Page 1

Installation Manual

20002158, Rev DI

March 2014

Micro Motion® ELITE® Coriolis Flow and Density

Sensors

Page 2

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EC declaration of conformity for directives that apply to this product. The EC declaration of

conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available on

the internet at www.micromotion.com or through your local Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive can be found on the internet at

www.micromotion.com/documentation.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the transmitter

configuration manual. Product data sheets and manuals are available from the Micro Motion web site at

www.micromotion.com/documentation.

Return policy

Micro Motion procedures must be followed when returning equipment. These procedures ensure legal compliance with

government transportation agencies and help provide a safe working environment for Micro Motion employees. Failure to follow

Micro Motion procedures will result in your equipment being refused delivery.

Information on return procedures and forms is available on our web support system at www.micromotion.com, or by phoning the

Micro Motion Customer Service department.

Micro Motion customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America Europe and Middle East Asia Pacific

United States 800-522-6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 318 495 555 New Zealand 099 128 804

Mexico +41 (0) 41 7686 111 France 0800 917 901 India 800 440 1468

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Venezuela +58 26 1731 3446 Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudia Arabia 800 844 9564

UAE 800 0444 0684

Page 3

Contents

Contents

Chapter 1 Planning ........................................................................................................................... 1

1.1 Installation checklist ........................................................................................................................1

1.2 Best practices ..................................................................................................................................2

1.3 Temperature limits ......................................................................................................................... 3

1.4 Recommendations for hygienic and self-draining applications ........................................................6

Chapter 2 Mounting ......................................................................................................................... 8

2.1 Recommendations for lifting heavy meters .....................................................................................8

2.2 Mount the sensor ............................................................................................................................9

2.3 Mount electronics of high-temperature sensors ............................................................................10

2.4 Mount a CMF010 sensor to a wall or pole ...................................................................................... 14

2.5 Mount a CMFS007, CMFS010 or CMFS015 sensor in a bracket .......................................................15

2.6 Mount a CMFS025, CMFS040 or CMFS050 sensor in a wall mount bracket .................................... 16

2.7 Secure wafer-style process connections ........................................................................................ 17

2.8 Attach extended electronics ......................................................................................................... 19

Chapter 3 Wiring ............................................................................................................................ 21

3.1 Options for wiring ......................................................................................................................... 21

3.2 Connect 4-wire cable .................................................................................................................... 22

3.3 Connect 9-wire cable .................................................................................................................... 26

Chapter 4 Grounding ...................................................................................................................... 28

Chapter 5 Supplementary information ............................................................................................29

5.1 Purge the sensor case ....................................................................................................................29

5.2 About rupture disks .......................................................................................................................31

Installation Manual i

Page 4

Contents

ii Micro Motion ELITE

Page 5

1 Planning

Topics covered in this chapter:

• Installation checklist

• Best practices

• Temperature limits

• Recommendations for hygienic and self-draining applications

1.1 Installation checklist

Make sure that the hazardous area specified on the approval tag is suitable for the

□

environment in which the meter will be installed.

Verify that the local ambient and process temperatures are within the limits of the

□

meter.

If your sensor has an integral transmitter, no wiring is required between the sensor

□

and transmitter. Follow the wiring instructions in the transmitter installation manual

for signal and power wiring.

If your transmitter has remote-mounted electronics, follow the instructions in this

□

manual for wiring between the sensor and the transmitter, and then follow the

instructions in the transmitter installation manual for power and signal wiring.

For the wiring between the sensor and the transmitter, consider maximum cable

□

lengths. The maximum distance between the sensor and transmitter depends on

the cable type. For all types of wiring, Micro Motion recommends using Micro

Motion cable.

Planning

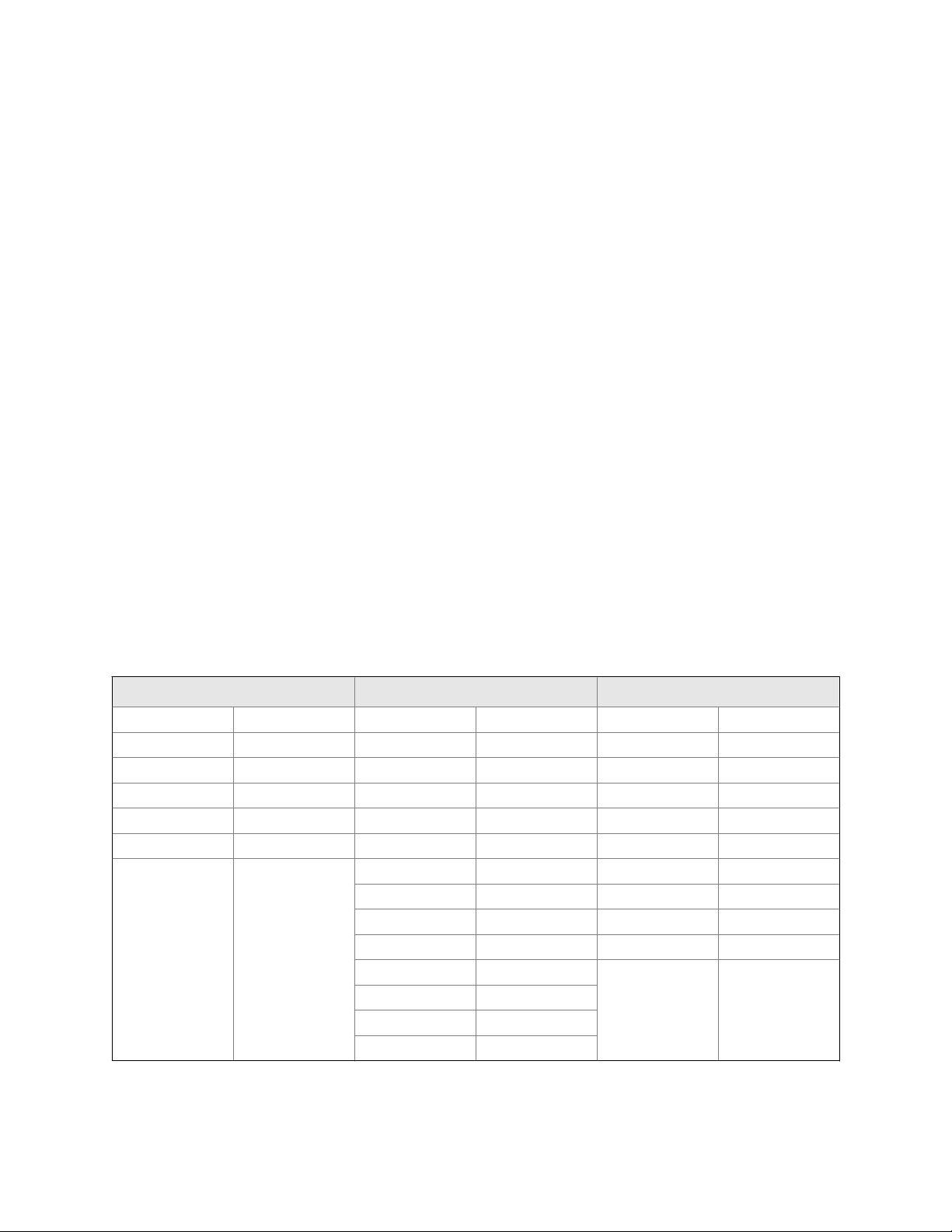

Maximum lengths for Micro Motion cableTable 1-1:

