Page 1

Part Number D301244X012

April 2020

DL8000 Preset Controller

Instruction Manual

Remote Au tomation Solutions

Page 2

DL8000 Preset Instruction Manual

ii Revised April 2020

Page 3

DL8000 Preset Instruction Manual

Contents

Chapter 1 – Overview 1-1

1.1 DL8000 Overview ............................................................................................................. 1-1

1.2 Hardware .......................................................................................................................... 1-3

1.2.1 Housing ................................................................................................................. 1-3

1.2.2 Electronics ............................................................................................................. 1-5

1.3 Security Gateway .............................................................................................................. 1-6

1.4 Additional Technical Specifications .................................................................................. 1-6

Chapter 2 – Installation and Use 2-1

2.1 Housing ............................................................................................................................. 2-1

2.1.1 Class I Zone 1 Housing ......................................................................................... 2-2

2.1.2 Securing the Cover to the Class I Zone I Case ..................................................... 2-4

2.1.3 Class I Div 2 Housing ............................................................................................ 2-5

2.2 Card Cage ........................................................................................................................ 2-6

2.2.1 Backplane .............................................................................................................. 2-7

2.3 Central Processor Unit (CPU) .......................................................................................... 2-8

2.3.1 Installing and Removing Wire Channel Covers................................................... 2-10

2.3.2 Removing and Installing Module Covers ............................................................. 2-11

2.3.3 Removing the CPU Module ................................................................................. 2-11

2.3.4 Installing the CPU Module ................................................................................... 2-12

2.4 License Keys .................................................................................................................. 2-12

2.4.1 Installing a License Key ....................................................................................... 2-13

2.4.2 Removing a License Key ..................................................................................... 2-14

2.5 Installation Planning ........................................................................................................ 2-15

2.6 Mechanical Installation ................................................................................................... 2-15

2.6.1 Planning Considerations ..................................................................................... 2-16

2.7 Electrical Installation ....................................................................................................... 2-18

2.7.1 General Considerations ....................................................................................... 2-18

2.7.2 Field Wiring Installation Guidelines: .................................................................... 2-18

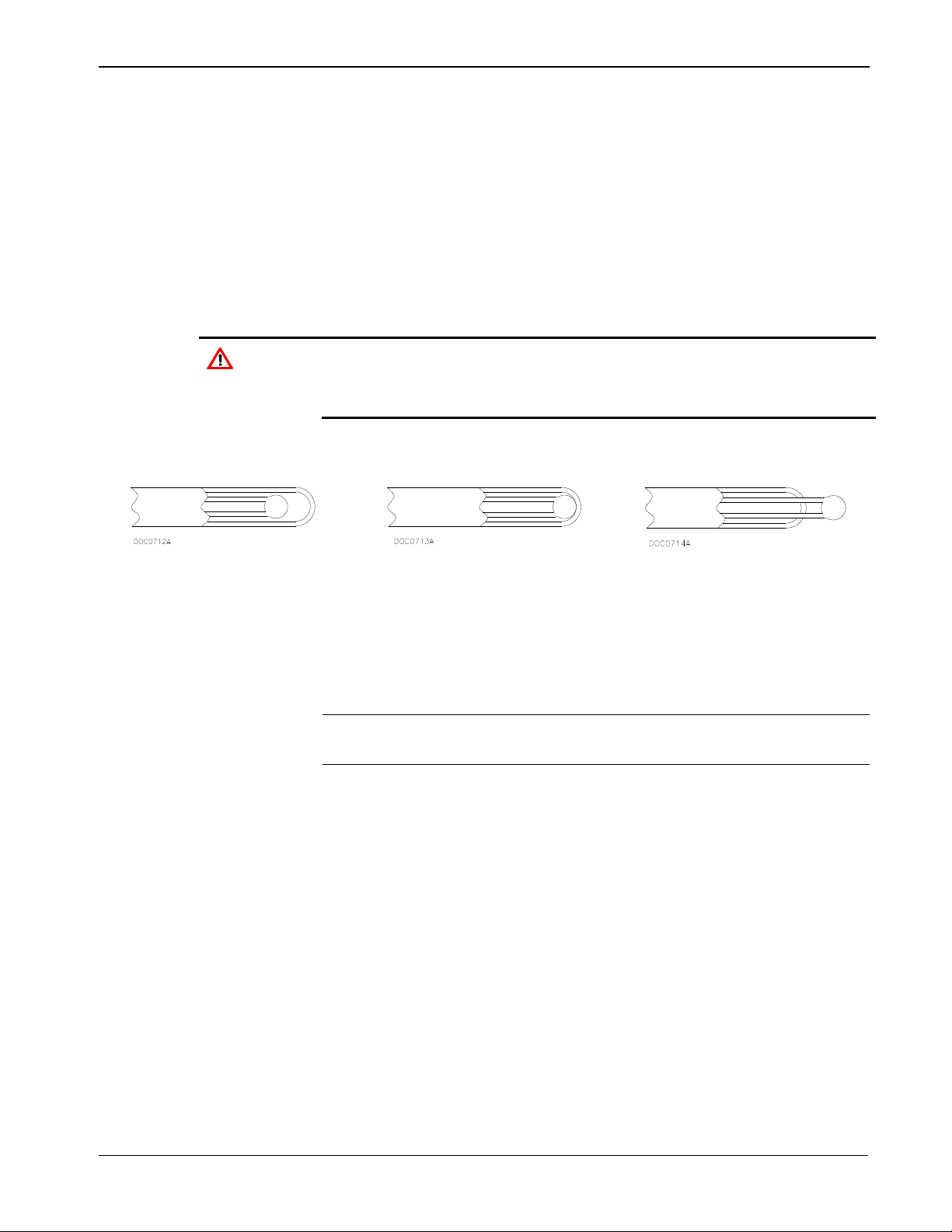

2.7.3 Electrical Wire and Cable Selection and Installation ........................................... 2-19

2.7.4 Input/Output Field Signal Wiring.......................................................................... 2-20

2.7.5 Electrical Grounds ............................................................................................... 2-20

2.7.6 Wire Conduit Selection and Installation .............................................................. 2-22

2.8 Operator Interface ........................................................................................................... 2-23

2.8.1 Keypad ................................................................................................................ 2-24

2.8.2 LED Status Indicators .......................................................................................... 2-25

Chapter 3 – Modules 3-1

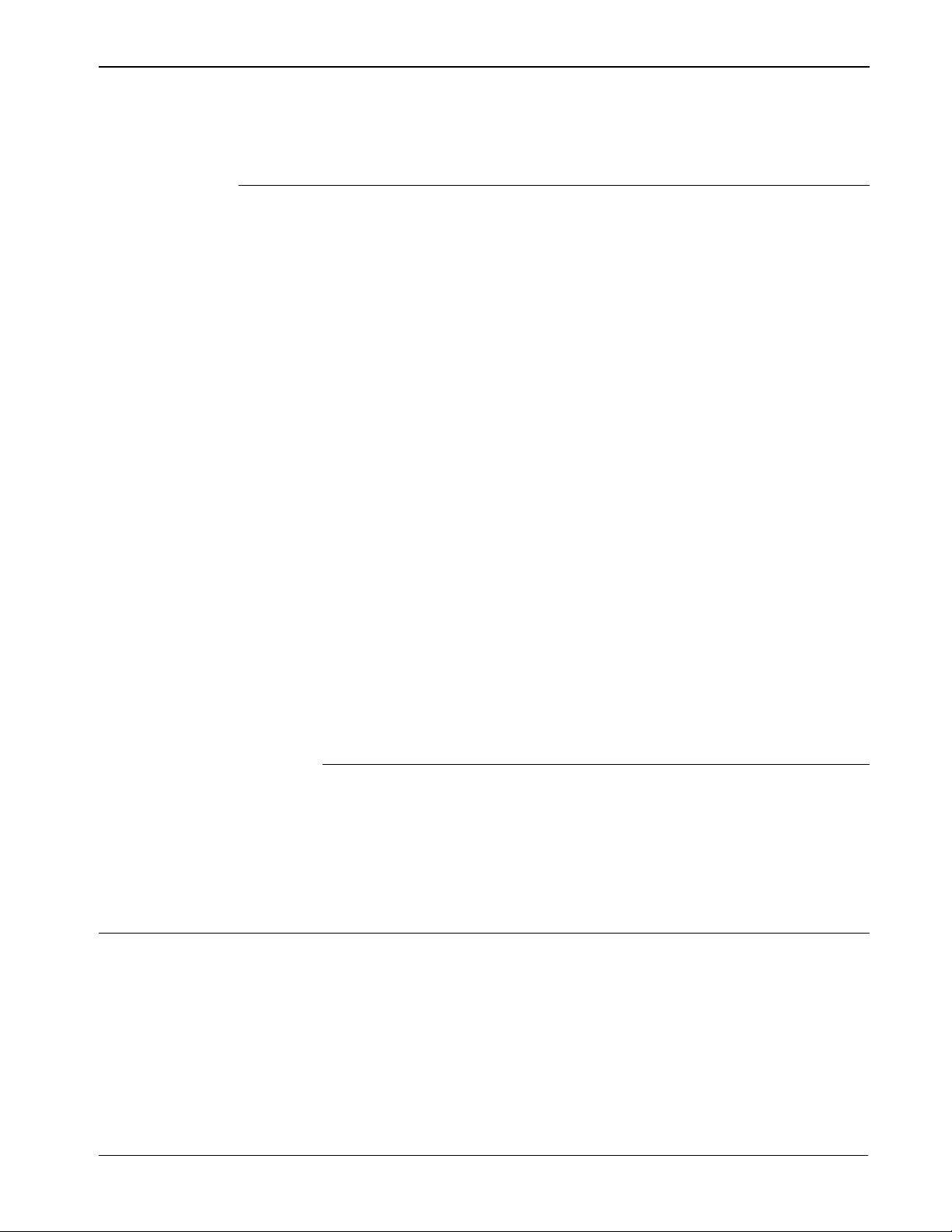

3.1 Power Input Module .......................................................................................................... 3-1

3.1.1 12 Volt DC Power Input Module ............................................................................ 3-2

3.2 Input/Output Modules ....................................................................................................... 3-3

3.2.1 General Installation ............................................................................................... 3-5

3.2.2 Installing an I/O Module ......................................................................................... 3-6

3.2.3 Removing an I/O Module ....................................................................................... 3-7

3.2.4 Wiring I/O Modules ................................................................................................ 3-7

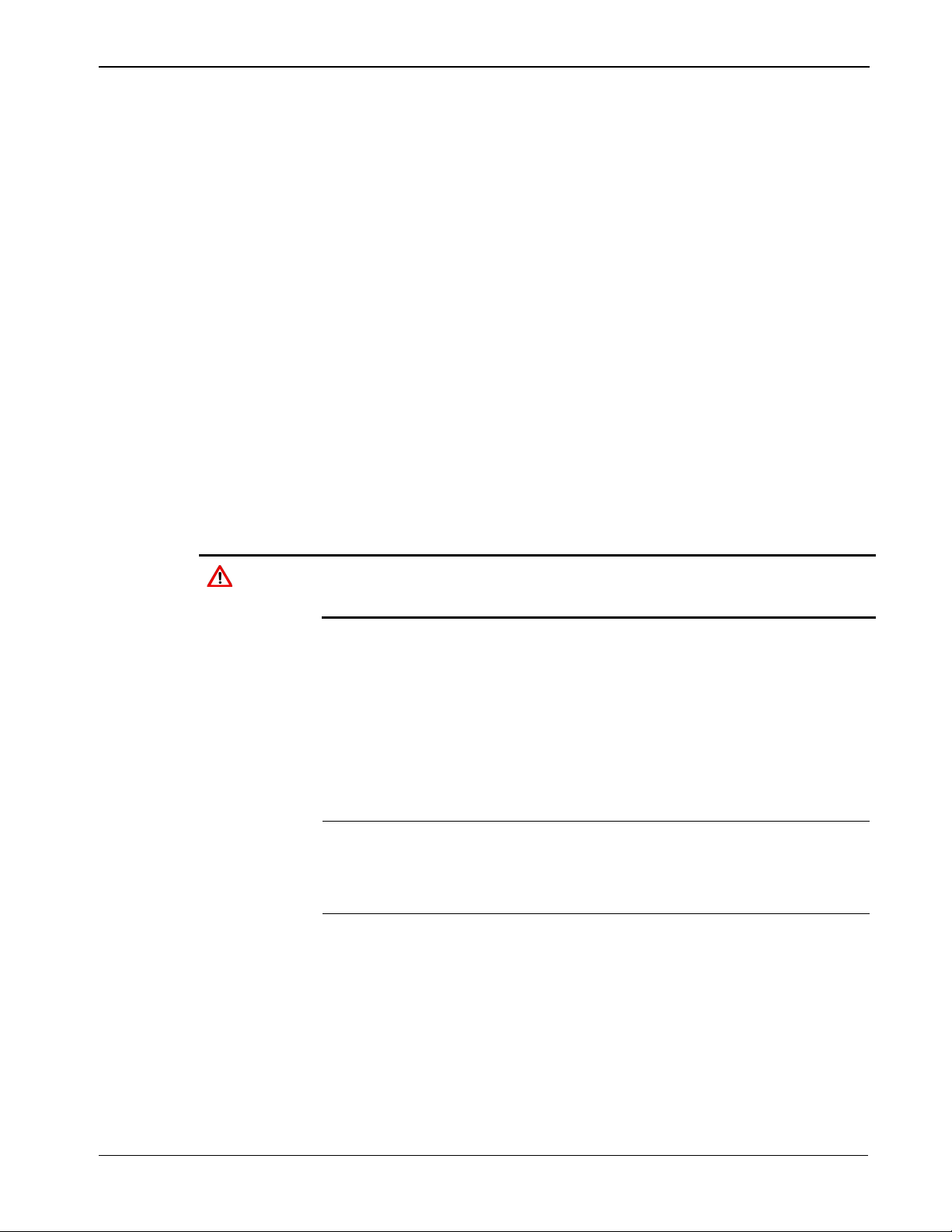

3.2.5 Analog Input (AI) Modules ..................................................................................... 3-7

