FB1200 Product Data Sheet

D301790X012 January 2021

Remote Automation Solutions

FB1200 Flow Computer

The FB1200 flow computer measures and controls oil and

gas flow for up to two differential pressure or linear meter

runs. With a rugged housing and multiple I/O,

communications, and power options, the FB1200 provides

accurate and reliable flow measurement in the harshest

conditions.

The FB1200 is part of Emerson’s new field mount flow

computer family that delivers a convenient approach to

remote oil and gas sites by addressing challenges to power,

safety, measurement reliability and accuracy.

Designed for simplified configuration and ease of use, the

FB1200 is also highly configurable and supports multiple

flow and fluid property calculations right out of the box. The

flexible design provides exactly what is required for each

application. The FB1200 can also be equipped with FBxWifi™

allowing you to configure the flow computer and retrieve

site data more safely than before.

The new flow computers also come with the latest

Rosemount™ sensor technology, providing high accuracy

differential pressure and static pressure measurement with

long term stability to help improve measurement

confidence and production efficiency.

Features

The FB1200 flow computer includes the following key

features:

▪ Increased measurement confidence, reduced

measurement uncertainty

▪ Industry leading differential and static pressure

measurement including 5-year stability

▪ High accuracy temperature measurement including

curve matching via the Callendar-Van Dusen equation

▪ Reduced need to re-calibrate resulting in less time spent

on site

▪ Simplified configuration and set-up with the

FBxConnect™ configuration software tool

▪ Flexible design with configurable I/O and communication

ports to meet site needs

▪ Standard firmware supports global calculations for

orifice, cone, Venturi, nozzle, conditioning orifice,

turbine, PD, Auto-Adjust and Coriolis

▪ Standard firmware supports Properties Calculations for

Natural Gas, Pure Gas, and Crude Oil

▪ Flexible PID control with override complimented by

configurable logic blocks and effects

▪ Simple selection of engineering units to suit local

requirements

▪ Global Hazardous Area Approvals – Class 1 Div 1 & 2,

ATEX & IEC Ex d & Ex nA

▪ FBxWifi allows secure local wireless access from safe area

▪ Ease of integration with support for Modbus, ROC, BSAP

and DNP3 protocols

▪ Enhanced security helps prevent unauthorized access

▪ Enhanced alarming and historical data storage, improved

audit trail

▪ Superior performance gives better control of your

operations and maximizes profits

▪ API 21.1 compliant

FBxWifi™

The optional FBxWifi communications enables you to

connect your laptop or tablet to the flow computer through

a secure wireless connection. Once connected wirelessly,

you can use FBxConnect configuration software to view

process values, edit configuration parameters, and collect

logs stored in the flow computer – all from within the safe

area.

FB1200

Aluminum Housing

Stainless Steel Housing

FB1200 January 2021

2 www.Emerson.com/FlowComputers

Firmware

The base firmware in the FB1200 flow computer comes with

all the calculations, features and functionality required to

provide consistent measurement with increased confidence

for gas metering and control. The flow computer measures

static pressure, differential pressure or pulse frequency, and

temperature for up to two meter runs.

The flow computer performs flow calculations based on the

following set of user selectable global calculations. To fully

satisfy local requirements the engineering units are fully user

selectable between either U.S. or metric, or a combination of

each.

The firmware supports the following flow calculations:

▪ AGA 3 1992/2013 (volume, mass/density, and

mass/relative density)

▪ ISO 5167 1991/1998/2003 (orifice, Venturi, and nozzle)

▪ Rosemount 405C Compact Orifice and 1595

Conditioning Orifice Plate

▪ McCrometer V-Cone

®

and Wafer Cone®

▪ NUFLO

™

Cone

▪ AGA 7 2006 (pulsed turbine, PD, and ultrasonic)

▪ AGA 11 2013 (Coriolis pulses)

▪ Auto-Adjust

™

meter

▪ AGA 9 (Multipath Ultrasonic)

▪ API 20.1 Liquid Allocation Measurement

▪ API 12.2 Calculation of Petroleum Quantities

The firmware supports the following property calculations:

▪ AGA 8 1994 (Detailed, Gross 1 and Gross 2)

▪ AGA8 2017 Part 1 and Part 2 (GERG 2008)

Note: AGA8 Part 2 / GERG provides support for the

following pure gases: Nitrogen, Carbon Dioxide,

Hydrogen, Oxygen, Carbon Monoxide, Water

Vapor, Hydrogen Sulfide, Helium, and Argon

▪ Speed of Sound calculated via AGA 10 and AGA 8 2017

Part 2

▪ NX-19 1962, MOD, VDI/VDE 2040

▪ ISO 12213 2009 (parts 2 and 3)

▪ SGERG 1991 (Std., Alt 1, Alt 2 and Alt 3)

▪ GPA 2172 2009 (including saturated vapor calculation)

▪ ISO 6976 1995 (Superior and Inferior, incorporating

Technical Corrigendum 2 [1997] and 3 [1999])

▪ API 11.1 Temperature and Pressure correction for Crude

Oils

The firmware accepts gas density, base density, and specific

gravity form any of the following sources:

▪ Up to 2 gas chromatographs (GC)

▪ Fixed value

▪ Periodic download from SCADA

▪ An external signal, such as analog input

▪ Calculated based on gas composition

The firmware includes the following flow rates and totals for

gas DP and gas linear meters:

▪ Indicated volume

▪ Corrected (standard) volume

▪ Mass

▪ Energy

▪ Integral Value (DP meter) or Pulse Totals (linear meter)

The firmware includes the following flow rates and totals for

API 12.2 and API 20.1 (low water):

▪ Indicated Volume / Mass

▪ Gross Volume

▪ Gross Standard Volume

▪ Net Standard Volume

▪ Water Volume

▪ Mass

▪ Flow time

▪ Pulses

The firmware includes the following flow rates and totals for

API 20.1 (high water):

▪ Indicated volume / mass

▪ Gross Volume

▪ Oil (Unshrunk and Theoretical Production)

▪ Natural Gas Liquid

▪ Flashed Gas

▪ Water (Uncorrected and Corrected Volume)

▪ Flow Time

▪ Pulses

Note: The firmware can accept a water cut from an online analyzer or from an off-line analyzer corrected to

metering conditions.

The firmware supports a fallback mode, when a process

variable's value is questionable. The fallback options can be

one of the following:

▪ Use last good value

▪ Use a fixed fallback value

Alarms and Events

The flow computer supports extensive alarming capability to

enhance operational efficiency and improve the audit trail.

Alarms are pre-allocated to meter runs and stations for

standard values such as pressure, temperature, differential

pressure or frequency as well as meter run and station flow

rates. In addition to these standard alarms, the FB1200

provides a number of user alarms that you can assign to

other database parameters simply by “filling in the blanks” in

user alarm templates in the FBxConnect configuration tool.

Storage is provided for the most recent 1000 alarms in the

Alarm log.