Cable type To transmitter Maximum length

Micro Motion 9-wire 9739 MVD transmitter 1000 ft (300 m)

All other MVD transmitters 60 ft (20 m)

Micro Motion 4-wire All 4-wire MVD transmitters 1000 ft (300 m)

Maximum lengths for user-supplied 4-wire cableTable 1-2:

Wire function Wire size Maximum length

Power (VDC) 22 AWG (0,35 mm2) 300 ft (90 m)

20 AWG (0,5 mm2) 500 ft (150 m)

18 AWG (0,8 mm2) 1000 ft (300 m)

Signal (RS-485) 22 AWG (0,35 mm2) or larger 1000 ft (300 m)

Installation Manual 1

Page 6

Planning

For optimal performance, install the sensor in the preferred orientation. The sensor

□

will work in any orientation as long as the flow tubes remain full of process fluid.

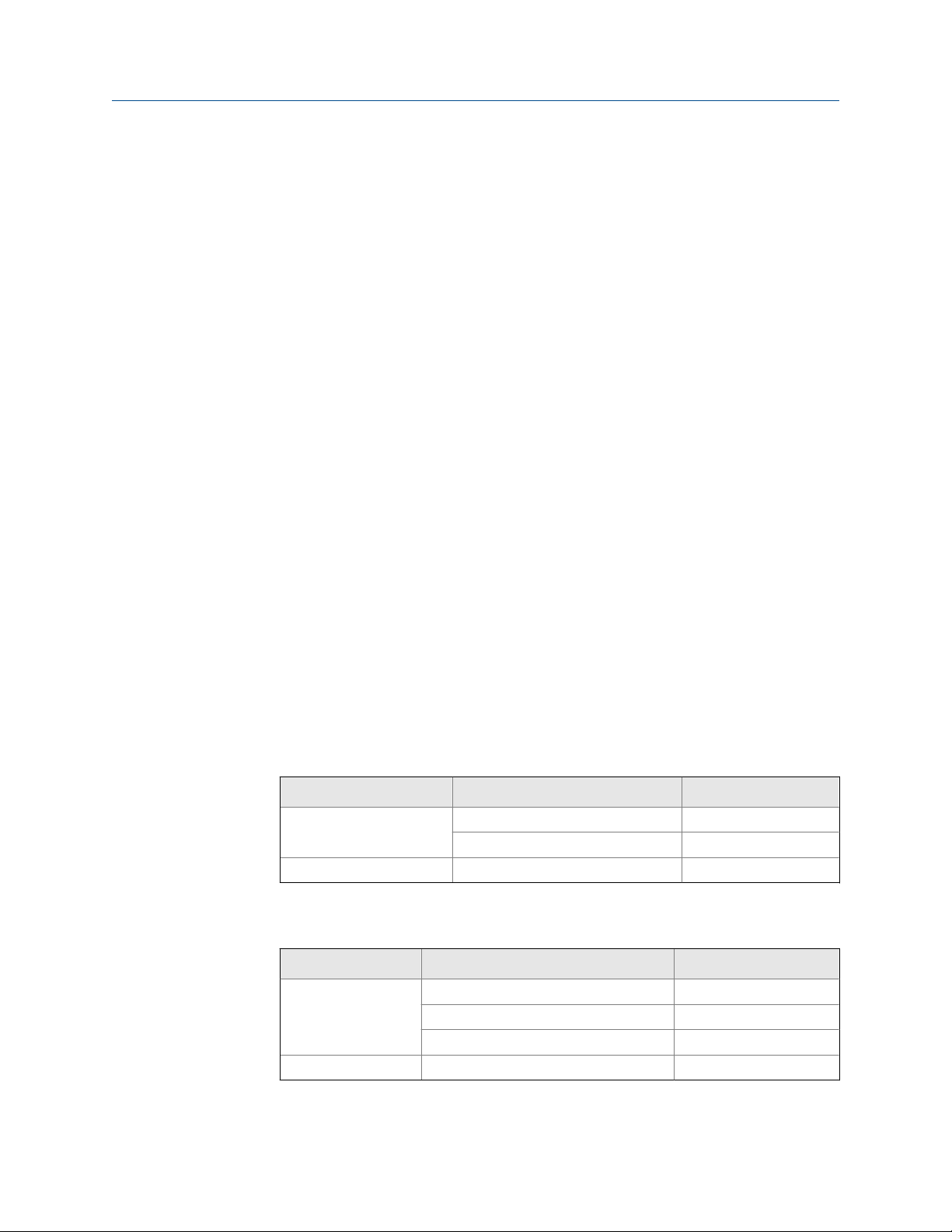

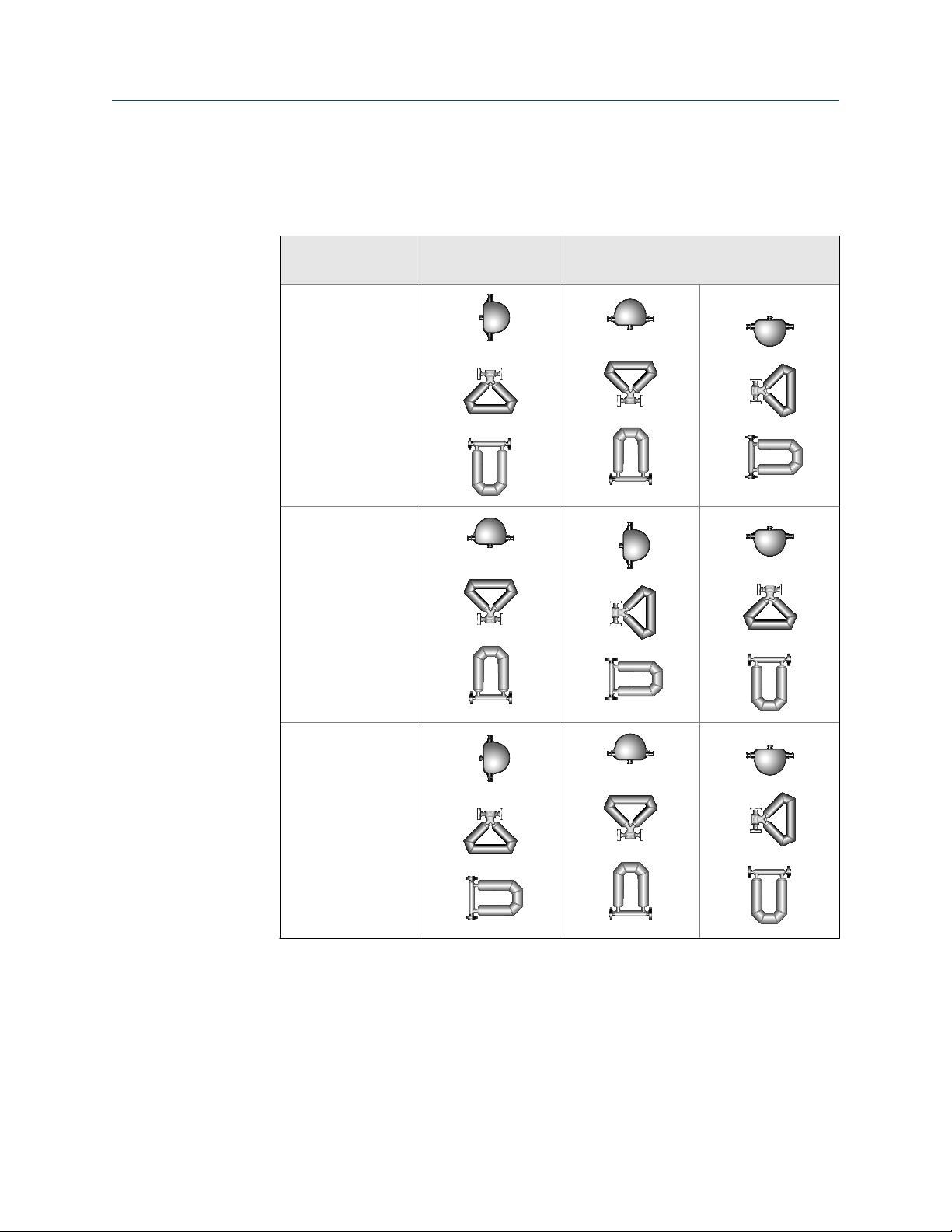

Preferred sensor orientationTable 1-3:

Process

Liquids

Gases

Preferred

orientation

Alternate orientations

Slurries

Install the meter so that the flow direction arrow on the sensor case matches the

□

actual forward flow of the process. (Flow direction is also software-selectable.)

1.2 Best practices

The following information can help you get the most from your sensor.

2 Micro Motion ELITE

Page 7

• There are no pipe run requirements for Micro Motion sensors. Straight runs of pipe

upstream or downstream are unnecessary.

• If the sensor is installed in a vertical pipeline, liquids and slurries should flow upward

through the sensor. Gases may flow upward or downward.

• Keep the sensor tubes full of process fluid.

• For halting flow through the sensor with a single valve, install the valve downstream

from the sensor.

• Minimize bending and torsional stress on the meter. Do not use the meter to align

