Page 1

Instruction Manual

CI-9110

Mar. 2007

Remote Set Regulator

Model 9110-00A

Series 9110

www.EmersonProcess.com/Bristol

Page 2

IMPORTANT! READ INSTRUCTIONS BEFORE STARTING!

Be sure that these instructions are carefully read and understood before any

operation is attempted. Improper use of this device in some applications may result

in damage or injury. The user is urged to keep this book filed in a convenient location

for future reference.

These instructions may not cover all details or variations in equipment or cover

every possible situation to be met in connection with installation, operation or maintenance. Should problems arise that are not covered sufficiently in the text, the purchaser is advised to contact Bristol for further information.

EQUIPMENT APPLICATION WARNING

The customer should note that a failure of this instrument or system, for

whatever reason, may leave an operating process without protection. Depending upon

the application, this could result in possible damage to property or injury to persons.

It is suggested that the purchaser review the need for additional backup equipment

or provide alternate means of protection such as alarm devices, output limiting, failsafe valves, relief valves, emergency shutoffs, emergency switches, etc. If additional

in-formation is required, the purchaser is advised to contact Bristol .

RETURNED EQUIPMENT WARNING

When returning any equipment to Bristol for repairs or evaluation, please note

the following: The party sending such materials is responsible to ensure that the

materials returned to Bristol are clean to safe levels, as such levels are defined and/or

determined by applicable federal, state and/or local law regulations or codes. Such

party agrees to indemnify Bristol and save Bristol harmless from any liability or

damage which Bristol may incur or suffer due to such party's failure to so act.

ELECTRICAL GROUNDING

Metal enclosures and exposed metal parts of electrical instruments must be

grounded in accordance with OSHA rules and regulations pertaining to "Design

Safety Standards for Electrical Systems," 29 CFR, Part 1910, Subpart S, dated: April

16, 1981 (OSHA rulings are in agreement with the National Electrical Code).

The grounding requirement is also applicable to mechanical or pneumatic instruments that include electrically-operated devices such as lights, switches, relays,

alarms, or chart drives.

EQUIPMENT DAMAGE FROM ELECTROSTATIC DISCHARGE VOLTAGE

This product contains sensitive electronic components that can be damaged by

exposure to an electrostatic discharge (ESD) voltage. Depending on the magnitude

and duration of the ESD, this can result in erratic operation or complete failure of the

equipment. Read supplemental document S14006 at the back of this manual for

proper care and handling of ESD-sensitive components.

Bristol Inc. 1100 Buckingham Street, Watertown, CT 06795

Telephone (860) 945-2200

Page 3

WARRANTY

A. Bristol warrants that goods described herein and manufactured by Bristol are free

from defects in material and workmanship for one year from the date of shipment

unless otherwise agreed to by Bristol in writing.

B. Bristol warrants that goods repaired by it pursuant to the warranty are free from

defects in material and workmanship for a period to the end of the original warranty

or ninety (90) days from the date of delivery of repaired goods, whichever is longer.

C. Warranties on goods sold by, but not manufactured by Bristol, are expressly limited

to the terms of the warranties given by the manufacturer of such goods.

D. All warranties are terminated in the event that the goods or systems or any part

thereof are (i) misused, abused or otherwise damaged, (ii) repaired, altered or

modified without Bristol's consent, (iii) not installed, maintained and operated in

strict compliance with instructions furnished by Bristol, or (iv) worn, injured or

damaged from abnormal or abusive use in service time.

E. THESE WARRANTIES ARE EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES EXPRESS OR IMPLIED (INCLUDING WITHOUT LIMITATION

WARRANTIES AS TO MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE), AND NO WARRANTIES, EXPRESS OR IMPLIED, NOR ANY

REPRESENTATIONS, PROMISES, OR STATEMENTS HAVE BEEN MADE BY

BRISTOL UNLESS ENDORSED HEREIN IN WRITING. FURTHER, THERE ARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THE

FACE HEREOF.

F. No agent of Bristol is authorized to assume any liability for it or to make any written

or oral warranties beyond those set forth herein.

A. Buyer's sole remedy for breach of any warranty is limited exclusively to repair or

replacement without cost to Buyer of any goods or parts found by Seller to be

defective if Buyer notifies Bristol in writing of the alleged defect within ten (10) days

of discovery of the alleged defect and within the warranty period stated above, and if

the Buyer returns such goods to Bristol's Watertown office, unless Bristol's Watertown office designates a different location, transportation prepaid, within thirty (30)

days of the sending of such notification and which upon examination by Bristol

proves to be defective in material and workmanship. Bristol is not responsible for

any costs of removal, dismantling or reinstallation of allegedly defective or defective

goods. If a Buyer does not wish to ship the product back to Bristol, the Buyer can

arrange to have a Bristol service person come to the site. The Service person's

transportation time and expenses will be for the account of the Buyer. However,

labor for warranty work during normal working hours is not chargeable.

B. Under no circumstances will Bristol be liable for incidental or consequential

damages resulting from breach of any agreement relating to items included in this

quotation, from use of the information herein or from the purchase or use by Buyer,

its employees or other parties of goods sold under said agreement.

REMEDIES

Page 4

How to return material for Repair or Exchange

Before a product can be returned to Bristol for repair, upgrade, exchange, or to verify

proper operation, form (GBU 13.01) must be completed in order to obtain a RA (Return

Authorization) number and thus ensure an optimal lead time. Completing the form is very

important since the information permits the Bristol Repair Dept. to effectively and

efficiently process the repair order.

You can easily obtain a RA number by:

A. FAX

Completing the form (GBU 13.01) and faxing it to (860) 945-3875. A Bristol Repair

Dept. representative will return call (or other requested method) with a RA number.

B. E-MAIL

Accessing the form (GBU 13.01) via the Bristol Web site (www.bristolbabcock.com)

and sending it via E-Mail to brepair@bristolbabcock.com

representative will return E-Mail (or other requested method) with a RA number.

C. Mail

Mail the form (GBU 13.01) to

Bristol Inc.

Repair Dept.

1100 Buckingham Street

Watertown, CT 06795

A Bristol Repair Dept. representative will return call (or other requested method)

with a RA number.

D. Phone

Calling the Bristol Repair Department at (860) 945-2442. A Bristol Repair Depart-

ment representative will record a RA number on the form and complete Part I, then

send the form to the Customer via fax (or other requested method) for Customer

completion of Parts II & III.

A copy of the completed Repair Authorization Form with issued RA number should be included with the product being returned. This will allow us to quickly track, repair, and

return your product to you.

. A Bristol Repair Dept.

Page 5

Bristol Inc. Repair Authorization Form (off-line completion)

(Providing this information will permit Bristol Inc. to effectively and efficiently process your return. Completion is required

to receive optimal lead time. Lack of information may result in increased lead times.)

Date___________________ RA #___________________SH_ Line No.____________

Standard Repair Practice is as follows: Variations to this is

practice may be requested in the “Special Requests” section.

• Evaluate / Test / Verify Discrepancy

• Repair / Replace / etc. in accordance with this form

• Return to Customer

Part I Please complete the following information for single unit or multiple unit returns

Address No. (office use only) Address No. (office use only)

Bill to : Ship to:

Purchase Order: Contact Name:____________________________________

Phone: Fax: E-Mail:

Part II Please complete Parts II & III for each unit returned

Model No./Part No. Description

Please be aware of the Non warranty standard charge:

• There is a $100 minimum evaluation charge, which is

applied to the repair if applicable (√ in “returned”

B,C, or D of part III below)

Range/Calibration S/N

Reason for return

: Failure Upgrade Verify Operation Other

1. Describe the conditions of the failure (Frequency/Intermittent, Physical Damage, Environmental Conditions,

Communication, CPU watchdog, etc.)

(Attach a separate sheet if necessary)

2. Comm. interface used: Standalone RS-485 Ethernet Modem (PLM (2W or 4W) or SNW) Other:______________

3. What is the Firmware revision? _____________________ What is the Software &version?

Part III If checking “replaced” for any question below, check an alternate option if replacement is not available

A. If product is within the warranty time period but is excluded due

to Bristol’s warranty clause, would you like the product:

repaired returned replaced scrapped?

B. If product were found to exceed the warranty period,

would you like the product:

C. If product is deemed not repairable would you like your product:

D. If Bristol is unable to verify the discrepancy, would you like the product:

repaired returned replaced scrapped?

returned replaced scrapped?

returned replaced *see below?

* Continue investigating by contacting the customer to learn more about the problem experienced? The person to contact

that has the most knowledge of the problem is: ______________________________ phone_____________________

If we are unable to contact this person the backup person is: _________________________

Special Requests: ____________________________________________________________________________________

____________________________________________________________________________________________________

Ship prepaid to: Bristol Inc., Repair Dept., 1100 Buckingham Street, Watertown, CT 06795

Phone: 860-945-2442 Fax: 860-945-

phone_____________________

2220 Form GBU 13.01 Rev. C 04/27/06

Page 6

Bristol

Training

GET THE MOST FROM YOUR BRISTOL

BABCOCK INSTRUMENT OR SYSTEM

• Avoid Delays and problems in getting your system on-line

• Minimize installation, start-up and maintenance costs.

• Make the most effective use of our hardware and software.

• Know your system.

As you know, a well-trained staff is essential to your operation. Bristol Inc. offers a full

schedule of classes conducted by full-time, professional instructors. Classes are offered

throughout the year at three locations: Houston, Orlando and our Watertown, CT

headquarters. By participating in our training, your personnel can learn how to install,

calibrate, configure, program and maintain any and all Bristol products and realize the full

potential of your system.

For information or to enroll in any class, contact our training department in Watertown at

(860) 945-2343. For Houston classes, you can also contact our Houston office, at (713) 685-

6200.

Page 7

A Few Words About Bristol Inc.

For over 100 years, Bristol® has been providing innovative solutions for the measurement

and control industry. Our product lines range from simple analog chart recorders, to

sophisticated digital remote process controllers and flow computers, all the way to turnkey

SCADA systems. Over the years, we have become a leading supplier to the electronic gas

measurement, water purification, and wastewater treatment industries.

On off-shore oil platforms, on natural gas pipelines, and maybe even at your local water

company, there are Bristol Inc. instruments, controllers, and systems running year-in and

year-out to provide accurate and timely data to our customers.

Getting Additional Information

In addition to the information contained in this manual, you may receive additional assistance in using this product from the following sources:

Help Files / Release Notes

Many Bristol software products incorporate help screens. In addition, the software typically

includes a ‘read me’ release notes file detailing new features in the product, as well as other

information which was available too late for inclusion in the manual.

Contacting Bristol Inc. Directly

Bristol's world headquarters is located at 1100 Buckingham Street, Watertown,

Connecticut 06795, U.S.A.

Our main phone numbers are:

(860) 945-2200

(860) 945-2213 (FAX)

Regular office hours are Monday through Friday, 8:00AM to 4:30PM Eastern Time,

excluding holidays and scheduled factory shutdowns. During other hours, callers may leave

messages using Bristol's voice mail system.

Telephone Support - Technical Questions

During regular business hours, Bristol's Application Support Group can provide telephone

support for your technical questions.