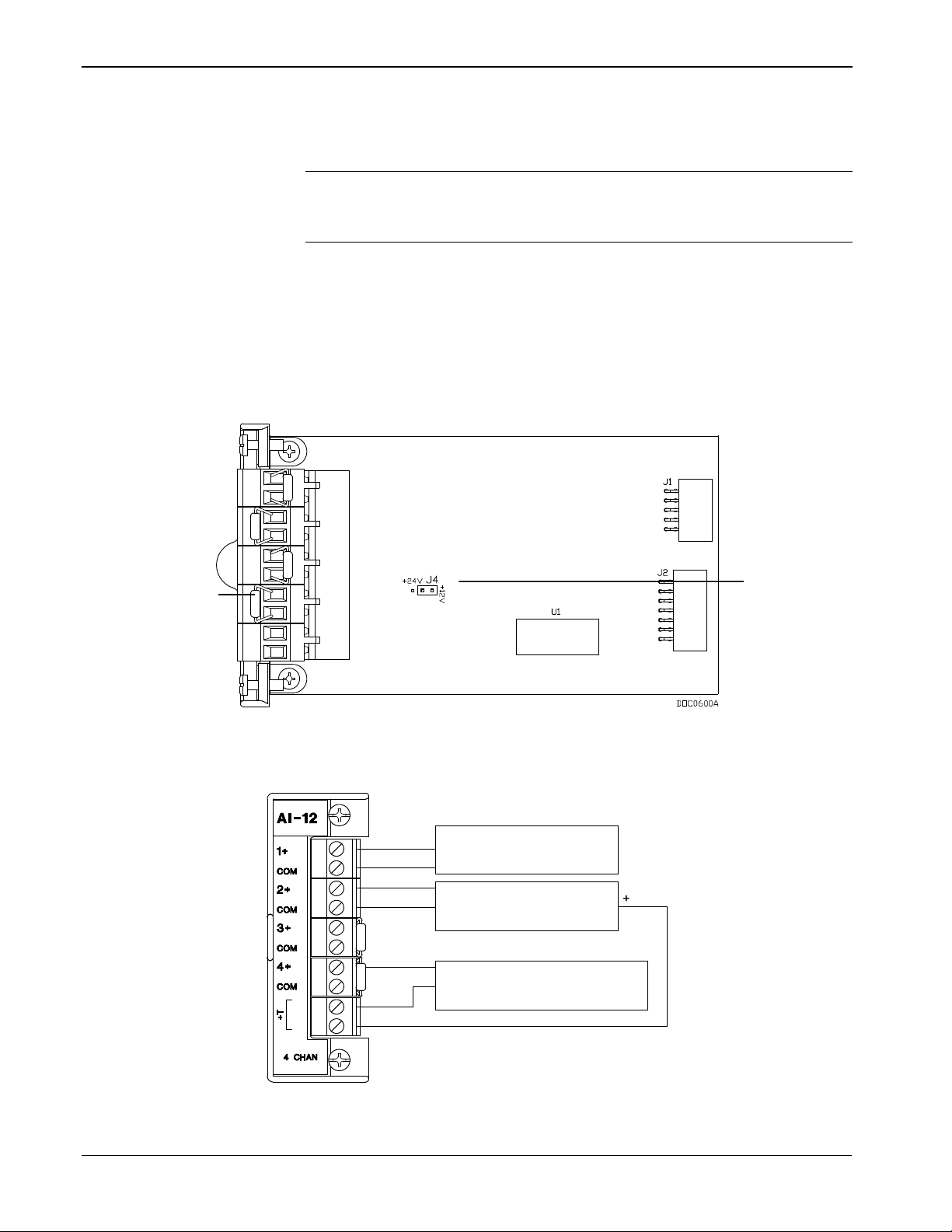

3.2.6 Analog Output (AO) Modules ................................................................................ 3-9

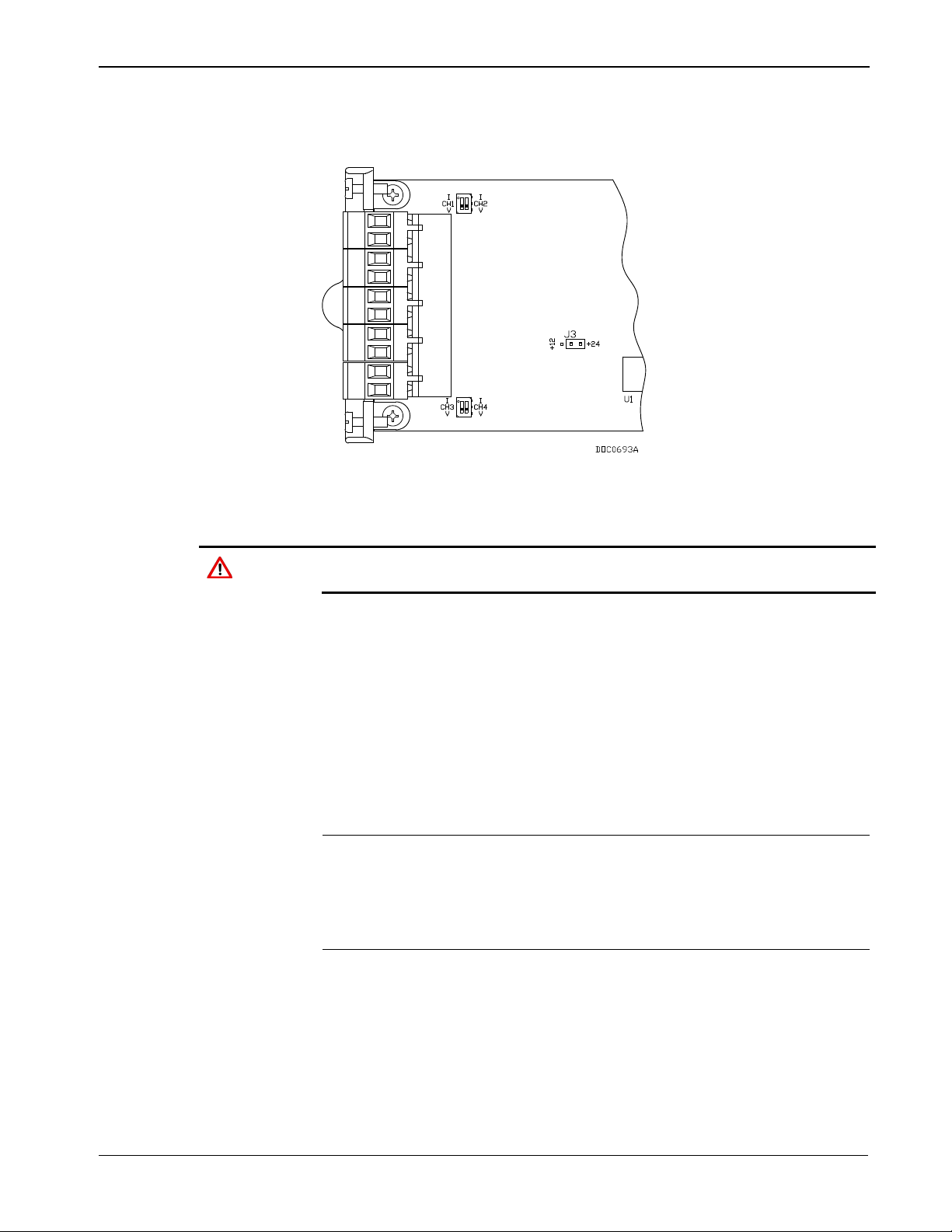

3.2.7 Discrete Input (DI) Modules ................................................................................. 3-10

Revised March 2020 Contents iii

Page 4

DL8000 Preset Instruction Manual

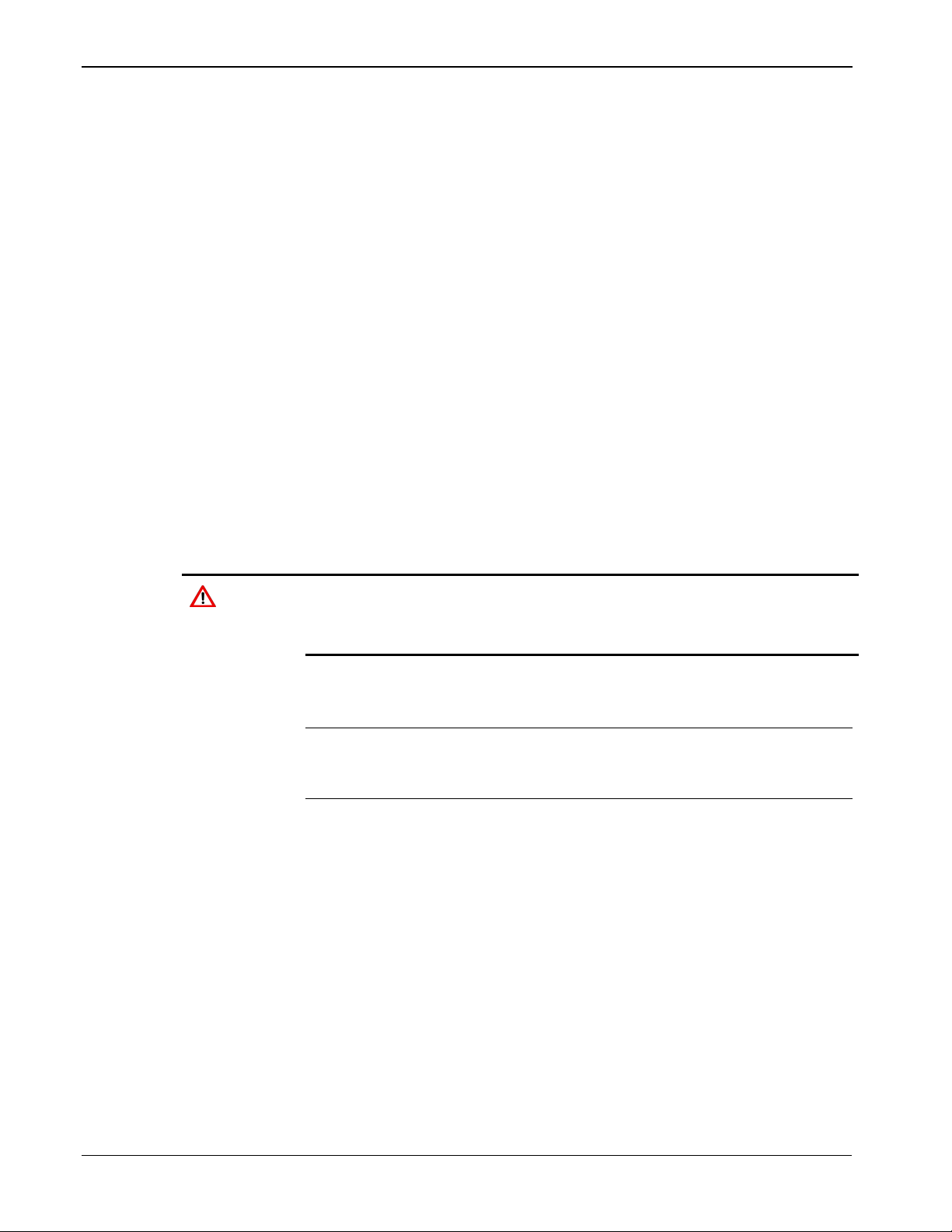

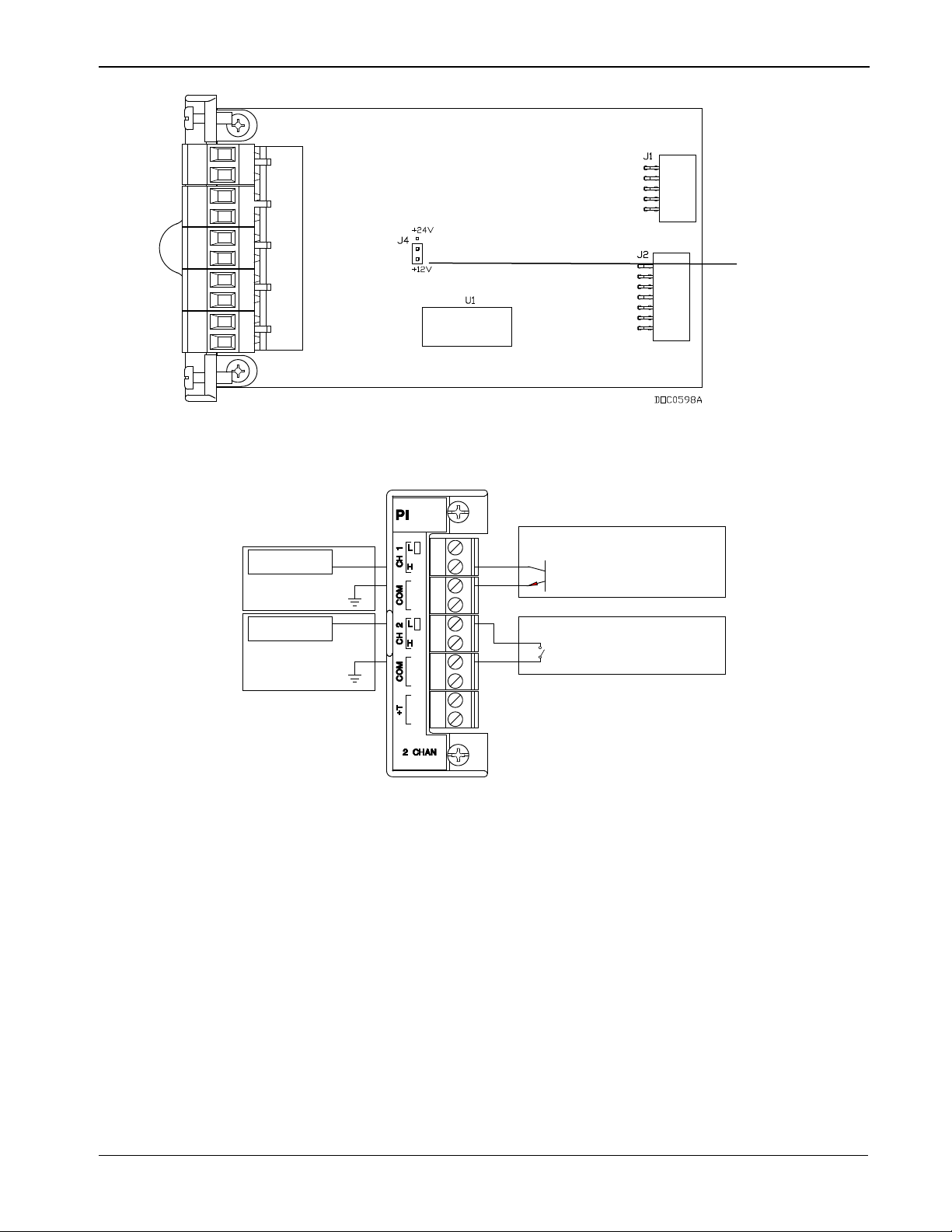

3.2.8 Pulse Input (PI) Modules ..................................................................................... 3-12

