Page 1

Process Management

TM

PRESSURE REGULATORS

Europe, Middle East, and Africa Only

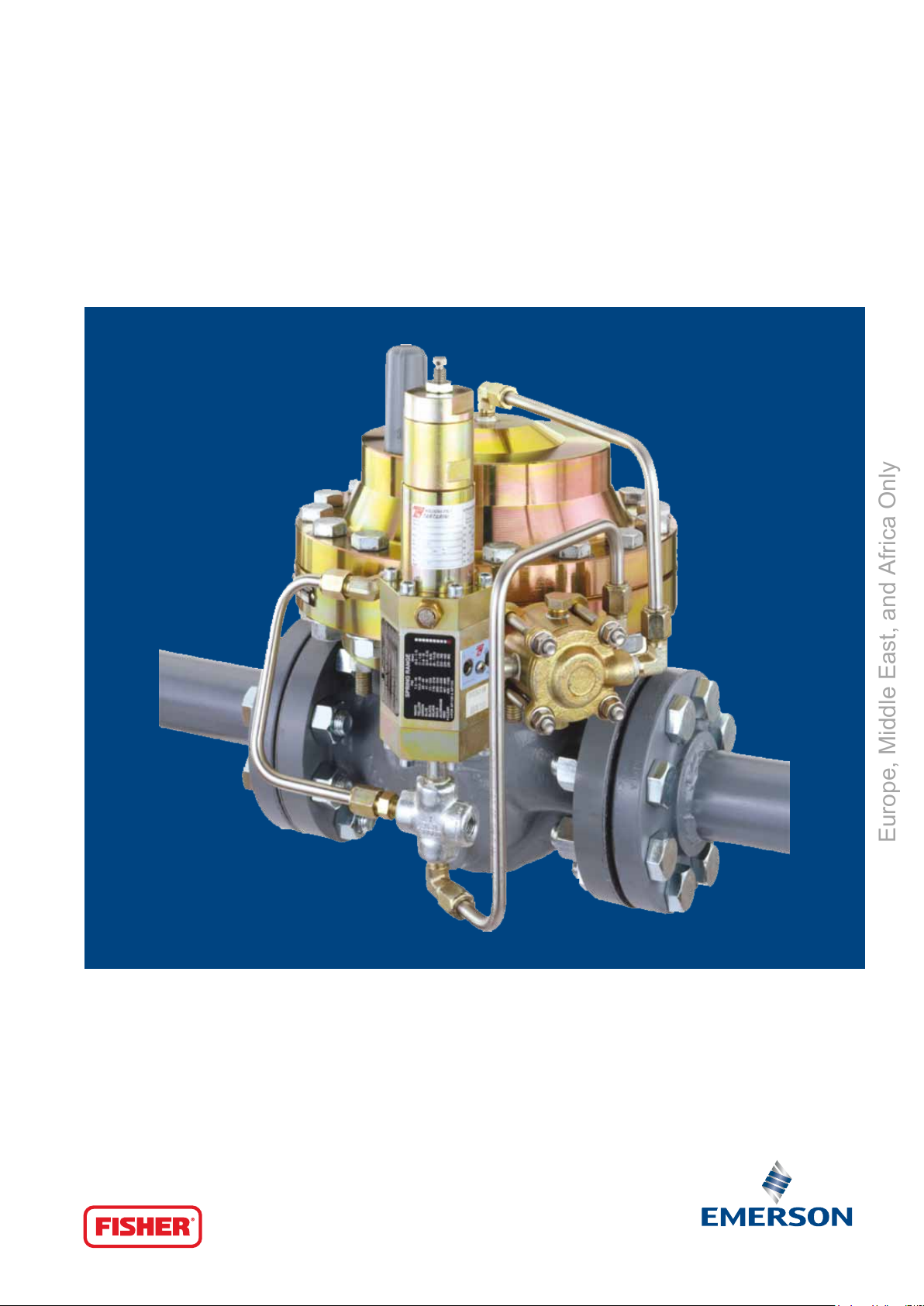

Type EZH and EZHSO

Page 2

EZH and EZHSO Regulators

Europe, Middle East, and Africa Only

Pressure Regulators

Type EZH and EZHSO (Spring-to-Open) regulators are accurate pilot-operated, pressure balanced, soft seated regulators.

They are designed for use in high pressure natural gas transmission/city gate stations, large capacity distribution systems, and

power plant feeds. They provide smooth, reliable operation, tight shutoff and long life.

The main benefits are as follows:

• Longlifeinsevereserviceapplications

• Highresistancetoaromaticsandparticleerosion

• Noiseattenuationmodule(optional)

• Highturndowncapacityforsystemswithlargevariationsindownstreamflowdemand

• Absolutelynobleedtoatmosphere

• Widerangeofflowcoefficientsforeachbodysize

• Bubbletightshutoff

• Accuratepressurecontrol

• Lowtemperaturestandardversion

• Integralstrength

• Easymaintenancesystem

• Spring-to-closeandspring-to-openversions

• Long life in severe service applications: The Type EZH

and EZHSO utilize a metal plug design to deect particles

and debris away from the soft-seat, which gives enhanced

resistance to particle erosion to provide a longer service life.

In addition, the Type EZH and EZHSO can be constructed with

uoroelastomer soft parts to extend service life in applications

where liquid aromatics are entrained in the gas.

• High turn down capability: The oversized diaphragm and

unique piloting system of the Type EZH and EZHSO allow for

a 100:1 turn down ratio, which will provide superior pressure

control in systems with large variations in downstream ow

demand.

