Page 1

1

AE29-1439 R2

January 2021

E2, E3, Site Supervisor, and XWEB settings for X-lines integration

TABLE OF CONTENTS

Safety Instructions ..................................................... 3

Safety Icon Explanation

Instructions Pertaining to Risk of Electrical Shock,

Fire, or Injury to Persons .......................................... 4

Safety Statements

1. Introduction ......................................................... 5

2. E2 Controller ....................................................... 5

2.1. E2 Controller Family Models and Capabilities

5

2.2. Software Licensing ....................................... 6

2.3. XCM25D Network Setup on Supervisory

Controllers ................................................................ 6

2.4. PC configuration for direct connection to E2 8

2.5. Upload the Description file via UltraSite .... 10

2.6. Final XCM25D integration into E2 Controller

13

2.7. Setup the COM Port for MODBUS............. 15

2.8. Network Wiring ........................................... 15

2.9. Communication Setup – XCM25D ............. 15

2.10. Send Device Configuration to E2 ............... 17

3. E3 / Site Supervisor .......................................... 18

3.1. Housing Dimensions and Mounting ........... 18

3.2. E3 / Site Supervisor Power, Serial, and IO

Positions ................................................................. 20

3.3. XCM25D Network Setup on the E3 / Site

Supervisor .............................................................. 21

3.4. Network Wiring ........................................... 22

3.5. Communication Setup – XCM25D ............. 22

3.6. Communication Setup – E3 / Supervisor ... 23

3.7. Integration File ........................................... 28

4. XWEB EVO ........................................................ 29

4.1. XCM25D Network Setup on XWEB EVO .. 29

4.2. Network Wiring ........................................... 29

6.5. XWEB Library .................................................. 35

10. General Guidelines and More Information . 35

TABLE OF FIGURES

Figure 1 - XCM25D ...................................................... 5

Figure 2 - E2 Enhanced Controller .............................. 5

Figure 3 - E2 Controller Manual Link ........................... 5

2.3.1. Adding the XCM25D to the E2 Controller

7

3.2.1. Site Supervisor Termination Jumpers 21

3.6.1. Setup the COM Port for MODBUS. .... 23

3.6.2. Adding the XCM25D in the E3 /

Supervisor program ............................................ 24

3.6.3. Sending the Device Configuration to the

E3 / Supervisor ................................................... 27

.......................................... 3

................................................... 4

Figure 4 - E2 Front Panel ............................................. 6

Figure 5 - PC Control Panel ......................................... 8

Figure 6 - PC Network and Sharing Center Screen ..... 8

Figure 7 - Ethernet options Submenu .......................... 9

Figure 8 - Network Configuration Screen ..................... 9

Figure 9 - UltraSite Login Screen ............................... 10

Figure 10 - UltraSite Directory Name Screen ............. 11

Figure 11 - E2 Address entering to UltraSite ............. 11

Figure 12 - UltraSite Connection command ............... 12

Figure 13 - Uploading Description file to E2 ............... 12

Figure 14 - Uploading 5270573.dsc file to E2 ............ 13

Figure 15 - E2 Login Screen ...................................... 13

Figure 16 - E2 Add License Screen ........................... 14

Figure 17 – E2 Add Devices Screen .......................... 14

Figure 18 - Modbus Configuration in E2 for X-line

connection .................................................................. 15

Figure 19 - XCM25D Modbus connection with E2 ..... 16

Figure 20 - X-line Unit Address Inclusion Screen ...... 16

Figure 21 - X-line Unit Integration Confirmation Screen

.................................................................................... 17

Figure 22 - Device Configuration sending to E2 ........ 17

Figure 23 - Site Supervisor ......................................... 18

Figure 24 - E3 Controller ............................................ 18

Figure 25 - Site Supervisor Dimensions ..................... 19

Figure 26 - Site Supervisor Detail .............................. 19

Figure 27 - Site Supervisor Manual QR Code ............ 19

Figure 28 - E3 Dimensions ......................................... 19

Figure 29 - Site Supervisor Power, Serial, and IO

Positions ..................................................................... 20

Figure 30 - E3 Power, Serial, and IO Positions .......... 21

Figure 31 - Termination Jumpers position .................. 21

Figure 32 – Site Supervisor and X-Line Interconnection

Diagram ...................................................................... 22

Figure 33 - E3 and X-Line Interconnection Diagram .. 23

Figure 34 - User and Password Screen in E3 /

Supervisor .................................................................. 23

Figure 35 - ModBus Connections Settings ................. 24

Figure 36 – E3 / Site Supervisor Log In Screen ......... 24

Figure 37 - ADF File selection Screen ....................... 25

Figure 38 – Enter License Screen .............................. 25

Figure 39 - XCM25D Selection Screen ...................... 26

Figure 40 - XCM25D Address Entry Screen .............. 26

Figure 41 – Control Inventory Screen ........................ 27

Figure 42 - Application Setup Page ............................ 27

Figure 43 - Read Configuration Screen ..................... 28

Figure 44 - XWEB EVO .............................................. 29

Figure 45 – XWEB EVO and X-Line Interconnection

Diagram ...................................................................... 30

Figure 46 – XWEB EVO Log In Screen...................... 30

© 2021 Emerson Climate Technologies, Inc.

Page 2

2

AE29-1439 R

Figure 47 – Stopping Acquisitions ............................. 31

Figure 48 – XWEB EVO Home Screen ..................... 31

Figure 49 – XWEB EVO Library Upload .................... 32

Figure 50 – XWEB EVO Library Update .................... 32

Figure 51 – XWEB EVO Devices Menu ..................... 33

TABLES

Table 1 - E2 Family Description ................................... 6

Table 2 - E2 Specifications .......................................... 6

Table 3 - Site Supervisor Specifications .................... 18

Table 4 - E3 Specifications ........................................ 18

Table 5 - E3 / Supervisor Family Descriptions ........... 20

Table 6 - XWEB EVO Specifications ......................... 29

REVISION TRACKING

Revision Tracking R2

Pg. 3:

- Addition of E3 information to the Safety

Instructions.

Pg. 5:

- Addition of E3 information to Introduction.

Pg. 6:

- Addition of E3 information to Section 2.3.

Pg. 18:

- Addition of E3 information in section 3 title.

- Addition of E3 information to Section 3.1.

- Figure 24 addition showing the E3 hardware.

