Page 1

Application Engineering

BULLETIN

Application Engineering

AE8-1385

for Copeland Scroll

BULLETIN

CoreSense

®

UltraTech® Air Conditioning Compressors

TABLE OF CONTENTS

Safety

Safety Instructions .................................................................2

Safety Icon Explanation ........................................................2

Instructions Pertaining to Risk of Electrical Shock, Fire,

or Injury to Persons ...............................................................3

Safety Statements .................................................................3

Introduction

Overview ...............................................................................4

Application Restrictions and Types .......................................4

Product Specifi cations ........................................................... 4

Installation

Mounting ............................................................................... 4

Terminal Description ..............................................................4

Operation

Compressor Protection ......................................................... 4

Module LED Description .......................................................5

Module Operation/Code Description .....................................5

Resetting Alert Codes ...........................................................6

Service

Module History Download ..................................................... 6

Warranty Information ............................................................. 6

Support ..................................................................................6

Figures and Tables

Wires Pulled Through Module ............................................... 6

Module Dimensions in Millimeters ......................................... 7

Terminal Locations ................................................................ 7

Wiring Diagram ..................................................................... 8

Flash Code Description ......................................................... 9

LED Troubleshooting Information ...................................... 10-12

™

Diagnostics

AE8-1385

October 2011

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

1

Page 2

AE8-1385

Application Engineering

BULLETIN

Safety Instructions

Copeland Scroll

U.S. and European Safety Standards. Particular emphasis has been placed on the user's safety. Safey icons are

explained below and safety instructions applicable to the products in this bulletin are grouped on Page 3. These

instructions should be retained throughout the lifetime of the compressor. You are strongly advised to follow

these safety instructions.

Safety Icon Explanation

®

compressors with CoreSense™ Diagnostics technology are manufactured according to the latest

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING

CAUTION

NOTICE

CAUTION

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

CAUTION, without the safety alert symbol, is used to address practices

not related to personal injury.

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

2

Page 3

Application Engineering

BULLETIN

Instructions Pertaining to Risk of Electrical Shock, Fire, or Injury to Persons

AE8-1385

WARNING

WARNING

WARNING

ELECTRICAL SHOCK HAZARD

• Failure to follow these warnings could result in serious personal injury.

• Disconnect and lock out power before servicing.

• Discharge all capacitors before servicing.

• Use compressor with grounded system only.

• Molded electrical plug must be used when required.

• Refer to original equipment wiring diagrams.

•

PRESSURIZED SYSTEM HAZARD

• Failure to follow these warnings could result in serious personal injury.

• System contains refrigerant and oil under pressure.

• Remove refrigerant from both the high and low compressor side before

removing compressor.

•

• Never install a system and leave it unattended when it has no charge,

a holding charge, or with the service valves closed without electrically

locking out the system.

• Use only approved refrigerants and refrigeration oils.

• Personal safety equipment must be used.

BURN HAZARD

• Failure to follow these warnings could result in serious personal injury or

property damage.

• Do not touch the compressor until it has cooled down.

• Ensure that materials and wiring do not touch high temperature areas of

the compressor.

• Use caution when brazing system commponents.

• Personal safety equipment must be used.

CAUTION

Safety Statements

• Refrigerant compressors must be employed only for their intended use.

•

install, commission and maintain this equipment.

•

• All valid standards and codes for installing, servicing, and maintaining electrical and

refrigeration equipment must be observed.

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

COMPRESSOR HANDLING

• Failure to follow these warnings could result in personal injury or

• Use the appropriate lifting devices to move compressors.

• Personal safety equipment must be used.

property damage.

3

Page 4

AE8-1385

Application Engineering

BULLETIN

INTRODUCTION

Overview

CoreSense™ Diagnostics is a breakthrough innovation

for troubleshooting residential air conditioning and heat

pump systems. The CoreSense Diagnostics module

is easily installed in the unit electrical panel near the

compressor contactor. By using the compressor as

a sensor, CoreSense Diagnostics helps the service

technician more accurately troubleshoot system and

compressor fault conditions.