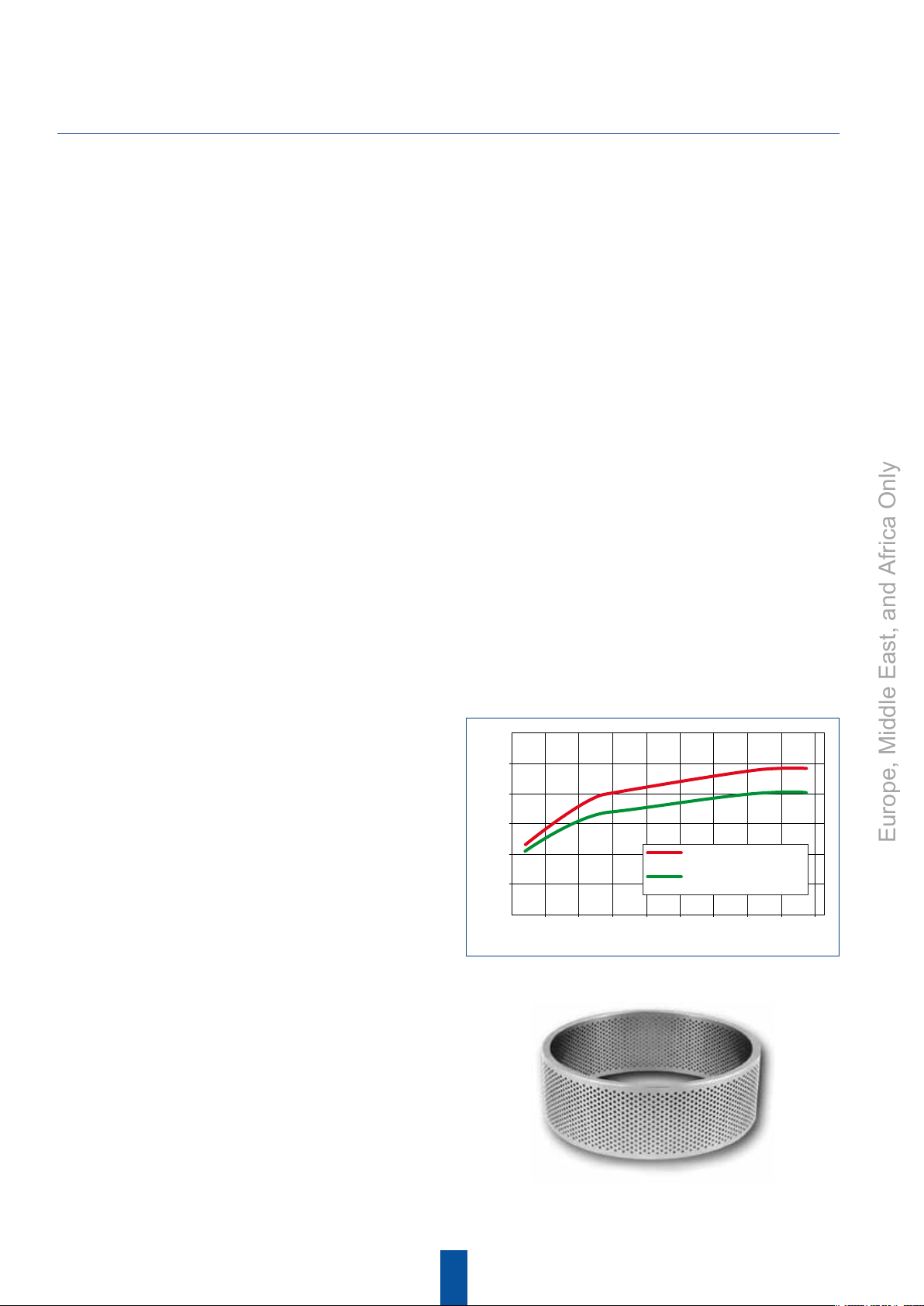

• Noise attenuation module: The EZH and EZHSO offer an optional

Whisper Trim Cage which is integral to the regulator therefore

maintaining the advantages of it's compact design. The Whisper

Trim Cage is available on DN 50, 80 and 100. It allows for a noise

attenuation up to 8 dB.

110

100

90

80

70

NOISE LEVEL (dBA)

60

50

9400

EZH AND EZHSO SERIES WITH

STANDARD CAGE

EZH AND EZHSO SERIES WITH

WHISPER TRIM® CAGE

18900 28400 37500 47100 56800 66200 75700 851000

FLOW RATE (Nm3/h)

Noise Comparison Diagram

• Absolutely no bleed to atmosphere: The Type EZH

and EZHSO eliminate nuisance and wasteful bleed gas to

atmosphere by utilizing a pilot-operated control system,

which bleeds 100% of the gas to the downstream system

while the regulator is operating.

• Wide range of flows coefficients for each body size:

EZH and EZHSO offer the possibility of ow reduction ranges

according to each body size. This is achieved by simply

replacing the standard seat by a reduction seat.

The

Whisper Trim Cage

2

Page 3

• Bubble tight shutoff: The Type EZH and EZHSO have a knife-

Europe, Middle East, and Africa Only

edged, metal plug and a soft seat which provides bubble

tight shutoff for use in applications where positive shutoff is

required. For example: dead-end systems.

• Accurate pressure control: The Type EZH and EZHSO use the

Type PRX and SA/2 pilot system to provide stable and accurate

downstream pressure control regardless of load changes or

inlet pressure variations.