misaligned piping.

• The sensor does not require external supports. The flanges will support the sensor in

any orientation. (Some sensor models installed in very small, flexible pipeline have

optional installation instructions that allow for external supports.)

1.3 Temperature limits

• Sensors can be used in the process and ambient temperature ranges shown in the

temperature limit graphs. For the purposes of selecting electronics options,

temperature limit graphs should be used only as a general guide. If your process

conditions are close to the gray areas, it may be inappropriate to use electronics

options other than a junction box. Consult consult with your Micro Motion

representative.

• In all cases, the electronics cannot be operated where the ambient temperature is

below –40 °F (–40 °C) or above +140 °F (+60 °C). If a sensor is to be used where the

ambient temperature is outside of the range permissible for the electronics, the

electronics must be remotely located where the ambient temperature is within the

permissible range, as indicated by the shaded area of the temperature limit graphs.

• Temperature limits may be further restricted by hazardous area approvals. Refer to

the hazardous area approvals documentation shipped with the sensor or available

from the Micro Motion web site (www.micromotion.com).

• The extended-mount electronics option allows the sensor case to be insulated

without covering the transmitter, core processor, or junction box, but does not

affect temperature ratings.

Planning

Installation Manual 3

Page 8

Planning

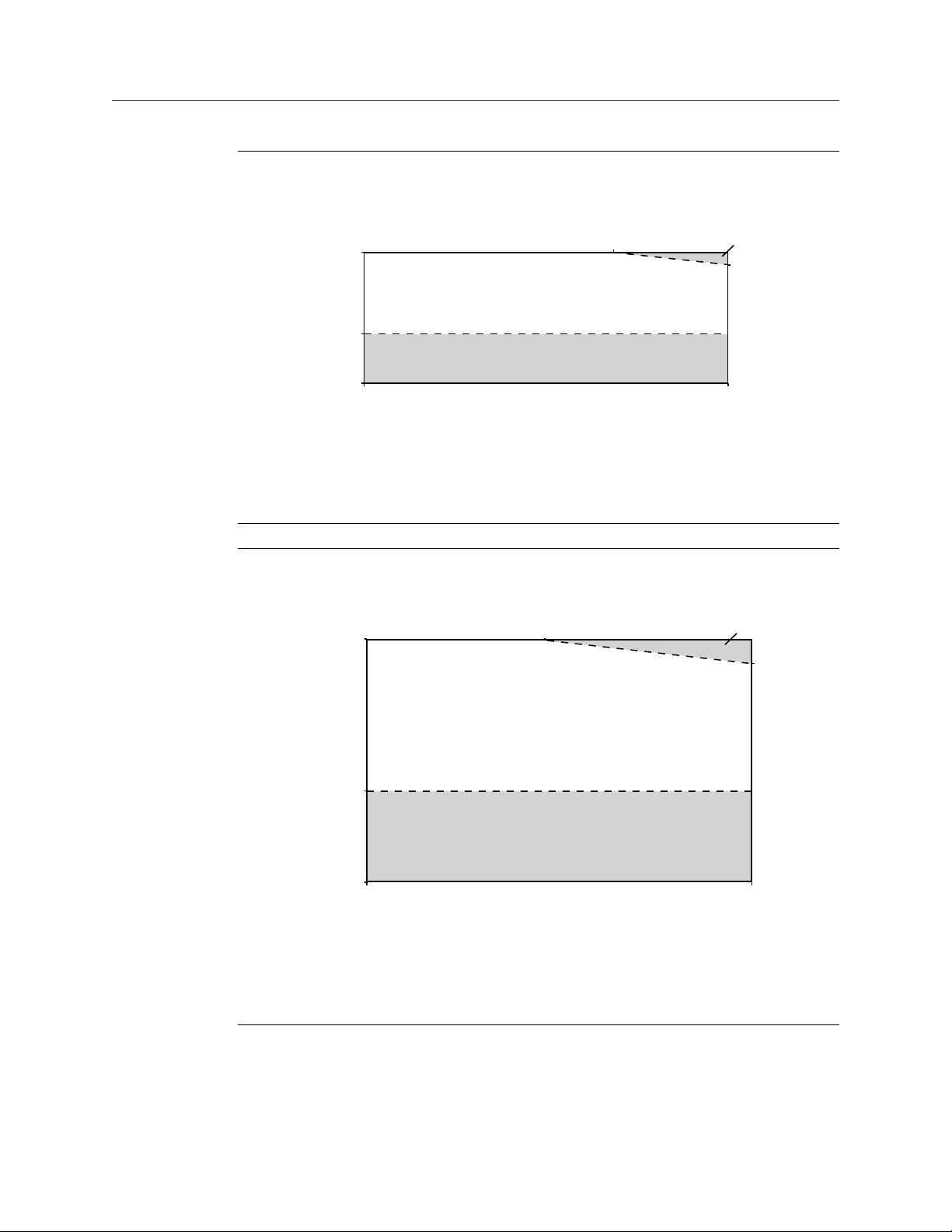

Figure 1-1:

