Page 1

Emerson FB2200 Flow Computer Instruction Manual

Emerson FB2200 Flow Computer

Instruction Manual

D301784X012

November 2020

Remote Automation Solutions

Page 2

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Device Safety Considerations

Reading these Instructions

Before operating the device, read these instructions carefully and understand their safety implications. In some

situations, improperly using this device may result in damage or injury. Keep this manual in a convenient location

for future reference. Note that these instructions may not cover all details or variations in equipment or cover

every possible situation regarding installation, operation, or maintenance. Should problems arise that are not

covered sufficiently in the text, immediately contact Customer Support for further information.

Protecting Operating Processes

A failure of this device – for whatever reason -- may leave an operating process without appropriate protection and

could result in possible damage to property or injury to persons. To protect against this, you should review the

need for additional backup equipment or provide alternate means of protection (such as alarm devices, output

limiting, fail-safe valves, relief valves, emergency shutoffs, emergency switches, etc.). Contact Remote

Automation Solutions for additional information.

Returning Equipment

If you need to return any equipment to Remote Automation Solutions, it is your responsibility to ensure that the

equipment has been cleaned to safe levels, as defined and/or determined by applicable federal, state and/or local

law regulations or codes. You also agree to indemnify Remote Automation Solutions and hold Remote

Automation Solutions harmless from any liability or damage which Remote Automation Solutions may incur or

suffer due to your failure to ensure device cleanliness.

Grounding Equipment

Ground metal enclosures and exposed metal parts of electrical instruments in accordance with OSHA rules and

regulations as specified in Design Safety Standards for Electrical Systems, 29 CFR, Part 1910, Subpart S, dated: April

16, 1981 (OSHA rulings are in agreement with the National Electrical Code). You must also ground mechanical or

pneumatic instruments that include electrically operated devices such as lights, switches, relays, alarms, or chart

drives.

Important: Complying with the codes and regulations of authorities having jurisdiction is essential to ensuring

personnel safety. The guidelines and recommendations in this manual are intended to meet or exceed applicable

codes and regulations. If differences occur between this manual and the codes and regulations of authorities

having jurisdiction, those codes and regulations must take precedence.

Protecting from Electrostatic Discharge (ESD)

This device contains sensitive electronic components which be damaged by exposure to an ESD voltage.

Depending on the magnitude and duration of the ESD, it can result in erratic operation or complete failure of the

equipment. Ensure that you correctly care for and handle ESD-sensitive components.

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to correctly install, configure,

program, calibrate, and trouble-shoot your Emerson equipment provides your engineers and technicians with the

skills and confidence to optimize your investment. Remote Automation Solutions offers a variety of ways for your

personnel to acquire essential system expertise. Our full-time professional instructors can conduct classroom

training at several of our corporate offices, at your site, or even at your regional Emerson office. You can also

receive the same quality training via our live, interactive Emerson Virtual Classroom and save on travel costs. For

our complete schedule and further information, contact the Remote Automation Solutions Training Department

at 800-338-8158 or email us at education@emerson.com.

Ethernet Connectivity

This automation device is intended to be used in an Ethernet network which does not have public access. The

inclusion of this device in a publicly accessible Ethernet-based network is

ii Contents

not recommended.

Page 3

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Contents

Section 1: Introduction 1

1.1 Safety Labels ......................................................................................................................................... 3

1.2 Features ................................................................................................................................................ 3

1.3 FB2200 Flow Computer Models ............................................................................................................. 4

1.3.1 FB2200 Flow Computer – With Sensor ..................................................................................... 4

1.3.2 FB2200 Flow Computer – No Integral Sensor ............................................................................ 5

Central Processing Unit (CPU) ............................................................................................................... 5

1.4

1.4.1 Memory ................................................................................................................................... 5

1.5 Inputs & Outputs (I/O) ........................................................................................................................... 5

1.6 Power Options ...................................................................................................................................... 7

1.7 Communications .................................................................................................................................. 7

1.8 Human-Machine Interface (HMI) Module .............................................................................................. 8

1.9 FBxWifi™ Communications ................................................................................................................... 8

1.10 Software Tools ...................................................................................................................................... 9

1.11 RoHS2 Compliance ............................................................................................................................... 9

1.12 Physical Security ................................................................................................................................... 9

Section 2: Installation 13

2.1 Hazardous Locations ........................................................................................................................... 13

2.2 Environmental Specifications .............................................................................................................. 13

2.3 Required Tools .................................................................................................................................... 14

2.4 Site Considerations ............................................................................................................................. 15

2.5 General Wiring Guidelines ................................................................................................................... 20

2.6 Grounding .......................................................................................................................................... 21

2.7 Opening/Closing the Enclosure ........................................................................................................... 21

2.8 Mounting the Enclosure ...................................................................................................................... 22

2.8.1 Bolting Considerations ........................................................................................................... 22

2.8.2 O-rings with Flange Adapters ................................................................................................. 25

2.8.3 Pole Mounting – Aluminum Enclosure .................................................................................... 26

2.8.4 Pole Mounting – Fiberglass Enclosure ..................................................................................... 27

2.8.5 Panel/Wall Mounting Dimensions – Aluminum Enclosure ....................................................... 28

2.8.6 Panel/Wall Mounting Dimensions – Fiberglass Enclosure ........................................................ 29

2.8.7 Rotating the Housing ............................................................................................................. 31

2.9 Power Modes ...................................................................................................................................... 32

2.9.1 Low Power Mode .................................................................................................................... 32

2.9.2 Standard Power Mode ............................................................................................................ 33

2.9.3 Notes on Battery Life .............................................................................................................. 34

2.10 Connecting Power ............................................................................................................................... 35

2.10.1 Connecting DC Power ............................................................................................................ 35

2.10.2 Connecting Battery Power ..................................................................................................... 36

2.10.3 Connecting Solar Power ......................................................................................................... 44

2.11 Installing the Optional 30W Solar Panel ............................................................................................... 50

2.12 Adjusting the Optional Solar Panel ...................................................................................................... 52

2.13 Connecting Communication Ports ...................................................................................................... 54

2.13.1 Connecting to COM1 ............................................................................................................. 54

2.13.2 Connecting to COM2 and COM3 ............................................................................................ 57

2.13.3 Connecting to Ethernet .......................................................................................................... 59

2.14 Security Intrusion Switch ..................................................................................................................... 61

Contents iii

Page 4

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Section 3: I/O Configuration and Wiring 63

3.1 Analog Inputs ...................................................................................................................................... 65

3.1.1 AI Wiring ................................................................................................................................ 67

3.2 Analog Outputs ................................................................................................................................... 68

3.2.1 AO Wiring .............................................................................................................................. 69

3.3 Digital Inputs ...................................................................................................................................... 70

3.3.1 DI Wiring................................................................................................................................ 71

3.4 Digital Outputs ................................................................................................................................... 72

3.4.1 DO Wiring .............................................................................................................................. 72

3.5 Pulse Inputs ........................................................................................................................................ 75

3.5.1 PI Wiring ................................................................................................................................ 76

3.6 Connecting the RTD/PRT ..................................................................................................................... 76

3.7 Connecting a Rosemount 4088B ......................................................................................................... 78

3.8 Wiring a Digital Output to the Optional Relay ...................................................................................... 81

3.9 Radio Wiring ....................................................................................................................................... 82

Section 4: Operation 83

4.1 Powering Up/Powering Down the Device ............................................................................................ 83

4.2 Establishing Communications ............................................................................................................. 83

Communicating with the SCADA Host.................................................................................... 83

4.2.1

4.2.2 Communicating with a Laptop Using One of the Serial Ports ................................................... 84

4.2.3 Communicating with a Laptop Using Ethernet ....................................................................... 84

4.2.4 Communicating with a Laptop Wirelessly with FBxWifi ........................................................... 85

4.3 Communicating Using the HMI Module ............................................................................................... 86

Section 5: Service and Troubleshooting 89

5.1 Returning the Unit for Repairs ............................................................................................................. 91

5.2 Interpreting the Status LEDs ................................................................................................................ 91

5.3 Switch and Buttons ............................................................................................................................. 93

5.4 Removing/Replacing the HMI Module ................................................................................................. 94

5.5 Replacing the Main Battery Pack.......................................................................................................... 94

5.6 Removing/Replacing the SRAM Battery ............................................................................................. 104

5.7 Upgrading System Firmware ............................................................................................................. 107

Appendix A: Special Instructions for Class I Division 2 Locations 109

Appendix B: ATEX Non-Sparking Zone 2 Certifications 113

Index 115

iv Contents

Page 5

Section 1: Introduction

This section covers the following topics:

Safety Labels

Features

FB2200 Flow Computer Models

Central Processing Unit (CPU)

Inputs & Outputs (I/O)

Power Options

Communications

Human-Machine Interface (HMI) Module

FBxWifi™ Communications

Software Tools

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

RoHS2 Compliance

Physical Security

The Emerson FB2200 Flow Computer measures pressure, differential pressure, and temperature

for one or two meter runs of natural gas. It works with both differential pressure-based meters

measuring static pressure (SP), differential pressure (DP), and temperature (T), and linear meters

measuring pulse or analog inputs, SP, and T.

This manual describes how to install and configure the Emerson FB2200 flow computer hardware.

For information on using the FBxConnect™ configuration software, see the online help that

accompanies FBxConnect.

Introduction 1

Page 6

Emerson FB2200 Flow Computer Instruction Manual

1

HMI module

2

Front cover

3

Data plate

4

Enclosure

5

Sensor module

D301784X012

November 2020

Figure 1-1. FB2200 Flow Computer

2 Introduction

Page 7

1.1 Safety Labels

DANGER

WARNING

CAUTION

SAFETY FIRST

This product may display safety label(s) to identify potential hazards. The same types of notices

appear within the documentation. Whenever you see an exclamation point (!) enclosed within a

triangle (shown to the left), consult the documentation for additional safety information about the

hazard and how to avoid it. The labels used are:

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

MAY CAUSE DEATH

Observe all precautionary signs posted on the equipment.

Failure to do so may result in death or serious injury to personnel.

DANGER TO PERSONNEL AND EQUIPMENT

Observe all precautionary signs posted on the equipment.

Failure to do so may result in injury to personnel or cause damage to the equipment.

MAY CAUSE INJURY TO PERSONNEL OR DAMAGE EQUIPMENT

Observe all precautionary signs posted on the equipment.

Failure to do so may result in injury to personnel or cause damage to the equipment.

1.2 Features

Introduction 3

General instructions and safety reminders.

The FB2200 flow computer includes the following key features:

Enclosure suitable for use in Class I Division 2 non-incendive and Ex nA Zone 2 non- sparking

environments. Enclosure available in either aluminum or compression-molded fiberglass

Optional Integral multi-variable sensor for measurement of Pressure (P) and Differential

Pressure (DP)

Optional static pressure sensor, typically used with linear meters

Connections for customer-supplied resistance temperature detector (RTD) for measurement

of temperature (T)

Base I/O consists of two on-board channels you can individually configure as digital input

(DI), digital output (DO), or pulse input (PI) and two on-board I/O channels you can

Page 8

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

individually configure as either analog input (AI) or analog output (AO). Optional expansion

I/O modules are available.

Power from a DC power supply or an optional lead acid battery/solar panel combination

Serial communication options for RS-232, RS-485/422 (4-wire), and RS-485 (2-wire)

Optional 10/100 Base T-Ethernet port

HMI module with optional display and back light for local operator interaction

Optional Wi-Fi

computer from a laptop without physical cable connection

Application software supports AGA3, AGA8, ISO 5167, ISO 6976, and API 21.1 calculations in

either U.S., metric, or other natural gas standard units

®

transceiver (802.11 b/g) enabling a field technician to access the flow

1.3 FB2200 Flow Computer Models

You can purchase two basic models of the FB2200 flow computer. In addition, each model is

available in either an aluminum enclosure or a compression-molded fiberglass enclosure.

Either model includes two ¾ in NPT pipe-threaded conduit ports on the bottom of the enclosure to

permit entry of field conduit for I/O and communication wiring.

