Page 1

Emerson Energy Systems

UM5C05C ( 169-2081-501 )

Helios Modular Switch Mode Rectifier

200I/48NT5C05C

Installation and User Manual

H E L I O S

I

0

A C / C A

V OL T

A

T H S D

H

MP

V S

D

F A

R

FA N

A L M

VO L T + VO U T -

L T

VO

C A L

C UR

C

AL

CL

A D J

E

Q

L

D

A

S E N

ON

AC

A

IL

F

CL

E

Q L

J

L

EQ

FF

1

F F 2

F L T

1 . 0 A

1 .0A

F LT

DJ

A

H VS D

AD

J

I

S T U P

D L Y

S L S F S

I

DC / CC

P0745680 Standard 6.00 October 2001

Page 2

Page 3

Helios Modular Switch Mode Rectifier

3

200I/48

NT5C05C

Installation and User Manual

Manual Number : UM5C05C ( 169-2081-501 )

Manual Status : Standard

Manual Issue : 6.00

Release Date : October 2001

P0745680

Copyright 2001 Astec Internat ional Lt d

All Rights Reserved

Published in Canada

The information contained in this manual is the property of Astec Int ernational Ltd and is subject to change without

notice. Astec International Ltd reserves the right to mak e c hanges in design or components as progress in engineering

and manufacturing may warrant. Except as specifically authorized in writing by the V.P. of E ngineering and Product

Manufacturing of Astec Internat ional Lt d, t he holder of this manual shall keep all information contained herein confidential

and shall protect same, in whole or in part, f rom disclosure and dissemi nat ion to all third parties, and use the sam e f or

start-up, operation, and maint enance purposes only. Any modific at i on t o the equipment must be approved by the person

responsible for product safety and design quality at Astec International Ltd to insure that the equipment com plies with t he

operation standards.

This equipment has been tested and f ound to comply with the limits for a Clas s A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harm ful interference when the equipment

is operated in a commerc ial environment. The equipment generates, uses, and can radiate radio frequency energy, and if

not installed and used in accordance with the ins t ructions contained in the Installation and User Manuals, can cause

harmful interference to radio communications. Operation of t his equipment in a residential area is likely to caus e harmful

interference, in which case the user will be required to correct the interference at his own expense.

Helios and Helios Candeo are trademarks of Astec I nternational Ltd. The Emerson logo is a trademark and service mark of

Emerson Electric Co.

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 4

Page 5

Publication history

October 2001

Standard Issue 6.00. Manual restructured and updated to reflect Emerson

Energy Systems and Emerson Network Power identities. ( ECN 102-26804 )

March 1998

Issue 5.0. Standard. Reference change from NT5C05CB to NT5C05C.

July 1997

Issue 4.0. Standard EMI compliance information and table of content

numbering corrections.

June 1995

Issue 3.0. Standard. Revised rectifier installation procedure in a cabinet.

September 1994

Issue 2.0. Standard. Few revisions and additions from the previous issue.

July 1994

Issue 1.0. Standard. Few changes from the previous issue and the document

is now rated “Standard”

5

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 6

6 Publication history

This page is left blank intentionally.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 7

Contents

1. General information .................................................................................... 11

1.1. Purpose of this manual .............................................................................. 11

1.2. Models and mounting configurations ......................................................... 12

2. Specifications..............................................................................................13

2.1. Mechanical and electrical specifications.................................................... 13

2.2. Operation specifications and ambient conditions....................................... 14

2.3. Mechanical and electrical specifications of a 1200 A cabinet.................... 16

2.4. Ambient conditions of a 1200 A cabinet..................................................... 16

3. Installation.................................................................................................... 17

3.1. Mounting configurations............................................................................. 17

3.2. Tools and test equipment........................................................................... 17

3.3. Cautions and Warnings.............................................................................. 17

3.3.1. Installing in a frame.............................................................................. 20

3.3.2. Installing in a cabinet ........................................................................... 20

3.4. Cabling and connecting.............................................................................. 22

3.5. Connecting the dc output terminals to the busbars.................................... 23

3.5.1. Securing the dc output terminals to the busbars in a 1200 A cabinet . 24

3.5.2. Running and connecting the dc between busbars and a rectifier........ 24

3.6. Connecting ac to the rectifiers.................................................................... 24

3.7. Connecting the control signals................................................................... 28

3.7.1. Monitoring of the shunt current............................................................ 29

4. Functional description................................................................................ 31

4.1. Overview .................................................................................................... 31

4.1.1. Input circuit .......................................................................................... 31

4.1.2. Output circuit........................................................................................ 31

4.1.3. Monitoring and control circuits............................................................. 32

4.1.4. Output capacitors................................................................................. 32

4.2. Description of the front panel ..................................................................... 32

4.2.1. Breakers .............................................................................................. 32

4.2.2. Switches, controls and LEDs............................................................... 33

4.2.3. Front panel LEDs................................................................................. 34

4.2.4. Local and remote adjustments and controls........................................ 35

4.2.5. Voltage / current displaytest and measurement............................... 36

4.2.6. Float and equalize voltage control....................................................... 37

4.2.7. Current limit adjustment and rectifier regulating test........................... 37

4.2.8. Rectifier parallel operation................................................................... 38

4.2.9. HVSD ( high voltage shutdown ).......................................................... 40

4.2.10. TR ( temporary inhibition ) and sequential start................................... 40

4.2.11. Control signals on connector P1.......................................................... 42

5. Operation...................................................................................................... 45

5.1. Standard settings ....................................................................................... 45

5.2. Starting up and adjusting ........................................................................... 46

7

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 8

8 Contents

6. Maintenance................................................................................................. 49

6.1. Replacing the air filter ................................................................................ 49

6.2. Replacing the fan unit ................................................................................ 49

6.3. Calibrating the Volt / Amp Multimeter......................................................... 50

6.4. Resetting the rectifier after an HVSD ( high voltage shutdown )................ 51

7. Troubleshooting.......................................................................................... 53

8. Appendix A : Replacement parts ............................................................... 55

9. Appendix B : Technical service assistance.............................................. 57

9.1. Local toll-free prefixes................................................................................ 57

9.2. Toll-free technical assistance numbers...................................................... 58

10. Abbreviations and acronyms..................................................................... 59

List of Figures

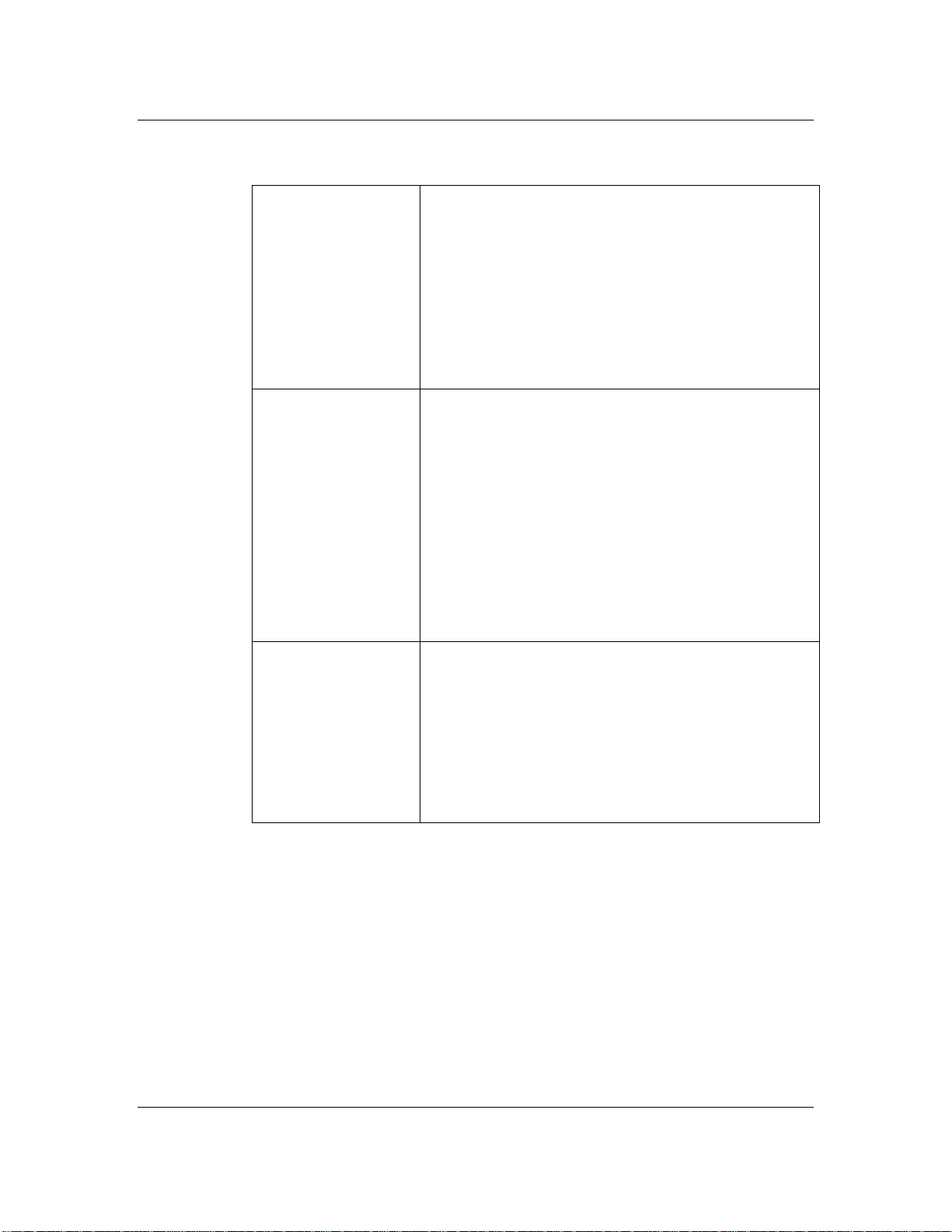

Figure 1 - Front view of the modular 200I / 48 switch mode rectifier................... 11

