Page 1

Instruction Manual

D103580X012

January 2021

Type BM5A Slam-Shut Valve

Table of Contents

Introduction ................................................................. 1

Specifications ............................................................. 2

Principle of Operation ................................................. 4

Transport and Handling .............................................. 5

Installation .................................................................. 7

Overpressure Protection ............................................. 8

Startup ........................................................................ 8

Slam-Shut Controller Adjustment ...............................9

Shutdown ....................................................................9

Maintenance ............................................................... 9

Parts Ordering ........................................................... 11

Spare Parts ............................................................... 11

Parts Lists ................................................................. 13

Type BM5A

WARNING

▲

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion

and/or fire causing property damage and

personal injury or death.

Tartarini™ slam-shut valve must be

installed, operated and maintained

in accordance with federal,

state and local codes, rules and

regulations and Emerson Process

Management Regulator Technologies,

Inc. (Emerson) instructions.

If the slam-shut valve vents gas or a

leak develops in the system, service

to the unit may be required. Failure

to correct trouble could result in a

hazardous condition.

Call a gas service person to service the

unit. Only a qualified person must install

or service the slam-shut valve.

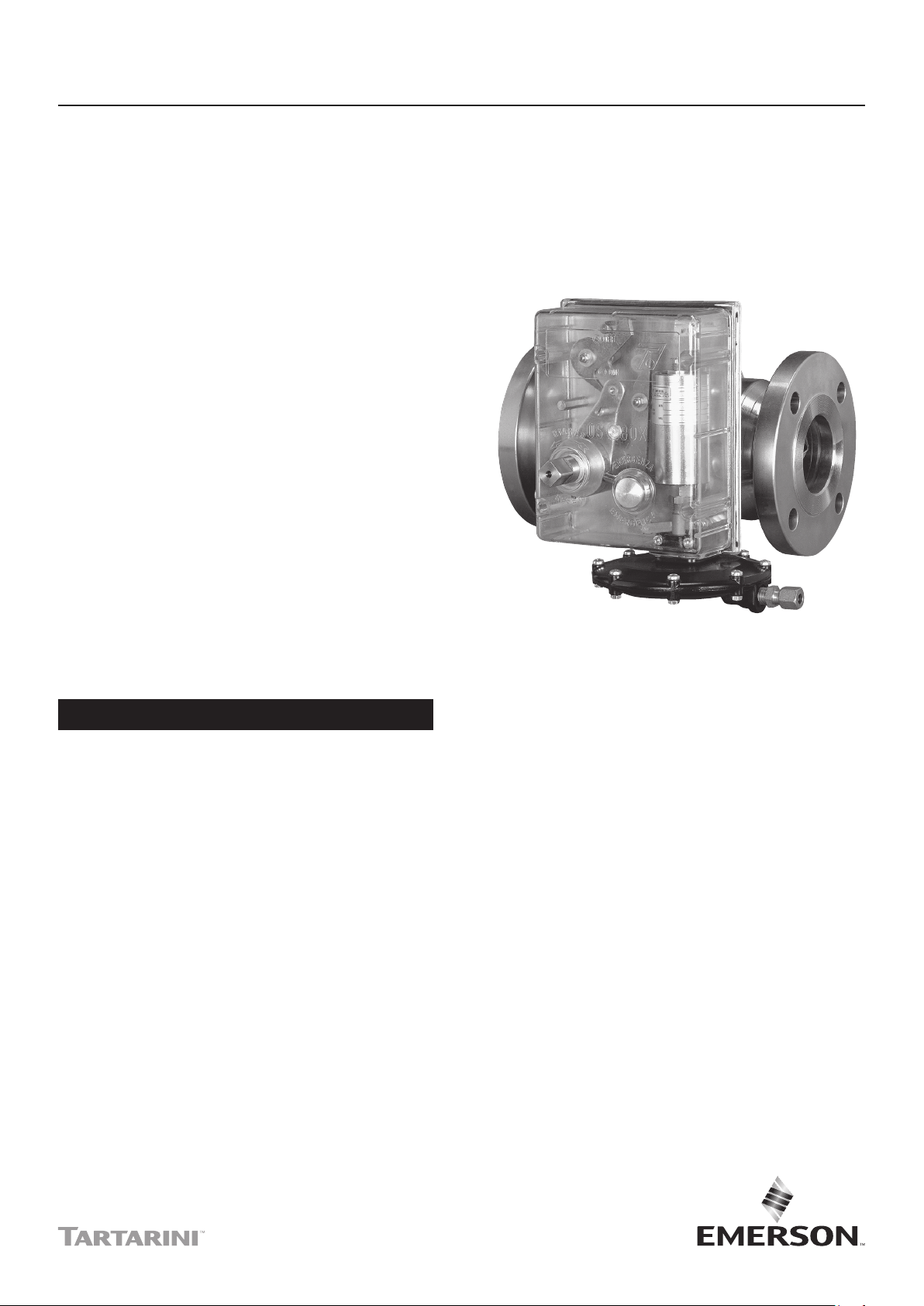

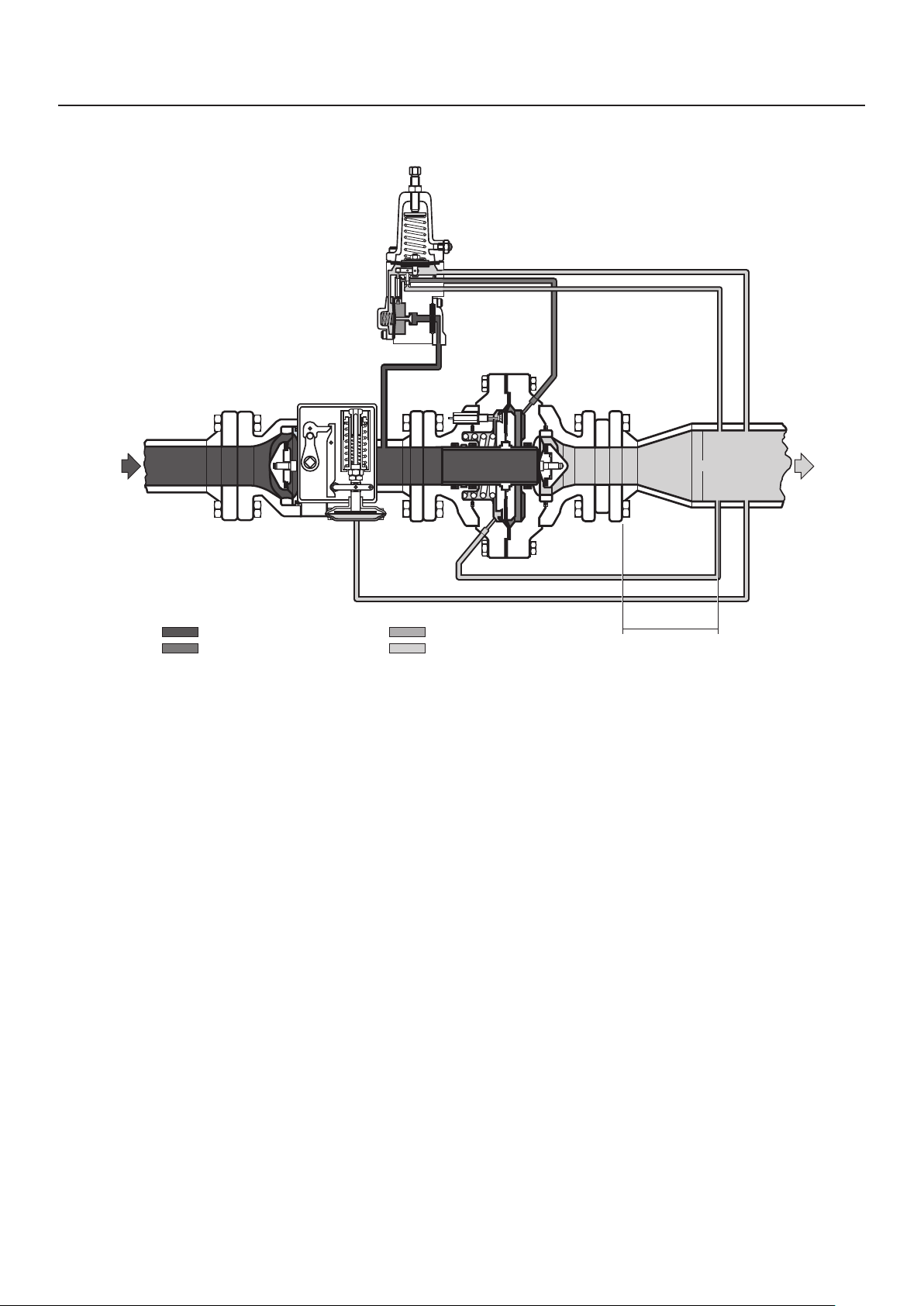

Figure 1. Type BM5A Slam-Shut Valve

Introduction

Scope of the Manual

This Instruction Manual provides instructions for

installation, startup, maintenance and spare parts

ordering for the Type BM5A slam-shut valves.

This manual also contains information for the

OS/80X Series slam-shut controller.

Product Description

The Type BM5A slam-shut valves are axial flow

type with a single seat and counterbalanced shutter.

They are designed for use in high pressure natural

gas transmission/city gate stations, large capacity

distribution systems and power plant feeds.

They provide smooth and reliable operation, tight

shutoff and long life.

Page 2

Type BM5A

Specifications

The Specifications section gives some general specifications for the Type BM5A slam-shut valve. The nameplates

give detailed information for a particular slam-shut valve as built in the factory.

Available Body Sizes

DN 25, 50, 80, 100 and 150 /

NPS 1, 2, 3, 4 and 6

