Page 1

ATCA-7350 Control via IPMI

Programmer’s Reference

6806800H29E

August 2011

Page 2

©

2011 Emerson

All rights reserved.

Trademarks

Emerson is a trademark registered in the U.S. Patent and Trademark Office. All other product or service names are the property of

their respective owners.

®

Intel

is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

™

and all other Java-based marks are trademarks or registered trademarks of Sun Microsystems, Inc. in the U.S. and other

Java

countries.

Microsoft

Microsoft Corporation.

PICMG

PCI Industrial Computer Manufacturers Group.

UNIX

®

, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

®

, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the

®

is a registered trademark of The Open Group in the United States and other countries.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Emerson assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Emerson reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Emerson to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

an Emerson website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Emerson,

It is possible that this publication may contain reference to or information about Emerson products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Emerson intends to announce such Emerson products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply unless

otherwise agreed to in writing by Emerson.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in Technical

Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and Documentation clause

at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Emerson Network Power - Embedded Computing GmbH

Lilienthalstr. 15

85579 Neubiberg-Munich/Germany

Page 3

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Feature Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2.1 HPM.1 Specific Firmware Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2.1.1 IPMC Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.1.2 BIOS Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.1.3 FPGA Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.2 Serial over LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.3 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.4 MAC Address Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.5 Asynchronous Event Notification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.6 Graceful Shutdown Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.7 Local System Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.8 External Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.9 Boot Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Supported Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Standard IPMI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.1 Global IPMI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.2 System Interface Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.3 Watchdog Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.4 SEL Device Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.5 FRU Inventory Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.6 Sensor Device Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.7 Chassis Device Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.7.1 System Boot Options Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.8 LAN Device Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2 PICMG 3.0 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3 Emerson Specific Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.1 Serial Output Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.1.1 Set Serial Output Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3.1.2 Get Serial Output Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 FRU Information and Sensor Data Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 FRU Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 MAC Address Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

3

Page 4

Contents

3.3 Sensor Data Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4 SOL Module Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.2 Configure the SOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.3 Enable SOL Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.4 Setup SOL Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.5 Query the Configuration of SOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6 Configure the SOL Module in OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1 Emerson Network Power - Embedded Computing Documents . . . . . . . . . . . . . . . . . . . . . . . 59

A.2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 5

List of Tables

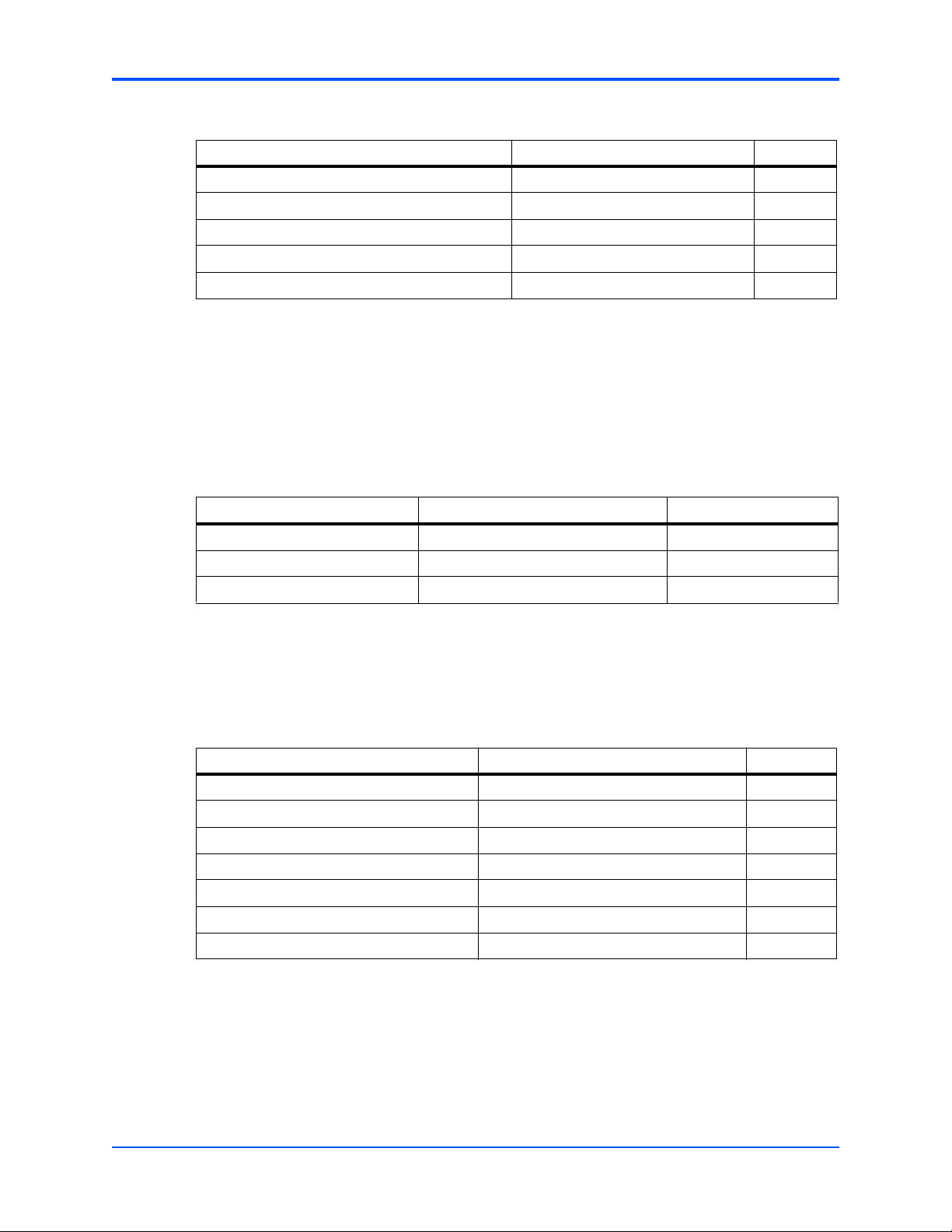

Table 1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 1-2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2-1 Supported Global IPMI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2-2 Supported System Interface Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2-3 Supported Watchdog Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 2-4 Supported SEL Device Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 2-5 Supported FRU Inventory Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 2-6 Supported Sensor Device Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 2-7 Supported Chassis Device Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 2-8 Configurable System Boot Option Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 2-9 System Boot Options Parameter #5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 2-10 System Boot Options Parameter #96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 2-11 System Boot Options Parameter #98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 2-12 System Boot Options Parameter #99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 2-13 Supported LAN Device Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 2-14 Supported PICMG 3.0 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 2-15 Serial Output Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 2-16 Request Data of Set Serial Output Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 2-17 Response Data of Set Serial Output Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 2-18 Request Data of Get Serial Output Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 2-19 Response Data of Get Serial Output Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 3-1 FRU Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 3-2 Emerson MAC Address Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 3-3 Emerson MAC Address Descriptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 3-4 Interface Type Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 3-5 IPMI Sensors Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 3-6 +12VCC Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 3-7 +3.3VCC Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 3-8 +3.3VSB Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 3-9 +5VCC Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 3-10 +5VSB Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 3-11 -48V Power1 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 3-12 -48V Power2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 3-13 ACPI State Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 3-14 BIOS Bank Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 3-15 BMC POST ERROR Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 3-16 Boot Errors Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 3-17 CPU0 Core Rem Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 3-18 CPU0 Status Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 3-19 CPU1 Core Rem Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