The Event log stores the significant events during operation

and can be configured to either store all events in a single log

of 2000 events or the user can select to store the

metrology/legal events in a separate log from the

operational events. With the latter option the event log

January 2021 FB1200

www.Emerson.com/FlowComputers 3

capacity is 1000 metrology events and 1000 operation

events.

History

The FB1200 features expanded and flexible history capability

to ensure measurement confidence and meet the increasing

demands for secure data.

The flow computer has four standard periodic logs available

providing hourly, daily, weekly, and monthly history. These

logs can contain up to 60 variables including flow weighted

average data, totals, and gas composition. For averaging,

the FB1200 supports either flow weighted or flow

dependent which can be linear or formulaic.

For gas meter averages, you can choose between flowdependent linear per API Chapter 21.1 (2013) or flowdependent formulaic, flow-weighted linear, or flowweighted formulaic averages per API Chapter 21.1 (1993).

Liquid allocation meter averages are flow-weighted averages

per API Chapter 21.2 (2000).

The FB1200 can store the following:

▪ Hourly logs 62 days

▪ Daily logs 12 months

▪ Weekly logs 12 months

▪ Monthly logs 60 months

The flow computer also supports two user periodic logs, the

duration or period of each is user selectable between 1

second and 200 hours. The first user periodic logs include 10

parameters over 4,000 periods and the second contains 20

parameters over 500 periods.

The flow computer with FBxConnect provides pre-formatted

EFM reports for hours and days. The format of the reports

can be .csv, .pdf or secure pdf.

In addition to the above reports, the flow computers can

produce FLOWCAL-complaint. cfx files through the

FBxConnect tool as well as calibration reports which contain

U.S. Bureau of Land Management specific parameters.

Housing

The FB1200 includes an explosion-proof and flame-proof

enclosure made of die-cast aluminum or stainless steel that

can operate in an unprotected outdoor environment. Wiring

for I/O, communications, and power enters the enclosure

through the four conduit fittings. The front end cap provides

a viewing window for the optional LCD. The rear end cap

provides access to the screw terminals with connections for

communications, I/O, and power. The end caps provide the

ability to fit wire security seals.

Hazardous Area Certifications

The FB1200 has the following Global Hazardous Area

Approvals:

▪ North American certification for Class I Division 1 Groups

C and D (explosion proof) and Class I Division 2 Groups A,

B, C and D

▪ ATEX and IECEx certification for Exd Zone 1 (flame proof)

and Exn Zone 2 hazardous locations

Power Options

The FB1200 has the following power options available:

▪ External DC supply

▪ External DC supply with internal battery back-up

▪ Solar panel charging internal battery, unit has built-in

solar regulator

The internal battery can power the device under normal

operating conditions without charging for up to 19 days.

Note: Internal battery option is not available with ATEX or

IEC approval.

Configuration Software

Emerson’s new FBxConnect™ tool is a Microsoft® Windows®-

based tool that enables you to easily monitor, configure,

service, and calibrate the FB1200 flow computer. Designed

for ease of use, FBxConnect provides at-a-glance monitoring,

quick access to commonly performed tasks, and a guided

configuration process to quickly get your measurement up

and running.

The wizard-driven approach simplifies configuration and

ensures that you only need to enter the required data once.

Whether you are an experienced engineer or a new

technician, you can be confident configuration is done

correctly the first time.

FBxConnect runs on a Windows PC or tablet. You connect

securely to the flow computer using one of its serial ports,

Ethernet port, or optionally through the FBxWifi wireless

connection. For more information, refer to product data

sheet FBxConnect (part D301789X012).