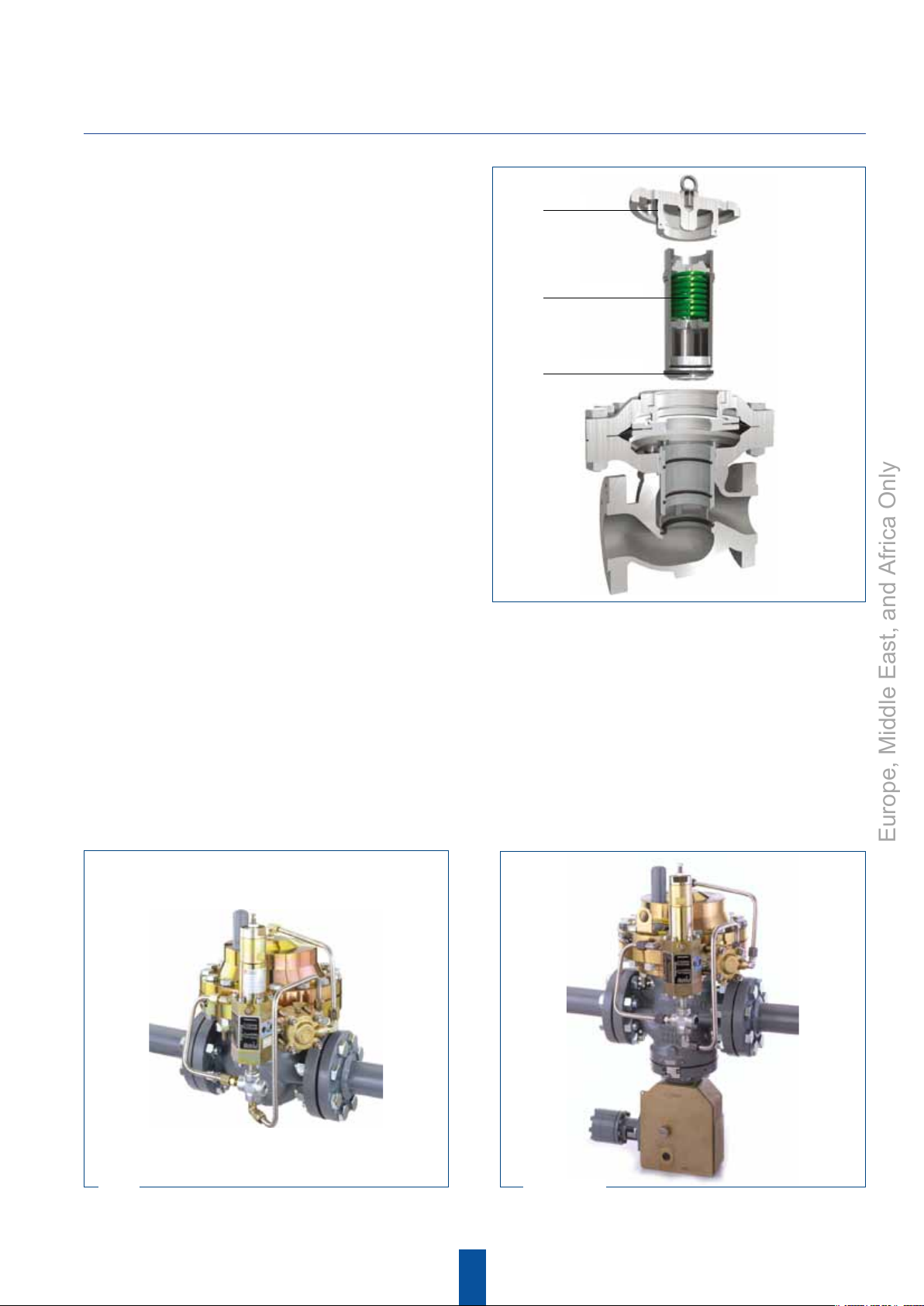

• Easy maintenance system: A top entry design reduces

maintenance time. Trim parts can be inspected, cleaned

and replaced without removing the body from the pipeline.

An innovative system has been designed for the EZH DN

100 which allows maintenance to be carried out by a single

operator. Maintenance is carried out by simply removing the

top plug, extracting the trim assembly (12.3 kg), removing

the pad holder and then changing the pad. Easy and fast

maintenance, no special tools requirement, makes the EZH

ownership low in cost.

• Spring-to-close and spring-to-open versions: Optional

positions to choose from in case of main valve diaphragm

failure or lack of supply pressure to the pilot. See table on

page 6 for "Failure Mode Analysis".

EZH and EZHSO Regulators

Plug

Trim assembly

Pad holder

EZH DN 100 Patent Pending Easy Maintenance System

Configurations

Type EZH: Pilot-operated pressure reducing regulator for low to high outlet pressure.

Type EZH-OS2: Type EZH pressure reducing regulator with an OS2 slam-shut device for overpressure or overpressure and

underpressure protection.

Type EZHSO: Spring-to-Open pilot-operated pressure reducing regulator for low to high outlet pressure.

Type EZHSO-OS2: Type EZHSO pressure reducing regulator with an OS2 slam-shut device for overpressure or overpressure and

underpressure protection.