Ambient and process temperature limits for ELITE CMF***M/L/H/P

(excludes cryogenic modifications) and CMFS007-015 meters

140 (60)

A

–40 (–40)

–148 (–100)

A. Ambient temperature °F (°C)

B. Process temperature in °F (°C)

C. All available electronic options

D. Extended or remote mount electronics only

Figure 1-2:

–400

(–240)

Ambient and process temperature limits for ELITE CMFS025–CMFS150

meters

140 (60)

C

D

B

140

(60)

140

(60)

D

113 (45)

400

(204)

D

113 (45)

C

A

–40 (–40)

D

–148 (–100)

A. Ambient temperature °F (°C)

B. Process temperature in °F (°C)

C. All available electronic options

D. Extended or remote mount electronics only

4 Micro Motion ELITE

–58

(–50)

B

400

(204)

Page 9

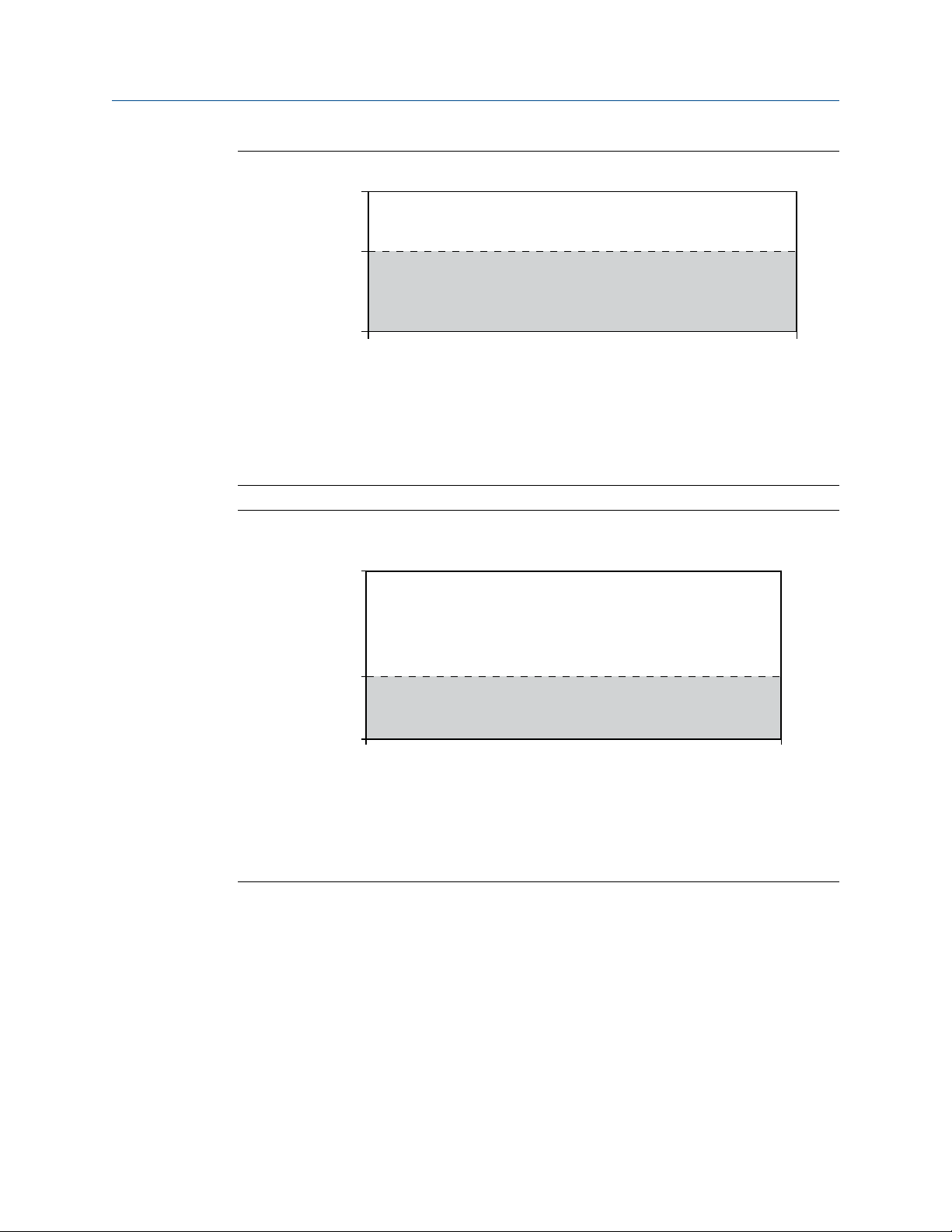

Ambient and process temperature limits for cryogenic ELITE metersFigure 1-3:

140 (60)

–40 (–40)

A

–148 (–100)

–400

(–240)

A. Ambient temperature °F (°C)

B. Process temperature in °F (°C)

C. All available electronic options

D. Extended or remote mount electronics only

Planning

C

D

176

(80)

B

Figure 1-4:

Ambient and process temperature limits for high temperature ELITE

meters

140 (60)

A

–40 (–40)

–148 (–100)

–50

(–58)

A. Ambient temperature °F (°C)

B. Process temperature in °F (°C)

C. All available electronic options

D. Extended or remote mount electronics only

C

D

B

662

(350)

