Page 1

© 2020 Emerson Climate Technologies, Inc.

1

TABLE OF CONTENTS

Safety

Safety Instructions ................................................... 3

Safety Icon Explanation

.......................................... 3

Introduction ................................................................ 5

Nomenclature .......................................................... 5

Application Considerations .......................................... 5

Internal Pressure Relief (IPR) Valve........................ 5

Discharge Temperature Protection.......................... 5

Heat Pump Protection ............................................. 6

Discharge Line Thermostat ..................................... 6

Air Conditioning Unit Protection ............................... 6

High Pressure Control ............................................. 6

Discharge Check Valve ........................................... 6

Motor Overload Protection ....................................... 6

Operating Envelope ................................................. 7

Power Supply ........................................................... 7

Accumulators ........................................................... 7

Screens .................................................................... 7

Crankcase Heat - Single Phase .............................. 7

Crankcase Heat - Three Phase ............................... 8

Pump Down Cycle ................................................... 8

Minimum Run Time.................................................. 8

Reversing Valves ..................................................... 8

Low Ambient Cut-Out .............................................. 8

Oil Type ................................................................... 8

Contaminant Control ................................................ 9

Long Line Sets/High Refrigerant Charge ................ 9

Discharge Mufflers ................................................... 9

Air Conditioning System Suction Line Noise and

Vibration ................................................................... 9

Mounting Parts....................................................... 10

Electrical Connections ........................................... 10

Deep Vacuum Operation ....................................... 10

Shell Temperature ................................................. 10

Suction and Discharge Fittings .............................. 10

System Tubing Stress ........................................... 10

Three Phase Scroll Compressor Electrical Phasing

............................................................................... 10

Brief Power Interruptions ....................................... 11

Manifolding Tandem Compressors........................ 11

Application Tests ........................................................ 11

Application Test Summary ..................................... 11

Continuous Floodback ........................................... 11

Field Application Test ............................................ 11

Continuous Floodback Test ................................... 12

Field Application Test ............................................. 12

Assembly Line Procedures ......................................... 12

Installing the Compressor ...................................... 12

Assembly Line Brazing Procedure ......................... 13

Tandem Assembly ................................................. 13

Pressure Testing .................................................... 13

Assembly Line System Charging Procedure ......... 13

“Hipot” (AC High Potential) Testing ........................ 14

Final Run Test ........................................................ 14

Unbrazing System Components ............................ 14

Service Procedures .................................................... 14

Copeland Scroll Compressor Functional Check .... 14

Compressor Replacement After a Motor Burn ....... 15

Start-Up of a New or Replacement Compressor ... 15

Figures & Tables

Figure 1 - Operating Envelope ................................... 16

Figure 2 - Oil Dilution Chart ........................................ 17

Figure 3 - ASTP Label ................................................ 18

Figure 4 - Crankcase Heater ...................................... 18

Figure 5 - Typical ZP*KC Tandem ............................. 19

Figure 6 - Tilted Tandem ............................................ 19

Figure 7- Scroll Suction Tube Brazing........................ 20

Figure 8- How Scroll Works ........................................ 21

Table 1 - Field Application Test .................................. 22

Table 2 - Design Configurations ................................. 22

Table 3 - Compressor Refrigerant Charge Limits ...... 22

Table 4 - Compressor Accessories ............................ 23

Table 5 - PED Details ................................................. 25

AE4-1365 R5

February 2020

5 to 12 Ton ZP*K3, ZP*KC, and ZP*KW R-410A

Copeland Scroll™ Compressors for Air Conditioning

Page 2

© 2020 Emerson Climate Technologies, Inc.

2

AE4-1365 R5

Revision Tracking R5

Pg.6 – Added Information on the Pressure Equipment Directive certification

Pg.6 – Updated Discharge Check Valve information

Pg.11 – Deleted the Tandem Application section. Note added to refer to AE4-1430 for multiples.

Pg.22 – Table 3, Tandem Charge Limit removed

Pg.23 – Table 4, Terminal Block part numbers updated. Comfort Alert Module Applications

Pg.23 – Table 5, PED Details Added.

Page 3

© 2020 Emerson Climate Technologies, Inc.

3

Safety Instructions

Copeland Scroll™ compressors are manufactured according to the latest U.S. and European

Safety Standards. Particular emphasis has been placed on the user's safety. Safety icons are

explained below and safety instructions applicable to the products in this bulletin are grouped on

Page 3. These instructions should be retained throughout the lifetime of the compressor. You are

strongly advised to follow these safety instructions.

Safety Icon Explanation

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation

which, if not avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

CAUTION, without the safety alert symbol, is used to address practices not related

to personal injury.

DANGER

WARNING

CAUTION

NOTICE

CAUTION

Page 4

© 2020 Emerson Climate Technologies, Inc.

4

AE4-1365 R5

I

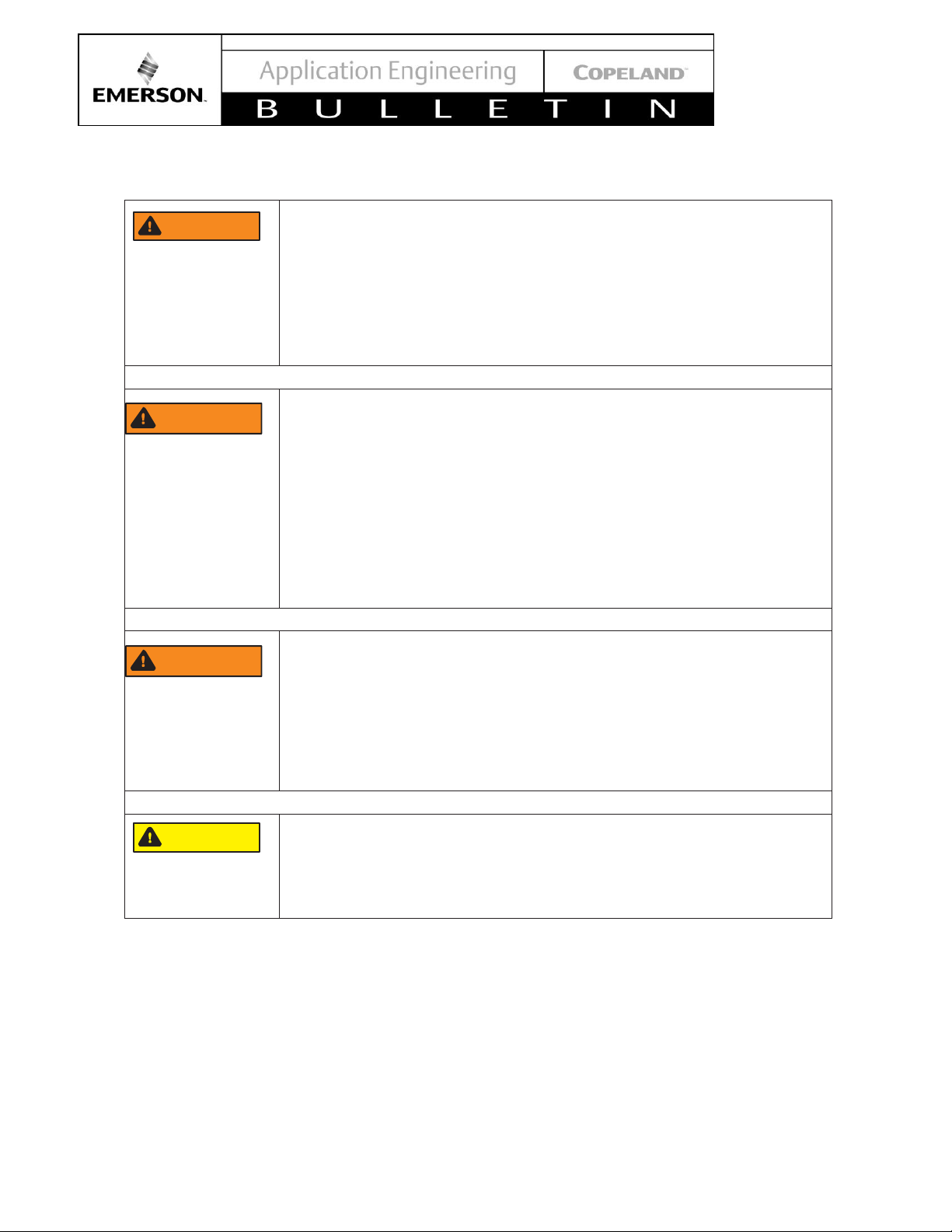

nstructions Pertaining to Risk of Electrical Shock, Fire, or Injury to Persons

WARNING

ELECTRICAL SHOCK HAZARD

• Disconnect and lock out power before servicing.

