Emerson FB2200 Flow Computer Quick Start Guide

Emerson FB2200 Flow Computer

Quick Start Guide

D301788X012

August 2020

Remote Automation Solutions

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

Device Safety Considerations

Reading these Instructions

Before operating the device, read these instructions carefully and understand their safety implications. In some

situations, improperly using this device may result in damage or injury. Keep this manual in a convenient location

for future reference. Note that these instructions may not cover all details or variations in equipment or cover every

possible situation regarding installation, operation, or maintenance. Should problems arise that are not covered

sufficiently in the text, immediately contact Customer Support for further information.

Protecting Operating Processes

A failure of this device — for whatever reason -- may leave an operating process without appropriate protection and

could result in possible damage to property or injury to persons. To protect against this, you should review the

need for additional backup equipment or provide alternate means of protection (such as alarm devices, output

limiting, fail-safe valves, relief valves, emergency shutoffs, emergency switches, etc.). Contact Remote

Automation Solutions for additional information.

Returning Equipment

If you need to return any equipment to Remote Automation Solutions, it is your responsibility to ensure that the

equipment has been cleaned to safe levels, as defined and/or determined by applicable federal, state and/or local

law regulations or codes. You also agree to indemnify Remote Automation Solutions and hold Remote Automation

Solutions harmless from any liability or damage which Remote Automation Solutions may incur or suffer due to

your failure to ensure device cleanliness.

Grounding Equipment

Ground metal enclosures and exposed metal parts of electrical instruments in accordance with OSHA rules and

regulations as specified in Design Safety Standards for Electrical Systems, 29 CFR, Part 1910, Subpart S, dated: April

16, 1981 (OSHA rulings are in agreement with the National Electrical Code). You must also ground mechanical or

pneumatic instruments that include electrically operated devices such as lights, switches, relays, alarms, or chart

drives.

Important: Complying with the codes and regulations of authorities having jurisdiction is essential to ensuring

personnel safety. The guidelines and recommendations in this manual are intended to meet or exceed applicable

codes and regulations. If differences occur between this manual and the codes and regulations of authorities

having jurisdiction, those codes and regulations must take precedence.

Protecting from Electrostatic Discharge (ESD)

This device contains sensitive electronic components which be damaged by exposure to an ESD voltage.

Depending on the magnitude and duration of the ESD, it can result in erratic operation or complete failure of the

equipment. Ensure that you correctly care for and handle ESD-sensitive components.

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to correctly install, configure,

program, calibrate, and trouble-shoot your Emerson equipment provides your engineers and technicians with the skills

and confidence to optimize your investment. Remote Automation Solutions offers a variety of ways for your personnel

to acquire essential system expertise. Our full-time professional instructors can conduct classroom training at several of

our corporate offices, at your site, or even at your regional Emerson office. You can also receive the same quality

training via our live, interactive Emerson Virtual Classroom and save on travel costs. For our complete schedule and

further information, contact the Remote Automation Solutions Training Department at 800-338-8158 or email us at

education@emerson.com.

ii

Safety First!

Never perform the installation/setup activities described in this document in a hazardous area.

Ensure the area is non-hazardous.

DANGER

EXPLOSION HAZARD: Never open the enclosure in a hazardous location. Opening the enclosure in

a hazardous location could result in an explosion.

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Important

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

Use only batteries supplied with the flow computer or sold by Emerson as spare parts for this

flow computer. If you substitute a battery you obtain elsewhere you will void your

certification unless it is the identical part from the same manufacturer as that supplied with

the flow computer from Emerson.

If you purchase a solar panel/external solar regulator combination other than the Emerson-

approved option, it must meet the specifications listed in the Emerson FB2200 Flow Computer

Instruction Manual (D301784X012).

DANGER

EXPLOSION HAZARD - Substitution of any components may impair suitability for Class I, Division 1

or Class I, Division 2.

DANGER

EXPLOSION HAZARD - Do not disconnect equipment unless power has been removed or the area

is known to be non-hazardous.

1

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

Required Tools

Certain tools and equipment are required for installing and servicing the flow computer.

Table 1: Required Tools

Tool Use

Torque wrench For bolting/mounting the flow computer

2.5 mm Hexagonal wrench For manipulating rotation set screw

#1 Phillips-head screwdriver For screws on HMI module

#2 Phillips-head screwdriver For screws on other modules and boards

#3 Phillips-head screwdriver For optional aluminum enclosure clamps

1/8 inch flat-head screwdriver For 5.08 mm pitch terminal block connections

Utility knife For 30W solar panel installation

Wire strippers For 30W solar panel installation

Wire cutters For 30W solar panel installation

7/32 inch flat-head screwdriver For 30W solar panel installation

Laptop PC running Field Tools with

FBxConnect™ configuration software

For software configuration

2

Emerson FB2200 Flow Computer Quick Start Guide

Opening/Closing the Enclosure

The enclosure opens/closes differently, depending upon whether you have the compressionmolded fiberglass enclosure or the aluminum enclosure.

DANGER

EXPLOSION HAZARD: Never open the enclosure in a hazardous location. Opening the enclosure in

a hazardous location could result in an explosion.