Installation Manual 5

Page 10

Planning

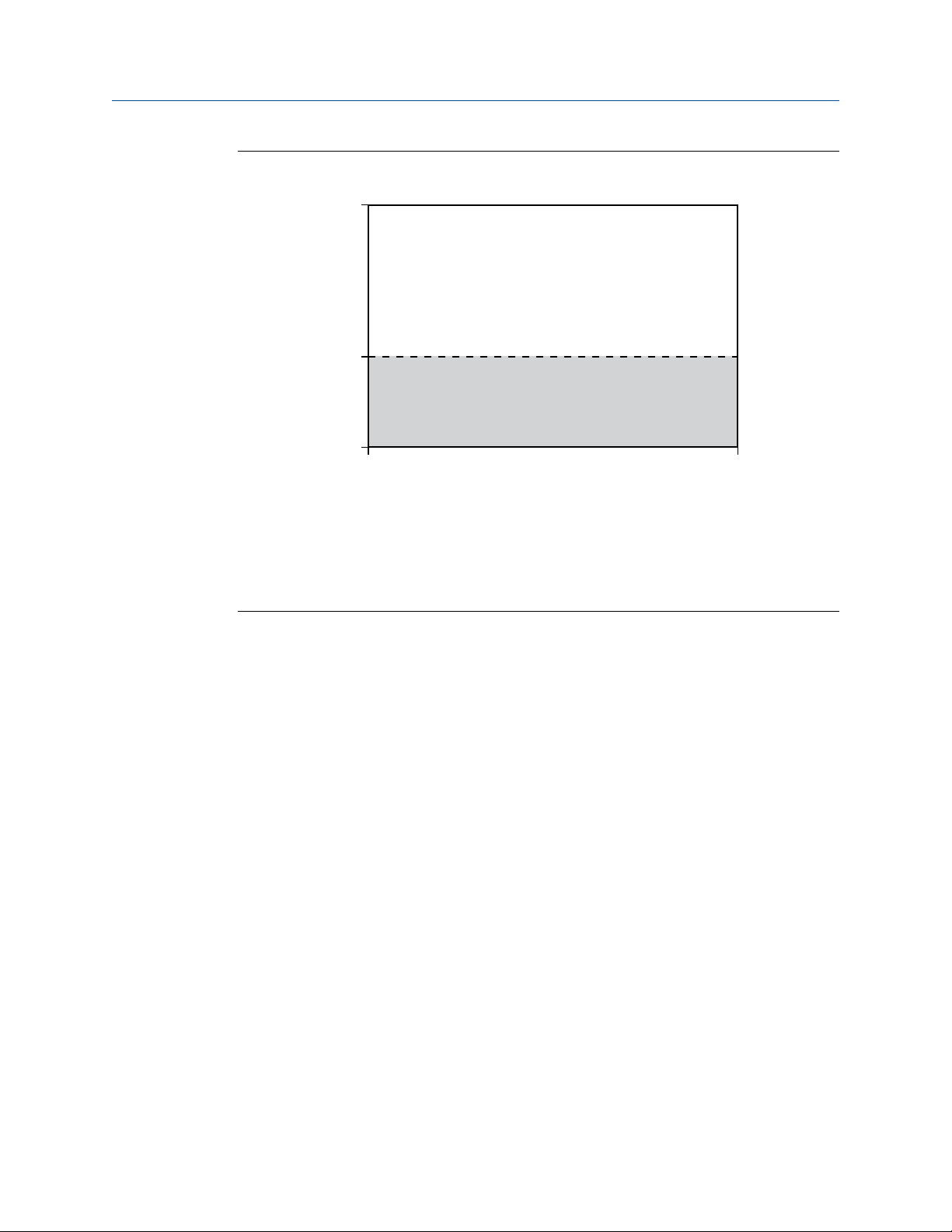

Ambient and process temperature limits for Super Duplex ELITE metersFigure 1-5:

140 (60)

A

–40 (–40)

–148 (–100)

–40

(–40)

A. Ambient temperature °F (°C)

B. Process temperature in °F (°C)

C. All available electronic options

D. Extended or remote mount electronics only

C

D

400

(204)

B

1.4 Recommendations for hygienic and selfdraining applications

CMFS sensors are certified EHEDG TYPE EL CLASS I for hygienic applications when installed

vertically with the process fitting and gasket combinations listed in the Position Paper of

the EHEDG Test Methods Subgroup (available at http://www.ehedg.org). Other process

connections/gasket combinations may be used provided they have been evaluated and

successfully tested for in-place cleanability according to the latest edition of EHEDG

Document 2. Refer to the ELITE Product Data Sheet for further information about fitting

options.

For optimal cleanability and drainability:

• If possible, install the sensor in a vertical pipeline with the process fluid flowing

upward through the sensor.

• If the sensor must be installed in a horizontal pipeline, drainage is accomplished by

air purge evacuation of the pipeline circuit.

• For clean-in-place (CIP) applications, Micro Motion recommends using the

generally-accepted flow velocity of at least 1.5 m/s for cleaning the sensor.

• The gap between the electronics housing and sensor body should be inspected

periodically. Manually clean this gap when necessary.

6 Micro Motion ELITE

Page 11

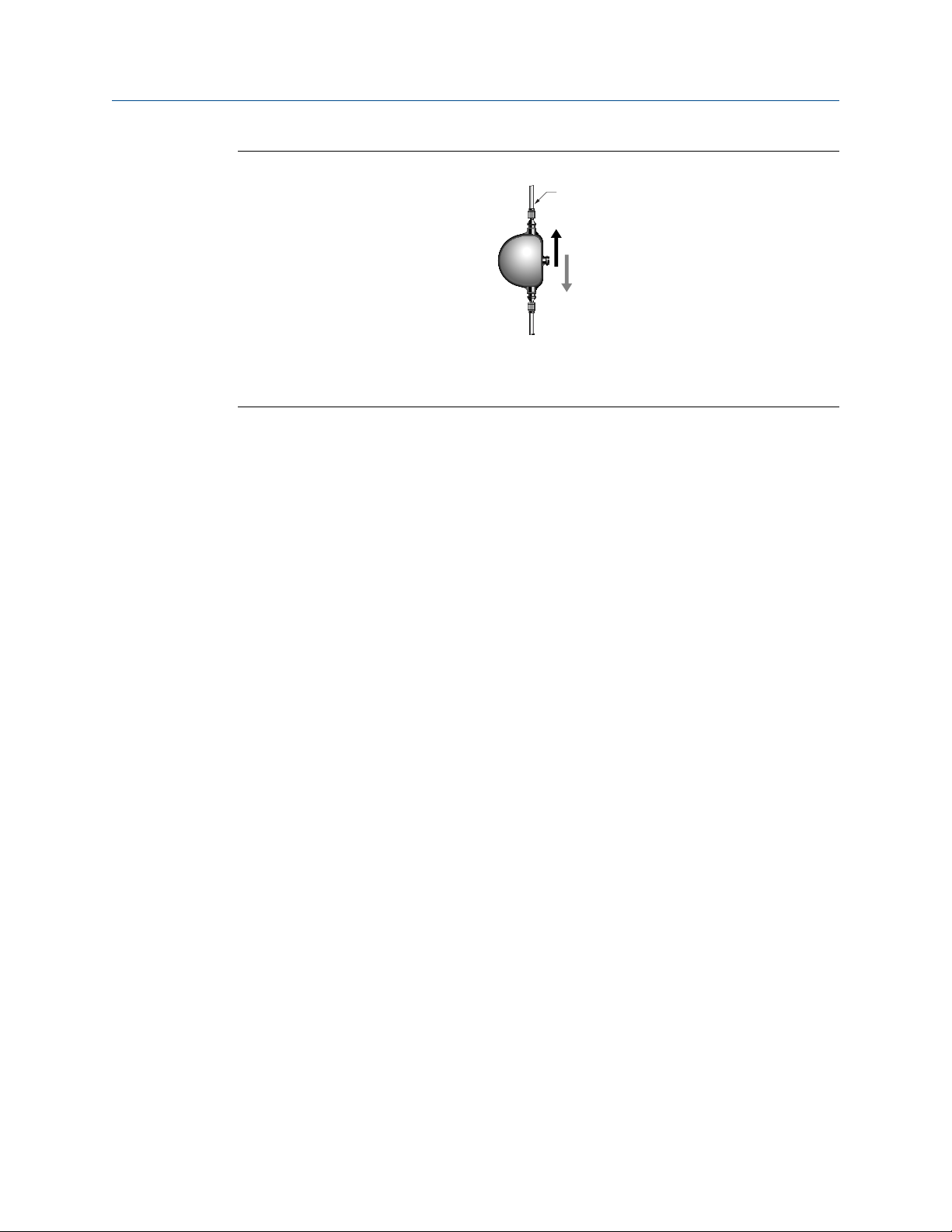

Installation for self-draining applicationsFigure 1-6:

A

B

C

A. Process pipeline

B. Direction of normal process flow

C. Direction of drainage

Planning

Installation Manual 7

Page 12

Mounting

2 Mounting

Topics covered in this chapter:

• Recommendations for lifting heavy meters

• Mount the sensor

• Mount electronics of high-temperature sensors

• Mount a CMF010 sensor to a wall or pole

• Mount a CMFS007, CMFS010 or CMFS015 sensor in a bracket

• Mount a CMFS025, CMFS040 or CMFS050 sensor in a wall mount bracket

• Secure wafer-style process connections

• Attach extended electronics

2.1 Recommendations for lifting heavy meters

Heavy meters (those over 50 lb. [22 kg]), and even lighter meters that must be installed in

elevated or difficult-to-reach places, usually require additional consideration when

transporting or lifting them into their installation location.