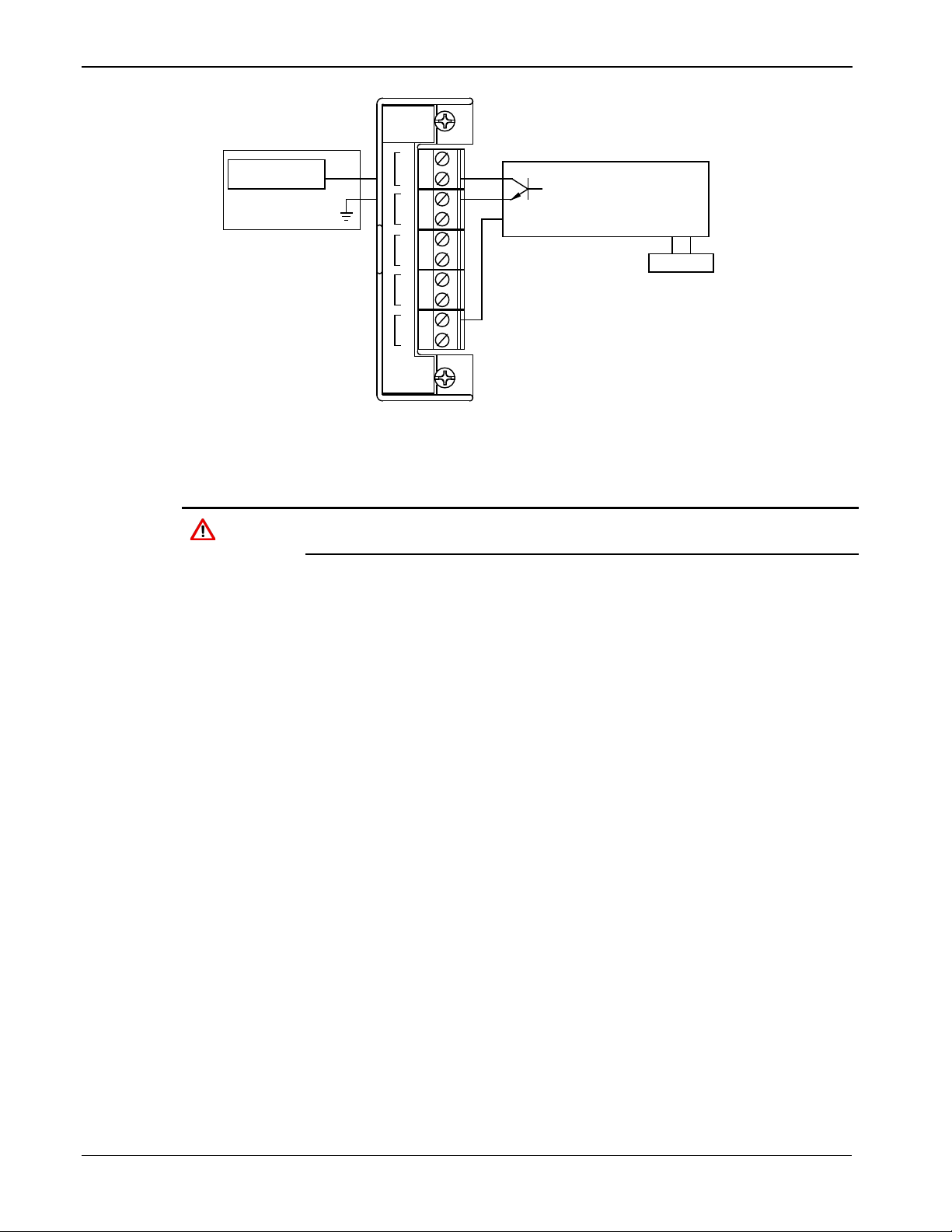

3.2.9 Discrete Output (DO) Modules ............................................................................ 3-14

3.2.10 Discrete Output Relay (DOR) Modules ............................................................. 3-15

3.2.11 Resistance Temperature Detector (RTD) Input Modules .................................. 3-17

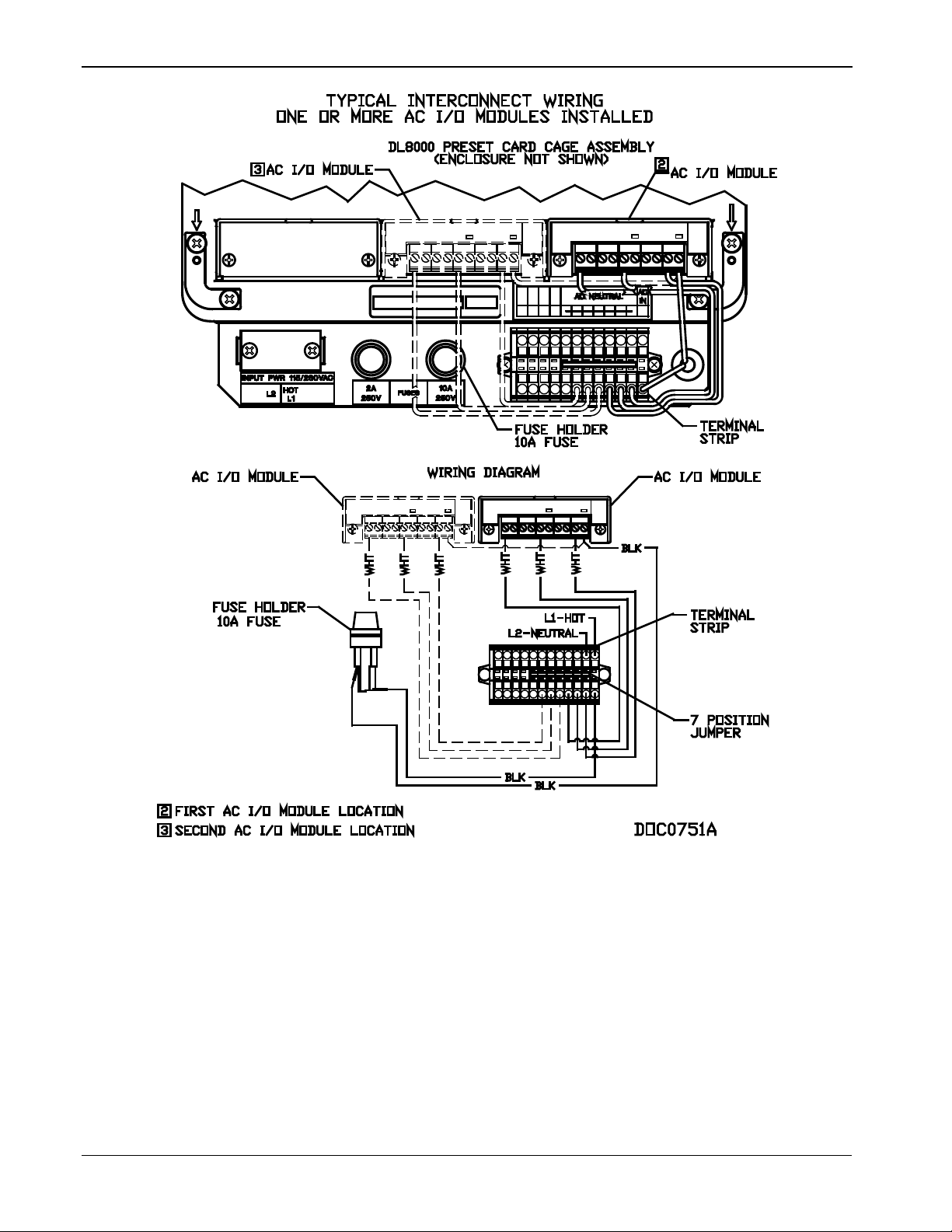

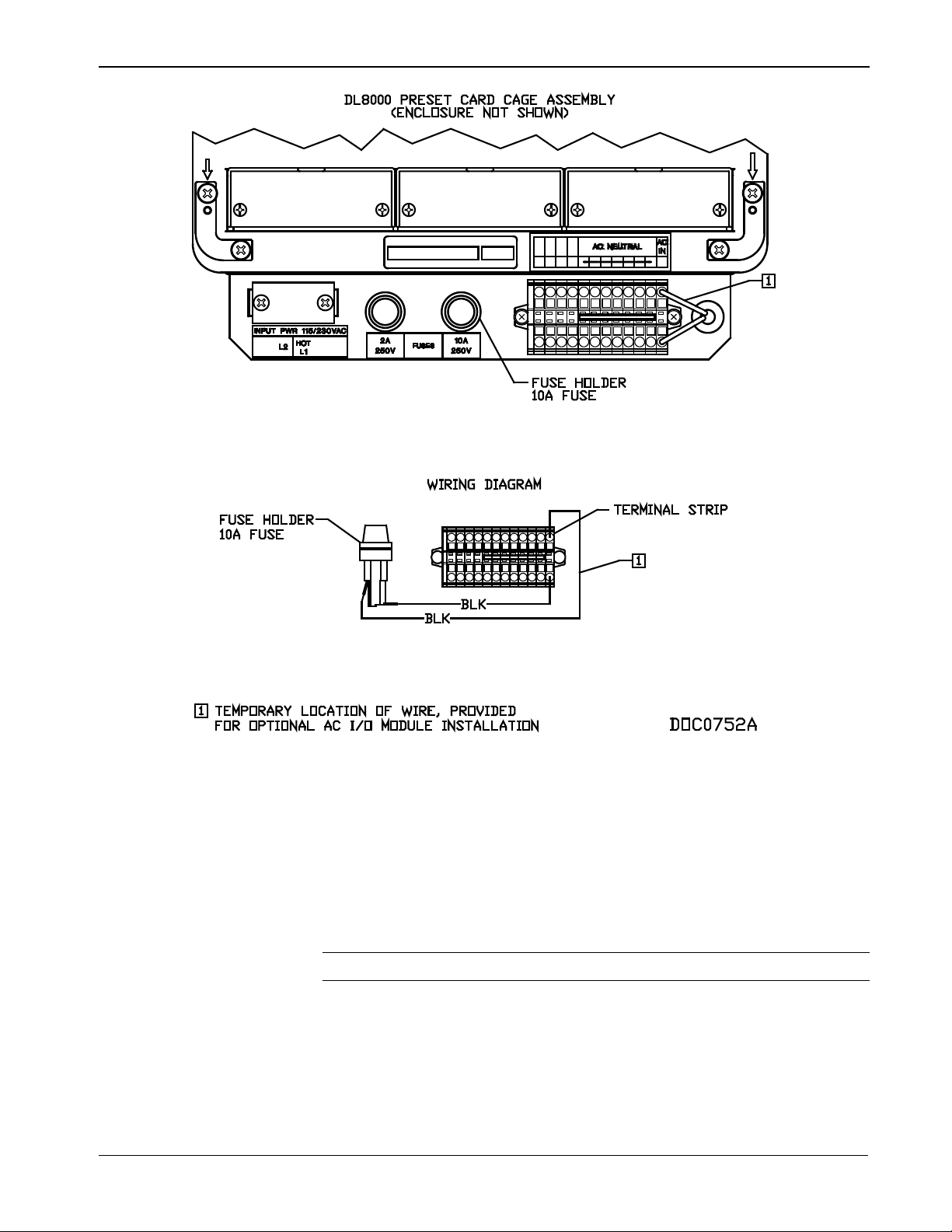

3.2.12 Alternating Current Input/Output (AC I/O) Module ............................................ 3-18

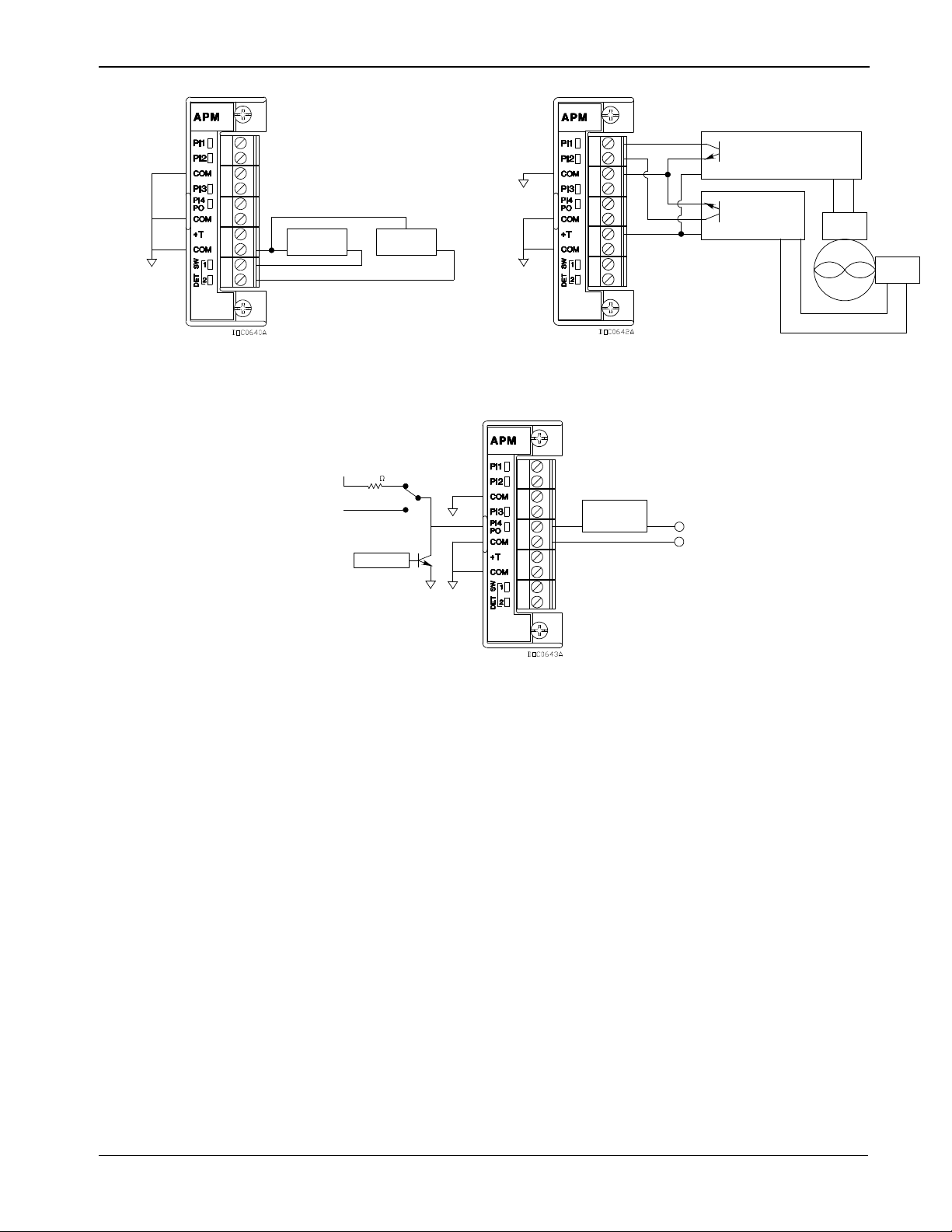

3.2.13 Advance Pulse Module (APM) ........................................................................... 3-23

3.2.14 Thermocouple (TC) Input Module...................................................................... 3-27

3.2.15 Highway Addressable Remote Transducer (HART

3.3 Communication Modules a nd Ports................................................................................ 3-32

3.3.1 Wiring Communications ...................................................................................... 3-34

3.3.2 Local Operator Interface (LOI – Local Port) ........................................................ 3-35

3.3.3 Using the LOI ...................................................................................................... 3-36

3.3.4 Ethernet Communications ................................................................................... 3-36

3.3.5 EIA-232 (RS-232) Serial Communications.......................................................... 3-38

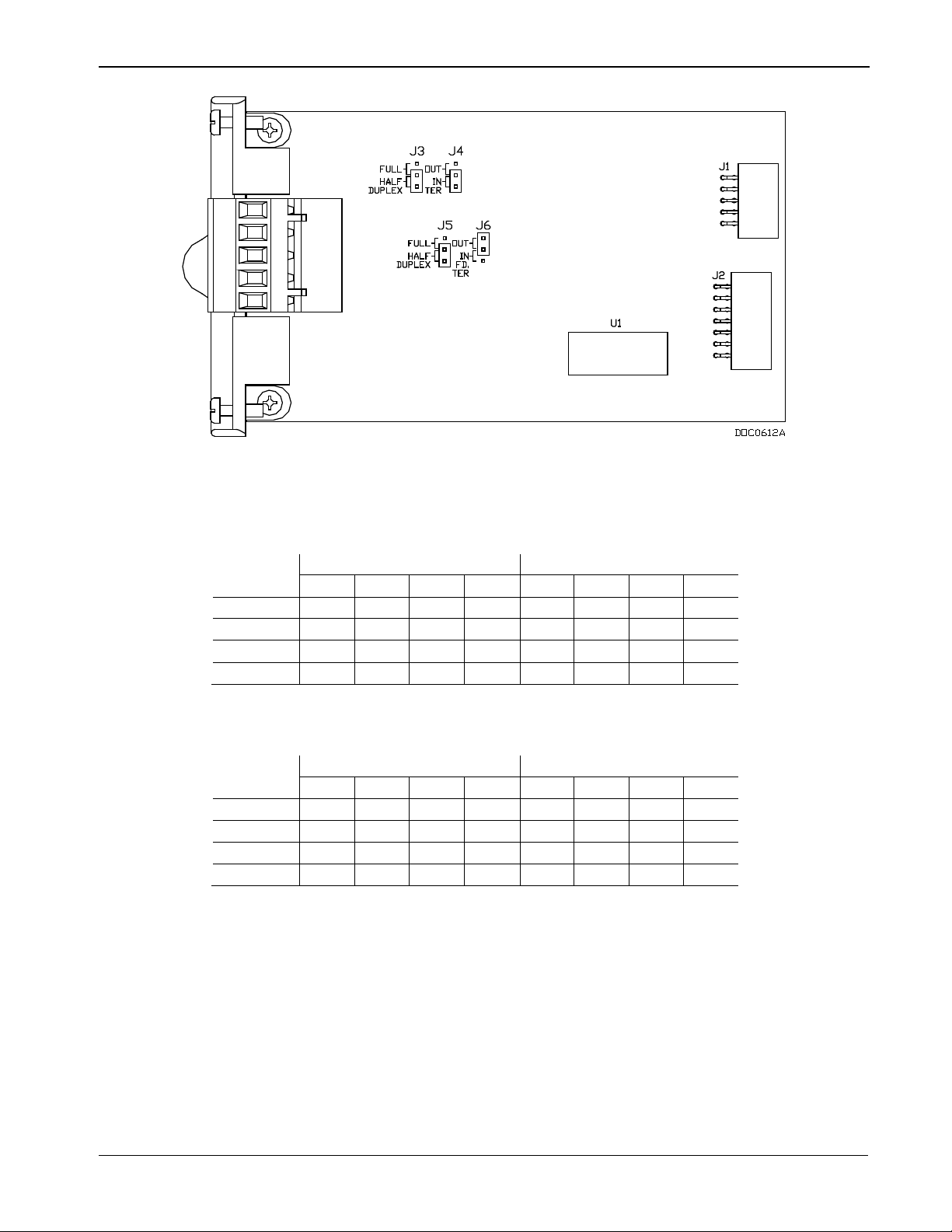

3.3.6 EIA-422/485 (RS-422/485) Serial Communications Module .............................. 3-39

3.3.7 EIA-422/485 (RS-422/485) Jumpers and Termination Resistors ....................... 3-40

3.3.8 Dial-up Modem Communications Module ........................................................... 3-41

3.4 Additional Technical Information .................................................................................... 3-43

Appendix A – Glossary A-1

Appendix B – Modbus Communications B-1

®

) Module ........................... 3-30

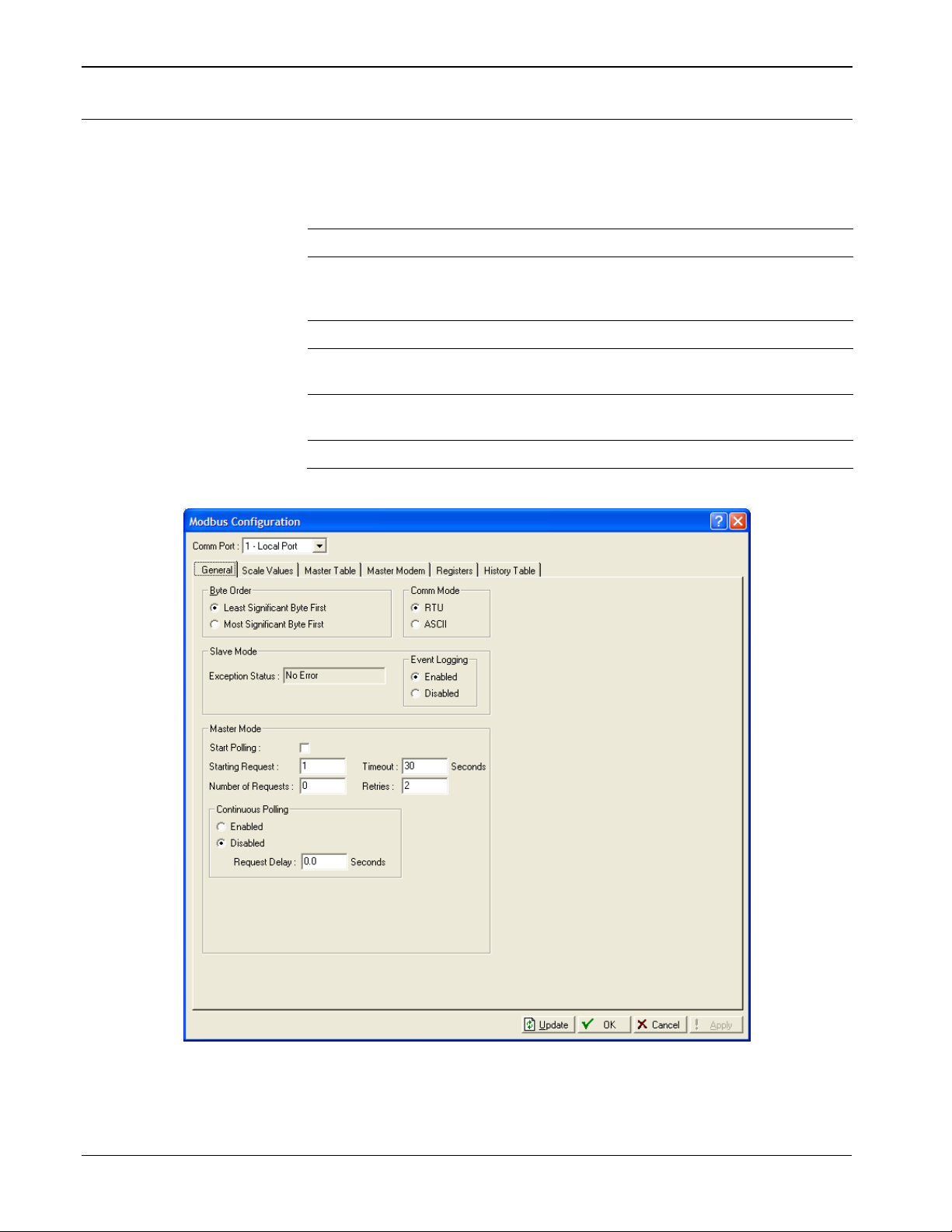

B.1 Modbus Communications ................................................................................................ B-1

B.2 Modbus Configuration ..................................................................................................... B-2

B.2.1 Modbus Configuration General Tab .................................................................... B-3

B.2.2 Modbus Configuration Scale Values Tab ............................................................ B-5

B.3 Modbus History ................................................................................................................ B-7

B.3.1 Modbus Configuration History Table Tab ............................................................ B-8

B.4 Modbus Events & Alarms Functionality ......................................................................... B-11

B.4.1 Reading Events & Alarms Register ................................................................... B-11

B.4.2 Acknowledging Events & Alarms ....................................................................... B-11

B.5 Modbus Registers .......................................................................................................... B-12

B.5.1 Modbus Configuration Registers Tab ................................................................ B-14

B.5.2 Modbus Conversion ........................................................................................... B-17

B.6 Modbus Master Table .................................................................................................... B-19

B.6.1 Modbus Configuration Master Table Tab .......................................................... B-20

B.7 Modbus Master Modem ................................................................................................. B-22

B.7.1 Modbus Configuration Master Modem Tab ....................................................... B-22

B.8 HMI Information ............................................................................................................. B-24

B.8.1 Sequentia l Ble nd ing ........................................................................................... B-24

B.8.2 Ratio Blending ................................................................................................... B-25

Appendix C – Wiring Diagrams C-1

C.1 Daniel Senior Sonic Meter to PI Module ......................................................................... C-1

C.2 Daniel 1818A and 1838 Turbine Pre-Amp to PI Module ................................................. C-2

C.3 Mi cro Motion RFT9739 & 2400S Transmitters to PI Module ........................................... C-3

C.4 Mi cro Motion RFT9739 & 2400S Transmitters to APM Module ...................................... C-4

C.5 3- and 4-Wire RTD to RTD Module ................................................................................. C-5

C.6 Daniel Senior Sonic Meter to APM Module ..................................................................... C-6

C.7 Daniel 1818A and 1838 Dual Turbine Pre-Amp to APM Module .................................... C-7

C.8 Daniel 1818A and 1838 Turbine Pre-Amp to APM Module ............................................. C-8

C.9 Two-Stage Valve with Two Limit Switches to APM Module ............................................ C-9

C.10 Micro Motion 1700 & 2700 T r ansmitter to PI Module ................................................... C-10

Appendix D – Communications Protocols D-1

D.1 Introduction ...................................................................................................................... D-1

iv Contents Revised March 2020

Page 5

DL8000 Preset Instruction Manual

D.1.1 Communication Channels ................................................................................... D-2

D.1.2 Communications Failure ...................................................................................... D-2

D.1.3 Supported Protocols ............................................................................................ D-3

D.1.4 Configuration ....................................................................................................... D-5

D.1.5 Commands .......................................................................................................... D-6

D.1.6 Status Flags ......................................................................................................... D-7

D.2 Batch Control in Auto Mode ............................................................................................. D-8

D.2.1 Steps for Authorizing a Transaction .................................................................... D-8

D.2.2 Steps for Authorizing a Batch ............................................................................ D-11

D.2.3 Stop/End of Batch .............................................................................................. D-12

D.2.4 End of Transaction............................................................................................. D-13

D.2.5 Batching Status States ...................................................................................... D-14

D.3 Communications Commands ........................................................................................ D-15

D.3.1 Modbus Commands........................................................................................... D-15

D.3.2 DanLoad 6000 Protoco l Com m ands ................................................................. D-30

D.4 Mapping Modbus Registers ........................................................................................... D-73

D.5 DanLoad 6000 Protocol Frame ..................................................................................... D-76

D.6 BCC Calculation ............................................................................................................ D-77

D.7 CRC-16 Checksum Table .............................................................................................. D-78

D.8 Status Flags Description [63,0,119] ............................................................................... D-80

D.9 Exception Codes ............................................................................................................ D-85

D.10 New/Unused DanLoad 6000 Exception Codes ............................................................ D-87

D.11 Alarm Logs .................................................................................................................... D-88

D.12 Error Codes ................................................................................................................... D-90

Appendix E – DL8000 Keypad Display E-1

E.1 Keypad Display Components .......................................................................................... E-1

E.1.1 Keypad ................................................................................................................. E-2

E.1.2 LED Status Indicators .......................................................................................... E-4

E.1.3 Liquid Crystal Display (LCD) ................................................................................ E-5

E.1.4 Power Failure ....................................................................................................... E-5

E.1.5 Operational Modes ............................................................................................... E-6

E.2 Loading Mode .................................................................................................................. E-6

E.2.1 Recipe Selection .................................................................................................. E-6

E.2.2 Invalid Recipe Selection ....................................................................................... E-7

E.2.3 Additive Selection ................................................................................................. E-7

E.2.4 Data Item Prompt ................................................................................................. E-7

E.2.5 Preset Quantity .................................................................................................... E-8

E.2.6 Invalid Preset ....................................................................................................... E-8

E.2.7 Loading ................................................................................................................ E-8

E.2.8 Transaction End Prompt .................................................................................... E-10

E.2.9 Conditional String Display for Temperature Correction String ........................... E-10

E.3 Program Mode ............................................................................................................... E-12

E.3.1 ROCLINK 800 Configuration .............................................................................. E-12

E.3.2 Log In ................................................................................................................. E-14

E.3.3 Initial Menu ......................................................................................................... E-14

E.3.4 Clear Alarms ...................................................................................................... E-15

E.3.5 Select Language ................................................................................................ E-15

E.3.6 Print Record ....................................................................................................... E-15

E.3.7 Display Setting ................................................................................................... E-16

E.3.8 Current Status .................................................................................................... E-16

E.3.9 Setup/ Configuration .......................................................................................... E-22

E.3.10 Generic TLP for Setup and Status ................................................................... E-45

E.3.11 Online Help ....................................................................................................... E-47

E.4 Calibration ...................................................................................................................... E-49

E.4.1 Calibrating Additive Meters ................................................................................ E-50

E.4.2 Calibrating Analog Input ..................................................................................... E-53

E.4.3 Calibrating RTDs ................................................................................................ E-55

Revised March 2020 Contents v

Page 6

DL8000 Preset Instruction Manual

E.4.4 Calibrating Product Meters ................................................................................ E-59

E.5 Diagnostics .................................................................................................................... E-75

E.5.1 Diagnosing Digital Outputs (DO) ....................................................................... E-75

E.5.2 Diagnosing Digital Inputs (DI) ............................................................................ E-76

E.5.3 Diagnosing Analog Outputs (AO) ...................................................................... E-81

E.5.4 Diagnosing Analog Inputs (AI) ........................................................................... E-85

E.5.5 Diagnosing AC Input/Outputs (AC I/O) .............................................................. E-89

E.5.6 Diagnosing RS-232 Communication Ports ........................................................ E-93

E.5.7 Diagnosing RS-485 Communication Ports ........................................................ E-97

E.5.8 Error Messages ................................................................................................ E-100

E.5.9 Translated Alarm and Status Messages .......................................................... E-101

Index I-1

vi Contents Revised March 2020

Page 7

Chapter 1 – Overview

Chapter 1

Provides an overview of the functions and hard w ar e

Chapter 3

Provides information on the Power Input,

Provides information on using the DL8000 keypad

This manual, the DL8000 Preset Controller Instruction Manual (part

D301244X012), provides operational information for the DL8000, and

contains the following chapters:

DL8000 Preset Instruction Manual

1.1 DL8000 Overview

General Information

Chapter 2

Installation and Use

Modules

Appendix A Provides a comprehensive glossary of terms.

