Page 1

Model 2081C/T

Conductivity Microprocessor Transmitter

Instruction Manual

PN 51-2081C/T/rev.B

April 2003

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its

products to meet many national and international standards.

Because these instruments are sophisticated technical products, you must properly install, use, and maintain them to

ensure they continue to operate within their normal specifications. The following instructions must be adhered to and integrated into your safety program when installing, using, and

maintaining Rosemount Analytical products. Failure to follow

the proper instructions may cause any one of the following situations to occur: Loss of life; personal injury; property damage;

damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product. If this Instruction Manual is not the correct

manual, telephone 1-800-654-7768 and the requested manual will be provided. Save this Instruction Manual for future

reference.

• If you do not understand any of the instructions, contact your

Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked on and

supplied with the product.

• Inform and educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install your equipment as specified in the Installation

Instructions of the appropriate Instruction Manual and per

applicable local and national codes. Connect all products to

the proper electrical sources.

• To ensure proper performance, use qualified personnel to

install, operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified

people use replacement parts specified by Rosemount.

Unauthorized parts and procedures can affect the product’s

performance and place the safe operation of your process at

risk. Look alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective

covers are in place, except when maintenance is being performed by qualified persons, to prevent electrical shock and

personal injury.

NOTE

The Model 2081C/T Two-wire transmitter is certified for use in areas requiring intrinsic safety area by FM, CSA, and CENELEC. However, the CENELEC certification requires that a Model 2081C/T used with contacting sensors be certified separately from those using inductive (toroidal) sensors. The type of sensor must be specified with the order for a CENELEC

certified transmitter.

Since this decision is required prior to shipment, the instruction manual covers both configurations. However, if the transmitter is reconfigured in the field, it may not meet CENELEC certification conditions.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2003

About This Document

This manual contains instructions for installation and operation of the Model 2081C/T Conductivity

Transmitter. The following list provides notes concerning all revisions of this document.

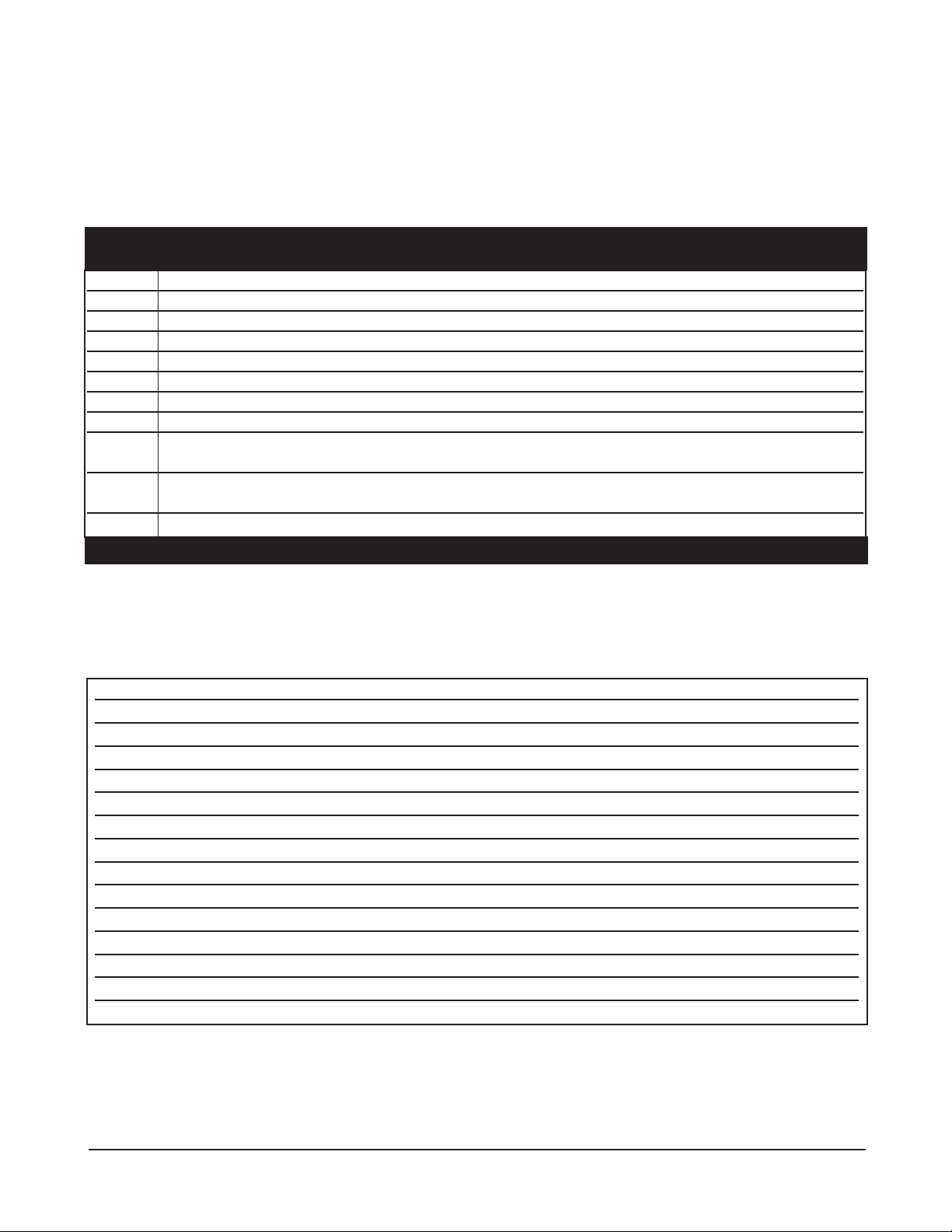

Rev. Level Date Notes

A 7/01 This is the initial release of the product manual. The manual has been refor-

matted to reflect the Emerson documentation style and updated to reflect any

changes in the product offering.

B 4/03 Updated CE certification

Page 3

MODEL 2081C/T CONDUCTIVITY

MICROPROCESSOR TRANSMITTER

TABLE OF CONTENTS

Section Title Page

1.0 INSTALLATION ...................................................................................................... 1

1.1 Unpacking and Inspection....................................................................................... 1

1.2 Mechanical Installation............................................................................................ 1

1.3 Wiring ...................................................................................................................... 1

1.4 Fault Mode and Security Jumpers .......................................................................... 2

1.5 Calibration and Setup.............................................................................................. 3

1.6 Hazardous Locations — Explosion Proof Installation ............................................. 3

1.7 Hazardous Locations — Intrinsically Safe Installation ............................................ 3

2.0 DESCRIPTION OF CONTROLS ............................................................................ 17

2.1 General.................................................................................................................... 17

2.2 Menu Selection ....................................................................................................... 17

2.3 Value Adjustment .................................................................................................... 17

3.0 RANGE CONFIGURATION .................................................................................... 18

3.1 General.................................................................................................................... 18

4.0 START UP AND CALIBRATION ............................................................................ 19

4.1 General.................................................................................................................... 19

4.2 Temperature Calibration.......................................................................................... 19

4.3 Entering the Cell Constant ...................................................................................... 19

4.4 Zeroing the System ................................................................................................. 19

4.5 Initial Loop Calibration............................................................................................. 19

4.6 Routine Standardization.......................................................................................... 21

4.7 Hold Mold for Maintenance ..................................................................................... 21

4.8 Sensor Maintenance ............................................................................................... 21

5.0 KEYBOARD SECURITY ........................................................................................ 22

5.1 Push Button Security............................................................................................... 22

5.2 Eeprom Security...................................................................................................... 22

6.0 DIAGNOSTICS AND TROUBLESHOOTING......................................................... 23

6.1 General.................................................................................................................... 23

6.2 Contact Conductivity Mode Bench Check............................................................... 24

6.3 Toroidal Conductivity Mode Bench Check .............................................................. 25

6.4 Systematic Troubleshooting.................................................................................... 25

7.0 THEORY OF OPERATION ..................................................................................... 29

7.1 General.................................................................................................................... 29

7.2 Overview ................................................................................................................. 29

8.0 DESCRIPTION AND SPECIFICATIONS................................................................ 31

8.1 Features .................................................................................................................. 31

8.2 Functional Specifications ........................................................................................ 32

8.3 Performance Specifications .................................................................................... 32

8.4 Physical Specifications............................................................................................ 33

8.5 Recommended Sensors.......................................................................................... 33

8.6 Ordering Information ............................................................................................... 34

8.7 Accessories ............................................................................................................. 34

9.0 RETURN OF MATERIAL........................................................................................ 36

i

MODEL 2081C/T TABLE OF CONTENTS

Page 4

ii

TABLE OF CONTENTS CONT’D.

LIST OF FIGURES

Figure No. Title Page

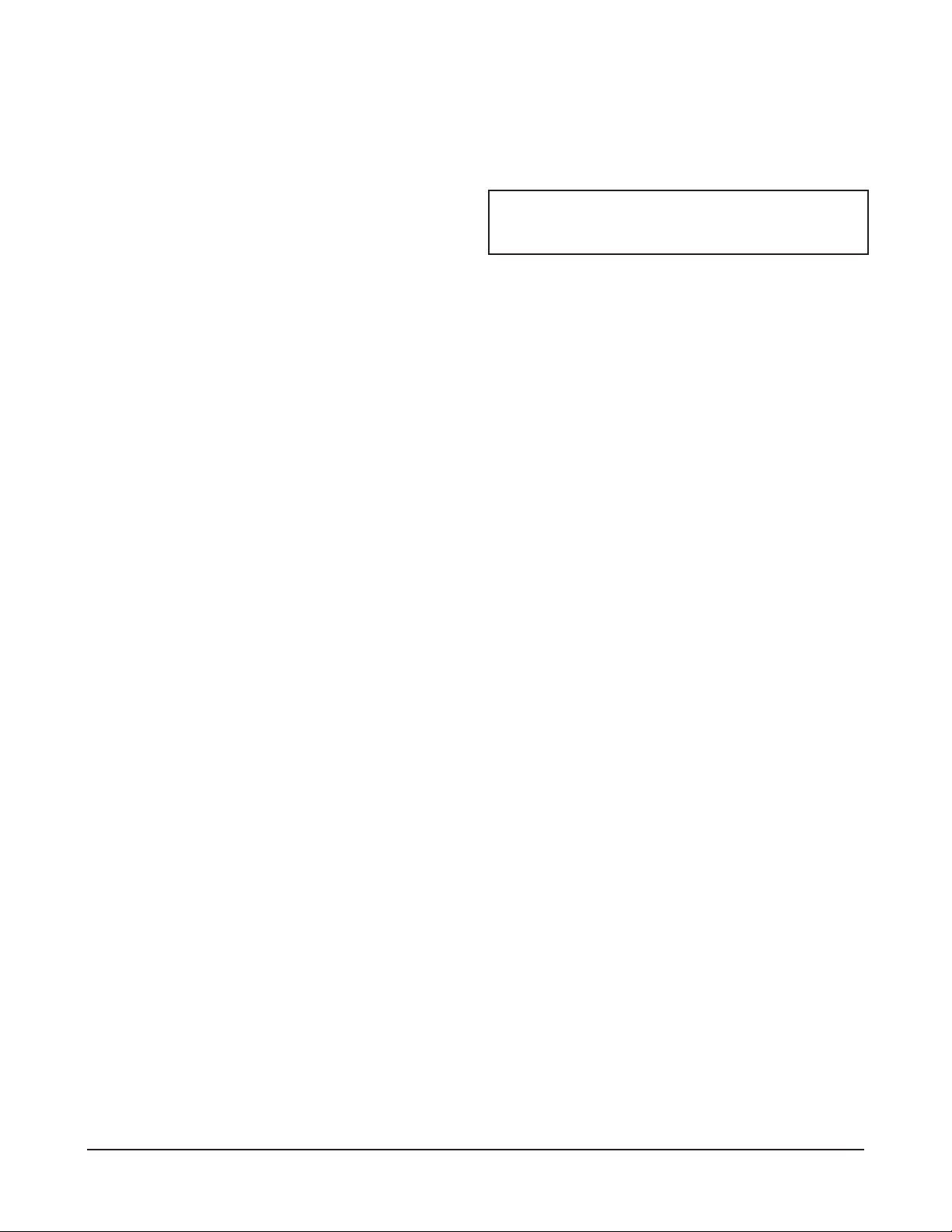

1-1 Model 2081C/T Dimensional/Mounting Instructions

with Power Supply/Loop Signal Wiring ................................................................... 4

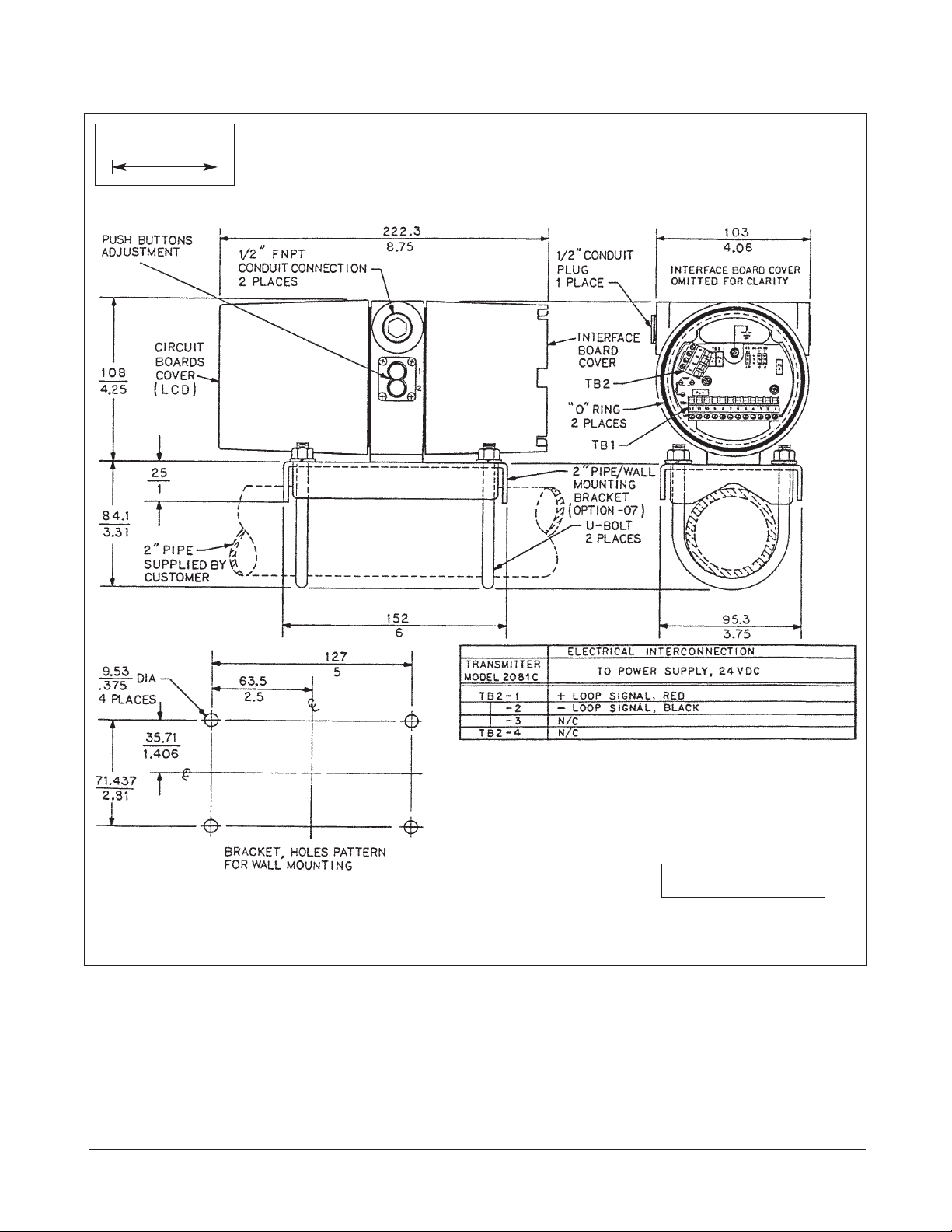

1-2 Model 2081C/T Contacting Electrode Wiring.......................................................... 5

