Page 1

ATCA-S201

Installation and Use

6806800H62B

July 2009

Page 2

2009 Emerson

All rights reserved.

Trademarks

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are

trademarks and service marks of Emerson Electric Co. © 2009 Emerson Electric Co. All other product or service

names are the property of their respective owners.

Intel® is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and

other countries.

Java™ and all other Java-based marks are trademarks or registered trademarks of Sun Microsystems, Inc. in the

U.S. and other Countries.

Microsoft®, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows

XP™ is a trademark of Microsoft Corporation.

PICMG®, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered

trademarks of the PCI Industrial Computer Manufacturers Group.

UNIX® is a registered trademark of The Open Group in the United States and other countries.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Emerson assumes no liability

resulting from any omissions in this document, or from the use of the information obtained therein. Emerson

reserves the right to revise this document and to make changes from time to time in the content hereof without

obligation of Emerson to notify any person of such revision or changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another

document as a URL to a Emerson website. The text itself may not be published commercially in print or

electronic form, edited, translated, or otherwise altered without the permission of Emerson,

It is possible that this publication may contain reference to or information about Emerson products (machines

and programs), programming, or services that are not available in your country. Such references or information

must not be construed to mean that Emerson intends to announce such Emerson products, programming, or

services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following

notice shall apply unless otherwise agreed to in writing by Emerson.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of

the Rights in Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial

Computer Software and Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Emerson Network Power - Embedded Computing

2900 South Diablo Way, Suite 190

Tempe, AZ 85282

USA

Page 3

Contents

PREFACE ................................................................................................................................................I

SAFETY SUMMARY ...........................................................................................................................................I

FLAMMABILITY ............................................................................................................................................... II

EMI CAUTION................................................................................................................................................II

SAFETY STATEMENT........................................................................................................................................ II

CE NOTICE (EUROPEAN COMMUNITY).............................................................................................................. II

NOTICE.........................................................................................................................................................II

ABOUT THIS MANUAL......................................................................................................................... IV

HOW THIS MANUAL IS ORGANIZED................................................................................................................... IV

CONVENTIONS USED IN THIS MANUAL............................................................................................................. IV

HARDWARE PREPARATION AND INSTALLATION ................................................................................ VI

UNPACKING INSTRUCTIONS ............................................................................................................................ VI

ANTISTATIC PRECAUTIONS ............................................................................................................................. VI

1 ATCA-S201 OVERVIEW ................................................................................................................7

1.1 FEATURES OF THE ATCA STORAGE MODULE ...................................................................................... 7

1.2 I/O PICMG STANDARDS COMPLIANCE .............................................................................................. 8

1.3 CHASSIS I/O CONNECTIONS ............................................................................................................. 8

1.3.1 AMC card connections ............................................................................................................ 9

1.3.2 DDR2 SODIMM........................................................................................................................ 9

1.3.3 Zone 1, power backplane connections ................................................................................... 9

1.3.4 Zone 2, backplane connections .............................................................................................. 9

1.3.5 Zone 3, Advanced RTM connector .......................................................................................... 9

1.4 LEDS........................................................................................................................................... 11

1.5 SOFTWARE DRIVER SUPPORT........................................................................................................... 12

1.6 PART NUMBER, SERIAL NUMBER, AND ADDRESS LABELS .................................................................... 12

2 ATCA-S201 INSTALLATION ........................................................................................................14

2.1 INSTALLATION AND REMOVAL OF THE ATCA CARRIER BLADE ............................................................... 14

2.2 IMPORTANT INFORMATION ABOUT YOUR CHASSIS ............................................................................. 14

2.3 SAFETY STATEMENT....................................................................................................................... 14

2.3.1 Observe maximum module current requirements................................................................ 14

2.4 BEFORE YOU INSTALL OR REMOVE THE ATCA CARRIER BLADE ............................................................. 15

2.4.1 Observe ESD Precautions ...................................................................................................... 15

2.4.2 Watch for Bent Pins or Other Damage.................................................................................. 15

2.5 USE CAUTION WHEN INSTALLING OR REMOVING THE ATCA CARRIER .................................................. 15

2.5.1 Preserve EMI Compliance ...................................................................................................... 15

2.5.2 Understand Hot Swap........................................................................................................... 16

2.6 CONNECTOR MECHANICAL KEYING ................................................................................................. 16

2.7 VERIFY SLOT USAGE ...................................................................................................................... 16

2.8 INSTALLING THE ATCA CARRIER BLADE ............................................................................................ 16

2.9 REMOVING THE ATCA CARRIER BLADE............................................................................................. 18

2.10 VERIFYING THE HARDWARE INSTALLATION ....................................................................................... 18

Page 4

To Verify the Hardware Installation ...................................................................................... 19

2.10.1

3 NEW SYSTEM CONFIGURATION................................................................................................. 20

3.1 RS232 CONSOLE PORT ................................................................................................................. 21

3.1.1 System boot overview ........................................................................................................... 21

3.1.2 Flash boot device contents.................................................................................................... 22

3.1.3 Linux serial console shell window ......................................................................................... 23

3.2 DEFAULT BLADE LOGIN ACCOUNTS AND PASSWORDS ......................................................................... 23

3.2.1 Password change procedure................................................................................................. 23

3.2.2 Password recovery procedure ............................................................................................... 23

3.3 FACTORY RESET ............................................................................................................................ 24

3.4 CONFIGURING A NEW ATCA-S201 BLADE....................................................................................... 24

3.4.1 Serial ports............................................................................................................................ 24

3.4.2 Ethernet ports ....................................................................................................................... 24

3.4.3 Management Configuration via HTML browser.................................................................... 25

3.4.4 Management configuration via secure shell (SSH) ............................................................... 25

3.4.5 Management configuration via serial console shell.............................................................. 25

3.5 COMMAND LINE CONFIGURATION TOOL ........................................................................................... 26

3.5.1 Change IP address of any Ethernet resource ......................................................................... 26

3.5.2 Shell, configuration scripting options................................................................................... 28

3.6 NEW SYSTEM CONFIGURATION, NO DHCP SERVER ........................................................................... 29

3.6.1 U-boot console tool............................................................................................................... 30

3.6.2 Essential U-boot user commands ......................................................................................... 30

3.6.3 U-boot environment variables .............................................................................................. 31

3.6.4 Manually assign management IP addresses ......................................................................... 32

3.7 NETWORK BOOT PROCEDURE ......................................................................................................... 33

4 NETWORK CONFIGURATION ..................................................................................................... 34

4.1 ENABLE HTML BROWSER ACCESS.................................................................................................... 35

4.2 HTML SECURITY CERTIFICATES (HTTPS:// ) ...................................................................................... 35

4.3 HTML LOGIN SCREEN .................................................................................................................... 35

4.3.1 Auto logout inactivity period ................................................................................................ 36

4.3.2 Single session management override ................................................................................... 36

4.4 HTML HOME PAGE ....................................................................................................................... 36

4.5 ESSENTIAL SYSTEM CONFIGURATION STEPS ...................................................................................... 37

4.6 SYSTEM IDENTIFICATION AND TIME ZONE ATTRIBUTES ....................................................................... 38

4.6.1 Hostname ............................................................................................................................. 39

4.6.2 Domain Name ...................................................................................................................... 39

4.6.3 Date ...................................................................................................................................... 39

4.6.4 Time............................................................................................................................... ....... 40

4.6.5 Time Zone ............................................................................................................................. 40

4.6.6 Name Server list .................................................................................................................... 41

4.6.7 NTP Server list ....................................................................................................................... 41

4.6.8 Network time protocol - NTP (On/Off).................................................................................. 42

4.6.9 Ethernet network port identification .................................................................................... 42

4.6.10 Enable (online/offline)........................................................................................................... 43

4.6.11 DHCP............................................................................................................................... ...... 43

4.6.12 IP address.............................................................................................................................. 43

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide ii

Page 5

Network (Subnet) mask ........................................................................................................ 43

4.6.13

4.6.14 Broadcast.............................................................................................................................. 44

4.6.15 Gateway................................................................................................................................ 44

4.6.16 MTU size................................................................................................................................ 44

4.6.17 MAC address ......................................................................................................................... 44

4.7 VLAN VIRTUAL LOCAL AREA NETWORK SUPPORT ............................................................................. 45

4.7.1 Viewing active VLAN ............................................................................................................. 46

4.8 LINK AGGREGATION AND BONDING.................................................................................................. 47

4.8.1 Bonding, CLI command syntax ............................................................................................. 48

4.9 SHELF COMMUNICATIONS .............................................................................................................. 49

4.10 I/O STATUS ATTRIBUTES ................................................................................................................ 50

4.11 BLADE MAINTENANCE, MISCELLANEOUS OPERATIONS......................................................................... 51

4.11.1 Rescan SAS Topology, disk refresh........................................................................................ 52

4.11.2 Software Reset SAS Controller .............................................................................................. 52

4.11.3 Reset I/O Status counters...................................................................................................... 52

4.12 CPU STATUS ATTRIBUTES .............................................................................................................. 53

4.13 ATCA STATUS ATTRIBUTES ............................................................................................................ 54

5 RAID VOLUME CONFIGURATION ............................................................................................... 57

5.1 HARDWARE RAID CONFIGURATION ................................................................................................ 57

5.1.1 JBOD mode............................................................................................................................ 58

