Page 1

Digital controller for medium-low temperature

refrigeration applications

XW60LH

1. GENERAL WARNING....................................................................................................................1

2. GENERAL DESCRIPTION ............................................................................................................1

3. CONTROLLING LOADS ................................................................................................................1

4. FRONT PANEL COMMANDS .......................................................................................................1

5. MAX & MIN TEMPERATURE MEMORIZATION ..........................................................................2

6. MAIN FUNCTIONS ........................................................................................................................2

7. PARAMETERS...............................................................................................................................2

8. DIGITAL INPUTS ...........................................................................................................................4

9. TTL SERIAL LINE – FOR MONITORING SYSTEMS ...................................................................4

10. X-REP OUTPUT – OPTIONAL ......................................................................................................4

11. INSTALLATION AND MOUNTING ................................................................................................4

12. ELECTRICAL CONNECTIONS .....................................................................................................4

13. HOW TO USE THE HOT KEY .......................................................................................................4

14. ALARM SIGNALS ..........................................................................................................................4

15. TECHNICAL DATA ........................................................................................................................5

16. CONNECTIONS .............................................................................................................................5

17. DEFAULT SETTING VALUES .......................................................................................................5

1. GENERAL WARNING

1.1 PLEASE READ BEFORE USING THIS MANUAL

• This manual is part of the product and should be kept near the instrument for easy and quick

reference.

• The instrument shall not be used for purposes different from those described hereunder. It cannot be

used as a safety device.

• Check the application limits before proceeding.

• Dixell Srl reserves the right to change the composition of its products, even without notice, ensuring

the same and unchanged functi onal ity.

1.2

SAFETY PRECAUTIONS

• Check the supply voltage is c orrect before connecting the ins trument.

• Do not expose to water or moisture: use the controller only within the operating limits avoiding sudden

temperature changes with high atmospheric humidity to prevent formation of condensation

• Warning: disconnect all electrical connections before any kind of maintenance.

• Fit the probe where it is not acc es sible by the End User. The instrument m ust not be opened.

• In case of failure or faulty operation send the instrument back to the distributor or to “Dixell S.r.l.” (see

address) with a detailed descri ption of the fault.

• Consider the maximum current w hi ch can be applied to each relay (see T ec hni cal Data).

• Ensure that the wires for probes, loads and the power supply are separated and far enough from each

other, without crossing or intertwining.

• In case of applications in industrial environments, the use of mains filters (our mod. FT1) in parallel

with inductive loads could be usef ul.

• Dixell Srl reserves the right to change the composition of its products, even without notice, ensuring

the same and unchanged functi onal ity.

2. GENERAL DESCRIPTION

Model XW60LH, format 38x 185mm, is microproces sor b ased co ntroller , suit able for appli cations on

medium or low temperature ventilated refrigerating units. It has 4 relay outputs to control compressor,

fan, defrost, which can be either electric al or r everse cycle (h ot gas) and a fourth configurable output .

They c ould be provid ed with a Real Time Cl ock which allows programmi ng of up to 6 daily defros t

cycles, divided into holidays and workdays. A “Day and Night” function with two different set points is

fitted for energy saving. They are al s o pr ov i d ed with up to four NTC or PTC probe inputs, the first one

for temperatur e control, the second one, t o be located ont o the evaporator , to control the d efrost

termination t emperature and to m anaged the fan. One of the digital in puts can oper ate as third

temperature pr ob e. T he fourth probe is used t o signal the co nd ens er t emp erat ur e alarm or to dis play

a temperature.

The HOT KEY output al lows to connect t he unit, by me ans of the external m odule XJ4 85-CX, t o a

network line ModBUS-RTU compatible such as the dIXEL monitoring units of X-WEB family. It

allows to program the controller by means the HOT KEY programming keyboard.

The instrumen t is fully configurabl e through special paramet ers that can be easily programmed

through the keyboard.

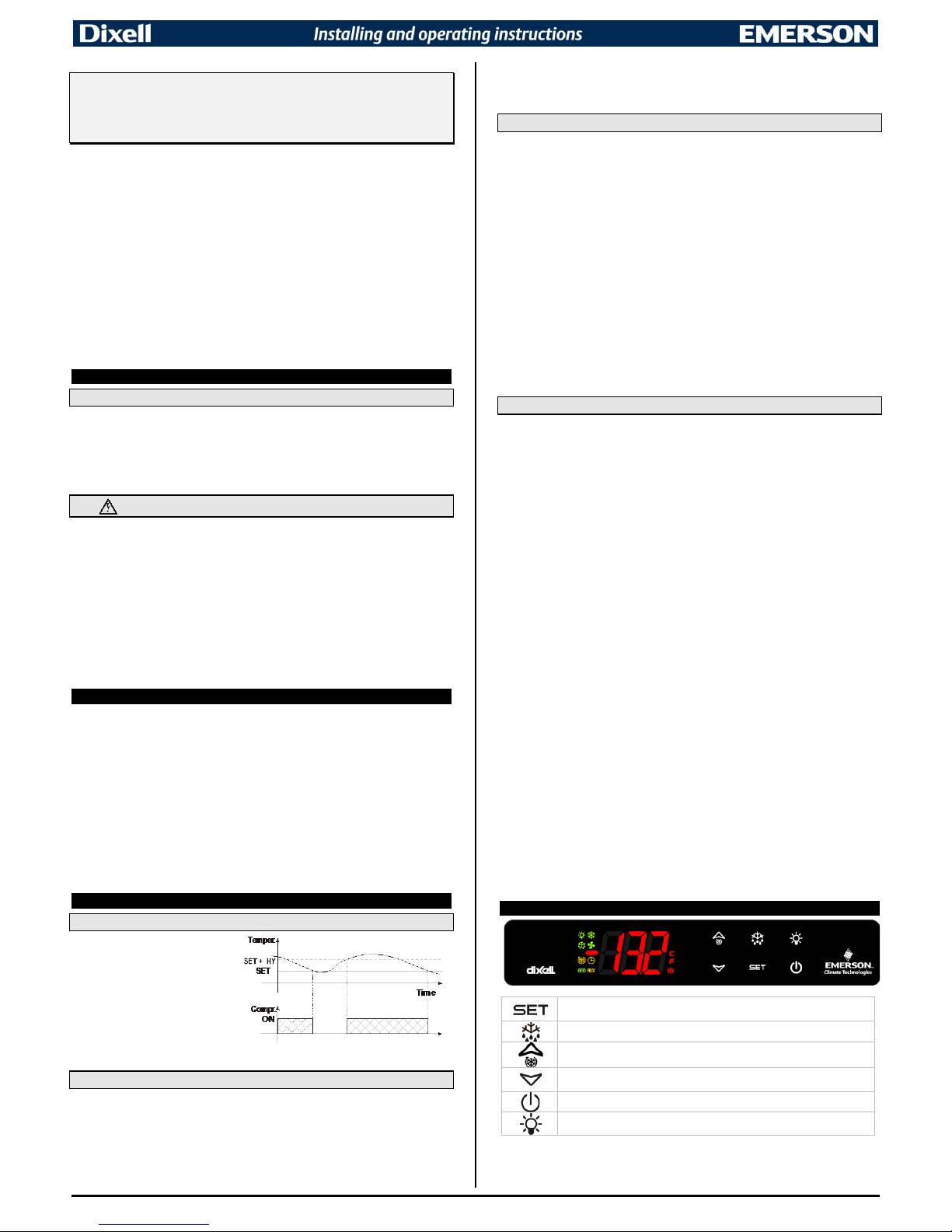

3. CONTROLLING LOADS

3.1 COMPRESSOR

The regulati on is perform ed accordin g

to the temperature measured by the

thermostat probe with a positive

differential from the set point: if the

temperature increases and reaches

set point plus differential the

compressor i s started an d then tur ned

off when the t emperature re aches the

set point value again.