5

Page 6

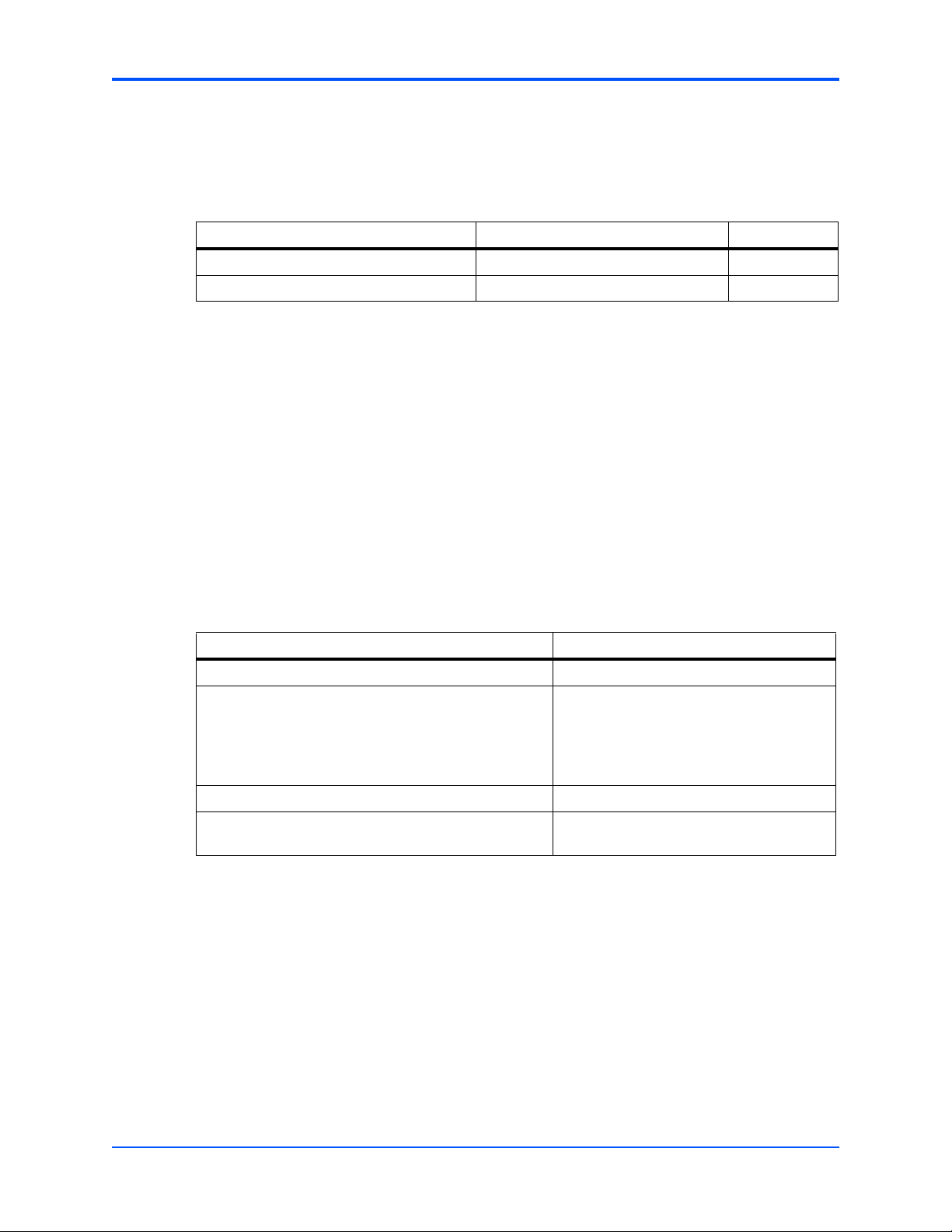

List of Tables

Table 3-20 CPU1 Status Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 3-21 CPU Inlet Temp Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 3-22 FBD Inlet Temp Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 3-23 FRU Hot Swap Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 3-24 FW Progress Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 3-25 Handle State Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 3-26 HD Env Temp Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 3-27 IPMB Link State Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 3-28 Log Disabled Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 3-29 PwrOk Sig. Drop Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 3-30 RTM Handle Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 3-31 RTM HS Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 3-32 SYSTEM RESTART Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 3-33 Ver Change Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 3-34 Watchdog Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table A-1 Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table A-2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 7

About this Manual

Overview of Contents

This manual is intended for users qualified in electronics or electrical engineering. Users must

have a working understanding of Intelligent Platform Management Interface (IPMI).

It provides information on how to control and monitor the functionality of the ATCA-7350 via

IPMI and contains the following chapters and appendices:

z Chapter 1, Introduction, on page 11 describes the main features of the IPMC firmware.

z Chapter 2, Supported Commands, on page 15 lists all the IPMI1.5 and IPMI2.0 standard

commands supported by the ATCA-7350.

z Chapter 3, FRU Information and Sensor Data Records, on page 27 provides the FRU

information and all the sensor data records.

z Chapter 4, SOL Module Configuration, on page 53 describes how to configure the Serial

over LAN.

z Appendix A, Related Documentation, on page 59 provides links to further ATCA-7350-

related documentation.

Abbreviations

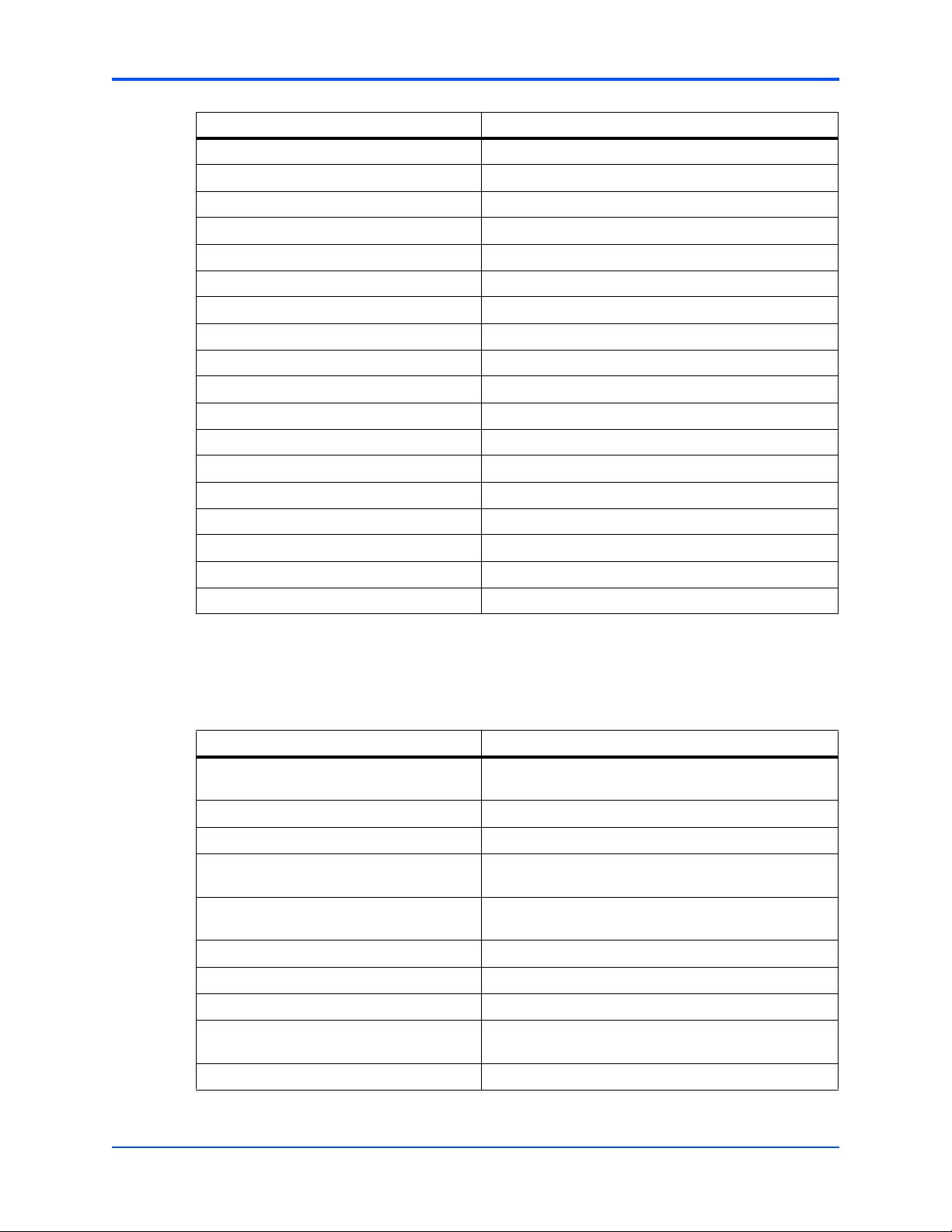

This document uses the following abbreviations:

Abbreviation Definition

ACPI Advanced Configuration and Power Interface

ATCA Advanced Telecom Computing Architecture

BIOS Basic Input/Output System

CMD IPMI Command Specified in Hexadecimal

CPU Central Processing Unit

FBD Fully Buffered DIMM

FPGA Field-Programmable Gate Array

FRU Field Replaceable Unit

FW Firmware

GA General Availability

GUID Global Unique Identifier

HD Hard Disk

IANA Internet Assigned Numbers Authority

IPMB Intelligent Platform Management Bus

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

7

Page 8

About this Manual

Abbreviation Definition

IPMC Intelligent Platform Management Controller

IPMI Intelligent Platform Management Interface

LAN Local Area Network

LED Light Emitting Diode

LSB Least Significant Bit

LUN Logical Units

MAC Media Access Control

MSB Most Significant Bit

NetFn IPMI Network Function in Hexadecimal

OEM Original Equipment Manufacturer

PICMG PCI Industrial Computer Manufacturers Group

PwrOk Power OK

RTM Rear-Transition Modules

SDR Sensor Data Records

SEL System Event Log

SOL Serial Over LAN

VCC Virtual Channel Connection

VER Version

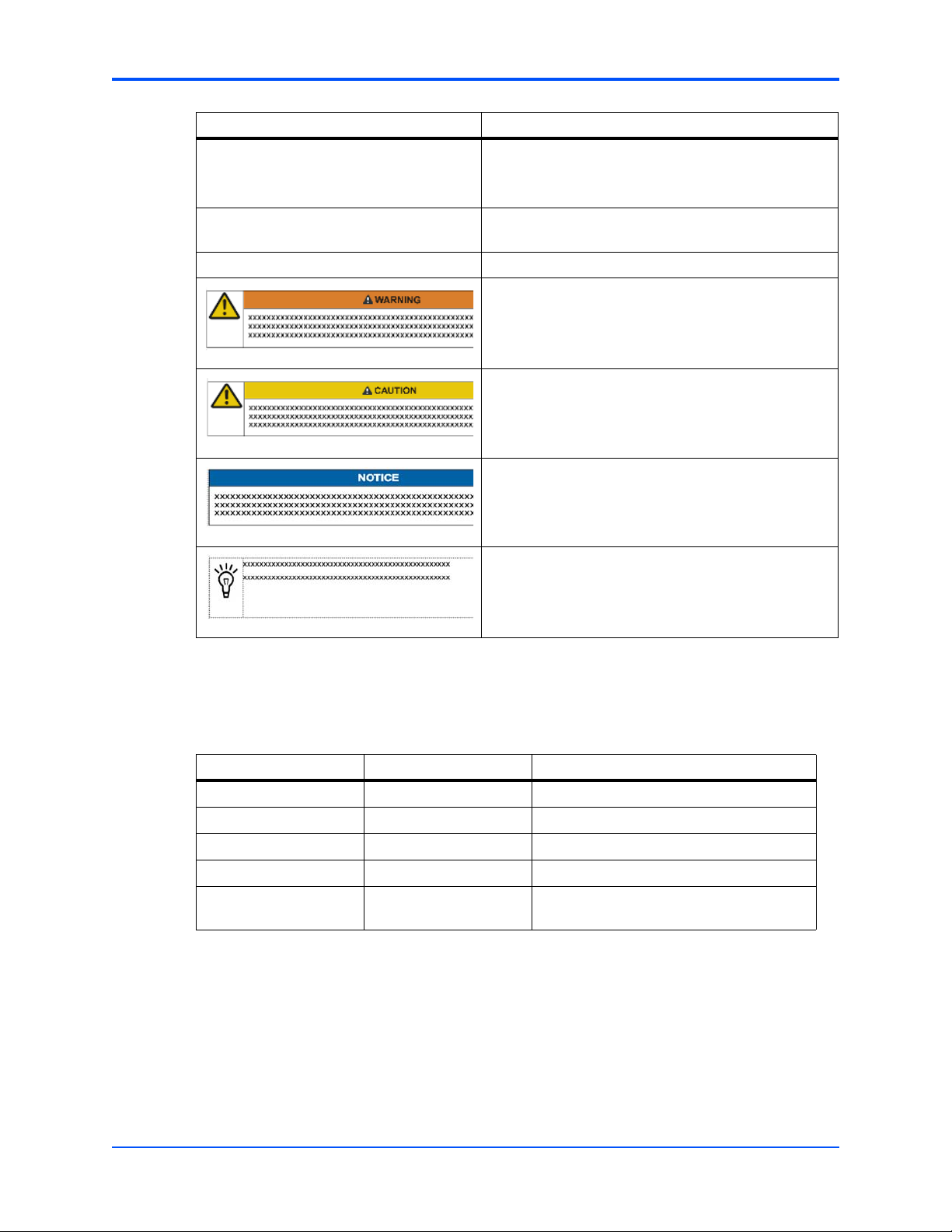

Conventions

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are 0

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related elements or

Courier + Bold Used to characterize user input and to separate it from

Reference Used for references and for table and figure descriptions

File > Exit Notation for selecting a submenu

through F), for example used for addresses and offsets

commands in body text

system output

<text> Notation for variables and keys

[text] Notation for software buttons to click on the screen and

parameter description

... Repeated item for example node 1, node 2, ..., node 12

8

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 9

About this Manual

Notation Description

.

.

.

.. Ranges, for example: 0..4 means one of the integers

| Logical OR

Omission of information from example/command that is

not necessary at the time being

0,1,2,3, and 4 (used in registers)

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury

Indicates a property damage message

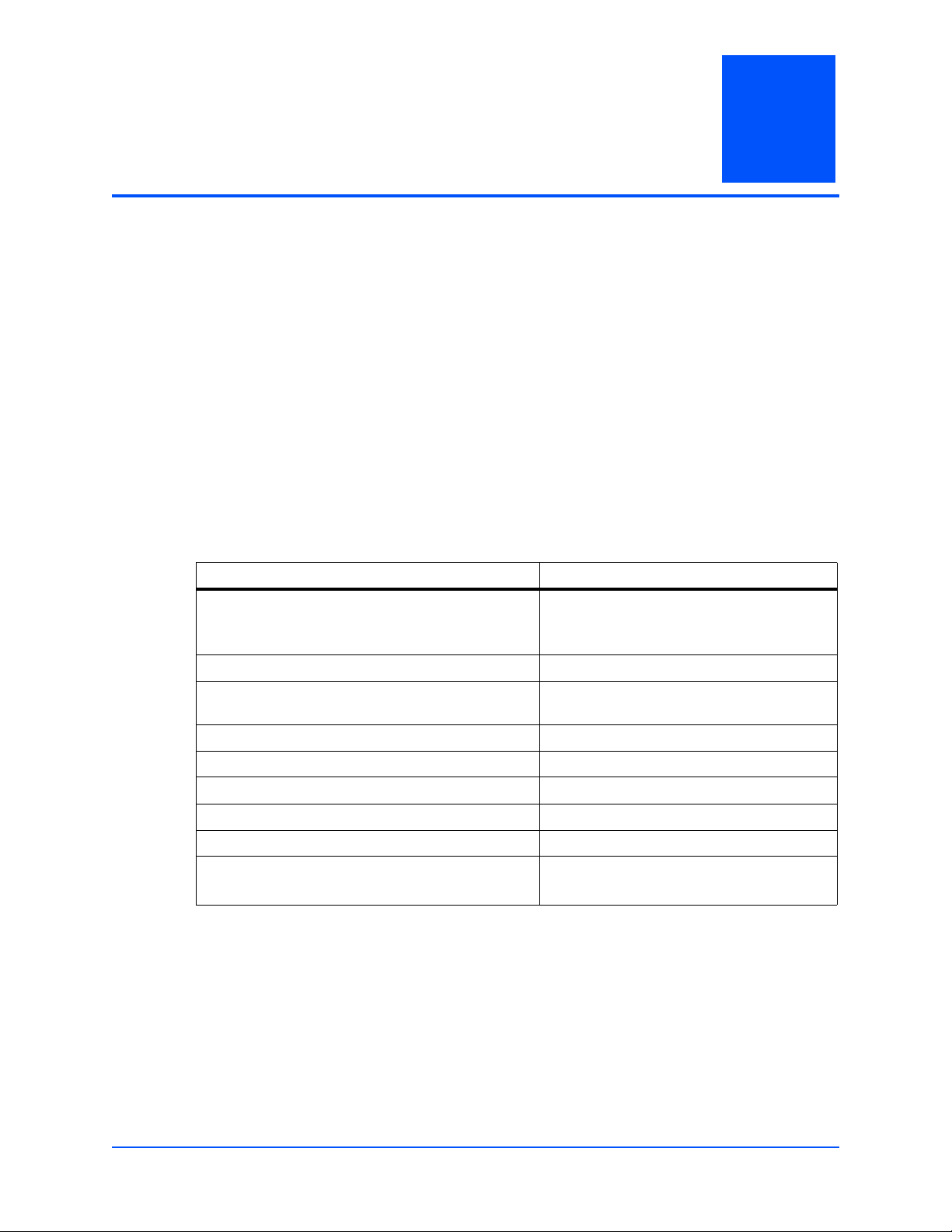

Summary of Changes

This manual has been revised and replaces all prior editions.

Part Number Publication Date Description

6806800H29A December 2008 First edition

6806800H29B January 2009 Second edition

6806800H29C January 2009 Third edition

6806800H29D February 2009 Fourth edition

6806800H29E August 2011 Added Table 3-30 on page 47 and Ta b le

Comments and Suggestions

No danger encountered. Pay attention to important

information

3-31 on page 48.

We welcome and appreciate your comments on our documentation. We want to know what you

think about our manuals and how we can make them better.

Mail comments to us by filling out the following online form:

http://www.emersonnetworkpowerembeddedcomputing.com/ > Contact Us > Online Form

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

9

Page 10

About this Manual

In "Area of Interest" select "Technical Documentation". Be sure to include the title, part number,

and revision of the manual and tell us how you used it.

10

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 11

Introduction

1.1 Overview

The ATCA-7350 provides an intelligent hardware management system as defined in the

AdvancedTCA Base Specification (PICMG 3.0; AMC.0). This system implements an Intelligent

Peripheral Management Controller (IPMC) based on the proprietary H8S reference design from

American Megatrends Inc.

The ATCA-7350 IPMC supports all standard Intelligent Peripheral Management Interface (IPMI)

commands and provides hardware interfaces for other system managements features such as

hot-swap control, LED control, power control and temperature and voltage monitoring. The

IPMC also supports a Keyboard Controller Style (KCS) based host interface for payload-to-IPMI

communication.

