Page 1

Africa

Instruction Manual

NTAEZH0811

November 2008 - Rev. 06

Types EZH and EZHSO

Types EZH and EZHSO Pressure Reducing Regulators

Contents

Introduction ........................................................................ 2

Characteristics ................................................................... 3

Labelling ............................................................................ 5

Dimensions and Weights ................................................... 6

Description ......................................................................... 8

Principle of Operation ......................................................... 8

Monitoring Systems ............................................................ 11

Installation ......................................................................... 13

Startup and Adjustment ..................................................... 15

Shutdown ........................................................................... 16

Maintenance ...................................................................... 17

Troubleshooting ................................................................. 24

Spare Parts ........................................................................ 25

Parts List ............................................................................ 26

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or re

causing property damage and personal

injury or death.

®

Fisher

operated, and maintained in accordance

with federal, state, and local codes, rules

and regulations, and Emerson Process

Management Regulator Technologies, Inc.

(Regulator Technologies) instructions.

If the regulator vents gas or a leak develops

in the system, service to the unit may be

required. Failure to correct trouble could

result in a hazardous condition.

Call a gas service person to service the

unit. Only a qualied person must install or

service the regulator.

regulators must be installed,

R94

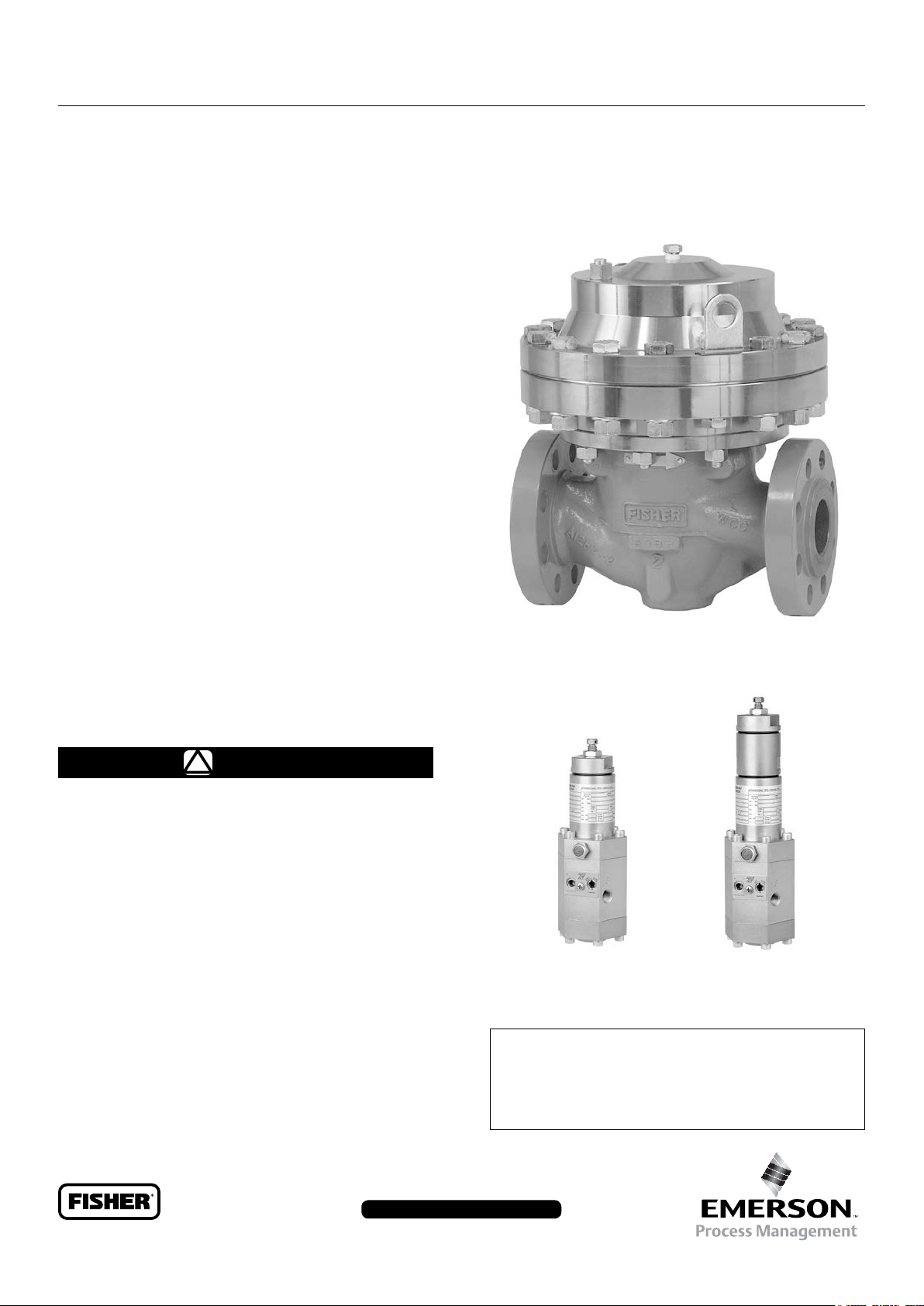

Figure 1. Type EZH Pressure Reducing Regulator

TYPE PRX-120/APTYPE PRX-120

Figure 2. PRX Series Pressure Reducing Pilots

Types EZH, EZHSO, EZH OS2, and EZHSO OS2

regulators are in conformity with the

Pressure Equipment Directive

PED 97/23/EC and are classied in Category IV.

www.fisherregulators.com

Page 2

Africa

Types EZH and EZHSO

INTRODUCTION

Scope of Manual

This manual provides installation, startup, maintenance,

and parts ordering information for the Types EZH and

EZHSO pressure-reducing regulators and Type PRX pilot

with Type SA/2 pilot supply lter regulator.

Information on other equipment used with this regulator is

found in separate manuals.

Product Description

Types EZH and EZHSO regulators are accurate pilotoperated pressure balanced, soft-seated regulators.

They are designed for use in high pressure natural gas

transmission/city gate stations, large capacity distribution

systems, and power plant feeds. They provide smooth,

reliable operation, tight shutoff, and long life.

Type EZHSO "Spring-to-Open" version could be used

when other overpressure protection options are foreseen,

for example in a monitor conguration. In this case, in

event of failure, the main regulator will stay completely

open, allowing the monitor to take control. The monitor

could be "Spring-to-Close" to ensure a double protection to

downstream pipe.

Available Congurations:

• Type PRX/120:

Outlet pressure range of 1 to 40 bar. The T ype PRX/120

can be used as the pilot on single stage pressure reducing

regulators, as the monitor pilot, or as the working pilot in

wide-open monitor systems.

• Type PRX/120-AP:

Outlet pressure range of 30 to 80 bar . The Type PRX/120-AP

can be used as the pilot on single stage pressure reducing

regulators, as the monitor pilot, or as the working pilot in

wide-open monitor systems.

• Type PRX/125:

Identical to the Type PRX/120, except the restriction screw

is removed. The Type PRX/125 can only be used as the

monitor override pilot on working monitor applications.

• Type PRX/125-AP:

Identical to the Type PRX/120-AP, except the restriction

screw is removed. The Type PRX/125-AP can only

be used as the monitor override pilot on working

monitor applications.

• Type SA/2 Pilot Supply Filter Regulator:

The Type SA/2 pilot supply lter regulator provides a

constant pressure supply to the PRX Series pilot of 3 bar

over the set pressure. The Type SA/2 has an integral

5-micron lter. For easy maintenance a block valve can

be installed to separate the regulator from the pilot.

• Types EZH and EZHSO ("E Body")

Single regulator without slam shut

• Types EZH and EZHSO ("X Body")

Single regulator in a X Body

In case of modication made on a pressure equipment

like cap replacement by a slam shut it's mandatory to

comply to the local codes, rules and regulations.

Contact us imperatively.

• Types EZH OS2 and EZHSO OS2 ("X Body")

Single regulator with integrated slam shut

Pilot Description

Type PRX Pilot

The Types EZH and EZHSO pressure-reducing regulators

can be equipped with a PRX Series pilot mounted on the

main valve for pressure reducing or wide-open monitoring

applications. The PRX Series pressure reducing pilots

have the ability to handle a wide range of setpoints from

1 to 80 bar:

Regulator Options

• Silencer (Figure 22)

The Type EZH silencer (Whisper III) is integrated in the

regulator and is composed of a drilled cage.

The Whisper III silencer is available for DN 25, 50, 80, and

100 and allows a noise attenuation up to 8dB.

• Flow Coefcient Reduction (Figure 16)

The ow reduction is realised by replacement of the

regulator standard seat by a reduction seat ( key 2).

• Type RPE Electrical Pilot Heater (Figure 25)

The Type RPE is used for reheating the gas supplying

pressure reducing regulator pilots. The Type RPE avoids

the inconveniences caused by freezing which can occur

during high pressure drops.

Actuator

The actuator is an integral pressure type. All pressure parts

are designed to resist up to 100 bar. The diaphragm is

strong and can resist to a differential of 100 bar.

2

Page 3

Africa

CHARACTERISTICS

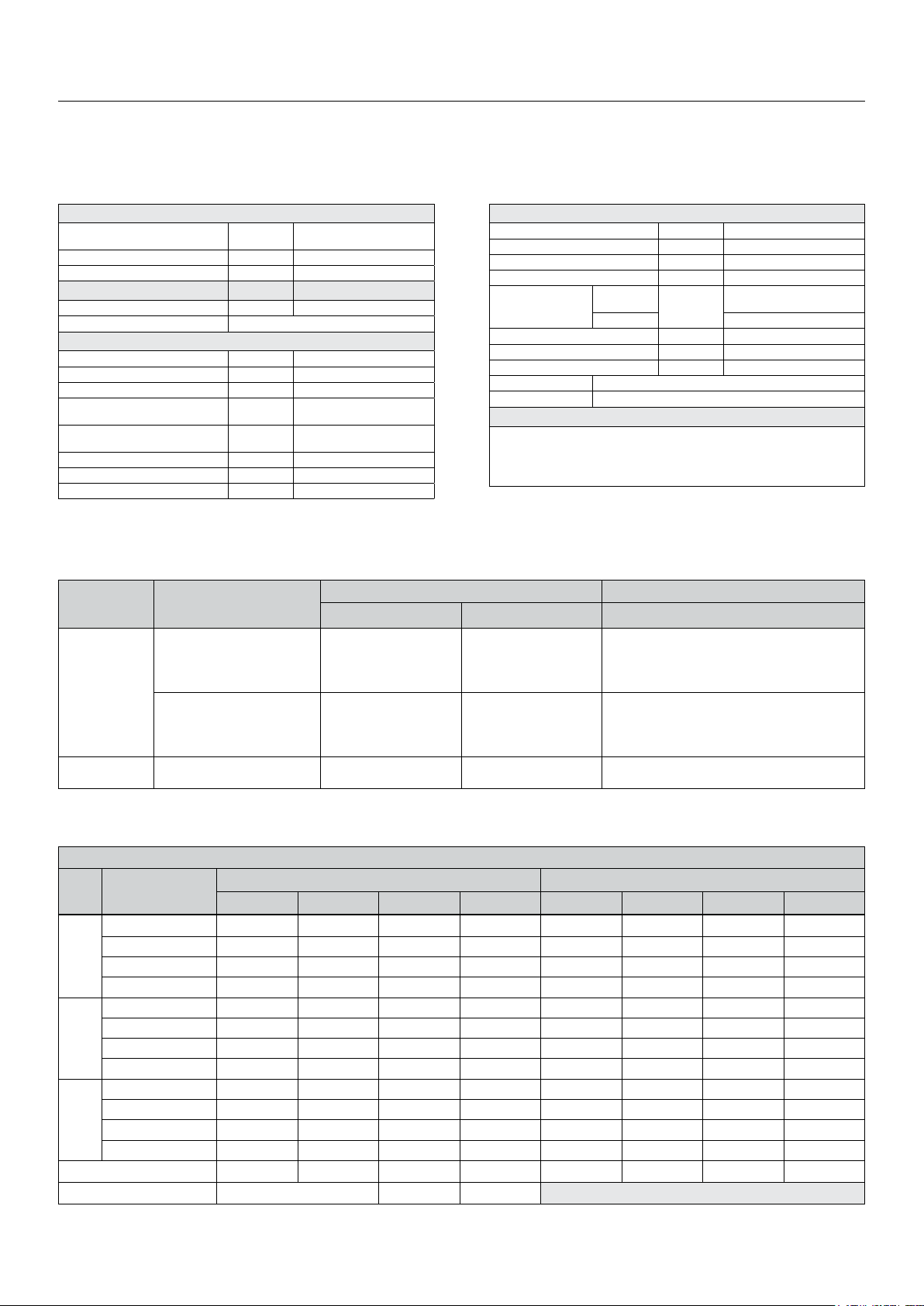

Table 1. General Characteristics for Types EZH and EZHSO Regulator

OPERATING PRESSURE

A352LCC Body, Actuator, Valve,

Pilot Body, Slam shut

Associated BMS

Type IS Integral strength

OPERATING TEMPERATURE

Sizes available DN 25, 50, 80, and 100

Noise level reduction Up to 8 dB

REGULATOR

European EN Standard EN 334

Inlet Pressure Pu 2 to 100 bar

Outlet Pressure Pd 1 to 80 bar

Minimum Differential DP min

Maximum Differential DP max

Accuracy (optimal) AC See Table 2

Lock-Up Pressure Class SG Up to 5%

Lock-Up Pressure Zone Class SZ Up to 5%

(1) BMS - Safety Manometric Box

(2) Standard version

(1)

, according to size PSD 10 to 100 bar

(2)

PS 100 bar max

TS -20 / 60°C Class 2

1 bar (Type EZH)

3.8 bar (Type EZHSO)

99 bar (Type EZH)

96.2 bar (Type EZHSO)

(3)

(3)

(3) Contact us with your operating conditions

(4) Depending on BMS conguration for Type EZH OS2

Types EZH and EZHSO

SLAM SHUT

European EN Standard EN 14382

Operation Class

(4)

Maximum Operating Differential DP max 100 bar

Response Time ta <1 s

Diaphragm,

Accuracy

Set Pressure Range

Flow Coefcient Q

Internal Automatic Bypass C

Rearming Manual after rectication of fault

Position Indicator On mechanism box

Groups 1 and 2 according to PED 97/23/EC, Gas 1

Bellows

Piston Up to ±5%

Wdu-Wdo

Fluid

EN 437, or other gases (compressed air, nitrogen).