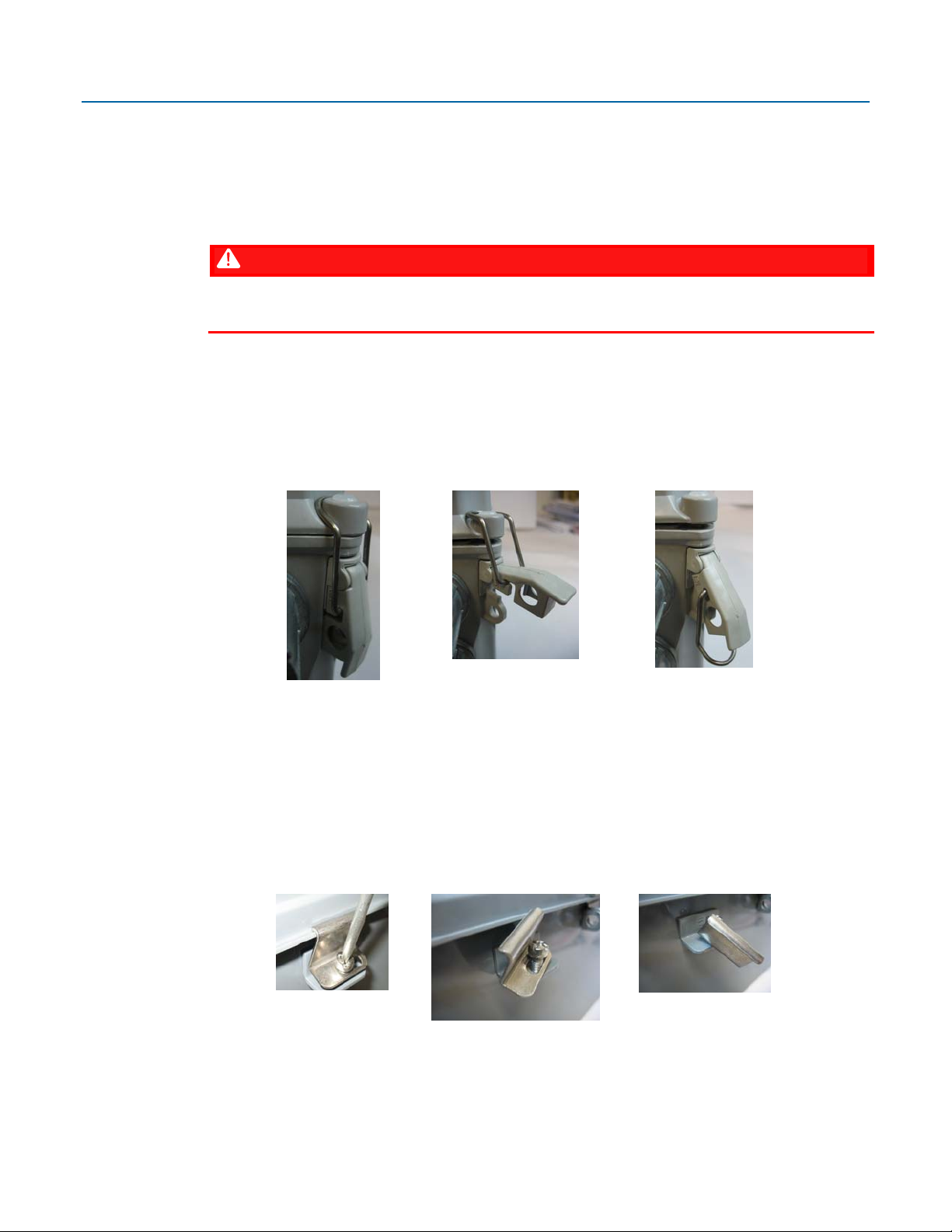

Compression-molded Fiberglass Enclosure

The enclosure includes two fasteners at the top and bottom of the door. To open the door,

lift the clasp to loosen the latch and pull it free of the post, then repeat for the other fastener

and open the door. To fasten the door, place the latch on the post and press down the clasp;

repeat for the other fastener.

D301788X012

August 2020

Aluminum Enclosure

The enclosure includes six clamps along the edge of the door (two at the top, two on the

bottom, two at the side). To open the door, use a Phillips-head screwdriver to loosen (but

not remove) the screws enough so you can then pop the clamp free of the lip of the door,

then repeat for the other clamps and open the door. To fasten the door, place the clamp

over the door lip then tighten the screw; repeat for the other clamps.