• Discharge all capacitors before servicing.

• Use compressor with grounded system only.

• Molded electrical plug must be used when required.

• Refer to original equipment wiring diagrams.

• Electrical connections must be made by qualified electrical personnel.

• Failure to follow these warnings could result in serious personal injury.

WARNING

PRESSURIZED SYSTEM HAZARD

• System contains refrigerant and oil under pressure.

• Remove refrigerant from both the high and low compressor side before

removing compressor.

• Never install a system and leave it unattended when it has no charge,

a holding charge, or with the service valves closed without electrically

locking out the system.

• Use only approved refrigerants and refrigeration oils.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in serious personal injury.

WARNING

BURN HAZARD

• Do not touch the compressor until it has cooled down.

• Ensure that materials and wiring do not touch high temperature areas of

the compressor.

• Use caution when brazing system components.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in serious personal injury or

property damage.

CAUTION

COMPRESSOR HANDLING

• Use the appropriate lifting devices to move compressors.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in personal injury or

property damage.

Safety Statements

• Refrigerant compressors must be employed only for their intended use.

• Only qualified and authorized HVAC or refrigeration personnel are permitted to install commission and

maintain this equipment.

• Electrical connections must be made by qualified electrical personnel.

• All valid standards and codes for installing, servicing, and maintaining electrical and

refrigeration equipment must be observed.

Page 5

© 2020 Emerson Climate Technologies, Inc.

5

Introduction

The 70 frame ZP*K3 and ZP*KC Copeland Scroll™

compressors are designed for a wide variety of light

commercial cooling and heat pump applications. The

ZP*KW Copeland Scroll compressors are designed

primarily for swimming pool heating and cooling. This

bulletin describes the operating characteristics, design

features, and application requirements for these

models.

For additional information, please refer to the online

product information accessible from the Emerson

website at

Emerson.com/OPI.

Operating principles of

the Copeland Scroll compressor are described in

Figure 8

of this bulletin.

The ZP*K3 and ZP*KC scrolls range in size from

50,000 to 57,000 Btu/hr (14.7 to 16.7 kW) and 61,000

to 147,000 Btu/hr (17.9 to 43.1 kW) respectively.

These models include all of the standard 50 and 60

Hertz, three phase voltages and some single phase

voltages. The ZP*KW scrolls are single-phase only

scrolls in 70,000 and 83,000 Btu/hr (20.5 and 24.3 kW)

displacements.

All of the compressors covered in this bulletin are in

the 70 frame family (7" diameter shell) and include a

number of features outlined in the matrix below.

Nomenclature

The model numbers of the Copeland Scroll

compressors include the approximate nominal 60 Hz

capacity at standard operating conditions. An example

would be the ZP67KCE-TFD, which has 67,000 But/hr

(19.6kW) cooling capacity at the AHRI high temperature

air conditioning rating point when operated at 60 Hz.

Note that the same compressor will have approximately

5/6 of this capacity or 55,000 Btu/hr (16.1kW) when

operated at 50 Hz. Please refer to the on-line product

information at

Emerson.com/OPI

for details.

APPLICATION CONSIDERATIONS

The following application guidelines shouldconsidered

in the design of a system using ZP*K3, ZP*KC, and

ZP*KW scroll compressors. Some of the guidelines are

recommended in this bulletin for good practice or best

in class, other guidelines must be followed to ensure a

safe and reliable application. The Application

Engineering department always welcomes suggestions

that will help improve these types of documents.

Internal Pressure Relief (IPR) Valve

The ZP91KC through ZP143KC compressors do

not have IPR valves.

All other compressors in this family have an internal

pressure relief valve which is located between the high

and low side of the compressor. It is designed to open

when the discharge-to-suction pressure differential

exceeds 550 to 625 psid (38-43 bar). When the valve

opens, hot discharge gas is routed back into the area

of the motor overload to cause a trip. During fan failure

testing, system behavior and operating pressures will

depend on the type of refrigerant metering device.

Fixed orifice devices may flood the compressor with

refrigerant, and thermostatic expansion devices will

attempt to control superheat and result in higher

compressor top cap temperatures. Fan failure testing

or loss of air flow in both cooling and heating should be

evaluated by the system designer to assure that the

compressor and system are protected from abnormally

high pressures.

Discharge Temperature Protection

Compressor top cap temperatures can be very hot.

Care must be taken to ensure that wiring or other

materials which could be damaged by these

temperatures do not come into contact with these

potentially hot areas.

Protection against abnormally high discharge

temperature is accomplished through one of the two

folowing methods:

The Therm-O-Disc™ or TOD is a temperature-sensitive

snap disc device located between the high and low

pressure side of the scroll. It is designed to open and

route excessively hot discharge gas back to the

Model

Application

IPR

Valve

Discharge Temp Protection

Internal

Overload

Electrical

Connections

AC

TOD

ASTP

ZP50-57K3

X

X X X X

MP, QC, TB

ZP61-83KC

X

X X X X

MP, QC, TB

ZP91KC

X

X

X X

MP, TB

ZP104-122KC

X

X

X X

MP, TB

ZP70-83KW

Pool Heating/Cooling

X X

X

MP, TB

ZP143KC

X

X

X X

MP, TB

Page 6

© 2020 Emerson Climate Technologies, Inc.

6

AE4-1365 R5

internal motor overload when the internal discharge

gas exceeds 290°F (144°C). When the internal motor

overload is subjected to hot discharge gas the overload

will reach its opening temperature and take the

compressor off-line. ZP91 and smaller compressors in

this family use this method of temperature protection.

The second type of discharge temperature protection is

referred to as Advanced Scroll Temperature Protection

(ASTP). During a high discharge temperature event, a

temperature-sensitive snap disk located in the

intermediate cavity of the scroll will open and vent the

intermediate cavity. This will result in the scrolls

separating and not pumping. The motor will continue to

run until the internal overload opens from a lack of

refrigerant flow/cooling. The temperature-sensitive disk

has a shorter reset time than the internal motor

overload, so when the internal overload resets and

brings the compressor back on line the compressor will

run and pump. Compressors that have ASTP are

identified with the ASTP label shown in

Figure 3

.

Heat Pump Protection

A low pressure control is highly recommended for loss

of charge protection and other system fault conditions

that may result in very low evaporating temperatures.

Even though these compressors have internal

discharge temperature protection, loss of system

charge will result in overheating and recycling of the

motor overload protector. Prolonged operation in this

manner could result in oil pump out and eventual

bearing failure. A cut out setting no lower than 20 psig

(1.4 bar) is recommended.

Discharge Line Thermostat

Some systems, such as air-to-air heat pumps, may not

work with the above low pressure control arrangement.

A discharge line thermostat set to shut the compressor

off before the discharge temperature exceeds 260°F

(125°C) may have to be used to achieve the same

protection. Mount the discharge thermostat as close as

possible to the compressor discharge fitting and insulate

well. See

Table 4

for recommended Emerson Climate

Technologies part numbers.