Appendix B Provides information on Modbus communications.

Appendix C

Appendix D

Appendix E

Index Provides a topical index to the manual.

for the DL8000.

Provides installation and usage information on the

components of the DL8000, including the housing,

card cage, and CPU. This chapter also addresses

installation issues.

Input/Output (I/O), and communication modules

available for the DL8000.

Provides sample wiring diagrams for several

Emerson devices.

Provides information of alternative communications

protocols.

display.

The DL8000 can be operated in an independent, stand-alone mode with

the operator controlling and monitoring batch delivery operations from

the control panel located on the front of the unit.

Note: Although the DL8000 can also function as a slave unit in a

The DL8000 accepts process input signals from and provides process

control signals to the common instruments and devices used in liquid

batch delivery systems. These instruments and devices include:

Liquid flow meters (volumetric or mass inputs from a turbine,

Coriolis, ultrasonic, or other flow measurement devices using single

or linearized meter factors).

Solenoid-controlled digital flow control valves (both digital and 2-

stage).

Additive injectors.

Security devices for verifying electrical ground connections and

compartment overfills.

Revised April 2020 Overview 1-1

terminal automation system (TAS) network, this manual only

discusses local operation of the DL8000 in the stand-alone

mode.

Page 8

DL8000 Preset Instruction Manual

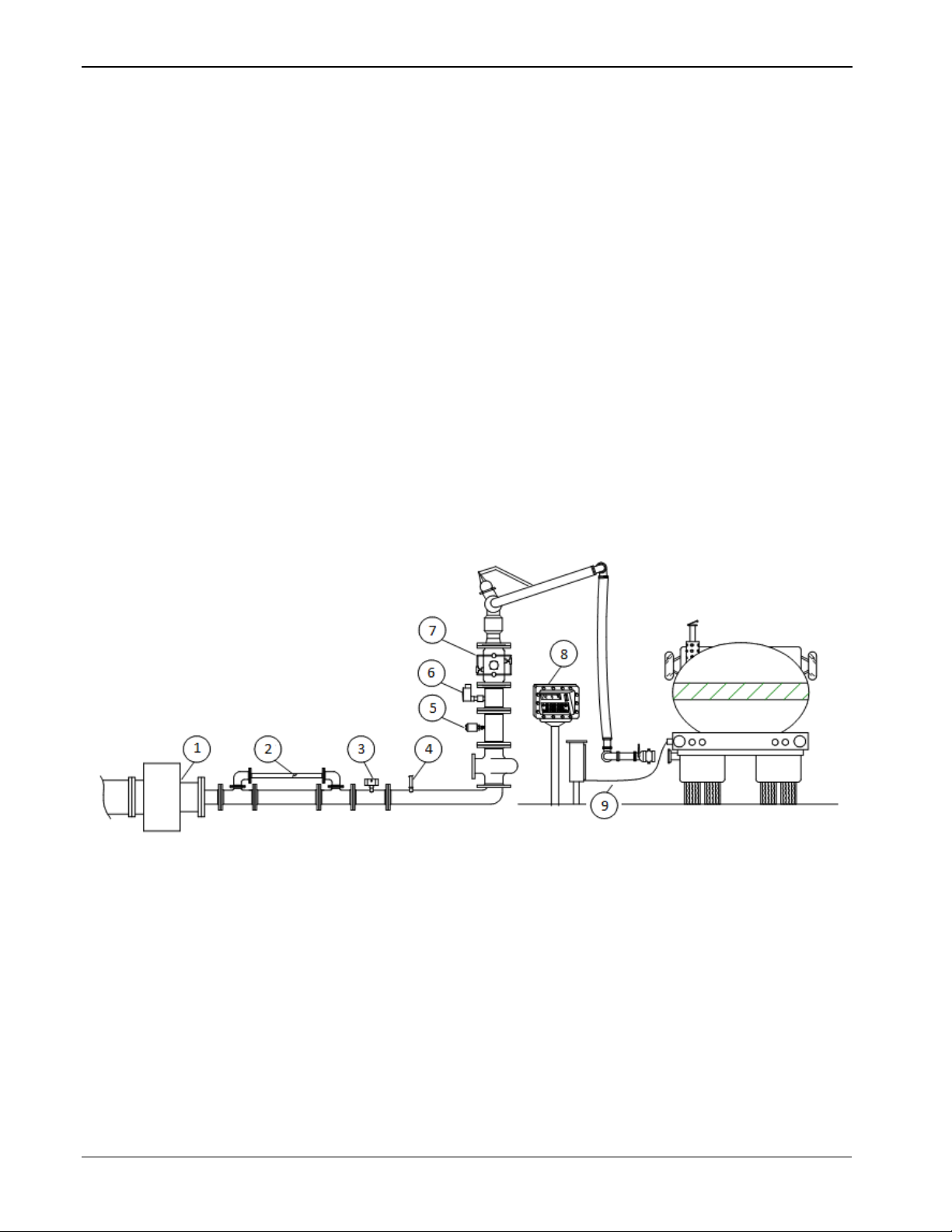

1: Pump Control Output

6. Temperature Probe

2

7

3

8

4

9

5. Meter Pulse Output

Electric motor driven pumps.

Motor operated block valves.

You can easily configure the DL8000 to deliver single component

liquids or to blend up to four liquid components in precise ratios, with

or without additive injection. Operator-selectable predefined delivery

control procedures (“recipes”) control the DL8000’s various possible

delivery and blending functions. Additive injection is controlled by

manual selection, recipe selection, or automatic selection from a

terminal automation system. These features allow one DL8000 and the

associated liquid delivery equipment to deliver many different

combinations of liquid products, based on requirements of the client or

receiver of the delivered product.

One common DL8000 application is to function as an on-site controller

for delivering refined liquid hydrocarbon products from loading

terminal storage tanks to mobile tanks (such as tanker trucks, rail cars,

or barges). Other applications include liquid component blending and /

or additive injection in refinery or chemical plant processes. In addition,

liquid components (with or without additive injection) can be blended

into flowing pipelines or into storage tanks. Figure 1-1 shows a typical

load rack installation with a DL8000 and associated equipment.

1-2 Overview Revised April 2020

. Density Transmitter

. Pressure Transmitter

. Additive Injection Output(s)

. Valve Control

. DL8000

. Permissive Contacts

Figure 1-1. Typical DL8000 Load Rack

Page 9

DL8000 Preset Instruction Manual

this product.

Factory Default

The DL8000 is factory-configured with a basic set of communication

Logical Functions

The flow measurement and logical functions listed below are available

Warning

Configuration

Overfill protection is critica lly important to your site. If your site DOES

NOT have overfill protection hardware installed, DO NOT set the

Overrun Limit Quantity value (defined on the Alarm Setup tab of the

Preset Setup screen in the Batching program) to zero. Setting that field

to zero DISABLES overfill protection. Remote Automation Solutions is

not responsible for damage resulting from disabling this critical safety

feature.

Additionally, you MUST have a redundant safe ty system (such as

Ground fault, Overfill) in place and operational. Otherwise, DO NOT use

and I/O modules to accommodate process I/O signals.

The default I/O module load—as well as any optional modules—is

determined during initial purchase. However, the I/O modules and

communications modules mix is field-reconfigurable, within the limits

of the DL8000’s central processing unit (CPU). The hardware

configuration determines the DL8000’s capacities for I/O signal

handling and the data logging/data communications.

in all hardware configurations of the DL8000. However, each unique

installation requires a specific complement of I/O modules, based on

the actual devices the DL8000 monitors and controls.

1.2 Hardware

1.2.1 Housing

The DL8000 can simultaneously monitor and control operation of up to

three flow meters, up to three flow control valves, and deliver up to four

products. The minimum configuration consists of one flow meter

measuring one component (liquid product), one control valve, one pump

start, and one permissive input. Product deliveries and component

blending deliveries are selected by up to 30 configurable recipes (batch

delivery/blending control procedures). The actual implementation of the

various possible process operations are covered in detail in other

sections of this manual.

The DL8000 has two primary physical components: the external

housing and the internal electronics. Refer to Chapter 2, Installation

and Use, for details on installation.

The DL8000 uses either of two external housings:

A cast aluminum casing with stainless steel front cover bolts. It is

flame-proof (in accordance with Class I, Zone 1, Group IIB) and

weatherproof (in accordance with IP66).

A 14-gauge stainless steel box with 12-gauge stainless steel

mounting flanges, CSA-rated as a Type 4 enclosure. The door is

Revised April 2020 Overview 1-3

Page 10

DL8000 Preset Instruction Manual

B

D

B

D

Note: For specific details, refer to the technical specification DL8000

made of 0.090 inch thick aluminum secured to the box with a

stainless steel piano hinge and two stainless steel spring latches.

Preset (part D301255X012), available at

www.EmersonProcess.com/Remote.

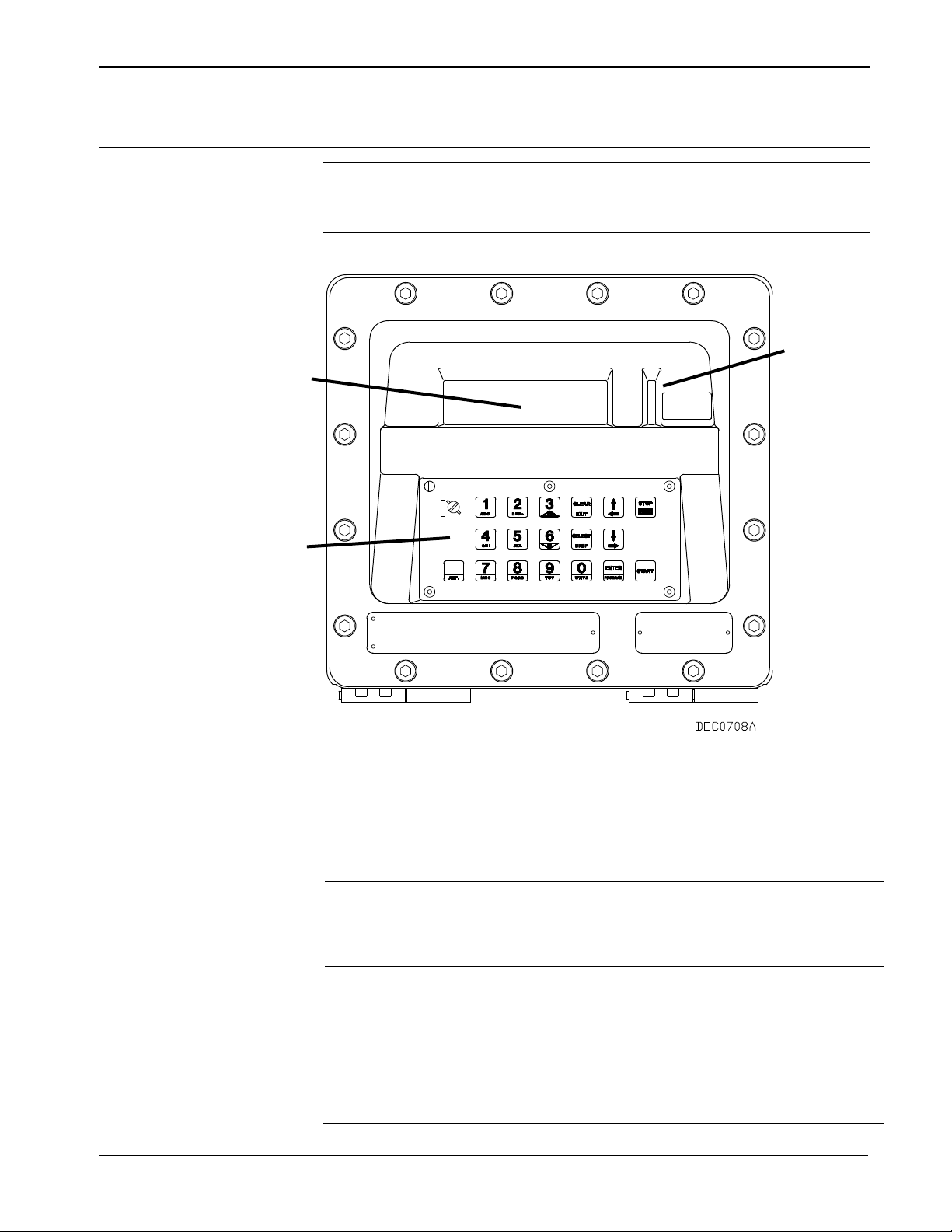

A Front cover bolts

Display

C Status LEDs

Weights & Measures switch

E Operator keypad

Figure 1-2. DL8000 (in Class I, Zone 1 Enclosure)

Sixteen stainless steel front cover bolts (M10 – 1.5 metric) secure the lid

to the housing. Two of the front bolts are longer and drilled close to the

threaded ends, allowing placement of Weight & Measures seal wires to

prevent undetected access to the electronics.

Bolt holes are tapped to 13 mm (0.50 inches); require an 8 mm (5/16inch) Allen wrench, and torque to 24 to 29 Newton/meters (18 to 21

foot/pounds) of force.

The operator keypad provides 18 rugged, Hall-Effect pushkeys which

are impervious to chemicals commonly associated with petroleum

applications. A sealable Weights & Measures switch provides security

to flow measurement parameters.

Secured behind non-glare glass, the liquid crystal display (LCD)

provides an 8-line by 40-column message area for operator interface.

The display uses a photo sensor and temperature sensor which can be

1-4 Overview Revised April 2020

Page 11

set to automatically adjust contrast and backlighting for optimal

viewing.

Light-emitting diodes (LEDs) displaying the status of alarms, operating

mode, and permissive powers are located to the right of the display.

With the front cover bolts removed, the lid hinges down to reveal the

electronic compartmen t.

1.2.2 Electronics

The DL8000’s CPU sits inside the cast aluminum enclosure. The

DL8000 uses a highly innovative and versatile CPU with a backplane to

which the CPU, Power Input module, input/output (I/O) modules, and

communication modules connect. The DL8000 unit has nine module

slots, three of which (slots 1, 2, and 3) can house communication

modules.

The DL8000 uses a 12 volt dc Power Input module to convert 120 to

250 V ac external input power to the voltage levels required by the

unit’s electronics and to monitor voltage levels to ensure proper

operation. For more information on the Power Input module, refer to

Chapter 3, Modules.

DL8000 Preset Instruction Manual

The DL8000 supports a number of I/O modules, which can satisfy a

wide variety of field I/O requirements (refer to Chapter 3, Modules). I/ O

modules include:

Analog Inputs (AI).

Analog Outputs (AO).

Discrete Inputs (DI).

Discrete Outputs (DO).

Digital Output Relay (DOR).

Alternating Current Input/Output (ACIO).

Advance Pulse Module (APM).

Pulse Inputs (PI) – High/Low Speed.

Resistance Temperature Detector Inputs (RTD).

Thermocouple (TC)

HART®

In addition to the built-in serial interface (the Local Operator Interface,

or LOI) and an Ethernet connection, the DL8000 also supports the

following communications modules:

EIA-232 Serial Communications.

EIA-422/485 Serial Communications.

Dial-up Modem.

Revised April 2020 Overview 1-5

Page 12

DL8000 Preset Instruction Manual

1.3 Security Gateway

For enhanced data security when using an IP/Ethernet connection,

Remote Automation Solutions recommends adding an industrial router

with VPN and firewall security. Recommended solutions include the

MOXA EDR-810, the Hirschman Eagle One, or the Phoenix mGuard

rs4000 (or equivalents). An example of how to install one of these

devices to the RTU/flow computer can be found in the Remote

Automation Solutions MOXA® Industrial Secure Router Installation

Guide (part number D301766X012). For further information, contact

your Local Business Partner or the individual vendor’s website.

1.4 Additional Technical Specifications

For further technical information on the DL8000, refer to the technical

specification DL8000 Preset (part D301255X012), available at

www.EmersonProcess.com/Remote.

1-6 Overview Revised April 2020

Page 13

Chapter 2 – 0BInstallation and Use

In This Chapter

2.1 Housing.………………………………………………………………………. 2-1

2.1.1 Class I Zone 1 Housing .............................................................. 2-2

2.1.2 Securing the Cover to the Class I Zone I Case .......................... 2-4

2.1.3 Class I Div 2 Housing ................................................................. 2-5

2.2 Card Cage.…………………………………………………………………… 2-6

2.2.1 Backplane ................................................................................... 2-7

2.3 Central Processor Unit (CPU)………………………………………………. 2-8

2.3.1 BInstalling and Removing Wire Channel Covers...................... 2-10

2.3.2 Removing and Installing Module Covers .................................. 2-11

2.3.3 Rem oving the CPU Mo dul e ...................................................... 2-11

2.3.4 Installing the CPU Module ........................................................ 2-12

2.4 License Keys ……………………………………………………………….. 2-12

2.4.1 Installing a License Key ............................................................ 2-13

2.4.2 Rem oving a Licens e Key .......................................................... 2-14

2.5 Installation Planning ……………………………………………………….. 2-15

2.6 Mechanical Installation ……………………………………………………. 2-15

2.6.1 Planning Considerations ........................................................... 2-16

2.7 Electrical Installation ………………………………………………………. 2-18

2.7.1 General Considerations ............................................................ 2-18

2.7.2 Field Wiring Installation Guidelines: ......................................... 2-18

2.7.3 Electrical Wire and Cable Selection and Installation ................ 2-19

2.7.4 Input/Output Field Signal Wiring ............................................... 2-20

2.7.5 Electrical Grounds .................................................................... 2-20

2.7.6 Wire Conduit Selection and Installation .................................... 2-22

2.8 Operator Interface …………………………………………………………. 2-23

2.8.1 Keypad ...................................................................................... 2-24

2.8.2 LED Status Indicators ............................................................... 2-25

DL8000 Preset Instruction Manual

This chapter describes the DL8000’s external housing, its internal

electronic components (the ROC800-Series CPU), and the specifics of

mechanical and electrical installation.

2.1 1BHousing

The DL8000 uses either of two external housings:

A cast aluminum casing with stainless steel front cover bolts. It is

flame-proof (in accordance with Class I, Zone 1, Group IIB) and

weatherproof (in accordance with IP66).