EZH EZH-OS2

3

Page 4

EZH and EZHSO Regulators

Europe, Middle East, and Africa Only

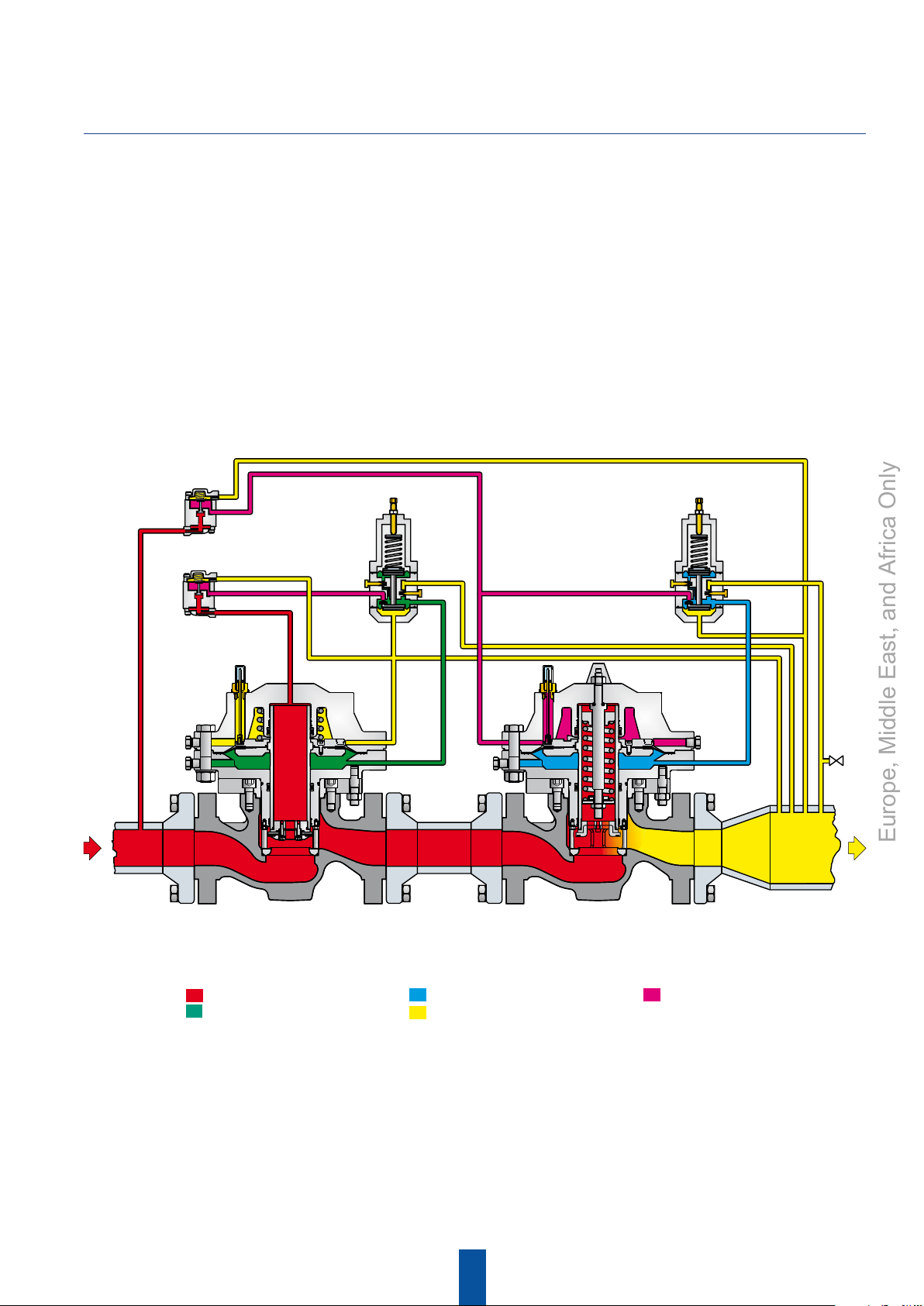

Operation

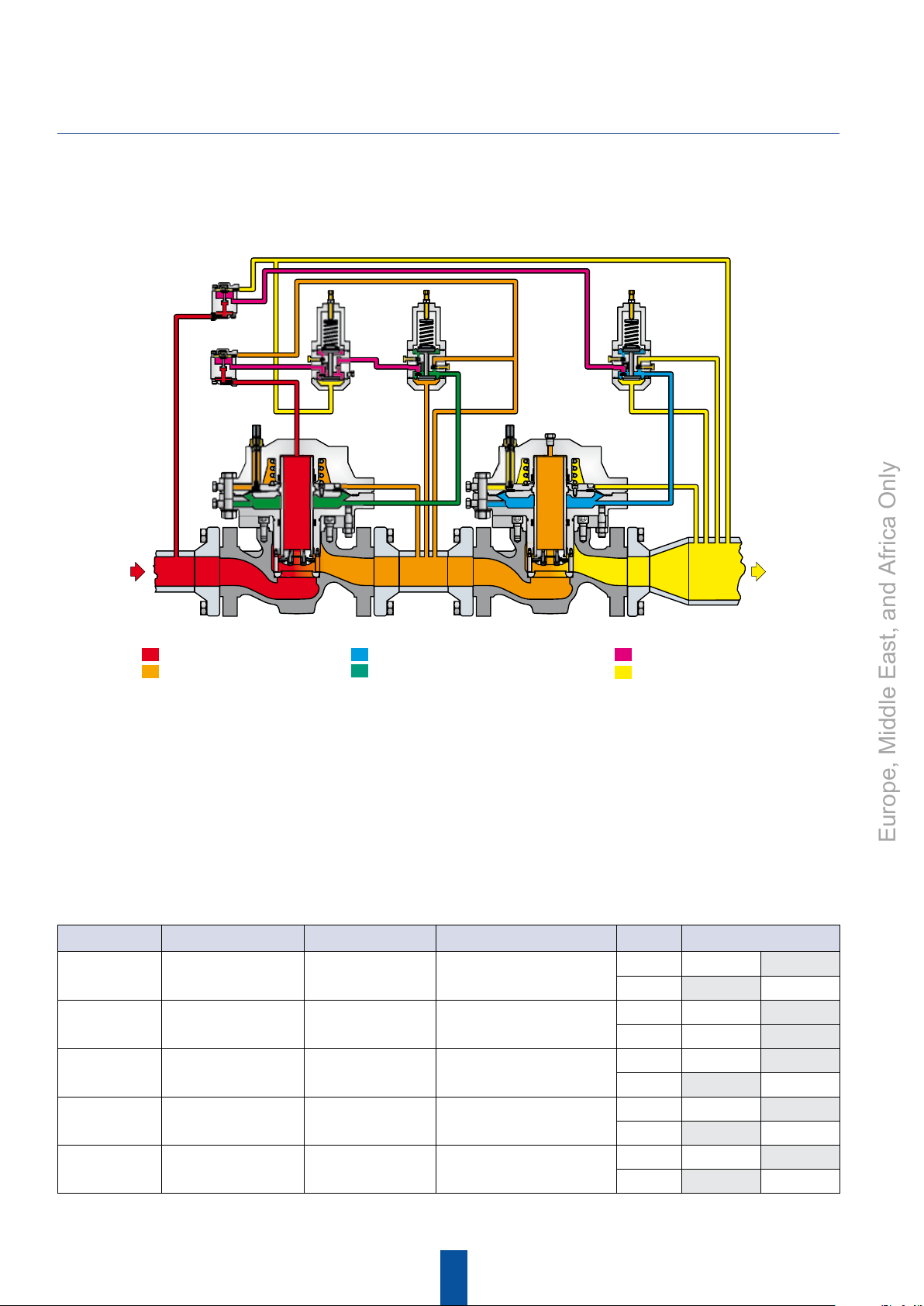

PRX/120

PRX/120-AP

SA/2

V

R

M

B

S

L

A

V

SA/2

M

R

PRX/120

PRX/120-AP

S

L

B

A

EZH Regulator

Inlet pressure Regulator motorization pressure

Outlet pressure Stabilized pressure

EZHSO Regulator

The pilot-operated type EZH uses inlet pressure as the operating medium, which is reduced through pilot operation to load the

actuator diaphragm. Outlet pressure (Pd) opposes the motorization pressure (Pm) in the actuator and also opposes the pilot control

spring. Type EZHSO Spring-to-Open version uses inlet pressure as the operating medium, which is reduced through pilot operation to

load the actuator diaphragm (lower chamber). The upper case of Type EZHSO actuator is filled with pressure coming from stabilizer

filter Type SA/2. This pressure on the upper chamber of the regulator actuator diaphragm opposes the main spring force that tends

to open the regulator. The outlet pressure opposes the pilot control spring.

For the start-up of Type EZHSO, it’s necessary to install a

vent valve in type PRX pilot bleed line connection (line from port S to downstream pipe) in order to vent the pressure from actuator lower

chamber to close the regulator.

Opening

When the outlet pressure (Pd) drops below the setting of the pilot control spring, pilot control spring force on the pilot diaphragm

thus opens the pilot valve plug, providing additional motorization pressure (Pm) to the actuator diaphragm. This diaphragm

motorization pressure opens the main valve plug, supplying the required flow to the downstream system. Any excess motorization

pressure on the actuator diaphragm escapes downstream through the bleed restriction in the pilot.

Closing

EZH -

When the gas demand in the downstream system has been satisfied, the outlet pressure (Pd) increases. The increased pressure

is transmitted through the downstream control line and acts on the pilot diaphragm. This pressure exceeds the pilot spring setting and

moves the diaphragm, closing the orifice. The motorization pressure (Pm) acting on the main diaphragm bleeds to the downstream

system through a bleed restriction in the pilot.

EZHSO - When the outlet pressure (Pd) increase over the setting of the pilot spring, the pilot valve disk will be closed, reducing motorization

pressure (Pm) to the lower chamber of the regulator actuator diaphragm; the pressure in the upper chamber will force the regulator to close.

Adjustment

The adjustment of the regulator is performed by means of the pilot adjusting screw, which causes variation of the compression of the

control spring. Adjustment is performed while the regulator is in operation with the aid of a pressure gauge to monitor downstream

pressure. The shut-off valve downstream of the regulator must not be completely closed, it is necessary that a small quantity of gas

flows downstream to allow the outlet side to vent when it is necessary to lower the pressure.

