Page 1

Next Generation Critical Cooling

for Room and Row

Liebert PEX

Effi ciency And Reliability For High Availability Cooling

Chilled Water Models

User Manual

Page 2

Liebert.PEX Chilled Water Series Air Conditioner

User Manual

Version V1.1

Revision date May 6, 2010

BOM 31011830

Emerson Network Power provides customers with technical support. Users may contact the

nearest Emerson local sales office or service center.

Copyright © 2010 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Page 3

Page 4

Contents

Chapter 1 Overview ........................................................................................................................................................... 1

1.1 Model Description ............................................................................................................................................... 1

1.2 Main Components ............................................................................................................................................... 1

1.3 Remote Monitoring Software ............................................................................................................................. 2

1.4 Environmental Requirements ............................................................................................................................ 2

1.4.1 Operation Environment ........................................................................................................................... 2

1.4.2 Storage Environment .............................................................................................................................. 3

Chapter 2 Mechanical Installation ................................................................................................................................... 4

2.1 Installation Preparation ...................................................................................................................................... 4

2.1.1 Transportation And Movement ............................................................................................................... 4

2.1.2 Unpacking ................................................................................................................................................ 4

2.1.3 Inspection ................................................................................................................................................. 5

2.1.4 Installation Notes ..................................................................................................................................... 6

2.2 System Installation Arrangement ...................................................................................................................... 6

2.2.1 General Arrangement .............................................................................................................................. 6

2.2.2 Mechanical Parameters ........................................................................................................................... 7

2.3 Installing Chilled Water AC Unit ...................................................................................................................... 14

2.3.1 Installation Requirement ....................................................................................................................... 14

2.3.2 Installation Procedures ......................................................................................................................... 15

2.4 Piping ................................................................................................................................................................. 19

2.5 Removing Transport Fastener And Vibration Absorber ................................................................................ 21

2.6 Adjusting Water Level Regulator ..................................................................................................................... 24

2.7 Installation Inspection ...................................................................................................................................... 25

Chapter 3 Electric Installation ........................................................................................................................................ 26

3.1 Work Introduction And Installation Notes ...................................................................................................... 26

3.2 Wiring Of Chilled Water AC Unit ...................................................................................................................... 26

3.2.1 Locating Electrical Interfaces ............................................................................................................... 26

3.2.2 Connecting Power Cable Of Chilled Water AC Unit............................................................................ 27

3.2.3 Connecting Control Cables .................................................................................................................. 28

3.3 Installation Inspection ...................................................................................................................................... 29

Chapter 4 System Start-Up Commissioning ................................................................................................................. 30

4.1 Locating MCBs .................................................................................................................................................. 30

4.2 Start-Up Commissioning .................................................................................................................................. 32

4.2.1 Preparation Before Commissioning..................................................................................................... 32

4.2.2 Commissioning Procedures ................................................................................................................. 32

4.2.3 Inspection After Commissioning ......................................................................................................... 33

Chapter 5 iCOM Controller ............................................................................................................................................. 34

5.1 LCD .................................................................................................................................................................... 34

5.2 Button And Indicator Panel .............................................................................................................................. 34

5.3 Structure Chart Of Control Menu ..................................................................................................................... 36

Page 5

5.4 Startup Interface ............................................................................................................................................... 36

5.5 Main Interface .................................................................................................................................................... 36

5.6 USER MENUS .................................................................................................................................................... 37

5.6.1 PASSWORD ........................................................................................................................................... 37

5.6.2 SETPOINTS ............................................................................................................................................ 37

5.6.3 EVENT LOG ............................................................................................................................................ 37

5.6.4 GRAPHICS .............................................................................................................................................. 39

5.6.5 SET ALARMS ......................................................................................................................................... 39

5.6.6 SENSOR DATA ...................................................................................................................................... 40

5.6.7 DISPLAY SETUP .................................................................................................................................... 41

5.6.8 TOTAL RUN HRS ................................................................................................................................... 42

5.6.9 SLEEP MODE ......................................................................................................................................... 43

5.6.10 SERVICE INFO ..................................................................................................................................... 43

5.6.11 ACTIVE ALARMS ................................................................................................................................. 43

5.7 SERVICE MENUS .............................................................................................................................................. 43

5.7.1 PASSWORD LEVEL ............................................................................................................................... 44

5.7.2 SETPOINTS ............................................................................................................................................ 44

5.7.3 STANDBY ............................................................................................................................................... 45

5.7.4 WELLNESS ............................................................................................................................................. 45

5.7.5 DIAGNOSTICS ........................................................................................................................................ 48

5.7.6 SET ALARMS ......................................................................................................................................... 50

5.7.7 CALIBRATION ........................................................................................................................................ 52

5.7.8 NETWORK SETUP ................................................................................................................................. 52

5.7.9 OPTIONS SETUP ................................................................................................................................... 53

5.7.10 SERVICE INFO ..................................................................................................................................... 54

5.8 ADVANCED MENUS .......................................................................................................................................... 54

5.8.1 PASSWORD LEVEL ............................................................................................................................... 54

5.8.2 FACTORY SETUP .................................................................................................................................. 55

5.9 MBV Settings ..................................................................................................................................................... 59

5.10 EVENT NAME AND DEFINITION .................................................................................................................... 60

Chapter 6 Application Of INTELLISLOT ........................................................................................................................ 64

6.1 Introduction Of Host Communication Card .................................................................................................... 64

6.2 Installing Host Communication Card .............................................................................................................. 65

6.3 Commissioning Host Communication Component ....................................................................................... 65

6.3.1 Setting HyperTerminal .......................................................................................................................... 66

6.3.2 Setting 485 Communication Card ........................................................................................................ 67

6.3.3 Setting TCP/IP Communication Card ................................................................................................... 68

6.3.4 Setting SNMP Parameters Of TCP/IP Communication Card .............................................................. 70

6.4 Host Communication Networking Diagram .................................................................................................... 73

Chapter 7 System Operation And Maintenance ........................................................................................................... 74

7.1 System Diagnosis Test ..................................................................................................................................... 74

7.1.1 Self-diagnosis Function ........................................................................................................................ 74

7.1.2 Electric Control Part .............................................................................................................................. 74

7.2 Filter ................................................................................................................................................................... 75

7.3 Fan Kit ................................................................................................................................................................ 76

Page 6

7.3.1 Fan Bearing And Blades ....................................................................................................................... 76

7.3.2 Belt .......................................................................................................................................................... 76

7.3.3 Motor....................................................................................................................................................... 76

7.4 Infrared Humidifier ............................................................................................................................................ 76

7.5 Electrical Heater ................................................................................................................................................ 78

7.6 Water Flow Control Valve ................................................................................................................................. 79

Chapter 8 Failure Diagnosis And Troubleshooting ...................................................................................................... 80

Appendix 1 The Structure Chart Of Electric Control Box ............................................................................................ 83

Appendix 2 Circuit Diagram ........................................................................................................................................... 86

Appendix 3 The Structure Chart Of Micro-processing Controller Menu .................................................................... 87

Page 7

Page 8

Chapater 1 Overview 1

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Chapter 1 Overview

The Liebert.PEX chilled water air conditioner (chilled water AC for short) is a medium-large sized precision

environment control system configured with electrical heater and humidifier, suitable for the environment

control of the equipment room or computer room. It uses the chilled water supplied by the cooling water units.

It aims to provide a sound operation environment for precision equipment, such as sensitive equipment,

industry processing equipment, communication equipment and computers.

This chapter introduces the model description, main components and environmental requirements of chilled

water AC.

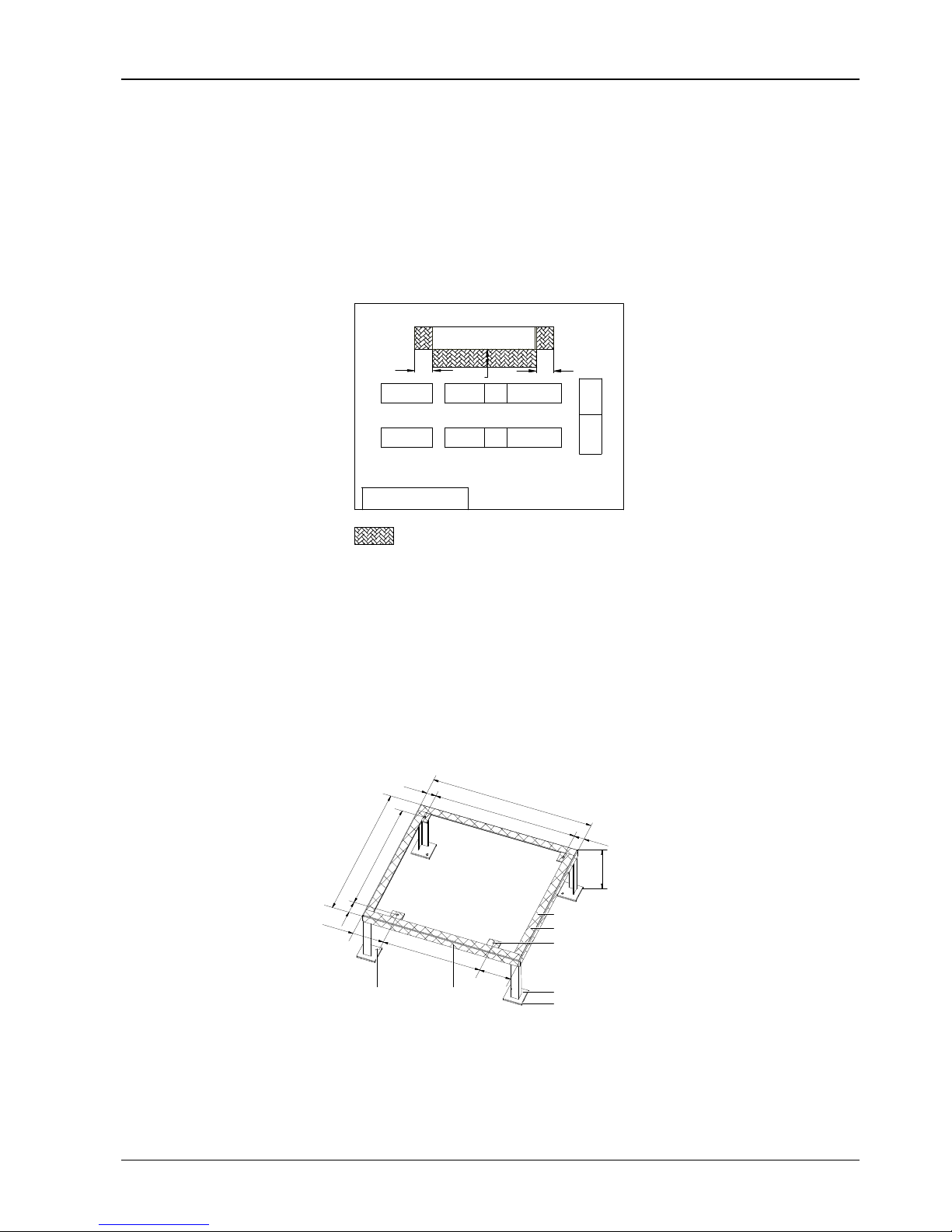

1.1 Model Description

The model description of the chilled water AC is shown in Figure 1-1.

P31

10VC2MS1RZ0

0

12345

678

9

10 11 12 13 14 15

Global PEX Chilled Water Model Nomenclature

Product R ang e

P

PEX

No. Modules-Bays/Fans

1

2

3

One

Two

Three

Nominal kW

20, 30, 40 to 150

Air Path

F

G

U

V

D

Downflo w (Forward Curve)

Downflow (EC Backward Curve)

Upflow (Forward Curve)

Upflow (EC Backward Curve)

Upflow Ducted (Forward Curve)

Cooling Type

C

Chilled W ater

Cooling Control

2

3

2 way CWV, CW, zero compressors

3 way CWV, CW, zero compressors

Voltage

M

400/3/50

iCOM Display

S

L

Small Disp lay

Large Display

Reheat Type

1

2

0

None

1 Stage

2 Stage

Humidifier

0

S

R

None

Infrared

Steam Ge nerating

Fac tor y C o nf igura ti o n Number

Z

A-Z

A-Z

Aust ralia & Ne w Ze aland

Options

Options

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Figure 1-1 Model description

1.2 Main Components

The chilled water AC unit includes heat exchanger, infrared humidifier, fan, electrical heater, water flow

control valve and micro-processing controller.

Heat exchanger

Use finned-tube heat exchanger with high heat emission efficiency. The model-specific distributions can

ensure the even distribution of chilled water in each loop and greatly improve the efficiency of the heat

exchanger, as well as minimize the water resistance of heat exchanging coil.

Page 9

2 Chapter 1 Overview

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Infrared humidifier

Configure with infrared humidifier which is easy for teardown, cleaning and maintenance. It is adjustable to a

wide range of water qualities, with fast startup and high humidifying efficiency.

Fan

Use forward centrifugal fan with high efficiency and reliability, large airflow and long blowing distance. With

the belt transmission mechanism, it is easy for maintenance. The user can also select electronically

commutated (EC for short) fan with backward blades. EC fan is energy-saving and space-saving with high

efficiency and low noise. It is also subject to stepless speed regulation. For the structure of EC fan downflow

unit, the solution of air supply by putting fan unit under floor is considered, which can significantly improve

the efficiency of air supply.

Electrical heater

Use screw finned U type stainless steel electrical heating tube, with fast heating speed and evenly distributed

heat volume.

Water flow control valve

The water flow control valve can adjust the chilled water flow quantity according to the cooling requirement. It

is connected to the system pipes with live joints, easy for field installation and maintenance, thus reducing

the project installation cost.