5.2 HARDWARE RAID CONFIGURATION MENU USAGE ............................................................................ 58

5.2.1 Hardware RAID levels and capabilities.................................................................................. 60

5.2.2 How new RAID definitions alter device menu display ........................................................... 60

5.2.3 Modify existing RAID configurations..................................................................................... 61

5.3 SOFTWARE RAID CONFIGURATION ................................................................................................. 63

5.3.1 Software RAID web-configuration menu usage.................................................................... 63

5.3.2 Software RAID, CLI command syntax ................................................................................... 64

5.3.3 Software RAID levels and capabilities ................................................................................... 66

6 PREPARE LOGICAL VOLUMES FOR ISCSI OR FILE SHARING......................................................... 67

6.1 BENEFITS OF A LOGICAL VOLUME GROUP (/DEV/VGA)........................................................................ 67

6.1.1 Benefits of a Logical device/disk (/dev/vga/lva0) .................................................................. 67

6.2 VIEWING PHYSICAL DISKS............................................................................................................... 68

6.2.1 Interpreting physical disk status ........................................................................................... 68

6.2.2 View physical disk properties ................................................................................................ 69

6.3 CREATE A LOGICAL VOLUME GROUP (/DEV/VGA) .............................................................................. 70

6.4 CREATING A LOGICAL DEVICE (/DEV/VGA/LVA0)............................................................................... 73

6.4.1 Extend/Expand a Logical Device (/dev/vga/lva0) .................................................................. 73

6.4.2 Delete a Logical device (/dev/vga/lva0) ................................................................................ 74

6.5 MANAGE SHARES (PREPARE LOGICAL DEVICE FOR SERVICE) ................................................................. 75

6.5.1 Commit a logical drive for iSCSI service ................................................................................ 75

6.5.2 Commit a logical drive for NAS service.................................................................................. 76

6.5.3 Un-commit an iSCSI share .................................................................................................... 77

6.5.4 Un-commit an NFS/SMB share.............................................................................................. 78

6.6 RE-NAME ISCSI SHARES, MAKE MORE ‘HUMAN-FRIENDLY’.................................................................. 79

7 ISCSI DEVICE SETUP TOOLS ....................................................................................................... 80

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide iii

Page 6

ISCSI CONFIGURATION MENU ......................................................................................................... 80

7.1

7.1.1 Add or create an iSCSI target ................................................................................................ 80

7.1.2 Add or create an iSCSI LUN.................................................................................................... 81

7.1.3 Remove an individual iSCSI LUN ........................................................................................... 83

7.1.4 Delete an iSCSI Target (and all LUNS) ................................................................................... 83

7.1.5 Advanced iSCSI configuration (expert mode) ....................................................................... 84

7.1.6 iSCSI Discovery filter configuration (expert mode)................................................................ 88

8 NFS/SMB SHARE SETUP TOOLS.................................................................................................. 89

8.1 NFS AND SMB MOUNT POINT CONFIGURATION MENUS ..................................................................... 89

8.1.1 Export an nfs or smb share.................................................................................................... 90

8.1.2 Remove an individual file-share Export................................................................................. 92

8.1.3 Advanced file share configuration (expert mode)................................................................. 93

9 BLADE MAINTENANCE AND FIRMWARE UPGRADES .................................................................. 95

9.1 BLADE MAINTENANCE ................................................................................................................... 95

9.1.1 Backup your blade configuration.......................................................................................... 95

9.1.2 Import (restore) a blade configuration ................................................................................. 96

9.2 ATCA FIRMWARE ......................................................................................................................... 96

9.2.1 Download New Firmware package....................................................................................... 97

9.3 NORMAL FIRMWARE UPDATE PROCEDURES ...................................................................................... 97

9.3.1 Web flash tool, update procedure details ............................................................................. 97

9.3.2 flash_update.sh tool usage and options .............................................................................. 99

9.3.3 CLI flash tool, update procedure details.............................................................................. 100

9.4 EMERGENCY FIRMWARE RECOVERY, THEORY OF OPERATION ............................................................. 101

9.4.1 Jumper Settings................................................................................................................... 101

9.4.2 Emergency flash recovery (factory reset)............................................................................ 102

9.4.3 Clear root password............................................................................................................ 103

10 ATCA-S201 MECHANICAL AND CONNECTOR INFORMATION.................................................. 105

10.1 SPECIFICATIONS FOR THE ATCA-S201.......................................................................................... 105

10.1.1 Physical dimensions............................................................................................................ 105

10.1.2 Power Requirements........................................................................................................... 105

10.1.3 Environmental Specifications and Compliance................................................................... 105

10.1.4 NEBS Compliance................................................................................................................ 106

10.1.5 Electromagnetic Compliance.............................................................................................. 106

10.2 CONNECTORS AND PIN ASSIGNMENTS ........................................................................................... 107

10.2.1 AMC Module Slots ............................................................................................................... 108

10.2.2 Zone 1 Connectors.............................................................................................................. 110

10.2.3 Zone 2 Connectors.............................................................................................................. 111

10.2.4 Zone 3 Connectors.............................................................................................................. 112

10.2.5 Power Supply Mezzanine Module ....................................................................................... 117

10.2.6 SODIMM DDR Module......................................................................................................... 117

11 RTM-ATCA-SXXX OVERVIEW ................................................................................................... 118

11.1 FEATURES OF THE ADVANCED REAR TRANSITION MODULE ............................................................... 118

11.2 I/O PICMG STANDARDS COMPLIANCE.......................................................................................... 118

11.3 I/O INTERFACES .......................................................................................................................... 118

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide iv

Page 7

External SAS Connector....................................................................................................... 119

11.3.1

11.3.2 Ethernet Management Port (RJ-45)..................................................................................... 119

11.3.3 Serial Console Port (RJ-45) .................................................................................................. 120

11.4 LEDS......................................................................................................................................... 120

11.5 SOFTWARE SUPPORT................................................................................................................... 121

11.6 PRODUCTS SUPPORTED BY THIS MANUAL....................................................................................... 121

11.7 IDENTIFICATION LABELS ............................................................................................................... 121

12 RTM-ATCA-SXXX INSTALLATION ............................................................................................. 124

12.1 INSTALLATION AND REMOVAL OF THE REAR TRANSITION MODULE .................................................... 124

12.2 IMPORTANT INFORMATION ABOUT YOUR CHASSIS .......................................................................... 124

12.2.1 Safety Statement ................................................................................................................ 124

12.2.2 Observe Maximum Module Current Requirements............................................................. 124

12.3 BEFORE YOU INSTALL OR REMOVE THE RTM ................................................................................. 125

12.3.1 Observe ESD Precautions .................................................................................................... 125

12.3.2 Watch for Bent Pins or Other Damage................................................................................ 125

12.4 USE CAUTION WHEN INSTALLING OR REMOVING RTM.................................................................... 126

12.4.1 Preserve EMI Compliance .................................................................................................... 126

12.4.2 Understand Hot Swap......................................................................................................... 126

12.5 VERIFY SLOT USAGE .................................................................................................................... 126

12.6 INSTALLING THE ADVANCED REAR TRANSITION MODULE ................................................................. 126

12.7 REMOVING THE ADVANCED REAR TRANSITION MODULE.................................................................. 128

12.8 VERIFYING THE HARDWARE INSTALLATION ..................................................................................... 128

13 RTM-ATCA-SXXX MECHANICAL AND CONNECTOR INFORMATION......................................... 129

13.1 SPECIFICATIONS FOR THE RTM-ATCA-SXXX ................................................................................ 129

13.1.1 Physical Dimensions ........................................................................................................... 129

13.1.2 Power Requirements........................................................................................................... 129

13.1.3 Environmental Specifications and Compliance................................................................... 129

13.1.4 NEBS Compliance................................................................................................................ 130

13.1.5 Electromagnetic Compliance.............................................................................................. 130

13.2 CONNECTORS AND PIN ASSIGNMENTS ........................................................................................... 131

13.2.1 SAS Connector Port............................................................................................................. 132

13.2.2 10/100/1000 Mb Management Port .................................................................................. 133

13.2.3 Serial Console Management Port........................................................................................ 134

13.2.4 Zone 3 Connectors.............................................................................................................. 134

14 IPMI FUNCTIONS LIST .............................................................................................................. 139

14.1 IPMI AND MANAGEMENT CONTROLLER (IPMC)............................................................................. 139

14.2 SENSOR DATA RECORDS ............................................................................................................... 139

14.2.1 RTM e-Keying Port Assignments ........................................................................................ 14‐2

14.3 SUPPORTED IPMI COMMANDS .................................................................................................... 14‐3

15 IPMC FIRMWARE UPGRADE PROCEDURE................................................................................ 15‐1

15.1 THE IPMITOOL UTILITY................................................................................................................. 15‐1

16 INDEX ..................................................................................................................................... 16‐3

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide v

Page 8

List of Figures

Figure 1, ATCA-S201 functional block diagram.......................................................................................... 9

Figure 3 ATCA-S201 Diagram Showing Identification Label Location .................................................... 13

Figure 4 Injector / Ejector latch and locking screw................................................................................... 17

Figure 5 Management communications port location diagram (Typical).............................................. 20

Figure 6 ATCA Blade boot sequence diagram........................................................................................... 22

Figure 7 Boot-Flash device contents.......................................................................................................... 22

Figure 8 HTML tool, startup screen............................................................................................................ 37