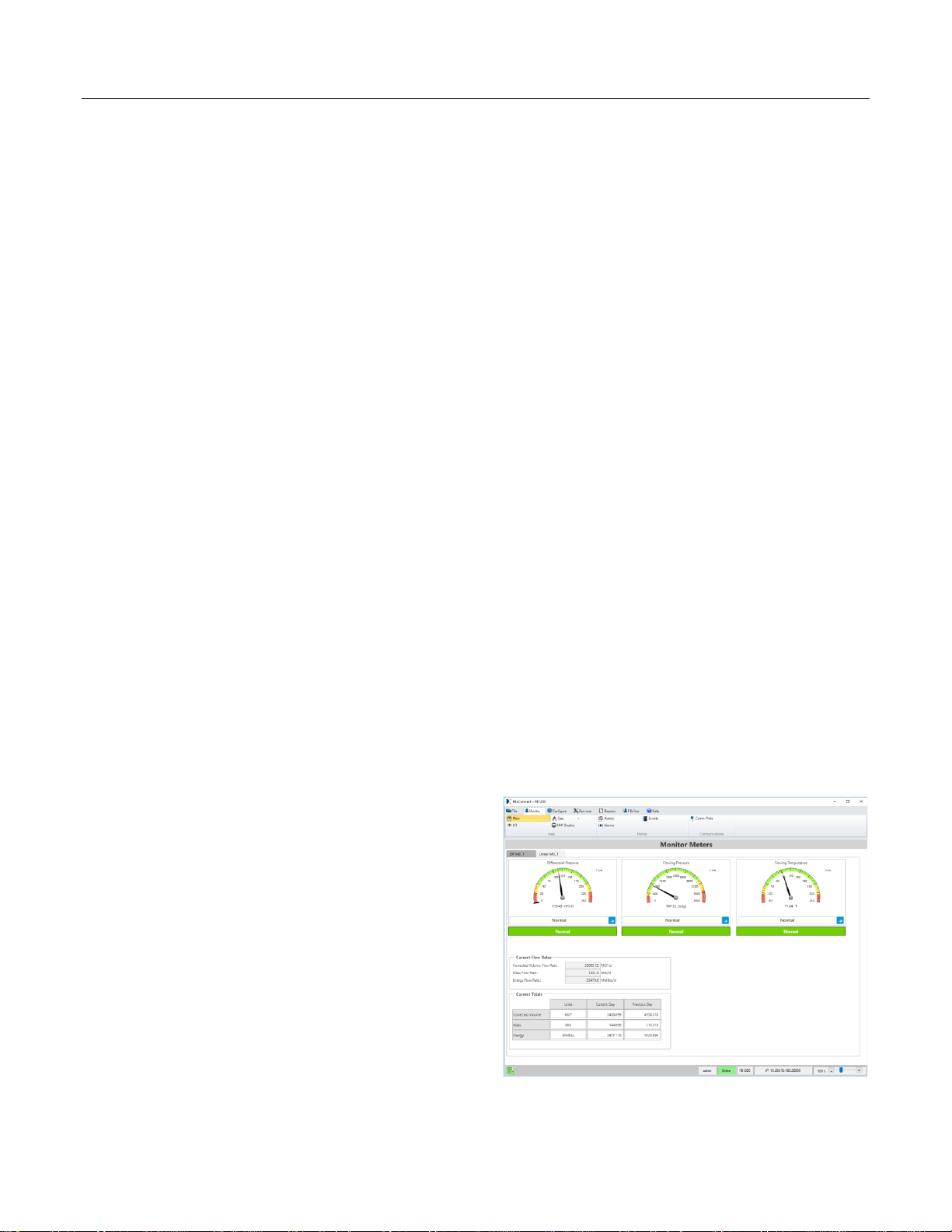

Monitor Screen

FB1200 January 2021

4 www.Emerson.com/FlowComputers

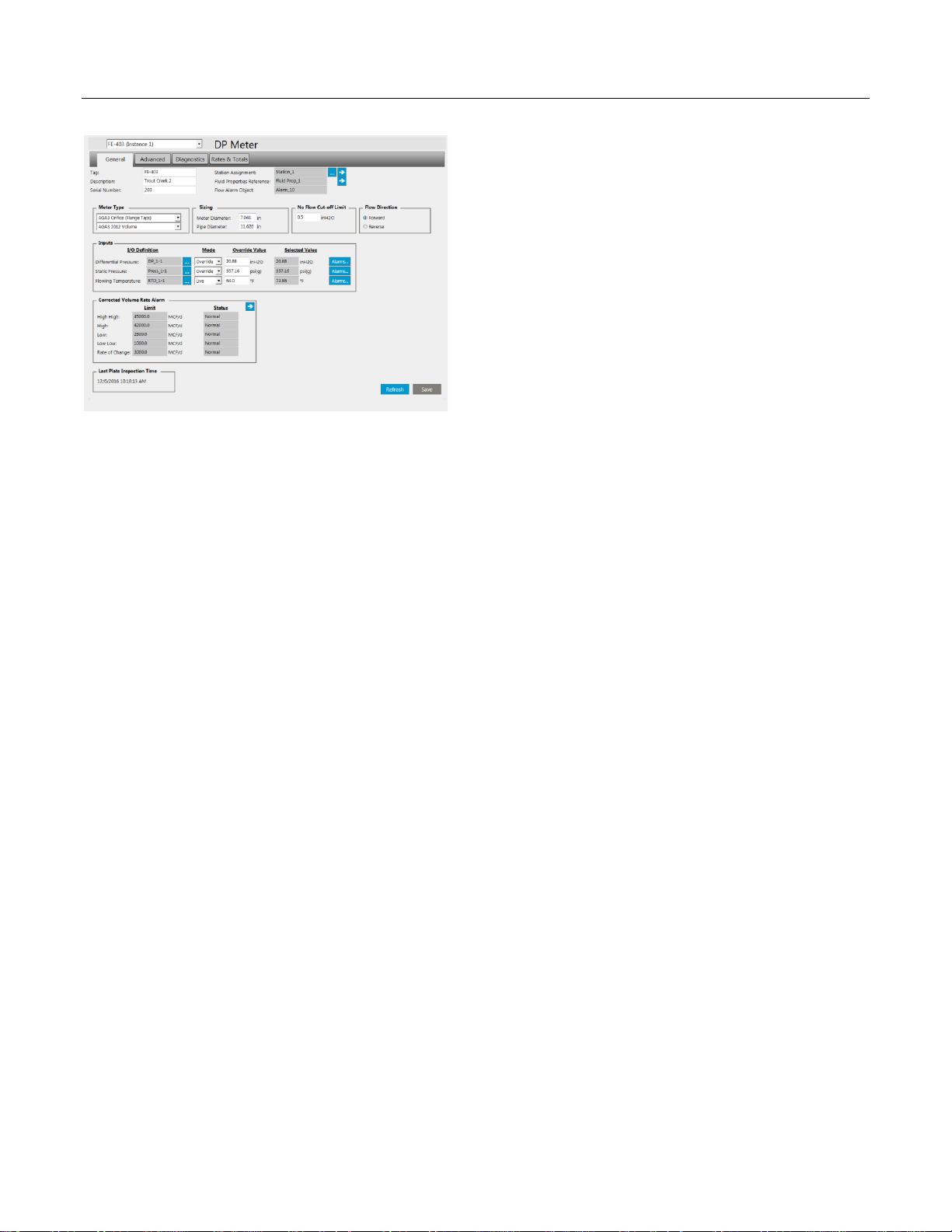

DP Meter

Security

To secure your valuable process and data, the FB1200

provides multi-level role-based access, user account

authentication, and password encryption.

The system administrator can set a minimum password

length (up to 20 characters) that accommodates lower case,

upper case, numbers, and symbols, as well as configure a

user lock-out feature that locks out invalid users after a

defined number of failed login attempts.

Integral Pressure Sensor Options

The flow computer can be supplied with one of three sensor

options to suit your metering needs:

▪ Integral Multivariable Transmitter (MVT) measuring both

Static Pressure and Differential Pressure (DP)

▪ Integral inline static pressure sensor

▪ NO integral pressure sensor – external transmitters are

used

If the FB1200 has an integral sensor, it can also

communicate with one remote 4088B transmitter. If it has

no integral sensor it can communicate with one or two

remote 4088B transmitters.

Enabled by superior sensor technology and engineered for

optimal flow performance, the integral pressure sensor on

the flow computer delivers unparalleled accuracy, over a

wide range of operating conditions and industry leading

stability to ensure you meet standards and regulations.

The pressure sensors on the flow computer can measure DPs

of up to 1000” of water / 2500 mBar and static pressures, up

to 4000 psi / 275 Bar in either gauge or absolute with

accuracies up to 0.075%.

Temperature Input (RTD/PRT)

With industry leading measurement accuracy, the

temperature measurement of the FB1200 will ensure that

you minimize your measurement uncertainty in all operating

conditions. The input accepts 2-, 3- or 4-wire connections

reducing any field wiring induced errors and supports sensor

curve matching utilizing the optional Callendar-Van Dusen

constants to define the unique characteristics of the

RTD/PRT to further improve process temperature

measurement uncertainty.

The FB1200 flow computer’s superior static pressure, DP,

and temperature measurement performance and stability

ensures you meet standards and regulations so you can

avoid fines, penalties, leaseholder disputes, and lost

revenue.

Inputs and Outputs

Base I/O

In addition to the integral pressure sensor, the FB1200

includes the following I/O points in the base un it:

▪ Two analog channels - individually software selectable as

analog inputs (AI) or analog outputs (AO)

▪ Two discrete channels - individually software selectable

as discrete inputs (DI), discrete outputs (DO), or pulse

inputs (PI)

▪ One RTD/PRT (2-, 3-, or 4 wire)

Analog Inputs (AI) are individually software configurable for

either 4 to 20 mA or 1 to 5 Vdc operation.

To keep measurement uncertainty at a minimum when

external transmitters are being used, both the AI and AO

channels have industry-leading measurement accuracy with

an excellent performance over a wide ambient temperature

range.

Each Discrete Input (DI) channel can also be software

configured to function as a latched DI.