- Table 4 addition showing E3 specifications.

Pg. 19:

Figure 52 – Adding a new device ............................... 33

Figure 53 – Adding via XWEB Library ........................ 34

Pg. 22:

- Addition of E3 information to Section 3.4.

Pg. 23:

- Addition of E3 information to Section 3.6.

- Addition of Figure 33.

Pg. 24:

- Addition of E3 information to Section 3.6.2.

- Addition of E3 information in Figure 36 title.

Pg. 27:

- Addition of E3 information to Section 3.6.3.

Pg. 20:

Pg. 21:

© 2021 Emerson Climate Technologies, Inc.

- Addition of Figure 28.

- Addition of E3 information to Section 3.2.

- Table 5 addition showing E3/Supervisor

Family models.

- Addition of Figure 30.

- Addition of E3 information to Section 3.3.

Scan this QR to access to an interactive course

about XCM25D.

You will need to login or create an account before

you’ll be able to access.

Course code: DL-XCM25D

Page 3

3

Safety Instructions

WARNING

CAUTION

NOTICE

DANGER

CAUTION

XCM25D, E2, E3, Site Supervisor™ and XWEB™ are manufactured according to the latest U.S. and European

Safety Standards. Particular emphasis has been placed on the user's safety. Safety icons are explained below and

safety instructions applicable to the products in this bulletin are grouped on Page 4. These instructions should be

retained throughout the lifetime of the compressor. You are strongly advised to follow these safety instructions.

Safety Icon Explanation

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

CAUTION, without the safety alert symbol, is used to address practices not related to

personal injury.

FLAMMABLE, Fire hazard! Sparking in a potentially explosive atmosphere! Explosion

hazard!

© 2021 Emerson Climate Technologies, Inc.

Page 4

4

AE29-1439 R

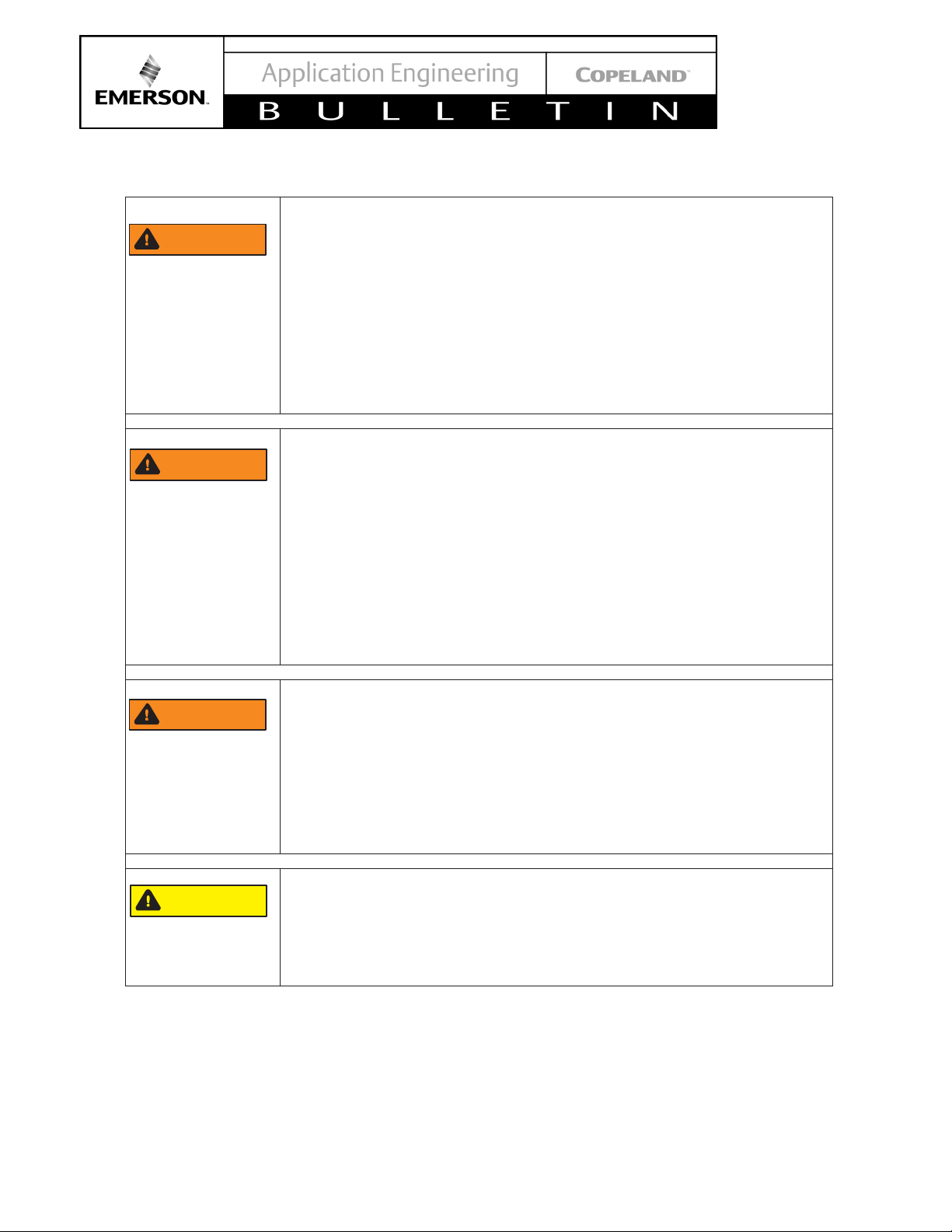

CAUTION

WARNING

WARNING

WARNING

Instructions Pertaining to Risk of Electrical Shock, Fire, or Injury to Persons

ELECTRICAL SHOCK HAZARD

• Disconnect and lock out power before servicing.

• Discharge all capacitors before servicing.

• Use compressor with grounded system only.

• Molded electrical plug must be used when required.

• Refer to original equipment wiring diagrams.

• Electrical connections must be made by qualified electrical

personnel.

• Failure to follow these warnings could result in serious personal

injury.

PRESSURIZED SYSTEM HAZARD

• System contains refrigerant and oil under pressure.

• Remove refrigerant from both the high and low compressor side

before removing compressor.

• Never install a system and leave it unattended when it has no

charge, a holding charge, or with the service valves closed without

electrically locking out the system.

• Use only approved refrigerants and refrigeration oils.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in serious personal

injury.