CoreSense Diagnostics also provides compressor

and system protection through its proprietary lockout

feature. Depending on the severity and frequency of

the fault that caused the trip condition, the CoreSense

Diagnostics module can lockout the compressor

contactor to prevent damage to the compressor and

system components. Less severe fault conditions

resulting in an occasional trip will not result in a lockout

condition.

Flashing LEDs communicate ALERT and LOCK codes

to the service technician.

Application Restrictions and Types

The CoreSense Diagnostics (571-0072-00) module

is designed and qualifi ed for use with ZPS*K5 single-

phase Copeland Scroll® UltraTech™ compressors.

Product Specifi cations

Operating Temp: - 40° to 150°F (- 40° to 65°C)

Storage Temp: - 40° to 175°F (- 40° to 80°C)

Supply Voltage: 18 to 28VAC , 48 to 62Hz

Module Current Sensing Range: 2 to 30A

Maximum Power Consumption: 2.5 VA (Excluding

solenoid load)

Terminal Description

The terminals for the CoreSense Diagnostics module

are ¼” spade terminals.

• COMMON (C)

The 24 volt common terminal for module power.

• DEMAND (Y)

The demand terminal requires a 24VAC signal

measured with respect to the COMMON (C)

terminal when there is a call for heating or

cooling. A signal above 6VAC indicates the

thermostat wants the compressor to be on, while

0-6VAC signal indicates the thermostat wants

the compressor to be off.

• SECOND STAGE DEMAND (Y2)

The demand (Y) and second stage demand

(Y2) terminals require a 24VAC signal measured

with respect to the COMMON (C) terminal when

there is a call for heating or cooling. A signal

above 10VAC indicates the thermostat wants the

Ultratech solenoid to be energized, while 0-10VAC

signal indicates the thermostat wants the Ultratech

solenoid to be deenergized.

• PROTECTION (PROT)

The protection terminal is internally connected

to the COMMON terminal through a solid state

switch.

• POWER (R)

The module requires a constant 24VAC supply

power to this terminal. The module must receive

an independent power supply in order to operate

properly. See Figure 4.

INSTALLATION

Mounting

Four #8 or #10 self tapping or sheet metal screws are

required for installation of the module. The maximum

mounting screw torque is 20 in.lbs. Locate the

module near the compressor contactor (wire routing

for compressor run, common, and start wires will be

easier in this position). The module can be mounted

in any orientation and LEDs should be visible for ease

of service.

The compressor’s run (R), common (C), and start (S)

wires are routed through the holes in the CoreSense

module marked “R”,”C”, and “S”. See Figure 1.

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

• Thermostat Communication (L)

Provides a 24V signal to an indoor thermostat

indicating the number of ALERT fl ashes displayed

on the module. (Reference thermostat manual for

available capability)

• Solenoid (DC SOL)

Provides a connection to the Copeland Scroll

UltraTech second stage compressor solenoid. This

solenoid is internal to the compressor, and has

a voltage range of 18 to 28VDC. Please refer to

bulletin AE-1311 for information on the Copeland

Scroll® UltraTech® compressor.

4

Page 5

AE8-1385

Application Engineering

BULLETIN

OPERATION

Compressor Protection

The CoreSense Diagnostics module utilizes proprietary

algorithms to protect the compressor and system from

repeated trips of system pressure controls and the

compressor internal overload. The protection terminal

of the module should be wired in series with the system

low pressure and high pressure cutouts, as well as

the compressor contactor. When the module detects

a series of trips as described below, it will activate a

lockout feature that opens the solid state switch in the

module, thereby cutting power to the contactor and deenergizing the compressor.

Module LED Description

POWER LED (Green): indicates the module is

powered with 18 to 28 volts.