Available End Connection Styles

CL300 RF and CL600 RF

Maximum Allowable Pressure

(1)

CL300 RF: 51.7 bar / 750 psig

CL600 RF: 103 bar / 1500 psig

(1)(2)

Maximum Operating Inlet Pressure (PS

max

)

CL300 RF: 50.0 bar / 725 psig

CL600 RF: 100 bar / 1450 psig

Inlet Pressure Range (bpu)

(1)(2)

CL300 RF: 0 to 50.0 bar / 0 to 725 psig

CL600 RF: 0 to 100 bar / 0 to 1450 psig

Overpressure Set Range (Wdo)

CL300 RF: 0.03 to 50.0 bar / 0.44 to 725 psig

CL600 RF: 0.03 to 80.0 bar / 0.44 to 1160 psig

Underpressure Set Range (Wdu)

CL300 RF: 0.01 to 50.0 bar / 0.15 to 725 psig

CL600 RF: 0.01 to 80.0 bar / 0.15 to 1160 psig

Accuracy Class (AG)

Up to ± 1%

Response Time (ta)

≤ 1 s

Minimum/Maximum Allowable Temperature (TS)

Class 1: -10 to 60°C / 14 to 140°F

Working Temperature Capabilities

(1)(2)

Standard Version, Nitrile (NBR) or

Fluorocarbon (FKM): -10 to 60°C / 14 to 140°F

Construction Materials

Slam-Shut Valve

Body: ASTM A105 Steel

Shutter: Steel

O-ring: Nitrile (NBR) or Fluorocarbon (FKM)

Pad: Nitrile (NBR) or Fluorocarbon (FKM)

Pad holder: Steel

OS/80X Series Slam-Shut Controller

Body: Aluminum (Types OS/80X-BP and

OS/80X-BPA-D) or Steel (Types OS/80X-MPA-D

and OS/80X-APA-D)

Diaphragm: Fabric-finished Nitrile (NBR)

O-ring: Nitrile (NBR)

Types OS/84X and OS/88X

Slam-Shut Controller

Body: Brass

Lip Seal: Polytetrafluoroethylene (PTFE)

O-ring: Nitrile (NBR)

Types PRX/181-PN, PRX/182-PN,

PRX-AP/181-PN and PRX-AP/182-PN Pilots

Body: Steel

Diaphragm: Fabric-finished Nitrile (NBR)

O-ring: Nitrile (NBR)

Slam-Shut Controller and Pilot Connection

1/4 NPT

Approximate Weights

See Table 3

(1)(2)

Accessories

• Proximity Switch or Micro Switch

for Remote Monitoring

• Solenoid Valve for Remote-controlled Closure

• IT/3V Three-Way Valve for Setting Control

Available Slam-Shut Controllers

See Table 2

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Published values are in accordance with EN14382 specications.

This product is designed to be used with fuel gases of

1st and 2nd family according to EN 437 and with other

non-aggressive and non-fuel gases. For any other

gases, other than natural gas, please contact your

local Sales Office.

Use of gas pressure devices (safety shut-off

devices - SSD slam-shut type) shall comply with

EN 12186 and EN 12279.

Safety slam-shut valves manufactured by Emerson

must use additional pressure accessories (e.g.

controller or filters) manufactured or approved

by Emerson. Emerson is not responsible for any

possible inefficiency due to installation of additional

pressure accessories not manufactured or approved

by Emerson.

When pressure containing parts of safety slam-shut

device (SSD) valve and controller have different

maximum allowable pressures (PS), the SSD is

differential strength type.

