Page 1

Technical Bulletin

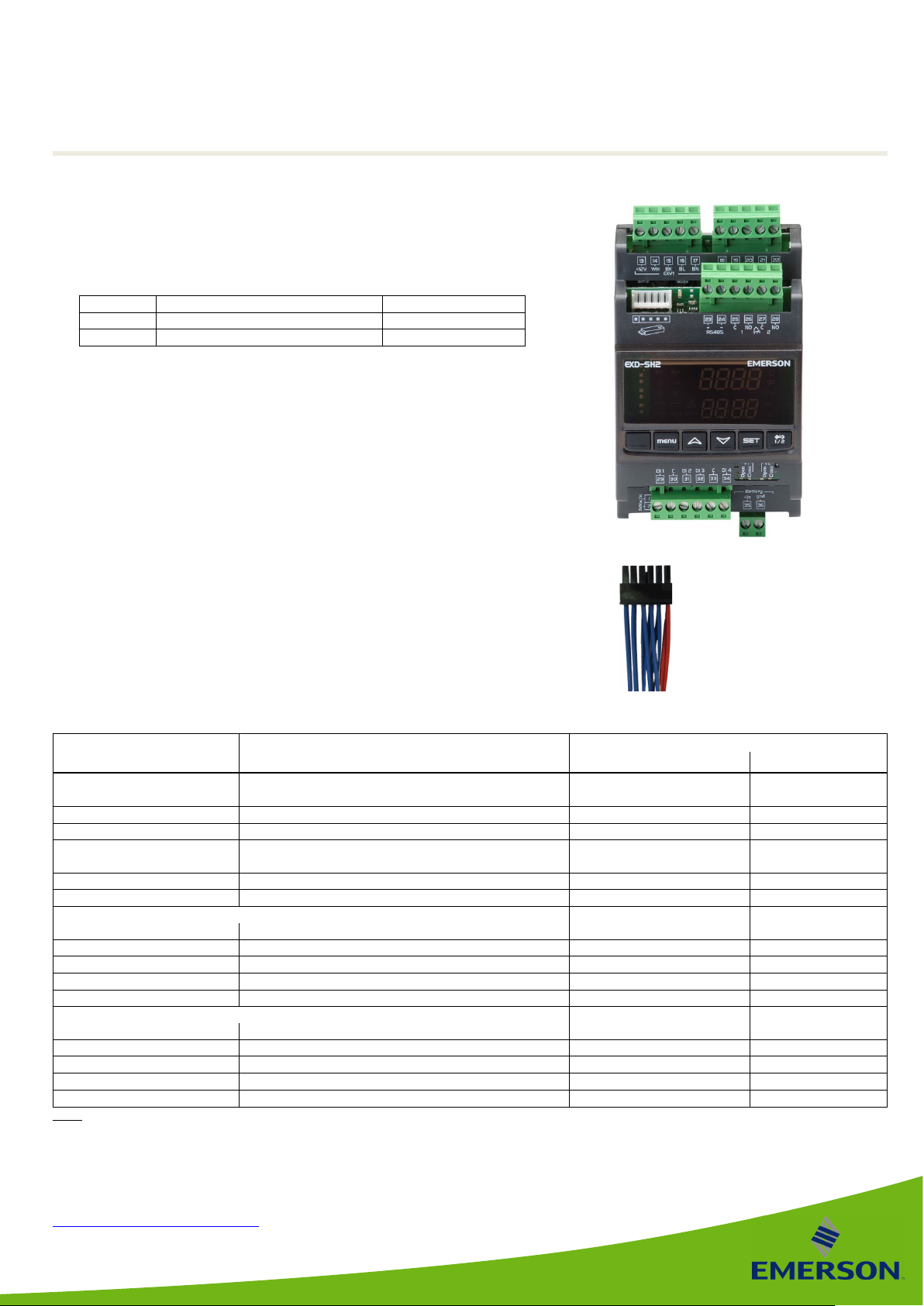

EXD-SH1/2 are stand-alone universal superheat and or temperature

Circuit 1

Circuit 2

EXD-SH1

Superheat or temperature control

EXD-SH2

Superheat or temperature control

Superheat Control

Other functions: Limitation of evaporating pressure (MOP), Low pressure

h EMERSON

Monitoring of sensors and detection of sensor

Optional upload/download key (accessory) for transmission of parameter

in type screw terminals included with

EXD-M03

Part No.

Multipack (pcs)

Single pack

Controllers

EXD-SH1

Controller for single refrigeration circuit

EXD-SH2

Controller for two independent refrigeration circuits

-

807856

EXD-M03

Molex terminal with 3 m wires

-

807865

Temperature sensors

TP1-NP3

Temperature sensor with 3 m cable

804489M (20)

804489

TP1-NP6

Temperature sensor with 6 m cable

804490M (20)

804490

ECN-Z60

Ultralow Temperature sensor with 6 m cable

-

807826

Pressure transmitters: PT5N (7/16-20UNF connection)

PT5N-07M

Sensing pressure range -0.8…7 bar

805350M (25)

805350

PT5N-18M

Sensing pressure range 0…18 bar

805351M (25)

805351

PT5N-30M

Sensing pressure range 0…30 bar

805352M (25)

805352

PT5N-50M

Sensing pressure range 0…50 bar

805353M (25)

805353

PT5N-150D

Sensing pressure range 0…150 bar (1/4- 18 NPT)

805379M (25)

805379

Pressure transmitters: PT5N (Brazing connection)

PT5N-07T / PT5N-07P-FLR

Sensing pressure range -0.8…7 bar

805380M / 805390M (25)

805380 / 805390

PT5N-010P-FLR

Sensing pressure range -0.8…10 bar

805391M (25)

805391

PT5N-18T

Sensing pressure range 0…18 bar

805381M (25)

805381

PT5N-30T / PT5N-30P-FLR

Sensing pressure range 0…30 bar

805382M / 805389M (25)

805382 / 805389

PT5N-50T

Sensing pressure range 0…50 bar

805383M (25)

805383

EXD-SH1/2 Controller for electrical control valves with ModBus Communication

Capability

controllers for air conditioning units or refrigeration systems.

Features

• EXD-SH1: Control of one valve

• EXD-SH2: Control of two valves in two independent circuits

• Main function

•

switch, freeze protection and manual positioning of valve(s)

• Self-adapting superheat control function in conjunction wit

EX4-8 (EX4-7-FLR) and CV4-7 series

• For multiple refrigerants, including ultralow temperature refrigerant R23

• Modbus (RTU) communication

• Integrated keyboard with two lines display

•

(ECN…/TP1…/PT5N…(FLR)) /stepper motor wiring failures

•

settings among controllers with the same setting

• Low/high superheat alarm as well as other function alarms

• Electrical connection via plug-

controller and Micro Molex EXD-M03 (must be ordered separately)

• DIN rail mounting housing

EXD-SH2

Selection table

Type

Note: Pressure range 18 bar for system with R410A, 30 bar for R410A economizer, 50/150 bar for CO

Description

- 807855

2

www.climate.emerson.com/en-gb

Page 2

Part No.

