Page 1

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

Fisher™ FIELDVUE™ DLC3100 and DLC3100 SIS

Digital Level Controllers

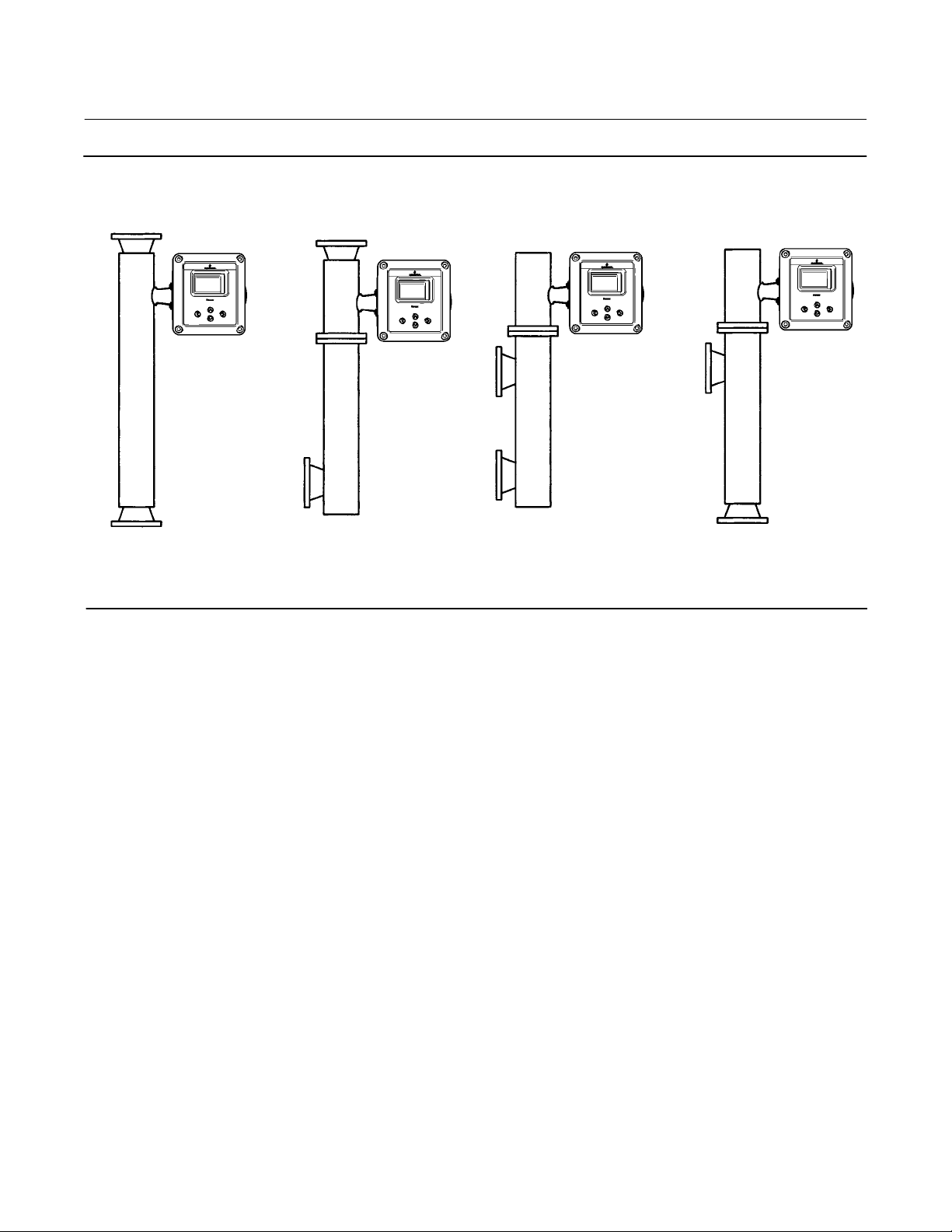

Figure 1. Fisher DLC3100 Digital Level Controller

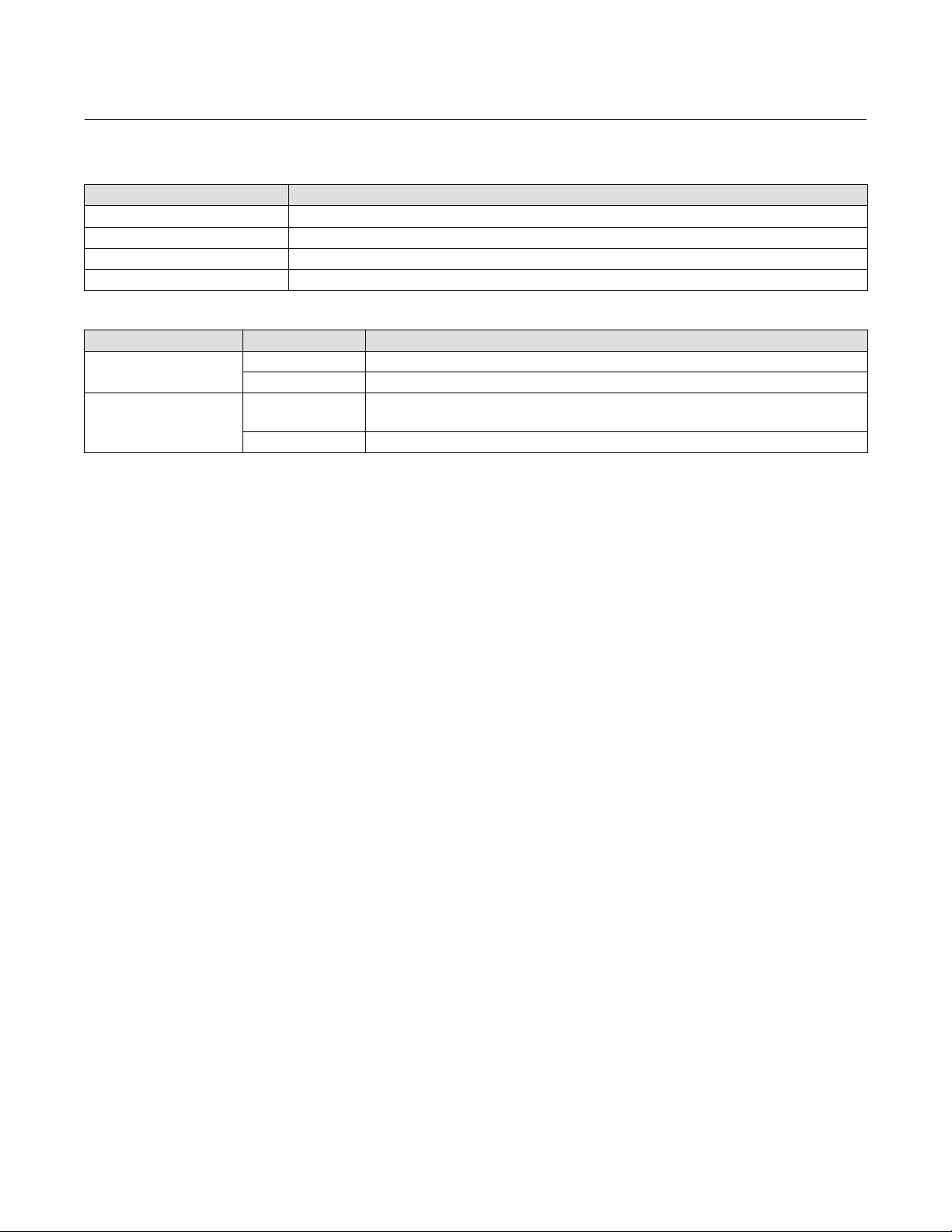

This manual applies to:

July 2019

Device Type

Device Revision

Hardware Revision

Firmware Revision

DD Revision

130D

1

1

1.0.9

1

Contents

Section 1 Introduction and Specifications 3.........

Scope of Manual 3.............................

Installation , Mounting and Electrical Connections,

and Initial Configuration and Calibration using

the Local User Interface 3....................

Conventions Used 3...........................

Description 3.................................

DLC3100 Digital Level Controller 3...........

249 Caged Sensors 5.......................

249 Cageless Sensors 5.....................

Related Documents 5..........................

Educational Services 8.........................

Section 2 Electrical Connections 13................

Test Connections 13...........................

Alarm Conditions 13...........................

Loop Test 14.................................

Section 3 Overview 15...........................

Status 15....................................

Primary Purpose Variables 15....................

Device Information 15.........................

Section 4 Configuration and Calibration using

AMS Device Manager or a Field Communicator 17...

Configuration Advice 20........................

Force Mode 20............................

Write Protection 20........................

Level Offset 20............................

Initial Setup 21................................

Device Setup 21...........................

PV Setup 23..............................

Process Setup 23..........................

X1456

Manual Setup 24..............................

General 25...............................

Device 25................................

Sensor 26................................

Process 26................................

HART 27.................................

Safety Recovery 27.........................

Alert Setup 28................................

Primary Variable 28........................

Rate Limit 29..............................

Temperature 29...........................

Operational 30............................

Informational 30..........................

Input Compensation 30.....................

Hardware 31..............................

Program and Memory 31...................

Alert Record 31............................

Calibration 32................................

Two Points Calibration 32...................

Min/Max Calibration 33.....................

Weight Calibration 34......................

www.Fisher.com

Page 2

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Two Points Time Delay Calibration 35.........

Zero Trim 36..............................

Gain Trim 36..............................

Torque Rate Gain 36.......................

Accuracy Considerations 37.....................

Effect of Proportional Band 37...............

Density Variations in Interface Applications 37..

Extreme Process Temperatures 38............

Temperature Compensation 38..............

Section 5 Service Tools 39.......................

Active Alerts 39...............................

Tests 40.....................................

Reset/Restore Device 41........................

Section 6 Maintenance and Troubleshooting 42.....

Alert Messages 42.............................

Hardware Diagnostics 43.......................

Removing the DLC3100 from the Sensor 45.......

Front Cover Assembly 48.......................

Removing the Front Cover Assembly 48.......

Replacing the Front Cover Assembly 49.......

Main Electronics Board 49......................

Removing the Main Electronics Board 49......

Replacing the Main Electronics Board 49.......

LCD Assembly 50..............................

Removing the LCD Assembly 50..............

Replacing the LCD Assembly 50..............

Terminal Box Electronics Board 50...............

Removing the Terminal Box

Electronics Board 50.....................

Replacing the Terminal Box

Electronics Board 51.....................

Packing for Shipment 51.......................

Section 7 Parts 52..............................

Parts Ordering 52.............................

Parts Kits 52..................................

Parts List 52..................................

Mounting Kits 56..............................

Sunshade 58.................................

Appendix A Principle of Operation 60..............

HART Communication 60.......................

Multidrop Communication 60...................

Digital Level Controller Operation 61.............

Appendix B Field Communicator Fast-Key

Sequence and Menu Tree 65.....................

2

Page 3

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

July 2019

Section 1

Introduction and Specifications

Scope of Manual

This instruction manual is a supplement to the DLC3100 and DLC3100 SIS Quick Start Guide (D104214X012) that

ships with every digital level controller. This instruction manual includes specifications, operating, and maintenance

information for FIELDVUE DLC3100 and DLC3100 SIS digital level controllers.

Notes

The DLC3100 SIS is identified by a label affixed to the terminal box cover.

Unless otherwise noted, the information in this document applies to both DLC3100 and DLC3100 SIS. However, for simplicity, the

DLC3100 model name will be used throughout.

This instruction manual supports the 475 Field Communicator with device description revision 1, used with DLC3100

instruments with firmware revision 1.0.9. You can obtain information about the process, instrument, or sensor using

the Field Communicator. Contact your Emerson sales office

to obtain the appropriate software.

Do not install, operate, or maintain a DLC3100 digital level controller without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is

important to carefully read, understand, and follow all the contents of this manual, including all safety cautions and

warnings. If you have any questions regarding these instructions, contact your Emerson sales office before proceeding.

Installation, Mounting and Electrical Connections, and Initial

Configuration and Calibration using the Local User Interface

Refer to the DLC3100 and DLC3100 SIS Quick Start Guide (D104214X012) for installation and connection information,

as well as initial configuration and calibration using the local user interface. If a copy of this quick start guide is needed

contact your Emerson sales office or visit Fisher.com.

Conventions Used

This manual describes using the Field Communicator to configure and calibrate the digital level controller.

Procedures that require the use of the Field Communicator have the text path and the sequence of numeric keys

required to display the desired Field Communicator menu.