© 2021 Emerson Climate Technologies, Inc.

BURN HAZARD

• Do not touch the compressor until it has cooled down.

• Ensure that materials and wiring do not touch high temperature

areas of the compressor.

• Use caution when brazing system components.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in serious personal

injury or property damage.

COMPRESSOR HANDLING

• Use the appropriate lifting devices to move compressors.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in personal injury or

property damage.

Safety Statements

• Refrigerant compressors must be employed only for their intended use.

• Only qualified and authorized HVAC or refrigeration personnel are permitted to install commission and

maintain this equipment.

• Electrical connections must be made by qualified electrical personnel.

• All valid standards and codes for installing, servicing, and maintaining electrical and refrigeration equipment

must be observed.

Page 5

5

AE29-1439 R

1. Introduction

The XCM25D is a controller used on X-Line condensing

units which combine multiple capabilities such as:

• Condensing Unit Controls

• Condenser Fan Controls

• Defrost control

• CoreSense™ diagnostics and protection with

alarming and on-board error data logging

• Demand Cooling™ compressor temperature

protection

• XFAM / XFAP Models – Suction line liquid

injection

• XFAL Models – (3/4 – 1¼ HP) – Direct liquid

injection

• XFAL Models – (2 – 6 HP) Enhanced Vapor

Injection (EVI)

• Voltage, Current and Phase monitoring.

The XCM25D can be interconnected with the E2, E3

and Site Supervisor to be integrated to a much greater

network in a Retail Solution.

The Scope of this Bulletin is to bring information related

to the E2, E3 and Site Supervisor configuration settings

to communicate with XCM25D (X-Line) Condensing

Units.

Stores/Small-Box Retails Solutions. Additional models

were added in the Supervisor family namely the SR

(Service Replacement) and SA (Site Aggregator).

Every Family Series consists of different models with

lower to higher capacities. A summary for both the E2

capabilities are depicted in Table 1.

For a complete detail of every Model Capability, please

refer to the QR codes shown on Error! Reference source

not found. or simply click on the codes.

Figure 1 - XCM25D

Figure 1 shows the XCM25D controller.

2. E2 Controller

The E2 controllers are microprocessor-based

controllers providing complete control of compressor

groups, condensers, refrigerated cases, and other

components related to refrigeration and building control.

These are the controlling components of network

configurations – RS485 I/O, Echelon® Lon-Works™

Networks (E2 only), MODBus, BACNet and Ethernet.

What’s included are input and output boards, remote

communication software, and a variety of sensors,

probes, and transducers. Figure 2 to 4 shows the

Supervisory controller hardware.

2.1. E2 Controller Family Models and Capabilities

The controllers come in different family models: RX, BX

and CX. The RX family is for Refrigeration Systems

Control, BX is HVAC Systems Control and CX is HVAC,

Lighting and Refrigeration Systems for Convenience

Figure 2 - E2 Enhanced Controller

Figure 3 - E2 Controller Manual Link

© 2021 Emerson Climate Technologies, Inc.

Page 6

6

AE29-1439 R

Table 1 - E2 Family Description

Single refrigeration

system

One Condenser and up to

Four suction groups

Single refrigeration

system

One Condenser and up to

Four suction groups

Two separate

refrigeration systems

Two condensers and up to

four suction groups

BX-300

Up to 6 AHUs2

BX-400

Up to 8 AHUs

CX-1003

Up to 4 AHUs

CX-300

Up to 6 AHUs

Standard Mount:

9.06” W x 12.06” H x 3.75” D

Recessed Mount:

9.06” W x 10.56” H x 2.0” D

Base:

10.56” W x 10.56” H x 3.75” D

Operating Temp.

-40°F to 149°F (-40°C to 65°C)

Storage Temp

-40°F to 158°F (-40°C to 70°C)

Operating

Humidity

5% - 95% RH non-condensing at

90°F

Storage Humidity

5% - 100% RH

24 VAC ±20%, 50/60 Hz,

Class 2

VA Load

50

E2 Family Models Models Capabilities

1

RX-100

E2 RX Refrigeration

E2 BX HVAC systems

HVAC, Lighting, and

refrigeration systems for

E2 CX

Convenience Stores and

Small-Box Retail

Facilities

RX-300

RX-400

CX-400 Up to 8 AHUs

Table 2 - E2 Specifications

Dimensions

Figure 4 - E2 Front Panel

2.2. Software Licensing

Some applications are available only when activated

with a unique license key that is obtained through

Emerson software.

Call your Emerson Sales Representative at 770-4252724 for more information about software licensing.

1

Low-cost alternative RX-300 with fewer capabilities and a monochrome Display.

2

Air Handling units: AHUs

3

Low-cost alternative to CX-300 with fewer capabilities and a monochrome Display

© 2021 Emerson Climate Technologies, Inc.

Power

RX- and CX-100 versions support monochrome display

only.

2.3. XCM25D Network Setup on Supervisory Controllers

The XCM25D can be monitored by a Supervisory

controller which will receive alarms and notice statuses

from the X-line unit. Currently, the E2, E3 and Site

Supervisor are the controllers available from Emerson

Page 7

7

AE29-1439 R

capable of monitoring storewide controls and can help

with maintenance and system troubleshooting.