• Safe handling during transportation and installation is the responsibility of the

installer – know and follow all safety practices and regulations for your facility and

for any lifting/rigging equipment being used

• A professional rigging crew with proper equipment should be used

• Typical equipment for handling heavy meters includes the following:

- Fixed hoist boom trucks or cranes

- Continuous web belt slings

- Eye to eye web belt slings

- Two leg wire rope slings

• Lift a meter by its case or on the case side of its process fittings.

• Do not lift a meter by its electronics (junction box, transmitter, or any electrical

fittings) or by its purge fittings

• It may be useful to identify the meter center of gravity

• Protect the sealed surfaces on the process fittings with factory-installed flange

protectors or comparable field-installed protection

8 Micro Motion ELITE

Page 13

A

Mounting

Acceptable lifting pointsFigure 2-1:

Center of gravity for large metersFigure 2-2:

A. Typical center of gravity

Note

Complete and detailed dimensional drawings, including the location of the center of gravity, can be

found through the product drawings link in our online store (www.micromotion.com/onlinestore).

2.2 Mount the sensor

Use your common practices to minimize torque and bending load on process connections.

Tip

To reduce the risk of condensation or excessive moisture, the conduit opening should not point

upward (if possible). The conduit opening of the junction box or core processor can be rotated freely

to facilitate wiring.

Installation Manual 9

Page 14

Mounting

CAUTION!

Do not lift the sensor by the electronics or purge connections. Lifting the sensor by the

electronics or purge connections can damage the device.

Mounting the sensorFigure 2-3:

Notes

• Do not use the sensor to support the piping.

• The sensor does not require external supports. The flanges will support the sensor in any

orientation. (Some sensor models installed in very small, flexible pipeline have optional installation

instructions that allow for external supports.)

2.3 Mount electronics of high-temperature sensors

The electronics of high-temperature sensors are attached to the end of a 32" (812 mm)

pre-installed flexible conduit. The electronics must be separately mounted on a wall or

instrument pole.

10 Micro Motion ELITE

Page 15

Components of a high-temperature sensorFigure 2-4:

B

A

C

D

A. Sensor

B. Electronics

C. Mounting bracket

D. Flexible conduit (minimum bend radius 6" [152 mm])

Mounting

With some large meter sizes, the meter may ship with the electronics attached to the

sensor case. The meter cannot be operated in this configuration. Detach the electronics

bracket from the sensor case and then proceed to mount the electronics to a wall or

instrument pole as described below.

Important

Do not operate the meter while the electronics are attached to the sensor case.

Installation Manual 11

Page 16

A

Mounting

Removing electronics from the sensor caseFigure 2-5:

A. Detach electronics from sensor case and mount to a wall or instrument pole

Procedure

• For wall mounting, use four 5/16" or four M8 bolts to secure the mounting bracket.

12 Micro Motion ELITE

Page 17

A

B

C

Mounting

Wall-mount componentsFigure 2-6:

A. Wall or flat surface

B. Electronics (enhanced core processor shown)

C. Flexible conduit

• For mounting to an instrument pole, use a 2-inch U-bolt pipe kit to secure the

mounting bracket.

Installation Manual 13

Page 18

A

B

C

Mounting

Pole-mount componentsFigure 2-7:

A. Instrument pole

B. Electronics (enhanced core processor shown)

C. Flexible conduit

2.4 Mount a CMF010 sensor to a wall or pole

The CMF010 sensor has an optional mounting configuration for use with small or flexible

pipeline. If the pipeline adequately supports the sensor, this procedure can be skipped.

1. Locate the optional mounting holes. For sensors with a junction box, the junction

box must be rotated to the side to expose the mounting holes.

14 Micro Motion ELITE

Page 19

Optional mounting for CMF010 sensorsFigure 2-8:

A

B

C

A. Two user-supplied 5/16" (M8) bolts

B. Junction box or core processor (junction box shown)

C. Mounting surface

Mounting

2. If necessary, install rigid standoffs between the sensor and the mounting surface.

3. Using two user-supplied 5/16" (M8) bolts (minimum length 2 1/4" [58 mm]), secure

the sensor case to the mounting surface.

2.5 Mount a CMFS007, CMFS010 or CMFS015 sensor in a bracket

The CMFS007, CMFS010 and CMFS015 sensors have an optional mounting bracket for use

with small or flexible pipeline. If the pipeline adequately supports the sensor, this

procedure can be skipped.

1. Secure the mounting bracket to a wall or other flat surface with four user-supplied

5/16" (8 mm) bolts.

2. Place the sensor into the bracket.

3. Secure the sensor in the bracket with the supplied 5/16" (M8) U-bolts.

Installation Manual 15

Page 20

A

B

C

Mounting

Mounting bracket for CMFS007, CMFS010, and CMFS015Figure 2-9:

A. Mounting bracket

B. Mounting holes

C. Supplied U-bolts

2.6 Mount a CMFS025, CMFS040 or CMFS050 sensor in a wall mount bracket

The CMFS025, CMFS040, and CMFS050 sensors have an optional wall mounting bracket.

1. Assemble the bracket.

Figure 2-10:

Assembled wall mounting bracket for CMFS025, CMFS040, and

CMFS050

2. Attach the bracket to the wall using fasteners appropriate for the mounting surface.

16 Micro Motion ELITE

Page 21

3. Place the sensor into the bracket.

4. Secure the sensor in the bracket with the supplied fasteners.

CMFS025, CMFS040, or CMFS050 wall mounted using bracketFigure 2-11:

Mounting

2.7 Secure wafer-style process connections

A wafer-style connection lets you clamp the sensor into the pipeline. A wafer installation

kit is shipped with a wafer-style sensor.

1. Make sure that the bolts provided are rated for your process connection.

2. Slip the sensor alignment rings over each end of the sensor wafer, then insert the

sensor between the process connections in the pipeline.

Tip

Micro Motion recommends installing gaskets (user-supplied).

Installation Manual 17

Page 22

D

C

B

A

E

C

B

A

Mounting

Wafer-style connection componentsFigure 2-12:

A. Flange nut

B. Gasket (user-supplied)

C. Alignment ring

D. Flange bolt

E. Sensor wafer

3. Insert the flange bolts through both process connections, and thread the flange nuts

onto the bolts.

4. With your fingers, tighten the flange nuts.

5. Rotate the sensor alignment rings in the direction that pushes the bolts outward.

Tip

Rotate both sensor aligment rings until the assembly is centered and tight.