4

Page 5

EZH and EZHSO Regulators

Europe, Middle East, and Africa Only

Operation

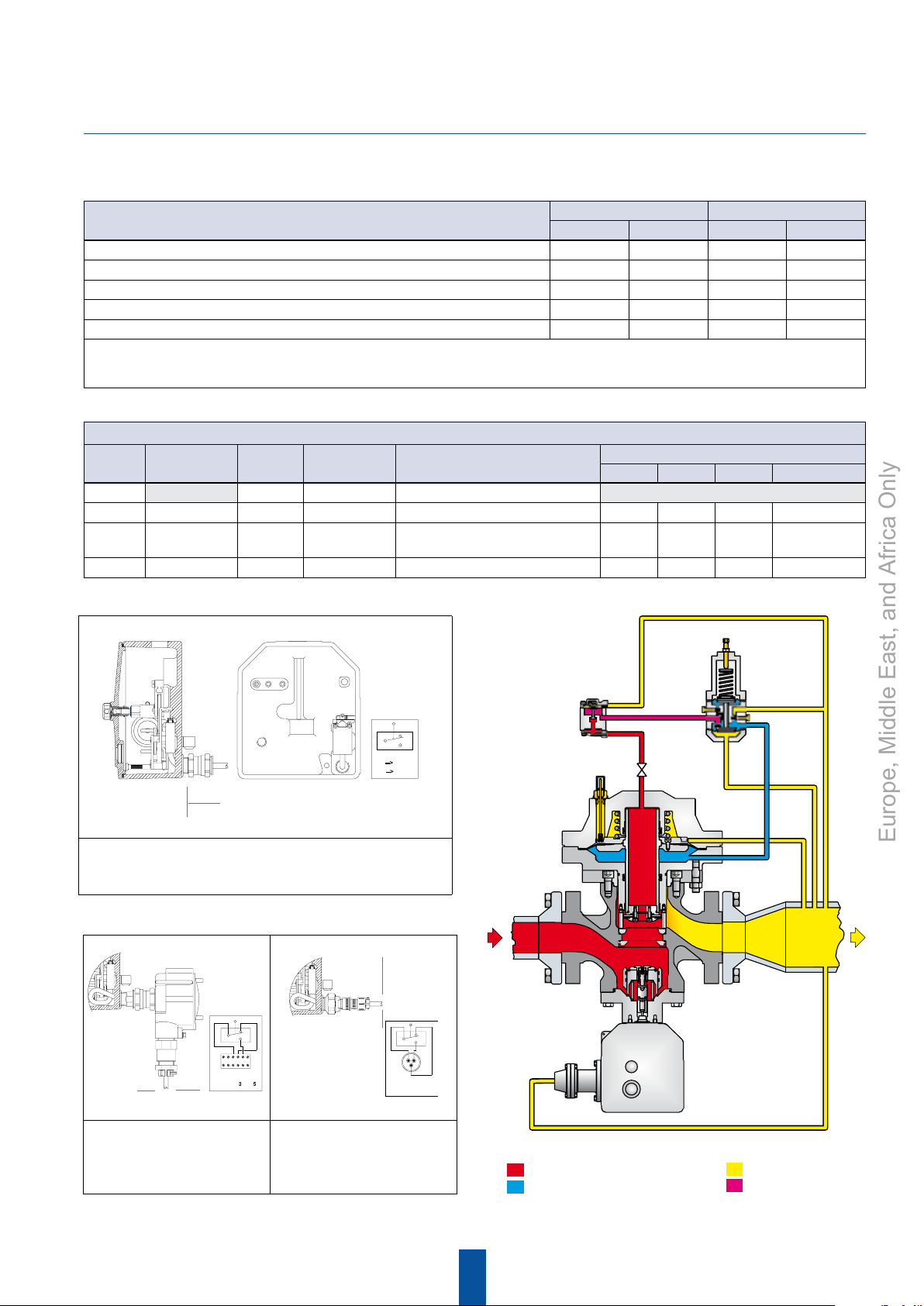

Monitoring System

Monitoring regulation is overpressure protection by containment, therefore, there is no relief valve to vent to the atmosphere.

When the working regulator fails to control the pressure, a monitor regulator installed in series, which has been sensing the

downstream and control pressure, goes into operation to maintain the downstream pressure at a slightly higher level than normal

pressure.

During an overpressure situation, the monitoring system keeps the customer on line.

Wide-Open Monitoring Systems

SA/2

V

R

M

SA/2

V

PRX/120

PRX/120-AP

S

PRX/120

PRX/120-AP

S

R

M

EZH Monitor EZHSO Regulator

Inlet pressure

Monitor motorization pressure

B

L

A

Regulator motorization pressure

Outlet pressure

B

Stabilized pressure

L

A

This figure shows an upstream wide open monitor Type EZH and a downstream active regulator Type EZHSO (Spring-to-Open).

In this installation, if the Type EZHSO no longer controls the outlet pressure, it will remain open, letting the Type EZH regulator to

reach the required outlet pressure.

In case of failure of the Type EZH, it will close and protect the downstream system from overpressure condition.

5

Page 6

EZH and EZHSO Regulators

Europe, Middle East, and Africa Only

Operation

Working Monitoring System

SA/2

M

SA/2

V

R

V

R

M

B

PRX/125

PRX/125-AP

S

L

A

B

PRX/120

PRX/120-AP

S

L

A

PRX/120

PRX/120-AP

S

B

L

A

EZH Monitor EZH Regulator

Inlet pressure

Intermediate pressure

Regulator motorization pressure

Monitor motorization pressure

Stabilized pressure

Outlet pressure

In a working monitoring system, the upstream regulator requires two pilots and it is always the monitoring regulator. In this way,

both units are always operating and can be easily checked for proper operation. In normal operation, the working regulator controls

the outlet pressure of the system. The monitoring regulator’s working pilot PRX/120 or PRX/120-AP controls the intermediate

pressure and the monitor pilot PRX/125 or PRX/125-AP senses the system’s outlet pressure. If the working regulator fails, the

monitoring pilot PRX/125 or PRX/125-AP will sense the increase in outlet pressure and take control. The working regulator must be

rated for the maximum allowable operating pressure of the system because this will be its inlet pressure if the monitoring regulator

fails. Also, the outlet pressure rating of the monitoring pilot PRX/125 or PRX/125-AP and any other components that are exposed to

the intermediate pressure must be rated for full inlet pressure. Working monitor installations require a Type EZH or EZHSO main valve

with a Type PRX/120 or PRX/120-AP working pilot and a Type PRX/125 or PRX/125-AP monitoring pilot for the upstream regulator,

and a Type EZH or EZHSO with the appropriate Type PRX/120 or PRX/120-AP pilot for the downstream regulator.