For technical questions about TeleFlow products call (860) 945-8604.

For technical questions about ControlWave call (860) 945-2394 or (860) 945-2286.

For technical questions regarding Bristol’s OpenEnterprise product, call (860) 945-3865

or e-mail: scada@bristolbabcock.com

Page 8

For technical questions regarding ACCOL products, OpenBSI Utilities, UOI and all other

software except for ControlWave and OpenEnterprise products, call (860) 945-2286.

For technical questions about Network 3000 hardware, call (860) 945-2502.

You can e-mail the Application Support Group at: bsupport@bristolbabcock.com

The Application Support Group maintains an area on our web site for software updates and

technical information. Go to: www.bristolbabcock.com/services/techsupport/

For assistance in interfacing Bristol hardware to radios, contact Bristol’s Communication

Technology Group in Orlando, FL at (407) 629-9463 or (407) 629-9464.

You can e-mail the Communication Technology Group at:

orlandoRFgroup@bristolbabcock.com

Telephone Support - Non-Technical Questions, Product Orders, etc.

Questions of a non-technical nature (product orders, literature requests, price and delivery

information, etc.) should be directed to the nearest sales office (listed on the rear cover of

this manual) or to your Bristol-authorized sales representative.

Please call the main Bristol Inc. number (860-945-2200) if you are unsure which office

covers your particular area.

Visit our Site on the World Wide Web

For general information about Bristol Inc. and its products, please visit our site on the

World Wide Web at: www.bristolbabcock.com

Training Courses

Bristol’s Training Department offers a wide variety of courses in Bristol hardware and

software at our Watertown, Connecticut headquarters, and at selected Bristol regional

offices, throughout the year. Contact our Training Department at (860) 945-2343 for course

information, enrollment, pricing, and scheduling.

Page 9

CI-9110

MODEL 9110-00A REMOTE SET REGULATOR

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 1 -INTRODUCTION

1.1 PRODUCT DESCRIPTION

1.2 THEORY OF OPERATION

1.2.1 Analog Regulator Model

1.2.2 Guard Input

1.2.3 Current Output

1.2.4 Raise/Lower Regulator Model

1.3 DATA PLATE

2.1 GENERAL

2.2 MOUNTING

2.2.1 Two-Inch Pipe Mounting

2.2.2 In-Line Mounting

2.3 PRESSURE CONNECTIONS

2.3.1 General Piping

2.3.2 Moisture in Lines

2.3.3 Line Size

2.3.4 Venting

2.4 INTERNAL ACCESS

2.4.1 Body and Cover

2.4.2 Electrical Conduit Port

2.5 INSTALLATION IN HAZARDOUS LOCATIONS

..........................................................................................................................1-4

.....................................................................................................................1-4

.......................................................................................................................1-6

Section 2 - INSTALLATION

.............................................................................................................................2-1

..........................................................................................................................2-1

.................................................................................................................2-1

......................................................................................................................2-2

.................................................................................................................2-3

................................................................................................................................2-4

..................................................................................................................................2-4

...........................................................................................................2-4

....................................................................................................................2-4

Section 3 - BOARD SETUP

...............................................................................................1-1

................................................................................................1-1

.....................................................................................................1-1

.............................................................................................1-6

.....................................................................................................2-1

.............................................................................................2-2

........................................................................................................2-5

...........................................................2-5

3.1 USING OPTION SWITCHES

3.1.1 Switch Functions

3.2 ANALOG INPUT MODELS

3.3 RAISE/LOWER MODELS

3.3.1 Continuous Signal

3.3.2 Incremental Signal

3.4 INPUT FILTER

3.5 GUARD INPUT

3.5.1 Guard logic

3.5.2 Static or Dynamic Guard Input

3.6 OUTPUT RATE OF CHANGE

3.7 ANALOG FAILURE MODES (Fail Hold & Fail Zero)

4.1 GENERAL

4.2 TERMINAL BLOCK IDENTIFICATION

9110 Remote Set Regulator Contents / 0-1

............................................................................................................................3-5

.............................................................................................................................4-1

............................................................................................3-1

..................................................................................................................3-2

................................................................................................3-2

...................................................................................................3-2

................................................................................................................3-3

...............................................................................................................3-3

....................................................................................................................3-4

....................................................................................................................3-5

..........................................................................................3-5

............................................................................................3-5

.....................................................3-6

Section 4 - FIELD WIRING

..........................................................................4-1

Page 10

SECTION TITLE PAGE #

Section 4 - FIELD WIRING (Continued)

4.3 ANALOG VOLTAGE INPUT (1-5 V) WITH GUARD ..................................................4-2

4.4 ANALOG CURRENT INPUT (4-20 mA) WITH GUARD............................................. 4-4

4.5 RAISE/LOWER INPUTS WITH GUARD ..................................................................... 4-4

4.6 4-20 mA CURRENT OUTPUT....................................................................................... 4-6

4.7 DC POWER ..................................................................................................................... 4-6

4.8 OPERATING NOTES..................................................................................................... 4-7

4.9 INITIAL CHECKS.......................................................................................................... 4-7

Section 5 - SERVICE

5.1 GENERAL.......................................................................................................................5-1

5.2 TROUBLESHOOTING HINTS ..................................................................................... 5-2

5.3 SETTING OUTPUT LIMITS ......................................................................................... 5-3

5.3.1 General Principles .......................................................................................................... 5-3

5.3.2 Test Setup ....................................................................................................................... 5-3

5.3.3 Procedure ........................................................................................................................ 5-3

5.4 CALIBRATION TEST SETUP ...................................................................................... 5-4

5.5 CALIBRATION PRECAUTION .................................................................................... 5-4

5.6 PRELIMINARY CALIBRATION CHECK .................................................................... 5-5

5.7 DETAILED CALIBRATION FOR ANALOG MODELS............................................... 5-6

5.7.1 Feedback Zero & Span.................................................................................................... 5-6

5.7.2 Current Output Span & Load ........................................................................................5-6

5.7.3 Pressure Output Check ..................................................................................................5-6

5.8 DETAILED CALIBRATION FOR RAISE/LOWER MODEL....................................... 5-7

5.8.1 Feedback Zero & Span.................................................................................................... 5-7

5.8.2 Current Output Span & Load ........................................................................................ 5-8

5.9 PCB REFERENCE DRAWINGS ................................................................................... 5-8

Section 6 - SPECIFICATIONS

6.1 ANALOG INPUT MODEL ............................................................................................. 6-1

6.2 RAISE/LOWER INPUT MODEL................................................................................... 6-1

6.3 GUARD INPUT ..............................................................................................................6-2

6.4 ANALOG OUTPUT ........................................................................................................ 6-2

6.5 ACCURACY - ANALOG MODELS................................................................................ 6-2

6.6 ACCURACY - RAISE/LOWER MODELS ..................................................................... 6-2

6.7 DC POWER ..................................................................................................................... 6-2

6.8 STEPPER DRIVE MECHANISM.................................................................................. 6-2

6.9 PRESSURE REGULATOR ASSEMBLY ......................................................................6-3

6.10 INSTRUMENT ENCLOSURE....................................................................................... 6-3

6.11 ENVIRONMENT. ........................................................................................................... 6-3

Section 7 - PARTS

7.1 MODEL 9110 MAIN PARTS.......................................................................................... 7.1

7.2 REMOTE SET REGULATOR BASIC PARTS.............................................................. 7-4

SUPPLEMENTAL INSTRUCTIONS

GUIDELINES FOR SYSTEM GROUNDING .........................................................S1400

CARE AND HANDLING OF PC BOARDS AND

ESD-SENSITIVE COMPONENTS ........................................................................S14006

0-2 / Contents 9110 Remote Set Regulator

Page 11

Chapter 1

INTRODUCTION

1.1 PRODUCT DESCRIPTION

Series 9110-00A, Remote Set Regulators are transducer devices that use an electrical input

signal to set the level of a pneumatic output signal. Depending on the actual model, the

electrical input may be either an analog or a raise/lower type signal. For analog models, the

input can be configured for a 1-5 V dc or 4-20 mA dc signal. For the Raise/Lower models,

the input can be configured to accept a continuous or pulse incremental dc signal.

The pneumatic output of a Remote Set Regulator may be specified with a 3-15, 3-27 or 6-30

psi output. All models can operate from pressure supplies up to 100 psi (Max). Minimum

supply pressure must be at least 3 psi above the maximum range value.

The Regulator also provides a guard input. This signal can be used to Enable (turn ON) or

Inhibit (turn OFF) the input for telemetry and security applications. When the guard signal

is Enabled, it allows the output to respond to a change of the input signal.

The Remote Set Regulator is contained in a weatherproof, explosion-proof enclosure having

a detachable threaded cover. Removal of the cover provides access to the field wiring

terminals and the programmable option switches.

Regulators are factory-furnished for 12 Vdc or 24 Vdc supply operation. These voltage

ratings are fixed and cannot be changed in the field.

In-line or pipe mounting are offered as for installations. The former uses a 1/4 inch rigid

pressure line for support, while the latter includes a special bracket for two-inch pipe

mounting.

1.2 THEORY OF OPERATION

The Remote Set Regulator contains a CPU Board and a Termination Board. The CPU

Board contains the central processor and its associated circuitry, while the Termination

Board contains the field wiring terminals and the input protection circuitry.

The Regulator is offered in Analog and Raise/Lower models. Both types use similar

circuitry but they perform different functions. A description of the Analog model follows

while the Raise/Lower model is explored later in the text.