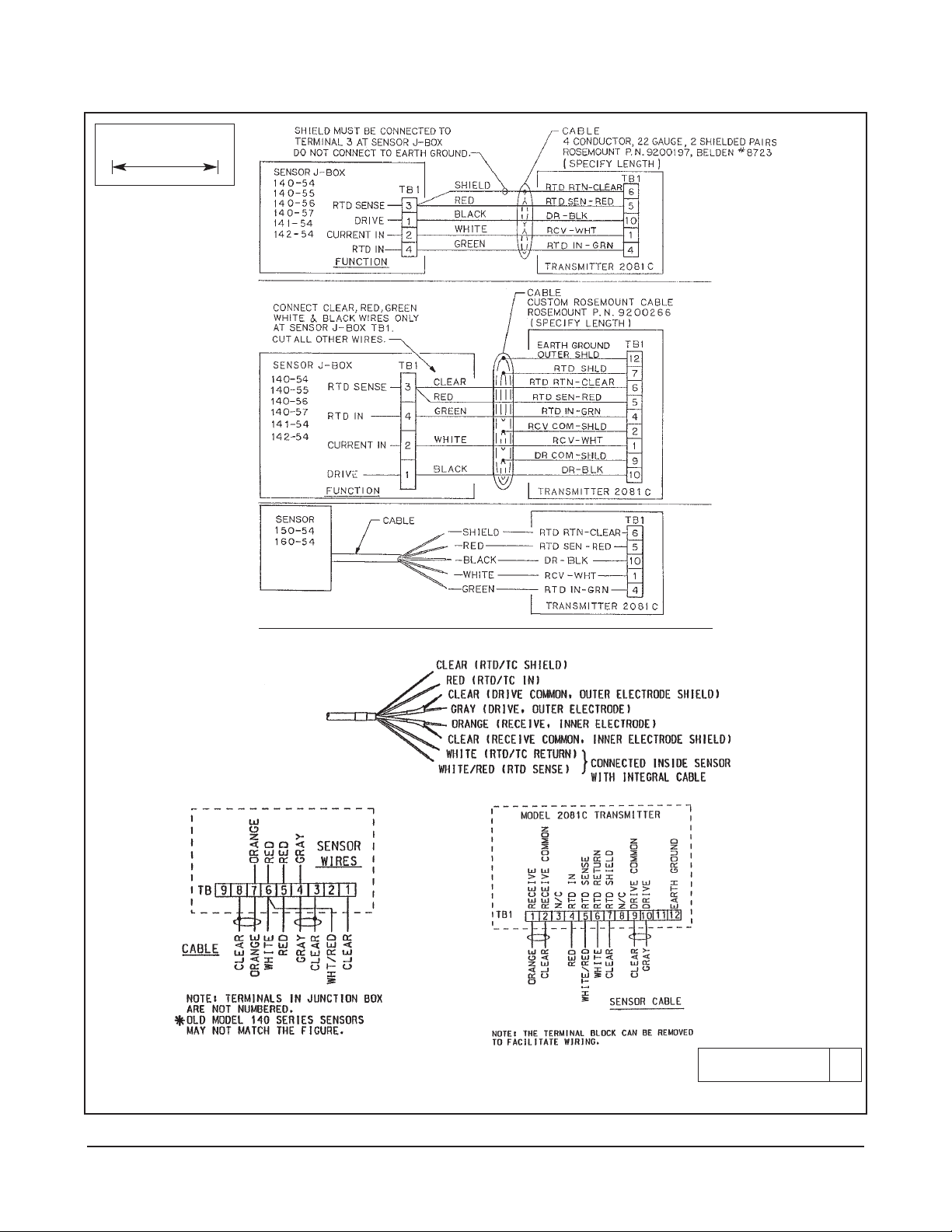

1-3 Model 2081C/T Inductive Sensor Wiring ................................................................ 6

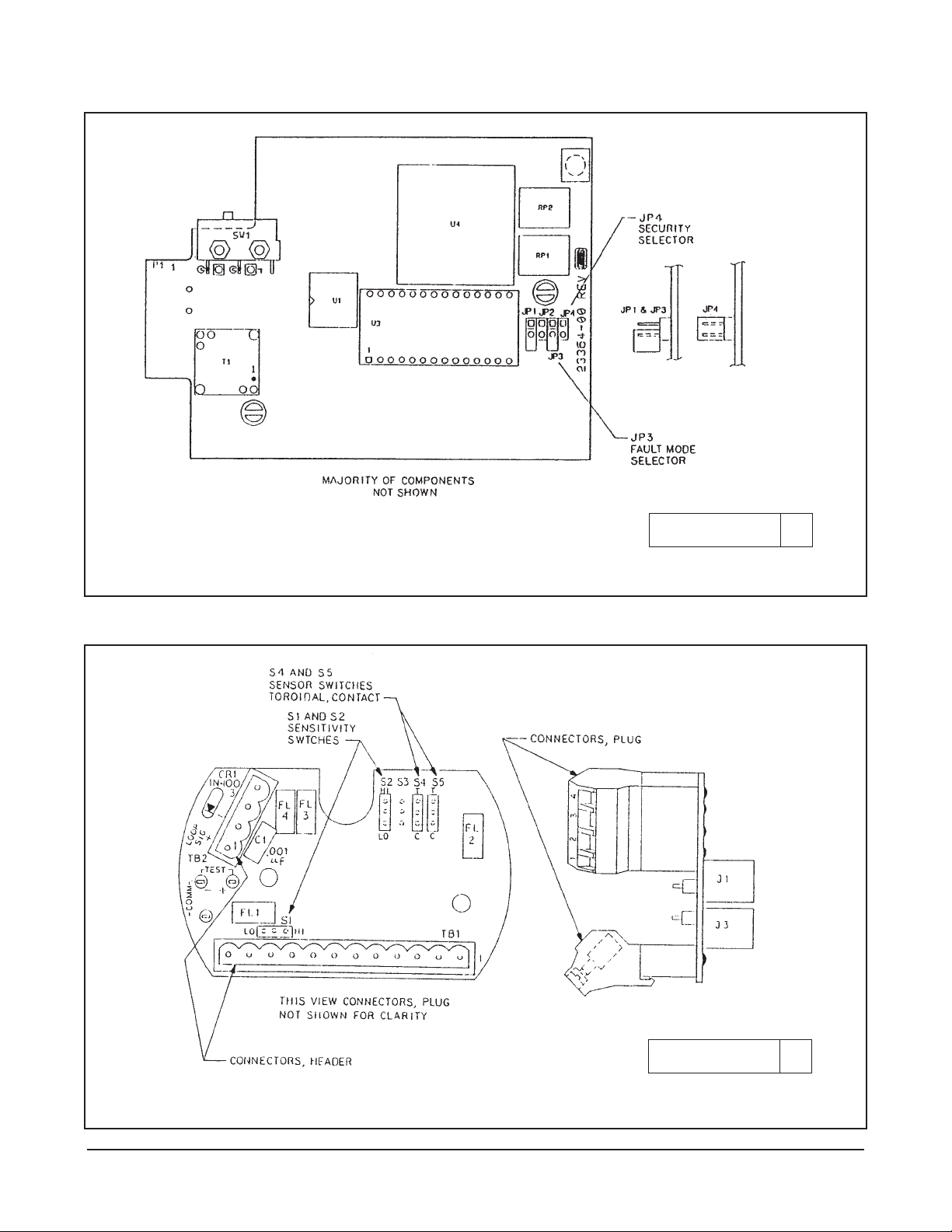

1-4 Fault and Security Jumper Locations...................................................................... 7

1-5 Sensor To Transmitter Switch Settings ................................................................... 7

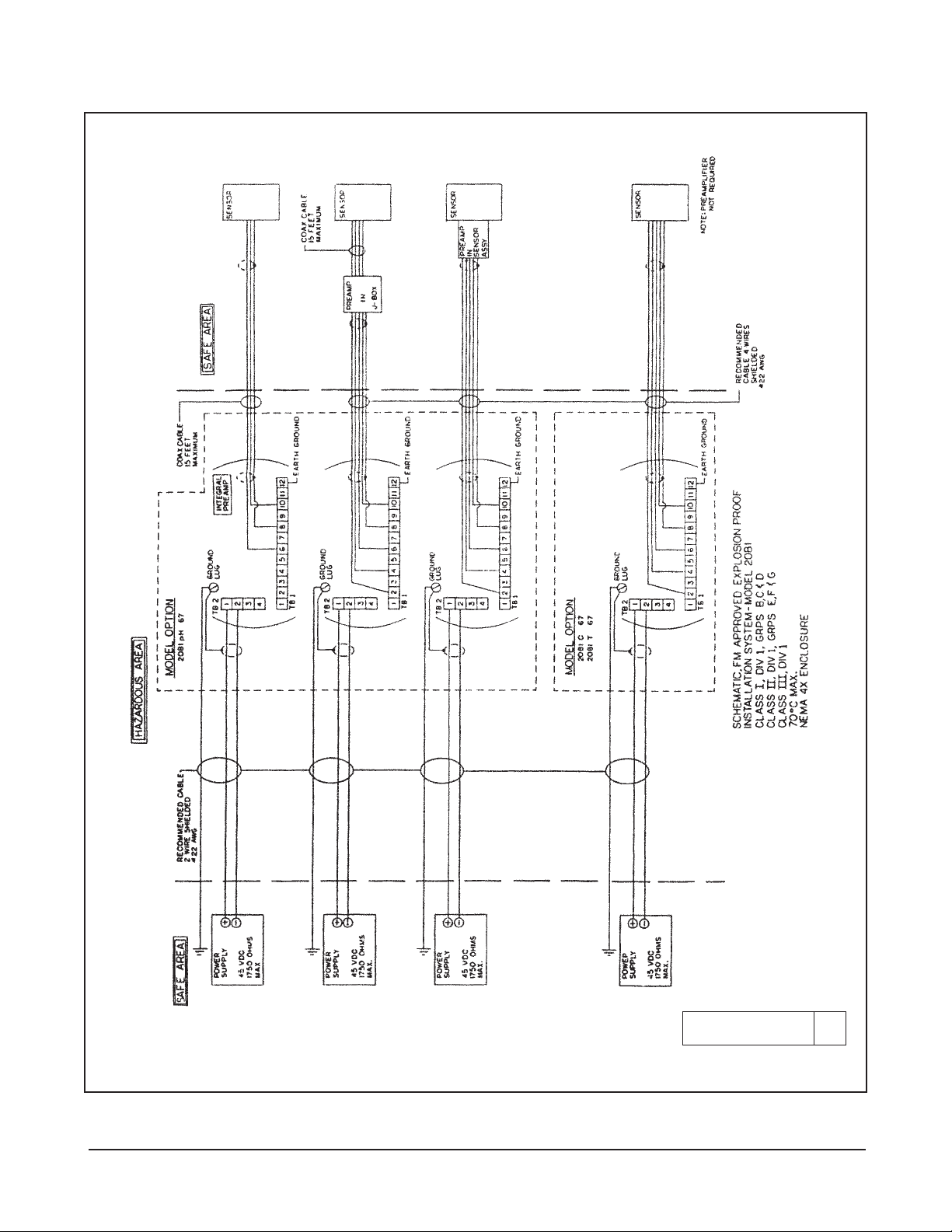

1-6 Explosion Proof System Installation Schematic ..................................................... 8

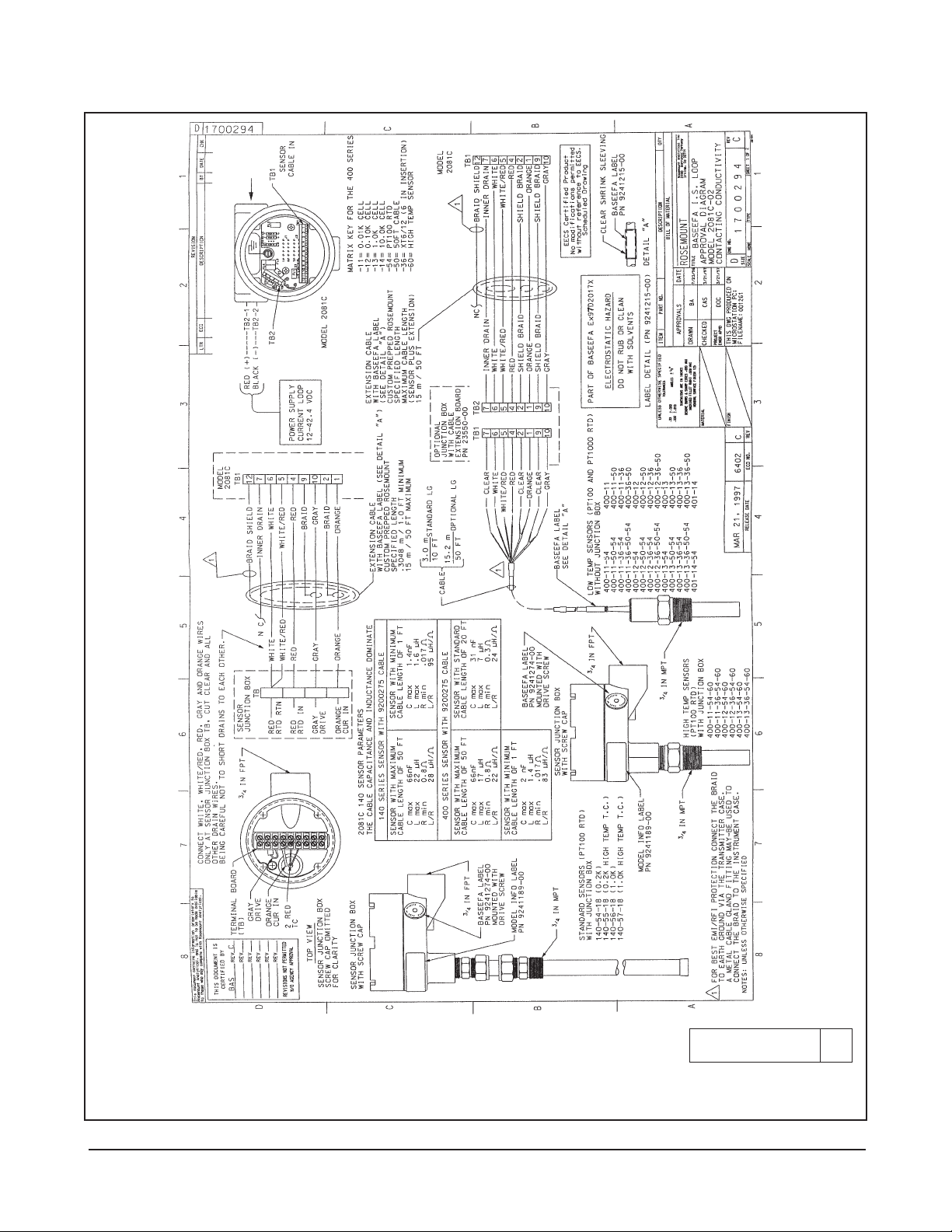

1-7 Intrinsically Safe (BASEEFA) Wiring for Model 2081C ........................................... 9