In case of fault i n the thermostat probe t he start and stop of the com pressor are timed thr ough

parameters Con and CoF.

3.2 DEFROST

Two defrost mo des are av ail able thr ough t he tdF parameter: defr ost thr ough el ectric al hea ter (t dF =

EL) and hot gas defrost (tdF = in).

The defrost i nterval depends on the presence of the RTC (optional). If the RTC is pr esent is

controlled by means of parameter EdF:

- EdF=in: a defrost starts after elapsing the idF time (standard way for controller without RTC).

EdF=rtC: defrosts are sched uled by using a real time cl ock system, dependi ng on the h ours set in

the parameters Ld1..Ld6, during workdays, and in Sd1…Sd6 during holidays.

Other paramet ers are used to control defr ost cycles: i ts maximum le ngth (MdF) and two defrost

modes: timed or controlled by the evaporator’s probe (P2P).

At the end of defros t dri pping ti me is starte d, it s lengt h is set in th e Fdt parame ter. Wit h Fdt=0 the

dripping time is disabled.

3.3 CONTROL OF EVAPORATOR FANS

The fan control mode is selected by means of the FnC parameter:

- FnC=C_n: fans will switch ON and OFF with the compressor and not run during defrost;

- FnC=o_n: fans will run even if the compressor is off, and not run during defrost;

- FnC=C_Y: fans will switch ON and OFF with the compressor and run during defrost;

- FnC=o_Y: fans will run continuously also during defrost.

After defrost, t h er e is a tim ed fan delay allowi n g f or drip time, set by mea ns of the Fnd parameter.

An additional paramet er FSt provid es the set ting of t emperat ure, de tected by the eva porator probe,

above which th e fans are always OFF. Thi s is used to make sure cir culation of air only if his

temperature is lower than set in FSt.

3.3.1 Forced activation of evaporator fans

This function , managed by the FCt parameter, is designed to av oid short c ycles of evaporator fans,

which c ould ha ppen whe n the con troller i s switc hed on or af ter a defr ost (wh en the room ai r warms

the evaporator ). If t he temperature differenc e b etwe en the ev a por ator and th e room pr obes is higher

than the value set in the FCt parameter th e fans are switched on. Wit h FCt=0 this function i s

disabled.

3.3.2 Fans cyclic activation with compressor off.

When FnC=C-n or C-Y (fans working in paral lel with the compr es s or ) , by means of th e Fon and FoF

parameters t he f a ns c a n c ar r y out on and off cy c l es ev e n if the compressor is switc h ed off. When th e

compressor i s st op ped t he f ans g o on work in g for the Fon time. Wit h Fon=0 the fans r emai n always

off, when the compressor is off.

3.4 AUXILIARY OUTPUT CONFIGURATION

The functioni ng of the auxili ary relay can b e set by the oAx parameters acc ording to the ki nd of

application. In th e fol l owing paragraph the possible settings are explaided.

3.4.1 Auxiliary thermostat

A possible use i s the anti c ondensing heater, with t he possibil ity of switc hing it on and off also by

keyboard.

Parameters involved:

- ACH: kind of regulation for the auxiliary relay: Ht: heating; cL: cooling;

- SAA: set point for auxiliary relay;

- SHy: differe ntial for auxili ar y rel ay ;

- ArP: probe for auxiliary relay;

- Sdd: auxiliary output off during defrost.

The differential is given by the SHy parameter.

The auxiliar y r el ay c a n be switched on al s o by using the AUX button. In this cas e i t remains on till it’s

manually switched off.

NOTE: If oAx=AUS and ArP=nP (no pr obe for auxiliary outp ut) , the AUX relay can b e activated onl y

by pushing the AUX button of the keyboard.

3.4.2 On/off relay – oAx = onF

In this case the relay is activat ed when the controll er is turned on and de-activate d when the

controller is turned off.

3.4.3 Neutral zone regulation

With oAx=db the AUX relay can control a heater element to perform a neutral zone action.

- output oAx cut in = SET-HY;

- output oAx cut out = SET.

3.4.4 Second compr es sor

With oAx=CP2, the AUX rel ay operat es as secon d compress or: it is acti vated in par allel wit h the

relay of the fir st compressor, with a proper activation delay (set i n the AC1 parameter). Bot h the

compressors are switched off at the same time.

3.4.5 Alarm relay

With oAx=ALr the A UX relay oper ates as alarm r elay. It i s activ ated ev ery tim e an al arm hap pens.

Its status depends on the tbA parameter:

- tbA=Y: the relay is silenced by pr es s i n g any key;

- tbA=n: the alarm relay remains on until the alarm condition recovers.

3.4.6 Night blind management during energy saving cycles

With oAx=HES the AUX relay o perates to m anage the ni ght blind: the relay i s energised w hen the

energy saving cycle is activated by digital input, frontal button or RTC (optional).

4. FRONT PANEL COMMANDS

To display targe t s et point; in programm i ng mode it selects a parameter or

confirm an operation.

(DEF) To start a manual defrost.

(UP) To see the max stored temperature; in programming mode it browses the

parameter codes or increases the displayed value.

(DOWN) To see the min stored temperature; in programming mode it browses

the parameter codes or decreases the displayed value.

(OFF) To switch the instrument off, if onF=oFF.

(LiG) To switch the light, if oA3=Lig.

1592036000 XW60LH GB r1.0 18.03.2015 XW60LH 1/6

Page 2

KEY COMBINATIONS:

+

To lock & unlock the keyboard.

+

To enter in programming mode.

+

To return to the room temperature display.

4.1 USE OF LEDS

Each LED function is described in the following table.

LED

MODE

FUNCTION

ON

Compressor enabled

Flashing

Anti-short cycl e delay enabled

ON

Defrost enabled

Flashing

Drip time in progress

ON

Fans enabled

Flashing

Fans delay after defrost in progr es s .

ON An alarm is occurring

ON

Continuous cy cle is running

ECO

ON

Energy saving enabled

ON Light on

ON

Auxiliary relay on

°C/°F

ON

Measurement unit

Flashing

Programming p hase

5. MAX & MIN TEMPERATURE MEMORIZATION

5.1 HOW TO SEE THE MIN TEMPERATURE

1. Press and release the DOWN key.

2. The “Lo” message will be displayed followed by the minimum temperature recorded.

3. By pressing the DOWN key again or by waiting 5 sec the normal dis pl ay wi ll be restored.

5.2 HOW TO SEE THE MAX TEMPERATURE

1. Press and release the UP key.

2. The “Hi” message will be displayed followed by the maximum recorded temperature.

3. By pressing the UP key again or by waiting 5 sec the normal display will be restored.

5.3 HOW TO RESET THE MAX AND MIN TEMPERATURE RECORDED

1. Keep SET key pressed m ore than 3 sec, while the max or min tem perature i s display ed. (rSt

message will be displayed).

2. To c onfirm the op eratio n the “r St” mess age st arts bli nking and th e normal temper ature w ill be

displayed.

6. MAIN FUNCTIONS

6.1 TO SET THE CURRENT TIME AND DAY (ONLY WITH RTC)

When the instrument is switched on, it’s necessary to program the time and day.