Description

DLC3100 Digital Level Controller

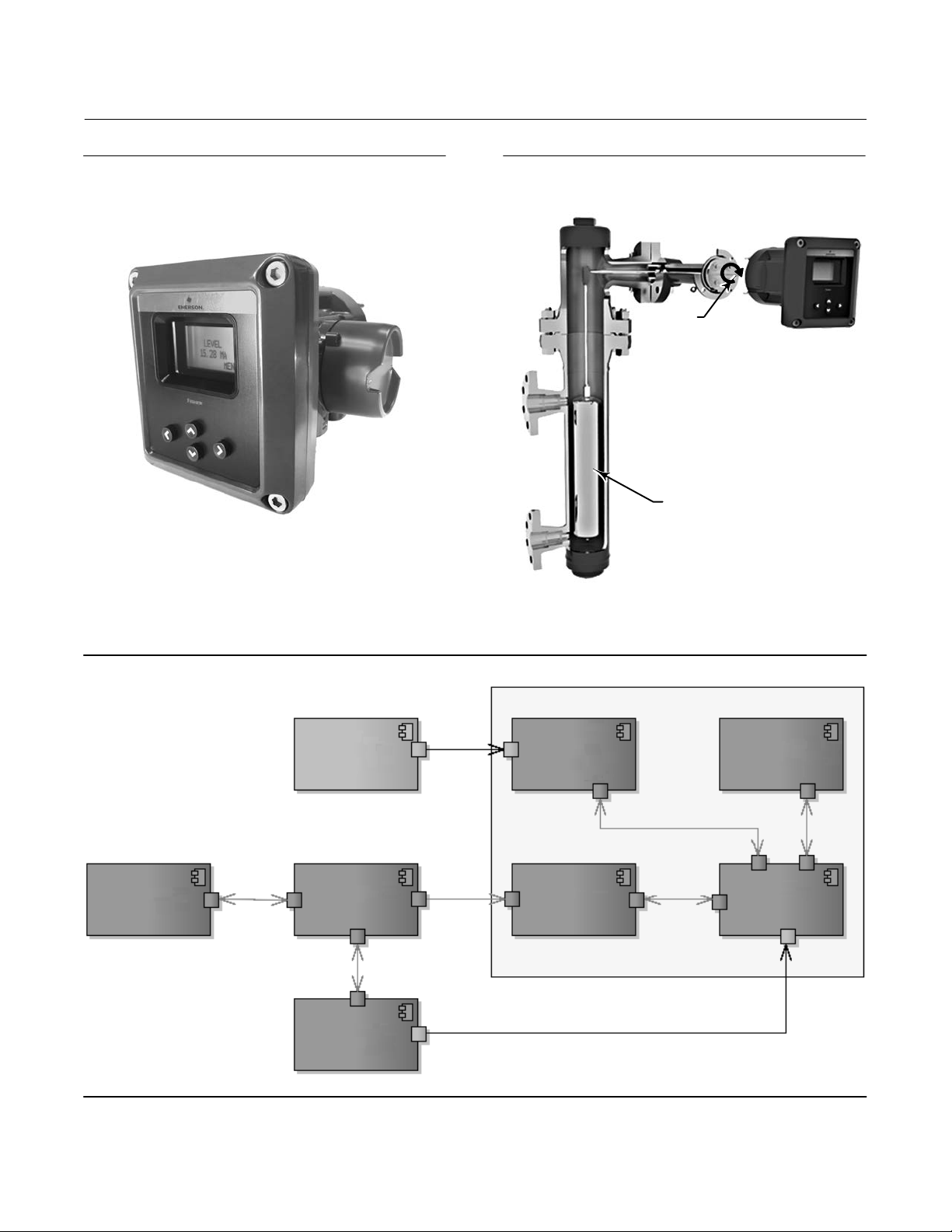

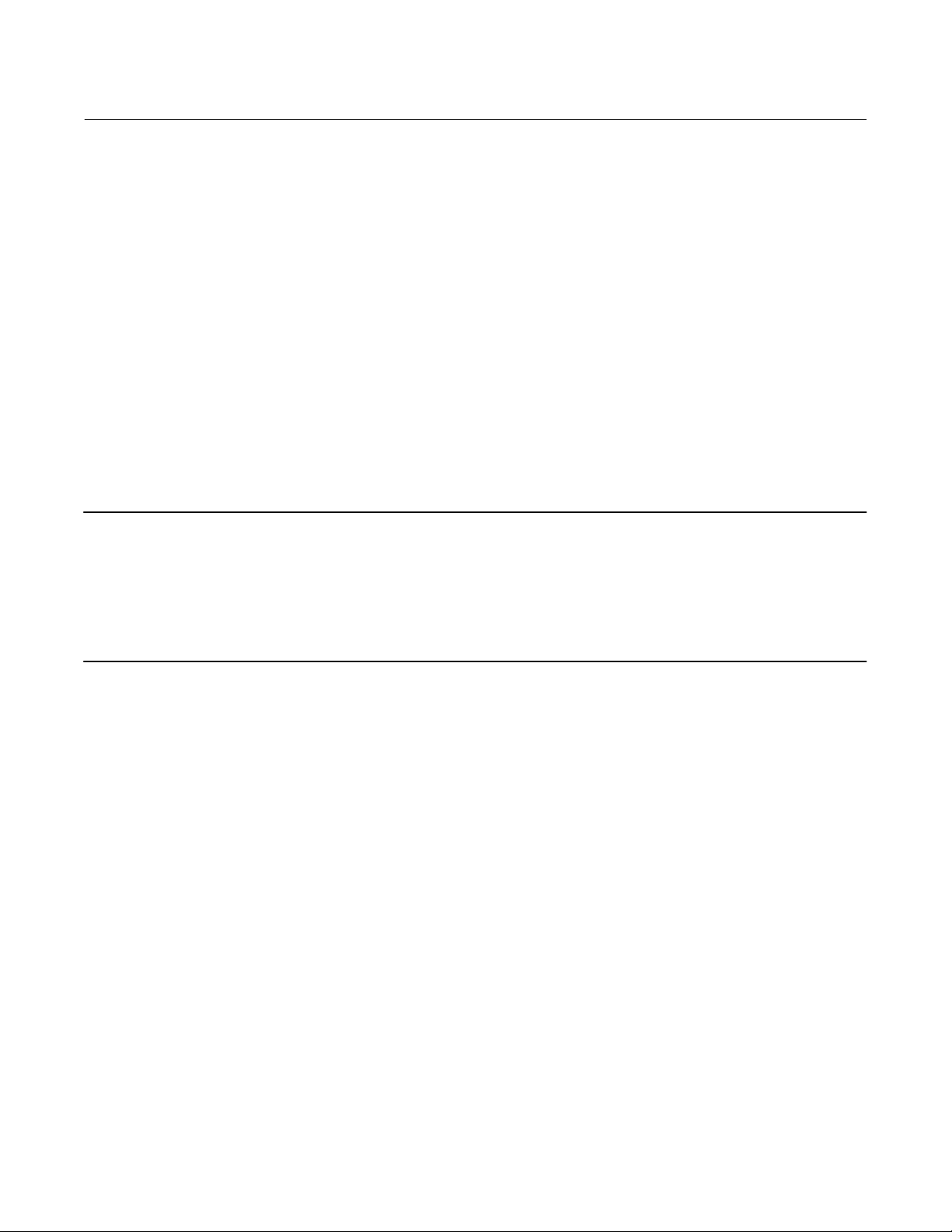

DLC3100 digital level controllers (figure 2) are used with level sensors to measure liquid level, the level of interface

between two liquids, or liquid density. Changes in level or density exert a buoyant force on a displacer, which rotates

the torque tube shaft (see figure 3). This rotary motion is applied to the digital level controller, transformed to an

electrical signal and digitized. The digital signal is compensated and processed per user configuration requirements,

and converted back to a 4-20 mA analog electrical signal. See the block diagram in figure 4.

3

Page 4

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Figure 2. Fisher DLC3100 Digital Level Controller

X1461

Figure 3. Fisher 249 Torque Tube Rotation

TORQUE

TUBE

DISPLACER

X1501

Figure 4. Mechanical Architecture

Mechanical

249 Torque Tube

Mechanical

Push Buttons

(with magnets)

Lever Assembly

Lock Mechanism

(with magnets)

Magnetic

Magnetic

Main Electronic Compartment - Ex 'd' IP66 Enclosure

LCD (with reed

switches)

Electrical

Electrical

Hall Sensor

Terminal

Compartment

(with cover)

Main PCB

Electrical

4

Page 5

Instruction Manual

D104213X012

Several operations with the DLC3100 can be performed using the Field Communicator. The digital level controller can

be configured, calibrated, or tested. Using the HART protocol, information from the field can be integrated into

control systems or be received on a single loop basis.

DLC3100 digital level controllers are designed to directly replace standard pneumatic and electro-pneumatic level

transmitters. DLC3100 digital level controllers mount on a wide variety of caged and cageless 249 level sensors. They

can also be mounted on other manufacturers’ displacer type level sensors with designed mounting kits.

DLC3100 Digital Level Controller

July 2019

CAUTION

There are many magnets used in the DLC3100 (lever assembly, push button, coupling handle). Care must be taken to avoid

having a high powered magnet in close proximity. This could cause permanent damage to the DLC3100. Potential sources

of damaging equipment include, but are not limited to: transformers, DC motors, stacking magnet assemblies.

General Guidelines for use of High Power Magnets:

Use of high power magnets in close proximity to any instrument which is operating a process should be avoided.

Regardless of the instrument model, high power magnets can affect its functionality.

249 Caged Sensors

249, 249B, 249BF, 249C, 249K and 249L sensors side-mount on the vessel with the displacer mounted inside a cage

outside the vessel.

249 Cageless Sensors

249BP, 249CP and 249P sensors top-mount on the vessel with the displacer hanging down into the vessel.

249VS sensor side-mounts on the vessel with the displacer hanging out into the vessel.

249W wafer-style sensor mounts on top of a vessel or on a customer-supplied cages.

Related Documents

Other documents containing information related to the DLC3100 digital level controllers and 249 sensors include:

D FIELDVUE DLC3100 and DLC3100 SIS Quick Start Guide (D104214X012

D CSA (United States and Canada) Hazardous Area Approvals - DLC3100 Digital Level Controller (D104232X012

D ATEX and IECEx Hazardous Area Approvals - DLC3100 Digital Level Controller (D104233X012)

D Fisher 249 Caged Displacer Sensors Instruction Manual (D200099X012

D Fisher 249 Cageless Displacer Sensors Instruction Manual (D200100X012

D Fisher 249VS Cageless Displacer Sensor Instruction Manual (D103288X012

D Fisher 249W Cageless Wafer Style Level Sensor Instruction Manual (D102803X012

)

)

)

)

)

)

D Simulation of Process Conditions for Calibration of Fisher Level Controllers and Transmitters (D103066X012

D Bolt Torque Information (D103220X012

D Bulletin 11.2:DLC3100 - FIELDVUE DLC3100 and DLC3100 SIS Digital Level Controllers (D104216X012

D Bulletin 34.2:249 - Fisher 249 Sensor, Level Controller, and Transmitter Dimensions (D200039X012

These documents are available from your Emerson sales office

)

)

)

or at Fisher.com.

)