Air Conditioning Unit Protection

Air-conditioning-only units can be protected against

high discharge temperatures through a low pressure

control in the suction line. Testing has shown that a cut

out setting of not lower than 55 psig (3.8 bar) will

adequately protect the compressor against overheating

from loss of charge, blower failure in a TXV system,

etc. A higher level of protection is achieved if the low

pressure control is set to cut out around 95 psig (6.7

bar) to prevent evaporator coil icing. The cut in setting

can be as high as 180 psig (12.5 bar) to prevent rapid

recycling in case of refrigerant loss. If an electronic

controller is used, the system can be locked out after

repeated low pressure trips.

High Pressure Control

The ZP91KC through ZP143KC compressors do

not have an internal pressure relief valve. A high

pressure control with a maximum cut out setting of

650 psig (45 bar) is required for all ZP91KC through

ZP143KC applications.

All other compressors in this family have an internal

pressure relief valve and the necessity of a high

pressure control switch is dependent on the working

pressure of the system components. The high pressure

control should have a manual reset feature for the

highest level of system protection.

It is not

recommended to use the compressor to test the

high pressure switch function during the assembly

line test.

Compressors requiring certification to the

Pressure Equipment Directive (PED):

The nameplate

will be marked with a TS min of -35°C where TS min is

defined as the minimum allowable temperature. The

nameplate will also be marked with a TS max of 150°C

where TS max is defined as the maximum allowable

temperature (°C, max design temperature, highest temp

that can occur during operation or standstill of the

refrigeration system or during test under test conditions,

specified by the manufacturer). See

Table 5

for PED

specific information. The nameplate will be marked with

the internal free volume (IFV) of the compressor. The

first two digits of the compressor serial number

references the year of manufacture.

Discharge Check Valve

A low mass, disk type check valve in the discharge

fitting of the compressor to prevent the high side, high

pressure discharge gas from flowing rapidly back

through the compressor after shutdown.

Motor Overload Protection

Conventional internal line break motor overload

protection is provided. The overload protector opens the

common connection of a single-phase motor and the

center of the Y connection on three-phase motors. The

three-phase overload protector provides primary singlephase protection. Both types of overload protectors

react to current and motor winding temperature.

Page 7

© 2020 Emerson Climate Technologies, Inc.

7

AE4-1365 R5

Operating Envelope

The ZP model family is approved, and U.L. recognized,

for use with R-410A only. See

Figures 1a and 1b

for

the R-410A operating envelope. The envelope

represents safe operating conditions with 20F° (11K)

superheat in the return gas. Please note that the ZP*KW

compressors have a smaller envelope for swimming

pool applications.

Power Supply

All motors for the ZP compressors, whether single or

three phase, with the exception of the “PFV” 208-230,

1Ø, 60 Hz motor, are designed to operate within a

voltage range of +/-10% of the voltages shown on the

nameplate. For example, a compressor with a

nameplate voltage of 200-230 volts can start and

operate within a range of 180-253 volts. Compressors

with a “PFV” designated motor such as ZP50K3E-PFV,

may only be operated in a range of 197-253 volts

under maximum load conditions.

Accumulators

The use of accumulators is very dependent on the

application. The Copeland Scroll compressor’s inherent

ability to handle liquid refrigerant during occasional

operating flood back situations make the use of an

accumulator unnecessary in standard designs such as

condensing units. Applications such as heat pumps

with orifice refrigerant control that allow large volumes

of liquid refrigerant to flood back to the compressor

during normal steady-state operation can dilute the oil

to such an extent that bearings are inadequately

lubricated, and wear will occur. In such a case an

accumulator must be used to reduce flood back to a

safe level that the compressor can tolerate. Heat

pumps designed with a TXV to control refrigerant

during heating may not require an accumulator if

testing assures the system designer that there will be

no flood back throughout the operating range. To test

for flood back conditions and determine if the

accumulator or TXV design is adequate, please see

the

Application Tests

section. The accumulator oil

return orifice should be from .040 to .055 inches (1 –

1.4mm) in diameter depending on compressor size

and compressor flood back results. A large-area

protective screen no finer than 30x30 mesh (0.6mm

openings) is required to protect this small orifice from

plugging. Tests have shown, that in the presence of

very fine debris, a small screen with a fine mesh can

easily become plugged causing oil starvation to the

compressor bearings. The size of the accumulator

depends upon the operating range of the system and

the amount of sub cooling and subsequent head

pressure allowed by the refrigerant control. System

modeling indicates that heat pumps that operate down

to and below 0°F (-18°C) will require an accumulator

that can hold around 70% to 75% of the system

charge. Behavior of the accumulator and its ability to

prevent liquid slugging and subsequent oil pump-out

at the beginning and end of the defrost cycle should

be assessed during system development. This will

require special accumulators and compressors with

sight tubes and/or sight glasses for monitoring

refrigerant and oil levels.

Screens

Screens finer than 30x30 mesh (.06mm openings)

should not be used anywhere in the system with these

compressors. Field experience has shown that finer

mesh screens used to protect thermal expansion

valves, capillary tubes, or accumulators can become

temporarily or permanently plugged with normal

system debris and block the flow of either oil or

refrigerant to the compressor. Such blockage can

result in compressor failure.

Crankcase Heat - Single Phase

A crankcase heater is

recommended

on single phase

compressors when the system charge amount exceeds

the limit shown in

Table 3

. A crankcase heater is

required

for systems containing more than 120% of

the compressor refrigerant charge limit listed in

Table

3

. This includes long line length systems where the

extra charge will increase the standard factory charge

above the 120% limit.

Experience has shown that compressors may fill with

liquid refrigerant under certain circumstances and

system configurations, notably after long off cycles

when the compressor has cooled. This may cause

excessive start-up clearing noise; or the compressor

may start and trip the internal overload protector

several times before running. The addition of a

crankcase heater will reduce customer noise and

dimming light complaints since the compressor will no

longer have to clear out liquid during starting.

Table 4

lists the crankcase heaters recommended for the

various models and voltages. voltages.

WARNING!

Crankcase heaters must be properly grounded.

The

heater should be installed on the compressor shell as

shown in

Figure 4

. Ideally the heater would come

together for clamping with the vertical shell seam weld

coming up through the area where the crankcase

heater is clamped together. See

Figure 4

for details.

Tighten the clamp screw carefully, ensuring that the

heater is uniformly tensioned along its entire length

and that the circumference of the heater element is in

complete contact with the compressor shell. It's

important that the clamp screw is torqued to the range

of 20-25 in-lb (2.3-8 N m) to ensure adequate contact

and to prevent heater burnout. Never apply power to a

heater in free air or before the heater is installed on the

Page 8

© 2020 Emerson Climate Technologies, Inc.

8

AE4-1365 R5

compressor to prevent overheating and burnout.

Crankcase Heat - Three Phase

A crankcase heater is

required

for three-phase

compressors when the system charge amount exceeds

the compressor charge limit listed in

Table 3.

Pump Down Cycle

A pump down cycle for control of refrigerant migration is

not recommended for scroll compressors of this size.

If

a pump down cycle is used, a separate discharge

line check valve must be added.

The scroll

compressor’s discharge check valve is designed to stop

extended reverse rotation and prevent high-pressure

gas from leaking rapidly into the low side after shut off.

Minimum Run Time

There is no set answer to how often scroll

compressors can be started and stopped in an hour,

since it is highly dependent on system configuration.

Other than the considerations in the section on

Brief

Power Interruptions

, there is no minimum off time

because Copeland Scroll compressors start unloaded,

even if the system has unbalanced pressures. The

most critical consideration is the minimum run time

required to return oil to the compressor after startup.

To establish the minimum run time, obtain a sample

compressor equipped with a sight tube (available from

Emerson) and install it in a system with the longest

connecting lines that are approved for the system. The

minimum on time becomes the time required for oil

lost during compressor startup to return to the

compressor sump and restore a minimal oil level that

will assure oil pick up through the crankshaft. Cycling

the compressor for a shorter period than this, for

instance to maintain very tight temperature control, will

result in progressive loss of oil and damage to the

compressor. See

AE17-1262

for more information on

preventing compressor short cycling.

Reversing Valves

Since Copeland Scroll compressors have very high

volumetric efficiency, their displacements are lower

than those of comparable capacity reciprocating

compressors.