1

In addition, the following features are included:

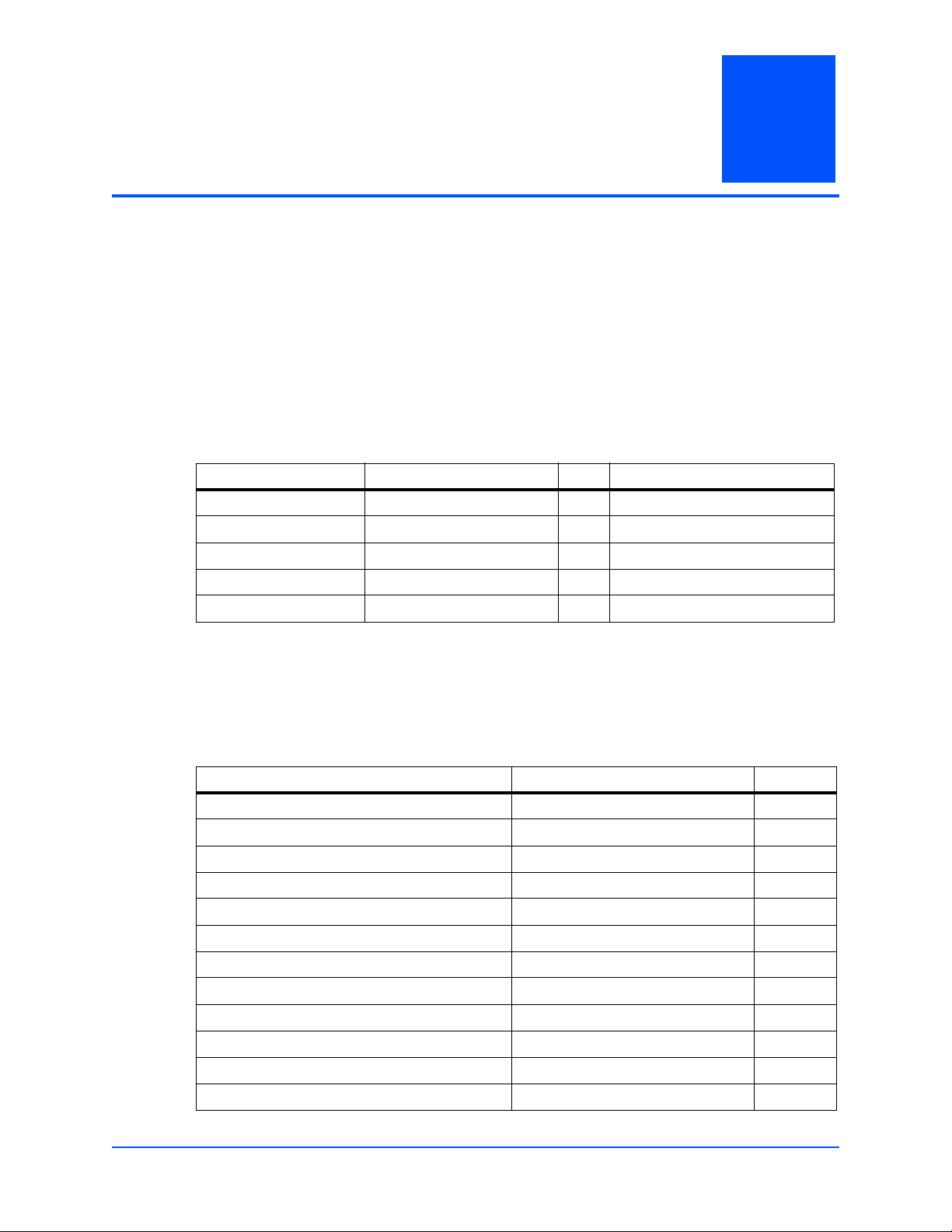

Table 1-1 Features

Feature Further Details...

Supported for fault tolerant field upgrade

Support for field updates of firmware via the payload

processor interface

Serial over LAN (SOL) Serial over LAN on page 13

Sensor management including, among others, power

good and boot bank supervision sensor

FRU inventory with MAC address record MAC Address Record on page 13

Asynchronous event notification Asynchronous Event Notification on page 13

Graceful shutdown timeout Graceful Shutdown Timeout on page 13

Local system event log (SEL) Local System Event Log on page 14

External watchdog External Watchdog on page 14

BIOS boot configuration via IPMI Boot Configuration Parameters on page 14

IPMC Firmware Upgrade on page 12

Sensors on page 13

Chassis Device Commands on page 18

1.2 Feature Description

Besides its basic functions, the ATCA-7350 provides the features described in this section.

1.2.1 HPM.1 Specific Firmware Upgrades

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

11

Page 12

Introduction HPM.1 Specific Firmware Upgrades

1.2.1.1 IPMC Firmware Upgrade

The IPMC firmware basically consists of five major parts:

z Boot loader

z Active and Backup IPMI firmware

z Active and Backup SDR data

The boot loader maintains redundant copies of the firmware in the flash memory of the ATCA-

7350. Each time the IPMC firmware is upgraded, the most recent firmware version is kept in

flash memory and the older firmware version is overwritten by the new one. Once the new IPMI

firmware is programmed, the IPMC resets itself to boot from the new image. The boot loader

validates the new IPMC firmware. Provided the IPMC can power up successfully the current

image is made active and the previously active image is made backup. In case of power-up

failures, the boot loader automatically recovers from crisis and boots from the previous image.

The IPMC can be upgraded via KCS and IPMB interface. To ensure that the payload is not

interrupted during IPMC firmware upgrade, the IPMC is storing all operational information (Ekeying, SOL parameters, hot-swap state, last events to be queued, graceful shutdown timeout,

latest pin settings…) in non-volatile storage.

The IPMC firmware is fully HPM.1 compliant. Thus in general also open source tools like

ipmitool can be used for IPMC firmware upgrade. However, we recommend to use the firmware

upgrade tools provided by Emerson (fcu, fuf, or ipmi_upd.sh). To obtain these tools contact your

local sales representative.

The SDR data is hold as a separate component which can be upgraded separately. The IPMC

holds an active and a backup component.

1.2.1.2 BIOS Upgrade

BIOS can either be upgraded via flash based tools provided from Emerson, or via IPMI with the

use of HPM.1 specific protocols. The BIOS firmware is fully implemented as HPM.1 specific

components with an active and an backup image. BIOS upgrade via IPMI is intended to be used

for crisis recovery only. This is because it is much more time consuming than using flash based

routines. Be aware that even when no BIOS boot bank is programmed at all (no boot loader)

crisis recovery via IPMI is always possible.

1.2.1.3 FPGA Upgrade

The FPGA can be upgraded via IPMI also. The IPMC controls an active component and a

backup component for crisis recovery.

12

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 13

Serial over LAN Introduction

1.2.2 Serial over LAN

Serial over LAN (SOL) is an IPMI v.2.0 defined capability that allows to establish a virtual serial

console connection with the payload over LAN. The serial data of the payload is transferred to

the IPMC. The IPMC generates RMCP+ packets, which are routed to the ethernet controller of

the base interfaces. Be aware that SOL/LAN configuration is only possible if the Ethernet

controller and its payload is fully powered, otherwise the completion code 0xD5 is returned. For

more information on how to use and configure SOL see Chapter 4, SOL Module Configuration,

on page 53.

1.2.3 Sensors

Apart from several voltage and temperature specific sensors (for details refer to Sensor Data

Records on page 29), the IPMC provides the following additional sensors:

Table 1-2 Sensors

Sensor Description

Firmware Progress, and Boot

Error Sensor

The IPMC firmware provides Firmware Progress (Table 3-24 on page

43), and Boot Error (Table 3-16 on page 37) sensors to enable

payload firmware and payload OS to report boot progress and OS

Boot via IPMI event messages.

1.2.4 MAC Address Record

The ATCA-7350 implements an MAC address FRU OEM record. You can retrieve all MAC

addresses of the blade from the FRU information. For more details refer to MAC Address

Record on page 27.

1.2.5 Asynchronous Event Notification

To enable payload applications to be informed about graceful shutdown/reboot requests, the

FRU Activate (Deactivate) and FRU Control (Graceful Reboot) command message is routed as

a LUN2 message to the payload interface.

If the payload application has registered to these commands via the OpenIPMI library, it gets

informed and can take all necessary actions before the payload is gracefully rebooted or shutdown.

1.2.6 Graceful Shutdown Timeout

The IPMI command Set System Boot Options together with the parameter #98 can be used to

persistently specify the timeout for Graceful Shutdown. For more information refer to Chassis

Device Commands on page 18.

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

13

Page 14

Introduction Local System Event Log

1.2.7 Local System Event Log

The IPMC provides a local system event log (SEL). Thus, event information is stored on-board

the ATCA-7350 as well.

1.2.8 External Watchdog

For crisis recovery purposes the IPMI building block provides an external hardware watchdog.

The IPMI firmware is reset if it does not trigger the watchdog anymore.

1.2.9 Boot Configuration Parameters

The IPMC supports BIOS boot order selection via IPMI partially. Be aware, that in case of the

BIOS boot order is selected via IPMI the boot order displayed in the BIOS menu doesn't reflect

the boot order selected via IPMI. For more information how to set the boot order via IPMI refer

to System Boot Option Commands, parameter #5.