1-8 Intrinsically Safe (BASEEFA) Wiring for Model 2081T .......................................... 11

1-9 Intrinsically Safe (CSA) Wiring for Model 2081C/T ................................................ 13

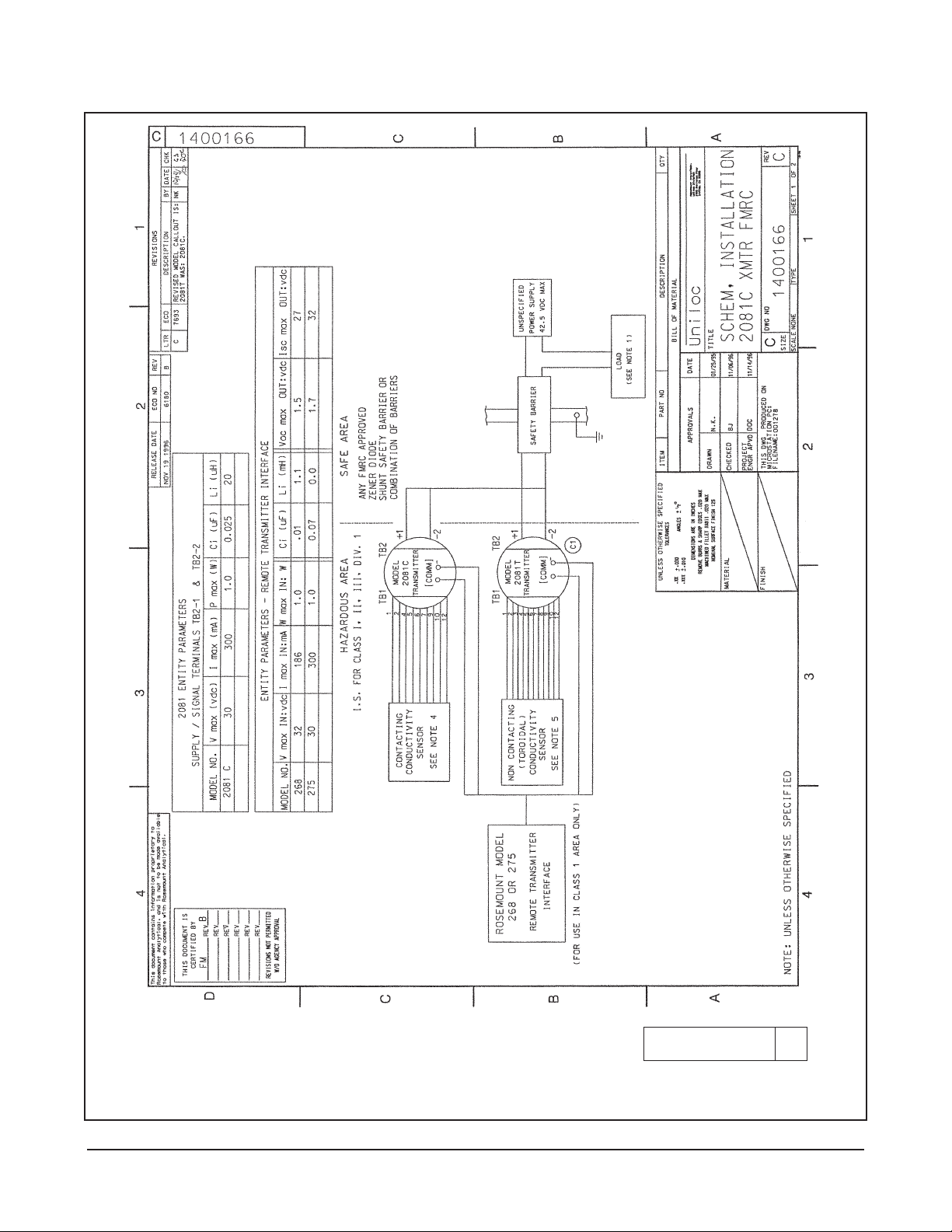

1-10 Intrinsically Safe (FM) Wiring for Model 2081C/T .................................................. 15

3-1 Menu Description .................................................................................................... 17

5-1 Jumper Locations.................................................................................................... 22

6-1 Bench Check (Contact Sensor) .............................................................................. 26

6-2 Bench Check (Toroidal Sensor) .............................................................................. 26

6-3 Troubleshooting Flow Chart .................................................................................... 28

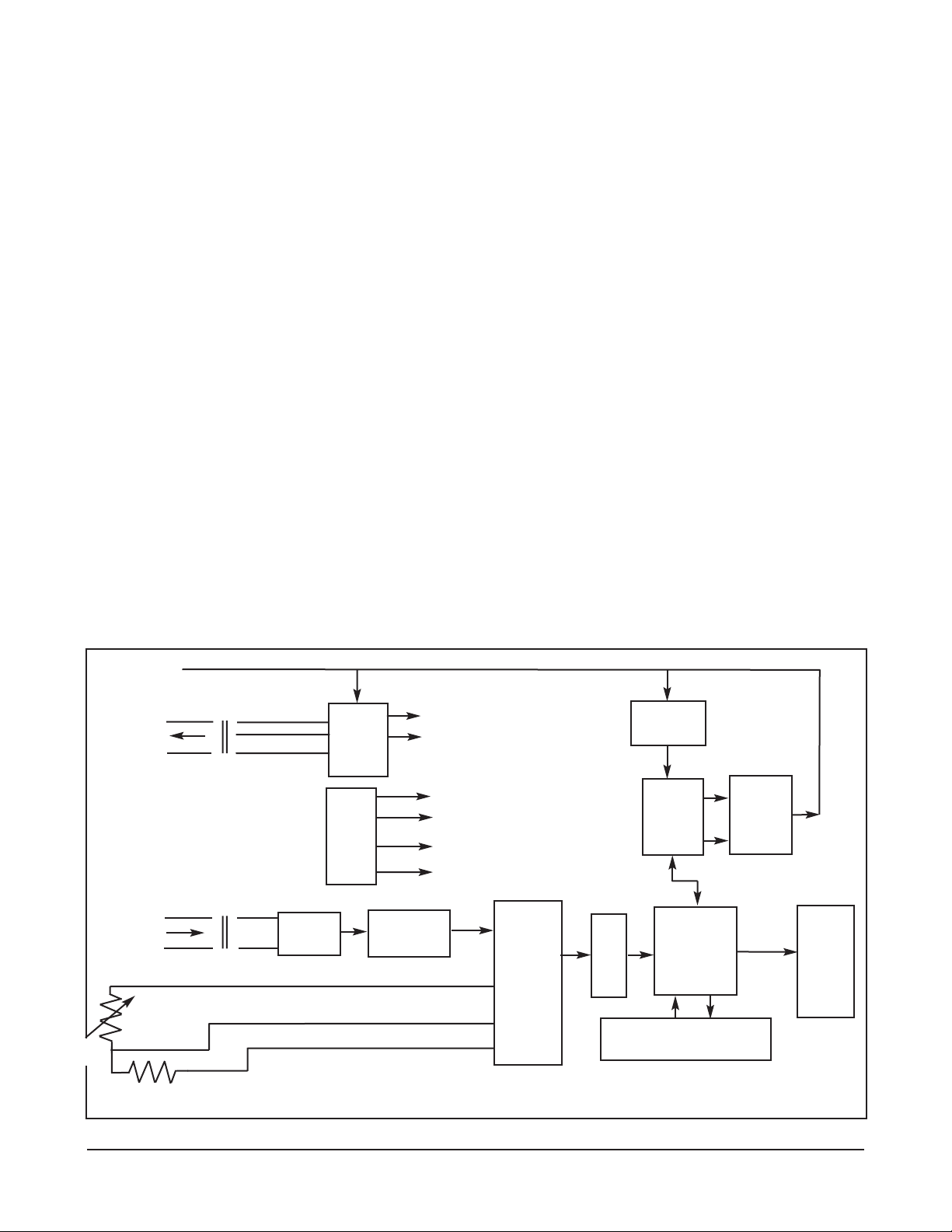

7-1 Block Diagram......................................................................................................... 29

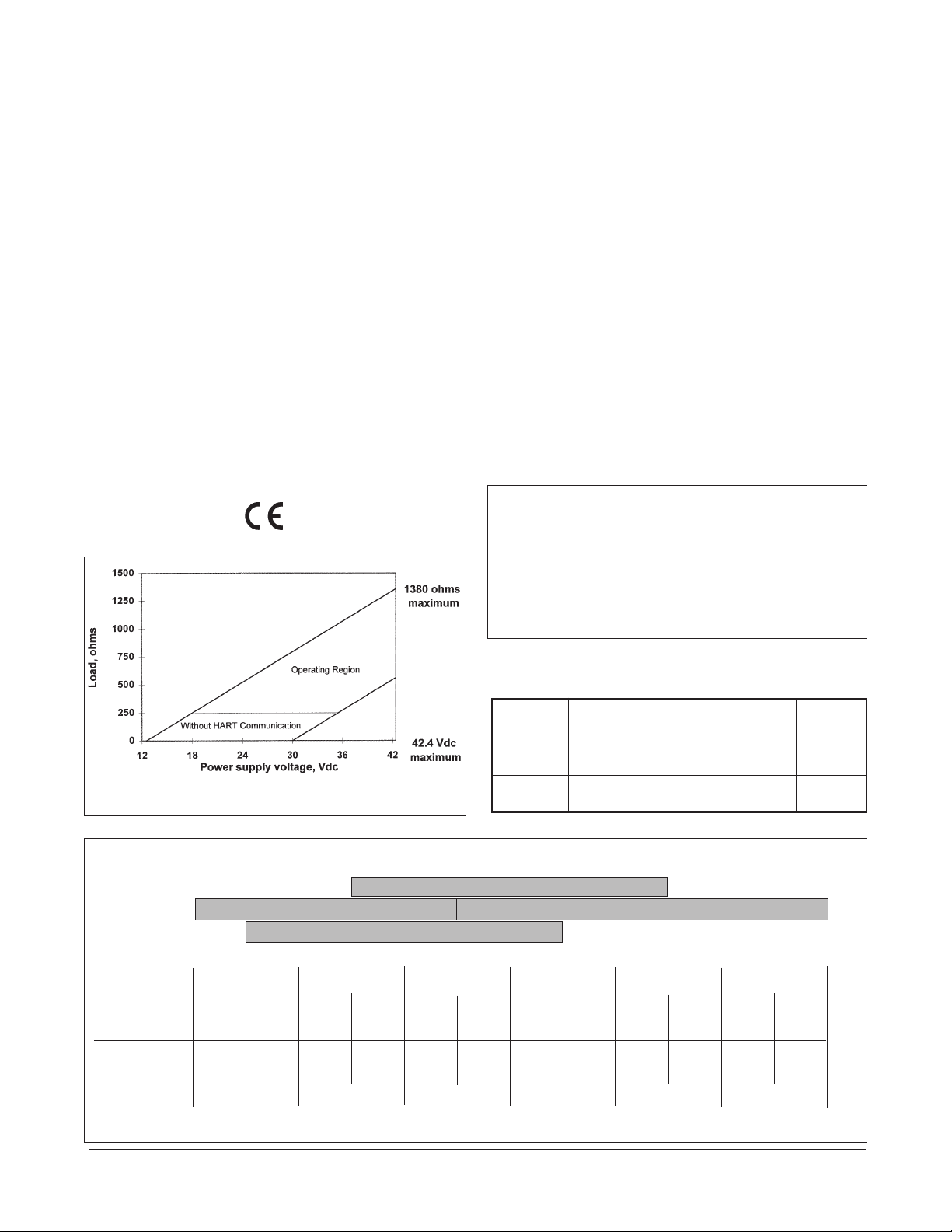

8-1 Load/Power Supply Requirements.......................................................................... 32

8-2 Model 275 HART

®

Communication Menu Tree-Model 2081C/T............................ 35

LIST OF TABLES

Table No. Title Page

3-1 Sensors used with Model 2081C/T conductivity..................................................... 18

3-2 Measurement Ranges............................................................................................. 18

6-1 Diagnostic Messages.............................................................................................. 23

6-2 Resistance Values (Temperature) ........................................................................... 24

6-3 Resistance Values (Conductivity)............................................................................ 24

6-4 Quick Troubleshooting Guide.................................................................................. 27

8-1 Local Interference Functions................................................................................... 32

8-2 Measurement Ranges............................................................................................. 32

MODEL 2081C/T TABLE OF CONTENTS

Page 5

SECTION 1.0 INSTALLATION

1.1 UNPACKING AND INSPECTION. Inspect the

transmitter for shipping damage. If damaged, notify the

carrier immediately.

Confirm that all items shown on the packing list are

present. Notify Rosemount Analytical if any items are

missing.

If the transmitter appears to be in satisfactory condition

proceed to Section 1.2.

NOTE

Save the original packing cartons and materials as most carriers require proof of damage

due to mishandling.

1.2 MECHANICAL INSTALLATION.

1.2.1 General. The transmitter may be installed in

harsh environments. However, it should be installed in

an area where sources of extreme temperature fluctuation, vibration and shock are at a minimum or absent.

Installation site should:

1. permit the use of the standard cable lengths

(unless a junction box is used),

2. be easily accessed by operating and maintenance

personnel, and

3. be at least 12 inches (.3 m) from sources of high

voltage.

NOTE

Before installing the transmitter, it should

be determined whether the Model 275 will

be used with the 2081C/T.

1.2.2 Mounting. The transmitter may be mounted on a

flat surface using the two threaded mounting holes

located on the bottom of the transmitter or through the

use of an optional 2-inch pipe/wall mounting bracket,

Code 07 (Figure 1-1).

NOTE

The meter may be installed in 90-degree

increments for easy viewing. Remove the

four screws holding the meter in place and

change the meter to the desired angle. Plug

in the display and tighten the four screws.