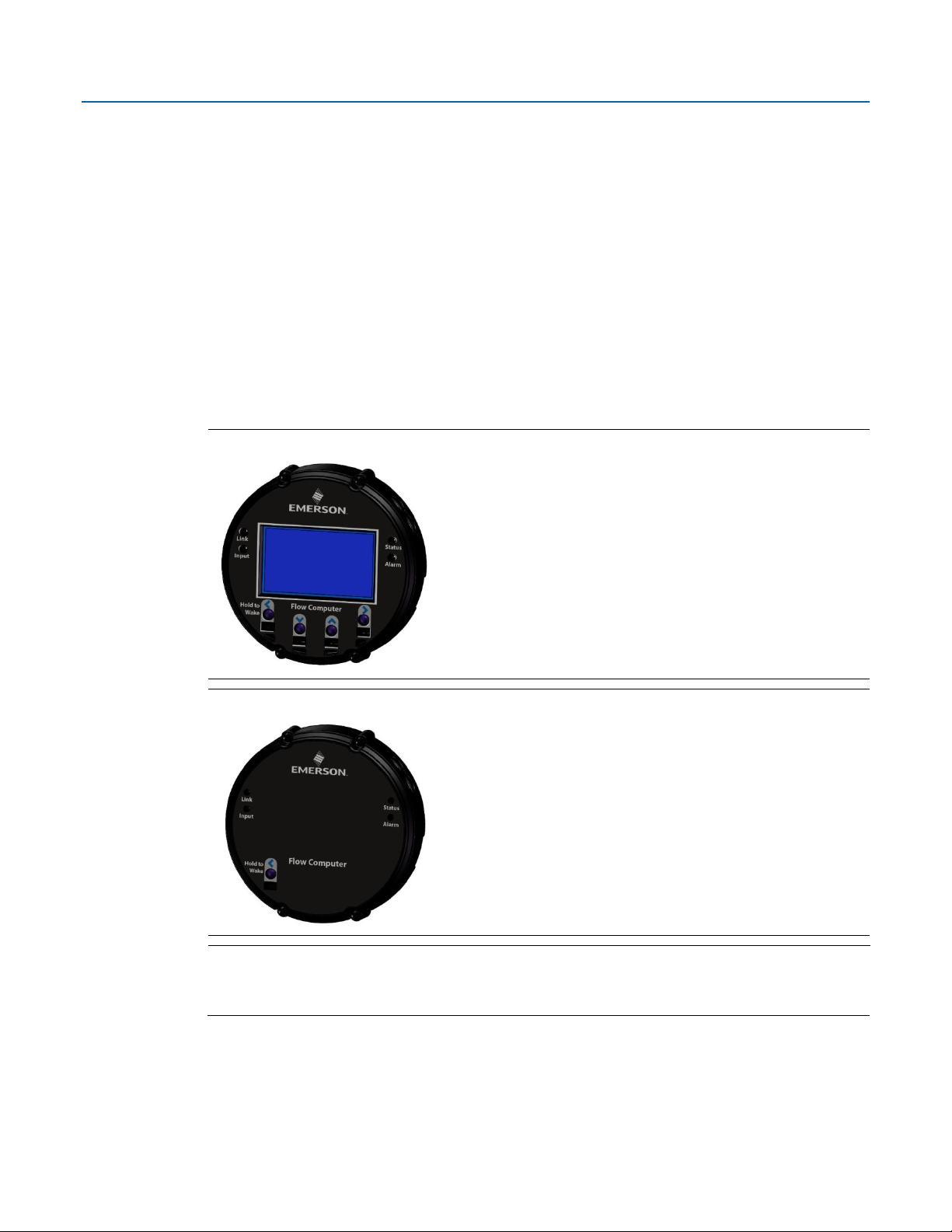

1.3.1 FB2200 Flow Computer – With Sensor

This version includes either a multi-variable (MV) sensor module (Figure 1-2) or a static pressure

sensor module (not shown).

Figure 1-2. FB2200 Flow Computer – Multivariable Sensor Version

4 Introduction

Page 9

Emerson FB2200 Flow Computer Instruction Manual

Memory

Usage

8 MB SRAM

Holds in-use configuration, current state of all variables

Holds firmware image, historical logs, configuration backup (if saved to flash),

1.3.2 FB2200 Flow Computer – No Integral Sensor

The no integral sensor version includes no sensor module. In this case the process variable data

used in flow computer calculations comes from external devices and enters the device through the

serial ports or I/O channels.

Figure 1-3. FB2200 Flow Computer – No Integral Sensor Version

D301784X012

November 2020

1.4 Central Processing Unit (CPU)

The flow computer’s CPU is a NXP® Kinetis® K61 series CPU with an ARM® Cortex® M4 processor

that operates at 4 to 60 MHz depending on the power mode. The CPU runs the Micrium operating

system.

1.4.1 Memory

The flow computer includes both static and flash memory.

Table 1-1: Memory

128 MB Flash

and the executing program

1.5 Inputs & Outputs (I/O)

The flow computer comes with base I/O from both the CPU and the built-in multi-variable (MV)

sensor.

Base I/O consists of:

Introduction 5

Page 10

Emerson FB2200 Flow Computer Instruction Manual

FB2200 Base Unit

FB2200 purchased with 8channel Expansion I/O Module

FB2200 purchased with 8-channel

Expansion I/O Module and 6channel Expansion I/O Module

MV Sensor (P, DP) or

MV Sensor (P, DP) or Static

MV Sensor (P, DP) or Static

2 DI/DO/PI channels

6 DI/DO/PI channels (4 residing

10 DI/DO/PI channels (4 residing

2 AI/AO channels

6 AI/AO channels (4 residing on

8 DI/DO channels (4 residing on

D301784X012

November 2020

Pressure (P) input from the MV sensor, differential pressure (DP) input from the MV sensor,

connections for temperature (T) input from a customer-supplied RTD/PRT -or – a single

Static Pressure Sensor with RTD/PRT connections. Alternatively, you can purchase the flow

computer without an integral sensor.

Two on-board I/O channels that you can individually configure as digital input (DI), digital

output (DO), or pulse input (PI)

Two on-board I/O channels that you can individually configure as either analog input (AI) or

analog output (AO)

An optional 8-channel expansion I/O board includes:

Four I/O channels that you can individually configure as digital inputs (DI), digital outputs

(DO), or pulse inputs (PI)

Four I/O channels that you can individually configure as either analog inputs (AI) or analog

outputs (AO)

If the optional 8-channel expansion I/O board is present, the device can optionally support an

additional 6-channel expansion I/O board which includes:

Four I/O channels that you can individually configure as digital inputs (DI), digital outputs

(DO), or pulse inputs (PI)

Two I/O channels that you can individually configure as either analog inputs (AI) or analog

outputs (AO)

Table 1-2. FB2200 I/O Configurations

Static Pressure (SP)

Sensor

Connections for

customer-supplied 2-,

Pressure (SP) Sensor

Connections for customersupplied 2-, 3-, or 4-wire

RTD/PRT

Pressure (SP) Sensor

Connection for customersupplied 2-, 3-, or 4-wire

RTD/PRT

3-, or 4-wire RTD/PRT

on the 8-channel expansion I/O

module).

on the 8-channel expansion I/O

module and 4 residing on the 6channel expansion I/O module)

6 Introduction

the 8-channel expansion I/O

module).

the 8-channel expansion I/O

module and 2 residing on the 6channel expansion I/O module)

Page 11

1.6 Power Options

Option

Usage

External DC Power

Lead Acid Battery Pack

12 Vdc

Port

Type

Use

COM1

Serial communications

RS-232, RS-485/422 (4-wire), or RS-485

COM2 Serial communications

RS-232 or RS-485 (2-wire)

COM3 Serial communications

RS-232 or RS-485 (2-wire)

You can power the flow computer using an external DC input, or an internal rechargeable battery

connected to a solar panel.

Important

Use only batteries supplied with the flow computer or sold by Emerson Remote Automation

Solutions as spare parts for this flow computer. If you substitute a battery you obtain elsewhere

you will void your certification unless it is the identical part from the same manufacturer as that

supplied with the flow computer from Emerson.

Table 1-3. Power Options

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Supply

10.5 Vdc to 30 Vdc external supply (Max power at 10 watts)

1.7 Communications

The flow computer includes three serial communication ports and one Ethernet port. The serial

ports allow communication using DNP3, Modbus, BSAP, and ROC protocols. The Ethernet port is an

RJ-45 connector; the FB2200 supports a maximum of six concurrent TCP connections (sockets)

through this port.

Table 1-4. Serial Ports

Software-selectable for RS-232, RS485/422 (4-wire), or RS-485 (2-wire)

operation

4-wire

10.5 Ah

Not suitable with ATEX or IECEx applications

Optional solar panel and charge controller to charge battery

(supplied separately)

(2-wire) communication to host or other

devices. 4-wire used with external radio.

Introduction 7

Software-selectable for RS-232 or RS-485

(2-wire) operation

2-wire

Software-selectable for RS-232 or RS-485

(2-wire) operation

2-wire

communication to host or other

devices.

communication to host or other

devices.

Page 12

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

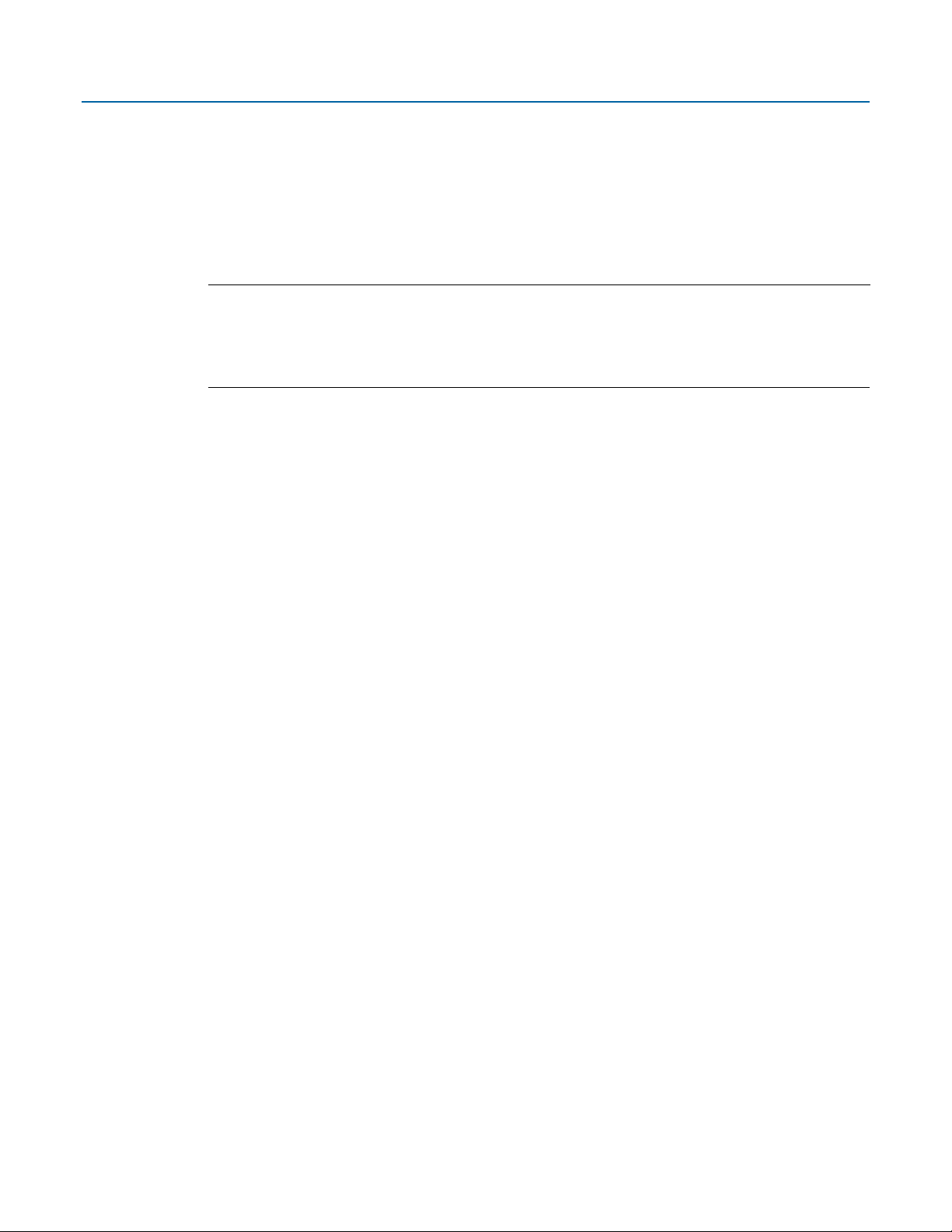

1.8 Human-Machine Interface (HMI) Module

The flow computer includes an HMI module with an optional liquid crystal display (LCD) for local

operator access to the device. The LCD, if present, shows a series of menus that sequentially

displays the current values of particular process variables. A configuration parameter in

FBxConnect determines whether you must first log in to view the menus. If required, you log in by

selecting alphanumeric characters by scrolling through a list until you select the correct character.

The HMI module includes four LEDs to provide status information. Units with the display include

four infrared (IR) buttons for operator interaction.

To conserve power the HMI module enters sleep mode after a period of inactivity. Sleep mode

disables FBxWifi communication. In FBxConnect, you can configure the number of minutes of

inactivity triggering sleep mode through the LCD Sleep Time parameter. Setting this parameter to

0 disables sleep mode which keeps the HMI module on but uses significantly more power.