14

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 15

Supported Commands

2.1 Standard IPMI Commands

The IPMC is fully compliant to the Intelligent Platform Management Interface v.1.5. This section

provides information about the supported IPMI commands.

2.1.1 Global IPMI Commands

The IPMC supports the following global IPMI commands.

Table 2-1 Supported Global IPMI Commands

Command NetFn (Request/Response) CMD Comments

Get Device ID 0x06/0x07 0x01 -

2

Cold Reset 0x06/0x07 0x02 -

Warm Reset 0x06/0x07 0x03 -

Get Self Test Results 0x06/0x07 0x04 -

Get Device GUID 0x06/0x07 0x08 -

2.1.2 System Interface Commands

The system interface commands are supported by blades providing a system interface.

Table 2-2 Supported System Interface Commands

Command NetFn (Request/Response) CMD

Set BMC Global Enables 0x06/0x07 0x2E

Get BMC Global Enables 0x06/0x07 0x2F

Clear Message Flags 0x06/0x07 0x30

Get Message Flags 0x06/0x07 0x31

Get Message 0x06/0x07 0x33

Send Message 0x06/0x07 0x34

Set Channel Access 0x06/0x07 0x40

Get Channel Access 0x06/0x07 0x41

Get Channel Info 0x06/0x07 0x42

Set User Access 0x06/0x07 0x43

Get User Access 0x06/0x07 0x44

Set User Name 0x06/0x07 0x45

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

15

Page 16

Supported Commands Watchdog Commands

Table 2-2 Supported System Interface Commands (continued)

Command NetFn (Request/Response) CMD

Get User Name 0x06/0x07 0x46

Set User Password 0x06/0x07 0x47

Set User Payload Access 0x06/0x07 0x4C

Get User Payload Access 0x06/0x07 0x4D

Set Channel Security Keys 0x06/0x07 0x5C

2.1.3 Watchdog Commands

The watchdog commands are supported by blades providing a system interface and a

watchdog type 2 sensor.

The pre-timeout option is not supported.

Table 2-3 Supported Watchdog Commands

Command NetFn (Request/Response) CMD

Reset Watchdog Timer 0x06/0x07 0x22

Set Watchdog Timer 0x06/0x07 0x24

Get Watchdog Timer 0x06/0x07 0x25

2.1.4 SEL Device Commands

Table 2-4 Supported SEL Device Commands

Command NetFn (Request/Response) CMD

Get SEL Info 0x0A/0x0B 0x40

Reserve SEL 0x0A/0x0B 0x42

Get SEL Entry 0x0A/0x0B 0x43

Add SEL Entry 0x0A/0x0B 0x44

Clear SEL 0x0A/0x0B 0x47

Get SEL Time 0x0A/0x0B 0x48

Set SEL Time 0x0A/0x0B 0x49

16

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 17

FRU Inventory Commands Supported Commands

2.1.5 FRU Inventory Commands

Table 2-5 Supported FRU Inventory Commands

Command NetFn (Request/Response) CMD

Get FRU Inventory Area Info 0x0A/0x0B 0x10

Read FRU Data 0x0A/0x0B 0x11

Write FRU Data 0x0A/0x0B 0x12

2.1.6 Sensor Device Commands

Table 2-6 Supported Sensor Device Commands

NetFn

Command

(Request/Response) CMD Comments

Get Device SDR Info 0x04/0x05 0x20 -

Get Device SDR 0x04/0x05 0x21 -

Reserve Device SDR Repository 0x04/0x05 0x22 -

Get Sensor Reading Factors 0x04/0x05 0x23 -

Set Sensor Hysteresis 0x04/0x05 0x24 -

Get Sensor Hysteresis 0x04/0x05 0x25 -

Set Sensor Threshold 0x04/0x05 0x26 -

Get Sensor Threshold 0x04/0x05 0x27 -

Set Sensor Event Enable 0x04/0x05 0x28 -

Get Sensor Event Enable 0x04/0x05 0x29 -

Get Sensor Event Status 0x04/0x05 0x2B -

Get Sensor Reading 0x04/0x05 0x2D -

Get Sensor Type 0x04/0x05 0x2F -

Set Event Receiver 0x04/0x05 0x00 -

Get Event Receiver 0x04/0x05 0x01 -

Platform Event 0x04/0x05 0x02 -

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

17

Page 18

Supported Commands Chassis Device Commands

2.1.7 Chassis Device Commands

Table 2-7 Supported Chassis Device Commands

Command NetFn (Request/Response) CMD

Set System Boot Options 0x00/0x01 0x08

Get System Boot Options 0x00/0x01 0x09

2.1.7.1 System Boot Options Commands

The IPMI system boot options commands allow you to control the boot process of a blade by

sending boot parameters to the blade’s boot firmware (for example BIOS, U-Boot or VxWorks).

The boot firmware interprets the sent boot parameters and executes the boot process

accordingly. Each boot parameter addresses a particular functionality and consists of a

sequence of one or more bytes. The IPMI specification assigns numbers to boot parameters.

Boot parameters 0 to 7 are standard parameters whose structure and functionality is defined

by the IPMI specification. The boot parameters 96 to 127 are OEM-specific which can be used

for different purposes.

The following table lists which boot properties can be configured and the corresponding boot

parameter number.

Table 2-8 Configurable System Boot Option Parameters

Configurable Boot Property Corresponding Boot Parameter Number

Boot flags 5

Selection between default and backup boot flash as

device to boot from

Selection between default and backup EEPROM as

device where the on-board FPGA loads its configuration

stream from

Timeout for graceful shutdown 98

Write Protection for BIOS boot banks and FRU

information

96

99

18

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 19

Chassis Device Commands Supported Commands

2.1.7.1.1 System Boot Options Parameter #5

This boot parameter is implemented as specified within the IPMI specification, but not all flags

are supported.

Table 2-9 System Boot Options Parameter #5

Data Byte Description

1 [7] - 1b = boot flags valid. The bit should be set to indicate that valid flag data is

present. This bit may be automatically cleared based on the boot flag valid bit

clearing parameter, above.

[6] - Not supported.

[5] - Not supported

[4:0] - reserved

2 [7] - 1b = CMOS clear

[6] - Not supported

[5:2] - Boot device selector

0000b = No override

0001b = Force PXE

0010b = Force boot from default Hard-drive

0011b = Not supported

0100b = Not supported

0101b = Force boot from default CD/DVD

0110b = Not supported

0111b-1110b = Reserved

1111b = Force boot from Floppy/primary removable media

[1] - 1b = Not supported

[0] - 1b = Not supported

3 Not supported

4 Not supported

5 Reserved

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

19

Page 20

Supported Commands Chassis Device Commands

2.1.7.1.2 System Boot Options Parameter #96

This boot parameter is an Emerson-specific OEM boot parameter. Its definition is given in the

following table.

Table 2-10 System Boot Options Parameter #96

Boot Option

Parameter Data Description

1 This parameter specifies the processor ID for which the boot option is to be set.

This parameter has to be 0 always for this blade.

2 This parameter is used to select the BIOS boot bank of which the payload shall

boot from:

[7:1] Reserved

[0] Default/backup boot flash selection

There is no Set Selector or Block Selector with this command.

The System Boot Options parameter #96 is non-volatile. Its parameter data remains

preserved after IPMC power cycles and firmware upgrades.

2.1.7.1.3 System Boot Options Parameter #98

This boot parameter is an Emerson-specific OEM parameter.

This timer specifies how long the IPMC waits for the payload to shut down gracefully. If the

payload software does not configure its OpenIPMI library to be notified for graceful shutdown

requests, the IPMC shuts down the payload when the timer expires.

Table 2-11 System Boot Options Parameter #98

Boot Option Parameter

Data Description

1 This parameter specifies the Graceful Shutdown Timeout LSB (given in

100 msec)

2 This parameter specifies the Graceful Shutdown Timeout MSB (given in

100 msec)

20

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 21

LAN Device Commands Supported Commands

There is no Set Selector or Block Selector with this command.

The System Boot Options parameter #98 is non-volatile. Its parameter data remains

preserved after IPMC power cycles and firmware upgrades.

2.1.7.1.4 System Boot Options #99

This parameter is an Emerson-specific OEM parameter. It is used to enable or disable BIOS

and FRU write protection

Table 2-12 System Boot Options Parameter #99

Boot Option Parameter

Data Description

1 This parameter enables/disables BIOS and FRU write protection:

[7:4] Bios ID (0= Boot Bank A, 1= Boot Bank B, 2= FRU information,

others reserved)

[3:0] write protect enable/disable (0= disable, 1= enable, others reserved)

There is no Set Selector or Block Selector with this command. The Boot Option parameter data

returned with the IPMI command Get System Boot Options provides the write protect status of

the two BIOS flashes and of the FRU information (one byte for each instance).