The gas must be non corrosive, clean

(ltration on inlet side necessary) and dry.

A or B (see Figure 3)

AG

Up to ±2.5%

0.010 / 100 bar

13

f

25

g

st

and 2nd family according to

Table 2. Outlet Pressure Ranges, Accuracy Class, and Pilot Spring Information

TYPE

PRX/120 and

PRX/125

PRX/120-AP and

PRX/125-AP

OUTLET PRESSURE

ADJUSTMENT RANGES (bar)

1.0 to 1.8

1.8 to 3.0

3.0 to 5.5

5.5 to 8.5

8.5 to 14.5

14.5 to 23.0

23.0 to 30.0

30.0 to 40.0

30.0 to 80.0 1% 2.5% Clear

AC (ACCURACY CLASS) PILOT CONTROL SPRING INFORMATION

TYPE EZH TYPE EZHSO Spring Colour

2.5%

2.5%

2.5%

2.5%

1%

1%

1%

1%

2.5%

2.5%

2.5%

2.5%

2.5%

2.5%

2.5%

2.5%

Yellow

Green

Blue

Black

Silver

Gold

Aluminium

Red

Table 3a. 2:1 Line Flow Coefcients, Regulator, and Slam-Shut Travel

TYPES EZH (DN 25 - 100) AND EZHSO (DN 25 - 100)

REDUCTION

0

Q

f

1

2

3

0

C

g

1

2

3

0

C

1

1

2

3

DN

284 1078 2247 3567 280 1088 2266 3696

210 908 1684 2969 218 829 1698 2902

126 671 1058 1763 128 607 1066 1784

79 385 685 1062 81 370 690 1072

550 2092 4359 6920 544 2110 4396 7170

408 1762 3266 5760 423 1609 3294 5630

245 1301 2052 3420 249 1177 2069 3460

154 746 1328 2060 157 718 1339 2080

31.3 38.3 30.8 32.5 35.5 33.5 30.8 31.4

34.3 35.3 33.9 35.3 38.7 31.9 33.9 34.2

33.6 38.8 37.8 37.3 39.7 35.6 37.8 36.3

32.1 40.8 33.6 37.1 39.1 38.2 33.6 37.3

Regulator travel (mm) 9 17 25 30 9 17 25 30

Slam-shut travel (mm) 15 30 50

WITH SLAM SHUT (X BODY) WITHOUT SLAM SHUT (E BODY)

25 DN 50 DN 80 DN 100 DN 25 DN 50 DN 80 DN 100

R95

R96

3

Page 4

Africa

Types EZH and EZHSO

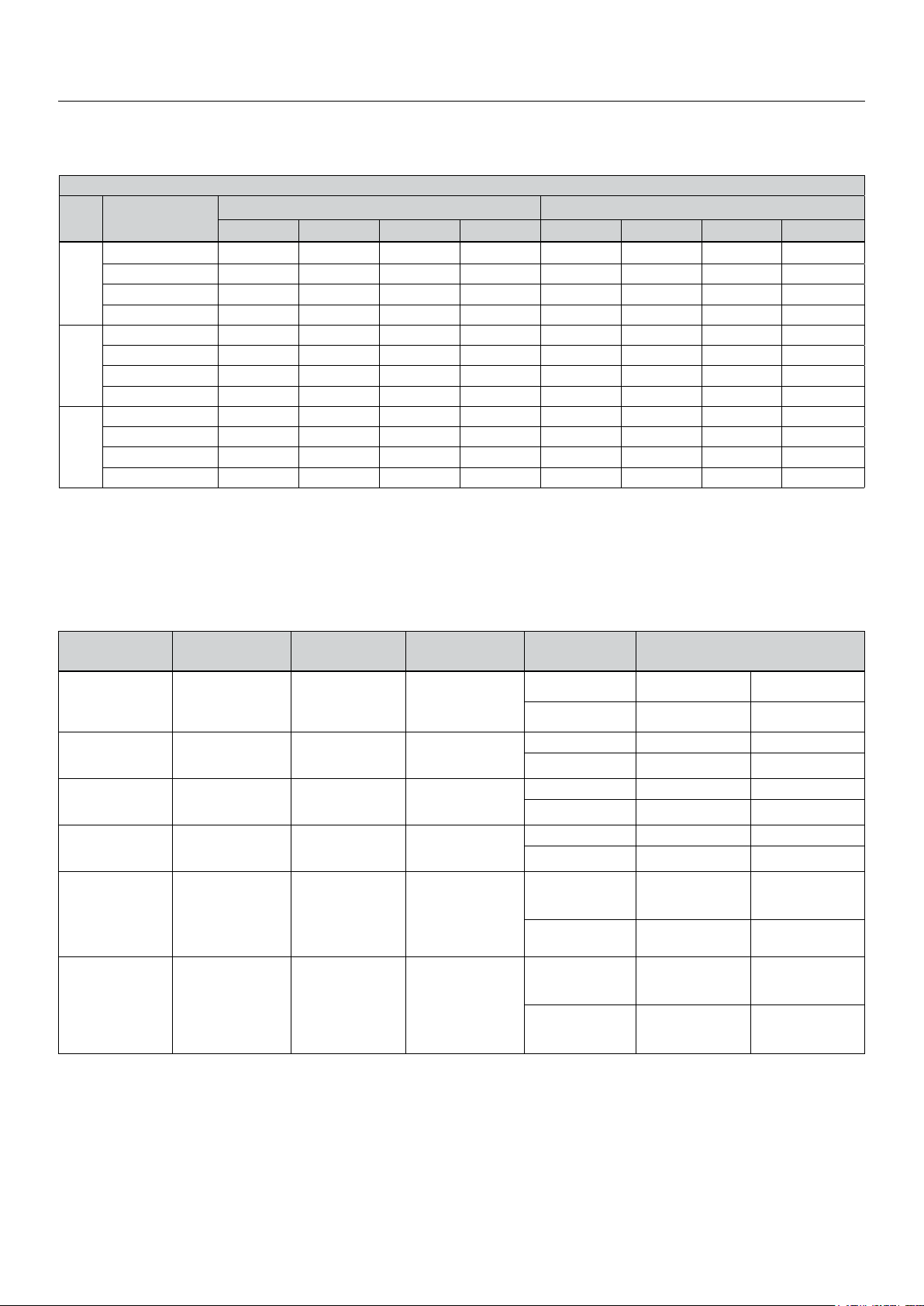

Table 3b. 2:1 Line Flow Coefcients, Regulator with Integrated Whisper III Silencer

TYPES EZH (DN 25 - 100) WITH WHISPER III AND EZHSO (DN 25 - 100) WITH WHISPER III

REDUCTION

0

Q

f

C

g

C

1

1

2

3

0

1

2

3

0

1

2

3

SLAM SHUT INTEGRATED (X BODY) WITHOUT SLAM SHUT (E BODY)

DN

25 DN 50 DN 80 DN 100 DN 25 DN 50 DN 80 DN 100

223 781 1693 2742 255 793 1708 2789

215 764 1418 2479 209 716 1172 2438

140 603 975 1644 127 566 984 1711

87 370 685 1041 81 358 690 1057

433 1516 3285 5320 495 1539 3313 5410

417 1482 2751 4810 406 1389 2774 4730

273 1169 1892 3190 247 1099 1908 3320

168 718 1328 2020 158 695 1339 2050

35.5 37 30.8 31.7 33.8 33.5 30.8 30.4

35.4 37.5 33.6 34.1 39.4 34.1 33.6 32.4

32.3 39.5 37.1 36.4 39.9 35.7 37.1 35.7

32.9 39.4 38.3 37.6 39.9 37.7 38.3 37.3

PART NAME

Filter

Pilot Disk Pilot cannot be closed

Pilot Lower

Diaphragm

Pilot Upper

Diaphragm

Regulator

Diaphragm

Pilot

FAILURE

(WORST CASE)

Filter blocked/

clogged

Pilot cannot control

Pilot cannot feed

the regulator

Not proper

performance of

the motorization

pressure chamber

Frozen Pilot,

Type SA/2 working

Table 4. Failure Mode Analysis

CAUSE OF

FAILURE

Debris or aromatics

present in the gas

Debris or aromatics

present in the gas

Debris or aromatics

present in the gas

Debris or aromatics

present in the gas

Debris or aromatics

present in the gas

Moisture in the gas,

high pressure drop

EFFECT REGULATOR TYPE REGULATOR REACTION MODE

Decrease of feeding

pressure gives

decrease of

motorization pressure

Increase

motorization

pressure

Decrease

motorization

pressure

Decrease

motorization

pressure

Balancing of

pressures and charge

or discharge of

the motorization

pressure chamber

Type SA/2 loading

upper casing of

regulator, Pilot

not supplying

loading pressure

to lower casing

EZHSO Open ---

EZH --- Close

EZHSO Open ---

EZH Open ---

EZHSO Open ---

EZH --- Close

EZHSO Open ---

EZH --- Close

EZHSO Open ---

EZH --- Close

EZHSO --- Close

EZH --- Close

R96B

4

Page 5

Africa

Types EZH and EZHSO

Connections

Inlet/Outlet : CL150 RF - CL300 RF - CL600 RF

PN 16B - PN 25B - PN 40B

Other congurations available

(contact factory)

Pilot feed: 1/4’’ NPT female

Pilot Reject: 1/4’’ NPT female

Pilot impulse: 1/4’’ NPT female

Slam-shut impulse: 1/4’’ NPT female

BM* vent: 1/4’’ NPT female

Impulse tube diameter: Interior Ø 8/10 mm

Contact switch: See NTAOS2

* BM - Mechanism Box

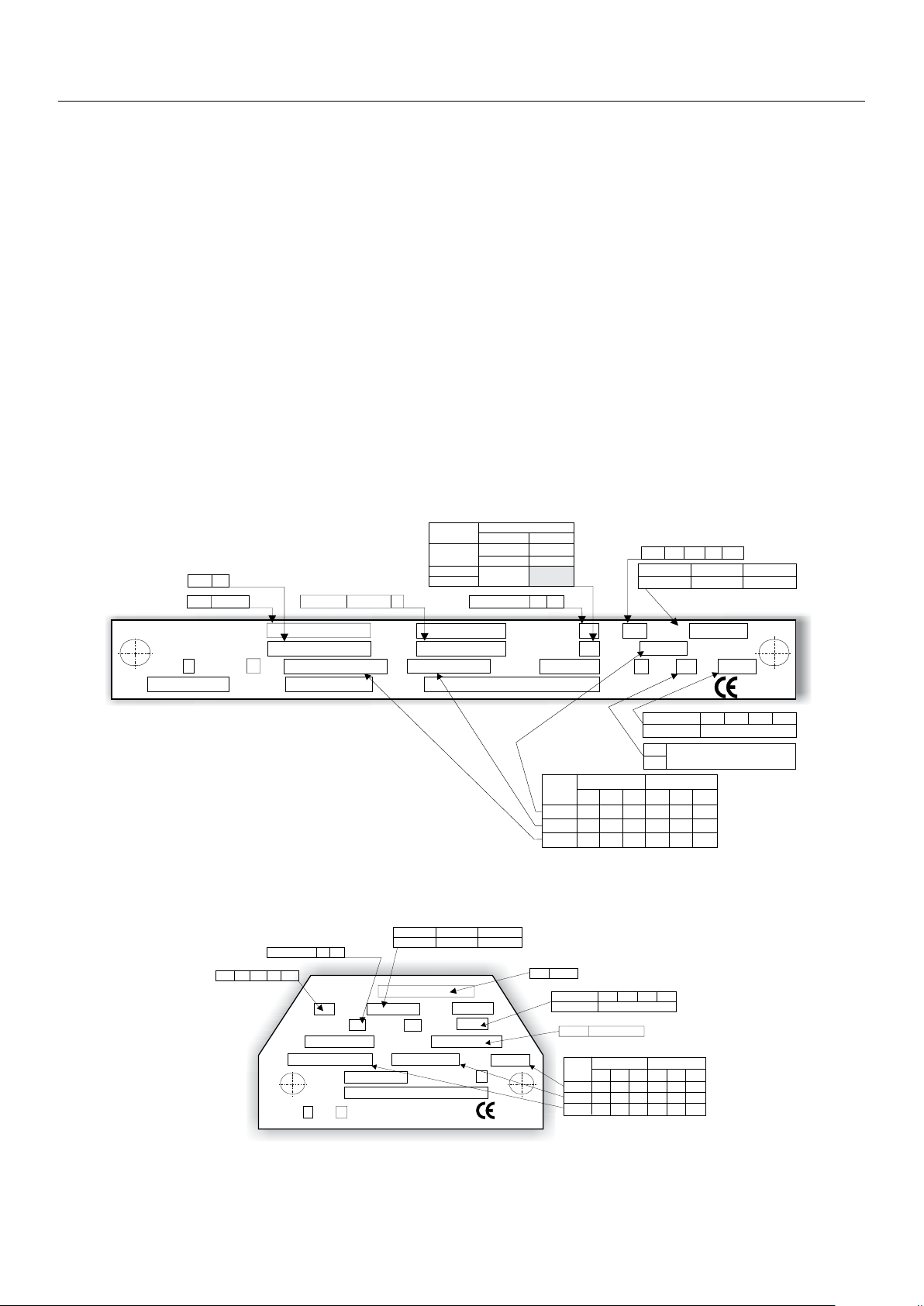

LABELLING

OS2 -

EZH EZHSO

REGULATEUR/REGULATOR

SECURITE/SLAM SHUT

1

GROUPE

série

N°

serial

(Gaz Naturel)