Figure 9 Emerson ATCA-S201 Maintenance Network .................................................................... 38

Figure 10 Link aggregation 802.3ad (bonding), theory of operation..................................................... 47

Figure 11 HTML tool, Emerson ATCA-S201 MaintenanceShelf ...................................................... 49

Figure 12 HTML tool, Emerson ATCA-S201 MaintenanceIO Status................................................ 50

Figure 13 HTML tool, Emerson ATCA-S201 MaintenanceCPU Status ............................................ 53

Figure 14 HTML tool, Emerson ATCA-S201 MaintenanceATCA Status.......................................... 54

Figure 15 HTML tool, Main navigation side-bar, Hardware RAID->Configuration................................. 58

Figure 16 Emerson ATCA-S201 Hardware RAID (new installation screen-shot) ............................... 59

Figure 17 Figure shows how RAID LUN definitions alter physical disk display ....................................... 61

Figure 19 Emerson ATCA-S201 MD RAID (new installation screen-shot) .......................................... 63

Figure 20 HTML tool, Emerson ATCA-S201 Physical Disk (summary screen)..................................... 68

Figure 22 HTML tool, Main navigation side-bar, LVM2->Configuration ................................................. 70

Figure 23 HTML tool, Emerson ATCA-S201 LVM2 Configuration........................................................ 71

Figure 25 HTML tool, Manage shares menu function .............................................................................. 75

Figure 26 HTML tool, Emerson ATCA-S201 iSCSI iSCSI Configuration............................................ 81

Figure 27 SCSI configuration screen updates to show the new LUN. ..................................................... 83

Figure 28 HTML tool, Emerson ATCA-S201 nfs nfs Configuration.................................................. 90

Figure 29 HTML tool, Emerson ATCA-S201 smb smb Configuration............................................. 91

Figure 30 ATCA-S201 Jumper locations .................................................................................................. 102

Figure 31 ATCA-S201 ATCA Module Connectors .................................................................................. 108

Figure 32 Zone 1 J10 Connector Port Pin Location Diagram................................................................. 111

Figure 33 Zone 2 Connector Port Pin Location Diagram........................................................................ 112

Figure 34 Zone 3, Connector Port Pin Location Diagram...................................................................... 113

Figure 35 ‘J30’ RTM Power Receptacle.................................................................................................... 116

Figure 36, RTM-ATCA-SXXX Functional Interconnect Diagram ............................................................ 119

Figure 37, Ethernet Management Port.................................................................................................... 120

Figure 38 RTM-ATCA-SXXX Front Panel LEDs......................................................................................... 121

Figure 39. RTM-ATCA-SXXX Top View (Two Disk Drives)...................................................................... 121

Figure 40 RTM-ATCA-SXXX Diagram Showing Identification Label Locations..................................... 123

Figure 41 Injector / Ejector Latch and Locking Screw............................................................................. 127

Figure 42 RTM-ATCA-SXXX Connectors.................................................................................................. 132

Figure 43. RTM-ATCA-SXXX Front Panel SAS Connector Pin-Out Diagram......................................... 132

Figure 44 10/100/1000 Mb Management Port Pin Location Diagram ................................................. 133

Figure 45 Serial Console Management Port Pin Location Diagram....................................................... 134

Figure 46 Zone 3, Connector Port Pin Location Diagram ...................................................................... 135

Figure 47 ‘J30’ RTM Power Receptacle.................................................................................................... 137

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide vi

Page 9

List of Tables

Table 1 Conventions used in this manual.................................................................................................... iv

Table 2 LED functional description ............................................................................................................ 12

Table 3 ATCA-S201 Identification Labels.................................................................................................. 12

Table 4 Max ATCA-S201 module Current requirements......................................................................... 14

Table 5 Console port, default terminal settings ....................................................................................... 21

Table 6 Built-in user accounts included on a new ATCA-S201................................................................. 23

Table 7 Ethernet ports for chassis communications (base/fabric).......................................................... 26

Table 8 Essential U-boot configuration commands ................................................................................. 30

Table 9 U-boot environment variables shown with printenv .................................................................. 31

Table 10 CLI command syntax, enable/disable GUI access ..................................................................... 35

Table 11 CLI command syntax, single session management override ................................................... 36

Table 12 CLI command syntax, set network property: hostname .......................................................... 39

Table 13 CLI command syntax, set network property: domain name.................................................... 39

Table 14 CLI command syntax, set network property: system date....................................................... 40

Table 15 CLI command syntax, set network property: system time....................................................... 40

Table 16 CLI command syntax, set network property: system time zone.............................................. 40

Table 17 Time Zone Selections .................................................................................................................. 41

Table 18 CLI command syntax, set network property: assign Name server........................................... 41

Table 19 CLI command syntax, set network property: assign NTP server.............................................. 42

Table 20 Ethernet ports for chassis communications (base/fabric)........................................................ 42

Table 21 CLI command syntax, set network property: Ethernet port configuration............................. 43

Table 22 Shelf configuration menu parameters....................................................................................... 50

Table 23 Blade, I/O Status indication......................................................................................................... 51

Table 24 ATCA status indication ................................................................................................................ 55

Table 25 CLI command syntax, blade_status for ATCA and AMC site status ......................................... 56

Table 26 CLI command syntax, set_raid: Add RAID configuration.......................................................... 59

Table 27 CLI command syntax, mdadm: manage RAID configuration................................................... 64

Table 28 CLI command syntax, create new volume groups .................................................................... 72

Table 29 CLI command syntax, create new logical device....................................................................... 73

Table 30 CLI command syntax, create iSCSI share ................................................................................... 76

Table 31 CLI command syntax, format a logical volume ......................................................................... 77

Table 32 CLI command syntax, create iSCSI share ................................................................................... 81

Table 33 iSCSI Advanced configuration and parameter definitions........................................................ 86

Table 34 CLI command syntax, create nfs share....................................................................................... 91

Table 35 CLI command syntax, create smb share .................................................................................... 92

Table 36 Common nfs export option definitions...................................................................................... 94

Table 37 JP1, jumper for primary/recovery Flash selection ................................................................... 101

Table 38 JP2, jumper for clearing master password............................................................................... 101

Table 39 Environmental specifications for the ATCA-S201 ................................................................... 106

Table 40 EMC Emission compliancy ........................................................................................................ 107

Table 41 Connector Port Identification and Location ............................................................................ 108

Table 42 AMC Slot 0, Port Assignments .................................................................................................. 109

Table 43 AMC Slot 1, Port Assignments .................................................................................................. 109

Table 44 AMC slot 2, Port Assignments .................................................................................................. 110

Table 45 AMC slot 3, Port Assignments .................................................................................................. 110

Table 46 Connector J10, Zone-1 Pin Assignments ................................................................................. 111

Table 47 Connector J23, Zone-2 Pin Assignments ................................................................................. 112

Table 48 Connector J23, Zone-2 Signal Descriptions............................................................................. 112

Table 49 Connector P32, Management infrastructure pin assignments.............................................. 113

Table 50 Connector J32, Management infrastructure signal descriptions........................................... 114

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide vii

Page 10

Table 51 Connector J33, PCIe and Miscellaneous RTM Pin Ass

Table 52 Connector J33, PCIe and Miscellaneous RTM Signal Descriptions......................................... 115

Table 53 J30, RTM Power Pin Header Assignment.................................................................................. 116

Table 54 Connector J30, RTM Power Pin Signal Descriptions................................................................ 116

Table 55 I/O Ports Available on RTM Faceplate ...................................................................................... 119

Table 56 LEDs On RTM Faceplate............................................................................................................. 120

Table 57 RTM-ATCA-SXXX Identification Labels..................................................................................... 122

Table 58 Max RTM Module Current Requirements ................................................................................ 124

Table 59 Max RTM Module Current Requirements ................................................................................ 129

Table 60 Environmental Specifications for the ATCA-S201................................................................... 130

Table 61 EMC Emission Compliancy........................................................................................................ 131

Table 62 Connector Port Identification and Location ............................................................................ 132

Table 63. RTM-ATCA-SXXX Front Panel SAS Connector Pin Assignments.......................................... 133

Table 64 10/100/1000 Management Port Connector Pin Assignments .............................................. 133

Table 65 Serial Console Management Port Connector Pin Assignments ............................................. 134

Table 66 Connector P32, Management Infrastructure Pin Assignments ............................................. 135

Table 67 Connector J32, Management Infrastructure Signal Descriptions.......................................... 136

Table 68 Connector J33, Miscellaneous RTM Pin Assignments............................................................. 136

Table 69 Connector J33, Miscellaneous RTM Signal Descriptions......................................................... 137

Table 70 J30, RTM Power Pin Header Assignment.................................................................................. 137

Table 71 Connector J30, RTM Power Pin Signal Descriptions................................................................ 138

Table 72. ATCA-S201 Sensor Data Records ........................................................................................... 14‐1

Table 73. RTM-ATCA-SXXX Sensor Data Records.................................................................................. 14‐1

Table 74 ATCA-S201 Example FRU Data Records.................................................................................. 14‐1

Table 75 RTM-ATCA-SXXX Example FRU Data Records ........................................................................ 14‐2

Table 76 Supported IPMI Commands..................................................................................................... 14‐4

Table 77 ipmitool options relevant to firmware upgrades ................................................................... 15‐1

ignments ............................................. 114

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide viii

Page 11

g

Preface

Safety Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this equipment. Failure to comply with these

precautions or with specific warnings elsewhere in this manual could result in

personal injury or damage to the equipment.