2.1.8 LAN Device Commands

Table 2-13 Supported LAN Device Commands

Command NetFn (Request/Response) CMD

Set LAN Configuration Parameters 0x0C/0x0D 0x01

Get LAN Configuration Parameters 0x0C/0x0D 0x02

Set SOL Configuration Parameters 0x0C/0x0D 0x21

Get SOL Configuration Parameters 0x0C/0x0D 0x22

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

21

Page 22

Supported Commands PICMG 3.0 Commands

2.2 PICMG 3.0 Commands

The Emerson IPMC is a fully compliant AdvancedTCA intelligent Platform Management

Controller i.e. it supports all required and mandatory AdvancedTCA commands as defined in

the PICMG 3.0 specifications.

Table 2-14 Supported PICMG 3.0 Commands

NetFn

Command

Get PICMG Properties 0x2C/0x2D 0x00 -

Get Address Info 0x2C/0x2D 0x01 -

FRU Control 0x2C/0x2D 0x04 -

Get FRU LED Properties 0x2C/0x2D 0x05 -

Get FRU LED Color Capabilities 0x2C/0x2D 0x06 -

Set FRU LED State 0x2C/0x2D 0x07 -

Get FRU LED State 0x2C/0x2D 0x08 -

Set IPMB State 0x2C/0x2D 0x09 -

Set FRU Activation Policy 0x2C/0x2D 0x0A -

(Request/Response) CMD Comments

Get FRU Activation Policy 0x2C/0x2D 0x0B -

Set FRU Activation 0x2C/0x2D 0x0C -

Get Device Locator Record ID 0x2C/0x2D 0x0D -

Set Port State 0x2C/0x2D 0x0E -

Get Port State 0x2C/0x2D 0x0F -

Compute Power Properties 0x2C/0x2D 0x10 -

Set Power Level 0x2C/0x2D 0x11 -

Get Power Level 0x2C/0x2D 0x12 -

Get IPMB Link Info 0x2C/0x2D 0x18 -

Set AMC Port State 0x2C/0x2D 0x19 -

Get AMC Port State 0x2C/0x2D 0x1A -

Get FRU Control Capabilities 0x2C/0x2D 0x1E -

Get target upgrade capabilities 0x2C/0x2D 0x2E -

Get component properties 0x2C/0x2D 0x2F -

Abort firmware upgrade 0x2C/0x2D 0x30 -

Initiate upgrade action 0x2C/0x2D 0x31 -

Upload firmware block 0x2C/0x2D 0x32 -

Finish firmware upload 0x2C/0x2D 0x33 -

Get upgrade status 0x2C/0x2D 0x34 -

22

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 23

Emerson Specific Commands Supported Commands

Table 2-14 Supported PICMG 3.0 Commands (continued)

NetFn

Command

Activate firmware 0x2C/0x2D 0x35 -

Query self-test results 0x2C/0x2D 0x36 -

Query rollback status 0x2C/0x2D 0x37 -

Initiate manual rollback 0x2C/0x2D 0x38 -

The firmware upgrade commands supported by the ATCA-7350 are implemented

according to the PICMG HPM.1 Revision 1.0 specification.

(Request/Response) CMD Comments

2.3 Emerson Specific Commands

The Emerson IPMC supports several commands which are not defined in the IPMI or PICMG

3.0 specification but are introduced by Emerson: serial output commands.

z Before sending any of these commands, the shelf management software must

check whether the receiving IPMI controller supports Emerson specific IPMI

commands, by using the IPMI command 'Get Device ID'. Sending Emerson specific

commands to IPMI controllers which do not support these IPMI commands will lead

to no or undefined results.

z Implementing any of the Emerson specific IPMI commands means that the software

is not portable to other IPMI controllers that do not use the IPMC firmware.

2.3.1 Serial Output Commands

Table 2-15 Serial Output Commands

Command Name NetFn (Request/Response) CMD Description

Set Serial Output 0x2E/0x2F 0x15 See Set Serial Output Command on

Get Serial Output 0x2E/0x2F 0x16 See Get Serial Output Command on

page 24

page 24

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

23

Page 24

Supported Commands Serial Output Commands

2.3.1.1 Set Serial Output Command

The Set Serial Output command selects the serial port output source for a serial port connector.

2.3.1.1.1 Request Data

The following table lists the request data applicable to the Set Serial Output command.

Table 2-16 Request Data of Set Serial Output Command

Byte Data Field

1 LSB of Emerson IANA Enterprise number. A value of 0xCD has to be used.

2 Second byte of Emerson IANA Enterprise number. A value of 0x65 has to be used.

3 MSB of Emerson IANA Enterprise number. A value of 0x00 has to be used.

4 Serial connector type

0: Face plate connector

All other values are reserved.

5 Serial connector instance number. A sequential number that starts from 0.

6 Serial output selector

0: payload serial console (default 9600 baud)

2: IPMC(default baud rate 115200 baud)

All other values are reserved.

2.3.1.1.2 Response Data

The following table lists the response data applicable to the Set Serial Output command.

Table 2-17 Response Data of Set Serial Output Command

Byte Data Field

1 Completion code

2 LSB of Emerson IANA Enterprise number.

3 Second byte of Emerson IANA Enterprise number.

4 MSB of Emerson IANA Enterprise number.

2.3.1.2 Get Serial Output Command

The Get Serial Output Command provides a way to determine which serial output source goes

to a particular serial port connector.

24

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 25

Serial Output Commands Supported Commands

2.3.1.2.1 Request Data

The following table lists the request data applicable to the Get Serial Output command.

Table 2-18 Request Data of Get Serial Output Command

Byte Data Field

1 LSB of Emerson IANA Enterprise number. A value of 0xCD has to be used.

2 Second byte of Emerson IANA Enterprise number. A value of 0x65 has to be used.

3 MSB of Emerson IANA Enterprise number. A value of 0x00 has to be used.

4 Serial connector type

0: Face plate connector

All other values are reserved.

5 Serial connector instance number. A sequential number that starts from 0.

2.3.1.2.2 Response Data

The following table lists the response data applicable to the Get Serial Output command.

Table 2-19 Response Data of Get Serial Output Command

Byte Data Field

1 Completion code

2 LSB of Emerson IANA Enterprise number.

3 Second byte of Emerson IANA Enterprise number.

4 MSB of Emerson IANA Enterprise number.

5 Serial output selector

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

25

Page 26

Supported Commands Serial Output Commands

26

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 27

FRU Information and Sensor Data Records

3.1 FRU Information

The ATCA-7350 supports FRU according to the PICMG 3.0 ATCA specification. The ATCA7350 supports six FRUs, including:

z FRU0: on the ATCA-7350

z FRU1: RTM-ATCA-7350

z FRU2-FRU3: for daughter cards on the RTM-ATCA-7350

z FRU6: SOL daughter card on the ATCA-7350

FRU0 and FRU1 are managed FRUs, whereas other FRUs are unmanaged ones.

Tab le 3 - 1 shows the FRU data format of RU0-FRU6.

Table 3-1 FRU Information

Area Description Value Access

Board info area Manufacturing

date/time

Board manufacturer EMERSON r/w

According to Platform Management FRU

information Storage Definition v1.0

3

r/w

Board product name ATCA-7350 r/w

Board serial number Defined by Emerson r/w

Board part number Defined by Emerson r/w

Product info area Product manufacturer EMERSON r/w

Product name Specific blade variant name r/w

Product serial

number

Product Version Defined by Emerson r/w

Product part number Defined by Emerson r/w

Multi record area OEM MAC address

record

Board point-to-point

connectivity record

3.2 MAC Address Record

The blade provides one OEM FRU record which contains information about on-board MAC

Defined by Emerson r/w

Emerson record ID 0x01 r/w

PICMG record ID 0x14 r/w

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

27

Page 28

FRU Information and Sensor Data Records MAC Address Record

addresses. The format of the record is described in the following tables.

Table 3-2 Emerson MAC Address Record

Offset Length Description

0 1 Record Type ID. A value of 0xC0

1 1 End of List/Version

[7] End of List. Set to 01b for the last record

[6:4] Reserved. Write as 0b0000.

[3:0] Record format version. Write as 0x2.

2 1 Record Length

3 1 Record Checksum. Holds the zero checksum of the record

4 1 Header Checksum. Holds the zero checksum of the header.

5 1 LSB of Manufacturer ID. Value is 0xCD

6 1 Second Byte of Manufacturer ID. Value is 0x65

7 1 MSB of Manufacturer ID. Value is 0x00

8 1 Emerson Record ID. Value is 0x01

9 1 Record Format Version. Value is: 0x00

10 1 Number of MAC Address Descriptors (N).

11 N*7 Emerson MAC Address Descriptors

Refer to Table 3-3 on page 28 for definitions of the Emerson MAC Address

Descriptor.

Table 3-3 Emerson MAC Address Descriptor

Offset Length Description

0 1 Interface type

Refer to Table 3-4 on page 28 for interface type assignments.

1 6 MAC Address. First octet comes first.

Table 3-4 Interface Type Assignments

Interface Type Description

0x01 AdvancedTCA base interface or AMC/MicroTCA common options region

0x02 AdvancedTCA fabric interface or AMC/MicroTCA fat pipe region

0x03 Face plate

0x04 AMC/MicroTCA extended fat pipe region

28

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 29

Sensor Data Records FRU Information and Sensor Data Records

3.3 Sensor Data Records

The sensors available on the ATCA-7350 are shown in the table below.

