Page 1

Installation Guide

English – May 2002

Type 112

Introduction

This installation guide provides instructions for installation,

startup, and adjustment. For further information refer to:

www.FISHERregulators.com.

P.E.D. Categories

This product may be used as a safety accessory with

pressure equipment in the following Pressure Equipment

Directive 97/23/EC categories. It may also be used outside of the Pressure Equipment Directive using sound

engineering practice (SEP) per table below.

EZISTCUDORPSEIROGETACEPYTDIULF

)hcni-4/1(6NDPES1

Specifications

Maximum Inlet Pressure

104 bar (1500 psig)

Proof Test Pressure

All Pressure Retaining Components have been

proof tested per Directive 97/23/EC - Annex 1,

Section 7.4

(1)

Installation

Clean out all pipelines before installation of the regulator

and check to be sure the regulator has not been damaged

or has collected foreign material during shipping. For NPT

bodies, apply pipe compound to the male pipe threads.

Startup and Adjustment

The Type 112 restrictor controls the regulator's proportional band (droop) and speed of response. The restrictor

can be used to fine tune the regulator for maximum performance by decreasing the restrictor setting for tighter

control (increased opening speed, decreased closing

speed); or increasing the restrictor setting for maximum

stability (decreased opening speed, increased closing

speed). A lower setting also provides a narrower proportional band for better accuracy. The START position has

the largest flow, is most stable, and easiest for startup,

however, using the START position is not necessary. The

“0” setting has the smallest (minimum) flow passage; at

no point of rotation will the Type 112 restrictor be completely shut off. After initial adjustment, the restrictor does

not need to be adjusted for maintenance or startup.

Taking Out of Service (Shutdown)

To avoid personal injury resulting from sudden

release of pressure, isolate the regulator from

all pressure before attempting disassembly.

Only qualified personnel should install or service

a regulator. Regulators should be installed,

operated, and maintained in accordance with

international and applicable codes and

regulations, and Fisher instructions.

If the regulator vents fluid or a leak develops in

the system, it indicates that service is required.

Failure to take the regulator out of service

immediately may create a hazardous condition.

Personal injury, equipment damage, or leakage

due to escaping fluid or bursting of pressurecontaining parts may result if this regulator is

overpressured or is installed where service

conditions could exceed the limits given in the

Specifications section, or where conditions

exceed any ratings of the adjacent piping or piping

connections.

To avoid such injury or damage, provide pressurerelieving or pressure-limiting devices (as required

by the appropriate code, regulation, or standard)

to prevent service conditions from exceeding

limits.

Additionally, physical damage to the regulator

could result in personal injury and property

damage due to escaping fluid. To avoid such injury

and damage, install the regulator in a safe

location.

1. The pressure/temperature limits in this installation guide and any applicable

standard or code limitation should not be exceeded.

www.FISHERregulators.com

D103056XENG

Page 2

Type 112

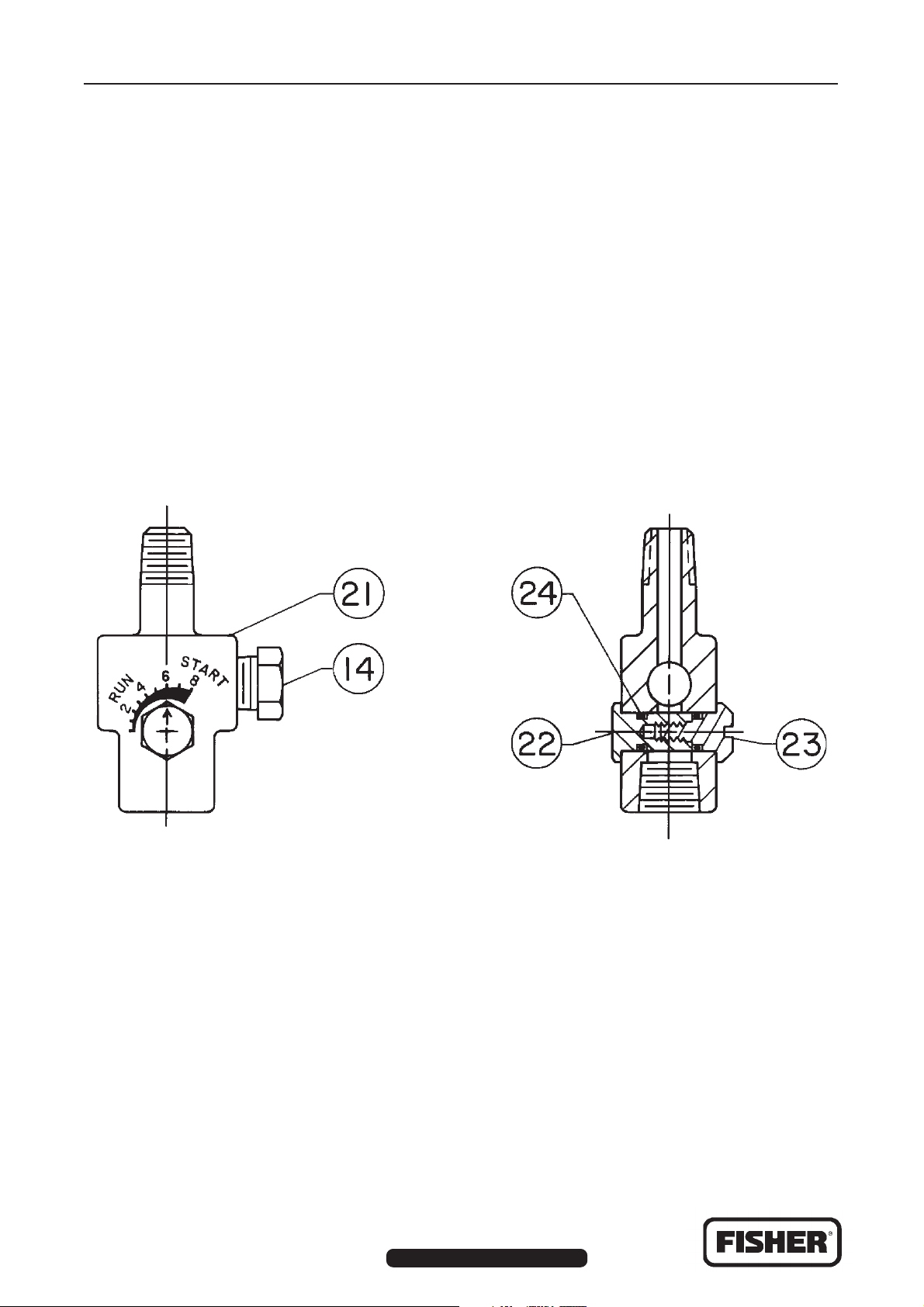

Parts List

Key Description

14 Pipe Plug

21 Restrictor Body

22 Groove Valve

23 Valve Retainer

24 O-ring

20B4393

Figure 1. Type 112 Assembly

©Fis her C ontro ls Inte rnati onal, I nc., 2002; All R ights Rese rved

Fisher and Fisher Regulators are marks owned by Fisher Controls International, Inc. The Emerson logo is a trade mark and service mark of Emerson Electric Co.

All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

For information, contact Fisher Controls, International:

Within USA (800) 588-5853 – Outside USA (972) 542-0132

France – (33) 23-733-4700

Singapore – (65) 770-8320

Mexico – (52) 57-28-0888

Printed in U.S.A.

www.FISHERregulators.com

Loading...

Loading...