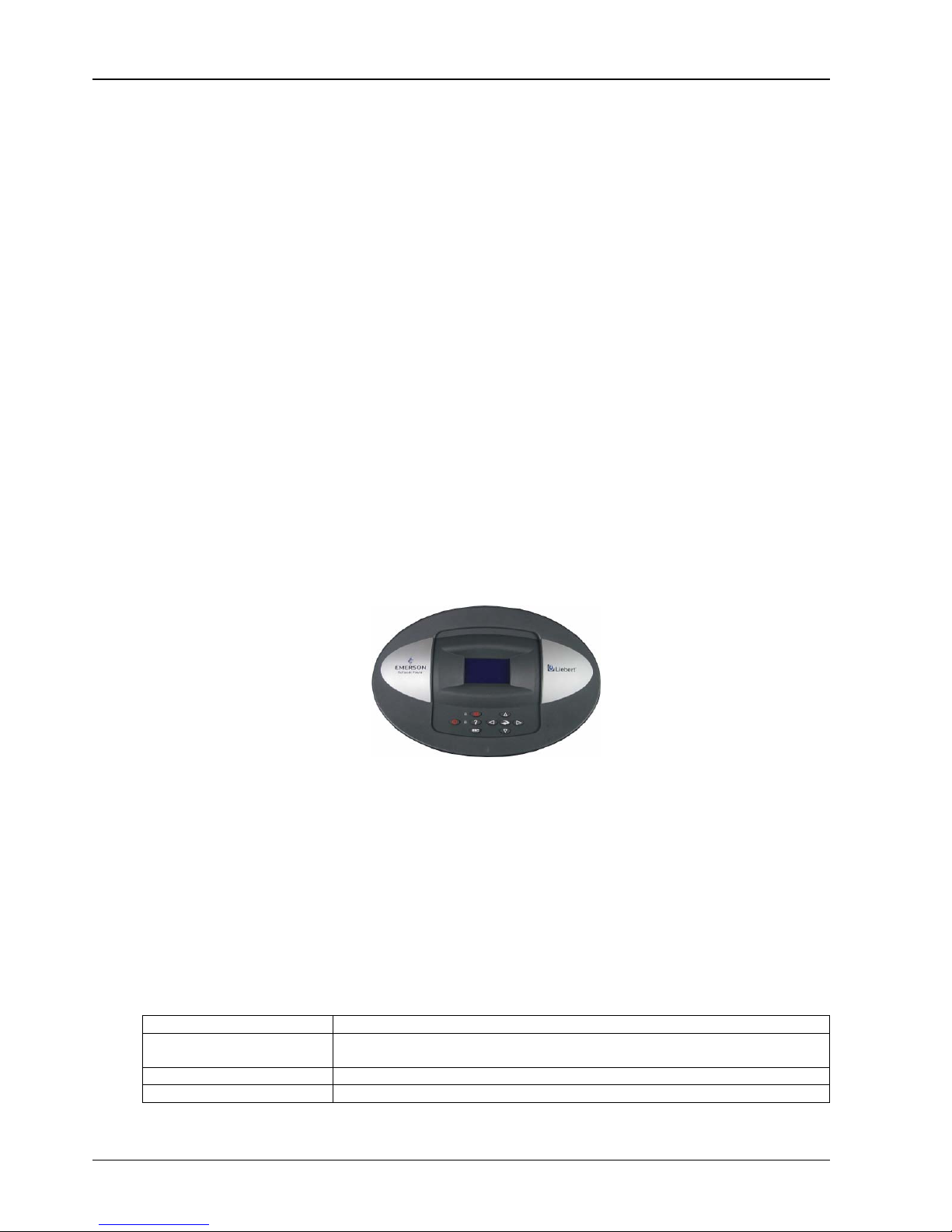

Micro-processing controller

The micro-processing controller of the chilled water AC uses an LCD screen with blue backlight and 128 × 64

dots. The user interface operation is simple. The multi-level password protection can effectively prevent

illegal operation. It also features power failure auto-restoration and high / low voltage protection function. The

operation time of components is available through the menus. The expert-level fault diagnosis system can

display the current fault information automatically, facilitating the maintenance. It can store up to 400 records

of historical events. The panel of micro-processing controller is shown in Figure 1-2.

Figure 1-2 Micro-processing controller panel

1.3 Remote Monitoring Software

The chilled water AC can communicate with the host computer through a configured communication port to

receive the control of the host software.

1.4 Environmental Requirements

1.4.1 Operation Environment

See Table 1-1 for details.

Table 1-1 Operation environment requirement

Item Requirement

Operation range

Indoor temperature: 4°C ~ 40°C

Chilled water supply temperature: 5°C ~ 13°C

Altitude < 1000m. Above that, derating is required

Operation voltage range 400V (-10% ~ +10%), three-phase AC, 50Hz

Page 10

Chapater 1 Overview 3

Liebert.PEX Chilled Water Series Air Conditioner User Manual

1.4.2 Storage Environment

See Table 1-2 for details.

Table 1-2 Storage environment requirement

Item Requirement

Storage environment Indoor, clean, no dust

Ambient humidity 5%RH ~ 85%RH (non-condensing)

Ambient temperature -20°C ~ +54°C

Storage time

Total transportation and storage time should not exceed 6 months. Otherwise, the performance

needs to be re-evaluated

Page 11

4 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Chapter 2 Mechanical Installation

This chapter introduces the mechanical installation of the chilled water AC, including the transportation and

movement, unpacking, inspection, installation notes and installation procedures.

2.1 Installation Preparation

2.1.1 Transportation And Movement

Railroad transportation and shipping are the recommended means of transportation. If truck transportation is

unavoidable, choose roads that are less bumpy in order to protect the equipment.

The chilled water AC is heavy (see Table 2-1 for the weight parameters). It is recommended to use a

mechanical handbarrow such as an electric forklift when unpacking and moving the equipment to the place

closest to the installation site. Insert the tines of the forklift below the pallet, as shown in Figure 2-1. Align the

tines with the center of gravity to prevent the unit from falling over.

Figure 2-1 Fork direction

Keep the obliquity within 75° ~ 105° during the movement, as shown in Figure 2-2. Extreme incline is not

allowed.

1

0

5

7

5

Figure 2-2 Moving obliquity

2.1.2 Unpacking

Move the equipment to the place closest to the final installation site and then unpack it.

Follow the procedures below to unpack the unit:

1. Removing the side boards and top cover

The chilled water AC uses international packaging. You can use a hammer or straight screwdriver to

straighten the hook, as shown in Figure 2-3.

Page 12

Chapter 2 Mechanical Installation 5

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Figure 2-3 Straightening the hook

At first, straighten all the hooks that fix side board I, and remove side board I. Then straighten all the hooks

that fix side board II, and remove side board II. At last remove top cover III, as shown in Figure 2-4.

Kg

1790 x 950 x 2020mm

1816 x 976 x 2175mm

I

I

III

II

II

Figure 2-4 Removing side boards and top cover

2. Removing the pallet

The chilled water AC is fixed onto the pallet with M10 × 70 screws, as shown in Figure 2-5. You can use an M10

open-end spanner, a ratchet spanner or a sleeve to remove the fixing screws.

底板固

定

Pallet fixing screw (M10 70)

×

Figure 2-5 Fixing screw position of pallet

2.1.3 Inspection

After receiving the product, you should check it against the packing list. If any parts are found missing,

distorted or damaged, please report to the carrier immediately. If any covert defects are found, please report

to the carrier and the local office of Emerson Network Power Co., Ltd.

Page 13

6 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

2.1.4 Installation Notes

To realize the designed performance and maximum product life, correct installation is vital. This section

should be used in conjunction with local industry standards for mechanical and electrical installations. Note

the following items:

1. The chilled water AC is designed for integrated floor installation. It should be installed on the floor of the

equipment room or computer room.

2. Before the installation, make sure that the installation environment meets the requirements (see 1.4

Environmental Requirements) and the building should be transformed to accommodate the construction work

of piping, wiring and ventilation ducts.

3. Follow the design drawings strictly when installing the equipment, and reserve the space for maintenance.

The engineering dimensions drawings provided by the manufacturer can serve as a reference.

2.2 System Installation Arrangement

2.2.1 General Arrangement

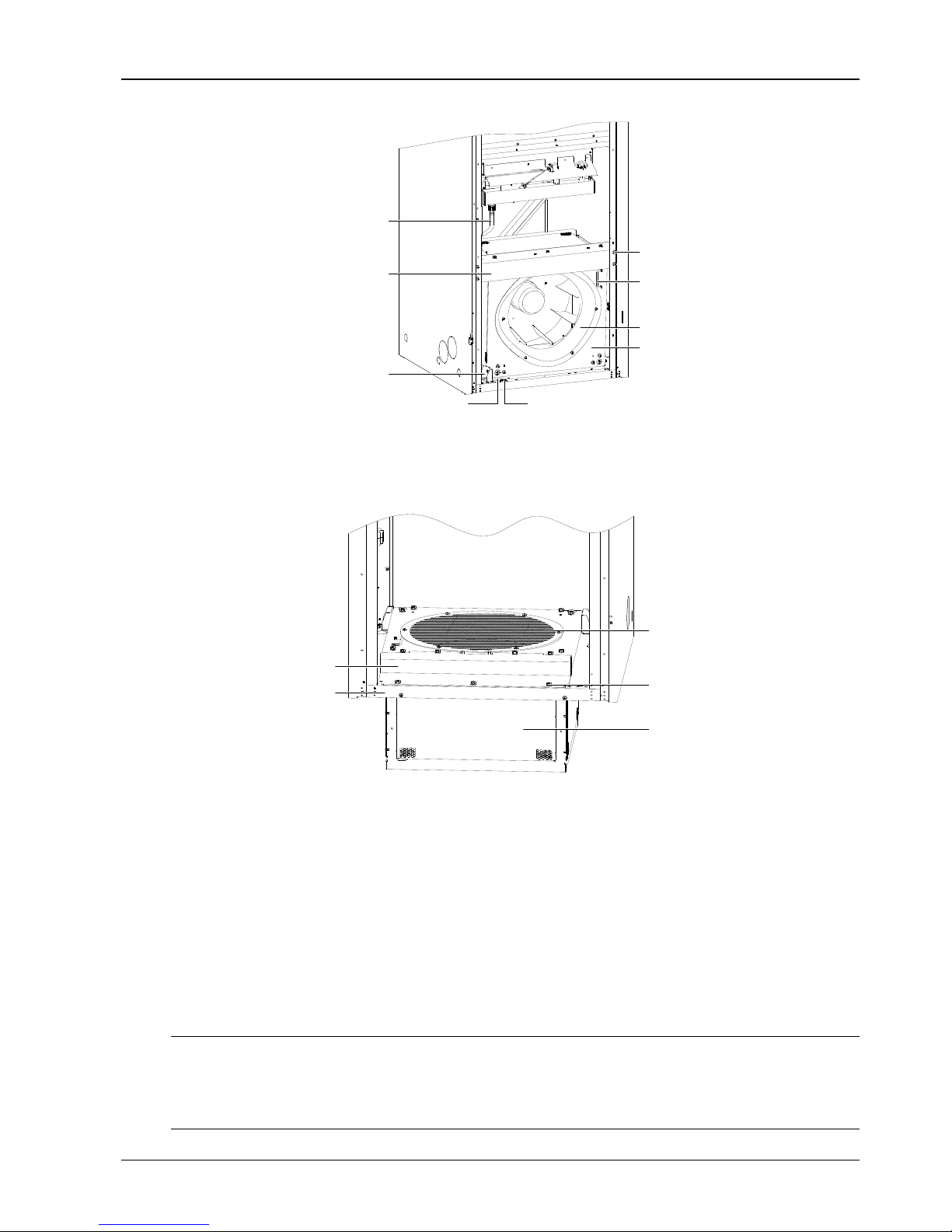

The general arrangement of the chilled water AC is shown in Figure 2-6.

Chille d wate r i nlet

Chille d wate r o utlet

Blance valve or iso lation valve*

Water filler

Isolation

valve

Drain valve

Hose

interf ac e

Welding interface of chilled

water inlet and outlet

Water flow regulating valve

BPH E coil

Exhaust valve

Balancing valve or is olatio n valve*

Water filter

Figure 2-6 General arrangement diagram

Note

1. : Factory piping.

2.

: Field piping (by technicians).

3. *: Components are not supplied by Emerson but are recommended for proper circuit operation and maintenance.

4. After the project installation, exhaust the AC unit before filling water to ensure the efficiency of the heat exchanger.

5. In winter, the AC unit in northern area does not operate for a long term; you must empty the water in AC unit to protect the

heat exchanger from frost cracking.