3

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

Bolting Considerations

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

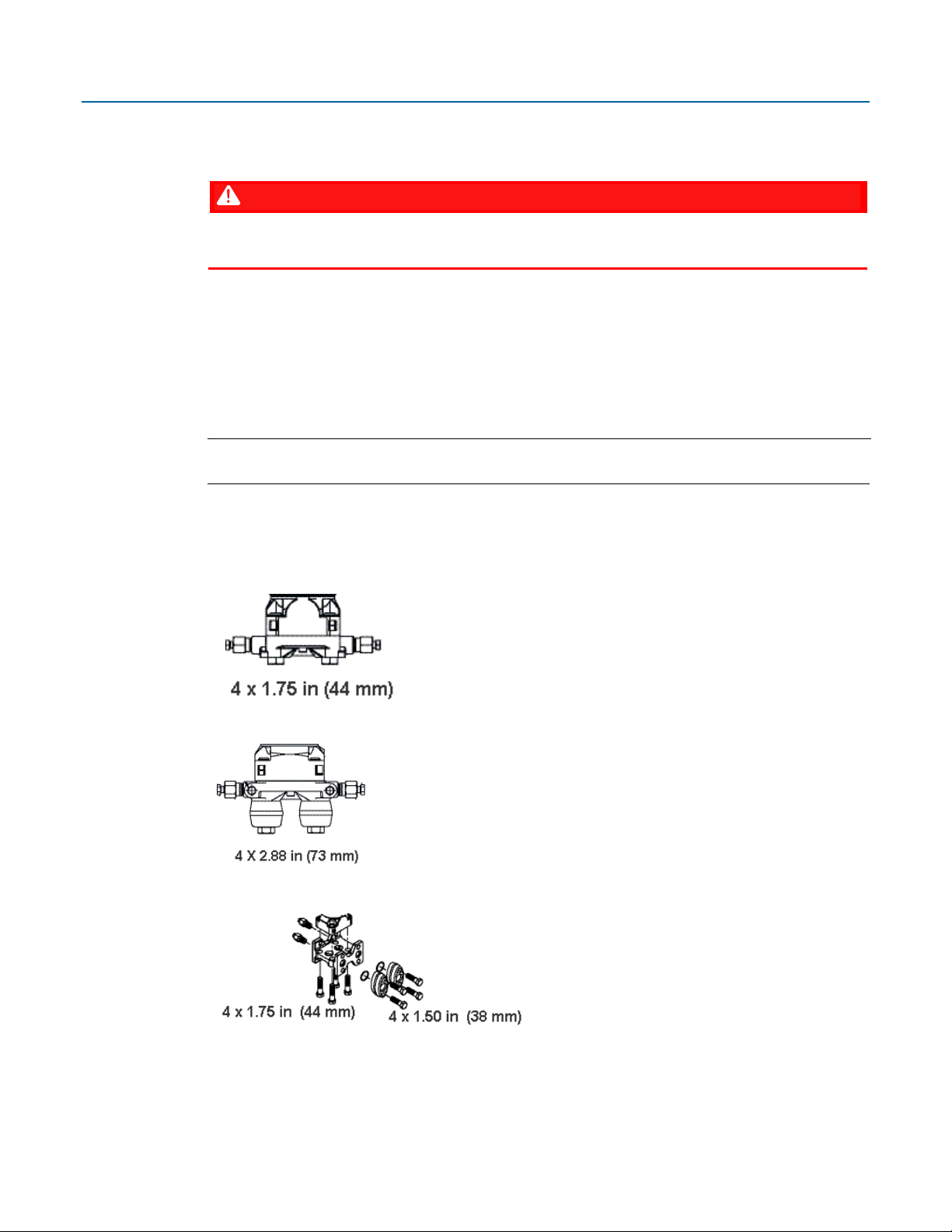

If the flow computer installation requires assembly of a process flange, manifold, or flange

adapters, follow these assembly guidelines to ensure a tight seal for optimal performance

characteristics of the flow computer.

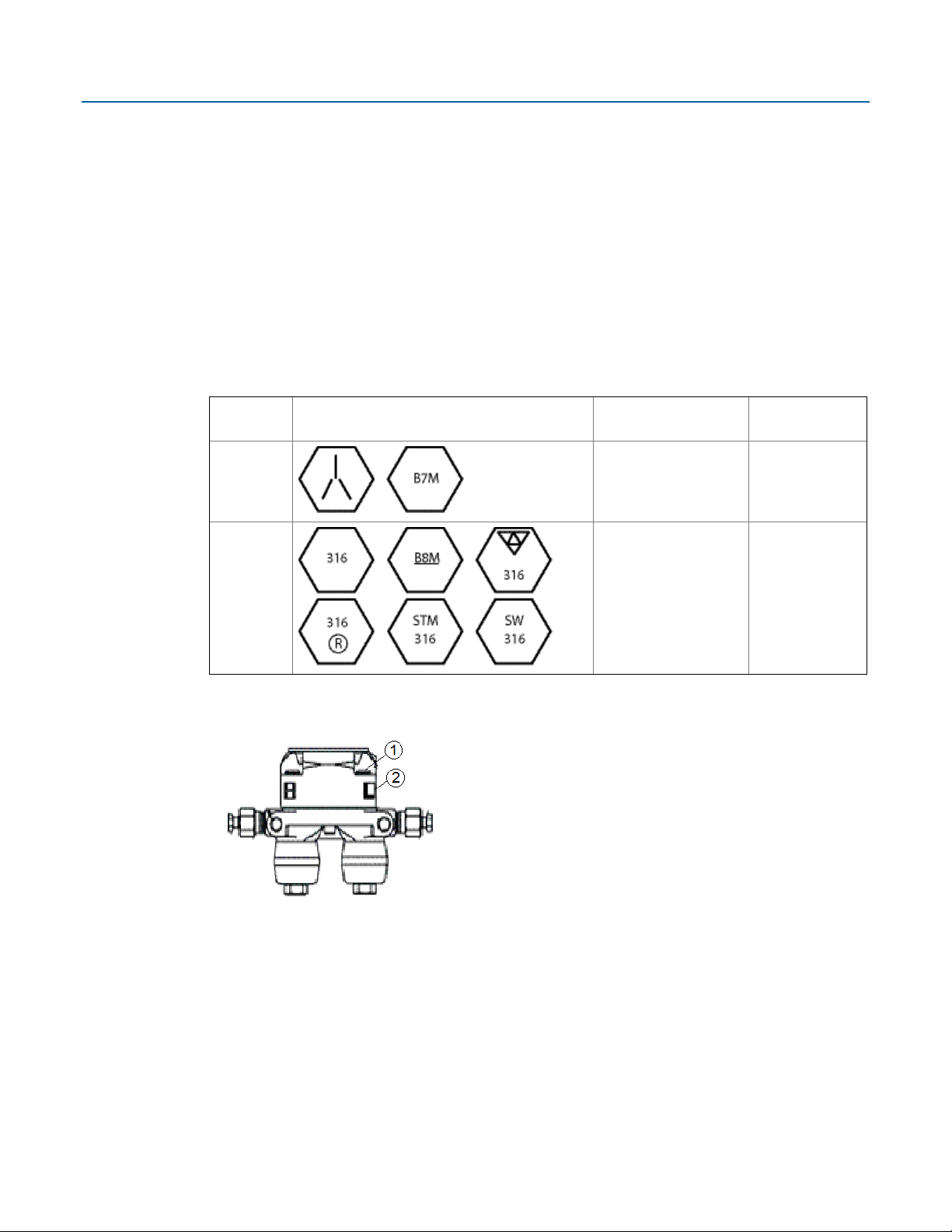

Only use bolts supplied with the flow computer or sold by Emerson as spare parts. Refer to the

figure below for common flow computer assemblies with the bolt length required for proper flow

computer installation. Bolt thread size is 7/16-20 UNF.