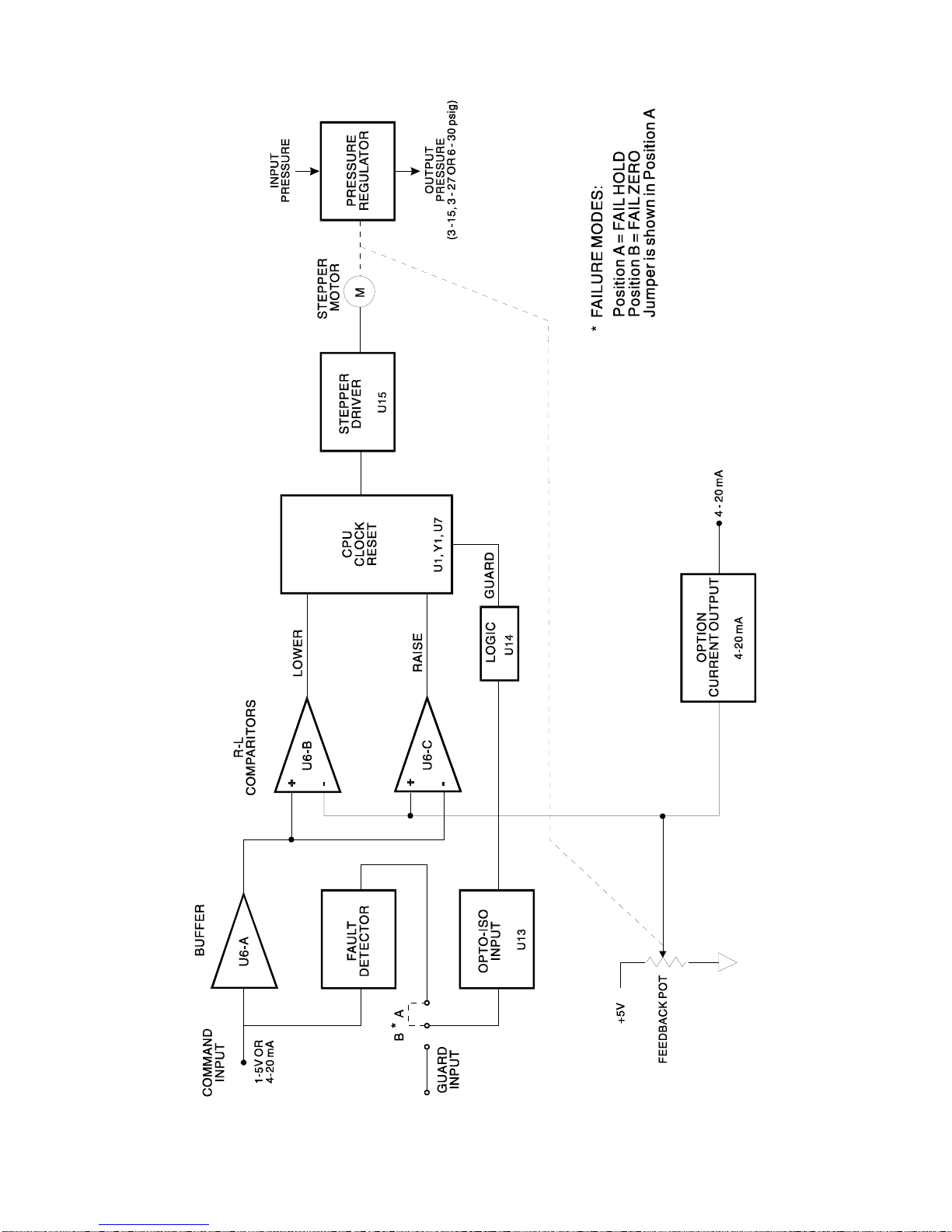

1.2.1 Analog Regulator Model

The Analog Regulator circuitry is shown in the block diagram of Figure 1-2. In this circuit,

the Command signal (1-5 V or 4-20 mA) is applied to a buffer amplifier which drives the

plus (+) input of the Lower Comparator and the minus (-) input of the Raise Comparator.

Also note that the opposing inputs of both comparators are referenced to the same point

which is the center arm of a feedback pot.

CI-9110 1-1 Introduction

Page 12

The CPU, clock and reset circuitry performs the timing, measurement and decision making

functions of the Remote Set Regulator. This circuit analyzes the comparator outputs and

sends data to the stepper driver which, in turn, pulses the stepper motor in either direction.

Since the driveshaft of the stepper motor is mechanically coupled to the feedback pot and a

pressure regulator valve, both will be set in accordance with data received from the CPU.

Introduction 1-2 CI-5450

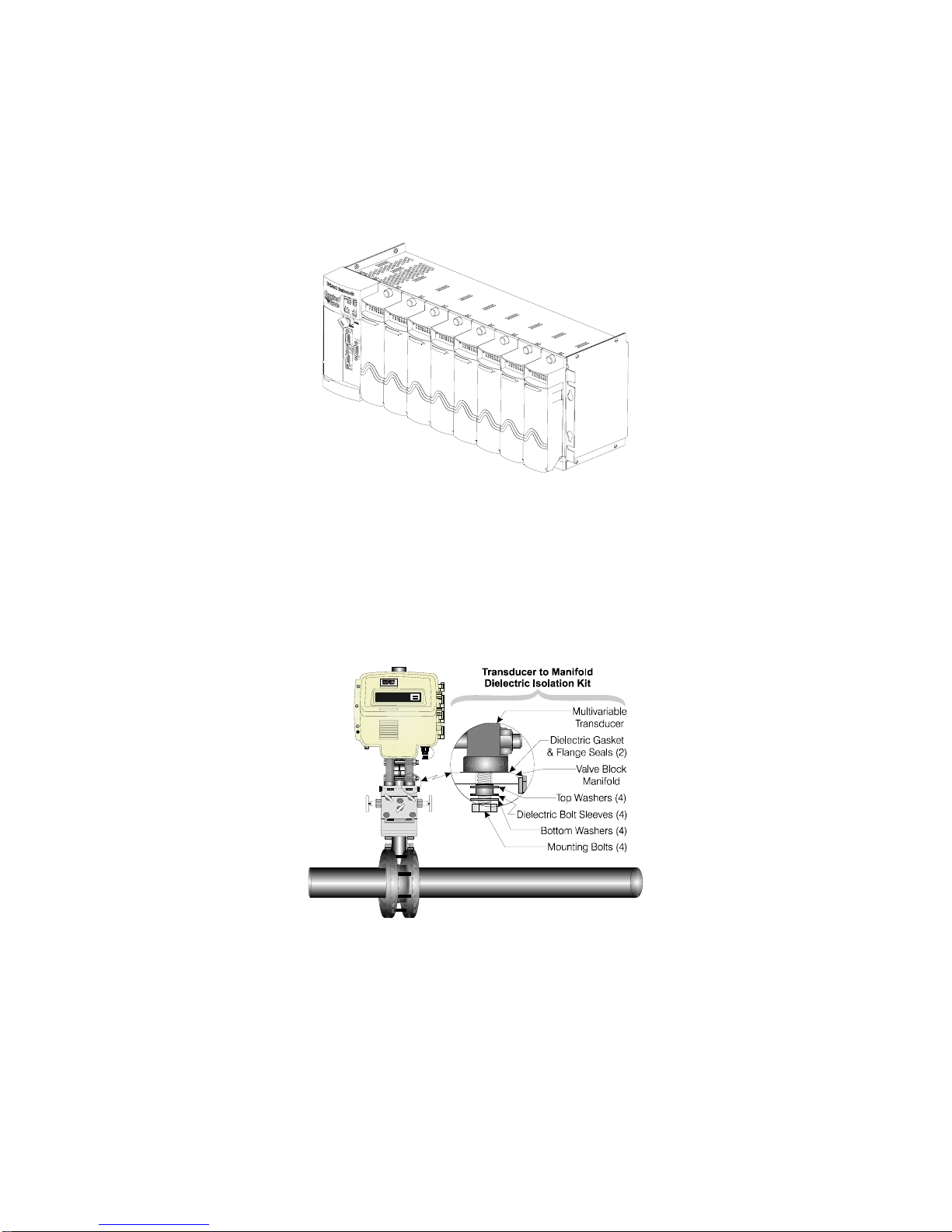

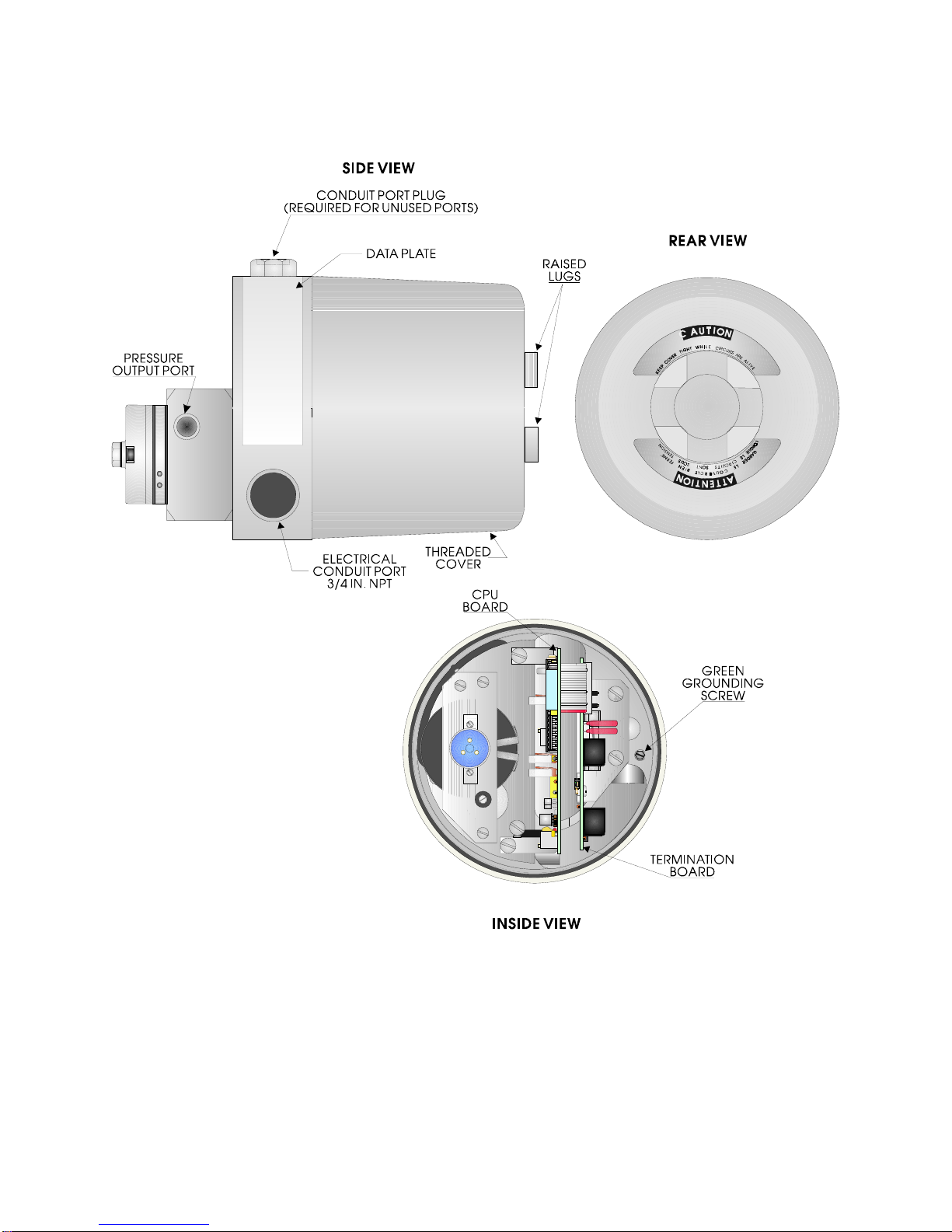

Figure 1-1 - Remote Set Regulator

Page 13

Figure 1-2 - Block Diagram of Analog Type Regulator

CI-9110 1-3 Introduction

Page 14

The feedback pot connects across a regulated +5 Vdc source. The voltage at the feedback

pot’s contact corresponds to the mechanical position of the pressure regulator. This

reference voltage is applied to the Raise and Lower Comparators.

If an increase in signal level occurs at the command input, the Raise Comparator will

become unbalanced since this signal will exceed the voltage present at the center arm of the

pot. The Lower Comparator will be unaffected since the input signal will be of opposite

polarity compared to the feedback pot voltage. The CPU senses the increased output at the

Raise Comparator and outputs a signal that drives the stepper motor in an upward

direction. The upward driving action will continue until the voltage at the pot’s center arm

becomes equal to the new signal level. Once the comparator is balanced, the CPU will turn

off the stepper motor and the pressure regulator will provide a corresponding pressure output level. Input changes that reduce the output value will have the opposite effect.