The Discrete Output (DO) channels are solid-state, normally

open switches rated at 500 mA, enough to directly drive

most samplers. Each DO channel can be software configured

as a latched, toggled, momentary, timed duration output

(TDO), or scaled pulse output.

The PI channels are most commonly used to interface with

turbine meters, Coriolis meters, ultrasonic meters, and

positive displacement (PD) meters. The high-speed input

supports signal up to 10.5 kHz.

Expansion I/O (optional)

In addition to the base I/O provided, the optional 6-point I/O

board adds the following I/O capabilities to the FB1200:

▪ Two additional channels that are individually software

selectable as either analog inputs or analog outputs

▪ Four additional channels that are individually software

selectable as discrete inputs, discrete outputs, or pulse

inputs

January 2021 FB1200

www.Emerson.com/FlowComputers 5

Control

The FB1200 optionally supports control functions including

PID control, basic programming through action blocks,

effects, and math blocks.

PID Control – The FB1200 supports up to three Proportional,

Integral, and Derivative (PID) control loops. Each PID

instance supports a primary and an override loop. Each loop

has its own user-defined input, output, and override

capability.

Typically, a PID control maintains a process variable at set

point. If you configure a PID override control, the primary

loop is normally in control of the control device but the

override loop can take over control of the process if required.

A typical example would be primary flow control with a

pressure override.

Action Blocks – The FB1200 supports up to 30 action blocks.

Action blocks are used in conjunction with effect blocks to

monitor a configured condition and to perform an action

(effect) when the logic is “true.” An action block consists of a

user defined Boolean logic statement with two variables.

These variables can either be live parameter values or

constants.

Multiple action blocks can be chained together to create

more complex logic. Each action block includes multiple

bypasses, which can temporarily halt the action to be taken

for maintenance and safety.

Effects – The FB1200 supports up to ten effects. Effects

cause an action to occur when the result of one or more

action blocks is active (“true”). Multiple action blocks can

cause the same effect, such as shutting a valve or enabling

an alert beacon.

You configure an effect by defining an output parameter and

the values to write to that parameter when the effect is

either active or inactive. You can also configure an active

effect to be self-clearing or to require a manual reset.

Math Blocks – The FB1200 supports up to ten math blocks.

Math blocks perform mathematical equations using userdefined variables as inputs. Each math block consists of up to

four user-defined variables, three mathematical calculations,

and the results of each calculation.

The result of the math block equation can be assigned to a

user data point, to drive an output point, to a calculated

value or to any other database parameter. Mathematical

calculations also support standard math functions (POW,

EXP, LOG, SQRT, etc.), constants, and operators.

FBxConnect checks each calculation string for the correct

syntax and uses double precision floating point math

throughout the calculation.

User Data Points

User data points are configurable storage areas in the data

base. These user data points can store the constants /

variables that are inputs to the math blocks in addition to the

calculated results of math blocks. They can also be used to

represent interim calculation values or values of additional

inputs or outputs etc. There are eight user data instances,

each with a tag and description, 30 integers (split between

byte, short and long), 20 single floating points, and 10

double floating points, providing storage for up to 480

variables.

Communications

The FB1200 provides up to five user-selectable

communications ports: three serial ports, one Ethernet port,

and one optional port that supports FBxWifi (802.11 b/g)

communications using DNP3 protocol.

▪ COM1 – 4-wire serial communications. Software

selectable for EIA-232 (RS-232), EIA-422 (RS-422), or EIA-

485 (RS-485) operation.

▪ COM2 – 2-wire serial communications. Software

selectable for EIA-232 (RS-232) or EIA-485 (RS-485)

operation.

▪ COM3 – 2-wire serial communications. Software

selectable for EIA-232 (RS-232) or EIA-485 (RS-485)

operation.

▪ COM4 –FBxWifi (802.11 b/g) communications

(optional).

▪ COM5 – Ethernet. 10/100BASE-T twisted pair. Supports

up to seven sessions.

The FB1200 supports multiple communications protocols,

including DNP3, Modbus master and slave (ASCII and RTU),

BSAP, and ROC on the three serial ports and DNP3 on the

FBxWifi port. In addition, the Ethernet port supports Modbus

over TCP/IP protocol (master and slave), DNP3/IP, ROC, and

BSAP.

FBxNet

FBxNet is a secure, easily configurable, peer-to-peer

communication network for exchanging data between

Emerson FB3000 RTUs and FB1200 and FB2200 flow

computers over an Ethernet connection. FBxNet supports

subscriber and publisher devices, where publishers provide

data to their subscribers. The FB3000 RTUs and FB1200 and

FB2200 flow computers can be publishers; only an FB3000

can be a subscriber. For more information, refer to FBxNet

product data sheet (part D301905X012).

Mounting Options

The FB1200 supports either direct mount to a manifold on

the pipeline or indirect mounting on a two-inch pipe or pole.

A mounting bracket and bolts are available for use with a

traditional flange, coplanar flange, or inline static pressure

options.

FB1200 January 2021

6 www.Emerson.com/FlowComputers

FB1200 Flow Computer

CPU Module

Processor

The central processing unit (CPU) of the flow computer is an NXP® Kinetis® K61 series CPU with an

ARM® Cortex® M4 processor.

Memory

SRAM

8 MB, holds current states of all variables and historical archives.

Flash

128 MB, holds firmware image and configuration files.

Clock

Type

Real-time clock

Accuracy

0 °C to 40 °C

60 seconds/year

-40 °C to 80 °C

110 seconds/year

Watchdog Timer

1175 milliseconds

Diagnostics

Battery voltage monitor, external voltage monitor, SRAM battery status

Communications

Ports

COM1

4-wire serial communications.

Software selectable for RS-232, RS-422, or RS-485 operation.

COM2

2-wire serial communications.

Software selectable for RS-232 or RS-485 operation.

COM3

2-wire serial communications.

Software selectable for RS-232 or RS-485 operation.

Can communicate to 4088B transmitters.

COM4

FBxWifi (optional) 802.11 b/g

COM5

Ethernet 10/100 Base-T supports up to 7 sessions (1 Modbus Master, up to 3

DNP3, others selectable between ROC, BSAP, and Modbus Slave)

Protocols

Serial ports support DNP3, Modbus slave (ASCII or RTU), BSAP, and ROC.

The Ethernet port supports Modbus over TCP/IP protocol (master and slave), DNP3, BSAP, and ROC

protocol.

Wi-Fi supports DNP3

DNP3 includes level 3 protocol subset

Base I/O

The base FB1200 includes the following I/O:

▪ 2 channels that are individually software selectable as either analog inputs or analog outputs

▪ 2 channels that are individually software selectable as either discrete inputs, discrete outputs, or pulse inputs

▪ 1 process temperature input (RTD/PRT)

Expansion I/O (optional)

6 Channel I/O Board

Provides 6 additional I/O channels in addition to the base I/O.