IV

CatPS

Date Fab/Test

Mfg/Testdate

Standard EN14382 -

norme

standard

norme

standard

bar

DD MM YEAR

Figure 3. Types EZH OS2 and EZHSO OS2 Label (X Body)

PT

matériau

shell

Material

Body: Steel

Connecting parts and bottom: Steel

Actuator: Steel

Regulator/Slam-shut orice: Stainless steel

Regulator valve plug: Stainless steel

Slam-shut valve plug: Stainless steel

Regulator plug disc/

Slam-shut O-rings: Nitrile (NBR) or

Fluorocarbon (FKM)

BMS Setting

BMS 027/017 BMS162

Max only

BMS 236/315 BMS071

Min onlyAll

Max-Min types of BMS

Failure mode FC

EN 334

bar

A352LCC+A350LF2

PS

SecurityClass

AB

FO

mode défaillance

failure mode

classe sécurité

slam shut class

Temp TS

-20/+60°C

Pumax 18.9

PT

PS

DN 25 50 80 100

CL150 RF CL300 RF CL600 RF

DN

Pumax bar

2

Class Type Cg

Reduction 0123

IS

DS

CLASS

150 300 600

16B 25B

5050100

32 79 158

18.9 100

PN16B PN25B PN40B

Otherconfigurations available (contactfactory)

PN

28320 Gallardon-France

FISHER

FRANCEL

0062

Cg See Table3

Depending on BMS

configuration

PN

40B

16

25

26 40

16

40

63

25

40

Failure mode FC FO

DN 25 50 80 100

N°

PS

GROUPE

(Gaz Naturel)

CL150 RF CL300 RF CL600 RF

PN16B PN25B PN40B

DN

mode défaillance

failure mode

série

serial

1

REGULATEUR/

REGULATOR

Temp TS

matériau

shell

IV

Cat

PN

Type

Date Fab/Test

Mfg/Testdate

bar

PT

-20/+60°C

A352LCC+A350LF2

FISHER

Other configurations available (contact factory)

norme

EN 334

standard

Cg

IS

bar

Pumax bar

Class

FRANCEL

28320 Gallardon-France

2

EZH

0062

Figure 4. Types EZH and EZHSO Label (E Body)

EZHSO

Reduction0123

Cg See table3

DD MM YEAR

Date

CLASS

150 300 600

Pumax 18.9

PT

PS

5050100

32 79 158

18.9 100

PN

16B 25B

16

26 40

16

40B

25

40

63

25

40

R97

5

Page 6

Africa

Types EZH and EZHSO

HIE

F

G

B

C

A

D

IH

E

25 mm

Mechanism box

removal clearance

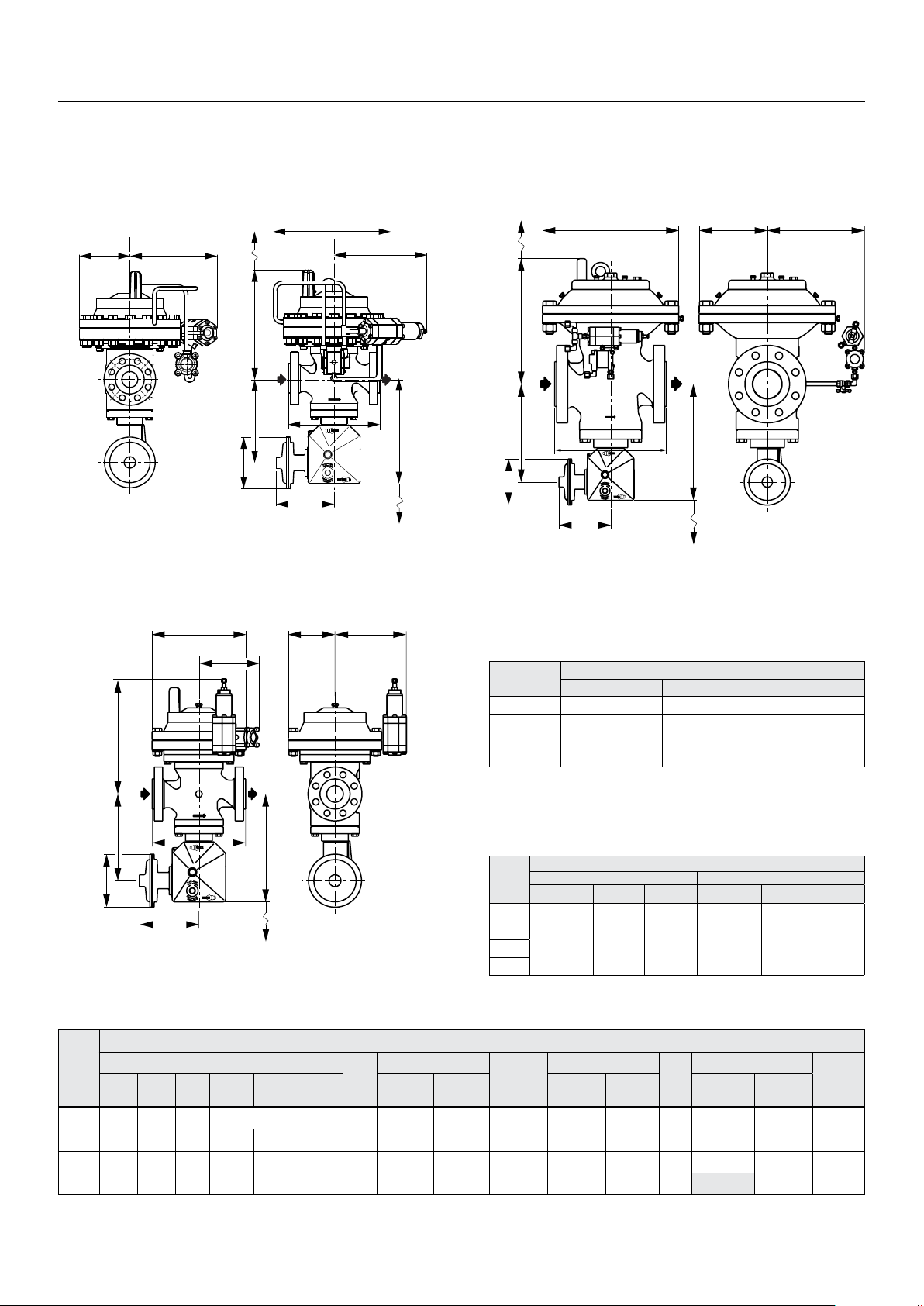

DIMENSIONS AND WEIGHTS

DN 25, 50, and 80 DN 100

E

I

H

Indicator cover

K

removal clearance

Indicator cover

J

K

removal clearance

C

B

G

F

A

D

25 mm

Mechanism box

removal clearance

C

B

G

F

D

A

25 mm

Mechanism box

removal clearance

R112a

Figure 5. Dimensions — Types EZH OS2 and EZHSO OS2

C

B

G

DN 25, 50, 80, and 100

F

J

A

I HE

D

25 mm

Mechanism box

removal clearance

Figure 6. Dimensions — Types EZH OS2 and EZHSO OS2

(Vertical Position)

(Horizontal Position)

For Type EZHSO OS2 version add 1 kg

Table 6a. Dimensions — Types EZH OS2 and EZHSO OS2

DN

25

50

80

100

Table 5. Approximate Regulator Weights

Types EZH OS2 and EZHSO OS2

DN

CL150/PN 16B CL300/PN 25B/PN 40B CL600

25 49 50 51

50 81 83 85

80 168 175 177

100 237 250 265

OVERALL DIMENSIONS (mm)

F G

Diaphragm Piston Bellows Diaphragm Piston Bellows

181 204 223 162 71 74

WEIGHTS (kg)

R113a

6

Table 6b. Dimensions — Types EZH OS2 and EZHSO OS2

MAXIMUM OVERALL DIMENSIONS (mm)

DN

CL150 CL300 CL600 PN 16B PN 25B PN 40B

A

B

Type PRX

Horizontal

25 184 197 210 193.5 250 290 310 315 320 260 250 113 280 190

50 254 267 286 254 267 265 320 320 330 380 310 310 144 270 190

80 298 317 337 310 317 301 400 400 366 500 390 390 200 270 270

100 352 368 394 350 368 345 442 427 410 580 394 394 240 140

C

Type PRX

Vertical

D E

Type PRX

Horizontal

H

Type PRX

Vertical

I

Type PRX

Horizontal

J

Type PRX

Vertical

K

38

51

R114a

Page 7

Africa

IH

E

C

K

B

IH

Indicator cover

removal clearance

E

Indicator cover

IH

E

C

K

B

A

IH

Indicator cover

removal clearance

E

JIH

B

C

K

A

Indicator cover

removal clearance

K

removal clearance

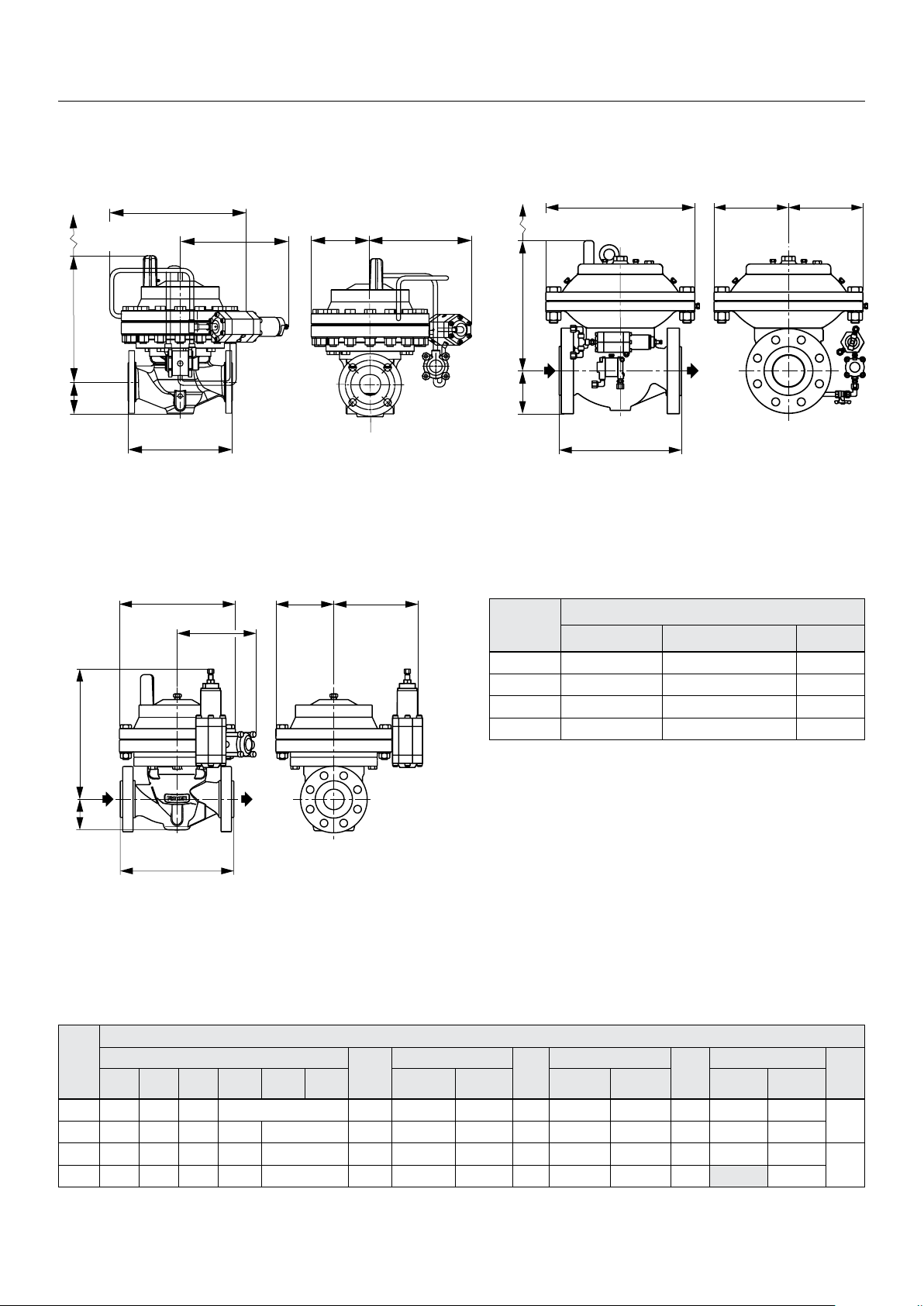

DN 25, 50, and 80

JIH

Types EZH and EZHSO

(1)