1. Enter the Pr1 programming menu, by pushing the SET+ DOWN keys for 3 sec.

2. The rtC parameter is displayed. Push the SET key to enter the real time clock menu.

3. The Hur (hour) parameter is displayed.

4. Push the SET and set c urrent hour by the UP and DOWN keys , then push SET to

confirm the value.

5. Repeat the same operations with Min (m inutes) and dAy (day) parame ter s .

To exit: Push both SET+UP keys or wait for 15 sec without pushing any keys.

6.2 HOW TO SEE THE SET POINT

1. Push and immediately release the SET key: th e di s play will show the

Set point value.

2. Push and immediately release the SET key or wait for 5 sec to

display the pro be val u e again.

6.3 HOW TO CHANGE THE SETPOINT

1. Pus h th e SET key more than 2 sec to change the Set point value;

2. The value of the set point will be displayed and the “°C” or “°F” LED will start blinking.

3. To change the Set value, push both UP and DOWN arrows within 10 sec.

4. To store the new set point value, push the SET key again or wait for 10 sec.

6.4 HOW TO START A MANUAL DEFROST

Push the DEF key more than 2 sec and to start a manual defrost.

6.5 HOW TO CHANGE A PARAMETER VALUE

To change any parameter, operate as follows:

1. Enter the P ro gramm in g mo de by pr ess in g both SET+DOWN keys for 3 sec (the “°C” or “°F” LED

will start blinking).

2. Select th e r equired parameter and then press the SET key to display its value.

3. Use UP or DOWN keys to change its value.

4. Press SET to store the new value and move to the following parameter.

To exit: press both SET+UP keys or wait for 15 sec without pressing any key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to expire.

6.6 THE HIDDEN MENU

The hidden menu shows all the parameters of the instrument.

6.6.1 HOW TO ENTER THE HIDDEN MENU (Pr2)

1. Enter t he Progr amming m ode by pres sing th e SET+DOWN k eys for 3 sec (the “°C” or “°F” LED

will start blinking).

2. Releas ed the key s and then push agai n the SET+DOWN keys more than 7 sec. The “Pr2” label

will be displayed immediately followed by the HY parameter.

NOW THE HIDDEN MENU IS DISPLAYED.

3. Select the required parameter.

4. Press the SET key to display its value

5. Use UP or DOWN keys to change its value.

6. Press SET to store the new value and move to the following parameter.

To exit: press SET+UP keys or wait for 15 sec without pressing any key.

NOTE1: i f no p aram eters are present in Pr 1, af ter 3 sec the “noP” mes sag e will be dis played . Keep

the keys pushed till the Pr2 message is displayed.

NOTE2: the set value is stored even when the procedure is exited by waiting the time-out to expire.

6.6.2 MOVE A PARAMETER FROM Pr2 TO Pr1 AND VICEVERSA.

Each paramet er present in the Pr2 (HIDDEN MENU) can be moved to th e Pr1 (user l evel) by

pressing both SET+DOWN keys.

When in Pr2 (hidden menu) if a parameter is visible in Pr1, then the decimal point will be on.

6.7 MANUALLY LOCK AND UNLOCK THE KEYBOARD

+

HOW TO LOCK THE KEYBOARD

1. Keep both UP+DOWN keys pressed more than 3 sec.

2. The “P oF” message will be displayed and the keyboard is locked.

At this point it is only possible the viewing of the set point or the

MAX o Min temperature stored and to switch ON and OFF the light,

the auxiliary output and the instrument.

HOW TO UNLOCK THE KEYBOARD

Keep bothj UP+DOWN keys pressed more than 3 sec.

6.8 THE CONTINUOUS CYCLE

When defrost is no t active, a continuous cycle can be activated by keeping the UP key press ed for

about 3 sec. The compressor operates to maintain the CCS set point for the time set through the CCt

parameter. T he cycle can be term inated before the end of the set time by keeping the UP key

pressed 3 sec.

6.9 THE ON/OFF FUNCTION

With onF=oFF, after pushing the ON/OFF key the instrument is switched off. The

“OFF” message will be displayed. In this configuration the regulation is disabled.

To switch the instrument on, push again the ON/OFF key.

WARNING: Loads connected to the normally closed contacts of the relays are always

supplied and under voltage, even if the instrument is in stand by mode.

7. PARAMETERS

rtC

Real time clock menu (only for controller with RTC): to set the time, date and

defrost start time.

REGULATION

HY

Differential: (0.1 to 25.5°C; 1 to 45°F) intervention differential for set point.

Compressor Cu t IN is S et Point + differ ential ( HY). Com pressor Cut OUT i s when th e

temperature reaches the set point.

LS

Minimum set point: (-55°C to SE T; -6 7°F to S ET) sets t he m ini mum v alu e for the s et

point.

US

Maximum set poin t: (SET to 15 0°C; SET to 302°F) set the maxim um value f or set

point.

ot

Thermostat probe calibration: (-12.0 to 12.0°C; -21 to 21°F) allows to adjust

possible offset of the thermos tat probe.

P2P

Evaporator probe presence: (n; Y) n = not present, the defrost stops by time;

Y = present, the defrost stops by temperature.

oE

Evaporator probe calibration: (-1 2. 0 t o 12.0°C; -21 to 21°F) allows t o adjust possibl e

offset of the ev aporator probe.

P3P

Third probe presence (P3): (n; Y) n = not pr esent, the terminal s 18-20 operate as

digital input; Y = present, the terminals 18-20 operate as third probe.

o3

Third probe calibration (P3): (-12.0 to 12. 0°C ; -21 to 21°F) allow s to adjus t possi ble

offset of the third probe.

P4P

Fourth probe presence: (n; Y) n = Not present; Y = present.

NOTE: only for XW60LH models.

o4

Fourth probe calibration: (-12.0 to 1 2.0°C; -21 to 21°F) allows to adjus t possible

offset of the fourth probe.

NOTE: only for XW60LH models.

odS

Outputs activ ation delay at start up: (0 to 2 55min) this func tion is enabl ed at the

initial start up of the i nstr ument a nd inhi bits a ny outpu t acti vati on for th e peri od of tim e

set in the parameter.

AC

Anti-short cycl e delay: (0 to 50m in) mini mum interv al betwe en the compr essor stop

and the following restart.

rtr

Percentage of the second and fir st prob e for regulatio n: (0 to 100; 100=P 1, 0=P2)

it allows to set the regulation according to the percentage of the first and second probe,

as for the following formula (rtr(P1-P2)/100 + P2).

CCt

Compressor ON time during continuous cycle: (0.0 to 24h00min, res. 10min) allows

to set the len gth of the conti nuous cycle. C ompressor stays on without interr uption

during CCt time. This is useful, for instance, when the room is filled with new products.

CCS

Set point for continuous cycle: (-55 to 150°C; -67 to 302°F) it sets the set poi nt used

during the continuous cycle.

Con

Compressor ON time with faulty probe: (0 to 255min) time during which the

compressor i s active in case of faulty ther mostat probe. W ith Con=0 com pressor is

always OFF.

CoF

Compressor OFF time with faulty probe: (0 to 255min) time during which the

compressor i s OFF in case of faulty therm ostat probe. With CoF=0 compres sor is

always active.

1592036000 XW60LH GB r1.0 18.03.2015 XW60LH 2/6

Page 3

DISPLAY

CF

Temperatur e me as u r ement unit: (°C; °F) °C = Celsius; °F = Fahrenheit.