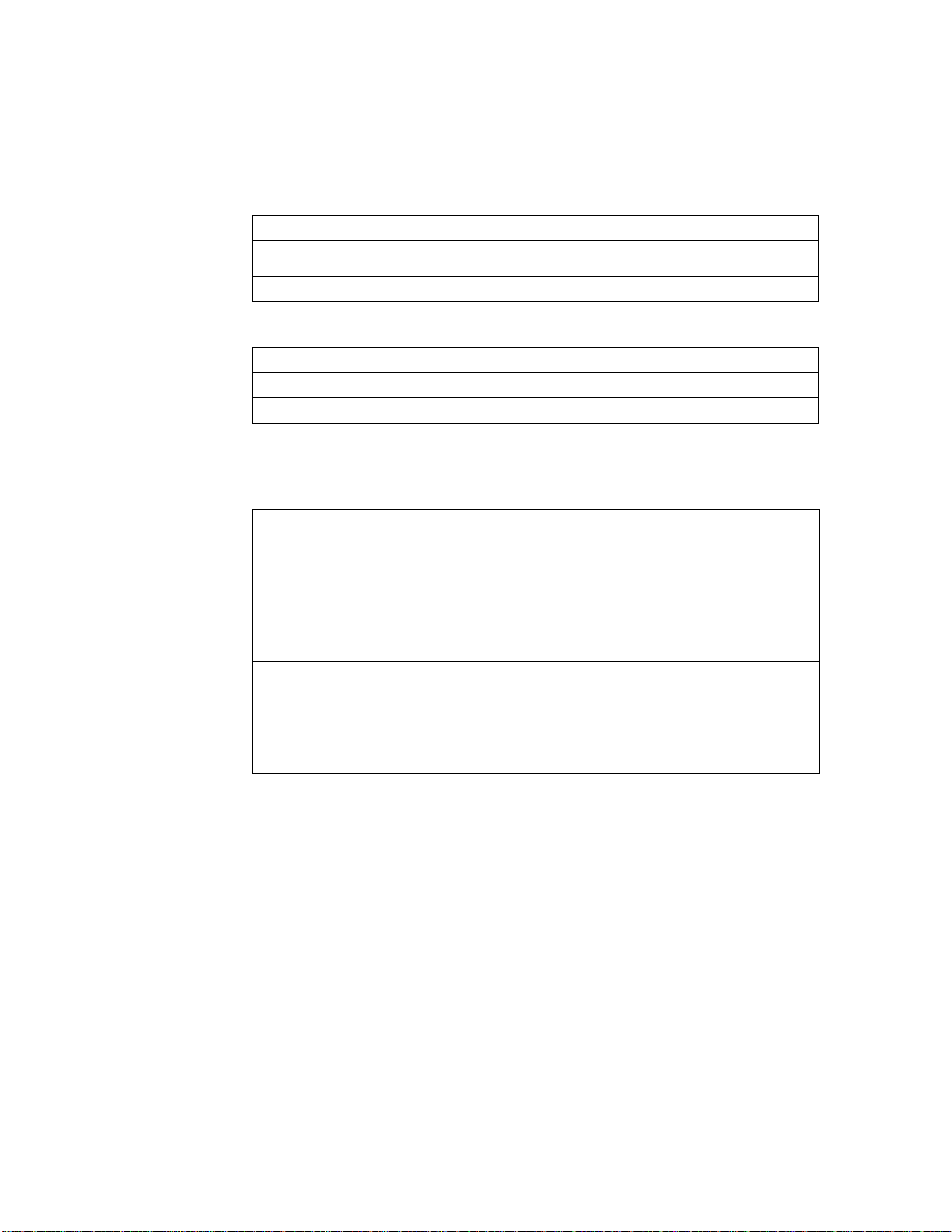

Figure 2 - Typical mounting in a cabinet or frame................................................ 12

Figure 3 - Anchoring the cabinet.......................................................................... 21

Figure 4 - Installing the rectifier............................................................................ 22

Figure 5 - Connecting the dc to the busbars with a shunt on the battery

side or a shunt on the ground side ...................................................... 23

Figure 6 - Cabling ac the NT5C05CA / CB rectifiers............................................ 26

Figure 7 - Connect the power leads to the L1, L2 and L3 terminals of the

rectifier................................................................................................. 26

Figure 8 - Connecting ac to the rectifier NT5C05CC........................................... 27

Figure 9 - Typical connections between rectifiers and the conventional

controller.............................................................................................. 28

Figure 10 - Front panel controls and LEDs.......................................................... 33

Figure 11 - Replacing the fan unit........................................................................ 49

List of Tables

Table 1 - Mechanical specifications of the rectifier .............................................. 13

Table 2 - Electrical specifications of the rectifier.................................................. 13

Table 3 - Operation specifications of the rectifier ................................................ 14

Table 4 - Ambient conditions for the rectifier ....................................................... 15

Table 5 - Mechanical specifications of the NT6C43CB 1200 A cabinet .............. 16

Table 6 - Electrical specifications of the NT6C43CB........................................... 16

Table 7 - Ambient conditions for the NT6C43CB 1200 A cabinet........................ 16

Table 8 - Pin assignment for connectors J7 to J12.............................................. 29

Table 9 - Pin assignment for connector J13 ........................................................ 30

Table 10 - Designation of the LEDs on the front panel........................................ 34

Table 11 - Adjusting the potentiometers and switches ........................................ 36

Table 12 - Rectifier input / output signals to the controller................................... 36

Table 13 - Setting the start-up delay....................................................................41

Table 14 - Control signal connections on P1 ....................................................... 42

Table 15 - Standard settings for the rectifier........................................................ 45

Table 16 - Diagnosing system faults....................................................................53

List of Procedures

Procedure 1 - Installing the rectifier in a frame.................................................... 20

Procedure 2 - Installing a rectifier in a cabinet..................................................... 21

Procedure 3 - Securing the dc output terminals to the busbars of the cabinet.... 24

Procedure 4 - Typical dc cabling in a frame application ...................................... 24

Procedure 5 - Cabling the ac input to the NT5C05CA / CB rectifiers .................. 25

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 9

Contents 9

Procedure 6 - Connecting the ac male plug between the NT5C05CC rectifier

and the ac female plug in a 1200 A cabinet.................................. 27

Procedure 7 - Connecting the NT5C05CC to the controller................................. 28

Procedure 8 - Connecting an NT5C05CC rectifier directly to a controller ........... 29

Procedure 9 - Starting up the rectifier.................................................................. 46

Procedure 10 - Replacing the fan unit ................................................................. 50

Procedure 11 - Calibrating the meter...................................................................51

Procedure 12 - Resetting the rectifier after a high voltage shutdown.................. 51

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 10

10 Contents

This page is left blank intentionally.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 11

1. General information

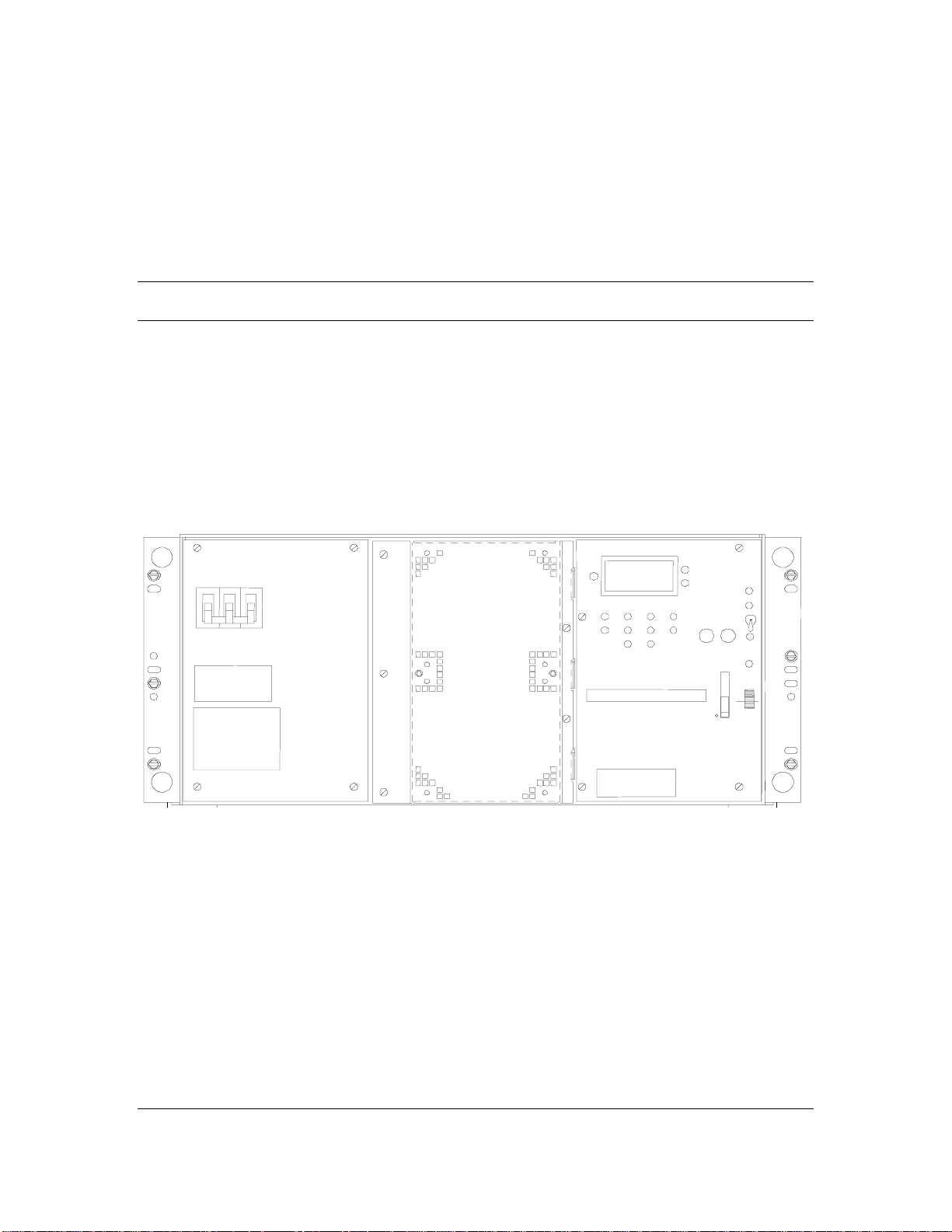

1.1. Purpose of this manual

This manual provides installation, operation and maintenance information

for the NT5C05CA / CB / CC 200I modular switch mode rectifiers with an

input voltage of 380 / 415 V ac and an output capacity of 200 A at a

nominal voltage of –48 volts. This manual covers all applications of the

rectifier referred to as the 200I ( “I” standing for “International” ) market.

Figure 1 - Front view of the modular 200I / 48 switch mode rectifier

H E L I O S

V O LT

AM P

T H S D

H V S D

RF A

F A N

AL M

V OL T + V O U T-

A C / C A

I

0

11

VO L T

C A L

R

CU

CA L

C L

A D J

E Q L

A D J

S E N

AC O N

FA I L

E Q L

C L

E QL

F F1

FF2

F LT

1

. 0 A

1 . 0 A

F

L T

AD J

H V SD

A DJ

I

S T U P

D L Y

S L S FS

I

D

C / C C

The NT5C05CA / CB / CC rectifiers are designed to operate continuously

in a -48 V power system, equipped with or without batteries. It can be

integrated into a small-embedded system or a larger power plant

configuration. It is forced air-cooled by four fans contained in the unit, one

of which is are redundant, if one fan fails this will not cause a shutdown of

the rectifier. The rectifiers can be operated in conjunction with other

Emerson rectifiers as well as with the models and conventional controllers

of other manufacturers available on the market.