2

Page 3

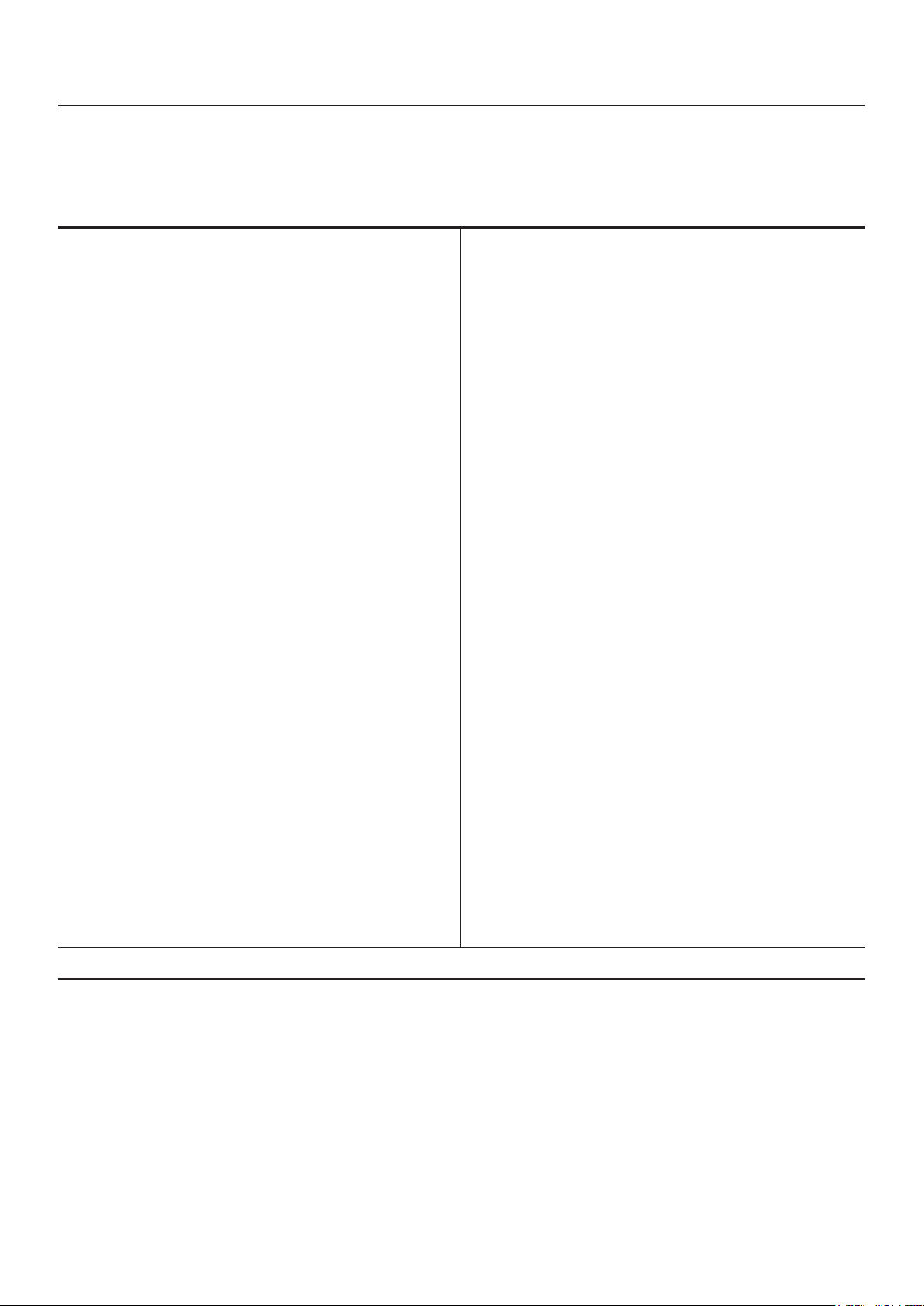

Note 1: See Body Size and End Connection Style

Note 2: Year of manufacture

Note 3: Class A or Class B

Note 4: Class 1: -10 to 60°C / 14 to 140°F

Note 5: Maximum Allowable Pressure (PS)

Figure 2. Type BM5A Slam-Shut Valves Nameplate

Table 1. PED Category for Type BM5A Slam-Shut Valves

PRODUCT SIZE CATEGORY FLUID GROUP

DN 25, 50, 80, 100, and 150 /

NPS 1, 2, 3, 4, and 6

IV 1

Only valves with overpressure and underpressure settings can be classied

in Class A.

CL300 RF: 50 bar / 725 psig

CL600 RF: 100 bar / 1450 psig

Type BM5A

Pressure Equipment Directive (PED)

Categories and Fluid Group

According to EN 14382, only in integral strength type

and Class A configuration (when both overpressure

and underpressure protections are set up) this

slam- shut valve can be classified like a safety

accessory according to PED.

The minimum PS between SSD valve and controller

shall be the PS of the safety accessory to comply the

provisions of EN 14382 about integral strength type.

This product, in its Class A and integral strength

configuration, is a safety accessory for pressure

equipment in the following PED 2014/68/EU

categories on Table 1.

Built-in pressure accessories (e.g. controllers

Types OS/80 and OS/80-X) conform to

PED Article 4 section 3 and were designed and

manufactured in accordance with sound engineering

practice (SEP).

Per Article 4 section 3, these “SEP” products must not

bear the CE marking.

ATEX Requirements

WARNING

▲

If the provisions of EN 12186 and

EN 12279, national regulations or any

specific manufacturer recommendations

are not put into practice before

installation and if purge by inert gas

is not carried out before equipment’s

start-up and shut-down operations,

a potential external and internal

explosive atmosphere can be present in

equipment and gas pressure regulating,

measuring stations or installations.

If a presence of foreign material in the pipelines is

foreseen and purge by inert gas is not carried out,

the following procedure is recommended to avoid any

possible external ignition source inside the equipment

due to mechanical generated sparks:

• Drainage to safe area via drain lines of foreign

materials, if any, by inflow of fuel gas with low

velocity in the pipe-work (5 m/sec.)