WARNING: Wh en t he me asur em ent unit i s c hang ed the S ET poi nt an d th e valu es of

the paramet ers HY, LS, US, ot, ALU and ALL hav e to be c hecked and modi fied (i f

necessary).

rES

Resolution (for °C): (in=1°C; dE=0.1°C) allows decimal point display.

Lod

Instrument di splay: (P1; P 2 , P 3, P 4, SET, dtr) i t s elects which pro b e is displayed by

the instrume nt. P1 = Therm ostat probe; P2 = Evaporator prob e; P3 = Thir d probe

(only for mo del with t his opti on enabl ed); P4 = Fourth pr obe, SET = set point; dtr =

percentage of visualization.

rEd

X-REP display (optional): (P1; P 2, P3, P4, SET, dtr) i t selects which probe i s

displayed by X - REP. P1 = Thermostat pr obe; P2 = Evapor ator probe; P3 = T hird

probe (only for model with this option enabled); P4 = Fourth probe, SET = set point;

dtr = percentage of visualization.

dLY

Display delay: (0 to 20min00s; res. 10s) when the temperature increases, the

display is updated of 1°C or 1°F after this time.

dtr

Percentage of the se cond an d first pr obe fo r visual izati on when L od=dtr : (0 to

99; 100=P1, 0=P2) if Lod=dtr it allows to set the visual ization according to t he

percentage of the first and second probe, as for the following formula (dtr(P1-

P2)/100 + P2).

DEFROST

EdF

Defrost mode (only for controller with RTC):

- rtC: Real Ti me Clock mode. De frost time follows Ld1 to Ld6 param eters on

workdays and Sd1 to Sd6 on holidays.

- in: inter val mode. The defr os t starts when the t ime idf is expired.

tdF

Defrost type: (EL; in) EL = electrical heater; in = hot gas.

dFP

Probe selection for defrost termination: (nP; P1; P2; P3; P4) nP = no probe;

P1 =t hermostat pr obe; P2 = evap orator probe; P3 =co nfigurabl e probe; P4 = Probe

on Hot Key plug.

dtE

Defrost termi nation t emperatur e: (-55 to 50°C; -67 to 122°F) (e nabled onl y when

EdF=Pb) sets the tem perat ure me asure d by th e evap orator pr obe, w hich c auses the

end of defrost.

idF

Interval betw een defrost cycl es: (0 to 120 hours) determin es the interval of time

between two defrost cycles.

MdF

(Maximum) length for defrost: (0 t o 255min) when P2P=n, (not evapor ator pr obe:

timed defrost) it sets the defrost duration. When P2P=Y (defrost end based on

temperature) it sets the maximum length for defrost.

dSd

Start defro st del ay: (0 to 9 9min) this i s us eful when differ ent defros t star t ti mes ar e

necessary to avoid overloading the plant.

dFd

Temperature displayed during defrost: (rt; it; SEt; dEF) rt = real temperature;

it = temperature at defrost start; SEt = set point; dEF = “dEF” label.

dAd

MAX display delay after d ef r o st: (0 to 25 5m i n ) s ets the maximum t i me between the

end of defrost and the restarting of the real room temperature display.

Fdt

Drip time: (0 to 120min) time interval between reaching defrost termination

temperature a nd the res toring of the cont rol’s normal op eratio n. This ti me allows the

evaporator to eliminate water drops that might have formed due to defrost.

dPo

First defrost af ter start-up: (n; Y) n = after the idF time, Y = immediately.

dAF

Defrost dela y after cont inuous cy cle: (0.0 t o 24h00min, r es. 10min) time interv al

between the end of the fast freezing cycle and the following defrost related to it.

FANS

FnC

Fans operatin g mode: (C-n; o-n; C-Y; o-Y) C-n = runs with the compr essor, OFF

during defrost; o-n = continuous mode, OFF during defrost; C-Y = runs with the

compressor, ON during defrost; o-Y = continuous mode, ON during defrost.

Fnd

Fans delay after defrost: (0 to 255min) interval betwe en end of defros t and evaporat or

fans start.

FCt

Temperatur e differential to avo id fan short cycl es: (0 to 59° C; 0 to 90°F) (N.B. :

FCt=0 means function disabled) if the difference of temperature between the

evaporator and the room probes is higher than FCt value, the fans will be switched on.

FSt

Fans stop temp erature: (-55 to 50°C; -67 t o 122°F) setti ng of temp erature, detected

by evaporator probe, above which fans are always OFF.

Fon

Fan ON time: (0 to 15min) with Fnc=C_n or C_Y, (fan activated in parallel with

compressor) i t sets the evaporator fan O N cycling tim e when the c ompressor is off.

With Fon=0 and FoF≠0 t he fan are always o ff, with Fon=0 and FoF=0 the fa n are

always off.

FoF

Fan OFF time: (0 to 15min)

With FnC=C_n or C_Y, (fan acti v ated in paral l el with compress or ) it sets the eva porator

fan off cycling time when the compressor is off.

With Fon=0 and FoF≠0 t he fan are always o ff, with Fon=0 and FoF=0 the fa n are

always off.

FAP

Probe selection for fan management: (nP; P1; P2; P3; P4) nP = no probe;

P1 =thermos tat pr obe; P2 = evaporator pr obe; P3 =configur able prob e; P4 = Probe on

Hot Key plug.

AUXILIARY THERMOSTAT CONFIGURATION

ACH

Kind of regulation for auxiliary relay: (Ht; CL) Ht = heating; CL = cooling.

SAA

Set Point for auxiliary r elay: (-55.0 to 150.0°C; -67 to 302°F) i t defines the ro om

temperature set point to switch auxiliary relay.

SHY

Differential for auxiliary output: (0.1 to 25.5° C; 1 to 45 °F) int erve ntion di ffer enti al for

auxiliary output set point.

• ACH=CL, AUX Cut in is [SAA+SHY]; AUX Cut out is SAA.

• ACH=Ht, AUX Cut in is [SAA–SHY]; AUX Cut out is SAA.

ArP

Probe select ion for aux iliar y: (nP; P1; P2; P3; P4) nP = no prob e, th e auxi liar y relay

is switched onl y by the digit al input; P1 = Probe 1 ( Thermostat probe); P2 = Probe 2

(evaporator pr obe); P3 = Probe 3 (display probe); P4 = Probe 4.

Sdd

Auxiliary relay off during defrost: (n; Y) n = the auxiliary relay operates during

defrost. Y = the auxiliary relay is switched off during defrost.

ALARMS

ALP

Probe selectio n for alarm: (nP; P1; P 2; P3; P4) nP = no probe, th e temperature

alarms are dis abled; P1 = Probe 1 (Ther mostat probe); P2 = Probe 2 (evap orator

probe);

P3 = Probe 3 (display probe); P4 = Fourth probe.

ALC

Temperature alarms configuration: (Ab; rE) Ab = absolute temperature, alarm

temperature i s giv en by the ALL or ALU val ues. rE = temperature al arms are ref erre d

to the set poi nt. Temperature alar m is enabled when the temperature exceeds the

[SET+ALU] or [SET-ALL] values.

ALU

MAXIMUM temperature alarm:

• If ALC=Ab: [ALL to 1 50.0°C or ALL to 302° F]

• If ALC=rE: [0.0 to 50.0°C or 0 to 90°F]

when this temperature is reached the alarm is enabled, after the ALd delay time.