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 12

12 General information

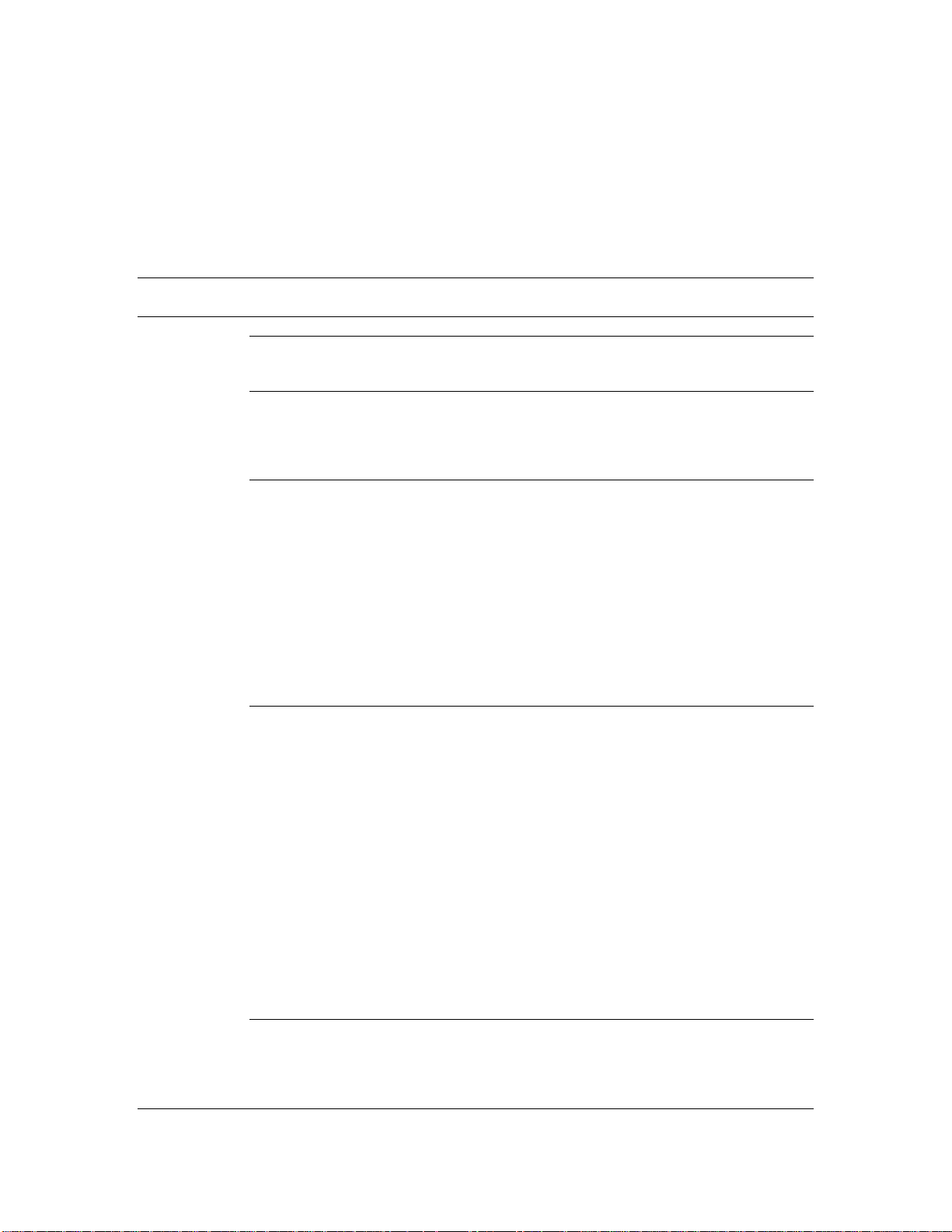

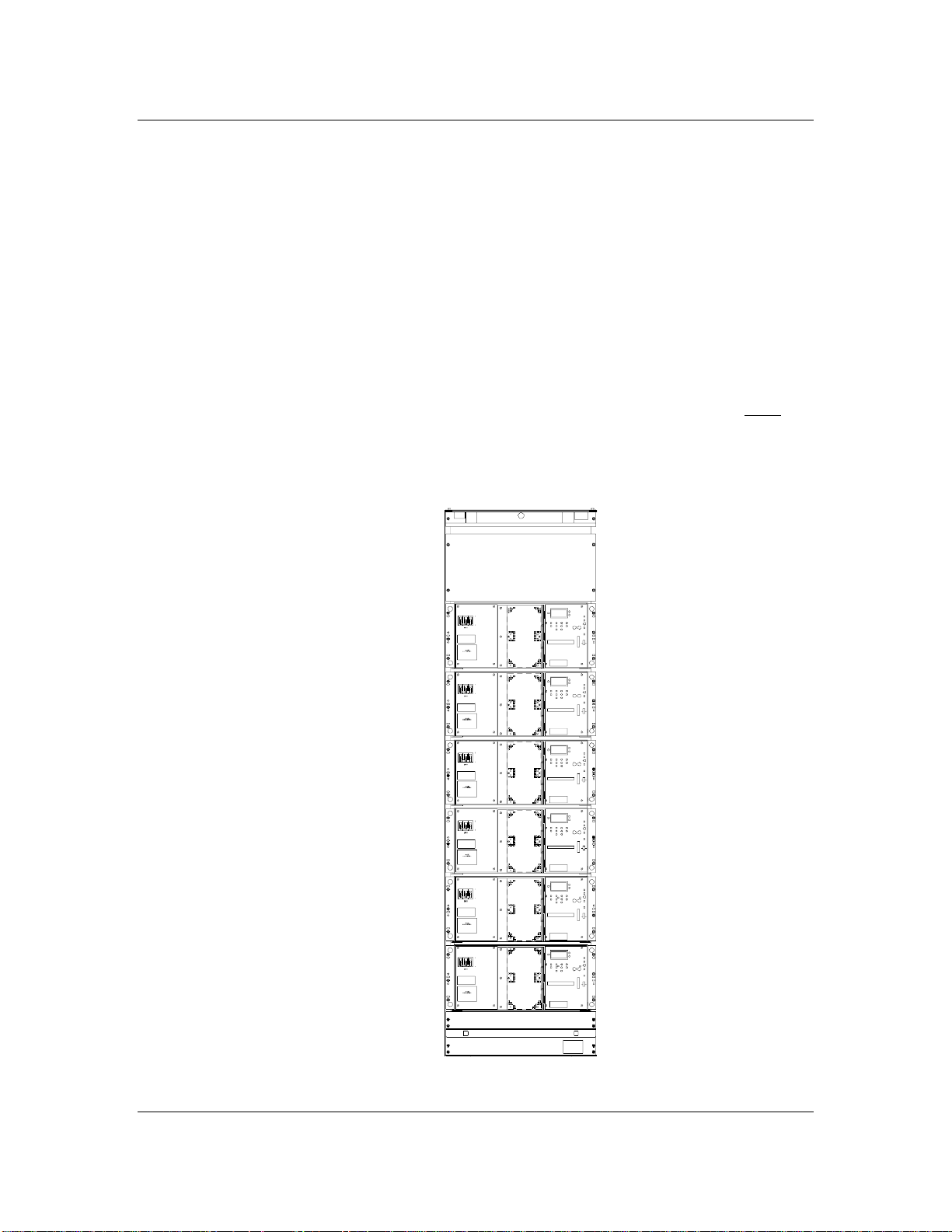

1.2. Models and mounting configurations

Two models of 200I rectifiers are available :

• Models NT5C05CA / CB, without an ac cable

• Model NT5C05CC, equipped with an ac cable terminated with a

male plug

Up to six switch mode 200I rectifiers can be installed in a 23-inch

NT6C43CB 1200 A cabinet or in an NT6C40 type frame. The cabinet is

specifically designed to provide modularity within a very compact unit.

For wooden floor applications in a zone 4 seismic region, up to three

rectifiers can be installed in a mounting frame mounting, but they must

installed in the three lowest mounting positions in the frame.

Figure 2 - Typical mounting in a cabinet or frame

be

RECTIFIER No. 1

RECTIFIERNo. 2

RECTIFIER No. 3

RECTIFIER No. 4

RECTIFIER No. 5

RECTIFIER No. 6

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 13

2. Specifications

2.1. Mechanical and electrical specifications

13

Table 1 - Mechanical specifications of the rectifier

Height :

Depth :

Width :

Weight :

Table 2 - Electrical specifications of the rectifier

Input voltage :

Input current :

Input protection :

Output floating

voltage :

Equalizing voltage :

High voltage

shutdown :

Output current :

Output protection :

Current limit :

10.0 inches ( 25.4 cm )

22.0 inches ( 55.9 cm )

20.5 inches ( 52.1 cm )

92.6 lbs ( 42 kg )

Nominal : 380 / 415 V ac

Range : 330 ±5 V ac to 475 ±5 V ac

Frequency : 47 to 63 Hz

Note: After an out of range line condition shutdown,

the rectifiers will restart automatically at a line

voltage within 350 ±5 V ac to 460 ±5 V ac.

Nominal: 18 A RMS ( at 415 V ac )

Worst case: 24 A RMS

25 A ac breaker, 3 Ø

−46 V dc to —58 V dc

0 to −4 V dc above the floating voltage

−52 V to −60 V dc

200 A ( 330 to 475 V ac input )

200 – 250 A dc circuit breaker

50% to 105% of the rated output current

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 14

14 Specifications

2.2. Operation specifications and ambient conditions

Table 3 - Operation specifications of the rectifier

Output regulation :

Temperature drift :

Output noise and

ripple :

Total harmonic

distortion ( THD ) :

Efficiency :

Power factor :

Heat dissipation :

Electromagnetic

interference ( EMI ) :

Reliability:

At the output terminals, the voltage is within ±0.5% of

the set voltage value for all specified input and output

variations, and within ±1% for any combination of

specified input, output and ambient conditions.

Unless otherwise stated, all input and output

parameters such as input voltage range, output current

and voltage, current limit, etc. shall not vary more than

2% over the operating temperature range.

• less than 22 dB of random noise on C band at voice

frequency over the entire operating range of the

rectifier, including operation in the current limit mode,

and at low, nominal and high input voltage conditions

( with or without batteries and measured at the point

of regulation )

• less than 20 mV RMS in any 3 kHz band between 10

kHz and 20 MHz ( measurements made with or

without batteries at the output terminals of the

rectifier and with the rectifier in the local sensing

mode )

• less than 250 mV peak to peak switching voltage

spikes ( measured differentially with an a 100 MHz

oscilloscope )

Less than 5%.

Better than 89% at a nominal input voltage of 350 V ac

and for an output current ( load ) greater than 80 A.

Better than 99% with an output current ( load ) greater

than 80 A.