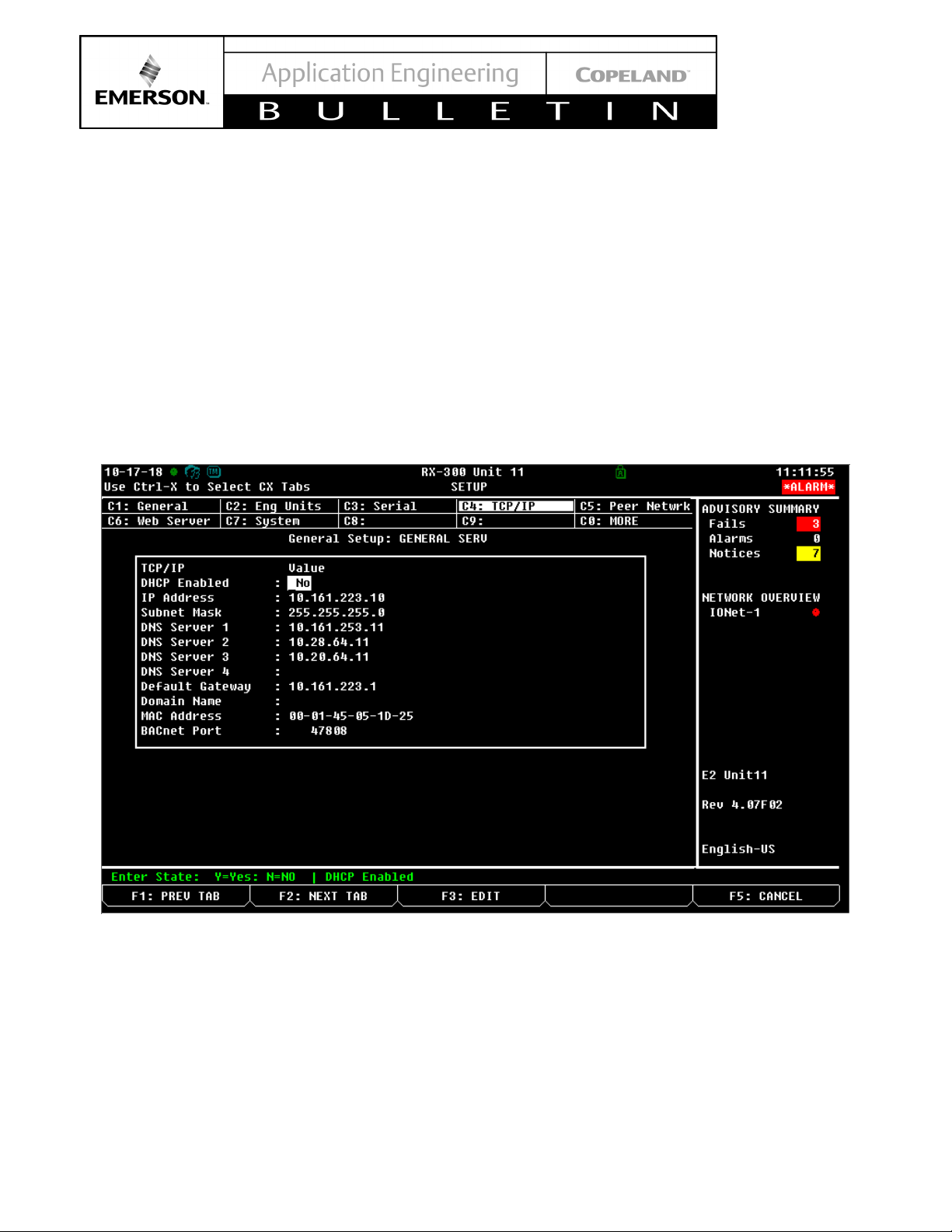

2.3.1. Adding the XCM25D to the E2 Controller

The XCM25D can be added to the E2 but it requires a

license key and a description file. Contact Emerson

technical support for the description file (.dsc), save the

.dsc file in your computer and take note of the license

key, to add instances of XMC25D. Below is the

information you need to provide to Emerson technical

support to generate the license key:

Press Menu>7>3>1 then Press F2: Next tab and go to

the TCP/IP tab, For the information listed below.

• E2 MAC Address

• E2 Model (Example: RX400), It is found on the top

middle portion of the screen

• Number of instances of XCM25D needed

• Description of purpose including for what site/store

Once you have secured the description file and license

key, you will need to connect your computer to the E2.

You must set the Internet protocol (TCP/IP) of PC to

static IP.

© 2021 Emerson Climate Technologies, Inc.