Figure 1-4. HMI Module with LCD

Figure 1-5. HMI Module without LCD

Note

If your flow computer does not include the LCD option (shown in Figure 1-4), you still have the

status LEDs and a single IR button for waking up the device (shown in Figure 1-5).

1.9 FBxWifi™ Communications

The flow computer has an optional Wi-Fi® transceiver (FBxWifi) that enables you to connect via a

laptop or tablet from a distance. The distance supported varies depending on the laptop/tablet

8 Introduction

Page 13

type and environmental conditions but is typically 70 to 100 feet from the front of the flow

computer and 40 to 60 feet from the side and rear of the flow computer.

This capability allows an operator to potentially remain outside the hazardous location and still

communicate with the flow computer. The operator's laptop must have Wi-Fi capability, line-ofsight access to the HMI module, and must be loaded with FBxConnect configuration software.

Once connected, the operator can view process values, edit configuration parameters, and collect

logs.

Note

The FBxWifi electronics reside inside the HMI module. The HMI module must be awake to use

FBxWifi communications You can wake it up manually by holding a finger against the front cover

glass over the Hold to Wake button (the left-most button) for typically from five to ten seconds.

1.10 Software Tools

The FBxConnect configuration software provides a series of wizards that allow you to perform

configuration activities for the flow computer. You connect a PC running the FBxConnect

configuration software to the flow computer using one of the communication ports or through a

wireless connection. You can then:

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Set parameters within your application

Configure I/O channels

Specify the serial communication method for a port (RS-232 to RS-485) as needed

View or collect audit trail information such as alarm, event, or historical logs

Update system firmware

1.11 RoHS2 Compliance

Device without Integral MVS or SP Sensor:

RoHS (2) EU Directive 2011/65/EU

Device with Integral MVS or SP Sensor:

RoHS (2) EU Directive 2011/65/EU: This product may be considered out-of-scope when used for

the intended design purpose in a Large Scale Fixed Installation (LSFI).

Consult https://www.emerson.com/compliance for up-to-date product information.

1.12 Physical Security

The flow computer enclosure enables you padlock the door shut. The fiberglass enclosure supports

two padlocks (left in Figure 1-6); the aluminum enclosure supports one padlock (right in Figure 1-6).

Introduction 9

Page 14

Emerson FB2200 Flow Computer Instruction Manual

1

Location where customer-supplied padlocks can be used to lock the door

1

Cap

2

Prying off the latch

3

Cap removed

4

Latch removed

D301784X012

November 2020

Figure 1-6. Possible Padlock Locations

Holes in the door latches of the fiberglass enclosure allow you to attach a wire seal.

Alternatively, you can use a pan head screw (#10-32 X 0.81 316 SS or Monel alloy 400) with an Oring (0.15 ID, 0.07 W) in place of one or both door latches to screw the door shut. In this case, you

pry off the latch with a flat head screwdriver and pop out the mating cap to free up the holes for the

screw.

Figure 1-7. Removing Cap and Latch from Fiberglass Enclosure

For ATEX/IEC-compliant installations with the fiberglass enclosure, you must use one of these three

choices (padlock, wire seal, or screw).

For either enclosure type, you may apply tamper-evident tape to the four sensor coupling screws

and two rotation set screws to provide evidence of unauthorized sensor adjustments. The four

coupling screws also include holes through which you could attach a wire seal.

10 Introduction

Page 15

Figure 1-8. Potential Locations for Tamper-evident Tape

1

Rotation Set Screws (2) – One shown

2

Coupling Screws (4) – Two shown

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Introduction 11

Page 16

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

12 Introduction

Page 17

Section 2: Installation

This section covers the following topics:

Hazardous Locations

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Environmental Specifications

Required Tools

Site Considerations

General Wiring Guidelines

Grounding

Opening/Closing the Enclosure

Mounting the Enclosure

Power Modes

Connecting Power

Installing the Optional 30W Solar Panel

Adjusting the Optional Solar Panel

Connecting Communications Ports

Door Contact Terminal

The flow computer ships from the factory fully assembled, except for the optional solar panel

assembly.

2.1 Hazardous Locations

For North America the FB2200 has certifications for Class I Division 2 (Groups A, B, C, & D) nonincendive, and non-hazardous locations only. Appendix A contains special information for Class I

Division 2 installations.

For other world areas the FB2200 has ATEX and IEC Ex certifications for Ex nA Zone 2 non-sparking

installations and non-hazardous locations only. See Appendix B for more information.

All certifications are listed on the data plate located on the top of the device.

2.2 Environmental Specifications

This section summarizes the environmental specifications for the device. For full details, refer to

the product data sheet FB2200 Flow Computer (D301792X012).

Installation 13

Page 18

Emerson FB2200 Flow Computer Instruction Manual

Specification

Configuration

Range

Aluminum Enclosure

Fiberglass Enclosure

Ambient

No battery, C1D2

–40 °C to +80 °C

–

35 °C to 80 °C

No Battery, C1D2,

–40 °C to 60 °C

–35 °C to 60 °C

Lead Acid Battery,

–40 °C to 45 °C

–35 °C to 45 °C

ATEX/IEC Ex nA

–25 °C to 55 °C

–25 °C to 55 °C

Humidity

5% to 95% non-condensing

Vibration

2g over 10 to 150 Hz; 1g over 150 to 200 Hz

Tool

Use

Torque wrench

For bolting/mounting the flow computer

2.5 mm hexagonal wrench

For manipulating rotation set screw

#1 Phillips-head screwdriver

For screws on HMI module

#2 Phillips-head screwdriver

For screws on other modules and boards

#3 Phillips-head screwdriver

For optional aluminum enclosure clamps

1/8 inch flat-head screwdriver

For 5.08 mm pitch terminal block connections

7/32 inch flat-head screwdriver

For installing external solar controller

Utility knife

For installing external solar controller

Wire cutters

For installing external solar controller

Wire strippers

For installing external solar controller

Laptop PC running Field Tools with FBxConnect

D301784X012

November 2020

Table 2-1. Environmental Specifications

Temperature

Relay installed

C1D2

No Battery

2.3 Required Tools

Certain tools and equipment are required for installing and servicing the flow computer.

Table 2-2. Required Tools

(-40 °F to +176 °F)

(–40 °F to 140 °F)

(–40 °F to 113 °F)

(–13 °F to 131 °F)

(–31 °F to 176 °F)

(–31 °F to 140 °F)

(–31 °F to 113 °F)

(–13 °F to 131 °F)

14 Installation

configuration software

For configuring

Page 19

Emerson FB2200 Flow Computer Instruction Manual

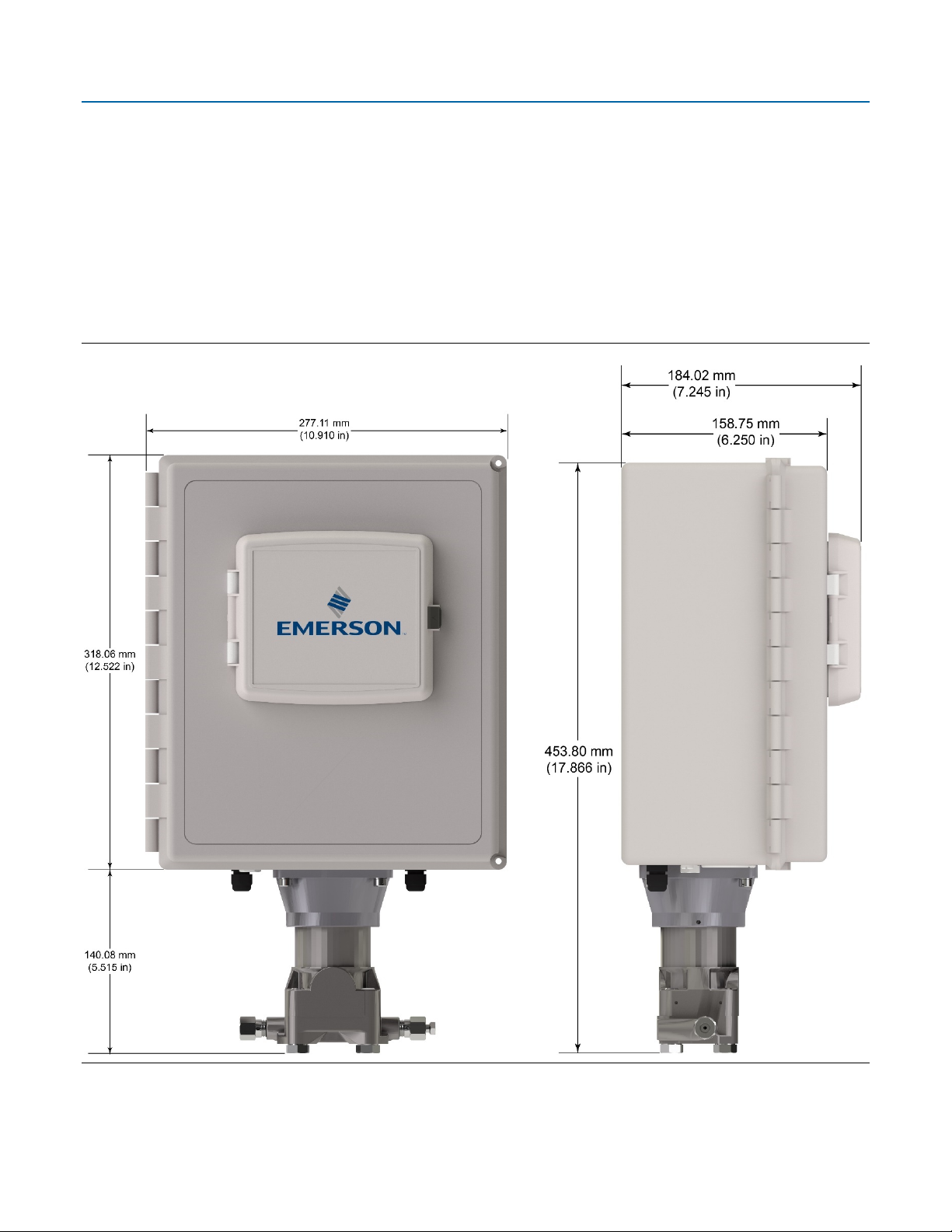

2.4 Site Considerations

The flow computer must reside in an accessible location for configuration and service. Refer to the

dimensional drawings for information on the space required.

Ensure the installation location provides easy access to the HMI module.

If your unit includes the optional solar panel, ensure the installation location provides

sufficient space to mount the solar panel and adequate sunlight to charge the battery.

If your unit includes the optional FBxWifi ensure the installation location provides line-ofsight access to the transceiver.

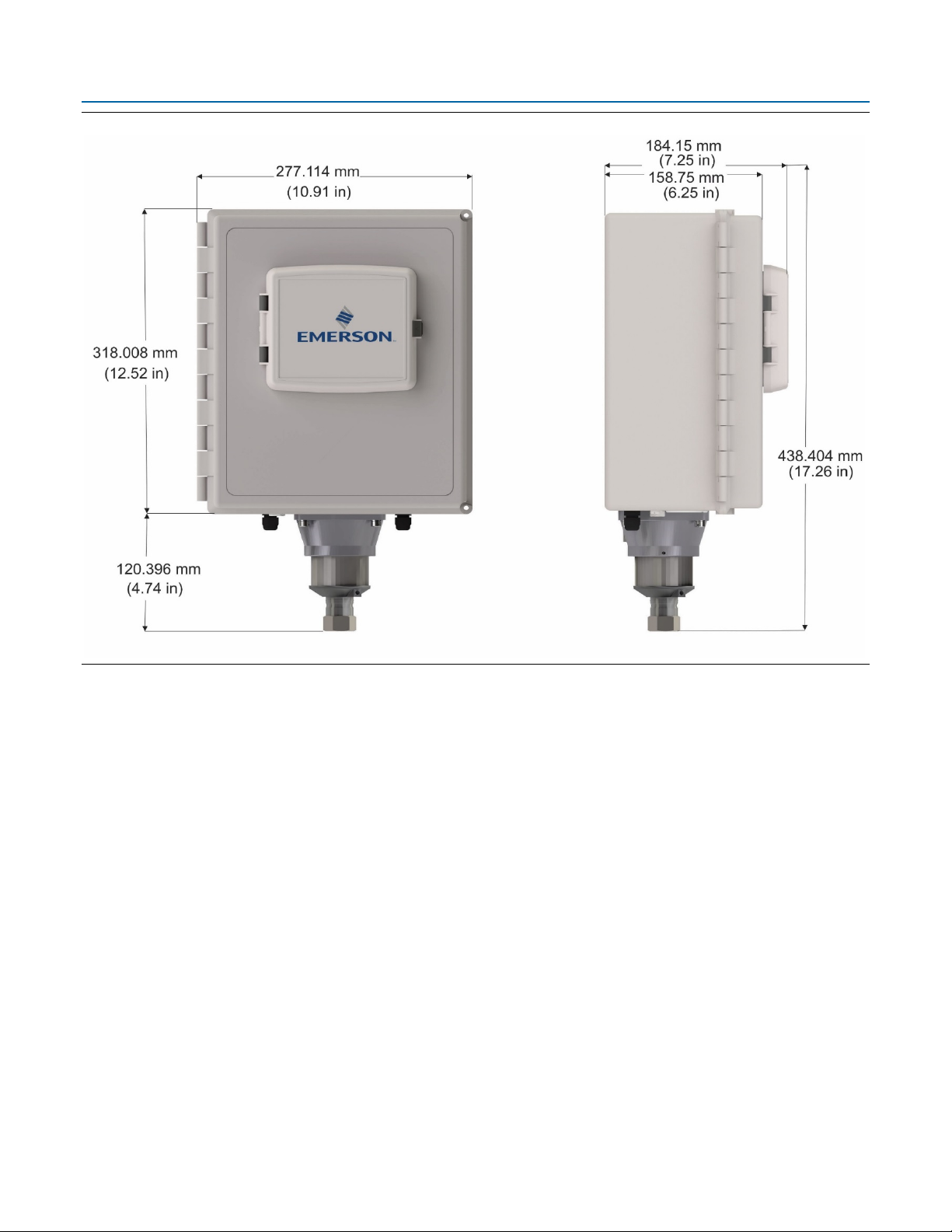

Figure 2-1. Dimensions – Multivariable Sensor Version - Fiberglass Enclosure

D301784X012

November 2020

Installation 15

Page 20

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Figure 2-2. Dimensions – Multivariable Sensor Version - Aluminum Enclosure