Multipack (20 pieces)

Single pack

M12 Plug and cable for pressure transmitters PT5N(FLR)

PT4-M15

1.5 m

804803M

804803

PT4-M30

3.0 m

804804M

804804

PT4-M60

6.0 m

804805M

804805

PT4-M60 FLR

6.0 m - 804806

Uninterruptible Power supply

ECP-024

Backup battery with two outputs for two controllers

-

804558

K09-P00

Electrical Terminal Kit for ECP-024

-

804560

EXD-PM

Super cap for only EXD-SH1

(two pieces of EXD-PM required for one EXD-SH2)

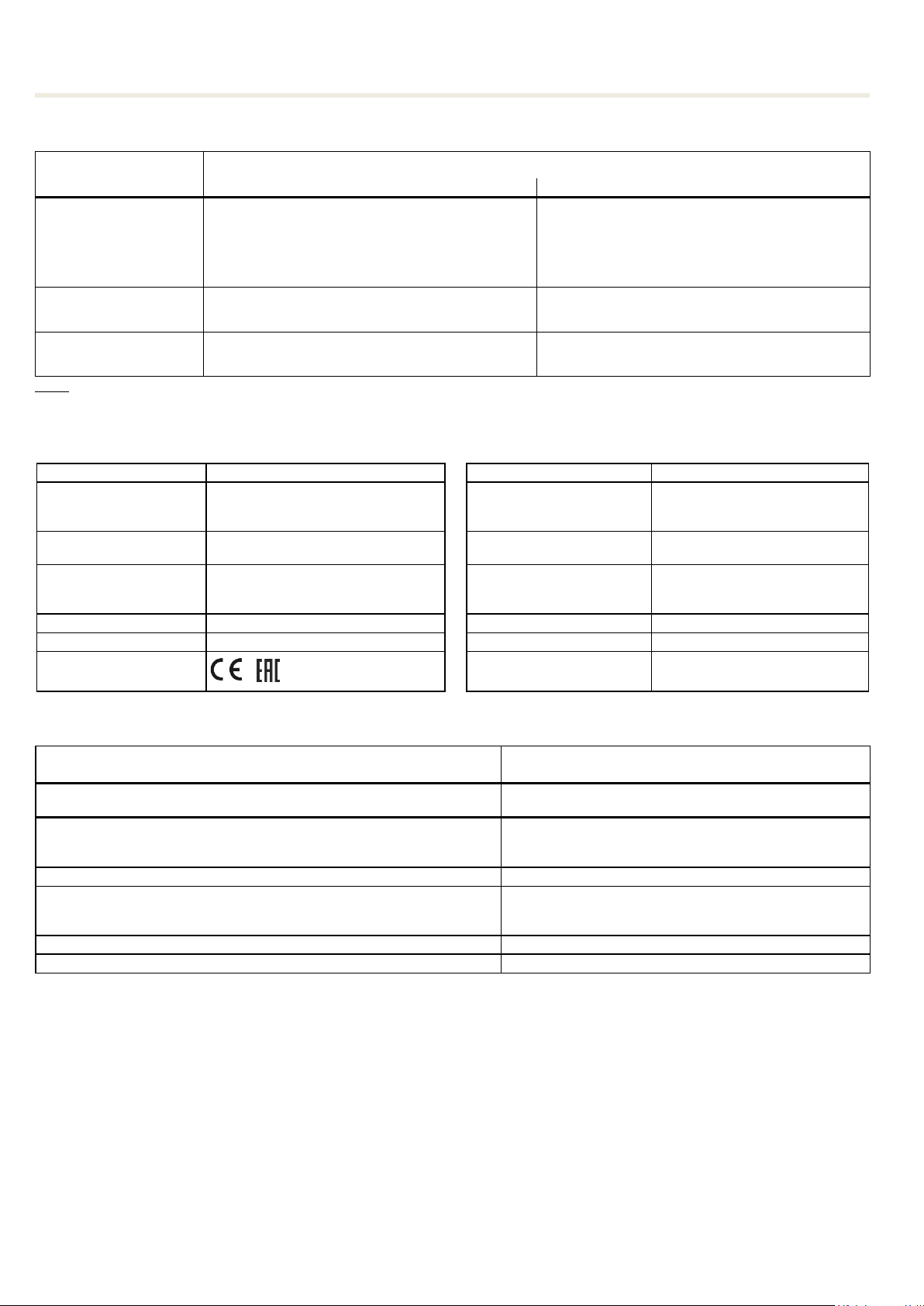

Temperature control in normal sense

1tAL 1tst 1tAH

Temperature control in reverse sense

1tAL 1tst/ 1tAH

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Accessories

Type Description

- 807854

Description of functions

Controllers are featured with a main function as superheat controller or temperature controller. The main function is selectable.

Superheat control of evaporators or economizers

This function requires the connection of temperature sensor(s) as well as pressure transmitters(s). The other functions are:

• MOP control: enables the limitation of saturated temperature of suction line (outlet of evaporator/economizer)

• Low pressure behaves similar to low pressure switch including alarm conditions

• Freeze protection is based on saturated temperature from converting measuring suction pressure. It provides alarm condition

below certain adjusted temperature.

Temperature controller

The function is to maintain desired temperature by modulating refrigerant mass flow. If controller is operated as temperature controller,

the connection of pressure transmitter is not required.

In order to fulfill varieties of the applications, the refrigerant mass flow variation can be set according temperature increase or decrease.

(A: Mass flow increases if temperature rises)

Valve opening %

100%

Temperature

0%

Examples of applications:

• Temperature control by throttling suction mass flow (normal sense, A)

• Temperature control by modulating hot gas into inlet or outlet of evaporators (reverse sense, B)

• Discharge temperature control by injecting liquid (normal sense, A)

• Head pressure control by means of temperature control (normal sense, A)

Valve opening %

100%

Temperature

0%

(B: Mass flow decreases if temperature rises)