Figure 5 - E2 Screen with needed information for Emerson Technical Support

Page 8

8

AE29-1439 R

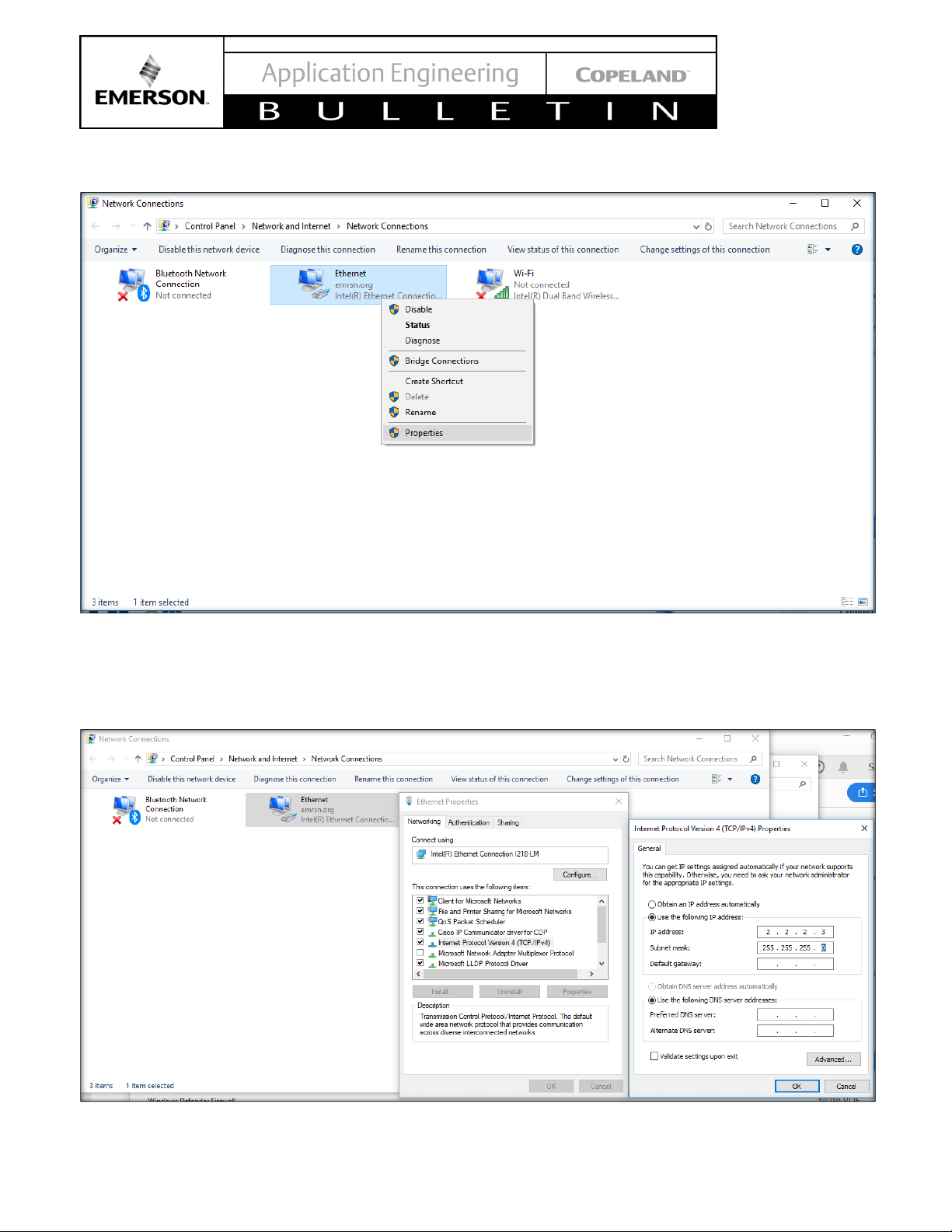

2.4. PC configuration for direct connection to E2

1. Open your PC, Press “Start” and go to “Control Panel” then click Network and Sharing Center. See figure below.

Figure 5 - PC Control Panel

2. Click Change adapter settings. See figure below.

© 2021 Emerson Climate Technologies, Inc.

Figure 6 - PC Network and Sharing Center Screen

Page 9

9

AE29-1439 R

3. Right click on Ethernet, then click Properties below.

Figure 7 - Ethernet options Submenu

4. Click Internet Protocol Version 4 (TCP/IPv4) > Click Properties > Put a tick mark on Use the following IP address

> Put the IP address to match the E2 IP address except for the last number, change this to a value slightly

different to what is set on the E2, also set corresponding subnet mask, same as what on E2. > Click OK. See

Figure below.

© 2021 Emerson Climate Technologies, Inc.

Figure 8 - Network Configuration Screen

Page 10

10

AE29-1439 R

2.5. Upload the Description file via UltraSite

Part Number

Description

File

5270744.dsc

Use the below description file if the XCM25D is not a native application on E2.

527-0744

XCM25D v1.3

For XFAM/XFAL units.

Download Configuration Files attached to this document.

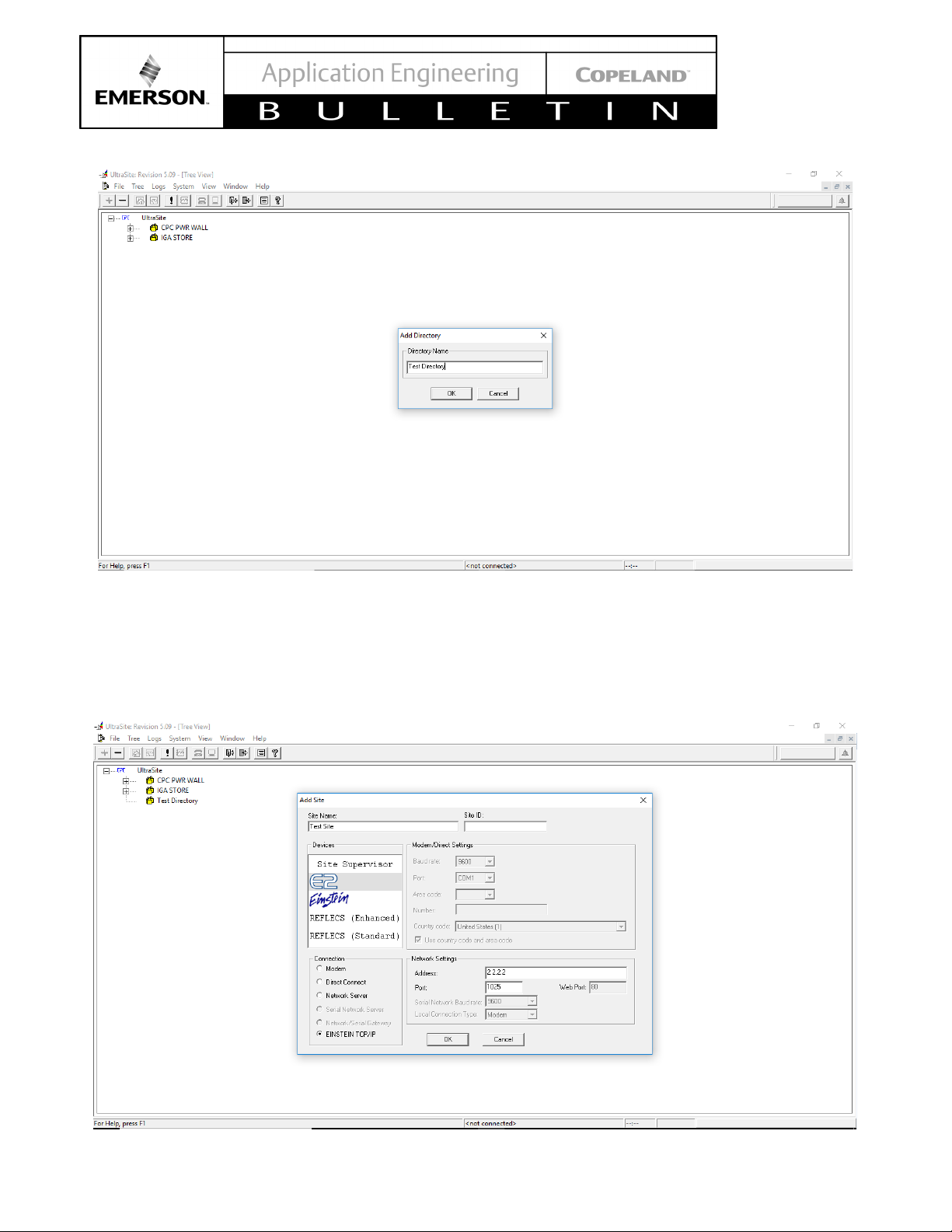

1. Launch UltraSite (Contact Tech Support for UltraSite Software)

2. Login on UltraSite. By default, the Login access is USER/PASS

3. Under tree view, Right click on UltraSite > click “Add Directory”

4. Specify the directory name > click OK. See figure below.

© 2021 Emerson Climate Technologies, Inc.

Figure 9 - UltraSite Login Screen

Page 11

11

AE29-1439 R

Figure 10 - UltraSite Directory Name Screen

5. Right click on the newly created directory (Yellow house) > click “Add Site”

6. Specify the Site name

7. Under Devices, Click E2

8. Under Connection, Click Einstein TCP/IP

9. Under Network settings, specify the IP address of the E2 controller.

© 2021 Emerson Climate Technologies, Inc.