Table 3-5 IPMI Sensors Overview

Sensor

Sensor Name Sensor Type

+12VCC Voltage 0x07 See Table 3-6 on page 30

+3.3VCC Voltage 0x05 See Table 3-7 on page 30

+3.3VSB Voltage 0x09 See Table 3-8 on page 31

+5VCC Voltage 0x08 See Table 3-9 on page 32

+5VSB Voltage 0x06 See Table 3-10 on page 33

-48V Power1 Power Supply 0x0C See Table 3-11 on page 34

-48V Power2 Power Supply 0x0D See Table 3-12 on page 34

ACPI State System ACPI Power State 0x16 See Table 3-13 on page 35

BIOS Bank Emerson-specific Discrete

Digital

Number Detailed SDR Description

0x19 See Table 3-14 on page 36

BMC POST ERROR Management Subsystem

Health

Boot Errors Boot Error 0x10 See Table 3-16 on page 37

CPU0 Core Rem Temperature 0x13 See Table 3-17 on page 38

CPU0 Status Processor 0x0E See Table 3-18 on page 39

CPU1 Core Rem Temperature 0x14 See Table 3-19 on page 39

CPU1 Status Processor 0x0F See Table 3-20 on page 40

CPU Inlet Temp Temperature 0x01 See Table 3-21 on page 41

FBD Inlet Temp Temperature 0x02 See Table 3-22 on page 42

FRU Hot Swap PICMG 3.0: FRU HotSwap 0x0A See Table 3-23 on page 42

FW Progress System Firmware

Progress

Handle State OEM reserved 0x11 See Table 3-25 on page 44

HD Env Temp Temperature 0x03 See Table 3-26 on page 44

IPMB Link State PICMG 3.0: IPMB Physical

Link

Log Disabled Event Logging Disabled 0x15 See Table 3-28 on page 46

PwrOk Sig. Drop Power Supply 0x12 See Table 3-29 on page 47

RTM Handle OEM reserved 0x30 See Table 3-30 on page 47

RTM HS PICMG 3.0: FRU HotSwap 0x31 See Table 3-31 on page 48

0x1A See Table 3-15 on page 36

0x18 See Table 3-24 on page 43

0x0B See Table 3-27 on page 45

SYSTEM RESTART System Boot Initiated 0x1B See Table 3-32 on page 49

Ver Change Version Change 0x1C See Table 3-33 on page 49

Watchdog Watchdog 2 0x17 See Table 3-34 on page 50

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

29

Page 30

FRU Information and Sensor Data Records Sensor Data Records

The following tables describe all on-board IPMI sensors in detail.

Table 3-6 +12VCC Sensor

Feature Raw Value Description

Sensor Name +12VCC -

Sensor LUN 0x00 -

Sensor Number 0x07 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x02 Voltage

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x04 Volts

Nominal Reading 0xBF 12.03

Upper non-recoverable threshold 0xE9 14.68

Upper critical threshold 0xE0 14.11

Upper non-critical threshold 0xD6 13.48

Lower non-recoverable threshold 0x94 9.32

Lower critical threshold 0x9D 9.89

Lower non-critical threshold 0xA7 10.52

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

Table 3-7 +3.3VCC Sensor

30

Feature Raw Value Description

Sensor Name +3.3VCC -

Sensor LUN 0x00 -

Sensor Number 0x05 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x02 Voltage

Event/Reading Type 0x01 Threshold

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 31

Sensor Data Records FRU Information and Sensor Data Records

Table 3-7 +3.3VCC Sensor (continued)

Feature Raw Value Description

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x04 Volts

Nominal Reading 0xBF 3.3

Upper non-recoverable threshold 0xD6 3.7

Upper critical threshold 0xD1 3.62

Upper non-critical threshold 0xCC 3.53

Lower non-recoverable threshold 0xA8 2.91

Lower critical threshold 0xAD 2.99

Lower non-critical threshold 0xB1 3.06

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

Table 3-8 +3.3VSB Sensor

Feature Raw Value Description

Sensor Name +3.3VSB -

Sensor LUN 0x00 -

Sensor Number 0x09 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x02 Voltage

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x04 Volts

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

31

Page 32

FRU Information and Sensor Data Records Sensor Data Records

Table 3-8 +3.3VSB Sensor (continued)

Feature Raw Value Description

Nominal Reading 0xC2 3.3

Upper non-recoverable threshold 0xD9 3.69

Upper critical threshold 0xD5 3.62

Upper non-critical threshold 0xD0 3.54

Lower non-recoverable threshold 0xAB 2.91

Lower critical threshold 0xB0 2.99

Lower non-critical threshold 0xB5 3.08

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

Table 3-9 +5VCC Sensor

Feature Raw Value Description

Sensor Name +5VCC -

Sensor LUN 0x00 -

Sensor Number 0x08 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x02 Voltage

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x04 Volts

Nominal Reading 0xC3 4.99

Upper non-recoverable threshold 0xDB 5.61

Upper critical threshold 0xD6 5.48

32

Upper non-critical threshold 0xD1 5.35

Lower non-recoverable threshold 0xAC 4.4

Lower critical threshold 0xB1 4.53

Lower non-critical threshold 0xB6 4.66

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 33

Sensor Data Records FRU Information and Sensor Data Records

Table 3-9 +5VCC Sensor (continued)

Feature Raw Value Description

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

Table 3-10 +5VSB Sensor

Feature Raw Value Description

Sensor Name +5VSB -

Sensor LUN 0x00 -

Sensor Number 0x06 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x02 Voltage

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x04 Volts

Nominal Reading 0xC3 4.99

Upper non-recoverable threshold 0xDB 5.61

Upper critical threshold 0xD6 5.48

Upper non-critical threshold 0xD1 5.35

Lower non-recoverable threshold 0xAC 4.4

Lower critical threshold 0xB1 4.53

Lower non-critical threshold 0xB6 4.66

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

33

Page 34

FRU Information and Sensor Data Records Sensor Data Records

Table 3-11 -48V Power1 Sensor

Feature Raw Value Description

Sensor Name -48V Power1 -

Sensor LUN 0x00 -

Sensor Number 0x0C -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x08 Power Supply

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x03 -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Event Offset: 0 Presence detected

- Event Offset: 1 Power supply failure detected

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x03 -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - -

Table 3-12 -48V Power2 Sensor

Feature Raw Value Description

Sensor Name -48V Power2 -

Sensor LUN 0x00 -

Sensor Number 0x0D -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x08 Power Supply

34

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x03 -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Event Offset: 0 Presence detected

- Event Offset: 1 Power supply failure detected

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 35

Sensor Data Records FRU Information and Sensor Data Records

Table 3-12 -48V Power2 Sensor (continued)

Feature Raw Value Description

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x03 -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - -

Table 3-13 ACPI State Sensor

Feature Raw Value Description

Sensor Name ACPI State -

Sensor LUN 0x00 -

Sensor Number 0x16 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x22 System ACPI Power State

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x40 -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Event Offset: 6 S4/S5 soft-off, particular S4/S5

state cannot be determined

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x40 -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - -

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

35

Page 36

FRU Information and Sensor Data Records Sensor Data Records

Table 3-14 BIOS Bank Sensor

Feature Raw Value Description

Sensor Name BIOS Bank -

Sensor LUN 0x00 -

Sensor Number 0x19 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0xD2 Emerson-specific Discrete Digital

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x0F -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Sensor Offset: 0 Last Boot from BIOS Bank A

- Sensor Offset: 1 Last Boot from BIOS Bank B

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x0F -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - -

Table 3-15 BMC POST ERROR Sensor

Feature Raw Value Description

Sensor Name BMC POST ERROR -

Sensor LUN 0x00 -

Sensor Number 0x1A -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x28 Management Subsystem Health

36

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x31 -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Event Offset: 0 Sensor access degraded or

unavailable

- Event Offset: 4 Sensor failure

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 37

Sensor Data Records FRU Information and Sensor Data Records

Table 3-15 BMC POST ERROR Sensor (continued)

Feature Raw Value Description

- Event Offset: 5 FRU failure

Deassertion Event Mask(Byte 17) 0x31 -

Deassertion Event Mask(Byte 18) 0x00 -

Deassertion Events - -

- Event Offset: 0 Sensor access degraded or

unavailable

- Event Offset: 4 Sensor failure

- Event Offset: 5 FRU failure

Threshold Mask(Byte 19) 0x31 -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - -

Table 3-16 Boot Errors Sensor

Feature Raw Value Description

Sensor Name Boot Errors -

Sensor LUN 0x00 -

Sensor Number 0x10 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x1E Boot Error

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x01 -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Event Offset: 0 No bootable media

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x01 -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

37

Page 38

FRU Information and Sensor Data Records Sensor Data Records

Table 3-16 Boot Errors Sensor (continued)

Feature Raw Value Description

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - See IPMI 1.5 Specification,

chapter "Sensor Type Codes and

Data"