CAUTION Reversing valve sizing

must be within the guidelines of the valve

manufacturer. Required pressure drop to ensure

valve shifting must be measured throughout the

operating range of the unit and compared to the

valve manufacturer's data. Low ambient heating

conditions with low flow rates and low pressure

drop across the valve can result in a valve not

shifting. This can result in a condition where the

compressor appears to be not pumping (i.e.

balanced pressures). It can also result in elevated

compressor sound levels.

During a defrost cycle,

when the reversing valve abruptly changes the

refrigerant flow direction, the suction and discharge

pressures will go outside of the normal operating

envelope. The sound that the compressor makes

during this transition period is normal, and the duration

of the sound will depend on the coil volume, outdoor

ambient, and system charge. The preferred method of

mitigating defrost sound is to shut down the

compressor for 20 to 30 seconds when the reversing

valve changes position going into and coming out of

the defrost cycle. This technique allows the system

pressures to reach equilibrium without the compressor

running. The additional start-stop cycles do not

exceed the compressor design limits, but suction and

discharge tubing design should be evaluated.

The reversing valve solenoid should be wired so that

the valve does not reverse when the system is shut off

by the operating thermostat in the heating or cooling

mode. If the valve is allowed to reverse at system

shutoff, suction and discharge pressures are reversed

to the compressor. This results in pressures equalizing

through the compressor which can cause the

compressor to slowly rotate backwards until the

pressures equalize. This condition does not affect

compressor durability but can cause unexpected

sound after the compressor is turned off.

Low Ambient Cut-Out

Because of internal discharge temperature protection,

a low ambient cut-out is not required to limit air-to air

heat pump operation. Air-to-water heat pumps must

be reviewed since this configuration could possibly run

outside of the approved operating envelope (

Figure 1

)

causing overheating or excessive wear.

Oil Type

POE may cause an allergic skin reaction and must

be handled carefully and the proper protective

equipment (gloves, eye protection, etc.) must be

used when handling POE lubricant. POE must not

come into contact with any surface or material that

might be harmed by POE, including without

limitation, certain polymers (e.g. PVC/ CPVC and

polycarbonate). Refer to the Safety Data Sheet

(SDS) for further details.).

Polyol ester (POE) oil is used in these compressors.

See the compressor nameplate for the original oil

charge. A complete recharge should be approximately

four fluid ounces (118 ml) less than the nameplate

value. Copeland™ Ultra 32-3MAF, available from

Emerson Wholesalers, should be used if additional oil

is needed in the field. Mobil Arctic EAL22CC,

Page 9

© 2020 Emerson Climate Technologies, Inc.

9

AE4-1365 R5

Emkarate RL22, Emkarate 32CF and Emkarate 3MAF

are acceptable alternatives.

Contaminant Control

Copeland Scroll compressors leave the factory with a

miniscule amount of contaminants. Manufacturing

processes have been designed to minimize the

introduction of solid or liquid contaminants.

Dehydration and purge processes ensure minimal

moisture levels in the compressor and continuous

auditing of lubricant moisture levels ensure that

moisture isn’t inadvertently introduced into the

compressor.

It is generally accepted that system moisture levels

should be maintained below 50 ppm.

A filter-drier is

required on all R-410A and POE lubricant systems

to prevent solid particulate contamination, oil

dielectric strength degradation, ice formation, and

oil hydrolysis and metal corrosion.

It is the system

designer’s responsibility to make sure the filter-drier is

adequately sized to accommodate the contaminants

from system manufacturing processes that leave solid

or liquid contaminants in the evaporator coil,

condenser coil, and interconnecting tubing plus any

contaminants introduced during the field installation

process. Molecular sieve and activated alumina are

two filter-drier materials designed to remove moisture

and mitigate acid formation. A 100% molecular sieve

filter can be used for maximum moisture capacity. A

more conservative mix of molecular sieve and

activated alumina, such as 75% molecular sieve and

25% activated alumina, should be used for service

applications.

Long Line Sets/High Refrigerant Charge

Some system configurations may contain higher-thannormal refrigerant charges either because of large

internal coil volumes or long line sets. If such a system

also contains an accumulator then the permanent loss

of oil from the compressor may become critical. If the

system contains more than 20 pounds (9 kg) of

refrigerant, it is our recommendation to add one fluid

ounce of oil for every 5 pounds (15 ml/kg) of

refrigerant over this amount. This recommendation is

a starting point if additional oil is required and the final

amount should be determined in the end use

application. Compressors with sight-glasses should

have their oil levels checked only when the

compressor is off, not while the compressor is running.

If the system contains an accumulator the

manufacturer of the accumulator should be consulted

for a pre-charge recommendation.

Other system components such as shell and tube

evaporators can trap significant quantities of oil and

should be considered in overall oil requirements.

Reheat coils and circuits that are inactive during part

of the normal cycle can trap significant quantities of oil

if system piping allows the oil to fall out of the

refrigerant flow into an inactive circuit. The oil level

must be carefully monitored during system

development, and corrective action should be taken if

the compressor oil level falls below the top of the

lower bearing bracket for more than two minutes. The

lower bearing bracket weld points on the compressor

shell can be used as a low-oil-level marker.

Discharge Mufflers

Flow through Copeland Scroll compressors is semicontinuous with relatively low pulsation. Because of

variability between systems, however, individual

system tests should be performed to verify

acceptability of sound performance. When no testing

is performed, mufflers are recommended in heat

pumps. The mufflers should be located a minimum of

six inches (15 cm) to a maximum of 18 inches (46 cm)

from the compressor for most effective operation. The

farther the muffler is placed from the compressor

within these ranges the more effective it may be. If

adequate attenuation is not achieved, use a muffler

with a larger cross-sectional area to inlet-area ratio.

Air Conditioning System Suction Line Noise and

Vibration

The vibration characteristics of the scroll compressor,

although low, include two very close frequencies.

These frequencies, which are present in all

compressors, may result in a low level “beat”

frequency that may be detected as noise coming

along the suction line into a house under some

conditions. Elimination of the “beat” can be achieved

by attenuating either of the contributing frequencies.

The most important frequencies to avoid are 50 and

60 Hz power supply line and twice-line frequencies for

single-phase compressors and line frequency for three

phase compressors. This is easily done by using one

of the common combinations of design configuration

described in

Table 2.

The scroll compressor makes

both a rocking and torsional motion, and enough

flexibility must be provided in the line to prevent

vibration transmission into any lines attached to the

unit. In a split system the most important goal is to

ensure minimal vibration is all directions at the service

valve to avoid transmitting vibrations to the structure to

which the lines are fastened.

Under some conditions the normal rotational starting

motion of the compressor can transmit an “impact”

noise along the suction line. This may be particularly

pronounced in three-phase models due to their

inherently higher starting torque. This phenomenon,

like the one described previously, also results from the

lack of internal suspension, and can be easily avoided

Page 10

© 2020 Emerson Climate Technologies, Inc.

10

AE4-1365 R5

by using standard suction line isolation techniques as

described in

Table 2

.

The sound phenomena described above are not

usually associated with heat pump systems because of

the isolation and attenuation provided by the reversing

valve and tubing bends.

Mounting Parts

Table 4

lists the mounting parts to be used with these

compressors. Many OEM customers buy the mounting

parts directly from the supplier, but Emerson’s

grommet design and durometer recommendation

should be followed for best vibration reduction through

the mounting feet. Please see

AE4-1111

for grommet

mounting suggestions and supplier addresses.

Electrical Connections

A molded electrical plug must be used with all -1XX

and -8XX compressor bills of material. The molded

plug must be installed by hand or with an approved

installation tool. A hammer must not be used to

install the plug.

Three different electrical connections are used within

this compressor family as illustrated in the matrix on

Page 4.

NOTICE The molded plug for the ZP104-122KC

compressors is larger and will not fit on smaller

compressors in this family. Refer to Table 4 for the

correct part number. When a molded plug is used

with ZP92-122KC compressors the terminal cover

must be also be used. This is not the case for

smaller compressors with the round terminal fence.