Figure 11 - E2 Address entering to UltraSite

Page 12

12

AE29-1439 R

10. Expand the Yellow house (Specific Directory) > right click on the Site > click Connect

Figure 12 - UltraSite Connection command

11. Expand the site by clicking the “+” icon on the blue house > Right click on the E2 controller on which the XCM is

connected > Click Upload Description file

© 2021 Emerson Climate Technologies, Inc.

Figure 13 - Uploading Description file to E2

Page 13

13

AE29-1439 R

Click Browse > Locate the description file that you saved from Tech support then Click Open> Click Upload >

Click Close > Manually reboot the E2

Figure 14 - Uploading 5270573.dsc file to E2

The description file is now added to the E2. Now you can add the XCM25D to the E2 controller

2.6. Final XCM25D integration into E2 Controller

1. After the reboot log in on the E2 controller by pressing the Login button.

© 2021 Emerson Climate Technologies, Inc.

Figure 15 - E2 Login Screen

Page 14

14

AE29-1439 R

2. From the Home Screen, Press Menu > 7 > 9 (Licensing), Press F1: Add feature, manually type the license

key received from Tech support. Wait for confirmation.

Figure 16 - E2 Add License Screen

3. From the Home Screen, Press Menu > 7 > 7 > 2, Press F2 to access Third Party devices. Specify the quantity

of the X-line units that you are commissioning and then press the staircase button to save the changes.

© 2021 Emerson Climate Technologies, Inc.

Figure 17 – E2 Add Devices Screen

Page 15

15

AE29-1439 R

2.7. Setup the COM Port for MODBUS.

1. Press Menu > 7 > 3 > 1, Press F2 to access Serial tab. Set one of the available COM ports except for Com1 and

Com3 to MODBUS via the F4: Look Up button. Set the configuration to the following:

Baud: 9600 baud

Data Size: 8

Parity: None

Stop Bits: 1

2.8. Network Wiring

XCM25D is connected on the E2 through the MODBUS

communication protocol.

Make sure to configure the port settings on the E2 that

is being used for the XCM25D, refer to the E2 manual

for steps to configure communication ports, or the

previously mentioned instructions.

The XCM is daisy chained to the E2 using shielded

twisted pair wiring. Belden cable is recommended. Refer

to Figure 19 for polarity at the connector wiring.

2.9. Communication Setup – XCM25D

1. The XCM25D controller will be able to communicate

© 2021 Emerson Climate Technologies, Inc.

Figure 18 - Modbus Configuration in E2 for X-line connection

with the E2 Modbus RTU Slave RS485 slave

protocol. The XCM25D Modbus parameters will be

configurable via the quick access menu or the

Wizmate software and the communication

parameters will be as follows:

Adr/T01: (x) Configurable

Baud rate: 9600

Byte length: 8

Stop bits: 1

Parity: None

Baud Rate, Byte length, Stop bits and Parity must

match the E2 configuration the XCM25D Modbus

address Adr/T01 must be the same as what is

configured/commissioned on E2. Network

Summary Screen. Note that the default setting in the

XCM25D is address 1, This may need to be

changed during commissioning.

Example: XCM25D Adr/T01 = 6 with the

corresponding X-LINE Modbus Address = 6 also.

(Refer to Section 2.7: Setup the COM Port for

MODBUS.)

2. Commission the XCM25D by accessing the E2

Network Summary screen set up, Press Menu > 7 >

7 > 1, Scroll down the devices then highlight the

recently added X-Line, Press F4 for Commission,

Specify the network address then press Enter twice.

See Figure 20.

Note: Make sure the Network address is same as

the Adr/T01 parameter on the XCM.

3. Wait for a few seconds until the X-Line shows

“Online”. See Figure 21

Page 16

16

AE29-1439 R

Figure 19 - XCM25D Modbus connection with E2

Figure 20 - X-line Unit Address Inclusion Screen

© 2021 Emerson Climate Technologies, Inc.

Page 17

17

AE29-1439 R

Figure 21 - X-line Unit Integration Confirmation Screen

2.10. Send Device Configuration to E2

The configured XCM25D parameters now need to be sent up to the E2.

To manually send the XCM configuration to E2. Go to the Status Screen of XCM, Press Enter > 9. Applications

Commands > 2. Send Device Cfg to E2 > Enter

You should now be able to view the correct device information on the status screen.

© 2021 Emerson Climate Technologies, Inc.

Figure 22 - Device Configuration sending to E2

Page 18

18

AE29-1439 R

Operating Temperature

-40°F to 149°F

Relative Humidity

20-85% RH

Enclosure Rating

UL 94 V-0

Dimensions

110mm x 183mm

Power In

24VAC 50/60 Hz +/- 10% 20VA

1 Can Bus

Expansion Module Connections

4 RS485 ports

MODBUS Com Ports 1, 2, 3,

3 Ethernet ports

Ports 1, 1, 0

Analog Inputs

8

MicroSD

1

Digital Inputs

4

Relay Outputs

4

Agency Approvals

Operating Temperature

-40°F to 149°F (-40°C to

65°C)

Operating Humidity

5% - 95% RH noncondensing at 90°F

Storage Humidity

5% - 100% RH

Power Supply

24 VAC ±20%, 50/60 Hz,

Class 2

Dimensions

12” L x 12.5” W x 3.75 H”

RS485 Ports

COMM 1 = RS485 Com 2 A

and B

Ethernet Ports

Ports 0,1

USB Ports

J2, J3

3. E3 / Site Supervisor

Figure 23 - Site Supervisor

2 USB Ports 1, 2

Table 4 - E3 Specifications

Only

and 4

ULE211299, CE

Figure 24 - E3 Controller

The Site Supervisor and E3 are systems that combine

energy management with the ability to monitor various

facility systems and provide alerts when there are issues

that need attention. These systems provide HVAC

control, Refrigeration System Monitoring and Control,

as well as Lighting Control. In addition, these controllers

can monitor and report energy consumption.