The safety precautions listed below represent warnings of certain dangers of which

Emerson is aware. You, as the user of the product, should follow these warnings and

all other safety precautions necessary for the safe operation of the equipment in

your operating environment.

ROUND THE INSTRUMENT. To minimize shock hazard, the equipment chassis and

G

enclosure must be connected to an electrical ground. If the equipment is supplied

with a three-conductor AC power cable, the power cable must be plugged into an

approved three-contact electrical outlet, with the grounding wire (green/yellow)

reliably connected to an electrical ground (safety ground) at the power outlet. The

power jack and mating plug of the power cable meet International Electrotechnical

Commission (IEC) safety standards and local electrical regulatory codes.

War nin

O NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE. Do not operate the equipment in any

D

explosive atmosphere such as in the presence of flammable gases or fumes.

Operation of any electrical equipment in such an environment could result in an

explosion and cause injury or damage.

EEP AWAY FROM LIVE CIRCUITS INSIDE THE EQUIPMENT. Operating personnel must not

K

remove equipment covers. Only Factory Authorized Service Personnel or other

qualified service personnel may remove equipment covers for internal subassembly

or component replacement or any internal adjustment. Service personnel should

not replace components with power cable connected. Under certain conditions,

dangerous voltages may exist even with the power cable removed. To avoid injuries,

such personnel should always disconnect power and discharge circuits before

touching components.

SE CAUTION WHEN EXPOSING OR HANDLING A CRT. Breakage of a Cathode-Ray Tube

U

(CRT) causes a high-velocity scattering of glass fragments (implosion). To prevent

CRT implosion, do not handle the CRT, and avoid rough handling or jarring of the

equipment. Handling of a CRT should be done only by qualified service personnel

using approved safety mask and gloves.

O NOT SUBSTITUTE PARTS OR MODIFY EQUIPMENT. Do not install substitute parts or

D

perform any unauthorized modification of the equipment. Contact your local

Emerson representative for service and repair to ensure that all safety features are

maintained.

BSERVE WARNINGS IN MANUAL. Warnings, such as the example below, precede

O

potentially dangerous procedures throughout this manual. Instructions contained in

the warnings must be followed. You should also employ all other safety precautions

which you deem necessary for the operation of the equipment in your operating

environment.

To prevent serious injury or death from dangerous voltages, use extreme caution

when handling, testing, and adjusting this equipment and its components.

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide i

Page 12

Preface

Flammability

All Emerson PWBs (printed wiring boards) are manufactured with a flammability

rating of 94V-0 by UL-recognized manufacturers.

EMI Caution

This equipment generates, uses, and can radiate electromagnetic energy. It

may cause or be susceptible to electromagnetic interference (EMI) if not

installed and used with adequate EMI protection.

Safety Statement

The ATCA-S201 is designed to comply with EN60950-1, and is intended to be used

with similarly tested ATCA and AMC products that have a user’s guide detailing user

installation of AMC module accessories.

CE Notice (European Community)

Emerson Networks products with the CE marking comply with the EMC Directive

(89/336/EEC). Compliance with this directive implies conformity to the following

European Norms:

EN55022 “Limits and Methods of Measurement of Radio Interference

Characteristics of Information Technology Equipment”; this product tested

to Equipment Class A

EN50082-1:1997 “Electromagnetic Compatibility–Generic Immunity

Standard, Part 1. Residential, Commercial and Light Industry”

System products also fulfill EN60950 (product safety), which is essentially the

requirement for the Low Voltage Directive (73/23/EEC).

Board products are tested in a representative system to show compliance with the

above mentioned requirements. A proper installation in a CE-marked system will

maintain the required EMC/safety performance.

In accordance with European Community directives, a “Declaration of Conformity”

has been made and is on file within the European Union. The “Declaration of

Conformity” is available on request. Please contact your sales representative.

Notice

While reasonable efforts have been made to assure the accuracy of this document,

Emerson Networks, Inc. assumes no liability resulting from any omissions in this

document, or from the use of the information obtained therein. Emerson reserves

the right to revise this document and to make changes from time to time in the

content hereof without obligation of Emerson to notify any person of such revision

or changes.

Electronic versions of this material may be read online, downloaded for personal

use. The text itself may not be published commercially in print or electronic form,

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide ii

Page 13

Preface

edited, translated, or otherwise altered without the permission of Emerson

Networks, Inc.

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide iii

Page 14

About This Manual

This manual supports the following configurations and model numbers.

Part Number Description

ATCA-S201 10GbE RAID Storage-IP Carrier blade

How this manual is organized

This manual is divided into the following chapters and appendices:

Chapter 1 provides a

6ATCA-S201 Overview

Chapter 2 provides instructions for Installation

Chapter 3 provides the procedures for a

6New System configuration

Chapter 4 Provides details regarding Network configuration

Chapter 5

Chapter 6

provides details for RAID Volume Configuration

provides instructions for sharing devices as NAS or iSCSI

Chapter 7 provides information for iSCSI LUN configurations

Chapter 8 provides information for NFS and SMB file sharing configurations

Chapter 9 provides

Chapter 10 provides

6Blade Maintenance and Firmware upgrades

6ATCA-S201 Mechanical and Connector Information

Chapter 11 provides overview on RTM-ATCA-SXXX

Chapter 12 provides instructions for installing the RTM-ATCA-SXXX

Chapter 13 provides RTM-ATCA-SXXX connector information

Chapter 14 provides

Chapter 15 provides

6IPMI Functions List

6IPMC Firmware Upgrade Procedure

Conventions Used in This Manual

The following typographical conventions are used in this document:

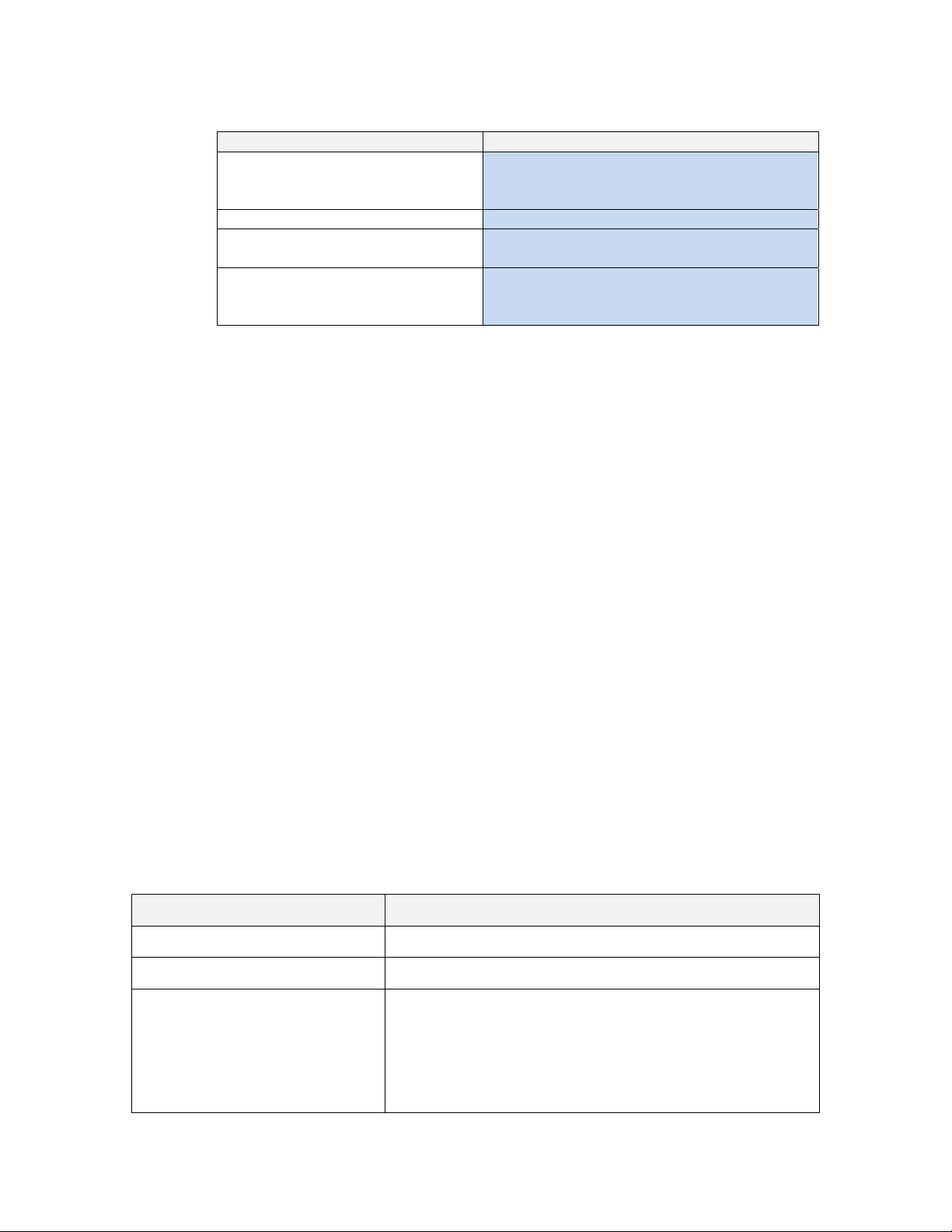

Table 1 Conventions used in this manual

Convention Is used for

bold

italic

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide iv

User input that you type just as it appears; it is also used for commands,

options and arguments to commands, and names of programs, directories

and files.