ALERT LED (Yellow): communicates an abnormal

system condition through a unique fl ash code. The

ALERT LED will fl ash a number of times consecutively,

pause and then repeat the process. The number of

consecutive fl ashes, defi ned as the Flash Code,

correlates to a particular abnormal condition. Detailed

descriptions of specifi c ALERT Flash Codes are

shown in Table 1.

TRIP/LOCK LED (Red): indicates either a TRIP or

LOCK condition.

• TRIP: is indicated by a solid illumination of the

LED. This means the compressor is not running

and demand is present at the module.

• LOCK: is indicated by a fl ashing LED correlating to

a LOCK condition in which the module will prevent

the compressor from starting.

Module Operation/Code Description

Code 1 – Long Run Time

The module will fl ash yellow one time when the

compressor operates for longer than 18 continuous

hours. This is an alert code only, and the module will

not lockout the compressor for this condition. This

code is inactive for heat-pumps.

Code 2 – Compressor (Pressure) Trips

The module will fl ash yellow two times when the

compressor operates from 12 seconds to 15 minutes

followed by a trip condition lasting longer than 7

minutes. When four consecutive or ten total Code

2 events are recorded, the module will lockout the

compressor and fl ash red two times.

Code 3 – Pressure Switch Cycling

The module will fl ash yellow three times when the

compressor operates from 12 seconds to 15 minutes

followed by a trip condition lasting between 35

seconds to 7 minutes. When four consecutive or ten

total Code 3 events are recorded, the module will

lockout the compressor and fl ash red three times.

Code 4 – Locked Rotor Trip

The module will fl ash yellow four times when the

compressor trips within 12 seconds of operation and

does not reset and start within 35 seconds. When ten

consecutive Code 4 events are recorded the module

will lockout the compressor and fl ash red four times.

Code 5 – Compressor (Moderate Run) Trip

The module will fl ash yellow fi ve times when the

compressor has operated between 15 minutes and

18 hours, followed by a compressor trip lasting longer

than 7 minutes. When four consecutive or ten total

Code 5 events are recorded, the module will lockout

the compressor and fl ash red fi ve times.

Code 6 – Open Start Circuit

The module will lockout the compressor and fl ash

red six times if the module detects a demand signal

in the “Y” terminal and current in the “R” winding of

the compressor, but no current is detected in the “S”

winding of the compressor for 2 seconds.

Code 7 – Open Run Circuit

The module will lockout the compressor and fl ash red

seven times if the module detects a demand signal

in the “Y” terminal and current in the “S” winding of

the compressor, but no current is detected in the “R”

winding of the compressor for 2 seconds.

Code 8 – Welded Contactor

The module will fl ash yellow eight times if it has

detected line currents in the “S” and “R” windings and

demand is absent for 15 seconds.

Code 9 – Low Voltage

The module will fl ash nine times if the module supply

voltage drops below 17VAC for 2 seconds. The

module will prevent the compressor from starting until

adequate voltage is established.

Code 10 – Over-Current Protection

When the current at the PROT terminal is greater than

2A for 40ms, the module will fl ash a Code 10. The red

LED will fl ash 10 times with the yellow LED remaining

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

5

Page 6

AE8-1385

Application Engineering

BULLETIN

off. This event will cause a lockout of the compressor

and indicates that the module is mis-wired or the

contactor coil is shorted to ground.

NOTICE

Code 10 is not specifi ed on the module label.

Resetting Alert Codes

When the CoreSense Diagnostics module has detected

a series of adverse conditions that have caused it to

lockout the compressor, and after the issue has been

resolved, it is necessary to manually reset the module

in order to clear the present alert code.

The primary way of clearing the code and resetting

the ALERT or TRIP/LOCK is to cycle the power to the

module by disengaging the COMMON (C) Terminal.

This will not clear the seven day operating history

contained in the module memory. It will only clear the

present ALERT or TRIP/LOCK and allow for normal

operation.

SERVICE

WARNING

Always disconnect and lockout the power supply

before beginning electrical troubleshooting.

