Page 1

Installation Sheet

Form 5876

December 2010

Position Monitor Bracket (PMB) Mounting Kit

Position Monitor Bracket (PMB) Mounting Kit

Introduction

This Installation Sheet covers the assembly and

installation instructions and parts list for Position

Monitor Bracket (PMB) Mounting Kit.

For more information on 4300 Series Wireless Position

Monitor and on regulators used with this product, refer

to full product literature:

Fisher® 4320 Wireless Position Monitor:

D103392X012

Type 63EG: D100315X012

Type 1098-EGR: D100339X012

Type 1190: D101644X012

Type 1290: D101645X012

Type EZR: D102600X012

The Position Monitor Bracket or PMB is the bracket

and hardware used to mount the 4300 Series Wireless

Position Monitors to the travel indicator of Types 63EG,

1098-EGR, 1190, 1290, and EZR regulators. The PMB

mounting kit is compatible with both Topworx 4310

(open/partially open/closed) and Fisher 4320 (open/

percent travel/closed) Wireless Position Monitors.

Specications

Construction Materials

Bracket: 304 Stainless steel

Hardware: 18-8 Stainless steel

Assembly and Installation

Read fully and understand the assembly and

installation instructions in this manual and the

nstruction manuals of the appropriate regulator type

and 4300 Series Wireless Position Monitor before

installing the Position Monitor Bracket Assembly.

The regulator cannot be in operation during the

assembly and installation of the position monitor and

the PMB assembly. Refer to the appropriate instruction

manual for proper shutdown of the system before

attempting to mount the position monitor.

For best results, the PMB Assembly should only be

installed on site.

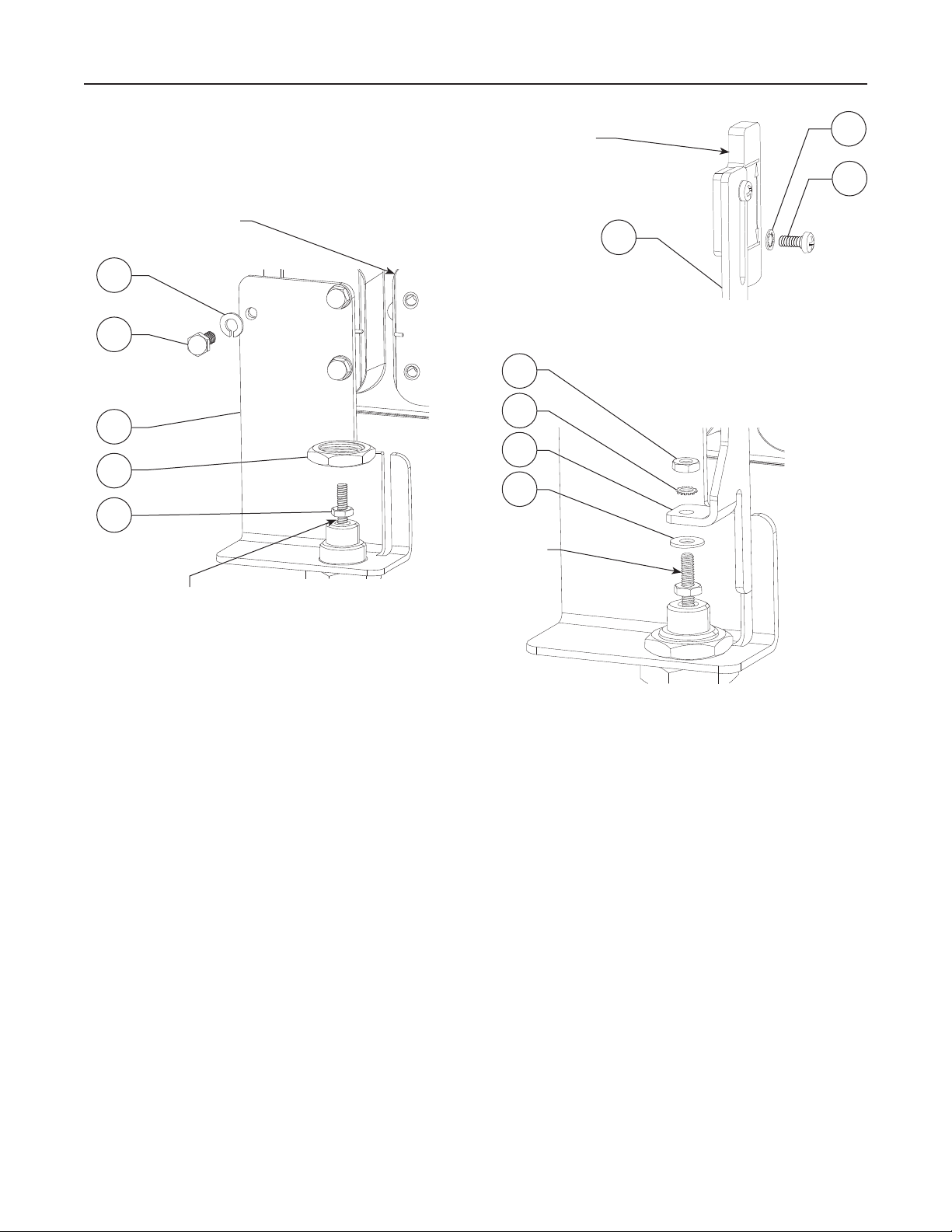

All key numbers are referenced in Figure 1.