Page 14

Chapter 2 Mechanical Installation 7

Liebert.PEX Chilled Water Series Air Conditioner User Manual

2.2.2 Mechanical Parameters

Dimensions

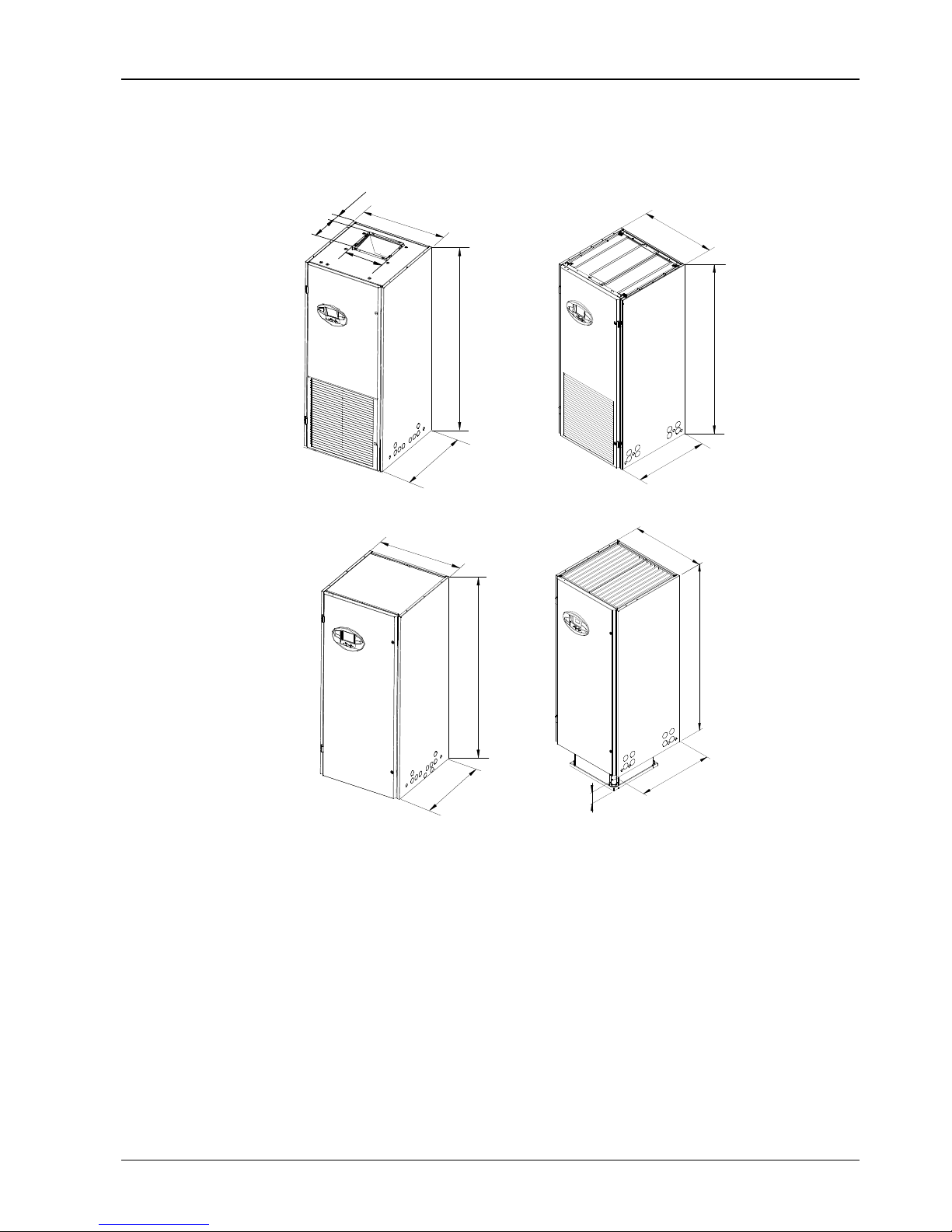

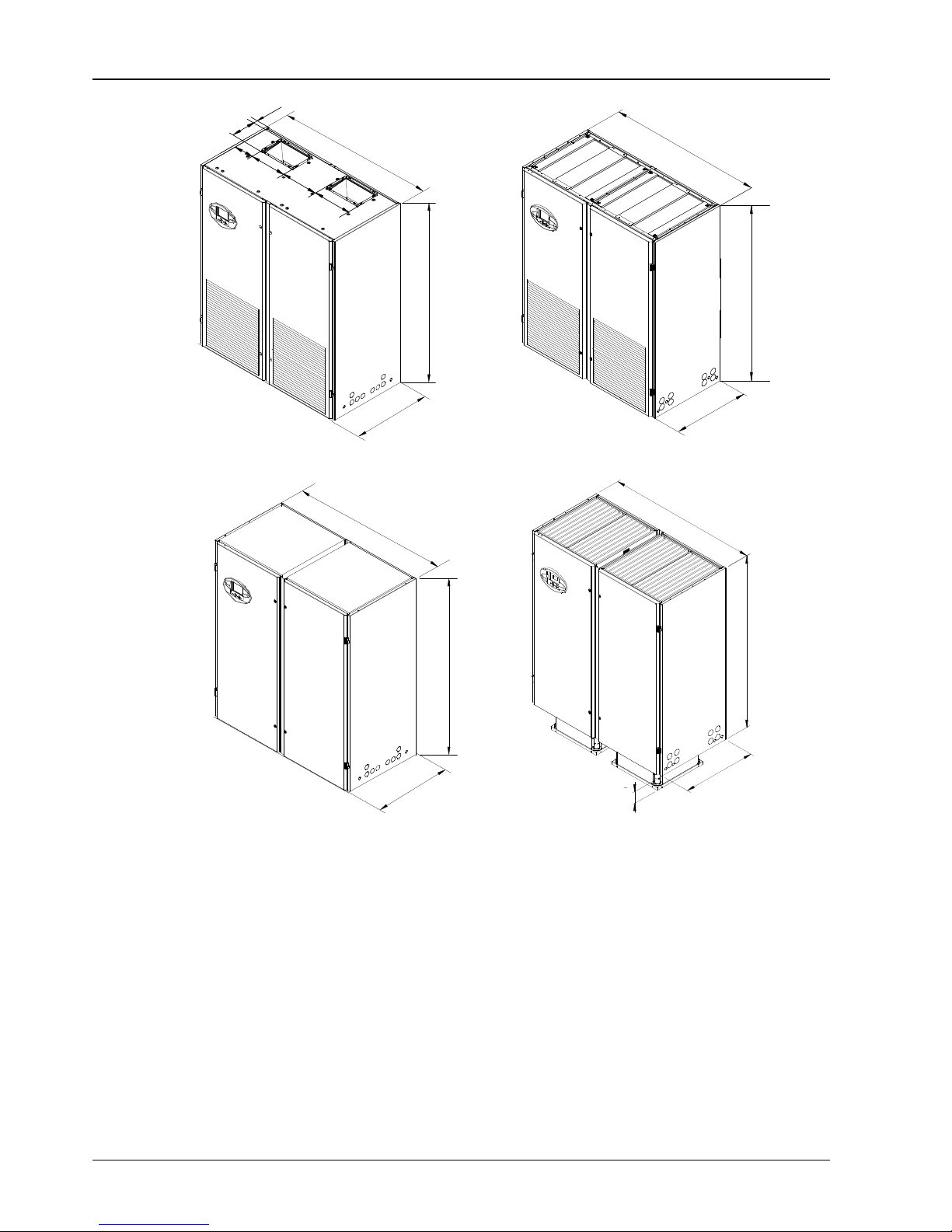

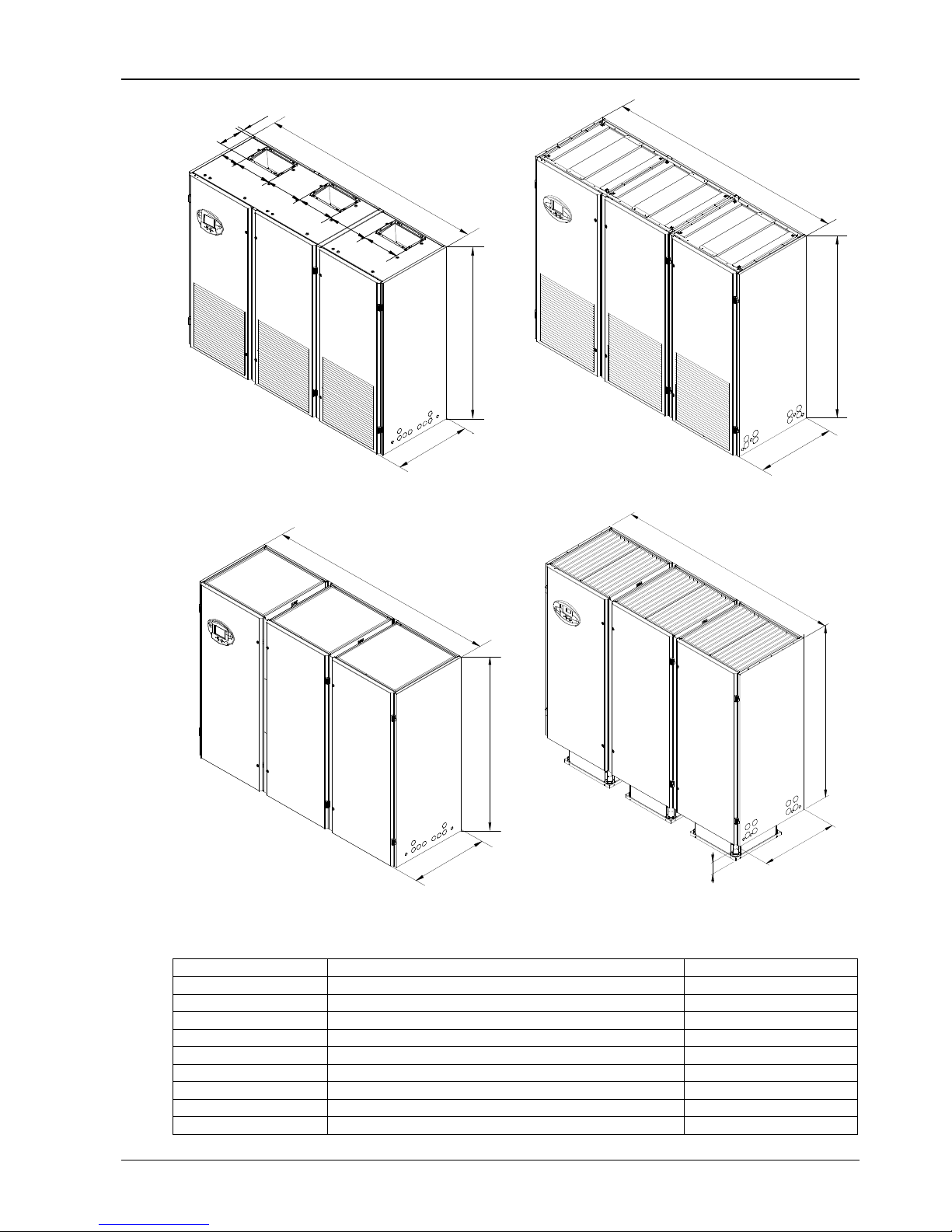

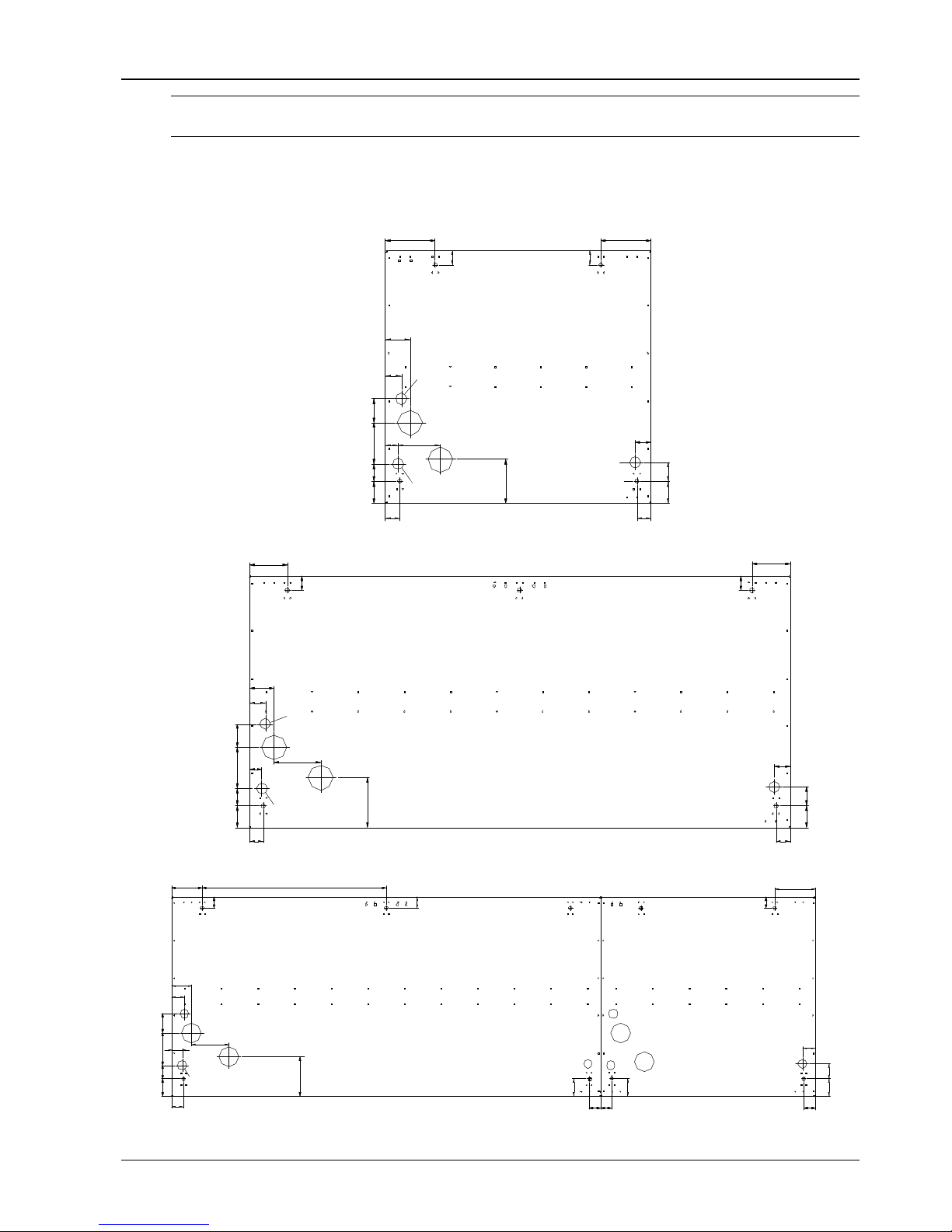

The dimensions of the chilled water AC are shown in Figure 2-7, Figure 2-8, Figure 2-9 and Table 2-1.

8

7

4

8

5

3

1970

8

5

3

1970

8

7

4

3

8

1

6

6

4

7

0

85

3

1970

8

7

4

8

5

3

1970

8

7

4

Upflow unit (forward fan) Upflow unit (backward fan)

1970

8

7

4

8

5

3

8

5

3

1970

8

7

4

8

7

4

1970

8

5

3

280

320

8

5

3

1970

8

7

4

Downflow unit (forward fan) Downflow unit (backward fan)

Figure 2-7 One-bay series (unit: mm)

Page 15

8 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

1

7

0

4

1970

8

7

4

1

7

0

4

1970

8

7

4

3

8

1

6

6

2

3

3

4

7

0

4

7

0

3

4

5

1970

8

7

4

1

70

4

1

7

0

4

1970

8

7

4

Upflow unit (forward fan) Upflow unit (backward fan)

1

7

0

4

1970

8

7

4

1

7

0

4

1970

8

7

4

1

7

0

4

1970

8

7

4

280

320

1

7

0

4

1970

8

7

4

Downflow unit (forward fan) Downflow unit (backward fan)

Figure 2-8 Two-bay series (unit: mm)

Page 16

Chapter 2 Mechanical Installation 9

Liebert.PEX Chilled Water Series Air Conditioner User Manual

2

5

5

3

1970

8

7

4

2

5

5

3

1970

8

7

4

6

6

3

8

1

2

3

3

4

7

0

4

7

0

3

4

5

4

7

0

3

8

2

1970

2

55

3

8

7

4

2

5

5

3

1970

8

7

4

Upflow unit (forward fan) Upflow unit (backward fan)

2

5

5

3

8

7

4

1970

2

5

5

3

1970

8

7

4

8

7

4

1970

2

5

5

3

280

320

8

7

4

1970

2

5

5

3

Downflow unit (forward fan) Downflow unit (backward fan)

Figure 2-9 Three-bay series (unit: mm)

Table 2-1 Dimension

Model Dimensions (W × D × H) (mm) Net weight (kg)

P1020 853 × 874 × 1970 ≤ 315

P1030 853 × 874 × 1970 ≤ 315

P1040 853 × 874 × 1970 ≤ 338

P1050 853 × 874 × 1970 ≤ 343

P2050 1704 × 874 × 1970 ≤ 476

P2070 1704 × 874 × 1970 ≤ 476

P2090 1704 × 874 × 1970 ≤ 505

P2100 1704 × 874 × 1970 ≤ 530

P3110 2553 × 874 × 1970 ≤ 656

Page 17

10 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Model Dimensions (W × D × H) (mm) Net weight (kg)