Table 3 - Site Supervisor Specifications

(-40°C to 65°C)

non-condensing

5/16

” x 7

3/16

”)

(4

24VDC +/- 10% .8A

and B

COMM 2 = RS485 Com 6

(isolated)

COMM 3 = RS485 Com 7

(isolated)

COMM 4 = RS485 Com 4 A

3.1. Housing Dimensions and Mounting

The Site Supervisor can be mounted to standard 35mm

DIN rail using the orange mountain clips. It can also be

screwed to a back plate by pulling the four (4) orange

mounting tabs out until they lock which will expose

mounting holes. See for Figure 25 detailed dimensions.

The E3 controller however is recessed mounted on

panels with the detailed hardware dimensions indicated

on Figure 28.

© 2021 Emerson Climate Technologies, Inc.

Page 19

19

AE29-1439 R

Figure 25 - Site Supervisor Dimensions

Figure 27 - Site Supervisor Manual QR Code

Figure 26 - Site Supervisor Detail

© 2021 Emerson Climate Technologies, Inc.

Figure 28 - E3 Dimensions

Page 20

20

AE29-1439 R

Table 5 - E3 / Supervisor Family Descriptions

Small Format

Retailers

Up to 4 AHUs; 6 Standard

Circuits

Single refrigeration

system

One Condenser and up to

Four suction groups

Two separate

refrigeration systems

Two condensers and up to

four suction groups

BXs

Up to 6 AHUs4

BXe

Up to 8 AHUs

HVAC, Lighting, and

Facilities

CXs

Up to 6 AHUs

SR

Service Replacement

SR

Max number of applications, All 400 Model level

Enable aggregating of data and device status all in one

screen

Supervisor Family Models Models Capabilities

SMF Small Format SMF

RXs

RX Refrigeration

RXe

BX HVAC systems

refrigeration systems for

CX

Convenience Stores and

Small-Box Retail

CXe Up to 8 AHUs

SA Site Aggregator SA

3.2. E3 / Site Supervisor Power, Serial, and IO Positions

Figure 29 - Site Supervisor Power, Serial, and IO Positions

4

Air Handling units: AHUs

© 2021 Emerson Climate Technologies, Inc.

Page 21

21

AE29-1439 R

Figure 30 - E3 Power, Serial, and IO Positions

3.2.1. Site Supervisor Termination Jumpers

The termination and biasing dip switches are located to the left of their respective communications port connectors.

Depending on the orientation of the board, the termination jumpers are set in the down position (always toward the

board - ON) for termination and up (always away from the board - OFF) for no termination.

Position 1 = Termination

Position 2 = Bias.

Figure 31 - Termination Jumpers position

Biasing

The transmission line into the RS-485 serial port enters an indeterminate state when it is not being transmitted to.

This indeterminate state can cause the receivers to receive invalid data bits from the noise picked up on the cable.

To prevent this, set the bias dip switch to ON (down) which will add the appropriate amount of resistance.

3.3. XCM25D Network Setup on the E3 / Site Supervisor

XCM25D can be monitored by the E3 / Supervisor which will receive alarms and notice statuses from the X-line unit.

Monitoring can deliver greater energy and maintenance savings than any other initiatives.

© 2021 Emerson Climate Technologies, Inc.

Page 22

22

AE29-1439 R

3.4. Network Wiring

XCM25D is connected to the E3 / Supervisor through MODBUS communication protocol. One key difference in the

communication wiring of the XCM25D with the two supervisory controllers is that only with the Site Supervisor does

the XCM25D has the same MODBus polarity. The E3 will be connected to the XCM25D with reverse polarity.

3.5. Communication Setup – XCM25D

The controller will be able to communicate with a Modbus RTU Slave RS485 slave protocol. The Modbus address

will be configurable in the Adr/T01 parameters and the communication parameters will be:

Baud rate 9600

Byte length: 8,

Stop bits: 1;

No parity bit as the std requirements.

Communication parameters are fixed.

© 2021 Emerson Climate Technologies, Inc.

Figure 32 – Site Supervisor and X-Line Interconnection Diagram

Page 23

23

AE29-1439 R

Figure 33 - E3 and X-Line Interconnection Diagram

E3 to XCM25D

3.6. Communication Setup – E3 / Supervisor

SHOULD BE WIRED

VIA RS485 MODBUS –

REVERSE POLARITY

3.6.1. Setup the COM Port for MODBUS.

1. Log-in. Use “USER” for username and “PASS” for password.

Figure 34 - User and Password Screen in E3 / Supervisor

2. Click the Menu Icon > Configure System > General System Properties > COM Ports. Use any of the 4 COM

ports for MODBUS with the below communication setup.

© 2021 Emerson Climate Technologies, Inc.

Page 24

24

AE29-1439 R

Figure 35 - ModBus Connections Settings

3.6.2. Adding the XCM25D in the E3 / Supervisor program

The Supervisor needs to have a firmware version of not later than 2.05F01. On this firmware, the XCM25D is nonnative but can be added. Contact Emerson Technical Support for the ADF file and license key to add instances of

XMC25D. Below is the information you need to provide to generate a license key:

• E3 / Supervisor MAC Address

• E3 / Supervisor Model (Example: SMF)

Once you secured a license key, below is how you can add it in the E3 / Supervisor.

1. Log-in. Use “USER” for username and “PASS” for password.

• Model/Version of XCM25D (Ex. XCM25D v.1.3

XFAL)

• Number of instances of XCM25D

2. Click on the Menu icon > Configure System > File Management & Licensing. Then click the “Install ADF file”

© 2021 Emerson Climate Technologies, Inc.

Figure 36 – E3 / Site Supervisor Log In Screen

button. Select the file and click “Install”.

Page 25

25

AE29-1439 R

Figure 37 - ADF File selection Screen

3. After confirming the installation of the ADF file, the E3 / Supervisor will reboot. Once back up, log-in once again

and go back to the File Management & Licensing. Click Install License and enter the license key provided by

technical support. Click “Go” to proceed.

© 2021 Emerson Climate Technologies, Inc.

Figure 38 – Enter License Screen

Page 26

26

AE29-1439 R

4. Click on the Control Inventory icon and under the Refrigeration tab click the “Add Control” and select the

XCM25D.

Figure 39 - XCM25D Selection Screen

5. Set the Name of the application. On port ID, select the Modbus you set previously. On the Address, set the

address you put on Adr/T01 parameter of XCM25D.

Figure 40 - XCM25D Address Entry Screen

6. When wiring and communication setup are correct, the device should appear online as shown on Figure 40.

© 2021 Emerson Climate Technologies, Inc.