Names of variables to which you assign values, for function parameters,

and for structure names and fields. Italic is also used for comments in

screen displays and examples, and to introduce new terms.

Page 15

courier

ENTER

CTRL

System output (for example, screen displays and reports), examples, and

system prompts.

The carriage return or Enter key.

The Control key. Execute control characters by pressing the CTRL key and

the letter simultaneously, for example, Ctrl+D.

6806800H62B ATCA‐S201InstallationandUseGuidev

Page 16

Hardware Preparation and Installation

Unpacking Instructions

If the shipping carton is damaged upon receipt, request that the carrier’s agent be

present during the unpacking and inspection of the equipment.

Unpack the equipment from the shipping carton. Refer to the packing list and verify

that all items are present. Save the packing material for storing and reshipping of

equipment.

Avoid touching areas of integrated circuitry. Static discharge can damage circuits.

After removing the product from the packaging:

Check for obvious physical damage.

Make sure that you disconnect the chassis from the main power supply

before you continue.

Antistatic Precautions

Emerson strongly recommends that you use an antistatic wrist strap and a

conductive foam pad when installing or upgrading a system. Electronic

components, such as disk drives, computer boards, and memory modules, can be

extremely sensitive to electrostatic discharge (ESD). After removing the component

from its protective wrapper or from the system, place the component flat on a

grounded, static-free surface (and, in the case of a board, component side up). Do

not slide the component over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by

wearing an antistatic wrist strap (available at electronics stores) that is attached to

an active electrical ground. Note that a system chassis may not be grounded if it is

unplugged.

Dangerous voltages, capable of causing death, are present in this equipment. Use

extreme caution when handling, testing, and adjusting.

Avoid touching areas of integrated circuitry. Static discharge can damage these

circuits.

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide vi

Page 17

1 ATCA-S201 Overview

The Emerson ATCA-S201 is an ATCA carrier blade that supplies multi-protocol IP storage

services to the chassis Zone-2 backplane using Ethernet connections. The ATCA-S201

virtualizes capacity of AMC SAS/SATA disks and creates multiple logical volumes which are

mapped as iSCSI, NFS or SMB targets. Using access control lists, ATCA server blades are

given authorization to connect with virtualized volumes via 10 GbE fabric or 1GbE base

connections.

The ATCA-S201 carrier can accommodate up to four AMC disk modules. Additional disks

may be added using an Advanced ARTM which adheres to the Advanced RTM zone-3

connector pin out.

Users may also deploy the ATCA-S201 to realize gateway functions with external equipment

including SAS and/or Fiber channel (FC) storage area networks (SANs). For example,

populate with an AMC 4 Gb FC controller modules, and establish gateway services between

LUN volumes in the FC data center and the ATCA GbE network.

1.1 Features of the ATCA Storage Module

ATCA-S201 Overview

The ATCA-S201 is single slot carrier board for ATCA shelves. Measuring 8U (280mm)

x 325 mm, the carrier includes four advanced mezzanine card (AMC) slots for

storage disks or SAN connections. Several on board Ethernet controllers provide

connections to the base and fabric interfaces.

The prominent digital components include:

Freescale® 1.3Ghz, super scalar PowerPC processor

Intel® dual port 10 GbE Ethernet controller

LSI® 8 port SAS controller, with RAID

PLX® 48 Lane PCI Express Switch

1GB SODIMM, 533MHz DDR2, with ECC (72b)

Carrier IPMC, with hot swap and LED control

FRUID serial EERPORM (note: The FRU ID is not a separate part but rather

embedded in the MMC controller.)

Temperature sensors

Voltage sensors

SPI flash memory

The ATCA-S201 is loaded with software which enables it to terminate several IP

protocols, and efficiently map these protocols to block I/O storage using SAS/SATA

disks, and optional RAID protection. This product can also map IP protocols to Fibre

Channel SAN resources, if populated with a 4Gb Fibre channel AMC module.

Key software services include:

iSCSI service (IETF RFC-3720)

NFS service version 3 (network file share)

SMB service (Server Message Block file system)

Integrated RAID0, RAID1 and RAID1E service

SNMP

HTML web configuration client

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide 7

Page 18

1.2 I/O PICMG standards compliance

The ATCA-S201 10Gb RAID Storage-IP Carrier ATCA is fully compliant with the

following PCI Industrial Computer Manufacturers Group (PICMG) specifications:

PICMG 3.0 Advanced Telecommunications Computing Architecture (ATCA)

PICMG 3.1 Ethernet for ATCA Systems

AMC.0 Advance Mezzanine Card Base Specification

AMC.1 PCI Express and Advanced Switching

AMC.3 AMC Storage

IPMI v1.5 Intelligent Platform Management Interface Specification

PCI Express 1.0a

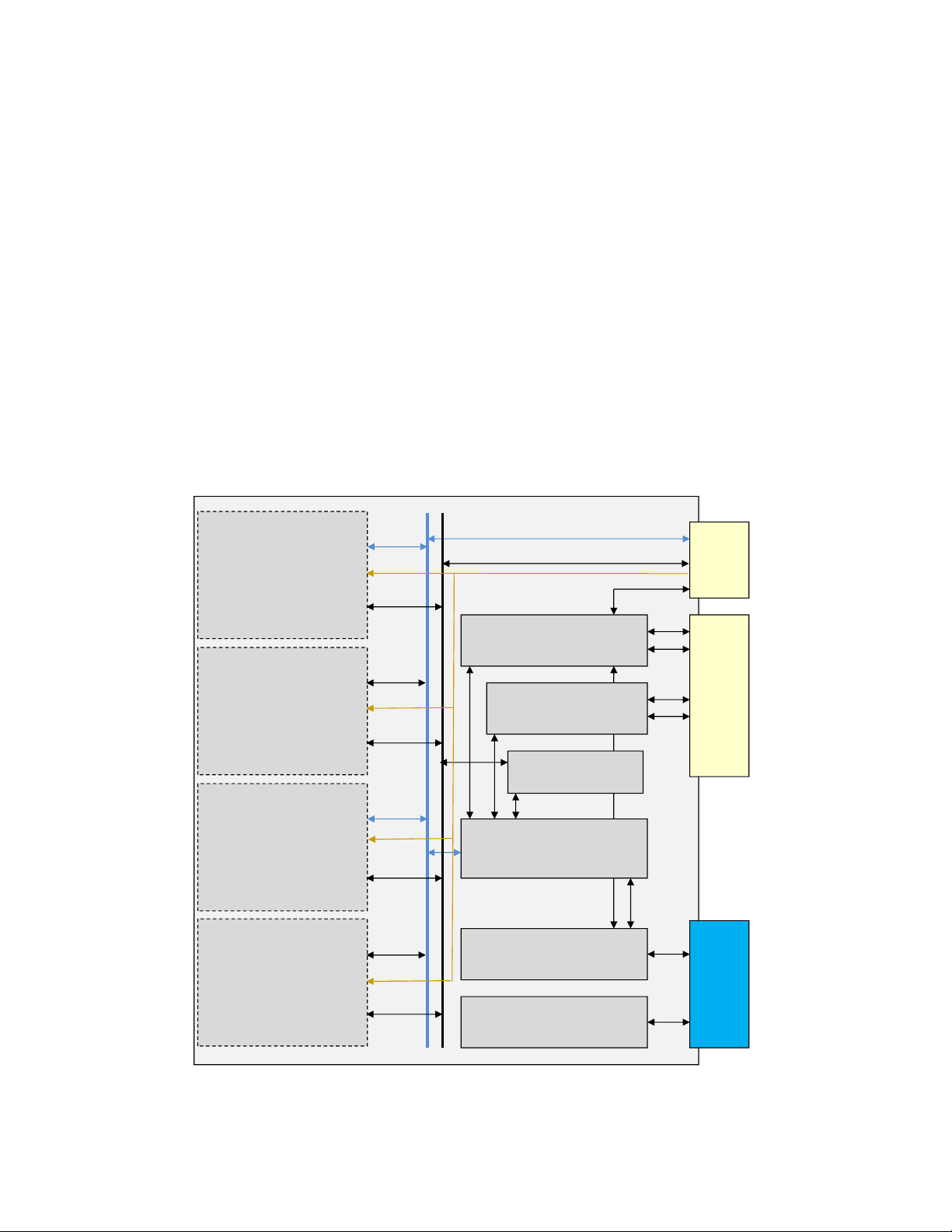

1.3 Chassis I/O connections

The ATCA-S201 provides several sockets and slots to facilitate operation in an ATCA

chassis. In addition to 4 AMC modules, the module includes chassis backplane

connections including ATCA zone-1 (power), zone-2 (fabric) and zone-3 (Advanced

rear transition module).