P3140 2553 × 874 × 1970 ≤ 706

P3150 2553 × 874 × 1970 ≤ 715

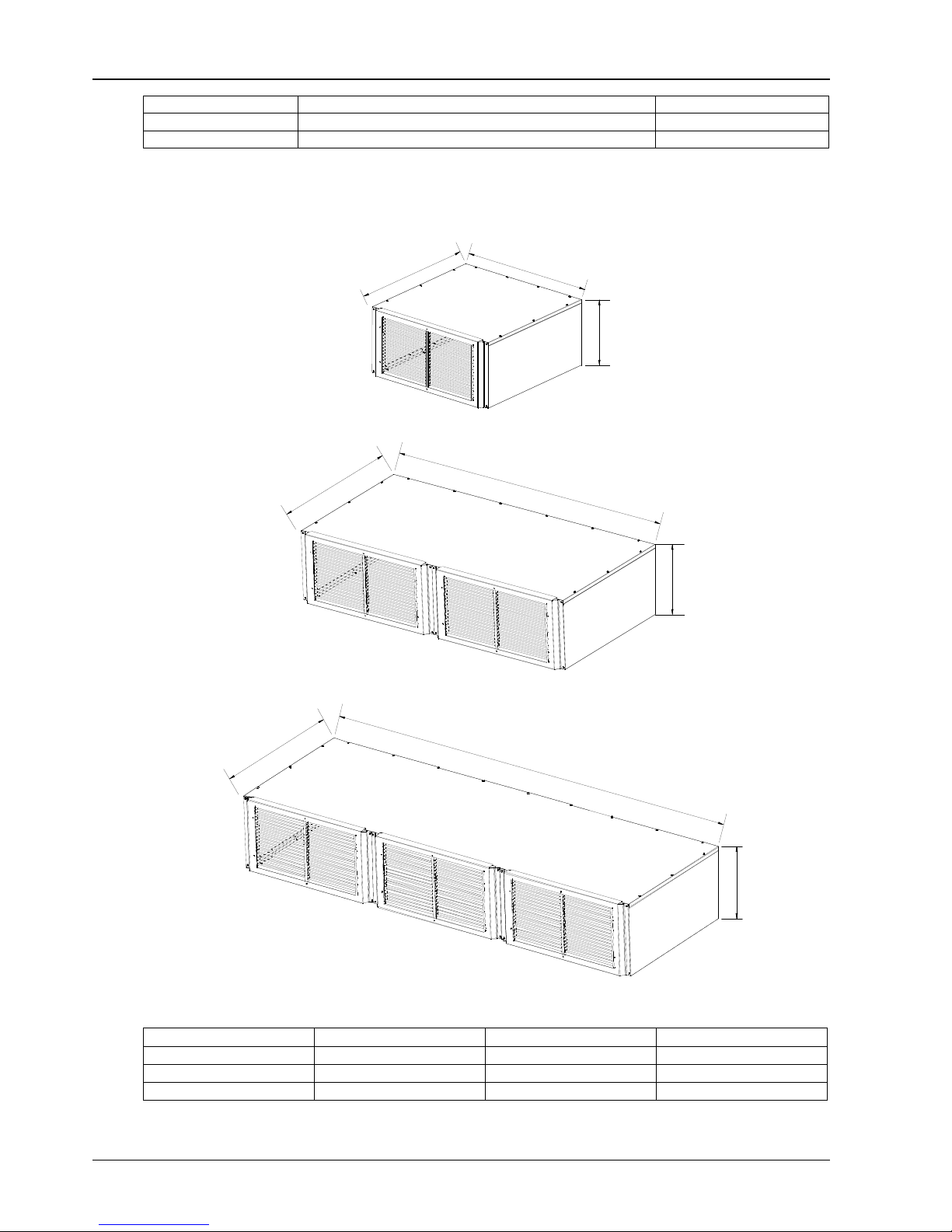

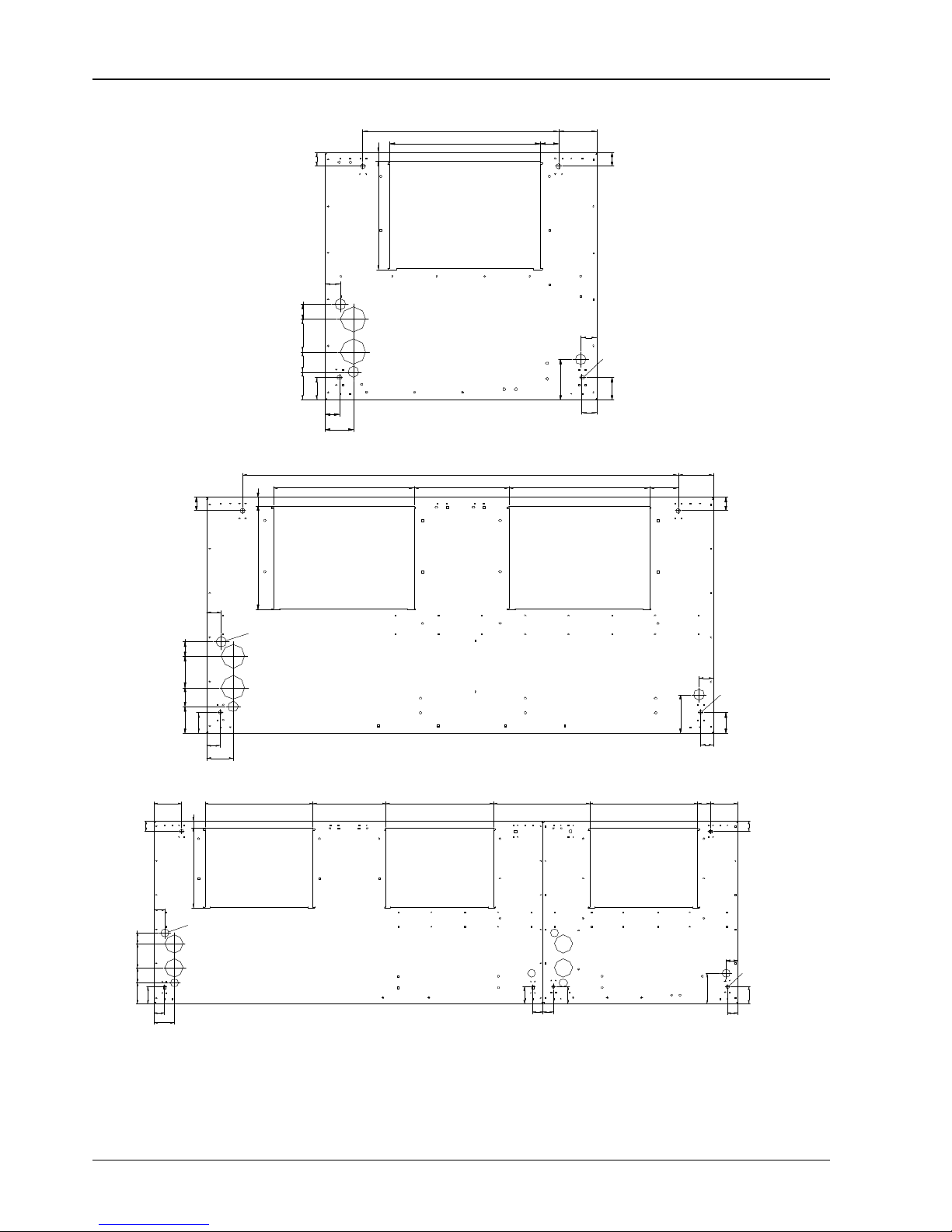

Plenum dimensions

You can select the air supply plenum with grids for the upflow system. The appearance of the plenum is

shown in Figure 2-10, Figure 2-11 and Figure 2-12. The detailed dimensions are listed in Table 2-2.

C

B

A

Figure 2-10 One-bay plenum

C

B

A

Figure 2-11 Two-bay plenum

C

B

A

Figure 2-12 Three-bay plenum

Table 2-2 Dimensions of plenum (unit: mm)

Type

A B C

One-bay 867 853 400 (600, optional)

Two-bay 867 1704 400 (600, optional)

Three-bay 867 2553 400 (600, optional)

Page 18

Chapter 2 Mechanical Installation 11

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Note

If the height of the plenum selected for air conditioner unit exceeds 600mm, consult the factory for non-standard production.

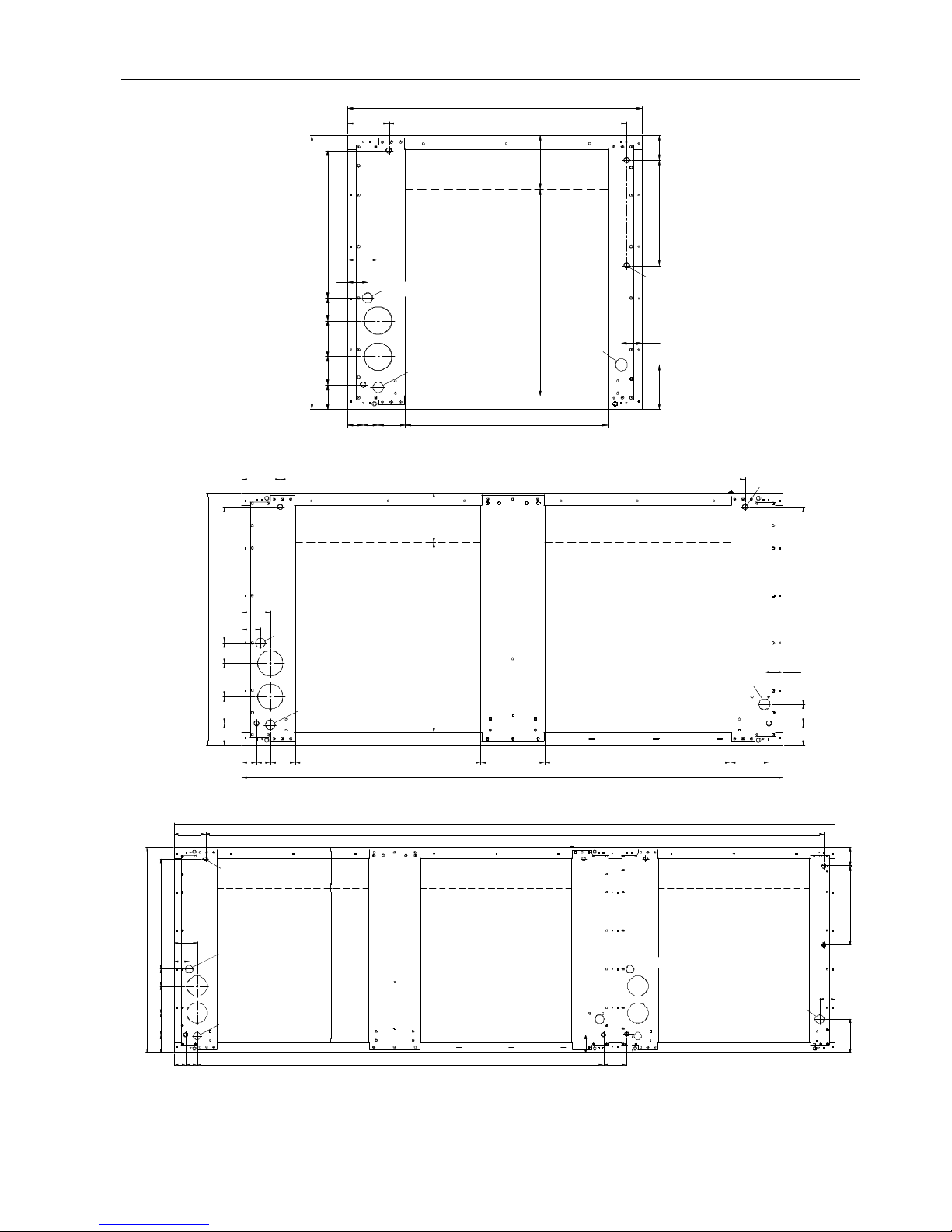

Base cut-out location dimensions

The base cut-out position dimensions of the chilled water AC are shown in Figure 2-13, Figure 2-14 and Figure

2-15.

6070

45

50

5570

45

40 134.7

130.1

138.4

160

45

45

160

78.3

50

74.9

Condensed water drain hole

Chilled water drain hole

Chilled water inlet opening

Water inlet opening

for humidifier

Cable inlet/

outlet opening

4 bottom plate

fastening holes

One-bay series

74.9

130.155

70

40

146.4

50

78.3

45

120

45

45

120

50

6070

45

159.6

Condensed water drain hole

Chilled water drain hole

Chilled water inlet opening

Cable inlet/outlet opening

4 bottom plate fastening holes

Water inlet opening

for humidifier

Two-bay series

146.4

50

40

130.1

74.9

5570

45

159.6

78.3

70

4545

72.5

50

45

70 60

160

45

730

45

45

120

Condensed water drain hole

Chilled water drain hole

Chilled water inlet opening

Water inlet opening

for humidifier

Cable inlet/outlet opening

7 bottom plate fastening holes

Three-bay series

Page 19

12 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Figure 2-13 Base cut-out locations of the upflow series (unit: mm)

612

471

119

45

45

350

48

48.5

105

6590

72.5

45

88.5

45

72.5

130

50

29

56.8

Air supply outlet

Condensed water drain hole

Chilled water inlet opening

Chilled water drain hole

Water inlet opening for humidifier

Cable inlet/

outlet opening

4 bottom plate

fastening holes

One-bay series

1460

318471

29

45

350

48

48.5

1056590

70

471 96.8

120

45

50

45

88.5

130

45

70

Air supply outlet Air supply outlet

Condensed water drain hole

Chilled water inlet opening

Chilled water drain hole

Water inlet opening for humidifier

Cable inlet/outlet opening

4 bottom plate

fastening holes

Two-bay series

120

45

29

471 318 471 420

350

48

48.5105

65

90

70

88.5

45

471 56.8 119

45

72.5

45

130

4545

70

72.5

50

Air supply outlet

Condensed water drain hole

Chilled water inlet opening

Chilled water drain hole

Water inlet opening for humidifier

Cable inlet/outlet opening

6 bottom plate

fastening holes

Air supply outlet

Air supply outlet

Three-bay series

Figure 2-14 Base cut-out locations of the forward fan downflow series (unit: mm)

Page 20

Chapter 2 Mechanical Installation 13

Liebert.PEX Chilled Water Series Air Conditioner User Manual

850

686

89

429

798

651058172

58

45 43 79

583

601

130

60

306

73

157

4 bottom plate

fastening holes

Air supply outlet

Condensed water drain hole

Chilled water inlet opening

Chilled water drain hole

Water inlet opening

for humidifier

Cable inlet/

outlet opening

One-bay series

120

1460

157

623

6070

59

122583200

1700

583

78

4445

429

789

651058470

58

89

601

4 bottom plate

fastening holes

Air supply outlet

Air supply outlet

Condensed water drain hole

Chilled water inlet opening

Chilled water drain hole

Water inlet opening

for humidifier

Cable inlet/

outlet opening

Two-bay series

6 bottom plate

fastening holes

Condensed

water drain hole

Air supply outlet Air supply outlet

Chilled water inlet opening

Chilled water drain hole

Water inlet opening for

humidifier

Cable inlet/outlet opening

120

2550

2385

89

429

798

58

6510584

70

157

601

4544

1566

90

70

73

Air supply outlet

130

60

306 73

Three-bay series

Figure 2-15 Base cut-out locations of the backward fan downflow series (unit: mm)