A 14-gauge stainless steel box with 12-gauge stainless steel

mounting flanges, CSA-rated as a Type 4 enclosure. The door is

made of 0.090 inch thick aluminum secured to the box with a

stainless steel piano hinge and two stainless steel spring latches.

Revised April 2020 Installation and Use 2-1

Page 14

DL8000 Preset Instruction Manual

2.1.1 9BClass I Zone 1 Housing

The DL8000 Class I Zone 1 housing is cast aluminum that, when

appropriately sealed, provides a flame-proof enclosure. Sixteen threaded

stainless steel fasteners secure the lower portion of the housing to the

hinged lid, which contains the display panel, operator keypad, and LED

status display. See Figures 2-1 and 2-2.

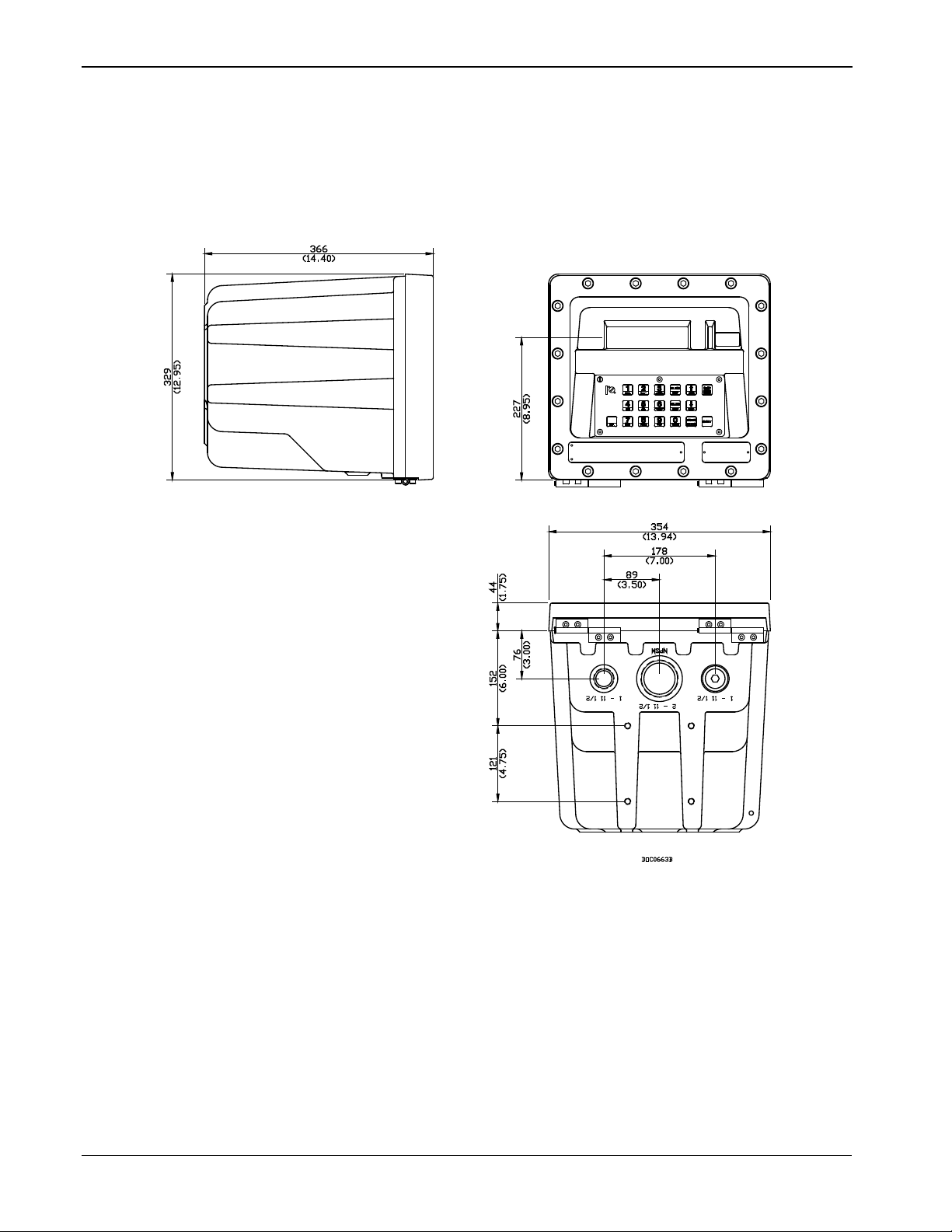

Figure 2-1. Standard DL8000 Enclosure

2-2 Installation and Use Revised April 2020

Page 15

DL8000 Preset Instruction Manual

Figure 2-2. Standard DL8000 Enclosure

Note: The four mounting holes on the bottom and back of the DL8000

case accept 10M (10mm) bolts.

The DL8000’s design makes it highly adaptable to a wide variety of

installations. Consequently, this manual cannot cover all possible

installation scenarios. Contact your local sales representative if you

require information concerning a specific installation not described in

this manual.

Revised April 2020 Installation and Use 2-3

Page 16

DL8000 Preset Instruction Manual

clean and free of damage.

Planning is essential to a good installation. Because installation

requirements depend on many factors (such as the application, location,

ground conditions, climate, and accessibility), this document only

provides generalized guidelines.

2.1.2 10BSecuring the Cover to the Class I Zone I Case

The DL8000 ships from the factory with the cover secured to the case

with one stainless steel fastener (“bolt”). The remaining bolts are

bagged and included with the DL8000. You must install all bolts.

Warning

Caution

Failure to install ALL cover bolts will compromise the flame-proof

characteristics of the enclosure.

The flanges between the case and the cover create a flameproof joint.

Before you secure the cover to the case, make sure the surfaces are

To secure the DL8000 cover:

Caution

Notes:

You must use a torque wrench for this procedure.

The bolt in position 9 (see Figure 2-3) is factory-installed. Be sure

that the bolts you install in positions 12 and 8 are the two longer

bolts with pre-drilled holes (for the Weights & Measures seal wires).

1. Swing the DL8000 cover up against the case.

2. Insert a bolt in position 1 (refer to Figure 2-3) and finger-tighten the

bolt until you feel resistance.

3. Insert a bolt in position 2 (refer to Figure 2-3) and finger-tighten the

bolt until you feel resistance.

4. Repeat step 3 for bolts in positions 3 through 16.

5. Using a torque wrench, tighten the bolt in position 1 to

specifications (24 to 29 Newton/meters or 18 to 21 foot/pounds of

force).

6. Tighten bolts in positions 2 through 16 to specifications.

Tighten the bolts in the numeric order shown in Figure 3-3 to prevent

deforming the cover and risking the integr ity of the seal between cover

and case. You must install all the bolts.

2-4 Installation and Use Revised April 2020

Page 17

Figure 2-3. Bolt Tightening Sequence

8

2

11

15

1

5

9

13 7 12

16 3 6

10

14

2.1.3 11BClass I Div 2 Housing

DL8000 Preset Instruction Manual

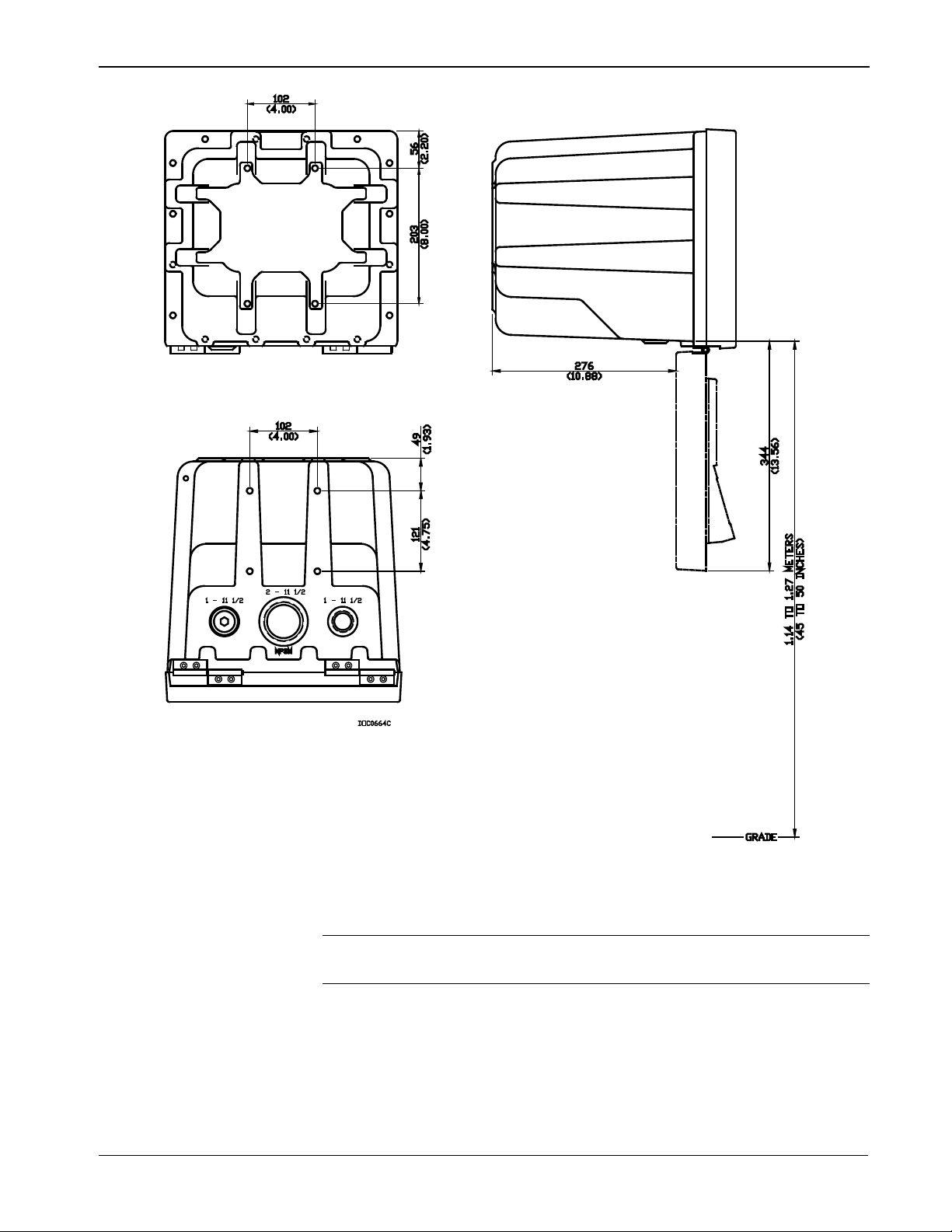

The Class I, Division 2 housing includes a 14-gauge stainless steel box

with 12-gauge stainless steel mounting flanges. The door is made of

.090 inch thick aluminum and is secured to the box via a stainless steel

piano hinge and two stainless steel spring latches. The latches include

features for padlocking or installing wire seals. The assembly includes a

door stop that locks the door in position at approximately 120 degrees

from the closed position. The viewing window in the enclosure door is

made from scratch / UV resistant polycarbonate/acrylic blend

(PC/PMMA). The keypad bezel is mounted to the front of the door and

is made from UV resistant polycarbonate. The assembly is rated by

CSA as a Type 4 enclosure, and can be either pole-mounted or flushmounted.

Revised April 2020 Installation and Use 2-5

Page 18

DL8000 Preset Instruction Manual

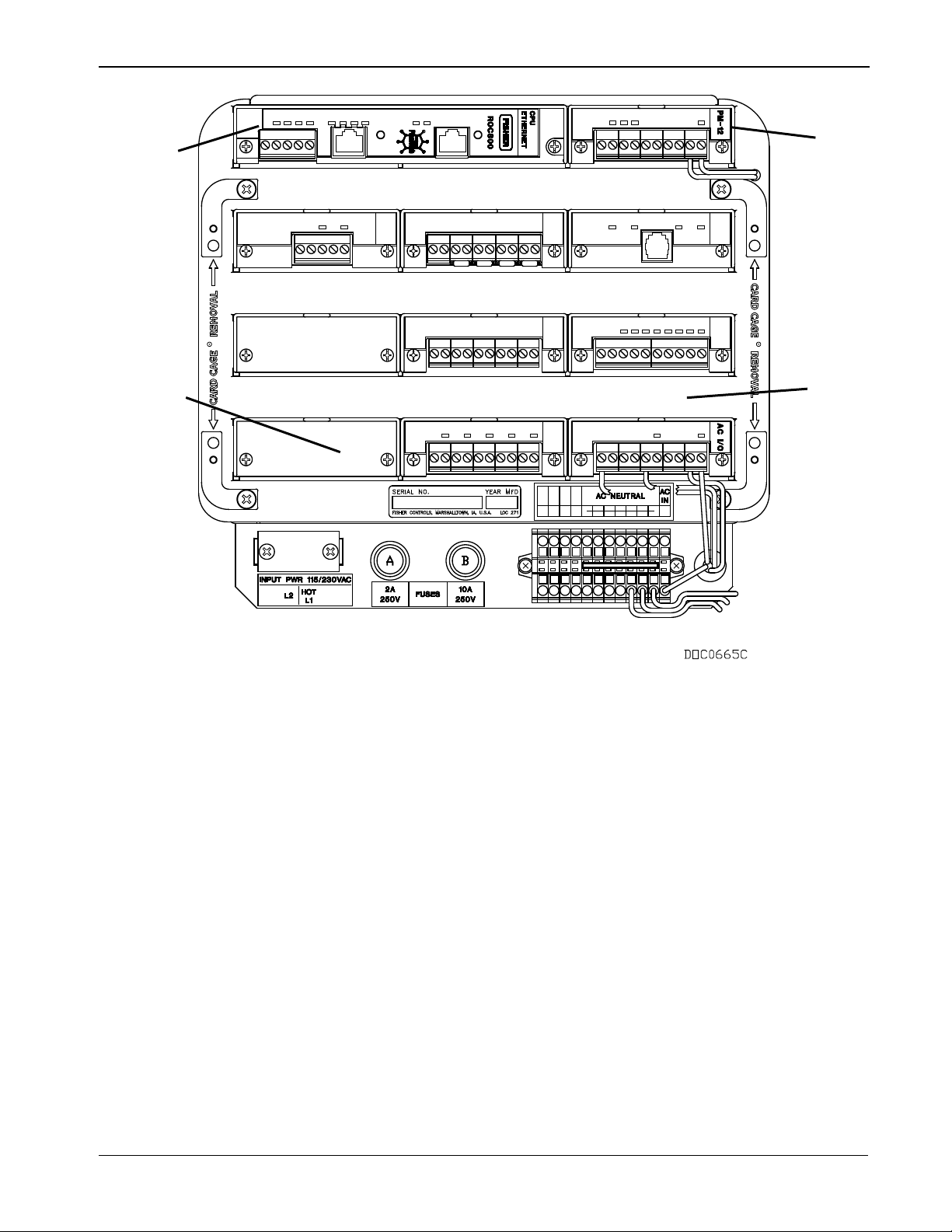

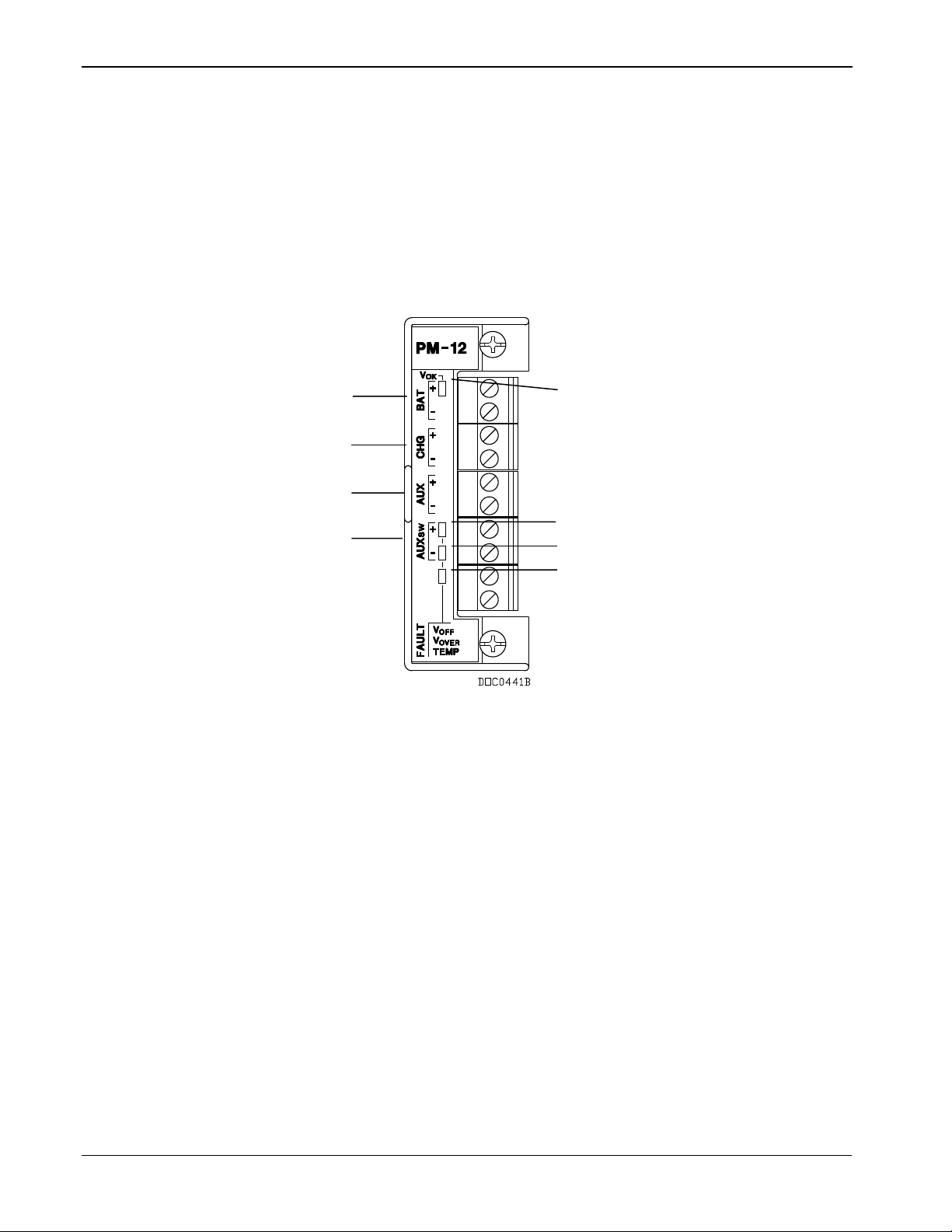

2.2 2BCard Cage

Figure 2-4. Class I Division 2 DL8000 Housing

The DL8000 uses electronic modules which fit into a card cage. The

card cage rests inside the cast housing. See Figure 2-5 for a view of the

card cage as it would appear when the housing is opened.

The card cage provides a backplane with sockets for installing a main

processor board, a DC power supply, up to nine process I/O boards, and

up to three communications cards. The card cage (see Figure 2-5)

supports a total of nine boards, in addition to the power supply and the

CPU.

Note: Board placement is critical for I/O assignments during startup.

Refer to Chapter 3, Modules, for further information.

2-6 Installation and Use Revised April 2020

Page 19

DL8000 Preset Instruction Manual

A

B

C

C

A

B

D

2.2.1 12BBackplane

The backplane has connectors for the CPU, the power input module, and

all the I/O and communication modules. When a module is completely

inserted into the module slot, the connector on the module fits into one

of the connectors on the backplane. The backplane does not require any

wiring, and there are no jumpers associated with the backplane.