Module History Download

The CoreSense Diagnostics module is capable of

communicating with a personal computer, tablet, or

laptop, via Emerson Climate Technologies computer

software interface and USB connection, in order to

download and store fault history and module operation

time. This information can be used to help diagnose

and review data from troubled systems in the fi eld. For

more information, please contact your Emerson Climate

Application Engineer.

Warranty Information

Emerson Climate Technologies, Inc. warrants its

diagnostic module to be free from defects in materials

and workmanship under normal use for a period of one

year from the date of purchase or twenty months from

manufacture, whichever comes fi rst. During this period,

Emerson Climate Technologies, Inc. will replace any

defective diagnostic module without charge.

For more information on product warranty please visit

www.EmersonClimate.com

Support

For more information visit www.EmersonClimate.com,

or contact Emerson Climate Technologies, Inc. at 1-888EMR-9950.

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

Figure 1

Wires Pulled Through Module

6

Page 7

Application Engineering

BULLETIN

47

AE8-1385

POWER

Flash Event

1 Long Run Time

2 Compressor (Pressure) Trip

3 Pressure Switch Cycling

4 Locked Rotor

5 Compressor (Mod Run) Trip

6 Open Start Circuit

7 Open Run Circuit

8 Welded Contactor

9 Low Voltage

62

Two Stage Control

DC SOL operating range: 18-28VDC

Compressor second stage is

energized when Y & Y2 are 24VAC

Active Protection

PROT breaks 24VAC common

leg of compressor contactor coil

Reset codes and PROT lockout

by removing 24VAC to module

ALERT

TRIP / LOCK

37

Figure 2 – Module Dimensions in Millimeters

67

R

C

112

S

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

For Use With

Copeland Scroll

UltraTech

Compressors

065312345

P/N: 543-XXXX-XX

Use With Class 2

Circuits Only

Supply 24VAC

50/60Hz

Power 1.5VA

Patent: 6,615,594