The maximum heat dissipation is 1420 watts

( 4846 BTU / hr ) for an output current ( load ) of 200 A

at –58 V dc ( when the ac input is 330-475 V )

The NT5C05CA / CB rectifiers when used in the

rectifier cabinet NT6C43CA / CB ( equipped with the

ac EMI filter kit NT6C18KB, or the NT5C05CC without

external EMI filter ) meet the CISPR requirements for

conducted and radiated EMI as specified in Publication

22 for Class "A" equipment.

The rectifier has an MTBF greater than 120 000 hours

under normal operating conditions, at 77°F ( 25°C ) as

per Telcordia Technologies TR332 method.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 15

Table 4 - Ambient conditions for the rectifier

Specifications 15

Operating

conditions

Transportation

conditions

Storage conditions

A minimum airflow clearance of 2 inches ( 5 cm ) is

required at the rear of the rectifier.

The rectifier will operate properly under the following

conditions.

Temperature: 32°F to 122°F ( 0°C to +50°C )

32°F to 104°F ( 0°C to +40°C ) with air

filters

Humidity: 0 to 95% RH ( non-condensing ) at 4

kPa max. equiv. to 7,000 ft. ( 2,100 m )

above sea level

During transportation, the rectifier can be subjected to

the following conditions without sustaining damage.

Temperature: –67°F ( –55°C ) for 16 hours

140°F ( +60°C ) dry heat

Humidity: 0 to 95% RH ( non-condensing ) at

4 kPa max.

Vibration: 38 mm / s max. ( 10 Hz to 30 Hz )

sinusoidal, 18-inch ( 457 mm ) drop

when packaged

Pressure: 12 kPa min. equiv. to 49,212 ft.

( 15,000 m above sea level)

Temperature shock : −58°F to 140°F ( −50°C to 60°C )

During storage, the rectifier may be subjected to the

following conditions without damage :

Temperature: –67°F ( –55°C ) for 16 hours to 140°F

( +60°C ) dry heat

Humidity: 0 to 95% RH ( non-condensing ) at

4 kPa maximum

The rectifier contains aluminum electrolytic capacitors

that have a shelf life of five years or greater at the

maximum rated storage temperature.

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 16

16 Specifications

2.3. Mechanical and electrical specifications of a 1200 A cabinet

Table 5 - Mechanical specifications of the NT6C43CB 1200 A cabinet

Height :

Depth :

Width :

Table 6 - Electrical specifications of the NT6C43CB 1200 A cabinet

Input voltage :

Output voltage :

Output current :

84.00 inches ( 213.36 cm )

23.63 inches ( 60.0 cm )

23.63 inches ( 60.0 cm )

380 / 415 V ac three phase

–46 V dc to –58 V dc

1200 A

2.4. Ambient conditions of a 1200 A cabinet

Table 7 — Ambient conditions for the NT6C43CB 1200 A cabinet

Operating

conditions

Storage conditions

The cabinet is designed for use under the following

ambient conditions.

Temperature: 0°C to 50°C ( 32°F to 122°F )

Humidity: 0 to 95% RH ( non-condensing )

Altitude: sea level to 7,000 ft ( 2,100 m )

During transportation and storage, the acceptable

ambient conditions are :

Temperature: –55°C ( –67°F )

Humidity: 0 to 95% RH ( non-condensing )

0° to 40°C ( 32° to 104°F ) with air

filters

+60°C ( 140°F ) dry heat

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 17

3. Installation

3.1. Mounting configurations

The NT5C05CA / CB / CC rectifiers are designed for installation in a

1200 A cabinet ( NT6C43CB ) or in a standard frame ( NT6C40 or

equivalent ). In this chapter, a different procedure is provided for each

mounting method. The rectifiers are shipped loose, not mounted in the

frame or cabinet. Upon reception, remove the rectifier from its shipping

carton and inspect it for physical damage. Report any damage to your

immediate supervisor.

3.2. Tools and test equipment

The following tools and test equipment are required :

• screwdriver, flat blade, 3/16 inch ( 5 mm )

• potentiometer screwdriver, Bourns No. 60, or equivalent

• heavy cable strippers or electrician’s knife

• heavy cable cutters ( AWG 4/0 or metric No. 110 )

• nut drivers ( set )

• socket set ( 1/2 inch or 15 mm drive )

• torque limiting wrench ( 1/2 inch. or 15 mm drive )

• crimper, T&B, 15CA54R Violet die

• digital multimeter, Fluke 8000A or equivalent

17

3.3. Cautions and Warnings

The following precautions must be adhered to at all times

and installing power equipment.

when handling

CAUTION

Protecting the premises

Protect the floors and walls against damage with sheets of

plywood, cardboard, or other suitable material when

handling the equipment.

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 18

18 Installation

CAUTION

Preventing damage caused by over-tightening

Do not over-tighten nuts and bolts. Over-tightening can

strip the threads or break the bolts. Apply the appropriate

torque values.

CAUTION

Personal safety and protecting the equipment

Use a dolly truck, forklift, or hoist whenever possible

when handling and moving the equipment, as power

equipment is heavy. If a forklift is used, do not remove the

packing material before having moved the equipment to

its final location. If a dolly truck is used, the packing

material can be removed in the reception area. When

handling cabinets with equipment installed in them,

exercise care to ensure they do not tip over, as they can be

top heavy.

CAUTION

Preventing personal injury

When cutting material, wear gloves and goggles. Break all

corners and sharp edges with a flat file.

CAUTION

Optimizing the life of the equipment

Make sure there are no obstructions in front of the

ventilation openings that can restrict the flow of air.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 19

Installation 19

WARNING

Generator requirements for Emerson Energy Systems

Power Systems

For information on selecting ac generators that will

effectively maintain peak performance and operating

characteristics, for all Astec APS power systems, go to the

partners’ section of the Emerson Energy Systems web site

at www.EmersonEnergy-NA.com

. To obtain access to the

partners’ section follow the instructions found on the

partner’ page, or dial our nearest local 1−800 technical

support line ( refer to “Appendix C : Technical service

assistance” of this manual for the telephone number ).

DANGER

Grounding

The frame ground leads must be connected before any

other leads. This is to prevent the cabinets and any other

metal structures from carrying dangerous ac or dc voltage

levels.

DANGER

Protecting against electrical shocks

The cabling of the power plant, and all other required

cabling, must be carried out by qualified personnel and in

conformance with local and national electrical codes. AC

input voltages to the rectifiers are at a dangerous level.

Ensure that the circuit breakers are locked in the OFF

position in the ac service panel before working on the

power plant. Dangerous voltages may be present at the

output dc terminals even if the rectifiers are OFF. Use a

voltmeter to verify for the presence of such voltages. Do

not put the circuit breakers to ON until the entire system

has been assembled and you have been instructed to do so.

Verify, and identify with a tag, the proper polarity of the

battery leads before connecting them to the power plant.

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 20

20 Installation

3.3.1. Installing in a frame

DANGER

Short circuit hazard

The rectifiers, and the batteries in particular, can deliver

high current if a short to ground occurs. When working

on live equipment, remove all personal jewellery, use

properly insulated tools, and cover any live busbars with

a insulating sheet of canvas to prevent short circuits that

could be caused by falling tools or parts.

When shipped, the NT5C05CA / CB / CC switch mode rectifiers are

configured for installation in a standard frame. As the rectifier is heavy,

use a manual forklift to mount the rectifier in a frame. If a forklift is not

available, two persons, exercising care, can lift the rectifier into place and

secure it.

Procedure 1 - Installing the rectifier in a frame

Step Action

Note : Install each rectifier beginning with the lowest mounting

1

position in the frame.

Align the mounting brackets of the rectifier with the mounting holes in

the frame and insert the locating pins into these holes.

2

3

4

Lift the rectifier and align the middle holes in the mounting brackets

of the rectifier with the locating pins inserted in the frame. Slide the

rectifier into position onto the locating pins.

Secure the rectifier to the frame by inserting and tightening a

mounting screw ( provided ) in the uppermost holes of each

mounting bracket ( one on the left side and one on the right side ).

Remove the locating pins and install the other six mounting screws.

Tighten the screws applying a torque of 6.5 ± 0.5 ft-lbs ( 8.5 ±

0.5 N-m ).

3.3.2. Installing in a cabinet

The cabinet is 23.56 inches ( 600 mm ) wide and deep, and 84 inches

( 2134 mm ) high. The anchors provided to secure the cabinet in place are

intended for installation on 3000 psi ( 2 kg per sq. mm ) compressive

strength concrete. Anchors for seismic applications are available upon

request. Slotted holes are provided in the base of the cabinet for anchoring.

The primary locations should be used as a first choice ( see Figure 3 ). If a

steel-reinforcing rod is encountered when drilling the holes for the anchors

end

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 21

in the concrete floor, the secondary anchor locations may be used. An

(

optional cabinet isolation kit is available consisting of four anchor

bushings and a base pad. If this kit is installed, place the pad on the floor

and the bushings on the anchors, and position the cabinet on top.

Figure 3 - Anchoring the cabinet

SECONDARY LOCATION

FOR FLOOR ANCHORS

600 mm

(23.56 po.)

Installation 21

m

po.)

m

0

(20.42

9

5

520 mm

)

.

o

p

3

1

.

3

2

PRIMARYLOCATION

FOR FLOORANCHORS

Procedure 2 - Installing a rectifier in a cabinet

Step Action

1

2

3

+

+

526 m m

(20.68 po.)

Loosen and remove the screws securing the mounting brackets to

each side of the rectifier.

Reposition and secure the mounting brackets to the holes located

nearest the front of the rectifier, on each side of the rectifier.

Remove the blank panel from the cabinet and put the self tapping

screws in a secure location, for future use.

continued

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 22

22 Installation

Procedure 2 - Installing a rectifier in a cabinet ( continued )

Step Action

4

Place the rectifier on the L-shaped guides located in the lowest

position of the cabinet and slide it towards the rear until the mounting

brackets come into contact with the frame of the cabinet. The front of

the rectifier should be flush with the front of the cabinet and the

output bussing should be in contact with the riser busbars located at

the rear of the cabinet.

5

Align the mounting holes in the brackets of the rectifier with the

mounting holes in the frame. Secure the rectifier in place by inserting

and tightening the self-tapping screws removed in Step 3.

Note : Install an external tooth lock washer on one of the screws to

Figure 4 - Installing the rectifier

assure good ground continuity between the rectifier and the

frame.

end

HELIOS

AC/CA

HELIOS

3.4. Cabling and connecting

The ac cables of the rectifier must always exit each rectifier from the right

side, when viewed from the rear.

The dc cables of the rectifier must always exit each rectifier from the left

side, when viewed from the rear.

The system alarm interface cable must always exit each rectifier from the

right side, when viewed from the front.