16 Installation

Page 21

Emerson FB2200 Flow Computer Instruction Manual

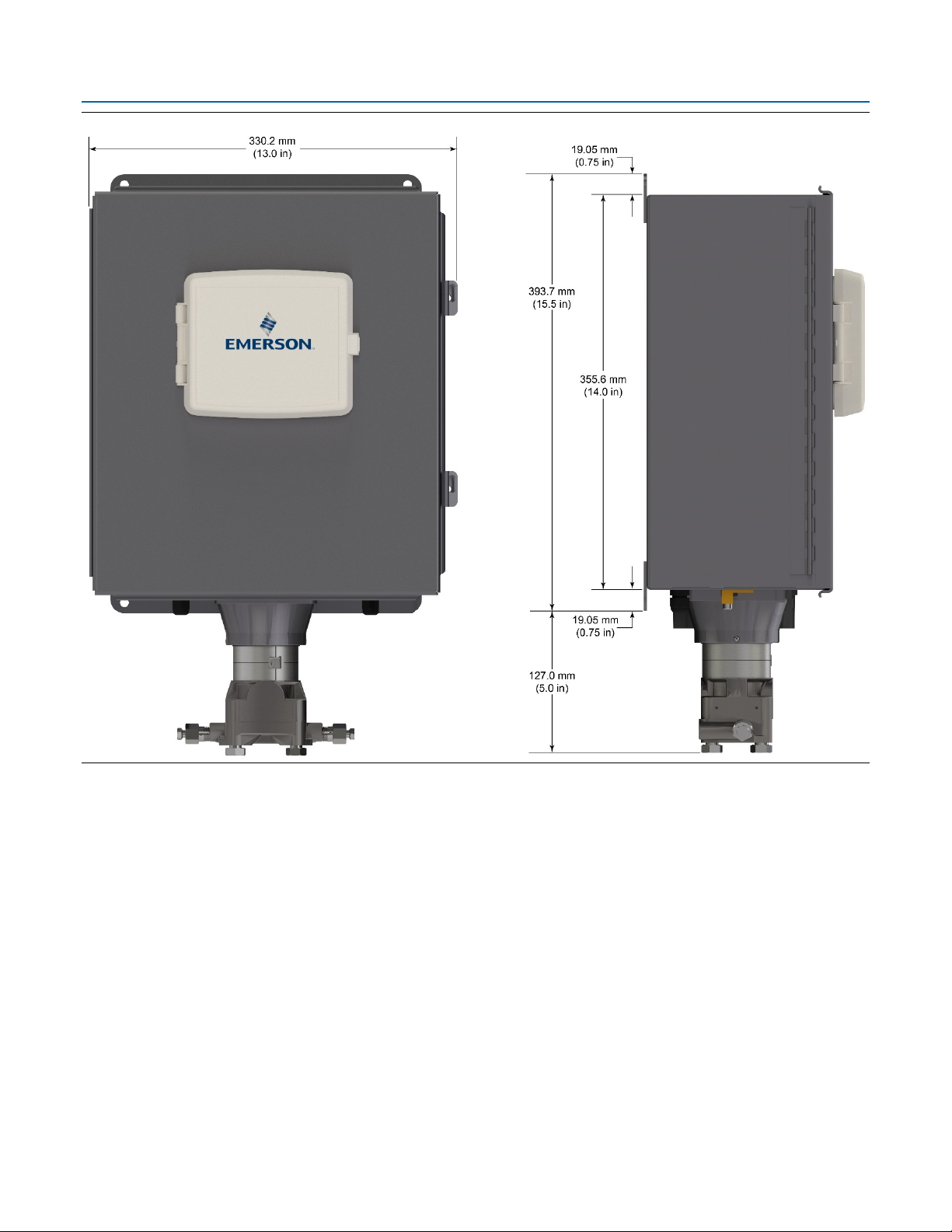

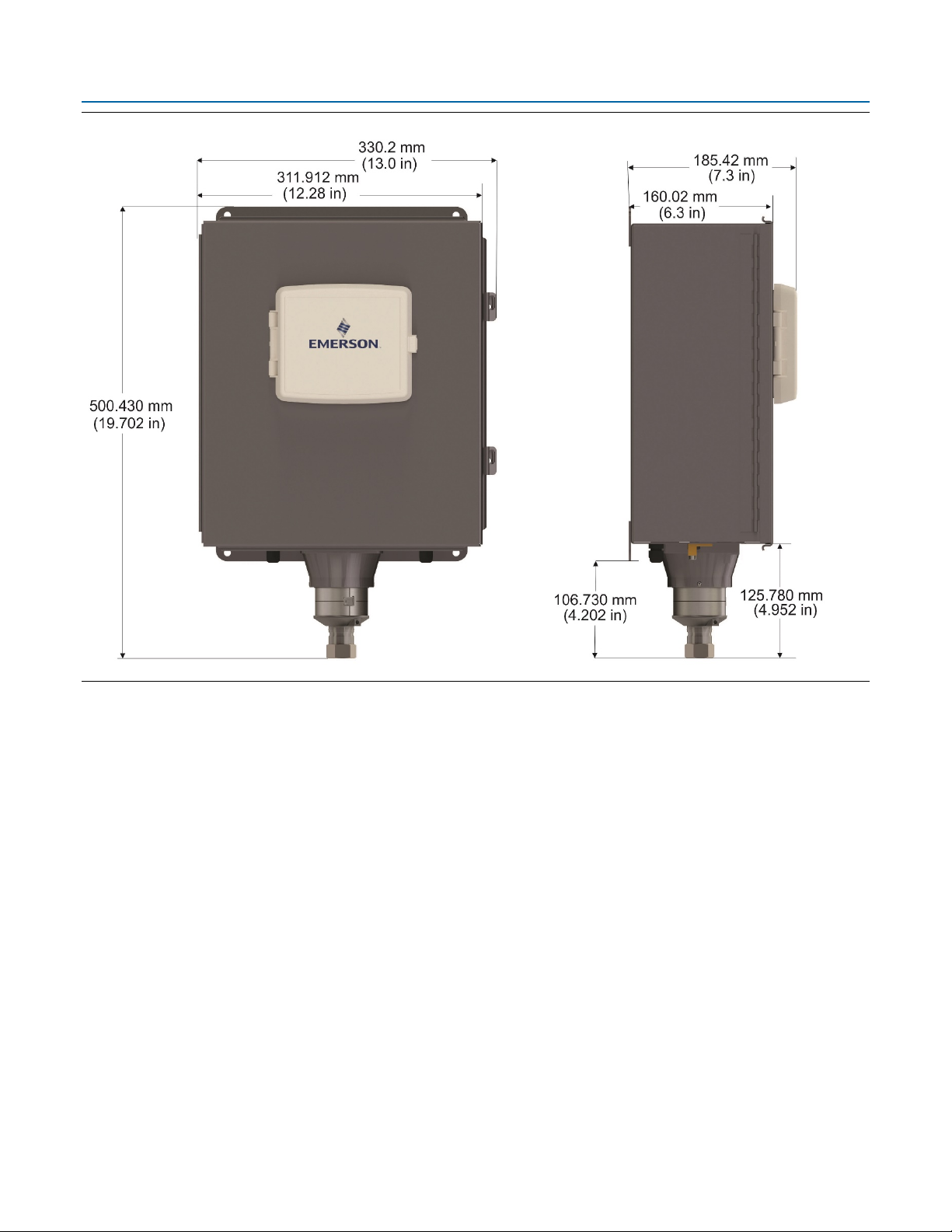

Figure 2-3. Dimensions – No Integral Sensor Version – Fiberglass Enclosure

D301784X012

November 2020

Installation 17

Page 22

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

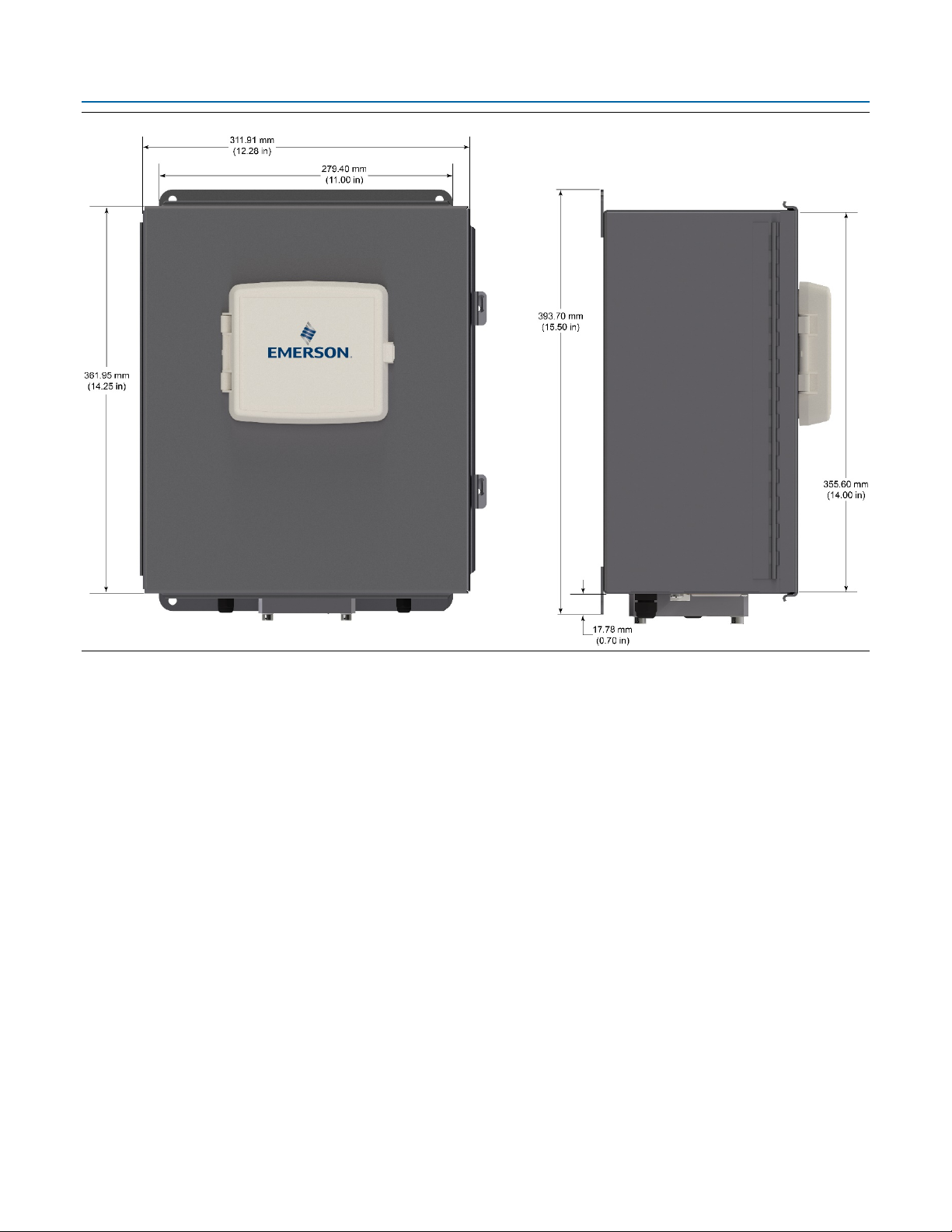

Figure 2-4. Dimensions – No Integral Sensor Version – Aluminum Enclosure

18 Installation

Page 23

Emerson FB2200 Flow Computer Instruction Manual

Figure 2-5. Dimensions – Static Pressure Sensor Version – Fiberglass Enclosure

D301784X012

November 2020

Installation 19

Page 24

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Figure 2-6. Dimensions – Static Pressure Sensor Version – Aluminum Enclosure

2.5 General Wiring Guidelines

The flow computer’s pluggable terminal blocks use compression-type terminals that

accommodate wire between 28 and 12 AWG.