Page 21

14 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

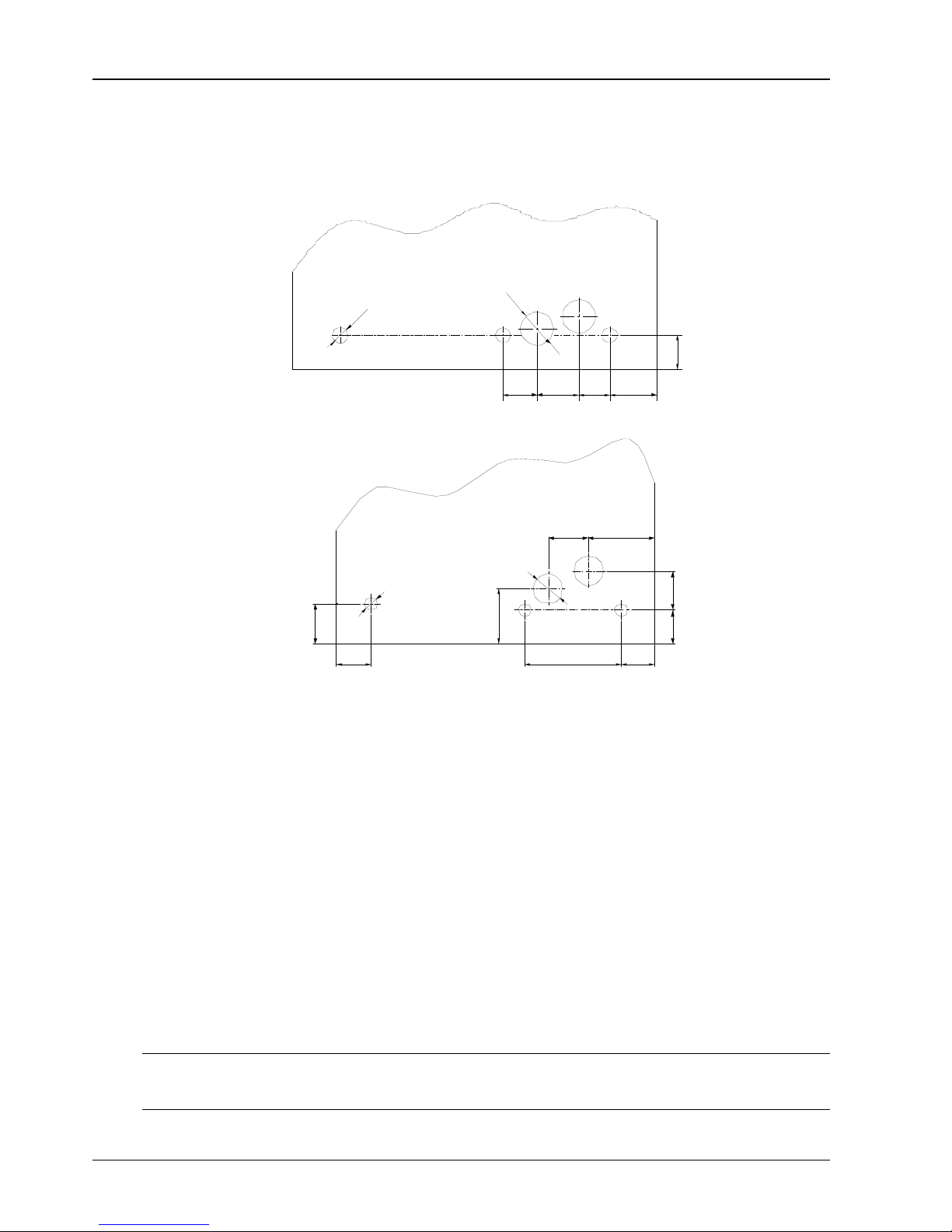

Side panel cut-out locations

If piping and wiring from the base are difficult, connection from side panel can be selected. The locations and

dimensions of knock-out holes are shown in Figure 2-16. You can select the in and out holes according to the

factual needs, but must confirm that any two cables of pipe, power cable and signal cable cannot use the

same hole.

2-Ф 80 knock-out holt

3-Ф 35 knoc k-o ut holt

79.3

95.7 70

110.8

80

Φ

Φ

knock-o ut hole

knock-o ut hole

Upflow series

108.5 174.7

90

90.2

253.5

147.5

91.4

107

105.5

2-Ф 80 knock-out holtΦ

3-Ф 35 knoc k-ou t holt

Φ

knock-o ut hole

knock-out hole

Downflow series

Figure 2-16 Knock-out holes of side panel (unit: mm)

2.3 Installing Chilled Water AC Unit

2.3.1 Installation Requirement

Equipment room requirement

The requirements of equipment room are as follows:

1. Damp proof and heat preservation must be done to make sure that the system can operate normally.

2. The equipment room should have good heat insulation and sealed damp proof layer. The damp proof layer

of the ceiling and walls must use polyethylene film, and the coating of the concrete wall and the floor must be

damp proof.

3. Prevent the outdoor air from entering the equipment room, because the outdoor air that enters the

equipment room may increase the load of heating, cooling, humidifying and dehumidification of the system. It

is recommended that the inhalation of outdoor air be kept below 5% of the total indoor airflow.

4. All the doors and windows should be closed and the seams should be as narrow as possible.

Installation space requirement

Note

The chilled water AC will generate condensed water, and water leakage may damage the precision equipment nearby. So do not

install the system in the vicinity of any precision equipment, and the installation site must provide drain pipes.

1. To ensure normal operation, the installation space for the indoor unit shall be capacious enough.

Page 22

Chapter 2 Mechanical Installation 15

Liebert.PEX Chilled Water Series Air Conditioner User Manual

2. Too small space for the indoor unit will baffle the airflow, shorten the cooling cycle; the air supply and air

exhaust may mix, and the decibel may rise.

3. Do not place the indoor unit in a concave or at the end of a strip area.

4. Do not huddle multiple indoor units, lest there should be mixed airflow, unbalanced load and competitive

operation.

5. For the convenience of daily maintenance, do not install other equipment (such as smoke detector) above

the cabinet.

6. Backward fan downflow unit: because the fan needs to sink during the operation, so the floor must be

higher than 400mm.

Figure 2-17 shows the installation place of the indoor unit.

Good place

Unit

Note:

The reserved maintenance space during the installation

600600

600

Bad place

Unit

Figure 2-17 Installation place of indoor unit (unit: mm)

Maintenance space requirement

Leave more than 600mm of maintenance space in the front and on both sides of the chilled water AC unit, as

shown in Figure 2-17.

2.3.2 Installation Procedures

The installation procedures of indoor unit are as follows:

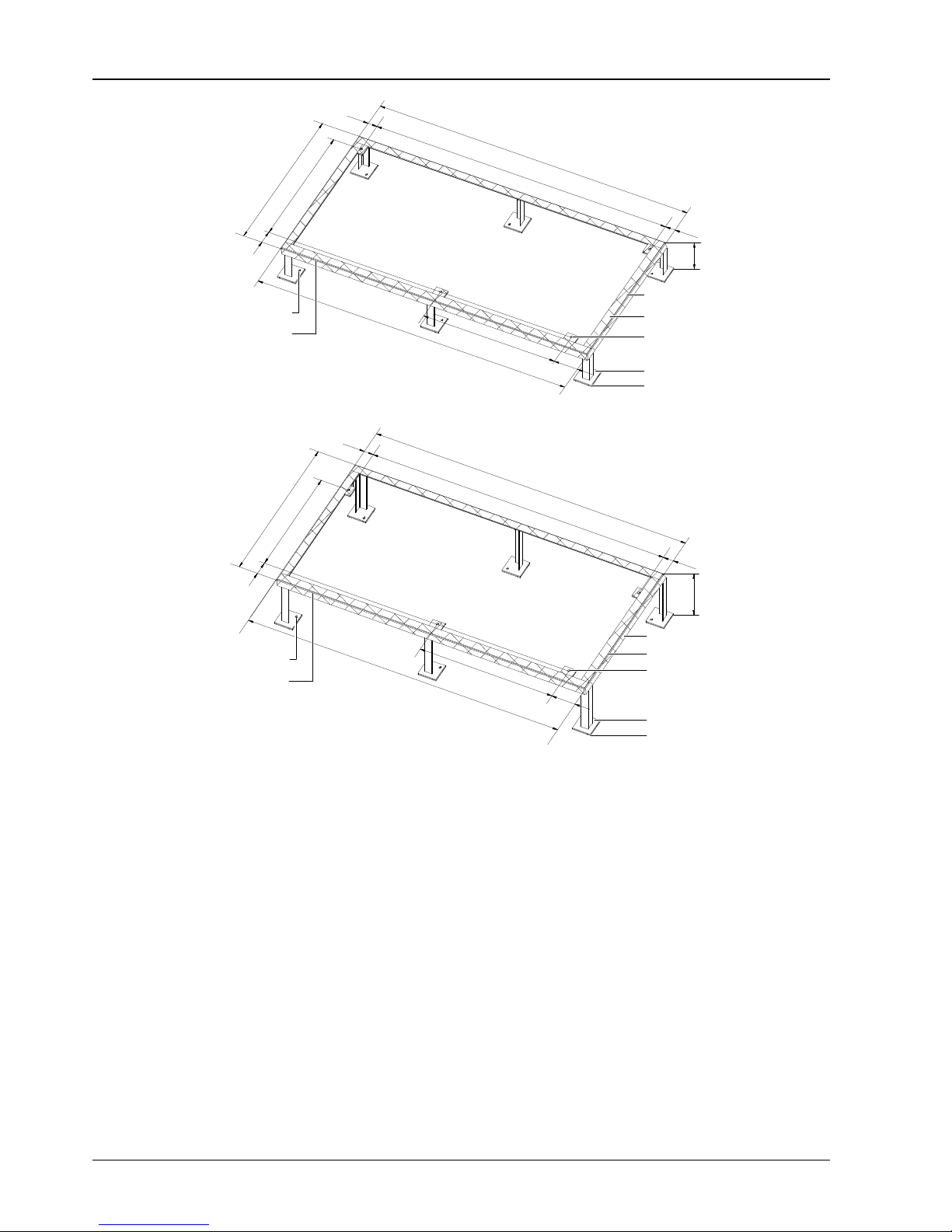

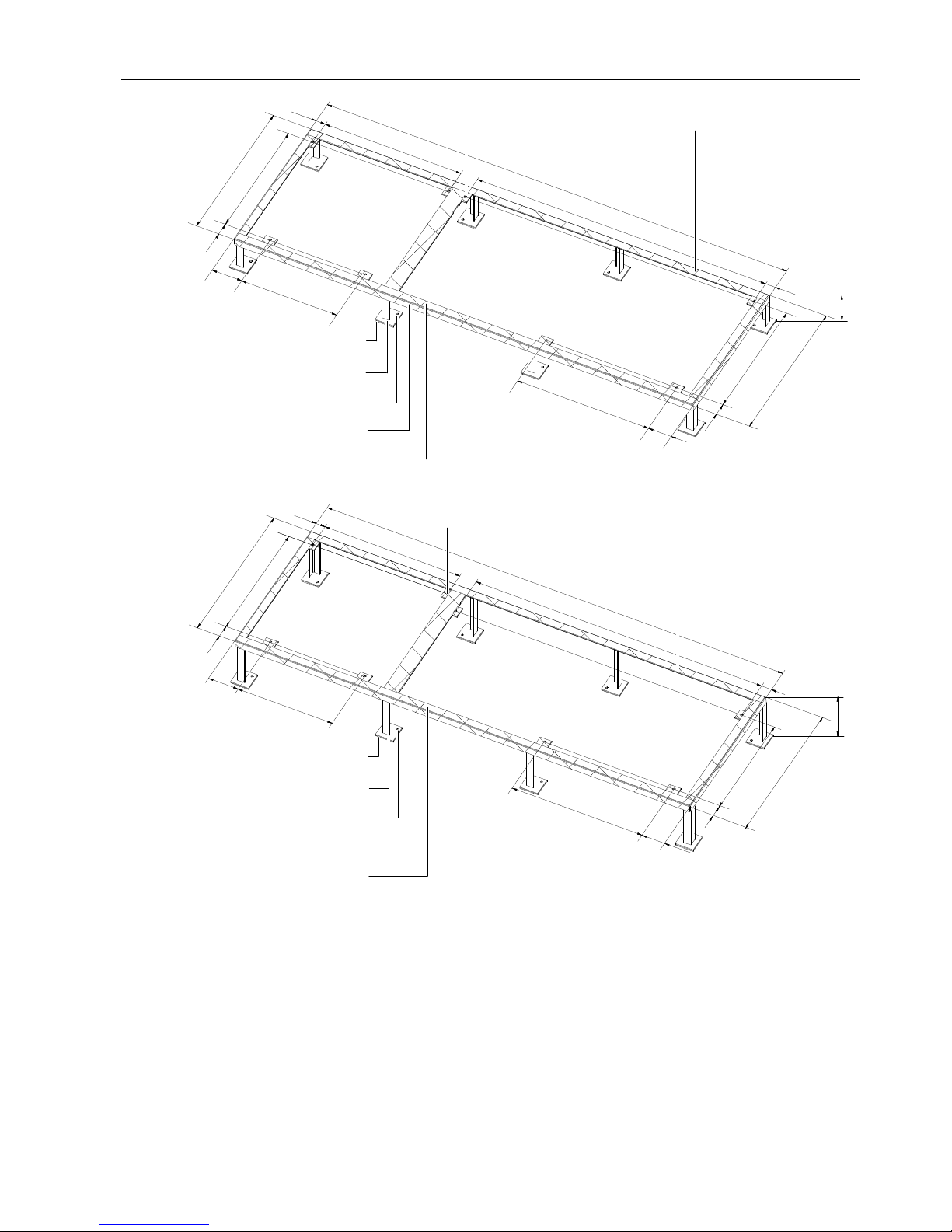

1. Make the mounting base according to the dimensions in Figure 2-18, Figure 2-19 and Figure 2-20 and the

requirements in Table 2-3. You can make it yourself or contact Emerson Network Power Co., Ltd. for

non-standard production.

1

6

1

.

5

5

3

0

1

6

1

.

5

6

7

6

8

0

.

5

8

2

0

4

6

.

5

7

6

0

8

5

3

H

4

6

.