CAUTION Never operate the compressor without

the terminal box cover installed.

Deep Vacuum Operation

Copeland Scroll compressors (as with any

refrigerant compressor) should never be used to

evacuate a refrigeration or air conditioning system.

The scroll compressor can be used to pump down

refrigerant in a unit as long as the pressures remain

within the operating envelope shown in

Figure 1.

Prolonged operation at low suction pressures will result

in overheating of the scrolls and permanent damage to

the scroll tips, drive bearing and internal seal. See

AE24-1105

for proper system evacuation procedures.

Shell Temperature

Compressor top cap temperatures can be very hot.

Care must be taken to ensure that wiring or other

materials which could be damaged by these

temperatures do not come into contact with these

potentially hot areas.

Certain types of system failures, such as condenser or

evaporator fan blockage or loss of charge, may cause

the top shell and discharge line to briefly or repeatedly

reach temperatures above 350°F (177°C) as the

compressor cycles on its internal overload protection

device. Care must be taken to ensure that wiring or

other materials which could be damaged by these

temperatures do not come into contact with these

potentially hot areas.

Suction and Discharge Fittings

Copeland Scroll compressors have copper plated steel

suction and discharge fittings. These fittings are far

more rugged and less prone to leaks than copper

fittings used on other compressors. Due to the different

thermal properties of steel and copper, brazing

procedures may have to be changed from those

commonly used. See

Figure 7

for assembly line and

field brazing recommendations.

System Tubing Stress

System tubing should be designed to keep tubing

stresses below 9.5 ksi (62 MPa), the endurance limit of

copper tubing. Start, stop and running (resonance)

cases should be evaluated.

Three Phase Scroll Compressor Electrical Phasing

Copeland Scroll compressors, like several other types

of compressors, will only compress in one rotational

direction. Direction of rotation is not an issue with

single phase compressors since they will always start

and run in the proper direction (except as described in

the section “Brief Power Interruptions”). Three phase

compressors will rotate in either direction depending

upon phasing of the power. Since there is a 50%

chance of connecting power in such a way as to cause

rotation in the reverse direction,

it is important to

include notices and instructions in appropriate

locations on the equipment to ensure that proper

rotation direction is achieved when the system is

installed and operated.

Verification of proper rotation

direction is made by observing that suction pressure

drops and discharge pressure rises when the

compressor is energized. Reverse rotation will result in

no pressure differential as compared to normal values.

Page 11

© 2020 Emerson Climate Technologies, Inc.

11

AE4-1365 R5

A compressor running in reverse will sometimes make

an abnormal sound.

There is no negative impact on durability caused by

operating three phase Copeland Scroll compressors in

the reversed direction for a short period of time (under

one hour). After several minutes of reverse operation,

the compressor’s internal overload protector will trip

shutting off the compressor. If allowed to repeatedly

restart and run in reverse without correcting the

situation, the compressor bearings will be permanently

damaged because of oil loss to the system. All threephase scroll compressors are wired identically

internally. As a result, once the correct phasing is

determined for a specific system or installation,

connecting properly phased power leads to the

identified compressor electrical (Fusite™) terminals will

maintain the proper rotational direction. It should be

noted that all three phase scrolls will continue to run in

reverse until the internal overload protector opens or

the phasing is corrected.

Brief Power Interruptions

Brief power interruptions (less than ½ second) may

result in powered reverse rotation of single-phase

Copeland Scroll compressors. This occurs because

high-pressure discharge gas expands backward

through the scrolls during interruption, causing the

scroll to orbit in the reverse direction. When power is

reapplied while reverse rotation is occurring, the

compressor may continue to run in the reverse

direction for some time before the compressor’s

internal overload trips. This will not cause any damage

to the compressor, and when the internal overload

resets, the compressor will start and run normally.

To avoid disruption of operation, an electronic control

that can sense brief power interruptions may be used

to lock out the compressor for a short time. This

control could be incorporated in other system controls

(such as defrost control board or the system

thermostat), or can be a stand-alone control. No time

delay is necessary for three phase models since the

motor starting torque is high enough to overcome

reverse rotation.

Manifolding Tandem Compressors

Tandem compressor assemblies are available for

purchase from Emerson. In lieu of purchasing the

assembled tandem, the OEM can choose to purchase

the tandem ready compressor and perform the

assembly. All of the ZP*KC compressors are available

for manifolding with another ZP*KC compressor of

equal capacity. Some tandems are assembled with

compressors of unequal capacity, check with

application engineering or on-line product information

for availability. Tandem ready compressors are

designated with a -4XX bill of material number at the

end of the model number (e.g. ZP61KCE-TFD-420).

See

Figure 5

for a picture of an assembled tandem

showing the hardware and parts required for assembly.

Drawings of tandem tubing assemblies are available

from Emerson Climate Technologies by contacting

your Application Engineer.

Tandem Applications

Tandem compressors follow the same application

guidelines as single compressors outlined in this

bulletin. The refrigerant charge limit for tandem

compressors is shown in

Table 3

. Crankcase heaters

must

be installed on each compressor in the tandem

set when the system charge amount exceeds the

tandem charge limit.

The compressors in a tandem set can be

started/stopped in any desired sequence. To help

reduce the probability of light dimming and to reduce

inrush current, starting the compressors individually is

recommended. Should a compressor fail in the tandem

set the complete tandem should be removed from the

unit and replaced with a new tandem set. Replacing

individual compressors is discouraged because of the

care that must be used when installing the oil

equalization tube and the availability of manifolds to

the aftermarket.

APPLICATION TESTS

Application Test Summary

There are a number of tests the system designer will

want to run to ensure the system operates as

designed. These tests should be performed during

system development and are dependent on the

system type and amount of refrigerant charge. These

application tests are to help identify gross errors in

system design that may produce conditions that could

lead to compressor failure. The Continuous Floodback

Test and Field Application Test, both outlined below,

are two tests to run to help verify the design. When to

run these tests can be summarized as follows:

Continuous Floodback

:

Required on all heatpumps.

Field Application Test

:

Required for any unit where both the design

system charge is higher than the compressor

refrigerant charge limit listed in

Table 3

; and a

capillary tube, fixed orifice, or bleed-type TXV is

used on either the indoor or the outdoor coil of the

unit.

Page 12

© 2020 Emerson Climate Technologies, Inc.

12

AE4-1365 R5

Continuous Floodback Test

It is expected that the design would not flood during

standard air conditioning operation. Running a partially

blocked indoor air filter or loss of evaporator air flow

test and comparing the sump temperature results to

Figure 2

is recommended. The use of a TXV in

heating does not guarantee operation without flood

back in the lower end of the unit/TXV operating range.

To test for excessive continuous liquid refrigerant flood

back, it is necessary to operate the system in a test

room at conditions where steady state flood back may

occur (low ambient heating operation). Thermocouples

should be attached with glue or solder to the center of

the bottom shell and to the suction and discharge lines

approximately 6 inches (15 cm) from the shell. These

thermocouples should be insulated from the ambient

air with Permagum® or other thermal insulation to be

able to record true shell and line temperatures. If the

system is designed to be field charged, it should be

overcharged by 15% in this test to simulate

overcharging often found in field installations.

The system should be operated at an indoor

temperature of 70°F (21°C) and outdoor temperature

extremes of 10°F (-12°C) or lower in heating to

produce flood back conditions. The compressor suction

and discharge pressures and temperatures as well as

the sump temperature should be recorded. The system

should be allowed to frost up for several hours

(disabling the defrost control and spraying water on the

outdoor coil may be necessary) to cause the saturated

suction temperature to fall below 0°F (-18°C). The

compressor sump temperature must remain above the

sump temperature shown in

Figure 2

or design

changes must be made to reduce the amount of flood

back. If an accumulator is used, this test can be used

to test the effectiveness of the accumulator. Increasing

indoor coil volume, increasing outdoor air flow,

reducing refrigerant charge, decreasing capillary or

orifice diameter, and adding a charge compensator can

also be used to reduce excessive continuous liquid

refrigerant flood back.