1.3 WIRING. The transmitter is equipped with two 1/2-

inch NPT conduit openings, one on each side of the

housing. One is for the power supply/signal wiring and

the other is for the sensor wiring.

The use of weathertight cable glands or conduit is

recommended to prevent moisture from entering the

housing. Conduit should be positioned to prevent condensation from draining into the housing. Conduit connections on the transmitter housing should be plugged

and sealed to avoid moisture accumulation inside the

terminal section of the housing.

CAUTION

If the connections are not sealed, mount transmitter with the electrical housing positioned

downward for drainage. Wiring should be

installed with a drip loop. The bottom of the

drip loop should be lower than the conduit connections or the transmitter housing.

1.3.1 Power Supply/Signal Wiring. It is recommended that the signal wiring be shielded, twisted pairs that

are grounded. The best place to ground the loop is at

the negative terminal of the power supply. Do not

ground the signal loop at more than one point. The

transmitter case shall be grounded. The power and

signal wiring terminal is TB2 terminals 1 through 4 as

shown in either Figures 1-1, 1-2, and 1-3.

Signal or sensor wiring should never be run in the

same conduit or open tray as AC power or relay actuated signal cables. Keep signal or sensor wiring at

least 12 in. (.3 m) from heavy electrical equipment.

NOTE

For best EMI/RFI protection the power supply/signal cable should be shielded and

enclosed in an earth grounded, rigid metal

conduit. Connect the cable’s outer shield to

the ground terminal near TB2, Figure 1-1. The

sensor cable should also shielded. The cable’s

outer shield shall be connected to the earth

ground terminal provided near TB2, Figure 1-

1. If the outer shield is braided an appropriate

metal cable gland fitting maybe used to connect the braid to earth ground via the instrument case.

A new addition to the suite of tests done to

ensure CE compliance is IEC 1000-4-5. This is

a surge immunity test that simulates overvoltages due to switching and lightning transients.

In order to meet the requirements of this test,

additional protection must be added to the

instrument in the form of a Transient Protector

such as the Rosemount Model 470D. This is a

3½-inch tube with ½-inch MNPT threads on

both ends. Inside the tube are gas discharge

and zener diode devices to limit surges to the

transmitter from the current loop. No additional protection is needed on the sensor connections.

1

MODEL 2081C/T SECTION 1.0

INSTALLATION

Page 6

2

1.3.2 Sensor Wiring. The sensor wiring terminals are

located on the side opposite to the LCD meter. Remove

the housing cover to gain access. Pass the sensor cable

through the transmitter’s conduit opening. Connect the

sensor wiring to TB1 terminals 1 through 12 as shown on

Figures 1-2 and 1-3.

NOTE

If the standard cable length is not sufficient

for the planned installation, the use of a

junction box with extension cable is strongly recommended. Do not exceed 250 feet

(76m) total cable length from the sensor to

the transmitter.

1.3.3 Matching Transmitter to sensor. Switches S4 and

S5 are used to normalize the transmitter for Toroidal or

contact sensors. See Figure 1-5.

Switches S4 and S5 should both be set to T when Toroidal

sensors are installed, C when Contact sensors are

installed.

Switches S1 and S2 are used to select the sensitivity

range of the LCD. To obtain desired switch settings, multiply the cell constant of the probe being used by the maximum low range value. If the working range of the process

is below this calculated value then set both switch to Lo.

If the working range of the process is above this calculated value then set both switch to Hi (see table below).

Sample: Model 142 sensor: .2 (cell constant) x

4,000µS (maximum low range value)= 800µS (calculated value).

1.4 FAULT MODE AND SECURITY

JUMPER

1.4.1 General This section describes how to set the

jumpers on the CPU board for the following (See

Figure 1-4).

1. Output value in fault (alarm) mode

2. Security - Write Disable

3. Security - Push Buttons

CAUTION

The circuit board is electrostatically sensitive.

Be sure to observe handling precautions for

static-sensitive components.

1.4.2 Fault Mode Output. The default output of the

transmitter during a fault condition is determined by the

position of the default current output jumper JP3 (refer to

Figure 1-4). The output can be set to default either:

– below 4mA - JP3 with jumper.

– above 20mA - JP3 without jumper (factory setting).

Store jumper on one post to prevent misplacing it. See

Section 8.0 for corrective actions for fault messages.

1.4.3 Security. Also explained in Section 6.0. These

jumpers are located on the CPU board. See Figure 1-4

for location.

– Disable 2081 push buttons - JP4 without jumper.

(Store jumper on one post to prevent misplacing it).

– Enable 2081 push buttons - JP4 with jumper (fac-

tory setting).

– Disable all changes to configuration - JP1. Jumper

in place disables any (EEPROM or push button)

changes.

– Allow changes to configuration - JP1 Jumper on

one post only will enable configuration changes.

Mnemonic Fault

SLP – FAIL - 2 point calibration error

AdC – FAIL - Transmitter electronics failure

(A/D converter)

rngE – LOOP - Conductivity value outside 4-20 mA

range points

tEnP – Lo - Temperature too low or RTD shorted

tEnP – Hi - Temperature too high or RTD open

Type Maximum Switch

Sensor Range Setting

Toroidal Below 400,000µS x Cell Constant Both “Lo”

Above 400,000µS x Cell Constant Both “Hi”

Contacting Below 4,000µS x Cell Constant Both “Lo”

Above 4,000µS x Cell Constant Both “Hi”

MODEL 2081C/T SECTION 1.0

INSTALLATION

Page 7

3

1.5 CALIBRATION AND SET-UP

Instructions for output current ranging, security set ups,

and calibration of sensor temperature, cell constant

etc, are contained in Sections 2.0 through 5.0.

1.6 HAZARDOUS LOCATIONS —

EXPLOSION PROOF INSTALLATIONS

In order to maintain the explosion proof rating for

installed transmitter, the following conditions must be

met.

1. Code 67 must be specified when ordering F.M.

(Factory Mutual) units.

2. Explosion proof installation must be in accordance

with Drawing Number 1400160 (see Figure 1-6).

3. The transmitter enclosure covers must be on hand

tight and the threads must not be damaged.

NOTE

These covers seat on rings which serve to

provide a dust proof enclosure for Class II

and Class III installations.

4. Explosion proof “Y” fittings must be properly

installed and plugged with a sealing compound to

prevent explosive gases from entering the transmitter. CSA has determined that the transmitter

housing is “Factory Sealed”. Installation of “Y” fittings and the use of sealing compound is not

required for CSA approved Explosion Proof installations.

NOTE

Do not install sealing compound until all

field wiring is completed.

CAUTION

Sealing compound must be installed prior

to applying power to the transmitter.

5. If one of the conduit connections on the housing is

not used, it must be closed with a threaded metal

plug with at least five threads engaged.

1.7 HAZARDOUS LOCATIONS —

INTRINSICALLY SAFE INSTALLATIONS

See Figure 1-7 for Model 2081C intrinsically safe installation (BASEEFA). See Figure 1-8 for Model 2081T

intrinsically safe installation (BASEEFA). See Figure 19 for Model 2081C and 2081T intrinsically safe installation (CSA). See Figure 1-10 for Model 2081C and

2081T intrinsically safe installation (FM).

MODEL 2081C/T SECTION 1.0

INSTALLATION

Page 8

4

FIGURE 1-1. Model 2081C/T Dimensional/Mounting Instructions with Power Supply/Loop Signal Wiring

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

DWG. NO. REV.

40208120 A

MODEL 2081C/T SECTION 1.0

INSTALLATION

Page 9

5

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

FIGURE 1-2. Model 2081C Contacting Electrode Wiring

PN 9200275

CABLE PN 9200275 - UNPREPPED

CABLE PN 23747-00 - PREPPED

CE approved cable for Sensor Models 140, 141, 142, 150, 400, 401, 402, 403, & 404 using cable PN 9200275 or 23747-00

WIRE FUNCTIONS

DWG. NO. REV.

40208119 A

MODEL 2081C/T SECTION 1.0

INSTALLATION

Page 10

6

FIGURE 1-3. Model 2081T Inductive Sensor Wiring

DWG. NO. REV.

40208106 C

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

MODEL 2081C/T SECTION 1.0

INSTALLATION

Page 11

7

FIGURE 1-5. Sensor to Transmitter Switch Settings

FIGURE 1-4. Fault and Security Jumper Locations

DWG. NO. REV.

40208110 B

DWG. NO. REV.

40208109 A

MODEL 2081C/T SECTION 1.0

INSTALLATION

Page 12

8

FIGURE 1-6. Explosion Proof System Installation Schematic (FM)

DWG. NO. REV.

1400160 A

MODEL 2081C/T SECTION 1.0

INSTALLATION

Page 13

9

MODEL 2081C/T SECTION 1.0

INSTALLATION

FIGURE 1-7. Intrinsically Safe (BASEEFA) Wiring for Model 2081C

Part 1 of 2

DWG. NO. REV.

1700294 C

Page 14

MODEL 2081C/T SECTION 1.0

INSTALLATION

FIGURE 1-7. Intrinsically Safe (BASEEFA) Wiring for Model 2081C

Part 2 of 2

DWG. NO. REV.

1700294 C

10

Page 15

MODEL 2081C/T SECTION 1.0

INSTALLATION

FIGURE 1-8. Intrinsically Safe (BASEEFA) Wiring for Model 2081T

Part 1 of 2

DWG. NO. REV.

1700291 D

11

Page 16

MODEL 2081C/T SECTION 1.0

INSTALLATION

FIGURE 1-8. Intrinsically Safe (BASEEFA) Wiring for Model 2081T

Part 2 of 2

DWG. NO. REV.

1700291 D

12

Page 17

MODEL 2081C/T SECTION 1.0

INSTALLATION

FIGURE 1-9. Intrinsically Safe (CSA) Wiring for Model 2081C/T

Part 1 of 2

DWG. NO. REV.

1400169 B

13

Page 18

MODEL 2081C/T SECTION 1.0

INSTALLATION

FIGURE 1-9. Intrinsically Safe (CSA) Wiring for Model 2081C/T

Part 2 of 2

DWG. NO. REV.

1400169 B

14

Page 19

MODEL 2081C/T SECTION 1.0

INSTALLATION

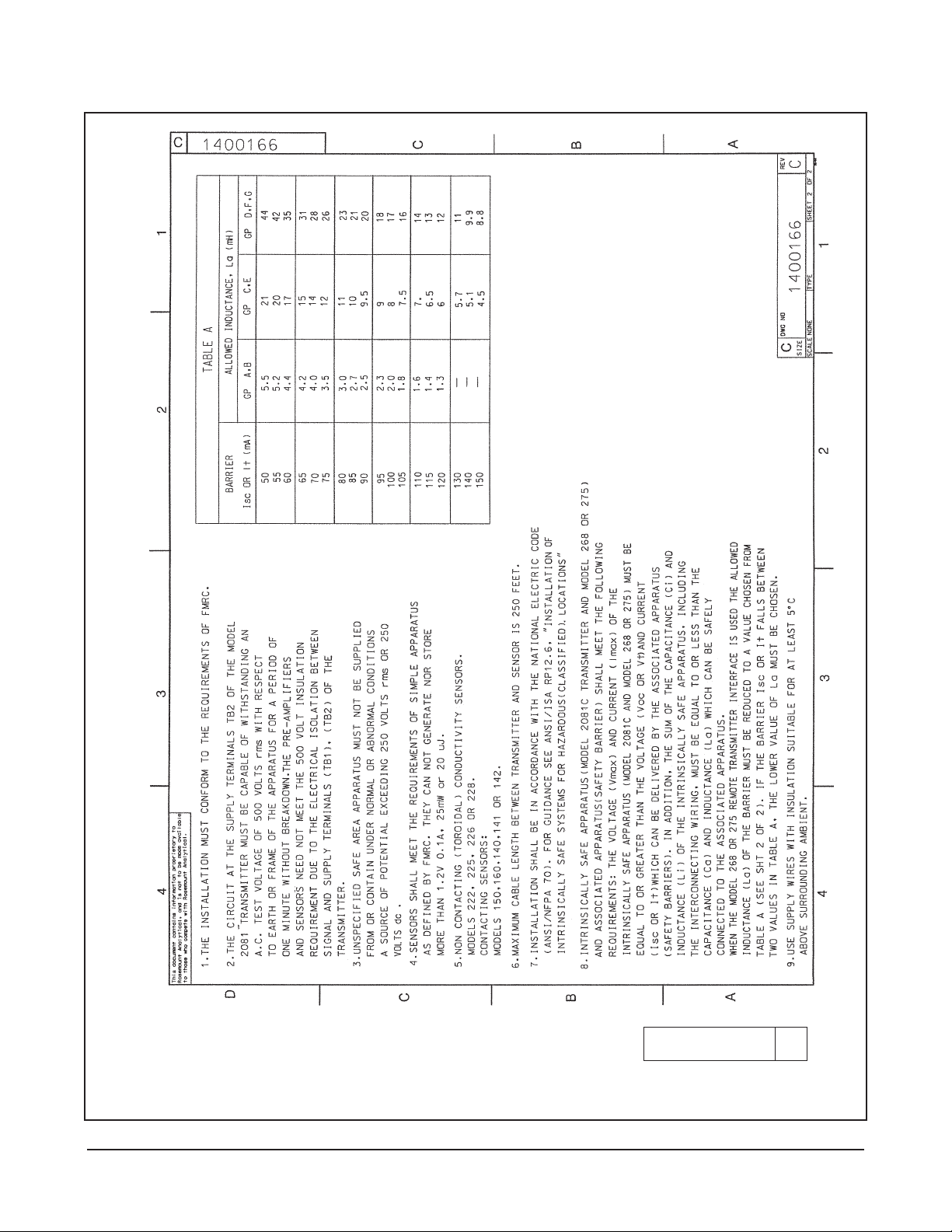

FIGURE 1-10. Intrinsically Safe (FM) Wiring for Model 2081C/T

Part 1 of 2

DWG. NO. REV.

1400166 C

15

Page 20

MODEL 2081C/T SECTION 1.0

INSTALLATION

FIGURE 1-10. Intrinsically Safe (FM) Wiring for Model 2081C/T

Part 2 of 2

DWG. NO. REV.