DN 100

E

Indicator cover

K

removal clearance

C

B

A

C

B

A

R115a

Figure 7. Dimensions — Types EZH and EZHSO

(Horizontal Position)

DN 25, 50, 80, and 100

E

J

DN

25 38 39 40

50 71 74 75

80 145 151 153

C

100 211 224 239

(1) For Type EZHSO version add 1 kg

Table 7. Approximate Regulator Weights

Types EZH and EZHSO

(1)

WEIGHTS (kg)

CL150/PN 16B CL300/PN 25B/PN 40B CL600

R116a

B

A

Figure 8. Dimensions — Types EZH and EZHSO

(Vertical Position)

Table 8. Dimensions — Types EZH and EZHSO

A

DN

CL150 CL300 CL600 PN 16B PN 25B PN 40B

25 184 197 210 193.5 62 290 310 320 260 250 113 280 190

50 254 267 286 254 267 83 320 320 380 310 310 144 270 190

80 298 317 337 310 317 105 400 400 500 390 390 200 270 270

100 352 368 394 350 368 137 442 427 580 394 394 240 140

MAXIMUM OVERALL DIMENSIONS (mm)

C

B

Type PRX

Horizontal

Type PRX

Vertical

E

Type PRX

Horizontal

H

Type PRX

Vertical

J

I

Type PRX

Horizontal

Type PRX

Vertical

K

38

51

R117a

7

Page 8

Africa

Types EZH and EZHSO

TYPE

FILTER

SA/2

V

R

M

TYPE

PRX/120

UPPER

DIAPHRAGM

PILOT DISK

S

B

L

A

Inlet pressure (Pu)

Motorization pressure (Pm)

Pilot feeding pressure (Pup)

Outlet pressure (Pd)

Atmospheric pressure (Pb)

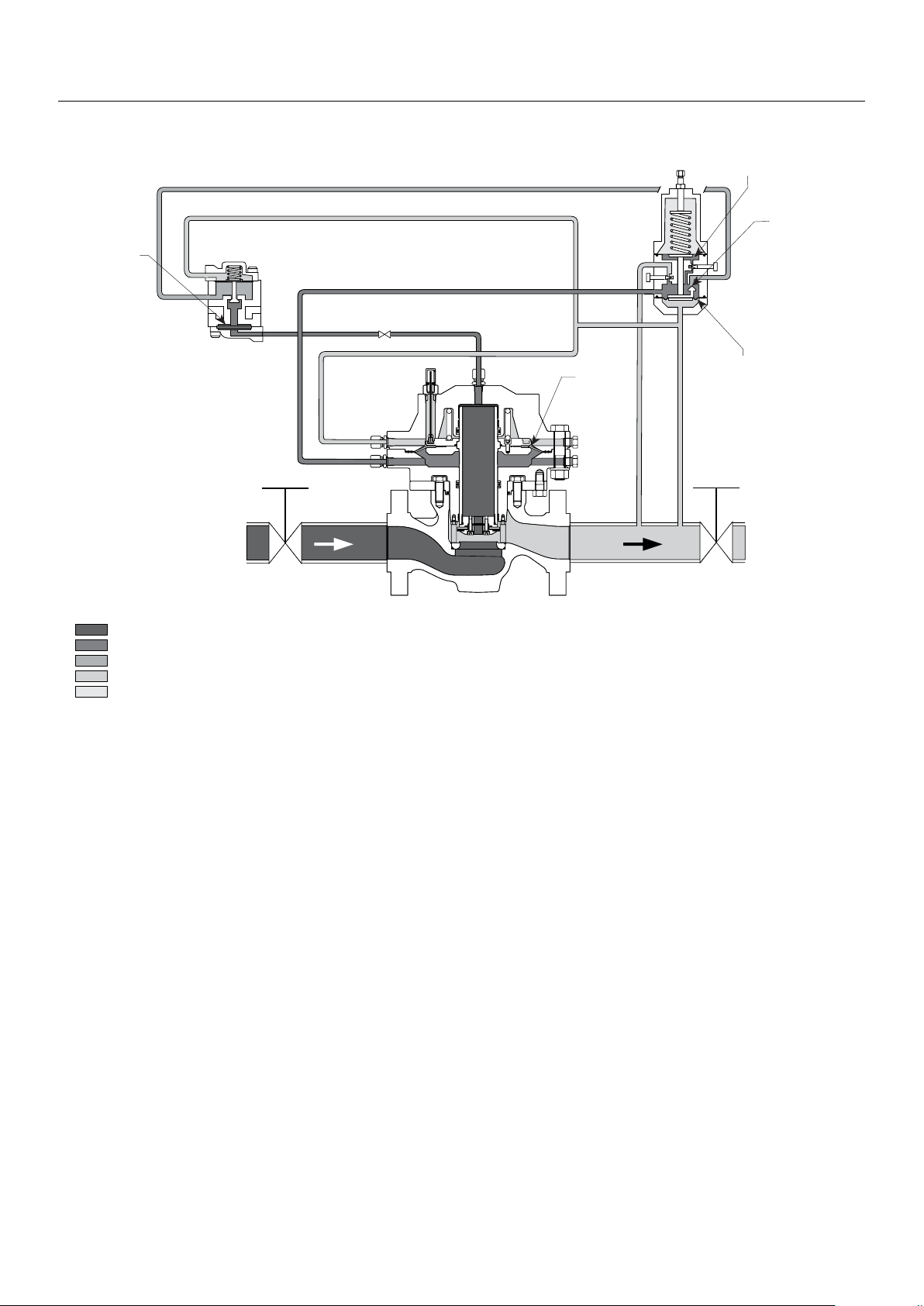

DESCRIPTION

REGULATOR

DIAPHRAGM

TYPE EZH

TYPE PRX:

S - BLEED PORT TYPE SA/2

B - SUPPLY PORT V - SENSING

L - MOTORIZATION PORT R - PILOT

A - SENSING PORT M - INLET

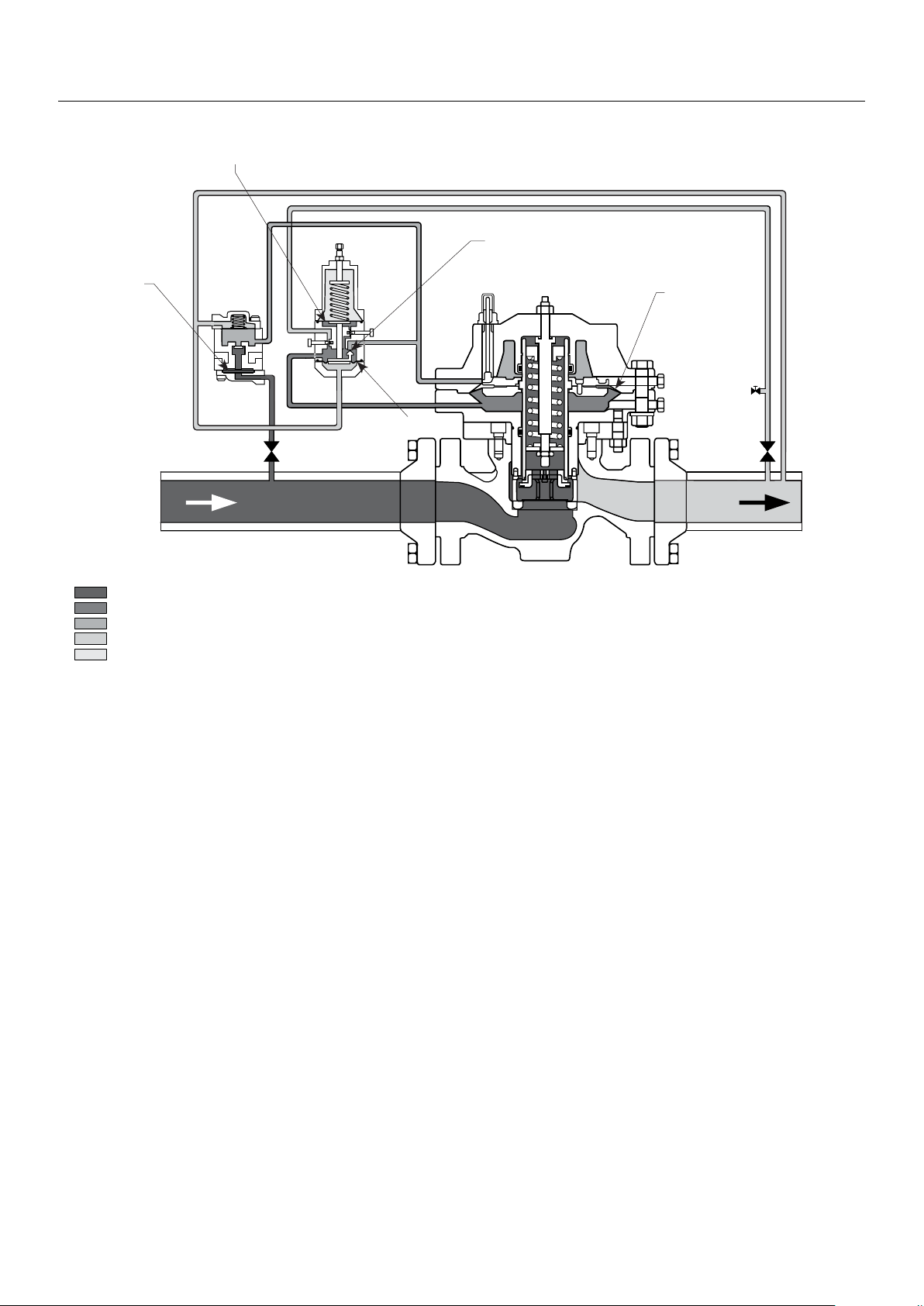

Figure 9. Type EZH DN 25/50/80 (Spring-to-Close Version) Operational Schematic

PRINCIPLE OF OPERATION

LOWER

DIAPHRAGM

R98

The Types EZH and EZHSO regulators consist of:

• Version without Integral Slam-Shut Valve:

- An "E Body" or an "X Body plus a cap"

- A compensation valve, an interchangeable orice

- An actuator with position indicator

- A pilot system adapted to the required pressure setpoint

• Version with Integral Slam-Shut Valve:

- Same parts and sub-assemblies as in the version

without slam shut

- An "X Body"

- A valve with tight shut-off O-ring

- An automatic slam-shut bypass

- A release relay Type OS2 (see instruction manual

NTAOS2) consisting of:

· A mechanism box (BM)

· A safety manometric box (BMS) connected to the

outlet side of the regulator

8

Type EZH — Spring-to-Close Version

Type EZH Single-Pilot Regulator

(Figures 9 and 10)

The pilot-operated Type EZH uses inlet pressure as the

operating medium, which is reduced through pilot operation

to load the actuator diaphragm. Outlet pressure (Pd)

opposes the motorization pressure (Pm) in the actuator and

also opposes the pilot control spring.

When the outlet pressure (Pd) drops below the setting of

the pilot control spring, pilot control spring force on the

pilot diaphragm thus opens the pilot valve plug, providing

additional motorization pressure (Pm) to the actuator

diaphragm. This diaphragm motorization pressure opens

the main valve plug, supplying the required ow to the

downstream system.

Any excess motorization pressure on the actuator diaphragm

escapes downstream through the bleed restriction in

the pilot.

Page 9

Africa

Types EZH and EZHSO

V

R

S

M

R2

L

B

A

RP IP

IS

Inlet pressure (Pu)

Motorization pressure (Pm)

Pilot feeding pressure (Pup)

Outlet pressure (Pd)

Atmospheric pressure (Pb)

TYPE PRX:

S - BLEED PORT TYPE SA/2

B - SUPPLY PORT V - SENSING

L - MOTORIZATION PORT R - PILOT

A - SENSING PORT M - INLET

Figure 10. Type EZH-OS2 DN 100 (Spring-to-Close Version) Operational Schematic

When the gas demand in the downstream system has

been satised, the outlet pressure (Pd) increases. The

increased pressure is transmitted through the downstream

control line and acts on the pilot diaphragm. This pressure

exceeds the pilot spring setting and moves the Type PRX

diaphragm, closing the Type PRX orice and interrupting

the motorization pressure supply to main valve actuator.

The excess of motorization pressure (Pm) acting on both

the main diaphragm and Type PRX pilot bleeds to the

downstream system through a bleed restriction in the pilot.

For Type EZH DN 100 a check valve (Figure 26) is installed

between outlet pressure and motorization pressure impulse

lines; this valve will protect the diaphragm assembly from

wrong procedures during startup, avoiding a too high pressure

differential between outlet and motorization pressure.