Note: Specifications for expansion I/O channels are identical to base I/O channels except where

noted.

Analog Inputs /

Analog Outputs

Quantity

2 channels

Each channel is individually software selectable as an AI or AO.

Discrete Inputs /

Discrete Outputs /

Pulse Inputs

Quantity

4 channels

Each channel is individually software selectable as a DI, DO, or

PI.

January 2021 FB1200

www.Emerson.com/FlowComputers 7

I/O Specifications

Analog Inputs

Type

Single-ended

Input Range

1 to 5 Vdc or 4 to 20 mA (software selectable)

Over Range

1 to 5 Vdc

0.8 to 5.2 Vdc

4 to 20 mA

3.2 to 20.8 mA

Resolution

16 bits

Scan Rate

10 samples per second

Input Impedance

1 to 5 Vdc

Inputs

200 kΩ

4 to 20 mA

Inputs

250 Ω

Fault Mode

User-entered default value or last good value

Software Filter

Software damping is available in FBxConnect configuration software

Input Filter

20 HZ @ -3 dB

Surge Suppression

30 Vdc

Reference

Accuracy

+/- 0.05% of span

Note: To achieve the stated accuracy when analog inputs are used in voltage mode,

you must wire analog input reference(s) to the AGND terminals separately from

the discrete and communication ground references.

Ambient

Temperature

Effect

+/- 0.05% of span per 10°C (18°F) from the calibration temperature

Long Term

Stability

3 years

SNR

87 dB

Loop Power

Base I/O

External

Optional 6point Expansion

I/O

Internal

Analog Outputs

Type

Single-ended, externally sourced

Output Range

4 to 20 mA

Resolution

14 bits

Surge Suppression

30 Vdc

Reference

Accuracy

+/- 0.1% of span

Note: To achieve the stated accuracy when analog outputs are used in voltage mode,

you must wire analog output reference(s) to the AGND terminals separately from

the discrete and communication ground references.

Ambient

Temperature

Effect

+/- 0.05% of span per 10 °C (18 °F) from the calibration temperature

Long Term

Stability

3 years

FB1200 January 2021

8 www.Emerson.com/FlowComputers

Fault Mode

User-entered default value or last good value

Scan Rate

1 second

Surge

Suppression

30 Vdc

Impedance

Current Mode

Configured to drive a load impedance of 0 to 900 Ω

250 Ω max with 10 Vdc supply

900 Ω max with 22.5 Vdc supply

Voltage Mode

100 kΩ

Load Loop

Resistance

0 to 900Ω

Max External

Supply

30 Vdc

Loop Power

Base I/O

External

Optional 6 point

I/O

internal

Discrete Inputs

Type

Dry contact or an open collector

Scan Rate

1 second

Input Filter

10 Hz

Input Current

Software selectable 66µA or 2mA

Voltage Rating

30 Vdc maximum

Frequency

10 Hz maximum

Input Type

Latched or unlatched

Loop Power

Internally sourced

Surge

Suppression

30 Vdc

Fault Mode

User-entered default value or last good value

Discrete Outputs

Type

Open drain

Current

500 mA maximum

Operating

Voltage Range

30 Vdc maximum

Frequency

50 Hz maximum

Output Type

Latched, momentary, toggle, TDO, or scaled pulse

Surge

Suppression

30 Vdc

Fault Mode

User-entered default value or last good value

Pulse Inputs

Type

Dry contact or open collector

Frequency

Low Range

0 to 300 Hz

High Range

0 to 10.5 kHz

Input Filter

Low Frequency

1 ms software selectable filter

January 2021 FB1200

www.Emerson.com/FlowComputers 9

High Frequency

30 µs software selectable filter

Input Current

Software selectable 66 µA or 2 mA

Voltage Rating

30 Vdc maximum

Loop Power

Internally sourced

Surge

Suppression

30 Vdc

Temperature Input

(RTD/PRT)

Type

2-wire, 3-wire or 4-wire (software selectable)

Measuring Range

-200 to +850°C (-328 to 1562 °F)

Reference

Accuracy

+/- 0.07 °C from -30 to 60°C (±0.126 °F from -22 to +140 °F)

+/- 0.1 °C from -60 to 200°C (±0.18 °F from -76 to +392 °F)

Ambient

Temperature

Effect

−30 to 60°C

+/- 0.017 °C per 10 °C (+/- 0.03 °F per 18 °F) from the

calibration temperature

−60 to 200°C

+/- 0.034 °C per 10 °C (+/- 0.06 °F per 18 °F) from the

calibration temperature

Calculation Type

User selectable

between

Callendar–Van Dusen

IEC 751/DIN 43760 (α 0.00385/°C)

IEC (α 0.003920/°C)

Resolution

24 bits

Scan Rate

1 second

Voltage Input

Impedance

Greater than 3 MΩ DC

Excitation Current

205 µA

Surge

Suppression

36 Vdc

Common Mode

Rejection

100 dB at DC

Normal Mode

Rejection

100 dB at 50/60 Hz

Integral Sensors

The FB1200 is available with the following integral sensor options:

▪ Multi-Variable Sensor – providing Differential Pressure and Static Pressure

▪ Static Pressure Sensor – providing Static Pressure only

▪ No integral sensor fitted – with interface to 4088B MVT transmitters or analog transmitters

FB1200 January 2021

10 www.Emerson.com/FlowComputers

Multivariable Sensor(optional)

The standard Rosemount™ MultiVariable™ sensor has a stainless steel coplanar flange, a stainless steel (316L) diaphragm, and

silicone fill fluid. Optional versions include:

▪ A Hastelloy

®

C-276 sensor diaphragm, a Hastelloy C-276 coplanar flange, with either NACE MRO175/ISO 15156 or MRO103

certification

▪ Stainless steel traditional flange, a stainless steel diaphragm, and silicon fill fluid.

Differential Pressure

Input

DP Range 1

−25 to 25 Inches H2O (−62.16 to 62.16 mbar)

Reference

Accuracy

± 0.1% span;

For spans less than 5:1, ± (0.025+0.015 [USL/Span]) % span

Stability

±0.2% USL for 1 year

Ambient

Temperature

Effect per 50°F

(28°C)

from 1:1 to

30:1

± (0.2% USL + 0.25% span)

from 30:1

to 50:1

± (0.24% USL + 0.15% span)

Static Pressure

Effects

Zero Error

± 0.25% USL per 1000 psi (69 bar)

Span Error

± 0.4% USL per 1000 psi (69 bar)

Over Pressure

Limit

SP Range 3

2000 psi (137.89 bar)

Burst Pressure

Limit

10,000 psi (689.47 bar)

Notes:

▪ 25-inch sensor is only available with static pressure SP Range 3, maximum

pressure limited to 2000 psi.

▪ 25-inch sensor is only available with stainless steel sensor and coplanar

flange.