1400166 C

16

Page 21

17

SECTION 2.0 DESCRIPTION OF CONTROLS

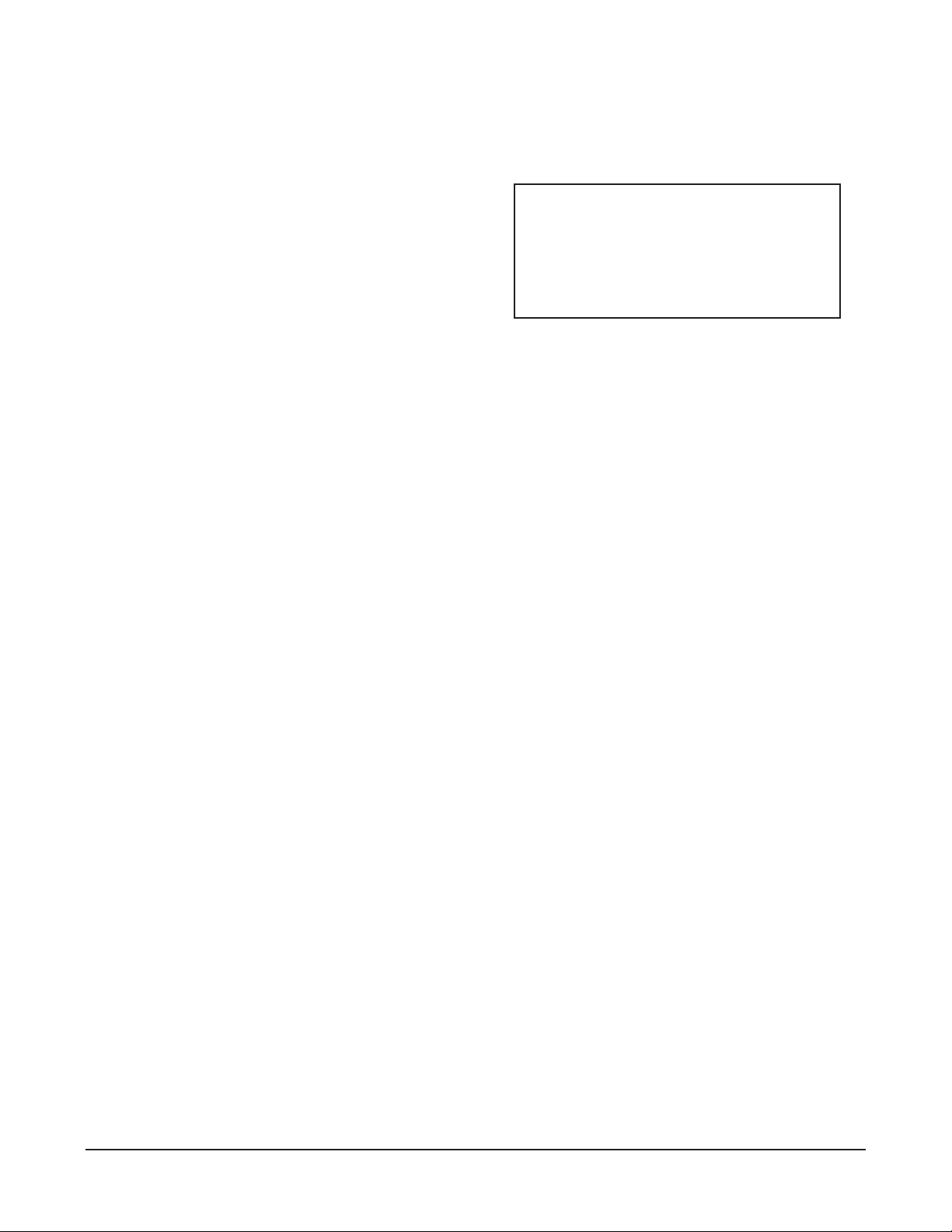

Figure 3-1. Menu Description

2.2.2 Display Flags and Hold Mode. The transmitter

displays a flag on the LCD corresponding to the appropriate units.

When the transmitter is in hold output mode a flashing

flag will appear on the middle right hand side of the display and HoLd will flash periodically. The output will

remain at the last process value. To return the transmitter to normal operation, scroll to hold again and

release both buttons.

2.3 VALUE ADJUSTMENT. Selection of a menu item

that has a user-adjustable value will cause a numeric

display with the right-most digit flashing.

• Depressing and holding push button #1 will cause

the number flashing to increment upwards, looping

back to zero.

• Depressing push button #2 will shift the flashing

cursor to the next decade.

• Decimal position is shifted by pressing button #2 when

the left most digit is flashing under the Std menu.

Decimal will start flashing. Change location by

pressing button #1.

• Select millisiemens/microsiemens flag by going

through decimal position sequence and then

pressing button #2. Flag will start flashing. Press

button #1 to position the flag on the proper

choice. Press button #2 once more and sensor

will return to the starting point to change values.

Press both buttons in momentarily to enter displayed value into memory.

NOTE

The autoranging feature on the 2081C/T will

make decimal point setting and engr. unit settings

unnecessary.

MAIN MENU

dISP – – – – – – – – – –

Ê

Std

Standardize Conductivity

hold Initiate and remove hold output mode

-0- Zero sensor loop

LoC 4 mA range point

HiC 20 mA range point

CELL Cell constant

tAdJ Standardize temperature, °C

Atc Automatic temperature compensation

SLP Electrode slope (mV/pH)

tP1 Calibration point one

tP2 Calibration point two

DISPLAY SUBMENU

Cond Conductivity value

fct Cell factor

curr Output in mA

DIo

Output in % of full scale

DC Temperature, °C

DF Temperature, °F

Cin Absolute conductivity

2.1 GENERAL. Nearly all functions of the transmitter

are accessed through the dual push buttons. The

transmitter uses no potentiometer.

2.2 MENU SELECTION. The dual push buttons are

located on the side of the transmitter. Press and hold

both buttons to display the transmitter menu items.

See Figure 3-1. The display will show each item for

about one second then scroll to the next item. It will

continue to loop through the items until one is selected. To select an item, release both push buttons when

the desired item is displayed.

NOTE

When no push button is pressed for a period of 60 seconds, the transmitter defaults to

reading conductivity. If the push buttons are

accidentally released and this would upset

the process (e.g. tP2), escape by waiting 60

seconds for the transmitter to default to the

conductivity reading.

2.2.1 Display Submenu. The display submenu (dISP) is

used to access secondary process values that cannot

be changed.

To enter the submenu, scroll thru the main menu. When dISP

is on the LCD release both buttons. The display will read Cond.

To see the conductivity value in this submenu, press both

push buttons momentarily.

To scroll thru the submenus, press both buttons and HOLD.

Submenu mnemonics will start scrolling. Release both buttons when mnemonic desired is displayed. Screen will display to value of submenu item selected. To view another

value in the submenu press both buttons momentarily.

Screen will revert to Cond, the entry screen for the submenus. – Repeat previous submenu actions.

To exit the submenu, press both push buttons and hold.

Display will start scrolling thru the main menu items or

take no action for 60 seconds and the display will default

to the conductivity reading.

• Press and hold both buttons auto

scrolls through main menu and

submenu.

• Release buttons to select item.

• Push button #1: Press and hold

auto scrolls digits.

• Push button #2: Press and hold

auto shifts decades.

• Enter a value: Depress both but-

tons briefly.

MODEL 2081C/T SECTION 2.0

DESCRIPTION OF CONTROLS

Page 22

SECTION 3.0 RANGE CONFIGURATION

3.1 GENERAL. The conductivity range of the transmit-

ter depends upon the sensor used. Table 3-1 can be

used to determine ranges available with the sensor

used. As shipped from the factory, 4 mA represents 0

siemens and 20 mA represents 2 siemens. The value

displayed for these output currents are user selectable. To change the displayed readings in siemens for

4mA and 20mA proceed:

A. Output Zero (4 mA) LoC

1. Depress and hold both push buttons. The display

will begin to auto scroll.

2. Release both keys when LoC is displayed. The

present 4 mA conductivity value in memory will be

displayed with the last digit flashing.

3. Depress and hold push button #1 (scroll) and #2

(shift) as needed to display the desired conductivity value.

4. Enter the value into memory by depressing both

push buttons briefly. The display will return to displaying the present conductivity value.

B. Full Scale (20 mA) HiC

1. Depress and hold both push buttons. The display

will begin to auto scroll.

2. Release both keys when HiC is displayed. The

present 20 mA conductivity value in memory will

be displayed with the last digit flashing.

3. Depress and hold push button #1 (scroll) and #2

(shift) as needed to display the desired conductivity value.

4. Enter the value into memory by depressing both

push buttons briefly. The display will return to displaying the present conductivity value.

NOTE

For a reverse output, enter the higher value

for LoC, and the lower value for HiC.

TABLE 3-1

SENSORS USED WITH MODEL 2081 CONDUCTIVITY

Conductivity Sensor 142 142 140 140, 141

Model Number 400 150, 400 141 150 150, 400 401 222 225 226 228

Cell Constant** 0.01 0.1 0.2 0.5 1.0 10.0 * 3.0 1.0 3.0

Min. Range 1 2 4 10 20 200 500 250 50 250

Max. Range 200 2,000 4,000 10,000 20,000 200,000

2,000,000 2,000,000 1,000,000 2,000,000

FULL SCALE MICROSIEMENS/cm

* 1 in. diameter = 6.0, 2 in. diameter = 4.0 (Typical)

** Typical

MODEL 2081C/T SECTION 3.0

RANGE CONFIGURATION

18

TABLE 3-2. Measurement Ranges

Type Maximum Switch

Sensor Range Setting

Toroidal Below 400,000µS x Cell Constant Both “Lo”

Above 400,000µS x Cell Constant Both “Hi”

Contacting Below 4,000µS x Cell Constant Both “Lo”

Above 4,000µS x Cell Constant Both “Hi”

Page 23

19

SECTION 4.0 START-UP AND CALIBRATION

4.1 GENERAL. A sensor must be wired to the trans-

mitter for calibration. See the appropriate sensor manual for additional instructions relating specifically to the

sensor.

4.2 TEMPERATURE CALIBRATION. For the most

accurate temperature compensation, the temperature

reading may need adjusting. The following steps

should be performed with the sensor in a grab sample

or process of known temperature.

NOTE

Calibrate at or near the process temperature for greatest accuracy.

1. Scroll through the menu items. Press and hold

both push buttons simultaneously.

2. When tAdJ, is displayed, release both buttons. The

display will show the present temperature value in

degrees Celsius with the last digit flashing. The

tenths digit will alternate between a value and °C.

3. Compare the displayed reading with a calibrated

temperature reading device. If the reading

requires adjustment, proceed to step 4. Otherwise, depress both push buttons briefly to accept

the displayed value.

4. Depress and hold push buttons #1 (scroll) and #2

(shift) as needed to display the desired temperature value.

5. Enter the correct value into memory by depressing

both push buttons briefly. The display will return to

displaying the present conductivity value.

4.3 ENTERING THE CELL CONSTANT. The first time

the analyzer is calibrated and any time there is a sensor change, the sensor cell constant must be entered

into memory. Entering a cell constant into memory will

reset the cell factor Fct to 1.0 and will initiate the analyzer. The cell factor gives an indication of sensor fouling or coating. Refer to Section 6.0.

NOTE

The cell constant (K) will be found on the

sensor label (i.e. K = 3.04, K = 1.00) located on the cable. For Models 140, 141, and

142. The cell constant is shown on the

junction box label. (For the Model 222 the

label is on spindle).

1. Scroll through the menu items. Press and hold both

push buttons simultaneously.

2. When CELL, is displayed release both buttons. The

display will show the cell constant in memory with

the right most digit flashing.

3. Press and hold buttons #1 (scroll) and #2 (shift) as

needed to display the correct cell constant.

4. Enter the correct value into memory by briefly

pressing both push buttons simultaneously. The

display will return to displaying the present conductivity value.

4.4 ZEROING THE SYSTEM. The transmitter must

calibrate the zero point before the sensor is placed into

the process solution.

CAUTION

DO NOT PLACE THE SENSOR IN THE

PROCESS. The sensor must be placed

into solution only after performing a system

zero.

1. Assure that the sensor is properly wired and out of

process (in air).

2. Scroll through the menu items. Press and hold

both push buttons simultaneously.

3. When -0-, is displayed, release both buttons. The

transmitter will calculate the loop zero point. This

takes about 10 to 20 seconds. -0- will flash on the

display while the transmitter is calibrating. The display will return to displaying conductivity when the

zero calibration is complete.

4. Place the sensor in solution and proceed with the

system calibration.

4.5 INITIAL LOOP CALIBRATION. Please read the

entire calibration section before proceeding to determine the best calibration procedure. Also, please

check the appropriate sensor manual’s calibration section for any specific instructions.

MODEL 2081C/T SECTION 4.0

START-UP AND CALIBRATION

Page 24

20

4.5.1 Two Point Calibration - Process temperature

slope not known. Recommended procedure for the initial calibration if the process temperature slope is not

known. If any of the steps below are impossible or

impractical to perform, refer to alternate Section 4.5.2.

1. Obtain a grab sample of the process to be measured.

2. Determine the sample’s conductivity using a calibrated instrument or portable analyzer. The instrument must be able to reference the conductivity to

25°C, or the solution must be measured at 25°C.

Record the reading.

NOTE

The transmitter must be in hold or off line.

3. Immerse the measuring portion of the sensor in

process solution. (Model 222 users should refer to

the sensor’s manual for special instructions). The

sensor body must be held away from the bottom

and sides of the sample’s container at a distance at

lease the diameter of the sensor.

Shake the sensor to ensure that no air bubbles are

present.

4. Adjust the sample’s temperature to either the normal high or normal low process temperature. (To

raise the sample’s temperature, a hot plate with

stirrer may be used. To lower the sample temperature, place the grab sample’s container in an ice

bath or let it slowly cool down).

5. Allow the sensor to acclimate to the sample temperature. (The temperature reading should be stable).

6. Scroll through the menu items. Press and hold

both push buttons simultaneously.

7. When tP1, is displayed, release both buttons. The

display will show the conductivity value in memory with the right most digit flashing.

8. Depress and hold buttons #1 (scroll) and #2 (shift)

as needed to display the grab sample’s conductivity value at 25°C as noted in step 2.

9. Enter the correct value into memory by briefly

depressing both push buttons simultaneously. The

display will return to displaying the present conductivity value.

10. Adjust the sample’s temperature to the process’s

other normal temperature extreme.

11. Allow the sensor to acclimate to the sample temperature. (The temperature reading should be stable).

12. Scroll through the menu items. Press and hold both

push buttons simultaneously.

13. When tP2 is displayed, release both buttons. The

display will show the conductivity value in memory with the right most digit flashing.

14. Depress and hold buttons #1 (scroll) and #2 (shift)

as needed to display the grab sample’s conductivity value at 25°C as noted in step 2.

15. Enter the correct value into memory by briefly

depressing both push buttons simultaneously. The

display will return to displaying the present conductivity value.

The analyzer then calculates the true cell constant and

the processes temperature slope, then returns to reading conductivity.

The temperature slope of the process can now be read

by selecting SLP from the menu.

The sensor may now be installed in the process.

NOTE

If the 2081 was placed in hold, be sure to

remove it from hold after the sensor is on line.

4.5.2. Single Point Calibration - Process Temp-

erature Slope Known. This is the recommended procedure for the initial calibration if the temperature slope of

the process is known. If you do not know the exact

temperature slope value, but wish to approximate it,

refer to the following guide.

Acids: 1.0 to 1.6%/°C

Bases: 1.8 to 2.2%/°C

Salts: 2.2 to 3.0%/°C

Water: 2.0%/°C

1. Scroll through the menu items. Press and hold both

push buttons simultaneously.