The comparators are biased so that they include a certain amount of hysteresis. This bias

keeps the stepper motor in a stable, deenergized zone that is less affected by noise bursts

that may appear on the command input line.

The stepper motor is actuated in incremental steps. The pulse signals received from the

stepper driver will increment the motor one step at a time. The motor requires approximately 22,000 steps for full rotation.

1.2.2 Guard Input

An optional signal can be applied to the guard input to Enable or Inhibit the command Signal. The guard circuit consists of a non-polarized, opto-isolated circuit whose output is

applied to the CPU via a logic circuit.

Analog Regulator models include a fault detector circuit that is activated through jumper

selection. The fault detector monitors the analog input value for a value that is less than

0% of scale. This condition, which occurs when the AI command input signal fails, will stop

the stepper motor and maintain the last output value prior to the failure.

Two types of signal failure modes are provided by jumper selection as shown at the left of

Figure 1-2. Position "A" of the jumper provides fail-hold mode, while position "B" provides

fail-hold zero. Should the AI signal fail (signal < 0% of scale), fail-zero mode will drive the

output slowly to zero, while fail-hold mode will retain its last output value.

Mechanical limiting is also provided by adjustable tangs located on the main drive gear of

the stepper motor. When the input signal is of a value that causes the stepper to drive

against a limit, a mechanical clutch on the drive shaft will slip. After making several

revolutions, the software will time out and cut off power to the motor. Power will be reapplied when the signal level returns to the normal operating range.

1.2.3 Current Output

A 4-20 mA current output is obtained via an amplifier/converter circuit. The input to this

circuit is the feedback pot whose center arm adjusts the current output to track the valve

position.

Introduction 1-4 CI-5450

Page 15

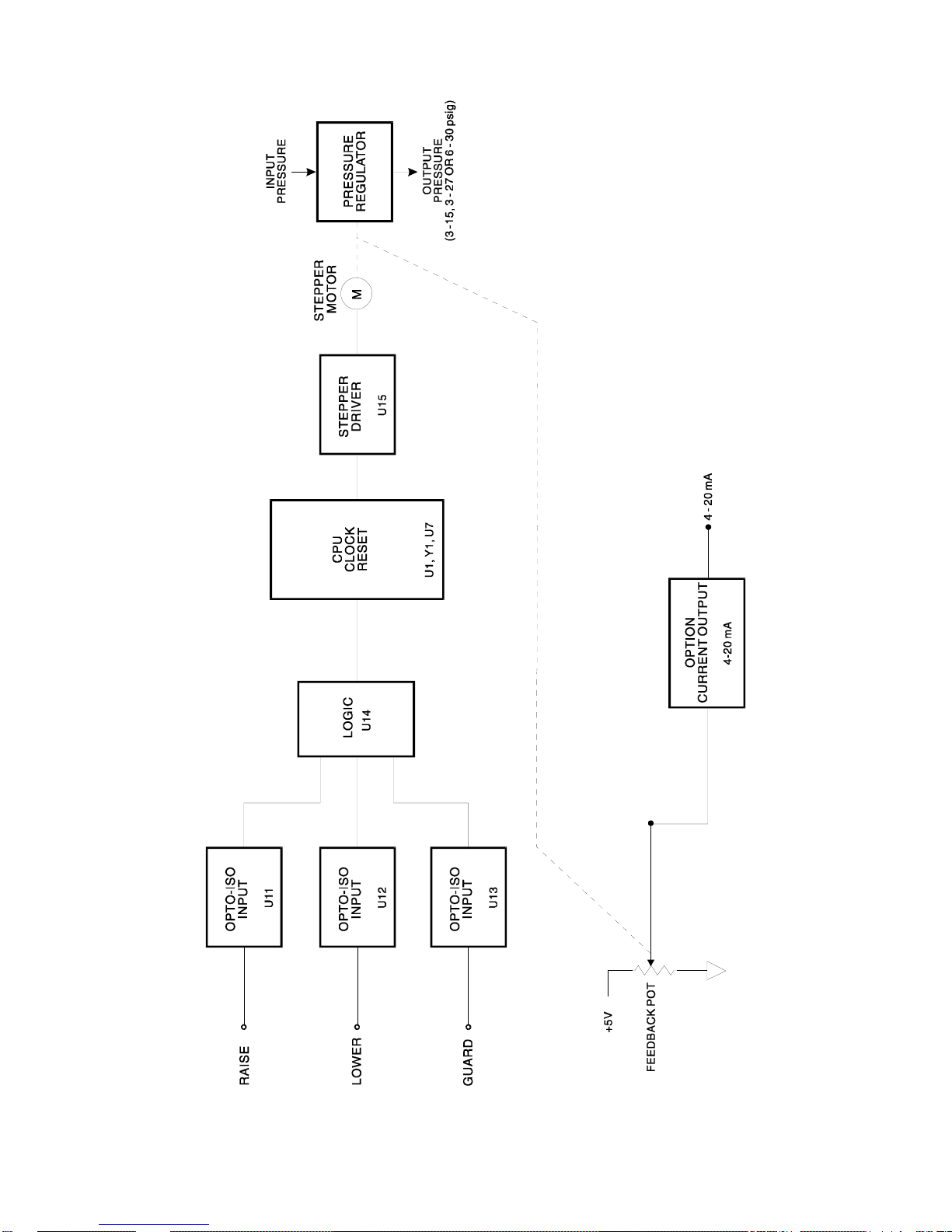

Figure 1-3 - Block Diagram of Raise/Lower Type Regulator

CI-9110 1-5 Introduction

Page 16

1.2.4 Raise/Lower Regulator Model

A block diagram for the Raise/Lower Regulator model is shown in Figure 1-3. It will be

noted that this diagram is similar to the Analog Regulator except for the input circuit arrangement. This circuit contains Raise, Lower and Guard input circuits which are optoisolated.

The outputs of all three opto-isolators are applied to a logic circuit that checks the status of

the three signals and determines whether the output will be in a Raise, Lower or Guard

mode.

Each Raise and Lower input may be configured to accept a continuous or pulse incremental

signal. The continuous signal is a dc input that, when switched to an ON state, allows the

stepper motor to rotate in the proper direction; when switched to an OFF state, it stops the

stepper motor and maintains a corresponding output value. The pulse incremental signal

can be a single dc pulse or a pulse train input that causes stepper motor to change the output by an incremented amount. The amount of the output increment is determined by the

settings of the configuration switches.

The outputs of all three opto-isolators in Figure 1-3 are status signals that, when processed

by the CPU, establish a pressure output value that corresponds to the input signals. The

remainder of the circuitry shown in the illustration operates in the same manner as

described for Analog Regulators.

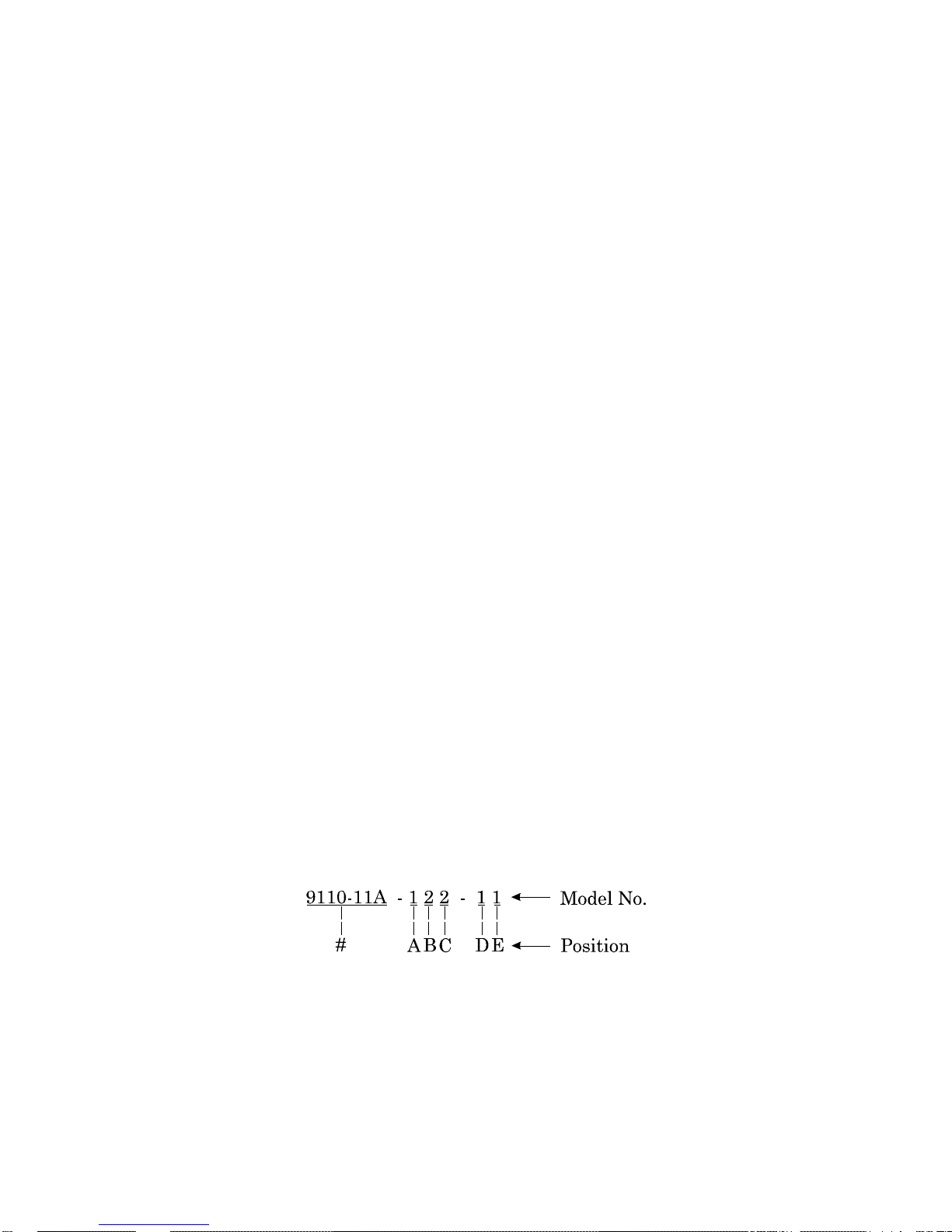

1.3 DATA PLATE

A data plate affixed to the Remote Set Regulator lists the instrument model, serial number

and other relevant information. The features and options present in an instrument can be

determined by comparing its model number to the model breakdown of Table 1-A.

Remote Set Regulators certified for use in hazardous areas will include the seal of the

certifying laboratory on the data plate. Certification will also be indicated as an element of

the instrument model number listed on the data plate.