ATCA‐S201Overview

Site B1

Site B2

Site B3

Site B4

x4 PCI-E

x1 SAS

x1 SAS

x4 PCI-E

x1 SAS

X1 SAS

x4 PCI-E

x1 SAS

X1 SAS

x4 PCI-E

x1 SAS

4 SA TA/SA S

8 PCI-E

8 PCI-E

8 PCI-E

24 PCI-E

24 PCI-E

8 PCI-E

4 SA TA/SA S

MPC8548E CPU

DDR2, FLA SH

8 SAS

8 PCIE

LSI 1068E

SAS/R AID

PLX8548

PCI-E Swi tch

IPM I (PPS)

XAUI

10GigE

2

I

C

1 Gb

1 Gb

1 Gb

10 Gb

10 Gb

Zone 3

to RTM

Zone 2

ATCA

Zone 1

Power

X1 SAS

Power Modul e

6806800H62B ATCA‐S201InstallationandUseGuide8

Page 19

Figure 1, ATCA-S201 functional block diagram

1.3.1 AMC card connections

The four AMC slots have identical features, and each accommodates a half width,

mid height module. The ATCA-S201 accepts AMC cards conforming to either PCI

express signaling (AMC.1) or Storage signaling options (AMC.3). AMC feature

support details:

PCI-Express x4 on AMC ports 4-7

PCI reference clock on FCLKA

3Gb SAS/SATA on AMC port2

3Gb SAS/SATA on AMC port3

SAS hot swap support

Face plate height x width, 18.96 x 73.8mm

IPMB-L

72W max each slot (120W shared with all AMC slots)

1.3.2 DDR2 SODIMM

ATCA‐S201Overview

A 72 bit SODIMM socket is populated with a DDR2 memory module, and operated

at 533MHz. The ATCA applies ECC (error correction code) algorithms to this

memory to ensure data integrity of both the storage and program code stored in it.

Single bit errors are automatically detected and corrected by these ECC algorithms.

1.3.3 Zone 1, power backplane connections

The Zone-1 connector brings 48V DC power into the ATCA main board. This power

is regulated and split into several lower voltages by discrete components and a pair

of power modules that are affixed to the ATCA carrier. Together, these devices

convert 48V source and distributes power amongst the ATCA local onboard needs,

AMC slots and advanced rear transition module (RTM).

1.3.4 Zone 2, backplane connections

This connector carries the Ethernet links to the chassis backplane. All Ethernet ports

on this connector are full duplex and all ports support access to advertised storage

resources. This connector includes the following Gigabit Ethernet ports:

2 Fabric channels, redundant 10GbE XAUI connections

2 Base channels, redundant 1GbE base connections

1.3.5 Zone 3, Advanced RTM connector

This connector conforms to the advanced rear transition module (RTM) 3-row

connector standard. The following functions are routed to this connector:

8x PCI-express

4x SAS/SATA target connections

4x SAS/SATA initiator connections

2

I

C support

6806800H62B ATCA‐S201InstallationandUseGuide9

Page 20

12V and 3.3V supply voltage

1GbE management

RS232 management

1.3.5.1 Ethernet Management port

An Ethernet management port is routed to the Zone 3 connector. An advanced RTM

with an RJ-45 connector is needed to access this port. The port auto negotiates to

either 10/100/1000BASE-T.

1.3.5.2 Serial Console Port

An RS232 serial management port is routed to the Zone 3 connector. An advanced

RTM with an RJ-45 connector is needed to access this port.

ATCA‐S201Overview

6806800H62B ATCA‐S201InstallationandUseGuide10

Page 21

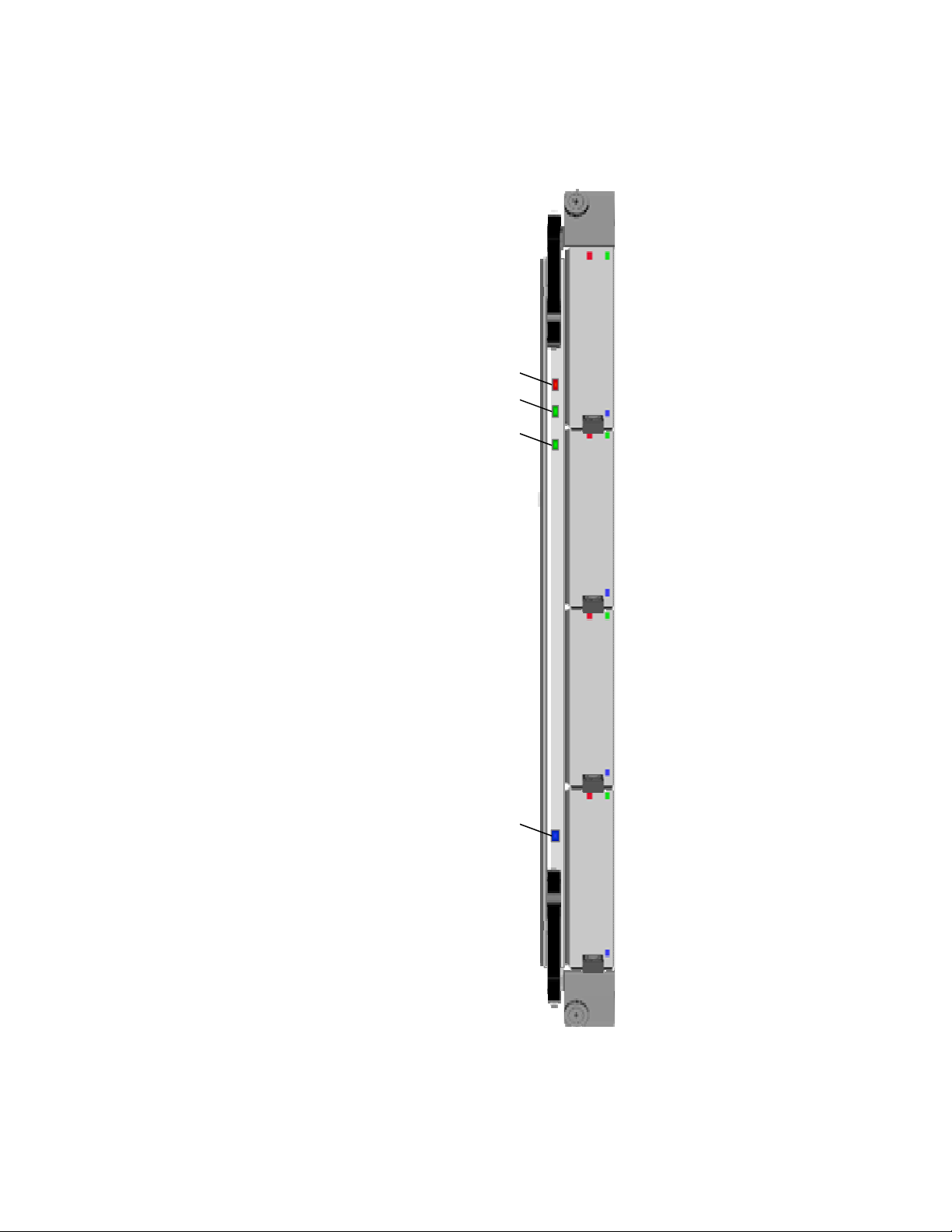

1.4 LEDs

ATCA‐S201Overview

Several LEDs are located on the panel of the ATCA-S201 Advanced TCA Carrier.

Out of Servi ce (OOS )

OK

Boot S ta tus

Hot Swap

Figure 2 Front view- fully populated ATCA-S201 showing panel LEDs

6806800H62B ATCA‐S201InstallationandUseGuide11

Page 22

Table 2 LED functional description

LED Description

ATCA Hot Swap LED

ATCA Blade OK LED Green-ON: Blade Optimal

ATCA Boot (Health) status

ATCA Out of service (OOS)

1.5 Software driver support

The ATCA-S201 provides several IP storage services over the 10GbE fabric and 1 GbE

base connections. Major services include iSCSI, NFS, and SMB. ATCA node boards

with standard OS installations, require no special drives from Emerson. This product

is compatible with the following operating systems and services:

Solaris 10 (SPARC) Operating System, NFS

Solaris 10 (SPARC) Operating System, iSCSI initiator

Solaris 10 (x86) Operating system, NFS

Solaris 10 (x86) Operating system, iSCSI initiator

SuSE Linux Enterprise Server 10, NFS

SuSE Linux Enterprise Server 10, iSCSI initiator

RedHat Enterprise Linux 5.0_u4, NFS

RedHat Enterprise Linux 5.0_u4, iSCSI initiator

Windows Server 2003 CIFS (a dialect of SMB)

Windows Server 2003, iSCSI initiator

ATCA‐S201Overview

Off: Normal, default state

Blue-Blinking: Preparing for hot swap

Blue-ON: ready for hot-swap removal

Amber: Blade is resetting

Green: Blade is optimal

Off: Normal, default state

Yellow-Blinking: firmware update in progress

Red-ON: Out of service (PPC/IPMC)