ALL

Minimum temperature alarm:

• If ALC=Ab: [-55°C to ALU; -67 to ALU]

• If ALC=rE: [0.0 to 50.0°C or 0 to 90°F]

when this temperature is reached the alarm is enabled, after the ALd delay time.

AFH

Differential for temperat ure alarm re covery: (0.1 to 2 5.5°C; 1 to 45°F ) interventi on

differential for recovery of temperature alarm.

ALd

Temperatur e alarm delay: ( 0 to 255 min) time int erval between t he detection of an

alarm condition and alarm signalling.

dAo

Exclusion of t emperature alarm at start-up: (0.0 to 24h00min, res. 10min) time

interval between the detection of the temperature alarm condition after instrument

power on and alarm signalling.

CONDENSER TEMPERATURE ALARM

AP2

Probe selection for temperature alarm of condenser: (nP; P1; P2; P3; P4)

nP = no probe; P1 = therm ostat probe; P2 = evaporator probe; P3 = configurable

probe; P4 = Probe on Hot Key plug.

AL2

Low temperature alarm of condenser: (-55 to 150°C; -67 to 302°F) when this

temperature is reached the LA2 alarm is signalled, possibly after the Ad2 delay.

Au2

High temperature alarm of condenser: (-55 to 150°C; -67 to 302°F) when this

temperature is reached the HA2 alarm is signalled, possibly after the Ad2 delay.

AH2

Differential for temperature condenser alarm recovery: 0.1 to 25.5°C; 1 to 45°F.

Ad2

Condenser temperature alarm delay: (0 to 255 min) time interval between the

detection of the condenser alarm condition and alarm signalling.

dA2

Condenser temperature alarm exclusion at start up: 0.0 to 24h00min, res. 10min.

bLL

Compressor off with low temperature alarm of condens er: (n; Y) n = c ompressor

keeps on wor king ; Y = compress or i s swit che d off ti ll t he al arm is pres ent, i n any cas e

regulation restarts after AC time at minimum.

AC2

Compressor of f with hi gh temp erature alarm of conden ser: (n; Y) n = compress or

keeps on wor king ; Y = compress or i s swit che d off ti ll t he al arm is pres ent, i n any cas e

regulation restarts after AC time at minimum.

OUTPUT RELAY

tbA

Alarm relay silencing (with oAx =ALr): (n; Y) n = silencing disabled: alarm relay stays

on till alarm c ondition lasts. Y = silencing e nabled: alarm relay i s switched OFF by

pressing a key during an alarm.

oA3

Third relay configuration (X60 L T: t er minals 1-3): (dEF ; F An; ALr; LiG; A US ; onF; db;

dEF2; HES) dEF = de frost; FAn = do n ot select it; ALr = alarm; LiG = light; AUS =

Auxiliary r elay; onF = alway s on with ins trum ent o n; db = neutral zone; dEF2 = do not

select it; HES = night blind.

AoP

Alarm relay pol ar ity: (CL; oP) it s et if the al ar m rel ay i s open or clos ed w he n an al arm

occurs. CL = terminals closed during an alarm; oP = terminals open during an alarm.

DIGITAL INPUTS

i1P

Digital input polar ity (1 3-14): oP: the di gi tal in put i s ac ti vat ed by o peni n g th e contact;

CL: the digital input is activated by closing the contact.

i1F

Digital input configuration (13-1 4): EAL= ex ter nal al arm : “E A” m ess a ge is di splay e d;

bAL= serious alarm “CA” mess age is displayed . PAL= pressure s witch alarm, “CA ”

message is di splayed; dor= d oor switch f unction; dEF= acti vation of a defrost cy cle;

AUS=not enabled ; Htr= kind of actio n inversion ( cooling – heating); FAn= not set it;

ES= Energy savi ng; HdF = Holi day de fr ost ( ena bl e onl y wi th RTC) ; onF = to s wi tch t he

controller off .

did

(050÷255 min) with i1F= EAL or i1F = bAL digital input alarm delay (13-14): delay

between the detection of the external alarm condition and its signalling.

with i1F= dor: door open signalling delay

with i1F= PAL: time for pressure switch function: ti me interval to calculate th e

number of the pressure switch activation.

i2P

2nd digita l input polarity (13-19): oP: the digital i nput is activated by openi ng the

contact; CL: the digital input is activated by closing the contact.

i2F

2nd digital input configuration (13-19): EAL= external alarm: “EA” message is

displayed; bAL= serious al arm “CA” message is displayed. PAL= pressure switch

alarm, “CA” m essage is displaye d; dor= door switch func tion; dEF= activation of a

defrost cycle; AUS=not enabled; Htr= kind of action i nversion (cool ing – heating); FAn=

not set it; ES= Energy sav ing; HdF = Holiday defr ost (enable only with RTC); onF = to

switch the contr ol ler off.

d2d

(0÷255 min) with i2F= EAL or i 2F= bAL 2nd digita l inp ut al arm d ela y (13-19): delay

between the detection of the external alarm condition and its signalling.

with i2F= dor: door open signalling delay

with i2F= PAL: time for pressure switch functi on: time interval to calculat e the

number of the pressure switch activation.

nPS

Pressure swit ch num ber: (0 ÷15) Num ber of ac tivati on of the pr essur e switc h, dur ing

the “did” interval, before signalling the alarm event (I2F= PAL).

If the nPS activation in the did time is r each ed, sw itch o ff an d on t he i nstr ument

to restart normal regulation.

odC

Compressor status when open door: (no; FAn; CPr; F_C: no = normal ; Fan = Fan

OFF; CPr = Compressor OFF; F_C = Compressor and fan OFF.

rrd

Outputs restart after door open alarm: (n; Y) n = outputs follow the odC parameter.

Y = outputs restart with a door open alarm.

HES

Delta temper ature du ring an E nerg y Savin g cycl e: (-30.0 t o 30.0° C; -54 to 5 4°F) it

sets the increasing value of the set point [SET+HES] during the Energy Saving cycle.

1592036000 XW60LH GB r1.0 18.03.2015 XW60LH 3/6

Page 4

CURRENT TIME AND WEEKLY HOLIDAYS (ONLY FOR MODELS WITH RTC)

Hur

Current hour: 0 to 23h.

Min

Current minute: 0 to 59min.

dAY

Current day: Sun to SAt.

Hd1

First weekly holiday: (Sun to nu) set th e fi r s t day of th e w e ek w hich follows the holiday

times.

Hd2

Second weekly h ol ida y: ( Sun t o nu) set t he s ec ond d ay of t he week whi ch fol lo ws t he

holiday times.

N.B.: Hd1, Hd2 can be set also as “nu” value (Not Used).

ENERGY SAVING TIMES (ONLY FOR MODELS WITH RTC)

ILE

Energy Saving cycle start during workdays: (0 to 23h5 0min) during the Energy

Saving cycle t he set point is increased by the value in HES so that th e operation s et

point is SET+HES.

dLE

Energy Saving cycle length during wor kdays: (0 to 24h00m in) sets the duration of

the Energy Saving cycle on workdays.

ISE

Energy Saving cycle start on holidays: 0 to 23h50min.

dSE

Energy Saving cycle length on holidays: 0 to 24h00min.

TO SET DEFROST TIMES (ONLY FOR MODELS WITH RTC)

Ld1...Ld6

Workday defrost start: (0 to 23h50min) t h ese parameters s et th e b egi nning of the 6

programmable defrost cycles during workdays. Ex: when Ld2=12.4 the second

defrost starts at 12.40 during wor k d ay s .