5

Page 6

DLC3100 Digital Level Controller

July 2019

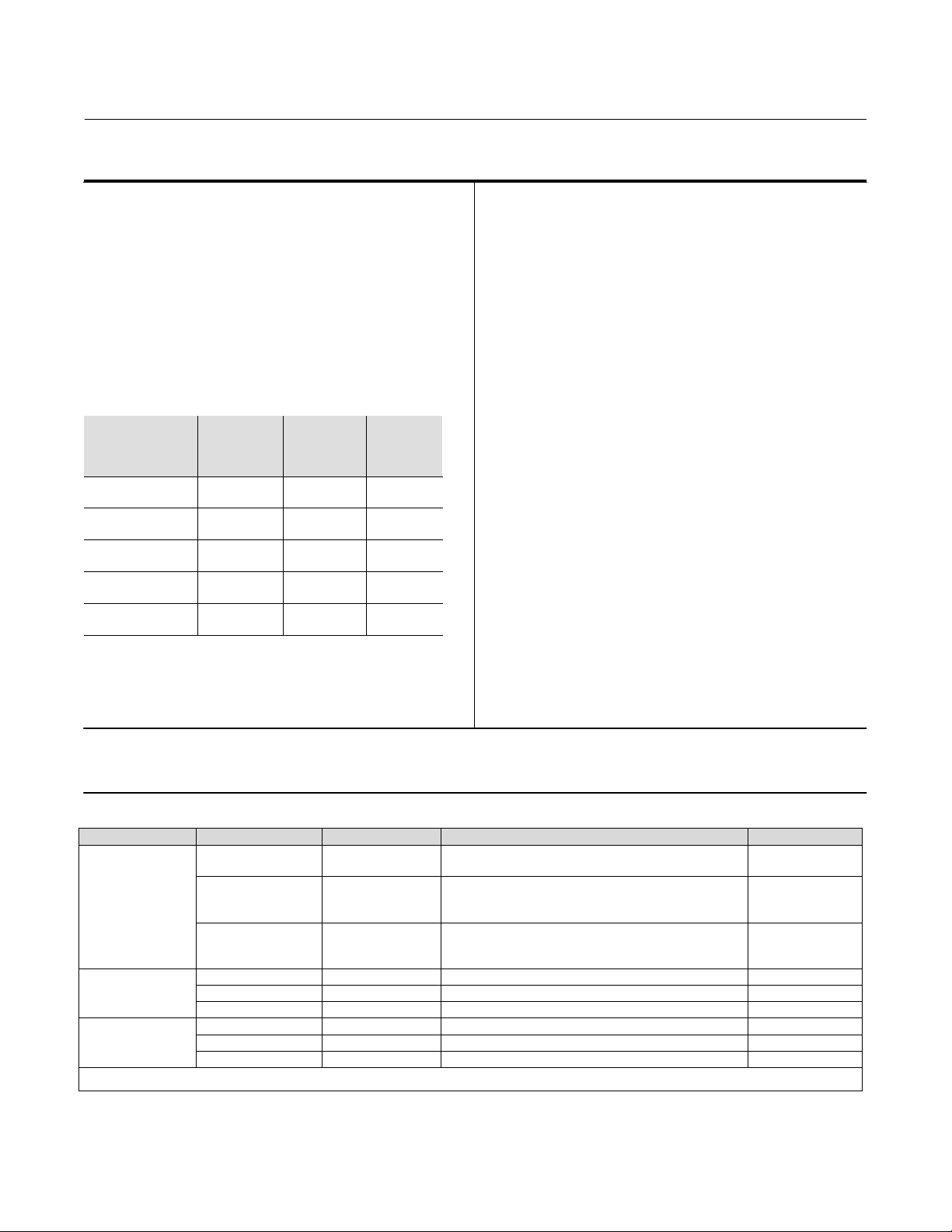

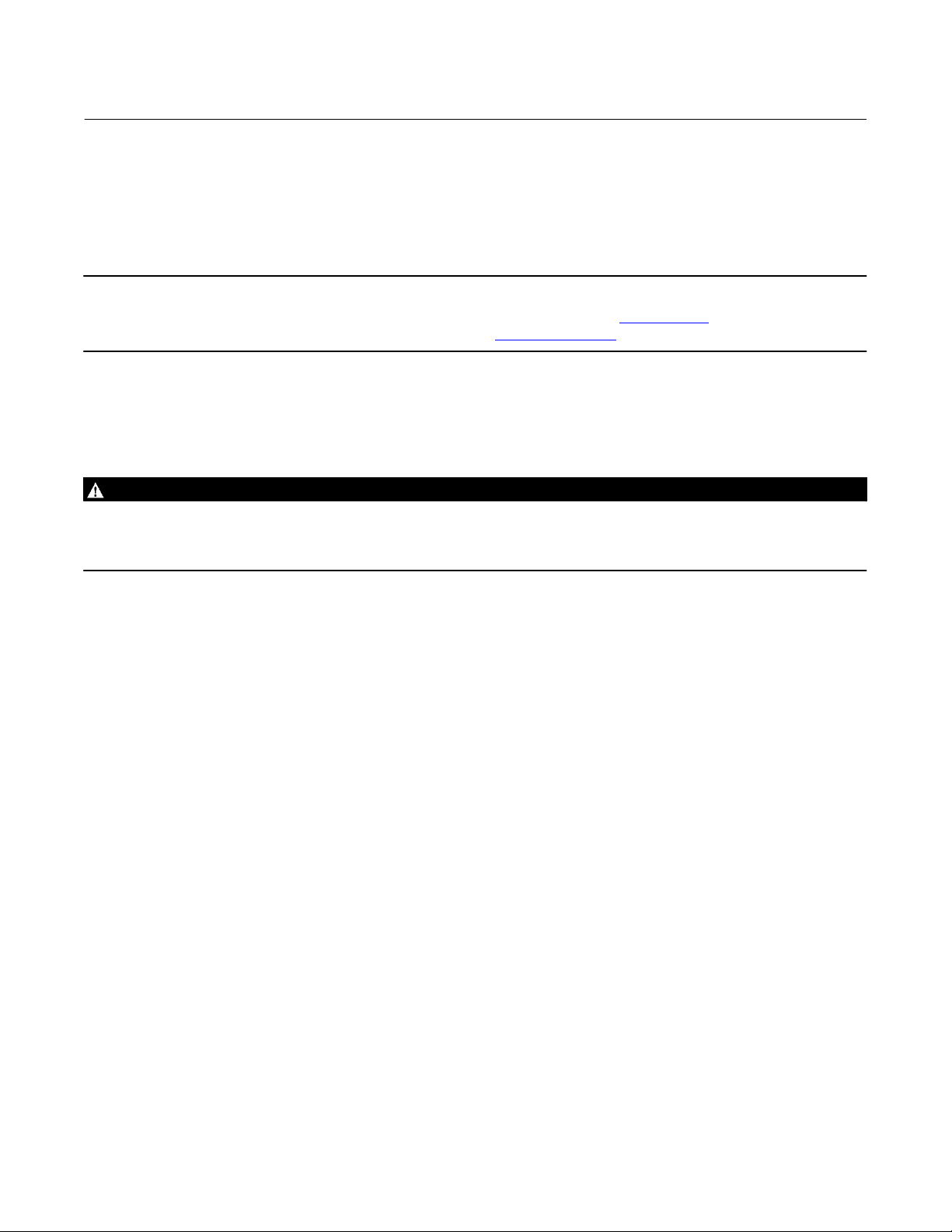

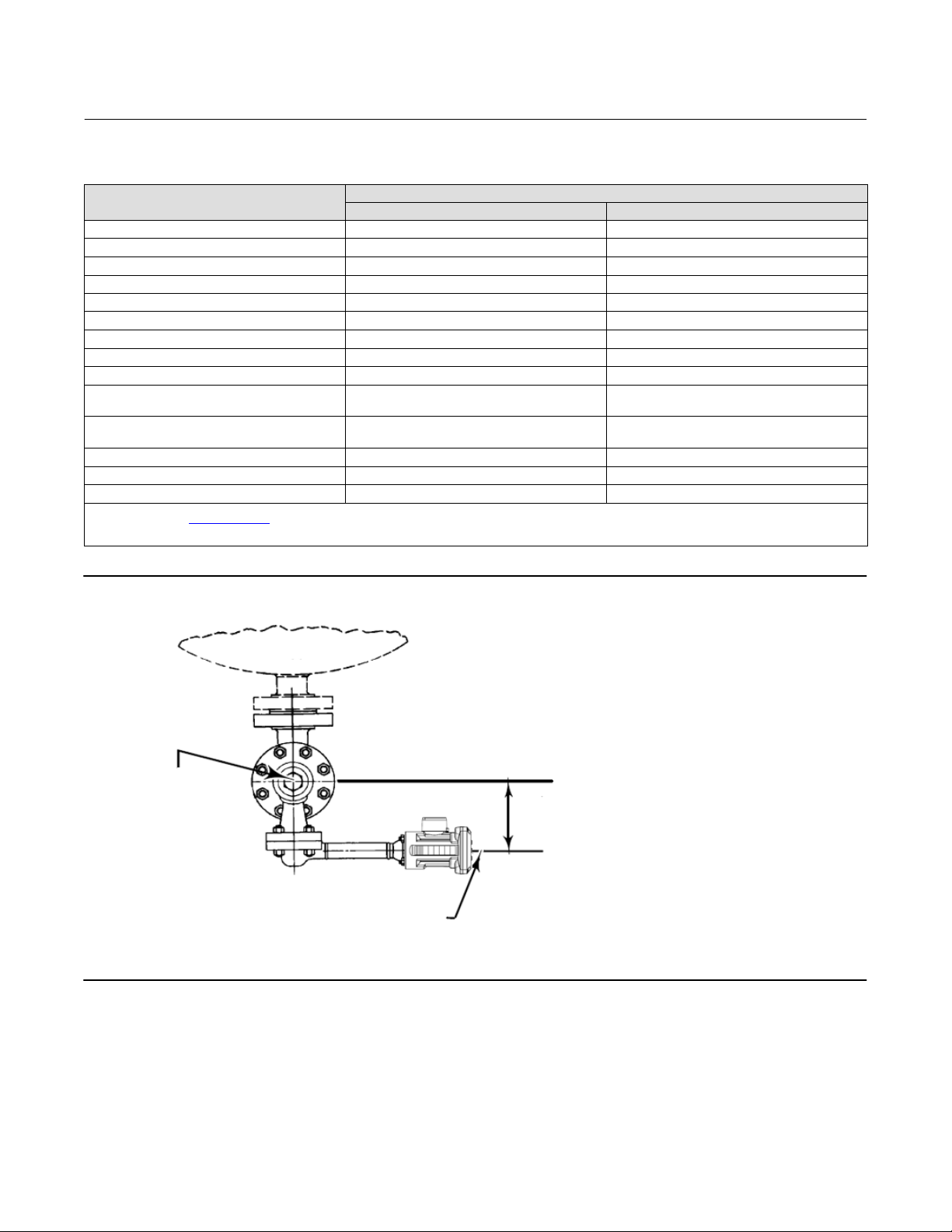

Table 1. Fisher DLC3100 Specifications

Instruction Manual

D104213X012

Available Configurations

Mounts on caged and cageless 249 sensors

Function: Transmitter

Communications Protocol: HART

Input Signal

(1)

Level, Interface, or Density

: Rotary motion of

torque tube shaft proportional to changes in liquid

level, interface level, or density that change the

buoyancy of a displacer.

Process Temperature: Interface for 2- or 3-wire

100 ohm platinum RTD for sensing process

temperature, or optional user-entered target

temperature to permit compensating for changes in

specific density.

Output Signal

Analog: 4 to 20 mA DC

J Direct action—increasing level, interface, or density

increases output; or

J Reverse action—increasing level, interface, or

density decreases output

High saturation: 20.5 mA

Low saturation: 3.8 mA

High alarm

Low Alarm

(2)

: > 21.0 mA

(2)

: < 3.6 mA

Digital: HART 1200 Baud Frequency Shift Keyed (FSK)

HART impedance requirements must be met to

enable communication. Total shunt impedance

across the master device connections (excluding the

master and transmitter impedance) must be between

230 and 600 ohms.

The transmitter HART receive impedance is defined

as:

Rx: 30.2 k ohms and

Cx: 5.45 nF

Supply Requirements

Transient Voltage Protection

Pulse Waveform

Rise Time

(ms)

10 1000 48.4 12.4

Decay

to 50% (ms)

Max VCL @ I

(Clamping

Voltage) (V)

pp

I

pp

(Peak Pulse

Current) (A)

Electrical Classification

Overvoltage Category II per IEC 61010 clause 5.4.2d

Pollution Degree 4

Altitude Rating

Up to 2000 meters (6562 feet)

Ambient Temperature

The combined temperature effect on zero and span

without the 249 sensor is less than 0.02% of full scale

per degree Celsius over the operating range -40 to

80_C (-40 to 176_F)

LCD operating temperature limits: -20 to 70_C

(-4 to 158_F)

(3)

Process Temperature

The process density and torque rate are affected by

the process temperature (figure 6). Temperature

compensation can be implemented to correct for

process density changes.

Process Density

The sensitivity to error in knowledge of process

density is proportional to the differential density of

the calibration. If the differential specific gravity is

0.2, and error of 0.02 specific gravity units in

knowledge of a process fluid density represents 10%

of span.

Hazardous Area

CSA

Class/Division: Intrinsically Safe, Explosion-proof

(4)

Division 2, Dust Ignition-proof

Zone: Intrinsically Safe, Flameproof, Type n, Dust by

intrinsic safety and Enclosure

ATEX/IECEx—Flameproof, Intrinsic Safety, Dust by

Intrinsic Safety

,

12 to 30 volts DC; 25 mA

Instrument has reverse polarity protection.

A minimum compliance voltage of 17.75 VDC (due to

HART impedance requirement) is required to

guarantee HART communication.

6

Electrical Housing

IP66, Type 4X

Electrical Connections: Two 1/2-14 NPT internal

conduit connections. Both are at the bottom of

terminal box.

-continued-

Page 7

Instruction Manual

D104213X012

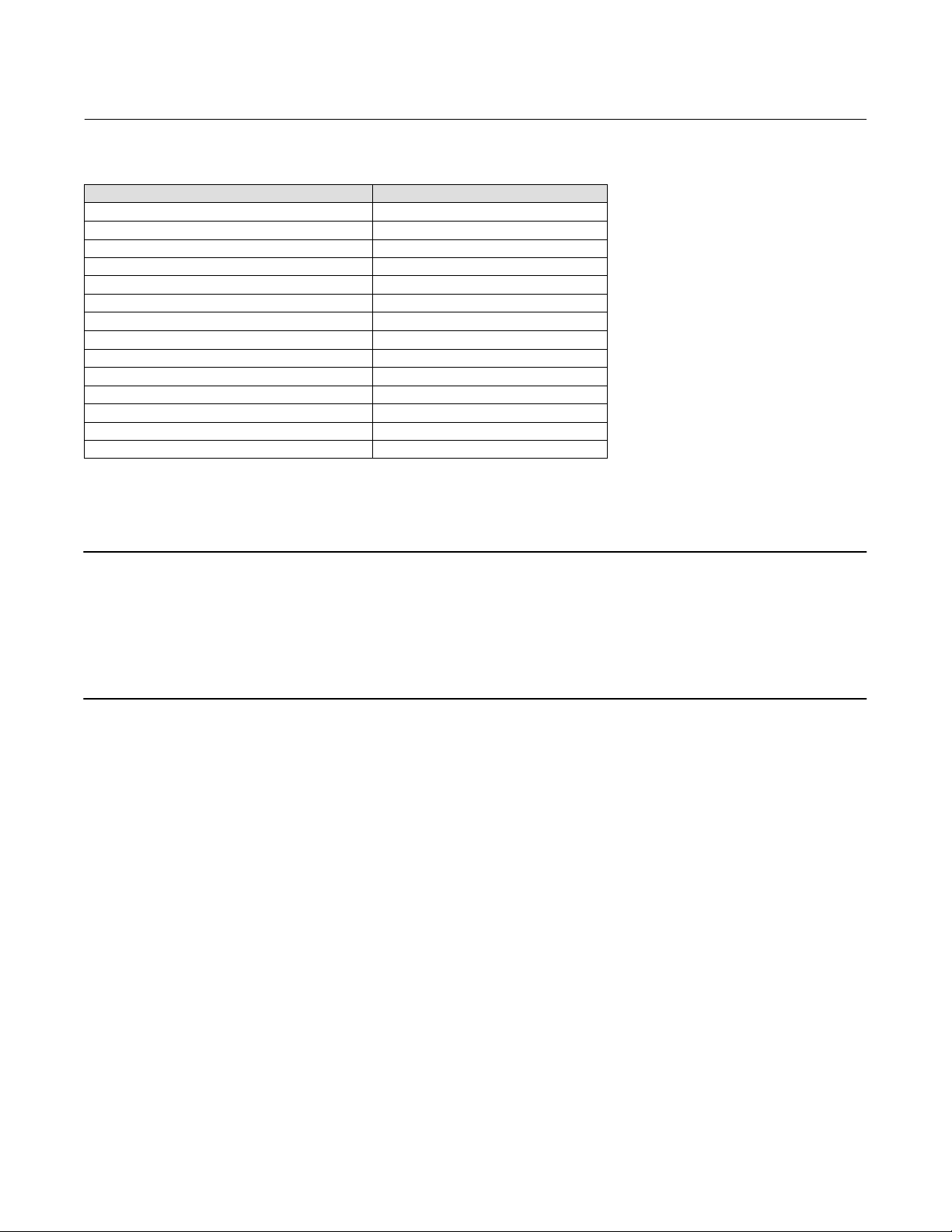

Table 1. Fisher DLC3100 Specifications (continued)

DLC3100 Digital Level Controller

July 2019

Electromagnetic Compatibility

DLC3100 meets EN61326-1:2013

Performance is shown in table 2

DLC3100 SIS meets EN61326-3-2:2008

Performance is shown in table 3

DLC3100 SIS

Safety Instrumented System Classification

SIL2 capable - certified by exida Consulting LLC

Performance

(1)

w/ NPS 3

249W, Using

a 14‐inch

Displacer

$0.8% of

output span

- - - - - -

$0.5% of

output span

- - - - - -

<1.0% of

output span

w/ All Other

249 Sensors

$0.5% of

output span

$0.3% of

output span

<1.0% of

output span

Performance

Criteria

Independent

Linearity

Hysteresis

Repeatability

Dead Band

Hysteresis plus

Deadband

NOTE: At full design span, reference conditions.

1. To lever assembly rotation inputs.

DLC3100

Digital Level

Controller

$0.25% of

output span

<0.2% of

output span

$0.1% of full

scale output

<0.05% of

input span

- - -

At effective proportional band (PB)<100%, linearity,

dead band, and repeatability are derated by the factor

(100%/PB)

Minimum Differential Specific Gravity

0.05 SGU

Construction Material

Housing and Cover: Low-copper aluminum die

casting alloy

Internal: Aluminum, and stainless steel; encapsulated

printed circuit board

Lever assembly: Plated steel, Neodymium iron boron

magnets

Hall Guard: Thermoplastic elastomer

Weight

Less than 3.45 kg (7.57 lb)

Options

J Heat insulator (see figure 5 for use guidelines)

J Sunshade J Mountings for Masoneilan, Yamatake,

Foxboro-Eckhardt sensors

J Factory Calibration:

available for instruments factory-mounted on 249

sensor, when application, process temperature and

density are supplied

1. Density application is not available in DLC3100 SIS.

2. Only one of the High/Low alarm definition is available in a given configuration. Both alarms are NAMUR NE43 compliant.

3. Outside of this limit, LCD will not be readable but it will not affect the functionality of DLC3100 if the temperature is still within the normal limits. Push buttons will be disabled when instrument

temperature is below -20°C (-4°F) or above 70°C (158°F) where LCD display might be intermittent.

4. Not for use in Ester and Ketone atmospheres.

Table 2. DLC3100 EMC Summary Results—Immunity per EN61326-1

Port Phenomenon Basic Standard Test Level Test Results

Electrostatic

discharge (ESD)

Enclosure

I/O signal/control

Protective earth

1. A = No degradation during testing. B = Temporary degradation during testing, but is self‐recovering. Specification limit = +/- 1% of span.

2. HART communication was considered as “not relevant to the process” and is used primarily for configuration, calibration, and diagnostic purposes.

Radiated EM field IEC 61000-4-3

Radiated power

frequency magnetic

field

Burst IEC 61000-4-4 1 kV A

Surge IEC 61000-4-5 1kV (line to ground only, each) B

Conducted RF IEC 61000-4-6 150 kHz to 80 MHz at 3 Vrms A

Burst IEC 61000-4-4 2 kV A

Surge IEC 61000-4-5 2 kV (line to ground only) B

Conducted RF IEC 61000-4-6 150 kHz to 80 MHz at 3 Vrms A

IEC 61000-4-2

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 3V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1 kHz AM at 80%

IEC 61000-4-8 30 A/m at 50 and 60 Hz A

4 kV contact

8 kV air

(1)(2)

A

A

7

Page 8

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Table 3. DLC3100 SIS EMC Summary Results—Immunity per EN61326-3-2

Port Phenomenon Basic Standard Test Level Test Results

Electrostatic

discharge (ESD)

IEC 61000-4-2

6 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

Enclosure

Radiated EM field IEC 61000-4-3

1400 to 2000 MHz @ 10V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 3V/m with 1 kHz AM at 80%

Radiated power

frequency magnetic

IEC 61000-4-8 100 A/m at 50 and 60 Hz A

field

Burst IEC 61000-4-4 1 kV A

I/O signal/control

Surge IEC 61000-4-5 1 kV (line to ground only, each) FS

Conducted RF IEC 61000-4-6 10 kHz to 80 MHz at 10 Vrms A

Burst IEC 61000-4-4 2 kV A

Protective earth

Surge IEC 61000-4-5 1 kV (line to ground only) A

Conducted RF IEC 61000-4-6 10 kHz to 80 MHz at 10 Vrms A

1. A = No degradation during testing. B = Temporary degradation during testing, but is self‐recovering. FS = Fail Safe. Specification limit = +/- 2% of span.

2. HART communication was considered as “not relevant to the process” and is used primarily for configuration, calibration, and diagnostic purposes.