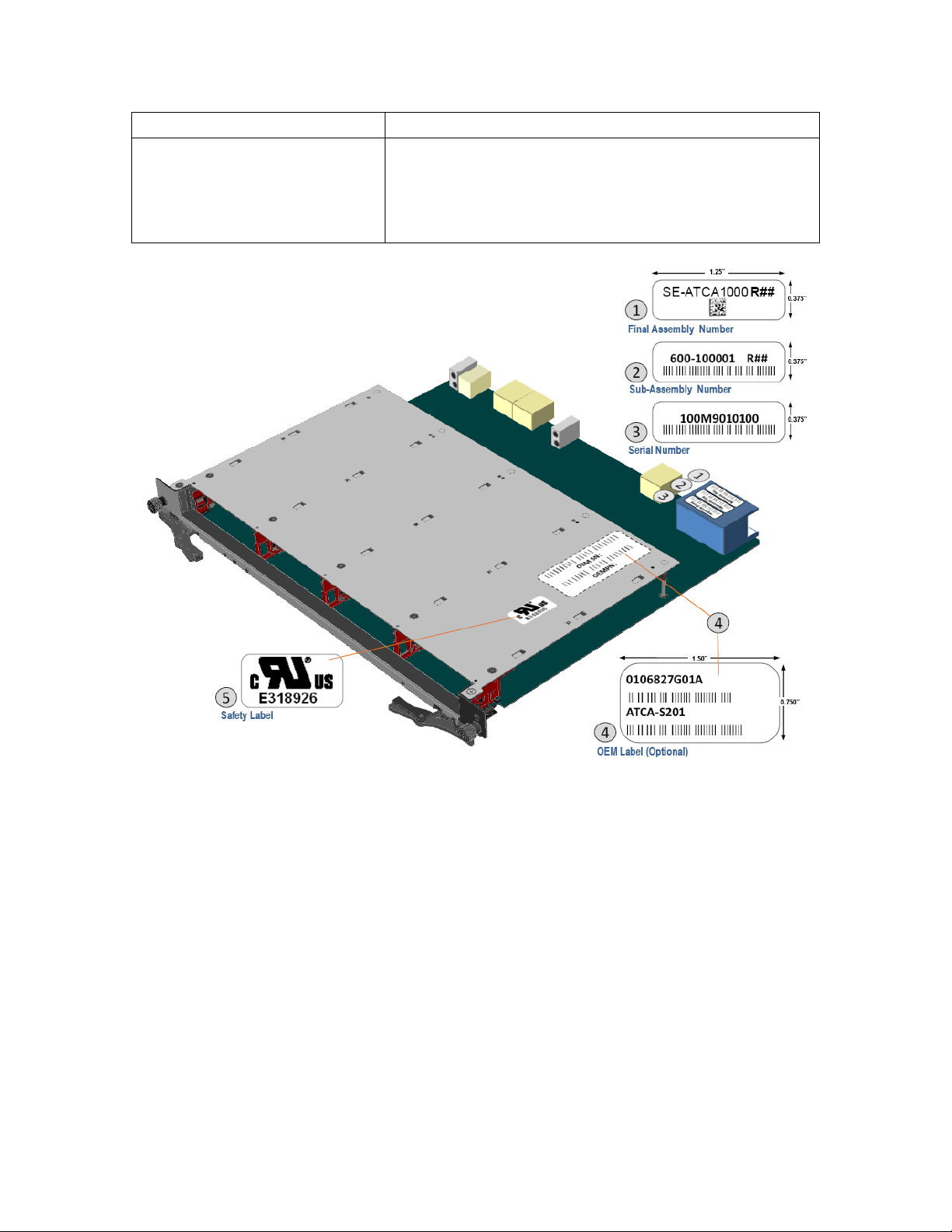

1.6 Part Number, Serial Number, and Address Labels

At manufacturing time, several labels are affixed to the ATCA-S201 as shown below.

For proper identification of the AMC module, use these barcode labels to determine

the module identity. The barcode labels provide the following information:

Table 3 ATCA-S201 Identification Labels

Label Description

Label 1: Top/Final assembly P/N For Internal Use Only

Label 2: Sub assembly P/N For Internal Use Only

Label 3: Serial number (S/N)

Format: AAALYMMSSSS

(example: 100S8031234)

6806800H62B ATCA‐S201InstallationandUseGuide12

AAA = Assembly Number (100)

L =Location of manufacturer (S)

Y = Calendar year of manufacturer (2008 = 8)

MM = Calendar month of manufacturer (March = 03)

SSSS = Sequence number (reset each month) (1234)

Page 23

ATCA‐S201Overview

Label 4: Part Numbers

(example:

0106826G01A

ATCA-S120)

This label contains 2 numbers:

Top = Internal Part Number

Bottom = Orderable Part Number

Figure 3 ATCA-S201 Diagram Showing Identification Label Location

6806800H62B ATCA‐S201InstallationandUseGuide13

Page 24

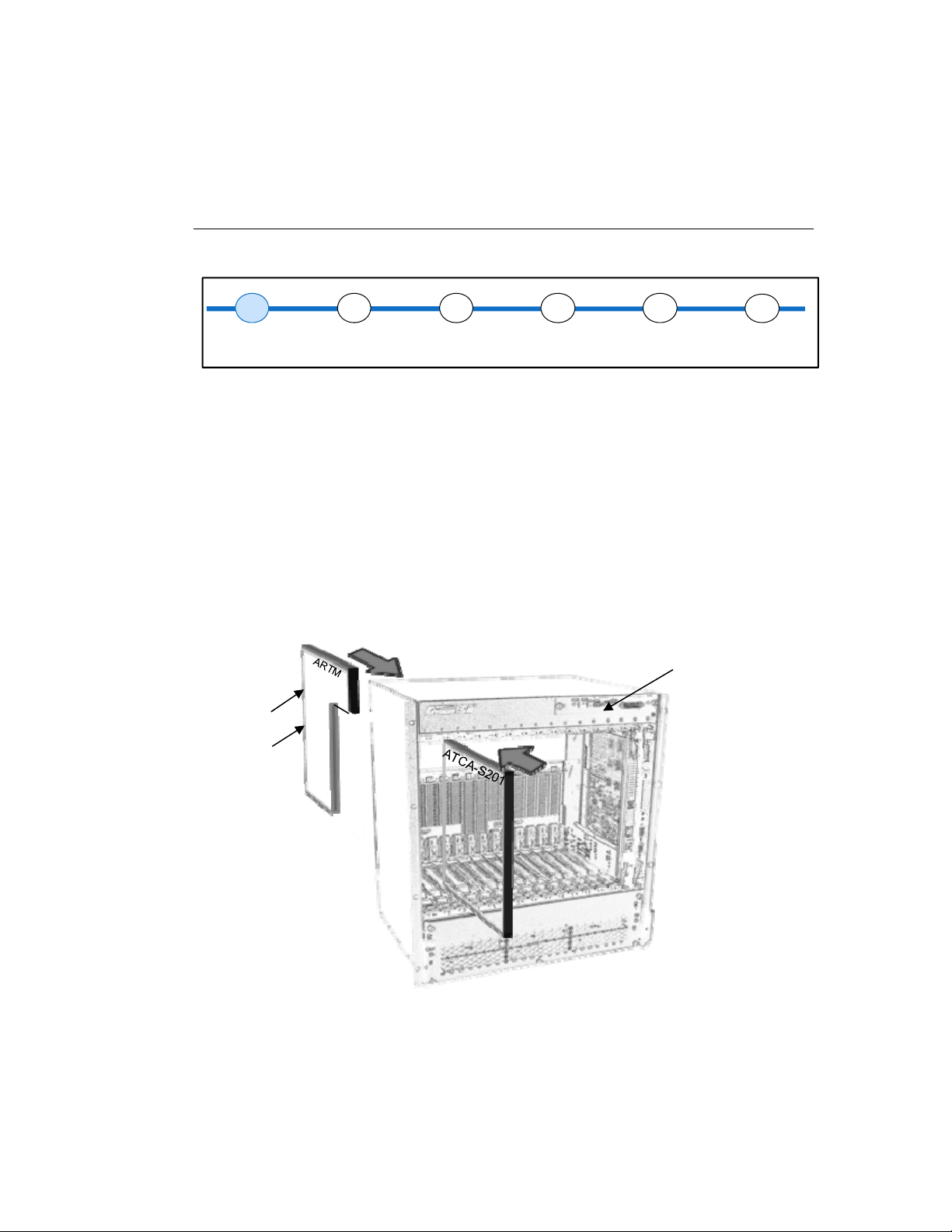

2 ATCA-S201 Installation

This chapter contains the procedures for installing and removing the ATCA-S201 10GbE RAID

storage services blade.

2.1 Installation and removal of the ATCA carrier blade

The ATCA-S201 10GbE RAID storage services blade can be installed into an ATCA

shelf (chassis) with a midplane made for front and rear board installations.

2.2 Important information about your chassis

The Chassis backplane often designates certain slots as hub slots and the others as

general purpose node slots. Be certain to select a general purpose node slot for

installation. If this installation includes a companion advanced rear transition

module (ARTM), install the ARTM first. These back-to-back slots have cut-outs that

permit the front carrier board to pass signals to the ARTM via the Zone-3 connector

complex.

Before installing the blade module, verify the module’s part number to ensure that

the correct module is being installed into the system. For information on identifying

the blade module, see Section 1.6 Part Number, Serial Number, and Address Labels.

2.3 Safety Statement

The ATCA-S201 is designed to comply with UL60950-1, and is intended to be used

with similarly tested ATCA and AMC products that have a user’s guide detailing user

installation.

2.3.1 Observe maximum module current requirements

Be sure to validate the host chassis, and the host chassis meets the maximum

current requirements.

The ATCA-S201 includes a stacked power supply module with maximum rated

output of 210W of power. This represents a surplus of power vs. the expected

power consumption.