2

EXD-SH12_TB_EN_0720_R08.docx

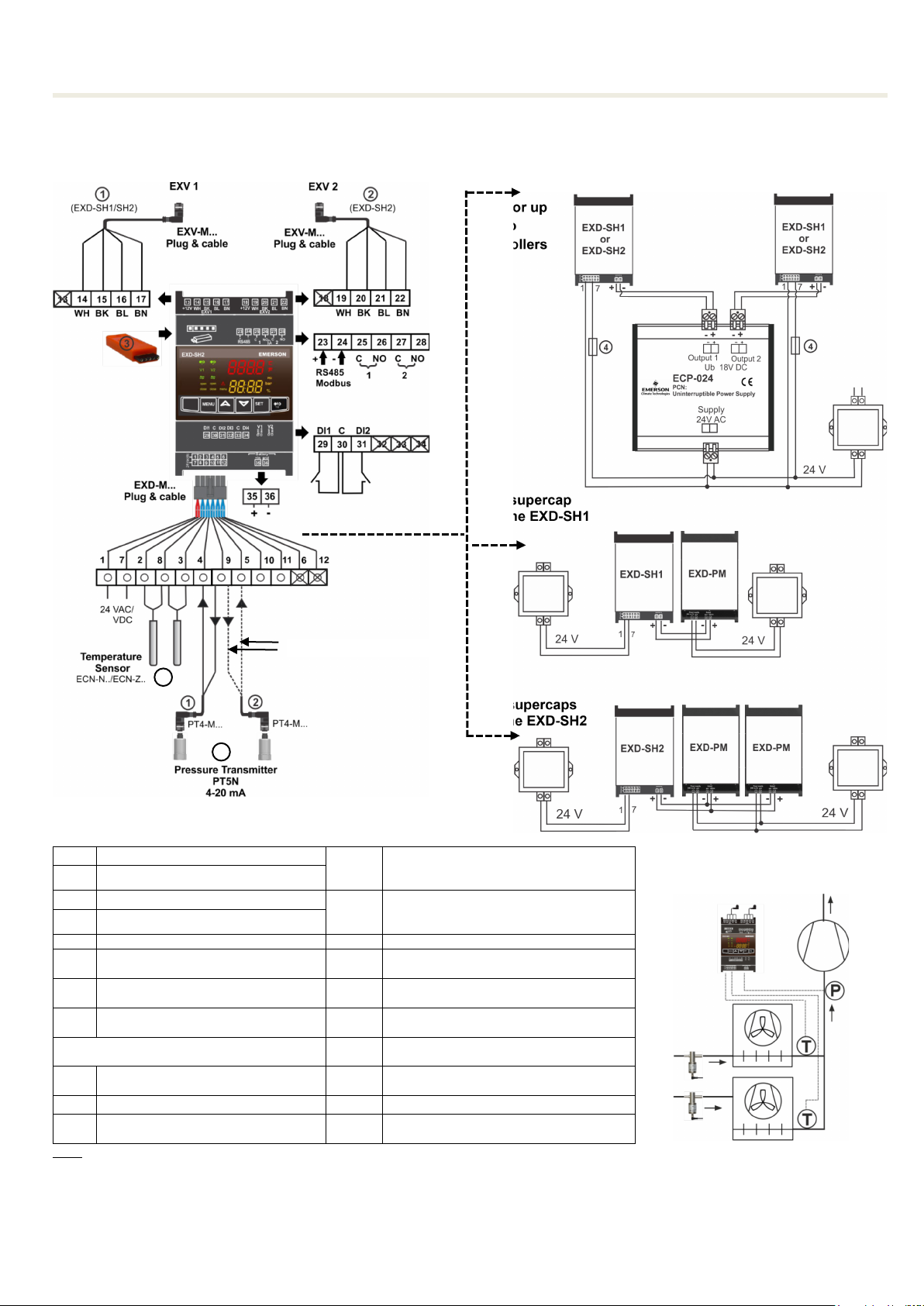

Page 3

Circuit 1 (EXD-SH1/SH2)

Electronic expansion valve circuit 1 (EXV1)

WH-white BK-black BL-blue BN-brown

*) Parameter 2uP with No. 8 = only

Download/upload key

Electronic expansion valve circuit 2 (EXV2)

WH-white BK-black BL-blue BN-brown

2 & 8

Temperature sensor circuit 1

23 & 24

RS485 (+/-terminal)

Alarm relay circuit 1 (C, NO) – Suitable for

24 VAC/DC

PT5N… circuit 1 & circuit 2

(white wire: 4…20 mA signal)

Alarm relay circuit 2 (C, NO) – Suitable for

24 VAC/DC

+ 12 VDC Voltage input for PT5N…

(brown wire)

Digital input circuit1 (DI1) – Dry contact,

potential free

Alternative ratiometric third Party Pressure

Transmitter:

Digital input circuit 2 (DI2) – Dry contact,

potential free

Pressure transmitter circuit 1 & circuit 2

(0.5…4.5 V signal)

11

+ 5 VDC voltage input

Fuse EXD-SH1 (1A), EXD-SH2 (2A)

6,12,13,

18,32-34

T

UPS for up

to two

controllers

One supercap

for one EXD

See parameter 2uP *

P

Two supercaps

for one EXD

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Wiring

Wiring options: UPS (ECP-024) /Supercap (EXD-PM)

Circuit 2 (EXD-SH2)

1 & 7 Supply voltage 24 VAC/DC

3 & 8 Temperature sensor circuit 2 25 & 26

14-17

19-22

-SH1

-SH2

EXV-M… Electrical plug: wire colors

EXV-M… Electrical plug: wire colors

Pressure sensor circuit 1 is used

4 & 5

9

4 & 5

10 GND Ground

Note: No hard failure detection if ground wire of transmitter to be interrupted.

EXD-SH12_TB_EN_0720_R08.docx

27 & 28

29 & 30

31 & 30

35 & 36 Battery/Super capacitor connection terminal

Not used (Terminals on EXD-SH12)

3

Page 4

EX

CV

Supply voltage

24 VAC/DC ±10%, 50/60 Hz

Mounting

DIN rail mounted

Temperatures

operating/ surrounding

0…+55°C

20…85%

non-condensing

Suitable for removable screw

Included in controller delivery

Accessory

3 m cable)

Protection class

IP 00

Housing

Self-extinguishing ABS

Compliance

EMC, RoHS,

Weight

320 g

Analogue input(s): NTC Temperature sensor

Analogue input: PT1000 Temperature sensor

TP1-N… (-45…+150°C operating range)

ECN-Z60 (-80…-40°C sensing range)

PT5N…

(total error: ≤ 1%)

Digital input(s)

Dry contact, potential free

Digital output(s): Alarm relay(s)

Contact is open: During normal operation and supply power OFF

Communication

RS485 RTU Modbus, two wires

Stepper motor output

Valves: EX4-8 (EX4-7-FLR), CV4-7

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Available configuration options

R22, R134a, R507, R404A, R407C, R410A, R124,

Refrigerants

Main function Superheat or and temperature control Superheat control

Pressure transmitters PT5N… or 3rd party ratio metric PT5N….

Note:

EXD-SH1/2 IS NOT ATEX APPROVED!

Technical Data: EXD-SH1/2

R744, R407A, R407F, R23, R32, R1234ze,

R448A, R449A, R450A, R513A, R290, R1270,

R454C

Selectable Valves

R744 (CO

)

2

Power consumption

Terminals 1 to 12 Suitable for 12 poles molex plug Relative humidity

Terminals 13 to 36

Marking

Input, Output EXD-SH1/2

Analogue input(s): 4…20 mA pressure transmitters

Analogue input(s): 0.5…4.5 V pressure transmitters

Contact is closed: During alarm condition

EXD-SH1: Max. 25 VA

EXD-SH2: Max. 50 VA

version: wire size 0.14…1.5 mm2

,

Description Specification

(12 poles molex plug with

Third party ratio metric pressure transmitters

Resistive Load 24 VAC/DC, max. 1 A

Inductive Load 24 V AC, max. 0.5 A

storage

-25…+60°C

Type: EXD-M03

(to be ordered separately)