Figure 3 – Terminal Locations

7

Y2

Y

Data Port

L

R

C

PROT

Solenoid

Page 8

AE8-1385

Application Engineering

BULLETIN

2-Stage

Thermostat

Y2

Y1

L

R

C

Indoor

Unit

Y2

Y1

L

R

C

Outdoor

Unit

Y2

Y1

Pressu re Swit ch

L

R

Co mpressor

C

Figure 4

Wiring Diagram

High/Low

Contactor

CC

CoreSense

Y2

Y

L

R

C

Prot

DC

Solenoid

Solenoid

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

8

Page 9

Application Engineering

BULLETIN

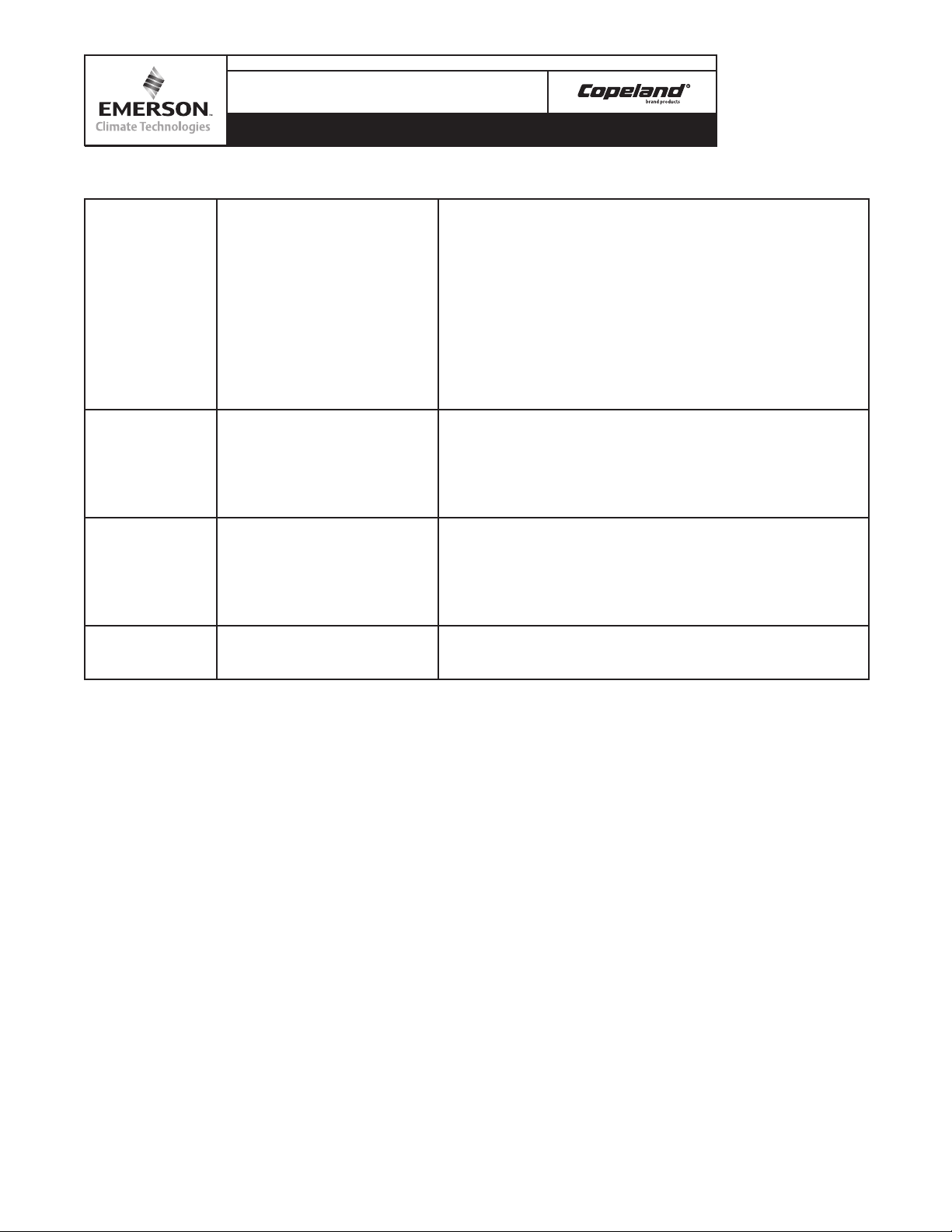

Table 1 – Flash Code Description

AE8-1385

Alert Code Alert Condition Lockout Level

Normal Run

Solid Green

Code1

Yellow Flash 1

Code2

Yellow Flash 2

Code 3

Yellow Flash 3

Code4

Yellow Flash 4

Code5

Yellow Flash 5

Code6

Red Flash 6

Normal operation, no trip. N/A N/A

Long run time. Compressor is running for more than

18 hours at full load. (Code1 is disabled in Heat Pump

mode.)

Compressor Pressure trip. Compressor runs for 12sec

to 15min followed by a compressor trip condition lasting

longer than 7min.

Pressure switch cycling. Compressor runs for 12sec to

15min followed by a compressor trip lasting between

35sec to 7min.

Locked rotor. Compressor trips within a compressor run

time of 12sec and does not start within 35sec.

Compressor moderate run trip. Compressor runs for

15min to 18hrs followed by a compressor trip lasting

longer than 7min.

Open start circuit. Module has detected Y or Y1, and

current in the R winding of the compressor and no

current in the S winding of the compressor for 2 seconds.

N/A N/A

4x consecutive,

10x total

4x consecutive,

10 total

10x consecutive Red: Flash 4

4x consecutive,

10x total

1 occurrence Red: Flash 6

Lockout

Indication

Red: Flash 2

Red: Flash 3

Red: Flash 5

Code7

Red Flash 7

Code8

Yellow Flash 8

Code9

Yellow Flash 9

Code10

Red Flash 10

Open run circuit. Module has detected Y or Y1, and

current in the S winding of the compressor and no current

in the R winding of the compressor for 2 seconds.