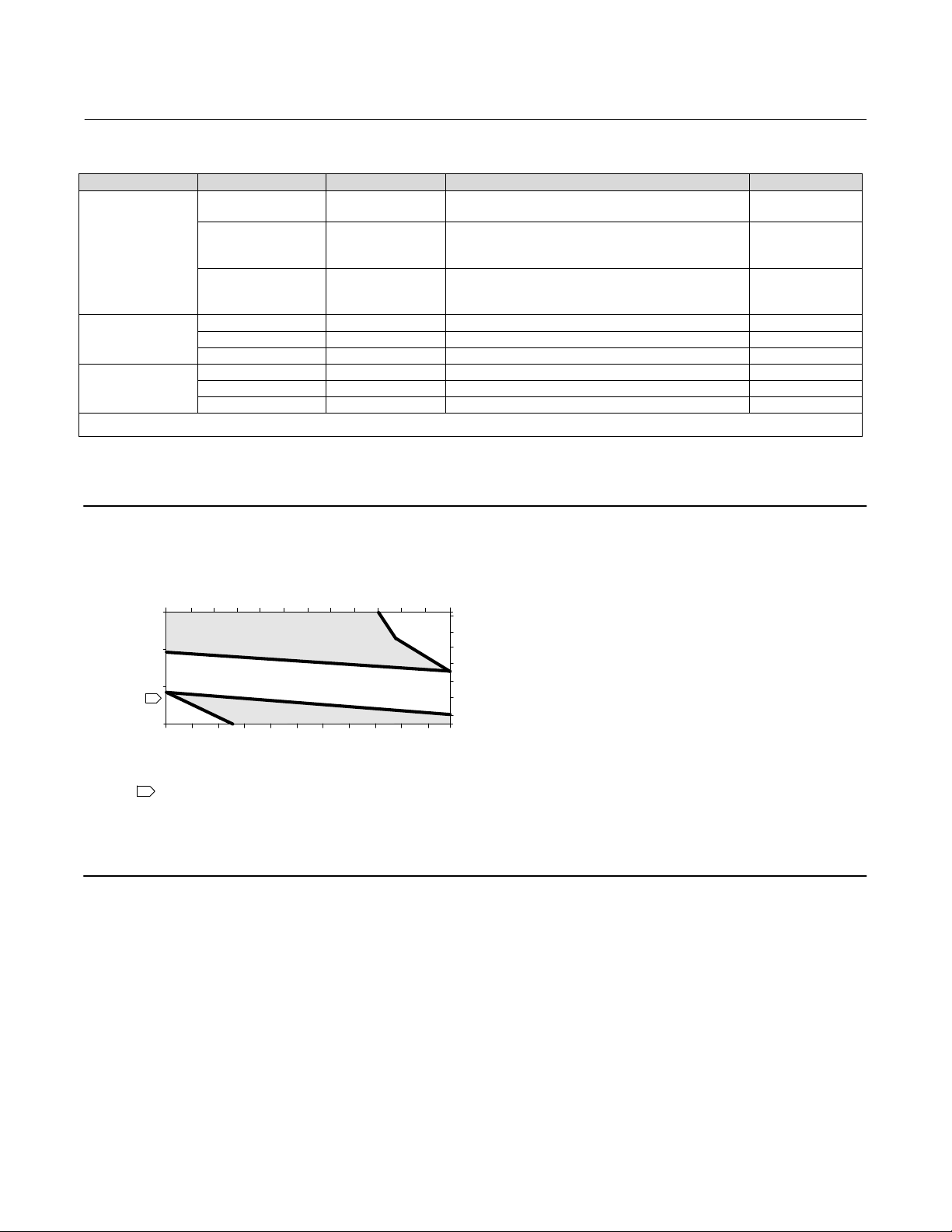

Figure 5. Guidelines for Use of Optional Heat Insulator Assembly

-40 -30

800

-20 -10

010 20

30 40 50 60

AMBIENT TEMPERATURE (_C)

HEAT INSULATOR

400

0

1

TOO

COLD

-325

PROCESS TEMPERATURE (_F)

0 20 40 60 80 100 120 140 160

-20-40

REQUIRED

NO HEAT INSULATOR NECESSARY

HEAT INSULATOR

REQUIRED

AMBIENT TEMPERATURE (_F)

STANDARD TRANSMITTER

NOTES:

1 FOR PROCESS TEMPERATURES BELOW -29_C (-20_F) AND ABOVE 204_C (400_F)

SENSOR MATERIALS MUST BE APPROPRIATE FOR THE PROCESS; SEE TABLE 5.

2. IF AMBIENT DEW POINT IS ABOVE PROCESS TEMPERATURE, ICE FORMATION MIGHT

CAUSE INSTRUMENT MALFUNCTION AND REDUCE INSULATOR EFFECTIVENESS.

39A4070‐B

A5494‐1

TOO

HOT

70

80

425

400

300

200

100

0

-100

-200

176

PROCESS TEMPERATURE (_C)

(1)(2)

A

A

Educational Services

For information on available courses contact:

Emerson Automation Solutions

Educational Services, Registration

Phone: +1-641-754-3771 or +1-800-338-8158

e‐mail: education@emerson.com

emerson.com/fishervalvetraining

8

Page 9

Instruction Manual

DLC3100 Digital Level Controller

D104213X012

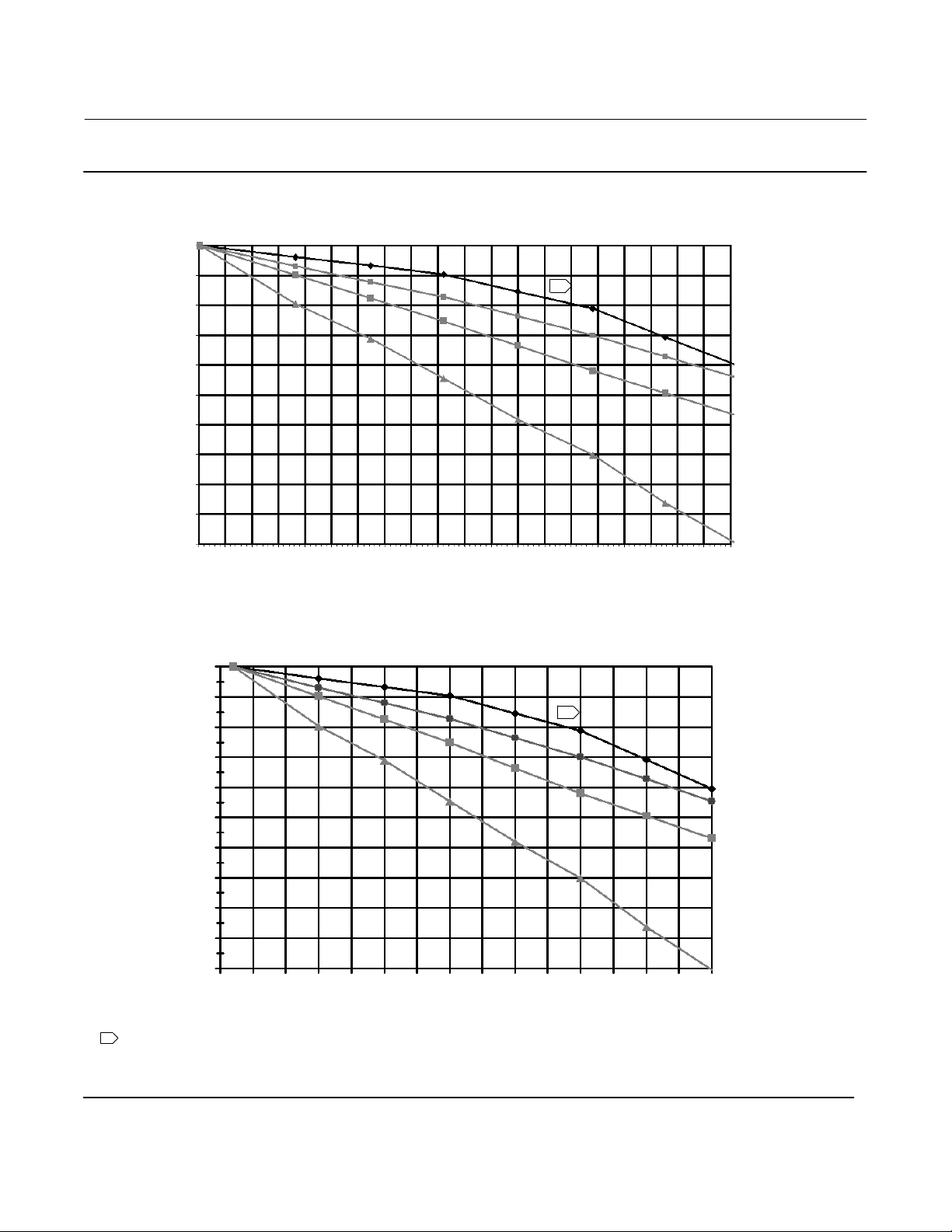

Figure 6. Theoretical Reversible Temperature Effect on Common Torque Tube Materials

TORQUE RATE REDUCTION

(NORMALIZED MODULUS OF RIGIDITY)

1.00

July 2019

0.98

0.96

0.94

0.92

0.90

norm

G

0.88

0.86

0.84

0.82

0.80

20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420

1

TEMPERATURE (_C)

TORQUE RATE REDUCTION

(NORMALIZED MODULUS OF RIGIDITY)

1.00

0.98

0.96

1

N05500

N06600

N10276

S31600

0.94

0.92

norm

0.90

G

0.88

0.86

0.84

0.82

0.80

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

TEMPERATURE (_F)

NOTE:

1 DUE TO THE PERMANENT DRIFT THAT OCCURS NEAR AND ABOVE 260_C (500_F), N05500 IS NOT

RECOMMENDED FOR TEMPERATURES ABOVE 232_C (450_F).

N05500

N06600

N10276

S31600

9

Page 10

DLC3100 Digital Level Controller

July 2019

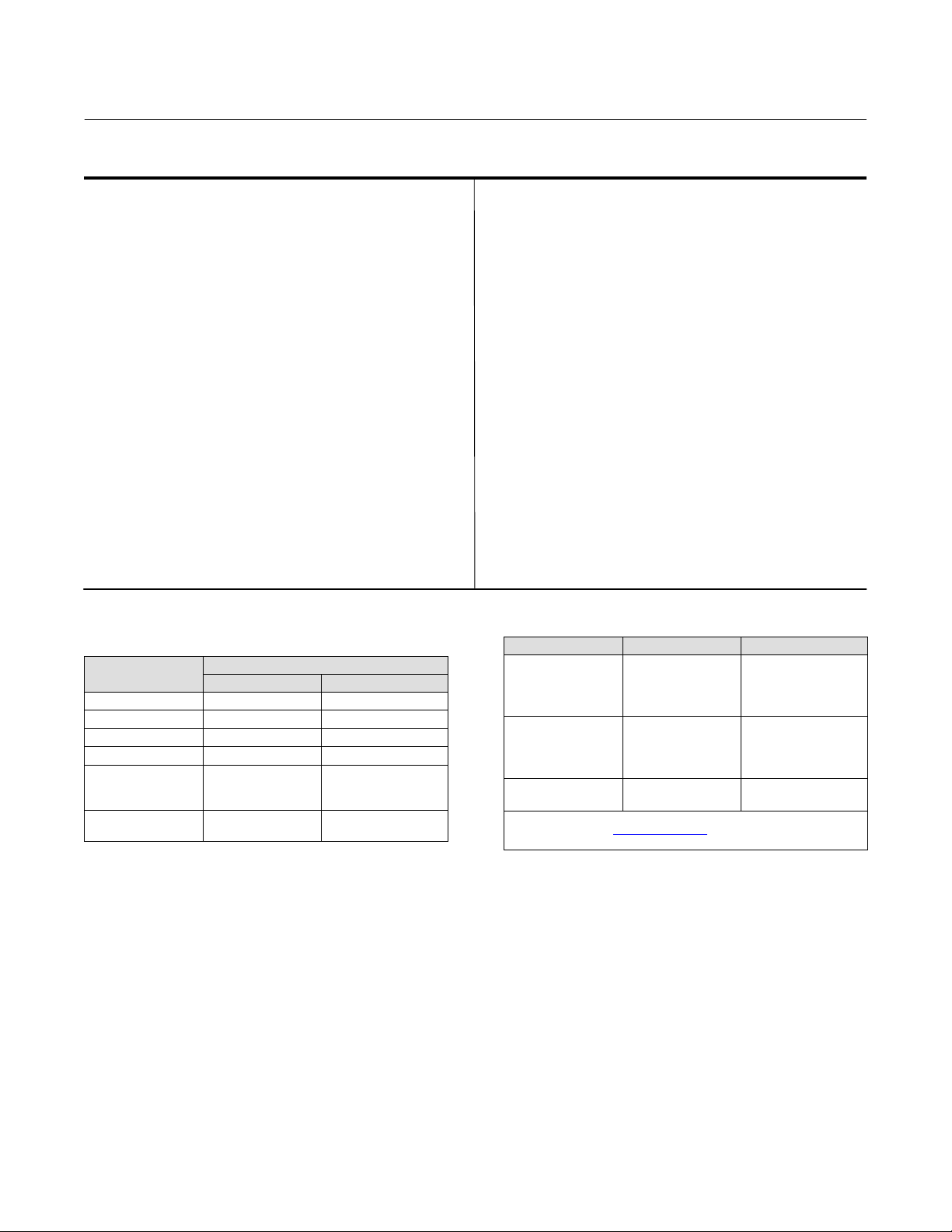

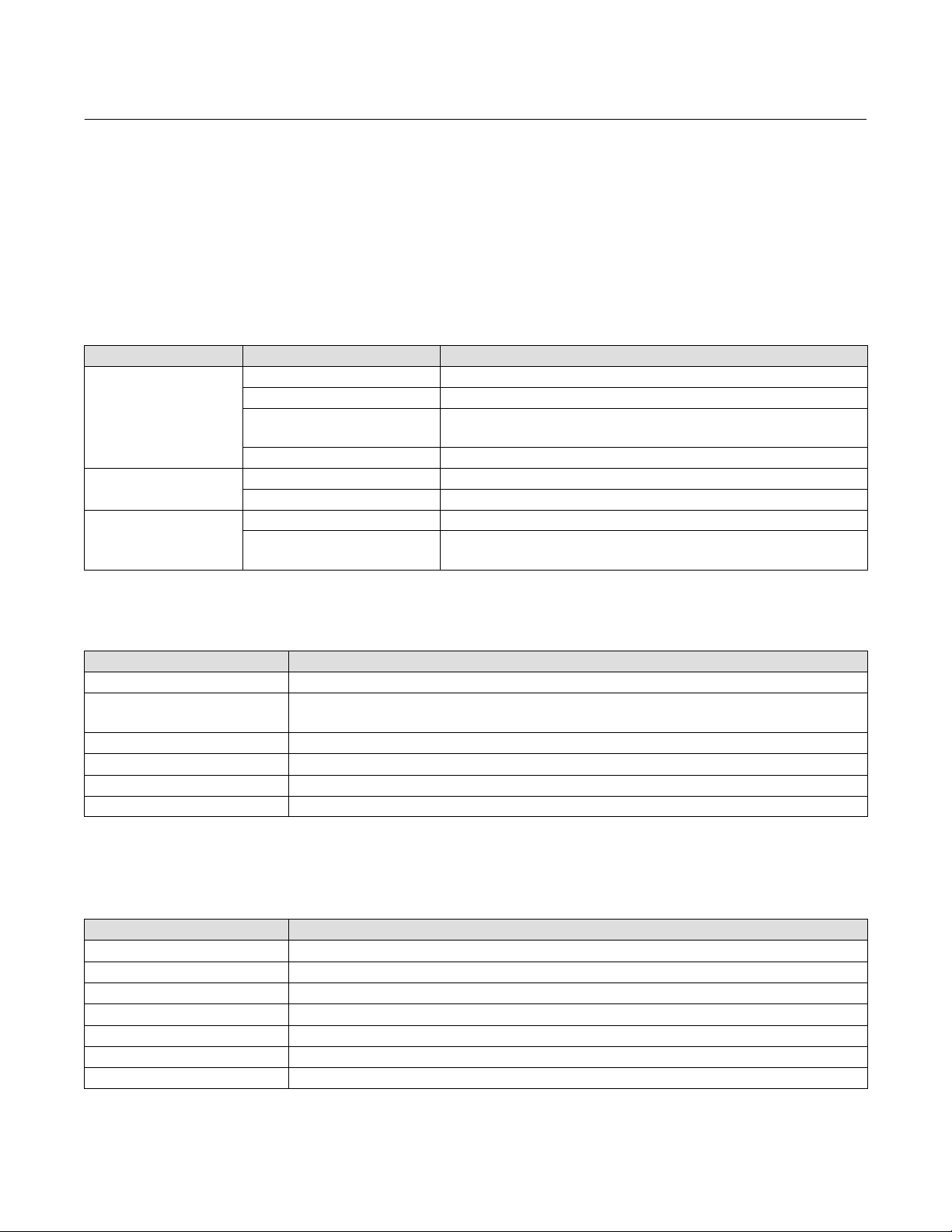

Table 4. Fisher 249 Sensor Specifications

Input Signal

Liquid Level or Liquid‐to‐Liquid Interface Level:

From 0 to 100 percent of displacer length

Liquid Density: From 0 to 100 percent of

displacement force change obtained with given

displacer volume—standard volumes are

J980 cm

or

J1640 cm

3

(60 inches3) for 249C and 249CP sensors

3

(100 inches3) for most other sensors;

other volumes available depending upon sensor

construction

Sensor Displacer Lengths

See tables 7 and 8 footnotes

Sensor Working Pressures

Consistent with applicable ANSI

pressure/temperature ratings for the specific sensor

constructions shown in tables 7 and 8

Caged Sensor Connection Styles

Cages can be furnished in a variety of end connection

styles to facilitate mounting on vessels; the

Instruction Manual

D104213X012

equalizing connection styles are numbered and are

shown in figure 7.