Table 3-17 CPU0 Core Rem Sensor

Feature Raw Value Description

Sensor Name CPU0 Core Rem -

Sensor LUN 0x00 -

Sensor Number 0x13 -

Entity ID 0x03 -

Sensor Type 0x01 Temperature

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x01 deg. C

Nominal Reading 0x1E 30

Upper non-recoverable threshold 0x65 101

Upper critical threshold 0x5E 94

Upper non-critical threshold 0x50 80

Lower non-recoverable threshold 0xE0 -32

Lower critical threshold 0xE5 -27

Lower non-critical threshold 0xEA -22

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

38

Reading Definition Analog reading byte Analog sensor reading

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 39

Sensor Data Records FRU Information and Sensor Data Records

Table 3-18 CPU0 Status Sensor

Feature Raw Value Description

Sensor Name CPU0 Status -

Sensor LUN 0x00 -

Sensor Number 0x0E -

Entity ID 0x03 -

Sensor Type 0x07 Processor

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x83 -

Assertion Event Mask(Byte 16) 0x01 -

Assertion Events - -

- Event Offset: 0 Internal error (IERR)

- Event Offset: 1 Thermal Trip

- Event Offset: 7 Processor presence detected

- Event Offset: 8 Processor disabled

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x83 -

Threshold Mask(Byte 20) 0x01 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - -

Table 3-19 CPU1 Core Rem Sensor

Feature Raw Value Description

Sensor Name CPU1 Core Rem -

Sensor LUN 0x00 -

Sensor Number 0x14 -

Entity ID 0x03 -

Sensor Type 0x01 Temperature

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

39

Page 40

FRU Information and Sensor Data Records Sensor Data Records

Table 3-19 CPU1 Core Rem Sensor (continued)

Feature Raw Value Description

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x01 deg. C

Nominal Reading 0x1E 30

Upper non-recoverable threshold 0x65 101

Upper critical threshold 0x5E 94

Upper non-critical threshold 0x50 80

Lower non-recoverable threshold 0xE0 -32

Lower critical threshold 0xE5 -27

Lower non-critical threshold 0xEA -22

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

Table 3-20 CPU1 Status Sensor

Feature Raw Value Description

Sensor Name CPU1 Status -

Sensor LUN 0x00 -

Sensor Number 0x0F -

Entity ID 0x03 -

Sensor Type 0x07 Processor

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x83 -

Assertion Event Mask(Byte 16) 0x01 -

Assertion Events - -

- Event Offset: 0 Internal error (IERR)

40

- Event Offset: 1 Thermal Trip

- Event Offset: 7 Processor presence detected

- Event Offset: 8 Processor disabled

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x83 -

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 41

Sensor Data Records FRU Information and Sensor Data Records

Table 3-20 CPU1 Status Sensor (continued)

Feature Raw Value Description

Threshold Mask(Byte 20) 0x01 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - -

Table 3-21 CPU Inlet Temp Sensor

Feature Raw Value Description

Sensor Name CPU Inlet Temp -

Sensor LUN 0x00 -

Sensor Number 0x01 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x01 Temperature

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x01 deg. C

Nominal Reading 0x1E 30

Upper non-recoverable threshold 0x58 88

Upper critical threshold 0x44 68

Upper non-critical threshold 0x37 55

Lower non-recoverable threshold 0xF6 -10

Lower critical threshold 0xFB -5

Lower non-critical threshold 0x05 5

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

41

Page 42

FRU Information and Sensor Data Records Sensor Data Records

Table 3-22 FBD Inlet Temp Sensor

Feature Raw Value Description

Sensor Name FBD Inlet Temp -

Sensor LUN 0x00 -

Sensor Number 0x02 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x01 Temperature

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x01 deg. C

Nominal Reading 0x1E 30

Upper non-recoverable threshold 0x5F 95

Upper critical threshold 0x48 72

Upper non-critical threshold 0x3E 62

Lower non-recoverable threshold 0xF6 -10

Lower critical threshold 0xFB -5

Lower non-critical threshold 0x05 5

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

Table 3-23 FRU Hot Swap Sensor

Feature Raw Value Description

Sensor Name FRU Hot Swap -

42

Sensor LUN 0x00 -

Sensor Number 0x0A -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0xF0 PICMG 3.0: FRU HotSwap

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0xFF -

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 43

Sensor Data Records FRU Information and Sensor Data Records

Table 3-23 FRU Hot Swap Sensor (continued)

Feature Raw Value Description

Assertion Event Mask(Byte 16) 0x00 -

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0xFF -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - See PICMG 3.0 Specification,

chapter "Reading the FRU HotSwap Sensor"

Table 3-24 FW Progress Sensor

Feature Raw Value Description

Sensor Name FW Progress -

Sensor LUN 0x00 -

Sensor Number 0x18 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x0F System Firmware Progress

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x0F -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Event Offset: 0 System firmware error (POST

Error)

- Event Offset: 1 System firmware hang

- Event Offset: 2 System firmware progress

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x0F -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

43

Page 44

FRU Information and Sensor Data Records Sensor Data Records

Table 3-24 FW Progress Sensor (continued)

Feature Raw Value Description

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - See IPMI 1.5 Specification,

chapter "Sensor Type Codes and

Data"

Table 3-25 Handle State Sensor

Feature Raw Value Description

Sensor Name Handle State -

Sensor LUN 0x00 -

Sensor Number 0x11 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0xEB OEM reserved

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x0F -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Sensor Offset: 0 Handle state ok (both in open/close

state)

- Sensor Offset: 1 Upper handle closed

- Sensor Offset: 2 Lower handle closed

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x0F -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - -

44

Table 3-26 HD Env Temp Sensor

Feature Raw Value Description

Sensor Name HD Env Temp -

Sensor LUN 0x00 -

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 45

Sensor Data Records FRU Information and Sensor Data Records

Table 3-26 HD Env Temp Sensor (continued)

Feature Raw Value Description

Sensor Number 0x03 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x01 Temperature

Event/Reading Type 0x01 Threshold

Assertion Event Mask(Byte 15) 0x95 -

Assertion Event Mask(Byte 16) 0x0A -

Deassertion Event Mask(Byte 17) 0x95 -

Deassertion Event Mask(Byte 18) 0x0A -

Threshold Mask(Byte 19) 0x3F -

Threshold Mask(Byte 20) 0x3F -

Base Unit 0x01 deg. C

Nominal Reading 0x1E 30

Upper non-recoverable threshold 0x5D 93

Upper critical threshold 0x4E 78

Upper non-critical threshold 0x3F 63

Lower non-recoverable threshold 0xF6 -10

Lower critical threshold 0xFB -5

Lower non-critical threshold 0x05 5

Rearm mode 0x01 Auto

Hysteresis Support 0x02 Readable and Setable

Threshold Access Support 0x02 Readable and Setable

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition Analog reading byte Analog sensor reading

Table 3-27 IPMB Link State Sensor

Feature Raw Value Description

Sensor Name IPMB Link State -

Sensor LUN 0x00 -

Sensor Number 0x0B -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0xF1 PICMG 3.0: IPMB Physical Link

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x0F -

Assertion Event Mask(Byte 16) 0x00 -

Deassertion Event Mask(Byte 17) 0x00 -

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

45

Page 46

FRU Information and Sensor Data Records Sensor Data Records

Table 3-27 IPMB Link State Sensor (continued)

Feature Raw Value Description

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x0F -

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

Threshold Access Support 0x00 No Thresholds

Event Message Control 0x00 Per Threshold / Discrete State

Reading Definition - See PICMG 3.0 Specification,

c h a p t e r " P h y s i c a l I P M B - 0 S e n s o r s "

Table 3-28 Log Disabled Sensor

Feature Raw Value Description

Sensor Name Log Disabled -

Sensor LUN 0x00 -

Sensor Number 0x15 -

Entity ID 0xA0 PICMG Front Board

Sensor Type 0x10 Event Logging Disabled

Event/Reading Type 0x6F Discrete (sensor-specific)

Assertion Event Mask(Byte 15) 0x3F -

Assertion Event Mask(Byte 16) 0x00 -

Assertion Events - -

- Event Offset: 0 Correctable memory error logging

disabled

- Event Offset: 1 Event 'type' logging disabled.

- Event Offset: 2 Log area reset/cleared

- Event Offset: 3 All event logging disabled

- Event Offset: 4 SEL Full.

- Event Offset: 5 SEL almost full.

Deassertion Event Mask(Byte 17) 0x00 -

Deassertion Event Mask(Byte 18) 0x00 -

Threshold Mask(Byte 19) 0x3F -

46

Threshold Mask(Byte 20) 0x00 -

Base Unit 0x00 (unspecified)

Rearm mode 0x01 Auto

Hysteresis Support 0x00 No Hysteresis or unspecified

ATCA-7350 Control via IPMI Programmer’s Reference (6806800H29E)

Page 47

Sensor Data Records FRU Information and Sensor Data Records

Table 3-28 Log Disabled Sensor (continued)

Feature Raw Value Description