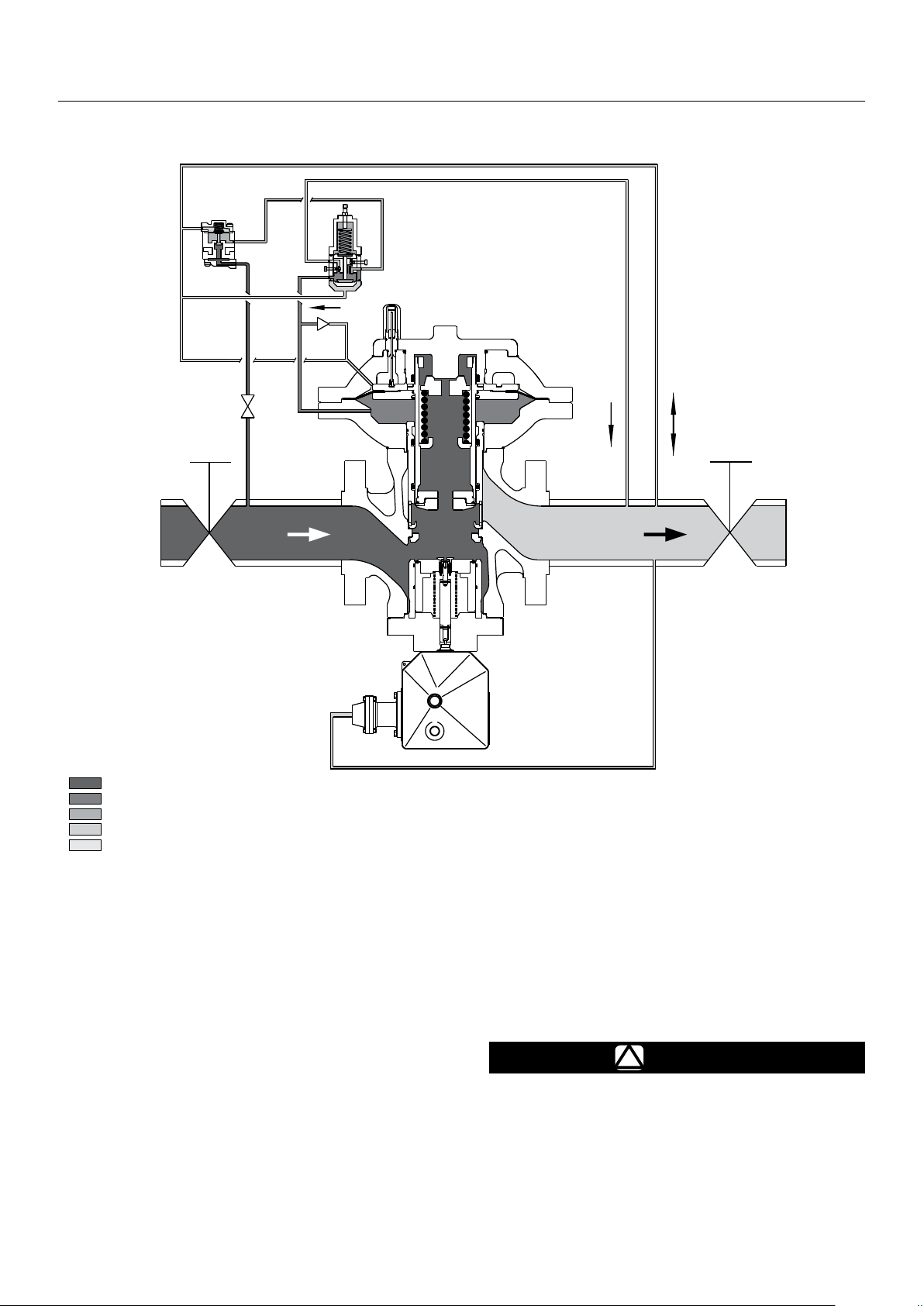

Type EZHSO — Spring-to-Open Version

Type EZHSO Single-Pilot Regulator

(Figures 11 and 12)

CAUTION

The pilot-operated Type EZHSO (Spring-toOpen version) will fail in open position in

case of main valve diaphragm failure or lack

of pressure supply to the pilot (see Table 4

for Failure Mode Analysis).

9

Page 10

Africa

Types EZH and EZHSO

UPPER DIAPHRAGM

FILTER

Inlet pressure (Pu)

Motorization pressure (Pm)

Pilot feeding pressure (Pup)

Outlet pressure (Pd)

Atmospheric pressure (Pb)

TYPE

SA/2

V

S

R

L

M

R2

TYPE PRX:

S - BLEED PORT TYPE SA/2

B - SUPPLY PORT V - SENSING

L - MOTORIZATION PORT R - PILOT

A - SENSING PORT M - INLET

A

LOWER DIAPHRAGM

TYPE

PRX/120

B

PILOT DISK

TYPE EZHSO

REGULATOR

DIAPHRAGM

R3

R4

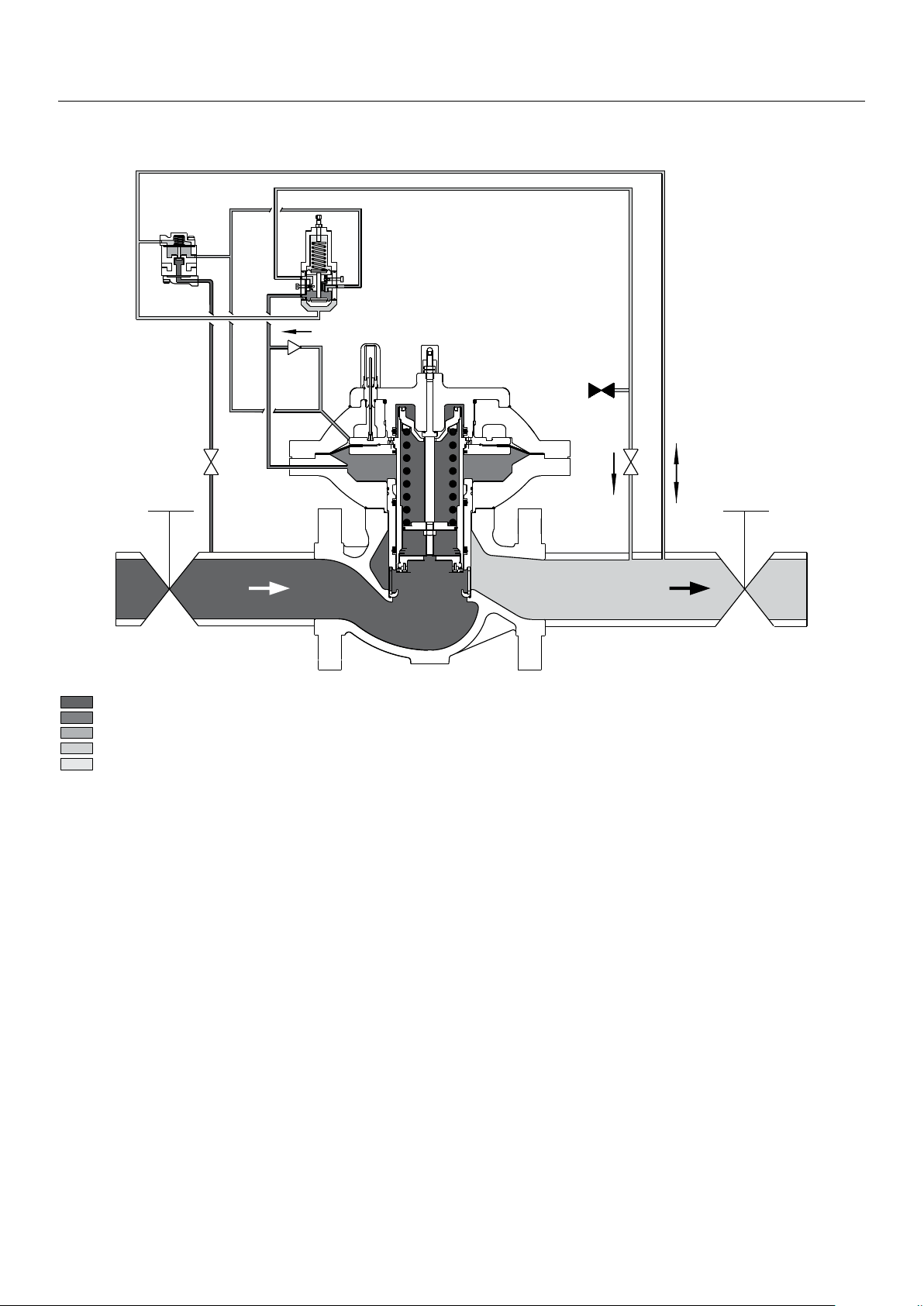

Figure 11. Type EZHSO DN 25/50/80 (Spring-to-Open Version) Operational Schematic

Type EZHSO uses inlet pressure as the operating medium,

which is reduced through pilot operation to load the

actuator diaphragm (lower chamber). The upper case of

Type EZHSO actuator is lled with pressure coming from

pre-regulator Type SA/2, which reduces inlet pressure (Pu)

to the constant value of outlet pressure plus approximately

3 bar. This pressure opposes the main spring force

that tends to open the regulator. Outlet or downstream

pressure (Pd) opposes the pilot control spring. When

outlet pressure drops below the setting of the pilot control

spring, pilot control spring force on the pilot diaphragm

opens the pilot valve plug, providing additional motorization

pressure (Pm) to the actuator diaphragm.

This diaphragm motorization pressure opens the main valve

plug, supplying the required ow to the downstream system.

Any excess motorization pressure on the actuator diaphragm

escapes downstream through the bleed restriction in the pilot.

When outlet pressure increases over the setting of the

pilot spring, the pilot valve plug will be closed reducing

motorization pressure to the actuator diaphragm; the

pressure in the upper case will force the regulator to close.

For Type EZHSO DN 100 a check valve (Figure 26) is

installed between outlet pressure and loading pressure

impulse lines; this valve will protect the diaphragm

assembly from wrong procedures during startup, avoiding

a too high pressure differential between outlet and

motorization pressure.

EZH and EZHSO Series Adjustment

The adjustment of the regulator is performed by means

of the pilot adjusting screw, which causes variation of the

compression of the control spring.

Adjustment is performed while the regulator is in operation with

the aid of a pressure gauge to monitor downstream pressure.

The shut-off valve downstream of the regulator must not be

completely closed, it is necessary that a small quantity of

gas ows downstream to allow the outlet side to vent when it

is necessary to lower the pressure.

Loosen the Type PRX pilot locknut and turn the adjusting

screw slowly clockwise to increase outlet pressure and

counterclockwise to decrease outlet pressure. Use a

pressure gauge to monitor the outlet pressure until the

desired pressure is reached. No adjustment is needed to

the Type SA/2 stabilizer lter.

10

Page 11

Africa

Types EZH and EZHSO

V

R

S

M

R2

Inlet pressure (Pu)

Motorization pressure (Pm)

Pilot feeding pressure (Pup)

Outlet pressure (Pd)

Atmospheric pressure (Pb)

L

TYPE PRX:

S - BLEED PORT TYPE SA/2

B - SUPPLY PORT V - SENSING

L - MOTORIZATION PORT R - PILOT

A - SENSING PORT M - INLET

B

A

R3

R4

RP IP

Figure 12. Type EZHSO DN 100 (Spring-to-Open Version) Operational Schematic

MONITORING SYSTEMS

Monitoring regulation is overpressure protection by

containment, therefore, there is no relief valve to vent to the

atmosphere. When the working regulator fails to control

the pressure, a monitor regulator installed in series, which

has been sensing the downstream and control pressure,

goes into operation to maintain the downstream pressure

at a slightly higher level than normal pressure. During an

overpressure situation, the monitoring system keeps the

customer on line.

Also testing is relatively easy and safe. To perform a

periodic test on a monitoring regulator, increase the outlet

set pressure of the working regulator and watch the outlet

pressure to determine if the monitoring regulator takes over

at the appropriate outlet pressure.

Wide-Open Monitoring Systems

In normal operation of a wide-open conguration, the

working regulator controls the system’s outlet pressure.

With a higher outlet pressure setting, the monitor regulator

senses a pressure lower than its setpoint and tries to

increase outlet pressure by going wide open. If the working

regulator fails, the monitoring regulator assumes control and

holds the outlet pressure at its outlet pressure setting.

Figure 13 shows an upstream wide-open monitor Type EZH

(Spring-to-Close) and a downstream active regulator

Type EZHSO (Spring-to-Open). With this conguration,

in case of regulator main diaphragm failure, it will fail in

open position letting the monitor work properly; in case

of monitor main diaphragm failure, it will fail in close

position guaranteeing a protection against overpressure to

downstream system.

11

Page 12

Africa

Types EZH and EZHSO

V

R

M

TYPE SA/2

Inlet pressure (Pu)

Motorization pressure (Pm)

Pilot feeding pressure (Pup)

Outlet pressure (Pd)

Atmospheric pressure (Pb)

TYPE SA/2

TYPE PRX

R2

R1

TYPE EZH TYPE EZHO

TYPE PRX:

S - BLEED PORT TYPE SA/2

B - SUPPLY PORT V - SENSING

L - MOTORIZATION PORT R - PILOT

A - SENSING PORT M - INLET

S

L

V

R

B

M

A

TYPE PRX

R4

S

L

B

A

R3

Figure 13. Upstream Wide-Open Monitoring System Operational Schematic for DN 25, 50, and 80

The schematic from Figure 13 represents the conguration

for the DN 25, 50, and 80, for the DN 100 the schematic

remains the same with the remark that a check valve

(Figure 26) must be installed between outlet pressure and

loading pressure impulse lines of the regulator and wide

open monitor as well.

Working Monitor System with PRX Pilot

(Figure 14)

In a working monitoring system, the upstream regulator

requires two pilots and it is always the monitoring regulator.