3

Page 4

Type BM5A

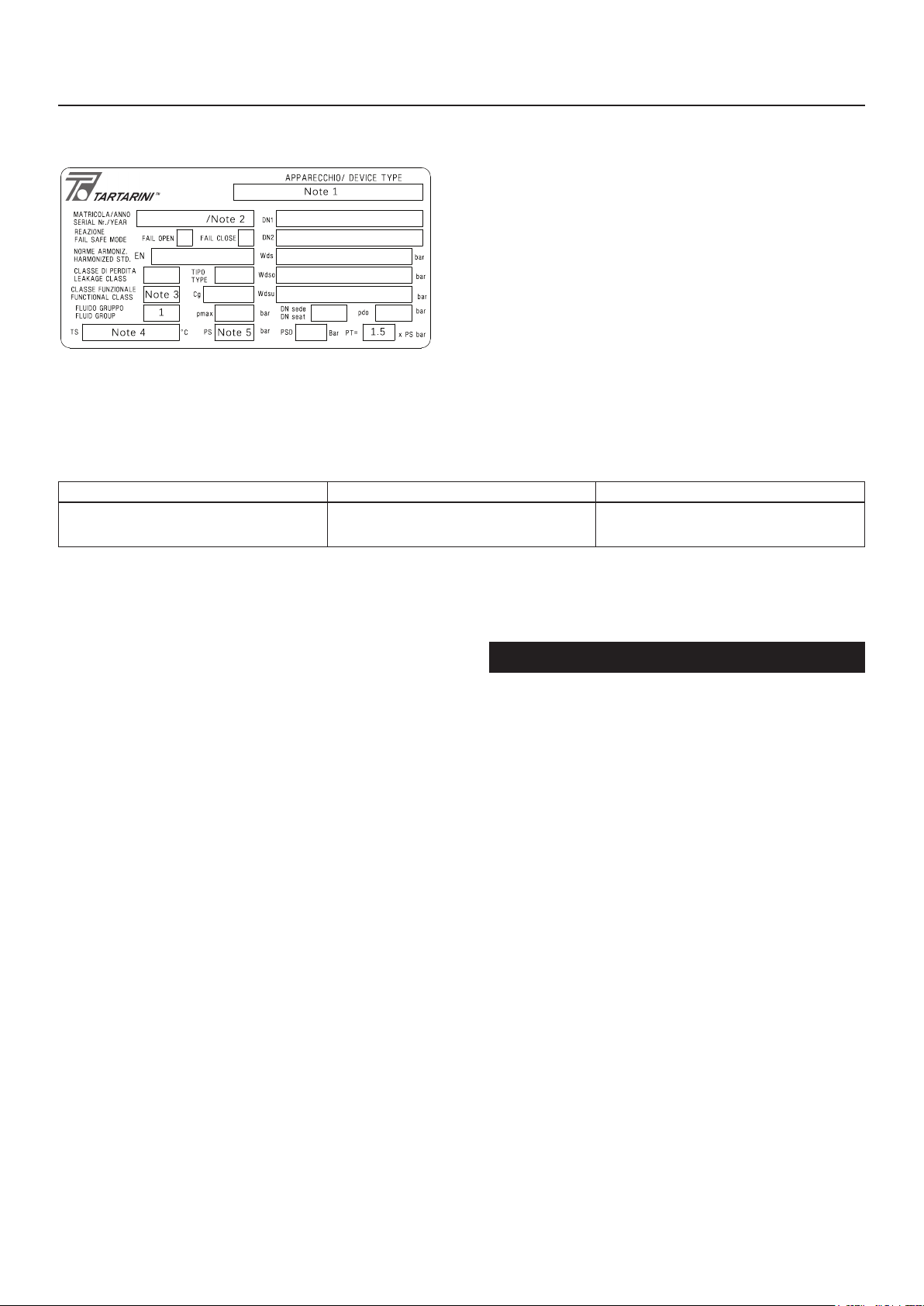

Figure 3. Type OS/80X-BP Slam-Shut Controller

Table 2. OS/80X and OS/80X-PN Series Slam-Shut Controller Details

TYPE

OS/80X-BP 5.0 73

OS/80X-BPA-D 20.0 290

OS/80X-MPA-D

OS/80X-APA-D 2.0 29 10.0 145 0.30 4.35 7.0 102

OS/84X 5.0 73 41.0 595 4.0 58 16.0 232

OS/88X 18.0 261 80.0 1160 8.0 116 70.0 1015

OS/80X-PN

OS/84X-PN

1. Type OS/80X-PN: Made of a Type OS/80X-APA-D, set at about 0.4 bar and Type PRX/182-PN pilot for overpressure and Type PRX/181-PN for underpressure as necessary to control the

system pressure. Type OS/84X-PN (Safety accessory): Made of a Type OS/84X, set at about 20 bar and Type PRX-AP/182-PN pilot for overpressure and Type PRX-AP/181-PN for underpressure as necessary to control the system pressure.

(1)

(1)

BODY RATING

bar psig bar psig bar psig bar psig bar psig

100 1450

OVERPRESSURE SET RANGE, W

Min Max Min Max

0.03 0.44 2.0 29 0.01 0.15 0.60 8.7 Aluminum

0.50 7.25 5.0 73 0.25 3.63 4.0 58

0.50 7.25 40.0 580 0.50 7.25 40.0 580 Steel

30.0 435 80.0 1160 30.0 435 80.0 1160 Brass

In any case,

• Provisions of Directive 1999/92/EC and 89/655/EC

shall be enforced by gas pressure regulating,

measuring station or installation’s end user.

• With a view to preventing and providing protection

against explosions, technical and/or organizational

DO

• External tightness test shall be carried out after

each reassembly at installation site using testing

pressure in accordance with national rules.

• Periodical check/maintenance for surveillance shall

be carried out complying with national regulations,

if any, and specific manufacturer recommendations.

UNDERPRESSURE SET RANGE, W

DU

BODY

MATERIAL

Steel

Brass

measures appropriate to the nature of the operation

shall be taken (e.g.: filling/exhausting of fuel

Principle of Operation

gas of internal volume of the isolated part/entire

installation with vent lines to safe area - 7.5.2 of

EN 12186 and 7.4 of EN 12279; monitoring of

settings with further exhaust of fuel gas to safe

area; connection of isolated part/entire installation

to downstream pipeline; ….)

• Provision in 9.3 of EN 12186 and 12279 shall be

enforced by pressure regulating/measuring station/

installation’s end user.

Slam-Shut Valve

Type BM5A slam-shut valve is made of an axial

flow valve and a controller which keeps the valve

open in normal conditions. The slam-shut valve

features a shutter valve sliding axially, therefore,

no by-pass is needed for its opening even in the

presence of pressurized gas. This valve can only

be opened manually by turning the eccentric

shaft counterclockwise.

4

Page 5

TYPE PS/79 OR PSA/79 PILOT

Type BM5A

BM5A SERIES

SLAM-SHUT VALVE

INLET PRESSURE, P

REGULATOR MOTORIZATION

PRESSURE, P

Figure 4. Type BM5A Slam-Shut Valve and Type FL or FLA1 Regulator Operational Schematics

u

m

TYPE FL OR FLA1

When the controlled pressure is within set values of

the slam-shut controller, the controller remains set and

prevents the rotation of the eccentric shaft, keeping

the valve open. When the controlled pressure varies

beyond setting limits, the controller releases the

eccentric shaft causing the valve close, following the

spring thrust.

The slam-shut controller has a manual release

push-button to quickly close the slam-shut valve

in case of emergency or during maintenance and

checking operations.

If the Type BM5A slam-shut valve is used with

pilot-operated pressure regulators, the supply

pressure to the pilot is taken from the downstream line

of the slam-shut valve. For this purpose, Type BM5A

slam-shut valve features a threaded hole which may

be used for the supply pressure to the pilot. This hole

is normally kept closed by a dowel.

STABILIZED PRESSURE, P

OUTLET PRESSURE, P

d

Slam-Shut Controller

The Type BM5A slam-shut valves are equipped with

the OS/80X or OS/80X-PN Series slam-shut controller.

The controllers are supplied in different models

according to set ranges required. The Type BM5A

with DN 150 / NPS 6 body size is equipped with a

reinforced version Type OS/80X-R.

OS/80X or OS/80X-PN Series slam-shut controller is

used to keep the slam-shut valve shutter open. These

Series are designed to operate on Overpressure

Shutoff (OPSO) only, Underpressure Shutoff (UPSO)

only, or Overpressure and Underpressure Shutoff

(OPSO/UPSO) protection.

Transport and Handling

Follow established transport and handling procedures

to avoid any damage on the pressure-containing parts

by shocks or excessive external pressure or stress.

Use appropriate eyebolts to aid in the handling of

heavy equipment.

Protect built-up sensing lines and pressure

accessories (e.g. slam-shut controller) from shocks or

excessive external pressure or stress.