When making a connection, insert the bare end of the wire (approx. 1/4" max) into the clamp

adjacent to the screw and secure the screw.

To prevent shorts, ensure that no bare wire is exposed.

Allow some slack in the wire while making terminal connections. Slack makes the wires more

manageable and helps minimize mechanical strain on the terminal blocks.

Use twisted pair, shielded and insulated cable for communication and I/O wiring to minimize

signal errors caused by electromagnetic interference (EMI), radio frequency interference

(RFI) and transients. When using shielded cable, ground all shields at only one point in the

appropriate system. This prevents circulating ground current loops that can cause signal

errors.

20 Installation

Page 25

2.6 Grounding

The flow computer includes a ground stud on the bottom of the battery compartment

Figure 2-7. Ground Stud

Once you have installed the unit, run a ground wire between the ground stud on the

bottom of the battery compartment and a known good earth ground. You route the

ground wire through one of the conduit fittings.

Use stranded copper wire to earth ground and keep the length as short as possible.

Clamp or braze the ground wire to the ground bed conductor (typically a stranded

copper AWG 0000 cable installed vertically or horizontally).

Run the ground wire so that any routing bend in the cable has a minimum radius of

30.48 cm (12 inches) below ground and 20.32 cm (8 inches) above ground.

For more information on grounding or if your installation uses cathodic protection, refer to Site

Considerations for Equipment Installation, Grounding, and Wiring (D301452X012).

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

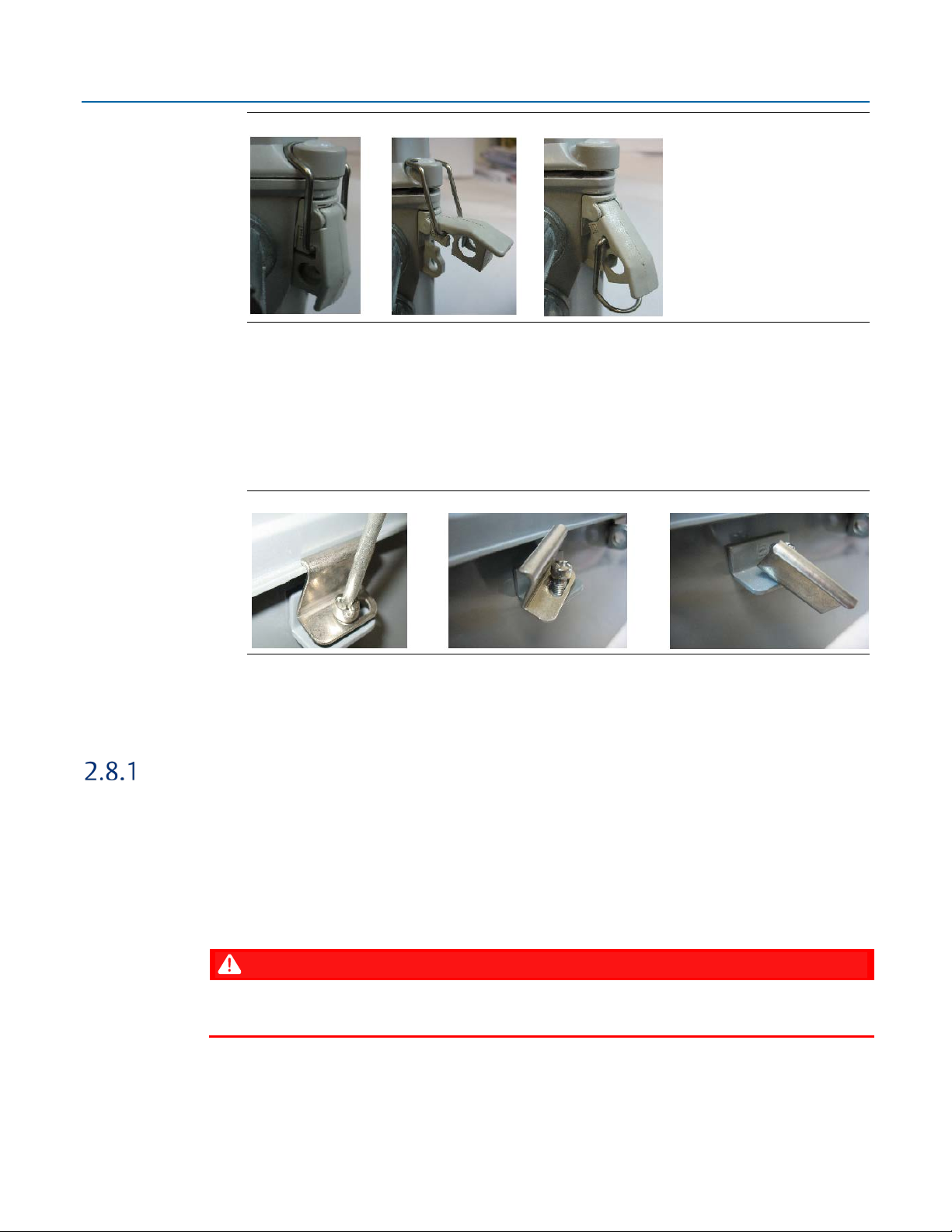

2.7 Opening/Closing the Enclosure

The enclosure opens/closes differently depending upon whether you have the fiberglass enclosure

or the aluminum enclosure.

DANGER

EXPLOSION HAZARD: Never open the enclosure in a hazardous location. Opening the enclosure in

a hazardous location could result in an explosion.

Fiberglass Enclosure

The enclosure includes two fasteners at the top and bottom of the door. To open the door,

lift the clasp to loosen the latch and pull it free of the post, then repeat for the other fastener

and open the door. To fasten the door, place the latch on the post and press down the clasp;

repeat for the other fastener.

Installation 21

Page 26

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Figure 2-8. Fiberglass Enclosure Fasteners

Aluminum Enclosure

The enclosure includes six clamps along the edge of the door (two at the top, two on the

bottom, two at the side). To open the door, use a Phillips-head screwdriver to loosen (but not

remove) the screws enough so you can then pop the clamp free of the lip of the door, then

repeat for the other clamps and open the door. To fasten the door, place the clamp over the

door lip then tighten the screw torqueing to 20 in-lbs (2.3 N m); repeat for the other clamps.

Figure 2-9. Aluminum Enclosure Clamps

2.8 Mounting the Enclosure

You can mount the flow computer directly to a pole. You can also mount it on a wall or panel.

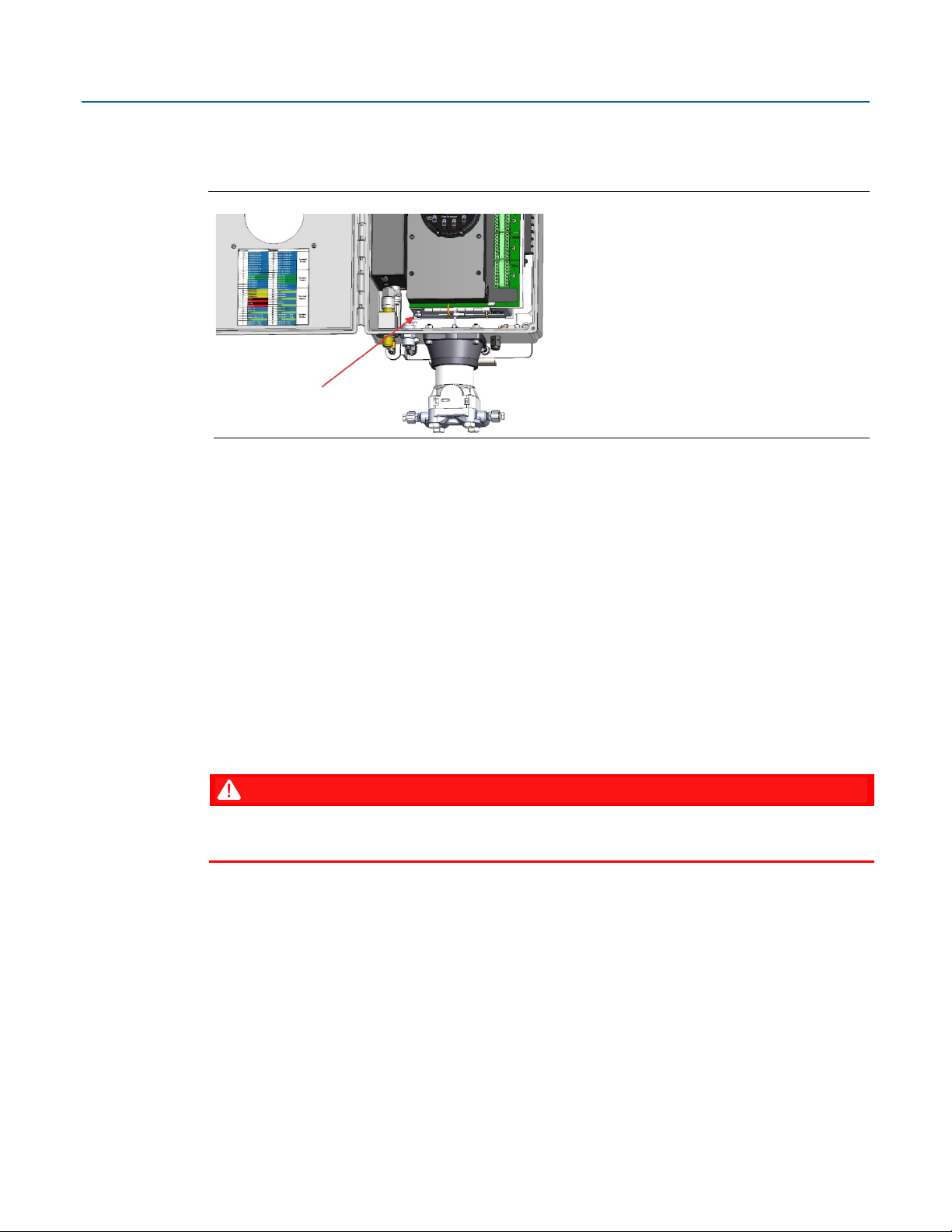

Bolting Considerations

If the flow computer installation requires assembly of a process flange, manifold, or flange

adapters, follow these assembly guidelines to ensure a tight seal for optimal performance

characteristics of the flow computer.

Only use bolts supplied with the flow computer or sold by Emerson Remote Automation Solutions

as spare parts. Refer to the figure for common flow computer assemblies with the bolt length

required for proper flow computer installation.

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

22 Installation

Page 27

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Note

For all other manifolds, contact your local Emerson Sales office or Emerson Impact Partner.