Mounting Positions

Most level sensors with cage displacers have a

rotatable head. The head may be rotated through

360 degrees to any of eight different positions.

Construction Materials

See tables 6, 7, and 8

Operative Ambient Temperature

See table 5

For ambient temperature ranges, guidelines, and use

of optional heat insulator see figure 5

Options

J Heat insulator J Gauge glass for pressures to

29 bar at 232_C (420 psig at 450_F), and

gauges for high temperature and pressure

applications

J Reflex

Table 5. Allowable Process Temperatures for

Common 249 Sensor Pressure Boundary Materials

MATERIAL

Cast Iron -29_C (-20_F) 232_C (450_F)

Steel -29_C (-20_F) 427_C (800_F)

Stainless Steel -198_C (-325_F) 427_C (800_F)

N04400 -198_C (-325_F) 427_C (800_F)

Graphite

Laminate/SST

Gaskets

N04400/PTFE

Gaskets

-198_C (-325_F) 427_C (800_F)

-73_C (-100_F) 204_C (400_F)

PROCESS TEMPERATURE

Min. Max.

Table 6. Displacer and Torque Tube Materials

Part Standard Material Other Materials

316 Stainless Steel,

Displacer 304 Stainless Steel

Displacer Stem

Driver Bearing,

Displacer Rod and

Driver

Torque Tube N05500

1. N05500 is not recommended for spring applications above 232_C

(450_F). Contact your Emerson sales office

temperatures exceeding this limit are required.

316 Stainless Steel

(1)

N10276, N04400,

Plastic, and Special

Alloys

N10276, N04400,

other Austenitic

Stainless Steels, and

Special Alloys

316 Stainless Steel,

N06600, N10276

or application engineer if

10

Page 11

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

July 2019

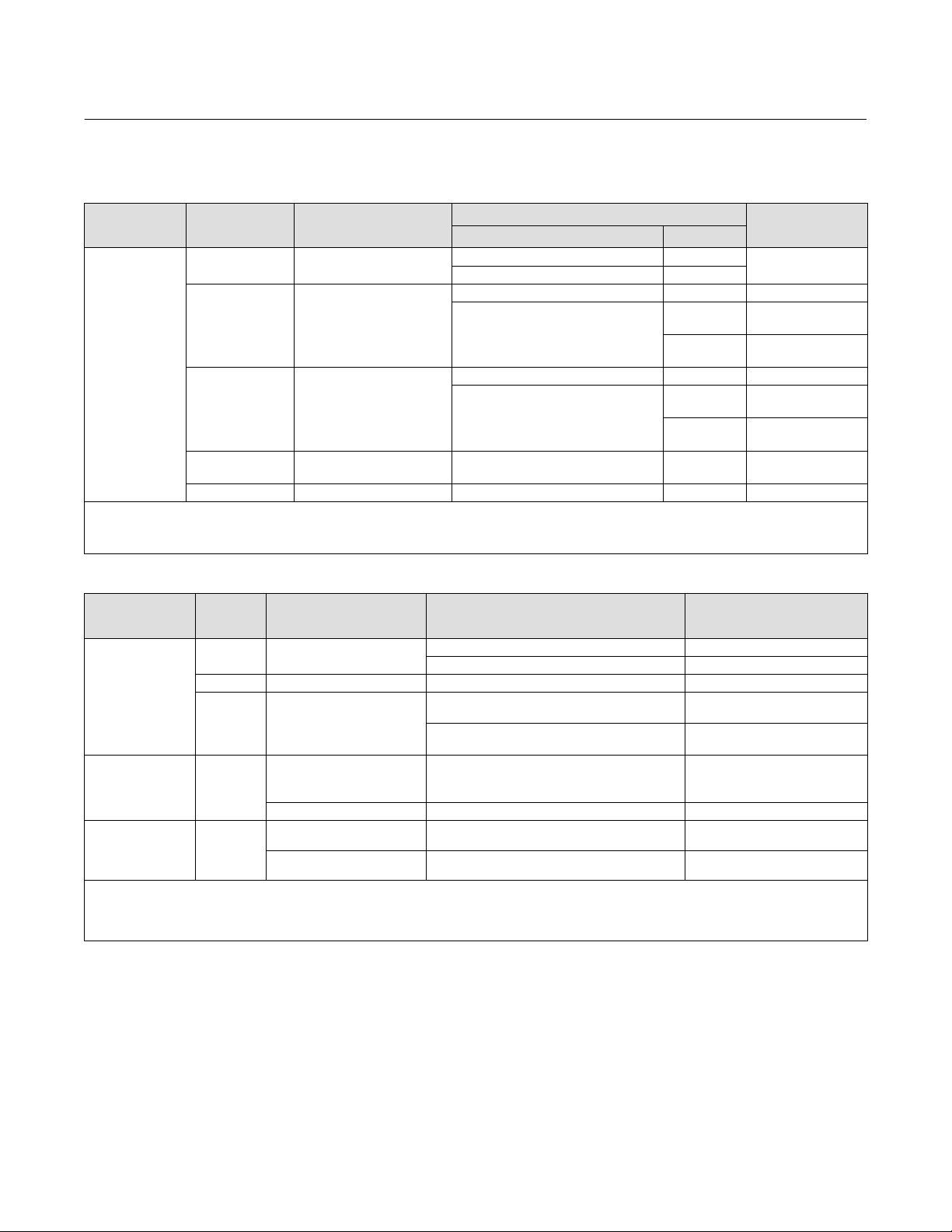

Table 7. Caged Displacer Sensors

TORQUE TUBE

ORIENTATION

249

SENSOR

(3)

(1)

STANDARD CAGE, HEAD,

AND TORQUE TUBE ARM

MATERIAL

Cast iron

EQUALIZING CONNECTION

Style Size (NPS)

Screwed 1‐1/2 or 2

Flanged 2

Screwed or optional socket weld 1‐1/2 or 2 CL600

1‐1/2

2

1‐1/2

Torque tube

arm rotatable

with respect to

equalizing

connections

249B, 249BF

(3)

249C

(4)

Steel

316 stainless steel

Raised face or optional ring‐type joint

flanged

Screwed 1‐1/2 or 2 CL600

Raised face flanged

2

249K Steel

249L Steel Ring‐type joint flanged 2

1. Standard displacer lengths for all styles (except 249) are 14, 32, 48, 60, 72, 84, 96, 108 and 120 inches. The 249 uses a displacer with a length of either 14 or 32 inches.

2. EN flange connections available in EMA (Europe, Middle East and Africa).

3. Not available in EMA.

4. The 249BF available in EMA only. Also available in EN size DN 40 with PN 10 to PN 100 flanges and size DN 50 with PN 10 to PN 63 flanges.

5. Top connection is NPS 1 ring‐type joint flanged for connection styles F1 and F2.

Table 8. Cageless Displacer Sensors

Mounting Sensor

(1)

Standard Head

(6)

Body

and Torque Tube

(2),

Wafer

Raised face or optional ring‐type joint

flanged

1‐1/2 or 2 CL900 or CL1500

(5)

Flange Connection (Size) Pressure Rating

Arm Material

NPS 4 raised face or optional ring‐type joint CL150, CL300, or CL600

NPS 6 or 8 raised face CL150 or CL300

NPS 4 raised face or optional ring‐type joint

NPS 6 or 8 raised face

CL900 or 1CL500

(EN PN 10 to DIN PN 250)

CL150, CL300, CL600, CL900,

CL1500, or CL2500

CL125, CL150, CL250, CL300,

For NPS 4 raised face or flat face

CL600, CL900, or CL1500

(EN PN 10 to DIN PN 160)

Mounts on

top of vessel

Mounts on

side of vessel

(4)

249BP

Steel

249CP 316 Stainless Steel NPS 3 raised face CL150, CL300, or CL600

(5)

249P

Steel or stainless steel

WCC (steel) LCC (steel), or

249VS

CF8M (316 stainless steel)

WCC, LCC, or CF8M For NPS 4 buttweld end, XXZ CL2500

Mounts on top of

vessel or on

customer

249W

supplied cage

1. Standard displacer lengths are 14, 32, 48, 60, 72, 84, 96, 108, and 120 inches.

2. Not used with side‐mounted sensors.

3. EN flange connections available in EMA (Europe, Middle East and Africa).

4. Not available in EMA.

5. 249P available in EMA only.

6. Wafer Body only applicable to the 249W.

WCC or CF8M For NPS 3 raised face CL150, CL300, or CL600

LCC or CF8M For NPS 4 raised face CL150, CL300, or CL600

PRESSURE RATING

CL125 or CL250

CL150, CL300, or

CL600

CL150, CL300, or

CL600

CL150, CL300, or

CL600

CL150, CL300, or

CL600

CL2500

(3)

(2)

11

Page 12

DLC3100 Digital Level Controller

July 2019

Figure 7. Style Number of Equalizing Connections

Instruction Manual

D104213X012

STYLE 1

TOP & BOTTOM

CONNECTIONS

SCREWED (S-1) OR

FLANGED (F-1)

E1697

STYLE 2 STYLE 3 STYLE 4

TOP & LOWER SIDE

CONNECTIONS

SCREWED (S-2) OR

FLANGED (F-2)

UPPER & LOWER SIDE

CONNECTIONS

SCREWED (S-3) OR

FLANGED (F-3)

UPPER SIDE & BOTTOM

SCREWED (S-4) OR

CONNECTIONS

FLANGED (F-4)

12

Page 13

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

July 2019

Section 2

Electrical Connections

Note

This information supplements the Electrical Connections section in the quick start guide (D104214X012

instrument. If a copy of this quick start guide is needed contact your Emerson sales office

or visit Fisher.com.

Test Connections

WARNING

Personal injury or property damage caused by fire or explosion may occur if this connection is attempted in an area which

contains a potentially explosive atmosphere or has been classified as hazardous. Confirm that area classification and

atmosphere conditions permit the safe removal of the terminal box cap before proceeding.

) that shipped with your

Test connections inside the terminal box can be used to measure loop current across an internal 1 ohm resistor.

1. Remove the terminal box cap.

2. Adjust the test meter to measure mV.

3. Connect the positive lead of the test meter to the + connection and the negative lead to the TEST connection inside

the terminal box.

4. Measure Loop current as mV = mA. For example, if the meter measures 12.5 mV, it means the loop current is

12.5 mA.

5. Remove test leads and replace the terminal box cover.

Alarm Conditions

Each digital level controller continuously monitors its own performance during normal operation. This automatic

diagnostic routine is a timed series of checks repeated continuously. If diagnostics detect a failure in the electronics,

the instrument drives its output to trip alarm current either below 3.6 mA or above 21 mA, depending on the position

(High/Low) of the alarm switch.

An alarm condition occurs when the self-diagnostics detect an error that would render the process variable

measurement inaccurate, incorrect, or undefined, or a user defined threshold is violated. At this point the analog

output of the unit is driven to a defined level either above or below the nominal 4-20 mA range, based on the position

of the alarm switch. The factory default Alarm Switch setting is High.

Refer to table 9 for alerts that will trigger the Trip Alarm Current when enabled.

13

Page 14

DLC3100 Digital Level Controller

July 2019

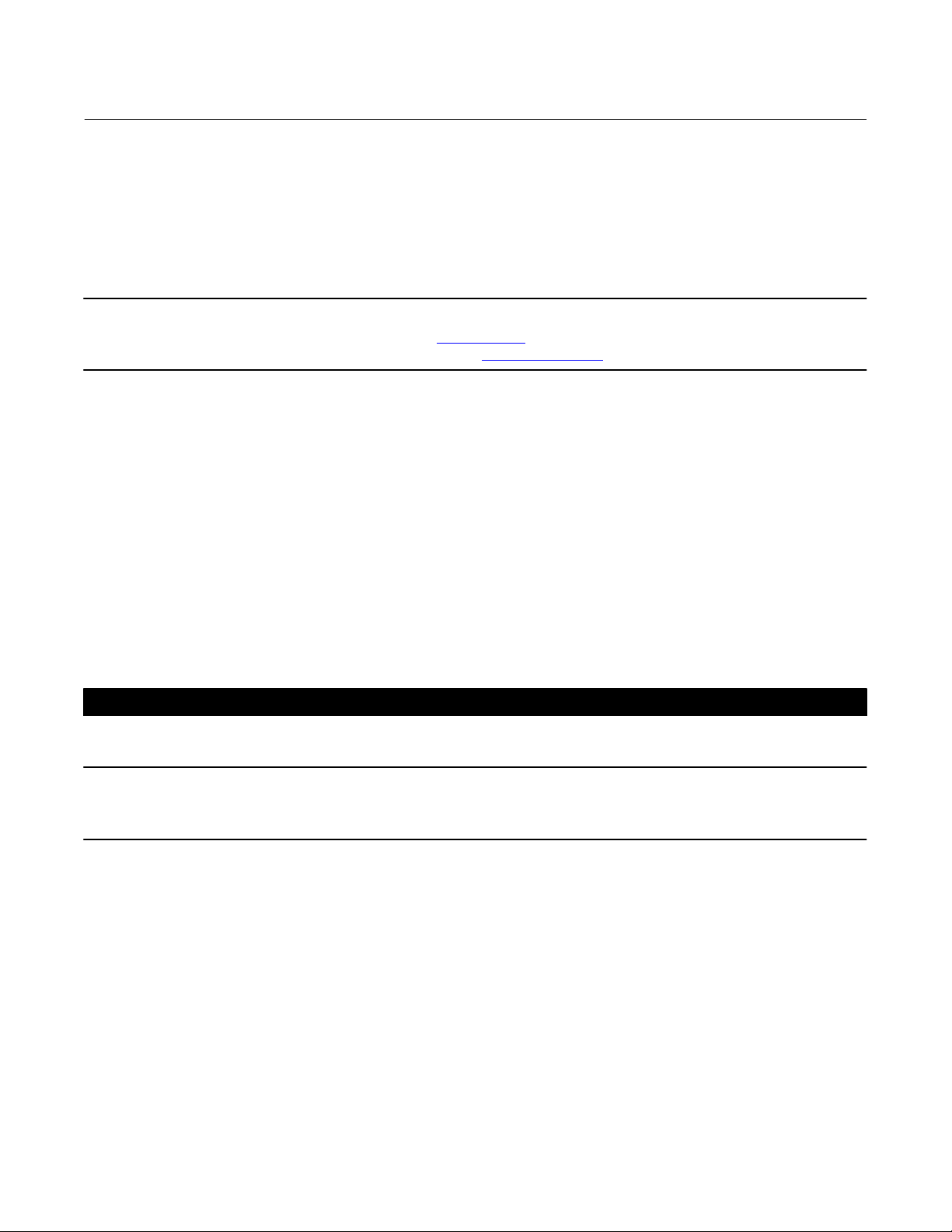

Table 9. Trip Alarm Current Default Setting

Alerts Trip Alarm Current Default Setting

Device Malfunction Enable

Reference Voltage Failed Enable

PV Analog Output Readback Limit Failed Enable

Instrument Temperature Sensor Alert Enable

Hall Sensor Alert Enable

RTD Sensor Alert Enable

Hall Diagnostic Failed Enable

RTD Diagnostic Failed Enable

Program Memory Failed Enable

NVM Error Enable

RAM Test Error Alert Enable

Watchdog Reset Executed Enable

PV HiHi Alert Disable

PV LoLo Alert Disable

Loop Test

Instruction Manual

D104213X012

Note

The DLC3100 must be put out of service during Loop Test. Place the loop into manual operation before putting device out of

service as the DLC3100 output may not be valid.