D

REGULATOR

≥ 4D

up

5

Page 6

Type BM5A

OUTLET PRESSURE

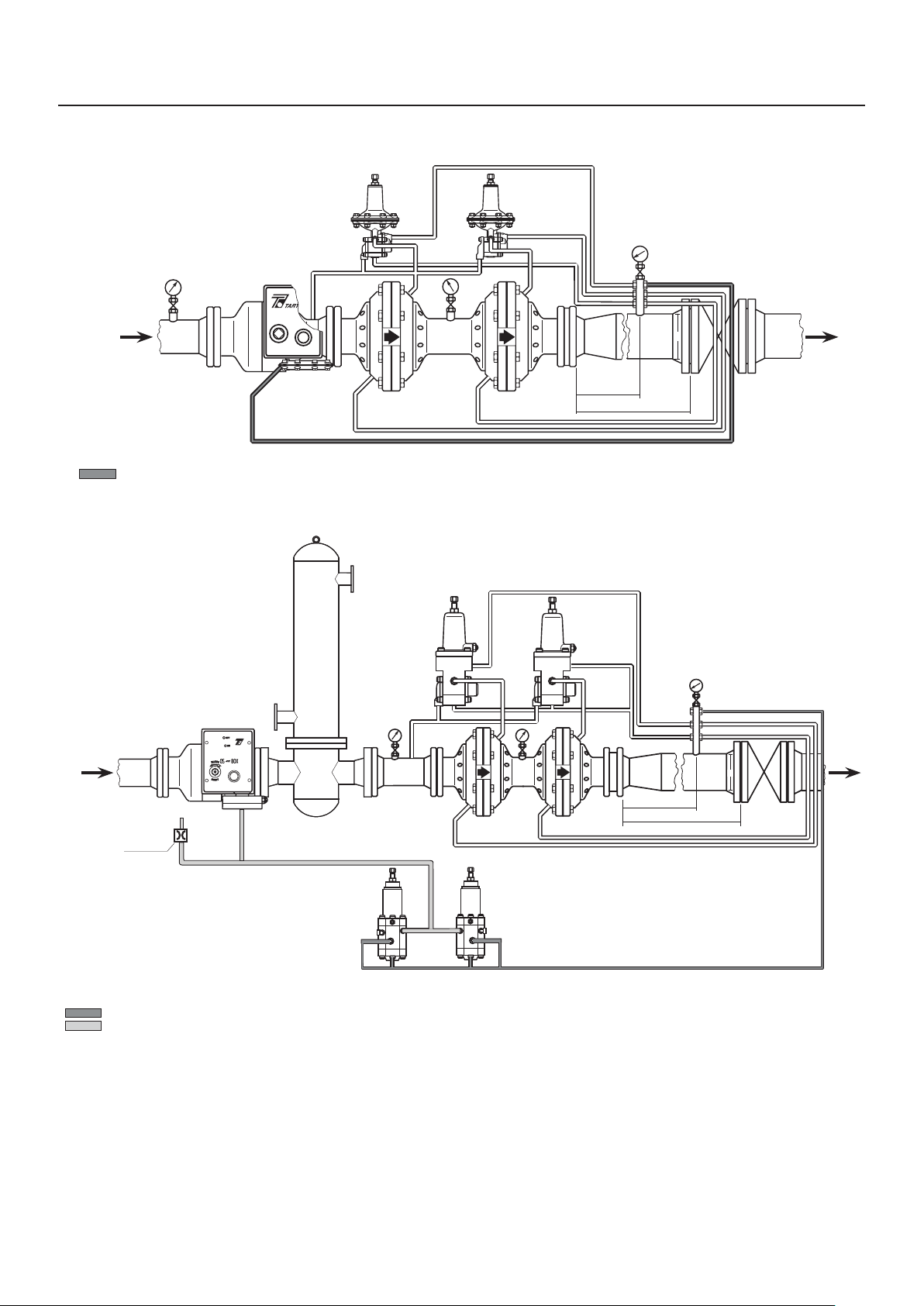

SLAM-SHUT VALVE WITH OS/80X SERIES CONTROLLER - INSTALLATION IN A LOW PRESSURE REGULATING LINE

BM5A SERIES

SLAM-SHUT VALVE

TYPE PS/79-1 TYPE PS/79-1

MONITOR

REGULATOR

D

≥ 4 X D

≥ 6 X D

BM5A SERIES

SLAM-SHUT VALVE

BLEED JET

(1 mm / 0.04 IN.)

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

TYPE PRX/18-PN

PRX SERIES:

B - SUPPLY PORT

L - LOADING PORT

A - SENSING PORT

TYPE PS/79 OR PSA/79

B

A

TYPE S PSA/79, PSA/80,

PSA/79-AP AND PSA/80-AP:

V - SENSING PORT

M - SUPPLY PORT

R - LOADING PORT

S - BLEED PORT

TYPE

PS/79 OR

PSA/79

V

R

SMM

MONITOR REGULATOR

TYPE PRX/182-PN

LL

B

A

R

V

S

D

≥ 4 X D

≥ 6 X D

SLAM-SHUT VALVE WITH OS/80X-PN SERIES CONTROLLER - OVERPRESSURE AND UNDERPRESSURE CONTROL DOWNSTREAM OF REGULATORS

Figure 5. Type BM5A Typical Connection/Installation Schematics

6

Page 7

Type BM5A

Installation

WARNING

▲

Personal injury or equipment damage,

due to bursting of pressure-containing

parts may result if this slam shut valve

is overpressured or is installed where

service conditions could exceed the

limits given in the Specification section

and on the appropriate nameplate or

where conditions exceed any rating of the

adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure limiting

devices to prevent service conditions

from exceeding those limits. Also, be sure

the installation is in compliance with all

applicable codes and regulations.

Additionally, physical damage to the slam

shut valve could break the slam shut

controller off the main valve, causing

personal injury and property damage due

to bursting of pressure containing parts.

To avoid such injury and damage, install

the slam shut valve in a safe location.

Installation procedures performed

by unqualified personnel may result

in improper adjustment and unsafe

operation. Either condition may result in

equipment damage or personal injury.

Only a qualified person shall install or

service the Type BM5A slam shut valve.

General Installation Requirements

• Ensure that the data found on the slam-shut valve

and slam-shut controller label are compatible with

usage requirements.

• Ensure the slam-shut is not damaged and remove

all foreign materials that might have collected

during shipping. Clean out all pipelines before

installing the slam-shut valve.

• Install the slam-shut valve in any position desired,

unless otherwise specified, but be sure flow

through the body matches the direction indicated

by the flow arrow stamped on the valve body.

• Install the slam-shut controller upright.

• Do not apply excessive external pressure or stress

on the body during installation.

• Use suitable line gaskets and bolting.

• Check and add any protection suitable for

specific environment.

• For outdoor installations, locate the slam-shut

devices away from vehicular traffic. Orient it in

correct position such that water, ice or other foreign

materials cannot enter into the device. Avoid

placing the slam-shut valve beneath eaves or

downspouts, and be sure it is above the probable

snow level. Install slam-shut valve in non-seismic

area and places away from fire or lightning.

• To avoid variations in the release values of

slam-shut valve and alteration of the trip pressure

setpoints of the slam-shut controller, make

pressure control line connection in a straight pipe

and away from bends, elbows or other areas of

turbulent flow.

Minimum and/or Maximum Setting

CAUTION

△

Slam shut controller must be mounted

as shown in Figure 6. If mounted

any other way, the controller will not

function properly.

