WARNING

TYPE NUMBER

Brass Steel

Trained personnel should test the back check

valve in a safe location.

To ensure that the valve is still functional,

back check closure should be checked

annually if there is no other regularly

scheduled test program.

Maintenance

Annually TEST back check valve for closure. Back check valves

are non-repairable. Replace non-functioning valves.

LPG Equipment

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Emerson Process Management Regulator Technologies, Inc. product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc., 2001, 2015; All Rights Reserved

Loading...

Loading...