When the DLC3100 is out of service, it is locked for exclusive access by the Primary/Secondary master that put it out of service. If

the instrument reports Locked by HART or Access Restricted when you attempt to configure it, and a master of the original

priority is not available, use Force Mode on the Local User Interface menu to force the instrument mode to In Service. You will

then be able to take it out of service with your own master to make changes.

Loop Test can be used to verify the controller output, the integrity of the loop, and the operations of any recorders or

similar devices installed in the loop. To initiate a loop test, perform the following procedure:

1. Connect a reference meter to the controller. To do so, either connect the meter to the test connections inside the

terminal box (see Test Connections procedure) or connect the meter in the loop as shown in figure 8.

2. Access Loop Test via Service Tools > Maintenance > Tests > Loop Test (3-4-2-2).

3. Select OK after you set the control loop to manual. The Field Communicator displays the loop test menu.

4. Put the instrument to “Not in Service” and select analog output level: 4mA, 20mA or Other to manually input a

value between 4 and 20 milliamps.

5. Check the reference meter to verify that it reads the value that is commanded. If the readings do not match, either

the controller requires an output trim, or the meter is malfunctioning.

After completing the test procedure, the display returns to the loop test screen and allows you to choose another

output value or end the test and put instrument back in service.

14

Page 15

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

July 2019

Section 3

Overview

Overview provides information about the current state of the instrument, measurement data, and device variables

that are of interest.

Status

Name Status Description

Device

Communications

Mode

Good

Failure

Maintenance

Advisory

Polled

Simulation Active

In Service

Not In Service

There are no active alerts and instrument is In Service.

The highest severity active alert is in the Failure category.

The highest severity active alert is in the Maintenance

category.

The highest severity active alert is in the Advisory category.

Communication with digital level controller is established.

Digital level controller is in alert simulation mode.

Digital level controller is online and performing its function.

Digital level controller is Out of Service. Output may not be

valid.

Primary Purpose Variables

Name Description

Process Fluid Name of the process fluid.

Process Fluid Compensated

Density

PV Actual measurement in percentage of span.

PV Value Actual measurement in unit.

Process Temperature Actual temperature of the process (via RTD or manual input).

Analog Output Current output of the digital level controller, in milliamps.

Density of the process fluid. If temperature compensation is enabled, the density

value is after compensation.

Device Information

Identification

Name Description

Tag A unique name to identify the HART device, up to 8 characters.

Long Tag A unique name to identify the HART device, up to 32 characters.

Model Field device model: DLC3100

Device ID The ID of the printed wiring board in the instrument.

Instrument Serial Number Serial number printed on the nameplate of the device.

Sensor Serial Number Serial number printed on the nameplate of the 249 sensor.

Instrument Assembly Code Unique code in device for traceability.

15

Page 16

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Revisions

Name Description

HART Universal Revision The revision number of the HART Universal Commands used by the instrument.

Device Revision The revision number of the instrument-to-HART communicator interface software.

Hardware The revision number of the instrument hardware.

Firmware The revision number of the instrument firmware.

Alarm Type and Security

Name Value Description

Alarm Switch

Protection

High Analog output will be >= 21mA when Trip Alarm Current is activated.

Low Analog output will be <= 3.6mA when Trip Alarm Current is activated.

Enable

When protection is enabled, writing to parameters and calibration are

not allowed.

Disable When protection is disabled, device can be configured and calibrated.

16

Page 17

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

Section 4

Configuration and Calibration using AMS Device Manager or a

Field Communicator

Note

Refer to the DLC3100 and DLC3100 SIS Quick Start Guide (D104214X012

interface. If a copy of this quick start guide is needed contact your Emerson sales office

DLC3100 has to be set to “Not In Service” during configuration and calibration which include:

D Device Setup

D PV Setup

D Process Setup

D Calibration

D Manual Setup

D Alert Setup

) for configuration and calibration using the local user

or visit Fisher.com.

July 2019

The DLC3100 will continue to regulate the current output based on lever assembly position. The output can be at

failed current value (determine by alarm switch on the Main Electronics Board) depending on the device alerts/status.

This current output shall not be treated as actual level/interface measurement as the device is “Not In Service”.

CAUTION

The control loop must be in manual before putting DLC3100 to Not In Service.

Note

When configuring the DLC3100 using the DD, the access of DLC3100 via Local User Interface will be locked.

If a DLC3100 digital level controller ships from factory mounted on a 249 sensor, initial setup and calibration may not

be necessary. The factory enters the sensor data, couples the instrument to the sensor, and calibrates the instrument

and sensor combination.

17

Page 18

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Note

If the digital level controller mounted on the sensor is received with the displacer blocked, or if the displacer is not connected, the

instrument will be coupled to the torque tube assembly and the lever assembly unlocked. To place the unit in service, if the

displacer is blocked, remove the rod and block at each end of the displacer and check the instrument calibration. (If the “factory

cal” option was ordered, the instrument will be pre-compensated to the process conditions provided on the requisition, and may

not appear to be calibrated if checked against room temperature with 0% and 100% water level inputs). If the displacer is not

connected, hang the displacer on the torque tube.

If the digital level controller mounted on the torque tube arm and the displacer is not blocked when received (such as in skid

mounted systems), the instrument will not be coupled to the torque tube assembly, and the lever assembly will be locked. To

place the unit in service, couple the instrument to the sensor and unlock the lever assembly.

When the 249 assembly is properly connected and coupled to the digital level controller, establish the zero process condition and

perform the Trim Zero procedure. The torque tube rate should not need to be recalibrated.

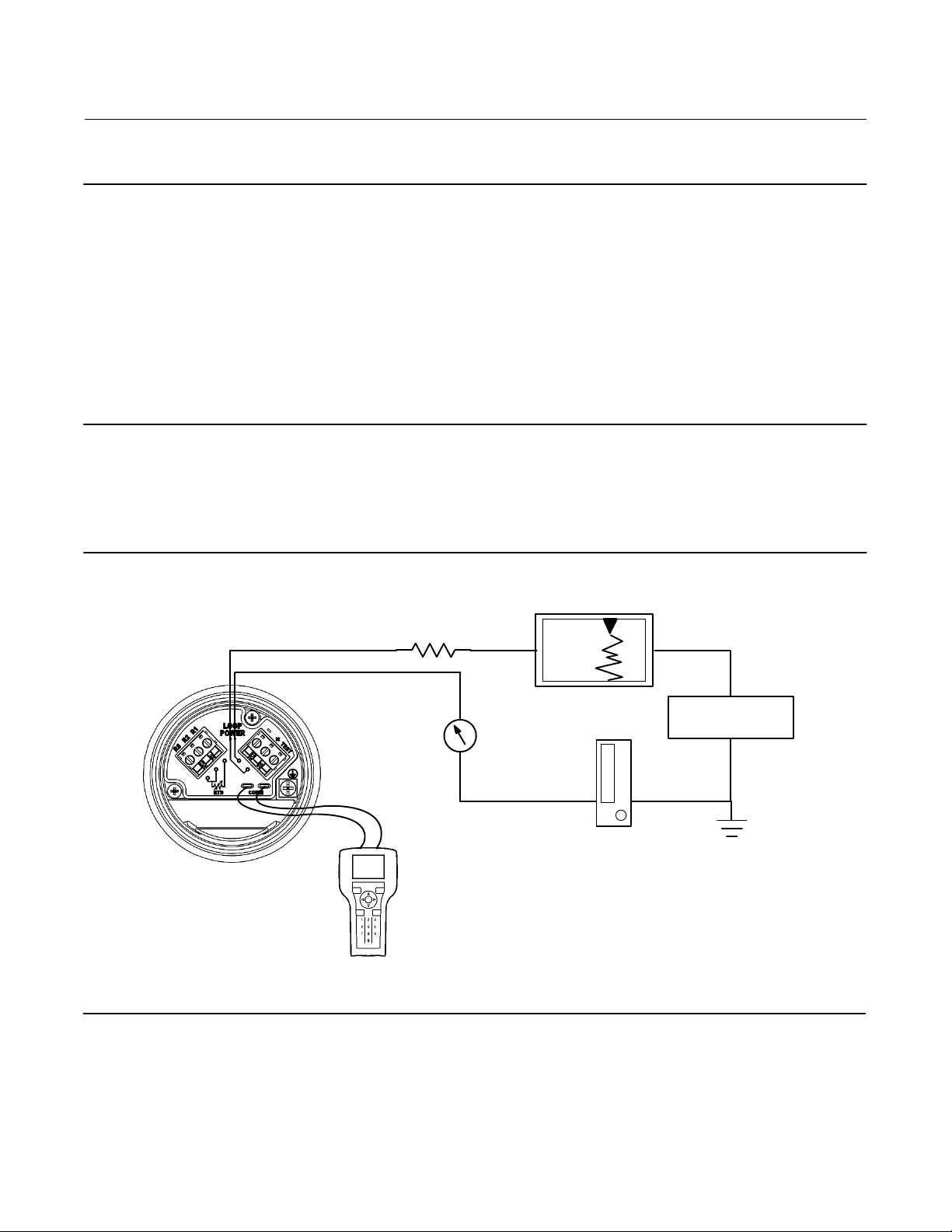

To review the configuration data entered by the factory, connect the instrument to a 24 VDC power supply as shown in

figure 8. Connect the AMS Device Manager/Field Communicator to the instrument and turn it on. Go to Configure and

review the data under Manual Setup and Alert Setup. If application data has been changed since the instrument was

factory-configured, refer to the Manual Setup section for instructions on modifying configuration data.

Figure 8. Connecting to a Power Supply

Field Communicator may be

connected at any termination

point in the signal loop other

than across the power supply.

Signal loop must have between

230 and 600 ohms load for

communication.

230 RL 600

−

Reference meter

+

for calibration

or monitoring

operation. May

be a voltmeter

across 250 ohm

−

resistor or a

current meter.

+

+

Signal loop may be grounded at

any point or left ungrounded.

−

+

POWER

SUPPLY

−

18

Page 19

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

July 2019

For instruments not mounted on a level sensor or when replacing an instrument, initial setup consists of entering

sensor information.

Sensor information includes displacer and torque tube information, such as:

D Displacer Information (Length, Volume and Weight)

D Driver Rod Length

D Mounting position (Left or Right of Displacer)

D Torque Tube Material

D Torque Tube Wall

D Measurement Application (Level, Interface or Density)

D Direct/Reverse Action

D Temperature Compensation (Enable/Disable)

D Process Fluid Density

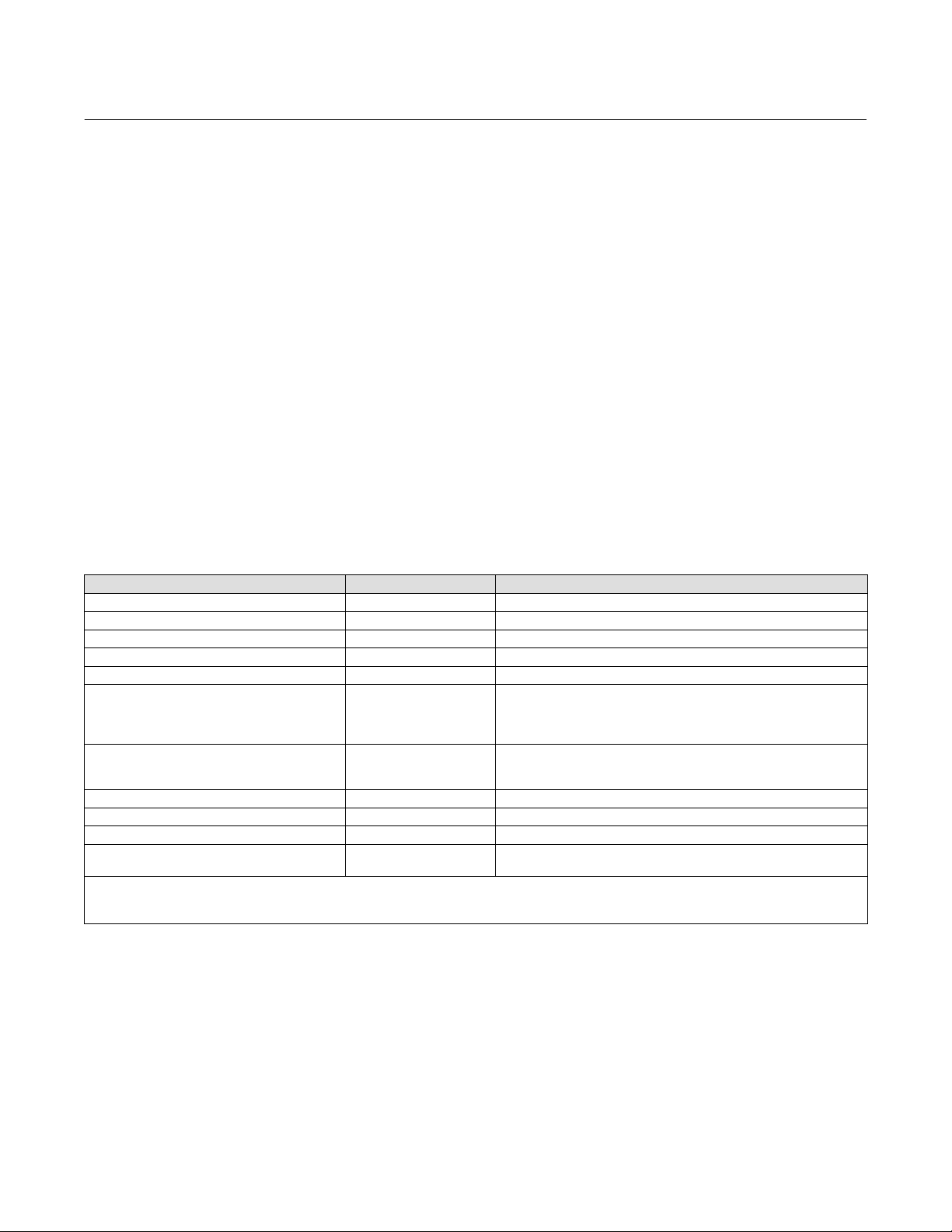

Refer to table 10 for information required to setup the DLC3100. Most of the information is available from the sensor

nameplate. The moment arm is the effective length of the driver rod length, and depends upon the sensor type. For a

249 sensor, refer to table 11 to determine driver rod (moment arm) length.