Sd1...Sd6

Holiday defro st star t: (0 to 23h50m in) t hese p aramet ers s et the begi nni ng of th e 6

programmable defrost cycles o n holidays. Ex: wh en Sd2=3.4 the secon d defrost

starts at 3.40 on h ol i day s .

N.B.: to disable a defrost cycle set it to “nu” (not used).

OTHER

LoC

Lock keyboard timer: nu(9) = keyboard never blocked, or 10 to 255 sec

Adr

Serial address: (1 to 247) identifies the instrument address when connected to a

ModBUS compatible monitoring system.

PbC

Type of probe: (PtC; ntC) it allows to set the kind of probe used by the instrument:

- PtC = PTC probe;

- ntC = NTC probe.

onF

On/Off key enabling: (nU; oFF; ES) nU = disabled; oFF = enabled; ES = not set it.

dP1

Thermostat probe display.

dP2

Evaporator pro be display.

dP3

Third probe dis pl ay .

dP4

Fourth probe display (only for XW60LH models).

rSE

Real set poi nt: it s ho ws t h e s et poi nt us ed dur in g th e en ergy s avin g cy cl e or duri ng the

continuous cycle.

rEL

Software release for internal use.

Ptb

Parameter table code: readable only.

8. DIGITAL INPUTS

The first digital input (XW60LH: terminals 13-14) is enabled if P3P=n.

With P3P=n and i1F=i2F the second digital input will be disabled.

The free voltage digital inputs are programmable by the i1F and i2F parameters.

8.1 GENERIC ALARM (i1F or i2F = EAL)

As soon as the digital input is activated the unit will wait for did time delay before signalling the “EAL”

alarm messag e. T he out p uts s tatus do esn’t change. The alar m s tops jus t aft er t he digi tal i npu t i s deactivated.

8.2 SERIOUS ALARM MODE (i1F or i2F = bAL)

When the digit al input is ac tivated, t he unit wil l wait for did del ay before si gnalling the “CA” alarm

message. The r elay out pu ts are s witc h ed OFF . T he al arm w il l st op as so on as th e digi tal inp ut is deactivated.

8.3 PRESSURE SWITCH (i1F or i2F = PAL)

If during the i nterval time set by did param eter, the pressure s witch has reached the number of

activation of the nPS parameter; the “CA” pressure alarm message will be displayed. The

compressor and the r egulati on are stoppe d. Whe n the di gital i nput is ON the compres sor i s always

OFF. If the nPS acti vation in the did time is reached, s witch off and on the instrument to

restart normal regulation.

8.4 DOOR SWITCH INPUT (i1F or i2 F = dor)

It signals the door stat us and t he c orres pondi ng rel ay out put stat us thr oug h the odC parameter: no:

normal (any change); FAn: Fan OFF; CPr: Compressor OFF; F_C: C om pressor and fan OF F.

Since the door is ope ned , a fter the delay ti me s et thr ou gh par am eter did, the door al arm is ena bled ,

the display s hows the m essage “dA” and th e regulation rest arts if rtr=YES. The alarm s tops as

soon as the ext er nal digital i npu t is disabled again. With the door open, the hi gh and low temp erature

alarms are disabled.

8.5 START DEFROST (i1F or i2F = dEF)

It starts a defr ost if th ere are t he right c onditi ons. A fter the de frost is finish ed, the n ormal re gulatio n

will restart only if the digital input i s disa bled ot herwis e the ins trume nt will wait unt il the MdF safety

time is expired.

8.6 SWITCH THE AUXILIARY RELAY (i1F or i2F = AUS)

With oAx=AUS the digital input will change the stat us of t h e aux i l iary relay.

8.7 INVERSION OF THE KIND OF ACTION: HE ATI NG-COOLING (i1F or i2F=Htr)

This function allows to invert the regulation of the controller: from cooling to heating and viceversa.

8.8 ENERGY SAVING (i1F or i2F = ES)

The Energy S aving function al lows to change the set point val ue as the result of th e SET+HES

(parameter) sum. This function is enabled until the digital input is activated.

8.9 ON OFF FUNCTION (i1F or i2F = onF)

To switch the controller on and off.

8.10 DIGITAL INPUTS POLARITY

The digital input polarity depends on the i1P and i2P parameters.

- i1P or i2P =CL: the input is activated by closing the contact.

- i1P or i2P=OP: the input is activated by opening the contact.

9. TTL SERIAL LINE – FOR MONITORING SYSTEMS

The TTL serial line, availabl e through the HOT K EY connector, all ows by means of th e external

TTL/RS485 co nverter, XJ485-CX, to connect the i nstrum ent to a mo nitoring sy stem ModBUS-RTU

compatible such as the X-WEB500/3000/300.

10. X-REP OUTPUT – OPTIONAL

As optional, an X-REP can be connected to the instrument, trough the dedicated connector.

To connect the X-REP to the

instrument the following

connectors must be used

CAB/REP1(1m), CAB/REP2

(2m), CAB/REP5 (5m),

11. INSTALLATION AND MOUNTING

The XW60LH s hall b e mou nted o n ver tical pan el, in a 15 0x31 mm h ole, a nd fix ed us ing t he spec ial

brackets sup plied wit h the contr ollers. The t emperature r ange all owed for corr ect opera tion is 0 to

60°C. Avoid places subject t o strong vibratio ns, corrosive gas es, excessive dirt or humidity. The

same recommendations apply to probes. Let the air circulate by the cooling holes.

11.1 CUT OUT

12. ELECTRICAL CONNECTIONS

The instrument s are pr ovi ded wi th scre w termi nal bl ock to c onnec t cabl es wi th a cros s sect ion up t o

2.5 mm

2

for the di gital and analog ue inputs. Rel ays and power s upply have a Fast on connection

(6.3mm). Heat-resi stant cables have t o be used. Before con necting cables mak e sure the power

supply compli es with the instrument’ s requirements. Separ ate the probe cables from t he power

supply cables , from the o utputs and the power connec tions. Do no t exceed the m aximum curre nt

allowed on each relay, in case of heavier loads use a suitable external relay.

N.B. Maximum current allowed for all the loads is 20A.

12.1 PROBE CONNECTION

The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid

infiltratio n. It is recommended to pl ace the thermostat probe away from air str eams to correctly

measure the av erage r oom temp eratur e. Plac e the def rost term inati on probe among t he eva porator

fins in the cold es t pl ac e , w here most ice is for med, far from heaters or from the warmest pl ace during

defrost, to prev ent premature d efr ost terminati o n.

13. HOW TO USE THE HOT KEY

13.1 PROGRAM A HOT KEY FROM AN INSTRUMENT (UPLOAD)

1. Program one controller with the front keypad.

2. When the contr oller is ON, insert the “HOT-KEY” and push UP button; the “uPL” message

appears followed a by a flashing “End” label.

3. Push SET button and the “End” will stop flashing.

4. Turn OFF the instrument, remov e t h e “HOT-KEY” and then turn it ON again.

NOTE: the “Err” mes sage appears in c ase of a failed progr amming operation. In thi s case push

again button if you want to restart the upload again or remove the “HOT-KEY” to abort the operation.

13.2 PROGRAM AN INSTRUMENT BY USING A HOT KEY (DOWNLOAD)

1. Turn OFF the instrument.

2. Insert a pre-programmed “HOT-KEY” into the 5-P IN receptacle and then turn the Controll er

ON.

3. The parameter l ist of the “HOT-KEY” will be autom atically downloade d into the Controller

memory. The “doL” message will bli nk followed a by a flashing “End” label.