DP Range 2:

Standard

0 to 250 Inches H2O (623 mbar)

Reference

Accuracy

± 0.1% span;

For spans less than 10:1, ± (0.01 [USL/Span]) % span

Stability

±0.1% USL for 1 year

Ambient

Temperature

Effect per 50°F

(28°C)

from 1:1 to

30:1

± (0.15% USL)

from 30:1

to 50:1

± (0.20% USL)

Static Pressure

Effects

Zero Error

± 0.1% USL per 1000 psi (69 bar)

For Static Pressures above 2000 psi:

± [0.2 + 0.0001 * (Ps - 2000)] % per 1000 psi

Span Error

± 0.2% USL per 1000 psi (69 bar)

Over Pressure

Limit

SP Range 1

1600 psi (110.32 bar)

SP Range 2

3626 psi (250.00 bar)

SP Range 3

3626 psi (250.00 bar)

Burst Pressure

Limit

10,000 psi (689.47 bar)

January 2021 FB1200

www.Emerson.com/FlowComputers 11

Note: 0.1% Accuracy is not available on traditional flange.

DP Range 2:

Enhanced

0 to 250 Inches H2O (623 mbar)

Reference

Accuracy

± 0.075% span;

For spans less than 10:1, ± (0.025 +0.005 [USL/Span]) % span

Stability

±0.125% USL for 5 years;

For ±50 °F (28 °C) temperature changes, up to 1000 psi (68.9

bar) line pressure

Ambient

Temperature

Effect per 50°F

(28°C)

± (0.0175% USL + 0.1% span) from 1:1 to 5:1,

± (0.035% USL + 0.125% span) from 5:1 to 100:1

Static Pressure

Effects

Zero Error

± 0.05% USL per 1000 psi (69 bar)

For Static Pressures above 2000 psi:

± [0.1 + 0.0001 * (Ps - 2000)] % per 1000 psi

Span Error

± 0.2% USL per 1000 psi (69 bar)

Over Pressure

Limit

SP Range 2

3626 psi (250.00 bar)

SP Range 3

3626 psi (250.00 bar)

Burst Pressure

Limit

10,000 psi (689.47 bar)

DP Range 3:

Standard

0 to 1000 Inches H2O (2.5 bar)

Reference

Accuracy

± 0.1% span;

For spans less than 10:1, ± (0.01 [USL/Span]) % span

Stability

±0.1% USL for 1 year

Ambient

Temperature

Effect per 50°F

(28°C)

from 1:1 to

30:1

± (0.15% USL)

from 30:1

to 50:1

± (0.20% USL)

Static Pressure

Effects

Zero Error

± 0.1% USL per 1000 psi (69 bar)

For Static Pressures above 2000 psi:

± [0.2 + 0.0001* (Ps - 2000)] % per 1000 psi

Span Error

± 0.2% USL per 1000 psi (69 bar)

Over Pressure

Limit

SP Range 2

3626 psi (250.00 bar)

SP Range 3

3626 psi (250.00 bar)

Burst Pressure

Limit

10,000 psi (689.47 bar)

Notes:

▪ 0.1% Accuracy is not available on traditional flange.

▪ 1000" DP range with 0.1% accuracy only available with stainless steel sensor

and coplanar flange.

▪ 1000" DP range is not available with 300 psi static pressure (SP Range 1).

FB1200 January 2021

12 www.Emerson.com/FlowComputers

DP Range 3:

Enhanced

0 to 1000 Inches H2O (2.5 bar)

Reference Accuracy

± 0.075% span;

For spans less than 10:1, ± (0.025 +0.005 [USL/Span]) %

span

Stability

±0.125% USL for 5 years;

For ±50 °F (28 °C) temperature changes, up to 1000 psi

(68.9 bar) line pressure

Ambient

Temperature Effect

per 50°F (28°C)

± (0.0175% USL + 0.1% span) from 1:1 to 5:1,

± (0.035% USL + 0.125% span) from 5:1 to 100:1

Static Pressure

Effects

Zero Error

± 0.05% USL per 1000 psi (69 bar)

For Static Pressures above 2000 psi:

± [0.1 + 0.0001* (Ps - 2000)] % per 1000 psi

Span Error

± 0.2% USL per 1000 psi (69 bar)

Over Pressure Limit

SP Range 2

3626 psi (250.00 bar)

SP Range 3

3626 psi (250.00 bar)

Burst Pressure Limit

10, 000 psi (689.47 bar)

Note: 1000" DP range is not available with 300 psi static pressure (SP Range 1).

Static Pressure Input

The following details are for the static pressure measurement of the MultiVariable sensor

SP Range 1

Gauge

−14.2 to 300 psig (−0.98 to 20.68 bar)

Absolute

0.5 to 300 psia (0.03 to 20.68 bar)

Reference Accuracy

Standard

± 0.1% span;

For spans less than 5:1, ± [0.017 (USL/Span)]

% span

Enhanced

± 0.075% span;

For spans less than 5:1, ±[0.013(USL/Span)]

% span

SP Range 2

Gauge

−14.2 to 1500 psig (−0.98 to 103.42 bar)

Absolute

0.5 to 1500 psia (0.03 to 103.42 bar)

Reference Accuracy

Standard

± 0.1% span;

For spans less than 5:1, ± [0.017 (USL/Span)]

% span

Enhanced

± 0.075% span;

For spans less than 5:1, ±[0.013(USL/Span)]

% span

SP Range 3

Gauge

−14.2 to 3626 psig (−0.98 to 250.00 bar)

Note: When used with 25” H20 DP Sensor, maximum static

pressure is 2000 psi.

Absolute

0.5 to 3626 psia (0.03 to 250.00 bar)

Note: When used with 25” H20 DP Sensor, maximum static

pressure is 2000 psi.

January 2021 FB1200

www.Emerson.com/FlowComputers 13

Reference Accuracy

Standard

± 0.1% span;

For spans less than 5:1, ± [0.017 (USL/Span)] %

span

Enhanced

± 0.075% span;

For spans less than 5:1, ±[0.013(USL/Span)] %

span

Stability

Standard Accuracy

±0.1% USL for 1 year

Enhanced Accuracy

±0.125% USL for 5 years

Ambient

Temperature

Effects per

28 °C (50 °F)

Standard Accuracy

± (0.175% USL) from 1:1 to 10:1,

± (0.225% USL) from 10:1 to 25:1

Enhanced Accuracy

± (0.050% USL + 0.125% span) from 1:1 to 10:1,

± (0.060% USL + 0.175% span) from 10:1 to 25:1

Static Pressure Sensor (optional)

The following section applies to the “in-line” integral static pressure sensor, without differential pressure, which would typically

be used with linear meters that provide a pulsed signal for flow.

These static pressure sensors are provided in stainless steel with a 1/2 “– 14 NPT female process connection.