Note

For all other manifolds, contact your local Emerson Sales office or Emerson Impact Partner.

Bolts are typically carbon steel or stainless steel. Confirm the material by viewing the markings on

the head of the bolt and referencing Table 2. If bolt material is not shown in the table, contact your

local Emerson representative for more information.

Transmitter with coplanar flange

Transmitter with coplanar flange and optional flange adapters

Transmitter with coplanar flange and optional flange adapters

Use the following bolt installation procedure:

4

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

1. Carbon steel bolts do not require lubrication. Stainless steel bolts are factory-coated with a

lubricant to ease installation. Do not apply any additional lubricant when installing either

type of bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern. See Table 2 for initial

torque value.

4. Torque the bolts to the final torque value using the same crossing pattern. See Table 2 for

final torque value.

5. Verify that the flange bolts protrude through the sensor module before applying pressure.

Table 2: Torque Values for the Flange and Flange Adapter Bolts

Bolt

material

Carbon

Steel (CS)

Stainless

Steel (SST)

Proper Bolt Installation

Head markings

Initial torque

300 in. -lbs.

(33.9 N m)

150 in. -lbs.

(16.9 N m)

Final torque

650 in. -lbs.

(73.4 N m)

300 in. -lbs.

(33.9 N m)

1

2

Bolt

Sensor module

5

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

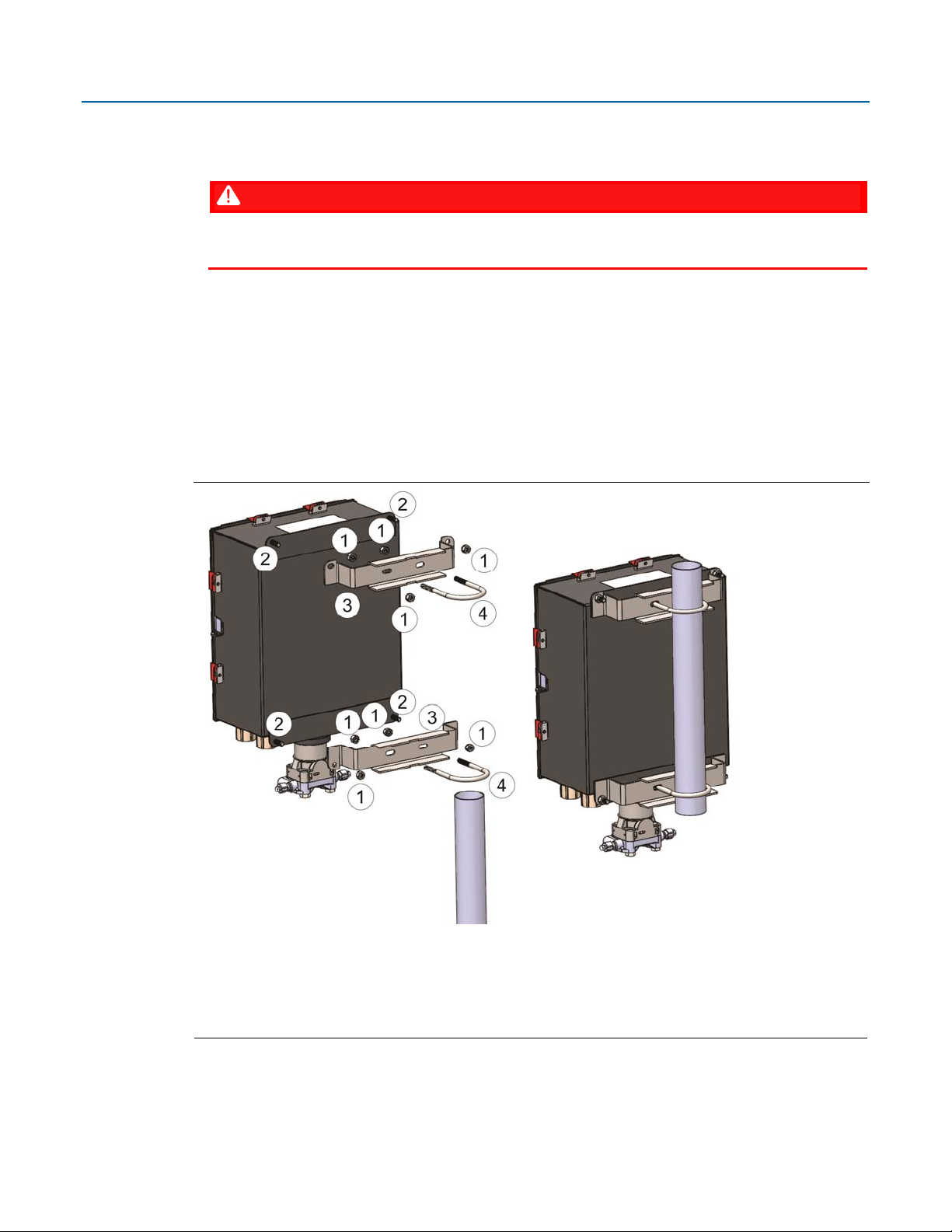

Pole Mounting — Aluminum Enclosure

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

1. Apply Loctite

screws (Item 2).