Table 10. Setup Information

Description Value Units Available in LUI

Displacer Length mm, cm, m, in, ft

Displacer Volume mm3, cm3, L, in

Displacer Weight G, kg, oz, lb

Driver Rod (Moment Arm) Length mm, cm, m, in, ft

Mounting Right of displacer, Left of displacer

249 Cast, 249A, 249B/249BF, 249BP, 249C, 249CP, 249K, 249L, 249N,

249 Sensor

Torque Tube Material

Torque Tube Wall Thin, Standard, Heavy, Unknown

Measurement Application Level, Interface, Density

Analog Output Action Direct, Reverse

Fluid Density

2. When setting up the density in Degrees Baume, note of the range supported:

Degrees Baume Heavy - 0 degree to 37.6 degree

Degrees Baume Light - 10 degree to 100 degree

Degrees API - 0 degree to 100 degree

249P (CL150-600), 249P (CL900-2500), 249PT, 249V, 249VS, 249VT

(TeeMount), 249VT (SideMount), 249W, 259, Other, Masoneilan,

Foxboro-Eckardt, Yamatake Honeywell, Unknown

K-Monel, Inconel, 316SST, Hasteloy C, DuraNickel, Monel, Alloy 20,

Incoloy, Hasteloy B2, 304SST, 304L SST, 316L SST, 321SST, 347SST,

Custom

SGU, g/cm3, g/mL, g/L, kg/m3, lb/in3, lb/ft3, lb/gal,

Degrees Baume – Heavy, Degrees Baume – Light, Degrees API

3

(2)

19

Page 20

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Configuration Advice

Force Mode

Local User Interface Menu > Force Mode

When the DLC3100 is out of service, it is locked for exclusive access by the Primary/Secondary master that put it out of

service. The same master must be used to put the instrument back in service; another master will not be able to

change anything on the device and the LCD will return a “Locked by HART” message, unless you run Force Mode.

Select Force Mode to force the instrument mode to In Service if the original master is not available.

Note

Make sure no outstanding tasks are on-going in the device, including configuration and calibration, before forcing the DLC3100 In

Service

Write Protection

To setup and calibrate the instrument, write protection must be set to disable.

Level Offset

Level Offset is the value DLC3100 reports when the process level is at the bottom of the displacer. Adding a level offset

permits the process variable value in engineering units to be reported with respect to a reference point other than the

bottom of the displacer. Examples include: bottom of the process vessel, the process set point, or sea level. Set Level

Offset is only available in Level or Interface measurement mode. Follow the prompts on the Field Communicator to

enter the offset value (2-3-2-1-6).

Level Offset will affect URV/LRV, PV Hi/Lo, PV HiHi/LoLo alerts. Changing PV alert points assumes you have already

considered the affect of Level Offset on the alert points. This parameter should be cleared to zero before running

Device Setup.

Figure 81. Example of the Use of Level Offset

URV

(10 FEET)

LRV

(6 FEET)

E0368

DISPLACER

LEVEL

OFFSET

(6 FEET)

20

Page 21

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

July 2019

Initial Setup

Initial Setup consists of the following:

D Device Setup

D PV Setup

D Process Setup

All three setup procedures must be completed when configuring the DLC3100 in order for the device to function

properly.

Initial Setup directs you through initialization of configuration data needed for proper operation. When the instrument

comes out of the box, the default dimensions are set for the most common Fisher 249 construction. If any data is

unknown, it is generally safe to accept the defaults. The mounting position - left or right of displacer - is important for

correct interpretation of positive motion. Use Manual Setup to locate and modify individual parameters when they

need to be changed. Refer to the Initial Setup section below for DLC3100 configuration.

Notes

The DLC3100 has to be “Not In Service” when carrying out Initial Setup. Place the loop into manual operation before putting

device out of service as the output will not be valid.

When the DLC3100 is out of service, it is locked for exclusive access by the Primary/Secondary master that put it out of service. If

the instrument reports Locked by HART or Access Restricted when you attempt to configure it, and a master of the original

priority is not available, use Force Mode on the Local User Interface menu to force the instrument mode to In Service. You will

then be able to take it out of service with your own master to make changes.

Guided setup is available to aid initial setup. Follow the prompts to enter information required by the setup. Most of

the information is available from the sensor nameplate.

Device Setup

AMS Configure > Guided Setup > Device Setup

Field Communicator Configure > Guided Setup > Device Setup (2-2-1)

Input the required information as follows:

D Displacer Information (Length, Weight and Volume)

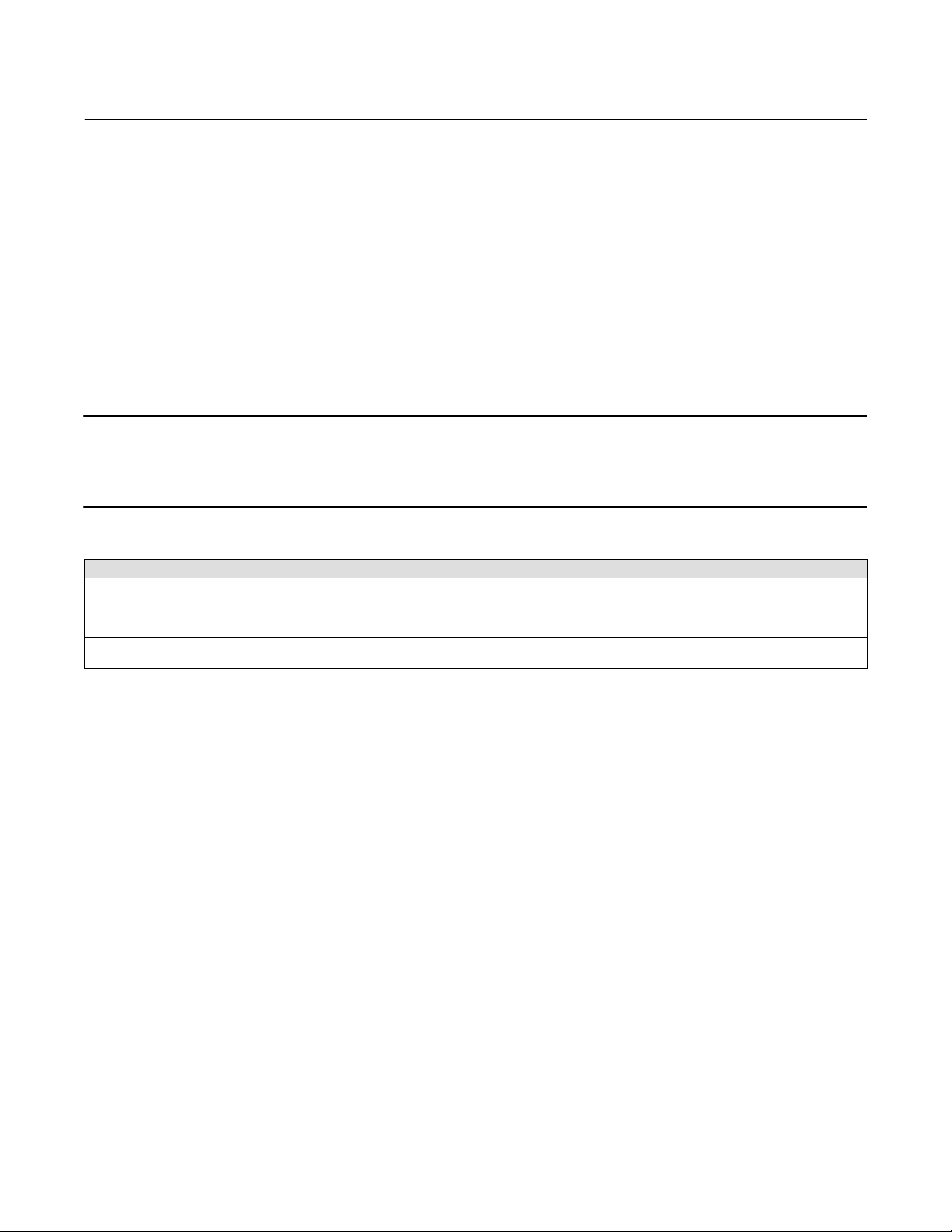

D Driver Rod Length (refer to table 11 and figure 9)

D Mounting Position (Left or Right of Displacer)

D 249 Sensor Model

D Torque Tube Material and wall thickness

The Driver Rod (moment arm) is the effective length of the driver rod length, and depends upon the sensor type. For a

249 sensor, refer to table 11 to determine driver rod length.

Once Device Setup is completed, configure the application settings using the PV Setup procedures.

21

Page 22

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Table 11. Driver Rod Length

SENSOR TYPE

249 203 8.01

249B 203 8.01

249BF 203 8.01

249BP 203 8.01

249C 169 6.64

249CP 169 6.64

249K 267 10.5

249L 229 9.01

249N 267 10.5

249P

(CL125-CL600)

249P

(CL900-CL2500)

249VS (Special)

249VS (Std) 343 13.5

249W 203 8.01

1. Driver rod length is the perpendicular distance between the vertical centerline of the displacer and the horizontal centerline of the torque tube. See figure 9. If you cannot determine the driver

rod length, contact your Emerson sales office

2. This table applies to sensors with vertical displacers only. For sensor types not listed, or sensors with horizontal displacers, contact your Emerson sales office for the driver rod length. For other

manufacturers' sensors, see the installation instructions for that mounting.

(1)

(2)

(1)

and provide the serial number of the sensor.

MOMENT ARM

mm Inch

203 8.01

229 9.01

See serial card See serial card

Figure 9. Method of Determining Moment Arm from External Measurements

VERTICAL C

DISPLACER

VESSEL

OF

L

MOMENT

ARM LENGTH

HORIZONTAL C

TORQUE TUBE

OF

L

22

Page 23

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

PV Setup

AMS Configure > Guided Setup > PV Setup

Field Communicator Configure > Guided Setup > PV Setup (2-2-2)

PV Setup consists of the following:

D Measurement Application (Level, Interface or Density) (see table 12)

D Analog Output Action (Direct or Reverse)

D Level Offset

D Measurement Range (Lower Range Value and Upper Range Value)

Note

For interface applications, if the 249 is not installed on a vessel, or if the cage can be isolated, calibrate the instrument with

weights, water, or other standard test fluid, in level mode. After calibrating in level mode, the instrument can be switched to

interface mode, then enter the actual process fluid specific gravity and range values, follow with Trim Zero.

July 2019

Table 12. Application Information

Measurement Application Description

The default process variable units are set to the same units chosen for displacer length. When level

Level, Interface

Density

offset is changed, range values will be initialized based on level offset and displacer length. The default

upper range value is set to equal to displacer length and the default lower range value is set to zero when

the level offset is 0.

The default process variable units are set to “SGU” (Specific Gravity Units). The default upper range value

is set to “1.0” and the default lower range value is set to ”0.1”.

When a DLC3100 with analog output is set for direct action the loop current will increase as the fluid level increases.

Upper Range Value is the process variable values at 20 mA and Lower Range Value is the process variable values at

4 mA.

Choosing Reverse action will swap the default values of the upper and lower range values. The loop current will

decrease as the fluid level increases. Upper Range Value is the process variable values at 4 mA and Lower Range Value

is the process variable values at 20 mA.

Once PV Setup is completed configure the process information using the Process Setup procedures.

Process Setup

AMS Configure > Guided Setup > Process Setup

Field Communicator Configure > Guided Setup > Process Setup (2-2-3)

Process Setup consists of the following:

D Process Temperature Input (None, Manual or RTD) (see table 13)

D Fluid Type (Water/Steam, Hydrocarbon, H

D Fluid Density

Aqueous Solution or Custom Fluid)

2SO4

23

Page 24

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Process Temperature Input allows the DLC3100 to know the temperature in the process to carry out temperature

compensation. Selecting Manual or RTD will enable the temperature compensation.

Table 13. Process Temperature Input Information

Process Temperature Input Temperature compensation

None Disable.

Manual Enable. input process temperature into DLC3100 manually.

RTD

Enable. install RTD to the DLC3100 terminal box. DLC3100 will base on the RTD reading and derive the

temperature of the process.

When Temperature Compensation is enabled (by selecting Manual or RTD in Process Temperature Input), select the

process fluid type, and enter the temperature/density table. The DLC3100 will use the best matched compensated

density value from the pre-loaded fluid type tables in DLC3100 for level measurement based on the actual process

temperature. If Custom Fluid is selected, input Temperature/Density values to custom fluid table. For level

measurement applications, only the lower fluid table is required. For interface measurement applications, both upper

fluid and lower fluid tables are required. Neither table is used for density applications.

Note

A minimum of two pairs of temperature/density values must be entered to the table. The temperatures entered must be in

ascending order.

Manual Setup

AMS Configure > Manual Setup

Field Communicator Configure > Manual Setup (3)

The DLC3100 digital level controller communicates via the HART protocol. This section describes the advanced

features that can be accessed with the DD/Field Communicator.

Note

Changing setup parameters will require instrument protection to be disabled, and the instrument to be put out of service. Place

the loop into manual operation before putting device out of service as the DLC3100 output may not be valid.

When the DLC3100 is out of service, it is locked for exclusive access by the Primary/Secondary master that put it out of service. If

the instrument reports Locked by HART or Access Restricted when you attempt to configure it, and a master of the original

priority is not available, use Force Mode on the Local User Interface menu to force the instrument mode to In Service. You will

then be able to take it out of service with your own master to make changes.

24

Page 25

Instruction Manual

D104213X012

General

Group Name Description

Device Information

Serial Numbers

Instrument Clock

Device

DLC3100 Digital Level Controller

July 2019

Tag

A unique tag to identify the HART device, up to 8

characters.

Date Calibration date entered by user.

Descriptor

A loop descriptor with a maximum length of 16

characters.

Message A message with a maximum length of 32 characters.

Instrument Serial Number Serial number on the instrument nameplate.

Sensor Serial Number Serial number on the sensor nameplate.

Dynamic date on the instrument clock for use in

Instrument Date

stamping logged events. The order of year, month and

day depends on the setting of the operating system.

Instrument Time

Time of day (hh:mm:ss) on instrument clock for use in

stamping logged events.

Group Name Description

Application Measurement application: Level, Interface or Density

PV Upper Range Value

Primary Variable

PV Lower Range Value

Primary Value Offset

Analog Output Action Analog Output Action

PV Upper Sensor Limit

Sensor Limits

PV Lower Sensor Limit

PV Damping

Damping

Input Filter Time

Defines the operational endpoint from which the

20 mA or 100% of the percent range are derived.

Defines the operational endpoint from which the 4 mA

or 0% of the percent range are derived.

The primary variable value you want the instrument to

report when physical level is at bottom of a displacer.

Defines whether loop current increases/decreases

when level changes.

Direct – Loop current increases as the fluid level

increases.

Reverse – Loop current decreases as the fluid level

increases.

Indicates the maximum usable value for the Upper

Range value.

Indicates the minimum usable value for the Lower

Range value.

Time constant of filter applied to PV signal after all

compensation and before generating AO command.

Time constant of filter applied to torque tube sensor

input signal.