Static Pressure Input

SP Range 1

Gauge

−14.7 to 150 psig (−1.01 to 10.34 bar)

Absolute

0 to 150 psia (0 to 10.34 bar)

SP Range 2

Gauge

−14.7 to 800 psig (−1.01 to 55.15 bar)

Absolute

0 to 800 psia (0 to 55.15 bar)

SP Range 3

Gauge

−14.7 to 4000 psig (−1.01 to 275.79 bar)

Absolute

0 to 4000 psia (0 to 275.79 bar)

Reference

Accuracy

Standard

± 0.1% span

For spans less than 10:1, ± (0.01 [USL/Span]) % span

Enhanced

± 0.075% span

For spans less than 10:1, ± (0.025 + 0.005 [USL / Span]) %

span

Stability

Standard

± 0.1% USL for 1 year

Enhanced

± 0.125% USL for 5 years

Ambient

Temperature

Effects per

28 °C (50 °F)

Standard

± (0.175% USL) from 1:1 to 30:1

± (0.225% USL) for 30:1 to 50:1

Enhanced

± (0.050% USL + 0.125% span) from 1:1 to 30:1

± (0.060% USL + 0.175% span) for 30:1 to 100:1

Over

Pressure

Limit

SP Range 1

1500 psi (103.42 bar)

SP Range 2

1600 psi (110.32 bar)

SP Range 3

6000 psi (413.69 bar)

BurstPressure

Limit

11,000 psi (758.42 bar)

FB1200 January 2021

14 www.Emerson.com/FlowComputers

Power

External DC Power

Supply

5.7 Vdc to 30 Vdc external supply (Max power at 10 watts)

Optional Rechargeable

Lead Acid Battery

Internal mounted 4.5 Ah 6.0 Vdc battery

The battery can power the unit for up to 19 days without any solar charging depending on display and

communications and I/O usage, and can be charged by a 6-watt solar panel or from a DC supply for

backup

Note: This option is available only with Class 1 Div 2 approval.

Solar Panel and

Regulator Options

If ordered with the rechargeable battery option, the FB1200 includes an integral solar regulator

Can be supplied with an optional 6-watt 6V solar panel

The solar panel input is rated to a maximum of 30V and 1.5A. A minimum of 8V is required to charge

the battery.

Note: This option is available only with Class 1 Div 2 approval.

SRAM Battery

Lithium coin cell type BR2335 or BR2330

Typical battery life 5-7 years with power; 10,000 hours without power

Power Modes

To keep power consumption to a minimum, especially for remote sites, the FB1200 can run in two different power modes, low

and standard. The FB1200 normally runs in low power mode for standard metering applications.

When running in low power mode, the radio power control function is used to switch to standard power mode and enable the

serial ports. During communication periods, the unit uses the standard power mode and then automatically reverts to low power

mode when the communication period is over.

Notes:

▪ Serial connection to a remote 4088B MVT can run in low power mode.

▪ If PID control, math/logic blocks, or Ethernet communications are enabled, or a serial port set to Modbus master, or the

additional 6 channel I/O board is fitted and enabled, the unit will run in the standard power mode.

The local display and FBxWifi can be configured to switch off after a period of inactivity (configurable between 1 and 60 minutes)

or be permanently left on.

When running in low power mode, if you need to use more than the default number of data points for logging, consult the

Emerson FB1200 Flow Computer Instruction Manual (D301782X012) to determine the possible impact on power consumption.

The figures below are typical power values in mW measured at room temperature.

Low Power Mode

Base unit with integral multivariable DP and pressure sensor and

temperature measurement, single meter run

47 mW @ 6.1Vdc

Base unit with integral Static Pressure sensor and temperature

measurement and pulsed input, single meter run

45 mW @ 6.1Vdc

Base unit with integral multivariable DP and pressure sensor and

temperature measurement, communicating to remote 4088 dual meter run (4088 externally powered)

82 mW @ 6.1Vdc

Additional Load

Options

Display and Backlight active

292 mW @ 6.1Vdc

FBxWifi

315 mW @ 6.1Vdc

FBxWifi and Display active

337 mW @ 6.1Vdc

DO active (1 Hz, 50:50 duty cycle, no

load)

1 mW @ 6.1Vdc

Standard Power Mode

Base unit with integral multivariable

DP and pressure sensor and

temperature measurement, single

meter run

230 mW @ 6Vdc

245 mW @ 12Vdc

287 mW @ 24Vdc

January 2021 FB1200

www.Emerson.com/FlowComputers 15

Base unit with integral Static Pressure

sensor and temperature

measurement and pulsed input),

single meter run

244 mW @ 6Vdc

260 mW @ 12Vdc

305 mW @ 24Vdc

Base unit with integral multivariable

DP and pressure sensor and

temperature measurement,

communicating to remote 4088 dual meter run (4088 externally

powered)

278 mW @ 6Vdc

306 mW @ 12Vdc

373 mW @ 24Vdc

Additional Load

Options

Display and

Backlight active

162 mW @ 6Vdc

168 mW @ 12Vdc

178 mW @ 24Vdc

FBxWifi

189 mW @ 6Vdc

185 mW @ 12Vdc

200 mW @ 24Vdc

FBxWifi and

Display active

204 mW @ 6Vdc

207 mW @ 12Vdc

221 mW @ 24Vdc

DO active (1 Hz,

50:50 duty cycle,

no load)

1 mW @ 6Vdc

1 mW @ 12Vdc

1 mW @ 24Vdc

PI active (10KHz,

50:50 duty square

wave)

13 mW @ 6Vdc

14 mW @ 12Vdc

15 mW @ 24Vdc

Additional 6

channel I/O board

fitted

40 mW @ 6Vdc

49 mW @ 12Vdc

80 mW @ 24Vdc

Ethernet enabled

100 Mbit

435 mW @ 6Vdc

421 mW @ 12Vdc

462 mW @ 24Vdc

Ethernet active

100 Mbit

459 mW @ 6Vdc

443 mW @ 12Vdc

489 mW @ 24Vdc

Physical

Construction

Die-cast aluminum, painted, with wire sealable end caps, or

Stainless steel (AISI 316/ASTM CF8M), unpainted, with wire sealable end caps

Ingress Protection

IEC 60529 IP66 & NEMA 4X

Dimensions

With Sensor

11.715 in. H by 6.0 in. W by 9.426 in. D

(297.7 mm H by 152.4 mm W by 239.4 mm D)

Without Sensor

5.995 in. H by 6.0 in. W by 9.426 in. D

(152.4 mm H by 152.4 mm W by 239.4 mm D)

Mounting

2 in. pipe or direct manifold

Wiring

Standard

Size 12 to 28 American Wire Gauge (AWG) (0.3 to 2mm diameter)

Optional

For units with optional 6-channel expansion card, size 16 to 28 AWG (0.3 to 1.3

mm diameter)

Wiring Access

4 conduit entry points

3/4 in. NPT (standard), M20 (optional)

Weight

FB1200 aluminum housing with MVS coplanar flange sensor: 6.75 Kg (14.9 lb)

FB1200 January 2021

16 www.Emerson.com/FlowComputers

FB1200 aluminum housing with static pressure sensor: 5.98 Kg (13.2 lb)

FB1200 aluminum housing without sensor: 4.22 Kg (9.3 lb)

FB1200 stainless steel housing with MVS coplanar flange sensor: 13.27 Kg (29.5 lb)

Optional Lead Acid Battery: 0.86 Kg (1.9 lb)

Display

Optional backlit liquid crystal display

HMI

20 characters per line; 4 lines in display.