2. Attach pole mounting brackets (Item 3) to enclosure using head cap screws (Item 2) and hex

nuts (Item 1). Torque hex nuts to 30 in-lbs (3.4 N m).

3. Apply Loctite #222 threadlocker sparingly to threads of U-bolts (Item 4).

4. Use U-bolts (Item 4) to mount enclosure to pole using hex nuts (Item 1). Torque hex nuts to

30 in-lbs (3.4 N m).

®

#222TM Low Strength Purple Threadlocker sparingly to threads of head cap

1 5/16-18 keps stainless steel hex nut

2 5/16-18 x 1.0 LG wire-lockable socket head cap screw

3 Pole mounting bracket

4 2-inch diameter 5/16-18 x 4.0LG U-bolt

6

Emerson FB2200 Flow Computer Quick Start Guide

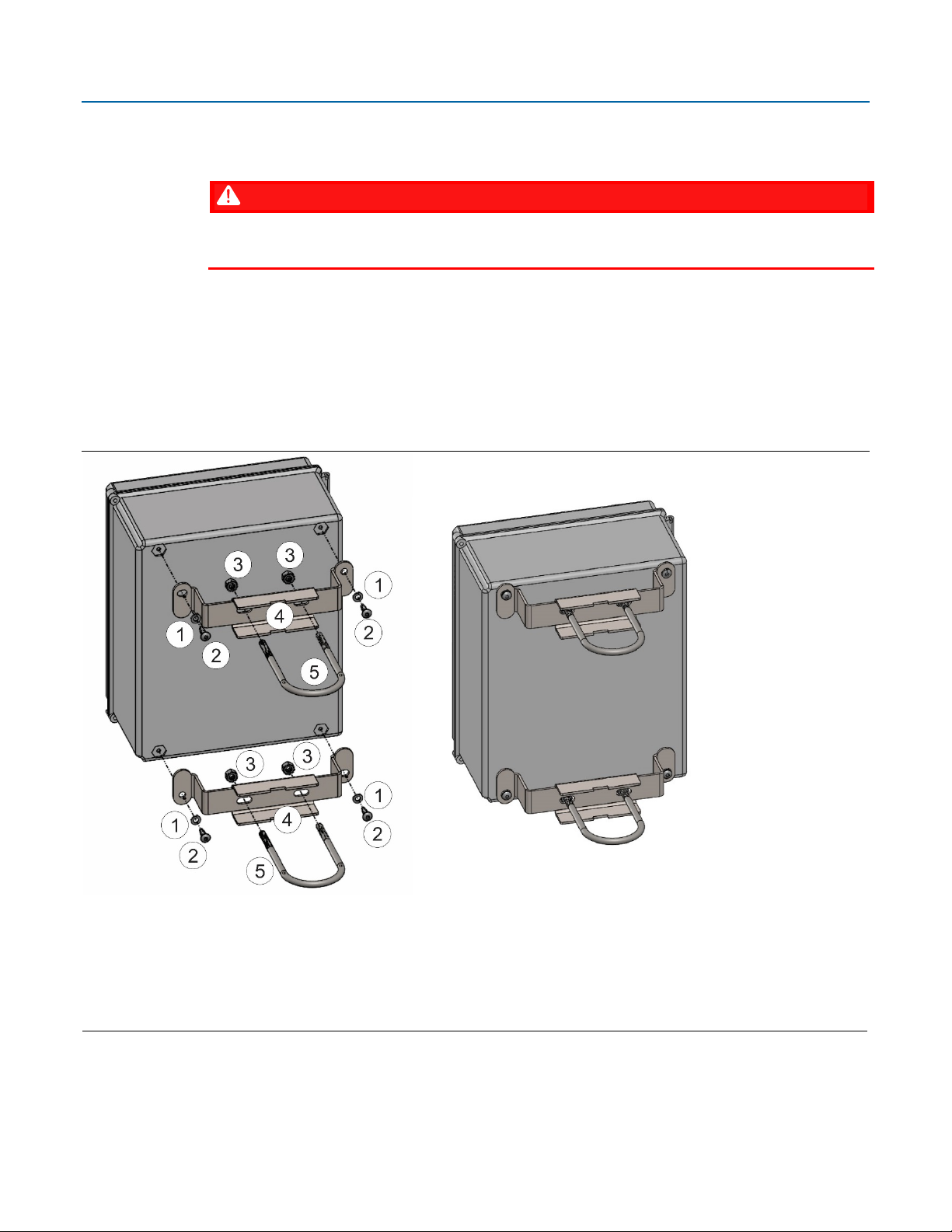

Pole Mounting —Fiberglass Enclosure

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

1. Attach pole mounting brackets (Item 4) to enclosure using split lock stainless steel washers

®

(Item 1) and Torx

2. Apply Loctite

bolts (Item 5).

3. Use U-bolts (Item 5) to mount enclosure to pole using hex nuts (Item 3). Torque hex nuts to

30 in-lbs (3.4 N m).

head screws (Item 2).