Failure Mode Analysis

Part Name Failure (Worst Case) Cause of Failure Effect Typ e Regulator Reaction Mode

Filter Filter blocked / clogged Dirty gas

Pilot Disk Pilot cannot be closed

Pilot Lower

Diaphragm

Pilot Upper

Diaphragm

Regulator

Diaphragm

Pilot cannot control

Pilot cannot feed the

regulator

Not proper performance

of the motorization

pressure chamber

Dirty gas

(microparticles),

sour gas

Fabric quality,

sour gas

Fabric quality,

sour gas

Fabric quality,

sour gas

Decrease of feeding pressure

gives decrease of

motorization pressure

Increase motorization pressure

Decrease motorization pressure

Decrease motorization pressure

Balancing of pressures and charge

or discharge of the motorization

pressure chamber

EZHSO Open

EZH Close

EZHSO Open

EZH Open

EZHSO Open

EZH Close

EZHSO Open

EZH Close

EZHSO Open

EZH Close

6

Page 7

Features

Europe, Middle East, and Africa Only

Applications

EZH and EZHSO series regulators are used in reduction, distribution and conveying stations of suitably filtered

natural gas. They can also be used for air, propane, butane, LPG, city gas, nitrogen, carbon dioxide and

hydrogen.

Technical Features

EZH and EZHSO Regulators

Allowable pressure PS

Inlet pressure P

Set range P

Min. operating differential pressure

Max. operating differential pressure

Functional Features

Accuracy class

Lock-up pressure class SG : up to + 5%

Class of lock-up pressure zone SZ : up to 5%

Operating temperature TS : -20 / 60 °C

Shut-off device

Max. operating differential pressure ∆p

Response time ta : < 1 s

Accuracy class

Set pressure range W

u

d

Type EZH ∆p

Type EZHSO ∆p

Type EZH ∆p

Type EZHSO ∆p

Type EZH AC : up to ± 1%

Type EZHSO AC : up to ± 2.5%

Diaphragm and bellows version AG : up to ± 2.5%

Piston version AG : up to ± 5%

du

: up to 100 bar

: 1 to 100 bar

: 1 to 80 bar

: 1 bar

min

: 3.8 bar

min

: 99 bar

min

: 96.2 bar

min

: 99 bar

max

- Wdo : 0.010 / 100 bar

Materials

Flanged connections

Same Inlet and outlet: DN 25 - 50 - 80 - 100*

* Available only for EZH and EZH-OS2 configurations

Flange rating: PN 16 B - PN 25 B - PN 40 B

ANSI 150 RF - ANSI 300 RF - ANSI 600 RF

Body Steel

Connecting parts and bottom Steel

Actuator Steel

Regulator / Slam-shut orifice Stainless steel

Regulator valve plug Stainless steel

Slam-shut valve plug Stainless steel

Regulator plug disc Nitrile or fluorcarbon (FKM)

Slam-shut O-rings Nitrile or fluorcarbon (FKM)

7

Page 8

EZH and EZHSO Regulators

Europe, Middle East, and Africa Only

Calculation Procedures

Symbols

Q = Natural gas flow rate in Stm3/h

P1 = Absolute inlet pressure in bar

P2 = Absolute outlet pressure in bar

= Flow rate coefficient

C

g

C1 = Body shape factor

d = Relative density of the gas

Flow Coefficients

Reduction

DN

0

Qf

C

g

C1

Regulator travel (mm) 9 17 25 30 9 17 25 30

Slam-shut travel (mm) 15 30 50

1

2

3

0

1

2

3

0

1

2

3

284 1078 2247 3567 280 1088 2266 3696

210 908 1684 2969 218 829 1698 2902

126 671 1058 1763 128 607 1066 1784

79 385 685 1062 81 370 690 1072

550 2092 4359 6920 544 2110 4396 7170

408 1762 3266 5760 423 1609 3294 5630

245 1301 2052 3420 249 1177 2069 3460

154 746 1328 2060 157 718 1339 2080

31.3 38.3 30.6 32.4 35.5 33.5 30.8 31.4

34.3 35.3 33.9 35.2 38.7 31.9 33.9 34.2

33.6 36.6 37.8 37.4 39.7 35.6 37.8 36.3

32.1 40.8 33.6 37.1 39.3 38.2 33.6 37.3

Slam-Shut (X Body) Without Slam-Shut (E Body)

25 DN 50 DN 80 DN 100 DN 25 DN 50 DN 80 DN 100

TYPE EZH DN25,50,80 and 100 - TYPE EZHSO DN 25, 50 and 80

Flow Rate Q

Sub-critical state with:

Q = 0.525 ⋅ C

N.B. the sine argument is expressed in sexagesimal degree.

Critical state with:

⋅ P1⋅ sine

g

P2 ≤

P2 >

3417

P1

C1

P1

2

P1-P2

⋅

°

P1

2

Q = 0.525 ⋅ C

g

⋅ P1

For other gases with different densities, the flow rate

calculated with the above formulas must be multiplied by

the correction factor:

0.6

F=

d

8

Gas

Air 1 0.78

City gas 0.44 1.17

Butane 2.01 0.55

Propane 1.53 0.63

Nitrogen 0.97 0.79

Carbon dioxide 1.52 0.63

Hydrogen 0.07 2.93

Relative Density

d

Factor

F

Page 9

DN Sizes

Europe, Middle East, and Africa Only

EZH and EZHSO Regulators

Calculate the required Cg with the following formula:

2

P2 >

P2 ≤

⋅

P1

2

Q

3417

⋅

C1

P1

2

1 - 0.002 ⋅ P

1 + P

u

P1 - P2

P1

u

°

Sub-critical with:

Cg =

0.525 ⋅ P1 ⋅ sine

N.B. The sine argument is expressed in sexagesimal degree.

Critical state with:

=

C

g

N.B. The above formulas apply to natural gas flow rate only. If the flow rate value (Q) refers to other gasses, divide it by the

Select the diameter of the regulator with Cg higher than calculated value.

After finding the DN of the regulator, check that gas speed on the seat does not exceed 120 m/sec, using the

following formula:

V = 345.92 ⋅

Q

0.525 ⋅ P1

correction factor F.