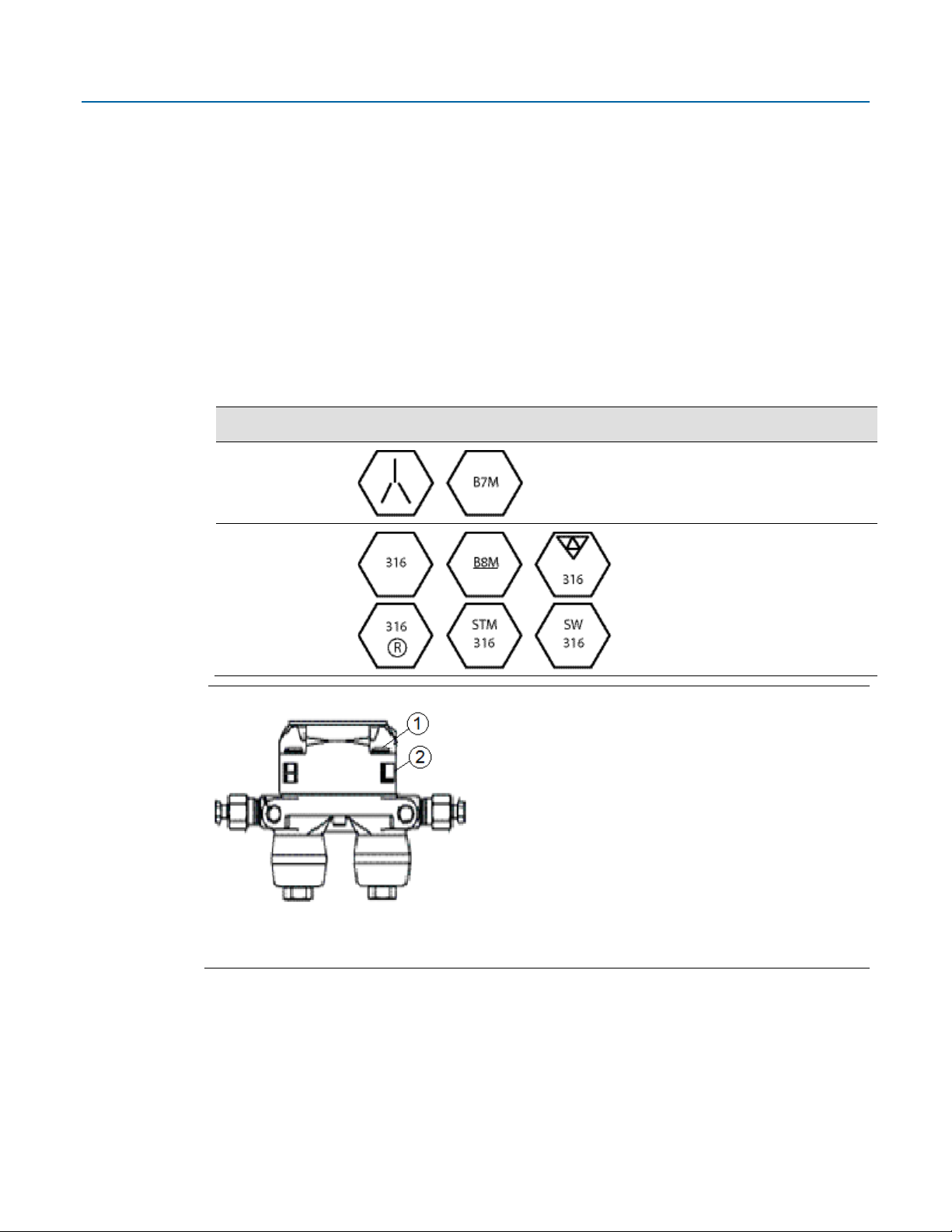

Bolts are typically carbon steel or stainless steel. Confirm the material by viewing the markings on

the head of the bolt and referencing the figure. If bolt material is not shown in the figure, contact

your local Emerson Remote Automation Solutions representative for more information.

Figure 2-10. Transmitter with Coplanar Flange

Figure 2-11. Transmitter with Coplanar Flange and Optional Flange Adapters

Figure 2-12. Transmitter with Traditional Flange and Optional Flange Adapters

Installation 23

Page 28

Emerson FB2200 Flow Computer Instruction Manual

Bolt Material

Head markings

Initial Torque

Final Torque

1

Bolt

2

Sensor module

D301784X012

November 2020

Use the following bolt installation procedure:

Carbon steel bolts do not require lubrication. Stainless steel bolts are factory-coated with a

1.

lubricant to ease installation. Do not apply any additional lubricant when installing either

type of bolt.

Finger-tighten the bolts.

2.

Torque the bolts to the initial torque value using a crossing pattern. See Table 2-3 for initial

3.

torque value.

Torque the bolts to the final torque value using the same crossing pattern. See Table 2-3 for

4.

final torque value.

Verify that the flange bolts protrude through the sensor module before applying pressure.

5.

T

able 2-3. Torque Values for the Flange and Flange Adapter Bolts

Carbon Steel (CS)

Stainless Steel

(SST)

Figure 2-13. Proper Bolt Installation

300 in. -lbs.

(33.9 N m)

150 in. -lbs.

(16.9 N m)

650 in. -lbs.

(73.4 N m)

300 in. -lbs.

(33.9 N m

24 Installation

Page 29

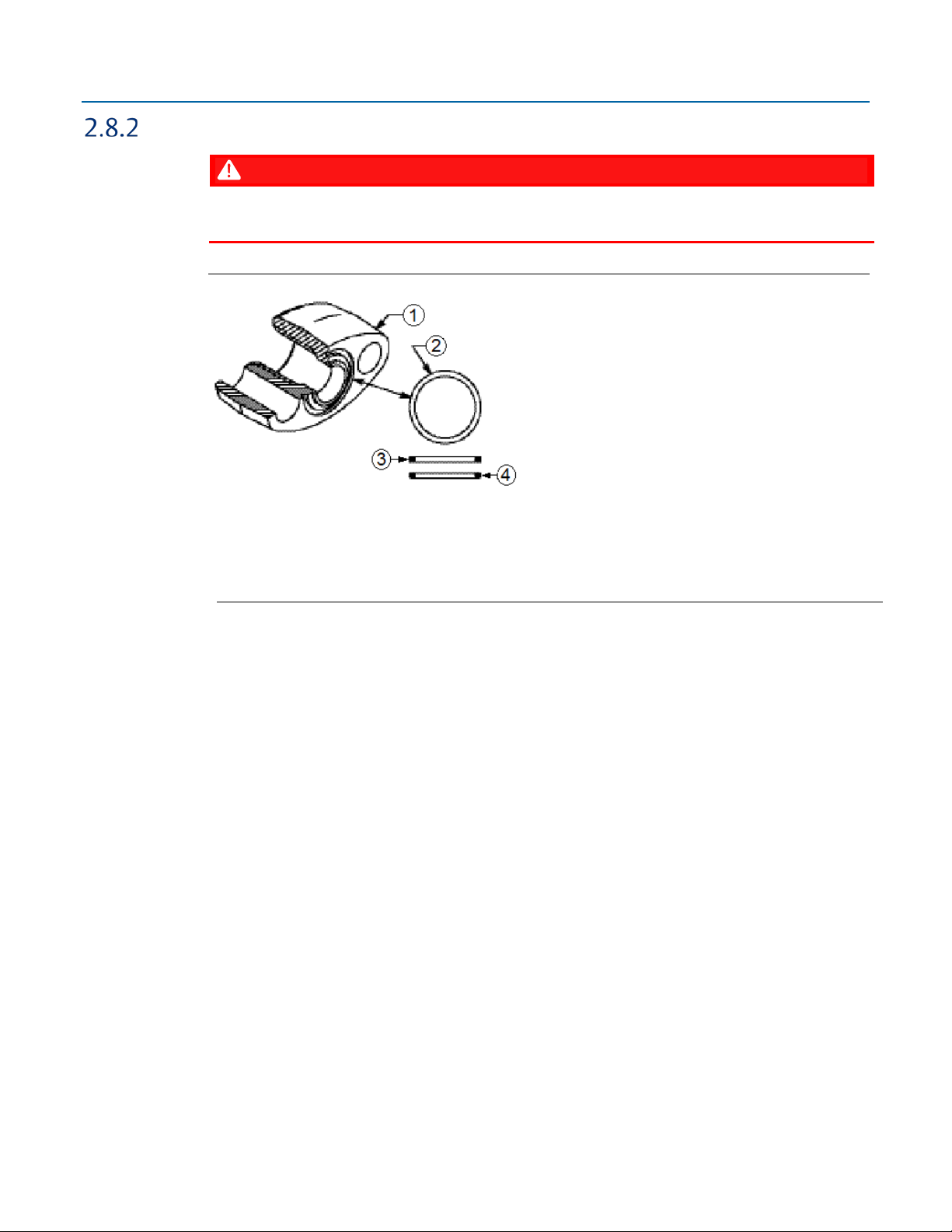

O-rings with Flange Adapters

1

Flange

2

O-ring

3

Square PTFE-based profile

4

Round Elastomer profile

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

DANGER

Failure to install proper flange adapter O-rings may cause process leaks, which can result in death

or serious injury. Only use the O-ring that is designed for its specific flange adapter.

Figure 2-14. O-rings with Flange Adapters

Whenever the flange or adapters are removed, visually inspect the O-rings.

1.

Replace the O-rings if there are any signs of damage, such as nicks or cuts.

2.

If the O-rings are replaced, re-torque the flange bolts and alignment screws after installation

3.

to compensate for seating of the O-rings.

Installation 25

Page 30

Emerson FB2200 Flow Computer Instruction Manual

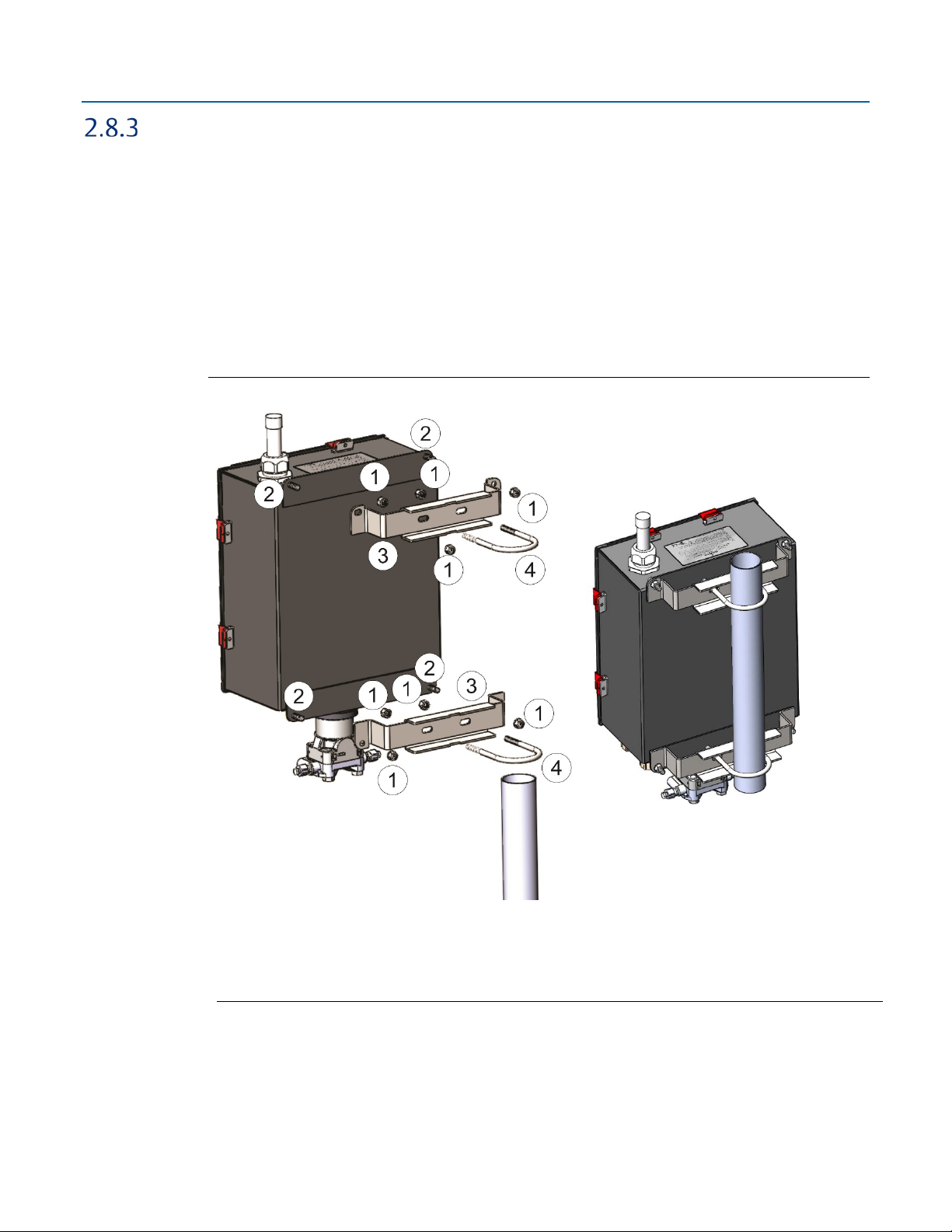

1

5/16-18 keps stainless steel hex nut

2

5/16-18 x 1.0 LG wire-lockable socket head cap screw

3

Pole mounting bracket

4

2-inch diameter 5/16-18 x 4.0LG U-bolt

D301784X012

November 2020

Pole Mounting – Aluminum Enclosure

Refer to Figure 2-15 during the mounting procedure.

Apply Loctite

1.

screws (Item 2).

Attach pole mounting brackets (Item3) to enclosure using head cap screws (Item 2) and hex

2.

nuts (Item 1). Torque hex nuts to 30 in-lbs (3.4 N m).

Apply Loctite 222 Threadlocker sparingly to threads of U-bolts (Item 4).