Removing the backplane from the housing is not recommended, as there

are no field-serviceable parts. If the backplane requires maintenance,

please contact your local sales representative.

CPU

Power module

Module cover

D Wire channel covers (removed)

Figure 2-5. Card Cage (with modules)

Revised April 2020 Installation and Use 2-7

Page 20

DL8000 Preset Instruction Manual

A

Securing screw

B

C

E

Ethernet port

F

B C D

E

F

A

A

A A B

C

D E F

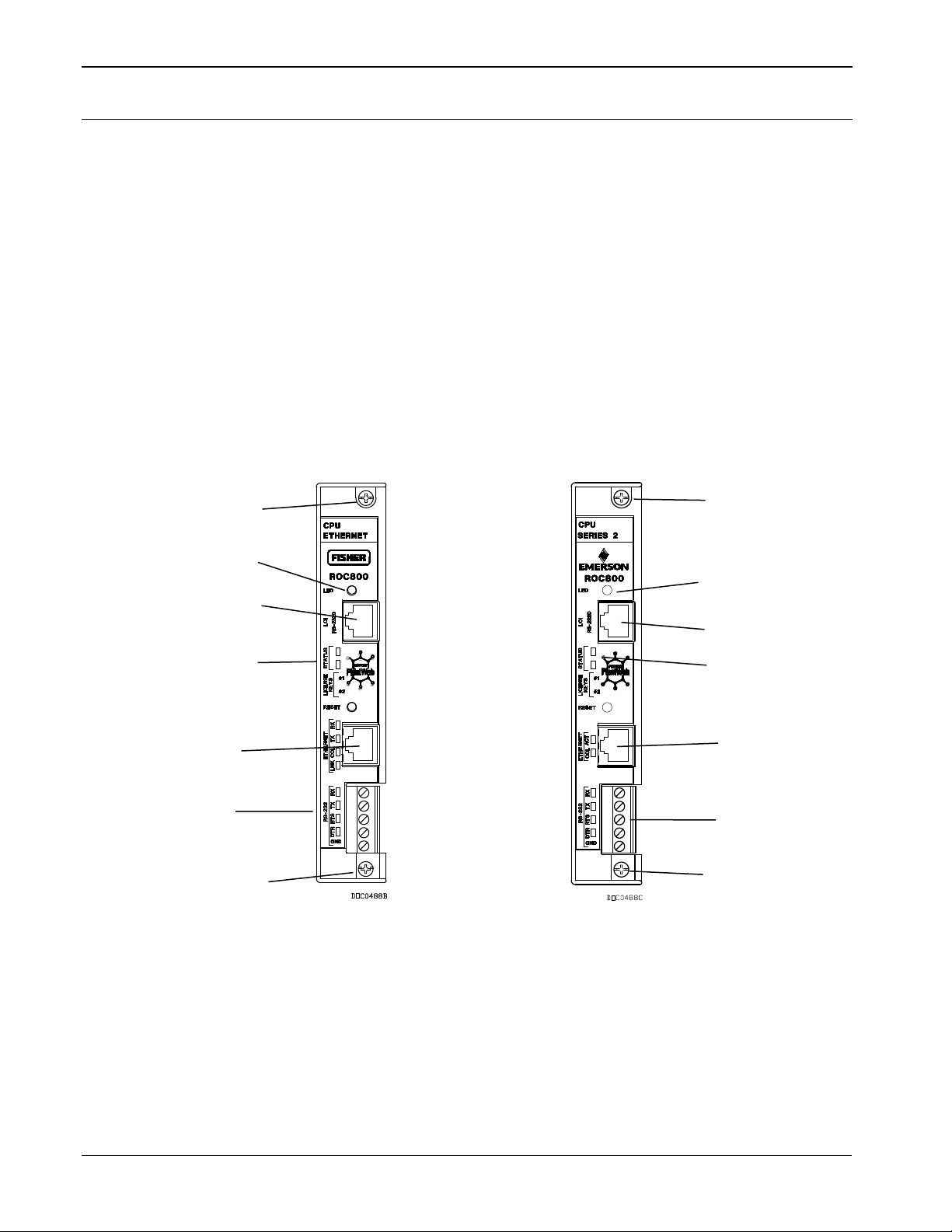

2.3 3BCentral Processor Unit (CPU)

The CPU contains the microprocessor, the firmware, connectors to the

backplane, three built-in communication ports (two with LEDs), a LED

low power wakeup button, a RESET button, the application license key

connectors, a STATUS LED indicating system integrity, and the main

processor. See Figure 2-6.

The 32-bit microprocessor is based on a Motorola® MPC862 Quad

Integrated Communications Controller (PowerQUICC™) PowerPC®

processor running at 65 MHz (in the Series 2 CPU module) or 50 MHz

(in the Series 1 CPU module).

The internal Sanyo 3 volt CR2430 lithium backup battery provides

backup of the data and the Real-Time Clock when the main power is not

connected.

Series 1 CPU Faceplate

(Gray)

Series 2 CPU Faceplate

(Black)

2-8 Installation and Use Revised April 2020

LED button

LOI – EIA-232 (RS-232D)

D Status LED

EIA0232 (RS0232C)

Figure 2-6. CPU Front View (Series 1 and Series 2 CPU Modules)

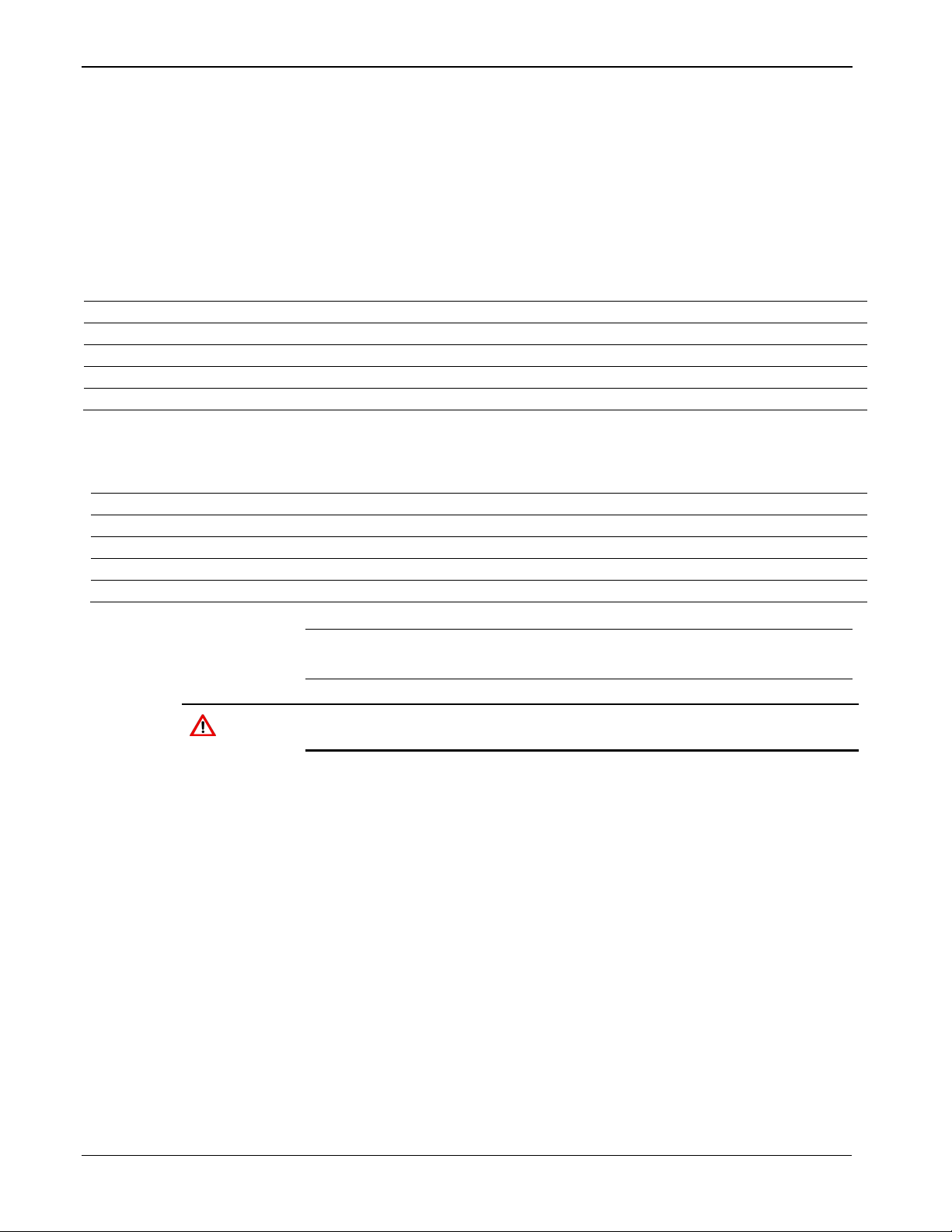

Page 21

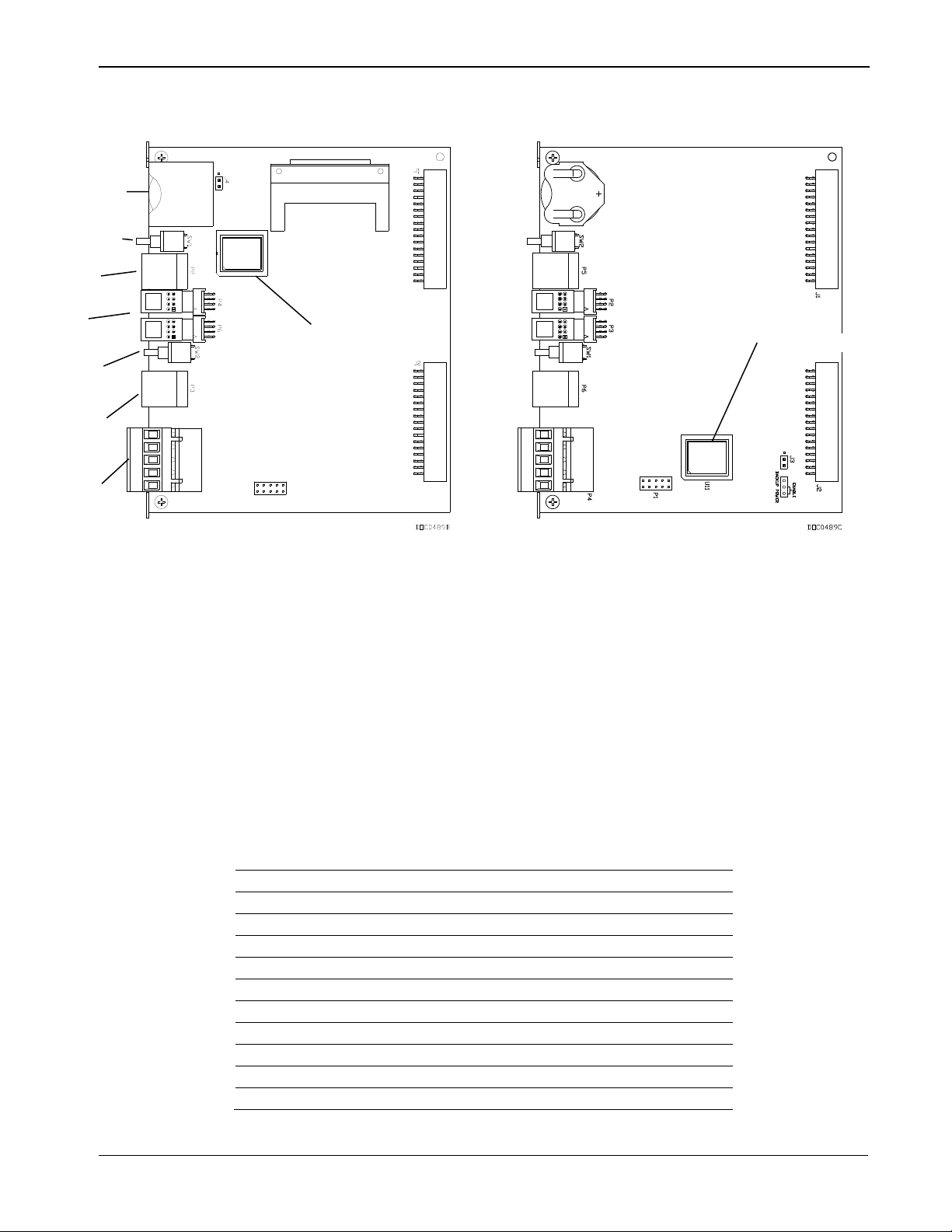

DL8000 Preset Instruction Manual

A

C

D

E

G

CPU Number

Series 1

Series 2

J1

Backplane connector

Backplane connector

J2

Backplane connector

Backplane connector

J3

Not Used

Battery Backup

J4

Battery Backup

Not Used

P2

LOI Port RJ-45

License Key Terminal

P3

Ethernet RJ-45

License Key Terminal

P4

License Key Terminal

RS-232

P5

Not Used

LOI Port RJ-45

P6

License Key Terminal

Ethernet RJ-45

SW1

LED Button

RESET Button

SW2

RESET Button

LED Button

A

B

D

E

C

H

H

F

G

Series 1 CPU (Green) Series 2 CPU (Black)

Battery

B LED Button

RJ-45 port

License keys

RESET button

F RJ-45 port

RS-232 port

H Microprocessor

Figure 2-7. CPU Connectors

Table 2-1. CPU Connector Locations

Revised April 2020 Installation and Use 2-9

Page 22

DL8000 Preset Instruction Manual

Status LED

Color

Definitions

Solution

Continually Lit

Green

DL8000 functioning normally.

N/A

Low Battery Voltage alert.

Charge battery.

System AI (Point number 1) LoLo Alarm.

Apply DC voltage source.

Flashing

Green

Firmware invalid.

Update firmware.

Green-Green

to Red-Red

Flashing

Green to Red

Firmware update is flashing image.

Do not restart the DL8000.

The CPU contains a microprocessor supervisory circuit. This device

monitors the battery voltage, resets the processor, and disables the

SRAM chip if the voltage goes out of tolerance. The CPU has an

internal Analog to Digital Converter (A/D). The A/D monitors the

supply voltage and board temperature. The CPU has two buttons (see

Figure 2-7):

LED – Press to turn on the LEDs on the CPU module, I/O modules,

RESET – Press to reset the DL8000 system to defaults.

The STATUS LED indicates the integrity of the DL8000. Refer to

Table 2-2.

Continually Lit Red

and communication modules when the DL8000 has timed out.

Table 2-2. STATUS LED Functions

Flashing

Firmware update in decompr ess ion. Do not restart the DL8000.

As a power-saving feature, you can enable or disable the LEDs on the

DL8000 (with the exception of the LED on the power module). You can

also use the ROCLINK™ 800 software to configure how long the LEDs

remains on after the LED button on the CPU module is pressed. For

instance, with the default setting of five minutes, all LEDs go off after

five minutes. If you press the LED button, LEDs become active again

for five minutes. If you enter a 0 (zero) setting, they always stay active.

2.3.1 13BInstalling and Re m ovi ng Wire Channel Covers

The DL8000 includes wire channel covers (see Figure 2-5) you install

over the wiring channels once you complete wiring the terminal blocks

on the modules.

To install a wire channel cover:

1. Align the wire channel cover over the wire channel, allowing

unobstructed wire access.

2-10 Installation and Use Revised April 2020

2. Press the wire channel cover into place until it snaps.

Note: The tabs on the top side of the wire channel cover should rest in

the slots on the top edge of the channel.

To remove a wire channel cover:

1. Grasp the wire channel cover at both the left and right ends.

Page 23

DL8000 Preset Instruction Manual

2. Start at the left or right and pull the wire channel cover out of the

wire channel.

2.3.2 14BRemoving and Installi ng Module Covers

Before you insert an I/O or communications module, remove the

module cover (see Figure 2-5) over the empty module slots in which

you intend to install the modules. Although you are not required to

remove the power to the DL8000 to perform this procedure, caution is

always advisable when working with a powered DL8000.

Caution

To avoid circuit damage when working inside the unit, use appropriate

electrostatic discharge precautions (such as wearing a grounded wrist

strap).

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing procedures. Performing these procedures in a

hazardous area could result in personal i n jury or property damage.

To remove a module cover:

1. Remove the wire channel cover.

2. Unscrew the two captive screws on the face of the cover.

3. Using the tab at the top side of the module cover, lift the module

cover from the DL8000.

Note: If you remove a module for an extended period, install a module

cover over the empty module slot to keep dust and other matter

from getting into the DL8000.

To install a module cover:

1. Place the module cover over the module slot.

2. Tighten the two captive screws on the face of the cover.

3. Replace the wire channel cover.

2.3.3 15BRemoving the CPU Module

To remove the CPU module:

Caution

Failure to exercise proper electrostatic discharge precautions (such as

wearing a grounded wrist strap) may reset the processor or damage

electronic components, resulting in interrupted operations.

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing procedures. Performing these procedures in a

hazardous area could result in personal i n jury or property damage.

1. Back up critical data.

Revised April 2020 Installation and Use 2-11

Page 24

DL8000 Preset Instruction Manual

hazardous area could result in personal i n jury or property damage.

Note: “Critical” data may include your device configuration file,

2. Remove power from the DL8000.

3. Remove the wire channel cover.

4. Unscrew the two captive screws on the front of the CPU module and

5. Place a small screwdriver under the ejector clip at the left or right of

6. Remove the CPU module carefully. Make sure not to pull on any

2.3.4 16BInstalling the CPU Module

To install the CPU module:

Caution

Failure to exercise proper electrostatic discharge precautions (such as

wearing a grounded wrist strap) may reset the processor or damage

electronic components, resulting in interrupted operations.

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing procedures. Performing these procedures in a

device alarms and events history, or displays.

remove the faceplate.

the CPU module and lightly pry the CPU module out of its socket.

You may find it easiest to carefully pry on the left ejector clip a

little, and then carefully pry the right ejector. You will feel and hear

the CPU as it detaches from the backplane.

cables attached to the CPU module.

2.4 4BLicense Keys

1. Slide the CPU module into the slot.

2. Press the CPU firmly into the slot, ensuring the ejector clips rest on

the module rail guides. The connectors at the back of the CPU

module fit securely into the connectors on the backplane.

3. Place the CPU faceplate on the CPU.

4. Tighten the two captive screws on the faceplate of the CPU module

firmly.

5. Replace the wire channel cover.

6. Return power to the DL8000.

License keys with valid license codes grant access to applications or, in

some cases, allow optional firmware functionality to execute. In some

situations, a license key may also be required before you can run the

application. Examples of licensed applications include DS800

Development Suite software, meter run calculations, and various User C

programs (such as LiquidCalcs in this application). You can then

2-12 Installation and Use Revised April 2020

Page 25

DL8000 Preset Instruction Manual

Failure to exercise proper electrostatic discharge precautions (such as

hazardous area could result in personal i n jury or property damage.

configure these applications using ROCLINK 800 or the DS800

Development Suite software.