25

Page 26

DLC3100 Digital Level Controller

July 2019

Sensor

Group Name Description

Displacer Length Full length of the displacer.

Displacer Volume Volume of the displacer.

Displacer Weight Weight of the displacer.

Sensor Dimensions

Sensor Units

Torque Tube

Driver Rod Length Length of the moment arm.

Instrument Mounting

Length Units

Volume Units The selected units for displacer volume.

Weight Units The selected units for displacer weight.

Temperature Units

Fluid Density Units

Torque Rate Units Unit of torque rate.

Compensated Torque Rate

Torque Tube Material

Torque Tube Wall The thickness of the torque tube used.

Sensor Type 249 model level sensor used.

Instruction Manual

D104213X012

The location of the instrument when mounted on the

level sensor, whether it is to the right or left of

displacer.

The selected units for length measurements and

parameters.

The selected units for temperature measurements and

parameters.

The selected units for density measurements and

parameters.

Compound torsion rate of torque tube, pilot shaft, and

instrument flexure, computed during calibration.

Selected torque tube material for torque tube

temperature compensation.

Process

Group Name Description

Process Fluid

Temperature

Compensation

Process Fluid Actual process fluid to be measured.

Process Fluid Compensated

Density

Fluid Density Units

Process Temperature Input

Actual fluid density after temperature compensation.

The selected units for density measurements and

parameters.

Temperature input to the instrument via RTD, manually

input, or none.

Process Temperature Actual temperature of the process.

Temperature Units

The selected units for temperature measurements and

parameters.

26

Page 27

Instruction Manual

D104213X012

HART

Group Name Description

Communication Settings

Polling Address

PV is

SV is

Variable Mapping

TV is

QV is

Safety Recovery (DLC3100 SIS)

Group Name Description

Recovery Trip Recovery Mode

DLC3100 Digital Level Controller

July 2019

The polling address for the instrument. If a

point-to-point configuration is used, enter 0. If a

multidrop configuration is used, enter a value in the

range of 1 to 62, and disable loop current mode.

Field device dynamic variable that has been mapped

into the Primary Variable.

Field device dynamic variable that has been mapped

into the Secondary Variable.

Field device dynamic variable that has been mapped

into the Tertiary Variable.

Field device dynamic variable that has been mapped

into the Quaternary Variable.

Auto: DLC3100 SIS is in Trip Alarm Current state; when

the alarm current condition is cleared, the instrument

will automatically revert back to normal operating

current condition.

Manual: DLC3100 SIS is in Trip Alarm Current state, when

the alarm current condition is cleared, instrument will

remain in trip alarm current state. You will need to

manually reset the instrument by “Safety Reset”.

27

Page 28

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Alert Setup

Note

The DLC3100 has to be put out of service when carrying out Alert Setup. Place the loop into manual operation before putting

device out of service as the output will not be valid.

When the DLC3100 is out of service, it is locked for exclusive access by the Primary/Secondary master that put it out of service. If

the instrument reports Locked by HART or Access Restricted when you attempt to configure it, and a master of the original

priority is not available, use Force Mode on the Local User Interface menu to force the instrument mode to In Service. You will

then be able to take it out of service with your own master to make changes.

Primary Variable

Group Description

PV Alert Deadband The monitored primary variable must move more than this value to clear the alert.

Indicates that the primary variable has violated the user-specified high high alert point.

PV Hi Hi Alert

PV Hi Alert Indicates that the primary variable has violated the user-specified high alert point.

PV Lo Alert Indicates that the primary variable has violated the user-specified low alert point.

PV Lo Lo Alert

Output current will be set to alarm current depending on the hardware Alarm Switch

configuration.

Indicates that the primary variable has violated the user-specified low low alert point.

Output current will be set to alarm current depending on the hardware Alarm Switch

configuration.

Note

PV alert settings will be affected by the analog output action. See tables 14, 15, and 16. When setting analog output action, always

check the PV alert settings to make sure the alert thresholds are according to the analog output action.

Table 14. Analog Output Action - Direct

Direct Action

(Span = Upper Range Value – Lower Range Value)

Alarm Variable Default Value in unit Default Value in percentage

PV Hi Hi Alarm Upper Range Value 100%

PV Hi Alarm 95% span + Lower Range Value 95%

PV Lo Alarm 5% span + Lower Range Value 5%

PV Lo Lo Alarm Lower Range Value 0%

Table 15. Analog Output Action - Reverse

Reverse Action

(Span = Lower Range Value – Upper Range Value)

Alarm Variable Default Value in unit Default Value in percentage

PV Hi Hi Alarm Lower Range Value 0%

PV Hi Alarm 95% span + Upper Range Value 5%

PV Lo Alarm 5% span + Upper Range Value 95%

PV Lo Lo Alarm Upper Range Value 100%

28

Page 29

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

July 2019

For example, with a 14 inch displacer, PV Hi and PV HiHi alert will be active when the fluid level goes beyond the alert

points. Likewise, PV Lo and PV LoLo will be active when the fluid level falls below the alert points.

Table 16. Example; 14 Inch Displacer

Action Range Value PV Alerts Units Percentage

URV 14 in

Direct

LRV 0 in

URV 0 in

Reverse

LRV 14 in

PV HiHi 13.3 in 95%

PV Hi 12.6 in 90%

PV Lo 1.4 in 10%

PV LoLo 0.7 in 5%

PV HiHi 13.3 in 5%

PV Hi 12.6 in 10%

PV Lo 1.4 in 90%

PV LoLo 0.7 in 95%

Rate Limit

Name Description

Displacer Rise Rate

Exceeded

Displacer Fall Rate

Exceeded

Indicates if the device detected a rise rate that exceeded the limit.

Indicates if the device detected a fall rate that exceeded the limit.

Temperature

Name Description

Process Temperature

Deadband

Instrument Temperature

Deadband

Process Temperature Hi

Alert

Process Temperature Lo

Alert

Instrument Temperature Hi

Alert

Instrument Temperature

Lo Alert

The process temperature must move more than this value to clear the alert.

The instrument temperature must move more than this value to clear the alert.

Indicates that the process temperature has violated the user-specified high alert

point.

Indicates that the process temperature has violated the user-specified low alert

point.

Indicates that the instrument temperature has violated the user-specified high alert

point.

Indicates that the instrument temperature has violated the user-specified the low

alert point.

29

Page 30

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Operational

Name Description

Calibration Validity Alert

Analog Output Fixed Indicates that the output is in fixed current mode, not tracking process.

Analog Output Saturated Indicates that the analog output is saturated at 3.8 mA or 20.5 mA.

PV Out of Limits

Non-PV Out of Limits

Device Malfunction Indicates that the field device has malfunctioned due to a hardware error or failure.

PV AO Readback Fail

Lever Assembly Locked

Calibration in Progress Set if a calibration routine is currently running in the instrument.

Indicates that parameters affecting calibration validity have been changed since the

last calibration was accepted.

Indicates that the process applied to the primary variable is outside the operating

limits of the field device.

Indicates that the process applied to the non-primary variable is outside the

operating limits of the field device.

Indicates that the output readback for the primary variable has deviated by the

hard-coded limits.

Indicates that the lever assembly is in locked position and will not respond to level

changes.

Informational

Name Description

Configuration Changed

Device Configuration

Locked

Out of Service Indicates that the device is not in service.

Cold Start

Indicates that a modification has been made to the configuration of the field device

(configuration variable, tag descriptor or date).

Indicates that the device is locked for exclusive access or in write-protect mode.

Indicates that a reset or selftest of the field device has occurred, or power has been

removed and reapplied.

Input Compensation

Name Description

Fluid Value Crossed

Invalid Custom Table

Temp Out of

Compensation Range

Indicates that process fluid density values have crossed. The upper fluid density is

too close to 0.1 SGU or has become greater than the lower fluid density.

Indicates that the custom process fluid density table or torque tube table being used

for temperature compensation is invalid.

Indicates that the compensation temperature has exceeded the compensation table

limits.

30

Page 31

Instruction Manual

D104213X012

DLC3100 Digital Level Controller

Hardware

Name Description

Reference Voltage

Failed

Hall Sensor Alert

RTD Sensor Alert

Hall Diagnostic Failed Indicates that the internal hall diagnostics has possible failure in the Hall circuitry.

RTD Diagnostic Failed Indicates that the device has failed to diagnose the integrity of the RTD.

Instrument

Temperature Sensor

Alert

Indicates that the reference voltage for the Analog/Digital converter is outside the

hard-coded limits.

Indicates that the hall sensor reading has not been changing for 10 consecutive samples

or has violated one of the hard-coded limits.

Indicates that the apparent resistance measured at the RTD terminals is less than 10 ohms

or greater than 320 ohms.

Indicates that both mainboard temperature sensors are reporting outside operating

temperature range or differ by more than 10 degC.

Program and Memory

Name Description

Watchdog Reset

Executed

Program Memory

Failed

NVM Error Indicates that data in the critical section of configuration memory is corrupt.

Program Flow Error Indicates that the instrument is not performing the expected series of calculations.

EEPROM Write

Accumulator

RAM Test Error Alert Indicates that an on-going RAM test has detected possible corruption in the critical data.

EEPROM Daily Write

Accumulator

Indicates that the watchdog timer has timed out, triggering a hardware reset.

Indicates that the program memory is corrupt.

Indicates that the total number of EEPROM writes has exceeded 950,000 cycles.

Indicates that the total number of EEPROM writes has exceeded 160 times within the day.

July 2019

Alert Record

Name Description

Alert Record Not

Empty

Alert Record Full

Instrument Time Not

Set

Indicates that the alert record has entries.

Indicates that the number of alert events has met or exceeded the storage capacity of the

instrument.

Indicates that the instrument time was not initialized after the last power cycle.

31

Page 32

DLC3100 Digital Level Controller

July 2019

Calibration

AMS Configure > Calibration

Field Communicator Configure > Calibration (2-4)

Two Points Calibration

Two Points

Calibration

Instruction Manual

D104213X012

st

nd

Turn on/off

temperature

compensation

No

Set DLC3100 to

“Not In Service”

Running at

process

conditions?

Yes

Select units for

PV

measurement

Capture 1

calibration point

Adjust level

by at least 5% of

nominal span

Capture 2

calibration point

Set DLC3100 to

“In Service”

Two-Points Calibration is usually the most accurate method for calibrating the sensor. It uses independent

observations of two valid process conditions, together with the hardware dimensional data and specific gravity

information, to compute the effective torque rate of the sensor. The two data points can be separated by any span

between a minimum of 5% to 100%, as long as they remain on the displacer. Within this range, the calibration accuracy

will generally increase as the data point separation gets larger. Accuracy is also improved by running the procedure at

process temperature, as the temperature effect on torque rate will be captured. (It is possible to use theoretical data

to pre-compensate the measured torque rate for a target process condition when the calibration must be run at

ambient conditions).

32

Page 33

Instruction Manual

D104213X012

Min/Max Calibration

DLC3100 Digital Level Controller

July 2019

Min/Max

Calibration

Set DLC3100 to

“Not In Service”

Turn on/off

temperature

compensation

No

Running at

process

conditions?

Yes

Capture Min

or Max

buoyancy?

Min

Confirm fluid(s)

density

Establish min

buoyancy and

capture

Establish max

buoyancy and

capture

Max

Establish max

buoyancy and

capture

Establish min

buoyancy and

capture

Set DLC3100 to

“In Service”

Min/Max Calibration can be used to calibrate the sensor if the process condition can be changed to the equivalent of a

completely dry and completely submerged displacer, but the actual precise intermediate values cannot be observed

(eg. no sight glass is available, but the cage can be isolated and drained or flooded). Correct displacer information and

the SG of the test fluid must be entered before performing this procedure.

33

Page 34

DLC3100 Digital Level Controller

July 2019

Weight Calibration

Instruction Manual

D104213X012

Weight

Calibration

Set DLC3100 to

“Not In Service”

Apply larger weight

of no more than max

load allowed on driver

rod and capture 1

calibration point

Apply smaller weight

than previous step on

driver rod and capture

nd

2

calibration point

1

Weight

st

Weight/

Counter-Weight?

Counter-

Weight

Apply smaller counter-

weight of at least min

load allowed and capture

st

calibration point

1

Apply larger counter-

weight than previous

step and capture 2

nd

calibration point

Set DLC3100 to

“In Service”

1 REFER TO TABLE 17 FOR MAXIMUM LOAD ALLOWED ON TORQUE TUBE.

Weight Calibration may be used on the bench or with a calibration jig that can apply a mechanical force to the driver

rod to simulate displacer buoyancy changes. It allows the instrument and sensor to be calibrated using equivalent

weights or force inputs instead of using the actual displacer buoyancy changes. If the displacer information has been

entered prior to beginning the procedure, the instrument will be able to compute reasonable weight value

suggestions for the calibration. The weight values suggested during the weight calibration aim to achieve maximum

torque tube rotation for better accuracy. It does not necessary mean the weight at 0% or 100%. The only preliminary

data essential for the correct calibration of the torque rate is the length of the driver rod being used for the calibration.

Weight equivalent to the net displacer weight at two valid process conditions must be available. The sensor must have

been sized properly for the expected service, so that the chosen process conditions are in the free motion linear range

of the sensor.

Table 17. Maximum Unbuoyed Displacer Weight

Sensor Type Torque Tube Wall Thickness Displacer Weight, WT (lb)

249, 249B, 249BP

249C, 249CP

249VS

249L, 249P

1. High pressure Class 900 through 2500.

34

(1)

249K

Thin

Standard

Heavy

Standard

Heavy

Thin

Standard

Thin

Standard

Thin

Standard

3.3

5.0

9.5

4.0

6.4

3.0

5.5

4.5

8.5

3.8

7.3

Page 35

Instruction Manual

D104213X012

Two Points Time Delay Calibration

Two Points

Time Delay

Calibration

DLC3100 Digital Level Controller

July 2019

Turn on/off

temperature

compensation

No

Set DLC3100 to

“Not In Service”

Running at

process

conditions?

Yes

Select units for

PV

measurement

First point

captured?

No

Capture 1

calibration point?

st

Yes

No

Use

previously

captured 1

point?

Select units for

measurement

Capture 2

calibration point

Set DLC3100 to

“In Service”

st

Yes

PV

nd

Two Points Time Delay is a two points calibration in which the two points captured can be taken some time apart. The

first point is captured and stored indefinitely until the second point is captured. All instrument configuration data is

needed to perform a Two Points Time Delay Calibration.

35

Page 36

DLC3100 Digital Level Controller

July 2019

Instruction Manual

D104213X012

Zero Trim

Turn on/off

temperature

compensation

No

Zero Trim

Partial

Calibration

Set DLC3100 to

“Not In Service”

Running at

process

conditions?

Yes

Select units for

PV

measurement

Input observed

PV

Gain Trim

Turn on/off

temperature

compensation

No

Gain Trim

Partial

Calibration

Set DLC3100 to

“Not In Service”

Running at

process

conditions?

Yes

Select units for

PV

measurement

Input observed

PV

Set DLC3100 to

“In Service”

Trim Zero computes the value of the input angle

required to align the digital Primary Variable with the

user’s observation of the process, and corrects the

stored input zero reference, assuming that the

calibration gain is accurate.

Set DLC3100 to

“In Service”

Gain Trim trims the torque rate value to align the

digital Primary Variable with the user’s observation.

This calibration assumes that sensor zero is already

accurate and only a gain error exists. Actual process

condition must be nonzero and able to be measured

independently. Configuration data must contain

density of calibration fluid(s), displacer volume, and

driver rod length.

Torque Rate Gain

Torque Rate Gain allows you to input the torque rate.

36

Page 37

Instruction Manual