Q

DN

V = Velocity (m/s)

345.92 = Numerical constant

Q = Flow rate under standard conditions (Stm3/h)

DN = Regulator nominal diameter (mm)

= Inlet pressure in relative value (bar)

P

u

Advanced Design Tools

9

Page 10

EZH and EZHSO Regulators

MECHANISM

BOX

LOCATION

FOR SWITCH

RESET PIN WITH

WHITE DOT

CLIP

SLIDING CLEVIS

STEM

SCREW AND

FLAT WASHER

TRIPPING PLATE

MANOMETRIC SENSING

DEVICE (BM1)

MANOMETRIC DEVICE

THREADED STEM

SECOND STAGE

RELEASING SHAFT

TRAVEL STOP

RESETTING TOOL

CAP SCREW

BONNET

2B

Europe, Middle East, and Africa Only

Slam-Shut Device

The optional slam-shut device can provide either overpressure or overpressure and underpressure protection by completely shutting

off the ow of gas to the downstream system. The slam-shut has a mechanism box and a manometric device. The manometric device

is a spring and diaphragm actuator. Its movement activates the detection stage of the mechanism box.

The shutoff is a two stage process, the detection stage and the power stage. This separation between detection stage and power

stage provides maximum precision, alleviating many false trips caused by environmental vibrations.

The slam-shut device includes a bypass valve that will allow pressure to be equalized when resetting the device. Once the slam-shut

device has been tripped, it must be manually reset.

For more information about the Type EZH and EZHSO with a slam-shut device, contact the local Sales Representative or Sales Ofce.

Spring Adjustment Ranges (BMS)

BMS Max. Only Min. Only Max. & Min.

Wdso Setting (bar) Wdsu Setting (bar) Wdsu Setting (bar)

Typ e Size

PMS

box

(bar)

Max.

low pt.

possible

Recommended Range

Max.

low pt.

Max.

high pt.

Min.

low pt.

possible

Recommended Range

Min.

low pt.

Min.

high pt.

Min.

low pt.

possible

Max.

high pt.∆1(bar)

0.010 0.015 0.035 0.010 0.015 0.035 0.010 0.035 0.004 0.010

0.025 0.040 0.080 0.025 0.040 0.080 0.025 0.080 0.005 0.025

0.045 0.080 0.140 0.045 0.080 0.150 0.045 0.140 0.010 0.050

162 10

0.070 0.070 0.240 0.070 0.070 0.240 0.070 0.240 0.014 0.060

0.115 0.140 0.380 0.115 0.150 0.400 0.115 0.380 0.018 0.150

0.140 0.300 0.750 0.140 0.300 0.650 0.140 0.750 0.050 0.350

Diaphragm

0.250 0.600 1.3 0.250 0.600 1.15 0.230 1.3 0.080 0.600

0.450 1.2 2.3 0.450 1.1 2.0 0.450 2.3 0.170 1.1

1.0 2.0 5.1 1.0 2.0 4.7 1.0 5.1 0.350 2.5

071 20

2.1 4.0 11.0 2.1 4.0 9.5 2.1 11.0 0.700 5.5

4.0 8.0 16.0 4.0 8.0 14.4 4.0 16.0 1.6 10.0

027 100

Piston

017 100

236 35

Bellows

315 72 17.5 35.0 72.0 17.5 28.0 65.0 17.5 72.0 5.0 33.0

16.0 16.0 22.0 16.0 16.0 19.0

22.0 22.0 40.0 19.0 19.0 38.0 6.5

40.0 40.0 55.0 38.0 38.0 50.0 7.0

Not possible with

only 1 BMS

55.0 55.0 100.0 50.0 50.0 90.0 12.0

5.5 11.0 22.0 5.5 11.0 16.0 5.5 22.0 1.6 10.0

8.3 16.0 35.0 8.3 16.0 28.0 8.3 35.0 2.5 20.0

Intervals

∆1&∆2

∆2

(bar)

3.0

BM1 BMS1

Mechanism Box (BM1) with

One Manometric

Sensing Device (BMS1)

BM2BMS

Mechanism Box (BM2) with

Two Manometric Sensing

Devices (BMS1 and BMS2)

MS1

OS2 Internal Parts

10

Page 11

Applications and Construction Guide

BK

BU

BN

A

B

C

NF --> BK(A)/BU(B)

NO --> BK(A)/BN(C)

WIRING

Europe, Middle East, and Africa Only

EZH and EZHSO Regulators

Application

Mechanism Box Manometric Sensing Device

BM1 BM2 BMS1 BMS2

Overpressure Shut-off (OPSO) Yes No Yes No

Underpressure Shut-off (UPSO) Yes No Yes No

Overpressure Shut-off (OPSO) and Underpressure Shut-off (UPSO) Ye s No Yes

Overpressure Shut-off (OPSO) and Underpressure Shut-off (UPSO) No Yes Yes

(1)

(2)

No

Yes

Overpressure Shut-off (OPSO), Overpressure Shut-off (OPSO) and Underpressure Shut-off (UPSO) No Yes Yes Yes

1. When using one manometric sensing device (BMS1) for both overpressure and underpressure shutoff, make sure that the difference between set pressures falls

within the maximum range shown in above table "Spring Adjustment Ranges".

2. When using two manometric sensing devices (BMS1 and a BMS2), the BMS1 can only be used for high trip.

Versions of Explosion Proof Limit Switches

Versions Installment Tightness Connection Mechanical connections

Common NF NO Connection

Electrical connections

C0 IP 68 Without Cap 1/2 NPT

C1 Explosion proof IP 68 Explosion proof 3 m wire Black Blue Brown Wires

C2 Explosion proof IP 65 Explosion proof

Connector box explosion proof

PE explosion proof

3 4 5 Screwed wiring

C3 Intrinsically safe IP 68 Explosion proof Intrinsically safe tight-shut connector A B C Welded wiring

PRX/120

PRX/120-AP

3 m

C1ContactVersion

Explosion proof connection with

cable and tight-shut packing gland

WIRING

BK

123456

NF --> BK(3)/BU(4)

NO --> BK(3)/BN(5)

C2ContactVersion

Explosion proof connection

with explosion proof

connector box

NF : Normally Closed

NO : Normally Open

BU

BN

C3ContactVersion

Explosion proof connection with

tight-shut connector for

intrinsically safe

WIRING

BK

NF --> BK/BU

NO --> BK/BN

SA/2

V

BU

BN

R

M

B

S

L

A

EZH-OS2

Inlet pressure

Regulator motorization pressure

Outlet pressure

Stabilized pressure

11

Page 12

EZH and EZHSO Regulators

Europe, Middle East, and Africa Only

Pilots

The Type EZH and EZHSO pressure reducing regulator includes a PRX Series pilot mounted on the Type EZH and

EZHSO main valve for pressure reducing or wide-open monitoring applications.