• Follow the provisions of EN 12186 and EN 12279 in

installing Type BM5A slam-shut valve:

– Provide all means of appropriate draining

methods in the equipment installed before the

slam-shut valve.

– Provide the cathodic protection and electrical

isolation to avoid any corrosion.

– Clean the gas using proper filters, separators

or scrubber to avoid any hazard of erosion

or abrasion of pressure containing parts

(clause 7.3/7.2).

CAUTION

△

Whenever minimum or maximum

(UPSO or OPSO) pressure setting is not

required, omit corresponding steps.

The slam-shut controller is factory set at approximately

midpoint of the spring range or at customer specified

set pressure. However, a field adjustment may

be required to obtain desired results. Perform the

following steps to achieve the correct settings.

1. Make sure that the lever (key 33) is in horizontal

position when slam-shut controller is reset.

If necessary, use nut and locknut (keys 69

and 70) to adjust the lever (see step 2,

Reassembly section).

7

Page 8

Type BM5A

2. Use maximum (OPSO) adjusting nut (key 50)

to completely load maximum pressure (OPSO)

spring (key 53). Loosen minimum (UPSO)

adjusting screw (key 49) to completely relieve

minimum pressure (UPSO) spring (key 54).

3. Disconnect pressure control piping at port A.

4. Through port A, apply pressure to the controller

using a pump or other appropriate means and

raise the pressure to normal operating level.

5. Reset slam-shut controller. Then, reduce the

pressure until it reaches minimum cutoff level.

6. Use minimum (UPSO) adjusting screw (key 49) to

load minimum pressure (UPSO) spring (key 54)

slowly until the desired cut-off point is achieved.

7. Repeat steps (4) and (5) above to achieve the

required setpoint.

8. Bring pressure back to normal values.

9. Reset slam-shut controller. Then, raise the

pressure until it reaches maximum cut-off level.

10. Using maximum (OPSO) adjusting nut (key 50),

slowly unload maximum pressure (OPSO) spring

(key 53) until the desired cut-off point is achieved.

11. Repeat steps (8) and (9) above to achieve the

required setpoint.

Startup

WARNING

▲

Remove lever unit (key 137) from reset

stem (key 6) of controller immediately

after reset and secure it in a safe place.

If violated, equipment damage and/or

personal injury may result.

CAUTION

△

To prevent damage to the controller

during Startup, the sensing and bleed

lines should be located on the same

side of the downstream block valve.

When red mark in controller gets to

“ON”, resetting has been completed.

Further operation will damage the

controller. Based on structural

characteristics, the torque for resetting

first increases then decreases with the

increase of rotation of handle.

Slam-Shut Valve

Once the slam-shut valve is properly installed, perform

the following steps to startup.

Overpressure Protection

The recommended maximum allowable pressures are

stamped on the slam-shut valve label.

Provide upstream overpressure protection if

inlet pressure to slam shut valve can go higher

than maximum allowable/operating pressure to

downstream equipment.

After slam-shut valve’s intervention, inspect the

slam-shut valve for damage and maintain downstream

side pressure within the actual maximum operating set

up range to avoid abnormal back pressures that can

damage the SSD’s controller.

Provide downstream overpressure protection if the

slam-shut valve outlet pressure can be greater than

the maximum allowable pressure (PS) of the pilot

(differential strength type).

Slam-shut valve operation below the limits specified

in the specifications section and slam-shut valve label

does not preclude the possibility of damage from

external sources or debris in the line.

1. Partially open t

downstream of the regulator enough to allow a

minimum gas flow.

2. Partially open isolation valve upstream of the

slam-shut valve to let a small amount of gas to

flow into the slam shut valve.

3. Turn the reset stem slowly counterclockwise using

the appropriate lever unit. This will let gas to flow

from inlet to outlet of slam-shut valve.

4. Wait for few seconds for the pressure to stabilize.

5. Repeat step 3 above, making sure that levers of

slam-shut controller keep the valve open and that

lever (key 33) is in horizontal position.

6. Slowly open the isolation valve upstream

of slam-shut valve completely. Then, slowly

open the isolation valve downstream of

regulator completely.

he isolation valve located

8

Page 9

Type BM5A

Slam-Shut Controller Adjustment

Perform the following steps to change the

slam-shut controller setpoints (overpressure

and/or underpressure).

1. Remove the spring closing cap of the controller.

2. Turn the adjusting screws clockwise to increase

setpoint or counterclockwise to decrease setpoint.

Monitor set pressure with a test gauge during

the adjustment.

Shutdown

WARNING

▲

To avoid personal injury resulting from

sudden release of pressure, isolate

the slam-shut valve from all pressure

and release trapped pressure from the

equipment and pressure line before

disassembly of equipment. In case of

disassembly of pressure retaining parts

for checks and maintenance procedures,

external and internal tightness

tests have to be done according to

applicable codes.

before applying the CE marking, shall also be covered

after every subsequent reassembly at installation

site, in order to ensure that the equipment will be safe

throughout its intended life.

The slam-shut device should be tested for both under

and overpressure shutoff activation and seat leak

annually with test intervals not to exceed 15 months

and at least one each calendar year. If the slam-shut

device does not close at the desired set pressure(s)

and/or leaks gas after closure, repair and/or replace

the slam-shut device.

Slam-Shut Valve (See Figure 7)

WARNING

▲

Only a qualified person may perform

maintenance procedures. If necessary,

contact our local Sales Office

for assistance.

Before proceeding with any

maintenance work, stop the fluid flow

to the unit. Turn off the isolation valves

upstream and downstream of the

slam-shut valve. Release pressure from

the equipment and control lines.

Maintenance

WARNING

▲

Only a qualified person may perform

maintenance procedures. If necessary,

contact our local Sales Office

for assistance.

Failure to test the slam-shut device for

proper shutoff can result in a hazardous

condition. Test the slam-shut device for

operation per applicable federal, state,

and local codes, rules and regulations,

and manufacturer’s instructions.

The slam shut valve and its accessories are subject

to normal wear and therefore, they must be inspected

periodically and replaced if necessary. The frequency

of inspection and replacement depends on the severity

of service conditions, test results found during the

annual test, and applicable codes and regulations. In

accordance with applicable National or Industry codes,

standards and regulations/recommendations, all

hazards covered by specific tests after final assembly

Disassembly

1. Disconnect all connections, remove slam-shut

valve from the line and place it in vertical position

(inlet flange at bottom and outlet flange at top).

Use appropriate protection method to prevent

damage to the flanges and their gasket surfaces.

2. Mark the position of the outlet flange (key 116) and

inlet flange (key 100) to keep the same/correct

alignment during reassembly.

3. Loosen the special screws (key 133) and dismount

the slam-shut controller.

4. Loosen screws (key 135) and remove hub

(key 124). Remove seeger ring (key 122) and

dismount parts. Replace O-rings [keys 120,125

and 126 (include key 130 for DN 150 / NPS 6)]

and anti-friction rings (key 119). Check bearing

[key 128 (include key 131 for DN 150 / NPS 6)]

and replace if necessary.

5. Slowly loosen nuts (key 112) to decompress the

spring (key 114).