SELF-TAPPING SCREW

( P097F813 )

ET LOCK WASHER

VOLT/AMP

VOUT-

VOLT

CAL

CUR

CL

CAL

ADJ

EQL

ADJ

SEN

FAIL

EQL

EQL

FLT

ACON

FF1

FF2

1.0A

1.0A

CL

FLT

ADJ

HVSD

ADJ

ST UP

DLY

SLS FS

DC/CC

VOLT

CAL

VOLT

AMP

THSD

RFA

FAN

HVSD

ALM

VOUT+

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 23

Installation 23

3.5. Connecting the dc output terminals to the busbars

The dc outputs of the rectifier are connected to the busbars as illustrated in

Figure 5. There are two methods :

• BAT GRD ( + ) of the rectifier connected to the CHG/ DISCH

GRD busbar and the –48 V of the rectifier connected to the

CHG BAT busbar

• BAT GRD ( + ) of the rectifier connected to the CHG GRD

busbar and the -48V of the rectifier connected to the CHG/

DISCH BAT busbar

Figure 5 - Connecting the dc to the busbars with a shunt on the battery side or a shunt on

the ground side

CHG / DISCH

+

RECTIFIER

-

+

RECTIFIER

-

BAT GRD

+

-48V

-

BAT GRD

+

-48V

-

SHUNT ON THE GRD SIDE ( PREFERRED CONFIGURATION )

GRD BUSBAR

CHG BAT

BUSBAR

SHUNTON THE BATTERY SIDE

CHG GRD

BUSBAR

CHG / DISCH

BATBU SBAR

SHUNT

SHUNT

LOAD

DISCHARGE

BATBUSBAR

DISCHARGE

GRD BUSBAR

FUSE

PANEL

FUSE

PANEL

LOAD

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 24

24 Installation

3.5.1. Securing the dc output terminals to the busbars in a 1200 A

3.5.2. Running and connecting the dc between busbars and a

cabinet

For cabinet applications, no dc cabling is required; the output terminals of

the rectifier are connected directly to the busbars.

Procedure 3 - Securing the dc output terminals to the busbars of the

cabinet

Step Action

1

2

Connect the BAT GRD output terminal of the rectifier to the BR

busbar, and the –48 V output terminal of the rectifier to the –48 V

busbar located at the rear of the cabinet.

Tighten the bolts by applying a torque of 6.5 ± 0.5 ft-lbs ( 8.5 ±

0.5 N-m ).

end

rectifier

For frame applications, use terminal lug A0361762, supplied with the unit,

and no. 110 ( 4/0 ) metric cable.

Procedure 4 - Typical dc cabling in a frame application

Step Action

1

2

Connect the BAT GRD output terminal of the rectifier to the CHG

GRD busbar of the power plant. Connect the –48 V output terminal

of the rectifier to the CHG / DISCH BAT busbar of the power plant

( see Figure 5 ).

Apply a torque of 6.5 ± 0.5 ft-lbs ( 8.5 ± 0.5 N-m ) on the bolts

securing the lugs to the rectifier terminals.

3.6. Connecting ac to the rectifiers

WARNING

Electrical connections should meet standards

The electrical installation must be carried out by qualified

personnel and in accordance with local electrical codes.

end

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 25

Installation 25

DANGER

Hazardous potentials

Input voltage to the cabinet is at a hazardous potential.

Make sure the power is OFF and that the lever in the ac

service panel is locked in the OFF position before

attempting to connect the input line voltage to the ac box

of the cabinet.

Procedure 5 - Cabling the ac input to the NT5C05CA / CB rectifiers

Step Action

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Install the ac breaker ( 30 A / 3 phase per rectifier ) in the 380 /

415 volts ac service panel and lock it in the open ( OFF ) position.

Put the ac breaker to OFF.

Run the ac armored cable ( metric no. 25 [ 10 AWG ] 3 conductors

and ground ) from the service panel, through the top of the cabinet,

to the rear of the rectifier.

Secure the ac cable to the side of the cabinet using cable ties and

adhesive anchors. Make sure the cable are located in a manner that

will not interfere with the insertion of the rectifier ( see Figure 6 ).

Ground the conduit sheath to the ac service panel. Insulate the

conduit connector at the rectifier end with electrical tape to isolate it

from the ac ground.

Remove the two ac protection plates located at the rear of the

rectifier.

Strip 10 inches ( 250 mm ) of armored insulation from the end of the

ac cable. Insert the wires in the 90° conduit connector ( see Figure

7 ).

Run the signal cable from the rectifier to the interconnect board or

controller as described in the "Control signal connections" section.

Connect the green ground wire to the FR GND terminal.

Connect the power leads to the L1, L2 and L3 terminals ( any phase

sequence ) ( see Figure 7 ).

Tighten the elbow connector and reassemble the ac protection plate.

Run the signal cable from the rectifiers to the interconnect board or

controller as specified in the " Connecting the control signals"

section.

Secure the signal cables to the insulating busbar support, located in

the cabinet, with cable ties.

Start-up the rectifier as described in the “ Start-up “ procedure.

end

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 26

26 Installation

C

A

e

Figure 6 - Cabling ac the NT5C05CA / CB rectifiers

SIGNAL

HEX HEAD CAP SCREW

BLES TOTHE

PLANT CONTROLLER

PART OF OPTIONAL

KIT P0872151

AND WASHERS

( 4 PLACES )

AA

REAR VIEW OF A

TOP FED ARRANGEMENT SHOWING

OPTIONAL BUSBAR COVER KIT P0872151

( WITH REAR PANELS REMOVED )

AC FEED TO

RECTIFIERS

SIGNAL CABLE

REMOVE PLATE TO

ACCESSCONNECTORS

CABLE

TIE

Note: Dress the cables carefully to

clear the insertion path of th

rectifier.

SECTIONA-A

SHOWING TOP VIEW

OF AC CABLING

Figure 7 - Connect the power leads to the L1, L2 and L3 terminals of the rectifier

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 27

Procedure 6 - Connecting the ac male plug between the NT5C05CC rectifier

and the ac female plug in a 1200 A cabinet

Step Action

1

Install the ac breaker ( 30 A / 3 phases per rectifier ) in the 380 /

415 volts ac service panel.

2

Put the ac breaker for the NT5C05CC rectifier, located in the ac

service panel, to OFF.

3

Run the metric no. 25 ( 10 AWG ) ac supply cable ( 3 conductors

and ground ) to the female receptacle ( see Figure 8 ). Connect the

female connector to the male connector.

4

Run the signal cable from the rectifier to the interconnect board or

controller as specified in the " Connecting the control signals "

section.

5

Secure the signal cables to the insulating busbar support, located in

the cabinet, with cable ties.

6

Start-up the rectifier as described in the “ Start-up “ section.

Figure 8 - Connecting ac to the rectifier NT5C05CC

Installation 27

end

A

GRD

TB1

L1 L2 L3

R1 (TB1-L1) BLUE

S2 (TB1-L2)

T3 (TB1-L3)

WIRE COLORCONNECTION

BROWN

BLACK

GREEN / YELLOW

A

BROWN

BLUE

GREEN/YELLOW

SECTA-A

FEMALE CONNECTOR

BLACK

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 28

28 Installation

3.7. Connecting the control signals

For all applications with conventional controllers ( such as NT6C25BA or

NT6C25BB ) or front access controllers ( NT6C25FA ), execute the steps

contained in Procedure 7 to connect the NT5C05CC rectifier ( see Figure

9 ).

Procedure 7 - Connecting the NT5C05CC to the controller

Step Action

1

2

Figure 9 - Typical connections between rectifiers and the conventional

Connect each rectifier to the NT6C43PB board ( positions J1 to J6 ),

located at the top front of the cabinet or frame, with P0747000

cables.

• Connect the NT6C43PB board ( positions J7 to J12 ) to the

controller with P0736355 cables for conventional controllers ;

and with P0736268 cables for front access controllers.

controller

end

Rectifier

#6

Rectifier

#5

Rectifier

#4

Rectifier

#3

Rectifier

#2

Rectifier

#1

NT6C43PB

MONITOR

Cables P0736355

Cables P0747000

J13

J1 J2 J3 J4 J5 J6

J7 J8 J9 J10 J11 J12

CONTROLLER NT

(NT6C25BA or NT6C25BB)

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 29

Installation 29

Procedure 8 - Connecting an NT5C05CC rectifier directly to a controller

Step Action

1

If an NT6C43PB interconnect board is not available, each rectifier

must be connected directly to the controller with the following

cables :

• P0723784, P0723785 or P0723786 ( for conventional

controllers )

• P0723708, P0723709 or P0723210 ( for front access

controllers )

end

For controllers not manufactured by Emerson Energy Systems see Table

12 in the " Functional Description " chapter describing the pin assignments

of the rectifier. Refer to Table 8 for the pin assignments of connectors J7

to J12 on board NT6C43PB.

Note: The alarm and control signals in Table 8 are all ground

signals except for the RC– signal that is a –48 V

battery signal.