2. Release both buttons simultaneously when SLP is

displayed. The slope value in memory will display

with the right most digit flashing.

3. Depress and hold buttons #1 (scroll) and #2 (shift)

as needed to display the desired temperature

slope value.

4. Enter the correct value into memory by briefly

depressing both push buttons simultaneously. The

display will return to displaying the present conductivity value.

MODEL 2081C/T SECTION 4.0

START-UP AND CALIBRATION

Page 25

6. Depress and hold buttons #1 (scroll) and #2 (shift)

as needed to display the conductivity value noted

in step 3.

Depress both push buttons simultaneously to

accept this value.

The transmitter will then calculate the proper cell

factor.

7. Depress both push buttons simultaneously and

release when diSP is displayed.

Depress both push buttons again and release

when Fct is displayed.

Note this value to determine a sensor maintenance schedule.

4.7 HOLD MODE FOR MAINTENANCE. Before per-

forming maintenance of the sensor, or buffer checks, the

transmitter should be placed in the HoLd mode. This mode

of operation maintains the output current at the last

process value. To initiate HoLd mode:

1. Depress and hold both push buttons simultaneously

until HoLd is displayed on the screen.

2. Release both buttons.

a. The HoLd flag will flash, and

b. The display will show HoLd every two seconds

to confirm the hold status.

To place the transmitter back into normal operation,

(remove from HoLd mode):

1. Depress and hold both push buttons simultaneously until HoLd is displayed on the screen.

2. Release both buttons.

a. The HOLD, flag will stop flashing.

b. The display will stop showing HoLd every two

seconds.

c. The transmitter output current will return to

normal operation.

4.8 SENSOR MAINTENANCE. Always calibrate after

cleaning or repair of the conductivity sensor.

Always place transmitter into the HoLd mode of operation while performing any maintenance to the sensor to

avoid loss of process control.

Always return transmitter to normal operation after

installing the sensor back into the process.

5. Obtain a grab sample of the process to be measured.

NOTE

Be sure the transmitter is in Hold or Off-Line.

6. Determine the sample’s conductivity using a calibrated instrument or a portable analyzer. The

instrument must be able to reference the conductivity to 25°C, or the solution must be at 25°C.

Write down the reading. Ensure that the analyzer

is in hold.

7. With the sensor in sample, depress and hold both

push buttons simultaneously to enter the transmitter menu. The transmitter will auto scroll through

the menu items. Release both push buttons when

Std is displayed. The conductivity value will display with the right most digit flashing.

8. Depress and hold buttons #1 (scroll) and #2 (shift)

as needed to display the conductivity value noted

in step 5. Depress both push buttons simultaneously

to accept this value. The transmitter will then calculate the proper cell constant.

NOTE

Return transmitter to normal operation from

Hold.

4.6 ROUTINE STANDARDIZATION. The sensor should

be standardized in-line routinely if it is suspected that the

process might degrade or coat the sensor. After the initial calibration, each time a standardization is performed

the cell factor Fct is changed. Refer to Section 4.3 for a

description of the cell factor.

To perform a standardization do the following:

1. Take a grab sample which is as close to the sensor

as possible. Record transmitter reading.

2. Determine the sample’s conductivity using a calibrated instrument or a portable analyzer. The

instrument must be able to reference the conductivity to 25°C, or the solution must be at 25°C.

Record the reading.

3. Note any change in the 2081’s present reading

from first reading recorded in Step 1. Add this

change (either + or –) to the calibrated instruments

value. Record this figure.

4. Scroll through the menu items. Press and hold both

push buttons simultaneously.

5. Release both push buttons when Std is displayed.

The conductivity value will display with the right most

digit flashing.

21

MODEL 2081C/T SECTION 4.0

START-UP AND CALIBRATION

Page 26

SECTION 5.0 KEYBOARD SECURITY

5.1 PUSH BUTTON SECURITY. This feature disables

the dual push buttons on the transmitter to prevent

accidental or unauthorized changes to the calibration

and configuration. HART communication is not affected

by this change. Perform the following steps to disable

the push buttons. See Figure 5-1 for jumper locations

on CPU board.

CAUTION

The circuit board is electrostatically sensitive.

Be sure to observe handling precautions for

static-sensitive components.

1. Remove the display side cover.

2. For easy access, the electronics assembly may be

removed by pulling the assembly straight out.

3. Remove jumper JP4 from the CPU board. To prevent misplacing the jumper, slide it back onto one

post only.

4. Replace the display side cover.

CAUTION

A minimum of seven cover threads must be

engaged in order for the transmitter to meet

explosion-proof requirements.

Replace the jumper to enable push button operation.

5.2 FAULT MODE SELECTION This feature allows the

user to select the desired mA output during a system

disabling fault condition.

CAUTION

The circuit board is electrostatically sensitive.

Be sure to observe handling precautions for

static-sensitive components.

1. Remove the display side cover.

2. For easy access, the electronics assembly may be

removed by pulling the assembly straight out.

3. JP3's Fault Mode Selection

Jumper on both posts: below 4.0 mA

Jumper on one post: above 20.0 mA

4. Replace the display side cover

CAUTION

A minimum of seven cover threads must be

engaged in order for the transmitter to

meet explosion-proof requirements.

FIGURE 5-1. Jumper Locations

NOTE:

JP1 and JP3 shown with

jumpers in open (store)

position.

DWG. NO. REV.

40208109 A

MODEL 2081C/T SECTION 5.0

KEYBOARD SECURITY

22

Page 27

23

SECTION 6.0 DIAGNOSTICS AND TROUBLESHOOTING

6.1 GENERAL: The Model 2081C/T Transmitter auto-

matically searches for fault conditions that would

cause an error in the measurement. If such a condition

exists, the 2081C/T transmitter will flash a diagnostic

message. If more that one fault exists, the display will

sequence through the diagnostic messages.This will

continue until the cause of the fault has been corrected.

Troubleshooting is easy as 1,2,3. . .

Step 1 Look for a diagnostic fault message on the display

to help pinpoint the problem. Refer to Table 6-1 for

an explanation of the message and a list of the possible problems that might have triggered it.

Step 2 Refer to the Quick Troubleshooting Guide,

Table 6-4 for common loop problems and the

recommended actions to resolve them.

Step 3 Follow the step-by-step troubleshooting

approach offered in Section 6.2 to diagnose

less common or more complex problems.

In addition, a theory of operation explanation is offered

in section 7.0 for those that may want a more detailed

understanding of the instrument.

NOTE

During fault conditions the output of the

transmitter is determined by the placement

of Jumper JP3 on the CPU board.

1. JP3 in place (shorted across both pins) Output

driven below 4 mA.

2. JP3 on one pin only - Output driven above 20 mA.

6.1.1 Diagnostic Messages. Table 6-1 lists the fault

displays, describes the meaning of each and lists

some appropriate corrective actions for each.

TABLE 6-1. Diagnostic Messages

Display Description Corrective Action

Adc - FaiL Transmitter electronics failure Turn power off, wait one minute, and power on.

Replace stack.

SnSr - rngE Conductivity value outside 4-20 Check Sensor cell constant and measurement range.

mA range points. Return conductivity to within range, or replace sensor.

SnSr - FaiL Sensor failure or A-D failure Replace sensor. Replace stack.

tEnP - Lo Temperature too low or RTD shorted

Check wiring, calibrate temperature, bring sensor within temperature

specifications, replace stack, replace sensor. Note: if in manual temp

mode, RTD or appropriate resistor must be in place. See Table 6-2.

SLP - FaiL Invalid temp. slope calculated. Turn power off and on.

Did not accept entry. Repeat temp. slope calibration procedure. (Must be

performed at 2 different process temperatures.)

-0- FaiL Too much resistance is sensed to Check wiring.

zero (over 1Meg). Did not accept entry.

Verify sensor is in air during sensor 0: Not partially submerged.

Std - FaiL Entered conductivity value is unacceptable

Conductivity calibration failed: verify conductivity standard or

(+/- 150 C). grab sample.

Temp. calibration failed: verify temp at the sensor: allow

20 minutes for stabilization.

LooP - rngE Conductivity value is outside of the present Bring conductivity back into the programmed range.

Lo and Hi range setpoints. Re-adjust Lo and Hi range setpoints.

Flashes You have attempted to enter a value that Verify the attempted procedure’s instructions.

bAd exceeds the allowable software. Check standard or instrumentation used.

FAIL The transmitter recognizes that its Check wiring

electronics have malfunctioned Turn power off and on.

Replace electronic stack.

NOTE: Some of the fault codes can be cleared by cycling the power off and on.

MODEL 2081C/T SECTION 6.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 28

24

6.1.2 Temperature Compensation. Table 6-2 (below)

is a reference of RTD resistance values at various temperatures. These are used for test and evaluation of

the sensor.

NOTE

Ohmic values are read across the RTD element and are based on the manufacturer’s

stated values (+/- 1%). Allow enough time

for the RTD element to stabilize to the surrounding temperature.

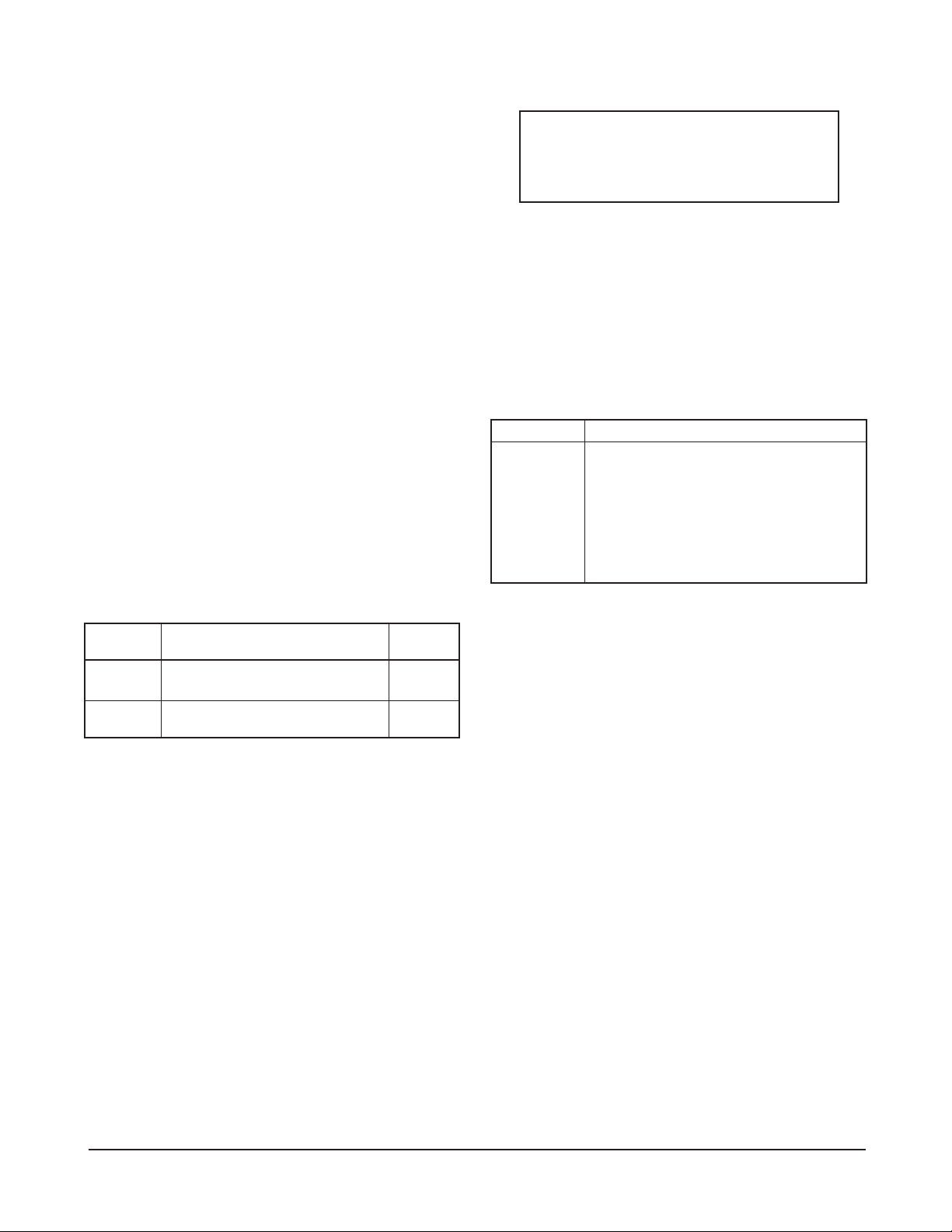

Table 6-2. Resistance Values (Temperature)

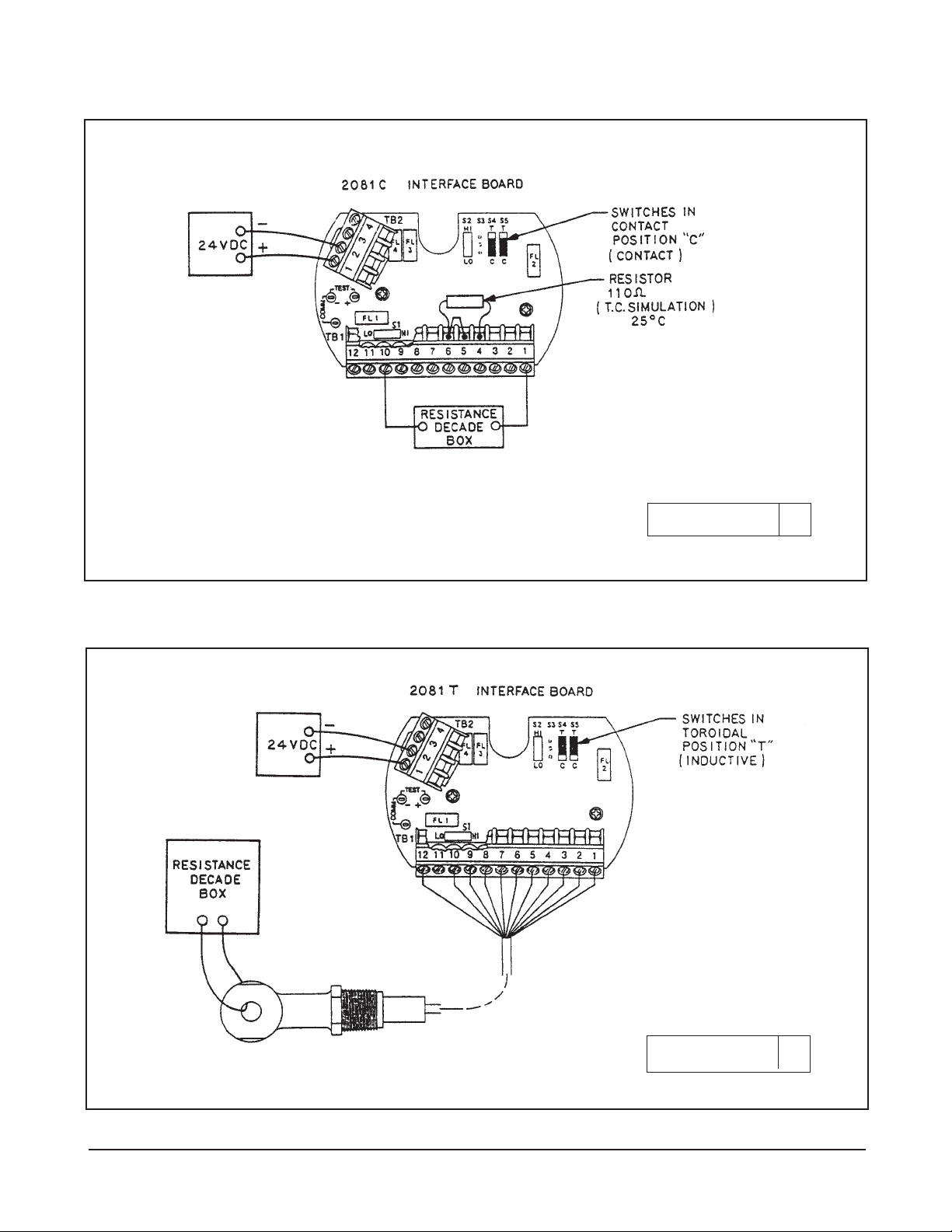

6.2 CONTACT CONDUCTIVITY MODE BENCH

CHECK: Sensor simulation may be used to check the

operation of the model 2081C/T. See Figure 6-1 for

wiring diagram to perform analyzer check.