4. After 10 seconds th e instrument wil l restart working wit h th e new parameters.

5. Remove the “HOT-KEY”.

NOTE: the m es sa ge “Err” is displaye d for f ail ed pro gramm in g. In t his cas e t urn the u nit off an d then

on if you want to restart the download again or remove the “HOT-KEY” to abor t t he o peration.

14. ALARM SIGNALS

Message

Cause

Outputs

P1

Room probe failure

Compressor output acc. to par . Con and CoF

P2

Evaporator pro be failure

Defrost end is timed

P3

Third probe failure

Outputs unchanged

P4

Fourth probe failure

Outputs unchanged

HA

Maximum temperature alarm

Outputs unchanged.

LA

Minimum temperature alarm

Outputs unchanged.

HA2

Condenser high temperature

It depends on the AC2 parameter

LA2

Condenser low temperature

It depends on the bLL parameter

dA

Door open

Compressor and fans restarts

1592036000 XW60LH GB r1.0 18.03.2015 XW60LH 4/6

Page 5

Message

Cause

Outputs

EA

External alarm

Output unchanged.

CA

Serious extern al alarm (i1F=bA L)

All outputs OFF.

CA

Pressure switch alarm (i1F=PAL)

All outputs OFF

rtC Real time clock alarm

Alarm output ON; Other outputs unchanged;

Defrosts accor ding to par. idF Set real time clock

has to be set.

rtF Real time clock board failure

Alarm output ON; Other outputs unchanged;

Defrosts accor ding to par. idF. Contact the

service.

14.1 SILENCING BUZZER / ALARM RELAY OU TPUT

- tbA=Y: the buzzer and the relay are is silenced by pressing any key.

- tbA=n: onl y the buzzer is silenc ed while the alarm rel ay is on until the alar m condition

recovers.

14.2 ALARM RECOVERY

Probe alarms P1, P2, P3 and P4 start som e seconds after the fault in the relate d probe; they

automatically stop some sec onds after the probe restarts normal operation. Check connections

before replaci n g the probe.

Temperature al arm s HA, LA, HA2 and LA2 automatically stop as soon as the temperature returns to

normal values.

Alarms EA and CA (with i1F=bAL) recover as soon as the digital input is disabled.

Alarm CA (with i1F=PAL) recovers only by switching off and on the instrument.

14.3 OTHER MESSAGES

on

Keyboard enabled after automatic lock.

LOC

Keyboard automatically locked

Pon

Keyboard unl ock ed.

PoF

Keyboard locked

noP

In programming mode: none parameter is present in Pr1

On the display or in dP2, dP3, dP4: the selected probe is nor enabled

15. TECHNICAL DATA

Housing: self extinguishing ABS

Case: facia 38x185 mm; depth [XW60LH: 76mm],

Mounting: panel mounting in a 150x31 mm panel cut-out with the 2 metal brackets supplied

Protection: IP20

Frontal protection: IP65

Connections: screw terminal block

≤ 2.5 mm

2

heat-resistant wirin g an d 6.3mm Faston

Power supply: 230Vac or. 120Vac or 24Vac

± 10%

Power absorption: 9VA max

Display: 3 digit s , white LED, 14.2 mm high

Inputs: Up to 4 NTC or PTC probes

Digital inputs: 2 free voltage

Relay outputs for XW60LH models: Total current on loads MAX. 20A

Compressor: relay SPST 20(8) A, 250Vac

Light: relay SPST 8 or 16(3) A, 250Vac

Fans: relay SPST 8(3) A, 250Vac

Defrost: relay SPST 8(3) A, 250Vac

Other output: buzzer

Serial output: TTL standard

Communication protocol: Modbus - RTU

Data storing: on the non-volatile memory (EEPROM)

Internal clock back-up: 24 hours (only for model with RTC)

Kind of action: 1B

Pollution degree: 2

Software clas s: A

Rated impulsive voltage: 2500V

Over voltage Category: II

Operating temperature: 0 to 60 °C (32 to 140°F)

Storage temperature: -30 to 85°C (-22 to 185°F).

Relative humidity: 20 to 85% (not condensing)

Measuring and regulation range:

NTC probe: -40 to 110°C (-40 to 230°F)

PTC probe: -50 to 150°C (-58 to 302°F)

Resolution: 0.1°C or 1°C or 1°F (selectable)

Accuracy (ambient temp. 25°C): ±0.7°C ±1 digit

16. CONNECTIONS

16.1 XW60LH

Supply: 120Vac or 24Vac: connect to terminals 11-12

The X-REP output is optional

The light relay can be also 16(5)A according to the model

17. DEFAULT SETTING VA LUES

Label

Name

Range

°C/°F

Level

Set

Set point

LS÷US

-5.0

- - -

rtc*

Real time clock menu

-

-

Pr1

Hy

Differential

0,1÷25.5°C/ 1÷ 255°F

2.0

Pr1

LS

Minimum set point

-50°C÷SET/-58°F÷SET

-50.0

Pr2

US

Maximum set point

SET÷110°C/ SET ÷ 230°F

110

Pr2

Ot

Thermostat probe calibration

-12÷12°C /-120÷120°F

0.0

Pr1

P2P

Evaporator probe presence

n=not present; Y=pres.

Y

Pr1

Label

Name

Range

°C/°F

Level

OE

Evaporator probe calibration

-12÷12°C /-120÷120°F

0.0

Pr2

P3P

Third probe presence

n=not present; Y=pres.

n

Pr2

O3

Third probe calibration

-12÷12°C /-120÷120°F

0

Pr2

P4P

Fourth probe presence

n=not present; Y=pres.

n

Pr2

O4

Fourth probe calibration

-12÷12°C /-120÷120°F

0

Pr2

OdS

Outputs delay at start up

0÷255 min

0

Pr2

AC

Anti-short cycle delay

0 ÷ 50 min

1

Pr1

Ac1

Second compressor start delay

0÷255s

5

Pr2

rtr

P1-P2 percentage for regulation

0 ÷ 100 (100=P1 , 0=P2)

100

Pr2

CCt

Continuous cycle duration

0.0÷24.0h

0.0

Pr2

CCS

Set point for continuous cycle

(-55.0÷150,0°C) (-67÷302°F)

-5

Pr2

COn

Compressor ON time with faulty probe

0 ÷ 255 min

15

Pr2

COF

Compressor OFF time with faulty probe

0 ÷ 255 min

30

Pr2

CF

Temperature measurement unit

°C ÷ °F

°C

Pr2

rES

Resolution

in=integer; dE= dec.point

dE

Pr1

Lod

Probe displayed

P1;P2

P1

Pr2

rEd2 X-REP display

P1 – P2 – P3 – P4 – SEt – dtr

P1

Pr2

dLy

Display temperature delay

0 ÷ 20.0 min (10 sec.)