Table 1A - Model Number Breakdown

- SAMPLE MODEL NUMBER -

# = BASE MODEL NUMBER

A = ELECTRICAL INPUT B = POWER

1 = Raise/lower Input 1 = 12V dc

2 = Analog Input (1-5V or 4-20 mA) 2 = 24V dc

Introduction 1-6 CI-5450

Page 17

Table 1A - Model Number Breakdown (Continued)

C = PNEUMATIC OUTPUT D = MOUNTING ARRANGEMENT

1 = 3-15 psi 1 = 2 In. Pipe Mtg. Bracket

2 = 3-27 psi 2 = In-Line Pressure Pipe

3 = 6-30 psi

E = CERTIFICATION

1 = None

2 = FM-EXP/NI

3 = CSA-EXP

NOTE: This table is only provided for product identity and not for or-

dering purposes. Contact the Bristol Sales Department for

ordering information.

CI-9110 1-7 Introduction

Page 18

BLANK PAGE

Page 19

Chapter 2

INSTALLATION

2.1 GENERAL

Proper installation techniques will ensure highest performance and also minimize

measurement errors. The Remote Set Regulator should be mounted in a location that is not

subject to radical temperature extremes, vibration and shock. See Section 6 Specifications

for environmental operating conditions.

This section describes the mechanical mounting arrangements of the Regulator and

explains the technique of bringing in wiring via electrical conduit.

The installation procedures described herein are furnished as a guideline and cannot cover

all possible variations. All deviations from the installation procedures described herein are

at the discretion of the user.

2.2 MOUNTING

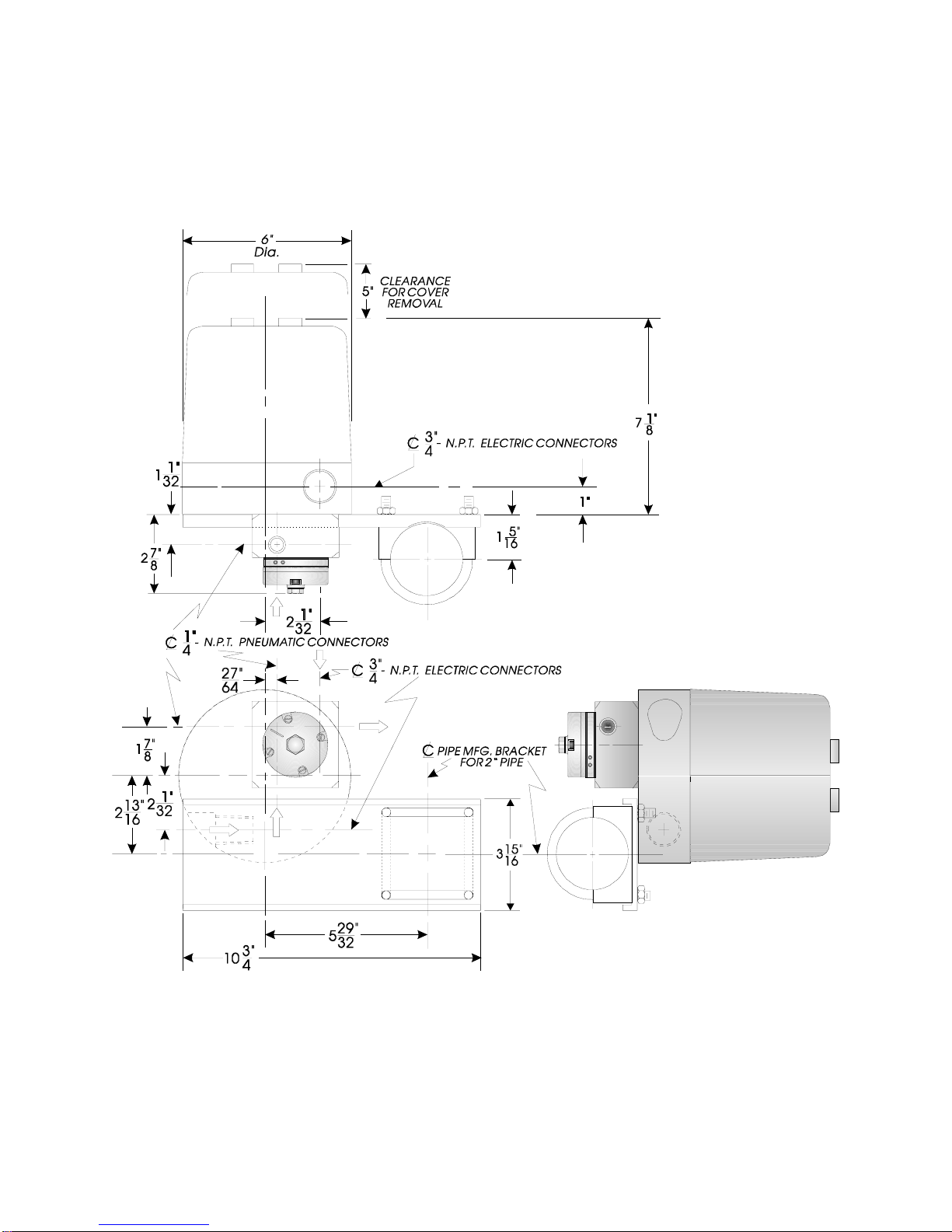

The overall mounting dimensions for the unit are given in Figure 2-1. Be sure that the

selected site has sufficient clearance to remove the Regulator cover and access internal

switches and terminals. Choose the appropriate mounting arrangement below as required

2.2.1 Two-Inch Pipe Mounting

Refer to the overall dimension of Figure 2-1 for views of the universal pipe mounting

bracket. For this type of installation, the bracket is assembled to the Regulator using three

screws. Select the desired set of bracket holes for either vertical or horizontal mounting

pipes.

Once the bracket is mounted, position the assembly next to the pipe as required and install

the u-bolts from the hardware kit into the appropriate bracket holes. Install nuts on the ubolts and tighten them until the instrument is self-supporting.

2.2.2 In-Line Mounting

In-line mounting can be used when the pressure line and electrical conduit provide

sufficient strength to support the weight of the unit. This type of mounting should never be

attempted on lines constructed of soft or low-strength materials. In-line mounting is also

not recommended for non-secured lines subject to excessive vibration or hammering.

Once the desired location has been selected, cut the pressure pipe and install proper fittings

(1/4 in. NPT male) to mate with the two pressure connection ports on the Regulator. It is

recommended that unions and shutoff valves also be installed in each line to allow an easy

disconnect for maintenance or troubleshooting operations.

CI-9110 2-1 Installation

Page 20

2.3 PRESSURE CONNECTIONS

Remote Set Regulators are furnished in models that provide 3-15, 3-27 or 6-30 psig outputs.

All models will accept 100 psig maximum on the supply side. Pressure supplies that exceed

this value will require an external pressure regulator or limiter.

Figure 2-1 - Overall Mounting Dimensions

2.3.1 General Piping

A basic piping diagram is shown in Figure 2-3. The pressure supply line may include a

pressure gauge, external regulator, filter and a shutoff valve as shown. Union type

connections are recommended for pressure lines to allow an easy disconnect. A pressure

Installation 2-2 CI-9110

Page 21

shutoff valve allows the supply source to be closed down during maintenance checks

without disturbing other equipment operating on the line.

2.3.2 Moisture in Lines

The Regulator should be installed so that the supply and output lines slope downward and

away. This arrangement allows any condensate trapped in the lines to drain away from the

instrument.

CI-9110 2-3 Installation

Figure 2-2 - Regulator Assembly

Page 22

2.3.3 Line Size

For most installations 1/4 inch pipe or tubing is satisfactory. However, if the input or

output lines run a great distance, the response lag time may become objectionable. In these

instances the use of 3/8 inch tubing is recommended.

2.3.4 Venting

The user should note that the Remote Set Regulator bleeds a small amount of pressure into

the atmosphere during operation. A 1/4 inch NPT vent is provided on the pressure regulator

body for this purpose. The vent location is shown in Figure 2-3.

When air is used as the pressure source, the vent fitting may be allowed to bleed into the

atmosphere. If fuel gas or other hazardous type gases are used as the pressure source for a

Remote Set Regulator, the VENT port must be piped to a safe location.

** Warning **

Covers of Remote Set Regulators operating in hazardous

areas should not be removed. If servicing is required, the

environment should first be made safe or the supply power

should be turned off, allowing the instrument to be disconnected and removed to a safe area.

Figure 2-3 - Typical Pressure Connections

2.4 INTERNAL ACCESS

The subtopics that follow discuss the main mechanical and electrical assemblies that will

be accessed during installation. They describe the method of removing and installing the

cover, the use of the electrical conduit ports, and the installation precautions to be

observed.

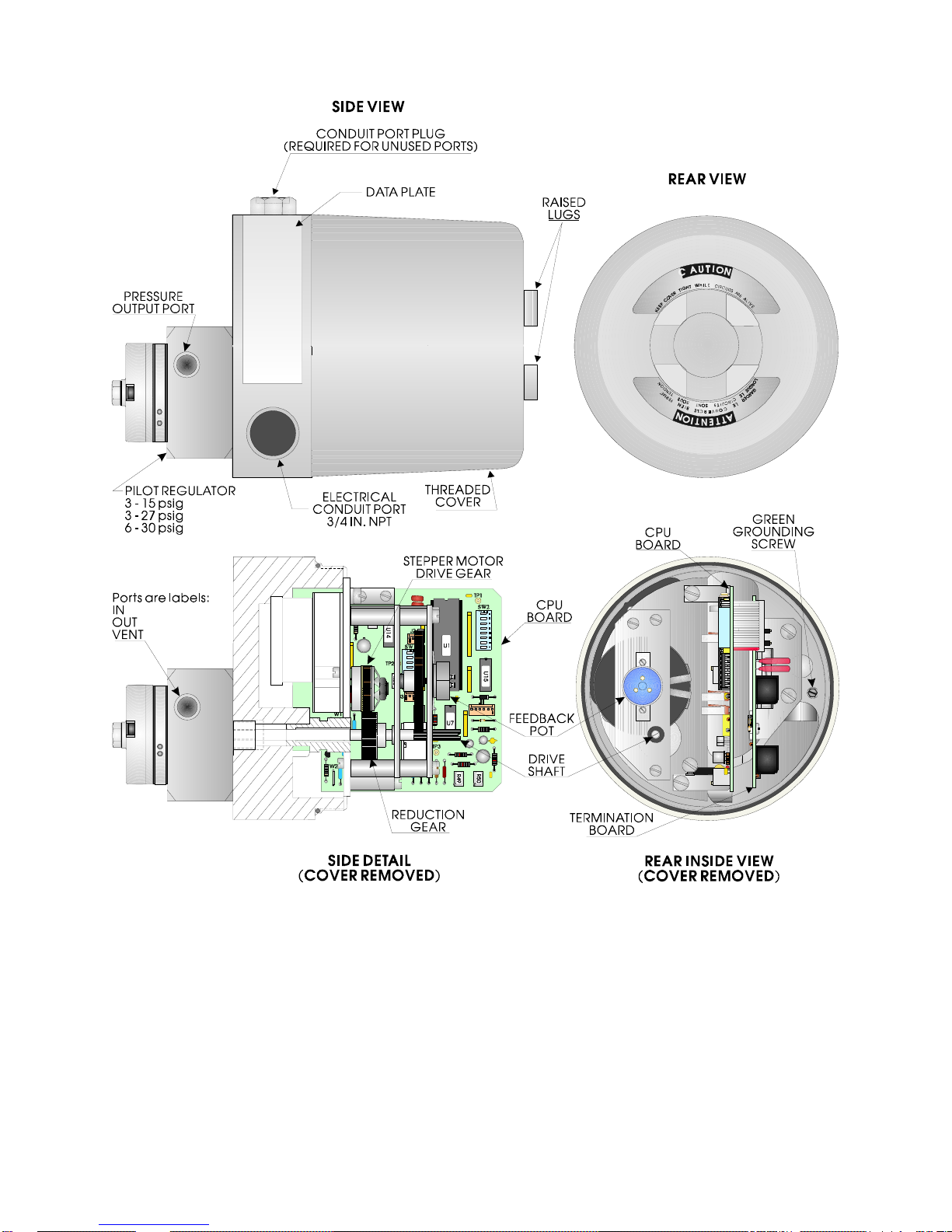

2.4.1 Body and Cover

The Remote Set Regulator is contained in a aluminum body with a gasketed screw-on cover

as shown in Figure 2-2. Four raised lugs on the cover permit it to be loosened or tightened

Installation 2-4 CI-9110

Page 23

using a flat metal bar or similar tool. When replacing the cover, it should be snugged in and

not over-tightened. The threads of the cover should also be coated with a layer of anti-seize

compound to prevent lockup.