Alignment ring usageFigure 2-13:

A. Direction to rotate the alignment ring

B. Direction the flange bolts are pushed

C. Flange bolt

18 Micro Motion ELITE

Page 23

6. With a wrench, tighten the nuts in an alternating order.

2.8 Attach extended electronics

If you ordered a sensor with extended electronics, you will need to install the extender

onto the sensor case.

Note

Extended core processors are matched at the factory to specific sensors. Keep each core processor

together with the sensor with which it was shipped.

CAUTION!

Keep the extender and feedthrough clean and dry. Moisture or debris in the extender or

feedthrough can damage electronics and result in measurement error or flowmeter failure.

Procedure

Mounting

1. Remove and recycle the plastic cap from the feedthrough on the sensor.

Installation Manual 19

Page 24

G

H

E

D

C

A

B

F

Mounting

Feedthrough and extender componentsFigure 2-14:

A. Transmitter or core processor

B. Extender

C. O-ring

D. Feedthrough

E. Clamping ring

F. Clamping screw

G. Plastic plug

H. Plastic cap

2. Loosen the clamping screw and remove the clamping ring. Leave the O-ring in place

on the feedthrough.

3. Remove and recycle the plastic plug from the extender.

4. Fit the extender onto the feedthrough by carefully aligning the notches on the

bottom of the extender with the notches on the feedthrough.

5. Close the clamping ring and tighten the clamping screw to 13–18 in-lbs.

(1,5–2 N-m).

20 Micro Motion ELITE

Page 25

Wiring

3 Wiring

Topics covered in this chapter:

• Options for wiring

• Connect 4-wire cable

• Connect 9-wire cable

3.1 Options for wiring

The wiring procedure you follow depends on which electronics option you have.

Wiring procedures by electronics optionTable 3-1:

Electronics option Wiring procedure

Integral transmitter No wiring is required between sensor and transmitter. See the transmitter

installation manual for wiring the power and signal cable to the transmitter.

MVD™Direct Connect

Core processor Connect a 4-wire cable between the sensor and transmitter. Refer to the 4-wire

Junction box Connect a 9-wire cable between the sensor and transmitter. Refer to the 9-wire

™

No transmitter to wire. See the MVD Direct Connect manual for wiring the

power and signal cable between the sensor and the direct host.

connection instructions in this manual.

connection instructions in this manual, as well as the Micro Motion 9-Wire

Flowmeter Cable Preparation and Installation Guide.

CAUTION!

Make sure the hazardous area specified on the sensor approval tag is suitable for the

environment in which the sensor will be installed. Failure to comply with the requirements for

intrinsic safety in a hazardous area could result in an explosion.

CAUTION!

Fully close and tighten all housing covers and conduit openings. Improperly sealed housings

can expose electronics to moisture, which can cause measurement error or flowmeter failure.

Inspect and grease all gaskets and O-rings.

Installation Manual 21

Page 26

Wiring

3.2 Connect 4-wire cable

3.2.1 Prepare the 4-wire cable

Important

For user-supplied cable glands, the gland must be capable of terminating the drain wires.

Note

If you are installing unshielded cable in continuous metallic conduit with 360º termination shielding,

you only need to prepare the cable – you do not need to perform the shielding procedure.

22 Micro Motion ELITE

Page 27

Wiring

4-wire cable preparationFigure 3-1:

Remove the core processor

cover

Cable glands

Micro Motion

cable gland

Pass the wires through the gland nut and clamping insert.

Gland nut

1. Strip 4-1/2 inch (115 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Strip all but 3/4 inch (19 mm) of shielding.

Clamping

insert

NPT

Wrap the drain wires twice around the shield and cut off

Gland supplier

Gland type

the excess drain wires.

Cable layout

through the gland.

Terminate the drain

wires inside the

M20

1. Strip 4-1/4 inch (108 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Strip all but 1/2 inch (12 mm) of shielding.

User-supplied

cable gland

Pass the wires

gland.

Metal conduit

Run conduit to

sensor

Lay cable in conduit

Done

(do not perform the

shielding procedure)

Drain wires

wrapped around

shield

Go to the shielding

procedure

Installation Manual 23

Page 28

Wiring

4-wire cable shieldingFigure 3-2:

From the preparation

procedure

Micro Motion

cable gland

Braided

(armored cable)

Apply the Heat Shrink

1. Slide the shielded heat shrink over the drain wires. Ensure that the

wires are completely covered.

2. Apply heat (250 °F or 120 °C) to shrink the tubing. Do not burn the

cable.

3. Position the clamping insert so the interior end is flush with the braid

of the heat shrink.

Assemble the Gland

1. Fold the shield or braid back over the clamping insert and 1/8 inch

(3 mm) past the O-ring.

2. Install the gland body into the conduit opening on the core processor housing.

3. Insert the wires through gland body and tighten the gland nut onto the gland body.

Cable shield

type

Shielded heat

shrink

Foil

(shielded cable)

NPT

Gland supplier

Gland type M20

After heat applied

User-supplied

cable gland

Trim 7 mm from the shielded

heat shrink

Trim

Terminate the shield

and drain wires in the

Assemble the gland

according to vendor

gland

instructions

Shield folded back

Done

Gland body

4-wire cable types and usage

Micro Motion offers two types of 4-wire cable: shielded and armored. Both types contain

shield drain wires.

The 4-wire cable supplied by Micro Motion consists of one pair of red and black 18 AWG

(0.75 mm2) wires for the VDC connection, and one pair of white and green 22 AWG

(0.35 mm2) wires for the RS-485 connection.

User-supplied 4-wire cable must meet the following requirements:

24 Micro Motion ELITE

Page 29

• Twisted pair construction.

• Applicable hazardous area requirements, if the core processor is installed in a

hazardous area.

• Wire gauge appropriate for the cable length between the core processor and the

transmitter.

Wire gaugeTable 3-2:

Wire gauge Maximum cable length

VDC 22 AWG (0.35 mm2) 300 ft (90 m)

VDC 20 AWG (0.5 mm2) 500 ft (150 m)

VDC 18 AWG (0.8 mm2) 1000 ft (300 m)

RS-485 22 AWG (0.35 mm2) or larger 1000 ft (300 m)

3.2.2 Connect the wires to the core processor terminals

After the 4-wire cable has been prepared and shielded (if required), connect the individual

wires of the 4-wire cable to the terminals on the core processor.

Wiring

Installation Manual 25

Page 30

Wiring

Core processor terminalsFigure 3-3:

From Step 1 or 2

Standard

core processor

Connect the wires to the core processor terminals:

Red wire > Terminal 1 (Power supply +)

Black wire > Terminal 2 (Power supply –)

White wire > Terminal 3 (RS-485/A)

Green wire > Terminal 4 (RS-485/B)

Reinstall and tighten the core processor cover

Core processor

type

Enhanced

core processor

Connect the wires to the core processor terminals:

Red wire > Terminal 1 (Power supply +)

Black wire > Terminal 2 (Power supply –)

White wire > Terminal 3 (RS-485/A)

Green wire > Terminal 4 (RS-485/B)

1. Reinstall the core processor cover.

2. Torque cover screws to:

• 10–13 in-lbs (1,13–1,47 N-m) for aluminum housing

• Minimum 19 in-lbs (2,1 N-m) for stainless steel

housing

Connect the wires to the transmitter

(see the transmitter manual)

terminals

3.3 Connect 9-wire cable

1. Prepare and install the cable according to the instructions in the Micro Motion 9Wire Flowmeter Cable Preparation and Installation Guide.