3.

Use U-bolts (Item 4) to mount enclosure to pole using hex nuts (Item 1). Torque hex nuts to

4.

30 in-lbs (3.4 N m).

Figure 2-15. Aluminum Enclosure Pole Mounting

®

222 Low Strength Purple Threadlocker sparingly to threads of head cap

26 Installation

Page 31

Emerson FB2200 Flow Computer Instruction Manual

1

¼ inch screw split lock stainless steel washer

2

¼-10 x .75LG thread forming torx head screw

3

5/16-18 keps stainless steel hex nut

4

Pole mounting bracket

5

2 inch diameter 5/16-18 x 4.0LG U-bolt

Pole Mounting – Fiberglass Enclosure

Refer to Figure 2-16 during the mounting procedure.

Attach plastic pole mounting brackets (Item4) to enclosure using split lock stainless steel

1.

washers (Item 1) and torx head screws (Item 2).

Apply Loctite 222 Low Strength Purple Threadlocker adhesive sparingly to threads of U-bolts

2.

(Item 5).

Use U-bolts (Item 5) to mount enclosure to pole using hex nuts (Item 3). Torque hex nuts to

3.

30 in-lbs (3.4 N m).

Figure 2-16. Fiberglass Enclosure Pole Mounting

D301784X012

November 2020

Installation 27

Page 32

Emerson FB2200 Flow Computer Instruction Manual

A

Mounting holes are 7.92 mm (0.312 in) diameter

D301784X012

November 2020

Panel/Wall Mounting Dimensions – Aluminum Enclosure

Figure 2-17. Aluminum Enclosure Panel/Wall Mounting

28 Installation

Page 33

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Panel/Wall Mounting Dimensions – Fiberglass Enclosure

Prior to mounting, attach mounting tabs to enclosure:

Figure 2-18. Attaching mounting tabs

Installation 29

Page 34

Emerson FB2200 Flow Computer Instruction Manual

A

Mounting holes are 7.9 mm (0.31 in) wide

D301784X012

November 2020

Figure 2-19. Fiberglass Enclosure Panel/Wall Mounting

30 Installation

Page 35

Rotating the Housing

1

To improve accessibility to the HMI module or to ease wiring, you can optionally rotate the

housing.

Important

Never rotate the housing more than 180 degrees from its original (as-shipped) position. Overrotation can break electronics within the unit.

Figure 2-20. Housing Rotation Set Screw (1 each side)

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Set Screw (one each side)

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

1. Loosen the two housing rotation set screws.

2. Rotate the housing no more than 180 degrees from its original (as-shipped) position.

3. Re-tighten the two housing rotation set screws. Torque to 6 in-lbs. (0.7 N m).

Installation 31

Page 36

Emerson FB2200 Flow Computer Instruction Manual

Description

Power Usage

(mW) at 12Vdc

Base flow computer with integral multivariable DP and pressure sensor and

Base flow computer with integral multivariable DP and pressure sensor and

Additional Load Options:

Display and backlight active

340

FBxWifi active

379

FBxWifi and display active

398

DO active (1 Hz, 50:50 duty cycle, no load)

12

PI active (10 KHz, 50:50 duty cycle, square wave)

12

D301784X012

November 2020

2.9 Power Modes

To keep power consumption to a minimum, especially for remote sites, the FB2200 can run in two

different power modes – Low Power Mode (4 MHz or 8 CPU MHz clock speed) or Standard Power

Mode (60 MHz CPU clock speed).

Low Power Mode

The FB2200 normally runs in low power mode for typical metering applications. The radio Power

Control function (configurable in FBxConnect) switches the flow computer into standard power

mode at specific times when serial communications are required, then it reverts to low power

mode when the communication period is over. A serial connection to a remote 4088B MVT can

occur in low power mode.

The local display (HMI module) with FBxWifi uses additional power. You can configure it in

FBxConnect to shut down after a period of inactivity.

Important

You must disable the Ethernet port (using a jumper) to run in low power mode. See Section 2.13.3.

Table 2-4. Typical Power Usage – Low Power Mode at Room Temperature

temperature measurement, single DO available, for a single meter run

Historical configuration supports maximum of:

4 averages

12 Station 1 history points (Group 4)

10 User Periodic history points (Group 1)

temperature measurement, 2 digital and 2 analog channels available for a

single meter run

Historical configuration supports maximum of:

4 averages

12 Station 1 history points (Group 4)

10 User Periodic history points (Group 1)

55

67

32 Installation

Page 37

Important

Description

Power Usage

(mW) at 12Vdc

Power Usage

(mW) at 24Vdc

Base flow computer with integral multivariable DP and

Base flow computer with temperature measurement (no

Base flow computer with integral multivariable DP and

Base flow computer with temperature measurement, integral

Base flow computer with integral multivariable DP and

If you increase the number of history points/averages beyond any of the maximum limits in Table 2-

4, the flow computer

mode.

cannot operate in low power mode and automatically runs in standard power

Standard Power Mode

When serial communication is active (other than to a remote 4088B MVT) the FB2200 operates in

standard power mode. The unit also uses standard power mode when:

The HMI module display is ON

FBxWifi is active

Ethernet port is enabled in the flow computer

Modbus Master communication is active

PID, Math/logic Blocks, Action Blocks, and Effect Blocks are enabled

Power control zone is enabled

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Table 2-5. Typical Power Usage – Standard Power Mode at room temperature

pressure sensor and temperature measurement for a single

meter run

integral sensor) communicating to remote 4088B (externally

powered) for a single meter run

pressure sensor and temperature measurement, 2 digital and

2 analog channels available for a single meter run

static pressure sensor and pulsed input for a single meter run

pressure sensor and temperature measurement,

communicating to remote 4088B (externally powered) for a

dual meter run

240 290

220 268

260 313

276 330

250 300

Installation 33

Page 38

Emerson FB2200 Flow Computer Instruction Manual

Description

Power Usage

(mW) at 12Vdc

Power Usage

(mW) at 24Vdc

Additional Load Options:

Display and backlight active

159

188

FBxWifi active

191

199

FBxWifi and display active

233

245

DO active (1 Hz, 50:50 duty cycle, no load)

20

23

PI active (10 KHz, 50:50 duty cycle, square wave)

14

15

8-channel expansion I/O module installed (isolated)

228

280

Additional 6-channel expansion I/O module installed

68

66

Ethernet enabled 100 Mbit

430

466

Ethernet active 100 Mbit

640

650

Loop power supply

310

393

D301784X012

November 2020

Table 2-5. (Continued)

(isolated)

Notes on Battery Life

Battery life varies based on numerous factors including temperature, communication usage, and

various load options. To achieve the maximum battery life noted in the product data sheet requires

that you:

Limit use of the display, backlight, and FBxWifi options.

Limit communication activity.

Disable power to all I/O (except for the MV or static pressure sensor, or RTD). To do this, click

Configure > I/O Setup > I/O Configuration > Properties and select Disable for each I/O

module.

Figure 2-21. Module Power Control

34 Installation

Page 39

2.10 Connecting Power

1

To external DC power supply

Power can come from an external DC supply or a lead acid battery pack with a solar panel.

Connecting DC Power

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

When power comes from an external DC supply, connect using the +DCIN and –DCIN terminals.

Use standard copper wire (#18 AWG minimum). The device supports both 12V and 24V power

supplies. It accepts DC voltage from 10.5 to 30V; the amount of power required varies depending

upon the options used.

Important

If your installation uses DC power for main power, do not wire battery power as a secondary (back

up) power source. Certification only allows a

void your certification.

Figure 2-22. DC Power Connections

single

main power source; wiring both sources will

Installation 35

Page 40

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Connecting Battery Power

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous

Performing this operation in a hazardous area could result in an explosion.

When power comes from an internal battery pack, the battery pack plugs into one of two pairs of

connectors.

2.10.2.1 Installing the Main Battery Pack

If you purchased one of the battery/solar panel options, you need to install the main battery pack

before you place the device in service.

The device provides a battery cable with two pairs of battery connectors, enabling you to hot-swap

the battery pack in a non-hazardous location. You can use either pair of connectors when you

install the battery.

Remove the battery pack from its packaging.

1.

2.

Remove the plastic tabs covering the connectors on the battery pack.

Figure 2-23. Removing Plastic Tabs from Battery Pack

Open the enclosure.

3.

36 Installation

Page 41

Emerson FB2200 Flow Computer Instruction Manual

1

Captive Fastening Screws

D301784X012

November 2020

Loosen the two captive fastening screws at the top of the of the battery compartment, while

4.

holding onto the battery compartment door. Carefully rotate the electronics assembly

towards you to reveal the inside of the battery compartment. A strap prevents the front of

the compartment from rotating too far forward.

Figure 2-24. Captive Fastening Screws

Installation 37

Page 42

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Figure 2-25. Rotate Assembly Forward

The battery cable inside the battery compartment is divided into two branches, each with its

5.

own pair of connectors. Take either pair of connectors and connect them to the battery; the

red (positive) wire connector attaches to the red connection point on the battery and the

black (negative) wire connector attaches to the black connection point on the battery.

38 Installation

Page 43

Figure 2-26. Connect the Battery

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Now you must secure the battery in the battery compartment so that it doesn’t move

6.

around. How you do this depends on which battery compartment configuration you have. If

the battery compartment includes a strap for holding the battery, see Section 2.10.2.1 –

Securing the Battery with a Strap; if the battery compartment includes an adhesive pad, see

Section 2.10.2.2 – Securing the Battery to the Pad.

Installation 39

Page 44

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

2.10.2.2 Securing the Battery with a Strap

This type of battery compartment allows for certain accessories to be installed such as a relay or

internal solar regulator.

1. If you have an internal solar regulator installed in the battery compartment, you must

remove its termination cover in order to fit the battery inside. Remove the two screws (left

and right) that fasten the termination cover to the solar regulator, and then set the

termination cover aside. (If you don’t have an internal solar regulator, skip to Step 2.)

Figure 2-27. Removing Termination Cover of Internal Solar Regulator

2. The battery strap must already be threaded through the holes of the battery compartment.

Figure 2-28. Battery Strap

3. Pick up the battery and carefully ease it into the battery compartment with the writing on

the battery facing out and the connectors on the upper right-hand side. Nothing (including

the strap) can be

40 Installation

behind the battery.

Page 45

Emerson FB2200 Flow Computer Instruction Manual

Figure 2-29. Easing Battery Pack into Compartment

D301784X012

November 2020

4. Carefully push the battery under the solar regulator (if present) and against the back of the

compartment, now strap it in tightly by pulling the ends of the strap.

Figure 2-30. Battery Pack Attached to Compartment

5. The strap includes a narrow opening into which you can slide the other end of the strap to

help you tighten it.

Installation 41

Page 46

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Figure 2-31. Battery Pack Attached to Compartment

6. Route the extra portion of the strap as well as the wires of the free portion of the battery

cable so that they sit in an open area of the battery compartment.

7. If you had to remove the termination cover of an internal solar regulator (Step 1), re-attach

the termination cover.

8. Rotate the electronics assembly up against the battery compartment and tighten the captive

fastening screws with a torque value of 2 to 4 in-lbs. (0.2 to 0.5 N m) to close the

compartment.

2.10.2.3 Securing the Battery to the Pad

For this type of battery compartment, a hook-and-loop adhesive pad on the back of the battery

secures it to the back of the battery compartment.

Pick up the battery and align it with the lower left edge of the battery compartment. Press it

1.

against the back of the compartment so the pad on the back of the battery secures to the

back of the battery compartment.

42 Installation

Page 47

Emerson FB2200 Flow Computer Instruction Manual

Figure 2-32. Battery Pack Attached to Compartment

D301784X012

November 2020

Route the wires of the free portion of the battery cable so that they sit completely inside the

2.

open area at the top of the battery compartment.

Rotate the electronics assembly up against the battery compartment and tighten the captive

3.

fastening screws with a torque value of 2 to 4 in-lbs (0.2 to 0.5 N m) to close the

compartment.

Close the enclosure.

4.

Installation 43

Page 48

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Connecting Solar Power

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Restriction

The solar panel and lead acid battery combination cannot be used with ATEX/IECEx applications.

When power comes from a solar panel/lead acid battery combination, connect using the BATT+

and BATT– terminals and standard copper wire (#18 AWG minimum).

Important

Only use batteries supplied with the flow computer or sold by Emerson as spare parts for this

flow computer. If you substitute a battery you obtain elsewhere

unless it is the identical part from the same manufacturer as that supplied with the flow

computer from Emerson.

If you purchase a solar panel/external solar regulator combination other than the Emerson-

approved option, it

must meet the specifications listed in Tables 2-6 and 2-7.