When the cover is removed, the PC board assemblies become accessible (see right view of

Figure 2-3). The Termination Board contains the field wiring terminals while the CPU

Board contains the option switches. The gear mechanism and feedback potentiometer are

also accessible.

2.4.2 Electrical Conduit Port

Two 3/4 in. NPT electrical ports are provided at the lower part of the housing. Either or

both ports may be used to bring in signal and supply wiring (left of Figure 2-3). These ports

accommodate a standard 3/4 inch NPT pipe thread connection. If a port is not used, it must

have a conduit plug installed to maintain the explosion-proof integrity of the unit.

2.5 INSTALLATION IN HAZARDOUS LOCATIONS

Instruments that operate in hazardous locations must adhere to the following rules of

safety:

A. All instrument wiring that runs through a hazardous area must be enclosed in metal

conduit. The point where the conduit connection meets the unit's housing should be

properly tightened to prevent entry of gas or other ignitable substances. Explosion-proof

wiring practices must be followed to prevent flashback through the conduit.

B. The cover of the installed unit must be screwed in hand tight and fully seated. The cover

must not be damaged and no threads should be stripped.

C. The cover of the unit must never be removed during operation unless the atmosphere is

made safe or all electrical power is removed from the instrument.

** Warning **

No maintenance procedures should be performed while the

unit is powered and operating in a combustible or

explosive environment. If on-site maintenance is a

necessity, steps must be taken to make the environment

safe (non-hazardous). Otherwise, the instrument must be

powered down, unwired, and brought into a safe area. A

failure to observe these precautions could result in fire or

explosion and injury to persons.

** Safety Note **

For certified instruments, all installation and operating

practices must conform to area classification and safety

codes as specified by the certifying laboratory. The seal of

the certifying laboratory will appear on the instrument

data plate along with the model and serial number.

CI-9110 2-5 Installation

Page 24

BLANK PAGE

Page 25

Chapter 3

BOARD SETUP

3.1 USING OPTION SWITCHES

Two switch assemblies (SW1 and SW2) are used to set options and select ranges. These

switches are located on the CPU Board as shown in Figure 3-1. Each assembly contains

eight (8) miniature SPST switches. The individual switches of each package are identified

as subsets of the main switch, e.g., SW1-1, SW1-2, etc.

Two types of switch assemblies are used for Regulators. One type uses cradle switches,

while the other uses slide-type switches. The operation of each type differs as follows:

Cradle Switches with OPEN Designation

OPEN side pressed down = OFF (open circuit)

Numbered side pressed down = ON (closed circuit)

Slide Switches with ON Designation

Set in direction of ON arrow = ON (closed circuit)

Set in opposite direction of arrow = OFF (open circuit)

The switch assemblies are fragile and require careful handling. Use a small, blunt object

such as a miniature screwdriver to set the switch positions. Do not use pencils, ballpoint

pens, or extremely sharp objects for this purpose.

WARNING

When starting a unit for the first time, all switch options must be set before

any power is applied. Improper switch settings can cause improper

operation or dangerous control situations that could damage process

equipment and property, or cause injury to persons.

NOTE

Attempting to change settings of any switch (excluding SW2-6 and SW2-8)

while the unit is on line will not

Although the switches have been set, the configuration will not take effect

until the power applied to the Regulator has been turned OFF and, after a

moment, turned back ON again.

If switch settings are changed without turning the power OFF, the present

on-line configuration will remain in effect until the unit is turned OFF and

powered up again.

:

:

produce a change of configuration.

CI-9110 3-1 Board Setup

Page 26

3.1.1 Switch Functions

The Regulator assembly is configured by two, eight-switch packages which perform the

functions listed in Table 3-1.

Table 3-1 - Regulator Assembly Switch SW1 & SW2 Functions & Settings

Switch

Label

SW1-1 R/L % per pulse increment 3-4

SW1-2 R/L % per pulse increment 3-4

SW1-3 R/L % per pulse increment 3-4

SW1-4 R/L % per pulse increment 3-4

SW1-5 R/L % per pulse increment 3-4

SW1-6 Not Used None

SW1-7 Not Used None

SW1-8 Input Filter 3-4

SW2-1 Guard (Dynamic/Static) 3-5

SW2-2 Actuator Output Rate of Change 3-6

SW2-3 Actuator Output Rate of Change 3-6

SW2-4 Actuator Output Rate of Change 3-6

SW2-5 Actuator Output Rate of Change 3-6

SW2-6 Guard (Active/Inactive) 3-5

SW2-7 Not Used None

SW2-8 Analog Input (V or I) 3-2

Switch

Function

Page

Ref. * Your Setting

**

Your Notes

* Record your switch settings (ON or OFF) here for future reference.

** List your corresponding switch functions or values here.

3.2 ANALOG INPUT MODELS

Initially, it will be necessary to check the position of switches SW1-1 through SW1-5. These

switches must be set to their OPEN positions to properly disable the functions associated

with Raise/Lower models. The other uses of these switches are described under topic 3.3.

Analog models can be set to accept a 4-20 mA or 1-5 V dc signal at the Command Input.

Switch SW2-8 selects these outputs as follows:

SW2-8

Analog Range

Close 4-20 mA dc

Open 1-5 V dc

3.3 RAISE/LOWER INPUT MODELS

Raise/Lower Actuator models can be set for continuous or incremental-type input signals

via switches SW1-1 through SW1-5. The switch positions are shown in Table 3-2. The

switch selections are described as follows:

Board Setup 3-2 CI-9110

Page 27

3.3.1 Continuous Signal

A continuous input signal is one that, when placed in a TRUE state, will cause the output

to change until the input is set FALSE. To achieve this mode of operation, all five switches

of SW1 should be set to the OPEN position (bottom condition of Table 3-2). This will configure the Regulator so that its output will change as long as the one signal applied to the

Raise and Lower Command Inputs is TRUE (dc = ON) and the other is FALSE (dc = OFF).

No other change will occur when both inputs are simultaneously set FALSE or TRUE.

Figure 3-1 - Option Switches on CPU Board

3.3.2 Incremental Signal

The five switches can be set for any increment from 0.110% per pulse to 1.830% per pulse.

The pulses that raise or lower the output perform in real time and are not stored. As a

requirement, each pulse must remain in a TRUE state for a period of time necessary for the

Remote Set Regulator to reach the new output value. Should the input change from a raise

to a lower operation (or vice-versa) before the completion of an incremental step, the unfinished increment will be cut off and the next pulse will be freshly processed.

A unit that is set up with a slower rate of change value or a greater percent of full scale

change per input pulse will require a longer input pulse. Therefore, the minimum time

period required for an ON and OFF pulse to produce an output change is dependent upon

the settings of switches SW1 (1-5). There are no maximum limits for either the ON or OFF

pulse periods (time between pulses).

CI-9110 3-3 Board Setup

Page 28

The relationship between an ON and OFF pulse time periods are shown by the following

two equations:

1) T on Minimum (sec.) = (.01 SR) + K

2) T off Minimum (sec.) = K

Where:

T on Minimum = Raise, Lower or Guard pulse

T off Minimum = Time between pulses.

S = Incremental step value (Table 3-2)

R = Rate of output change (Table 3-3)

K = .04 sec. with R/L filter active or 0.01 sec. with R/L filter turned

off. See Section 3.6 - "Output Rate of Change."

Table 3-2 - Switch SW1 (1-5), Pulse Increments

SW1-5 SW1-4 SW1-3 SW1-2 SW1-1

Close Close Close Close Close Disabled

Close Close Open Open Close 0.110% / Pulse

Open Close Close Close Open 0.182% / Pulse

Open Close Close Open Close 0.365% / Pulse

Open Close Open Close Close 0.730% / Pulse

Open Close Open Open Close 1.090% / Pulse

Open Close Open Open Open 1.280% / Pulse

Open Open Close Close Close 1.460% / Pulse

Open Open Close Close Open 1.640% / Pulse

Open Open Close Open Close 1.830% / Pulse

Open Open Open Open Open Continuous *

Output Change

(nominal, ±15%)

* Analog Regulator models must always have these switches

set for Continuous Mode.

3.4 INPUT FILTER

A raise or lower input signal can contain noise pulses of an amplitude sufficient to affect

the output. In these situations, switch SW1-8 can be set to activate an input filter. The

switch positions are given below. For Analog models, this switch must always be set to

OPEN.

SW1-8

Close Active

Open Inactive

Filter Status

Board Setup 3-4 CI-9110

Page 29

3.5 GUARD INPUT

The guard input (TB1-5 & TB1-6) is used to Enable or Inhibit the command input. This

feature provides assurance that the command input will read its signal only during a

security period selected by the user. The guard input can be used with either Analog or

Raise/Lower (R/L) models.

3.5.1 Guard Logic

The guard logic can be set for logical operation so that a TRUE-state signal “enables” the

Command input, while a FALSE-state signal “inhibits” it. The Guard input logic can also be

set internally so that it is kept ON continuously; in this mode the Command input will be

“enabled” at all times. Switch SW2-6 is used to set the guard mode as follows:

SW2-6

Open Active (Guard signal must be in TRUE state to accept input)

Close Inactive (All inputs accepted)

Guard Mode

3.5.2 Static or Dynamic Guard Input

The Guard input may be set to operate in a static or dynamic mode. The static mode, which

can be used with either Analog or Raise/Lower command signals, allows the output to

respond to a Command signal only when the Guard terminal is in a TRUE state.

The dynamic mode, which is only available with Raise/Lower models, responds to the

simultaneous transition of two pulse-type signals. Consequently, the output will only

change when a guard pulse and a command pulse (either a raise or lower) occur at the same

moment. Furthermore, both pulses must remain TRUE until the actuator output change is

complete. If either a guard or command pulse is not completed before the specified time, the

pressure output will be held at its last value until a new change occurs. This arrangement

can be used to obtain greater system security from extraneous signals and signal failure.