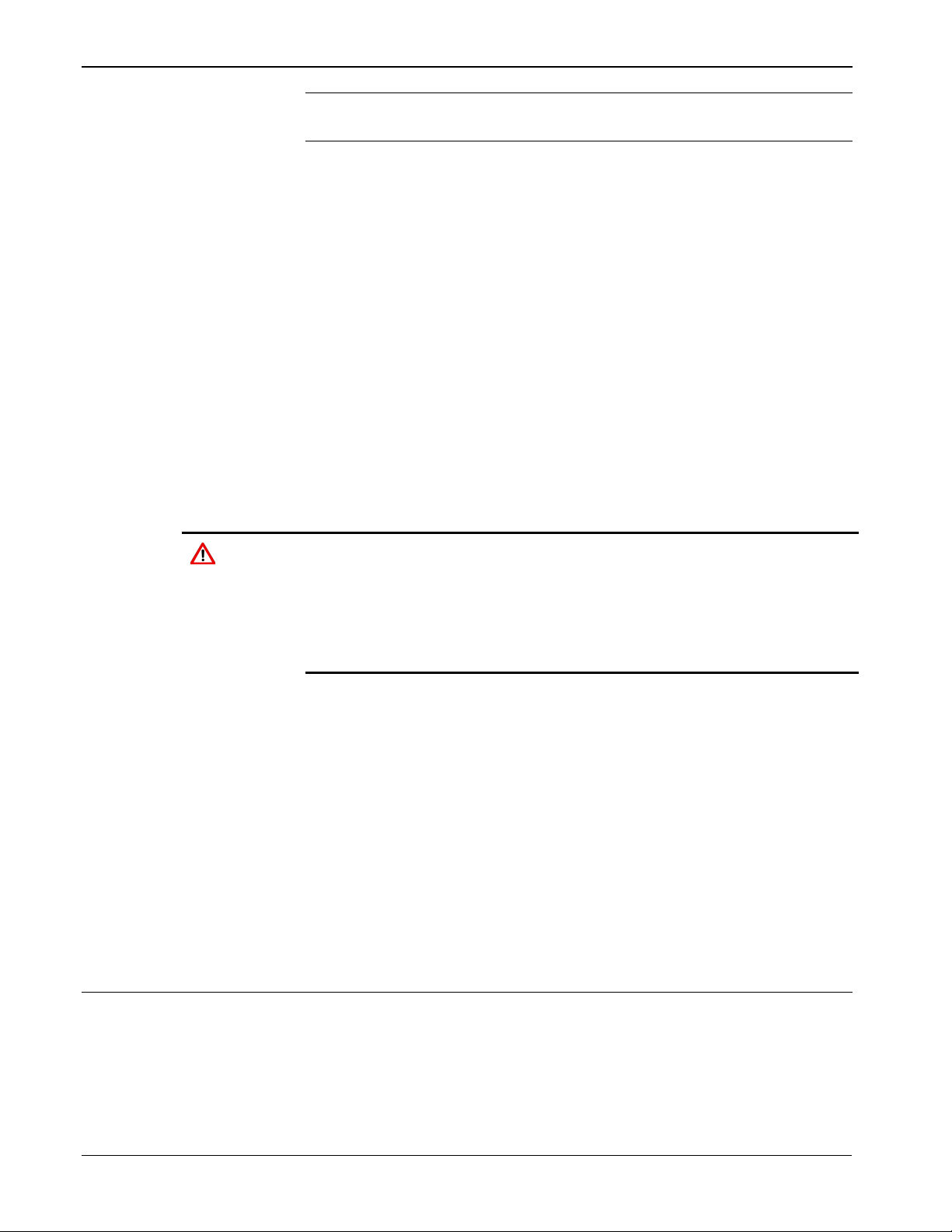

The term “license key” refers to the physical piece of hardware (see

Figure 2-8 and Figure 2-9) that can contain up to seven different

licenses. Each DL8000 can have none, one, or two installed license

keys. If you remove a license key after enabling an application, the

firmware disables the task from running. This prevents unauthorized

execution of protected applications in a DL8000.

Figure 2-8. License Key

2.4.1 17BInstalling a License Ke y

Note: For the DL8000, license keys are a factory-installed option.

Under normal operation, you should not need to install, remove,

or replace a license key.

To install a license key:

Caution

wearing a grounded wrist strap) may reset the processor or damage

electronic components, resulting in interrupted operations.

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing procedures. Performing these procedures in a

1. Back up critical data.

Note: “Critical” data may include your device configuration file,

device alarms and events history, or displays. Refer to Saving

and Retrieving Configurations in the ROCLINK 800

Configuration Software User Manual (for DL8000) (part

D301259X012) for further information.

2. Remove power from the DL8000.

3. Remove the wire channel cover.

Revised April 2020 Installation and Use 2-13

4. Unscrew the captive screws from the CPU faceplate and remove it.

Page 26

DL8000 Preset Instruction Manual

hazardous area could result in personal i n jury or property damage.

5. Place the license key in the appropriate terminal slot in the CPU (see

Figure 2-9. License Key Installation

6. Press the license key into the terminal until it is firmly seated (refer

7. Reattach the CPU faceplate and tighten the two captive screws.

8. Replace the wire channel cover.

Figure 2-7).

Note: If you are installing a single license key, place it in the

uppermost slot (closest to the LOI port).

to Figure 2-9).

9. Restore power to the DL8000.

2.4.2 18BRemoving a License Key

To remove a license key:

Caution

Failure to exercise proper electrostatic discharge precautions (such as

wearing a grounded wrist strap) may reset the processor or damage

electronic components, resulting in interrupted operations.

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing procedures. Performing these procedures in a

1. Back up critical data.

Note: “Critical” data may include your device configuration file,

device alarms and events history, or displays. Refer to Saving

and Retrieving Configurations in the ROCLINK 800

Configuration Software User Manual (for DL8000) (part

D301259X012) for further information.

2. Remove power from the DL8000.

3. Remove the wire channel cover.

4. Unscrew the two captive screws on the CPU faceplate and remove

it.

5. Remove the license key from the appropriate terminal slot in the

CPU (see Figure 2-9).

6. Reattach the CPU faceplate and tighten the two captive screws.

2-14 Installation and Use Revised April 2020

Page 27

7. Replace the wire channel cover.

8. Restore power to the DL8000.

2.5 5BInstallation Planning

Installation planning is very important due to the DL8000’s physical

and functional reconfigurable capabilities. Installation planning consists

of the following three major tasks.

Assure that the DL8000 contains the required number and type of

Determine the functions the DL8000 will perform. You selectively

Design the mechanical/electrical installation with special

DL8000 Preset Instruction Manual

process I/O boards to monitor and control the other devices in the

product delivery system.

enable these functions during the DL8000’s configuration

procedure.

consideration for both the operator’s safety and ease-of-use and the

maintenance technicians’ safety and ease-of-access to instruments

and devices.

2.6 6BMechanical Installation

In planning the physical installation of the DL8000, consider ease of use

of the instrument with the operator in a safe and comfortable position.

Also consider how maintenance tasks may be performed without

disrupting ongoing product delivery operations in close proximity.

Drawing rough diagrams of normal operator actions during the different

possible batch delivery related tasks may be helpful. Note especially the

operator’s location in relation to the location of one or two tanker

vehicles and their related loading arm and bottom loading hose

connections.

Some location or position restrictions may be present when a DL8000 is

retrofitted or upgraded into an existing installation. However,

mechanical installation planning should still be performed. It may be

possible to correct an existing inconvenient controller mounting location

in a current loading rack installation when retrofitting a DL8000 at the

installation.

Following are the major steps performed during installation.

1. Plan the installation.

2. Fabricate device supports and lay electrical conduit.

3. Mount the DL8000 and other load rack devices.

4. Run and connect all wiring.

5. Verify and tag each wire.

Revised April 2020 Installation and Use 2-15

Page 28

DL8000 Preset Instruction Manual

6. Seal conduit within 50 mm (2 inches) of the DL8000.

7. Secure cases and covers of all devices.

8. Apply electrical power.

9. Configure (set up) the DL8000 and any other devices as required.

10. Disable product block valves and additive block valves to

11. Enable one product block valve at a time and one additive

12. Perform meter proves to determine DL8000 meter calibration.

2.6.1 19BPlanning Considerations

Note: Install certified conduit plugs in any unused entries.

prevent any product or additive flow. Then verify system monitor

and control functions with dry piping.

injection system at a time. Then verify the piping integrity and

system operation in increments for each product and each additive

handling system.

Consider the following points during DL8000 mechanical installation

planning:

Maintenance Access

The operator panel is hinged at the bottom side and opens down for

maintenance access. Route all conduit to the rear, sides, or bottom of

the unit. Do not locate any object under the DL8000 or in front of

the conduit connections for a distance of approximately 533 mm (21

inches) below the instrument.

Mounting Height

Recommended mounting height is approximately 1.14 to 1.27

meters (45 to 50 inches) above grade to the bottom of the DL8000

case (see Figure 2-2). Mounting height determines the ease of

viewing the display panel and ease of use of the keypad.

Mounting Position

North/south/east/west orientation of the operator control panel is

somewhat predetermined by the loading facility design. Consider the

location of the operator in relation to one or two tanker vehicles

present and connected at the loading island.

Mounting Fixtures

You must fabricate mounting fixtures for the DL8000. Each

DL8000 comes with four M10-1.5 x 15 mm metric thread bolts for

mounting. You can either rear-mount or bottom-mount the DL8000,

although bottom-mounting is preferred due to the DL8000’s weight.

The mounting attachment should be a 4 mm (0.16 inch) (minimum)

thick mild steel member with four 11.5 mm (0.44 inch) diameter

2-16 Installation and Use Revised April 2020

Page 29

DL8000 Preset Instruction Manual

holes that match the bolting pattern being used. The steel member

may be sheet, angle, channel, or another shape.

Center the forward pair of mounting screw holes in bottom-mount

fixtures no more than 19 mm (0.75 inch) from the edge. The case

has a taper to the rear. The standard case may need a shim at the rear

pair of screws to level the DL8000. Level the case to allow for the

best conduit alignment.

Special Installation Considerations

The DL8000 is designed for installation in an outdoor environment.

The instrument is weatherproof and explosion-proof in accordance

with applicable standards. Some of the following installation

suggestions concerning environmental protection describe accepted

engineering practices and should not be considered to be limitations

on the utility of the instrument.

• If the loading rack or loading island area is covered, locate the

DL8000 so that the operator is protected or partially protected

from direct rainfall.

• In tropical climates, place sunshades above the DL8000 and

other electronic instruments, such as process transmitters. Locate

sunshades to prevent direct sunlight on the instruments during

the hottest part of the day (10:00 to 15:00). Construct sunshades

of metal, fiberglass, or other suitable materials. Sunshades

should be rear-sloping to direct rain to the rear of the instrument

and away from the operator. Avoid sharp edges or corners on

sunshades to prevent injuries.

• In desert areas or areas of blowing sand, install a cover to

protect the operator control panel during idle time. Continuous

blowing sand over an extended period of time can sandblast the

display panel and pushkey legends, affecting readability.

Fabricate a cover from raw materials or use a modified NEMA 4

weatherproof enclosure with a sealed rear cutout, placing it over

the operator panel. Use care in the design of any hinged cover so

that wind gusts do not move the cover and cause injuries. Any

cover design must allow for maintenance access to the DL8000.

The operator panel is hinged to open in the down direction for

maintenance access.

• In areas of continuous high humidity, place a 76.2mm x

76.2mm (3-inch x 3-inch) desiccant pack inside the DL8000

case. Place desiccant packs so that any expansion due to

moisture absorption does not interfere with any of the equipment

or wiring inside the case. Two sources of desiccant packs are:

o Waterguard® Desiccants

PO Box 1079

16023 I-10 East, Suite 30

Channelview, TX 77530

Revised April 2020 Installation and Use 2-17

Page 30

DL8000 Preset Instruction Manual

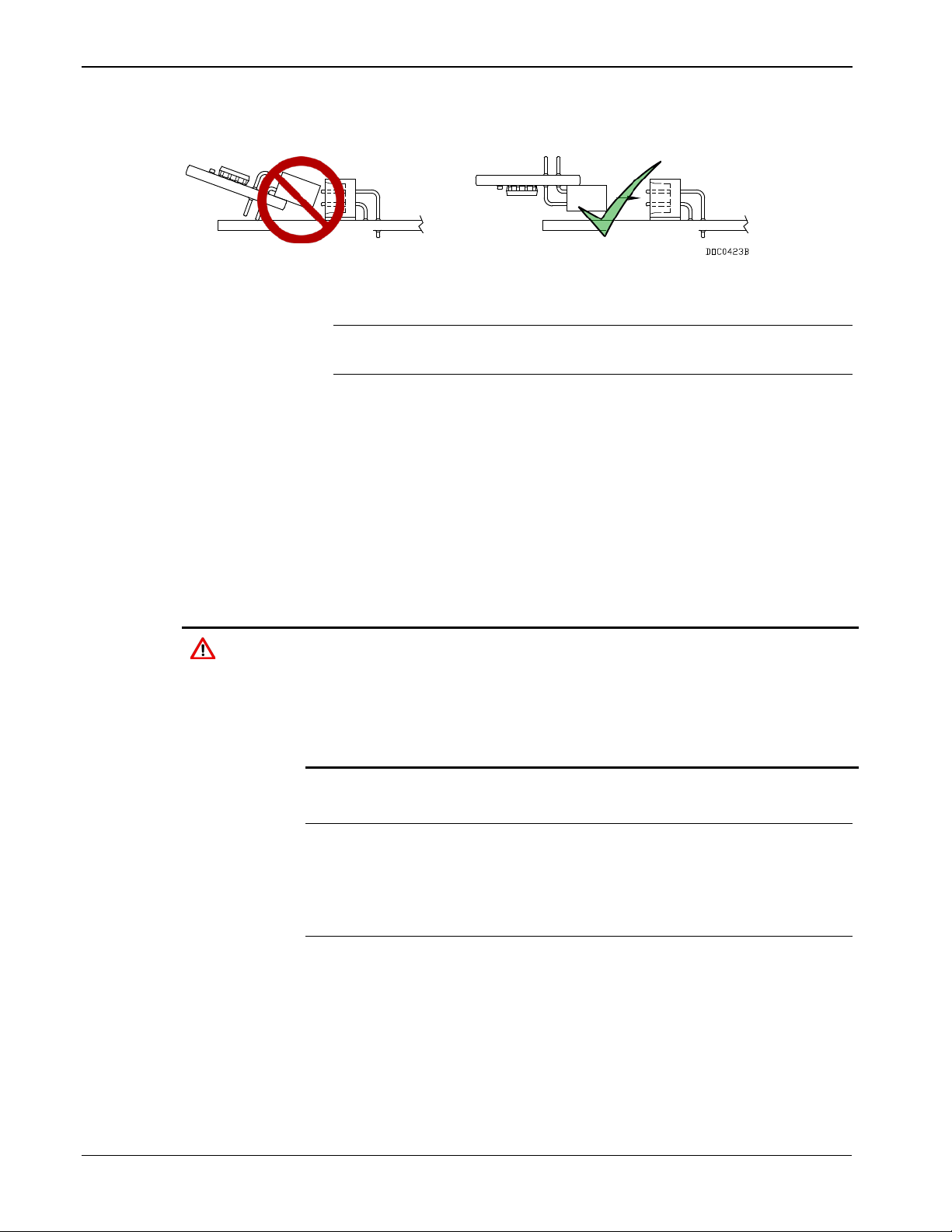

Seal all cable entries within 50 mm (2 inches) of the enclosure with

2.7 7BElectrical Installation

Caution

Shut off all sources of AC and DC power to the loading island site

before installing the DL8000.

2.7.1 20BGeneral Considerations

Use any of three cable entries located on the bottom of the housing for

wiring access to the DL8000.

A threaded 25.4 mm (1-inch) female NPSM connection on the left

side of the unit (for AC power and control / status signals).

A spare threaded 25.4 mm (1-inch) female NPSM connection on the

right side of the unit (may be used for meter pulse wiring to

segregate meter pulse wiring from all other signals).

o A+ Corporation

40462 Highway 42

Prarieville, LA 70769

A threaded 50 mm (2-inch) female NPSM connection for DC

cabling and low voltage level signals in the center.

Caution

suitable sealing or potting compound.

2.7.2 21BField Wiring Installation Guidelines:

Route external AC and DC wiring in separate conduits.

Record cable and wire routing and interconnection information to

simplify the creation of as-built documentation for the system.

Provide remote circuit breakers and optional disconnect switches for

all AC and DC power input circuits.

Follow power and signal field wiring grounding standards.

Use only stranded copper wire, equal to or of larger gauges as

indicated on the basic wiring diagrams located at the rear of this

section. Take care not to cut or weaken wire strands during the

removal of insulation.

Clearly mark all wire ends with slip-on wire tags or similar devices.

Preferably, color-code the wire tags to indicate the voltage level and

mark tags with the specific signal name.

Cut power and signal wires with an additional length of

approximately 50 mm (2 inches) for service loops to allow terminal

board and connector removal.

2-18 Installation and Use Revised April 2020

Page 31

DL8000 Preset Instruction Manual

Position all wiring within the unit to avoid unnecessary crimping

and overcrowding and to insure proper clearance for the instrument

door and hinges.

After completion, thoroughly check the wiring to insure that input

AC power and all field I/O signals are correctly connected at the

DL8000 terminations and at the terminations located on the

corresponding field device.

2.7.3 22BElectrical Wire and Cable Selection and Installation

All wiring must conform to the National Electrical Code; to local, state,

or other jurisdictions; and to company standards and practices.

Following are recommendations for 115/230 Volts ac power wiring:

Use multi-strand copper conductor wire and cable when connecting

the DL8000 to the power source and the field devices.

Ensure that all wire and cable is in new condition and adheres to the

manufacturer's quality standards with the size, type of insulation,

and voltage rating.

Use the following recommended wire types and sizes for AC power

input to the DL8000:

• Power feed should be 100 or 240 Volts ac, 50 to 60 Hertz, single

phase, three-wire. Locate a 15 Amp circuit breaker and

optionally a power disconnect switch in a safe area.

• Use wire size AWG 14 for power feed for distances up to 250

feet.

• Use wire size AWG 12 for power feed for distances of 250 to

500 feet.

• Use wire size AWG 10 for power feed for distances of 500 to

1000 feet.

Note: Power feed distances greater than 1000 feet are not

recommended.

• Single-conductor wiring must be THWN type, which is moisture

and heat-resistant thermoplastic with nylon jacket, approved for

dry-and-wet locations, and has a maximum operating

temperature of 75 degrees Celsius (167 degrees Fahrenheit). The

wire or cable jacket must contain the Underwriters Laboratories,

Inc. mark for Gasoline and Oil Resistant, II.

Ensure that shielded wires and cables for meter pulse signals have

shield-drain wires. The shield-drain wires must not be more than

two AWG sizes smaller than the conductors for the cable. The

shield-drain wire must be connected to ground at only one end of the

run.

Revised April 2020 Installation and Use 2-19

Page 32

DL8000 Preset Instruction Manual

Connect RS-485 serial data signals via two twisted pairs with

Use AWG 28 to AWG 18 RS-232 single ended serial data signals

Ensure that all cables have either Teflon® or PVC exterior jackets.

Install insulated wire and cable in accordance with the

Use suitable lubrication during wire pulls in conduit to prevent wire

Place cable or wire markers at the terminations of all cables and

overall shield, AWG 28 to AWG 22. Ideally, the capacitance should

not be greater than 16 pF per foot (Belden 9842 for example). The

use of a signal common (ground) conductor connected to each

device is a recommended option. Capacitance greater than 16 pF per

foot may be used at reduced baud rates and/or with shorter data

communication cable runs.

for cable lengths up to 15 meters (50 feet).

manufacturer's recommendation. Do not exceed maximum wire

tension, maximum insulation pressure, or minimum bending radius.

stress.

individual wires. Markers should contain the specific wire or cable

codes designated for that part icu lar circuit. The wire and cable

markers should be legible and permanent.