Environmental

Operating Temperature

−40 C to +80 C (−40 F to +176 F) (see ambient temps in Approvals section)

Note: Please check Approvals section for any restrictions. The display exhibits increased response time and

decreased contrast at temperatures below −30 C (–22 F).

Storage Temperature

−40 to 85 °C (−40 to 185 °F)

Operating Humidity

5 to 95%, non-condensing

Conformal Coating

All boards are conformal coated with a coating that complies with ANSI/ISA 71.04 Class G3

environments.

Environmental Rating

Product conforms to ANSI/ISA 71.04 Class G3 environmental standards with all conduit openings

sealed.

Electro Magnetic

Compatibility

The following EMC Emissions and Immunity are evaluated per EMC directive 2014/30/EU.

Harmonized standards used:

EN 61326-2-3-2013 Immunity

EN 61326-1-2013 Emissions

Immunity

EN 61000-4-2 (Electro Static Discharge)

EN 61000-4-3 (Radiated Immunity) *

EN 61000-4-4 (Fast Transients)

EN 61000-4-5 (Surges)

EN 61000-4-6 (Conducted RF)

EN 61000-4-8 (Power Frequency Magnetic Field)

EN 61000-4-17 (Voltage Ripple)

EN 61000-4-29 (Voltage Dips and Interrupts)

*Meets CE compliance at 10V/m for industrial requirements (deviations < 1% span for RTD

and Pressure readings in addition to original specification)

Emissions

EN 550022 Class A

Vibration

2g over 10 to 150 Hz

1g over 150 to 200 Hz

January 2021 FB1200

www.Emerson.com/FlowComputers 17

Approvals

Product Markings for

Hazardous Locations

UL

Class 1, Div 1 Groups C, D, Temperature Code, T6

Class1, Div 2 Groups A, B, C, D, Temperature Code T4

Ambient Temperature

Aluminum enclosure

-40 °C to +80°C (-40 °F to +176 °F) (no battery)

-40 °C to +80°C (-40 °F to +176 °F) (with

rechargeable lead acid battery)

Evaluated per Approval

Standards

Per Class 1, Div 1:

UL 1203 5th Ed.

UL/IEC 61010-1 Part 1 3rd Ed.

CSA C22.2 No. 30-M1986

CSA C22.2 No. 61010-1-12 Part 1 3rd Ed.

Per Class 1, Div 2:

ANSI/ISA 12.12.01-2015

CSA C22.2 No. 213-15

CSA C22.2 NO. 61010-1-12 Part 1 3rd Ed

UL61010-1 Part 1 3rd Ed

UL

ATEX Cert: DEMKO 15 ATEX 1349X

IECEx Cert: IECEx UL 15.0024X

Ex db IIB T4 Gb, -40°C to +80°C

Ambient Temperature

II 2 G.

−40°C to +80 °C (−40 to +176 °F)

Evaluated per Approval

Standards:

Directive 2014/34/EU

EN 60079-0:2012+A11:2013

EN 60079-1:2014

ATEX Cert: DEMKO 15 ATEX 1367X

IECEx Cert: UL 15.0044X

Ex nA IIC T4 Gc

Ambient Temperature

II 3 G.

−40 °C to +80 °C (−40 to +176 °F)

Evaluated per Approval

Standards

Directive 2014/34/EU

EN 60079-0:2012+A11:2013

EN 60079-15:2010

Note: ATEX and IECEx approval requires the use of an external DC power

supply.

Miscellaneous Approvals

Customs Union

TR CU 004/2011, TR CU 020/2011

Conforms to the requirements of the technical regulations of the Customs

Union

FB1200 January 2021

18 www.Emerson.com/FlowComputers

RoHS2

Device without integral MVS or SP Sensor:

RoHS (2) EU Directive 2011/65/EU

Device with integral MVS or SP Sensor:

RoHS (2) EU Directive 2011/65/EU: This product may be considered out-ofscope when used for the intended design purpose in a Large Scale Fixed

Installation (LSFI).

Consult https://www.emerson.com/compliance for up-to-date product

information.

RoHS

NEPSI China

National Supervision and Inspection Centre for Explosion Protection and Safety

of Instrumentation

Cert. No. GYJ18.1015X

Ex d IIB T4 Gb

Cert. No. GYJ17.1350X

Ex Na IIC T4 Gc

CCOE India

Chief Controller of Explosives

Approval No. A/P/HQ/MH/104/5885 (P420948)

Ex db IIB T4 Gb

Approval No. A/P/HQ/MH/104/5887 (P420946)

Ex Na IIC T4 Gc

NMi

Report Number: NMi-1901499-02

API Chapter 21.1:2013 compliance for “Flow measurement using Electronics

Metering Systems – Electronic Gas Measurement” and independent verification

for natural gas properties and flow calculations

January 2021 FB1200

www.Emerson.com/FlowComputers 19

This page is left intentionally blank.

FB1200 January 2021

For customer service and technical support,

visit www.Emerson.com/SupportNet.

Global Headquarters,

North America, and Latin America:

Emerson Automation Solutions

Remote Automation Solutions

6005 Rogerdale Road

Houston, TX 77072 U.S.A.

T +1 281 879 2699 | F +1 281 988 4445

www.Emerson.com/RemoteAutomation

© 2019-2021 Remote Automation Solutions, a business unit of Emerson Automation

Solutions. All rights reserved.

This publication is for informational purposes only. While every effort has been made to ensure

accuracy, this publication shall not be read to include any warranty or guarantee, express or

implied, including as regards the products or services described or their use or applicability.

Remote Automation Solutions (RAS) reserves the right to modify or improve the designs or

specifications of its products at any time without notice. All sales are governed by RAS terms

and conditions which are available upon request. RAS accepts no responsibility for proper

selection, use or maintenance of any product, which remains solely with the purchaser and/or

end-user.

Europe:

Emerson Automation Solutions

Remote Automation Solutions

Unit 1, Waterfront Business Park

Dudley Road, Brierley Hill

Dudley DY5 1LX UK

T +44 1384 487200 | F +44 1384 487258

Middle East/Africa:

Emerson Automation Solutions

Remote Automation Solutions

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone – South 2

Dubai U.A.E.

T +971 4 8118100 | F +971 4 8865465

Asia-Pacific:

Emerson Automation Solutions

Remote Automation Solutions

1 Pandan Crescent

Singapore 128461

T +65 6777 8211| F +65 6777 0947

Remote Automation Solutions

Loading...

Loading...