®

#222 Low Strength Purple Threadlocker adhesive sparingly to threads of U-

D301788X012

August 2020

1 ¼ inch screw split lock stainless steel washer

2 ¼-10 x .75LG thread forming Torx head screw

3 5/16-18 keps stainless steel hex nut

4 Pole mounting bracket

5 2 inch diameter 5/16-18 x 4.0LG U-bolt

7

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

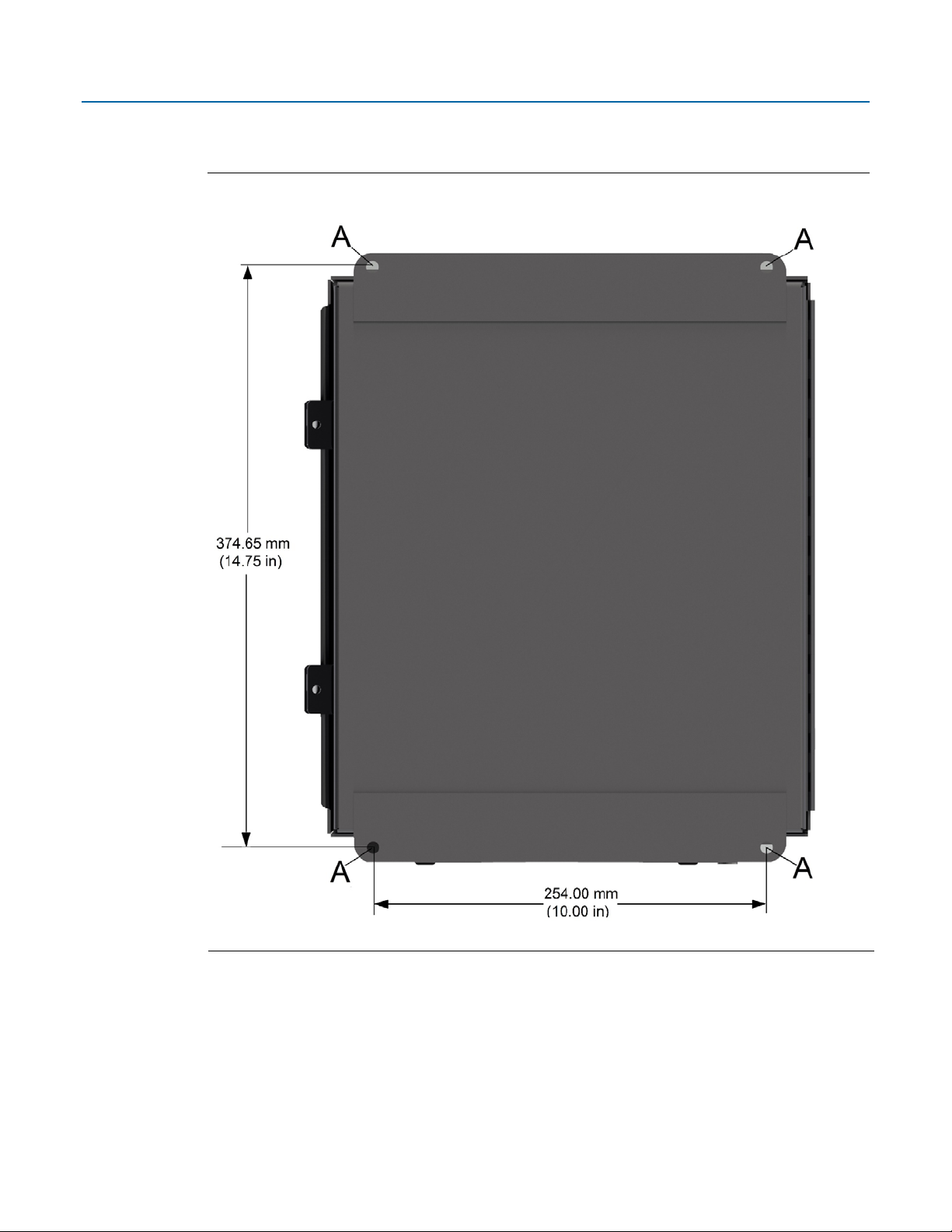

Panel/Wall Mounting Dimensions — Aluminum Enclosure

Aluminum Enclosure Panel/Wall

Mounting

A Mounting holes are 7.92 mm (0.312 in) diameter

8

Emerson FB2200 Flow Computer Quick Start Guide

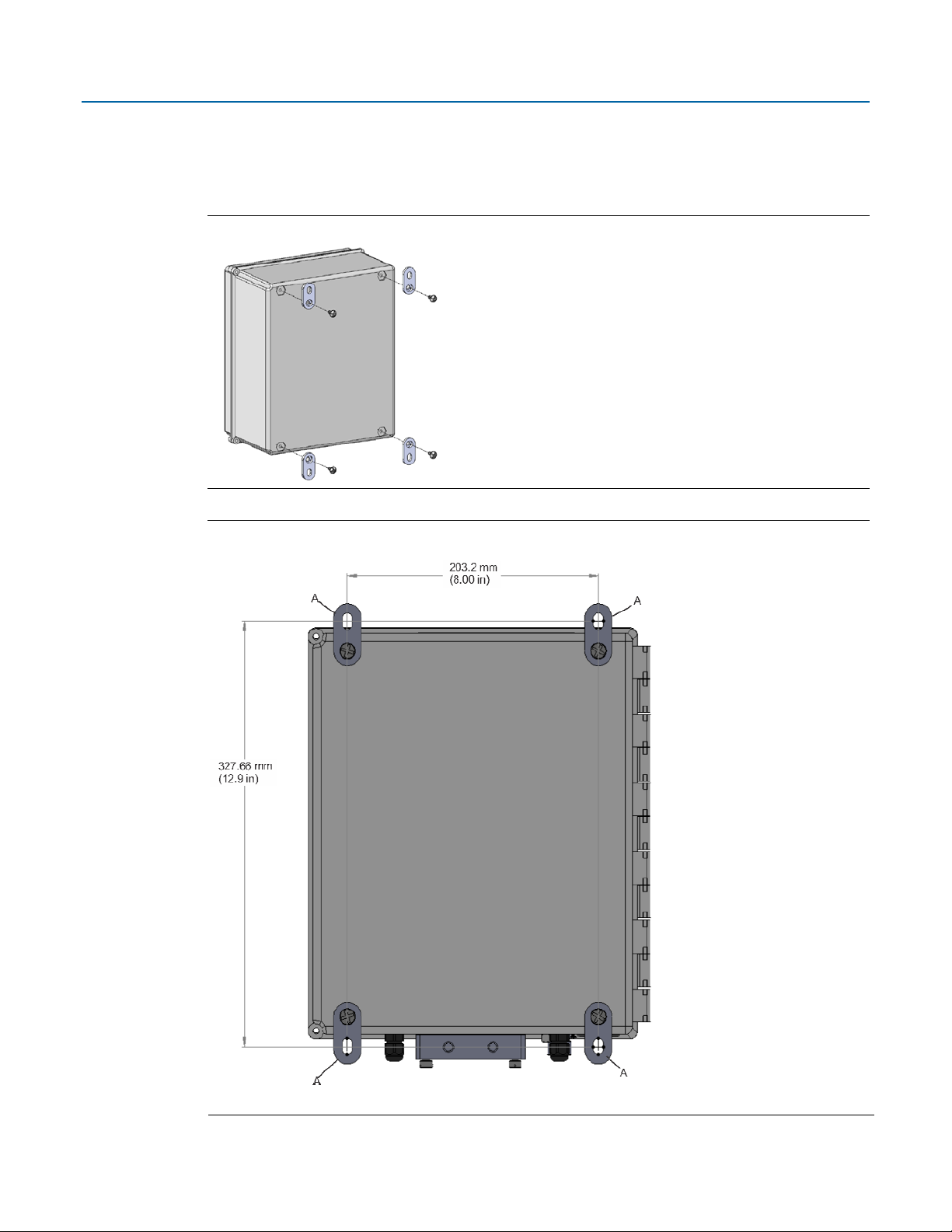

Panel/Wall Mounting Dimensions — Fiberglass Enclosure

Prior to mounting, attach mounting tabs to enclosure:

Attaching mounting tabs

D301788X012

August 2020

Fiberglass Enclosure Panel/Wall Mounting

A Mounting holes are 7.9 mm (0.31 in) wide

9

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

Grounding

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

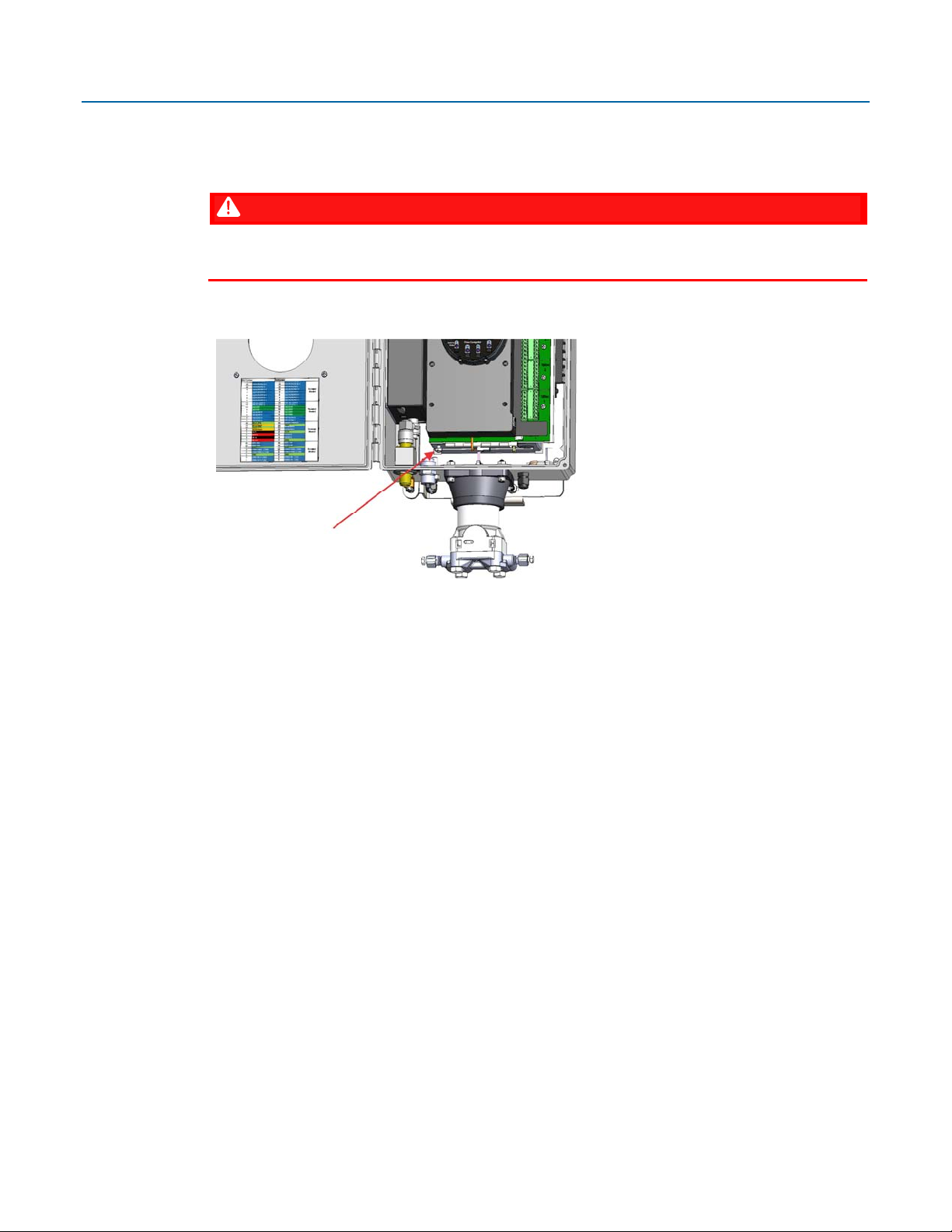

The flow computer includes a ground stud on the bottom of the battery box enclosure.

Once you have installed the unit, run a ground wire between the ground stud on the

bottom of the battery box enclosure and a known good earth ground. You route the

ground wire through one of the conduit fittings.

Use stranded copper wire to earth ground and keep the length as short as possible.

Clamp or braze the ground wire to the ground bed conductor (typically a stranded

copper AWG 0000 cable installed vertically or horizontally).