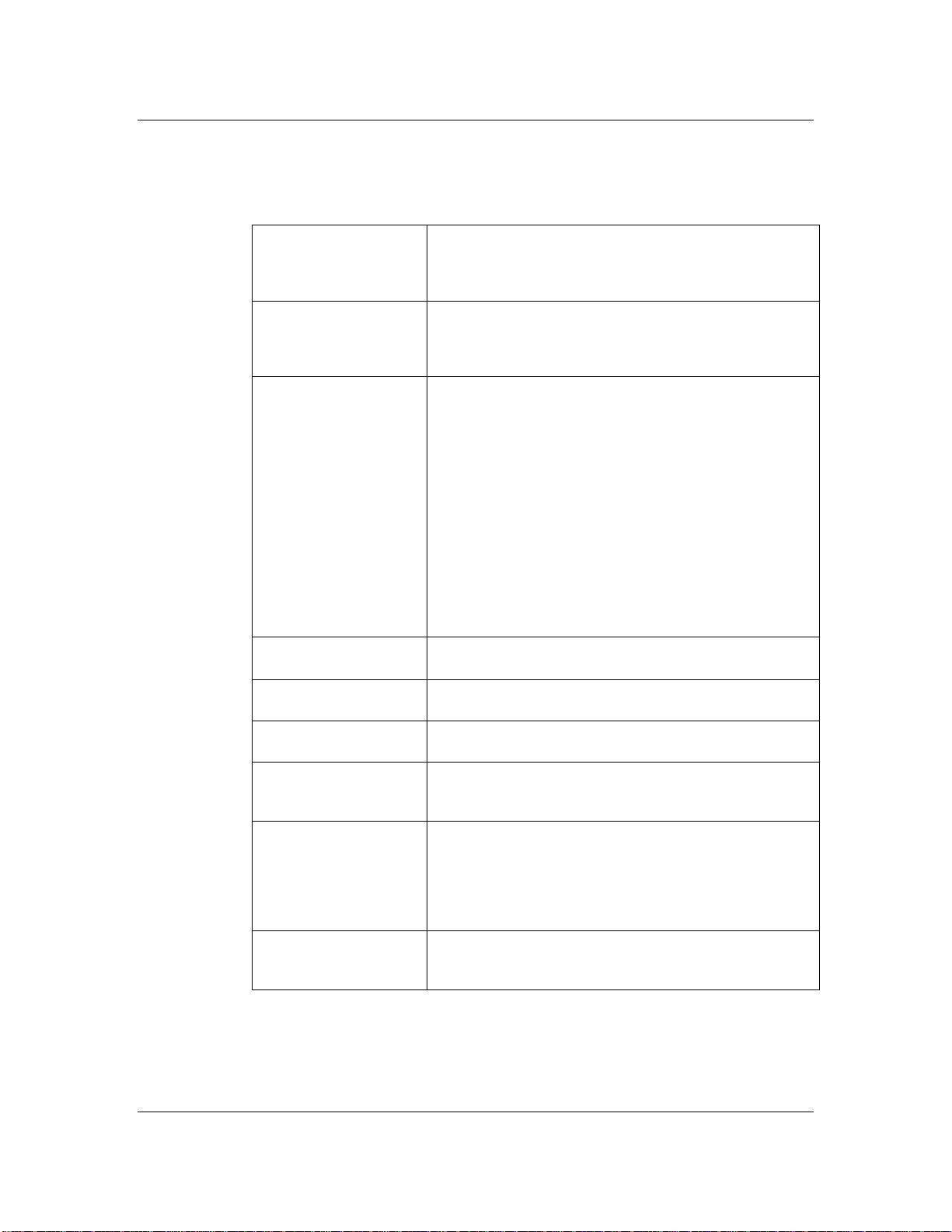

Table 8 - Pin assignment for connectors J7 to J12

Pin Label Function Input/ Output

1

2

3

4

5

6

7

8

EQL Equalize Input

RG+ Remote sense Input

RC– Remote sense Input

FAN ALM Fan fail alarm Output

HVSDR High voltage shutdown reset Input

HVSD High voltage shutdown Input

RFA Rectifier failure alarm Output

TR Temporary release Input

3.7.1. Monitoring of the shunt current

A 12-pin connector ( J13 ) is also available on the NT6C43PB

interconnect board for monitoring the individual output current shunt

readings ( 250 A / 50 mV for example ) of each rectifier in a cabinet or a

frame ( see Table 9 ).

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 30

30 Installation

Table 9 - Pin assignment for connector J13

Pin Function

J13-1 SH+ ( rectifier 1 )

J13-2

J13-3 SH+ ( rectifier 2 )

J13-4

J13-5 SH+ ( rectifier 3 )

J13-6

J13-7 SH+ ( rectifier 4 )

J13-8

J13-9 SH+ ( rectifier 5 )

J13-10

J13-11 SH+ ( rectifier 6 )

J13-12

SH− ( rectifier 1 )

SH− ( rectifier 2 )

SH− ( rectifier 3 )

SH− ( rectifier 4 )

SH− ( rectifier 5 )

SH− ( rectifier 6 )

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 31

4. Functional description

4.1. Overview

4.1.1. Input circuit

The input circuit offers the following characteristics :

• ac rectifying

• EMI filtering

• inrush current limiting, a walk-in circuit limits the output current

rise to 25 A per second

• low and high ac inhibit

• power factor compensation

• surge voltage protection

• ac breaker for input protection

For all input and output conditions specified in this manual, when the

rectifier is turned on, the ac current will not exceed the maximum steadystate value.

31

4.1.2. Output circuit

The output circuit offers the following characteristics :

• shunt for output dc current sensing

• 225 A dc circuit breaker for output protection

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 32

32 Functional description

4.1.3. Monitoring and control circuits

The monitoring and control circuits offer the following characteristics :

• soft start

• rectifier fail alarm ( RFA )

• control for local and remote equalize ( EQL )

• temporary release ( TR )

• thermal shutdown ( THSD )

• input ac monitoring

• local and remote high voltage dc shutdown ( HVSD )

• local and remote HVSD reset

• fan failure detection

4.1.4. Output capacitors

The output capacitors will be completely discharged ( < 2 V ) two minutes

after the ac power has been removed and the rectifier has been

disconnected from the batteries or the parallel rectifiers.

4.2. Description of the front panel

4.2.1. Breakers

DC circuit breaker

A dc circuit breaker is provided to protect against current overload and to

manually disconnect from the power plant.

When the breaker is in the 0 ( OFF ) position, an RFA is triggered and the

remote sense leads RG+ and RC– are internally disconnected. The rectifier

will continue to operate, allowing the adjustment of the FLT, EQL and

HVSD set points.

AC breaker

The input ac circuit breaker can be used to locally turn the rectifier ON or

OFF. The local ON / OFF control overrides any remote control signals

( for example, TR ). Putting the breaker to OFF causes an RFA to be

issued and the RFA LED to light up, as long as the rectifier output is

connected to batteries.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 33

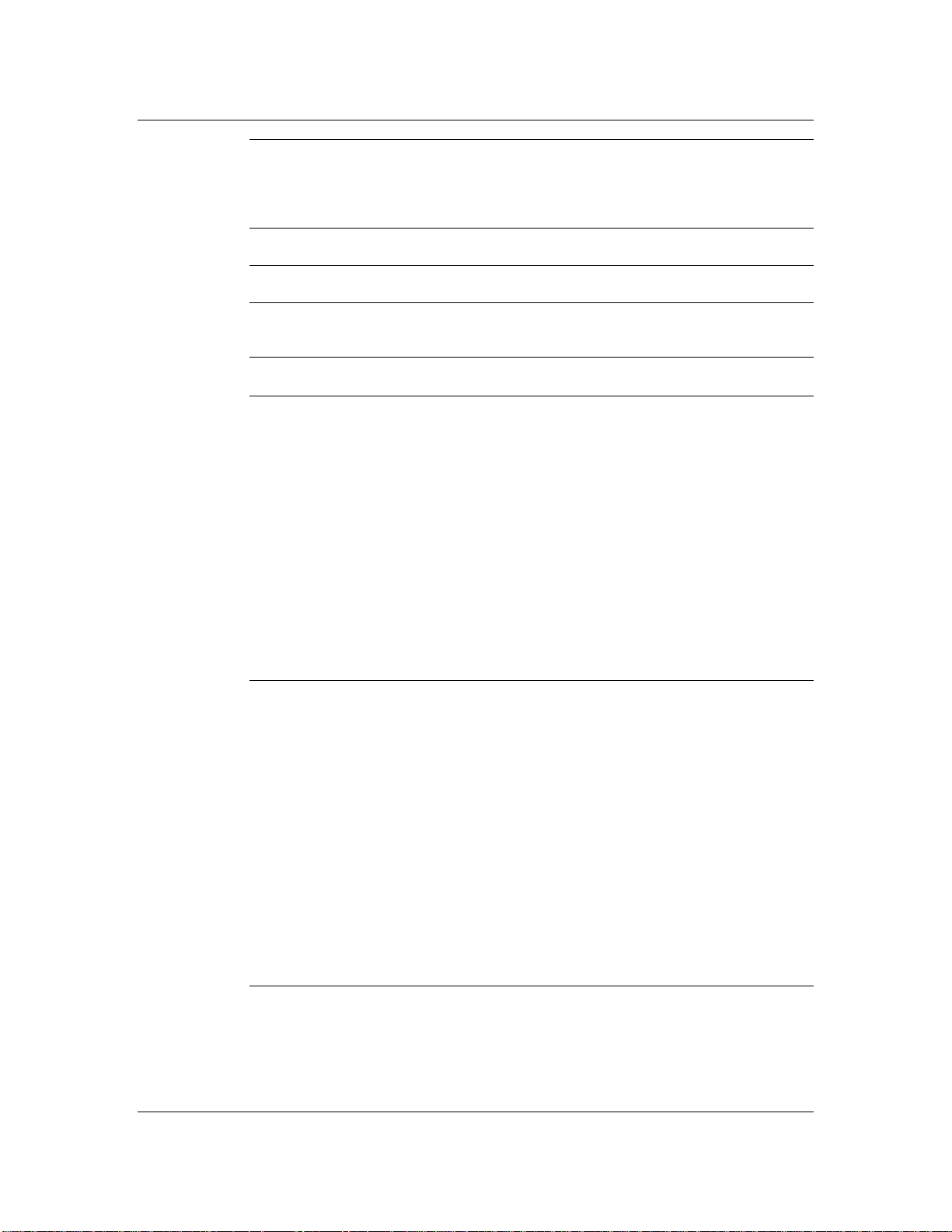

4.2.2. Switches, controls and LEDs

A

A

There are switches and potentiometers on the front panel to adjust the

operating parameters of the rectifier. The LED indicators indicate the

operating and alarm conditions.

Figure 10 - Front panel controls and LEDs

Functional description 33

VOLT

MP

THSD

HVSD

RFA

FAN

ALM

VOUT+

VOLT/AMP

SEN

FAIL

EQL

VOUT-

C ON

CL

VOLT

CAL

CUR

CAL

FF1

1.0A

DC/CC

FF2

1.0A

HVSD

ST UP

DLY

SLS

CL

ADJ

EQL

ADJ

EQL

FLT

FLT

ADJ

ADJ

FS

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 34

34 Functional description

4.2.3. Front panel LEDs

Table 10 - Designation of the LEDs on the front panel

LED Color Description

AC ON Green Input ac voltage operational

CL Yellow Current Limit

EQL Yellow Rectifier is in equalize mode

FAN ALM Red Fan fail alarm

HVSD Red High voltage shutdown

RFA Red Rectifier fail alarm

SEN FAIL Red Remote sense fail

THSD Red Thermal shutdown

AC ON ( ac voltage monitoring )

The rectifier monitors the input voltage and if the voltage exceeds the set

limit, it will inhibit its operation and trigger a rectifier failure alarm

( RFA ). The rectifier will resume its normal operation automatically when

the specified input voltage has been re-established.

CL ( current limit indicator )

This LED lights up if the rectifier is in current limit. The rectifier limits

the output current to 205 A +

5 A ( adjusted in the factory ), 50% to 105%

of the rated output current.

EQL ( equalize )

Indicates the rectifier is in equalizing mode.

FAN ALM ( fan failure alarm )

This LED lights up when the FAN ALM is activated due to a defect in the

fan system. The fan configuration includes redundancy to ensure the

rectifier will continue working properly if one of the fans fails. If only one

fan fails, a rectifier failure alarm RFA will not be triggered. It is, however,

imperative to repair or change the fan unit as soon as possible to preserve

this redundant feature.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 35

Functional description 35

HVSD ( high voltage shutdown )

The rectifier monitors itself for high voltage and will shut down when its

output voltage exceeds a preset adjustable value ( between -52 V and

-60 V ).

RFA ( rectifier failure alarm )

The rectifier monitors its operation and triggers a global RFA if it detects

an internal failure, causing the RFA LED to light up. One of the following

will trigger an alarm :

• abnormal or out of range ac input voltage

• output fuse failure

• system or internal shutdown ( thermal, HVSD, TR )

• internal failure causing a power switching malfunction

If the switching malfunction is caused by an improper adjustment of the

output float voltage, the RFA alarm will not be triggered. The RFA feature

will be activated if the ac power is removed in a system where batteries are

present.