4

EXD-SH12_TB_EN_0720_R08.docx

Page 5

Supply voltage

24 VAC/DC ±10%, 50/60 Hz

Protection class

IP 20

Output voltage

12 VDC

Mounting

DIN rail mounted

Temperatures

operating/ surrounding

-10…+60°C

Power consumption

12 VA

Housing

Self-extinguishing ABS

Suitable for removable screw version:

wire size 0.14…1.5 mm2

Output: to

driver/controller

Suitable for one EXD-SH1

Two EXD-PM for one EXD-SH2

Charging time

60 seconds

Weight

125 g

Max. cable length

EXD-SH1/2

Backup battery type

Lead acid gel rechargeable battery

Protection class

IP 20

Number of backup

batteries

Supply voltage

24 VAC ±10%, 50-60 Hz

Housing

Aluminum

Screw terminals

for wire size 0.5…2.5 mm2

Number of outputs to

drivers

< 90%

non-condensing

K09-U00

Part No: 804559

Temperatures

operating/ surrounding

-10…+60°C

Weight

1200 g

,

70

35

35

117,5

Ø4,3

110

1

2

5

,

5

4

5

59,5

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Optional EXD-PM Supercap

Max. output current

Terminals

- 1.2 A

- 350 mA during charging

Storage

Relative humidity

between EXD-PM and

50 cm

AWG18 wire size

Marking

Optional Uninterruptible Power Supply ECP-024

2, each 12 VDC, 0.8 Ah Mounting DIN rail mounted

Output voltage, UB 18 VDC Connection

2 Relative humidity

Battery recharge time approximately 2 hours Accessories: Terminals

Storage

-20…+65°C

Marking

-20…+70°C

20…85%

non-condensing

,

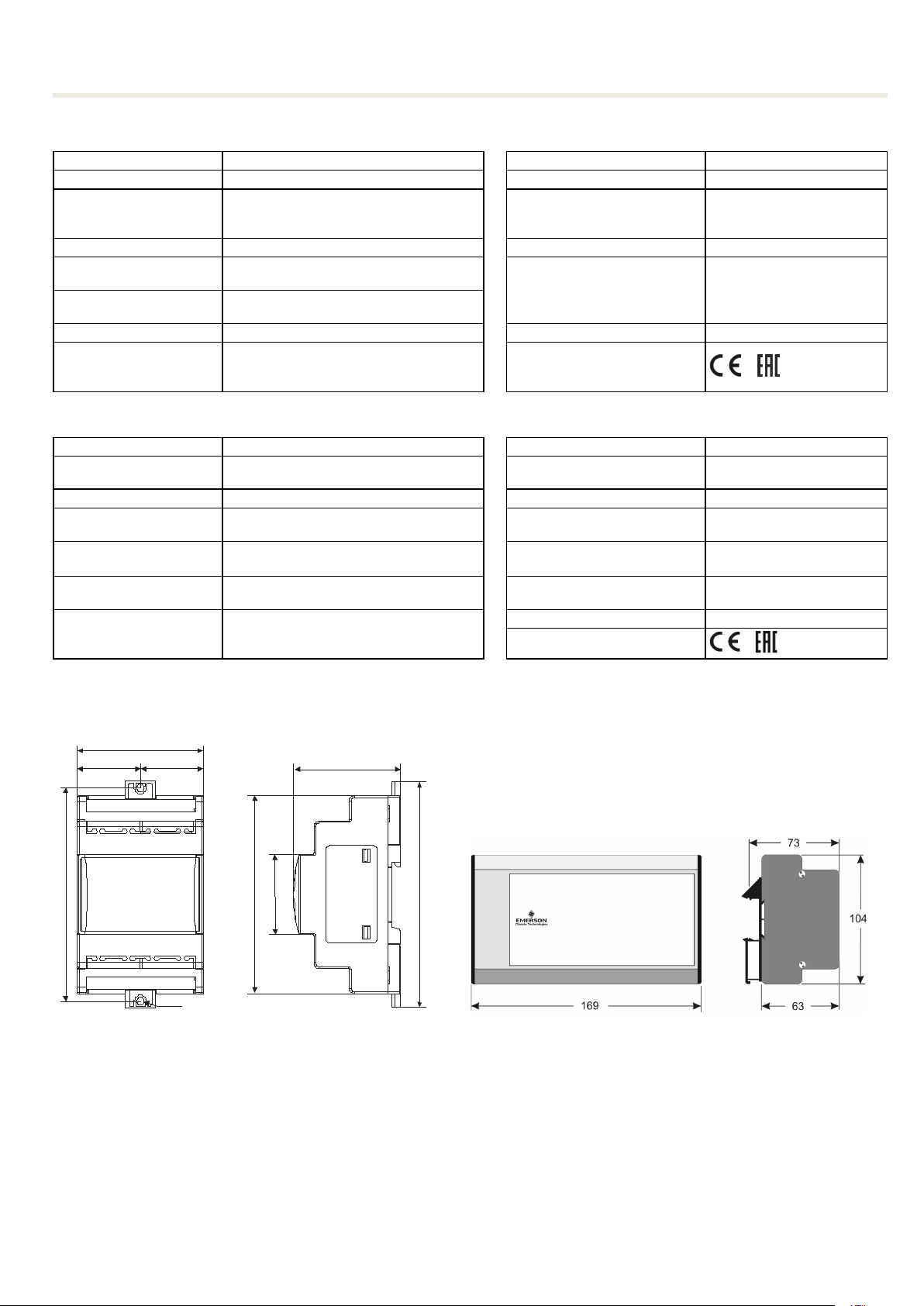

Dimensions (mm)

EXD-SH1/2 or EXD-PM ECP-024

EXD-SH12_TB_EN_0720_R08.docx

5

Page 6

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Communication

The use of communication is not necessary/mandatory; however, the communication is available for connection to upper level of system

controller (third party controller) in order to perform data and commands transfer as well as data logging. EXD-SH1/2 act as slave and

third party controller is master. In case of several EXD-SH1/2 connections to master, each driver needs to be addressed for proper

communication.

Bus topology

ModBus protocol details

Mode: RTU

Modbus slave address range: 1 to 127 (parameter Adr)

Baud rate: 9600 bps, 19200 bps (default, parameter Br)

Start bit: 1

Data bits: 8

Parity: even (default), no parity (parameter Par)

Stop bits: 1

Master response timeout: 500ms

Transmission Details

ModBus register address ranges

Read-only data: Starting address: 0x0100 (256)

Writable data: Starting address: 0x0200 (512)

Configuration data: Starting address: 0x0300 (768)

6

EXD-SH12_TB_EN_0720_R08.docx

Page 7

Function code

1 Byte

0x03

Starting Address

2 Bytes

0x0000 to 0xFFFF

Register count

2 Bytes

1 to 125 (0x7D)

Function code

1 Byte

0x03

Byte count

1 Byte

2 x N*

Holding Registers

N* x 2 Bytes

Error code

1 Byte

0x83

Exception code

1 Byte

01 or 02 or 03

Function code

1 Byte

0x06

Starting Address

2 Bytes

0x0000 to 0xFFFF

Value

2 Bytes

0x0000 to 0xFFFF

Function code

1 Byte

0x06

Starting Address

2 Bytes

0x0000 to 0xFFFF

Value

2 Bytes

0x0000 to 0xFFFF

Error code

1 Byte

0x86

Exception code

1 Byte

01 or 02 or 03

Function code

1 Byte

0x10

Start Address

2 Bytes

0x0000 to 0xFFFF

Register count

2 Bytes

0x0001 to 0x0078

Byte count

1 Byte

2 x N

Registers values

2 x N Bytes

Value

Function code

1 Byte

0x10

Starting Address

2 Bytes

0x0000 to 0xFFFF

Register count

2 Bytes

0x0001 to 0x0078

Error code

1 Byte

0x90

Exception code

1 Byte

01 or 02 or 03

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Read Data transmission

Available through Modbus Function code 03 (0x03) Read Holding Registers

Request

Response

*N = Quantity of Input Registers

Error

01 = Function code not supported

02 = Starting Address or register count out of range

03 = Register count out of range

Write Data transmission (single register)

Available through Modbus Function code 06 (0x06) Write Holding Register

Request

Response

Error

01 = Function code not supported

02 = Starting Address out of range

Write Data transmission (multiple registers)

Available through Modbus Function code 16 (0x10) Write Holding Registers

Request

N = register count.