6. Remove sleeve (key 117), disk (key 110) and

pad holder (key 101); loosen screw (key 104)

and replace pad unit (key 102). Replace O-ring

[key 107 (include key 129 for DN 65 / NPS 2-1/2

to DN 150 / NPS 6)].

9

Page 10

Type BM5A

7. Replace O-ring (key 115).

8. Check all moving parts, especially nickel plated

surfaces. Replace any that are worn or damaged.

9. Clean all stripped-down parts.

Reassembly

Lubricate all seals with silicone-based lubricant and be

careful not to damage the seals when reassembling.

Reassemble the parts in the reverse order of the

above steps.

As you proceed, make sure that parts move freely and

without too much friction.

In addition:

• Complete reassembly and make sure to tighten all

screws uniformly.

• When reassembling the hub (key 124), make sure

that the pawl of shaft unit (key 121) is facing the

inlet flange (key 100).

• Check that slam-shut sleeve (key 117) opens when

shaft unit (key 121) is rotated counterclockwise.

• Before reassembling the slam-shut controller, make

sure that the pawl of shaft unit (key 121) is against

the sleeve (key 117). Ensure that the slam-shut

actuator is correctly mounted.

• After reassembling check if all parts are properly

functioning. Check the valve with suds to ensure

that there are no leaks.

• Reinstall slam shut valve on the line and reestablish

all connections.

Routine slam-shut controller maintenance

entails periodic checking of the diaphragm on

the Type OS/80X (the piston Gaco flex on the

Type OS/84X) and the movement of the levers (the

levers should move freely with minimum friction). If

necessary, lubricate pins with silicone-based lubricant.

Disassembly

1. Remove screws (key 40) and casing (key 47).

2. Remove dowels (key 12) and bushing (key 13).

3. Slide off stem (key 6), lever assembly (keys 17

and 2), balls (key 10) or rollers for Type OS/80X-R

and shim ring (key 15). Wash parts, replace any

if worn-out.

4. Remove nuts (key 18), levers (keys 20 and 36)

and springs (keys 37 and 21).

5. Remove nut (key 30), screw (key 29) and lever

(key 33).

6. Remove minimum (UPSO) adjusting screw

(key 49), maximum (OPSO) adjusting nut (key 50)

and springs (keys 53 and 54).

7. Remove cover (key 61) on OS/80X Series or plug

on Types OS/84X and OS/88X, and proceed as

directed in replacing diaphragm/O-ring section.

8. Remove nut (key 70) and locknut (key 69), then

slide off stem unit (key 57).

9. Loosen screw (key 3), unscrew nut (key 9),

remove balls holder (key 5) and check seals

(keys 4 and 8) for wear.

Slam-Shut Controller (See Figure 8)

WARNING

▲

Only a qualified person may perform

maintenance procedures. If necessary,

contact our local Sales Office

for assistance.

Before proceeding with any

maintenance work, disconnect impulse

connection (A) to release pressure

inside the slam-shut controller.

After maintenance operation, check the

tightness of the connections with suds.

10

10. Clean all removed parts. Replace any that are

worn or damaged.

Replacing Diaphragm (OS/80X Series only)

1. Remove screws (key 27) and cover (key 61).

2. Replace diaphragm (key 62).

3. To remount diaphragm, coat it with grease, set

it in place around the edge of cover (key 61)

and evenly tighten screws (key 27) to ensure

proper sealing.

Page 11

Type BM5A

Replacing O-ring

(Types OS/84X and OS/88X only)

1. Remove plug (key 61) and extract piston (key 68)

from body (key 60).

2. Replace O-ring (key 67) and Gaco flex (key 66).

3. Reassemble in the reverse order of the

above procedures.

Reassembly

Reassemble all parts in the reverse order of the steps

in the disassembly section.

As you proceed, make sure all parts move freely

without too much friction. If necessary, lubricate them

with silicone-based lubricant.

Make sure to:

1. Screw the nuts (keys 30 and 18) without

overtightening them to allow the levers (keys 33,

36 and 20) to move freely without friction.

2. Before mounting minimum (UPSO) spring

(key 54), register position of lever (key 33) by

means of nut (key 70), locking it into place with

locknut (key 69).

Note

The lever (key 33) is in proper position

when it is exactly horizontal and in the

center of the groove of lever (key 36).

3. Remount lever assembly (keys 17 and 2), balls

(key 10) or rollers for Type OS/80X-R, keeping

them in their seat with grease and stem (key 6),

which is to be turned so the balls/rollers enter their

seats. The stem and lever assembly should now

be tightly fitted together.

4. Remount bushing (key 13); make sure that the

dowels (key 12) are firmly set in the grooves of the

stem (key 6).

5. Repeatedly check if pilot resets properly and,

lastly, remount minimum (UPSO) spring (key 54).

6. Check controller setting.

Periodical Checks

Perform the following procedures to check that the

slam-shut valve is working properly.

Cut-off Test

1. Cut-off the fluid flow to slam shut valve by

closing upstream and downstream isolation

valves and disconnect the pressure sensing line

to port A of slam shut controller. The slam-shut

controller should cut-off for minimum pressure

(Underpressure Shut-off - UPSO), if set.

2. Through port A, using a small pump or other

appropriate means, raise the pressure to normal

operating level. Reset slam-shut controller if it was

cut-off in step 1.

3. Simulate pressure increase until maximum

pressure cutoff value (Overpressure Shut-off –

OPSO) is reached. The slam-shut valve should

cut-off at this point.

4. Connect the sensing line back to port A of the

controller and return the slam shut valve to

operating conditions by following the instructions

described in the Startup section.

Valve-seal Check

1. Slowly close the downstream isolation valve.

2. Press the “EMERGENCY” button. The slam-shut

controller should immediately close and cut-off the

flow through the valve.

3. Loosen a connector in the downstream line of

the slam-shut valve or of the regulator. Check

the connector with soap and water, to make sure

there are no leaks; repair the slam-shut valve

if necessary.

Parts Ordering

When corresponding with our local Sales Office about

this equipment or to order spare parts or kit, always

refer to the type of slam-shut valve or slam-shut

controller and its serial number.

When ordering replacement parts, reference the key

number of each needed part as found in the following

parts list.

Spare Parts

Store spare parts in compliance with national

standard/rules to avoid over aging or any damage.

11

Page 12

Type BM5A

FLOW FROM RIGHT TO LEFT FLOW FORM LEFT TO RIGHT

UPWARD FLOWDOWNWARD FLOW

Figure 6. Type BM5A Slam-Shut Valve Flow Orientation

Table 3. Approximate Weights

END

CONNECTION STYLE

CL300 RF / CL600 RF 17 37.5 30 66 62 137 105 231 280 617

12

DN 25 / NPS 1 DN 50 / NPS 2 DN 80 / NPS 3 DN 100 / NPS 4 DN 150 / NPS 6

kg lbs kg lbs kg lbs kg lbs kg lbs

Page 13

Type BM5A

Table 4. Troubleshooting Guide for Type BM5A Slam-Shut Valve

SYMPTOMS POSSIBLE CAUSE RECOMMENDED ACTIONS

Slam-shut device does not remain set.

Sleeve does not seal properly.