CAUTION

Do not use over 55 volts to check the loop.

Damage to the transmitter may result.

1. Set up transmitter as shown in Figure 6-1.

2. Simulate a conductivity value by choosing a typical resistance value from Table 6-3 and entering

this resistance value into the decade box.

TABLE 6-3. Resistance Values (Conductivity)

NOTE

Chart assumes a cell constant of 1.0.

Therefore, Resistance = 1/Conductivity.

3. Apply power to the Loop.

4. Set the CELL constant to 1.00.

5. Set the atc to USEr. Enter the user value of 25° C.

(This eliminates temperature condition.)

6. Remove one test lead from the resistance decade

box to simulate 0.00 Microsiemens.

7. Select the zero function -0- from the Level 1

menu.

8. The display will flash -0- while the unit zeros.

9. Reconnect the test lead to the decade box to simulate full-scale conductivity.

10. If calibrated, the display should read close to the

full-scale conductivity value.

11. Scroll to Std and enter the desired full-scale conductivity value

12. Check half-scale reading by doubling the resistance value entered into the decade box.

13. The transmitter conductivity circuitry is operating

correctly if it will zero, read the full-scale and halfscale conductivity values.

Simulate Full Scale

Conductivity Of:

20 microsiemens

200 microsiemens

2000 microsiemens

20,000 microsiemens

Resistance Value

To Use:

50,000 ohms

5,000 ohms

500 ohms

50 ohms

Temperature Resistance

0

0

C 100.00 Ohms

100C 103.90 Ohms

200C 107.90 Ohms

300C 111.67 Ohms

400C 115.54 Ohms

500C 119.40 Ohms

600C 123.24 Ohms

700C 127.07 Ohms

800C 130.89 Ohms

900C 134.70 Ohms

1000C 138.50 Ohms

MODEL 2081C/T SECTION 6.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 29

25

6.3 TOROIDAL CONDUCTIVITY MODE BENCH

CHECK: Sensor simulation may be used to check the

operation of the Model 2081C/T. See Figure 6-2 for

wiring diagram to perform analyzer check.

CAUTION

Do not use over 55 volts to check the loop.

Damage to the transmitter may result.

1. Set up transmitter as shown in Figure 6-2.

2. Simulate a full scale conductivity value by choosing a typical resistance value from Table 6-3 and

entering this resistance value into the decade box.

TABLE 6-3. Resistance Values (Conductivity)

NOTE

Chart assumes a cell constant of 1.0.

Therefore, Resistance = 1/Conductivity.

3. Apply power to the Loop.

4. Set the CELL constant to 1.00.

5. Set the atc to USEr. Enter the user value of 25° C.

(This eliminates temperature correction.)

6. Remove one test lead from the resistance decade

box to simulate 0.00 Microsiemens.

7. Select the zero function -0- from the Level 1

menu.

8. The display will Flash -0- while the unit zeros.

9. Reconnect the test lead to the decade box to simulate full-scale conductivity.

10. If calibrated, the display should read close to the

full-scale conductivity value.

11. Scroll to Std and enter the desired full-scale conductivity value.

12. Check half-scale reading by doubling the resistance value entered into the decade box.

13. The transmitter conductivity circuitry and the sensor are operating correctly if it will zero, read the

full-scale and half-scale conductivity value. If not,

refer to the appropriate sensor instruction manual

to perform tests on the toroidal sensor. If the sensor tests O.K, then replace the transmitters electronic stack.

6.4 SYSTEMATIC TROUBLESHOOTING.

Not all problems that you encounter will be typical. If

you are unable to resolve your problem using the

Quick Troubleshooting Guide, Table 6-4, then try the

step-by-step approach offered in Figure 6-3.

Simulate Full Scale

Conductivity Of:

20 microsiemens

200 microsiemens

2000 microsiemens

20,000 microsiemens

Resistance Value

To Use:

50,000 ohms

5,000 ohms

500 ohms

50 ohms

MODEL 2081C/T SECTION 6.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 30

26

FIGURE 6-1. Bench Check (Contact Sensor)

FIGURE 6-2. Bench Check (Toroidal Sensor)

DWG. NO. REV.

40208113 B

DWG. NO. REV.

40208113 B

MODEL 2081C/T SECTION 6.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 31

27

SYMPTOM PROBLEM ACTION

fct below 0.5 or above 2.0. 1. Old or coated sensor. 1. Clean or replace glass electrode.

Actual range determined by user. 2.

A preceding standardization was incorrect.

Value locks up (no change of 1. Incorrect wiring. 1. Verify wiring.

reading in different standards). 2. Open sensor. 2. Perform sensor checks.

3. Replace sensor.

2081C/T value not the same as 1. Grab sample incorrect. 1. Re-evaluate sample technique and

grab sample of process. equipment.

2. Unclear what is correct. 2. Test with standard solution.

3. 2081C/T out of calibration. 3.

Recalibrate per start-up and calibration sections.

Fault Code TEnP-Lo, or 1. Incorrect wiring. 1. Check wiring between the sensor and the

TEnP-Hi transmitter.

2. Open or shorted RTD. 2. Replace RTD or sensor.

3. Manual temperature 3. Appropriate resistor must be in place mode. TB1-6 to 8. See Table 6-2.

Zero Conductivity reading. 1. Sensor wired incorrectly. 1. Repair wire connection.

2. Solids coating sensor. 2. Clean sensor.

3. Open wire in sensor. 3. Replace sensor.

Fault code rn9E-LOOP. 1. Process value is outside 1. Return process to normal. Check

4-20 mA range points. grab sample.

Fault Code FAIL. 1.Range selection switches 1. Calculate the maximum low range value

S1 and S2 are set and set the switches accordingly. See

incorrectly. Section 1.3.3.

2. Defective PCB stack. 2. Reconnect power or if necessary,

replace PCB stack.

No output current. 1. Defective PCB stack. 1. Replace PCB stack.

2. Incorrect wiring. 2. Check for short.

Low output current. 1. Circuit loading with excess- 1. consult output loading limits 2081C/T

sive resistance on output. specifications (1840 ohms max load).

Drifting or Unstable readings. 1. Air bubbles in process 1. Mount sensor to decrease exposure to

affecting reading. air bubbles.

2. Electrical or grounding 2. Verify sensor works in a standard soluinterference. tion outside of the process.

3.

Verify near by vendor pumps are properly

grounded.

4. Verify that sensor shield never touches

an Earth ground.

5. Run sensor cable though grounded

metal conduit to reduce RFI effects.

Fault code "LOOP" flashing inter- 1. Model 268 or other host 1. Model 268 or other host can return

mittently with Conductivity and has set the output to a transmitter to normal operation.

output value. specific value.

Can't calibrate new sensor. 1. Wrong sensor for meas- 1. Verify that cell content is correct for the

urement range. measurement range.

2. Sensor incompatible with 2. Verify sensor has a PT-100 temperature

analyzer. compensator.

Transmitter won't 1. Incorrect wiring. 1.

Check wiring and model 268 connections.

communicate. 2. Insufficient load resistance. 2. Verify minimum of 500 Ohm loop

resistance.

3. Electronics failure. 3. Replace electronic stack.

TABLE 6-4. Quick Troubleshooting Guide

MODEL 2081C/T SECTION 6.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 32

FIGURE 6-3. TROUBLE SHOOTING FLOW CHART

28

Conductivity Measurement

Problem (in the process)

Remove sensor from process and

place sensor in air. Zero instrument. Refer to Section 4.4.

OK?

OK?

Place sensor in process and

standardize. Refer to Section 4.6

Check wiring again

for short/open

NOTE:

Before starting this procedure make

sure that all wiring is correct.

YES

YES

NO

NO

Does problem

still exist?

YES

NO

Check diagnostic

messages

Refer to Table 6-1

Restart

Analyzer

Check for ground

loops and/or improp-

er installation

Remove sensor from process and

test in known conductivity solution

OK?

Refer to Sensor man-

ual for sensor checks

Verify earth ground is not connect-

ed to sensor shields

Isolate sensor shield from any ground metal (conduit)

Consult service center

Check T.S. Guide

Table 6-4

Verify transmitter

operation with bench

check procedures

Section 6.2 & 6.3

YES

NO

MODEL 2081C/T SECTION 6.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 33

29

7.1 GENERAL: Conductivity is the conductance per

unit of length. The 2081C/T measures and calculates

conductivity using the relation ship I=GV. Where:

G = conductance,

V = the reference voltage, and,

I = the resultant current directly proportional to

conductance.

7.2. OVERVIEW: Refer to Figure 7-1 2081C/T Block

Diagram.

Power Supply: Power for the 2081C/T is derived from

the +12 to 55 volt DC loop power. This power is dropped

to a regulated +9 volts DC and maintained by comparison with the output of a 2.5 volt op-amp comparator.

The 9 volts DC is switched by a 28.8 KHz square wave

signal from the Oscillator across the center tapped primary of the drive transformer. This provides the raw 4.5

VAC for the 4.5 Volt DC power supply.

The 28.8 KHz square wave signal from the oscillator

also develops an AC at the secondary that is used to

drive a toroidal (or contacting) conductivity sensor.

When a contacting conductivity sensor is used this isolates the 2081C/T electronics from the process, and

the AC signal also prevents polarizing of the fluid surrounding a contacting conductivity sensor.

Oscillator: The 1.8432 MHz oscillator output is divided

down to provide:

1. a 921.6 KHz CPU clock signal.

2 a 460.8 KHz MODAC clock signal.

3 a 57.6 KHz demodulator sample signal.

4. the 28.8 KHz transformer drive signal.

Input Signals: RTD and sensed cable line voltages

appear at an input to the Mux. These voltages are

converted to digital values by the A/D circuits, and stored

by the CPU. The CPU subtracts the unwanted cable voltage from the RTD voltage and uses these readings with

a reference voltage to calculate the sensor temperature.

This value is used to compensate the absolute conductivity using the temperature slope of the liquid, and can be

sent to the LCD to be displayed.

1. Sensors: This transmitter can be used with either

type of sensor. Contacting or Toroidal inductive).

•

Power &

28.8

KHz

Drive

Osc.

and

Divider

Preamp

Demodulate

& Auto-Zero

Mux

A/D

CPU

ROM

Display

Drivers

DAC

MODAC

Modem

4 to 20

mA

Current

Loop

Summer

HART

Input Filter

+12 to 55 Volts

Loop Power &

HART Comm

Conductivity

Probe Out

(Toroidal or

contacting

Conductivity

Probe In

(Toroidal or

contacting)

PT

100

RTD

Receive

Transformer

RTD source

RTD return

)(

)(

)(

)(

)(

)(

Drive Transformer

+ 9 Volts

+ 4.5 Volts

921.6 KHz (CPU Clock)

460.8 KHz (MODAC Clock)

57.6 KHz (Sample)

28.8 KHz (Drive)

Sense Line

SECTION 7.0 THEORY OF OPERATION

Figure 7-1. Block Diagram

MODEL 2081C/T SECTION 7.0

THEORY OF OPERATION

Page 34

30

Sensors: This transmitter can be used with either type

of sensor. Contacting or toroidal (inductive). Currents

developed by the conductivity probe through the

Receive Transformer are converted to a voltage and

amplified by the preamplifier block. This voltage is

demodulated (in the demodulate and auto-zero block)

in phase with the transmitter toroid resulting in a DC

voltage representing the absolute conductivity.

a. Contact Conductivity Probe. In the contacting sen-

sor, the area and distance between the two electrodes

determine a cell constant, the volume of fluid between

the electrodes acts as a resistor whose value

depends on the conductance of the fluid.

b. Toroidal Conductivity Sensor. Consists of two

independent transformers that have a common

turn, the path of the liquid. The transmitter toroid,

or driver, induces a voltage in the path of the liquid

which is the voltage across the toroid winding

divided by the number of turns in the winding. The

voltage times the conductance results in a current

that is proportional to the conductance. This current is sensed by the receiver toroid. The current

out of this toroid is the current in the liquid loop

divided by the number of turns in its winding. The

result is I = G*V/(N1*N2), where:

N1 is the number of turns of the transmitter toroid.

N2 is the number of turns of the receiver toroid.

V is the voltage across the receive transformer.

G is the conductance of the liquid loop.

I is the resultant current developed in the receiver

transformer by the receive toroid.

HART communication signals. Super-imposed on the

4 to 20 mA current loop, are passed through the HART

Input filter (to reduce noise). This FSK signal is then

demodulate by the MODAC ASIC (Application Specific

Integrated Circuit) and sent on to the CPU via the

MODAC. A FSK signal is an AC signal, whose frequency is shifted higher or lower depending on the

condition of the digital signal (High or Low), This

Frequency Shift Keying is mixed with the DC value of

the 4 to 20 mA signal, using Bell 202 protocol. This

communication conforms to the Rosemount HART

specification and may be used to configure and interrogate the transmitter.

CPU: A 68HC11 micro controller computer chip contains

the central processing unit (CPU). This chip also contains

volatile Random Access Memory (RAM) and nonvolatile

Electrically Erasable Programmable Read Only Memory

(EEPROM). CPU instructions, however, are stored in an

external ROM. The CPU communicates with this external

ROM, Mux, Analog to Digital (A/D) converter, the two

push buttons on the side of the 2081C/T, and the Model

275 Smart Interface through the MODAC. It also controls

the display drivers,

When requested by the CPU the input signals from

either the Contacting or Toroidal sensor are zeroed

and scaled between user supplied setpoints to determine what the proportional current value of the 4 to 20

mA loop should be. This value is sent to control the

Digital to Analog Converter (DAC) in the MODAC

ASIC. The MODAC also produces a weighted Pulse

Width Modulated output representing digital information generated by the CPU to communicate with other

digital devices on the current loop. Both of these signals are sent to the current loop summer. The summer

then mixes this PWM signal with the current loop value

to produce the correct 4 to 20 mA output value for the

transmitter.