Welded Contactor. Module has detected line currents

in R and S windings, and Y or Y1 is at 0 VAC for 15

seconds.

Low Voltage. Module has detected a 24 VAC supply

voltage below 17 VAC +/- 1 VAC for 2 seconds

Over Current Protection. PROT terminal has above a 2A

input for more than 40 milliseconds.

1 occurrence Red: Flash 7

N/A N/A

N/A N/A

1 occurrence Red: Flash 10

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

9

Page 10

Application Engineering

BULLETIN

Table 2 – CoreSense Diagnostics LED Troubleshooting Information

Flash Code number corresponds to the number of LED fl ashes, followed by a pause and then repeated.

TRIP and ALERT LEDs fl ashing at same time means control circuit voltage is too low for operation (brown-out conditions).

Status Description Troubleshooting Information

Solid Green “RUN”

Solid Red “TRIP”

Yellow “ALERT”

Flash Code 1

Yellow “ALERT”

Flash Code 2

Module has power and

operating normally

Thermostat demand signal Y is

present, but the compressor is

not running

Long Run Time

Low Refrigerant Charge

Compressor is running extremely

long run cycles

Compressor (Pressure) Trip

High Refrigerant Charge

Discharge pressure out of limits

or compressor overloaded

Supply voltage is present at module terminals

1. Compressor protector is open

• Check for high head pressure

• Check compressor supply voltage

2. Outdoor unit power disconnect is open

3. Compressor circuit breaker or fuse(s) is open

4. Broken wire or connector is not making contact

5. High pressure switch open if present in system

6. Compressor contactor has failed open

“ALERT” Flash Codes

1. Low refrigerant charge

2. Evaporator blower is not running

• Check blower relay coil and contacts

• Check blower motor capacitor

• Check blower motor for failure or blockage

• Check evaporator blower wiring and connectors

• Check indoor blower control board

• Check thermostat wiring for open circuit

3. Evaporator coil is frozen

• Check for low suction pressure

• Check for excessively low thermostat setting

• Check evaporator airfl ow (coil blockages or return air fi lter)

• Check ductwork or registers for blockage

4. Faulty metering device

• Check TXV bulb installation (size, location and contact)

• Check if TXV/fi xed orifi ce is stuck closed or defective

5. Liquid line restriction (fi lter drier blocked if present in system)

6. Thermostat is malfunctioning

• Check thermostat sub-base or wiring for short circuit

• Check thermostat installation (location, level)

1. Condenser fan is not running

• Check fan capacitor

• Check fan wiring and connectors

• Check fan motor for failure or blockage

2. High head pressure

• Check high pressure switch if present in system

• Check if system is overcharged with refrigerant

• Check for non-condensable in system

3. Condenser coil poor air circulation (dirty, blocked, damaged)

4. Return air duct has substantial leakage

AE8-1385

Yellow “ALERT”

Flash Code 3

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

Pressure Switch Cycling

Compressor is running only

briefl y due to pressure switch

cycling

1. Time delay relay or control board defective

2. If high pressure switch present go to Flash Code 2 information

10

Page 11

Application Engineering

BULLETIN

Yellow “ALERT”

Flash Code 4

Yellow “ALERT”

Flash Code 5

Yellow “ALERT”

Flash Code 8

Yellow “ALERT”

Flash Code 9

Red “LOCKOUT”

Flash Code 2

Yellow Off

Red “LOCKOUT”

Flash Code 3

Yellow Off

Red “LOCKOUT”

Flash Code 4

Yellow Off

Table 2 Continued

Locked Rotor

Compressor (Moderate Run)