0.0

Pr2

dtr

P1-P2 percentage for display

1 ÷ 99

50

Pr2

EdF*

Kind of interval for defrost

rtc ÷in

in

Pr2

tdF

Defrost type

EL=el. heater; in= hot gas

EL

Pr1

dFP

Probe selection for defrost termination

nP; P1; P2; P3; P4

P2

Pr2

dtE

Defrost termination temperature

-50 ÷ 50 °C

8

Pr1

IdF

Interval between defrost cycles

1 ÷ 120 ore

6

Pr1

MdF

(Maximum) length for defrost

0 ÷ 255 min

30

Pr1

dSd

Start defrost delay

0÷99min

0

Pr2

dFd

Displaying during defrost

rt, it, SEt, DEF

it

Pr2

dAd

MAX display delay after defrost

0 ÷ 255 min

30

Pr2

Fdt

Draining time

0÷120 min

0

Pr2

dPo

First defrost after start-up

n=after IdF; y=immed.

n

Pr2

dAF

Defrost delay after fast freezing

0 ÷ 23h e 50’

0.0

Pr2

Fnc

Fan operating mode

C-n, o-n, C-y, o-Y

o-n

Pr1

Fnd

Fan delay after defrost

0÷255min

10

Pr1

Fct

Differential of temperature for forced activation

of fans

0÷50°C

10 Pr2

FSt

Fan stop temperature

-50÷50°C/-58÷122°F

2

Pr1

Fon

Fan on time with compressor off

0÷15 (min.)

0

Pr2

FoF

Fan off time with compressor off

0÷15 (min.)

0

Pr2

FAP

Probe selection for fan management

nP; P1; P2; P3; P4

P2

Pr2

ACH

Kind of action for auxiliary relay

CL; Ht

cL

Pr2

SAA

Set Point for auxiliary relay

-50,0÷110°C / -58÷230°F

0,0

Pr2

SHy

Differential for auxiliary relay

0,1÷25.5°C/ 1÷ 255°F

2,0

Pr2

ArP

Probe selection for auxiliary relay

nP / P1 / P2 / P3/P4

nP

Pr2

Sdd

Auxiliary relay operating during defrost

n÷y

n

Pr2

ALP

Alarm probe selection

nP; P1; P2; P3; P4

P1

Pr2

ALc

Temperat. alarms configuration

rE= related to set;

Ab = absolute

Ab Pr2

ALU

MAXIMUM temperature alarm

Set÷110.0°C; Set÷230°F

110,0

Pr1

ALL

Minimum temperature alarm

-50.0°C÷Set/ -58°F÷Set

-50,0

Pr1

AFH

Differential for temperat. alarm recovery

(0,1°C÷25,5°C) (1°F÷45°F)

2,0

Pr2

ALd

Temperature alarm delay

0 ÷ 255 min

15

Pr2

dAO

Delay of temperature alarm at start up

0 ÷ 23h e 50’

1,3

Pr2

AP2

Probe for temperat. alarm of condenser

nP; P1; P2; P3; P4

P4

Pr2

AL2

Condenser for low temperat. alarm

(-55 ÷ 150°C) (-67÷ 302°F)

-40

Pr2

AU2

Condenser for high temperat. alarm

(-55 ÷ 150°C) (-67÷ 302°F)

110

Pr2

AH2

Differ. for condenser temp. alar. recovery

[0,1°C ÷ 25,5°C] [1°F ÷ 45°F]

5

Pr2

Ad2

Condenser temperature alarm delay

0 ÷ 254 (min.) , 255=nU

15

Pr2

dA2

Delay of cond. temper. alarm at start up

0.0 ÷ 23h 50’

1,3

Pr2

bLL

Compr. off for condenser low temperature alarm

n(0) - Y(1)

n

Pr2

AC2

Compr. off for condenser high temperature

alarm

n(0) - Y(1)

n Pr2

tbA

Alarm relay disabling

n=no; y=yes

y

Pr2

oA3

Fourth relay configuration

ALr = alarm; dEF = do not select it;

Lig =Light; AUS =AUX; onF=always

on; Fan= do not select it; db =

neutral

zone; cP2 = second compressor; dF2

= do not select it; HES = night blind

Lig Pr2

AoP

Alarm relay polarity (oA3=ALr)

oP; cL

cL

Pr2

i1P

Digital input polarity (13-14)

oP=opening;CL=closing

cL

Pr1

i1F

Digital input 1 configuration (13-14)

EAL, bAL, PAL, dor; dEF; Htr, AUS

dor

Pr1

did

Digital input alarm delay (13-14)

0÷255min

15

Pr1

i2P

Digital input polarity (13-19)

oP=opening;CL=closing

cL

Pr2

i2F

Digital input configuration (13-19)

EAL, bAL, PAL, dor; dEF; Htr, AUS

EAL

Pr2

d2d

Digital input alarm delay (13-19)

0÷255min

5

Pr2

Nps

Number of activation of pressure switch

0 ÷15

15

Pr2

odc

Compress and fan status when open door

no; Fan; CPr; F_C

F-c

Pr2

rrd

Regulation restart with door open alarm

n – Y

y

Pr2

HES

Differential for Energy Saving

(-30°C÷30°C) (-54°F÷54°F)

0

Pr2

Hur*

Current hour

0 ÷ 23

-

rtc

Min*

Current minute

0 ÷ 59

-

rtc

dAY*

Current day

Sun ÷ SAt

-

rtc

Hd1*

First weekly holiday

Sun÷ SAt – nu

nu

rtc

Hd2*

Second weekly holiday

Sun÷ SAt – nu

nu

rtc

ILE*

Energy Saving cycle start during workdays

0 ÷ 23h 50 min.

0

rtc

dLE*

Energy Saving cycle length during workdays

0 ÷ 24h 00 min.

0

rtc

ISE*

Energy Saving cycle start on holidays

0 ÷ 23h 50 min.

0

rtc

dSE*

Energy Saving cycle length on holidays

0 ÷ 24h 00 min.

0

rtc

Ld1*

1st workdays defrost start

0 ÷ 23h 50 min. - nu

6.0

rtc

Ld2*

2nd workdays defrost start

0 ÷ 23h 50 min. - nu

13.0

rtc

Ld3*

3rd workdays defrost start

0 ÷ 23h 50 min. - nu

21.0

rtc

Ld4*

4th workdays defrost start

0 ÷ 23h 50 min. - nu

0.0

rtc

Ld5*

5th workdays defrost start

0 ÷ 23h 50 min. - nu

0.0

rtc

Ld6*

6th workdays defrost start

0 ÷ 23h 50 min. - nu

0.0

rtc

Sd1*

1st holiday defrost start

0 ÷ 23h 50 min. - nu

6.0

rtc

Sd2*

2nd holiday defrost start

0 ÷ 23h 50 min. - nu

13.0

rtc

Sd3*

3rd holiday defrost start

0 ÷ 23h 50 min. - nu

21.0

rtc

Sd4*

4th holiday defrost start

0 ÷ 23h 50 min. - nu

0.0

rtc

Sd5*

5th holiday defrost start

0 ÷ 23h 50 min. - nu

0.0

rtc

Sd6*

6th holiday defrost start

0 ÷ 23h 50 min. - nu

0.0

rtc

Adr

Serial address

1÷247

1

Pr2

PbC

Kind of probe

Ptc; ntc

ntc

Pr2

onF

on/off key enabling

nu, oFF; ES

oFF

Pr2

1592036000 XW60LH GB r1.0 18.03.2015 XW60LH 5/6

Page 6

Label

Name

Range

°C/°F

Level

dP1

Room probe display

--

-

Pr2

dP2

Evaporator probe display

--

-

Pr2

dP3

Third probe display

--

-

Pr2

dP4

Fourth probe display

--

-

Pr2

rSE

Real set

actual set

-

Pr2

rEL

Software release

--

1.8

Pr2

Ptb

Map code

--

Pr2

* Only for model with real time clock

2

Only for XW60LH with X-REP output

1592036000 XW60LH GB r1.0 18.03.2015 XW60LH 6/6

Loading...

Loading...