Response

Error

01 = Function code not supported

02 = Register Address invalid

03 = Register Value out of range

EXD-SH12_TB_EN_0720_R08.docx

7

Page 8

256 / 0x100

Software version

0 = superheat control

2 = reverse temperature control

258 / 0x102

Valve opening circuit 1

1/100%

0x0000: No demand

0x0001: Demand

260 / 0x104

Digital output circuit 1

0x0001: alarm relay

261 / 0x105

P1 suction pressure circuit 1

1/100 barg

262 / 0x106

T1 suction temperature circuit 1

1/100°C

263 / 0x107

Sat. Temp circuit 1

1/100°C

0 = No failure

1 = Failure

0 = No failure

1 = Failure

0x0001 = N/A 0x0002 = Low pressure

0x0040 = Min. Temp (Temp. control)

0x0001 = Temp sensor 1 0x0002 = Temp sensor 2 (SH2)

0x0100 = Config inconsistency 2 0x0200 = Power Failure

0 = OFF 5 = Alarm

4 = Closing

269 / 0x10D

Superheat set point circuit 1

1/100 K

270 / 0x10E

Superheat circuit 1

1/100 K

271 / 0x10F

Valve opening circuit 2

1/100%

0 = no demand

1 = demand

273 / 0x111

Digital output circuit 2

0x0001: alarm relay

274 / 0x112

P2 suction pressure circuit 2

1/100 bar

275 / 0x113

T2 suction temperature circuit 2

1/100°C

276 / 0x114

Sat. Temp circuit 2

1/100°C

0 = No failure

1 = Failure

278 / 0x116

Temp 2 sensor failure circuit 2

0 = No failure

1 = Failure

279 / 0x117

Functional alarm circuit 2

0x0001 = N/A 0x0002 = Low pressure

0x0010 = Freeze

280 / 0x118

Application state circuit 2

0 = OFF 5 = Alarm

4 = Closing

281 / 0x119

Superheat setpoint circuit 2

1/100 K

282 / 0x11A

Superheat circuit 2

1/100 K

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Read-only variables

Modbus

address

dec. / hex.

Description Unit Remarks

Circuit 1

257 / 0x101 Main function, circuit 1

259 / 0x103 Digital input circuit 1

264 / 0x108 Pressure 1 sensor failure circuit 1

265 / 0x109 Temp 1 sensor failure circuit 1

266 / 0x10A Functional Alarm set circuit 1

267 / 0x10B Hardware alarm set

268 / 0x10C Application state circuit 1

1 = temperature control

0x0004 = High superheat 0x0008 = Low superheat

0x0010 = Freeze 0x0020 = Max. Temp (Tem p. control)

0x0004 = Pressure sensor 0x0008 = Pressure sensor 2 (SH2)

0x0010 = Stepper 1 0x0020 = Stepper 2 (SH2)

0x0040 = Modbus timeout (3 sec.) 0x0080 = Config inconsistency 1

1 = Waiting startup (valve ref pending) 6 = Manual mode

2 = Startup 7 = Power fail

3 = Control 8 = MOP

272 / 0x110 Digital input circuit 2

277 / 0x115 Pressure 2 sensor failure circuit 2

Circuit 2

0x0004 = High superheat 0x0008 = Low superheat

1 = Waiting startup (valve ref pending) 6 = Manual mode

2 = Startup 7 = Power fail

3 = Control 8 = MOP

8

EXD-SH12_TB_EN_0720_R08.docx

Page 9

Description

512 / 0x200

Factory default

1 = do a factory default

513 / 0x201

Future use

514 / 0x202

Alarm reset

1 = Resets alarms (only the alarms which are set as manual reset)

Manual mode Circuit 1

0 = off

1 = on

516 / 0x204

1HP

Manual valve opening Circuit 1

%

only active while manual mode is ”on”

Alternative to digital input, circuit 1 via

Modbus

Demand circuit 1

0

1 = enabled

Pressure circuit 1 via Modbus

Pressure if 1uP selection is Modbus Range: -0.1 to 150 barg

Minimum update rate: 1s Alarm timeout: 3 sec.

Digital output circuit 1

To set the relay 1 manually, only active when manual mode circuit1 is

”

0

1 = on

Manual mode

0 = off

1 = on

521 /0x209

2HP

Manual valve opening Circuit 2

%

only active while manual mode 2 = on

Alternative to digital input, circuit 2 via

Modbus

Demand circuit 2

0

1 = enabled

Pressure

Pressure if 2uP selection is Modbus Range: -0.1 to 150 barg

Minimum update rate: 1s Alarm timeout: 3 sec.

Digital output circuit 2

To set the relay 2 manually, only active when manual mode circuit 2 is

“

0

1 = on

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Writable variables

Modbus

address

dec. / hex.

Display

code

Units Remarks

515 / 0x203 1Ho

517 / 0x205

518 / 0x206

519 / 0x207

520 / 0x208 2Ho

522 / 0x20A

523 / 0x20B

524 / 0x20C

Note: References to control circuit 2 of EXD-SH2 are invisible in configuration/write list if disabled.

circuit 2 via Modbus 1/100 barg

1/100 barg

Circuit 2

= disabled

on”

= off

= disabled

on”

= off

EXD-SH12_TB_EN_0720_R08.docx

9

Page 10

768 /0x300

H5

Password

12

1 - 1999

769 /0x301

Adr

Modbus address

1 1 - 127

0 = 9600 baud

1 = 19200 baud

0 = parity even

1 = no parity

0 = circuit 2 disabled

1 = circuit 2 enabled Only EXD-SH2

0 = °C, K, barg 1 = °F, psig

based.

775 / 0x307

Future use

776 / 0x308

Future use

Changes only allowed if circuit 1 is in “OFF” state

2 = Temperature control Reverse sense

0 = standard control

3 = adjustable fixed PID

Changes only allowed if circuit 1 is in “OFF” state

18 = R1270 19 = R454C

Changes only allowed if circuit 1 is in “OFF” state

8 = Modbus

781 / 0x30D

1Prr

Ratio metric range 1

1/10 bar

30

3 - 60

If ratio metric is used

Changes only allowed if circuit 1 is in “OFF” state

12 = CV7

783 / 0x30F

1uF

Valve scaling 1

%

100

5 - 100

784 / 0x310

1uu

Start opening valve1

%

10

0 - 100

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

Basically 2 variants are possible to set the parameters:

1. Configuration parameters in flash memory - Max. 1000 overwrite cycle limitation!

2. Configuration parameters in RAM memory - unlimited overwrite cycles possible

1. Configuration parameters In Flash memory - Max. 1000 overwrite cycle limitation

Modbus

address

dec. / hex.

770 / 0x302 br Modbus baudrate 0 0 - 1

771 / 0x303 PAr Modbus parity 0 0 - 1

773 / 0x305 -C2 Circuit 2 Enabled

Display

Note: In case of power failure, the stored data from the RAM memory will be lost and controller switches to the

configuration data. (Factory setting)

code

Description Unit

2

1 0 - 1

Default

value

Range Remarks

774 / 0x306 -uC Units conversion 0 0 - 1

Note: 2) References to control circuit 2 if EXD-SH2 are invisible in configuration/write list if disabled

Modbus

address

dec. / hex.