5

F ront side of cabinet

R ubbe r c ushion

(lateral)

Installa tion hole

for expansion bolt

R e ar side of ca bine t

S teel plate

R ubbe r c ushion ( bottom)

Angle steel

R ubbe r c ushion ( top)

4-Ф 14 cabinet installation hole

Φ

Figure 2-18 Mounting base of one-bay series (unit: mm)

Page 23

16 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

1

7

0

3

7

3

0

1

2

1

.

5

6

7

8

2

0

6

8

3

4

6

.

5

1

6

1

0

1

7

0

3

H

4

6

.

5

F ront side of cabinet

Installation hole

for expansion bolt

Rubber cushion (lateral)

R e ar side of ca bine t

S teel plate

R ubbe r c ushion ( bottom)

Angle steel

R ubbe r c ushion ( top)

4-Ф 14 cabinet installation hole

Φ

Upflow

7

3

0

1

7

0

3

1

2

1

.

5

4

6

.

5

6

7

8

2

0

5

9

3

1

6

1

0

1

7

0

3

4

6

.

5

H

F ront side of cabinet

R e a r side of ca binet

Ins talla tion hole

for expansion bolt

Rubber cushion (lateral)

S teel plate

R ubbe r c us hion (bottom)

Angle steel

R ubbe r c us hion (top)

4-Ф 14 cabinet installation hole

Φ

Downflow

Figure 2-19 Mounting base of two-bay series (unit: mm)

Page 24

Chapter 2 Mechanical Installation 17

Liebert.PEX Chilled Water Series Air Conditioner User Manual

4

6

.

5

8

2

0

1

6

1

0

1

6

1

.

5

6

7

5

3

0

7

3

0

6

8

3

1

2

1

.

5

6

7

6

8

0

.

5

8

2

0

7

6

0

2

5

5

3

H

4

6

.

5

F ront side of cabinet

R e ar side of ca bine t

Installa tion hole for expansion bolt

Rubber cushion (lateral)

S teel plate

R ubbe r cushion ( bottom)

Angle steel

R ubbe r cushion ( top)

8-Ф 14 cabinet installation hole

Φ

Upflow

6

7

7

3

0

1

2

1

.

5

6

8

0

.

5

1

6

1

.

5

6

7

8

2

0

5

3

0

4

6

.

5

7

6

0

1

6

1

0

2

5

5

3

5

9

3

8

2

0

4

6

.

5

H

R ubbe r c ushion ( top)

F ront side of cabinet

8-Ф 14 cabinet installation hole

R e ar side of ca bine t

Installa tion hole for expansion bolt

Rubber cushion (lateral)

S teel plate

R ubbe r cushion ( bottom)

Angle steel

Φ

Downflow

Figure 2-20 Mounting base of three-bay series (unit: mm)

Page 25

18 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

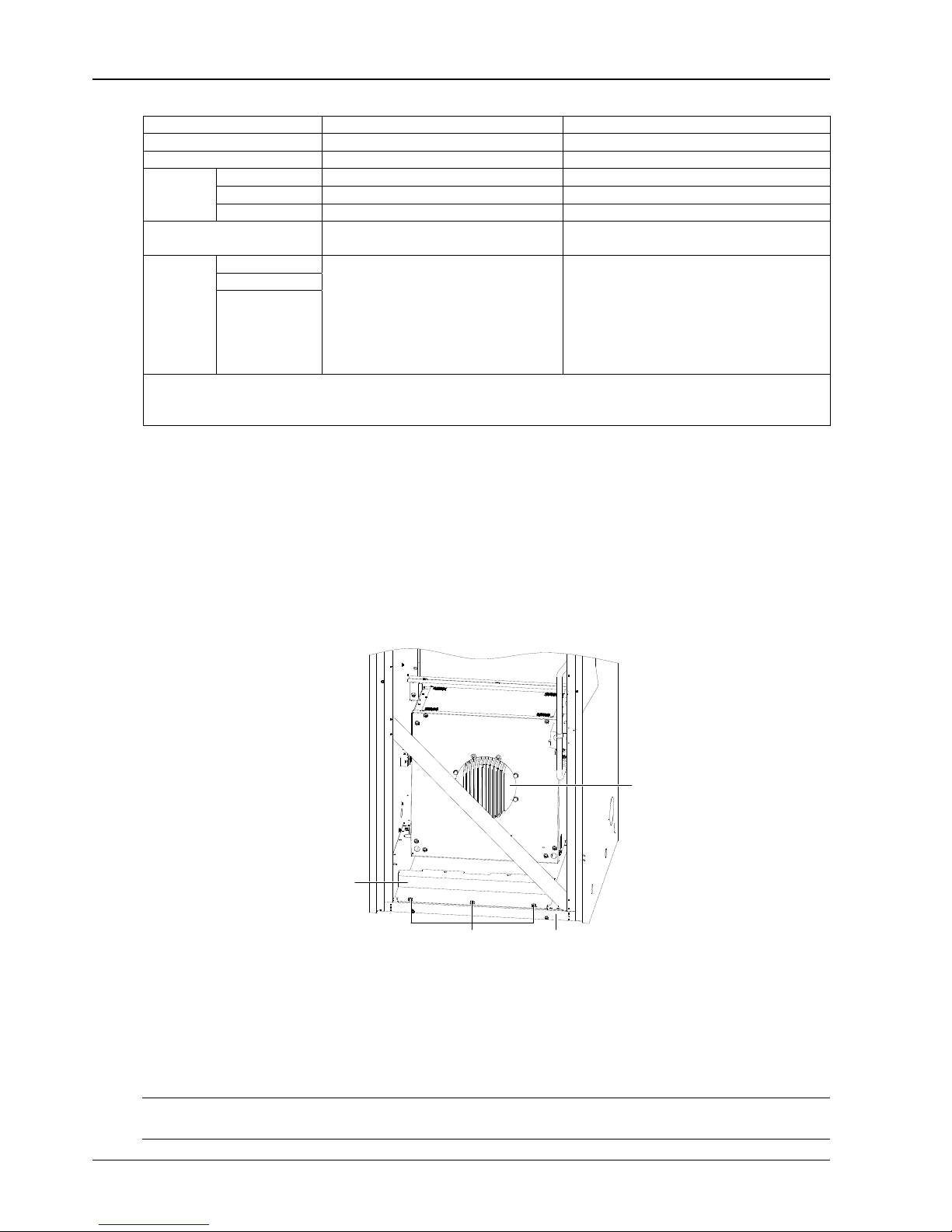

Table 2-3 Specifications of indoor unit mounting base

Item Specification Remark

Steel plate 100mm × 100mm × (5 ~ 6.5)mm -

Angle steel 40mm × 40mm × 3mm -

Rubber

cushion

Top Thickness: 3mm ~ 5mm -

Lateral Thickness: 2mm ~ 3mm -

Bottom Thickness: 10mm ~ 12mm -

Installation hole for

expansion bolt

-

Install the bolts according to your

requirements

H

One-bay

H = 200mm (upflow unit)

H = 300mm (forward fan downflow unit,

according to the floor height)

H ≥ 400mm (backward fan downflow

unit)

1. The forward downflow unit needs guide

plate.

2. Size H here is for reference only, and it

shall be determined according to the actual

needs. Backward fan downflow unit: because

the fan needs to sink during the operation,

size H must be larger than 400mm

Two-bay

Three-bay

Note:

The external side boards of the unit cannot bear weight. Take this into consideration while selecting angle steels and

fixing holes

2. Lay a layer of rubber cushion on the top, lateral of mounting base and on the bottom of the steel plate

respectively. See Figure 2-18, Figure 2-19 and Figure 2-20 for their positions and see Table 2-3 for the

thickness.

3. Determine the installation position. Fix the mounting base onto the mounting base according to the site

conditions and your requirement.

4. Fix the AC unit onto the mounting base with nuts, spring washers, flat washers and bolts.

5. Backward fan downflow unit: the fan must sink under floor, the detailed operation procedures are as

follows:

a. Before placing the unit to the actual installation location, open the rear board and remove the backward fan

fixing board, then install the rear board, see Figure 2-21;

Fan fixing board

Remove the three

fixing screws

Pallet

Backward fan

Figure 2-21 Removing backward fan fixing board

b. Place the unit to the actual installation location, and remove backward fan transportation fixing board and

pallet, see Figure 2-22;

Remove the humidifier water tray drain pipe;

Remove the transportation fixing board (7 fixing screws);

Remove the pallet (2 fixing screws);

Note

When removing the pallet, you must grasp the handle and support the fan so as to prevent the fan from falling.

Page 26

Chapter 2 Mechanical Installation 19

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Fixing screws (7 pcs)

Back ward fan

Handle

Transportation

fixing board

Pallet

Fixing screws (2 pcs)

Revolving axis (each

in left and right side)

Pallet

Humidifier water

tray drain pipe

Figure 2-22 Removing backward fan transportation fixing board and pallet

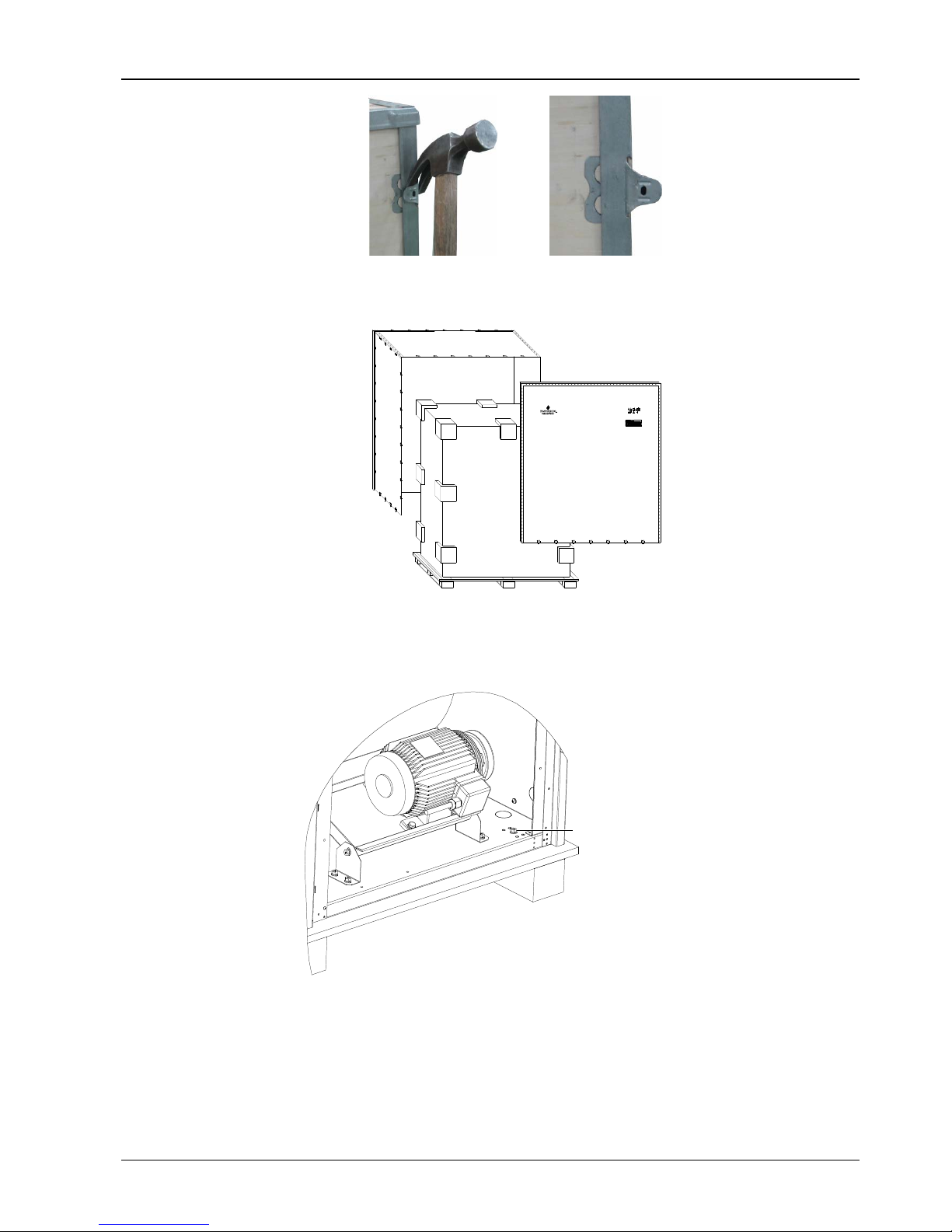

c. Grasp the handle, make a slow 90° rotation CCW of backward fan, so the fan would sink under pallet, see

Figure 2-23;

d. Install the fan fixing board, and tighten the 5 fixing screws, see Figure 2-23.

Backward fan

Pallet

Fan fixing board

Fan protective screening

Fixing screws (5 pcs)

Figure 2-23 Fan sinking under floor

2.4 Piping

The pipes to connect include:

1. Water drain-pipe of the unit.

2. Water inlet pipe of infrared humidifier.

3. Chilled water inlet and outlet pipes.

Connecting the water drain-pipe of the unit

The condensing water of infrared humidifier and evaporator is converged by the cross connector and drains

through the drain pipe, as shown in Figure 2-24. The outer diameter (OD) of the pipe is 25mm. If the drain pipe

is used by three or more units, the minimal OD of the pipe should be 40mm.

Note

1. A Φ25 hose clamp is delivered as an accessory to connect the drain pipe.

2. Because the humidifier contains boiling water, the plastic pipe must be rated higher than 194°F.

3. When connecting the drain pipe, make sure that the U bend is installed vertically and the ‘U’ shape is not distorted, so as to

ensure that the cooling water can be drained immediately and effectively.

Page 27

20 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Infrared humidifier

water in connecting

pipe

Connecting pipe of

condensed water drain

pipe

Condensed water

tray connection

Condensed water

drain pipe connection

Hose clamp

Cross connector

Infrared

humidifier water

tray conncetion

Condensed water

tray connection

Figure 2-24 Connection of water in and out pipes

Connecting water inlet pipe of infrared humidifier

Connect water pipes for the infrared humidifier. To facilitate maintenance, a strainer / non-return isolation

valve is fitted to the supply water pipe. The infrared humidifier reserves a copper pipe (OD: 6.35mm) as shown

in Figure 2-25. 1/4” copper screw nut is put at the end of the copper pipe. Please connect it with the 1/4” × 1/2”

converted copper thread in the attached bag. Connect it with pipes according to the site condition. Make sure

the connection is well sealed to prevent leakage. The pipe pressure is 100kPa ~ 700kPa.

Where the main pressure may rise above 700kPa, a pressure reducer should be fitted. Where the pressure

falls below 100kPa, a water tank and pump system should be used.

Note

Main water supply connections must be made in accordance with local laws and regulations.