SEN FAIL ( sense fail alarm )

This LED lights up if the remote sense leads are not connected, or if the

RC fuse has blown.

THSD ( thermal shutdown )

This LED lights up when the rectifier is protecting itself against

overheating by suspending its operation for the duration of the high

temperature condition. An RFA alarm will also be triggered.

4.2.4. Local and remote adjustments and controls

The current and voltage calibration, adjustment and control can be set

through potentiometers and switches ( see Table 11 ) located on the front

panel, or by remote signals sent from the controller ( see Tables 8 and 12 ).

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 36

36 Functional description

Table 11 - Adjusting the potentiometers and switches

Potentiometers Description

CL ADJ Current limit adjust ( 100 A to 210 A )

CUR CAL Current reading calibration

EQL ADJ

FLT ADJ

HVSD ADJ

VOLT CAL Voltage reading calibration

Switches Description

EQL / FLT Equalize / Float selection switch

SLS / FS Slope load sharing / Forced load sharing selection

ST UP DELAY Start-up delay selection DIP ( 4 sec to 2 min )

VOLT / AMP Voltage and current display selection switch

Table 12 - Rectifier input / output signals to the controller

Designation Description

RG+ / RC−

HVSD Remote High Voltage Shutdown input activated by a

HVSDR Remote High Voltage Shutdown Reset input activated by

TR Remote Inhibit input activated by a BAT RTN signal.

EQL Remote Equalize input activated by a BAT RTN signal.

RFA Rectifier Failure Alarm output activating a form C contact

F ALM Fan Failure Alarm output activating a form C contact

SHUNT ( + ) and

SHUNT ( − )

CURRENT

SHARE

Equalize voltage adjust ( 0 V to −4 V )

Float voltage adjust ( −46 V to −58 V )

High voltage shutdown adjust ( −52 V to −60 V )

External reference voltage across the batteries

measured through the controller to regulate the voltage.

BAT RTN signal.

a BAT RTN signal.

Rectifier Current input / output ( 50 mV / 250 A )

Common Forced Current Share Mode ( 0-12 V )

4.2.5. Voltage / current displaytest and measurement

CUR CAL / VOLT CAL potentiometers

These potentiometers are used to calibrate the digital display meter for

current and voltage measurements. As the two potentiometers affect each

other, current calibration must be performed before voltage calibration.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 37

VOLT / AMP digital meter switch

This switch is used to select the measurement display mode of the digital

meter. The output voltage or the output current modes can be selected.

VOUT+, VOUT−−−− test points

These test points are used to measure the voltage at the point of regulation.

A 5 kohm resistor is placed in series with both sensing leads to prevent

short-circuits at the jack terminals. The resist or may affect reading

accuracy, depending on the impedance of the meter. Refer to the

Instruction Manual for your meter to determine its internal impedance and

correction factor.

4.2.6. Float and equalize voltage control

Local FLOAT / EQL switch and potentiometers

The rectifier is equipped with a FLOAT / EQL switch.

Functional description 37

When the FLOAT / EQL switch is held in the EQL position, the rectifier

goes into equalize mode and boosts the output voltage to the value set by

the EQL potentiometer.

When the switch FLOAT / EQL is held in the FLT position, the rectifier

delivers a float voltage set by the FLT potentiometer.

Remote equalize control EQL

The rectifier is equipped with remote equalize control. This control is

activated by a remote ground signal ( BAT RTN ). The rectifier returns to

normal ( float voltage ) operation when this signal is removed.

4.2.7. Current limit adjustment and rectifier regulating test

CL ADJ potentiometer

The rectifier limits the output current to a select value ranging from 100 A

to 210 A, set by the CL ADJ potentiometer. The factory adjustment is

205 A ±5 A. Extended periods of operation in the current limiting mode

and repeated transitions between constant-voltage operation and constantcurrent operation have no detrimental effect on the performance or service

life of the rectifier.

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 38

38 Functional description

The rectifier can be started when it is connected across a completely

discharged battery without requiring human intervention or operating

protective devices. A transition from constant voltage operation to

constant current operation and from constant current operation to constant

voltage operation occurs automatically, as determined by the output

current. The current limiting circuit is functional in float and equalize

modes.

4.2.8. Rectifier parallel operation

The rectifier can operate in parallel with other rectifiers having similar

output characteristics. It shares the total load in proportion to its output

rating. Two methods for sharing load current are available :

• Slope sharing

• Forced sharing

Selecting either mode is done by setting the two bottom DIP switches,

SLS / FS, located on the front panel. The rectifier is factory set to the slope

sharing mode.

Slope sharing ( SLS )

When both bottom DIP switches are set to the SLS position, conventional

load sharing is achieved through a -300 mV slope on the output voltage of

the rectifier, from no load to full load. This mode should be used when

rectifiers from different manufacturers are not all equipped with the forced

load-sharing feature. In this mode, the units will share the load within

±10% of their maximum output rating.

To accurately preset the float voltage of the rectifier, its current in the plant

environment must be predicted and the preset output floating voltage must

be calculated using the formula found below. In the formula, 0.8 volts is

added to the float voltage to compensate for an internal voltage drop when

the rectifier dc breaker is put in the ON position.

V ( preset ) = Vo ( desired ) + 0.8 V + ( Io ( running

) x 300 mV )

200

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 39

Functional description 39

Example 1 : If the rectifier is expected to provide 100 A at 48 V

V ( preset ) = 48 V + 0.8 V + ( 100

x 300 mV )

200

V ( preset ) = 48 V + 0.8 V + 0.15 V = 48.95 V

Example 2 : If the rectifier is expected to provide 40 A at 48 V

V ( preset ) = 48 V + 0.8 V + ( 40

x 300 mV )

200

V ( preset ) = 48 V + 0.8 V + 0.06 V = 48.86 V

Forced sharing ( FS )

When both bottom DIP switches ( SLS / FS ) are set to the FS position,

forced load sharing is achieved by an internal control circuit that modifies

the loop reference to equally share the output currents between rectifiers.

The setting of the output voltage is not modified with changes in output

load, as is the case in the slope share mode. In this mode, the rectifiers will

share the load within ±2 % of their maximum output rating.

For this to occur the rectifiers must communicate their operating current to

the other rectifiers in the same power plant. The current share terminal of

all the rectifiers ( P1-17 ) in the same power plant must be connected

through the control cables and controller. In applications using the

NT6C43PB interconnect board, such a connection is implemented

automatically.

Adjust the rectifier float voltage to the desired system float voltage, plus

0.8 volts, to compensate for an internal drop when the rectifier dc breaker

is put in the ON position.

Example 3 : for 48 V float voltage

V ( preset ) = 48 V + 0.8 V = 48.8 V

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 40

40 Functional description

4.2.9. HVSD ( high voltage shutdown )

HVSD ADJ ( high voltage shutdown adjust ) potentiometer

Use this potentiometer to set the internal threshold level at which the local

high voltage shutdown condition should occur.

Remote HVSD

In addition to the local high voltage shutdown feature, the controller of the

power plant controller can shut down any rectifier by sending a high

voltage shutdown signal, ground ( BAT RTN ) pulse. The rectifier will

shut down within 50 ms if it is supplying more than 10% of its full load

rating.

As is the case for the internal high voltage shutdown condition, two HVSD

events must occur within an interval of two minutes to lock out the

rectifier permanently. An ac breaker reset or an HVSDR signal can be

used to restart the rectifier.

Local and remote HVSD reset

The rectifier may be reset from an HVSD condition locally by :

• toggling the ac circuit breaker to OFF then to ON ( or the ac

breaker in the distribution panel )

• sending a remote ground signal to the HVSDR input through the

controller restart ( provided the 'TR' lead has not been activated )

4.2.10. TR ( temporary inhibition ) and sequential start

Sequential start

The TR input can be interfaced to an external sequential start circuit.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 41

Table 13 - Setting the start-up delay

Functional description 41

01

NOTE: Switches 3

to 6 ( top four

switches ) are

used to s et the

sta r t- up de l a y .

SWITCH

#

6

5

4

3

2

1

POSITION DELAY POSITION DELAY

1

6

5

4

3

6

5

4

X

3

6

5

X

4

3

6

5

X

4

X

3

6

X

5

4

3

6

X

5

4

X

3

6

X

5

X

4

3

6

X

5

X

4

X

3

0

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

4 SEC

12 SEC

20 SEC

28 SEC

36 SEC

44 SEC

52 SEC

60 SEC

1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

0

X

X

X

X

X

X

X

X

X

X

X

X

68 SEC

76 SEC

84 SEC

92 SEC

100 SEC

108 SEC

116 SEC

124 SEC

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 42

42 Functional description

Remote ON / OFF control TR

When a ground signal is applied to the 'Temporary Release' ( TR ) input,

the rectifier inhibits its operation and triggers the RFA. When the remote

ground signal is discontinued the rectifier returns to normal operation ( see

Table 14 ).

Start up delay DIP switch

The rectifier can provide a start-up delay of from 4 seconds up to

120 seconds, with a resolution of 8 seconds and an accuracy of +

Use of this feature is recommended when two or more rectifiers are

connected to a common ac input to stagger the inrush currents. A front

panel DIP switch can be set to provide the start-up delays listed in Table

13.

4.2.11. Control signals on connector P1

The P1 connector, located at the rear of the rectifier, can be used to verify

all the control and alarm signals when troubleshooting the rectifier ( see

Table 14 ).

1 second.

The control inputs are activated by a ground ( BAT RTN ) signal. The

alarms, extended by relay contacts, are isolated from each other and the

rectifier frame. All contacts are rated 60 V and 0.5 A dc. The normal status

of each contact is defined when the rectifier operates normally in the

remote sense mode with no alarm. Contacts NC ( normally closed ) and

NO ( normally opened ) refer to the de-energized state of their relay coils.

Table 14 - Control signal connections on P1

Connection Signal Description

P1-1 EQL Equalize

P1-2

P1-3 HVSDR High voltage shutdown reset

P1-4 RFA ( NC ) Rectifier fail alarm ( NC )

P1-5 FAN ALM ( NC ) Fan fail alarm ( NC contact )

P1-6 FAN ALM ( C ) Fan fail alarm ( C )

P1-7

P1-8 RFA ( NO ) Rectifier fail alarm ( NO )

P1-9 SENSE ( C ) Sense fail alarm ( C )

P1-10 SENSE ( NO ) Sense fail alarm ( NO )

RC − Remote sense ( − )

SH−

continued

Output current shunt voltage ( - )

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 43

Functional description 43

Table 14 - Control signal connections on P1 ( continued )

Connection Signal Description

P1-11 NC No connection

P1-12 NC No connection

P1-13 CB OFF ( NC ) Output breaker OFF ( NC )

P1-14 RG+ Remote sense ( + )

P1-15 TR Rectifier temporary released by

controller

P1-16 HVSD High voltage shutdown

P1-17 CURRENT SHARE Forced share link

P1-18 RFA ( C ) Rectifier fail alarm ( C )

P1-19 SH+ Shunt ( + )

P1-20 FAN ( NO ) Fan fail ( NO )

P1-21 GRD Reference ground

P1-22 SENSE FAIL ( NC ) Sense fail alarm ( NC )

P1-23 NC No connection

P1-24 NC No connection

P1-25 CB OPEN ( C ) Output breaker OFF ( C )

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 44

44 Functional description

This page is left blank intentionally.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 45

5. Operation

5.1. Standard settings

The parameters of the NT5C05CA / CB / CC rectifiers are set as indicated

in Table 15. For different settings refer to User Manual Voltage_level

entitled Voltage Level Limits for Power Plants, Rectifiers and Controllers.