777 / 0x309 1Fct Function circuit 1 0 0 - 2

778 / 0x30A 1u4 Control mode circuit 1 0 0 - 3

779 / 0x30B 1u0 Refrigerant circuit 1 1 0 - 19

780 / 0x30C 1uP Pressure sensor type 1 1 0 - 8

Display

code

Description Unit

Default

value

Circuit 1

Range Remarks

This parameter only affects the display. Internally (as well

as for MODBUS communication) the units are always SI-

0 = superheat control

1 = Temperature control Normal sense

1 = slow control

2 = intermediate control

0 = R22 1 = R134a 2 = R507

3 = R404A 4 = R407C 5 = R410A

6 = R124 7 = R744 8 = R407A

9 = R407F 10 = R23 11 = R32

12 = R1234ze 13 = R448A 14 = R449A

15 = R450A 16 = R513A 17 = R290

0 = PT5N-07x 1 = PT5N-18x

2 = PT5N-30x 3 = PT5N-50x

4 = PT5N-150 5 = PT5N-10P-FLR

6 = Ratio metric(gauge) 7 = Ratio metric(absolute)

782 / 0x30E 1ut Valve type 1 0 0 - 12

10

0 = EX4-6 1 = EX7 2 = EX8 3 = N/A

4 = N/A 5 = N/A 6 = N/A 7 = N/A

8 = N/A 9 = N/A 10 = CV4 11 = CV5+6

EXD-SH12_TB_EN_0720_R08.docx

Page 11

785 / 0x311

1u9

Start opening duration valve 1

s 5 0 - 120

0 = disabled

2 = enabled manual reset

787 / 0x313

1u5

Superheat setpoint circuit 1

1/10 K 6 0.5 - 30

Range = 3 – 30K with 1uL = 1 or 2

0 = disabled

1 = enabled

789 / 0x315

1u3

MOP sat. temp. limit circuit1

1/10°C

see MOP table (page 16)

0 = disabled

2 = enabled manual reset

Low pressure alarm cut-out

circuit1

Low pressure alarm delay

circuit1

Low pressure alarm cut-in

circuit1

0 = disabled

2 = enabled manual reset

795 / 0x31B

1P2

Freeze alarm cut-out circuit1

1/10°C 0 -5 - 5

796 / 0x31C

1P5

Freeze alarm delay circuit1

s

30

5 - 199

High superheat alarm mode

circuit 1

0 = disabled

1 = enabled auto-reset

High superheat alarm setpoint

circuit 1

High superheat alarm delay

circuit 1

800 / 0x320

1tSt

Temperature set point

1/10°C 4 -80 - 50

801 / 0x321

1tbd

Temperature band

1/10 K 2 1 - 10

0 = disabled

1 = enabled

Min. temperature alarm setpoint

804 / 0x324

1tdL

Min. temperature alarm delay

min 3 1 - 10

Max. temperature alarm setpoint

806 / 0x326

1tdH

Max. temperature alarm delay

min 3 1 - 10

807 / 0x327

Future use

808 / 0x328

Future use

0 = TP1-N…

1 = ECN-Z60

Superheat control circuit1

fixed PID Kp factor

Superheat control circuit1

fixed PID Ti factor

Superheat control circuit1

fixed PID Td factor

Display 1/10K,

Kd = Kp*Td

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

1. Configuration parameters In Flash memory - Max. 1000 overwrite cycle limitation (continued)

Modbus

address

dec. / hex.

Display

code

Description Unit

Default

value

Range Remarks

786 / 0x312 1uL

788 / 0x314 1u2 MOP mode circuit 1 1 0 - 1

790 / 0x316 1P9

791 / 0x317 1PA

792 / 0x318 1Pb

793 / 0x319 1Pd

794 / 0x31A 1P4 Freeze alarm mode circuit1 0 0 - 2

797 / 0x31D 1uH

798 / 0x31E 1uA

799 / 0x31F 1ud

Low superheat alarm mode

circuit 1

Low pressure alarm mode

circuit1

1 0 - 2

0 0 - 2

1/10 bar 0 -0.8 - 17.7

s 5 5 - 199

1/10 bar 0.3 -0.5 - 18

0 0 - 1

1/10 K 30 16 - 40

min 3 1-15

1 = enabled auto-reset

1 = enabled auto-reset

1 = enabled auto-reset

802 / 0x322 1tAF Temperature Alarm Enable 0 0 - 1

803 / 0x323 1tAL

805 / 0x325 1tAH

809 / 0x329 1tt- Temperature sensor type 0 0 - 1

852 / 0x354 1P-

853 / 0x355 1i-

854 / 0x356 1d-

1/10°C 0 -50 - 50

1/10°C 15 -50 - 50

1/10 1.0 0.1 - 10 Display 1/10K

s 100 1 - 350 Ki = Kp/Ti

1/10s 3.0 0.1 – 30

EXD-SH12_TB_EN_0720_R08.docx

11

Page 12

0 = standard control

3 = adjustable fixed PID

Changes only allowed if circuit 2 is in OFF state

18 = R1270 19 = R454C

Changes only allowed if circuit 2 is in “OFF” state

circuit1

813 / 0x32D

2Prr

Ratio metric range circuit 2

1/10 bar

30

3 - 60

If ratio metric is used

Changes only allowed if circuit 2 is in “OFF” state

12 = CV7

815 / 0x32F

2uF

Valve scaling circuit 2

%

100

5 - 100

816 / 0x330

2uu

Start opening valve circuit 2

%

10

0 - 100

Start opening duration valve

circuit 2

0 = disabled

2 = enabled manual reset

819 / 0x333

2u5

Superheat setpoint circuit 2

1/10 K

6

0.5 - 30

Range = 3 – 30K with 1uL = 1 or 2

0 = disabled

1 = enabled

821 / 0x335

2u3

MOP sat. temp. limit circuit 2

1/10°C

see MOP table (page 16)

0 = disabled

2 = enabled manual reset

Low pressure alarm cut-out

circuit 2

Low pressure alarm delay

circuit 2

Low pressure alarm cut-in

circuit 2

0 = disabled

2 = enabled manual reset

827 / 0x33B

2P2

Freeze alarm cut-out circuit 2

1/10°C

0

-5 - 5

828 / 0x33C

2P5

Freeze alarm delay circuit 2

s

30

5 - 199

High superheat alarm mode

circuit 2

0 = disabled

1 = enabled auto-reset

High superheat alarm setpoint

circuit 2

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

1. Configuration parameters In Flash memory - Max. 1000 overwrite cycle limitation (continued)

Modbus

address

dec. / hex.