Field Application Test

To test for repeated, excessive liquid flood back during

normal system off-cycles, perform the

Field

Application Test

that is outlined in

Table 1

. Obtain a

sample compressor with a sight-tube to measure the

liquid level in the compressor when it is off.

Note: The sight-tube is not a good liquid level indicator

when the compressor is running because the top of the

sight-tube is at a lower pressure than the bottom

causing a higher apparent oil level.

Set the system up in a configuration with the indoor

unit elevated several feet above the outdoor unit with a

minimum of 25 feet (8 meters) of connecting tubing

with no traps between the indoor and outdoor units. If

the system is designed to be field charged, the system

should be overcharged by 15% in this test to simulate

field overcharging. Operate the system in the cooling

mode at the outdoor ambient, on/off cycle times, and

number of cycles specified in

Table 1

. Record the

height of the liquid in the compressor at the start of

each on cycle, any compressor overload trips, or any

compressor abnormal starting sounds during each test.

Review the results with Application Engineering to

determine if an accumulator or other means of off cycle

migration control are required.

This test does not

eliminate the requirement for a crankcase heater if

the system charge level exceeds the values in

Table 3

. The criteria for pass/fail is whether the liquid

level reaches the level of the compressor suction tube

connection. Liquid levels higher than this can allow

refrigerant/oil to be ingested by the scrolls and pumped

out of the compressor after start-up.

The tests outlined above are for the common air

conditioning and heat pump applications of

compressors in this family. Many other

applications of the compressors exist, and tests to

effectively evaluate those applications and designs

can’t possibly be covered in this bulletin. Please

consult with Application Engineering on

applications outside of those outlined above for

the appropriate application tests.

ASSEMBLY LINE PROCEDURES

Installing the Compressor

Use care and the appropriate material handling

equipment when lifting and moving compressors.

Personal safety equipment must be used.

Copeland Scroll compressors leave the factory

dehydrated, with a dry air holding charge. If

compressors are stored in a cold ambient (i.e. outside

during the winter), the suction and discharge plugs

should not be removed until the compressor has had

sufficient time to warm up to the plant ambient

temperature. The suggested warm up time is one hour

per 4°F (2K) difference between outdoor and indoor

temperature. It is suggested that the larger suction plug

Page 13

© 2020 Emerson Climate Technologies, Inc.

13

AE4-1365 R5

be removed first to relieve the internal pressure.

Removing the smaller discharge plug could result in a

spray of oil out of this fitting since some oil

accumulates in the head of the compressor after

Emerson’s run test. The inside of both fittings should

be wiped with a lint free cloth to remove residual oil

prior to brazing. A compressor containing POE oil

should never be left open longer than 20 minutes.

Assembly Line Brazing Procedure

Personal safety equipment must be used during

brazing operation. Heat shields should be used to

prevent overheating or burning nearby temperature

sensitive parts. Fire extinguishing equipment

should be accessible in the event of a fire.

Figure 7

discusses the proper procedures for brazing

the suction and discharge lines to a scroll compressor.

NOTICE It is important to flow nitrogen through the

system while brazing all joints during the system

assembly process.

Nitrogen displaces the air and

prevents the formation of copper oxides in the system.

If allowed to form, the copper oxide flakes can later be

swept through the system and block screens such as

those protecting capillary tubes, thermal expansion

valves, and accumulator oil return holes. Any blockage

of oil or refrigerant may damage the compressor

resulting in failure.

Tandem Assembly

When lifting tandem compressor assemblies, both

compressors must be lifted by their respective

lifting rings. Use care and exercise extreme

caution when lifting and moving compressors.

Personal safety equipment must be used.

The first step in the tandem assembly process is to

securely mount both compressors to the rails using the

appropriate mounting hardware listed in

Table 4

. After

both compressors are mounted to the rails, the suction,

discharge, and gas equalization manifolds can be

brazed to the appropriate stub tubes of each

compressor using standard brazing practices with a

nitrogen purge. Special consideration needs to be

given to the oil equalization line that connects the oil

sumps of the two compressors. The ZP92-122KC

compressors have oil fittings that are different than

other compressors in this family. For tandem

applications the 1/4" Schrader fitting should be

removed from the oil fittings so the oil equalization line

can be attached via rotalock connection or brazing.

The oil in the single, tandem ready compressor is

located at the center of the oil equalization fitting. After

both compressors are mounted to the compressor rails

and prior to removing the rubber plug in the oil

equalization stubs, the assembly should be tilted back

a minimum of 12° from horizontal (see

Figure 6

) to

move the oil level away from the oil equalization fitting

for brazing. The oil equalization stubs of both

compressors should be wiped clean with a lint free

towel to remove any oil residue before brazing.

Pressure Testing

Never pressurize the compressor to more than 475

psig (33 bar) for leak checking purposes. Never

pressurize the compressor from a nitrogen

cylinder or other pressure source without an

appropriately sized pressure regulating and relief

valve.

The pressure used on the line to meet the UL burst

pressure requirement must not be higher than 475 psig

(33 Bar). Higher pressure may result in permanent

deformation of the compressor shell and possible

misalignment or bottom cover distortion.

Assembly Line System Charging Procedure

Systems should be charged with liquid on the high side

to the extent possible. The majority of the charge should

be pumped in the high side of the system to prevent low

voltage starting difficulties, hipot failures, and bearing

washout during the first-time start on the assembly line.

If additional charge is needed, it should be added as

liquid

to the low side of the system with the compressor

operating. Pre-charging on the high side and adding

liquid on the low side of the system are both meant to

protect the compressor from operating with abnormally

low suction pressures during charging.

NOTICE Do not

operate the compressor without enough system

charge to maintain at least 55 psig (3.8 bar) suction

pressure. Do not operate the compressor with the

low pressure cut-out disabled. Do no operate with a

restricted suction or liquid line.

Depending on the

discharge pressure, allowing pressure to drop below 55

psig (3.8 bar) for more than a few seconds may

overheat the scrolls and cause early drive bearing

damage.

NOTICE Do not use the compressor to test

the opening set point of a high pressure cutout.

Bearings are susceptible to damage before they have

had several hours of normal running for proper break in.

Page 14

© 2020 Emerson Climate Technologies, Inc.

14

AE4-1365 R5

“Hipot” (AC High Potential) Testing

Use caution with high voltage and never hipot

when compressor is in a vacuum.

Copeland Scroll compressors are configured with the

motor down and the pumping components at the top of

the shell. As a result, the motor can be immersed in

refrigerant to a greater extent than hermetic

reciprocating compressors when liquid refrigerant is

present in the shell. In this respect, the scroll is more

like semi-hermetic compressors that have horizontal

motors partially submerged in oil and refrigerant.

When Copeland Scroll compressors are hipot tested

with liquid refrigerant in the shell, they can show

higher levels of leakage current than compressors with

the motor on top. This phenomenon can occur with

any compressor when the motor is immersed in

refrigerant. The level of current leakage does not

present any safety issue. To lower the current leakage

reading, the system should be operated for a brief

period of time to redistribute the refrigerant to a more

normal configuration and the system hipot tested

again. See

AE4-1294

for megohm testing

recommendations.

Under no circumstances should

the hipot test be performed while the compressor

is under a vacuum.

Final Run Test

Customers that use a nitrogen final run test must be

careful to not overheat the compressor. Nitrogen is not

a good medium for removing heat from the

compressor, and the scroll tips can be easily damaged

with high compression ratios and/or long test times.

Copeland Scroll compressors are designed for use

with refrigerant, and testing with nitrogen may result in

a situation where the compressor does not develop a

pressure differential (no pump condition). When

testing with nitrogen, the compressor must be allowed

to cool for several minutes between tests.