A direction

Amplification in A direction

Transport fastener

Water level regulator

Charge

electromagnetic

valve

Water level sensor

Heating over-temperature

protection switch (at the

bottom of water tray)

Charge pipe

Water tray

Heating over-temperature

protection switch

Water out connector

Ceramic terminal base

Overheat protective ralay

Stainless steel

double-screw bolt

Water tray fixing screw

(one at each side)

Water in pipe ODФ 6.35 mm

Φ

Figure 2-25

Infrared humidifier

Connecting chilled water inlet and outlet pipes

The chilled water inlet and outlet pipes are connected with the chilled water unit by welding, as shown in

Figure 2-26. Inlet and outlet pipes should be welded according to the labels on the unit. Please do not reverse

the connection. Chilled water inlet and outlet pipes can be connected through the bottom plate or the side

plate. For the pipe entrance, please refer to Figure 2-13, Figure 2-14 and Figure 2-15. The chilled water inlet

and outlet pipes should have soft connector at the unit connections. The chilled water inlet pipes should be

equipped with the water filter with over 60 meshes to facilitate the clearance of impurities in the pipes. The

chilled water inlet and outlet pipes need to be equipped with several isolation valves, which can cut off water

sources during maintenance. One of the isolation valves can be a balancing valve. Chilled water system with

a balancing valve would be more efficient and more accurate in controlling water distribution. For detailed

distribution, please refer to Figure 2-6.

Water pressure should be able to overcome the water pressure drop caused by all the components of water

system. Considering the possibility that water pressure drop would increase due to incrustation and

impurities resulted from long-time running of the system. Therefore, when choosing the head components

Page 28

Chapter 2 Mechanical Installation 21

Liebert.PEX Chilled Water Series Air Conditioner User Manual

(e.g. pump), we should consider making 20% ~ 25% redundancy. The weight of the water pipes connected

with the unit should not be assumed by the unit. The chilled water inlet and outlet pipes must be kept warm.

Table 2-4 shows the connecting dimensions of chilled water in and out pipes of various units.

Water in pipe

Water out pipe

Water outlet pipe

Water inlet pipe

Figure 2-26 Welding figure of chilled water in and out pipes

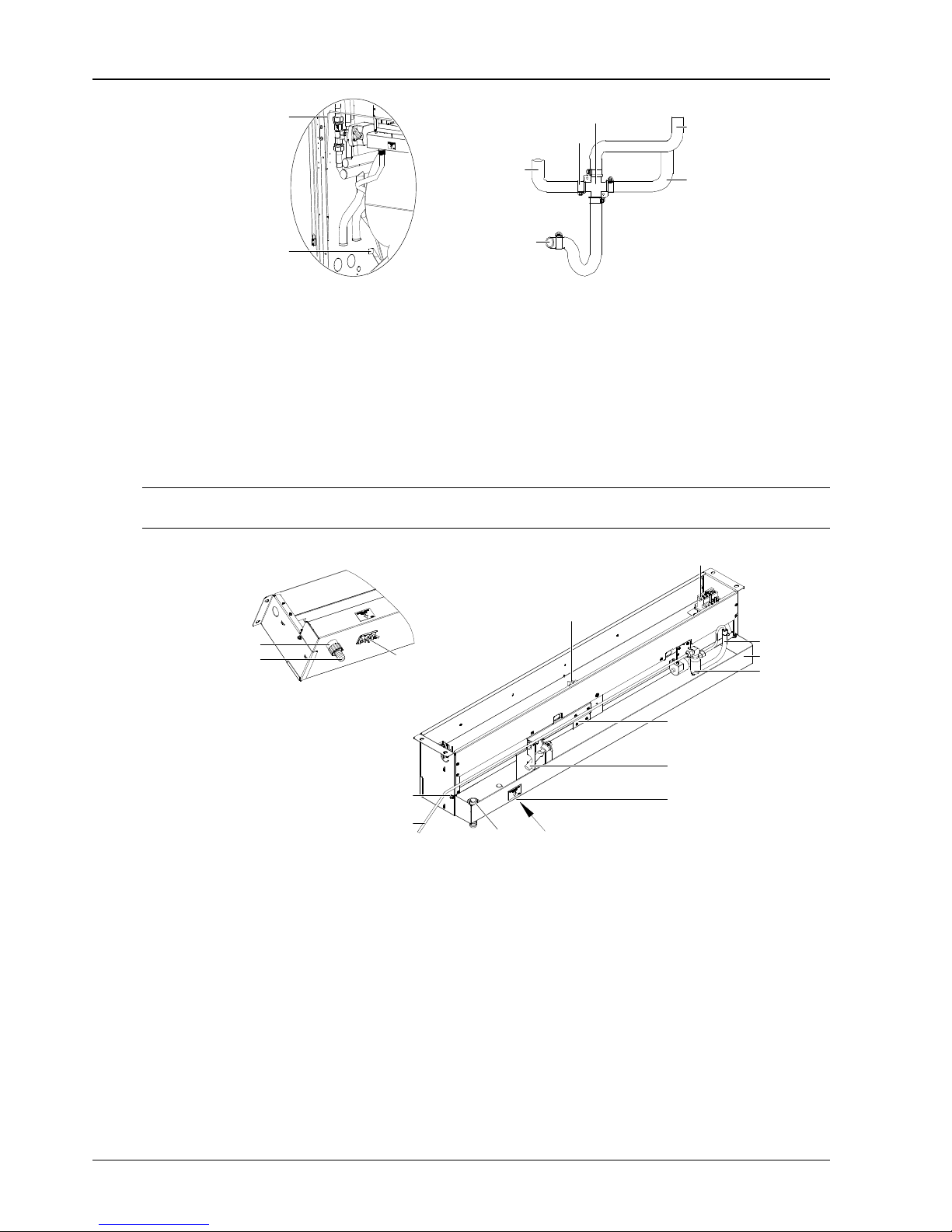

Table 2-4 OD of chilled water in and out pipes

Model

OD of chilled water in and out pipes

(mm)

Model

OD of chilled water in and out pipes

(mm)

P1020 32 P2090 42

P1030 32 P2100 42

P1040 32 P3110 54

P1050 32 P3140 54

P2050 42 P3150 54

P2070 42

2.5 Removing Transport Fastener And Vibration Absorber

In order to protect partial components from being damaged and distorted due to bumping, impact and

resonation, fasteners and vibration absorbers are mounted at certain locations before delivery. Remove the

fasteners and vibration absorbers before installation and commissioning.

Removing transport binding belt of front door

To protect the front door from moving during transport, tighten the gemel of the front door with binding string.

Before putting the unit into operation, you should cut the binding string. Each front door needs two binding

strings. See Figure 2-27 for their position.

Front door

Binding string

Gemel

Figure 2-27 Binding string of front door

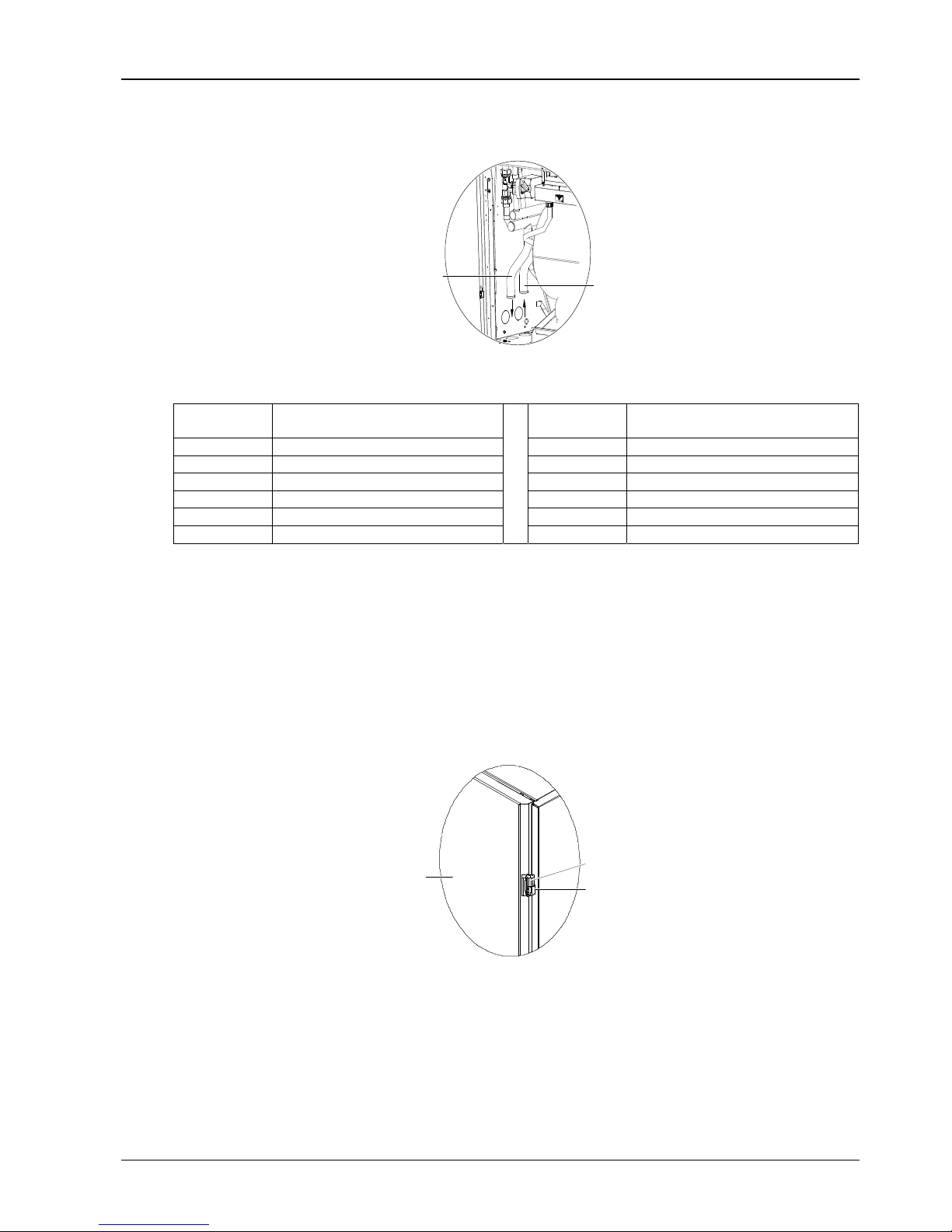

Removing transport fastener of fan components

1. Upflow unit

To minimize the fan operation noise and prolong the belt life, the motor base of the fan is designed with a

semi-free self-tension structure. During transportation, to protect the semi-free structure from failing or

collapsing due to resonation, the upflow unit is especially fastened with sheet metal connector (left and right

symmetrical, one at each side), as shown in Figure 2-28.

Page 29

22 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

You should cut the binding string on the belt and remove the sheet metal connectors on both sides of the

motor before the power-on operation. Removing the sheet metal connectors requires the collaboration of two

persons, with one holding the motor and the other removing the sheet metal connector.

Note

After opening the front door of unit, you will see a warning label concerning the removal of the sheet metal connector on the

sealing panel of the fan. Do remove the sheet metal connector by following the preceding instructions.

Sheet metal connector,

one at each side

Binding string

Figure 2-28 Transportation fan unit binding screw and string

2. Downflow unit

During transportation, to protect the semi-free structure from falling or collapsing due to resonation, the

motor mounting plate is fixed on the bottom plate with connector by bolts, as shown in Figure 2-29. You must

remove the two connectors before the power-on operation.

Sheet metal connector,

one at each side

Figure 2-29 Transportation fan unit binding screw

Note

In any case, never put hands into the triangle gap between the motor installation board and base.

Removing the transport components of infrared humidifier

In order to protect the infrared humidifier lamp from being damaged during transportation, the transport

protection foam should be fitted to the infrared humidifier components. Before operating the unit, check the

protection foam, and connect high water-level detection switch cable. If you operate the unit without

complying with this, the infrared humidifier cannot operate normally and fire may be caused.

Page 30

Chapter 2 Mechanical Installation 23

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Detailed operation procedures are as follows:

1. Cut off the binding wire, and remove the protection foam fixed under the lamp, as shown in Figure 2-30 and

Figure 2-31.

High water-level

test switch cable

Cable tie

Protection foam is at the

bottom of metal sheet

Cable hole of high water-level

test switch cable

Figure 2-30 Removing protection foam 1

保护泡沫

灯管

保护泡沫

Pump

Protecti on

foam

Protecti on fo am

Lamp

Figure 2-31 Removing protection foam 2

2. Remove the four self-tapping screws in the front cover plate of the infrared humidifier connection box, and

then remove the front cover plate, as shown in Figure 2-32.

Remove secf-tapping

screw (4 pcs)

Remove front cover plate

of infrared humidifier

connection box

Remove self-tapping

screw (4 pcs)

Figure 2-32 Opening front cover plate of the connection box

3. Lead the detection switch cable of the high water-level through the cable access hole, as shown in Figure

2-30. Then insert the corresponding cable terminals and the HWA cable terminals in the connecting box, as

shown in Figure 2-33.

Page 31

24 Chapter 2 Mechanical Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

HWA cable

Terminal inserting

High water-level test switch cable

Figure 2-33 Connecting the corresponding cable terminals of the high water-level detection

switch and the HWA cable terminal

4. Close the front cover of the infrared humidifier’s connection box, and tighten the self-tapping screw.

5. The infrared humidifier’s high water-level detection switch floating pole and its body have been tightened

with the rubber string in factory, as shown in Figure 2-34. Before operating the unit, remove the rubber string,

otherwise the unit cannot detect and alarm the high water-level.

Rubber string

Floating pole

Figure 2-34 Floating pole of the high water-level sense switch

Remove the rubber string to fix the pipe

To avoid the sheet-metal from damaging the longer copper pipe, the damping foam is used to underlay or

clamp the pipe before it leaves the factory. The foam should be removed and cleaned before commissioning.

2.6 Adjusting Water Level Regulator

The water level regulator of the infrared humidifier is screwed down completely. Before commissioning,

unscrew the water level regulator till its head is 45mm above the water tray bottom, as shown in Figure 2-35.

4

5

4

5

Figure 2-35 Adjusting distance from the water tray

Page 32

Chapter 2 Mechanical Installation 25

Liebert.PEX Chilled Water Series Air Conditioner User Manual

2.7 Installation Inspection

After the mechanical installation is completed, you should check that:

1. A certain space is left around the unit for maintenance. For details, see Maintenance space requirement in

2.3.1 Installation Requirement;

2. The equipment is installed vertically and the installation fasteners have been fixed;

3. The pipes connecting the indoor unit and outdoor unit have been connected;

4. The condensate pump (if needed) has been installed;

5. The drain pipe has been connected;

6. The water supply pipe for infrared humidifier has been connected;

7. All pipe joints have been fixed;

8. The transport fasteners have been removed;

9. The water level regulator of the infrared humidifier has been unscrewed to the required height;

10. The debris (such as transportation materials, structure materials and tools) inside or around the

equipment has been cleaned.