Parts List

Type BM5A Slam-Shut Valve

(See Figure 7)

Key Description

100 Inlet ange

101 Pad holder

102* Pad unit

103 Pad retainer

104 Screw

105 Label

106 Rivet

107* O-ring

108 Label support

109 Label

110 Disk

111 Washer

112 Nut

113 Stud bolt

114 Spring

115* O-ring

116 Outlet ange

117 Sleeve

118 Screw

The sensing line to port (A) of slam-shut controller

is not connected properly.

Downstream pressure coincides with the maximum

or minimum (OPSO or UPSO) slam-shut settings.

Diaphragm (key 62) [or Gaco ex (key 66) on

Types OS/84X and OS/88X] is damaged.

Seal gaskets are worn out. Check gaskets and replace as necessary.

Sleeve has dirt deposits. Check sleeve and clean as necessary.

Shaft unit (key 121) is damaged. Check shaft unit and repair or replace as necessary.

Key Description

119* Anti-friction ring

120* O-ring

121 Shaft unit

122 Seeger ring

123 Pin

124 Hub

125* O-ring

126* O-ring

127 Disk

128 Bearing

129* O-ring

130* O-ring

131 Bearing

132 Spacer

133 Special screw

134 Bushing

135 Screw

136 Eyebolt

137 Lever unit

Check the sensing line connections (A).

Check slam-shut settings.

Replace the diaphragm or Gaco Flex.

* Rubber parts are supplied in the “spare parts kit”, recommended as stock.

13

Page 14

Type BM5A

OS/80X Series Slam-Shut Controller

(See Figure 8)

Key Description

1 Plate

2 Releasing bushing

3 Screw

4* Gasket

5 Balls holder

6 Stem

7 Roller

8* O-ring

9 Reloading nut

10 Ball (Roller for Type OS/80X-R)

11 Roller

12 Dowels

13 Reloading bushing

14* O-ring

15 Ring

17 Reloading lever unit

18 Self-locking nut

19 Washer

20 Return lever

21 Spring

22 Fulcrum

24 Label

26 Nut

27 Screw

28 Reloading pin

29 Screw

30 Self-locking nut

31 Washer

32 Plate fulcrum

33 Lever

34 Screw

35 Cone

36 Releasing lever

37 Spring

38 Plug

39 Locking pin

Key Description

40 Screw

41 Indicator pin

42 On-O indicator

43 Button

44* O-ring

45 Spring

46 Gasket

47 Casing

48 Screw

49 Minimum pressure (UPSO) adjusting screw

50 Maximum pressure (OPSO) adjusting nut

51 Pipe assembly

52 Washer

53 Spring

54 Spring

55 Lower spring holder unit

56 Seeger ring

57 Stem unit

58 Spring

59 Plate holding stem unit

60 Top cover (Body for Types OS/84X and OS/88X)

61 Lower cover (Plug for Types OS/84X and OS/88X)

62* Diaphragm

63 Screw

64 Block

65* O-ring

66* Gaco ex

67* O-ring

68 Piston

69 Locknut

70 Nut

71 Microswitch

73* Gasket (only for Types OS/80X-BP, -BPA-D and -MPA-D)

74 Filter

* Rubber parts are supplied in the “spare parts kit”, recommended as stock.

14

Page 15

Type BM5A

OFF

ON

R

M

A

I

O

T

E

E

S

OS-80X

G

R

E

M

E

E

M

E

R

G

E

N

Z

A

Y

C

N

E

R

R

105

104103102101

106 107 109 106 110 111 112 113100

125126127128

124

123

122

121

108

120 119

114 115

116

117

118

MLM1499

Figure 7. Type BM5A Slam-Shut Valve Assembly

15

Page 16

Type BM5A

136

PAD HOLDER

DN 65 / NPS 2-1/2 TO

DN 150 / NPS 6

101

133

137 137

DN 150 / NPS 6 LEVER UNIT

135

DN 150 / NPS 6 REOPENING HUB

MLM1499

16

102

103

104

129

119 120

134

133

124125

Figure 7. Type BM5A Slam-Shut Valve Assembly (continued)

126

122

123

135

128

130

131

132

131

121

Page 17

10

Type BM5A

5

DETAIL OF TYPE OS/80X-R REINFORCED

FOR TYPE BM5A DN 150 / NPS 6

2220 21

19

18

17

6

40

71

DETAIL OF OS/80X SERIES

WITH PROXIMITY SWITCH

OFF

1

ON

SECTION D-D

2

MLM1389

15

1314

12 11

SECTION C-C

3

4

R

M

A

I

O

5

R

6

7

R

8

OS-80X

T

E

E

S

G

R

E

M

E

E

M

E

R

G

9

10

Figure 8. OS/80X Series Slam-Shut Controller Assembly (Standard Version)

E

N

Z

A

Y

C

N

E

17

Page 18

Type BM5A

41

42 19 18 43

4544

29

30

31

32

38 3722

SECTION A-A

C

D D

A

28

39

36

3435

26

47 48 49 50 51

46

B

52

53

54

52

24

OMT

33

70

69

48

73

55

56

57

58

59

MLM1389

18

A

C

27 26

Figure 8. OS/80X Series Slam-Shut Controller Assembly (Standard Version) (continued)

B

A

SECTION B-B

60

62

61

Page 19

Type BM5A

65 62 61

59 63 64 60

34

27

TYPE OS/80X-APA-D DETAIL TYPE OS/80X-MPA-D DETAIL

34 59 63

6465 60

62 61

74

74 74

65 34 59 63 64 60 62 61

73

27

34 59 63

64

6660

67

73

27

68

TYPE OS/80X-BPA-D DETAIL TYPE OS/84X DETAIL

59

34

68

63 64 60 66 67

61

61

MLM1389

TYPE OS/88X DETAIL

Figure 8. OS/80X Slam-Shut Controller Assembly (Standard Version) (continued)

19

Page 20

Type BM5A

Webadmin.Regulators@emerson.com

Tartarini-NaturalGas.com

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Emerson Process Management s.r.l.

Emerson Automation Solutions - Stabilimento di/Site of: Castel Maggiore - Bologna

Sede Legale/Legal Entity: Piazza Meda 5, 20121 Milano, Italy

Sede Amministrativa/Administrative Headquarters: OMT Tartarini, Via Clodoveo Bonazzi 43,

40013 Castel Maggiore (Bologna), Italy

C.F. - P.I. e R.I. di MI 13186130152 - REA di MI/n.1622916

Direz. e Coord. (art. 2497 bis CC): EMERSON ELECTRIC CO. St. Louis (USA) Socio Unico

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D103580X012 © 2021 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 01/21.

The Emerson logo is a trademark and service mark of Emerson Electric

Co. All other marks are the property of their prospective owners.

Tartarini™ is a mark owned by O.M.T. Ocina Meccanica Tartarini s.r.l.,

a business of Emerson Automation Solutions.

The contents of this publication are presented for informational

purposes only, and while every eort has been made to ensure their

accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein

or their use or applicability. All sales are governed by our terms and

conditions, which are available upon request. We reserve the right to

modify or improve the designs or specications of such products at any

time without notice.

Emerson Process Management Regulator Technologies, Inc does not

assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

Loading...

Loading...