The additional pilot PRX/125 or PRX/125-AP permits the

monitoring regulator to act as a series regulator to control an

intermediate pressure during normal operation. In this way,

both units are always operating and can be easily checked

for proper operation.

In normal operation, the working regulator controls the outlet

pressure of the system. The monitoring regulator’s working

pilot Type PRX/120 or PRX/120-AP controls the intermediate

pressure and the monitor pilot Type PRX/125 or PRX/125-AP

senses the system’s outlet pressure. If the working regulator

fails, the monitoring pilot Type PRX/125 or PRX/125-AP will

sense the increase in outlet pressure and take control.

CAUTION

The working regulator must be rated for the

maximum allowable operating pressure of the

system because this will be its inlet pressure

if the monitoring regulator fails. Also, the

outlet pressure rating of the monitoring

pilot Type PRX/125 or PRX/125-AP and any

other components that are exposed to the

intermediate pressure must be rated for full

inlet pressure.

Working monitor installations require a Type EZH or EZHSO

main valve with a Type PRX/120 or PRX/120-AP working

pilot, a Type PRX/125 or PRX/125-AP monitoring pilot for

the upstream regulator, and a Type EZH or EZHSO with

the appropriate Type PRX/120 or PRX/120-AP pilot for the

downstream regulator.

Adjusting the monitor regulator is the same as adjusting the

main regulator. Monitor setpoints are set slightly higher than

the main regulator. However, the value of this difference

cannot be determined in advance, as it depends on the

particular characteristics of each application.

12

Page 13

Africa

Types EZH and EZHSO

TYPE SA/2

V

R

Inlet pressure (Pu)

Motorization pressure (Pm)

Pilot feeding pressure (Pup)

Outlet pressure (Pd)

Atmospheric pressure (Pb)

M

TYPE PRX/120

R1

TYPE EZH TYPE EZH

TYPE PRX:

S - BLEED PORT TYPE SA/2

B - SUPPLY PORT V - SENSING

L - MOTORIZATION PORT R - PILOT

A - SENSING PORT M - INLET

S

L

TYPE PRX/125

S

B

A

L

R2

B

TYPE SA/2

V

R

M

TYPE PRX/120

S

L

A

B

R100

Figure 14. Working Monitoring System Operational Schematic with Two EZH (Spring-to-Close) for DN 25, 50, and 80

The schematic from Figure 14 represents the conguration for

the DN 25, 50, and 80, for the DN 100 the schematic remains

the same with the remark that a check valve (Figure 26) must

be installed between outlet pressure and loading pressure

impulse lines of the regulator and working monitor as well.

INSTALLATION

WARNING

!

Personal injury or equipment damage, due

to bursting of pressure-containing parts may

result if this regulator is overpressured or

is installed where service conditions could

exceed the limits given in the characteristics

section and on the appropriate nameplate,

or where conditions exceed any rating of

the adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions

from exceeding those limits. Also, be sure

that installation is in compliance with all

applicable code and regulations.

Physical damage to the regulator can break

the pilot off the main valve, causing personal

injury and property damage due to bursting

of pressure-containing parts. To avoid such

injury and damage, install the regulator in a

safe location.

Only personnel qualied through training

and experience should install, operate, and

maintain a regulator.

Before installation, make sure that there is no

damage to, or debris in the regulator.

Make sure that all tubing and piping are clean

and unobstructed.

The regulator must be installed on

horizontal pipeline. For the version with

slam shut, the release relay must be

situated towards the bottom.

Installation according to EN 12186

is recommended.

When assembling with adjacent elements

take care not to create pressure force on

the body. The assembling elements (bolts,

O-rings, anges) should be compatible with

the geometry and working conditions of the

equipment. If the case arises a support must

be used to avoid pressure force on the body

(a support can be installed under the anges).

13

Page 14

Africa

Types EZH and EZHSO

Connect the actuator to the impulse plug

keeping a minimum distance of 4 x D to a

straight run of the outlet pipe.

In the version with integrated slam shut

connect the safety manometric box (BMS) to

the outlet pipe keeping a minimum distance

of 4 x D to a straight run of the pipe.

In the case of functioning class B for the

slam shut it is necessary to regularly check

the safety manometric box (BMS) diaphragm.

Connect the reject tab to the outlet pipe.

It is recommended to separate the slam-shut

impulse from that of the actuator. Do not

connect impulses on the lower generator line.

It is recommended to install and isolation

tap and a vent tap. These can be useful for

slam-shut settings and verications.

Check that the pilot impulse is connected

and in the case of an isolating tap (not

recommended) that it is open.

No modification should be made to the

structure of the equipment (drilling,

grinding, soldering...).

It is recommended to install a servicing valve

on the outlet pipeline to facilitate adjustments

and bleeding off to the atmosphere.

In the version with integral slam shut, verify

that the safety manometric box (BMS)

and spring correspond to the appropriate

operating conditions on the outlet side of

the regulator.

All Installations (Single Regulator or

Monitor Systems)

A Type EZH or EZHSO regulator bleeds no gas to

atmosphere during normal operation, thus making the

regulator suitable for installation in pits and other enclosed

locations without elaborate venting systems.

This regulator can also be installed in pits subject to

ooding by venting the pilot spring case above the expected

ood level so that the pilot setting can be referenced to

atmospheric pressure.

1. Install the regulator so that the ow arrow on the main

valve matches the ow direction of process uid through

the regulator.

2. Apply pipe compound to the male pipeline threads

before installing a regulator with threaded NPT end

connections. Use gaskets between pipeline and

regulator anges when installing a regulator with

anged end connections. When installing buttweld end

connections, remove trim before welding and make

sure to use approved welding practices. Use approved

piping procedures when installing the regulator.

3. Type PRX pilots have a 1/4-inch NPT vent connection

in the spring case. To remotely vent gas from the

spring case, remove the screened vent, and connect

1/4-inch piping or tubing to the spring case connection.

The piping or tubing should vent to a safe location,

have as few elbows as possible, and have a screened

vent on it’s exhaust. Install the regulator and any

remote vent piping or tubing so that the vent is

protected from condensation, freezing, or substances

that my clog it.

The equipment should not receive any type

of shock, especially the release relay.

The user should verify or carry out a

protection adapted to the environment.

For DN 25 to 80, use long screws or threaded

stems when opening the actuator (warning

compressed spring).

The action of re, seismic and lightening

are not taken into consideration in standard

regulators. If required, a special product

selection and/or specic calculations may be

supplied according to specic requirements.

A regulator may vent some gas to the

atmosphere. In hazardous or ammable gas

service, vented gas may accumulate, causing

personal injury, death, or property damage

due to bursting of pressure-retaining parts.

Vent a regulator in hazardous gas service to

a remote, safe location away from air intakes

or any hazardous location. The vent line or

stack opening must be protected against

condensation or clogging.

CAUTION

To avoid freeze up due to pressure drop

and moisture in the gas, use anti-freeze

practices, such as heating the supply

gas or adding a de-icing agent to the

supply gas.

4. Connect the actuator to the downstream sense

line on a straight run of outlet pipe 8/10 (inside

diameter). Connect the other end of that impulse to

the Type PRX port.

5. Connect the PRX pilot port to the outlet pipeline at

a minimum distance of 4 x D from the regulator’s

outlet ange.

6. For Type EZHSO installation, a vent valve downstream

of the regulator is needed. It should be installed

directly in the Type PRX pilot bleed line connection

(line from port "S" to pipe). A full bore NPS 1/4

ball valve for the vent line is preferred to provide

sufcient ow.

14

Page 15

Africa

Types EZH and EZHSO

Wide-Open Monitor Regulator

1. Follow the procedures in the All Installations section,

and then continue with step 2 of this section. The

sense and bleed control lines of both the upstream and

downstream pilots will be connected to the downstream

piping (see Figure 13).

2. Connect the pilot supply line for the downstream

regulator to the outlet "R" port of the Type SA/2 pilot

supply lter regulator.

Working Monitor Regulator

1. Follow the procedure in the All Installations section, and

then continue with step 2 of this section. The sense line

of the upstream monitor pilot and the bleed and sense

lines of the downstream pilot will be connected to the

downstream piping (see Figure 14).

2. Connect an inlet supply line from the upstream piping

to the inlet "M" port of the downstream Type SA/2 pilot

supply lter regulator.

3. Connect a control (sense) line from the "A" port of the

upstream working Type PRX pilot to the intermediate

pressure portion of piping, using 8/10 (inside diameter) tube.

4. Connect a downstream bleed line from the "S"

port of the upstream working Type PRX pilot to the

intermediate pressure portion of piping, using 8/10

(inside diameter) tube.

ST ARTUP AND ADJUSTMENT

Pre-startup Considerations

Each regulator is factory-set for the outlet pressure specied

on the order. If no setting was specied, outlet pressure

was factory-set at the mid-range of the pilot control spring.

Before beginning the start-up procedure in this section make

sure the following conditions are in effect:

• Block valves isolate the regulator

• Vent vales are closed

• A bypass, if any, is in operation.

In all cases, check the control spring setting to make sure it

is correct for the application.

TYPE EZH OS2 SLAM-SHUT VERSION

In the case of opening the mechanism box lid:

1.

After arming, never leave the key on the stem

2. Never put your ngers in or near the

reset mechanism area

Note

When using a Type SA/2 pilot supply lter

regulator, the differential pressure across the

regulator must be at least 3 bar for optimum

regulator performance. The Type SA/2 can

be removed if differential pressure across the

regulator is less than 3 bar and inlet pressure

stays at or below 13.8 bar.

Startup

Type EZH Startup:

1. Make sure all block valves, vent valves, and control line

valve(s) are closed.

2. Back out the pilot adjusting screw(s).

3. Slowly open the valves in the following order:

- Inlet block valves.

- Pilot supply and control line valve(s), if used.

4. Crack open the outlet block valve or bypass valve to

allow minimum ow.

5. After adjusting the Type PRX pilot(s) to the desired

pressure setting(s), slowly open the downstream block

valve wide open.

6. Close the bypass valve, if used.

Type EZHSO Startup:

1. Make sure all block valves, except valve R4, vent

valves, and control line valve(s) are closed.

2. Back out the pilot adjusting screw(s).

3. Introduce upstream pressure by slowly opening inlet valve.

4. Slowly open valve R2.

CAUTION

Be sure to slowly introduce pressure into the

system to prevent downstream overpressure

due to potential rapid pressure increase.

Pressure gauges should always be used to

monitor downstream pressure during startup.

Procedures used in putting this regulator

into operation must be planned accordingly

if the downstream system is pressurized by

another regulator or by a manual bypass.

5. Open valve R3.

6. Close valve R4, the regulator Type EZHSO close.

7. Open valve R4.

8. Close valve R3.

9. Slowly open downstream valve, making sure that

there is a constant sufcient pressure drop across the

regulator. If downstream pressure climbs too close to

upstream pressure, the regulator will again fully open.

In this case, start-up procedure needs to be repeated.

15

Page 16

Africa

Types EZH and EZHSO

For a single regulator, set the pilot to the desired outlet

(control) pressure according to the Pilot Adjustment procedure.

For a wide-open downstream monitor installation, adjust

the upstream working pilot until intermediate pressure is

higher than the desired setpoint of the monitor pilot. Adjust

the downstream monitoring pilot to the desired monitoring

takeover pressure. Reduce the upstream pilot to the normal

outlet pressure setting.

For a wide-open upstream monitor installation, adjust

the downstream working pilot to a setpoint higher than

the setpoint of the monitor pilot. Adjust the upstream

monitoring pilot to the desired monitoring takeover

pressure. Reduce the downstream pilot to the normal

outlet pressure setting.

For a working monitor installation, adjust the setpoint

of the upstream monitor pilot to the desired maximum

pressure. Adjust the upstream working pilot to the desired

intermediate pressure setting. Adjust the downstream

pilot to a pressure setting slightly above the upstream

monitor pilot pressure setting. Adjust the upstream

monitor pilot to its desired setpoint. Establish nal desired

downstream pressure by adjusting the downstream working

regulator pilot.

10. After adjusting the Type PRX pilot(s) to the desired

pressure setting(s), slowly open the downstream block

valve wide open.

11. Close the bypass valve, if used.

Type OS2 Manometric Box Set Point

Verication Procedure

Using the vent valve supply a pressure equal to the set

pressure foreseen for the regulator.

st

- 1

release relay stage

à Set (Stage 1)

- Slam-shut valve plug

Type PRX Pilot Adjustment

To adjust a standard Type PRX pilot, loosen the locknut, and

turn the adjusting screw.

Turning the adjusting screw clockwise into the spring case

increases the spring compression and pressure setting.

Turning the adjusting screw counter clockwise decreases the

spring compression and pressure setting

When the required pressure setting is maintained for several

minutes, tighten the locknut to lock the adjusting screw

in position.

Type PRX Pilot Restrictor and Damper

Screw Adjustment

Note

Recommended initial setting of the restrictor

screw is turned completely in (clockwise)

and then turned out 1/2 turn. The damper

screw initial setting is turned completely out

(counter clockwise).

The Type PRX/125 (upstream monitor pilot in

working monitor installations) does not have

a restrictor screw.

The restrictor screw of the Type PRX pilot can be used if there

is hunting of the set pressure. Slowly turning out the restrictor

screw (counterclockwise) will help steady the set pressure.