Single phase scrolls with an electrical nomenclature of

“PFV” (208-230 volt, 1Ø, 60 Hertz) at the end of the

model number are guaranteed to start at 187 volts or

higher and must have a voltage no lower than 197

volts once the compressor is running under load. All

other compressor voltages, both single and three

phase, 50 & 60 Hertz are guaranteed to start and run

at 10% below the lowest voltage shown on the

nameplate.

Variable transformers used on assembly lines are

often incapable of maintaining the starting voltage

when larger compressors are tested. To test for

voltage sag during starting, the first compressor in a

production run should be used to preset the voltage.

Remove the start wire from the compressor and apply

200 volts to the compressor. With the start winding

removed, the compressor will remain on locked rotor

long enough to read the supply voltage. If the voltage

sags below the minimum guaranteed starting voltage,

the variable transformer must be reset to a higher

voltage. When discussing this starting amperage it

should be noted that “inrush current” and locked rotor

amps (LRA) are one and the same. The nameplate

LRA is determined by physically locking a compressor

and applying the highest nameplate voltage to the

motor. The amperage that the motor draws after four

seconds is the value that is used on the nameplate.

Since there is a direct ratio between voltage and

locked rotor amperage, the lower the line voltage used

to start the compressor, the lower the locked rotor

amperage will be.

Unbrazing System Components

Before attempting to braze, it is important to

recover all refrigerant from both the high and low

side of the system.

If the refrigerant charge is removed from a scrollequipped unit by recovering one side only, it is very

possible that either the high or low side of the system

remains pressurized. If a brazing torch is then used to

disconnect tubing, the pressurized refrigerant and oil

mixture could ignite when it escapes and contacts the

brazing flame. Instructions should be provided in

appropriate product literature and assembly (line

repair) areas. If compressor removal is required, the

compressor should be cut out of the system rather than

unbrazed. See

Figure 7

for proper compressor

removal procedure.

SERVICE PROCEDURES

Copeland Scroll Compressor Functional Check

A functional compressor test during which the suction

service valve is closed to check how low the

compressor will pull the suction pressure is not a good

indication of how well a compressor is performing.

NOTICE Such a test will damage a scroll

compressor in a few seconds.

The following

diagnostic procedure should be used to evaluate

whether a Copeland Scroll compressor is functioning

properly:

Proper voltage to the unit should be verified.

Determine if the internal motor overload has opened

or if an internal motor short or ground fault has

Page 15

© 2020 Emerson Climate Technologies, Inc.

15

AE4-1365 R5

developed. If the internal overload has opened,

the compressor must be allowed to cool

sufficiently to allow it to reset.

Check that the compressor is correctly wired.

Proper indoor and outdoor blower/fan operation

should be verified.

With service gauges connected to suction and

discharge pressure fittings, turn on the

compressor. If suction pressure falls below

normal levels the system is either low on charge

or there is a flow blockage in the system.

Single phase compressors

– If the compressor

starts and the suction pressure does not drop and

discharge pressure does not rise to normal levels,

either the reversing valve (if so equipped) or the

compressor is faulty. Use normal diagnostic

procedures to check operation of the reversing

valve.

Three phase compressors

– If suction

pressure does not drop and discharge pressure

does not rise to normal levels, reverse any two of

the compressor power leads and reapply power to

make sure the compressor was not wired to run in

reverse. If pressures still do no move to normal

values, either the reversing valve (if so equipped)

or the compressor is faulty. Reconnect the

compressor leads as originally configured and

use normal diagnostic procedures to check

operation of the reversing valve.

To test if the compressor is pumping properly, the

compressor current draw must be compared to

published compressor performance curves using

the operating pressures and voltage of the

system. If the measured average current deviates

more than +/-20% from published values, a faulty

compressor may be indicated. A current

imbalance exceeding 20% of the average on the

three phases of a three-phase compressor should

be investigated further. A more comprehensive

trouble-shooting sequence for compressors and

systems can be found in Section H of the

Emerson Climate Technologies

Electrical

Handbook, Form No. 6400.

Before replacing or returning a compressor, be certain

that the compressor is actually defective. As a

minimum, recheck compressors returned from the

field in the shop or depot by testing for a

grounded, open or shorted winding and the ability

to start. The orange tag in the service compressor

box should be filled out and attached to the failed

compressor to be returned. The information on

this tag is captured in our warranty data base.

Compressor Replacement After a Motor Burn

In the case of a motor burn, the majority of

contaminated oil will be removed with the compressor.

The rest of the oil is cleaned with the use of suction

and liquid line filter driers. A 100% activated alumina

suction filter drier is recommended but must be

removed after 72 hours. See

AE24-1105

for clean up

procedures and

AE11-1297

for liquid line filter-drier

recommendations.

NOTICE It is highly

recommended that the suction accumulator be

replaced if the system contains one.

This is because

the accumulator oil return orifice or screen may be

plugged with debris or may become plugged shortly

after a compressor failure. This will result in starvation

of oil to the replacement compressor and a second

failure. The system contactor should be inspected for

pitted/burnt contacts and replaced if necessary. It is

highly recommended that the run capacitor be replaced

when a single phase compressor is replaced.

Start-Up of a New or Replacement Compressor:

It is good service practice, when charging a system with

a scroll compressor, to charge liquid refrigerant into the

high side only. It is not good practice to dump liquid

refrigerant from a refrigerant cylinder into the crankcase

of a stationary compressor. If additional charge is

required, charge liquid into the low side of the system

with the compressor operating.

CAUTION Do not start

the compressor while the system is in a deep

vacuum.

Internal arcing may occur when any type of

compressor is started in a vacuum.

NOTICE Do not

operate the compressor without enough system

charge to maintain at least 55 psig (3.8 bar) suction

pressure. Do not operate with a restricted suction or

liquid line. Do not operate with the low pressure cutout disabled.

Allowing suction pressure to drop below

55 psig (3.8 bar) for more than a few seconds may

overheat the scrolls and cause early drive bearing

damage. Never install a system in the field and leave it

unattended with no charge, a holding charge, or with the

service valves closed without securely locking out the

system. This will prevent unauthorized personnel from

accidentally ruining the compressor by operating with no

refrigerant flow.

Page 16

© 2020 Emerson Climate Technologies, Inc.

16

Figure 1 – Operating Envelope

Figure 1a – Operating Envelope

Figure 1b - Operating Envelope

Figure 1 - Operating Envelope

Page 17

© 2020 Emerson Climate Technologies, Inc.

17

AE4-1365 R5

Figure 2 - Oil Dilution Chart

Note 1:

Operation in this refrigerant dilution area is safe in air-to-air heat pump heating mode. For other applications, such as

AC only, review expansion device to raise superheat. A cold sump may result in high refrigerant migration after shut down.

Page 18

© 2020 Emerson Climate Technologies, Inc.

18

AE4-1365 R5

Figure 4 - Crankcase Heater

Connect the heater so that the connection point straddles the compressor seam weld.

Verify the correct

crankcase heater voltage

for the application and

ensure heater is properly

grounded.

Figure 3 - ASTP Label

Page 19

© 2020 Emerson Climate Technologies, Inc.

19

AE4-1365 R5

Figure 5 - Typical ZP*KC Tandem

Figure 6 - Tilted Tandem

Page 20

© 2020 Emerson Climate Technologies, Inc.

20

AE4-1365 R5

Figure 7- Scroll Suction Tube Brazing

New Installations

•

The copper-coated steel suction tube on scroll

compressors can be brazed in approximately the

same manner as any copper tube.

• Recommended brazing materials: Any silfos

material is recommended, preferably with a

minimum of 5% silver. However, 0% silver is

acceptable.

• Be sure suction tube fitting I.D. and suction tube

O.D. are clean prior to assembly. If oil film is

present wipe with denatured alcohol, DichloroTrifluoroethane or other suitable solvent.

• Using a double-tipped torch apply heat in Area 1. As

tube approaches brazing temperature, move torch

flame to Area 2.

• Heat Area 2 until braze temperature is attained,

moving torch up and down and rotating around tube

as necessary to heat tube evenly. Add braze

material to the joint while moving torch around joint

to flow braze material around circumference.