Trip

Welded Contactor

Compressor always runs

Low Supply Voltage

Voltage below 18V

“LOCKOUT” Flash Codes

Compressor (Pressure) Trip

Compressor is locked out

after 4 consecutive or 10 total

compressor (pressure) trip events

Pressure Switch Cycling

Compressor is locked out after 4

consecutive or 10 total pressure

cycling events

Locked Rotor

Compressor is locked out after 10

consecutive locked rotor events

AE8-1385

1. Run capacitor has failed

2. Low line voltage (contact utility if voltage at disconnect is low)

• Check wiring connections

3. Excessive liquid refrigerant in compressor

4. Compressor bearings are seized

• Measure compressor oil level

1. Evaporator blower is not running

• Check blower relay coil and contacts

• Check blower motor capacitor

• Check blower motor for failure or blockage

• Check evaporator blower wiring and connectors

• Check indoor blower control board

• Check thermostat wiring for open circuit

2. Faulty metering device

• Check TXV bulb installation (size, location and contact)

• Check if TXV/fi xed orifi ce is stuck closed or defective

3. Condenser coil poor air circulation (dirty, blocked, damaged)

4. Low refrigerant charge

1. Compressor contactor has failed closed

2. Thermostat demand signal not connected to module

1. Control Circuit transformer is overloaded

2. Low line voltage (contact utility if voltage at disconnect is low)

1. Condenser fan is not running

• Check fan capacitor

• Check fan wiring and connectors

• Check fan motor for failure or blockage

2. High head pressure

• Check high pressure switch if present in system

• Check if system is overcharged with refrigerant

• Check for non-condensable in system

3. Condenser coil poor air circulation (dirty, blocked, damaged)

4. Return air duct has substantial leakage

1. Time delay relay or control board defective

2. If high pressure switch present go to Flash Code 2 information

1. Run capacitor has failed

2. Low line voltage (contact utility if voltage at disconnect is low

• Check wiring connections

3. Excessive liquid refrigerant in compressor

4. Compressor bearings are seized

• Measure compressor oil level

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

11

Page 12

Application Engineering

BULLETIN

Red “LOCKOUT”

Flash Code 5

Yellow Off

Red “LOCKOUT”

Flash Code 6

Yellow Off

Red “LOCKOUT”

Flash Code 7

Yellow Off

Red “LOCKOUT”

Flash Code 10

Table 2 Continued

Compressor (Moderate Run)

Trip

Compressor is locked out

after 4 consecutive or 10 total

compressor (moderate run) trip

events

Open Start Circuit

Current only in run circuit

Open Run Circuit

Current only in start circuit

Over Current Protection

Current to PROT is greater than

2A mps

AE8-1385

1. Evaporator blower is not running

• Check blower relay coil and contacts

• Check blower motor capacitor

• Check blower motor for failure or blockage

• Check evaporator blower wiring and connectors

• Check indoor blower control board

• Check thermostat wiring for open circuit

2. Faulty metering device

• Check TXV bulb installation (size, location and contact)

• Check if TXV/fi xed orifi ce is stuck closed or defective

3. Condenser coil poor air circulation (dirty, blocked, damaged)

4. Low refrigerant charge

1. Run capacitor has failed

2. Open circuit in compressor start wiring or connections

• Check wiring and connectors between supply and the

compressor “S” terminal

3. Compressor start winding is damaged

• Check compressor motor winding resistance

1. Open circuit in compressor run wiring or connections

• Check wiring and connectors between supply and the

compressor “R” terminal. Confi rm proper wire routing per

Figure 1.

2. Compressor run winding is damaged

• Check compressor motor winding resistance

1. Check for contactor shorted to ground

2. Check for mis-wiring to the PROT terminal

The contents of this publication are presented for informational purposes only and they are not to be construed as warranties or guarantees, express or implied, regarding the products or

services described herein or their use or applicability. Emerson Climate Technologies, Inc. reserves the right to modify the designs or specifi cations of such products at any time without

notice. Emerson Climate Technologies, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of

any Emerson Climate Technologies, Inc. product remains solely with the purchaser and end-user.

© 2011 Emerson Climate Technologies

Printed in the U.S.A.

12

Loading...

Loading...