PRX Series pressure reducing pilots have the ability to handle a wide range of set points from 1 to 80 bar:

Type PRX/120

Outlet pressure range of 0.5 to 42 bar. The Type PRX/120 can be used as the pilot on single stage pressure reducing

regulators or as the monitor pilot or as the working pilot in wide-open monitor systems.

Type PRX/120-AP

Outlet pressure range of 30 to 80 bar. The Type PRX/120-AP can be used as the pilot on single stage pressure reducing

regulators or as the monitor pilot or as the working pilot in wide-open monitor systems.

Type PRX/125

Identical to the Type PRX/120 except the restriction screw is removed. The Type PRX/125 can only be used as the

monitor override pilot on working monitor applications.

PRX/ Series

Type PRX/125-AP

Identical to the Type PRX/120-AP except the restriction screw is removed. The Type PRX/125-AP can only be used

as the monitor override pilot on working monitor applications.

The Type SA/2

Pilot supply lter regulator, provides a constant supply pressure to the PRX Series pilot that is 3 bar over set

pressure. The Type SA/2is equipped with a 5µ filtering degree filter and is suitable for heating.

Application

Regulator or

Monitor

PRX/120

PRX-AP/120

1/4” NPT female threaded connections

Operating Monitor

Regulator Monitor

PRX/120 PRX/125

PRX-AP/120 PRX-AP/120

Allowable

Pressure

PS (bar)

100

Set Range

W

(bar)

d

0.5 - 42

30 - 80

Body and

Covers

Material

Steel

The SA/2 pressure pre-reducer must be used with PRX/ series pilots.

SA/2

1/4” NPT female threaded connections

Model

SA/2

Allowable Pressure

PS (bar)

100

12

Supplied Pressure

3 bar + Downstream pressure

Body and Covers

Material

Steel

Page 13

Examples of Connections

Europe, Middle East, and Africa Only

R

SA/2

V

R

M

R

SA/2

V

B

R

M

S

L

A

PRX/120

PRX/120-AP

EZH and EZHSO Regulators

PRX/120

PRX/120-AP

B

S

L

A

EZHEZH-OS2

RegulatorMonitor

4DN

6DN

EZH-OS2 Monitor with OS2 Slam-Shut and EZH Regulator

R

SA/2

V

R

M

S

L

A

PRX/120

PRX/120-AP

B

R

SA/2

V

R

M

B

A

PRX/120

PRX/120-AP

S

L

EZH

Monitor

Inlet pressure

Regulator motorization pressure

EZH

Regulator

EZH Monitor and EZH Regulator

Monitor motorization pressure

Stabilized pressure

13

4DN

6DN

Outlet pressure

R

To the heating system

Page 14

EZH and EZHSO Regulators

E

IH

IH

E

IH

Europe, Middle East, and Africa Only

Overall Dimensions and Weights

J

C

C

B

A

EZH and EZHSO with PRX Pilot

Vertical Position

DN

25 38 39 40

50 71 74 75

80 145 151 153

100* 211 224 239

Note: For EZHSO version add 1 kg

PN 16 B

ANSI 150

Weights (kg)

PN 25 B - PN 40 B

ANSI 300

ANSI 600

B

Indicator cover

K

removal clearance

C

B

A

EZH and EZHSO DN 25, 50 and 80 with PRX Pilot

Horizontal Position

E

A

Overall Dimensions (mm)

DN

ANSI

ANSI

150

300

25 184 197 210 193.5 62 404 282 225 238 190 113 210

50 254 267 286 254 267 83 445 287 287 267 286 144 197

80 298 317 337 310 317 105 532 425 400 325 349 200 337

*

100

* Available only for EZH and EZH-OS2 configurations - Threaded 1/4” NPT female impulse connections

352 368 394 350 368 137 442 427 480 342 394 240 140

ANSI

600

A

PN

16 B

PN

25 B

PN

40 B

B

Horizontal

PRX

14

C

PRX

Vertical

EZH DN 100 with PRX Pilot

Horizontal Position

H

E

PRX

Horizontal

PRX

Vertical

I J K

38

51

Page 15

IHE

IHE

Overall Dimensions and Weights

Europe, Middle East, and Africa Only

J

EZH and EZHSO Regulators

C

B

G

F

A

D

25 mm

Mechanism box

removal clearance

EZH-OS2 and EZHSO-OS2 with PRX Pilot

Vertical Position

Weights (kg)

DN

25 49 50 51

50 81 83 85

80 168 175 177

*

100

Note: For EZHSO version add 1 kg

PN 16 B

ANSI 150

237 250 265

PN 25 B - PN 40 B

ANSI 300

ANSI 600

C

B

G

F

A

D

25 mm

Mechanism box

removal clearance

EZH-OS2 and EZHSO-OS2 DN 25, 50 and 80 with PRX Pilot

Horizontal Position

Indicator cover

K

removal clearance

C

HIE

Slam-Shut Overall Dimensions (mm)

DN

Diaphragm

25

50

80

100

DN

25 184 197 210 193.5 250 404 282 315 225 238 190 113 210

50 254 267 286 254 267 265 445 287 330 287 267 286 144 197

80 298 317 337 310 317 301 532 425 366 400 325 349 200 337

100

* Available only for EZH and EZH-OS2 configurations - Threaded 1/4” NPT female impulse connections

181 204 223 162 71 74

*

ANSI

150

*

352 368 394 350 368 345 442 427 410 480 342 394 240 140

F G

Piston Bellows

ANSI

ANSI

300

600

A

16 B

Diaphragm

PN

25 B

PN

Piston Bellows

Overall Dimensions (mm)

B

PN

40 B

Horizontal

PRX

B

G

F

D

A

25 mm

Mechanism box

removal clearance

EZH-OS2 DN 100 with PRX Pilot - Horizontal Position

C

Vertical

PRX

D E

Horizontal

PRX

H

PRX

Vertical

15

I J K

38

51

Page 16

Process Management

TM

Natural Gas Technologies

Europe, Middle East, and Africa Only

Emerson Process Management

Regulator Technologies, Inc.

O.M.T.

Ofcina Meccanica Tartarini s.r.l.

Via P. Fabbri, 1

I - 40013 Castel Maggiore (Bologna), Italy

Tel. : +39 - 0514190611

Fax: +39 - 0514190715

E-mail: info.tartarini@emersonprocess.com

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

NCAEZH0903EN©Emerson Process Management Regulator Technologies, Inc., 07/2011; All Rights Reserved

Francel S.A.

Z.A. La Croix Saint Mathieu

28320 Gallardon

France

Tél : +33 (0)2 37 33 47 00

Fax : +33 (0)2 37 31 46 56

Loading...

Loading...