• After braze material flows around joint, move torch

to heat Area 3. This will draw the braze material

down into the joint. The time spent heating Area 3

should be minimal.

• As with any brazed joint, overheating may be

detrimental to the final result.

Field Service

Remove refrigerant charge from both the low and

high side of the compressor before cutting the

suction and discharge lines to remove the

compressor. Verify the charge has been

completely removed with manifold gauges.

•

To disconnect: Reclaim refrigerant from both the

high and low side of the system. Cut tubing near

compressor.

• To reconnect:

•

Recommended brazing materials: Silfos with

minimum 5% silver or silver braze material with

flux.

•

Insert tubing stubs into fitting and connect to

the system with tubing connectors.

• Follow New Installation brazing

Page 21

© 2020 Emerson Climate Technologies, Inc.

21

Figure 8- How Scroll Works

Page 22

© 2020 Emerson Climate Technologies, Inc.

22

AE4-1365 R5

Table 1 - Field Application Test

Outdoor Ambient

85°F (29°C)

95°F (35°C)

105°F (40°C)

System On-Time (Minutes)

7

14

54

System Off-Time (Minutes)

13 8 6

Number of On/Off Cycles

5 5 4

Table 2 - Design Configurations

Recommended Configuration

Component

Description

Tubing Configuration

Shock loop

Service Valve

"Angled valve" fastened to unit

Suction muffler

Not required

Alternate Configuration

Component

Description

Tubing Configuration

Shock loop

Service Valve

"Straight through" valve not fastened to unit

Mass / Suction muffler

May be required (Acts as dampening mass)

Table 3 - Compressor Refrigerant Charge Limits

Model

Frame

Size*

Charge Limit

120% x Limit**

Tandem Charge Limit

Pounds

kg

Pounds

kg

Pounds

kg

ZP50 - 57K3

ZP70 - 83KW

ZP61 - 91KC

70

10.0

4.5

12.0

5.4

12.0

5.4

ZP104-122KC

ZP143KC

11.0

5.0

13.0

6.0

13.0

6.0

Page 23

© 2020 Emerson Climate Technologies, Inc.

23

AE4-1365 R5

Table 4 - Compressor Accessories

Part

Category

Part Description

Part Number

Models Notes

Mounti

ng

Compressor Mounting Kit

527-0116-00

ZP50-57K3

ZP61-83KC

ZP70-83KW

35-45 Durometer

Compressor Mounting Kit

527-0221-00

ZP91-143KC

35-45 Durometer

Oil

POE Oil

32-3MAF

All Models

Purchase From Emerson Wholesaler

Oil Adjustment Fitting

510-0715-00

ZP104-143KC

Oil Sight-Glass

070-0040-00

Sight-Glass Rotalock Nut

005-1514-00

O-Ring Seal For Sight-Glass

020-0028-05

Crankcase Heater

Crankcase Heater, 240V, 70W

018-0095-00

All Models

21" Leads

Crankcase Heater, 480V, 70W

018-0095-01

21" Leads

Crankcase Heater, 575V, 70W

018-0095-02

21" Leads

Crankcase Heater, 120V, 70W

018-0095-07

48" Leads

Crankcase Heater, 400V, 70W

018-0095-08

48" Leads

Crankcase Heater, 277V, 70W

018-0095-09

21" Leads

Crankcase Heater Junction Box

998-7024-00

All Models

Electric

al

Terminal Cover

005-1213-00

ZP50-57K3

ZP61-91KC

ZP70-83KW

Terminal Cover Gasket

020-0964-00

Terminal Cover

005-1494-00

ZP104-143KC

Terminal Cover Gasket

020-1390-00

Terminal Block

021-0227-03

ZP104-143KC

All Voltages

Terminal Block

021-0234-00

ZP50-57K3

ZP61-91KC

ZP70-83KW

230 Volt Only

Terminal Block

021-0235-00

ZP50-57K3

ZP61-91KC

ZP70-83KW

All Voltages Except 230

Terminal Block Screw

100-0550-01

ZP104-143KC

(3) Required, 10-32 Screw x 1/2"

Terminal Block Screw

100-0550-00

ZP50-57K3

ZP61-91KC

ZP70-83KW

(3) Required, 10-32 Screw x 3/8"

Flag Terminal Kit

998-0021-00

ZP50-57K3

ZP61-83KC

ZP70-83KW

Grounding Screw

100-0605-00

All Models

10-32 x 8mm Long, Taptite Screw

Molded Plug

529-0370-00

ZP50-57K3

ZP61-91KC

ZP70-83KW

Universal Plug, 10 Gauge Wire, 42"

Leads

Molded plug

529-0099-00

ZP104-143KC

8 Gauge Wire, 42" Leads

Molded Plug Retainer Clip

032-0717-00

ZP50-57K3

ZP61-91KC

ZP70-83KW

Optional Part, Locks the Molded Plug

to the Fence

Flexible Metal Conduit Retainer

032-7051-01

Optional Part, Use with 032-0717-00

Run Capacitor

Refer to Online Product Information at

Emerson.com/OPI for Model Specific Requirements

Start Capacitor

Page 24

© 2020 Emerson Climate Technologies, Inc.

24

AE4-1365 R5

Part

Category

Part Description

Part Number

Models Notes

Start Relay

SecureStart™

943-0120-00

ZP50-54K3

1-Phase Only

Diagno

stics & Protection

CoreSense™ Diagnostics

971-0066-00

ZP50-57K3

ZP72KC

ZP70-83KW

2-Wire Module, 1-Phase Only

CoreSense™ Diagnostics

971-0067-00

3-Wire Module, 1-Phase Only

Comfort Alert™ Module

543-0010-01

2-Wire Module, 1-Phase Only

Comfort Alert™ Module

543-0010-01

3-Wire Module, 1-Phase Only

Comfort Alert™ Module

543-0032-00

1-Phase Only, Has "L" Terminal

Comfort Alert™ Module

543-0067-00

1-Phase Only, Geothermal

CoreSense™ Protection

ESC1AFPT-

CC-901

1-Phase Only

Comfort Alert™ Module

543-0038-02

All Models

3-Phase Only

Discharge Line Thermostat

998-7022-02

ZP50-57K3

ZP61-83KC

Fits 1/2" Tube

Discharge Line Thermostat

not available

ZP91KC

Fits 3/4" Tube

Discharge Line Thermostat

998-0071-02

ZP104-143KC

Fits 7/8" Tube

Suction & Discharge

Discharge Rotalock Pipe Plug

036-0008-16

ZP104-143KC

1/8"-27 NPTF

Discharge Rotalock O-Ring Seal

028-0028-00

ZP50-57K3

ZP61-83KC

Discharge Rotalock O-Ring Seal

020-0028-02

ZP91-143KC

Suction Rotalock O-Ring Seal

028-0028-05

ZP50-57K3

ZP61-91KC

Suction Rotalock O-Ring Seal

020-0028-03

ZP104-143KC

Discharge Rotalock Service Valve, 1/2"

998-0510-98

ZP50-57K3

ZP61-83KC

Discharge Rotalock Service Valve, 7/8"

998-0510-90

ZP91-143KC

Suction Rotalock Service Valve, 7/8"

998-0510-90

ZP50-57K3

ZP61-91KC

Suction Rotalock Service Valve, 1-1/8"

998-0510-02

ZP104-143KC

Discharge Rotalock Adapter to 1/2" Sweat

998-0034-18

ZP50-57K3

ZP61-83KC

Discharge Rotalock Adapter to 7/8" Sweat

998-0034-08

ZP91-143KC

Suction Rotalock Adapter to 7/8" Sweat

998-0034-08

ZP50-57K3

ZP61-91KC

Suction Rotalock Adapter to 1-3/8" Sweat

998-0034-10

ZP104-143KC

1/2" Discharge Stub to 1"-14 Rotalock

Adapter

036-0538-00

ZP50-57K3

ZP61-83KC