2. Insert the stripped ends of the individual wires into the terminal blocks. Ensure that

no bare wires remain exposed.

26 Micro Motion ELITE

Page 31

Wiring

3. Match the wires color for color. For wiring at the transmitter or remote core

processor, refer to the transmitter documentation.

4. Tighten the screws to hold the wires in place.

5. Ensure integrity of gaskets, then tightly close and seal the junction box cover and all

housing covers on the transmitter or core processor.

6. Refer to the transmitter installation manual for signal and power wiring instructions.

Installation Manual 27

Page 32

Grounding

4 Grounding

The meter must be grounded according to the standards that are applicable at the site.

The customer is responsible for knowing and complying with all applicable standards.

Prerequisites

Micro Motion suggests the following guides for grounding practices:

• In Europe, IEC 79-14 is applicable to most installations, in particular Sections

12.2.2.3 and 12.2.2.4.

• In the U.S.A. and Canada, ISA 12.06.01 Part 1 provides examples with associated

applications and requirements.

If no external standards are applicable, follow these guidelines to ground the sensor:

• Use copper wire, 14 AWG (2,0 mm2) or larger wire size.

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

CAUTION!

Ground the flowmeter to earth, or follow ground network requirements for the facility.

Improper grounding can cause measurement error.

Procedure

Check the joints in the pipeline.

- If the joints in the pipeline are ground-bonded, the sensor is automatically grounded

and no further action is necessary (unless required by local code).

- If the joints in the pipeline are not grounded, connect a ground wire to the grounding

screw located on the sensor electronics.

Tip

The sensor electronics may be a transmitter, core processor, or junction box. The grounding

screw may be internal or external.

28 Micro Motion ELITE

Page 33

5 Supplementary information

Topics covered in this chapter:

• Purge the sensor case

• About rupture disks

5.1 Purge the sensor case

If the sensor has purge fittings, they should remain sealed at all times. After a purge plug

has been removed, the sensor case should be purged with argon or nitrogen and resealed.

Purging the case protects internal components. The sensor is purged of all oxygen and

sealed at the factory. If the purge plugs are never removed, it is not necessary to purge or

re-seal the sensor. For more information, contact Micro Motion Customer Service.

If a purge plug is removed from the sensor case, it will be necessary to repurge the case.

Supplementary information

CAUTION!

Take all necessary precautions when removing purge plugs. Removing a purge plug

compromises the secondary containment of the sensor and could expose the user to process

fluid.

CAUTION!

Improper pressurization of the sensor case could result in personal injury. Removing a purge

plug will require the sensor case to be repurged with a dry inert gas. Follow all instructions

provided in the case purging procedure.

Prerequisites

Make sure the following are available before beginning the purge procedure:

• Teflon® tape

• Argon or nitrogen gas sufficient to purge the sensor case

Procedure

1. Shut down the process, or set control devices for manual operation. Before

performing the case purging procedure, shut down the process or set the control

devices for manual operation. Performing the purge procedure while the flowmeter

is operating could affect measurement accuracy, resulting in inaccurate flow signals.

2. Remove both purge plugs from the sensor case. If purge lines are being used, open

the valve in the purge lines.

3. Prepare the purge plugs for reinstallation by wrapping them with 3–5 turns of Teflon

tape.

Installation Manual 29

Page 34

Supplementary information

4. Connect the supply of nitrogen or argon gas to the inlet purge connection or open

5. Make sure that there is a tight seal between the inlet connection and sensor case, so

6. Run purge gas through the sensor.

inlet purge line. Leave the outlet connection open.

• Exercise caution to avoid introducing dirt, moisture, rust, or other contaminants

into the sensor case.

• If the purge gas is heavier than air (such as argon), locate the inlet lower than the

outlet, so that the purge gas will displace air from bottom to top.

• If the purge gas is lighter than air (such as nitrogen), locate the inlet higher than

the outlet, so that the purge gas will displace air from top to bottom.

that air cannot be drawn by suction into the case or purge line during the purging

process.

The purge time is the amount of time required for full exchange of atmosphere to

inert gas. The larger the line size, the greater amount of time is required to purge

the case. If purge lines are being used, increase the purge time to fill the additional

volume of the purge line.

Note

Keep the purge gas pressure below 30 psig (2 bar).

Purge timeTable 5-1:

Sensor model Purge rate, in ft3/hr (l/h) Time, in minutes

CMF010 20 (566) 1

CMF025 20 (566) 1

CMF050 20 (566) 2

CMF100 20 (566) 5

CMF200 20 (566) 12

CMF300 20 (566) 30

CMF350 20 (566) 45

CMF400 20 (566) 55

CMFHC2 20 (566) 100

CMFHC3 20 (566) 170

CMFHC4 20 (566) 268

CMFS007 20 (566) 1 1/2

CMFS010 20 (566) 1 1/2

CMFS015 20 (566) 1 1/2

CMFS025 20 (566) 4 1/2

CMFS040 20 (566) 4 1/2

CMFS050 20 (566) 4 1/2

CMFS075 20 (566) 6

30 Micro Motion ELITE

Page 35

Purge time (continued)Table 5-1:

Sensor model Purge rate, in ft3/hr (l/h) Time, in minutes

CMFS100 20 (566) 6

CMFS150 20 (566) 6

7. At the appropriate time, shut off the gas supply, then immediately seal the purge

outlet and inlet connections with the purge plugs.

Note

Avoid pressurizing the sensor case. If pressure inside the case elevates above atmospheric

pressure during operation, the flowmeter density calibration will be inaccurate.

8. Make sure that the purge fitting seals are tight so that air cannot be drawn by

suction into the sensor case.

5.2 About rupture disks

Supplementary information

Rupture disks are meant to vent process fluid from the sensor case in the event of a flow

tube rupture. Some users connect a pipeline to the rupture disk to help contain escaping

process fluid. For more information about rupture disks, contact Micro Motion Customer

Service.

If the sensor has rupture disks, they are installed in the sensor purge fitting openings. The

rupture disks should remain installed at all times. If you remove a rupture disk from the

sensor case, it will be necessary to re-purge the case.

CAUTION!

Stay clear of the rupture disk pressure relief area. High-pressure fluid escaping from the sensor

can cause severe injury or death.

Installation Manual 31

Page 36

Micro Motion Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.micromotion.com

Micro Motion Europe

Emerson Process Management

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 318 495 555

F +31 (0) 318 495 556

www.micromotion.nl

*20002158*

20002158

Rev DI

2014

Micro Motion Asia

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6777-8211

F +65 6770-8003

Micro Motion United Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Micro Motion Japan

Emerson Process Management

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T +81 3 5769-6803

F +81 3 5769-6844

©

2014 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Process

Management family of companies. All other marks are property of

their respective owners.

Loading...

Loading...