Display

code

Description Unit

Default

value

Circuit 2

Range Remarks

810 / 0x32A 2u4 Control mode circuit 2 0 0 - 3

811 / 0x32B 2u0 Refrigerant circuit 2 1 0 - 19

812 / 0x32C 2uP Pressure sensor type circuit 2 1 0 - 9

814 / 0x32E 2ut Valve type circuit 2 0 0 - 12

817 / 0x331 2u9

818 / 0x332 2uL

Low superheat alarm mode

circuit 2

s 5 0 - 120

1 0 - 2

1 = slow control

2 = intermediate control

0 = R22 1 = R134a 2 = R507

3 = R404A 4 = R407C 5 = R410A

6 = R124 7 = R744 8 = R407A

9 = R407F 10 = R23 11 = R32

12 = R1234ze 13 = R448A 14 = R449A

15 = R450A 16 = R513A 17 = R290

0 = PT5N-07x 1 = PT5N-18x

2 = PT5N-30x 3 = PT5N-50x

4 = PT5N-150 5 = PT5N-10P-FLR

6 = Ratio metric(gauge) 7 = Ratio metric(absolute)

8 = Modbus

9 = Pressure sensor type and refrigerant settings from

0 = EX4-6 1 = EX7 2 = EX8 3 = N/A

4 = N/A 5 = N/A 6 = N/A 7 = N/A

8 = N/A 9 = N/A 10 = CV4 11 = CV5+6

1 = enabled auto-reset

820 / 0x334 2u2 MOP mode circuit 2 1 0 - 1

822 / 0x336 2P9

823 / 0x337 2PA

824 / 0x338 2Pb

825 / 0x339 2Pd

826 / 0x33A 2P4 Freeze alarm mode circuit 2 0 0 - 2

829 / 0x33D 2uH

830 / 0x33E 2uA

Low pressure alarm mode

circuit 2

0 0 - 2

1/10 bar 0 -0.8 - 17.7

s 5 5 - 199

1/10 bar 0.3 -0.5 - 18

0 0 - 1

1/10 K 30 16 - 40

1 = enabled auto-reset

1 = enabled auto-reset

12

EXD-SH12_TB_EN_0720_R08.docx

High superheat alarm delay

circuit 2

Page 13

0 = TP1-N…

1 = ECN-Z60

Superheat control circuit 2

fixed PID Kp factor

Superheat control circuit 2

fixed PID Ti factor

Superheat control circuit 2

fixed PID Td factor

Display 1/10K,

Kd = Kp*Td

1792 / 0x700

NA

1793 / 0x701

NA

1794 / 0x702

NA

1795 / 0x703

NA

0 = circuit 2 disabled

1 = circuit 2 enabled Only EXD-SH2

0 = °C, K, barg

This parameter only affects the display. Internally (as well

-

based.

1799 / 0x707

Future use

1800 / 0x708

Future use

Changes only allowed if circuit 1 is in “OFF” state

2 = Temperature control Reverse sense

0 = standard control

3 = adjustable fixed PID

Changes only allowed if circuit 1 is in “OFF” state

18 = R1270 19 = R454C

Changes only allowed if circuit 1 is in “OFF” state

8 = Modbus

1805 / 0x70D

1Prr

Ratio metric range 1

1/10 bar

30

3 - 60

If ratio metric is used

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

1. Configuration parameters In Flash memory - Max. 1000 overwrite cycle limitation (continued)

Modbus

address

dec. / hex.

Display

code

Description Unit

Default

value

Range Remarks

831 / 0x33F 2ud

832 / 0x340 2tt- Temperature sensor type 0 0 - 1

833 / 0x341 2P-

834 / 0x342 2i-

835 / 0x343 2d-

min 3 1-15

1/10 1.0 0.1 - 10 Display 1/10K

s 100 1 - 350 Ki = Kp/Ti

1/10s 3.0 0.1 – 30

2. Configuration parameters in RAM memory - unlimited overwrite cycles

Note: In case of power failure, the stored data from the RAM memory will be lost and switch to the configuration data. (Factory setting)

Modbus

address

dec. / hex.

1797 / 0x705 -C2

1798 / 0x706 -uC Units conversion 0 0 - 1

Display

code

Description Unit

Circuit 2 Enabled

3

Default

value

1 0 - 1

Range Remarks

1 = °F, psig

as for MODBUS communication) the units are always SI

Note: 3) References to control circuit 2 of EXD-SH2 are invisible in configuration/write list if disabled

Modbus

address

dec. / hex.

1801 / 0x709 1Fct Function circuit 1 0 0 - 2

1802 / 0x70A 1u4 Control mode circuit 1 0 0 - 3

1803 / 0x70B 1u0 Refrigerant circuit 1 1 0 - 19

1804 / 0x70C 1uP Pressure sensor type 1 1 0 - 8

Display

code

Description Unit

Default

value

Circuit 1

Range Remarks

0 = superheat control

1 = Temperature control Normal sense

1 = slow control

2 = intermediate control

0 = R22 1 = R134a 2 = R507

3 = R404A 4 = R407C 5 = R410A

6 = R124 7 = R744 8 = R407A

9 = R407F 10 = R23 11 = R32

12 = R1234ze 13 = R448A 14 = R449A

15 = R450A 16 = R513A 17 = R290

0 = PT5N-07x 1 = PT5N-18x

2 = PT5N-30x 3 = PT5N-50x

4 = PT5N-150 5 = PT5N-10P-FLR

6 = Ratio metric(gauge) 7 = Ratio metric(absolute)

EXD-SH12_TB_EN_0720_R08.docx

13

Page 14

Changes only allowed if circuit 1 is in “OFF” state

12 = CV7

1807 / 0x70F

1uF

Valve scaling 1

%

100

5 - 100

1808 / 0x710

1uu

Start opening valve1

%

10

0 - 100

Start opening duration valve

1

0 = disabled

2 = enabled manual reset

1811 / 0x713

1u5

Superheat setpoint circuit 1

1/10 K

6

0.5 - 30

Range = 3 – 30K with 1uL = 1 or 2

0 = disabled

1 = enabled

1813 / 0x715

1u3

MOP sat. temp. limit circuit1

1/10°C

see MOP table (page 16)

0 = disabled

2 = enabled manual reset

Low pressure alarm cut-out

circuit1

Low pressure alarm delay

circuit1

Low pressure alarm cut-in

circuit1

0 = disabled

2 = enabled manual reset

1819 / 0x71B

1P2

Freeze alarm cut-out circuit1

1/10°C 0 -5 - 5

1820 / 0x71C

1P5

Freeze alarm delay circuit1

s

30

5 - 199

High superheat alarm mode

circuit 1

0 = disabled

1 = enabled auto-reset

High superheat alarm

setpoint circuit 1

High superheat alarm delay

circuit 1

1824 / 0x720

1tSt

Temperature set point

1/10°C

4

-80 - 50

1825 / 0x721

1tbd

Temperature band

1/10 K

2

1 - 10

0 = disabled

1 = enabled

Min. temperature alarm setpoint

Min. temperature alarm

delay

Max. temperature alarm setpoint

Max. temperature alarm

delay

1831 / 0x727

Future use

1832 / 0x728

Future use

0 = TP1-N…

1 = ECN-Z60

Superheat control circuit1

fixed PID Kp factor

Superheat control circuit1

fixed PID Ti factor

Superheat control circuit1

fixed PID Td factor

Display 1/10K,

Kd = Kp*Td

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

2. Configuration parameters in RAM memory - unlimited overwrite cycles possible (continued)

Modbus

address

dec. / hex.