Check all wiring connected to the DL8000 for continuity, proper

size, and proper classification. Verify the source or destination of

each circuit before connecting to the DL8000 and related devices.

2.7.4 23BInput/Output Field Signa l Wiring

Following are recommendations for process signal wiring:

Use metal conduit for all process signal wiring.

Use separate conduits for AC and DC voltage circuits.

Ensure that all process signal wiring is a single, continuous length

between field devices and the DL8000, unless the length and/or

conduit runs require that multiple pulls be made. In these instances,

interconnect the individual conductors with suitable terminal blocks.

2.7.5 24BElectrical Grounds

Following are recommendations for electrical grounds:

A clamp type ground lug is located on the inside bottom front of the

case. Chassis ground conductors (color code green) inside the

DL8000 enclosure should be stranded, insulated, copper wire.

Connect these device chassis ground conductors to the clamp type

ground lug.

A clamp type ground lug is located on the outside of the case at the

rear of the lower right (facing the operator panel) casting rib.

2-20 Installation and Use Revised April 2020

Page 33

DL8000 Preset Instruction Manual

Connect this ground point to a copper ground rod as described

below.

• Connect a single-point ground (the outside case ground lug) to a

copper-clad, ten-foot long, 19 mm (0.75 inch) diameter steel rod,

which is buried, full-length, vertically, into the soil as close to

the equipment as is practical. (Grounding rod furnished by

others.)

Note: We recommend cad welding the wire to the rod to ensure

proper grounding.

• Resistance between the copper-clad steel ground rod and the

earth ground must not exceed 25 ohms. If necessary, additional

ground rods may be driven into the ground, while a spacing of

not less than 1.8 meters (6 feet) is used to separate each of the

ground rods. Additionally, the ground rods must be

interconnected with a continuous stranded wire, sized as

indicated below.

• When several DL8000 units are located in close proximity, each

single-point equipment ground must be inter-connected to the

single point grounds of the other DL8000s. These interenclosure equipment grounding connections must be “daisychained” so that only one point of the grounding daisy-chain is

connected to the actual ground rod.

Size the equipment-grounding conductors used between DL8000

units and the copper-clad steel ground rod or for inter-enclosure

equipment ground connections according to the following

specifications:

• Stranded, insulated, copper wire size AWG 8 for distances of

less than 4.5 meters (15 feet).

• Stranded, insulated, copper wire size AWG 6 for distances of 4.5

to 9 meters (15 to 30 feet).

• Stranded, insulated, copper wire size AWG 4 for distances of (9

to 30.5 meters (30 to 100 feet).

• All inter-enclosure equipment-grounding conductors should be

protected by metallic conduit.

• Shield-drain wires should be connected to ground at only one

end of the shielded conductor run.

• External equipment (such as data printers or terminal automation

systems which are connected to the DL8000) should be powered

via isolation transformers to minimize the ground loops caused

by the internally shared safety and chassis grounds.

Revised April 2020 Installation and Use 2-21

Page 34

DL8000 Preset Instruction Manual

2.7.6 25BWire Conduit Selection and Installation

Following are recommendations for conduit installation:

Ensure that all conduit and the associated assembly and installation

Ensure that all conduit runs have an explosion-proof sealing

Ensure that the conduit installation is vapor tight, with threaded hub

Square all conduit cutoffs. Cutoffs must be made by a cold cutting

Coat all conduit fitting threads, including factory-cut threads, with a

materials used for the installation of the DL8000 are in new

condition and adhere to the manufacturer's quality standards.

(potting) fitting located within 50 mm (2 inches) distance from the

conduit entrance to the DL8000.

fittings, sealed conduit joints and gaskets on covers, or other

approved vapor-tight conduit fittings.

tool, hacksaw, or by some other approved means that does not

deform the conduit ends or leave sharp edges.

metal-bearing conducting grease (such as Crouse-Hinds STL or

equivalent) prior to assembly.

Temporarily cap the ends of all conduit runs immediately after

installation to prevent accumulation of water, dirt, or other

contaminants. Swab out conduits prior to installing the conductors.

Where applicable, install explosion-proof seals in the conduit.

Install drain fittings at the lowest point in the conduit run and install

seals at the point of entry to the DL8000 to prevent vapor passage

and accumulation of moisture.

Use liquid tight conduit fittings (such as Myers Scru-tite® or

equivalent) for conduit which is exposed to moisture.

2-22 Installation and Use Revised April 2020

Page 35

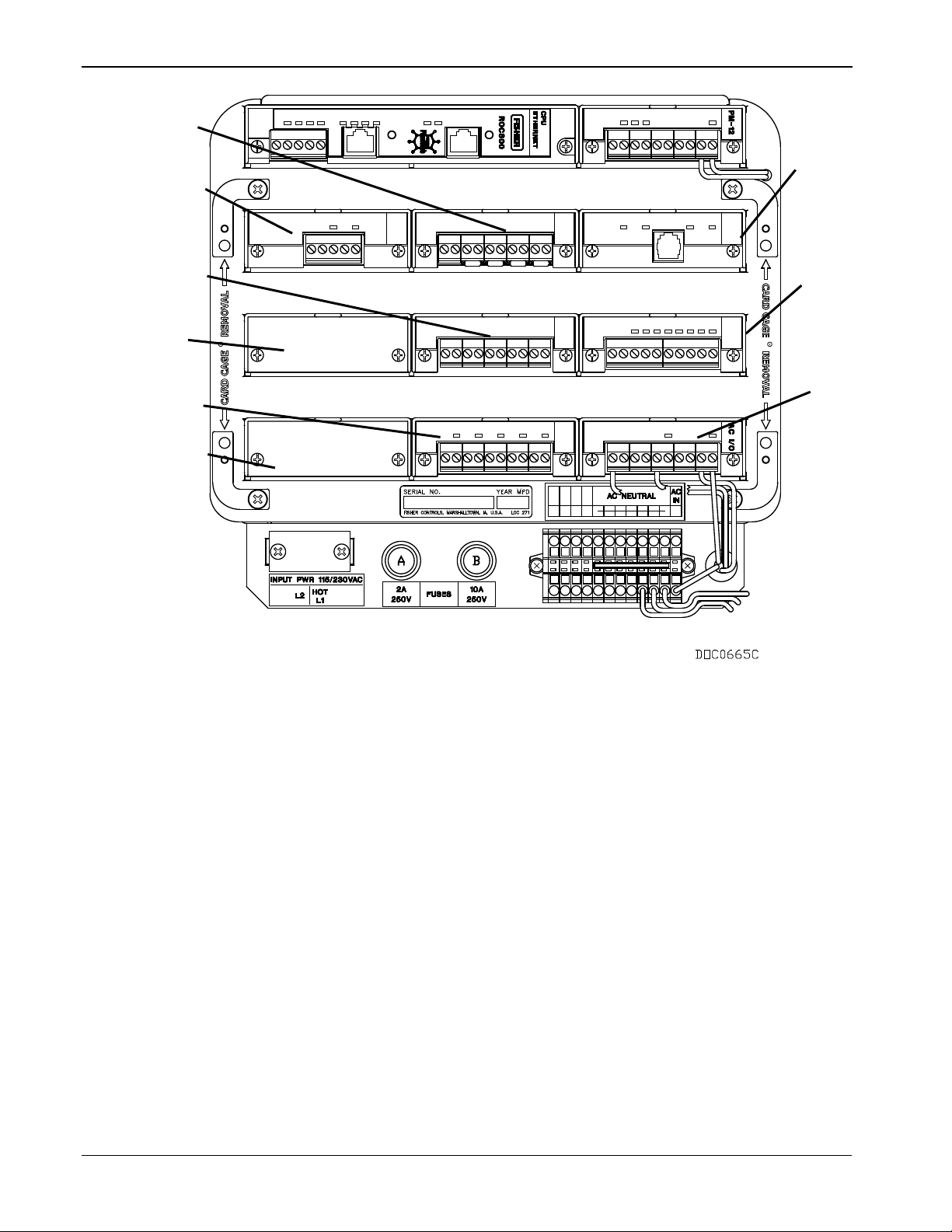

2.8 8BOperator Interface

Component

Use

A

C

B

Note: Refer to Appendix E, DL8000 Keypad Display, in this manual

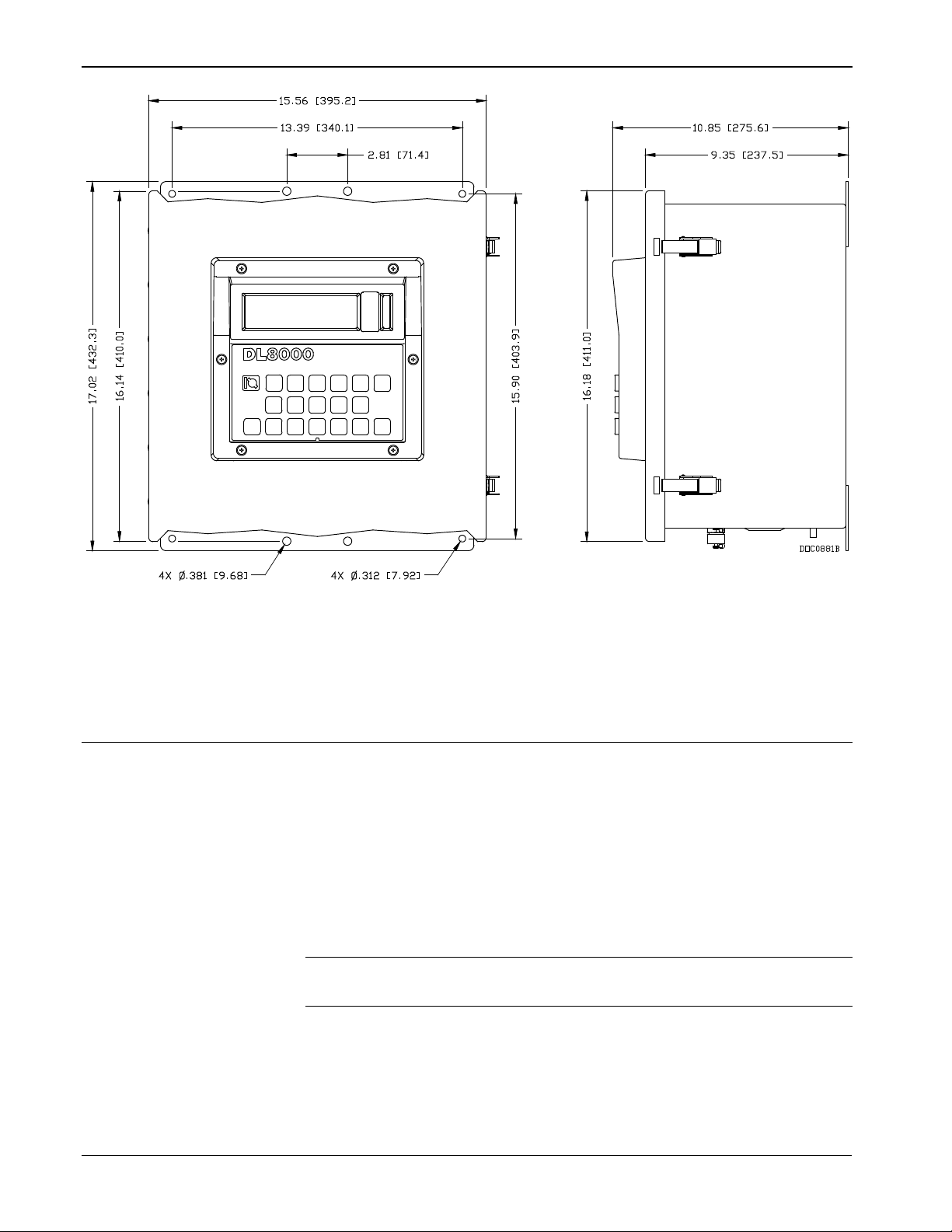

The DL8000’s keypad display has the following parts:

DL8000 Preset Instruction Manual

for a complete discussion of the features and functionalities of

the DL8000 keypad display.

A: Display

B: LED Status Indicators

C: Keypad

Figure 2-10. DL8000 Operator Interface

Keypad

Display

LED Status Indicators

Revised April 2020 Installation and Use 2-23

Enables the operator to select recipes, enter the

desired quantity, and control batch deliveries.

Note: With appropriate authority, the operator can

also program the DL8000.

A liquid crystal display (LCD) panel divided into two

sections (right and left). Each section provides

eight lines of up to 40 characters in widt h . The

display and keypad provide the primary method for

operating the DL8000.

Three light-emitting diodes (LEDs) display through

the vertical window to the right of the LCD,

indicating the DL8000’s operational status.

Page 36

DL8000 Preset Instruction Manual

Key

Function

0 through 9

Provide numeric digits for data entry.

are currently not supported.

ENTER/PROGRAM

Accept the manually entered value and continue.

supported.

CLEAR/EXIT

Reject the manually entered value and continue.

ALT+EXIT leaves the display.

SELECT/BKSP

Toggle the On/Off option for each defined additive.

back one character at a time.

Scroll down or move the select box to the next item

ALT+ moves to the next display.

Scroll up or move the select box to the previous item

ALT+ moves to the next display.

START

Initiate the batch loading operation after batch setup

data has been entered.

STOP/PRINT

Stop the batch loading operation.

supported.

ALT

Enable alternative functions on selected keys.

A

2.8.1 26BKeypad

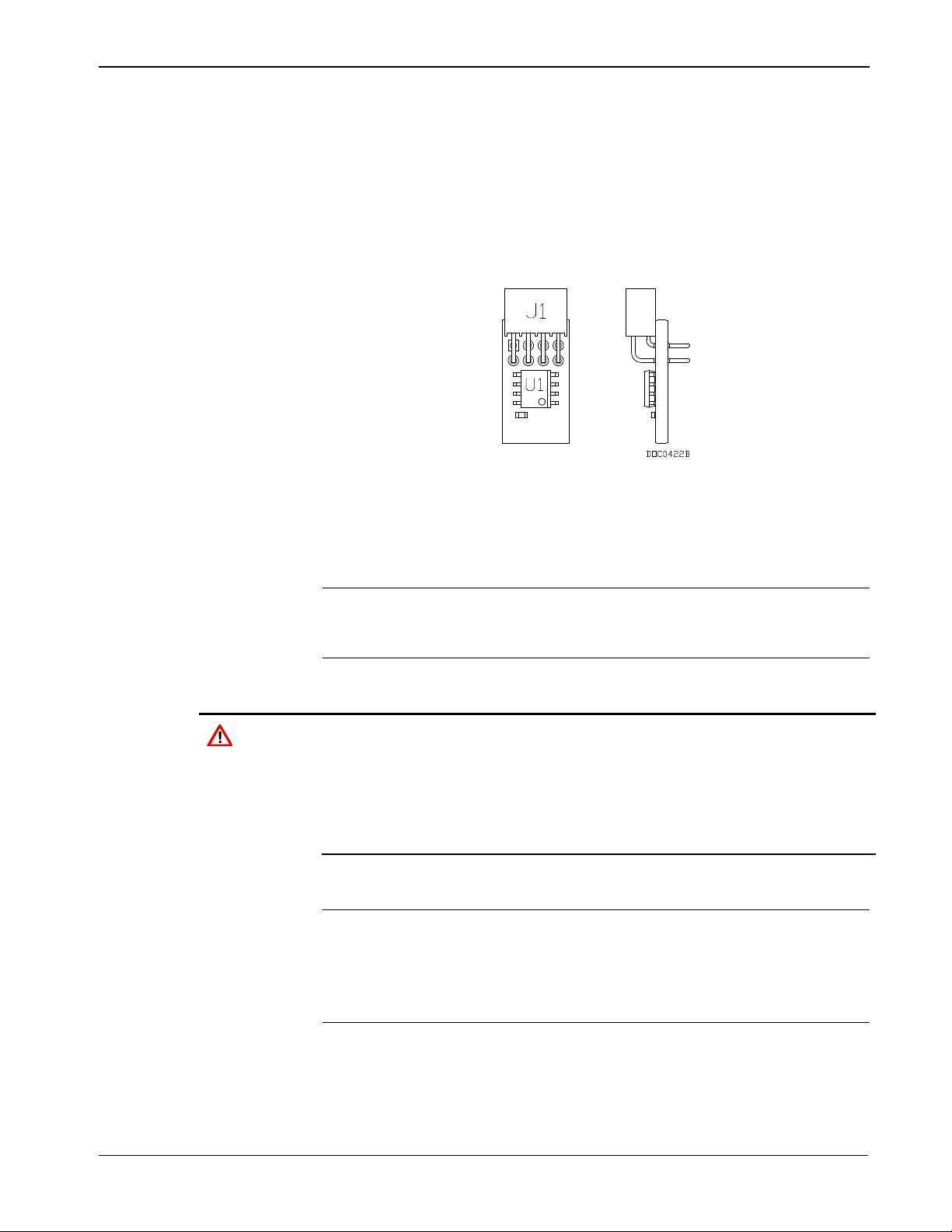

The DL8000 keypad enables the operator to select recipes, enter the

desired preset quantity, control batch deliveries, and (with appropriate

authority) program the DL8000. See Figure 2-11.

A: Weights & Measures Switch

Figure 2-11. DL8000 Keypad

/

/

ALT+3 increases the brightness of the display;

ALT+6 decreases the brightness of the display.

Note: The alphabetic values on the numeric keys

Note: The ALT+PROGRAM function is not currently

ALT+BKSP (Backspace) moves the cursor position

in the Recipes Selection display.

in the Recipes Selection display.

2-24 Installation and Use Revised April 2020

Note: The ALT+PRINT function is not currently

Page 37

Note: The Weights & Measures switch, located in the left upper corner

LED

Mode

Status

Function

YELLOW

Manual

Off

DL8000 is operating in Manual mode.

Manual or Auto mode.

Auto

On

DL8000 is operating in Auto mode (linked to a

host computer and operating as a slave unit.

Flashing

Two short pulses each second: case

situation.

GREEN

Permissive Power

On

The permissive power circuit is closed (the

supply) and is not programmable.

Off

The permissive power circuit is open. This

supply) and is not programmable.

RED

Alarm Status

On

A primary (or critical) alarm is active. You must

batch or new transaction.

Off

All alarms are inactive.

Flashing

A secondary (non-critical) alarm is active.

of the keypad, is lockable and wire-sealable to restrict access to

the flow calculations.

2.8.2 27BLED Status Indicators

The yellow, red, and green LEDs (see Figure 2-10) provide information

about the DL8000’s operational status.

DL8000 Preset Instruction Manual

Note: Local operation is identical in either

internal temperature is too high, the

keypad/display is disconnected, or power is

removed from the keypad/display.

One short pulse every two seconds:

Condition that caused the alarm has

returned to normal. Power up the DL8000 or

reset to continue using the keypad/display.

Rapid flashing: Power failure or low power

normal state when a batch delivery is in

progress).

Note: The green LED indicator’s function

depends on the state of the permissive

circuit (which is located in the power

indicates an abnormal state which is due to

permissive power failure or failure of one or

more permissive circuits wired in series (wired

AND) with the permissive power source

Note: The green LED indicator’s function

depends on the state of the permissive

circuit (which is located in the power

clear this alarm before you can begin a new

Revised April 2020 Installation and Use 2-25

Page 38

DL8000 Preset Instruction Manual

This page is intentionally left blank.

2-26 Installation and Use Revised April 2020

Page 39

Chapter 3 – Modules

In This Chapter

3.1 Power Input Module ............................................................................... 3-1