Turning out the restrictor screw will slightly decrease set

pressure, so adjustment of the pilot adjusting screw may

be necessary.

The damper screw can be turned in (clockwise) to slow the

response of the regulator. It is advisable that adjustment of

the damper and restrictor screws be limited to 1/4 turn at a

time to observe the response of the regulator(s).

TRIGGERED POSITION

16

à Open (Stages 2 and 3)

à Progressively increase the pressure until tripping occurs

à Adjust setting if necessary (NTAOS2). Note the

set point value on the equipment or mark it on a

commissioning document

R121

STAGE 1

Figure 15. Setpoint Verication Phase

STAGES 2 AND 3

SHUTDOWN

CAUTION

If the pilot bleed control line pressure is shut

down rst, the downstream system may be

subjected to full inlet pressure (Pu).

1. If the pilot setting must be disturbed, be sure to keep

some tension on the spring. This will prevent trapping

inlet pressure during blow down.

2. Slowly close the valves in the following order:

- Inlet block valve,

- Outlet block valve,

- Control line valve(s), if used.

3. Open the vent valves to depressurize the system.

Page 17

Africa

Types EZH and EZHSO

MAINTENANCE

For both Types EZH and EZHSO DN 100, never remove or

disconnect the check valve installed between the two casings.

The regulator parts are subject to normal wear and must be

inspected periodically and replaced as necessary.

The frequency of inspection and replacement depends on

the severity of service conditions and on applicable codes

and regulations.

Use silicone grease for O-rings and diaphragm, molybdenum

graphite grease for spring and mechanical parts.

WARNING

!

To avoid personal injury or property

damage from sudden release of pressure,

isolate the regulator from the pressure

system, and release all pressure from the

pilot and main valve before performing

maintenance operations.

CAUTION

Use proper lifting techniques, when lifting

the upper and lower actuator casings

(keys 11 and 5, Figure 16) off the body

(key 1, Figure 16).

The actuator assembly weighs more than 45 kg.

Main Valve and Actuator Maintenance

Disk Maintenance DN 25, 50, and 80

(Figure 16)

Type EZH Disk Maintenance

1. Remove screws (key 24).

2. Carefully lift the upper actuator casing and lower

actuator casing assembly (keys 11 and 5) off the body

(key 1).

3. Remove the hex socket cap screws (key 33) and spring

lock washers (key 32). Lift off the disk holder assembly

(key 30) and disk retainer (key 31).

6. Set the seat ring (key 2) back in the body (key 1) with

the curved side down and the seat edge up. To check

O-ring (key 7), skip to the Intermediate Flange O-ring

Maintenance section. Place the cage (key 3) on top of

seat ring. The cage will engage the step on the seat ring.

7. Place the disk holder assembly (key 30) and disk

retainer (key 31) on the sleeve adaptor (key 27).

8. Insert the spring lock washers (key 32) and hex

socket cap screws (key 33) and tighten. See Torque

Specication table for proper torque.

9. Carefully lift the upper actuator casing and lower

actuator casing assembly (keys 11 and 5) and place on

the body (key 1). Secure the screws (key 24).

See Torque Specication table for proper torque.

Type EZHSO Disk Maintenance

1. Remove screws (key 24).

2. Carefully lift the upper actuator casing and lower

actuator casing assembly (keys 11 and 5) off the body

(key 1).

3. Remove the hex socket cap screw (key 154). Lift off the

disk holder assembly (key 30).

4. Remove the O-ring (key 29). Inspect the O-ring for

damage or wear, and replace if necessary. Lightly

lubricate O-ring before placing in the sleeve adaptor

(key 27).

5. Remove the cage (key 3), seat ring (key 2) and O-ring

(key 34). Inspect the O-ring for damage or wear, and

replace if necessary. Lightly lubricate O-ring before

placing in the body (key 1). Do not attempt to remove

the sleeve adaptor.

6. Set the seat ring (key 2) back in the body (key 1) with

the curved side down and the seat edge up. To check

O-ring (key 7), skip to the Intermediate Flange O-ring

Maintenance section. Place the cage (key 3) on top of

seat ring. The cage will engage the step on the seat ring.

7. Place the disk holder assembly (key 30) on the sleeve

adaptor (key 27).

8. Insert the hex socket cap screw (key 154) and tighten.

See Torque Specication table for proper torque.

9. Carefully lift the upper actuator casing and lower

actuator casing assembly (keys 11 and 5) and place on

the body (key 1). Secure the screws (key 24).

See Torque Specication table for proper torque.

4. Remove the O-ring (key 29). Inspect the O-ring for

damage or wear, and replace if necessary. Lightly

lubricate O-ring before placing in the sleeve adaptor

(key 27).

5. Remove the cage (key 3), seat ring (key 2) and O-ring

(key 34). Inspect the O-ring for damage or wear, and

replace if necessary. Lightly lubricate O-ring before

placing in the body (key 1).

Disk Maintenance Type EZH DN 100

(Figure 17)

1. Remove screws (key 77).

2. Carefully lift the cap (key 70) off the upper casing

(key 11) and unscrew the eye bolts (key 35) from the

cap (key 70).

17

Page 18

Africa

Types EZH and EZHSO

3. Remove the O-ring (key 75). Inspect for damage or

wear, and replace if necessary.

4. Remove the O-ring (key 69). Inspect for damage or

wear, and replace if necessary. Lightly lubricate O-ring

before placing inside cap (key 70).

5. Remove smart screws (key 68) from sleeve.

6. Fit eye bolt (key 35) into ring nut (key 73) threaded hole.

7. Carefully remove the trim system from the sleeve guide

utilizing the eye bolt (key 35).

8. Remove the hex socket cap screws (key 33) and lock

washers (key 32).

9. Lift off the disk retainer (key 31) and disk assembly

(key 30). Inspect for damage or wear, and replace

if necessary.

10. Remove the O-ring (key 29). Inspect the O-ring for

damage or wear, and replace if necessary.

11. Place disk assembly (key 30) onto disk retainer (key 31).

12. Place disk retainer assembly into sleeve adapter

(key 27) and align screw holes.

13. Place lock washer (key 32) on screws (key 33).

14. Screw together the disk retainer assembly into the

sleeve adapter assembly. See Torque Specication

table for proper torque.

15. Lubricate the sleeve (key 14).

16. Carefully insert the trim system into the sleeve guide

(key 61) utilizing eye bolt (key 35). Align sleeve utilizing

the socket head cap screw (key 74) as a guide.

17. Screw smart screws (key 68) to afx the sleeve system.

See Torque Specication table for proper torque.

18. Remove eye bolt (key 35) from ring nut (key 73)

threaded hole.

19. Carefully place the cap on the upper casing (key 11).

20. Lubricate cap screws (key 77) and attach cap (key 70)

to the upper casing using cap screws (key 77).

See Torque Specication table for proper torque.

Note

Disk Maintenance Type EZHSO DN 100

(Figure 19)

1. Remove cap screws (key 77).

2. Carefully lift the cap (key 70) off of the upper casing

(key 11).

3. Remove O-ring (key 75). Inspect the O-ring for damage

or wear, and replace if necessary.

4. Remove O-ring (key 69). Inspect the O-ring for damage

or wear, and replace if necessary. Lubricate O-ring

before placing inside cap.

5. Remove special screws (key 68) from sleeve.

6. Carefully remove the trim system from the sleeve guide

utilizing the eye bolt (key 35) or stem nut.

7. Remove socket head cap screws (key 154).

8. Lift off the disk holder assembly (key 30).

9. Remove the O-ring (key 29). Inspect the O-ring for

damage or wear, and replace if necessary. Lightly

lubricate O-ring before placing in the sleeve adaptor

(key 27).

10. Place disk holder assembly (key 30) into sleeve adaptor

(key 27) and align screw holes.

11. Place on screws (key 154). Screw together the disk

holder assembly into the sleeve adaptor assembly.

See Torque Specication table for proper torque.

12. Lubricate the sleeve (key 14).

13. Carefully insert the trim system into the sleeve guide

(key 61). Align sleeve utilizing the socket hex cap screw

(key 74) as a guide.

14. Screw smart screws (key 68) to afx the sleeve system.

See Torque Specication table for proper torque.

15. Place O-ring (key 69) on the cap (key 70).

16. Carefully place the cap on the upper actuator casing

(key 11).

17. Lubricate cap screws (key 77) and attach cap (key 70)

to the upper casing using cap screws (key 77).

See Torque Specication table for proper torque.

Rotate the cap such that the outer holes for

sensing lines are in line with upper casing

holes for sensing lines: to validate the

alignment and before attaching cap, check

that travel indicator is aligned on the cap and

on the upper casing.

21. Mount O-ring (key 75) on the cap.

22. Screw the eye bolts (key 35) on the cap (key 70).

18

Note

Rotate the cap such that the outer holes for

sensing lines are in line with upper casing

holes for sensing lines: to validate the

alignment and before attaching cap, check

that travel indicator is aligned on the cap and

on the upper casing.

18. Mount O-ring (key 75) on the cap.

Page 19

Africa

Types EZH and EZHSO

Intermediate Flange O-ring Maintenance for

Types EZH and EZHSO (DN 25, 50, and 80)

1. Remove screws (key 24).

2. Carefully lift the upper and lower actuator casing

assembly (keys 11 and 5) off the body (key 1).

3. Remove cap screws (key 6).

4. Lift off intermediate ange (key 25).

5. Remove O-ring (key 7). Inspect the O-ring for damage

or wear, and replace if necessary. Lightly lubricate

O-ring before placing in the body (key 1).

6. Place the intermediate ange (key 25) on the body, make

sure to position the screws (key 24) holes on the outside

of the body (key 1). Secure with cap screws (key 6).

See Torque Specication table for proper torque.

7. Continue with "Disk Maintenance" section, step 7.

Actuator Assembly Maintenance

DN 25, 50, and 80

Type EZH Actuator Maintenance

1. Make a mark on the upper actuator casing (key 11)

lower actuator casing (key 5), intermediate ange

(key 25) and body (key 1) to indicate proper alignment.

2. Remove travel indicator assembly (keys 138, 139, 140,

141, 142, 143, 144, 145, and 192), by loosening the

travel indicator tting (key 141) and lifting out the travel

indicator assembly.

3. Replace the two opposite bolts (keys 21, 22, and 23) with

the two threaded stems and nuts delivered with the unit.

CAUTION

Secure the removal of the casings (keys 11 and

5) by nishing with these two threaded stems.

4. Remove screws, washers and hex nuts (keys 21, 22,

and 23). Remove all the screws rst, then the two

threaded stems and bracket. Take care to balance the

upper actuator casing while removing the spring tension.

Carefully lift the upper actuator casing (key 11) off the

lower actuator casing (key 5).

5. Remove spring (key 13).

6. Remove screws (key 16). Lift off diaphragm (key 20)

and the inlet plate (key 18). Remove O-rings (keys 15

and 17). Inspect the diaphragm and O-rings for damage

or wear, and replace if necessary.

O-ring and split rings. Place the split rings in the body

rst, then slide the O-ring between the split rings.

8. Remove screws (key 24). Lift off the lower actuator

casing (key 5). Remove screws (key 33) and spring

lock washers (key 32). Lift off the disk holder assembly

(key 30) and disk retainer (key 31).

9. Slide the sleeve (key 14) out of the lower actuator

casing (key 5) and slide the outlet plate (key 19) off the

sleeve. Check the sleeve for scratches, burrs, or other

damage and replace if necessary.

10. Remove the sleeve adaptor (key 27) from the sleeve

(key 14). Take care not to damage the sleeve while

removing the sleeve adaptor. Check the O-ring (key 28)

for damage, and replace if necessary.

11. Place the sleeve adaptor on the sleeve and tighten.

12. Inspect the lower actuator casing (key 5), O-ring (key 9),

anti-friction split rings (key 8), and anti-friction ring

(key 4) for damage or wear. If damaged, remove the

O-ring and split rings; replace with new parts. Lightly

lubricate the O-ring and split rings. Place the split rings

in the body rst, then slide the O-ring between the

split rings.

13. Slide the outlet plate (key 19) onto the sleeve (key 14)

and slide the sleeve into the lower actuator casing

(key 5). Place the disk holder (key 30) and disk retainer

(key 31) on the sleeve adaptor (key 27). Insert the spring

lock washers (key 32) and screws (key 33) and tighten.

See Torque Specication table for proper torque.

14. Lightly lubricate the O-rings (keys 15 and 17) and the

inner and outer diaphragm (key 20) edges. Place the

inlet plate (key 18) and the diaphragm (key 20) on the

sleeve (key 14). Make sure O-rings (key 15 and 17) are

correctly positioned. Insert and tighten the hex socket

cap screws (key 16). See Torque Specication table for

proper torque.

15. Carefully lift the lower actuator casing assembly (key 5)

and place on the body (key 1). Take care to match up

the alignment marks. Secure with screws (key 24).

See Torque Specication table for proper torque.

16. Lightly lubricate the spring (key 13) and place on the

inlet plate (key 18).

17. Carefully place the upper actuator casing (key 11)

on the lower actuator casing (key 5). Take care to

match up the alignment marks. Insert the two threaded

stems 180° apart and away from anges. Place the

washers and hex nuts (keys 22 and 23) and brackets

on the long cap screws and evenly tighten. Install

remaining small cap screws (key 21), washers, and

hex nuts. Replace the two threaded stems by two bolts

(keys 21, 22, and 23). See Torque Specication table

for proper torque.