Table 4 Max ATCA-S201 module Current requirements

Module ATCA-S201

Max ATCA blade Current Draw (unpopulated) 1.04 @ 48V (50 watts)

Max current draw (each AMC slot) 72 watts (max

each)

Max current draw (ARTM slot) 25 watts (max)

3.12 Total Maximum

2.08 @ 48V (100

watts) total shared

power pool

6806800H62B ATCA-S201ATCA-S201 Installation and Use Guide 14

Page 25

ATCA‐S201Installation

2.4 Before you install or Remove the ATCA carrier blade

Boards may be damaged if improperly installed or handled. Please read and follow

the guidelines in this section to protect your equipment.

2.4.1 Observe ESD Precautions

Emerson strongly recommends that you use an antistatic wrist strap and a

conductive foam pad when installing or upgrading a system. Electronic

components, such as disk drives, computer boards, and memory modules, can be

extremely sensitive to electrostatic discharge (ESD). After removing the component

from its protective wrapper or from the system, place the component flat on a

grounded, static-free surface (and, in the case of a board, component side up). Do

not slide the component over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by

wearing an antistatic wrist strap (available at electronics stores) that is attached to

an active electrical ground. Note that a system chassis may not be grounded if it is

unplugged.

2.4.2 Watch for Bent Pins or Other Damage

Bent pins or loose components can cause damage to the board, the backplane, or

other system components. Carefully inspect your board and the backplane for both

pin and component integrity before installation. Our suppliers take significant steps

to ensure there are no bent pins on the backplane or connector damage to the

boards prior to leaving our factory. Bent pins caused by improper installation or by

boards with damaged connectors could void the warranty for the backplane or

boards.

If a system contains one or more crushed pins, power off the system and contact

your local sales representative to schedule delivery of a replacement chassis

assembly.

2.5 Use Caution When installing or removing the ATCA carrier

When installing boards in an empty chassis, we recommend that you start

at the left of the card cage and work to the right. This helps to avoid mistakes in

matching slots with the intended carrier boards.

When inserting or removing a board in a slot adjacent to other boards, use extra

caution to avoid damage to the pins and components located on the primary or

secondary sides of the boards.

2.5.1 Preserve EMI Compliance

To preserve compliance with applicable standards and regulations for

electromagnetic interference (EMI), during operation all front and rear openings on

6806800H62B ATCA‐S201InstallationandUseGuide15

Page 26

ATCA‐S201Installation

the chassis or board faceplates must be filled with an appropriate card or covered

with a filler panel. If the EMI barrier is open, devices may cause or be susceptible to

excessive interference.

2.5.2 Understand Hot Swap

The ATCA module is electrically designed for hot swap within a fully powered

chassis. To facilitate hot swap, there is a blue LED on the front faceplate. This LED is

under software control of the IPMC managers.

The manager will illuminate the blue hot swap LED on the front faceplate when

software has stopped and it is safe to remove the advanced rear transition module.

If the blue-LED is not illuminated or blinking, it is not ready for removal. Powering

down or removing a board before the operating system or other software running

on the board has been properly shut down may cause corruption of data or file

systems.

2.6 Connector Mechanical keying

The ATCA supports mechanical connector keying to help prevent installation with

incompatible components and RTM. The ATCA carrier board utilizes an A1/K1 key

that is set at for universal)

2.7 Verify Slot Usage

Prevent possible damage to module components by verifying the proper slot usage

for your configuration.

In most cases, electronic keying (E-keying) will prevent power on of a board into an

incompatible slot. However, as an extra precaution, you should be familiar with the

slot purpose.

2.8 Installing the ATCA carrier blade

This section describes a recommended procedure for installing the ATCA carrier

module in a chassis.

Before you install your module, please read all cautions, warnings, and instructions

presented in this section.

Handling modules and peripherals can result in static damage. Use a grounded wrist

strap, static-dissipating work surface, and antistatic containers when handling and

storing components.

Insert the board by holding the Module Handles–do not exert unnecessary pressure

on the faceplate.

Hot swap compliant modules may be installed while the system is powered on. If a

module is not hot swap compliant, you should remove power to the slot or system

before installing the module.

1. Verify that you have taken the necessary antistatic precautions.

6806800H62B ATCA‐S201InstallationandUseGuide16

Page 27

ATCA‐S201Installation

2. Go to the front of the system and choose an appropriate slot for the ATCA

carrier blade.

If also installing a companion advanced rear transition module (RTM), install it

before installing the ATCA node board. For example, if the ATCA node board is

planned for slot B4, first install the ARTM at the back of the system in slot B4.

3. Remove the slot filler panel from the selected node board slot, if necessary.

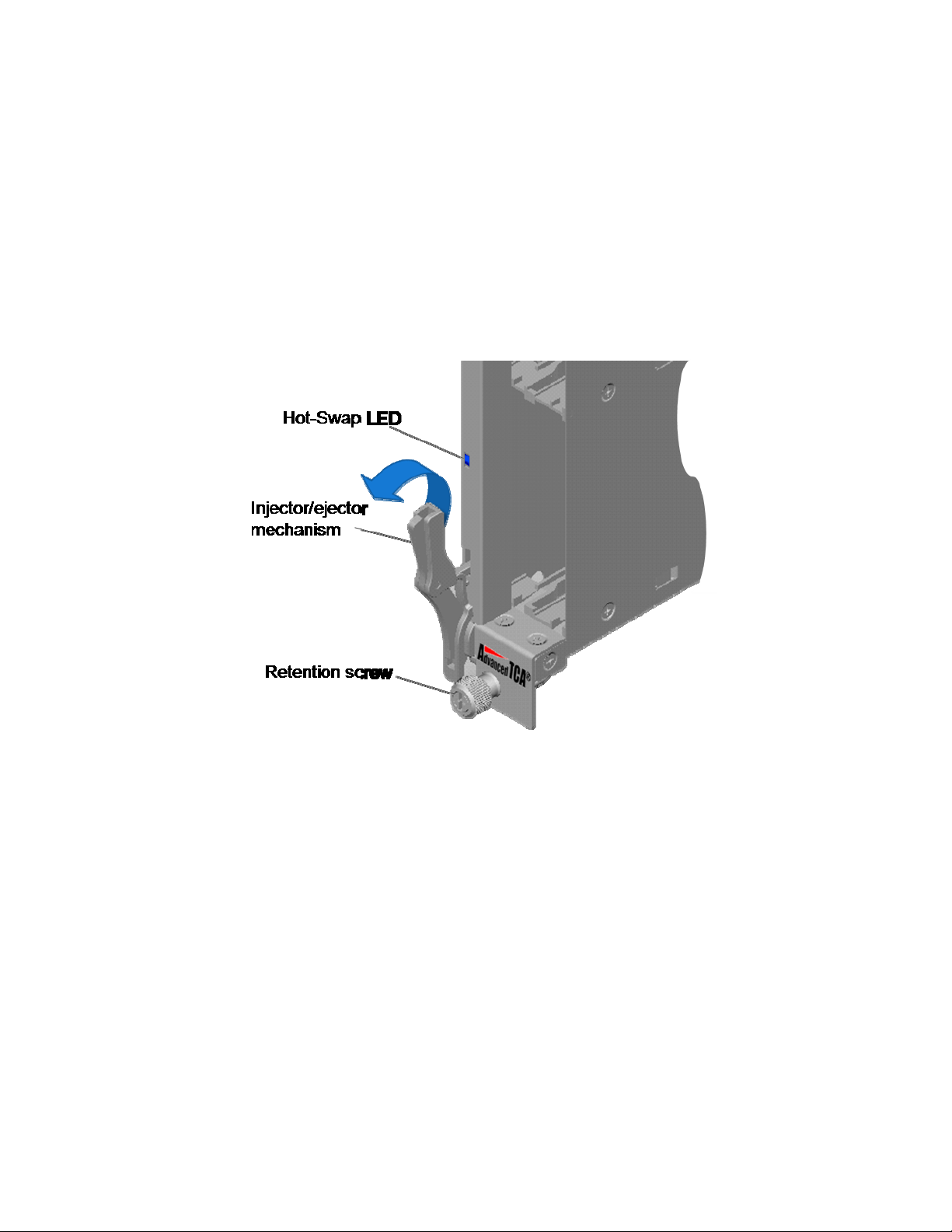

4. Prepare the module by loosening the locking screws and opening the

injector/ejector latch at the top and bottom of the module as shown in the

figure below.

Figure 4 Injector / Ejector latch and locking screw

5. Carefully align the edges of the module with the guides in the appropriate slot.

It might be helpful to look into the enclosure to verify correct alignment of the

rails in the guides. Align the edges of the module with the card cage rail guides

in the appropriate slot.

6. Taking care to keep the module aligned in the guides, apply equal and steady

pressure and slide the module in until the injector/ejector mechanism engages

the retention bars.

7. Position your thumbs at the top and bottom of the ATCA carrier board;

simultaneously push in the module and rotate the injector/ejector mechanisms

inward to their closed position to seat and secure ATCA carrier blade. DO NOT

FORCE THE BOARD INTO THE SLOT.

8. Tighten the two module retention screws to secure the module into the shelf.

6806800H62B ATCA‐S201InstallationandUseGuide17

Page 28

ATCA‐S201Installation

9. Power on the system, if necessary. Refer to your system manual for instructions

on correctly powering on the system. Once power is applied to the chassis, the

internal MMC controller runs a self-test that runs for approximately 10 seconds.

Upon a successful power up self-test, the blue hot swap LED will blink and then

turn off, indicating that the module has been placed in operation.