Page 27

27

AE29-1439 R

Figure 41 – Control Inventory Screen

3.6.3. Sending the Device Configuration to the E3 / Supervisor

1. Once the device is online, click on the application name to open the application setup page.

Figure 42 - Application Setup Page

© 2021 Emerson Climate Technologies, Inc.

Page 28

28

AE29-1439 R

Part Number

Description

Version

File

531-0105.adf

531-0136.adf

2. Click on the icon located on the tope right corner of the screen. Select the “Read Configuration from Device”.

A confirmation message should appear when the read is successful.

Figure 43 - Read Configuration Screen

3.7. Integration File

Use the below ADF if the XCM25D is not a native application on Supervisor.

531-0105

531-0136

XCM25D_13_FAL

XCM25D_13_FAM

1.3

1.3

Download Configuration Files attached to this document.

© 2021 Emerson Climate Technologies, Inc.

Page 29

29

AE29-1439 R

Maximum voltage

and current that can

be applied to the

humidity, special

Electrical safety

Maximum current to

4. XWEB EVO

Figure 44 - XWEB EVO

XWEB represents one of the most advanced monitoring,

control and supervision systems available on the market

today. The user will benefit from a power device, which

is easy to use and highly customizable for all

requirements. It uses the most advanced technology for

displaying the web pages and is based on the Linux™

operating system which guarantees its efficiency and

reliability. The hardware is based on highly reliable

industrial boards that require practically no maintenance

whatsoever.

4.1. XCM25D Network Setup on XWEB EVO

XCM25D can be monitored by a XWEB EVO which will

receive alarms and notice statuses from the X-line unit.

Monitoring can deliver greater energy and maintenance

savings than any other initiatives.

4.2. Network Wiring

XCM25D is connected on the WEB EVO through

MODBUS communication protocol.

4.3. Communication Setup – XCM25D

The controller will be able to communicate with a

Modbus RTU Slave RS485 slave protocol. The Modbus

address will be configurable in the Adr/T01 parameters

and the communication parameters will be:

Baud rate 9600

Byte length: 8,

Stop bits: 1;

No parity bit as the std requirements.

Communication parameters are fixed.

Table 6 - XWEB EVO Specifications

Power supply 24V or 100-230V (DIN

models)

230V (“COOLMATE”

models)

Power 15VA Max (DIN models)

20VA Max (“COOLMATE”

models)

24V

AUX1-2-3 terminals

Operating conditions

(temperature,

conditions)

(reference

standards)

Electromagnetic

compatibility

(reference

standards)

the USB device

T: 10-60°C R.H.20-85%

(non-condensing) (DIN

models) T: 0-60°C, R.H. 20-

85% (non-condensing)

(“COOLMATE” models)

Standard EN 60950-1

Immunity

EN 61000-6-2:2005

EN 55024:1998 + /A1:2001

+/A2:2003

EN 61000-4-2:2009

EN61000-4-3:2006

+/A1:2008

EN61000-4-4:2004

EN 61000-4-5:2006

EN 61000-4-6:2009

EN 61000 -4 -8:1993 +/

A1:2001

EN 61000-4-11:2004

Emissions

EN 55022:2006+/A1:2007

EN 61000-3-2:2006

+/A1:2009 +/A2:2009

EN 61000-3-3 :2008

200

© 2021 Emerson Climate Technologies, Inc.

Page 30

30

AE29-1439 R

Figure 45 – XWEB EVO and X-Line Interconnection Diagram

4.4. Communication Setup – XWEB EVO

1. Open your Internet Browser and type the XWEB EVO’s IP Address to Log-in. Use “Admin” for

username and “Admin” for password.

© 2021 Emerson Climate Technologies, Inc.

Figure 46 – XWEB EVO Log In Screen

Page 31

31

AE29-1439 R

2. Make sure acquisitions are off by clicking on the Acquisition Button then Confirm.

Figure 47 – Stopping Acquisitions

3. Expand the System tab and select Update

4. Click Update button and select Upload. Locate the zip file on your drive

© 2021 Emerson Climate Technologies, Inc.

Figure 48 – XWEB EVO Home Screen

Page 32

32

AE29-1439 R

Figure 49 – XWEB EVO Library Upload

5. Click Update

6. Expand the Devices tab and select Settings

© 2021 Emerson Climate Technologies, Inc.

Figure 50 – XWEB EVO Library Update

Page 33

33

AE29-1439 R

Figure 51 – XWEB EVO Devices Menu

7. Click the + button to add a new device.

© 2021 Emerson Climate Technologies, Inc.

Figure 52 – Adding a new device

Page 34

34

AE29-1439 R

8. Set the Source to Library and look for the device to be added under the Library

Figure 53 – Adding via XWEB Library

9. Use these settings for the Protocol and the Peripheral:

Protocol: Modbus 485 (dixell485)

Peripheral: RS485 1 (RS1)

Add the Modbus address and the Quantity required. Click Add when done.

© 2021 Emerson Climate Technologies, Inc.

Figure 50 – XWEB EVO Modbus Setup

Page 35

35

AE29-1439 R

6.5. XWEB Library

Market

Description

Version

File

XCM25D_0045000D0006. zip

XCM25D_0045000D0007. zip

P/N

Title

E2 Installation and Operation Manual for

Refrigeration, BX HVAC, and CX

Convenience Store Controllers

Site Supervisor Controller 2.08 User

Guide

Emerson Product Technical Sheet

Binder

The contents of this publication are presented for informational purposes only and are not to be construed as warranties or guarantees, express or implied,

remains solely with the purchaser or end user.

Use the below Library if the XCM25D is not a native application on XWEB EVO.

Asia XCM25D 1.3

America XCM25D_13_FAM 1.3

Download Configuration Files attached to this document.

10. General Guidelines and More Information

For general E2, Site Supervisor and XWEB EVO

information please visit Emerson.com/OPI

your Application Engineer.

Emerson publications listed below can be ordered on

their printed version by contacting Emerson:

026-1614

RX

026-1800

026-1904

or contact

regarding the products or services described herein or their use or applicability. Emerson Climate Technologies, Inc. and/or its affiliates (collectively

"Emerson"), as applicable, reserve the right to modify the design or specifications of such products at any time without notice. Emerson does not assume

responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson product

© 2021 Emerson Climate Technologies, Inc.

Loading...

Loading...