After confirming the preceding points, you can then start the electrical installation.

Page 33

26 Chapter 3 Electric Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Chapter 3 Electric Installation

This chapter introduces the electric installation of the chilled water AC, including the work introduction,

installation notes, wiring of the unit and installation inspection.

3.1 Work Introduction And Installation Notes

Wires to be connected on-site

1. Unit power cables.

2. Unit input and output control cables.

Installation notes

1. The connection of all power cables, control cables and ground cables must comply with local electrician

regulations;

2. See the equipment nameplate for the full load current. The cable sizes should meet the local wiring rules;

3. Mains supply requirement: 380Vac, 50Hz;

4. The electrical installation must be completed by trained personnel;

5. Before the wiring, use a multimeter to measure the power supply voltage and make sure that the power

supply has been switched off.

3.2 Wiring Of Chilled Water AC Unit

3.2.1 Locating Electrical Interfaces

Opening the front door of the chilled water AC unit can reveal the interfaces of electrical control box, as

shown in Figure 3-1, Figure 3-2 and Figure 3-3.

Control interface

N/PE terminal block

Power interface

Upflow

Power interface

Control interface

N/PE terminal block

Downflow

Page 34

Chapter 3 Electric Installation 27

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Figure 3-1 Electrical control box interfaces of one-bay series

Power interface

Control interface

N/PE terminal block

Upflow

Power interface

Control interface N/PE terminal block

Downflow

Figure 3-2 Electrical control box interfaces of two-bay series

Power interface

Control interface

N/PE terminal block

Upflow

Power interface

Control interface N/PE terminal block

Downflow

Figure 3-3 Electrical control box interfaces of three-bay series

3.2.2 Connecting Power Cable Of Chilled Water AC Unit

The power interfaces are located as shown in Figure 3-1, Figure 3-2 and Figure 3-3 and the power interface is

amplified as shown in Figure 3-4. Connect terminals L1, L2, L3, N, and PE to their counterparts of external

power supply. Fix the input cables to the cable clamp located on the right inner side panel, as shown in Figure

3-5. As for the cable specification, see the unit maximum operation current in Table 3-1.

Page 35

28 Chapter 3 Electric Installation

Liebert.PEX Chilled Water Series Air Conditioner User Manual

PEN

L3L2L1

PEN

L3L2L1

PEN

Cable clamp

Figure 3-4 Amplified figure of power interface Figure 3-5 Cable clamp

Note

The cable sizes should meet the local wiring rules.

Table 3-1 Maximum operation current of AC unit

Model Maximum operation current (A)

Model Maximum operation current (A)

P1020 13.1 P2090 23.5

P1030 13.1 P2100 23.5

P1040 13.1 P3110 28.2

P1050 13.1 P3140 28.2

P2050 23.5 P3150 28.2

P2070 23.5

3.2.3 Connecting Control Cables

The control interfaces are located as shown in Figure 3-1, Figure 3-2 and Figure 3-3. The control interface is

amplified in Figure 3-6. The upper part of the terminal block is connected to the AC unit, while the lower part is

used as user control signal interfaces.

Connecting with

smoke sensor, 91# is

its common terminal

Alarm output of

smoke sensor

Connecting

with common

alarm

Short connecting line, no

short line if the remote

shut down is connected

50,51,55 is defined

alarm terminals, 24# is

its common terminal

50,51,52 are defined

Figure 3-6 Wiring of control interfaces

Note

Before connecting the control cables, the wiring personnel must take antistatic measures.

Page 36

Chapter 3 Electric Installation 29

Liebert.PEX Chilled Water Series Air Conditioner User Manual

You can connect the following monitoring and alarm devices.

Remote shutdown (RSD)

Terminals 37 and 38 can be connected to the remote shutdown switch. By default, terminals 37 and 38 are

shorted. Remove the shorting wire if remote shutdown is needed. When terminals 37 and 38 are open, the

system is shut down.

Smoke detect (SDC)

Terminals 91, 92 and 93 can be connected to the smoke sensor, with 91 being the common terminal, 92 being

the NO contact, and 93 being the NC contact. You can select NO or NC contact according to the smoke sensor

logic.

Terminals 80 and 81 are used to output external alarms for the smoke sensor.

Customized alarm terminals

Terminals 50, 51, 55 can be connected to three kinds of sensors, including fire sensor and water sensor.

Terminal 24 is the common terminal. After connecting sensors to the terminals, you should set the

corresponding customized alarm through the microprocessor. See 5.7.6 SET ALARMS for details. When the

contactor is open and there is no external alarm, the input state of the customized terminal is open. But when

the contactor is closed and the external alarm is raised, the input state of the customized terminal will be

shorted. At this time, the system will raise sirens, and the LCD of indoor unit will display the alarm information.

If a PC installed with Emerson monitoring software is connected to the system, the alarm will also be

displayed on the PC.

The terminals can be defined as follows:

Terminals 50 and 24: remote alarm (optional).

Terminals 51 and 24: water sensor (by default).

Terminals 55 and 24: safe switch for condensation water pump (optional).

Water-under-floor sensor (WUF)

Each unit is equipped with one WUF sensor. You should connect one end of the sensor to terminal 51, and the

other end to the common terminal 24. The number of sensors in parallel connection is not limited, but there is

only one water-under-floor alarm for each unit.

Condensing pump safe switch (CPSS)

When the CPSS is configured, you should connect one end of the CPSS to terminal 55, and the other end to

the common terminal 24.

External common alarm terminals

Terminals 75 and 76 can be used as external common alarm terminals. They are controlled by the external

alarm relay K3 on the circuit board. They output signals to external alarm devices, such as the alarm indicator.

When critical alarm occurs, the contactor will close to trigger remote alarms, send signals to the building

management system or dial the paging system automatically. The power supply of the external alarm system

is user self-prepared.

Refer to Appendix 2 Circuit Diagram for the detailed definition of other terminals.

3.3 Installation Inspection

After the electrical installation is completed, you should check and confirm that:

1. The power resource voltage meets the rating on the nameplate.

2. The system electric loop has no open circuit or short circuit.

3. Power cables and grounding cables are connected to the circuit breakers, indoor unit and outdoor unit.

4. The ratings of the circuit breakers and fuses are correct.

5. The control cables are properly connected.

6. All the cable connections are fastened, with no loose screws.

You can start commissioning after confirming the preceding points.

Page 37

30 Chapter 4 System Start-Up Commissioning

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Chapter 4 System Start-Up Commissioning

This chapter introduces the start-up commissioning of the chilled water AC, including preparation before

commissioning, commissioning procedures and inspection after commissioning.

4.1 Locating MCBs

The MCBs are located as shown in Figure 4-1, Figure 4-2 and Figure 4-3.

1234

5

Upflow

1234

5

Downflow

Figure 4-1 MCBs of one-bay series

Page 38

Chapter 4 System Start-Up Commissioning 31

Liebert.PEX Chilled Water Series Air Conditioner User Manual

1234

5

Upflow

1234

5

Downflow

Figure 4-2 MCBs of two-bay series

1234

5

Upflow

1234

5

Downflow

Figure 4-3 MCBs of three-bay series

1: Fan MCB 3: Infrared humidifier MCB 5: Main isolation switch

2: Electrical heater MCB 4: Control board MCB

Page 39

32 Chapter 4 System Start-Up Commissioning

Liebert.PEX Chilled Water Series Air Conditioner User Manual

4.2 Start-Up Commissioning

4.2.1 Preparation Before Commissioning

Mechanical and system part

1. Check that the protection materials during transportation have been removed;

2. Check that the motor pulley and the fan pulley are fixed, the motor bearing and fan bearing are parallel, the

belt is perpendicular to the two bearings and the tension of the belt is proper;

3. The pressure-leak detection of the chilled water system has been done and the chilled water system is

confirmed to be qualified;

4. The cleaning and emptying of the chilled water system have been done (air vent valve is located in the top

of the heat exchanger coil);

5. The chilled water system has been confirmed ready for operation;

6. The water supply-/drainage-pipe system of the humidification system has been reliably connected

according to the material requirements and has been checked against leakage;

7. Make sure the equipment room temperature is above 68°F with sufficient heat load. If the heat load is

insufficient, heat the equipment room with other heating devices, or by forcibly hand-running the heater of the

unit or adjacent other equipment (in this case, go through the following procedures till the third step of 4.2.2

Commissioning Procedures) to make sure the heat load is sufficient for the commissioning.

Electrical part

1. Check that the input voltage of the main power is -10% ~ +15% of the rating;

2. Check that all electrical or control cables are correctly connected. Fasten all the connecting terminals;

3. The power cables and the low voltage control cables are laid away from each other;

4. Check the phase sequence. The phase sequences of all three-phase devices have been adjusted consistent

before delivery. During commissioning, you only need to ensure the phase sequence of a random three-phase

device is correct. In step two of 4.2.2 Commissioning Procedures, you can use a straight screwdriver to click

on the fan contactor within the electric control box to judge the phase sequence by observing the wind

direction. If the phase sequence is wrong, exchange any two phases of the L line of the power supply.

4.2.2 Commissioning Procedures

1. Turn off the MCBs of various parts. Turn on the main MCB and control MCB and check the control voltage.

2. Switch on the fan MCB and click on the contactor of the indoor fan with a screwdriver to confirm the

rotation direction of the fan. Start the equipment and measure all the phase currents of the fan.

3. Switch on the electrical heater MCB and change the temperature setting to start the electric reheat, or start

the heater manually. Measure all the phase currents of electrical heater.

To trigger the electrical heater, you should:

Change the temperature setting (see 5.7 SERVICE MENUS) to 9°F higher than the indoor temperature. The

system should then trigger the call for heating and the electric reheat starts to work. Then set the temperature

setting to 9°F lower than the indoor temperature. If the electrical heater stops working, it means the heating

function is normal. Keeping the temperature setting can make no heating requirement. Continue the following

commissioning steps.

4. Switch on the humidification MCB and change the humidity setting to start the humidifier, or start the

humidifier manually. Measure all the phase currents of the humidifier. Manually charge water into the cooling

system to check that the charge-/drainage-pipes do not leak and the drainage pipes are clear.

To trigger the humidifier, you should:

Adjust the humidity setting (see 5.7 SERVICE MENUS) to 10% higher than the indoor relative humidity. The

control system should then trigger the call for humidification, and the humidifier starts to work. If the

humidifier stops working when the humidity setting is lower than the indoor relative humidity, it means the

humidifying function is normal.

Note

After commissioning, restore the humidity setting to the default or the original setting.

Page 40

Chapter 4 System Start-Up Commissioning 33

Liebert.PEX Chilled Water Series Air Conditioner User Manual

5. Change the temperature setting and start the refrigeration, or start the refrigeration manually. Record the

water flow quantity of the system and water resistance.

To start the refrigeration (open the water flow control valve), you should:

Change the temperature setting (see 5.7 SERVICE MENUS) to 9°F lower than the indoor temperature. The

control system should then trigger the call for refrigeration, and the water flow control valve switches on.

After at least three minutes of refrigeration, change the temperature setting to 9°F higher than the indoor

temperature. If the water flow control valve is closed, it means the refrigeration function is normal.

6. Change the humidity setting and the unit will enter a dehumidifying status. Record the water flow quantity

of the system and water resistance.

To trigger dehumidification, you should:

Change the humidify setting (see 5.7 SERVICE MENUS) to 10% lower than the indoor relative humidity. The

control system should then trigger the call for dehumidification, the water flow control valve switches on.

Note that during the commissioning process, if the indoor temperature is 5.4°F higher than the temperature

setting, the system may enter the forced refrigeration mode, and the dehumidification demand will not be

responded. After commissioning, restore the humidity setting to the default or the original setting.

4.2.3 Inspection After Commissioning

1. Check that all output functions are automatic;

2. Check that the temperature & humidity settings and control precisions are set reasonably;

3. Make sure all the other functions are set reasonably.

Page 41

34 Chapter 5 iCOM Controller

Liebert.PEX Chilled Water Series Air Conditioner User Manual

Chapter 5 iCOM Controller

The iCOM controller adopts menu operation. It can monitor, display and operate the precision cooling air

conditioner and control the environment within a set range. This chapter expounds the LCD, button and

indicator panel, structure chart of control menu, startup interface, main interface, USER MENUS, SERVICE

MENUS, ADVANCED MENUS and EVENT NAME AND DIFINITION of the iCOM controller.

5.1 LCD

An LCD is located on the front panel of the Liebert.PEX2 series air conditioner. The LCD can display the

current state of the equipment room, such as temperature and humidity, and so on. You can also read and

modify the equipment configuration through the LCD.

The LCD uses blue backlight. If no button is pressed within a certain period of time (settable; default: 5min),

the backlight will be off, until the next time any button is pressed.

5.2 Button And Indicator Panel

Nine buttons and two indicators are located on the button and indicator panel, including:

Indicators: alarm indicator and operation indicator.

Buttons: ON/OFF button, enter button, ESC button, up button, down button, left button, right button,

alarm silence button and help button.

The button and indicator panel is shown in Figure 5-1.

Alarm indicator

Alarm silence button

Left button

Up button

Enter button

Right button

Down

button

Help

button

ESC

button

ON/OFF button

Operation indicator

Figure 5-1 Button and indicator panel

The indicators are described in Table 5-1.

Table 5-1 Indicator description

Indicator Description

Alarm indicator The alarm indicator turns on in red upon alarms. It is off after the alarm is cleared

Operation indicator

The operation indicator is on in green when the unit is operating. When the unit is shut down, it

will be on in yellow

Page 42

Chapter 5 iCOM Controller 35

Liebert.PEX Chilled Water Series Air Conditioner User Manual

The functions of the buttons are described in Table 5-2.

Table 5-2 Function description of buttons

Button Function description

ON/OFF

button

1. Switch on/off the system.

Press the ON/OFF button to shut down an operating system, or to start an idle system.

2. Test the display state of the backlight of the LCD and the operation indicator.

After powering-on, when the system is in the standby state (defined as test state in this manual), pressing

the ON/OFF button will switch between the operation indicator (green then) and the LCD backlight. This

function is used to test whether the LCD backlight and the operation indicator are normal

Enter

button

1. Enter the selected menu, or save the setting after parameters are changed. When you are entering a

menu or changing a parameter, the menu and the parameter will be high lighted.

2. Test the display of characters.

When the system is in the test state, pressing the enter button will display the ASCII code. This function is

used to test whether the characters are displayed normally on the LCD

ESC button

1. Quit the current menu.

2. Abolish the current change of parameter.