Table 15 - Standard settings for the rectifier

Rectifier float output voltage ( FLOAT ) 52.1 ±0.1 V dc

Rectifier equalize output voltage

( EQUALIZE )

Rectifier high voltage shutdown threshold 56.5 ±0.1 V dc

Rectifier output current limit 205 A ±5 A

Rectifier start delay 4 sec

Low ac input disconnect 330 ±5 V ac

Low ac input reconnect 350 ±5 V ac

High ac input disconnect 475 ±5 V ac

High ac input reconnect 460 ±5 V ac

Load sharing method Slope

45

Parameter Setting

52.8 ±0.1 V dc

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 46

46 Operation

5.2. Starting up and adjusting

Procedure 9 - Starting up the rectifier

Step Action

1

2

3

4

5

6

7

Put the dc circuit breaker to OFF ( 0 position ). Open the sensing

leads by removing the corresponding RC fuse ( when the rectifier is

used with a controller ) or by disconnecting the alarm and control

cable ( when the rectifier is used without a controller ).

Put the ac circuit breaker in the main ac service panel to ON.

Put the 25 A, 3Ø, ac circuit breaker of the rectifier being tested to

ON. The green ac ON LED should light up.

Note : The output capacitors are precharged automatically when the

dc cables are connected at the rear of the rectifier.

Put the meter selector to the VOLT position. The meter will display

the voltage value to which the rectifier has been adjusted.

Connect a digital multimeter to test points VOUT+ and VOUT– on

the front panel. The voltage reading should be within 1% of the

rectifier meter reading. If not, calibrate it as described in the

“ Maintenance ” section.

Determine the system requirements for float, equalize and HVSD

limits by referring the User Manual Voltage_Level entitled Voltage

Level Limits for Power Plants, Rectifiers and Controllers.

If the factory threshold limits of the rectifier must be verified or

changed, go to Step 8; otherwise go to Step 14.

Adjusting the high voltage shutdown ( HVSD )

8

9

10

11

12

13

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Put the dc circuit breaker to OFF ( O ).

Turn the HVSD potentiometer fully clockwise.

Turn the FLT potentiometer slowly clockwise to set the output

voltage on the display of the rectifier to the required HVSD threshold.

The EQL / FLT switch and the EQL potentiometer are used if the

voltage cannot be set with the FLT potentiometer.

Turn the HVSD potentiometer counterclockwise until the rectifier

shuts down.

Turn the FLT potentiometer counterclockwise two turns and put the

ac breaker to OFF.

Wait a few seconds for the rectifier to shut down and put the ac

breaker to ON to reset it.

continued

Page 47

Procedure 9 - Starting up the rectifier ( continued )

Step Action

Adjusting the float voltage

14

15

Ensure that the EQL / FLT switch is on the FLT position.

To adjust the float voltage to the proper level, turn the FLT

potentiometer clockwise to increase the voltage or counterclockwise

to decrease it.

Adjusting the equalize voltage ( EQL )

16

Set the EQL / FLT switch to EQL. Turn the EQL potentiometer

clockwise to increase the voltage or counterclockwise to decrease it.

17

Put the FLOAT / EQL switch in the FLOAT position.

Adjusting the slope share

18

Select the slope share mode

by setting the two bottom DIP switches

to SLS ( see Figure 10 ). Verify that the rectifier displays the required

float value. If required, adjust it with the FLT potentiometer.

19

Connect the sense leads by inserting the RC fuse in the controller or

by reconnecting the control cable.

20

21

Put the dc breaker located on the front of the rectifier to ON.

The rectifier is now connected to the system and should carry some

current. If it is connected in parallel with other rectifiers, verify that

the total system current is shared equally amongst the rectifiers. Put

the switch on each rectifier to AMP. Find the mean current of the

rectifiers by adding all the currents measured on each rectifier and

dividing the total current by the number of rectifiers

I

= I

+ 1

+I

T

1

2

… + I

3

n n

Operation 47

n

Set the current from each rectifier to this mean value. If the current

reading of one of the rectifiers is too low, or is 0, slowly increase the

current by turning the FLT potentiometer clockwise until proper

sharing is achieved. If the current reading is too high or if rectifier is

in the current limit mode, turn the FLT potentiometer

counterclockwise.

Note : Adjust all the rectifiers in sequence to the mean value of the

currents, and readjust more precisely if necessary.

Verifying the current limit

22

Turn OFF some of the other rectifiers to force the rectifier under test

to pick up a load current of at least 210 A. When the rectifier reaches

about 205 A, the yellow CL LED should light up.

continued

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 48

48 Operation

Procedure 9 - Starting up the rectifier ( continued )

Step Action

23

Setting the start-up delay

24

Adjusting the forced load sharing

25

26

27

28

Turn ON the other rectifiers in the system.

Use this feature to reduce the inrush currents when two or more

rectifiers are connected to a common ac input. Set the DIP switches

on the front panel for the required start-up delay, from 4 to 124

seconds ( see Table 13 ).

If the forced share mode

rectifier to the appropriate value plus 0.8 volts in slope share mode,

as described above. For example, to have a 52.1 V float voltage :

This compensates for the internal voltage drop when the dc breaker

of the rectifier is put in the ON position. Connect all the FS wires of

the rectifiers together and set the two bottom DIP switches, located

on the front panel, to FS for forced load sharing ( see Figure 10 ).

If the rectifiers are connected to the NT6C43PB board, in the cabinet

or frame option, the P1-17 signals from all the rectifiers are

automatically connected. After step 25 has been completed, the

rectifiers will automatically share the output current.

When forced load sharing is desired, but the NT6C43PB board is not

used or is bypassed, pins P1-17 of all the rectifiers must be made

common at a single point. This connection could be a splice

connection of all the P1-17 wires in the control cables, using a 2B16

splice from T&B ( or equivalent ) in the control panel.

The E1 terminal on the NT6C43PB board can be used when forced

load sharing is desired amongst rectifiers on two, or more, cabinets

or frames. In this case, the E1 terminal from all the cabinets or racks

must be daisy chained with metric No. 7 ( AWG 22 ) wire.

Repeat step 21, but in equalize mode, to verify that the current is

shared equally amongst the rectifiers when a remote equalize signal

is applied, or when all local FLOAT / EQL toggle switches are

toggled in the EQL position. If the current reading is too low, or is 0,

turn the EQL potentiometer clockwise until proper sharing is

achieved. If the current is too high, or if the rectifier is in the current

limit mode, turn the EQL potentiometer counterclockwise.

Deactivate the EQL mode to return to the normal float mode.

is chosen, adjust the float voltage of each

52.1 V +0.8 V = 52.9 V.

end

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 49

6. Maintenance

6.1. Replacing the air filter

In dusty environments, the use of air filters is strongly recommended. If

used they should be replaced at least once a year.

6.2. Replacing the fan unit

The fan unit, consisting of four fans and a fan plate, can be replaced. To

install a new fan unit, execute the steps outlined in Procedure 10 and

illustrated in Figure 11.

Figure 11 - Replacing the fan unit

H E L I O S

I

0

A C / C A

V OL T

AM P

T H S D

H

V S

D

FA

R

FA N

A

L M

V OL T + V O U T-

49

O L T

V

C A L

C

U R

C A L

C L

A D J

E Q L

A D J

S E N

A C ON

FA I L

E Q L

C L

E Q L

F F 1

FF2

F L T

1 . 0 A

1 . 0 A

F LT

A DJ

H V

S

D

D J

A

I

UP

ST

D L Y

S L S FS

I

D

C / C C

RE M O VE T H E SE F I V E S C RE W S

Emerson Energy Systems Rectifier 200I/48NT5C05C Installation and User Manual

Page 50

50 Maintenance

CAUTION

Preventing short circuits

The replacement operation is safe, as only SELV

circuitry is present behind the fan assembly. However,

due to the possible presence of residual charges in the

output circuit, do not use metal tools within the rectifier

enclosure. To remove the fan assembly mounting screws

you need a screwdriver, but all the other operations

described below can and should be performed without

any tools.

Procedure 10 - Replacing the fan unit

Step Action

Disassembling

1

2

3

4

Re-assembling

5

6

7

8

9

Put the ac and dc breakers to OFF.

Remove the five screws securing the fan plate ( see Figure 11 ).

Swing open the assembly and disconnect all four fan cables.

Lift the assembly out the holes and pull it out towards you.

Insert the hinged bracket of the new assembly into the slotted holes

on the left and reconnect the cables to the four fans.

Place the four fan cables close to the display panel, removing as

much slack length as possible, so the cables will not interfere with

the fan blades after the fan unit is secured in place.

Swing the fan unit closed and secure it in plate with the five screws.

Check fan fuses FF1 and FF2 and replace as required.

Put the ac and dc breakers to ON.

end

6.3. Calibrating the Volt / Amp Multimeter

In a cabinet or frame application, where the signal cables are connected to

the NT6C43PB board, use a digital multimeter, at J13 on the NT6C43PB

board, to monitor the shunt reading of the rectifier, as indicated in Table 9.

In any applications where the NT6C43PB board is absent or has been

bypassed, pins P1-19 and P1-7 of the signal connector provide the shunt

reading. To access pins P1-19 and P1-7 use a cut P0747000 cable. If the

meter must be calibrated execute the steps in Procedure 11.

UM5C05C P0745680 Standard 6.00 October 2001 Emerson Energy Systems

Page 51

Maintenance 51

Procedure 11 - Calibrating the meter

Step Action

1

2

3

4

5

Make sure the remote sense leads are disconnected by removing

the corresponding RC− fuse from the controller.

Set the VOLT/AMP switch to AMP. Set the output load of the plant

so the rectifier delivers a current of approximately 100 A. Measure

the voltage between VOUT+ and VOUT −, located on the front panel,

with a digital meter.

Convert this measured voltage to a current value ( 50 mV

corresponding to 250 A ).

current

voltage 50 mV

If the voltage measured is 20.2 mV :

measured current

Rotate the CUR CAL potentiometer on the display panel until this

value is displayed.

Put the VOLT / AMP switch to VOLT. Adjust the V CAL