Run the ground wire so that any routing bend in the cable has a minimum radius of

30.48 cm (12 inches) below ground and 20.32 cm (8 inches) above ground.

For more information on grounding or if your installation uses cathodic protection, refer to

Site Considerations for Equipment Installation, Grounding, and Wiring (D301452X012).

10

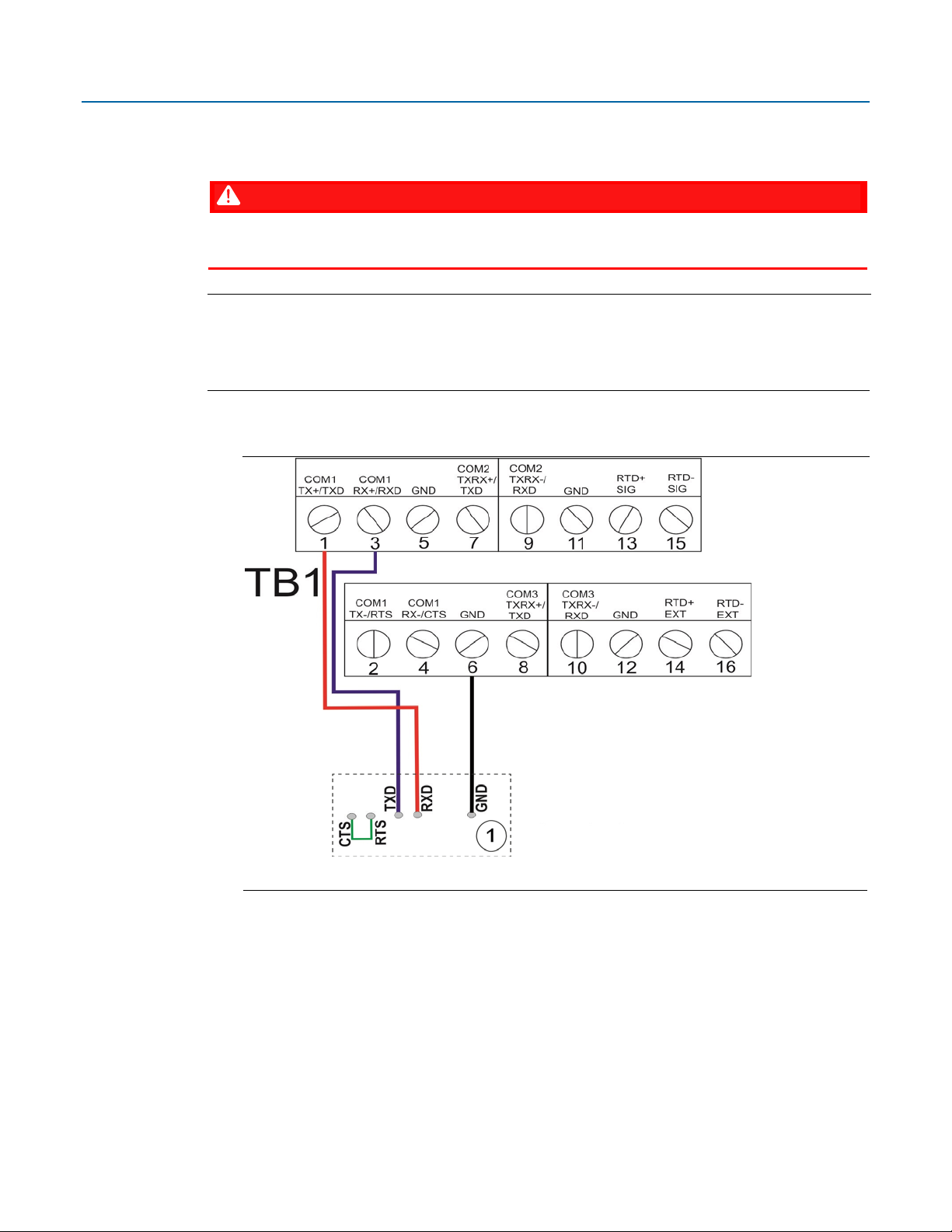

Wiring Communications

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

Notes

You do not need to add termination resistors; you can configure termination through

software selections in FBxConnect.

You should terminate all shields at chassis ground.

COM1

Emerson FB2200 Flow Computer Quick Start Guide

D301788X012

August 2020

1 RS-232 port on other device

11

Loading...

Loading...