1. If used, remove the protective cap covering the

regulator stem and travel indicator.

CAUTION

Securely grip the regulator stem when

removing attached parts and when

installing the hex nut (key 6) to prevent

the stem from potentially backing down

into the regulator.

Remove all parts attached to the regulator stem

and install a new hex nut (key 6).

2. Fasten the position monitor to the monitor bracket

(key 1) using three cap screws (key 4) and

three lock washers (key 5). Apply Threadlocker

adhesive (key 11, not shown) and securely torque

the cap screws to 100 inch-pounds / 11 N•m.

3. Install the monitor bracket and position monitor

setup (from step 3) to the regulator using the panel

nut (key 3). This joint allows the monitor bracket

(key 1) to slide back and forth and from side to side

for optimal adjustment. Finger tighten only until

nal adjustment.

Note

The PMB mounting kit is designed for

small but necessary adjustments at

most of the fastened joints. Because an

adhesive is required on all the fasteners

of the PMB assembly, all fasteners must

www.sherregulators.com

D103260X012

Page 2

Position Monitor Bracket (PMB) Mounting Kit

5

4

1

3

6

POSITION MONITOR

POSITION MONITOR

MAGNET

6

8

2

7

REGULATOR STEM

10

9

2

MONITOR MAGNET AND MAGNET ARRAY

BRACKET (KEY 2) PRE-ASSEMBLY (STEP 4)

REGULATOR STEM

INSTALLING THE BRACKET (KEY 1) TO THE POSITION MONITOR

AND REGULATOR STEM (STEPS 1 THROUGH 3)

Figure 1. PMB Mounting Kit Assembly and Installation

be nger tightened only until the position

monitor and bracket assembly have

been properly located. Apply

Threadlocker adhesive and fully tighten

the joints to the specied torque values

only during nal adjustment.

4. Pre-assemble the monitor magnet to the

magnet array bracket (key 2) using two machine

screws (key 9) and two external tooth star

washers (key 10). Finger tighten only until

nal adjustment.

Note

The mounting slot of the magnet array

bracket (key 2) is designed for multiple

regulators. The optimal location of the

array bracket is determined by the limits

INSTALLING THE PRE-ASSEMBLED MAGNET ARRAY BRACKET

(KEY 2) TO THE REGULATOR STEM (STEP 5)

of the regulator and the wireless position

monitor. Consult the appropriate

instruction manual to determine the

optimal location.

5. Fasten the pre-assembled magnet array bracket

(key 2) to the regulator stem using a at washer

(key 7), an external tooth star washer (key 8), and

a hex nut (key 6). Additional vertical adjustment of

the monitor magnet may be obtained through

this fastening joint. Finger tighten only until

nal adjustment.

6. Both the monitor bracket (key 1) and magnet

array bracket (key 2) are designed to allow

adjustments in the assembly so that the monitor

magnet array can be located properly as specied

by the wireless position monitor Instruction Manual.

2

Page 3

Position Monitor Bracket (PMB) Mounting Kit

4300 SERIES WIRELESS

POSITION MONITOR

45

1

3

9 10

2

REGULATOR TRAVEL INDICATOR

STEM ASSEMBLY

Figure 2. PMB Mounting Kit Assembly Drawing

After the monitor magnet array has been

properly located, perform nal adjustments

to all previously nger-tightened joints. Apply

Threadlocker adhesive and tighten the joints to

the following specications:

• From step 3, torque the panel nut (key 3) to

700 inch-pounds / 79 N•m.

• From step 5, torque the hex nut (key 6) to

15 inch-pounds / 1.7 N•m.

• From step 4, securely tighten the two

machine screws (key 9).

Startup and Adjustment

After mounting the wireless position monitor on the

regulator, the monitor should be calibrated before the

regulating system is turned back on.

A known method of locating the minimum and

maximum travel to calibrate the 4300 Series Wireless

6 7 8

Position Monitor is required before it can become

operational. Calibrate the wireless position monitor

based on the procedure found in the appropriate

instruction manual.

Follow all local procedures and refer to the appropriate

regulator instruction manual when restarting the

regulating system.

Parts List (Figure 2)

Key Description

1 Monitor Bracket ERAA00141A0

2* Magnet Array Bracket ERAA00142A0

3* Panel Nut ERAA00160A0

4* Cap Screw (3 required) ERAA00178A0

5 Lock Washer (3 required) ERAA00179A0

6* Hex Nut (2 required) ERAA00181A0

7* Flat Washer ERAA00161A0

8 External Tooth Star Washer ERAA00180A0

9* Pan Head Machine Screw (2 required) ERAA00182A0

10* External Tooth Star Washer (2 required) ERAA00183A0

11* Threadlocker (adhesive, not shown) ERAA00184A0

*Recommended spare part.

3

Page 4

Position Monitor Bracket (PMB) Mounting Kit

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Emerson Process Management Regulator Technologies, Inc. product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Chartres 28008, France

Tel: +33 2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9499

©Emerson Process Management Regulator Technologies, Inc., 2010; All Rights Reserved

Loading...

Loading...