MODEL 2081C/T SECTION 7.0

THEORY OF OPERATION

Page 35

31

SECTION 8.0 DESCRIPTION AND SPECIFICATIONS

• UTILIZES EITHER CONTACTING OR INDUCTIVE CONDUCTIVITY SENSORS to meet a

wide range of application requirements.

• FIELD MOUNTED TRANSMITTER ideal for central data processing and control.

• MEMBER OF THE ROSEMOUNT SMART FAMILY

®

.

• LOCAL, PUSH-BUTTON INTERFACE for convenient calibration and range adjustment.

• WEATHERPROOF, CORROSION-RESISTANT ENCLOSURE.

• CONTINUOUS DIAGNOSTICS drive the output to a jumper-selectable high or low value in

the event of a failure.

• HOLD OUTPUT MODE for manual control during sensor maintenance.

8.1 FEATURES

The Model 2081 C Smart Transmitters, with the appropriate sensor, are designed to continuously measure

contacting, toroidal, or conductivity in industrial and

municipal processes. These two-wire transmitters are

members of the Rosemount SMART FAMILY of instruments, which are designed to communicate with the

hand-held Model 275 SMART FAMILY Interface and

any other hosts that support the HART®communications protocol. See Figure 8-1. The Model 2081 design

permits remote configuration, interrogation, testing,

and diagnostics.

The Model 2081 C features an easy-to-use, dual pushbutton interface on the transmitter housing for local calibration and range adjustment. The LCD display indicates the conductivity value as well as temperature,

current output value, range values, temperature slope,

and fault messages. Unauthorized adjustments may be

prevented by a jumper-selectable setting on a circuit

board. All functions are microprocessor based.

The isolated 4-20 mA output is continuously expandable over the measurement range, and may be displayed in either milliamps or percent of full scale. A hold

output function is available for manual control during

routine sensor maintenance. While in hold mode the

current output signal (refer to Table 1) will remain constant at the last current value.

In the event of a failure, the transmitter diagnostic routine will drive the output below 4 mA or above 20 mA

(user selectable) in addition to displaying a fault code

on the transmitter. This routine alerts the user to errors

due to temperature slope, faulty temperature compensation element, open wiring and transmitter electronics

failure. The transmitter will also go into a fault mode if

the conductivity value is outside the output range settings.

With a two-point calibration, the transmitter automatically calculates the temperature slope and the cell constant. On-line standardization is easily accomplished

by simply entering the conductivity value of a grab sample into the transmitter. The transmitter uses a Pt100

RTD signal from the sensor to reference the conductivity reading to 25°C.

The Model 2081 C transmitter is designed to be weatherproof and corrosion resistant to meet NEMA 4X

(IP65) standards. An optional pipe or wall mounting

bracket is available.

The transmitter communicates via the HART®protocol,

which uses an industry standard BELL 202 frequency

shift keying (FSK) technique. Communication is

accomplished by superimposing a digital signal on top

of the 4-20 mA output signal. The Rosemount implementation of this technique allows simultaneous communication and output without compromising loop

integrity.

The Model 2081 requires an external power supply

such as the Model 515 Isolated Power Supply or DC

loop power from a distributed control system. The

Model 515 Power Supply provides power for up to 10

transmitters. Two transmitters may be wired directly to

the power supply. For more than two transmitters, junction boxes are available, each accommodating wiring

for a maximum of ten transmitters.

Remote alarms with independently adjustable setpoints

and hysteresis are available in the Model 230A Alarm

Module. Contacts of the Model 230A may be specified

for high/low, high/high, or low/low operation.

MODEL 2081C/T SECTION 8.0

DESCRIPTION AND SPECIFICATIONS

Page 36

32

8.2 FUNCTIONAL SPECIFICATIONS

Output: Two-wire 4-20 mA with superimposed HART

digital signal.

Power Supply and Load Requirements: See Figure

8-1 below. A minimum loop resistance (load) of

250 ohms and minimum power supply voltage of

18 volts DC is required for digital communication.

Local Indication: Four digit LCD

Ambient Temperature: –30 to 70°C (–22 to 158°F)

Failure Mode Alarm: The analog signal will be driven

either below 4 mA or above 20 mA (user-selectable)

Transmitter Security: Security activation (by internal

jumper) prevents changes to the transmitter configuration from the local interface.

Relative Humidity : 0-95%

Automatic Temperature Compensation: Pt100 RTD

0 to 200°C (32 to 392°F)

Enclosure: Weatherproof and corrosion-resistant,

explosion proof

EMI/RFI: EN-61326

8.3 PERFORMANCE SPECIFICATIONS

Range*: See Table 8-2

Output Scale: Zero Suppression: Up to 90% of full

scale

Span: From 10 to 100% of full scale

Accuracy: ±0.5% full scale @ 25°C

Resolution: 0.1% full scale, 0.1°C

Repeatability: ±0.25% full scale

Stability: 1%/ year at 25°C

Temperature Effect: 0.02% F.S./°C

Vibration Effect: ±1.0% of F.S. per SAMA PMC

31.1

* Not applicable for ultra pure water applications. See the

products data sheets for Model 3081C/81C or Model

1054B LC for these applications.

• Display output in mA/% of full

scale

• Hold output mode

• Set 4-20 mA output range

• Display temperature in °C/°F

• Input or display cell constant

• Display cell factor

• Electronic zero

• Auto/manual temperature

compensation

• Two point calibration

• Standardize temperature

• Standardize conductivity

• Input or display temperature

slope

• Display absolute conductivity

TABLE 8-1. Local Interface Functions

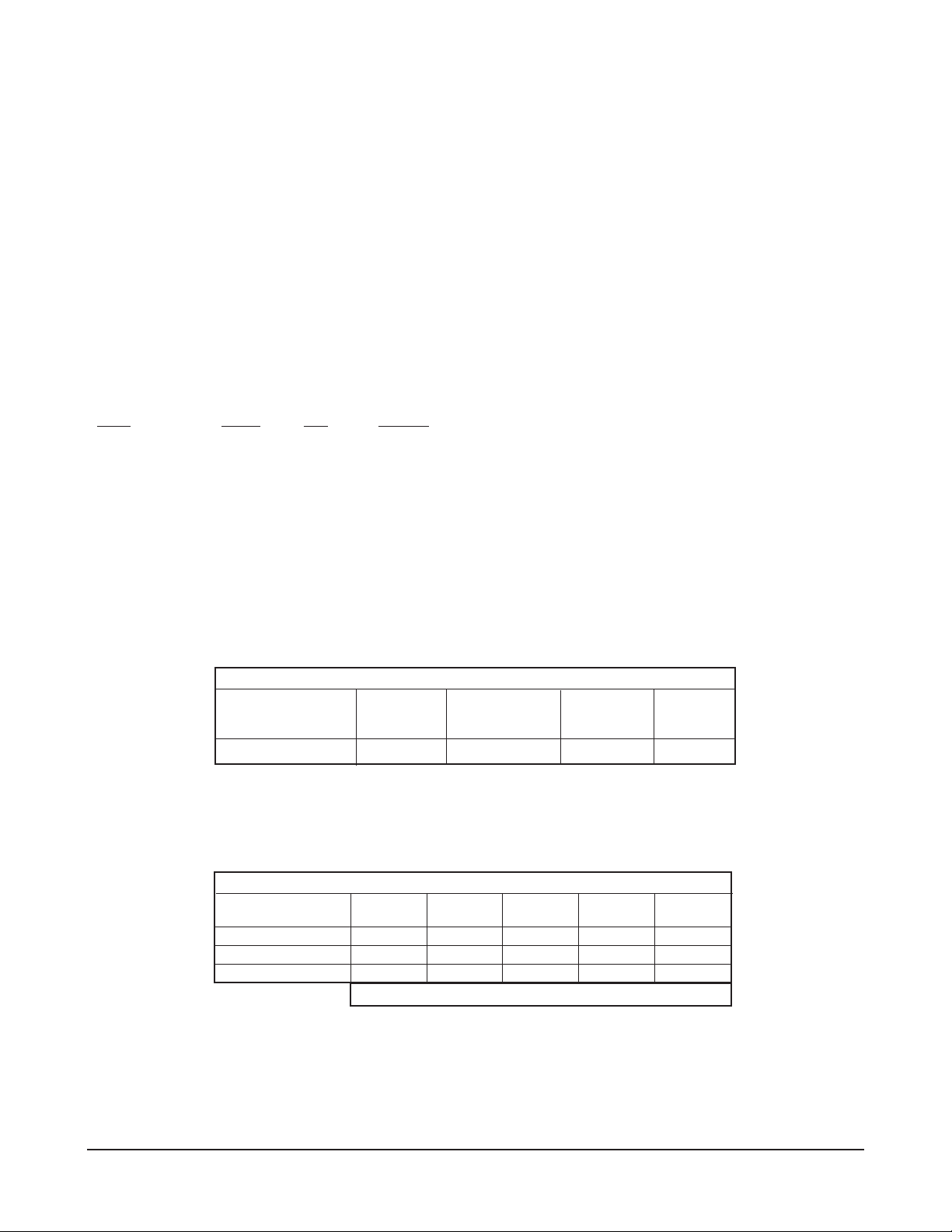

TABLE 8-2. Measurement Ranges

FIGURE 8-1. Load/Power Supply Requirements

MODEL 2081C/T SECTION 8.0

DESCRIPTION AND SPECIFICATIONS

Type Maximum Switch

Sensor Range Setting

Toroidal Below 400,000µS x Cell Constant Both “Lo”

Above 400,000µS x Cell Constant Both “Hi”

Contacting Below 4,000µS x Cell Constant Both “Lo”

Above 4,000µS x Cell Constant Both “Hi”

Resistivity

(Ω-cm)

Conductivity

(µS/cm)

.05kΩ

20,000µS

2,000µS

500µS

200µS

100µS

20µS

10µS

2µS

1µS

.2µS

.1µS

.05µS

.02µS

.5kΩ

2kΩ

5kΩ

10kΩ

50kΩ

100kΩ

500kΩ

1MΩ

5MΩ

10MΩ

20MΩ

50MΩ

Operating Ranges for Various Contacting Cells Constants (not to scale)

1.0 cm

-1

10.0 cm

-1

0.01 cm

-1

0.1 cm

-1

Page 37

33

8.4 PHYSICAL SPECIFICATIONS

Electrical Connections: 1/2 in. NPT.

Model 275 SMART FAMILY Interface connections

permanently fixed to terminal block. The terminal

block also has removable connectors for bare wire

sensor connections.

Housing: Epoxy-polyester painted over low

coppercast aluminum. BUNA-N O-rings on

cover.

Recommended Cable: Transmitter to power supply

two-wire, 18 AWG, shielded, Belden 8760 or

equal (Rosemount Analytical PN 9200001).

Weight/Shipping Weight: 2.18 kg/2.68 kg (4.8 lb/5.9 lb)

Hazardous Area Classification:

FM Certification:

Type Class Div. Groups

I.S. I, II, III I ABCDEFG

Dust/Ignition II, III I EFG

N.I. I 2 ABCD

CENELEC Certification*:

Contacting Conductivity-

I.S. EEXia IIC T5 (Tamb = 40°C) or

EEXia IIC T4 (Tamb = 70°C)

Toroidal Conductivity- I.S. same specifications

* user must specify sensor type in order to receive an

Intrinsically safe loop

8.5 RECOMMENDED SENSORS:

(CONTACTING)

Model 140 Retractable Conductivity

Model 141/142 Insertion Conductivity

Model 150 Insertion/Submersion Conductivity

Model 400 Screw-In Low Conductivity

Model 401 Screw-In High Conductivity

INDUCTIVE FULL SCALE

Minimum Maximum

Model 222 Sensor 0-500 µS/cm 0-2000 mS/cm

Model 226 Sensor 0-50 µS/cm 0-1000 mS/cm

Model 225 Sensor 0-250 µS/cm 0-2000 mS/cm

Model 228 Sensor 0-250 µS/cm 0-2000 mS/cm

MODEL 2081C/T SECTION 8.0

DESCRIPTION AND SPECIFICATIONS

NOTE: Not applicable for conductivity less than 10 mS/cm. For these applications, please

see product data sheets for Models 1054BLC, 1055C, or 3081/81C.

CONTACTING SENSORS

Conductivity Sensor 142 142 140, 141 401-14

Model Number 400 150 150 402/403

402/403/404 400/402/403/404 400/402/403

Cell Constant 0.01 0.1 1.0 10.0

FULL SCALE MICROSIEMENS/cm

INDUCTIVE SENSORS

Conductivity Sensor

Model Number 226 228 225 222 (1in.) 222 (2 in.)

Cell Constant* 1.0 3.0 3.0 6.0 4.0

Minimum Range 50 250 250 500 500

Maximum Range 1,000,000 2,000,000 2,000,000 2,000,000 2,000,000

* Typical

Page 38

34

8.6 ORDERING INFORMATION

2081C/T 67 EXAMPLE

Code Input (Required selection)

C Contacting Conductivity

T Toroidal Conductivity

Code Options

11 Stainless steel tag (specify marking)

Code Agency Approvals

67 FM approved, Intrinsically Safe (when used with approved sensor and safety barrier) and

explosion-proof, Contacting and Toroidal

69 CSA approved, Intrinsically Safe (when used with approved sensor and safety barrier) and

explosion-proof, Contacting and Toroidal

73 CENELEC approved, Intrinsically Safe (safety barrier required), Contacting and Toroidal

MODEL

2081 HART SMART TWO-WIRE CONDUCTIVITY TRANSMITTER

Model 2081C/T conductivity Two-Wire Transmitter is compatible with both contacting and inductive conductiv-

ity sensors (indicate sensor type if known). It is housed in a NEMA 4X (IP65) weatherproof, corrosion-resistant

enclosure suitable for pipe mounting. Standard features include HART digital communications capability, LCD

digital display, isolated 4-20 mA output, and automatic temperature compensation.

PN DESCRIPTION RECOMMENDED SPARES

23419-00 PCB, 2081 LCD Display 1

23533-00 PCB, 2081 Interface

23421-02 PCB Stack, 2081C (CPU/Sensor loop and display) 1

23421-03 PCB Stack, 2081T (Sensor loop and display)

23519-00 Push Buttons, 2081, Kit 1

33197-00 Enclosure, Middle

2002518 Enclosure Cover, LCD Display Side

2002577 Pipe Mounting Bracket

2002603 O-ring Kit (Qty 2), Window

2002604 O-ring Kit (Qty 2), Enclosure 2

3002468 Enclosure Cover, Tall

9200001 Cable, 2 Conductor, 18 AWG, Shielded

9240008-00 Overlay, 2081pH LCD Display 1