1806 / 0x70E 1ut Valve type 1 0 0 - 12

Display

code

Description Unit

Default

value

Range Remarks

0 = EX4-6 1 = EX7 2 = EX8 3 = N/A

4 = N/A 5 = N/A 6 = N/A 7 = N/A

8 = N/A 9 = N/A 10 = CV4 11 = CV5+6

1809 / 0x711 1u9

1810 / 0x712 1uL

1812 / 0x714 1u2 MOP mode circuit 1 1 0 - 1

1814 / 0x716 1P9

1815 / 0x717 1PA

1816 / 0x718 1Pb

1817 / 0x719 1Pd

1818 / 0x71A 1P4 Freeze alarm mode circuit1 0 0 - 2

1821 / 0x71D 1uH

1822 / 0x71E 1uA

1823 / 0x71F 1ud

Low superheat alarm mode

circuit 1

Low pressure alarm mode

circuit1

s 5 0 - 120

1 0 - 2

0 0 - 2

1/10 bar 0 -0.8 - 17.7

s 5 5 - 199

1/10 bar 0.3 -0.5 - 18

0 0 - 1

1/10 K 30 16 - 40

min 3 1-15

1 = enabled auto-reset

1 = enabled auto-reset

1 = enabled auto-reset

1826 / 0x722 1tAF Temperature Alarm Enable 0 0 - 1

1827 / 0x723 1tAL

1828 / 0x724 1tdL

1829 / 0x725 1tAH

1830 / 0x726 1tdH

1833 / 0x729 1tt- Temperature sensor type 0 0 - 1

1876 / 0x754 1P-

1877 / 0x755 1i-

1878 / 0x756 1d-

1/10 °C 0 -50 - 50

min 3 1 - 10

1/10°C 15 -50 - 50

min 3 1 - 10

1/10 1.0 0.1 - 10 Display 1/10K

s 100 1 - 350 Ki = Kp/Ti

1/10s 3.0 0.1 – 30

14

EXD-SH12_TB_EN_0720_R08.docx

Page 15

0 = standard control

3 = adjustable fixed PID

Changes only allowed if circuit 2 is in “OFF” state

18 = R1270 19 = R454C

Changes only allowed if circuit 2 is in “OFF” state

circuit1

1837 / 0x72D

2Prr

Ratio metric range circuit 2

1/10 bar

30

3 - 60

If ratio metric is used

Changes only allowed if circuit 2 is in “OFF” state

12 = CV7

1839 / 0x72F

2uF

Valve scaling circuit 2

%

100

5 - 100

1840 / 0x730

2uu

Start opening valve circuit 2

%

10

0 - 100

Start opening duration valve

circuit 2

0 = disabled

2 = enabled manual reset

1843 / 0x733

2u5

Superheat setpoint circuit 2

1/10 K

6

0.5 - 30

Range = 3 – 30K with 1uL = 1 or 2

0 = disabled

1 = enabled

1845 / 0x735

2u3

MOP sat. temp. limit circuit 2

1/10°C

see MOP table (page 16)

0 = disabled

2 = enabled manual reset

Low pressure alarm cut-out

circuit 2

Low pressure alarm delay

circuit 2

Low pressure alarm cut-in

circuit 2

0 = disabled

2 = enabled manual reset

Freeze alarm cut-out circuit

2

1852 / 0x73C

2P5

Freeze alarm delay circuit 2

s

30

5 - 199

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

2. Configuration parameters in RAM memory - unlimited overwrite cycles (continued)

Modbus

address

dec. / hex.

Display

code

Description Unit

Default

value

Circuit 2

Range Remarks

1834 / 0x72A 2u4 Control mode circuit 2 0 0 - 3

1835 / 0x72B 2u0 Refrigerant circuit 2 1 0 - 19

1836 / 0x72C 2uP

1838 / 0x72E 2ut Valve type circuit 2 0 0 - 12

1841 / 0x731 2u9

1842 / 0x732 2uL

Pressure sensor type circuit

2

Low superheat alarm mode

circuit 2

1 0 - 9

s 5 0 - 120

1 0 - 2

1 = slow control

2 = intermediate control

0 = R22 1 = R134a 2 = R507

3 = R404A 4 = R407C 5 = R410A

6 = R124 7 = R744 8 = R407A

9 = R407F 10 = R23 11 = R32

12 = R1234ze 13 = R448A 14 = R449A

15 = R450A 16 = R513A 17 = R290

0 = PT5N-07x 1 = PT5N-18x

2 = PT5N-30x 3 = PT5N-50x

4 = PT5N-150 5 = PT5N-10P-FLR

6 = Ratio metric(gauge) 7 = Ratio metric(absolute)

8 = Modbus

9 = Pressure sensor type and refrigerant settings from

0 = EX4-6 1 = EX7 2 = EX8 3 = N/A

4 = N/A 5 = N/A 6 = N/A 7 = N/A

8 = N/A 9 = N/A 10 = CV4 11 = CV5+6

1 = enabled auto-reset

1844 / 0x734 2u2 MOP mode circuit 2 1 0 - 1

1846 / 0x736 2P9

1847 / 0x737 2PA

1848 / 0x738 2Pb

1849 / 0x739 2Pd

1850 / 0x73A 2P4 Freeze alarm mode circuit 2 0 0 - 2

1851 / 0x73B 2P2

Low pressure alarm mode

circuit 2

0 0 - 2

1/10 bar 0 -0.8 - 17.7

s 5 5 - 199

1/10 bar 0.3 -0.5 - 18

1/10°C 0 -5 - 5

1 = enabled auto-reset

1 = enabled auto-reset

EXD-SH12_TB_EN_0720_R08.docx

15

Page 16

High superheat alarm mode

circuit 2

0 = disabled

1 = enabled auto-reset

High superheat alarm

setpoint circuit 2

High superheat alarm delay

circuit 2

0 = TP1-N…

1 = ECN-Z60

Superheat control circuit 2

fixed PID Kp factor

Superheat control circuit 2

fixed PID Ti factor

Superheat control circuit 2

fixed PID Td factor

Display 1/10K,

Kd = Kp*Td

Min.

Max.

Default

Min.

Max.

Default

Min.

Max.

Default

R22

-70

50

+13

R744

-40

-4

-5

R449A

-57

66

+12

R134a

-57

66

+15

R407A

-66

48

+10

R450A

-57

66

+19

R507

-75

42

+7

R407F

-66

48

+10

R513A

-57

66

+13

R404A

-76

42

+7

R23

-70

-18

-40

R290

-66

48

+15

R407C

-66

48

+15

R32

-52

30

+15

R1270

-66

48

+15

R410A

-52

30

+15

R1234ze

-57

66

+24

R454C

-66

48

+17

R124

-45

91

+50

R448A

-57

66

+12

EXD-SH1/2 Controller for electrical control valves with ModBus Communication Capability

2. Configuration parameters in RAM memory - unlimited overwrite cycles (continued)

Modbus

address

dec. / hex.

Display

code

Description Unit

Default

value

Range Remarks

1853 / 0x73D 2uH

1854 / 0x73E 2uA

1855 / 0x73F 2ud

1856 / 0x740 2tt- Temperature sensor type 0 - 1

1857 / 0x741 2P-

1858 / 0x742 2i-

1859 / 0x743 2d-

0 0 - 1

1/10 K 30 16 - 40

min 3 1-15

1/10 1.0 0.1 - 10 Display 1/10K

s 100 1 - 350 Ki = Kp/Ti

1/10s 3.0 0.1 – 30

MOP saturation temperature limit table

Refrigerant

°C

Refrigerant

°C

Refrigerant

°C

EXD-SH12_TB_EN_0720_R08.docx

Emerson Climate Technologies GmbH shall not be liable for errors in the stated capacities, dimensions, etc., as well as typographic errors. Products, specifications, designs and technical data contained in

this document are subject to modi fication by us without prior notice. Illustrations are not binding.

The Emerson Climate Technologies logo is a trademark and service mark of Emerson Electric Co. Emerson Climate Technologies Inc. is a subsidiary of Emerson Electric Co.

Loading...

Loading...