7. Inspect the upper actuator casing (key 11), O-ring (key 9),

anti-friction split rings (key 8), and anti-friction ring (key 4)

for damage or wear. If damaged, remove the O-rings and

split rings; replace with new parts. Lightly lubricate the

18. Place the travel indicator assembly (keys, 138, 139,

140, 141, 142, 143, 144, 145, and 192) in the upper

actuator casing (key 11) by hitting the tip of the stem

(key 139) to clip the tting (key 144) into the plate

(key 18) and tighten the travel indicator tting (key 141).

19

Page 20

Africa

Types EZH and EZHSO

Type EZHSO Actuator Maintenance

1. Make a mark on the upper actuator casing (key 11),

lower actuator casing (key 5), intermediate ange

(key 25), and body (key 1) to indicate proper alignment.

2. Remove travel indicator assembly (keys 138, 139,

140, 141, 142, 143, 144, 145, and 192), if present, by

loosening the travel indicator tting (key 141) and lifting

out the travel indicator assembly.

3. Remove protective cap (key 146). Loosen and remove

hex nuts (key 151).

4. Remove cap screws (key 21), washers (key 22), and

hex nuts (key 23). Remove protective cap (key 146)

and remove hex nuts (key 151). Carefully lift the upper

actuator casing (key 11) off the lower actuator casing

(key 5).

5. Remove the socket head cap screws (key 16). Lift off

the diaphragm (key 20) and the inlet plate (key 18).

Remove O-rings (keys 15 and 17). Inspect the

diaphragm and O-rings for damage or wear, and

replace if necessary.

6. Inspect the upper actuator casing (key 11), O-ring

(key 9), anti-friction split rings (key 8), and anti-friction

ring (key 4) for damage or wear. If damaged, remove

the O-ring and split rings, and replace with new parts.

Lightly lubricate the O-ring and split rings. Place the

split rings in the body rst, then slide the O-ring between

the split rings.

7. Remove screws (key 24). Lift off the lower actuator

casing (key 5). Remove the hex socket cap screw

(key 154). Lift off the disk holder assembly (key 30).

8. Slide the sleeve (key 14) out of the lower actuator

casing (key 5) and slide the outlet plate (key 19) off of

the sleeve. Check the sleeve for scratches, burrs, or

other damage, and replace if necessary.

9. Inspect the lower actuator casing (key 5), O-ring

(key 9), anti-friction split rings (key 8), and anti-friction

ring (key 4) for damage or wear. If damaged, remove

the O-ring and split rings, and replace with new parts.

Lightly lubricate the O-ring and split rings. Place the

split rings in the body rst, then slide the O-ring between

the split rings.

10. Slide the outlet plate (key 19) onto the sleeve

(key 14) and slide the sleeve into the lower actuator

casing (key 5). Place the disk holder assembly

(key 30) on the sleeve adaptor (key 27). Insert the hex

socket cap screw (key 154) and tighten. See Torque

Specication able for proper torque.

11. Lightly lubricate the O-rings (keys 15 and 17) and the

inner and outer diaphragm (key 20) edges. Place the

inlet plate (key 18) and the diaphragm (key 20) on the

sleeve (key 14). Make sure O-rings (keys 15 and 17)

are correctly positioned. Insert and tighten the hex

socket cap screws (key 16). See Torque Specication

table for proper torque.

12. Carefully lift the lower actuator casing assembly (key 5)

and place on the body (key 1). Make sure to match up

the alignment marks. Secure with screws (key 24).

See Torque Specication table for proper torque.

13. Carefully place the upper actuator casing (key 11) on

the lower actuator casing (key 5). Make sure to match

up the alignment marks. Insert the two long bolts 180°

apart and away from anges. Place the washers

(key 22), hex nuts (key 23), and brackets (key 35) on

the long bolts and evenly tighten. Using proper bolting

techniques, install remaining short cap screws (key 21),

washers, and hex nuts. See Torque Specication table

for proper torque.

14. Tighten hex nuts (key 151), install protective cap

(key 146).

15. Place travel indicator assembly (keys 138, 139, 140,

141, 142, 143, 144, 145, and 192) in the upper actuator

casing (key 11), if present, and tighten the travel

indicator tting (key 141).

Type EZH DN 100 Actuator Assembly

Maintenance (Figure 17)

1. Remove travel indicator assembly (keys 71, 138, 139,

140, 141, 142, 143, 144, 145, and 192), if present, by

loosening the travel indicator tting (key 141) and lifting

out the travel indicator assembly.

2. Remove hex head cap screws (key 21), washers

(key 22), and hex nuts (key 23). Carefully lift the

upper actuator casing (key 11) off the lower actuator

casing (key 5). Inspect the upper actuator casing

(key 11), O-rings (key 9) and anti-friction rings

(key 8) for damage or wear. If damaged, remove and

replace with new parts. Place the anti-friction rings

in the body rst, then slide the O-ring between the

anti-friction rings.

3. Lift off the diaphragm/plates system. Remove O-ring

(key 15). Inspect diaphragm and O-rings for damage or

wear, and replace if necessary.

4. Remove sleeve guide (key 61) utilizing cap (key 70)

to unscrew.

5. Remove cage (key 78).

6. Remove seat ring (key 2). Inspect seat ring for damage

or wear. If damaged, replace with new parts.

7. Remove O-ring (key 34) from body. Inspect for damage

or wear. If damaged, replace with new parts.

20

Page 21

Africa

Types EZH and EZHSO

8. Lubricate O-ring (key 34) and replace into the body.

9. Place seat ring (key 2) on top of O-ring in body.

10. Place cage (key 78) on the top of seat ring (key 2).

11. Screw sleeve guide into lower casing (key 5) utilizing

cap (key 70).

12. Lubricate the sleeve (key 14) in the upper plate contact

area and assemble the diaphragm/plates system on the

sleeve system.

13. Screw the smart screws (key 68) — already on the

sleeve — to x the diaphragm/plates system on the

sleeve system. See Torque Specication table for

proper torque.

14. Lubricate lower casing (key 5) on the diaphragm

contact area.

15. Carefully insert the trim system into the sleeve guide

(already assembled on the body) utilizing the eye-bolt

(key 35) that ts in the ring nut (key 73) threaded hole.

16. Lubricate the diaphragm (key 20) on the upper casing

contact area.

17. Carefully place the top actuator casing on the top of the

lower actuator casing/trim system using a stud to guide.

Note

Rotate the upper casing such that the outer

holes for sensing lines are perpendicular to

gas ow.

18. Lubricate threads on bolts (key 21).

Type EZHSO DN 100 Actuator Assembly

Maintenance (Figure 19)

1. Remove closing cap (key 146), unscrew 2 nuts

(key 151). If present, remove travel indicator assembly

by unscrewing the travel indicator tting (key 141), then

pull out the stem (key 139).

2. Remove hex head cap screws (key 21), washers

(key 22), and hex nuts (key 23). Carefully lift the

upper actuator casing (key 11) off the lower actuator

casing (key 5). Inspect the upper actuator casing

(key 11), O-rings (key 158) and anti-friction rings

(key 157) for damage or wear. If damaged, remove

and replace with new parts. Place the anti-friction rings

in the cap rst, then slide the O-ring between the

anti-friction rings.

3. Unscrew 8 smart screws (key 68). Lift up and remove

the sleeve assembly (key 14). Lift off the diaphragm/

plates system. Remove O-ring (key 15) and replace

as needed. Inspect diaphragm (key 20) for damage

or wear, remove screws (key 16), lift off inlet plate

(key 18) to replace diaphragm and O-ring (key 17)

if necessary.

4. Unscrew 8 screws (key 77) to remove cap (key 70) from

the upper casing (key 5). Align screw holes on the cap

(key 70) to the sleeve guide screw (key 66). Remove

sleeve guide (key 61) utilizing cap (key 70) to unscrew.

Inspect O-rings (key 8), (key 64) and (key 153) for

damage or wear, replace anti-friction ring (key 9) and

O-ring (key 8) if necessary. Unscrew 8 bolts (key 6) and

remove washer (key 67). Lift off lower casing (key 5).

Inspect O-rings (key 7) and (key 63) for damage or

wear, replace them if necessary.

19. Bolt together the upper and lower actuator casings using

bolts (key 21), washers (key 22), and nuts (key 23).

See Torque Specication table for proper torque.

20. Lubricate and mount the O-ring (key 69) on the cap

(key 70).

21. Lubricate and mount O-rings (key 9) and anti-friction

rings (key 8) inside the cap (key 70).

22. Carefully place the cap on the upper casing (key 11).

23. Lubricate cap screws (key 77) and attach cap (key 70)

to the upper casing using cap screws (key 77). See

Torque Specication table for proper torque.

24. Mount O-ring (key 75) on the cap (key 70).

25. Screw the eye-bolts (key 35) on the cap (key 70).

26. Place travel indicator assembly (keys 138, 139, 140,

141, 142, 143, 144, 145, and 192) in the upper actuator

casing (key 11), if present, and tighten the travel

indicator tting (key 141).

5. Remove cage (key 78).

6. Remove seat ring (key 2). Inspect seat ring for damage

or wear. If damaged, replace with new parts.

7. Remove O-ring (key 34) from body. Inspect for damage

or wear. If damaged, replace with new parts.

8. Lubricate O-ring (key 34) and replace into the body.

9. Place seat ring (key 2) on top of O-ring in body.

10. Place cage (key 78) on the top of seat ring (key 2).

11. Place lower casing (key 5) on top of body. Replace

washer (key 67) and tighten bolts (key 6). Screw

sleeve guide into lower casing (key 5) utilizing cap

(key 70).

12. Lubricate the sleeve (key 14) in the upper plate contact

area and assemble the diaphragm/plates system on the

sleeve system. Tighten screws (key 16) using a "star"

criss-cross pattern for ve times until proper specied

torque is achieved.

21

Page 22

Africa

Types EZH and EZHSO

13. Screw the smart screws (key 68) — already on the

sleeve — to x the diaphragm/plates system on

the sleeve system. See Torque Specication table

for proper torque. Tighten screws (key 68) using a

"star" criss-cross pattern until proper specied torque

is achieved.

14. Lubricate lower casing (key 5) on the diaphragm

contact area.

15. Carefully insert the trim system into the sleeve guide

(key 61).

16. Lubricate the diaphragm (key 20) on the upper casing

contact area.

17. Lubricate and mount the O-ring (key 69) on the cap

(key 70). Lubricate and mount O-rings (key 9) and antifriction rings (key 8) inside the cap (key 70). Carefully

place the cap on the actuator upper casing (key 11).

Align the travel indicator hole on the cap (key 70) to the

upper casing travel indicator hole. Screw 8 screws

(key 77) to tighten cap (key 70) to the upper casing

(key 5). Carefully place the top actuator casing on the

top of the lower actuator casing/trim system using a stud

to guide.

Note

Rotate the upper casing such that the outer

holes for sensing lines are perpendicular to

gas ow.

18. Lubricate threads on bolts (key 21).

5. Remove mechanism box.

6. Unscrew screws (key 50) from the connecting part

(key 48).

7. Remove connecting part (key 48), O-rings (keys 56 and

49) and if necessary the two guide rings (rep. 54).

8. Remove spring (key 55) and valve plug (key 46).

9. Unscrew bypass (key 53) and remove valve O-ring.

10. Removing the seat (key 52) (not recommended) from

the body (key 47) requires a special extraction tool.

Type PRX Pilot Maintenance (Figure 23)

CAUTION

Always remove spring (key 7) tension before

performing maintenance on this unit.

To remove spring tension loosen locknut

(key 2) and backout adjusting screw

(key 1) until compression is removed from

the spring.

Lower Case Maintenance

1. Disconnect pilot and remove it from the line.

2. Remove screws (key 10) from lower cover (key 21) and

the separate lower cover from the body (key 16).

19. Bolt together the upper and lower actuator casings using

bolts (key 21), washers (key 22), and nuts (key 23).

See Torque Specication table for proper torque. Tighten

screws (key 16) using a "star" criss-cross pattern for

ve times until proper specied torque is achieved.

20. Assemble one nut (key 151) to the stem (key 147) until

achieve specied torque, and then assemble another nut

(key 151) to lock position of stem. Screw on the closing

cap (key 146). Mount O-ring (key 75) on the cap (key 70).

21. If present, set the stem (key 139) through the casing

hole and tap it into the groove in the diaphragm plate

(key 18). Slide the travel indicator tting (key 141) over

the stem and tighten to the cap (key 70).

Type EZH OS2 Regulator with Slam-shut

Maintenance (Figure 20)

1. Unscrew the BMS (safety manometric box) impulse

line connector.

2. Remove cover (key 57) from the mechanism box (BM).

3. Unscrew fastening screw (key 51).

4. Remove holding pin.

3. Use a wrench to hold the stem (key 23) and break

loose the stem nut (key 20). Remove the stem nut and

washer (key 11).

4. Remove the diaphragm plate (key 13), diaphragm

(key 14), pad holder (key 22) and O-ring (key 18).

Inspect parts for damage or wear, replace if necessary.

5. Remove orice (key 19) and O-ring (key 17). Inspect

the parts for damage or wear, and replace if necessary.

Lightly lubricate the O-ring and place in the body

(key 16). Install the orice.

6. Set the pad holder (key 22) in the body (key 16).

7. Lightly lubricate the rims of the diaphragm (key 14)

and place it on top of the pad holder (key 22). Set the