2.10.3.1 Wiring the 30W Solar Panel

For the 30W solar panel option with an external solar controller (charger/regulator) purchased

through Emerson (Emerson-approved option) connect the external solar controller to the flow

computer battery using the instructions in this section.

you will void your certification

If you are using your own external solar controller/30W solar panel not purchased through

Emersion, you can use this section as an example of a typical installation. You should also consult

the manufacturer’s instructions for your solar panel/solar regulator.

In either situation, you must use the battery, cables, and fuses supplied by Emerson for your

connections to the solar controller/solar panel.

Note

When making connections to the junction box or the solar regulator, you will need a suitable cable

gland/grommet to prevent water ingress to the junction box.

See Figure 2-39 for wiring instructions if you ordered the internal solar regulator.

44 Installation

Page 49

Emerson FB2200 Flow Computer Instruction Manual

Characteristic

Value/Range

Peak Power

30W ± 10%

Voltage (@peak power)

17.9V

Current (@peak power)

1.68A

Open Circuit Voltage

22.1V

Short Circuit Current

1.74A

Characteristic

Value/Range

Rated Solar Input

6A

Nominal System Voltage

12V

Maximum Solar Voltage

30V

3 stage charging

Bulk, PWM, and float

13.7V

Temperature Compensation

30 mV / °C

Operating Temperature

40 °C to 70 °C

Humidity

100%

Short Circuit Current

reverse polarity

Table 2-6. Solar Panel Electrical Characteristics

Table 2-7. Solar Regulator Electrical Characteristics

D301784X012

November 2020

Regulation Voltage

14.1V

Float Voltage

lightning and transient surges

short circuit

high temperature

overcurrent

reverse current at night

1. The solar controller comes with plastic mounting feet used only for surface mounting

applications. Remove the mounting feet but save the lock nut.

2. The solar controller also comes with fork connectors.

Installation 45

Page 50

Emerson FB2200 Flow Computer Instruction Manual

1

Solar controller

2

Fork connectors

1

Junction box

2

Knock-outs

3

Lock nut

D301784X012

November 2020

Figure 2-33. Solar Controller

3. Remove the fork connectors and trim back the insulation on the wires ¼ inch.

Figure 2-34. Removing Fork Connectors

4. Remove the junction box cover. Use a utility knife to remove the knock-outs (Item 2) in the

junction box (Item 1) and feed the wires from the solar controller into the junction box, and

through the solar controller lock nut (Item 3).

Figure 2-35. Wiring Solar Power – External Regulator

46 Installation

Page 51

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

5. Use the solar controller lock nut to attach the solar controller to the junction box and use a

7/32” flat head screwdriver to attach the wires from the controller to the junction box

connectors as shown.

Figure 2-36. Wiring Solar Power – External Regulator

6. Route the BATT+ and BATT– wires from the flow computer into the junction box.

Figure 2-37. Routing Battery Wires

7. Connect the wires as shown. Replace the junction box cover.

Installation 47

Page 52

Emerson FB2200 Flow Computer Instruction Manual

1

2

Conduit

3

Battery

D301784X012

November 2020

Figure 2-38. Wiring Solar Power – External Regulator

Fast-acting 6.3A one-time fuse

If you ordered the flow computer with an internal solar regulator for the 30W solar panel, wire it

according to Figure 2-39.

48 Installation

Page 53

Figure 2-39. Wiring Solar Power – Internal Regulator

1

Solar Panel

2

Conduit

3

Fast acting 6.3A one time fuse

4

Solar Regulator

5

Solar

6

Battery

7

Load

8

Battery

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Installation 49

Page 54

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

2.11 Installing the Optional 30W Solar Panel

If you purchased the lead acid battery/30W solar panel kit for main power, you need to install the

supplied solar panel. Refer to Figure 2-40 during this procedure.

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Solar panel installation involves:

Mounting the solar panel on a pole

Wiring power to the solar panel. (See Section 2.10.3)

Setting the tilt angle of the panel for maximum solar exposure. (See Section 2.13)

Install the solar panel as follows:

Attach the adjustable angle bracket (Item 2 in Figure 2-40) to the solar panel (Item 1) using

1.

the hex screws (Item 5), flat washers (Item 6), lock washers (Item 7), and hex nuts (Item 8).

Torque hex nuts (Item 8) to 60 in-lbs (6.8 N m).

2.

Apply Loctite® 222MS™ Purple Threadlocker Low Strength sparingly to hex nut threads

3.

(Item 8) after torqueing.

Attach pole mounting bracket (Item 3) to angle bracket (Item 2) using hex screws (Item 12),

4.

flat washers (Item11), lock washers (Item 10) and hex nuts (Item 9).

Torque hex nuts (Item 9) to 108 in-lbs (12.2 N m).

5.

Apply Loctite 222MS Threadlocker sparingly to hex nut threads (Item 9) after torqueing.

6.

Attach entire solar panel assembly to pole by attaching pole mounting bracket (Item 3) to U-

7.

bolt assembly (Item 4). Torque nuts in U-bolt assembly to 60 in-lbs (6.8 N m).

Apply Loctite 222MS Threadlocker sparingly to hex nut threads (Item 8) after torqueing.

8.

Attach a ground wire at the back of the solar panel. For more information on grounding,

9.

refer to Site Considerations for Equipment Installation, Grounding, and Wiring Manual

(D301452X012).

50 Installation

Page 55

Figure 2-40. Installing 30W Solar Panel

1

30W solar panel

2

Adjustable angle bracket

3

Pole mounting bracket

4

U-bolt assembly (2)

5

¼ x 20 x .75LG Hex head cap screw (2)

6

¼ flat washer (2)

7

¼ lock washer (2)

8

¼-20 hex nut (2)

9

5/16-18 hex nut (4)

10

5/16 lock washer (4)

11

5/16 flat washer (4)

12

5/16-18 x 0.75 LG Hex head cap screw (4)

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Installation 51

Page 56

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Figure 2-41. 30W Solar Panel Installed

2.12 Adjusting the Optional Solar Panel

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Point the solar panel surface due south (in the northern hemisphere) or due north (in the

southern hemisphere) at an angle determined by the latitude of the site. Table 2-8 shows the

angle (from horizontal) at which you should install the solar panel to maximize annual energy

output. At most latitudes, you can improve performance by reducing the angle during the

summer and increasing the angle during the winter. If no seasonal adjustments in panel

direction are needed, then adjust the position for the worst-case December-February angle.

Solar insolation is the amount of solar energy in hours received each day by an optimally

tilted panel during the worst month of the year. An insolation rating of one hour means that

the site, on average, would receive one hour of solar energy at the panel's rated power level

(1000W/m

than six hours in the Sahara Desert.

2

per day). This rating varies from less than one hour in northern Canada to more

52 Installation

Page 57

Table 2-8. Solar Panel Tilt Angle

Latitude

Installation Angle

0 to 4

°

10° from horizontal

°

Add 5° to the local latitude

°

Add 15° to the local latitude

1

Tilt angle adjustment (2 of 4 shown)

5 to 20

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

21 to 45

°

Add 10° to the local latitude

46 to 65

66 to 75

°

80° from horizontal

To adjust the tilt angle on the 30W solar panel, loosen the four (4) nuts in the adjustable angle

bracket and move the panel to the desired tilt angle. When in the proper position, torque the nuts

®

to 108 in-lbs (12.2 N m) and apply Loctite

222MS Threadlocker sparingly to hex nut threads after

torqueing.

Figure 2-42. Adjusting the 30W Solar Panel Tilt Angle

The mounting brackets allow you to adjust the solar panel for maximum solar exposure.

Installation 53

Page 58

Emerson FB2200 Flow Computer Instruction Manual

1

RS-232 Port on other device

D301784X012

November 2020

2.13 Connecting Communication Ports

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

The communication ports allow you either to connect to a PC or laptop running FBxConnect

software or to other devices.

Open the enclosure door to access the terminal blocks for the three serial communication ports

and the Ethernet port.

You route communication cables through the conduit fittings and connect the cables to the

terminal blocks.

Note

The optional local serial port connector on the base of the enclosure is hard-wired to COM2.

Connecting to COM1

COM1 can be configured for RS-232, RS-485 (2-wire), or RS-485/422 (4-wire) communications.

When connecting COM1 to another device using RS-232, use a cable with configurations as shown

in Figure 2-43:

Figure 2-43. Connecting a Device to COM1 Using RS-232

When connecting COM1 to another device using RS-485/422 (4-wire), use a cable with

configurations as shown in Figure 2-44:

54 Installation

Page 59

Emerson FB2200 Flow Computer Instruction Manual

1

RS-485/422 (4-wire) Port on other device

Figure 2-44. Connecting a Device to COM1 Using RS-485/422 (4-wire)

D301784X012

November 2020

When connecting COM1 to another device using RS-485 (2-wire), use a cable with configurations

as shown in Figure 2-45:

Installation 55

Page 60

Emerson FB2200 Flow Computer Instruction Manual

1

RS-485 (2-wire) Port on other device

D301784X012

November 2020

Figure 2-45. Connecting a Device to COM1 Using RS-485 (2-wire)

Regardless of the interface standard (RS-232, RS-485 [2-wire], or RS-485/422 [4-wire]) you must

use FBxConnect to configure the port for proper usage.

56 Installation

Page 61

Emerson FB2200 Flow Computer Instruction Manual

1

RS-232 Port on other device

Connecting to COM2 and COM3

COM2 and COM3 operate identically. Each can be configured for either RS-232 or RS-485 (2-wire)

communication.

When connecting COM2 or COM3 to an RS-232 port on another device (a PC or another

controller/flow computer) use a cable with configurations as shown in Figure 2-46:

Figure 2-46. Connecting a Device to COM2 or COM3 Using RS-232

D301784X012

November 2020

When connecting COM2 or COM3 to an RS-485 (2-wire) port on another device (for example, a

transmitter), use a cable with configurations as shown in Figure 2-47:

Installation 57

Page 62

Emerson FB2200 Flow Computer Instruction Manual

1

RS-485 (2-wire) Port on other device

D301784X012

November 2020

Figure 2-47. Connecting a Device to COM2 or COM3 Using RS-485 (2-wire)

Regardless of the interface standard (RS-232 or RS-485 2-wire), you must use FBxConnect to

configure the port for proper usage.

58 Installation

Page 63

Connecting to Ethernet

1

Ethernet Port

The Ethernet port is a standard 8-pin 10/100 Base T RJ-45 modular connector located on the

bottom right side of the CPU enclosure.

Figure 2-48. Connecting to Ethernet

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Installation 59

Connect to an Ethernet switch using the appropriate Category 5 shielded patch cable.

Note

The default Ethernet IP address is 192.168.1.10; the default port is 20000.

If you ordered Ethernet, the unit ships with Ethernet enabled. If you need to operate the device in

lower power mode, you

determines whether Ethernet is enabled or disabled. Refer to the CPU Enclosure and Electronics Field

Replacement Guide (D301803X012) for information on how to open the unit to gain access to the

CPU module.

must disable Ethernet. Jumper J10 on the CPU module (see Figure 2-49)

Page 64

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

Figure 2-49. Ethernet port jumper

60 Installation

Page 65

2.14 Security Intrusion Switch

If ordered from the factory, the door contact wires to a momentary switch as shown using cable

part number 399331-01-0.

Figure 2-50. Wiring the Door Contact Terminal to a Momentary Switch

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

If you order the optional security intrusion switch, the flow computer ships from the factory with

the door switch option enabled. To verify this, you can run FBxConnect software and select

> Board Info. This allows you to view/modify the enable/disable setting for the Door Switch. The

door switch is always on

Figure 2-51. Board Info Screen in FBxConnect

Module_3.

Services

Installation 61

Page 66

Emerson FB2200 Flow Computer Instruction Manual

D301784X012

November 2020

62 Installation

Page 67

Emerson FB2200 Flow Computer Instruction Manual

Section 3: I/O Configuration and Wiring

This section covers the following topics:

Analog Inputs

D301784X012

November 2020

Analog Outputs

Digital Inputs

Digital Outputs

Pulse Inputs

Connecting the RTD/PRT

Connecting a Rosemount 4088B Transmitter for Use in a Second Meter Run

Wiring a Digital Output to the Optional Relay

Radio Wiring

I/O in the FB2200 flow computer comes from the integrated multivariable sensor and RTD

connector, the CPU board, as well as the optional mixed I/O modules.

Note

When using a digital output to drive an inductive load (such as a relay coil), place a suppression

diode across the load. This protects the DO from the reverse Electro-Motive Force (EMF) spike

generated when the inductive load is switched off.

Notes About Power for an External Device Connected to a Flow Computer I/O Point:

If the external device does not include its own integrated power supply, you must provide your own

external supply (30Vdc maximum) for that device.

If your FB2200 flow computer includes the optional 8-channel Expansion I/O Module, you may be