This feature should not be used with Analog models.

The selection of static or dynamic mode is obtained via switch SW2-1 as follows:

SW2-1

Close Dynamic (R/L type only)

Open Static (AI or R/L types) *

* The "Open" position must always be used when "Fail Zero" mode is selected

Guard Status

(see Section 3.7 - "Analog Failure Modes").

3.6 OUTPUT RATE OF CHANGE

The Regulator includes provisions for changing the time required by the stepper motor to

sweep the entire pressure output range. This feature, which is available on both Analog and

Raise/Lower models, is implemented by setting switches SW2-2 through SW2-5 as noted in

Table 3-3.

CI-9110 3-5 Board Setup

Page 30

Table 3-3 - Switch SW2 (2-5), Output Rate Of Change

SW2-5 SW2-4 SW2-3 SW2-2

Rate Of Change, ±15%

Nominal

Close Close Close Close 1.8 Min. Full Scale Travel

Close Close Close Open 5.5 Min. Full Scale Travel

Close Close Open Close 11.0 Min. Full Scale Travel

Close Close Open Open 16.5 Min. Full Scale Travel

Close Open Close Close 21.9 Min. Full Scale Travel

Close Open Open Close 32.9 Min. Full Scale Travel

Close Open Open Open 38.3 Min. Full Scale Travel

Open Close Close Open 43.8 Min. Full Scale Travel

Open Close Open Open 60.3 Min. Full Scale Travel

Open Open Close Close 65.85 Min. Full Scale Travel

Open Open Close Open 69.4 Min. Full Scale Travel

3.7 ANALOG FAILURE MODES (Fail Hold & Fail Zero)

Analog models have an "Analog Fault Detector" feature which, when selected by jumpers on

the Termination Board, provides a selection of two failure modes, Fail Hold and fail Zero. In

the "Fail Hold" mode, the Analog Fault will stop the stepper motor at the last pressure

output value prior to the loss of the analog input signal. Note that the Guard terminals are

not available for external usage in this mode. The Fault Detector trip point for this mode is

factory set at 0.8 volts which corresponds to -5% of fullscale.

In the alternate "Fail Zero" mode, the Guard terminals are available for use with an

external signal. In this mode, the analog input signal is “enabled” by a signal at the Guard

terminal. If the input drops to zero while the Guard signal remains TRUE, the output will

also go to zero.

The selection of either failure mode is accomplished via two jumpers, W1 and W2. These

jumpers are located on the Termination Board as shown in Figure 3-2. These jumpers may

be plugged in position A or B; however, both jumpers must always be in the same position.

The configurations are selected as follows:

In the "A" position, a failure of the AI Command Input (value fails below 0%) causes the

pressure output to remain at the value of the last valid sampling period. This condition is

maintained until a normal AI is received.

Board Setup 3-6 CI-9110

FAIL-HOLD MODE

(Both Jumpers in A position)

Page 31

FAIL-ZERO MODE

(Both Jumpers in B position)

In the "B" position (if the Guard signal remains TRUE), a failure of the AI Command Input

signal (value fails below 0%) causes the pressure output to decay to 0% of scale and remain

there until a normal AI is received. Should the Guard Input go FALSE prior to the AI

command failure, the last pressure output value will be held.

Figure 3-2 - Jumper Location on Analog Termination Board

CI-9110 3-7 Board Setup

Page 32

BLANK PAGE

Page 33

Chapter 4

FIELD WIRING

4.1 GENERAL

This section illustrates and describes the field wiring terminals and various wiring

configurations that apply to Analog, Raise/Lower, and Guard inputs, as well as the 4-20 mA

current output and the dc power source. The wiring arrangements described herein are

general and are not intended to cover every application.

4.2 TERMINAL BLOCK IDENTIFICATION

The Termination Board contains the field wiring terminals. Access to this board is obtained

by removing the cover as described in Section 2 - Installation.

Two terminal blocks (TB1 & TB2) are located on the termination Board as shown in Figure

4-1. Each of these blocks contain six (6) terminal screws for field wiring connections. TB1

contains terminals TB1-1 through TB1-6, while TB2 contains TB2-1 through TB2-6.

The function of each terminal depends on whether the Regulator is an Analog or

Raise/Lower model. The terminal designations for the Analog type are given in Table 4-1,

while designations for the R/L types are given in Table 4-2.

CI-9110 4-1 Field Wiring

Figure 4-1 - Field Wiring Terminals

Page 34

Table 4-1 - Terminal Identification For Analog Input Models

TERMINAL

LEGEND

TB1-1

TB1-2

TB1-3

TB1-4

TB1-5

TB1-6

TB2-1

TB2-2

TB2-3

TB2-4

TB2-5

TB2-6

Green Screw

FUNCTION

Unused

Unused

Analog In+ (Command Input)

Analog In- (Command Input)

Guard

Guard Com

Unused

Current Out +

Current Out Supply +

Supply Unused

Chassis

Table 4-2 - Terminal Identification For Raise/Lower Models

TERMINAL

LEGEND

TB1-1

TB1-2

TB1-3

TB1-4

TB1-5

TB1-6

TB2-1

TB2-2

TB2-3

TB2-4

TB2-5

TB2-6

Green Screw

FUNCTION

Raise (Command) Input)

Raise Com (Command) Input)

Lower (Command) Input)

Lower Com (Command) Input)

Guard +

Guard Com

Remote/Local Status

Current Out +

Current Out Supply +

Supply Unused

Chassis

Note: Raise, Lower & Guard Terminals are

non-polarized and opto-isolated.

4.3 ANALOG VOLTAGE INPUT (1-5 V) WITH GUARD

A voltage signal can be used as the Command Input as shown in Figure 4-2. In this

example, a Bristol Babcock, METATONE B, Analog FSK Tone Receiver (Model 8772-31B)

provides the input to the Remote Set Regulator. Switch SW2-8 must be set to the OPEN

position to accommodate a 1-5 V input.

Field Wiring 4-2 CI-9110

Page 35

Figure 4-2 - Analog Voltage Input with Guard

Figure 4-3 - Analog Current Input with Guard

CI-9110 4-3 Field Wiring

Page 36

For the application of Figure 4-2, the Carrier Presence output signal of the receiver may be

connected to the Guard terminal as shown. Should the tone carrier fail, the Regulator will

hold the last valid output value and prevent the Command Input from responding to

extraneous signals.

4.4 ANALOG CURRENT INPUT (4-20 mA) WITH GUARD

In Figure 4-3, a 4-20 mA signal is obtained from the collector of an output transistor and

wired to the input of the Regulator. Switch SW2-8 is set to the CLOSE position to bring the

loop resistor into the circuit. The equivalent 1-5 volt drop across the 250 ohm loop resistor

provides the Regulator input.

A switch or contact signal may be wired to the Guard Terminal as shown in Figure 4-3.

This signal will be in an ON state when valid command data is sent and in an OFF state if

the telemetry link opens.

The Guard signal may also emanate from an open collector circuit such as shown in Figure

4-2

4.5 RAISE/LOWER INPUTS WITH GUARD

The Raise and Lower inputs will accept either a continuous or incremental signal. A

continuous signal is one that is held in a TRUE state to obtain a change of output pressure.

An incremental signal is one that produces a step change of the output value for each

TRUE input pulse that is received. Both types of inputs will maintain the last output value

during the FALSE or failed states of the signal. The wiring illustrations described herein

are applicable to either type.

The Guard input performs the same function as described under the previous analog

subtopics. Since the Guard input is electrically identical to the Raise and Lower inputs, it

can be wired in the same manner.

Figure 4-4 shows all inputs wired to external relay contacts or switches. Each contact is

wired to a positive voltage source which must have the same value as the supply voltage

required to power the Regulator (12 or 24 V type). When a contact is closed, the input is set

ON (TRUE). When a contact is open, it is set OFF (FALSE).

The arrangement of Figure 4-5 receives all three inputs from a METATONE B FSK TriState Receiver. This receiver provides a MARK and SPACE output which connect to the

respective Raise and Lower input terminals, and a CARRIER output that connects to the

Guard terminal. The Receiver's tri-state outputs are provided as open collectors that drive

the opto-isolated inputs of the Regulator. When any of the receiver's driver transistors

conduct, the corresponding Regulator input will be set TRUE. When any driver transistor

is cut off, the corresponding Regulator input will be set FALSE.

Field Wiring 4-4 CI-9110

Page 37

Figure 4-5 - Raise/Lower & Guard Inputs from Relay Contacts

Figure 4-5 - Raise/Lower & Guard Inputs from Open Collectors

CI-9110 4-5 Field Wiring

Page 38

CAUTION

When using the Regulator with a device that provides latching type

outputs (output stays ON until turned OFF), the Raise/Lower inputs

must be set for a pulse incremental signal. (see Section 3 - Board

Setup). This will prevent the Regulator from driving full scale should

the telemetry line open while in the middle of a Raise or Lower

command. By using this configuration, the pressure output value will

only change when input pulses are received.

Figure 4-6 - Current Output to FSK Bi-State Transmitter

4.6 4-20 mA CURENT OUTPUT

The current output of the Regulator can be used to drive a METATONE B, FSK Analog

Transmitter as shown in Figure 4-6. The 4-20 mA current signal is referenced to signal

common and flows through the loop resistor present at the input of the Analog Transmitter.

The current signal modulates a tone carrier which communicates with an Analog Tone

Receiver at the command site (not shown).

4.7 DC POWER

The Remote set Regulator is factory-shipped for 12 or 24 Vdc supply operation. Before

power is applied, a check should be made to ensure that the Regulator type matches the

supply source.

The dc supply source is wired to the Regulator in Figure 4-7. An earth ground must be

provided for both the Regulator housing and the supply. The connection for the Regulator is

made to the green grounding screw located inside the housing (see Section 2 - Installation

for illustration).

WARNING

Metal enclosures and exposed metal parts of all electrical

instruments and devices must be grounded to prevent accidental

electrical shock. Grounding must be in accordance with latest

OSHA rules and regulations pertaining to "Design Safety

Standards For Electrical Systems."

Field Wiring 4-6 CI-9110

Page 39

Figure 4-7 - DC Supply Connections

4.8 OPERATING NOTES

The startup procedures described herein are general for most applications. It is assumed

that the user is familiar with all the external process devices such as shutoff valves,

pressure limiters, circuit breakers, fuses, electrical supply, etc. and operates these devices

in a manner that produces a safe startup. It is also assumed that the unit is properly wired

and grounded as described in this section.

4.9 INITIAL CHECKS

Prior to starting the Regulator, its supply pressure and dc power source should be turned

OFF. Also, the process associated with the Regulator should also be turned OFF or placed

under some form of guarded control. A process that is not guarded may run out of control

and cause property damage and injury to persons. Once these conditions have been met,

proceed as follows:

1. The Regulator will be furnished as a 12 or 24 V dc type. Make sure that the supply

voltage is correct for the Regulator.

2. Remote Set Regulators will be furnished with a 3-15, 3-27 or 6-30 psig output range.

Check input pressure to the Regulator. It should be set to at least 3 psig above the

upper range value, and not more than 100 psig. Pressures greater than 100 psig will

require an external pressure limiter or regulator to maintain a safe input pressure.

3. To start the Remote Set Regulator, apply supply pressure and turn ON the dc power.

4. When power is applied, the stepper motor will operate immediately and set the output

to a value that corresponds to the level of the Command input signal.

CI-9110 4-7 Field Wiring

Page 40

5. If the output pressure of the Remote Set Regulator fails to change even with a change at

the Command input, the internal fuse may be blown. Check and replace it as required

with a 1A, 250V 3AG type. If the fuse continues to blow, check for wiring mistakes at

the field wiring terminals or check for a defective PC board. Do not attempt further

operation until the problem has been resolved.

6. Once all the above checks have been completed, turn on the associated process and

verify that the Regulator is operating properly. Startup is complete.

Field Wiring 4-8 CI-9110

Page 41

Chapter 5

SERVICE

5.1 GENERAL

The servicing and calibration procedures described in this section should only be performed

by qualified technical personnel.

These procedures should not be performed while the Remote Set Regulator is connected to

an on-line process. A laboratory setup is recommended for calibration and servicing. If this

is not possible, steps should be taken to close down the process or to isolate the Regulator in

such a manner that it has no control over the process.

** Warning **

Models intended for operation in hazardous areas require

additional precautions. Under no circumstances should

the cover be removed while the instrument is powered and

operating. If access is required, either the dc power must

be turned off, or the environment must be made safe, i.e.,

non-hazardous. An electrical spark in a hazardous environment could cause fire or an explosion and result in

property damage and injury to persons.

Figure 5-1 - Rear View of Gear Drive Assembly

CI-9110 5-1 Service

Page 42

5.2 TROUBLESHOOTING HINTS

Some basic types of problems that can occur in the field are listed as follows:

○ Unit dead, no motor movement

Measure across power terminals TB2-4 & -5 with a DVM. The reading should be 12 or 24 V

dc depending upon model. Incorrect or no voltage indicates an external supply problem. If

proper voltage is present, check Fuse F1 on the Termination Board. Fuse F1 should be a

1A, 250 V, 3AG type. If replacement fuses continue to blow, a short may be present at the

field wiring terminals or in the PC boards.

○ Output drift on Analog model

Check for open signal lead at input terminals TB1-2 & -3. Measure across terminals with a

DVM and check for proper voltage range.

○ Output stays constant with input change

If Guard mode is used, check for proper signal at Guard terminals TB1-5 & -5. If Guard is

not used, make sure SW2-6 is in the CLOSE position.

○ Severe output tracking errors on Analog model

Check setting of switches SW1 (1-5). If any are set to Pulse Increment mode, the output will

not balance properly. These switches must be set OPEN for Analog models.

○ Noisy or Erratic Output on Raise Lower Model

Try SW1-8 in both positions and choose the one with the lowest noise level. For Analog

models, this switch must be set OPEN.

○ Raise or Lower function does not work on Raise/Lower model

Check voltage at Raise or Lower terminals TB1 (1-4) with voltmeter during activation. Also

check across Guard terminals TB1-5 & -6, if used. If no voltage change occurs at any given

input, check for broken signal leads or a defect in the external device.

○ Output pressure does not rise above certain point

A high limit may be set too low or the pressure regulator vent may be restricted. Also check

for water or oil in pressure lines.

○ Output pressure drops off with constant level input

Check for leaks in pressure lines or loose fittings.

Service 5-2 CI-9110

Page 43

5.3 SETTING OUTPUT LIMITS

5.3.1 General Principles

The Regulator provides mechanical output limits that prevent the output from

underranging or overranging the process. When the Command Input is of a value that

causes the stepper motor to drive against a limit, the clutch will allow the driveshaft to slip.

After the motor has completed several revolutions, the software will turn it OFF to prevent

clutch wear. The motor will remain OFF until the Command Input signal returns to a value

that is within the set limits.

5.3.2 Test Setup

When a Remote Set Regulator leaves the factory, the low limit is set to about -10% below

the minimum range value, and +10% above the high range value. These limits may be

changed in the field if the user has the capability to adjust the dc input signal over the full

range of the Regulator and to monitor the pressure output. Bench calibration setups similar

to that shown in Figures 5-2 or 5-3 may be used to set the mechanical limits on Analog or

Raise/Lower models. The DMMs (digital multimeters) shown in both illustrations are not

required for setting limits.

5.3.3 Procedure

The method of setting the mechanical Hi and Lo Limit adjustments are described as

follows:

1. Check that pressure supply to Remote Set Regulator is at proper value. Turn off dc

power source (12 or 24 V dc) to Remote Set Regulator and remove Regulator Cover.

2. For all models, set switch SW2-6 to CLOSE to disable the Guard input.

3. For Analog models, set jumpers W1 and W2 for Fail/Hold mode. See Section 3, Board

Setup. Turn ON dc power source.

4. Locate two limit adjustment tangs on main gear assembly. Refer to Figure 5-1.

5. Adjust dc test input level to approximately -20% below minimum range value. Pressure

output will fall to a minimum value and remain there.

6. If limit tangs were previously set at factory their positions on main gear will appear

about as shown in Figure 5-1. If tangs are at different positions, other limit values may

have been field-selected.

7. Turn off dc power. Limits are set by estimating positions on main gear assembly. To set

a limit, slightly lift edge of tang from teeth of main gear and carefully move tang to approximate desired position. Release tang to lock its position. If access to a tang is

blocked, re-apply dc power and adjust dc input level to a value that will rotate main

gear in a direction to make tang accessible. Turn off dc power and set limits as required.

CI-9110 5-3 Service

Page 44

8. Once limits have been set, re-apply dc power and adjust input test circuit (analog or

raise/lower) for range value above upper limit. When upper limit is reached, main gear

will stop rotating and output pressure will hold constant at value of desired limit.

** Caution **

Do not attempt to turn main gear or driveshaft by hand to

reach a limit. The force generated in this manner can

easily damage the gear teeth and limit tangs. Always use a

dc test input signal to drive the main gear through its

range.

9. If limit values are not at desired points, continue to experiment with tangs until correct

positions can be found.

10. When adjustments are complete, disconnect test setup and recheck board configuration

as required. Replace cover and restore unit to normal operating status.

5.4 CALIBRATION TEST SETUP

The calibration of the Remote Set Regulator will require a laboratory bench setup. The

setup of Figure 5-2 is used for Analog models, while that of Figure 5-3 is used for

Raise/Lower models.

In Figure 5-2, the Analog model uses a precision 1 - 5 volt test source to provide an adjustable input signal. In Figure 5-3, the Raise/Lower model uses a switch test circuit consisting of two pushbutton switches that apply dc power to either the Raise or Lower inputs.

As long as a switch is pressed, the output will be raised or lowered assuming continuous dc

input configuration.

From this point on, the test setups of Figures 5-2 and 5-3 are identical. A digital multimeter

(DMM #1) is connected across test points TP3 and TP4 to monitor the voltage at the center

arm of the feedback potentiometer. The 250 ohm resistor and switch circuit is used to load

the current output circuit, while DMM #2,functioning as a milliammeter, measures the load

current.

On the pneumatic side, a constant supply pressure is applied to the pressure regulator assembly. A precision test gauge monitors the pressure output signal. The pressure regulator

assembly of the unit does not have calibration adjustments. All adjustments are electrical.

5.5 CALIBRATION PRECAUTION

During calibration, the stepper motor will be driven to both ends of it operating range.

Since this movement is extremely slow, do not be tempted to run the unit up or down range

by manually forcing the main gear or driveshaft. Doing so can cause damage to the gear

teeth and the mechanical limit tangs. Always use a dc test input signal to reposition the

main gear and allow the Remote Set Regulator to balance itself out.

Service 5-4 CI-9110

Page 45

5.6 PRELIMINARY CALIBRATION CHECK

Once the test setup of Figure 5-2 or 5-3 has been completed, the following conditions must

be established.

1. For all models, set switches SW1 (1-5) to OPEN for continuous operation, and SW2-6 to

OPEN to disable Guard circuit. For Analog models only, set SW2-8 to OPEN for 1 - 5 V

input.

2. Determine the output range of the Regulator (3-15, 3-27 or 6-30 psi). See if it is possible

to scan the complete range of the regulator by adjusting the input test circuit and

observing the pressure test gauge. If range of travel is not complete, mechanical limits

are less than output span or:

0% < Limits < 100%

At this time, position limits to following settings (see topic 5.3):

Lo Limit = -10% (approximately)

Hi Limit = +110% (approximately)

If full range cannot be obtained even with above limits, other problems may be

indicated. Refer to topic 5.2 for troubleshooting hints before proceeding.

3. Set input test circuit for 0.995 V reading on DMM #1. DMM #2 should read 4 mA, ±.02

mA Test gauge should read minimum range value (3 or 6 psi), ±5.0%.

4. Press input test circuit push-buttons for 4.995 V, ±0.004 V reading on DMM #1. Reading

on DMM #2 should be 20 mA, ±.02 mA. Test gauge should read maximum output range

value (15, 27 or 30 psi), ±5.0%.

CI-9110 5-5 Service

Figure 5-2 - Analog Test Setup

Page 46

5. If above readings are within stated specifications, stop! No calibration is required.

Restore instrument to normal operation. Otherwise, proceed to topic 5.7 or 5.8 as

required.

5.7 DETAILED CALIBRATION FOR ANALOG MODEL

If calibration errors were found in topic 5.6, the procedures described here for Analog

models are performed.

5.7.1 Feedback Zero & Span

Precision voltage of an input test circuit is used to calibrate the zero and span as follows:

1. Adjust input test circuit for 1.000 V output.

2. DMM #1 should read 0.995 V, ±.004 V.

3. If reading of step 2 is out of tolerance, slightly loosen two screws on body of feedback pot

(Figure 5-1) and rotate body until DMM #1 reads as specified in step 2. Secure pot

screws to lock in setting.

4. Adjust the input test circuit for 5.000 V.

5. DMM #1 should read 4.995 V, ±.004 V

6. If the reading of step 5 is out of tolerance, adjust potentiometer R35 on CPU to correct.

7. Recheck both points and readjust zero and span if required.

5.7.2 Current Output Span & Load

The current output circuitry is provided with two calibration adjustments. Potentiometer

R50 is used for span adjustment and R49 for load compensation. For these tests, DMM #2

(used as a milliammeter) is connected in series with a 250 ohm load resistor as shown in

Figure 5-2. The pushbutton switch is used for load testing.

1. Adjust input test circuit for 5.000 V.

2. DMM #2 should read 20 mA, ±.02 mA. If necessary, adjust pot R50 to correct.

3. Press load pushbutton while observing DMM #2. If current reading increases, adjust

R49 CCW. If reading decreases, turn it CW. Repeat procedure until change is less than

±.02 mA.

4. Final reading should be 20 mA, ±.02 mA. If necessary, reset pot R50 and repeat the

procedure.

5.7.3 Pressure Output Check

1. Adjust input test circuit for 1.000 V.

Service 5-6 CI-9110

Page 47